- Architectural Engineering Department, United Arab Emirates University, Al Ain, United Arab Emirates

The potential of modular construction to deliver affordable housing can be enhanced through automation. However, high upfront investment for automation raises concerns about its economic feasibility. This study aims to evaluate the economic viability and sustainability of automating modular construction manufacturing for affordable housing delivery by conducting a cost-benefit analysis. The study employs a two-stage quantitative approach. The first stage involves using simulation results from a previous study conducted by the authors to analyse the production time of manual and automated factory setups, while the second stage entails collecting and comparing the costs and metrics associated with both setups, focusing on labor wages, robot and machinery costs, and energy consumption. Results show that automation reduces production time by almost 40% per unit, labor wages by 69.7% per unit, and energy consumption cost by 11.6% per unit. While adopting automation requires a high investment in robotic systems—approximately 321% higher than the cost of manual setup—and increases annual maintenance costs by the same amount, the long-term savings and increased efficiency demonstrate the economic viability of automation, with an estimated payback period of around 3 years. The study concludes that automation offers substantial economic and operational benefits for modular manufacturing, offering valuable insights for stakeholders in the modular construction industry aiming to optimize their production systems for affordability and sustainability. The analysis is limited to the direct costs and benefits of the main manufacturing process, excluding idle time, indirect costs, and environmental and quality impacts. Future research should expand the model’s scope to include full factory operations, MEP integration, logistics, and full assembly; apply probabilistic sensitivity analysis to capture uncertainty; and assess the environmental and life-cycle impacts of automation.

1 Introduction

Modular construction has emerged as a viable solution to address the growing demand for affordable housing, particularly in urban environments where traditional construction methods often fall short on speed, cost, and sustainability. By manufacturing components in a controlled factory environment and assembling them on-site, modular construction offers advantages such as reduced construction time, improved quality control, and minimized material waste (Parisi and Donyavi, 2024; Tsz et al., 2023). The reduction in construction duration through the synchronization of offsite and onsite work minimizes delays caused by weather and other site disruptions. This not only accelerates housing delivery but also helps mitigate the rising costs associated with prolonged construction periods (Salama et al., 2020). Modular construction is particularly suitable for affordable housing projects due to its ability to reduce costs through economies of scale, optimized process and material use, and the need for fewer skilled workers on site (Abiodun et al., 2024; Liu and Zainul, 2024). Sustainability is another benefit, as modular construction promotes resource efficiency, energy conservation, and waste reduction (Sajid et al., 2024). Despite its numerous benefits, the adoption of modular construction faces challenges such as initial setup costs, a shortage of skilled labor, and process complexity (Saliu et al., 2024). To address these challenges, the construction industry is increasingly looking towards automation and digital technologies (Chen et al., 2022; Kapoor and Sharma, 2024). The automation of manufacturing processes demonstrates significant benefits, including reduced production time, improved precision, and lower long-term labor costs (Haque, 2023). Hence, its integration in modular construction manufacturing presents further opportunities to enhance efficiency, consistency, and scalability (Islam et al., 2025). Automated modular factories can utilize robotic arms for framing, welding, insulation, and panel assembly to optimize the manufacturing process (Xu et al., 2025). However, their high initial costs, advanced maintenance requirements, and the need for specialized operational expertise remain key barriers to widespread adoption (Fu et al., 2024).

Purchasing robotic systems, integrating automated production lines, and modifying factory layouts require substantial capital, which raises concerns about the financial feasibility of automation, particularly for affordable housing projects. Additionally, automated processes may increase energy consumption, and their cost-effectiveness depends on long-term operational savings and productivity gains. Given these complexities, a detailed cost-benefit analysis is necessary to determine whether automation can offer economic advantages over traditional manual manufacturing in modular construction. This study aims to evaluate the economic viability and sustainability of automating modular construction manufacturing for affordable housing delivery. To achieve this, the study conducts a cost-benefit analysis of manual and automated production setups using simulation results established from a previous study conducted by the authors (Ouda and Haggag, 2024). The specific objectives are to:

• Utilize simulation results to compare manual and automated modular-factory setups and analyze differences in production time.

• Quantify and assess key cost components under both production scenarios: labor, machinery, and energy consumption.

• Evaluate the economic feasibility of automation through financial indicators such as Net Present Value (NPV), Benefit-Cost Ratio (BCR), and Payback Period.

• Interpret the implications of automation for affordable housing delivery, highlighting potential benefits for industry practice and policy development.

2 Cost-benefit analysis in modular construction automation

Cost-benefit analysis (CBA) is a key method for assessing the financial viability of an investment by identifying, quantifying, and comparing all relevant costs against the expected returns (Khalil and Tallozy, 2025). In modular manufacturing automation, CBA examines the economic, operational, and environmental implications of technological adoption, including production time, labor costs, machinery expenses, and energy use (Burggräf et al., 2019). The first aspect of CBA is costs. Capital investment is one of the most significant costs associated with automation, due to the advanced technologies and the need for integration with existing infrastructure. Also, automation systems require ongoing maintenance, software updates, and technical support to maintain productivity. Beyond that, the workforce needs adaptation and training, all of which adds to the costs. The other aspect of CBA assesses benefits, which requires a structured approach to quantifying both direct and indirect returns (Khalil and Tallozy, 2025; Hu et al., 2020).

2.1 Economic evaluation frameworks

Literature explored several CBA frameworks. The traditional discounted cash flow (DCF) framework is employed for most feasibility studies, employing indicators of investment performance like net present value (NPV), benefit-cost ratio, internal rate of return, and payback period (Pivorienė, 2017). While these indicators are widely applied for feasibility assessment, several studies emphasize their limitations when evaluating automation in construction. DCF methods assume deterministic costs and stable conditions, which may underrepresent uncertainties in production variability, maintenance, and energy prices. Also, they exclude indirect costs such as maintenance, downtime, and salvage value. Nevertheless, they remain the industry standard for early-stage decision-making because they provide quick and comparable measures of financial performance without requiring extensive data. Studies such as (Khalil and Tallozy, 2025; Hu et al., 2020) confirm the practicality of DCF-based CBA for automation investments, while others like (Heralova, 2017; Jayawardana et al., 2022; Landscheidt and Kans, 2016) advocate complementing them with life-cycle or total cost-of-ownership approaches when detailed data are available. Life-cycle cost analysis (LCCA) framework calculates design, production, transportation, installation, maintenance, and disposal costs over the project lifetime (Heralova, 2017). A recent conceptual study has proposed a framework that combines LCC with environmental and social LCA to capture broader impacts (Jayawardana et al., 2022). Total cost of ownership considers maintenance, downtime, and disposal costs, with direct costs, better estimating long-term savings (Landscheidt and Kans, 2016). Process-oriented costing methods, such as Activity-Based Costing (ABC) and its variants, allocate indirect costs (utilities, equipment depreciation, and maintenance) more precisely than traditional methods, resulting in more accurate per-unit costs. Time-Driven ABC estimates labor/time per activity (e.g., welding, assembly), enabling production line simulation to compute detailed cost-time profiles. Such methods allow sensitivity analysis, exploring the impact of improving productivity or automating a step on the total module cost (Lee et al., 2015). Similarly, Risk Adjusted CBA includes uncertainty when estimating net benefits through sensitivity analysis, scenario testing, or probabilistic modelling (Khalil and Tallozy, 2025). Some studies utilize value-based or multi-criteria frameworks, where non-monetized benefits (quality, speed, environmental gains) are translated into monetary or index values and included alongside cost in an overall assessment (Antillón et al., 2014). Broader approaches like LCCA, TCO, ABC, and Value-Based CBA offer greater scope but require detailed long-term datasets rarely available in early-stage automation projects (Jayawardana et al., 2022). Given the purpose and method of this paper, the DCF framework is appropriate and consistent with prior CBA research.

