Abstract

Introduction:

Maintaining traceability within the food supply chain is key to ensuring food safety, quality, and regulatory compliance. In recent years, digital technologies—especially blockchain – have been adopted to enhance transparency and trust in ‘farm-to-fork’ traceability systems, reducing fraud risk and enhancing recall management and strengthening consumer trust. However, their adoption differs based on variability in technological readiness, economic viability, and regulatory requirements.

Methods:

This paper provides a scoping review of the application of such digital tools to enhance traceability throughout the European agri-food supply chain. being applied across the European agri-food supply chain to improve traceability. Following PRISMA-ScR guidelines, we searched multiple databases (Web of Science, ProQuest, IEEE Xplore, Alcorze) for relevant literature and included 60 peer-reviewed studies (primarily 2010–2025) that met our criteria (focus on blockchain, IoT, AI, or big data in European food supply chain traceability).

Results and Discussion:

Blockchain emerged as the most frequently studied technology for food traceability —appearing in over 40% of the selected studies —often deployed in combination with IoT sensors, RFID tags, or QR codes to create end-to-end transparency. These digital interventions are reported to strengthen traceability and consumer trust, improve supply chain efficiency, and support sustainability initiatives. However, adoption remains uneven. Most studies describe conceptual frameworks or pilot implementations rather than fully realized systems, and real-world deployment is hampered by interoperability challenges, scalability issues, regulatory uncertainties, and high costs. In conclusion, blockchain-based traceability shows great promise for the European food sector, but targeted efforts are needed to overcome it.

Systematic Review:

Introduction

Food safety incidents such as the E. coli outbreak and the horsemeat scandal have exposed serious gaps in the traceability of food products, eroding consumer trust and causing economic damage (Guenther et al., 2022; Liu et al., 2018). In response, consumers and regulators now demand “farm-to-fork” visibility for food products (Charlebois et al., 2024; Patel et al., 2023). Traceability is critical for food safety by allowing the identification and tracking of food products across the whole supply chain, from manufacturing to consumption. This capability enables prompt response to food safety situations, such as contamination or recalls, by identifying the source of the problem and quickly removing damaged items, hence decreasing consumer risk and minimizing economic costs for businesses and stakeholders (Patel et al., 2023). Traceability systems also serve to re-establish and sustain consumer trust in food safety by providing transparency about how food is produced, processed, and handled (Zhang et al., 2016). Modern traceability is based on modern technologies like the Internet of Things, blockchain, and smart sensors, which improve the accuracy, security, and efficiency of tracking food items (Cromwell et al., 2025; Huang et al., 2024). Historically, traceability in the EU has been reinforced by regulations like EC 178/2002 mandating one-step-forward, one-step-back record-keeping (Asioli et al., 2014). However, traditional paper-based or siloed electronic record systems often fall short in providing real-time, tamper-proof information across complex, global supply chains.

Digital technologies have recently emerged as powerful tools to enhance food traceability and supply chain transparency. Blockchain technology offers a decentralized and immutable ledger for recording food provenance, making it virtually impossible to alter records of a product’s journey (Patelli and Mandrioli, 2020). When combined with the Internet of Things (IoT) —e.g., sensors and RFID tags that capture data on product origin, handling, and storage conditions–blockchain can enable secure, real-time tracking of food from farm to fork. Other innovations like big data analytics and artificial intelligence further help in analysing traceability data for patterns, optimizing logistics, and even predicting risks (Gadge et al., 2024; Rehman et al., 2025). Together, these digital solutions promise to reduce food fraud and improve recall management, thereby strengthening consumer trust in the food system.

Quality improvement and market demands motivate companies in Central and Eastern Europe demands. Digitalization is expected to benefit sales, logistics, and production, even though obstacles such as infrastructure, costs, and regulatory challenges remain (Szegedi et al., 2022). Digital traceability systems are increasingly being adopted to meet consumer expectations and regulatory requirements, but their integration is complex and varies from country to country (Charlebois et al., 2024). The European Union has recognized the potential of such digitalization efforts. Initiatives under the EU’s Farm to Fork strategy and the Digital Single Market encourage the integration of digital tools to improve supply chain efficiency, transparency, and sustainability (European Commission, 2023). Yet, the adoption of blockchain and related technologies varies widely across Europe. Some countries lead in implementing advanced traceability platforms, while others lag due to high costs, resistance to technological change, and fragmented infrastructure (European Commission, 2023; Zhao et al., 2024). This uneven landscape raises important questions: How extensively are digital traceability tools being studied and implemented in different parts of Europe? What levels of adoption? What benefits and challenges are reported, and do these tools truly enhance outcomes like efficiency, sustainability, and resilience in the agri-food sector? This is the aim of this paper, focusing on a scoping review of how such digital tools are being applied across the European agri-food supply chain to improve traceability. This review intentionally focuses on the European agri-food sector, where the EU has taken a leading position through schemes such as the Farm to Fork strategy (European Commission, 2020) and the Digital Single Market (European Commission, 2015). By setting these geographic boundaries, we aim to provide a step-by-step and comparable picture of digital trends in European countries. While generalizability to alternative world regions is automatically limited by this scope, a valuable benchmark for comparative studies is offered, and the specific institutional and cultural drivers’ alteration of digital transformation in Europe are displayed. To the best of our knowledge, no prior scoping review has focused exclusively on the European agri-food sector while integrating traceability, transparency, and sustainability.

By consolidating various elements, this evaluation offers an in-depth look at the adoption landscape in Europe and provides opportunities for policy, practice, and research. For policymakers, the results underline the importance of harmonized regulatory frameworks and incentives to promote adoption. For industry actors, they stress both potential efficiency gains and persistent barriers to implementation. For researchers, the synthesis determines critical knowledge gaps and indications for future research.

Methods

Objective

Through this scoping review, we aim to provide a comprehensive overview of the current state of knowledge regarding the use of digitalization in the European agri-food sector. Specifically, it seeks to identify current approaches, innovations, and technological developments; to assess how these digitalization efforts enhance traceability, efficiency, transparency, sustainability, resilience, and food safety; and to explore the factors influencing the adoption and integration of these tools across different stages of the supply chain. As a result, the following research questions are formulated:

RQ1: Which digitalization tools are applied in the European agri-food supply chain, and at what stages?

RQ2: What levels of adoption (conceptual, pilot, full) are reported, and how do these vary by sector and geography?

RQ3: What benefits and challenges are associated with these tools, and what gaps remain in the evidence base?

Research protocol and data source

This paper adopts a scoping review methodology approach proposed by (Arksey and O’Malley, 2005) with enhancements outlined by (Levac et al., 2010) to analyse digital technology adoption trends in the European food supply chain. The PRISMA methodology (Moher et al., 2009) and specifically the PRISMA-ScR, an extension for scoping reviews (Tricco et al., 2018), served as the foundation for the research approach. The PRISMA methodology is the most popular and frequently referenced framework for conducting meta-analyses and systematic reviews. Its extension is used to synthesize data and evaluate the scope of the literature. A step-by-step summary of the protocol procedure is provided in the document. Inclusion of certain databases (Web of Science, ProQuest, IEEE Xplore and Alcorze) enabled studies from various fields to be retrieved, consolidating technological, managerial, and sustainability perspectives. Boolean operators (“AND”, “OR”, “NOT”) and combinations of controlled and free-text terms such as “digitalisation”, “blockchain”, “IoT”, “RFID”, “traceability”, “food supply chain” and “Europe” were employed to construct search strings. Truncation and synonyms were used to account for terminological variations (Table 1).

TABLE 1

| Focus | Type of publications | Language | Keywords/Topics covered | Aspects of the agro-food system | Location |

|---|---|---|---|---|---|

| Studies focusing on the implementation and utilization of digitalization tools within the agri-food supply chain (food and beverages) | Research articles and scholarly publications | Literature is available in English | Studies covering topics related to the provided keywords, including “digitalization tools”, blockchain, RFID, IoT, “Internet Of Things”, “QR code” and “traceability” | Literature addressing aspects of the agro-food system such as Agrifood system”, agri-food, “food supply chain”,” food industry”, and “food safety” | Studies covering topics related only to European countries |

Inclusion criteria.

To minimize bias and error, the duplicate records were removed. All the references were screened. This was done on predetermined inclusion and exclusion criteria. A second reviewer also carried out double screening of a subset of studies to ensure consistency in the selection process. Additionally, a protocol that details the objectives, eligibility criteria, and methodological approach of this scoping review was registered in the Open Science Framework (OSF; registration DOI: https://doi.org/10.17605/OSF.IO/M34VE), to enhance transparency and reproducibility. These efforts were made to reduce selection and publication bias while maintaining methodological rigor throughout the review process.

Inclusion and exclusion criteria

To ensure relevance and consistency, studies were selected based on predefined inclusion criteria (Table 1).

We excluded studies that did not specifically address the agri-food sector or that lacked a traceability aspect, as well as non-English and non-peer–reviewed literature.

We used the PICOS framework to organize our research question and eligibility criteria (Table 2), thereby increasing transparency. This framework clarifies the target population, interventions, comparators, outcomes, and study designs considered in this scoping review.

