- 1Department of Material Science and Engineering, African University of Science and Technology, Abuja, Nigeria

- 2DAF Materials and Mineral Research Group, African University of Science and Technology, Abuja, Nigeria

- 3AUST Baryte Research Group, African University of Science and Technology, Abuja, Nigeria

- 4Advanced Manufacturing Technology Development Institute AMTDI Jalingo, National Agency for Science and Engineering Infrastructure NASENI Abuja, Abuja, Nigeria

- 5Department of Energy and Mineral Engineering, Pennsylvania State University, University Park, PA, United States

- 6Department of Mechanical Engineering, African University of Science and Technology, Abuja, Nigeria

- 7Department of Civil, Environmental and Architectural Engineering, Worcester Polytechnic Institute (WPI), Worcester, MA, United States

Lithium is a critical element in battery technology for renewable energy storage applications. The mineral offers potential solutions to the current surge in global energy demand and can position Nigeria as a potential key player in the lithium supply chain. However, little to nothing is known of the lithium deposits in Nigeria. This review explores the formation, geology, and ongoing exploration activities of lithium in Nigeria. The study provides an overview of the geological settings and mineralogical characteristics of the Nigerian lithium-bearing pegmatites and ores, comparing them with global deposits. It also examines current lithium mining and processing techniques, identifies significant developmental challenges and recommends potential solutions to lithium exploration in Nigeria. Additionally, the paper discusses Nigeria’s policy landscape, investment gaps, and the government’s efforts to establish a sustainable lithium processing industry. The findings emphasise the need for best mineral extraction practices, improved beneficiation technologies, and strategic policy reforms to enhance Nigeria’s position in the global lithium market. The study concludes that with proper investment and regulatory frameworks, Nigeria has the potential to become a significant lithium supplier and contribute to the global transition towards clean energy.

1 Introduction

Lithium is one of the world’s most sought-after minerals/metals in 2024, and Nigeria is not left out (Abdulfattah et al., 2023). In the past year, there has been a notable and abrupt escalation in the activities related to the exploration and extraction of Lithium ore, primarily attributed to the surge in demand stemming from technological advancement (Sahoo et al., 2024). This demand has directly contributed to the heightened interest and efforts in the mining sector. The world has witnessed the rise of electric vehicles because of their many advantages, and because they are environmentally friendly compared to petrol and diesel. This rise in electric car manufacturing led to an increase in battery manufacturing for electric power storage, a significant component of which is lithium (Ebikemefa and Basu, 2023). Several sources of lithium have been discovered and explored in Australia, Chile, China and Argentina. However, very little is said about lithium deposits in Nigeria as part of the global lithium deposits. Similarly, the African lithium deposits are poorly documented or under-reported despite massive mineral extraction and processing happening in Nigeria, and several other Sub-Saharan African countries (Han et al., 2023; Kavanagh et al., 2018; Talens Peiró et al., 2013). Considering the potential of lithium in green energy transition and energy storage technologies, the data on the volume and percentage LiO2 of lithium deposits in Nigeria and Africa is critical to meeting the global demands for lithium.

Lithium metal was discovered in 1817 by Johan Arfvedson. It is a silver-white, light metal with an atomic weight of 6.93 and does not occur naturally in metallic form owing to its reactivity with air (Caprara et al., 2023). Lithium has excellent properties and is considered a battery element. Typically, lithium has low standard reduction potential, thus making it the lightest metal for high-density, high-voltage cells applications. The metal may exist in oxide form under the earth as lithium-rich minerals (Caprara et al., 2023; Whittingham and Yoshino, 2019). These minerals, which include spodumene, lepidolite, petalite, amblygonite, cookite, and zinnwaldite, are associated with pegmatite rock along with primarily quartz, feldspar, and mica interlocking mineral grains (Dessemond et al., 2019). Lithium, a crucial element in the composition of battery raw materials, has witnessed a consistent rise in demand, growing at approximately 20% annually in recent times. The increase in the utilization of electric vehicles in response to the environmental transition indicates a probable continuation of this trend (Bhattacharya et al., 2024; Greim, Solomon, and Breyer, 2020; Salazar and Bengoechea, 2021). However, appropriate mapping of lithium deposits is critical to align the demand for energy transition with environmental transition to achieve the sustainable development goals (SDGs) while meeting global energy needs.

This review presents an exhaustive review of lithium deposits in thirteen (13) States in Nigeria. It critically examines data on the geological characteristics and prospects of the lithium deposits in Nigeria presented by the Nigeria Geological Survey Agency and published literature as part of the preliminary studies on the lithium deposits of Nigeria. This paper evaluates contemporary methodologies in mining and processing techniques, assesses lithium exploration practices, identifies developmental challenges to sustainable lithium extraction in Nigeria. Considering the growing need for lithium in the global energy transition, the reviews assess the potentials of lithium ore quality and identify research gaps critical to the lithium value chain. These gaps include the local processing of lithium ores in Nigeria and the technological advancements necessary to attract investments for lithium in Nigeria. This review presents relevant data for future research on the lithium deposits in the thirteen (13) States/territories in the country.

2 Geology of lithium

Lithium is a crucial and indispensable strategic metal for advancing and developing new energy technologies and solutions. It exhibits a geological concentration predominantly found in various types of deposits, and unique characteristics and formation mechanisms distinguish each deposit. The primary types of lithium resources include brine deposits, complex rock pegmatites, and sedimentary clay deposits. Brine deposits are found in salars or salt flats. These deposits are the most dominant and difficult to extract from the earth compared to other lithium deposits. Conversely, pegmatites, are easy to mine and typically contain significant amounts of spodumene as the lithium-bearing mineral (Wang et al., 2024; Rob et al., 2020).

Pegmatites are typically the lithium–cesium–tantalum (LCT) ores. They are one of, the oldest lithium deposits, dated back to 3,000–3,100 Ma, and are associated with the continental crust formation at the onset of plate tectonics (Grew, 2020). The pegmatites and associated metasomatic rocks are significant sources of lithium, especially highly peralkaline pegmatite deposits rich in manganese (Grew, 2020). Sedimentary clay deposits are common within lacustrine basins and are characterized by large output scales, shallow depths, stable orebody distributions and high ore grades. These deposits primarily contain lithium in clay minerals such as smectite and illite and occasionally in independent lithium-bearing minerals like jadarite (Wang et al., 2024).

The formation of lithium ore deposits involves various activities, mineralization styles and geological process. These include the interaction of Li-rich magmatic-hydrothermal fluids with sedimentary clays and the adsorption of lithium adsorption by clay minerals from Li-rich brines (Wang et al., 2024). The two stable isotopes of Lithium, namely, 6Li and 7Li, play a crucial role in offering significant perspectives on various geological phenomena, including the recycling of crust and mantle, the process of silicate weathering, as well as the interactions between hydrothermal fluids and rocks. Advances in analytical techniques, such as multi-collector inductively coupled plasma mass spectrometry (MC-ICP-MS) and secondary ion mass spectrometry (SIMS), have facilitated precise lithium isotope measurements, enhancing our understanding of these processes (Penniston-Dorland et al., 2017; Li et al., 2011). Lithium’s unique physicochemical properties, including its high solubility in fluid phases and significant isotopic fractionation, make it a useful tracer in geochemical studies, helping to elucidate water/rock interactions, metamorphic and magmatic processes, and the evolution of brines (Takuya et al., 1993).

Geochronological analysis of lithium deposits reveals their formation across different geological epochs, with pegmatite deposits prominent in the Kenoran, Columbian, and Rodinian supercontinent cycles. Similarly, the Pangean cycle described the formation of lithium-fluorine rare-metal granites. In the current Amasian cycle, salars in geodynamically active areas are the primary lithium resource base (Tkachev et al., 2019). The geological settings in which lithium deposits are found, and the detailed examination of the mechanisms involved in their formation, have attempted to describe the intricate nature and profound economic importance of this essential resource. The diverse range of geological environments where lithium accumulates, coupled with the complex processes that contribute to its deposition, collectively emphasize the multifaceted nature of this critical mineral and underscore its significant impact on global economies. The insights from the geological characteristics of lithium ore deposits are useful for the design of flowsheets for the extraction of lithium from lithium-rich minerals embedded in the lithium ore matrixes.

2.1 Distribution of major lithium deposits worldwide: key regions and types of lithium ores

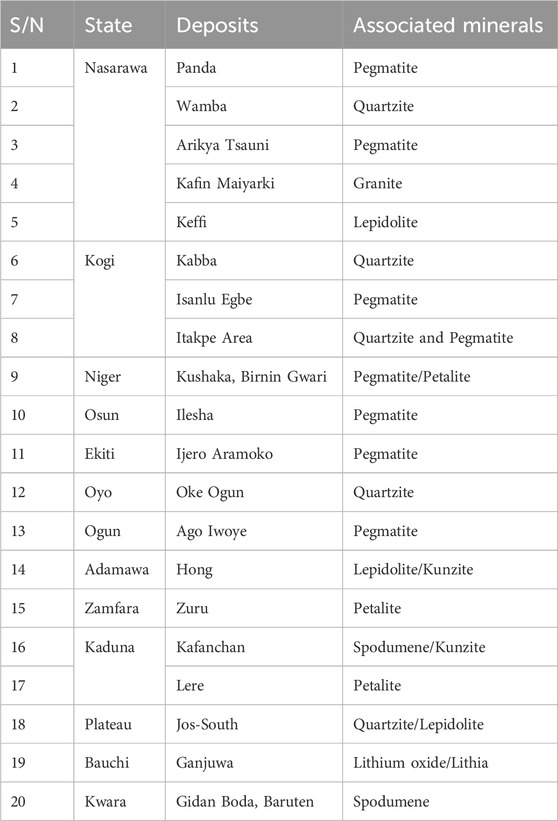

The global distribution of major lithium deposits is characterized by three primary types: pegmatite, salar evaporites, and sedimentary clay deposits, each with distinct geographical and geological settings. Pegmatite deposits, mainly those containing spodumene, are significant due to their ease of exploitation and are predominantly found in regions that experienced supercontinent cycles, such as the Kenoran, Columbian, and Rodinian cycles, with notable occurrences in the Pangean cycle as well (Bowell et al., 2020; Tkachev et al., 2019) Salar deposits, which hold the largest lithium reserves, are primarily located in the lithium triangle of South America, encompassing Bolivia, Chile, and Argentina. Bolivia’s Uyuni salt flats and Chile’s Atacama Desert are particularly noteworthy, with the latter being one of the richest lithium brine sources globally (Aguirre, 2022; Jones, 2022). The global distribution of significant lithium deposits is primarily concentrated in three key regions: South America, Australia, and China, each characterized by distinct types of lithium ores, as shown in Figure 1.

Figure 1. A world map of lithium-producing countries. This is a figure showing countries where lithium ores are processed between 100 and 55,400 tonnes. Source: Statistical Review of World Energy, 2022.