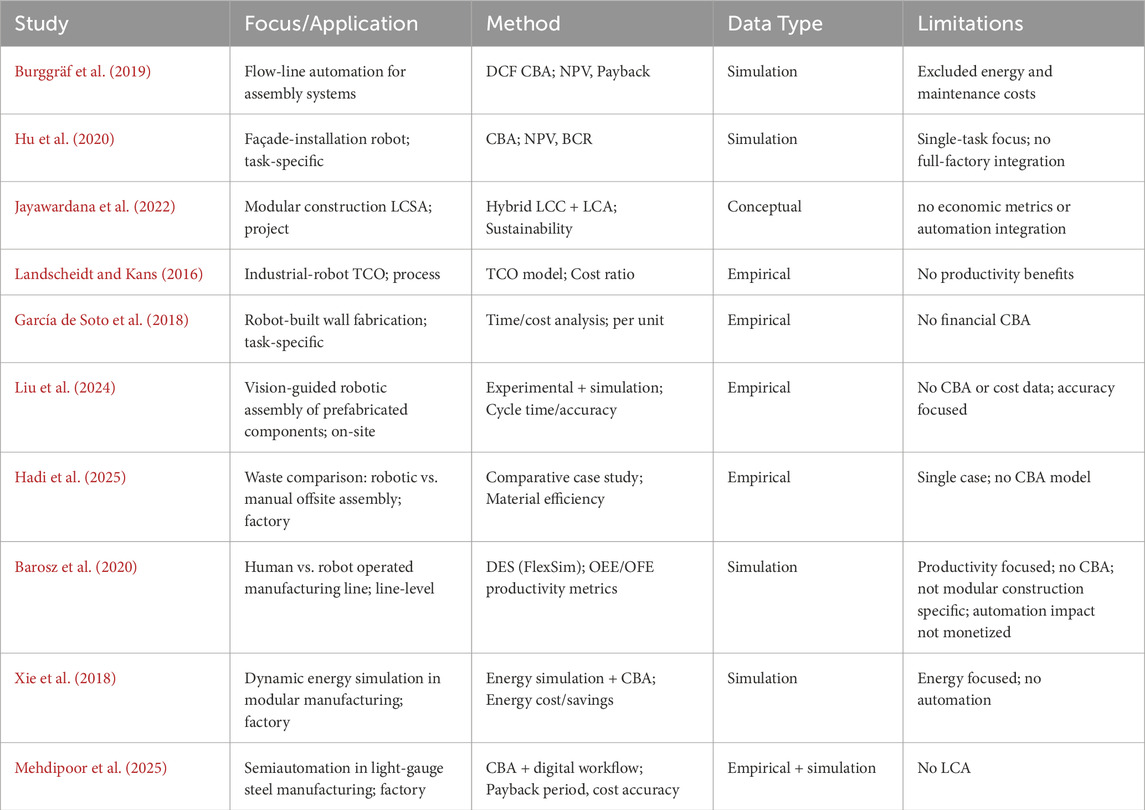

Table 1 summarizes representative studies that have applied CBA or equivalent frameworks to construction automation and prefabrication contexts. Most address individual robotic tasks or conceptual frameworks with limited financial scope. Early deterministic CBAs (Burggräf et al., 2019; Hu et al., 2020) quantified profitability but excluded indirect and energy-related costs. Broader frameworks such as TCO and LCCA (Jayawardana et al., 2022; Landscheidt and Kans, 2016) improved life cycle understanding but remained detached from automation performance data. Task-specific or performance-oriented studies (García de Soto et al., 2018; Liu et al., 2024; Hadi et al., 2025; Barosz et al., 2020; Xie et al., 2018) focused on technical feasibility rather than financial viability. Recent contributions (Mehdipoor et al., 2025) began integrating simulation and economic assessment, but remains scope-limited. These studies collectively reveal that quantitative economic evaluations of process-scale automation linking production simulation with financial metrics are still scarce, particularly in the context of affordable housing modular manufacturing, which remains underdeveloped.

2.2 Automation cost drivers in modular manufacturing

Several studies have discussed the cost breakdown of automatic manufacturing systems that utilize industrial robots. Across different applications, cost structures divide the total cost into acquisition, operation, maintenance, and disposal costs, as well as intangible costs such as downtime (Landscheidt and Kans, 2016). Traditional frameworks often focus on tangible costs and overlook the hidden costs caused by idle loss, efficiency loss, and quality loss, among others. Some studies also ignored costs associated with debugging, upgrading, and disposal due to data scarcity and a focus on feasibility (García de Soto et al., 2018; Zhao et al., 2021). Consequently, the initial economic evaluation of modular manufacturing automation can examine the primary operating expenses of factory processes, specifically labor, machinery and equipment, and energy costs. Other costs, such as overhead or administrative expenses, while relevant in broader economic evaluations, can be excluded in a process-oriented approach.

2.2.1 Workforce

Automation can significantly reduce labor requirements, thereby lowering recurring expenditures and enhancing workforce productivity (Delgado et al., 2019). While these benefits are offset initially by the capital cost of robotic systems and the need for specialized operators and technicians, automation promises long-term savings through improved efficiency and productivity, optimized resource allocation, and decreased energy consumption (Feldmann, 2022; Xiaoyi, 2024). Studies emphasize that workforce restructuring and reskilling are essential to realize automation cost savings and productivity gains (Xu et al., 2025; Delgado et al., 2019).

2.2.2 Level of automation

In automation research, production strategies are often described along a spectrum from manual to semi-automated, human-robot-collaborative (HRC), and fully automated systems (Fu et al., 2024). Semi-automated lines integrate mechanized handling or guided assembly while retaining substantial human control, offering flexibility at a moderate cost. Fully automated factories represent the upper-limit benchmark for productivity and capital intensity. Positioning the current study at this end of the spectrum allows assessment of automation’s maximum potential benefits, serving as a reference point for future comparisons with hybrid or phased-adoption strategies.

2.2.3 Production time

One of the primary advantages of modular construction is its reduced production time compared to traditional building methods. Automated manufacturing is expected to further reduce construction time compared to manual processes (Abkar et al., 2023). Studies report time reductions ranging from 30% to 50% when robotics are integrated into production lines (Ouda and Haggag, 2024; Hu et al., 2020; García de Soto et al., 2018; Gao and You, 2017). Although automation accelerates production, researchers note that savings depend on production volume and system utilization. Under-utilized automated lines may extend payback periods (Burggräf et al., 2019). Consequently, automation’s time efficiency must be contextualized within demand and factory capacity planning, which is critical for affordable housing projects.

Overall, the literature agrees that automation’s cost advantage emerges over time through efficiency and consistency rather than immediate expense reduction. This justifies the use of long-term financial indicators, such as NPV, BCR, and Payback Period, to evaluate the feasibility of automation in modular construction factories.

2.3 Energy

Energy represents a major operational cost and a sustainability determinant in manufacturing, directly impacting total production expenses and the environmental footprint (Mohamed et al., 2019). While industrial robots and machines are high-powered, studies show that lighting and HVAC systems are the main energy consumers in a factory (Al Momani et al., 2023; Cai et al., 2025). Consequently, total energy per module can decrease when automation boosts output and streamlines cycle times (Gao and You, 2017). For example, a fully automated steel-module line in China achieved 22% higher output while using 10% less total energy than the prior semi-manual setup, equivalent to a 25%–30% reduction in energy per unit (CSCEC, 2024). Likewise, studies of specific processes show even larger savings, where collaborative robots used 41%–71% less energy per weld than manual welding (Ruprecht, 2025). However, most analyses exclude indirect energy loads such as HVAC, logistics, and IT systems, which may underestimate total consumption. Recognizing these boundaries clarifies that automation’s energy advantage is process-specific rather than absolute.

2.4 Environmental considerations

The prefabricated nature of modular buildings promotes materials efficiency and mitigates the environmental harm typically associated with onsite construction. Automation contributes to the overall sustainability by increasing precision in fabrication and reducing waste, production time, and energy use (Feldmann, 2022; Wuni and Shen, 2020). Industrial robots are designed to enhance precision and minimize errors and waste, which lead to cost savings (Chau et al., 2024; Yang et al., 2017; Chea et al., 2020). For example, ABB Robotics reported a U.S. project where robotic assembly of modular homes boosted production efficiency by 15%, sped by more than 38%, while cutting waste by about 30% (ABB, 2021). This is particularly significant given that up to 25% of materials delivered to construction sites end up as waste. By adopting sustainable construction practices, waste can be reduced through optimized building design and efficient construction methods (Dindorf and Wos, 2024). While these improvements contribute to lower carbon footprints, most current evaluations stop short of quantifying full-life-cycle environmental impacts. Integrating cost, time, and environmental metrics through combined life-cycle cost and life-cycle assessment approaches would provide a more comprehensive understanding of automation’s role in sustainable, affordable housing delivery.

2.5 Summary and research gap

The existing literature confirms that automation can improve efficiency and sustainability in modular construction, but raises concerns about its high upfront investment and operational costs. While cost-benefit analysis is a common evaluation tool for investment projects, comprehensive economic evaluations of modular construction automation for affordable housing remain limited. Most analyses examine either individual robotic processes or conceptual feasibility, leaving a gap for simulation-based economic evaluation of main process automation. This study addresses the gap by applying simulation-based data established in prior research within a DCF-based CBA to evaluate manual and automated factory setups for affordable-housing manufacturing, focusing on production time, labor and robot costs, and energy consumption. By linking process-level modeling to financial indicators, this research provides a simulation-driven foundation for assessing automation’s potential to enhance affordability and sustainability, as well as an upper-bound estimate of financial benefits.

3 Methodology

3.1 Research design

This study employs a comparative cost-benefit analysis framework to evaluate the economic viability of automating modular construction manufacturing for affordable housing. The methodology is structured into four main phases: simulation results, data collection, cost-benefit analysis, and sensitivity analysis. A quantitative simulation-based comparative analysis was conducted between two factory setups: a manual production line and an automated production line. The comparison focused on key performance indicators, including production time, labor costs, robot costs, and energy consumption.