TABLE 2

| Element | Specification |

|---|---|

| Population | There are studies addressing the agri-food supply chain in European countries, with a focus on food and beverage sectors |

| Intervention | The process involves the implementation and utilization of digitalization tools, such as blockchain, Internet of Things (IoT), RFID, QR codes, artificial intelligence (AI), and big data applications |

| Comparator | This statement is not directly applicable, as scoping reviews do not require intervention comparators. However, studies were compared across different supply chain stages, sectors, adoption levels (conceptual, pilot, full), and geographic regions |

| Outcomes | There have been reported impacts on traceability, transparency, efficiency, sustainability, resilience, consumer trust, and food safety |

| Study design | The research includes peer-reviewed empirical studies, conceptual studies, and case studies. Non-peer-reviewed, non-English, and studies outside the agri-food sector were excluded |

The PICOS framework applied to this scoping review.

Search and screening process

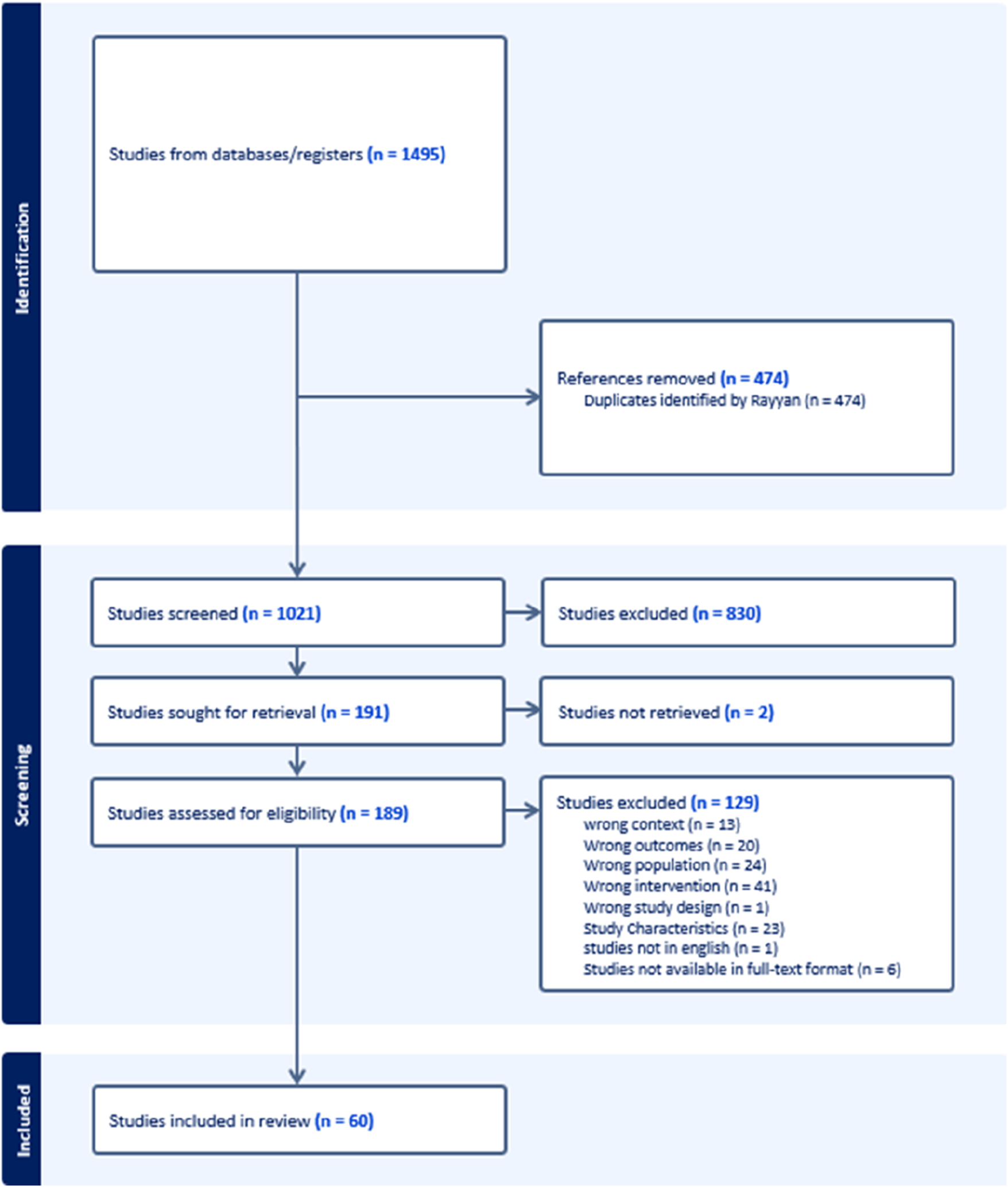

This study was developed based on the guidelines in the Preferred Reporting Items of Systematic Reviews and Meta-Analyses Extension for Scoping Reviews (PRISMA-ScR) (

Tricco et al., 2018). After finalizing the search strategy and selecting the databases, references were exported from each database and imported into the screening platform RAYYAN. Duplicates were identified and removed prior to screening. The screening process was carried out in two stages. At each stage, the articles were assessed based on predefined inclusion and exclusion criteria. The initial examination was carried out by the first reviewer, and a subset of studies was checked independently by a second reviewer to ensure consistency of the selection process. Any disagreement has been resolved by discussion. The overall process is summarized in a PRISMA flow chart (

Figure 1), which reports the number of records identified, analyzed, excluded, and ultimately included in the review.

Title and abstract screening: A total of 1495 sources were initially identified, of which 665 met the eligible criteria for abstract review and, after screening abstracts, 189 for full texts. Data was extracted on digital tools used, adoption patterns, barriers and enablers, and outcomes related to food traceability and safety, while 830 were excluded.

Full text screening: The full texts of 189 articles were assessed, resulting in 60 studies meeting the inclusion criteria. The remaining 111 were excluded based on predefined eligibility criteria.

FIGURE 1

PRISMA flow diagram of study selection.

Data extraction process

The data extraction process commenced upon completing the full-text screening. Information was extracted, using Covidence platform, from 60 studies. Consistent with scoping review methodology, we did not exclude studies based on quality, nor formally assess risk of bias, as the aim was to map the literature rather than weigh evidence.

The data from the studies included were systematically mapped using a structured Excel extraction form developed specifically for the purposes of this review. The form was designed to capture comprehensive information in several key areas to ensure both coherence and comparability. For each study, metadata was recorded, including the author, year of publication, and source of dissemination. Study characteristics, such as design, sample size, sector, and geographical orientation were also documented. The type of digital technology that was controlled, such as blockchain, IoT, big data, or artificial intelligence, has been identified. In addition, the level of adoption was classified as conceptual, mixed, or complete adoption. The reported results have been systematically mapped, with the focus on improving traceability, transparency, efficiency, sustainability, and consumer confidence. The extraction also included barriers and contextual factors that influence adoption as well as relationships and effect size reported when available. Finally, study limitations were recorded to facilitate a critical assessment of the body of samples. This structured and comprehensive approach to data mapping provided a solid basis for both descriptive mapping and thematic synthesis of findings.

Results

This section presents the interpretation and analysis of the data obtained from the selected papers using R software.

Selection of source evidence

Figure 1 Bekkouche and de-Magistrisrepresents the flow of articles through the search and screening process. The database search identified 1495 articles. After duplicate citations were removed, articles underwent the first round of relevance screening, of which did not meet the eligibility criteria for inclusion. The full texts of the remaining 189 articles were retrieved and subject to relevance screening. A further 129 articles were excluded at this stage. 60 articles were included in the review and underwent data characterization (Figure 1).

After the full text screening, we analysed the overall results to present an overview of the existing literature on digitalization tools in the European agri-food sector. We focused on literature presenting demographic data of the solutions (year, source type, geographical focus, and agri-food sector) and the data related to digitalization tools (digital tools, adoption level, supply chain stage, and adoption barriers). We have also computed and analysed, in various diagrams, the results of the scoping review. Finally, we summarize and discuss the finding for each of our research questions.