South America, particularly the “Lithium Triangle” comprising Bolivia, Chile, and Argentina, is renowned for its vast lithium brine deposits, which account for approximately 56% of the world’s lithium resources and 52% of its reserves (Giglio, 2021; Sanchez-Lopez, 2023). These brine deposit are found in salt flats and are considered economically advantageous due to their low extraction costs, although they pose significant socio-environmental challenges, such as water resource depletion and community displacement (Giglio, 2021). In Australia, lithium is predominantly extracted from hard rock pegmatite deposits, with spodumene being the primary lithium-bearing mineral (Bowell et al., 2020). This region has rapidly expanded its mining operations, making it a leading producer of lithium globally (Sanchez-Lopez, 2023).

Sedimentary clay deposits, although less exploited, are gaining attention due to their high development potential and are mainly distributed in North America, Europe, and China. These deposits are typically found in lacustrine basins and are characterized by large-scale output and high ore grades (Wang et al., 2024). The diversity in lithium deposit types and their distribution is influenced by geological processes such as plate tectonics and the formation of continental crust, which have concentrated lithium in specific environments over geological time (Balaram et al., 2024; Grew, 2020). Despite the varied distribution, the global lithium resources are estimated to exceed 62 million tons, suggesting no imminent shortage, although future production may be constrained by environmental and social factors rather than resource availability (Bowell et al., 2020).

2.2 Geochemistry of lithium ores (chemical composition and common minerals associated with lithium ores (spodumene, lepidolite, and other lithium ores)

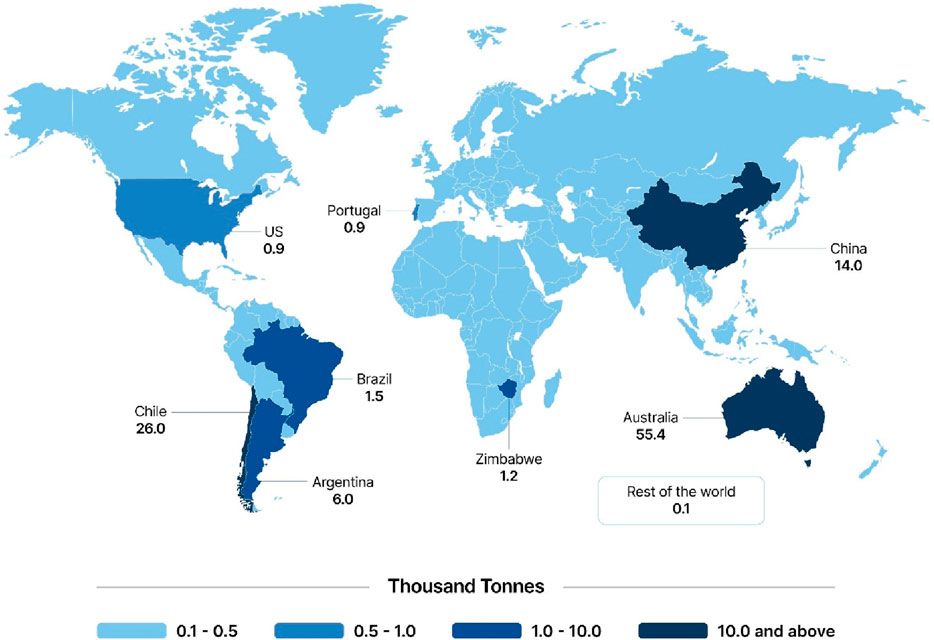

The geochemistry of lithium ores is diverse, reflecting the geological settings and processes that lead to their formation. Lithium resources are primarily categorized into three types: brine, hard rock, and sedimentary clay deposits. Lacustrine sedimentary clay-type lithium deposits are found in North America, Europe, and China. They are characterized by lithium occurring mainly in clay minerals such as smectite and illite, with occasional presence in independent lithium-bearing minerals like jadarite. These deposits are formed through the interactions between Li-rich magmatic-hydrothermal fluids and sedimentary clays or by Li adsorption in clay minerals from Li-rich brines (Wang et al., 2024). In contrast, hard rock lithium deposits like those in the Ukrainian Shield involve Li-pegmatites formed through magmatic and hydrothermal-metasomatic processes, as shown in Figure 2. These deposits feature minerals like petalite and spodumene, which crystallize during different stages of pegmatite formation (Heichenko et al., 2023; Syomka et al., 2022). Lithium-bearing pegmatites within southern Thailand, are rich in lepidolite, K-feldspar, plagioclase, and quartz, and accessory minerals, including fluorite, cassiterite, apatite, monazite, and beryl (Fanka and Tadthai, 2023). These forms of lithium resources are found in several States in Nigeria, as shown in Tables 1–3.

Figure 2. A map showing the global distribution of lithium deposits/resources (minerals and brine deposits) Source: Graham et al., 2021 on Researchgate.

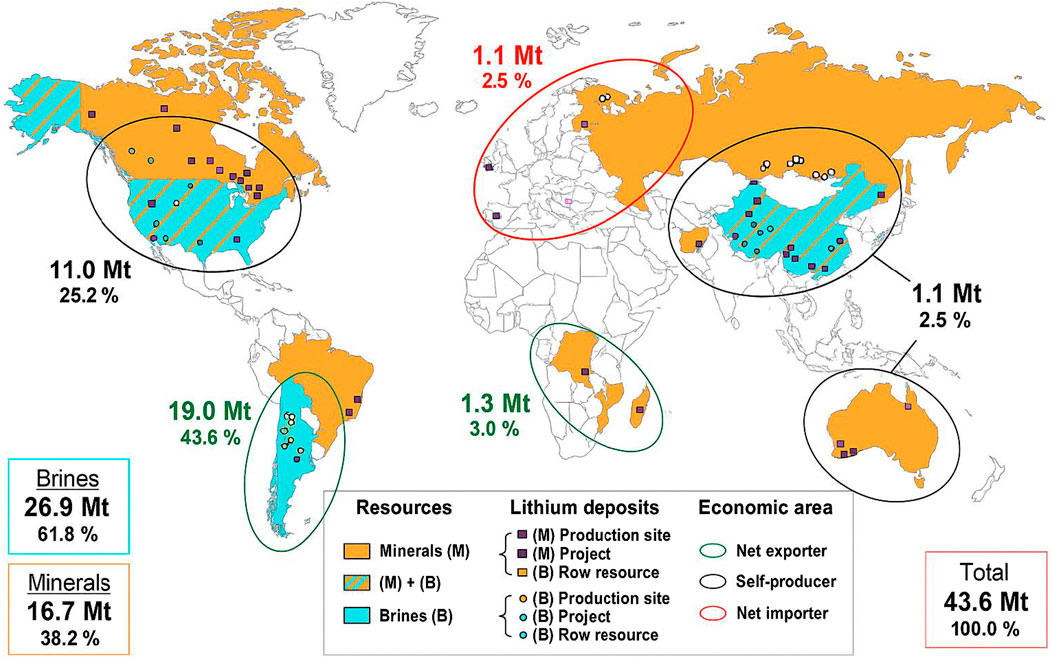

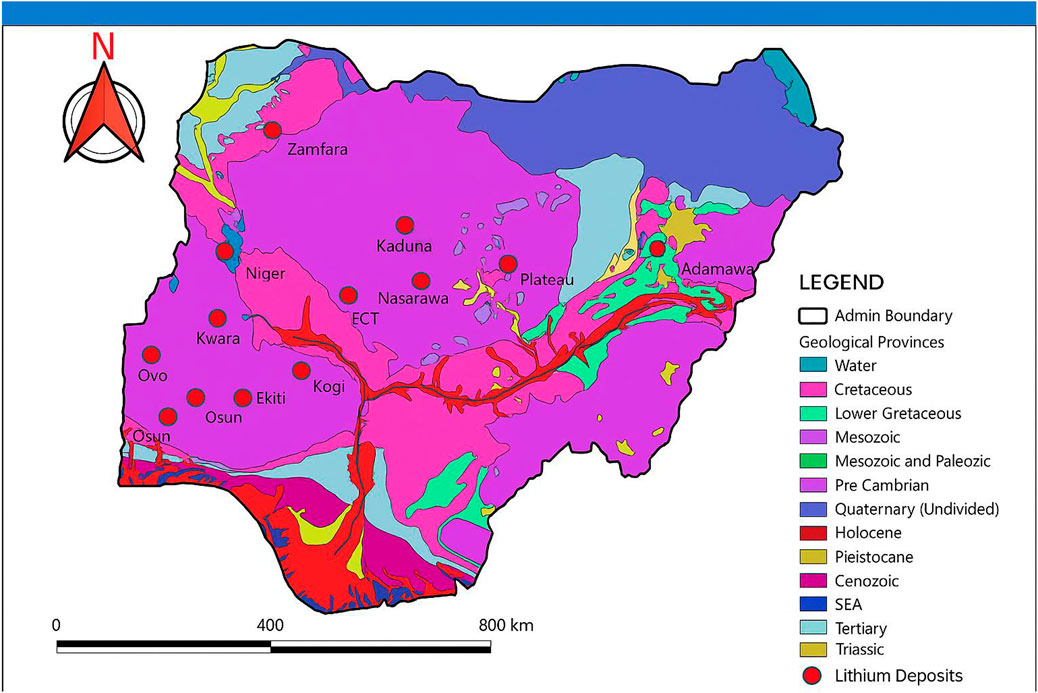

Table 1. Reserve estimates of lithium oxide in the LCT pegmatites dispersed in Nigerian states (MMSD/NGSA, 2023).

Additionally, the environmental and resource potential of lithium-bearing granite-pegmatite mining wastes is significant, with potential for reuse and recycling. However, they pose environmental or ecological risks due to the presence of elements like uranium (U) and thorium (Th) (Hudson-Edwards, 2024). In brine deposits such as the Lakko Co Salt Lake in Tibet, lithium is sourced from deep geological processes, including the weathering of surrounding rocks and contributions from hot springs (Li Z et al., 2024). Globally, lithium minerals are predominantly found in lithium–cesium–tantalum (LCT) granitic pegmatites, highly peralkaline pegmatites and metasomatic rocks, with spodumene being a major lithium ore mineral (Brennan et al., 2024; Grew, 2020). Spodumene, along with lepidolite, petalite, amblygonite, and zinnwaldite, are key lithium minerals, with spodumene being particularly significant due to its high lithium content and economic value (Sultanova and Michurin, 2024). The chemical composition of spodumene varies, with trace elements such as Fe, Mn, Ga, and Sn influencing its geochemical properties (Brennan et al., 2024).

Geochemical exploration techniques, such as those used in Iran, further illustrate the complexity of lithium geochemistry. Lithium is associated with elements like Be, Cs, and U, and is influenced by geological units like volcanic and tuff formations (Koohzadi et al., 2021; Saadati et al., 2020). Overall, the geochemistry of lithium ores is influenced by a combination of geological, mineralogical, and environmental factors, necessitating diverse exploration and extraction strategies.