3.2 Simulation and scope

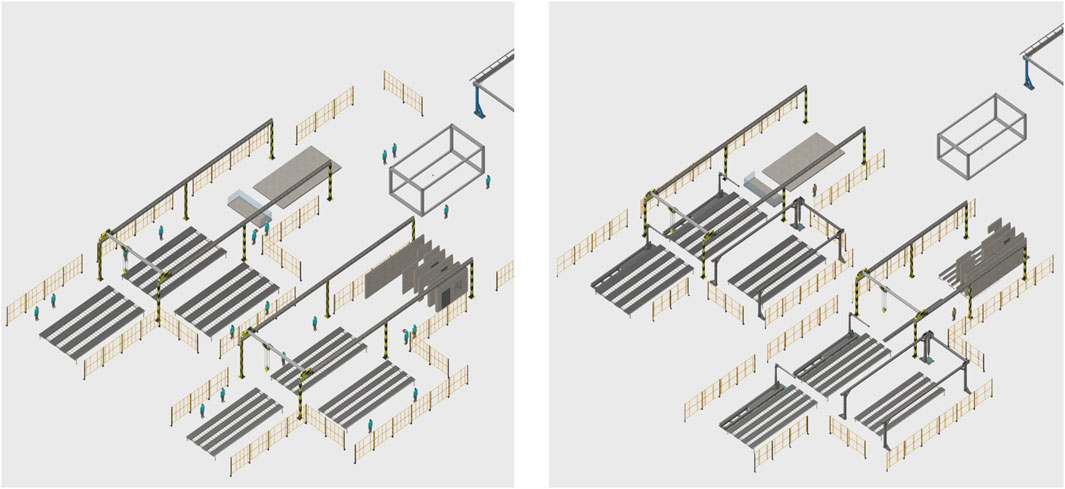

This CBA builds on established simulation results from a previous study conducted by the authors (Ouda and Haggag, 2024). Factory operations for both scenarios were modelled (Figure 1) using the 3D simulation software Visual Components Premium OLP v4.9. Simulated operations related only to the assembly of the module panels, specifically framing, sheathing, insulation (without Mechanical, electrical, and plumbing (MEP) work), and fixtures. The focus on the assembly process was because it represents the most labor and time-intensive stage of modular production and therefore provides a reliable basis for comparing manual and automated scenarios. MEP installations, as well as material procurement, logistics, and quality-control operations, were excluded because simulating these processes would require additional real-factory data that were unavailable at the time of model development. Cycle times were recorded for both scenarios:

• Manual Scenario: Simulated using human labor across all stations.

• Automated Scenario: Simulated using robotic systems across most stations.

Figure 1. Manual (left) and Automatic (right) factory setups (Ouda and Haggag, 2024).

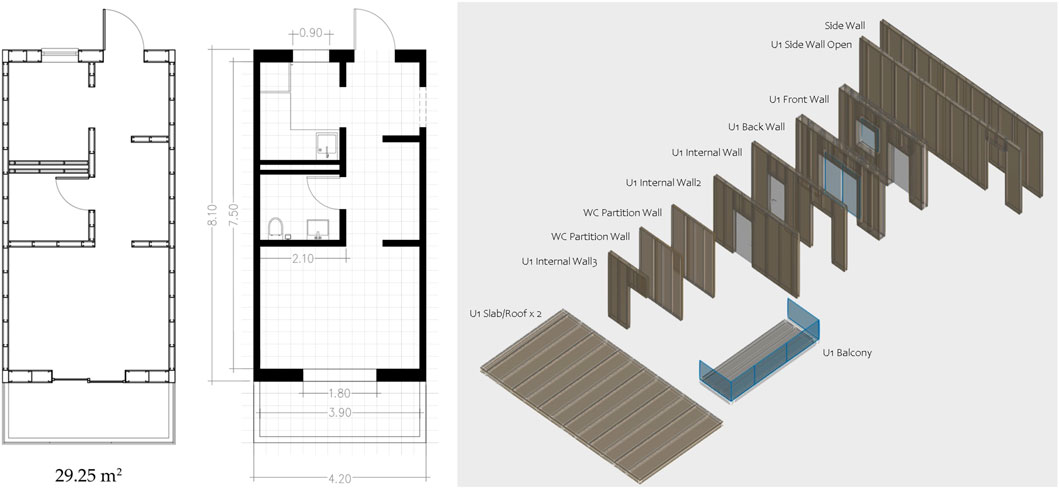

A standard studio unit (Figure 2) was designed and created in both setups. The unit size is 29.25 m2, composed of four main walls, two slab panels, five interior walls, and a balcony. The structure is composed of a light-gauge steel frame, insulated, and covered with plasterboards to meet thermal, acoustic, and fire resistance requirements. A 300 mm grid is used to ensure manufacturing modularity, reducing waste and costs.

Figure 2. Studio unit plan and assemblies (Ouda and Haggag, 2024).

3.3 Model validation and reliability

The simulation model established the process logic, parameters, and performance data for manual and automated factory setups through multiple deterministic simulation runs for four different module designs, ensuring process stability and reliability of production time outputs. While the results were not empirically validated against real-world data or benchmarks specific to automated modular factories due to data unavailability, the simulation design, sensitivity analysis, and internal consistency were reviewed to ensure representative modeling of modular-factory operations.

This paper builds upon those deterministic results, using them as input data for the cost-benefit analysis rather than rerunning the simulation. All production time, labor, and energy values are therefore based on the verified model. This approach ensures methodological continuity while allowing the current study to focus specifically on the economic feasibility dimension of automation for affordable housing manufacturing.

3.4 Data collection

Data were collected from:

• Simulations of modular factory processes from the previous study (production time).

• Manufacturer and market reports on robot costs, labor wages, and energy consumption.

• Literature sources to indicate environmental impact and energy savings in automated systems.

3.5 Cost-benefit analysis framework

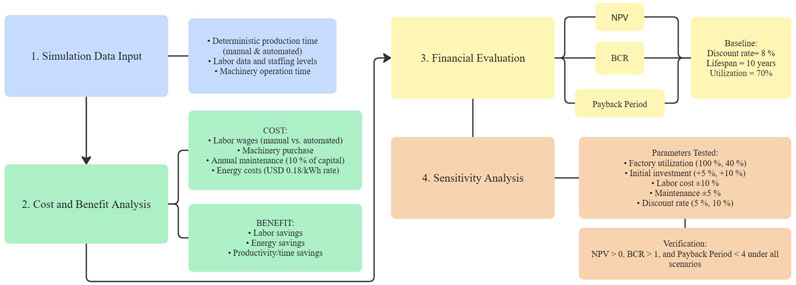

The CBA was conducted using the structure shown in Figure 3. After collecting data, the study analyses production time, labor wages, machinery costs (initial investment), and energy consumption. Afterward, it evaluates the long-term financial viability using Net Present Value (NPV), Benefit-Cost Ratio (BCR), and Payback Period. Finally, it conducts sensitivity analysis using various assumptions on the main financial parameters.

3.6 Sensitivity analysis

A sensitivity analysis was conducted to test the robustness of the economic evaluation. Key financial parameters, including factory utilization, initial investment, labor wages, maintenance costs, and discount rate, were varied one by one within realistic ranges while keeping other factors constant. The resulting changes in NPV, BCR, and discounted payback period were analyzed to assess how these assumptions influence the overall feasibility of automation.

4 Results and discussion

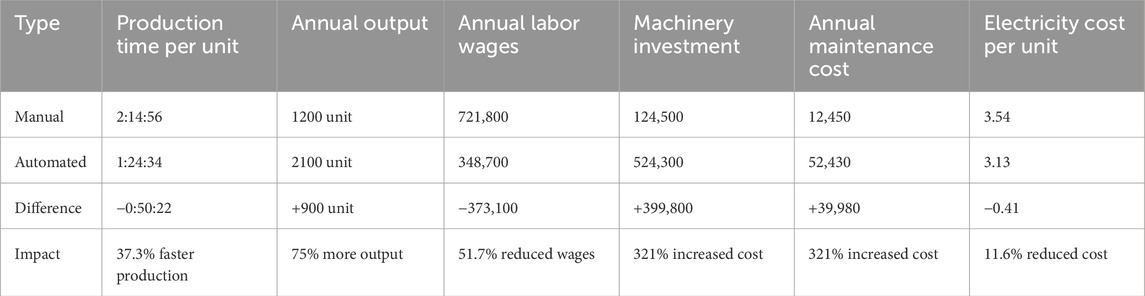

4.1 Production time

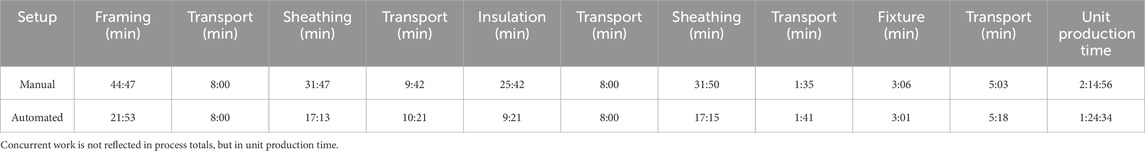

Production time is a critical factor in the cost-benefit analysis of modular construction manufacturing. It directly affects labor costs, factory output, and return on investment. Faster production translates into reduced labor hours per unit, shorter project durations, and increased annual output; all of which contribute to the financial viability of automation. Based on the simulation results summarized in Table 2, the automated process completed a studio unit in 1 h 24 min, whereas the manual process required 2 h 15 min. This means automation reduced production time by approximately 37%, enabling higher throughput. This result is similar to the ABB report stating increased production speed by more than 38% (ABB, 2021).