Synthesis of results

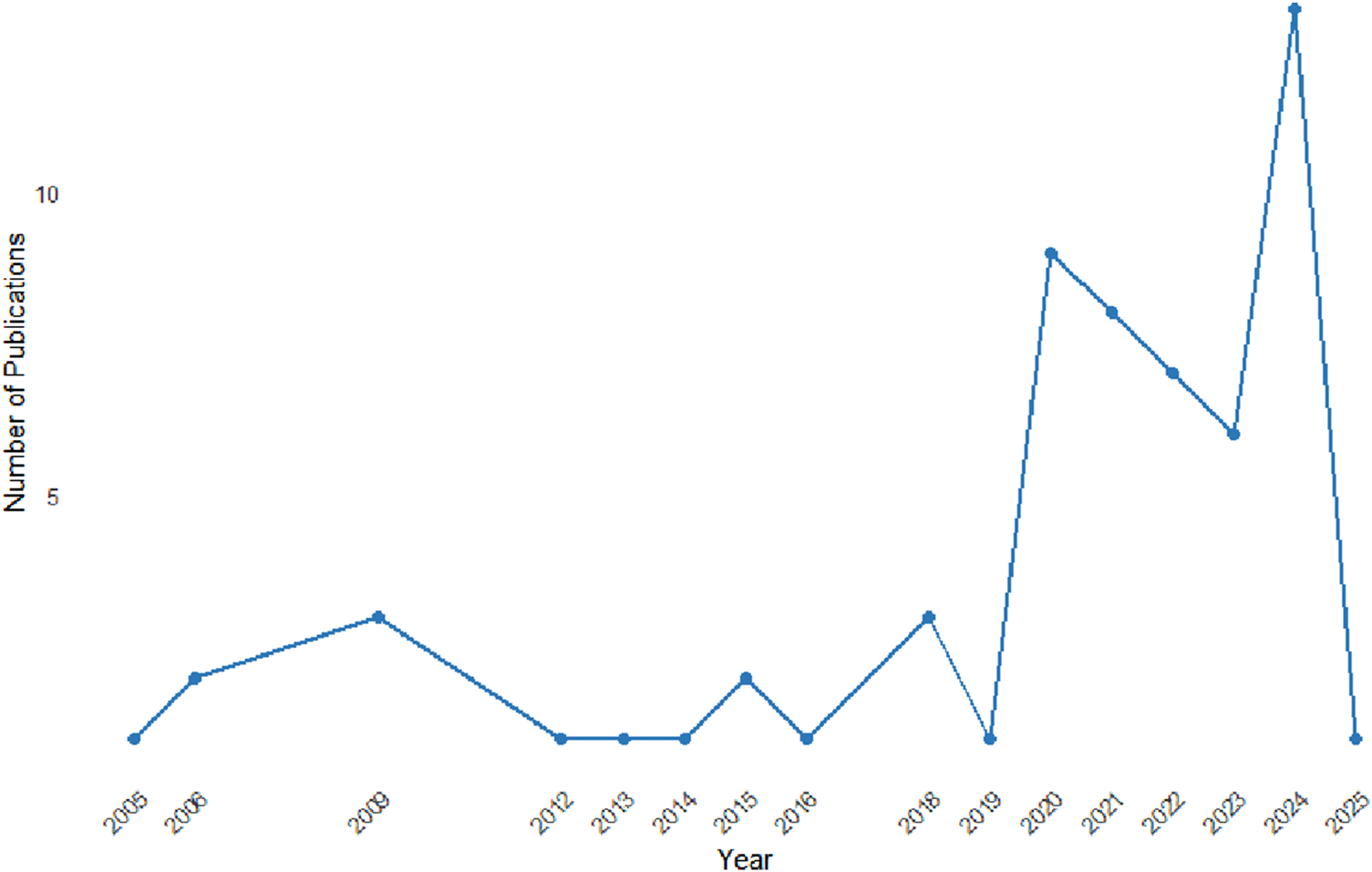

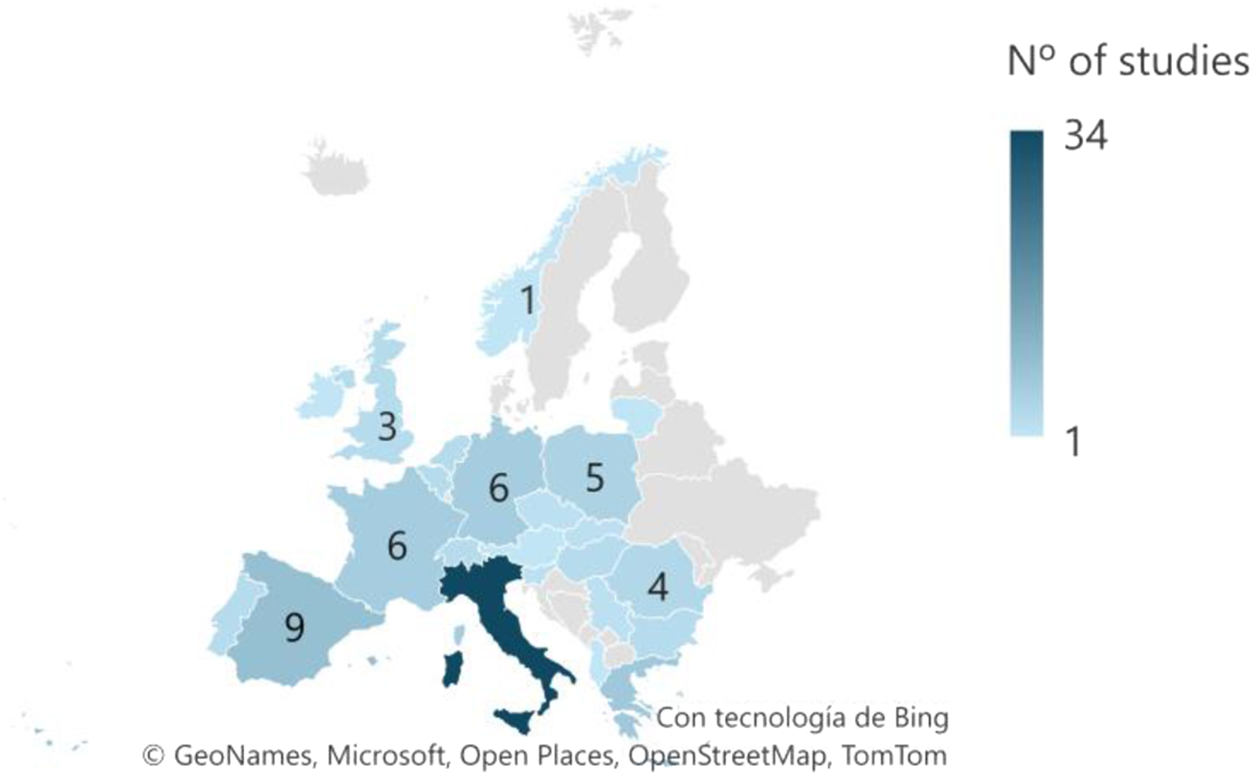

The first analysis concerns the detection of the year of publication and the geographical focus of the studies. The selected papers were released across European countries from 2005 to 2025 and reveal a notable acceleration in research output over time (Figures 2,3), particularly from 2020 onward. The earliest contributions date back to the mid-2000s, with isolated publications from the UK (2005) and Portugal, Spain, and Italy (2006), suggesting an initial interest in digitalization themes.

FIGURE 2

Number of publications per year.

FIGURE 3

Distribution of studies per country.

Bekkouche and de-MagistrisHowever, it is from 2018 onward that a marked increase is observed. The year 2020 serves as a pivotal turning point, with a significant uptick in contributions across various countries, especially from Italy (5 publications), Poland, Romania, and Switzerland. This surge likely reflects growing policy, market, and societal attention on transparency, traceability, and sustainability in food systems. The peak in research activity is observed in 2022 and 2024, with Italy dominating the landscape—publishing 5 publications in 2021, 6 in 2022, and 7 in 2024. Italy’s sustained output across several consecutive years positions it as the clear leader in the scholarly discourse on food supply chain digitalization.

Other countries showing significant contributions include France, Germany, Greece, and Spain, albeit with more intermittent publication patterns. Greece exhibits a rapid rise in activity from 2021 onward, contributing 3 publications in 2024 and 2 in 2025, signalling its growing engagement in this field. On the other hand, Albania, Austria, Bulgaria, the Czech Republic, Hungary, and the Baltic states have made occasional contributions, usually limited to a single publication per year. These sporadic entries suggest either nascent academic activity or limited research capacity in this domain. Lastly, 2025 shows continued momentum, with contributions from over 10 countries, including Italy, France, Germany, Greece, Austria, and Slovakia, indicating that interest in the digital transformation of the agri-food sector remains strong and is likely to persist in future research agendas.