3 Geology of Nigeria lithium

The geology of lithium deposits in Nigeria is associated with complex interconnection and diverse geological frameworks prevalent in the region. This framework includes a wide array of rock formations, such as igneous, metamorphic, and sedimentary rocks, all of which play a significant role in the formation and distribution of lithium deposits. Nigeria’s Precambrian Basement Complex comprises of crystalline igneous and metamorphic rocks, which form the oldest geological foundation and are interspersed with sedimentary basins of Cretaceous and Cenozoic age (Beob and Kim, 2023; Kazeem and Shitta, 2009). Lithium-bearing minerals such as lepidolite, spodumene, and petalite are primarily found in pegmatite fields, which are steeply inclined intrusive bodies within the basement rocks of gneisses and schistose assemblages, occasionally pulsed with isolated granitic bodies (Akinola, 2014; Akinola et al., 2014). These pegmatites are rich in lithium and other valuable minerals like tantalum, niobium, tin, and beryllium, with significant deposits in Kogi, Nasarawa, Ekiti, Kwara, Cross River, Oyo, and Plateau States (Chigozie et al., 2019).

The lepidolite from the Ijero-Aramoko pegmatite field exhibits a layered structure with high silica content (49.43%–57.81%) and notable concentrations of lithium (1,656 ppm–1859 ppm), aluminium, and potassium, making it suitable for industrial applications, including lithium-ion batteries and pharmaceuticals (Akinola, 2014; Akinola et al., 2014). Additionally, the polylithionite ore from Keffi in Nigeria has been successfully extracted in chloride media, demonstrating a high lithium leaching efficiency of 83.82% under optimal conditions (Omoniyi et al., 2020). The geological settings of these lithium deposits are further characterized by the presence of various rock types, including charnockite and granite, which are part of the older granite suite occupying significant portions of the area (Kazeem and Shitta, 2009).

The diverse mineralogy and geochemical characteristics of lithium-containing rocks are evident and primarily associated with high silica and barium content, indicating a sedimentary protolith origin derived from a continental environment (Ayodele, 2015). Nigeria’s rich endowment of lithium and other solid mineral resources underscores the potential for economic diversification from petroleum exploration. Research and technological advancement are also targeted at achieving local beneficiation and refining of these ores or minerals-containing rocks to drive economic growth and create wealth for the citizenry (Abdulfattah et al., 2023; Omoniyi et al., 2020; Chigozie et al., 2019). Nigeria’s geological, structural, and tectonic settings have not only facilitated the exploitation of these mineral deposits but also contributed to the geomorphological evolution of the landscapes, offering considerable aesthetic and touristic potential (Beob and Kim, 2023).

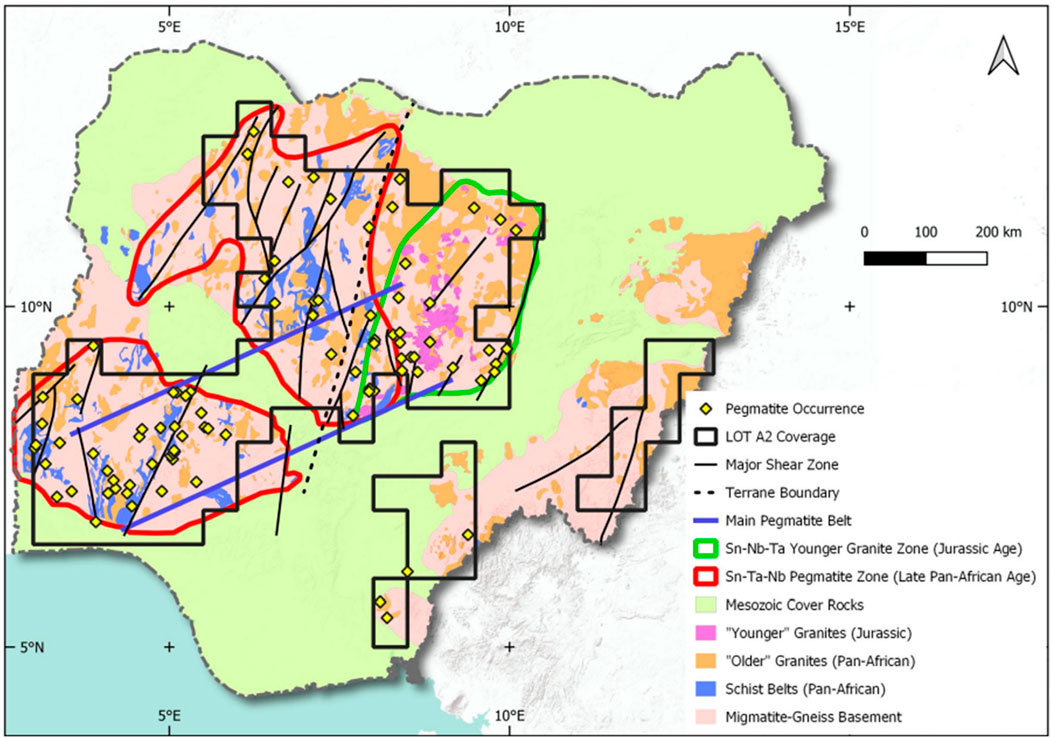

As shown in Figures 3, 4, Nigeria’s lithium deposits are dispersed within the WSE-ENE trending called the Lithium Belt or pegmatite metallogenic province. This zone spans over 700 km, covering an area from Oyo State in Southwestern Nigeria to Plateau State in the north-central region. As mentioned, the belt is characterised by Lithium-Caesium-Tantalum (LCT) pegmatites that are rich in lithium-bearing minerals, including lepidolite and spodumene. Similarly, the zone is within the Precambrian basement complex, as indicated on the geological map (Figure 3). In addition to the LCT pegmatites, the rare-metal pegmatites are a new lithium belt, which is slightly north and west of the Tin-Tantalum Belt. Overall, the Nigerian Lithium Belt reveals a vast lithium mineralisation that is rich in high-grade lithium ores, with some low-to medium-grade metasediments embedded in metavolcanic rocks of the Proterozoic Schist Belts.

Figure 3. Geological map of Nigeria. A figure showing the geological map of Nigeria with lithium deposits distributed across the thirteen (13) States in Nigeria (Sources: MMSD, 2022; Mustapha et al., 2022).

Figure 4. A figure showing the lithium-cesium-tantalum (LCT) pegmatites occurrence in Nigeria. Source: MMSD/NGSA, 2023.

4 Major lithium ore deposits in Nigeria

Nigeria possesses a substantial reserve of lithium ore deposits. This valuable resource has garnered increasing significance in response to the escalating worldwide need for lithium, notably in the context of lithium-ion batteries and other sustainable energy applications. Nigeria’s primary lithium ore reserves are located in Kogi, Nasarawa, Ekiti, Kwara, Cross River, Oyo, and Plateau States. These deposits contain various lithium-bearing minerals such as amblygonite, lepidolite, spodumene, and petalite, which are essential for the production of lithium-ion batteries used in numerous high-tech devices and electric vehicles (Abdulfattah et al., 2023; Chigozie et al., 2019).

Specifically, the polylithionite ore from Keffi in Nasarawa State has been studied for its lithium content, showing promising results with a lithium assay of 3.25 wt% and an extraction efficiency of 83.82% under optimal conditions (Omoniyi et al., 2020). Additionally, the Egbe District in Kabba Province of Kogi State is notable for its nigerite-group minerals, containing essential lithium, as demonstrated by Secondary Ion Mass Spectrometry (SIMS) analysis (Armbruster and Feenstra, 2004). The financial market theory of development has been applied to optimize lithium ore exploration in Nasarawa State, revealing a high presence of lithium, with concentrations exceeding 1859 parts per million (ppm) (Ayeni and Isah, 2024).

Despite these promising deposits, the full potential of Nigeria’s lithium resources remains underutilized due to various challenges, including the need for a robust supply chain and sustainable mining practices (Kesandu-Uchenyi and Harris, 2022). The reserve estimates of the resources in the LCT pegmatites in a few locations are shown in Table 1. However, further analysis using X-ray fluorescence revealed the percentage of lithium oxide present in the LCT pegmatites and other associated minerals, as indicated in Table 2. These resources can help address the rising global demand for lithium, which is driven by the expansion of the lithium battery market, underscoring the importance of research and investment in lithium ore development in Nigeria. The Nigerian government and stakeholders are encouraged to invest in the beneficiation and refining of lithium ores to harness these resources effectively and contribute to the global supply chain of lithium (Kesandu-Uchenyi and Harris, 2022). Furthermore, the presence of lithium in phosphate rocks in the Sokoto Sedimentary basins, although primarily noted for rare earth elements, also highlights the diverse mineral wealth of Nigeria that could be further explored for lithium content, as shown in Table 2 (Mustapha et al., 2022).

5 Lithium ores processing in Nigeria

5.1 Overview of lithium processing methods (general processing methods for lithium ores)

Bowagate Global Limited, in an article dated 12th of December 2023, on exporting lithium ore from Nigeria, highlighted the processes involved in lithium extraction, which include.

1. Mining: Ore deposits are located and extracted through conventional mining methods. The choice of mining method depends on several factors, such as the depth of the deposits, their size, and economic viability.

2. Crushing and Grinding: The mined ore undergo mechanical processes, leading to deformation and breakage, subsequent reduction of the ores’ particle size and efficient liberation, and separation of recovery of lithium and non-lithium minerals within the ores. This process is described as comminution.

3. Froth Flotation: This mineral processing method ensures the separation and recovery of lithium mineral based on its surface properties. In the context of primary lithium ores, froth flotation is used to concentrate lithium minerals such as spodumene and lepidolite from pegmatitic deposits. For instance, studies on European lithium ore deposits have demonstrated the use of froth flotation to achieve Li2O concentrates, although mineralogical challenges such as fine quartz and albite inclusions can limit the efficiency of the process (Sousa et al., 2019) The process relies on the differences in the surface properties of minerals, allowing stable air-bubble attachment and stability to guarantee selective separation either by direct or reverse flotation.

4. Roasting: The concentrate from froth flotation is roasted to convert lithium mineral into water-soluble compounds. This step is crucial for subsequent leaching. Philippe Yolka’s study on lithium recovery from spent lithium-ion batteries (LIBs) demonstrates that sulfuric acid roasting at 750 °C effectively converts lithium oxide into lithium sulfate, which is then dissolved in water (Jha et al., 2023). Another approach, as explored by Dong et al. (2024) involves calcium sulfate roasting of overhaul slag, which converts lithium into a soluble form, NaLi(SO4), that can be extracted through water leaching (Dong et al., 2024).