Table 2. Summary of total process times and overall unit production duration (Ouda and Haggag, 2024).

Beyond the quantitative reduction in cycle time, these results have strategic implications for affordable housing delivery. Shorter production time translates directly into faster turnover of housing units, allowing developers to meet demand more efficiently and governments to scale subsidy programs. For factory operators, the 37% reduction indicates higher capacity utilization and greater resilience against schedule delays, improving financial performance in high-volume projects.

4.2 Labor costs

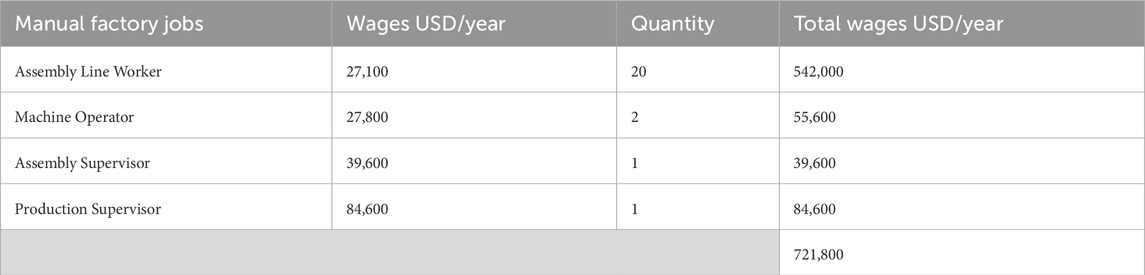

Labor costs are one of the most significant recurring expenditures in modular construction and are therefore central to the cost-benefit analysis of automation. Manual factory setups typically require a larger workforce with varying skill levels, resulting in higher cumulative wages and longer-term operational costs. In contrast, automated factories rely on fewer personnel, often focused on oversight, machine operation, and quality control, thereby reducing labor dependency and associated costs. As this study focuses on assembly lines, only jobs directly related to it were considered:

• Assembly Line Worker: performs repetitive, specialized tasks on a production line to assemble parts into modular components.

• Machine Operator: operates general manufacturing machines (e.g., panel cutters, nailing machines, framing stations), specific to manual setups.

• Production Operator: operates machinery or robotic stations, specific to automatic setups.

• Assembly Supervisor: directly supervises workers on the assembly line, focuses on daily tasks, quality, and workflow

• Production Supervisor: oversees entire production process, including multiple lines/stations, manages schedules and targets

Both setups are assumed to require a minimum of one assembly supervisor and one production supervisor for any production line. The manual factory has 20 assembly line workers, as simulated in (Chea et al., 2020), and is assumed to require two machine operators (one per line). The automated factory has four assembly line workers and is assumed to need three production operators to control and monitor the machinery (one per two stations) (Barosz et al., 2020). Tables 3, 4 detail the annual labor costs for manual and automated production setups, where average wages are based on the US market for factory and manufacturing industry, collected through “official government salary data, surveys, and other sources such as job postings which contain salary information” (Average Salary in United States, 2025). Reductions in workforce size can significantly shorten the payback period for automation investments.

Table 3. Assumed annual labor costs for manual factory setup [based on US market data (Average Salary in United States, 2025)].

Table 4. Assumed annual labor costs for automatic factory setup [based on US market data (Average Salary in United States, 2025)].

The decline in direct labor cost represents not only savings but also a structural shift in workforce composition. Automation reduces the need for repetitive manual tasks while increasing the demand for skilled technicians, maintenance staff, and digital production managers. Affordable housing projects are often reliant on subsidized labor or public sector incentives; therefore, this finding highlights the need for complementary training and upskilling programs to ensure that workforce transformation supports, rather than displaces, employment. Policymakers can leverage these savings to invest in programs that prepare workers for automated manufacturing environments.

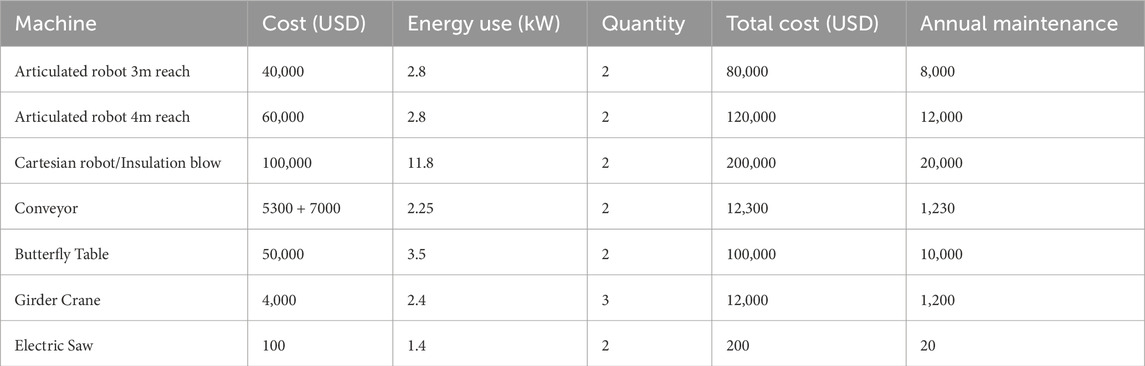

4.3 Machinery costs

Machine acquisition and integration costs form a substantial initial investment in automated modular construction manufacturing. Unlike ongoing labor costs, robot costs are typically capital expenditures with long-term value. In a cost-benefit analysis, it is essential to account not only for the purchase price of robotic systems but also for related expenses such as maintenance and operational energy consumption (Lindborg, 2020). Table 5 outlines the estimated costs of robotic systems used in the automated factory, as well as other machinery used in both setups. Costs were collected through direct quotes from manufacturers, such as ABB, and global suppliers, like Alibaba (X-Tilt Steel Frame, 2025; BOOSTON, 2025; IRB, 2024). The annual maintenance cost was estimated to be 10% of the purchase price (Landscheidt and Kans, 2016). The manual setup would require an investment of USD 124,500 in machinery, while the automatic setup would require USD 524,300 (an additional USD 399,800 for robotic systems). By comparing these costs against labor savings and production gains, the economic feasibility of adopting robotic systems in affordable housing manufacturing can be more accurately evaluated.

Although machinery acquisition substantially increases initial capital expenditure, it represents long-term assets rather than recurring expenses. When evaluated across the projected service life of robotic systems, the higher purchase price and annual maintenance translate into predictable, depreciable costs that improve financial planning accuracy. For developers and policymakers, this underscores the importance of designing financing mechanisms and incentives, such as low-interest loans or automation grants, to mitigate adoption barriers for smaller enterprises. Moreover, standardizing maintenance contracts and supply chains can further reduce operational uncertainty, ensuring that machinery costs are offset by consistent production efficiency and quality gains.

4.4 Energy consumption

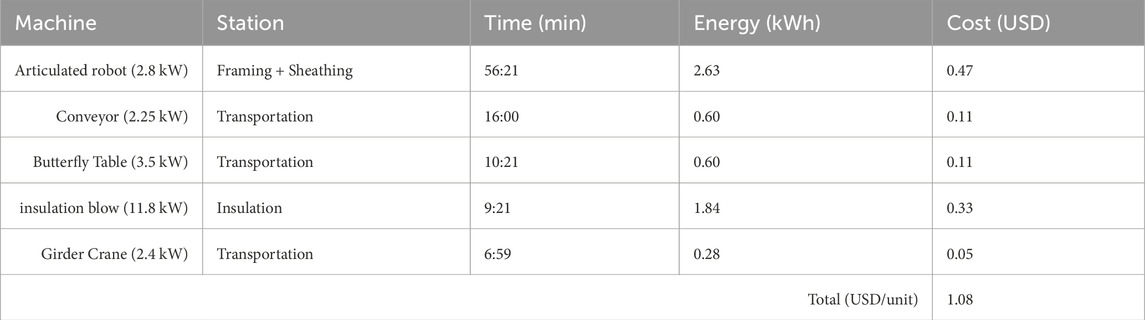

Energy consumption is a critical operational cost that influences the overall economic and environmental performance of modular construction factories. A comprehensive calculation of electricity consumption in a factory would consider direct and indirect uses. Direct uses refer to the energy consumed by equipment that transforms materials into products, such as robots, machines, assembly-line tools, conveyor systems, and crane systems. Indirect uses support infrastructure and operations of the factory but do not directly contribute to the output, including lighting, HVAC systems, material handling, and amenities (Koncz and Gludovatz, 2021). Automated factories generally consume more electricity due to the high-power demands of robotic systems and machinery, whereas manual factories rely more on human labor and have lower direct energy demands. However, automation often leads to faster production cycles, hence, less energy use per module. In this study, energy consumption was calculated based on direct uses and the lighting system alone, as other electricity uses in the factory were not accounted for due to a lack of available data. This means the total energy costs per unit may be underestimated, compared to real-world factory conditions.