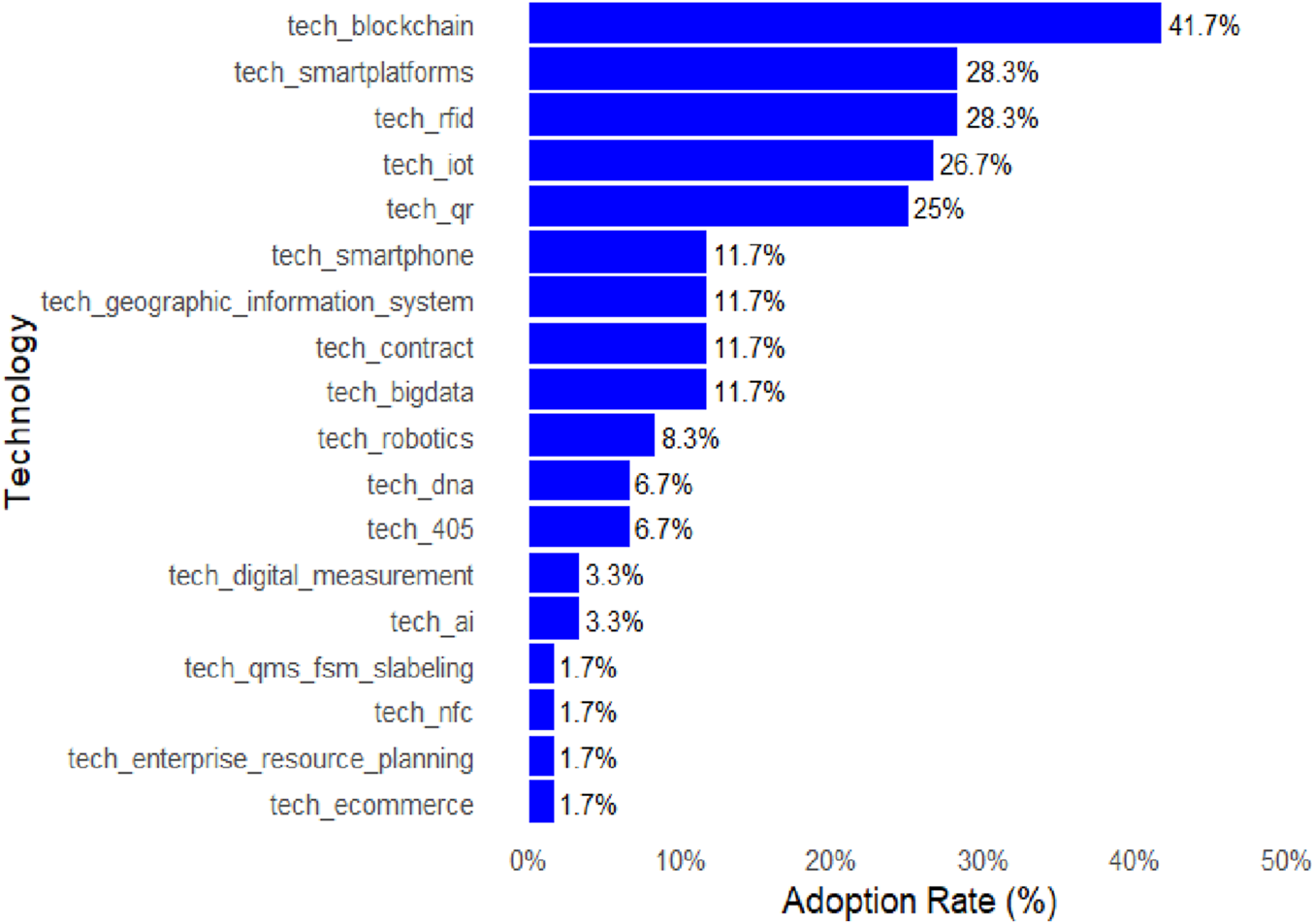

RQ1: Which digitalization tools are applied in the European agri-food supply chain, and at what stages?

The examination of digital technology use across time has demonstrated a discernible upward trend in its adoption, with specific technologies demonstrating more consistent and pervasive usage than others (Figure 4). Among the digital tools evaluated, blockchain exhibited the highest average usage over the observed period, with an adoption rate in 25 studies (41.7%), underscoring its role in enhancing transparency, traceability, and trust in agri-food supply chain (Azevedo et al., 2023; Ciasullo et al., 2022; Cocco et al., 2021; Commandré et al., 2021; Fiore et al., 2024; Florez et al., 2021; Garzoni et al., 2020; Gaspar et al., 2021; Ioannidis et al., 2022; Kosior and Młodawska, 2024; Marchesi et al., 2022; Martínez-Castañeda and Feijoo, 2023; Mazzù et al., 2021; Melissari et al., 2024; Perboli et al., 2018; Petrontino et al., 2024; Scuderi et al., 2022; Scuderi and Timpanaro, 2019; Sepe, 2024; Sharma et al., 2024; Toader et al., 2024; Urtecho et al., 2024; Valle and Oliver, 2020; Vasileiou et al., 2024; Vodenicharova, 2020). Subsequent to this, the most prevalent technologies were RFID and smart platforms, each reported in 17 studies (28.3%) RFID is widely used for real-time tracking and logistics optimization (e.g., Gandino et al., 2009), while smart platforms provide integrated digital solutions for monitoring and managing agri-food processes (e.g., Charatsari et al., 2024; Mascarello et al., 2024). The Internet of Things (IoT) was cited in 16 studies (26.7%)) often linked to sensor-based monitoring for food quality, safety, and logistics (Benavides-Espinosa et al., 2023; Charatsari et al., 2024; Ciasullo et al., 2022; Cocco et al., 2021; Fiore et al., 2024; Florez et al., 2021; Garzoni et al., 2020; Gaspar et al., 2021; Martínez-Castañeda and Feijoo, 2023; Scuderi et al., 2022; Sharma et al., 2024; Urtecho et al., 2024; Valle and Oliver, 2020; Varbanova et al., 2023; Venturi et al., 2024). It is noteworthy that QR codes also attracted an impressive and significant proportion of 25% (15 studies), underscoring their significance in facilitating consumer engagement and expeditious access to product information. (Azevedo et al., 2023; Ciasullo et al., 2022; Corallo et al., 2020; Fiore et al., 2024; Guido et al., 2020; Ignjatijević et al., 2020; Marchesi et al., 2022; Mascarello et al., 2024; Mazzù et al., 2021; Melissari et al., 2024; Petrontino et al., 2024; Radu et al., 2018; Urtecho et al., 2024; Vukatana et al., 2016; Žurbi and Gregor-Svetec, 2023).

FIGURE 4

Distribution of digitalization tools across studies.

Conversely, emerging technologies such as smart contracts, GIS, big data, and smartphones each appeared in 7 studies (11.7%); DNA-based technologies and Industry 4.0/5.0 (4 studies, 6.7%), robotics has a usage rate of 8.33% in 5 studies; and AI along with digital measurement are relatively low at 3.33% in only 2 studies. The least used technologies, each at 1.67%, are enterprise resource planning, QMS/FSM/labelling systems, NFC, and e-commerce, exhibiting significantly lower adoption levels, suggesting a more limited diffusion within the food supply chain.

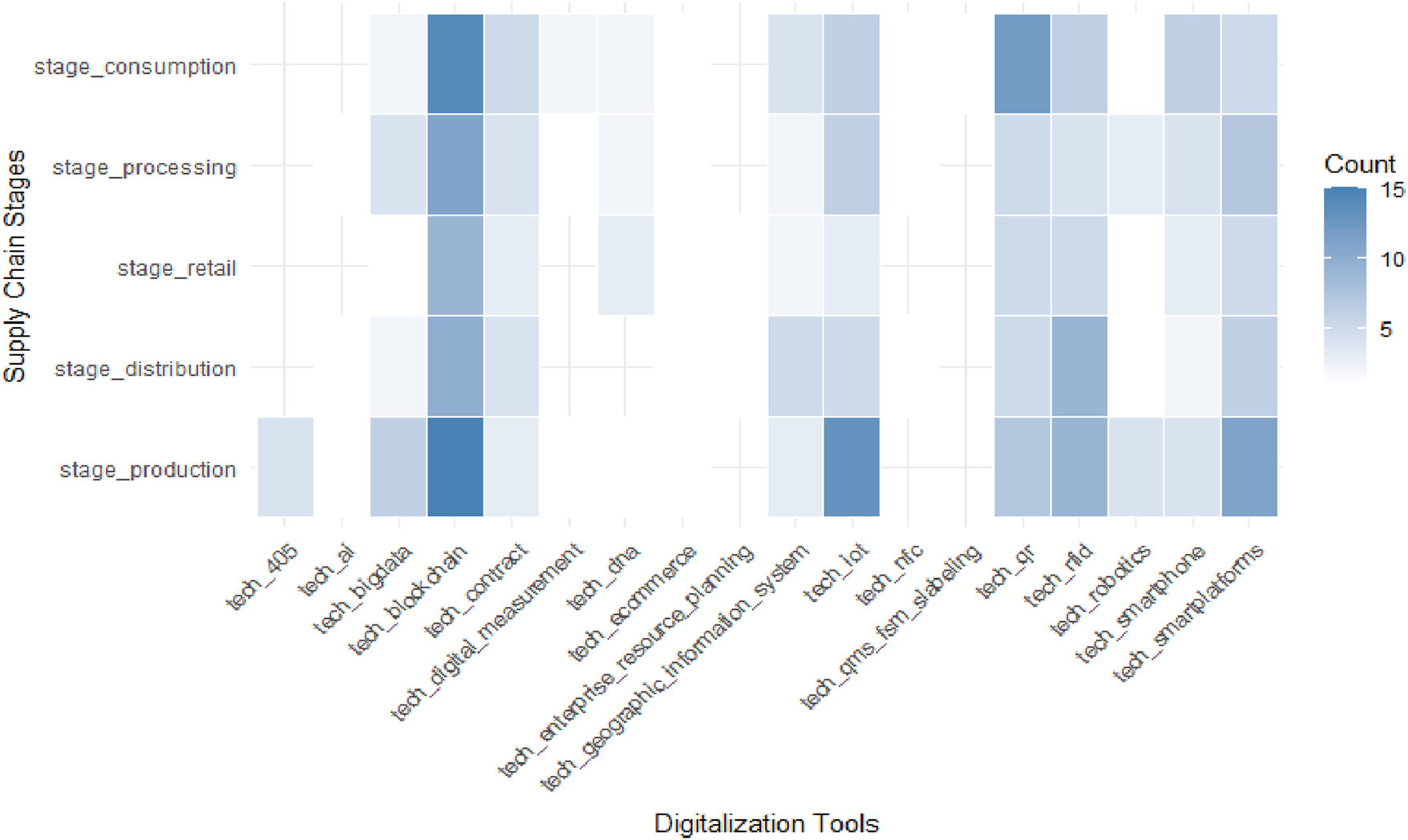

RQ2: At which stages of the agri-food supply chain are these technologies applied, and what levels of adoption (conceptual, pilot, full implementation) are reported?