5. Leaching: This involves the use of laboratory chemicals or reagents to dissolve one or more of the minerals present in the ore at standard conditions. The roasted concentrate is subjected to a chemical process called leaching, where lithium is selectively dissolved in an acid solution. This solution is further processed to extract lithium carbonate or lithium hydroxide (water-soluble compound of lithium). Chen et al. (2024) effectively recovers lithium from rare earth molten salt electrolytic slag, achieving a high extraction rate of 98.52% under optimal conditions, with significant economic and environmental benefits due to its low acid consumption and high selectivity for lithium (Chen et al., 2024). Phosphoric acid leaching explored by Paris et al. (2024) presents a promising alternative for extracting lithium from spodumene, achieving over 40% efficiency, though it requires further optimization to enhance its viability (Paris et al., 2024). Liu et al. (2024) investigated the calcination-leaching method using oxalic acid for lithium-bearing clay minerals, achieving a recovery rate of 91.35% by promoting lithium release through phase transformation and ion exchange (Liu et al., 2024). Electrochemical leaching, as developed by Zhang et al., 2024, offers a novel approach for spodumene, utilizing H2O2 to facilitate electron transfer and achieve a leaching efficiency of 92.2%, highlighting its potential to reduce environmental impact and energy consumption (Zhang et al., 2024). Mubarok et al. (2021) demonstrated hydrochloric acid leaching for lithium extraction from geothermal mud, achieving a recovery rate of 98.3% under optimized conditions, showcasing the potential of utilizing waste materials for lithium recovery (Mubarok et al., 2021). Additionally, the use of sodium bicarbonate solutions for leaching lithium-rich bauxite flotation tailings, as studied by Han et al. (2024) achieved a 91.75% lithium recovery, emphasizing the role of ion substitution in the leaching mechanism (Han et al., 2024).

Lithium extraction techniques involve methods leading to the separation and recovery of lithium mineral from different sources, including lithium-bearing minerals and brines. The methods are broadly categorized into chemical, electrochemical, and physical processes. Each process or method has its advantages and limitations. As reported in the literature, chemical processing of lithium ores is a standard method for extracting lithium from spodumene. This involves the use of acid and alkali, such as sulfuric acid, hydrofluoric acid, hydrochloric acid, nitric acid, sodium hydroxide, calcium hydroxide, and sodium carbonate. Additionally, salt roasting processes, such as carbonate and sulfate roasting, and chlorination processes, which involve chloride salts or chlorine gas, are employed. These methods typically involve pre-treatment of the lithium mineral by chemical pre-processing, leaching, and separation of lithium from insoluble residues, followed by purification and precipitation using sodium carbonate to obtain lithium carbonate (Abdel-Aal et al., 2024).

Electrochemical extraction of lithium from brines and seawater is an innovative approach to lithium recovery. This method involves a four-step process using a lithium iron phosphate (LFP) electrode. The electrode is inserted into lithium-containing brine or seawater, and a negative current is applied to intercalate lithium ions into the electrode. The electrode containing lithium ions is placed in a recovery solution and charged to release lithium, which is subsequently precipitated as lithium carbonate. This method is scalable with minimal environmental impact, as it can extract lithium from oceans with minimal energy requirements (Brabson et al., 2022).

Similarly, ion exchange methods are used for lithium extraction. These involve reversible cation exchange with H+ ions, utilizing metal oxide or metalloid-oxide cation-exchange materials that preferentially bind lithium ions over other cations like H+ and Na+. This method effectively extracts lithium from solutions containing lithium ions (Snydacker et al., 2019). Mechanical and physical processes, such as mineral element phase transfer, are employed to treat lithium-containing minerals. The lithium concentrates or lithium-rich minerals are mixed with inorganic salts by mechanical activation, ultrasound, microwaves, and plasma treatment to facilitate lithium transition into a soluble salt. This method is environment-friendly and cost-effective, with a high lithium leaching rate.

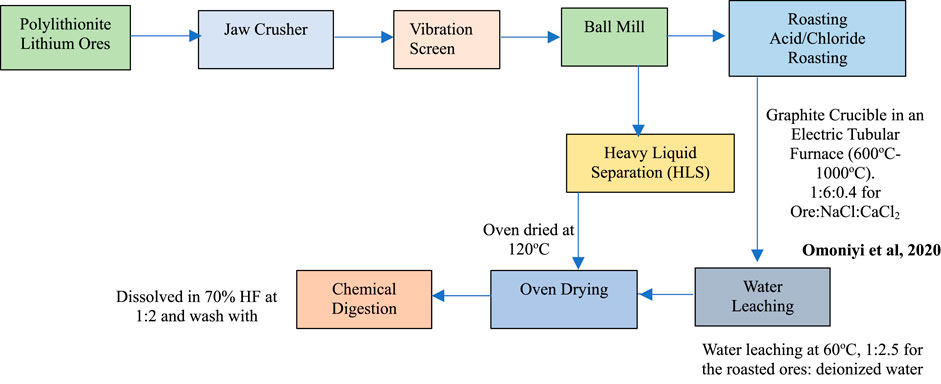

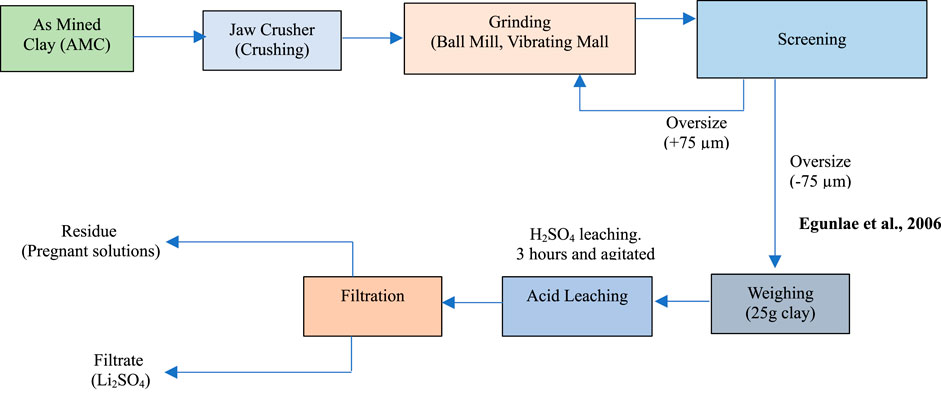

The extraction of lithium utilizes a variety of methodologies, which are specifically designed to accommodate distinct sources and environmental contexts. Chemical techniques are commonly employed for the extraction of minerals, whereas electrochemical and ion exchange approaches are increasingly recognized for their efficacy and ecological advantages. Figures 5, 6 present the process flowsheets of laboratory trials on the extraction of lithium from the polylithionite ores and clays deposits in Nigeria. The selection of a particular method is influenced by several considerations. These include the nature or sources of lithium deposits, mineralogical/chemical compositions, level of impurity or the quantity of gangue present in the ore, peculiar environmental implications, and economic viability. Collectively, these techniques play a significant role in meeting the growing global demand for lithium, owing to its requirement in which is propelled by its essential function in battery technologies advancement and other applications for renewable energy generation.

Figure 5. A sketch of laboratory-scale trials on the processing of Nigerian lithium ores from Nasarawa polylithionite Ores (Source: Omoniyi et al., 2020).

Figure 6. A sketch of laboratory-scale trials on the processing of Nigerian lithium ores from Ijero-Ekiti Clay (Source: Adapted/modified from Egunlae et al., 2006).

5.2 Local lithium processing capabilities in Nigeria; current state of lithium ore processing in Nigeria

Nigeria and several countries within Sub-Saharan Africa are endowed with substantial mineral resources and have recently realised an urgent need to develop technological and industrial capabilities to add value to the mineral resources locally. The limitations to mineral value addition in Nigeria have hindered economic diversification and global competitiveness. While the government is willing to develop the resources, sustainable solutions require multifaceted approaches, which include regulatory reforms, strategic industrial policies, and investment in innovation and technology. In the absence of technologies and capacities for the development of the sector, Nigerian government is open to foreign investors who are willing to set up processing and refining plants in for lithium in Nigeria.

Large-scale primary-level lithium processing began in Nigeria in 2023 with the commencement of operation by the Ganfeng Lithium Industry Ltd. Similarly, the Avatar New Energy Materials Company Ltd opened a lithium processing facility in Nasarawa, Nigeria, with a daily capacity of 4,000 tons. This effort aligns with Nigeria’s goal to become Africa’s solar and battery energy storage hub. The facility is expected to generate $500 million in revenue within a 15–20-year mining lifespan and contribute to Nigeria’s economic diversification and growth. A typical process flowsheet of an industrial-scale lithium processing plant is presented in Figure 7. Also, the Nigerian government expects investors to establish factories for the complete value chain from mining to processing and refining and then lithium battery manufacturing. However, it is uncertain that full-scale lithium processing is ongoing at their sites owing to peculiar mining and mineral extraction limitations in Nigeria.

Figure 7. A sketch of process flowsheet for industrial-scale lithium ore beneficiation in Nigeria. (Adapted from the JXSC process flowsheet – Source: JXSC Minerals).

In a holistic report on the Nanyang Technological University website (ntu.edu.sg) (China to Process Lithium in Nigeria | NTU-SBF Centre for African Studies (CAS) | NTU Singapore, n. d.) published on the 27th of May 2024. This report provided a basis for the potential of lithium processing in Nigeria. China’s Avatar New Energy Materials, the Nigeria’s largest lithium processing plant in Nasarawa State, is an estimated US$100 million facility and has a production capacity of 4,000 tonnes per day. While it is anticipated that Nigerian lithium will continue to attract investors owing to the presence of several lithium-rich minerals in different States, the future of local lithium processing in Nigeria is uncertain as there is a massive dominance of foreign investors in the Nigerian lithium processing space. Thus, there is a need for local or indigenous investment and research into lithium ore processing and beneficiation to guarantee the sustainable development of lithium ore reserves in Nigeria. This research should focus on developing African-adaptive, efficient and environment-friendly extraction and purification technologies to harness lithium full economic potential, regionally and globally. Similarly, research institutions and industries must collaborate to develop Nigerian lithium. These adaptive local methods will consider the economic, environmental, and other strategic factors peculiar to Nigeria. By addressing these challenges, the lithium industry can move towards more sustainable and economically viable practices, supporting the growing demand driven by the energy transition and electrification efforts.

5.3 Environmental and economic considerations for lithium mining and processing

Lithium and lithium-rich minerals is associated with silica, alumina, rare earth metals and heavy metals, and the unregulated lithium extraction contribute to severe environmental degradation. Such occurrences include chemical leaching, water depletion and contamination, air pollution, and soil degradation, and devastating public health issues similar to those experienced in the Niger Delta due to oil spills and gas flaring (Otorkpa et al., 2024). The lithium extraction process often involves the use of hazardous chemicals and heavy metals, which directly contribute to air and water pollution, posing risks to both ecosystems and human health (Biswas et al., 2024). Additionally, lithium mining result in groundwater depletion and land destruction, displacing communities and disrupting local ecosystems (López et al., 2023). The environmental footprint of lithium extraction is further compounded by the energy-intensive nature of the process, which contributes to carbon emissions and other ecological burdens (Siwiec et al., 2024).

In Nigeria, the potential for lithium-ion battery production is significant, yet it remains underutilized due to challenges in establishing a sustainable supply chain and regulatory framework (Onyenwe and Orah, 2022). The environmental impacts of lithium mining are not limited to Nigeria; globally, the extraction of lithium lower-grade lithium brines is associated with higher environmental impacts, particularly concerning water use in already water-scarce regions (Chordia et al., 2022). The presence of potentially toxic elements (PTEs) in groundwater due to mining activities poses serious health risks, as evidenced by studies in other Nigerian mining areas (Orosun et al., 2024).