4.4.1 Direct energy consumption–assembly line

The automated process requires higher direct energy use due to machinery at different stations, including articulated robots for framing and sheathing, conveyors, a butterfly table, a crane system for transportation, and an insulation blow system. The transportation process is the same in both setups. However, the framing and insulation stations are fully manual in the manual process, eliminating direct energy use, and the sheathing station requires an electric saw for cutting panels.

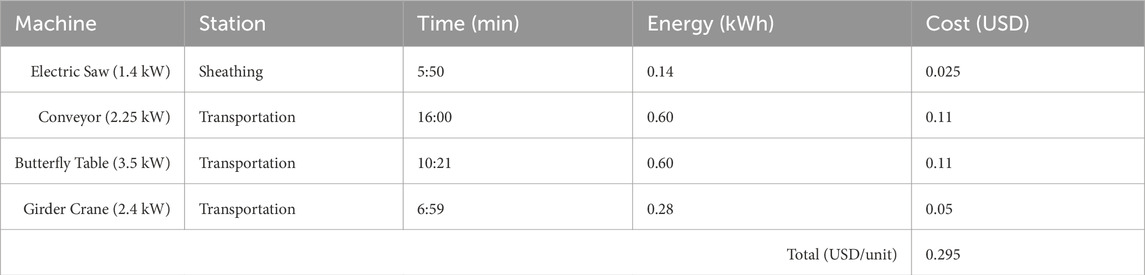

This study uses an international electricity cost rate of USD 0.18/kWh (World Population Review, 2025). Using Equations 1, 2, Tables 6, 7, calculate the energy consumption and cost per unit according to machine use at assigned stations in the automated and manual processes.

Table 6. Energy consumption of automated assembly line (based on electricity cost rate of USD 0.18/kWh).

Table 7. Energy consumption of manual assembly line (based on electricity cost rate of USD 0.18/kWh).

4.4.2 Indirect energy consumption - lighting

According to Neufert, an industrial warehouse with a height of 2–5 m requires 200–500 lux. For this study, the target illuminance is set to 400 lux in assembly line areas (Neufert and Neufert, 2012). The total lumens required is found by multiplying the area (m2) by the lux. Thus, for an approximate assembly line area of 2000 m2 (as simulated), the total luminous flux required is 800,000 lumens (2000 m2 × 400 lux). As referenced in a case study, the factory’s lighting system will utilize 2 × 18 W LED tube luminaires due to their cost efficiency and ease of installation, with a luminous flux value of 3600 lumens and a 99% luminaire efficiency (Uydur, 2022). The number of fixtures needed can be determined by dividing the total Lumens Required (800,000) by the Lumens per fixture (3,600), which is approximately 223 fixtures. With a Luminaire Power (Watt) of 36 for each, the total power consumption of the assembly line’s lighting system is around 8 kW. Therefore, based on 10 operating hours per day, 300 working days per year, and a rate of USD 0.18/kWh, the lighting’s annual energy consumption is 24,000 kWh/year, and the annual cost is USD 4,320. Assuming the same lighting conditions for both setups, the manual production of one unit (2.25 h) would consume 18 kW and cost USD 3.24, while the automated production of one unit (1.41 h) would use 11.28 kW and cost USD 2.03.

While the automated system incurs a higher direct energy cost per unit (USD 1.1) compared to the manual process (USD 0.3), it significantly outperforms in terms of production speed, reducing indirect energy cost. Therefore, the total energy consumption cost for the automated would be USD 3.13 per unit, while the manual would be USD 3.54 per unit. This means that automation reduces energy cost per unit by approximately 11.6%, improving efficiency per unit.

While energy savings appear modest on a per-unit basis, scaling these reductions across annual production yields meaningful environmental benefits. The lower energy intensity reduces factory-level greenhouse gas emissions and aligns with sustainability goals. Incorporating such automation-driven efficiencies into housing frameworks could help governments meet both affordability and sustainability targets simultaneously.

4.5 Summary

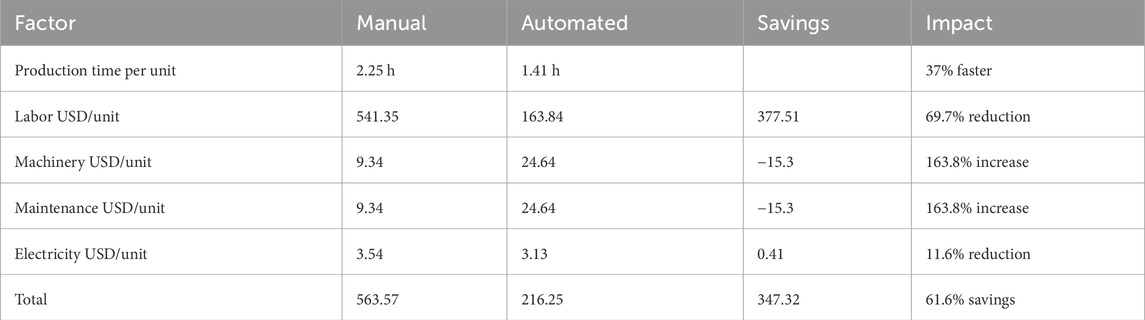

Table 8 summarizes the key economic indicators. This analysis helps clarify the economic viability of adopting automation instead of manual operations.

5 Cost-benefit analysis

Despite a significantly high initial investment, the automated system demonstrated long-term financial advantages. This study assumes a working schedule of 10 operating hours per day, for 300 working days per year, meaning 3,000 h per year. According to ABB robotics, the expected lifetime of articulated robots is 40,000 h (ABB, 2025). Therefore, the lifetime of a robot would be around 13 years. To simplify the calculations in this study, the operational lifespan is rounded to 10 years. The production time per unit was reduced by 37.3%, with automated assembly taking 1 h 24 min compared to 2 h 14 min in manual operations. This directly translates into increased output capacity and higher productivity. At full capacity, the output is estimated to increase by 900 units, a 75% increase. One of the most notable benefits is in labor wages savings, with annual wages in the automated factory reduced by USD 373,100, approximately 51.7%, from USD 721,800 in the manual setup to USD 348,700. This translates to a 69.7% reduction (USD 377.5 per unit), as calculated using Equations 3, 4. This substantial reduction in human labor not only decreases recurring expenses but also reduces dependency on workforce availability. While automation integration required an investment of USD 399,800, representing a 321% increase, the per-unit machinery cost rose by 163.8%, amounting to USD 15.3, as calculated using Equation 5. This is relatively minor compared to the labor savings. Similarly, the annual maintenance cost increased by USD 39,980, approximately 321%, which translates to a USD 15.3 (163.8%) increase per unit, calculated using Equation 6. In terms of energy consumption, although automated machines operate at higher power levels, their faster production rates reduce electricity cost per unit by USD 0.41 (11.6%), from USD 3.54 per unit in the manual process, to USD 3.13 per unit in the automated process.

These results highlight the economic advantages of automation through faster throughput, reduced labor dependence, and improved energy efficiency, despite the higher upfront investment. This reinforces the long-term cost efficiency of automation, especially when scaled to annual or multi-year production volumes. Costs per unit include labor wages, robotic maintenance and depreciation (operational) costs, and electricity consumption. The total savings per unit through automation are calculated by summing all the per-unit costs and savings, which equals about USD 347, as summarized in Table 9. Calculating the total costs and savings on a per-unit basis, rather than per year, allows for estimating the total savings of automation regardless of the annual output, and captures the benefits of automation per unit.

5.1 Economic evaluation

To evaluate the long-term financial viability of automation integration in modular housing production, three core financial metrics were calculated based on the analysis: Net Present Value (NPV), Benefit-Cost Ratio (BCR), and Payback Period. These measures provide a comprehensive understanding of the return on investment (ROI) and cost-efficiency over time (Ceroni and Nof, 2009). To calculate these measures, the discount rate is assumed to be 8% (Fregonara and Ferrando, 2023), the operational lifespan is 10 years, and the factory output is assumed to be 70% of demand, reflecting the industry. This means that the annual savings are the cost of producing 1470 units in an automated setup, subtracted from the cost of producing 840 units manually.