The examination of digital technologies across the various phases of the supply chain reveals distinct patterns of adoption (Figure 5). The most widely applied tool is blockchain, which is used at all stages, with particularly high occurrences in production (n = 15), consumption (n = 14), and distribution (n = 10). Other technologies include IoT and smart platforms, both of which have a strong presence in production (n = 13 and 11, respectively) and across multiple other stages. Furthermore, QR codes assume a pivotal function, particularly in the domains of consumption (n = 12) and production (n = 7), thereby underscoring their pivotal role in fostering connections between producers and consumers. Similarly, RFID is applied, especially in distribution (n = 9) and production (n = 9). Conversely, some technologies remain niche. The presence of AI, NFC, and robotics is in limited numbers and stages, with robotics mainly concentrated in production and processing. The supply chain has been moderate but steady in terms of tool use, such as big data, contract-based systems, and smartphones. The only technology that is present at every stage is e-commerce, but it occurs at a very low frequency, while GIS is more prevalent in distribution and consumption.

FIGURE 5

Effect of digitalization tools across supply chain stages.

Factors drive or hinder the adoption and integration of digital tools along with the associated benefits and challenges

The adoption level of digital technologies varied considerably across different sectors. Several studies referred to the agri-food system in general without providing sector-specific detail. The frequencies reported in the remaining studies are therefore relative to each sector. Within the “Agri-Food” category, many studies reported conceptual adoption (n = 19; 66%), while fewer indicated mixed adoption (n = 9; 31%) or full implementation (n = 1; 3%). Cereal and cereal products demonstrated the highest prevalence of mixed adoption (n = 4; 57%), followed by conceptual adoption (n = 2; 29%) and full adoption (n = 1; 14%). The conceptual stage was found to be the predominant phase for fat and oil products (n = 6; 86%), with only a small share (n = 1; 14%) reporting mixed adoption. Fish and fish products displayed an even split between the conceptual (n = 2; 40%) and mixed (n = 3; 60%) stages. Meat and meat products were evenly distributed between the conceptual (n = 2; 40%) and mixed (n = 2; 40%) stages, with a smaller proportion (n = 1; 20%) achieving full adoption. Milk and milk products demonstrated a more balanced distribution, with (n = 3; 43%) conceptual adoption, (n = 2; 29%) mixed adoption, and (n = 2; 29%) full adoption. Sweets and sugar products were largely conceptual (n = 4; 80%), with the remainder showing mixed adoption (n = 1; 20%). Vegetables showed a majority at the conceptual stage (n = 4; 57%), followed by mixed adoption (n = 2; 29%) and full adoption (n = 1; 14%). Beverages and fruit had identical distributions. (n = 3; 50%) of these were mixed. (n = 2; 33%) were conceptual. (n = 1; 17%) was full adoption. Lastly, seeds (n = 1; 100%) and spices (n = 2; 100%) were only mentioned at the mixed adoption stage, even though these groups were backed by just a few studies.

The overall findings confirm that most digitalization initiatives in the agri-food sector remain at the conceptual or pilot stage, with only a small number of studies reporting full operational deployment at scale.

Adoption level across supply chain stages and geographical focus

Across the examined studies, digitalization has been found to be predominantly at the conceptual stage within the European food supply chain, with full adoption only being observed in a few instances. The highest number of reported cases was consistently accounted for by Italy across all supply chain stages, particularly in conceptual adoption within consumption (n = 12), distribution (n = 8), production (n = 8), and retail (n = 6). Italy was the most frequent location (n = 8) for adoption patterns, with six in distribution, five in processing, and four in production. This suggests that partial implementation or uneven integration across processes may be in place. While full adoption, which was frequently restricted to stages like processing, production, and retail, was reported primarily in Belgium, Germany, the Netherlands, and Slovenia, Spain, France, and Germany were among the other countries with noteworthy conceptual adoption counts. By stage, conceptual adoption was prevalent in consumption and distribution, mixed adoption was more common in processing and production, while retailers showed a more polarized pattern, with both conceptual and occasional full adoption. In general, the results suggest that although digitalization is extensively acknowledged and strategized, comprehensive operational integration across the supply chain remains uncommon and geographically concentrated.

Adoption level by technology used

Adoption levels analysis by technology reveals that the conceptual stage is the most prevalent, particularly for blockchain (n = 13), radio-frequency identification (RFID) (n = 9), the Internet of Things (IoT) (n = 8), and QR codes (n = 8). A few other technologies with notable mentions in the conceptual theme are smart platforms (n = 6), big data analytics (n = 4), and geographic information systems (n = 4). Some less noted yet mentioned tools are digital measurement, DNA-based on tracking, smartphones, and smart contracts. Incomplete or inconsistent adoption, also referred to as mixed adoption, is prevalent with blockchain (n = 11), followed by the IoT (n = 8), RFID (n = 7), and smart platforms (n = 7). QR codes (n = 4), big data (n = 3), smart contracts (n = 3), geographic information systems (n = 3), and robotics (n = 3). Full adoption remains low. The highest number of reported cases is observed for smart platforms (n = 4), followed by QR codes (n = 2) and smartphones (n = 2). In contrast, RFID, robots, and Industry 4.0 Industry 5.0 categories are each represented by only a single occurrence. The findings indicate that while a very broad range of digital technology is under investigation, most are still in the conceptual phase, with only a handful having shown signs of full operational integration.

Barriers across sectors

The analysis indicates that economic and financial constraints are the most prevalent obstacles across the agri-food sector, with 18.6% of all reported barriers falling into this category. This predominance is especially evident in the domains of fruit (25%), fat and oil (23.5%), and vegetable (20%) supply chains. While economic issues are primary, the prevalence of technical/technological and organizational barriers (both 16.3%) highlights the complex, multi-dimensional nature of challenges to digitalization and innovation. The prevalence of these barriers varies according to sub-sector, with technical and technological barriers being the most prevalent in the fish and spices sector and organizational barriers being the most prevalent in the meat and meat products sector. Furthermore, a few typical patterns have been demonstrated in niche industries; for example, cultural barriers (20%) are the most prevalent issue in the cereals and their products market. This intensive information indicates that effective innovation needs not only capital investment but also specific measures to overcome technological adoption, organizational forms, and resistance on cultural grounds. These measures are targeted to meet the individual demands of every supply chain segment.

Barriers to adoption of digital technologies across supply chain stages

Analysis of the barriers to the adoption of digital technology in agri-food supply chains reveals that economic and financial constraints are among the most frequently reported challenges, particularly for technologies such as geographic information systems (GIS) (28.6%), radio-frequency identification (RFID) (18.5%), and smart platforms (15.2%). Technical and technological constraints also play an important role, with the greatest impact on DNA-based systems (42.9%), followed by QR codes (18.8%) and smart platforms (17.4%). Organisational challenges are most evident in blockchain deployments (18.4%), followed by the Internet of Things (IoT) (14.8%) and RFID (11.1%). Data privacy issues are most closely associated with the IoT (13%), blockchain (7.9%) and QR codes (9.4%). Cultural challenges are most prevalent in RFID (14.8%), smart platforms (17.4%) and smartphones (12.5%), indicating that user adoption and behavioural change remain primary challenges. Strategic misalignments are an ongoing issue for blockchain (13.2%), contracts (10%), and big data applications (15%). Although regulatory obstacles are less prevalent overall, they persist for certain technologies, such as GIS (9.5%) and RFID (9.3%). Infrastructure deficiencies are common in RFID (14.8%), QR codes (15.6%) and the IoT (11.1%), which may reflect ongoing issues with logistics and connectivity. Interestingly, consumer access barriers, such as trust issues and concerns about ease of use, are more prevalent for QR codes (15.6%) and smartphones (18.8%). In general, the findings show that, although different technologies face the same types of barriers, the degree and nature of the obstacles vary considerably. This means that technology-specific adoption strategies are needed to make up for technical and socio-economic impediments.

Economic and technical barriers are the primary impediments to adoption in the production stage, notably for capital-intensive technologies such as GIS (28.6% noting economic restraints) and DNA-based traceability (42.9% citing technical limitations). Infrastructure deficiencies, such as insufficient connectivity, undermine the implementation of the IoT and RFID in rural areas. These data suggest that financial incentives, investments in rural infrastructure, and technological adaptation to varied agricultural conditions are necessary for adoption to be successful. Barriers to processing and dissemination become more strategic, organizational, and data governance issues. Situations where inter-organizational cooperation and alignment with business models are crucial include blockchain (18.4% organizational obstacles) and the IoT (14.8%). The sensitivity of data sharing in multi-actor scenarios is reflected in the substantial prevalence of privacy concerns (15.4% of cases involve distribution). To promote confidence among stakeholders, this stage would benefit from the establishment of explicit interoperability standards, contractual frameworks, and open governance models. Cultural and customer barriers influence the retail adoption environment. Smartphone-based apps (18.8%) and QR codes (15.6%) face hurdles relating to consumer perception of their utility, trust in the technology, and ease of use. Addressing these issues requires consumer education campaigns, user-friendly interface design, and open communication about the benefits of traceability.