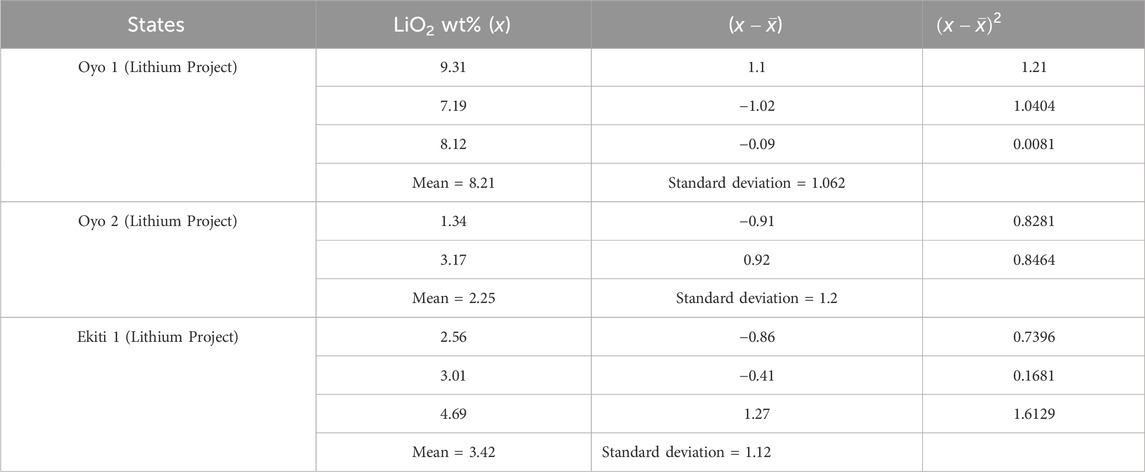

6 Quality of lithium in Nigeria

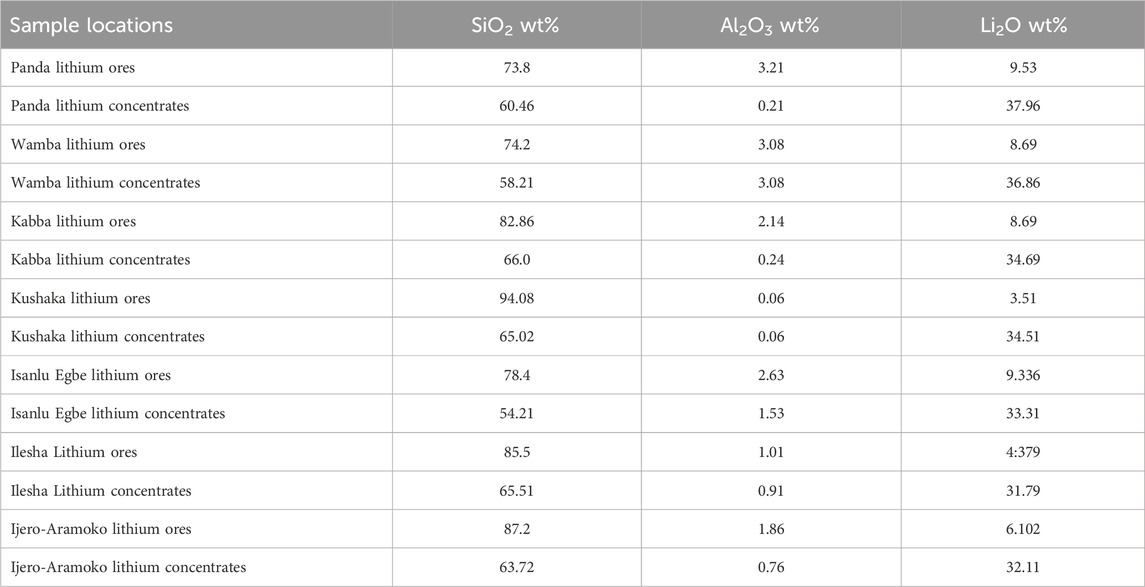

The percentage of lithium in the Nigerian lithium ores or lithium-containing minerals vary across locations and mineral grades. Mineralogical or chemical characterisation of rocks or ores by the Nigerian Ministry of Mines and Steel Development identified the presence of several lithium-rich minerals as shown in Table 3. Further analysis of the lithium rich minerals also confirmed the presence of lithium oxide, as shown in Tables 4 and 5. Lithium ores at Panda have an average of 9.53 wt%. This value is far above the highest percentage of lithium oxide in spodumene reported globally. However, the percentage of lithium oxide in ore deposits at Kushaka is 3.51%. The ore obtained from all the locations show economic source of lithium if the right mining and beneficiation techniques are adopted.

Table 4. Results of ED–XRF chemical analysis of sourced lithium ore at different deposits within Nigeria, indicating the maximum/height weight percent (wt%) of lithium oxide reported at the location (MMSD, 2022).

Table 5. Initial scout lithium ore sampling results by the Thor Exploration Ltd for new lithium mining projects (Thor Exploration Ltd, 2023).

Previous research on lithium processing has shown that lithium oxide can be extracted from lithium-rich minerals by froth flotation. Optimum recovery of lithium oxide from lithium ores led to a significant increase in Li2O in Kukasha deposits from 3.51 wt% to 34.51 wt% and 9.53 wt% to 37.96 wt% in Panda lithium deposits. Table 6 shows the results of the EDXRF analysis of lithium concentrates obtained by froth flotation, indicating a significant reduction of the major gangue mineral in the ores (SiO2) and an increase in lithium oxide (Li2O). The weight percent (wt%) of lithium oxide in each ore was determined following the general laboratory protocols of the energy dispersive X-ray fluorescence (EDXRF). A Thermo Fisher Scientific Energy Dispersive X-ray Fluorescence (EDXRF) was used to analyse lithium ores from different locations. The analysis was conducted using the standard method, which relies on the calibration curve. The ores were ground into a fine powder using a laboratory mortar. 2 g of the pulverised ores were poured into the sample holder, which was placed in a vacuum for 10 min. The samples were inserted into the EDXRF for elemental analysis, and the results were extracted from the device after 10 min of analysis. The results were assessed/standardised using standard reference materials obtained from the International Atomic Energy Agency (IAEA) and presented in Table 5.

Table 6. Results of EDXRF chemical analysis of beneficiated lithium ores using froth flotation processing method (MMSD, 2022).

Tables 7, 8 show countries that dominate the global processing/production of lithium-based on the volume of deposits or reserves, mine production and distribution. Nigeria belongs to the “other” category. Despite abundant lithium ores in thirteen (13) states and scattered across twenty (20) lithium deposit sites, Nigeria has yet to commence operations leading to full-scale lithium processing and developing the lithium processing value chain. Much is needed on Nigeria’s lithium deposits in exploration, exploitation, processing, research, and reporting. This will enable Nigeria to develop a mineral processing road map and flowsheet for lithium ores.

Table 7. Global lithium production and reserves (brines and deposits) in tons (US Geological survey, 2018).

7 Research gaps and future directions

7.1 Unexplored areas for lithium exploration in Nigeria

Despite Nigeria’s abundant mineral resources, including lithium deposits, a significant gap exists in comprehensive geological mapping and research on the characterisation of these resources (Abdulfattah et al., 2023). As mentioned, pegmatites and polylithionite ores have been mapped in thirteen (13) Nigerian states by satellite and airborn remote sensing. However, the detailed mapping of key lithium-rich minerals, such as spodumene and lepidolite, within the pegmatites in Oke-Ogun (Oyo State) and Kakafu (Kwara State), is ongoing. Similarly, the mapping of five (5) pegmatite ores in Oyo state and three (3) locations in Ekiti state by Thor’s Exploration Ltd was concluded in 2023. The mapping of pegmatites in Kwara, Ekiti, FCT, Nasarawa and Plateau States in Nigeria by the Ministry of Mines and Steel Development (MMDS) and the Nigerian Geological Survey Agency (NGSA), as shown in Figure 4 and Table 1, provided details on the reserve estimates of lithium oxide within the locations.

In addition to large-scale detailed mapping, laboratory-scale assessment of ores at Kakafu pegmatites in Kwara State (Tanko et al., 2024; Olade, 2025), Egbe-Isalu pegmatites in Kogi State (Babatunde, 2021), and Makarfi LGA in Kaduna State (Abdulrahman et al., 2024) is an indication of the relevance of detailed mapping of lithium ores to research advancement and development of lithium in Nigeria. Aside from the five (5) states where extensive mapping of the pegmatitic ores is ongoing, no known extensive exploration activities are ongoing at the remaining eight (8) States where pegmatites and other lithium ores have been reported, as presented in Figure 3. Pegmatites also occur in several Nigerian states beyond the thirteen (13) States known for lithium-caecium-tantalum (LCT) pegmatite, as shown in Figures 3, 4. These locations and many others within the State that are known for lithium occurrence have not been mapped despite the prospect for lithium ores.

The current focus is on the beneficiation and extraction of lithium. Omoniyi et al. (2020) reported on the hydrometallurgical extraction of lithium from polylithionite ore in Keffi, indicating 83.82% efficiency in lithium recovery (Omoniyi et al., 2020). However, the potential of other lithium-bearing minerals, such as lepidolite in the Ijero-Aramoko pegmatite field, remains underexplored (Akinola, 2014).

The integration of advanced geophysical methods to delineate lithologies and hydrothermal alteration zones is pivotal in identifying new lithium-rich areas (Kariya et al., 2024). For instance, the use of airborne magnetic and radiometric data has shown certain possibilities for potential in mapping mineralization zones. Such data analytical methods are yet to be applied in lithium exploration and extraction (Adebiyi et al., 2024).

Moreover, the potential of associated petroleum waters as a lithium source has been suggested, yet this remains largely unexplored in Nigeria (Kudryavtsev and Kudryavtsev, 2018). The Paleoproterozoic rocks of the West African Craton, which include parts of Nigeria, also offer a new Frontier for lithium exploration, given their pegmatite deposits with significant lithium-bearing potential (Kazapoe, 2023). In summary, while some progress has been made towards the optimisation of lithium extraction techniques, there is a need for comprehensive geological surveys, advanced geophysical mapping, and exploration of unconventional lithium sources to realize Nigeria’s lithium potential fully.

7.2 Technological and infrastructure gaps

As highlighted in several studies, the need for improved processing technology and infrastructure for lithium ore beneficiation is a significant research gap. In Nigeria, a few studies on the beneficiation of lithium ores and lithium-rich clay are energy-intensive and involve the use of toxic chemicals such as hydrofluoric acid (HF) for roasting. These processes, as described in Figures 5, 6, are expensive, dependent on imported chemical reagents, and therefore, they are not sustainable and cannot be scaled up (Kanagasundaram et al., 2024; Sahoo et al., 2024). Current beneficiation methods, such as flotation, gravity concentration, and electrochemical processes, face challenges related to reagent chemistry, surface properties, and mineralogical limitations, which affect the efficiency of lithium recovery from pegmatite ores (Sahoo et al., 2024; Sousa et al., 2019). For instance, fine quartz and albite inclusions in lithium silicates can hinder the production of high-grade Li2O concentrates, indicating a need for more refined processing technologies (Sousa et al., 2019).