5.1.1 Net present value (NPV)

NPV is the difference between the present value of benefits (or cash inflows) and the present value of costs (or cash outflows) over a period of time (Nugroho and Maulana, 2020). A positive NPV means that the benefits outweigh the costs; hence, it is a profitable investment. A negative NPV means the project will result in a net loss. NPV is calculated using Equation 7:

Where Ct is the net savings in year t, T is the operational lifespan, r is the discount rate per period, and t is the number of time periods.

According to the analysis in this study, the initial investment for the automated system is USD 399,800. Using the total per-unit costs calculated in Table 9, the annual savings at a 70% demand can be found by subtracting the automated setup annual cost (USD 317,887.50) from the manual setup annual cost (USD 473,398.80), which equals USD 155,511.30. Considering the assumed discount rate of 8% and an operational lifespan of 10 years, the NPV is calculated to be USD 643,693. This positive value indicates that investing in automation yields substantial long-term economic benefits, confirming the profitability of transitioning to automation.

5.1.2 Benefit-cost ratio (BCR)

BCR is the ratio of the present value of benefits to the present value of costs. It shows the return per dollar spent on the project. If the value is greater than 1, benefits exceed costs. If it is less than 1, costs exceed benefits. BCR is calculated using Equation 8:

The calculated BCR is 2.61, which implies that for every USD 1 invested in automation, the present value of returns is USD 2.61. This high ratio reinforces the efficiency and productivity improvements associated with automation in modular construction.

5.1.3 Payback period

The payback period is the amount of time it takes for an investment to recover its initial cost, and it can be calculated with or without a discount rate. Equation 9 calculates the simple payback period, which is 2.57 years, or about 2 years and 7 months, for the automated factory setup. This means that the initial investment will be fully recovered in under 3 years through operational savings and increased productivity.

Even when calculated using Discounted Payback Period (Equation 10), the period is almost 3 years. Such a short payback period indicates a strong return on investment.

5.1.4 Policy and investment implications

These positive financial indicators demonstrate that, even under conservative assumptions, automated modular factories can achieve viable returns within typical investment horizons for affordable housing projects. The short payback period of about 3 years suggests that targeted financial incentives, such as tax breaks or low-interest financing, could accelerate adoption.

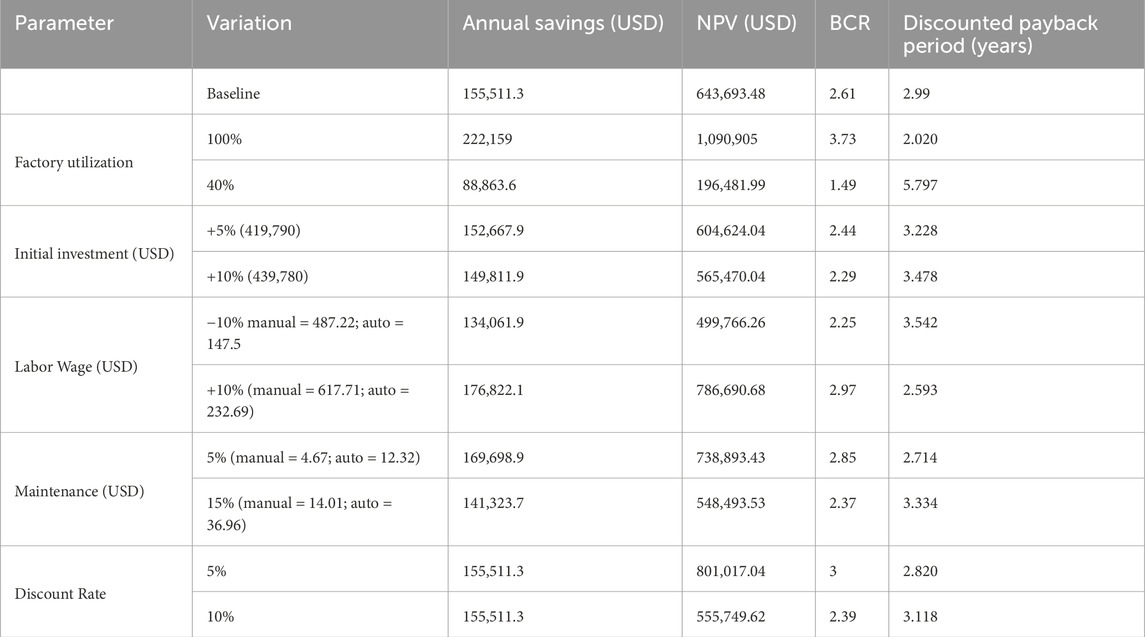

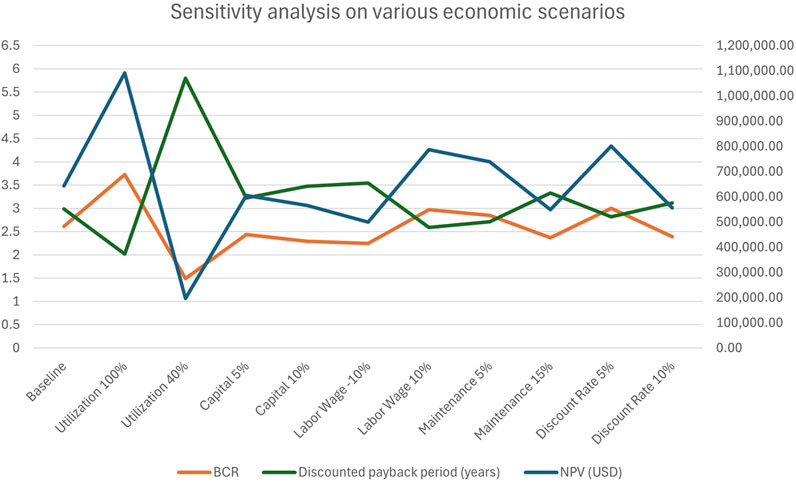

5.2 Sensitivity analysis

A sensitivity analysis was conducted to evaluate the effect of key parameters on financial outcomes. The analysis varied factory utilization (100%, 40%), initial investment (+5%, +10%), labor cost ±10%, maintenance ±5%, and discount rate (5%, 10%), each at a time while keeping other factors constant (Table 10; Figure 4). Results show that factory utilization has the most decisive influence on project returns: increasing utilization from 70% to 100% raises the NPV from USD 643,693 to USD 1.09 million and the BCR from 2.61 to 3.73, shortening the discounted payback period to about 2 years. At 40% utilization, NPV falls to USD 196,482 and BCR to 1.49, extending payback to nearly 5.8 years. Labor wage variation had a comparable impact: a 10% increase improved NPV to USD 786,691 (BCR 2.97), whereas a 10% reduction decreased it to USD 499,766 (BCR 2.25).

Varying the discount rate between 5% and 10% changed the NPV from USD 801,017 to USD 555,750 and the BCR from 3.0 to 2.39, with payback periods ranging from 2.8 to 3.1 years. Changes in initial investment and maintenance cost produced moderate effects; a 10% increase in capital reduced NPV to USD 565,470 (BCR 2.29), while higher maintenance (15%) lowered NPV to USD 548,494 (BCR 2.37).

Overall, all tested conditions produced BCRs greater than 1, positive NPVs, and payback periods of less than 4 years (except low factory utilization), indicating that automation remains economically viable under realistic fluctuations in financial and operational parameters. The sensitivity results confirm that automation’s economic viability is robust but dependent on utilization efficiency. Factory utilization is the dominant driver of profitability; underutilization sharply reduces NPV and extends payback, highlighting the need for consistent production demand to sustain returns. Changes in capital, maintenance, or labor costs have moderate effects, suggesting manageable financial exposure. The discount rate modestly influences NPV and BCR but does not overturn project feasibility. These results could guide decisions on implementing and scaling automation for affordable modular housing manufacturing.

5.3 Limitations and future research

This study has several limitations that should be acknowledged when interpreting its findings. The CBA was based on a previously established simulation of the panel assembly process only and did not extend to all aspects of modular production. Mechanical, electrical, and plumbing (MEP) work; material procurement and logistics; factory downtime; and multi-unit coordination were excluded from the model. Consequently, the reported production times and cost savings represent direct manufacturing efficiencies rather than complete life-cycle performance.

The analysis also focused on direct economic parameters, labor, machinery, and energy costs, while excluding certain indirect or long-term factors such as workforce training, idle time, maintenance downtime, salvage value, and quality/environmental impacts. These exclusions were necessary to maintain analytical clarity and comparability, but may lead to underestimation of total costs in fully operational factories.

Additionally, the energy assessment was limited to direct assembly line consumption and lighting. Other electricity uses, including HVAC, IT systems, and administrative operations, were not included due to unavailable data. A comprehensive energy life-cycle analysis would capture the broader environmental implications of automation.

Another methodological limitation concerns uncertainty quantification. The present study used outputs from a previously published deterministic simulation conducted by the authors; all process durations, sequencing, and resource allocations are fixed, without probabilistic modeling or statistical replication. Therefore, the reported reductions, such as 37% in production time and 69.7% in labor cost per unit, represent exact model outputs rather than statistical estimates. Future work should incorporate stochastic elements and multiple replications to enable confidence interval estimation and significance testing.