Table 3 represents a descriptive characteristic derived from the included studies, highlighting the authorship, year of publication, journal, technology tools focused on, geographical focus, and key findings of these studies.

TABLE 3

| Author | Journal | Industry sector | Country region | Technology used | Key findings |

|---|---|---|---|---|---|

| Jones et al. (2005) | British Food Journal | Agri-Food | UK | RFID | UK food retailers can leverage RFID technology for improved supply chain control, reduced shrinkage, and EU regulation compliance, but face operational, strategic, and financial challenges |

| Maldini et al. (2006) | Aquaculture | Fish and their products | Italy, Spain | DNA markers | The efficacy of AFLP markers in accurately tracing fish and seafood, creating a species-specific database for 32, thereby ensuring food safety and promoting sustainable fisheries management |

| Pinto et al. (2006) | Food Research International | Cereal and their products | Portugal | Smart platform | PaniGest is a user-friendly software that integrates quality control, production, inventory, and cost analysis, reducing paperwork, enabling rapid recalls, and helping SMEs overcome resource constraints |

| Gandino et al. (2009) | IEEE Transactions on Industrial Electronics | Agri-Food | Italy | RFID | RFID technology enhances traceability management in the agri-food sector by managing detailed data in less time, increasing production flow, and providing a payback period of about 2 years for small/medium companies |

| Bahlmann and Spiller (2009) | Journal on Chain and Network Science | Meat and meat products | Germany | Smart platforms | The German QS system evolved from certification to a third-party supply chain coordinator, enhancing fragmented meat supply chains through standard harmonization, information integration, public communication, and incentive sanction mechanisms |

| Chrysochou et al. (2009) | Appetite | Agri-Food | Denmark, Greece | RFID | Consumers’ perceptions of traceability technologies are influenced by credibility, convenience, product quality, safety, health, environment, and privacy, with electronic carriers raising concerns and simpler labels being more trustworthy |

| Scarano et al. (2012) | Italian Journal of Agronomy | Cereal and their products, fat and oil, vegetables | Italy | DNA markers | DNA markers like SSR and AFLP enable genetic traceability of agricultural products, authenticating cultivars in raw materials and processed foods like pasta, olive oil, and tomatoes |

| Manzini and Accorsi (2013) | Journal of Food Engineering | Agri-food, Fat and oil | Italy | RFID | The framework assesses food supply chains, focusing on quality, safety, sustainability, and logistics efficiency, using a case study of an international edible oil shipment for cost-effective control |

| Mottola et al. (2014) | Albanian Journal of Agricultural Sciences (Special edition) | Fish and their products | Italy | DNA markers | 42% of fishery products were mislabelled, highlighting the importance of DNA barcoding for species identification, food traceability, safety, and fraud prevention in the seafood industry |

| Medini et al. (2015) | Food Chemistry | Fat and oil | France | GIS | Validated protocol measuring the87Sr/86Sr isotopic (GIS) ratio in olive oil, revealing geographical tracer differences between Nîmes and Morocco, potentially combating fraud |

| Jiménez-Ariza and Correa (2015) | Food and Bioprocess Technology | Agri-Food | Spain | RFID | Low-cost wireless sensors during transport revealed significant temperature gradients, highlighting the need for distributed sensors for accurate thermal stress assessment, as a single average reading is insufficient for quality assurance |

| Vukatana et al. (2016) | Foods (MDPI) | Beverages | Albania | QR codes, smartphone, RFID, smart platforms | The Albanian wine sector is implementing a low-cost system using GS1-adapted data model and encrypted QR codes to improve transparency, safety, and competitiveness |

| Perboli et al. (2018) | IEEE Access | Agri-Food | Italy | Blockchain, Smart Contracts | The lean framework for designing real-world blockchain solutions is demonstrated in a fresh food supply chain, demonstrating its economic viability through cost savings and improved efficiency |

| Pop and Brătulescu (2018) | Economic Engineering in Agriculture and Rural Development | Fruit and vegetables | Romania | GIS, GPS, RFID, bar codes | Efficient traceability systems, like GIS maps and GPS, can enhance short supply chain management for fresh food by real-time monitoring of production locations and storage conditions |

| Radu et al. (2018) | Annals of “Dunarea de Jos” University of Galati, Mathematics, Physics, Theoretical Mechanics | Agri-Food | Romania | QR codes Smartphones, Tablets | Romanian consumers are keen on QR codes on food labels for durability, allergens, and nutrition information, with 75% of smartphone owners making this technology feasible |

| Scuderi and Timpanaro (2019) | Quality - Access to Success | Agri-Food | Italy | Blockchain | Blockchain technology can enhance agri-food supply chains like Italian PDO/PGI by ensuring traceability, combating fraud, and ensuring food safety, as demonstrated in the Sicilian Blood Orange juice supply chain |

| Guido et al. (2020) | International Journal of Industrial Engineering and Management | Fat and oil | Italy (Calabria) | Web and mobile applications, QR codes. Blockchain | A traceability framework for extra-virgin olive oil, utilizing document tracking, DNA analysis, and QR code technology, significantly increased revenue, improved operational efficiency, combated fraud, and promoted “Made in Italy” branding |

| Valle and Oliver (2020) | IEEE Access | Agri-Food | Spain | Blockchain, IoT, AI, Cloud, Smart Contracts | Blockchain is a sustaining innovation, improving existing processes, with five key enablers:access,value-creation, interoperability, remote, and social. It’s still in an explorative phase, with a 3–5-year timeline for widespread industrial adoption |

| Ignjatijević et al. (2020) | Economics of Agriculture | Sweets and sugar | Serbia | QR code, smartphones | QR codes are particularly useful for consumers, particularly younger, educated ones, as they provide information on product quality certification, chemical composition, health benefits, and authentic product identification |

| Baralla et al. (2020) | Concurrency and Computation: Practice and Experience | Agri-Food | Greece and Italy (comparative study) | Smart farming | A proposed blockchain-based platform using Ethereum smart contracts and IoT devices to ensure the origin, provenance, and integrity of local food products, enhancing transparency and trust in Smart Tourism |

| Garzoni et al. (2020) | Management Decision | Agri-Food | Italy | Industry 4.0/DT: IoT, Blockchain, Big Data, AI | Proposing a four-level roadmap for SMEs to transition to digital technologies, emphasizing the importance of human and social capital, networking, and community building, to overcome SMEs’ reluctance towards Industry 4.0 |

| Wincewicz-Bosy et al. (2020) | European Research Studies Journal | Agri-Food | Poland | RFID, bar codes, GIS | RFID and traceability systems can enhance military food supply chain efficiency by improving tracking, quality control, and managing goods flow, while fostering modern logistical practices |

| Vodenicharova (2020) | International Journal of Retail and Distribution Management | Cereal and their products, milk and milk products, Meat and meat products, fruits and vegetables, seeds, fish, spices, sweets and sugar | Bulgaria | ICT, Blockchain, RFID | Bulgaria’s food supply chain lacks integration and cooperation, with low ICT and blockchain implementation, highlighting opportunities for development through stronger partnerships and technology adoption |

| Corallo et al. (2020) | Trends in Food Science and Technology | Fruit, vegetables, cereal and their products, milk and milk products | Italy | RFID, QR code, data management software, mobile app | Traceability systems are widely adopted in the Italian agri-food industry, primarily for improving company image and marketing strategy, despite perceived barriers like consumer trust and data privacy concerns |

| Rusu et al. (2020) | Lucrări Ştiinţifice Seria Medicină Veterinară | Agri-Food | Romania | GS1, RFID, EPCIS | Traceability is a key component of European Union food safety regulations, requiring operators to identify suppliers and recipients through target groups, lot sizes, identification technology selection, and data recording |

| Cocco et al. (2021) | IEEE Access | Cereal and their products | Italy | Blockchain, Smart Contracts, IPFS, IoT, WSN, RFID, NFC | Blockchain, Internet of Thing, NFC, and RFID technologies are combined in manufacturing to enhance traceability, improve data management, and ensure product quality through secure, transparent, and distributed relationships |

| Gallo et al. (2021) | Food Control | Fruit | Italy | Geographic Information System (GIS) | Introducing a new traceability tool that uses GIS and weather services to integrate fragmented data sources, estimate missing information, and quantify safety, sustainability, and quality indicators for logistics and quality managers |

| Gaspar et al. (2021) | Applied Sciences | Milk and milk products, fat and oil, sweets and sugar, fruit, meat and meat products, wine | Portugal | IoT drones, AI, BigData, Blockchain, Robotics | Portugal’s agro-industry is lagging in IoT adoption, but potential efficiency gains is suggested through knowledge transfer and gradual IoT implementation, starting with CRM and ERP systems |