Hence, bridging these developmental gaps in research and practice can ensure the efficient mapping of the lithium ores in Nigeria, supporting a reliable domestic supply of lithium and reducing import dependency (Melentiev et al., 2022; Xing et al., 2022).

In Nigeria, lithium extraction from polylithionite ore, as demonstrated by Omoniyi et al. (2020), highlights the potential for industrial application but also points to the necessity for advanced beneficiation techniques to enhance lithium recovery efficiency beyond the reported 83.82% (Omoniyi et al., 2020). Beyond the lab-scale beneficiation of lithium, large-scale lithium processing in Nigeria has not been reported. While there are several exploration projects such as the Kwara, Ekiti, and Oyo States Lithium projects of Thor’s Exploration Ltd and the Rare-earth projects of the Nigerian government, these projects do not translate into local lithium production other than the characterisation of the ores.

The economic production model proposed by Abam and Isah (2024), emphasizes the importance of optimizing mining systems to maximize profit, which inherently requires sophisticated and reliable processing technologies to handle the complex geo-mining conditions present in Nigeria (Abam and Isah, 2024). Furthermore, the burgeoning demand for lithium-ion batteries, as discussed by Ichu and Onochoja (2020), presents a significant opportunity for Nigeria, given its rich mineral resources (Ichu and Onochoja, 2020). However, the developing a local lithium-ion battery industry is contingent upon establishing a robust supply chain, which is currently hampered by underutilized resources and inadequate processing infrastructure (Onyenwe and Orah, 2022). Addressing these technological and infrastructural gaps is essential for advancing lithium beneficiation and meeting the growing global demand for this critical mineral.

7.3 Environmental and sustainability challenges

The environmental impacts of lithium supply chains in Nigeria and Africa, highlight the inefficiencies of existing processing methods (lab-scale) for commercialisation. These methods depend on imported materials and cannot be sustained using the hydroelectric power, which is the main source of electricity in Nigeria. Similarly, the existing techniques are characterized by high carbon footprints caused by energy-intensive refining processes (acid/chloride roasting) and leaching, as shown in Figure 5 (Feng et al., 2024). Integrating environmental, social, and governance (ESG) issues in the Lithium Triangle is crucial for sustainable extraction, necessitating improved water cycle understanding, biodiversity impact integration, and enhanced community participation in decision-making processes (Petavratzi et al., 2022). While these environmental and sustainability challenges in lithium mining present significant research gaps, a balanced and independent research is required to address the knowledge gaps and power asymmetries between companies and local communities, and to ensure a sustainable lithium production (Van Pampus et al., 2023).

The potential socio-economic and environmental impacts of lithium mining include groundwater depletion and community displacement considering the existing mineral developmental structure in Nigeria. Addressing the long-term impacts will necessitate dynamic modeling and policy interventions similar to battery recycling and reforestation framework, adopted elsewhere (López et al., 2023). Recycling lithium-ion batteries through hydrometallurgical methods offers a sustainable alternative to mitigate the environmental impacts of mining, emphasizing the need for cleaner production and life cycle assessments (Liang et al., 2021). The electric vehicle battery value chain faces sustainability challenges, requiring multifaceted solutions and a climate-smart framework to balance decarbonization goals with resource efficiency (Jannesar et al., 2024).

Finally, the ecotoxicological effects of lithium in soil-plant systems reveal its potential as an emerging contaminant, necessitating further research into its environmental behavior and phytoremediation strategies (Xu et al., 2024). In Nigeria, the potential for lithium-ion battery development is hindered by the underutilisation of raw minerals and a lack of robust supply chains, which are essential for sustainable growth in this sector (Onyenwe and Orah, 2022). The lack of robust regulatory frameworks and sustainable practices in Nigeria’s mining sector exacerbates these challenges, as seen in the quarrying industry, where habitat destruction and pollution are prevalent due to inadequate policies (Ogechukwu et al., 2024). Collectively, these studies underscore the urgent need for comprehensive research and policy frameworks to address the environmental and sustainability challenges in lithium mining.

7.4 Policy and investment gaps

Nigeria’s abundant lithium resources present a significant opportunity for economic diversification away from oil dependency (Abdulfattah et al., 2023). However, the country faces challenges in optimising lithium extraction and beneficiation processes, as demonstrated by studies on the hydrometallurgical extraction of lithium from Nigerian polylithionite ore, which highlight the need for further research and value addition at industrial scale (Omoniyi et al., 2020). Also, developing a Mining Resource Corridor (MRC) is proposed as a strategic approach to integrate mineral extraction with broader economic activities. While the approach can change the narrative, it requires the implementation of robust institutional frameworks and policies backed by community engagement to succeed (Azubuike et al., 2023). Furthermore, the global demand for lithium, which is driven by the growing lithium-ion battery market, underscores Nigeria need to establish a secure and sustainable supply chain for the mineral (Onyenwe and Orah, 2022).

The environmental and socio-economic impacts of lithium mining also necessitate the implementation of policies that promote sustainable practices, such as environment-friendly battery recycling and reforestation initiatives (López et al., 2023). Governance issues, particularly the need for improved economic regulation and raw material politics, are critical for attracting responsible investments and ensuring the effective management of lithium resources (Bravo, 2023). Additionally, the optimization of mining systems through economic production models, currently explored in Nasarawa, highlights the potential for increased profitability and efficiency in lithium exploration (Abam and Isah, 2024). Addressing these research gaps requires a coordinated effort to develop an active-based road map and policies to attract investments aligned with sustainable development goals, leveraging Nigeria’s rich lithium deposits to foster economic growth and diversification.

8 Nigeria government contributions towards safe and sustainable lithium mining and processing

The transition to clean energy has significantly increased global demand for lithium to drive renewable energy sources and advance battery technology. This energy transition becomes sustainable by ensuring a continued supply of lithium, which requires efficient mining of lithium ores and the extraction of lithium using environment-friendly approaches. The government’s contribution is significant in combating illegal mining, enforcing mining regulations, and protecting resources, miners, the mining community, and the environment. However, the activities of illegal miners in Nigeria are complicated owing to poor documentation, limited data on these activities and their locations. While the licensed miners are formalised into groups, the formalisation of the illegal miners has proven challenging due to economic hardship, corruption and terrorism. Addressing these developmental challenges to lithium extraction in Nigeria will boost the confidence of licensed mining firms, attract potential investors, and ensure a sustainable supply of lithium mineral and other rare earth minerals in lithium ores for the energy transition.

The Associated Press (one of Nigerian Newspapers) reported on the 27th of May 2024 (Adebayo, 2024) that Nigeria had intensified its efforts to combat illegal lithium mining. Recent operations have led to multiple arrests of foreign nationals and other local illegal miners, highlighting the involvement of foreign entities in illegal mining activities. Illegal mining has been linked to several issues ranging from banditry and corruption. The government’s effort through the formalisation of artisanal and small-scale miners and the enactment of mining regulations has helped to minimise illegal mining and extraction of lithium and other minerals in Nigeria. Similarly, the reactivation of “The Solid Minerals Development Fund (SMDF) through the government’s partnership with the Africa Finance Corporation (AFC) will stimulate private sector mining investments and active engagement support promising mining projects and provide funding opportunities needed for sustainable investment in lithium extraction. This partnership will also support the construction of midstream processing plants in Nigeria for lithium, nickel, and other energy transition metals, which is critical for the global clean energy transition, increased investment, and environmental protection.

The Nigerian government recently implemented the Electronic Mining Cadastre System (eMC+), a digital platform that facilitates the online management of mineral titles. Since its inception, the platform has increased revenue generation for the Nigerian government, boasting transparency and efficiency in the process. However, there are no records of sanctions against defaulters and illegal miners, nor of the closure of illegal mining operations. While the platform aims to enhance transparency in licensing and regulation by improving communication between the government and industry stakeholders, its impact is primarily felt in revenue generation, rather than on the process, practices and the people. A holistic data acquisition and analysis of lithium mining activities is critical for formalising the process and the people involved, and to ensure that digitalising systems and processes can transform the mining industry.

9 Conclusion and recommendations for future work

The review of Nigeria’s lithium resources has established the quality and reserve estimates of the deposits at different locations. The geological features of these resources indicated that several locations of lithium occurrences are poorly mapped or have not been mapped at all, owing to several identified developmental challenges. Key findings identified multiple locations of pegmatitic formations, which are enriched with spodumene and lepidolite–the main lithium-bearing minerals of high-grade lithium content. The resource base is vast and can be developed to meet the global demand for lithium, similar to other lithium-producing countries. However, certain limitations to lithium extraction and efficient processing of quality lithium concentrates were identified, as follows. Recommendations for future work, as potential solutions to the limitations, are also provided.

1. Poor infrastructure and technological capacity for scale-up, reliance on imported material for laboratory methods, limited technological expertise, illegal lithium mining, corruption, inadequate documentation of mining activities and qualitative data, and weak regulatory institutions. A declaration of a state of emergency in the mining and mineral extraction sector, particularly for lithium ores, is necessary to ensure a continued supply of lithium mineral.

2. Further geological surveys using advanced tools and sustainable investment in mining infrastructure would help Nigeria accurately estimate and characterise its lithium resources, determine the most efficient extraction methods, and attract international investments and partnerships.

3. Developing a strong research-industry-government-community nexus for the development of the Nigerian lithium ore can position Nigeria as a critical supplier of lithium and other rare earth metals, supporting local economic development and global sustainable energy solutions.

4. Given the contributions of Nigerians in diaspora to regional and global development, and its vast human resources within over five hundred (500) research and higher institutions in Nigeria, increasing investment for future research on lithium extraction and national security, and the enforcement of laws can address most of the developmental challenges to lithium processing.

Author contributions

SO: Conceptualization, Data curation, Funding acquisition, Investigation, Methodology, Writing – original draft, Writing – review and editing. HA: Writing – review and editing. OO: Supervision, Writing – review and editing. DA: Supervision, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. The Research is funded through by Rsif-PASET through a PhD scholarship offered to the first author.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abam, O. A., and Isah, A. S. (2024). Constrained maximization of the economic production model of lithium ore exploration in Nasarawa. Afr. J. Math. Statistics Stud. 7 (2), 208–224. doi:10.52589/AJMSS-O1EZNDIB

Abdel-Aal, E.-S., El-Sayed, D., and Abdel-Ghafar, H. (2024). Extraction of lithium from naturally occurring Li -bearing minerals. Int. J. Mater. Technol. Innovation 0 (0), 1–13. doi:10.21608/ijmti.2024.259834.1100

Abdulfattah, F., Bwala, M. D., Alabi, O. O., Sayyadi, M. G., and Hassan, S. B. (2023). “Characterization and beneficiation of Nigerian lithium ore: an overview,” in Rare metal technology 2023. Editors T. Ouchi, K. Forsberg, G. Azimi, S. Alam, and N. R. Neelameggham (Switzerland: Springer Nature), 239–246. doi:10.1007/978-3-031-22761-5_24

Abdulrahman, M., Jumare, H. H., and Isa, I. (2024). Mineralogical study of lithium -caesium tantalum (LCT) pegmatite rocks in Makarfi L.G.A, Kaduna state. Int. J. Adv. Eng. Manag. (IJAEM) 6 (10), 389–398. doi:10.35629/5252-0610389398

Adebayo, T. (2024). Nigeria government cracks down on illegal Lithium mining operations AP News. Available online at: https://apnews.com/article/nigeria-illegal-critical-minerals-lithium-arrests-tin-4c639e034f6bca724bf26cdc55805d4e.