Finally, while the framework structure is transferable, the analysis uses U.S. labor and energy costs, which may limit generalizability to regions with different market conditions or labor structures.

Future studies should explore region-specific applications, integrate hybrid or human-robot collaborative systems, expand the framework to include environmental and social life-cycle assessments, and employ stochastic or Monte Carlo simulations to evaluate the sensitivity of economic indicators to changes in input variables with different scenarios simultaneously. These extensions would provide a more holistic understanding of automation’s economic and sustainability implications for affordable housing manufacturing.

6 Conclusion

This study aimed to evaluate the economic viability of automating modular-construction manufacturing for affordable housing through a comparative cost-benefit analysis of manual and automated production setups. Using established simulation data from prior research, the study examined production time, labor and machinery costs, and energy consumption as the main economic indicators. The findings indicate that automation substantially improves manufacturing efficiency, reducing production time by roughly 37%, labor costs per unit by about 70%, and unit energy costs by approximately 12%. Despite higher upfront investment and maintenance expenses of around 321%, the overall financial evaluation, reflected in a positive NPV (USD 640 000), a BCR greater than 2, and a payback period of around 3 years, suggests that automation is economically feasible for modular construction factories operating under comparable conditions. The sensitivity analysis confirms that automation in modular construction remains financially sound under typical economic fluctuations. However, project viability is most sensitive to factory utilization, underscoring the importance of sustained production capacity and effective cost control for maximizing long-term returns, especially in affordable-housing manufacturing.

While these results demonstrate promising potential, they should be interpreted within the study’s defined scope. The analysis focused on the active panel-assembly stage, excluded MEP work and other indirect costs, and applied deterministic rather than stochastic modeling. Consequently, the outcomes provide indicative rather than universal evidence of economic advantage. Future research should expand the model’s scope to include full factory operations, MEP integration, logistics, and full assembly; apply probabilistic sensitivity analysis to capture uncertainty; and assess the environmental and life-cycle impacts of automation. Cross-regional case studies comparing different labor markets and hybrid human-robot systems would also enhance the generalizability and policy relevance of the findings.

This study highlights the economic and operational benefits of automation, providing valuable insights for stakeholders in the modular construction industry to optimize their production systems for both affordability and sustainability. For developers and manufacturers, the results support gradual or phased automation strategies targeting high-labor, repetitive processes such as framing, sheathing, and insulation to shorten production cycles and improve cost efficiency. Policymakers and housing authorities can use these insights to design incentive schemes, such as tax, grants, or low-interest loans, to offset initial capital costs and encourage technology adoption in affordable housing delivery. Industry leaders and training institutions should anticipate workforce transformation by developing reskilling programs focused on robotic operation, maintenance, and digital production management. Overall, this study contributes to the growing evidence that well-planned automation can enhance both the affordability and sustainability of modular-construction manufacturing when applied with informed economic and policy strategies.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

EO: Data curation, Writing – original draft, Investigation, Software, Conceptualization, Methodology, Resources, Formal Analysis, Validation. MH: Supervision, Writing – review and editing, Investigation, Visualization, Methodology, Project administration, Funding acquisition, Conceptualization, Validation.

Funding

The authors declare that financial support was received for the research and/or publication of this article. The publication fees will be supported by the Research and Sponsored Projects Office at the United Arab Emirates University (grant numbers 12N091).

Acknowledgements

The authors thank the Research and Sponsored Projects Office and the College of Engineering at the United Arab Emirates University for supporting this research.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

ABB (2021). ABB robotics advances construction industry automation to enable safer and sustainable building. Available online at: https://new.abb.com/news/detail/78359/abb-robotics-advances-construction-industry-automation-to-enable-safer-and-sustainable-building (Accessed July 12, 2025).

ABB (2025). ROBOTICS product manual IRB 6720, 117. Available online at: https://www.abb.com/global/en/areas/robotics/products/robots/articulated-robots/large-robots/irb-6720 (Accessed October 30, 2025).

Abiodun, B. A., Tochi, C. O., Azubuike, C. O., Obinna, I., and Gil-Ozoudeh, I. (2024). Integrating modular and prefabricated construction techniques in affordable housing: architectural design considerations and benefits. Compr. Res. Rev. Sci. Technol. 2, 010–019. doi:10.57219/crrst.2024.2.1.0030

Abkar, M. M. A., Yunus, R., Al-Shameri, ASAS, Harouache, A., and Gamil, Y. (2023). An empirical investigation of automation technology as material waste mitigation measure at Johor construction sites. Front. Built Environ. 9, 1232195. doi:10.3389/fbuil.2023.1232195

Al Momani, D., Al Turk, Y., Abuashour, M. I., Khalid, H. M., Muyeen, S. M., Sweidan, T. O., et al. (2023). Energy saving potential analysis applying factory scale energy audit – a case study of food production. Heliyon 9, e14216. doi:10.1016/j.heliyon.2023.e14216

Antillón, E., Morris, M., and Gregor, W. (2014). “A value-based cost-benefit analysis of prefabrication processes in the healthcare sector: a case study,” in 22th Annual Conference of the International Group for Lean Construction IGLC 2014, 995–1006. Available online at: https://iglc.net/papers/Details/972 (Accessed September 2, 2025).

Average Salary in United States (2025). World Salaries. Available online at: https://worldsalaries.com/average-salary-in-united-states/ (Accessed July 7, 2025).

Barosz, P., Gołda, G., and Kampa, A. (2020). Efficiency analysis of manufacturing line with industrial robots and human operators. Appl. Sci. 10, 2862. doi:10.3390/app10082862

BOOSTON (2025). BOOSTON - butterfly table from stock 12m. Machineseeker. Available online at: https://www.machineseeker.com/booston-er-03hr%2F1200/i-10960511 (Accessed July 7, 2025).

Burggräf, P., Wagner, J., Dannapfel, M., Fluchs, S., Müller, K., and Koke, B. (2019). Automation decisions in flow-line assembly systems based on a cost-benefit analysis. Procedia CIRP 81, 529–534. doi:10.1016/j.procir.2019.03.150

Cai, W., Bu, K., Zha, L., Zhang, J., Lai, D., and Bao, H. (2025). Energy consumption of plant factory with artificial light: challenges and opportunities. Renew. Sustain. Energy Rev. 210, 115235. doi:10.1016/j.rser.2024.115235

Ceroni, J. A. (2009). “Economic rationalization of automation projects,” in Springer handbook of automation. Editor S. Y. Nof (Berlin, Heidelberg: Springer Berlin Heidelberg), 699–713. doi:10.1007/978-3-540-78831-7

Chau, H.-W., Jamei, E., Muttil, N., and Noguchi, M. (2024). Japanese prefabricated housing manufacturers. Encyclopedia 4, 1073–1090. doi:10.3390/encyclopedia4030069

Chea, C. P., Bai, Y., Pan, X., Arashpour, M., and Xie, Y. (2020). An integrated review of automation and robotic technologies for structural prefabrication and construction. Transp. Saf. Environ. 2, 81–96. doi:10.1093/tse/tdaa007

Chen, X., Chang-Richards, A. Y., Pelosi, A., Jia, Y., Shen, X., Siddiqui, M. K., et al. (2022). Implementation of technologies in the construction industry: a systematic review. Eng. Constr. Archit. Manag. 29, 3181–3209. doi:10.1108/ECAM-02-2021-0172

CSCEC (2024). “Vigorously develop intelligent construction methods,” in China State construction. Available online at: https://www.cscec.com/kccx_new/ly/202412/3837698.html#:∼:text=%E4%BA%A7%E5%93%81%E4%BA%AE%E7%82%B9 (Accessed July 12, 2025).