| Cannas (2021) | Journal of Small Business Management | Milk and milk products, vegetables, wine | Italy | data platforms, ICT | Digital transformation in agrifood SMEs involves developing dynamic capabilities, influenced by contextual factors, personal and relational skills, and reshaping societal structures, such as increasing worker responsibility and promoting female leadership in innovation |

| Florez et al. (2021) | Journal of the International Council for Small Business | Agri-Food | France | AI, IoT, Blockchain, Big Data, Ecommerce, Robots | French agri-tech start-ups are driving digitalization in the food value chain, enhancing sustainability by increasing yields, reducing environmental impact, empowering local markets, and reducing food loss |

| Commandré et al. (2021) | Sustainability | Agri-Food | France | Blockchain | Blockchain implementation in food chains often fails to achieve decentralization, concentrating control in initiating actors like retailers and large companies. Farmers face surveillance and data privacy issues, while producers benefit from better remuneration. Blockchain raises power asymmetries and raises concerns about data ownership |

| D’Oronzio and Sica (2021) | Economia agro-alimentare/Food Economy | Agri-Food | Italy | GIS, Sensors, Decision Support Systems Robotics, Cloud Computing | European Innovation Partnerships in Basilicata promote digital innovation in agriculture, overcoming barriers like digital divide, skills gaps, and inadequate infrastructure for Precision Farming |

| Mazzù et al. (2021) | Foods | Milk and milk products | Germany, Italy, UK | Blockchain, QR code | Blockchain-certified packaging enhances perceived health and flavor, varying based on milk type, but not significantly across three countries |

| Marchesi et al. (2022) | IEEE Access | Sweets and sugar | Italy | Blockchain, Smart Contracts, QR Codes | A proposed framework automates smart contracts and user interfaces from supply chain descriptions, reducing development time, costs, and reliance on specialized blockchain developers for agri-food businesses |

| Bouranta et al. (2022) | New Medit | Agri-Food | Greece, Italy, Spain | QMS/FSMS labelling (e.g., HACCP, ISO 22000/9001) | Mediterranean consumers exhibit significant differences in food safety perceptions, with Spanish trust in supply chains, Italian attention to product characteristics, and Greek differences despite shared food cultures and retail structures |

| Conti (2022) | IEEE Access | Fat and oil | Italy | NFC tags, smartphones, GPS | A low-cost, user-friendly food traceability system using NFC technology and smartphones is proposed for small and medium-sized farms, tracing the entire extra virgin olive oil production chain and increasing consumer confidence |

| Ioannidis et al. (2022) | International Journal of Business and Economic Sciences Applied Research | Agri-Food | Greece | Digital Platforms, AI, Robotics, Big Data, Blockchain | Digital technology adoption in Greek agro-food firms is early, primarily through basic platforms and the internet. Entrepreneur specialization and workforce digital skills encourage adoption, but barriers include funding and high costs |

| Castellini et al. (2022) | Food Control | Vegetables | Italy | Omics technologies (genomics, transcriptomics, metabolomics) | Italian consumers, despite being unfamiliar with “omics” technologies, are showing interest in certified vegetables, with 76.4% willing to pay 9% more, driven by favorable attitudes, environmental concerns, and younger age |

| Scuderi et al. (2022) | Agriculture | Fruit | Italy | IoT, IoF, Big Data, Blockchain, mobile devices, smart robots, drones), AI | The Italian citrus sector faces low adoption of “Agriculture 4.0”technologies due to cultural resistance, small farms, and lack of skills. Investment in technology, skills, and training is needed for competitiveness and sustainability |

| Ciasullo et al. (2022) | Administrative Sciences | Agri-Food (vegetables) | Italy | QR codes, AI: IoT, VR, big data, blockchain | Digitalization enhances SMEs’ international omnichannel strategies by integrating tools like QR codes, cloud computing, and AI-powered chatbots, improving data handling efficiency, collaboration, and fostering a data-driven culture |

| Gorini et al. (2023) | Foods | Fish and their products, spices, cereal and their products | Italy | DNA barcoding | DNA barcoding and mini barcoding as fast, reliable methods for quality and safety assurance and identifies optimized DNA extraction and barcoding workflows tailored to different food categories |

| Benavides-Espinosa et al. (2023) | British Food Journal | Agri-Food | Spain | Digital Transformation (DT) (IoT, AI) | Innovation capacity positively impacts digital transformation (DT), which in turn positively impacts agrifood companies’ business performance, acting as a critical mediator |

| Varbanova et al. (2023) | Serbian Journal of Management | Agri-Food | Bulgaria, Serbia, Hungary, Poland, Slovakia, Czech Republic | Industry 4.0 technologies: IoT, Big Data, AI, robotics | The implementation of Industry 4.0 in the agri-food sector is significantly influenced by five strategic factors: leadership, management strategy, organizational culture, business environment, and circular economy |

| Azevedo et al. (2023) | Operations Management Research | Meat and meat products | Portugal | Blockchain Smart Contracts, QR codes, RFID | The study showcases a decentralized traceability system architecture in Portugal, integrating Blockchain, Smart Contracts, and PKI with digital certificates for products and supply chain actors |

| Martínez-Castañeda and Feijoo (2023) | Telecommunications Policy | Fish and their products, meat and meat products, beverages | Spain | Blockchain); IoT, RFID, AI | Blockchain adoption in Spanish agri-food sector is in pilot stage, facing challenges like lack of data standards, bureaucracy, governance, and scalability issues, making projects unsustainable post-public funding |

| Žurbi and Gregor-Svetec (2023) | SAGE Open | Milk and milk products | Slovenia | QR codes | QR codes, despite widespread usage, are primarily used for product origin and traceability information on dairy products in Slovenia, indicating a need for integration into a broader marketing strategy |

| Venturi et al. (2024) | Applied Sciences | Wine | Italy | Industry 5.0, smartwatches, smart rings, IoT, AI | Implantation of industry 5.0 in the sector of wine to enhanced collaboration between humans and machines to improve production efficiency and quality |

| Sepe (2024) | Sinergie Italian Journal of Management | Agri-Food | Italy | Blockchain | Blockchain-based food labels enhance consumer trust and intention, with younger consumers driving purchase intentions but lacking in older generations due to perceived transparency |

| Sharma et al. (2024) | IEEE Transactions on Engineering Management | Agri-Food | Italy | Blockchain, IoT, AI, RFID | Policies are crucial for BCT adoption in all four economies, but factors like smart irrigation, fair financial audits, and crop monitoring vary by country, necessitating tailored strategies |

| Fiore et al. (2024) | Internet Technology Letters | Agri-Food | Netherlands | Blockchain, IoT sensors, Smart Contracts, QR Codes | Apulian consumers are willing to pay more for agri-food products with blockchain-enabled traceability, with quality and healthiness information being the most valued |

| Mascarello et al. (2024) | Sustainability | Honey | Italy | QR codes, RFID, Web application | Italian consumers are eager to learn about honey’s origin and production processes and are open to digital traceability tools like QR codes, despite paying a premium for transparency |

| Petrontino et al. (2024) | Frontiers in Sustainable Food Systems | Cereal and their products | Italy | Blockchain (via QR Codes) | High WTP for pasta using blockchain/QR code technology for traceability and information. Credence attributes like safety, sustainability, and innovation are valued, attracting pasta businesses to invest in traceability technologies |

| Charatsari et al. (2024) | Information (MDPI) | Agri-Food | Greece, Italy | Smart farming, IoT, platforms | Greece and Italy’s AKIS recognize digitalization opportunities but struggle to leverage them, especially for small-scale farmers due to limited stakeholder engagement and regulatory constraints |

| Urtecho et al. (2024) | IEEE Access | Fat and oil | Spain | IoT, Blockchain, QR codes | The integration of IoT and blockchain in a SaaS model can enhance farm efficiency, sustainability, transparency, and product traceability for small and mid-sized farms |

| Melissari et al. (2024) | Journal of Sensor and Actuator Networks | Milk and milk products | Greece, Belgium | Blockchain, Smart Contracts, QR codes | The feasibility of modelling PDO Feta cheese production and implementing a dual-blockchain traceability system using a private Quorum chain and public Ethereum, addressing scalability, speed, and cost challenges |

| Toader et al. (2024) | Agriculture (MDPI) | Agri-Food | Switzerland, Germany, Italy, France, Spain, Romania, Poland, Czech Republic | Blockchain | Agri-Food Supply Chain Partner Preparedness” is the most influential factor in blockchain platform usage intention, followed by “Performance Expectancy,” Effort Expectancy, and Perceived Trust |

| Vasileiou et al. (2024) | Advanced Sustainable Systems | Milk and milk products | Greece | IoT,GPS, Blockchain | The PDO Feta cheese supply chain faces vulnerabilities like manual data entry and authenticity checks, while blockchain technology can enhance traceability, verify authenticity, and improve auditing |

| Georgiev & Penov (2024) | AIP Conference Proceedings | Agri-Food | Bulgaria | Digitalization (Smart Farming) | Digitalization network is weakly connected, with public/state organizations being central actors. Agri-food companies adopt digital technologies slowly, and the IT sector’s presence is weak |

| Kosior and Młodawska (2024) | Agriculture (MDPI) | Agri-Food | Poland | RFID, sensors, GPS, mobile apps, blockchain | Agri-food actors benefit from traceability systems, but high costs, administrative burdens, low digitalization, and consumer misinterpretation hinder participation. Clear value propositions, financial incentives, and strong data governance are crucial |

| Giagnocavo et al. (2025) | Technology in Society | Agri-Food | Austria, Belgium, France, Germany, Greece, Hungary, Italy, Spain, Slovakia, Switzerland | Smart farming tools, data management platforms | Advisors and producer organizations are optimistic about digital technologies, but farmers struggle due to lack of awareness. Barriers include cost, complexity, and unsuitability, while drivers include collaboration and financial support |

Characteristics and key findings of included studies.