Adebiyi, L. S., Falade, S. C., Dopamu, K. O., and Alejolowo, E. A. (2024). “Mineral potential of parts of southwestern Nigeria from magnetic and radiometric methods,” in 2024 international Conference on Science, Engineering and Business for driving sustainable development goals (SEB4SDG) (IEEE), 1–3.

Aguirre B, F. (2022). The lithium triangle – the importance of Bolivia. J. Energy and Nat. Resour. Law 40 (2), 183–202. doi:10.1080/02646811.2021.1930708

Akinola, O. O. (2014). Lithostructural framework and rare metal (Ta-Nb-Sn-Li-Be) mineralisation in lepidolite from the Ijero-Aramoko pegmatite field, south-western Nigeria. Afr. J. Sci. Technol. Innovation Dev. 6, 127–133. doi:10.1080/20421338.2014.924263

Akinola, O. O., Olugbenga, A., and Obasi, A. R. (2014). Physico-chemical characteristics and industrial potentials of lepidolite from Ijero-Aramoko pegmatite field, Southwestern Nigeria. International Journal of Scientific and technology research,

Armbruster, T., and Feenstra, A. (2004). Lithium in nigerite-group minerals. Eur. J. Mineralogy 16 (2), 247–254. doi:10.1127/0935-1221/2004/0016-0247

Ayeni, O. A., and Isah, A. S. (2024). Constrained Maximization of the economic production model of lithium ore exploration in Nasarawa. doi:10.52589/ajmss-o1ezndib

Ayodele, O. S. (2015). The geology, geochemistry and petrogenetic studies of the Precambrian Basement rocks around Iworoko, Are and Afao area, Southwestern Nigeria. J. Geol. Geophys 04 (212), 2. doi:10.4172/2381-8719.1000212

Azubuike, S. I., Nakanwagi, S., and Pinto, J. (2023). Mining Resource Corridor development in Nigeria: critical considerations and actions for a diversified and sustainable economic future. Mineral. Econ. 36 (1), 59–75. doi:10.1007/s13563-022-00307-5

Babatunde, W. S. (2021). Mineralogy, geochemistry and economic potentials of pegmatites at Egbe-Ejiba-Isanlu Sheet 225 Southwestern Nigeria. Nigeria: Kwara State University.

Balaram, V., Santosh, M., Satyanarayanan, M., Srinivas, N., and Gupta, H. (2024). Lithium: a review of applications, occurrence, exploration, extraction, recycling, analysis, and environmental impact. Geosci. Front. 15 (5), 101868. doi:10.1016/j.gsf.2024.101868

Bhattacharya, T., Brennan, P. R., Ibarra, D. E., Gagnon, C. A., Butler, K. L., Terrazas, A., et al. (2024). Pleistocene shifts in Great Basin hydroclimate seasonality govern the formation of lithium-rich paleolake deposits. Quat. Sci. Rev. 335, 108747. doi:10.1016/j.quascirev.2024.108747

Biswas, N., Ghosh, A., Mitra, S., and Majumdar, G. (2024). “Environmental issues associated with mining and minerals processing,” in Comprehensive materials processing (Elsevier), 77–86. doi:10.1016/B978-0-323-96020-5.00135-7

Bowell, R. J., Lagos, L., De Los Hoyos, C. R., and Declercq, J. (2020). Classification and characteristics of natural lithium resources. Elements 16 (4), 259–264. doi:10.2138/gselements.16.4.259

Bowell, R. J., Lagos, L., de los Hoyos, C. R., Declercq, J., and Julien, D. (2020). Classification and characteristics of natural lithium resources. Elements 16, 259–264. doi:10.2138/GSELEMENTS.16.4.259

Brabson, L., Huang, P.-W., Filippas, A., and Liu, N. (2022). A novel electrochemical method to extract lithium from Aqueous solutions. ECS Meet. Abstr. (55), 2288. doi:10.1149/MA2022-01552288mtgabs

Brennan, C. J., Student, J. J., Hill, T., Martins, T., and Sirbescu, M.-L. C. (2024). Trace element concentrations and chemical zoning of spodumene from magmatic and hydrothermal origins. Ore Geol. Rev. 169, 106089. doi:10.1016/j.oregeorev.2024.106089

Chen, S., Gong, Q., Li, P., Xu, S., and Liu, N. (2024). Describing geochemical backgrounds of lithium in rock-soil-sediment systems. Appl. Geochem. 162, 105908. doi:10.1016/j.apgeochem.2024.105908

Chigozie, I., Fabian, O., and Ufuoma, O. (2019). Lithium ion battery research and development: the Nigerian potential.

China to process lithium in Nigeria (2023). NTU-SBF Centre for African studies (CAS) NTU Singapore. Available online at: https://www.ntu.edu.sg/cas/news-events/news/details/china-to-process-lithium-in-nigeria.

Chordia, M., Wickerts, S., Nordelöf, A., and Arvidsson, R. (2022). Life cycle environmental impacts of current and future battery-grade lithium supply from brine and spodumene. Resour. Conservation Recycl. 187, 106634. doi:10.1016/j.resconrec.2022.106634

Dessemond, C., Lajoie-Leroux, F., Soucy, G., Laroche, N., and Magnan, J. F. (2019). Spodumene: the lithium market, resources and processes. Minerals 9 (6), 334. doi:10.3390/min9060334

Dong, L., Jiao, F., Liu, W., Wang, C., Wang, D., and Qin, W. (2024). Selective recovery of lithium from overhaul slag by the calcium sulfate roasting—water leaching. SSRN. doi:10.2139/ssrn.4833321

Ebikemefa, C., and Basu, M. (2023). Benefits Of Lithium Mining To Nigeria’s Economic Development. Innovare J. Soc. Sci., 15–18. doi:10.22159/ijss.2024.v12i1.49993

Egunlae, O. O., Obisesan, P. O., and Adeloye, A. O. (2006). Lithium recovery from Ekiti clays. Niger. J. Eng. Manag. (NJEM) 7 (4), 46–52.

Fanka, A., and Tadthai, J. (2023). Petrology and geochemistry of Li-bearing pegmatites and related granitic rocks in southern Thailand: implications for petrogenesis and lithium potential in Thailand. Front. Earth Sci. 11, 1221485. doi:10.3389/feart.2023.1221485

Feng, Y., Wang, P., Li, W., Zhang, Q., Chen, W.-Q., and Feng, D. (2024). Environmental impacts of lithium supply chains from Australia to China. Environ. Res. Lett. 19 (9), 094035. doi:10.1088/1748-9326/ad69ac

Fornari Caprara, A. L., Durante, I., and Pitton Rissardo, J. (2023). The Intermittencies of lithium. J. SAARC Psychiatric Fed. 1 (2), 94–96. doi:10.4103/jspf.jspf_18_23

Giglio, E. (2021). Extractivism and its socio-environmental impact in South America. Overview of the “lithium triangle.”. América Crítica, 47-53 Paginazione. doi:10.13125/AMERICACRITICA/4926

Greim, P., Solomon, A. A., and Breyer, C. (2020). Assessment of lithium criticality in the global energy transition and addressing policy gaps in transportation. Nat. Commun. 11 (1), 4570. doi:10.1038/s41467-020-18402-y

Grew, E. S. (2020). The minerals of lithium. Elements 16 (4), 235–240. doi:10.2138/gselements.16.4.235

Han, Y., Bedrossian, S., Fraser, R., Bellino, M., and Bibienne, T. (2023). Lithium-ion batteries recycling trends and Pathways: a Comparison. Proc. 62nd Conf. Metallurgists, COM 2023, 197–203. doi:10.1007/978-3-031-38141-6_22

Han, D., Shen, L., Song, E., and Peng, Z. (2024). Leaching behaviors of lithium-rich bauxite flotation tailings in sodium bicarbonate solution. J. Sustain. Metallurgy 10, 241–249. doi:10.1007/s40831-024-00787-5

Heichenko, M. V., Falkovich, O. L., Mienasova, A.Sh., and Liventseva, H. A. (2023). Current state's condition of lithium ore deposits in Ukraine. Mineralogical J. 45 (1), 83–94. doi:10.15407/mineraljournal.45.01.083

Hu, C., He, Y., Liu, D., Sun, S., Li, D., Zhu, Q., et al. (2019). Advances in mineral processing technologies related to iron, magnesium, and lithium. Rev. Chem. Eng. 36 (1), 107–146. doi:10.1515/revce-2017-0053

Hudson-Edwards, K. A. (2024). Geochemistry and mineralogy of wastes from lithium-bearing granite-pegmatite mining: resource potential and environmental risks. Front. Geochem. 2, 1378996. doi:10.3389/fgeoc.2024.1378996

Ichu, B. C., and Onochoja, U. F. C. (2020). Lithium ion battery research and development: the Nigerian potential. Pac. Int. J. 3 (1), 13–18. doi:10.55014/pij.v3i1.88

Jannesar Niri, A., Poelzer, G. A., Zhang, S. E., Rosenkranz, J., Pettersson, M., and Ghorbani, Y. (2024). Sustainability challenges throughout the electric vehicle battery value chain. Renew. Sustain. Energy Rev. 191, 114176. doi:10.1016/j.rser.2023.114176

Jha, M. K., Choubey, P. K., Panda, R., Dinkar, O. S., and Singh, N. (2023). “Recovery of lithium from waste LIBs using sulfuric acid roasting and water Washing,” in The minerals, metals and materials Society (Nature Switzerland: Springer), 1155–1161. doi:10.1007/978-3-031-22524-6_108

Jones, W. D. (2022). A rich Harvest in the Desert. IEEE Spectr. 59 (11), 14–15. doi:10.1109/MSPEC.2022.9941047

Kanagasundaram, T., Murphy, O., Haji, M. N., and Wilson, J. J. (2024). The recovery and separation of lithium by using solvent extraction methods. Coord. Chem. Rev. 509, 215727. doi:10.1016/j.ccr.2024.215727

Kariya, I. I., Haruna, A. I., Lawal, A., Abdulmumin, Y., Nabage, A., Kamale, H. I., et al. (2024). Field occurrences of lithium and its’ associated minerals from Kariya and Environs, Ganjuwa LGA, Bauchi state, NE Nigeria. Int. J. Earth Sci. Knowl. Appl. 6 (2), 158–165. Available online at: https://dergipark.org.tr/en/pub/ijeska/issue/87240/.