Delgado, J., Oyedele, L., Ajayi, A., Akanbi, L., Akinade, O., Bilal, M., et al. (2019). Robotics and automated systems in construction: understanding industry-specific challenges for adoption. J. Build. Eng. 26, 100868. doi:10.1016/j.jobe.2019.100868

Dindorf, R., and Wos, P. (2024). Challenges of robotic technology in sustainable construction practice. Sustainability 16, 5500. doi:10.3390/su16135500

Feldmann, F. G. (2022). Towards lean automation in Construction—Exploring barriers to implementing automation in prefabrication. Sustainability 14, 12944. doi:10.3390/su141912944

Fregonara, E., and Ferrando, D. G. (2023). The discount rate in the evaluation of Project economic-environmental sustainability. Sustainability 15, 2467. doi:10.3390/su15032467

Fu, Y., Chen, J., and Lu, W. (2024). Human-robot collaboration for modular construction manufacturing: review of academic research. Autom. Constr. 158, 105196. doi:10.1016/j.autcon.2023.105196

Gao, J., and You, F. (2017). Can modular manufacturing be the next game-changer in shale gas supply chain design and operations for economic and environmental sustainability? ACS Sustain Chem. Eng. 5, 10046–10071. doi:10.1021/acssuschemeng.7b02081

García de Soto, B., Agustí-Juan, I., Hunhevicz, J., Joss, S., Graser, K., Habert, G., et al. (2018). Productivity of digital fabrication in construction: cost and time analysis of a robotically built wall. Autom. Constr. 92, 297–311. doi:10.1016/j.autcon.2018.04.004

Hadi, A., Cheung, F., and Adjei, S. (2025). Comparative analysis of construction waste: robotic vs. manual offsite assembly. IGLC33, 775–786. doi:10.24928/2025/0225

Haque, R. (2023). Automation in manufacturing: a systematic review of advanced time management techniques to boost productivity. Am. J. Sch. Res. Innovation, 50–78. doi:10.63125/z1wmcm42

Heralova, R. S. (2017). Life cycle costing as an important contribution to feasibility Study in construction projects. Procedia Eng. 196, 565–570. doi:10.1016/j.proeng.2017.08.031

Hu, R., Iturralde, K., Linner, T., Zhao, C., Pan, W., Pracucci, A., et al. (2020). A simple framework for the cost–benefit analysis of single-task construction robots based on a case Study of a cable-driven facade installation robot. Buildings 11, 8. doi:10.3390/buildings11010008

IRB (2024). IRB 6700. ABB. Available online at: https://new.abb.com/products/robotics/robots/articulated-robots/irb-6700 (Accessed July 22, 2024).

Islam, M. M., Prodhan, R. K., Shohel, M. S. H., and Morshed, A. (2025). Robotics and Automation in Construction Management Review focus: the application of robotics and automation technologies in construction. J. Next-Gen Eng. Syst., 2. doi:10.70937/jnes.v2i01.63

Jayawardana, J., Zhang, G., Kulatunga, A. K., Sandanayake, M., and Jayasinghe, JASC (2022). Life cycle sustainability assessment for modular construction – a proposed conceptual framework. IOP Conf. Ser. Earth Environ. Sci. 1101, 042039. doi:10.1088/1755-1315/1101/4/042039

Kapoor, G., and Sharma, P. (2024). Reviewing the potential of automation in the construction sector: BIM and digital technology applications. AIP Conf. Proc. 2919, 090015. doi:10.1063/5.0184387

Khalil, M. A. A., and Tallozy, A. (2025). “Evaluating automation investments: integrating cost-benefit analysis into the dynamo++ decision-support model,” in Blekinge institute of technology. Sweden.

Koncz, A., and Gludovatz, A. (2021). Calculation of indirect electricity consumption in product manufacturing. Int. J. Energy Prod. Manag. 6, 229–244. doi:10.2495/EQ-V6-N3-229-244

Landscheidt, S., and Kans, M. (2016). Method for assessing the total cost of ownership of industrial robots. Procedia CIRP 57, 746–751. doi:10.1016/j.procir.2016.11.129

Lee, J., Park, M., Lee, H.-S., Lee, K.-P., and Hyun, H. (2015). Application of activity-based Costing(ABC) for modular building construction indirect costs calculation at the manufacturing stage. Korean J. Constr. Eng. Manag. 16, 139–145. doi:10.6106/KJCEM.2015.16.4.139

Lindborg, I. (2020). Analysis of capital investment in industrial robot: case X. Helsinki: Haaga-Helia University of Applied Science. Available online at: https://www.theseus.fi/handle/10024/340856 (Accessed July 7, 2025).

Liu, H., and Zainul, N. (2024). A review on research of prefabricated building costs: exploring collaborations, intellectual basis, and research trends. Sustainability 16, 9823. doi:10.3390/su16229823

Liu, C., Wu, J., Jiang, X., Gu, Y., Xie, L., and Huang, Z. (2024). Automatic assembly of prefabricated components based on vision-guided robot. Autom. Constr. 162, 105385. doi:10.1016/j.autcon.2024.105385

Mehdipoor, A., Iordanova, I., and Al-Hussein, M. (2025). Enhancing the manufacturing process in light-gauge steel off-site construction using semiautomation. J. Constr. Eng. Manag. 151, 04025055. doi:10.1061/JCEMD4.COENG-15335

Mohamed, N., Al-Jaroodi, J., and Lazarova-Molnar, S. (2019). Leveraging the capabilities of industry 4.0 for improving energy efficiency in smart factories. IEEE Access 7, 18008–18020. doi:10.1109/ACCESS.2019.2897045

Nugroho, R. E., and Maulana, I. (2020). Analysis of investment feasibility of 25mw power plant development Project in paper factory in Karawang in financial aspects, technology and environmental. Saudi J. Bus. Manag. Stud. 5, 438–447. doi:10.36348/sjbms.2020.v05i07.008

Ouda, E., and Haggag, M. (2024). Automation in modular construction manufacturing: a comparative analysis of assembly processes. Sustainability 16, 9238. doi:10.3390/su16219238

Parisi, L., and Donyavi, S. (2024). Modular momentum: assessing the efficacy of modular construction in alleviating the UK housing crisis. Discov. Appl. Sci. 6, 548. doi:10.1007/s42452-024-06268-4

Pivorienė, A. (2017). Real options and discounted cash flow analysis to assess strategic investment projects. Econ. Bus. 30, 91–101. doi:10.1515/eb-2017-0008

Ruprecht, J. (2025). Comparative study of robotic and manual welding for energy consumption and efficiency in a high mix, low volume manufacturing environment. Grand Forks: University of North Dakota. Theses and Dissertations. Available online at: https://commons.und.edu/theses/7152 (Accessed July 12, 2025).

Sajid, Z. W., Ullah, F., Qayyum, S., and Masood, R. (2024). Climate change mitigation through modular construction. Smart Cities 7, 566–596. doi:10.3390/smartcities7010023

Salama, T., Figgess, G., Elsharawy, M., and El-Sokkary, H. (2020). Financial modeling for modular and offsite construction. Int. J. Eng. Adv. Technol. 10, 207–213. doi:10.35940/ijeat.B2085.1210220

Saliu, L. O., Monko, R., Zulu, S., and Maro, G. (2024). Barriers to the integration of Building information modeling (BIM) in modular construction in Sub-Saharan Africa. Buildings 14, 2448. doi:10.3390/buildings14082448

Tsz, W. C., Wai Yi, P., Ibrahim Olanrewaju, O., Abdelmageed, S., Hussein, M., Tariq, S., et al. (2023). A critical analysis of benefits and challenges of implementing modular integrated construction. Int. J. Constr. Manag. 23, 656–668. doi:10.1080/15623599.2021.1907525

Uydur, C. C. (2022). “Evaluation of lighting systems: textile factory case study,” in 2nd international conference on engineering and applied natural sciences. Konya.

World Population Review (2025). Cost of electricity by country 2025. Available online at: https://worldpopulationreview.com/country-rankings/cost-of-electricity-by-country (Accessed July 6, 2025).

Wuni, I. Y., and Shen, G. Q. (2020). Barriers to the adoption of modular integrated construction: systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 249, 119347. doi:10.1016/j.jclepro.2019.119347

X-Tilt Steel Frame (2025). Modular building automation. Available online at: https://www.modularbuildingautomation.eu/x-tilt-steel-frame (Accessed July 7, 2025).

Xiaoyi, D. (2024). Study on sustainable development strategies for enterprises: application of modular design and smart manufacturing in low-carbon production. J. Industry Eng. Manag. 2, 111–114. doi:10.62517/jiem.202403117

Xie, H., Chowdhury, M. M., Issa, R. R. A., and Shi, W. (2018). Simulation of dynamic energy consumption in modular construction manufacturing processes. J. Archit. Eng. 24, 04017034. doi:10.1061/(asce)ae.1943-5568.0000289

Xu, L., Zou, Y., Lu, Y., and Chang-Richards, A. (2025). Automation in manufacturing and assembly of industrialised construction. Autom. Constr. 170, 105945. doi:10.1016/j.autcon.2024.105945

Yang, Y., Pan, W., and Pan, M. (2017). “Manufacturing of modular buildings: a literature review,” in Modular and offsite construction (MOC) summit proceedings. doi:10.29173/mocs52

Keywords: modular construction, automation in construction, robotic assembly, human-robotcollaboration, sustainable construction

Citation: Ouda E and Haggag M (2025) Cost-benefit analysis of automating modular construction manufacturing for affordable housing. Front. Built Environ. 11:1713686. doi: 10.3389/fbuil.2025.1713686

Received: 29 September 2025; Accepted: 03 November 2025;

Published: 19 November 2025.

Edited by:

Assed N. Haddad, Federal University of Rio de Janeiro, BrazilReviewed by:

Nermine Abdel Gelil Mohamed, Effat University, Saudi ArabiaOsabhie Paul Esangbedo, Heriot-Watt University, United Kingdom

Copyright © 2025 Ouda and Haggag. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mahmoud Haggag, bWhhZ2dhZ0B1YWV1LmFjLmFl

Enaam Ouda

Enaam Ouda Mahmoud Haggag

Mahmoud Haggag