Kavanagh, L., Keohane, J., Garcia Cabellos, G., Lloyd, A., and Cleary, J. (2018). Global lithium sources—industrial use and future in the electric vehicle industry: a review. Resources 7 (3), 57. doi:10.3390/resources7030057

Kazapoe, R. W. (2023). Assessing the lithium potential of the Paleoproterozoic rocks of the West African craton; the case so far. Geosystem Eng. 26 (6), 257–271. doi:10.1080/12269328.2023.2229351

Kesandu-Uchenyi, O., and Harris, O. O. (2022). Lithium ion battery production in Nigeria: issues and challenges. Eur. J. Eng. Technol. Res. doi:10.24018/ejeng.2022.7.3.226

Koohzadi, F., Afzal, P., Jahani, D., and Pourkermani, M. (2021). Geochemical exploration for Li in regional scale utilizing Staged Factor Analysis SFA and Spectrum-Area S-A fractal model in north central Iran. Iran. J. Earth Sci. 13 (4). doi:10.30495/ijes.2021.685397

Kudryavtsev, Р. G., and Kudryavtsev, N. P. (2018). Lithium: resources, production and prospects of world market development. Altern. Energy Ecol. (ISJAEE) 10-12, 70–81. doi:10.15518/isjaee.2018.10-12.070-081

Li, X. H., Li, Q. L., Liu, Y., and Tang, G. Q. (2011). Further characterization of M257 zircon standard: a working reference for SIMS analysis of Li isotopes. J. Anal. Atomic Spectrom. 26 (2), 352–358. doi:10.1039/c0ja00073f

Li, P., Gong, Q., Chen, S., Li, P., Li, J., Wu, X., et al. (2024). Regional geochemical characteristics of lithium in the Mufushan area, south China. Appl. Sci. 14 (5), 1978. doi:10.3390/app14051978

Li, Z., He, M.-Y., Li, B., Wen, X., Zhou, J., Cheng, Y., et al. (2024). Multi-isotopic composition (Li and B isotopes) and hydrochemistry characterization of the Lakko Co Li-rich salt lake in Tibet, China: origin and hydrological processes. J. Hydrology 630, 130714. doi:10.1016/j.jhydrol.2024.130714

Liang, Z., Cai, C., Peng, G., Hu, J., Hou, H., Liu, B., et al. (2021). Hydrometallurgical recovery of spent lithium ion batteries: environmental strategies and sustainability evaluation. ACS Sustain. Chem. and Eng. 9 (17), 5750–5767. doi:10.1021/acssuschemeng.1c00942

Liu, J., Xu, R., Sun, W., Wang, L., and Zhang, Y. (2024). Lithium extraction from lithium-bearing clay minerals by calcination-leaching method. Minerals 14 (3), 248. doi:10.3390/min14030248

López, C. D., Reyes, Ma. F., Martínez, J., and Morcillo, J. D. (2023). “Simulation of the environmental and socio-economic impact from the lithium industry within producing countries,” in Proceedings of the international Conference on industrial Engineering and operations management. 6th European international Conference on industrial Engineering and operations management, Lisbon, protugal. doi:10.46254/EU6.20230108

Melentiev, G. B., Yurgenson, G. A., and Delitzyn, L. M. (2022). Prospects and priorities for the reconstruction and development of lithium mining production on the basis of domestic raw materials. IOP Conf. Ser. Earth Environ. Sci. 962 (1), 012055. doi:10.1088/1755-1315/962/1/012055

MMSD/NGSA (2023). National integrated minerals exploration project – rare earth pegmatite project report of the federal Ministry of mines and Steel development (MMSD) – Nigerian geological survey agency (NGSA), federal republic of Nigeria

Mubarok, M. Z., Madisaw, R. F., Kurniawan, M. R., and Hidayat, T. (2021). Experimental study of lithium extraction from a lithium-containing geothermal mud by hydrochloric acid leaching. J. Sustain. Metallurgy 7 (3), 1254–1264. doi:10.1007/S40831-021-00415-6

Mustapha, S. O., Olatunji, A. S., Ajayi, F. F., and Isibor, R. A. (2022). Mineralogy and geochemistry of some phosphate deposits for possible rare earth elements mineralization potentials within Sokoto Basin, Northwestern Nigeria. Indian J. Sci. Technol. 15 (46), 2570–2578. doi:10.17485/ijst/v15i46.1603

Oche, J. O., Joseph, O. O., and E, S. (2024). Environmental and health impacts of unregulated lithium mining practices: lessons from Nigeria’s oil industry. Afr. J. Environ. Nat. Sci. Res. 7 (3), 1–4. doi:10.52589/AJENSR-H1OG8F5U

Omoniyi, K. I., Agaku, P. I., and Baba, A. A. (2020). “Optimal hydrometallurgical extraction conditions for lithium extraction from a Nigerian polylithionite ore for industrial application,” in Rare metal technology 2020. Editors G. Azimi, K. Forsberg, T. Ouchi, H. Kim, S. Alam, and A. A. Baba (Springer International Publishing), 33–45. doi:10.1007/978-3-030-36758-9_4

Onyenwe, K.-U., and Orah, H. O. (2022). Lithium ion battery production in Nigeria: issues and challenges. Eur. J. Eng. Technol. Res. 7 (3), 88–93. doi:10.24018/ejeng.2022.7.3.2826

Orosun, M. M., Ajibola, T. B., Olawoyin, H. O., Adenekan, M. O., Salawu, N. B., Akinyose, F. C., et al. (2024). “Environmental impact of mining,” in Geology and natural resources of Nigeria Editors S. S. Dada, S. B. Olobaniyi, and K. O. L Omosanya 1st ed. (Boca Raton, United States: CRC Press), 520–531. doi:10.1201/9781003454908-30

Oshim, F. O., Ijeh, E. C., Amaefule, W. A., Ayajuru, N. C., Amaefule, E. O., and Anumaka, C. C. (2024). Socioeconomic and environmental impacts of quarrying in Nigeria: a comprehensive review of sustainable quarrying practices and innovative technologies. Int. J. Res. Sci. Innovation XI (VI), 324–349. doi:10.51244/IJRSI.2024.1106026

Otorkpa, O. J., Alao, J. O., and Emmanuel, S. (2024). Environmental and health impacts of unregulated lithium mining practices: lessons from Nigeria's oil industry. Afr. J. Environ. Nat. Sci. Res. 7 (3), 1–4. doi:10.52589/ajensr-h1og8f5u

Paris, J., Mohammadi-Jam, S., Li, R., Liang, J., Oh, H. J., Kökkılıç, O., et al. (2024). Preliminary investigation into lithium extraction by phosphoric acid leaching of spodumene. Miner. Eng. 209, 108613. doi:10.1016/j.mineng.2024.108613

Penniston-Dorland, S., Liu, X. M., and Rudnick, R. L. (2017). Lithium isotope geochemistry. Rev. Mineralogy Geochem. 82 (1), 165–217. doi:10.2138/rmg.2017.82.6

Petavratzi, E., Sanchez-Lopez, D., Hughes, A., Stacey, J., Ford, J., and Butcher, A. (2022). The impacts of environmental, social and governance (ESG) issues in achieving sustainable lithium supply in the Lithium Triangle. Mineral. Econ. 35 (3–4), 673–699. doi:10.1007/s13563-022-00332-4

Saadati, H., Afzal, P., Torshizian, H., and Solgi, A. (2020). Geochemical exploration for lithium in NE Iran using the geochemical mapping prospectivity index, staged factor analysis, and a fractal model. Geochem. Explor. Environ. Anal. 20 (4), 461–472. doi:10.1144/geochem2020-020

Sahoo, S. K., Tripathy, S. K., Nayak, A., Hembrom, K. C., Dey, S., Rath, R. K., et al. (2024). Beneficiation of lithium bearing pegmatite rock: a review. Mineral Process. Extr. Metallurgy Rev. 45 (1), 1–27. doi:10.1080/08827508.2022.2117172

Salazar, E., and Bengoechea, J. (2021). Research paper lithium and its role in the new energy transition. Mexico: Geneva Business School.

Sanchez-Lopez, M. D. (2023). Geopolitics of the Li-ion battery value chain and the Lithium Triangle in South America. Lat. Am. Policy 14 (1), 22–45. doi:10.1111/lamp.12285

Siwiec, D., Frącz, W., Pacana, A., Janowski, G., and Bąk, Ł. (2024). Analysis of the ecological footprint from the extraction and processing of materials in the LCA phase of lithium-ion batteries. Sustainability 16 (12), 5005. doi:10.3390/su16125005

Snydacker, D. H., Hegde, V. I., Aykol, M., and Wolverton, C. M. (2019). Method for lithium extraction via ion exchange, 10. Evanston, IL (United States): Northwestern Univ., 950. Available online at: https://www.osti.gov/doepatents/biblio/1568475.

Soberón Bravo, E. (2023). Governance on lithium mining shareholdings: expanding Environment, Social and Governance (ESG) indicators to economic regulation and raw material politics. Mineral. Econ. 36 (2), 333–347. doi:10.1007/s13563-022-00358-8

Sousa, R., Ramos, V., Guedes, A., Noronha, F., and Leite, M. M. (2019). Flotation of lithium ores to obtain high-grade Li2 O concentrates. Are there any mineralogical imitations? Int. J. Min. Mater. Metallurgical Eng. doi:10.11159/ijmmme.2019.002

Sultanova, A. G., and Michurin, S. V. (2024). Some issues of lithium geochemistry and its distribution in Rifhean rocks of the Southern Urals. Geol. Vestn. 2, 65–80. doi:10.31084/2619-0087/2024-2-6

Syomka, V. O., Ponomarenko, O. M., Stepanyuk, L. M., Bondarenko, S. M., Sukach, V. V., Kurylo, S. I., et al. (2022). Lithium ores of stankuvatka and polokhivka ore fields (Ukrainian sheild). Mineralogical J. 44 (4), 102–124. doi:10.15407/mineraljournal.44.04.102

Takuya, M., Eizo, N., Tsuyoshi, I., and Tsuyoshi, I. (1993). Geochemistry and cosmochemistry of lithium: utility of the Li isotopes as a geochemical tracer. J. Mineralogy, Petrology Econ. Geol. 88, 415–431. doi:10.2465/GANKO.88.415

Talens Peiró, L., Villalba Méndez, G., and Ayres, R. U. (2013). Lithium: sources, production, uses, and recovery outlook. Jom 65, 986–996. doi:10.1007/s11837-013-0666-4

Tanko, I. Y., Magaji, I. A., Dauda, B. I., and Segun, A. B. (2024). The geology and geochemistry of Kakafu pegmatites: an investigation for lithium ore bearing minerals (Lepidolite-Spodumene), pategi north Central Nigeria. Br. J. Earth Sci. Res. 12 (3), 45–67. doi:10.37745/bjesr.2013/vol12n34567

Tkachev, A. V., Rundqvist, D. V., and Vishnevskaya, N. A. (2019). The main features of lithium metallogeny in geological time. Dokl. Earth Sci. 484 (1), 32–36. doi:10.1134/S1028334X1901015X