RQ3: What benefits, challenges, and impacts—especially regarding transparency, efficiency, sustainability, and food safety—are associated with the use of blockchain and related digital tools in the European context?

A substantial body of the reviewed literature emphasizes the pivotal role of digital technologies within the agri-food sector, which have been primarily associated with improvements in both sustainability and efficiency, with certain technologies contributing across multiple outcome dimensions. The most widely reported technology among these was blockchain, which has been closely associated with sustainability outcomes (11 studies), especially due to its capacity to improve consumer trust, traceability, and transparency in a variety of in diverse sectors, including cereals, dairy, meat and meat products, fruits, and beverages in several European contexts, such as Italy, Portugal, Spain, Greece, France, and Poland. (Azevedo et al., 2023; Fiore et al., 2024; Florez et al., 2021; Gaspar et al., 2021; Ioannidis et al., 2022; Kosior and Młodawska, 2024; Scuderi et al., 2022; Sepe, 2024; Urtecho et al., 2024). It was also strongly associated with efficiency outcomes (8 studies), particularly in Belgium, Italy, Greece, France, and Germany, where it supported supply chain coordination and process optimization (Ciasullo et al., 2022; Commandré et al., 2021; Garzoni et al., 2020; Ioannidis et al., 2022; Sepe, 2024; Toader et al., 2024; Valle and Oliver, 2020; Vodenicharova, 2020). Similarly, it has been reported in 9 studies that IoT-enabled monitoring systems enhance sustainable production by optimizing input utilization, minimizing waste, and reducing environmental footprints across sectors such as beverages, dairy products, fruit, and oils in countries including Italy, Portugal, Spain and Greece (Benavides-Espinosa et al., 2023; Fiore et al., 2024; Florez et al., 2021; Gaspar et al., 2021; Scuderi et al., 2022; Urtecho et al., 2024; Varbanova et al., 2023; Venturi et al., 2024). For efficiency outcomes, IoT was reported in 7 studies, supporting resource optimization and monitoring in Italy, Belgium, Greece, Spain, and beyond (Benavides-Espinosa et al., 2023; Charatsari et al., 2024; Ciasullo et al., 2022; Garzoni et al., 2020; Valle and Oliver, 2020; Varbanova et al., 2023; Venturi et al., 2024).

The link between the use of digital platforms and positive sustainability outcomes has been demonstrated, especially with the adoption of smart platforms (7 studies) in Italy and Greece by improving coordination and reducing inefficiencies (Corallo et al., 2020; Manzini and Accorsi, 2013; Mascarello et al., 2024; Scuderi et al., 2022). Smart platforms also contribute efficiency by facilitating stakeholder integration and decision-making in Greece, Italy, Bulgaria, and Germany (8 studies) (Bahlmann and Spiller, 2009; Cannas, 2021; Charatsari et al., 2024; Ciasullo et al., 2022; Garzoni et al., 2020; Ioannidis et al., 2022; Vodenicharova, 2020; Vukatana et al., 2016).

Other technologies, such as QR codes and RFID were mostly associated with sustainability outcomes. QR codes (6 studies) support consumer information and product authenticity in Italy, Spain, and Portugal (Azevedo (Azevedo et al., 2023; Corallo et al., 2020; Fiore et al., 2024; Petrontino et al., 2024; Urtecho et al., 2024), though two studies also linked them to efficiency (Ciasullo et al., 2022; Vukatana et al., 2016). RFID was connected to both sustainability (6 studies) and efficiency (6 studies) where it supported supply chain monitoring and traceability (Azevedo et al., 2023; Chrysochou et al., 2009; Corallo et al., 2020; Kosior and Młodawska, 2024; Manzini and Accorsi, 2013; Mascarello et al., 2024; Pop and Brătulescu, 2018; Rusu et al., 2020; Vodenicharova, 2020; Vukatana et al., 2016; Wincewicz-Bosy et al., 2020).

Big data technologies, robotics, and GIS were less represented but consistently highlighted for their potential in strengthening sustainability in facilitating location-based sustainability assessments, precision agriculture practices, consumer involvement, and low-impact logistics (Florez et al., 2021; Gaspar et al., 2021; Ioannidis et al., 2022; Scuderi et al., 2022; Varbanova et al., 2023) and efficiency (Ciasullo et al., 2022; Garzoni et al., 2020; Ioannidis et al., 2022; Varbanova et al., 2023). Robotics, in particular, appeared in sustainability-focused studies in Portugal, Greece, and Italy (Gaspar et al., 2021; Ioannidis et al., 2022; Scuderi et al., 2022), with limited but notable links to efficiency in Greece and Bulgaria (Ioannidis et al., 2022; Vodenicharova, 2020).

Although the quality of the environmental evidence was highly variable, twenty-two of the papers included addressed the concept of sustainability explicitly. None of the papers quantified or directly measured environmental outcomes. For instance, Gallo et al. (2021) and Manzini and Accorsi (2013), measured decreases in carbon emissions, fuel consumption, and energy expenditure across food distribution networks. In contrast, Venturi et al. (2024) monitored winery emissions, air quality, and resource utilisation as potential indicators of carbon neutrality. Similarly, Gaspar et al. (2021) and Florez et al. (2021) connected using less of the world’s limited natural resources and wasting less food to the IoT and big data applications.

Several studies (Azevedo et al., 2023; Scuderi et al., 2022; Varbanova et al., 2023) have established the connection between digitalisation and the principles of the circular economy, along with the reduction of waste. Other studies have examined sustainability from the perspectives of consumers and policymakers. For example, Fiore et al. (2024) and Petrontino et al. (2024) investigated consumers’ willingness to pay more for products with environmental labels. This is a social rather than a biophysical outcome. The remaining studies (e.g., Benavides-Espinosa et al., 2023; Cannas, 2021; Sepe, 2024) addressed sustainability rhetorically, as motivation, expectation, or agreement with the SDGs, rather than presenting concrete environmental actions. Only a third of the studies gave real, measurable environmental information, which shows that most literature still has a theoretical approach to sustainability rather than an empirical one.

The effect of digitalization tools on food safety, traceability, and quality assurance in the European agri-food sector

Throughout the literature reviewed, digital technologies have been extensively used to improve traceability and food safety in the agri-food supply chain, with blockchain, RFID, QR codes, IoT, smart platforms, and supporting tools such as smartphone applications, smart contracts, and geographic information systems identified as key enablers. Blockchain is the most prominent traceability technology (19 studies), with applications in the cereal, meat, dairy, fish, fruit, and beverage sectors. It is widely used in Southern and Central Europe, particularly Italy, Spain, Portugal, France, and Greece (Azevedo et al., 2023; Ciasullo et al., 2022; Cocco et al., 2021; Commandré et al., 2021; Fiore et al., 2024; Florez et al., 2021; Gaspar et al., 2021; Kosior and Młodawska, 2024; Marchesi et al., 2022; Martínez-Castañeda and Feijoo, 2023; Melissari et al., 2024; Petrontino et al., 2024; Scuderi and Timpanaro, 2019; Sepe, 2024; Toader et al., 2024; Urtecho et al., 2024; Vodenicharova, 2020). Blockchain was also linked to food safety in eight studies, particularly through its role in contamination tracking and rapid recall management (Azevedo et al., 2023; Commandré et al., 2021; Marchesi et al., 2022; Martínez-Castañeda and Feijoo, 2023; Melissari et al., 2024; Sepe, 2024; Urtecho et al., 2024; Vodenicharova, 2020).

RFID was the second most prominent technology, identified in 15 studies on traceability with broad cross-sector and geographical application, from Italy and Poland to Norway and Malta, underlying its versatility and long-time use in supply chain monitoring (Azevedo et al., 2023; Chrysochou et al., 2009; Cocco et al., 2021; Corallo et al., 2020; Gandino et al., 2009; Jones et al., 2005; Kosior and Młodawska, 2024; Manzini and Accorsi, 2013; Martínez-Castañeda and Feijoo, 2023; Mascarello et al., 2024; Rusu et al., 2020; Vodenicharova, 2020; Vukatana et al., 2016; Wincewicz-Bosy et al., 2020). RFID was equally cited for food safety outcomes (8 studies), with applications in monitoring cold chains, reducing spoilage, and enhancing quality assurance (Azevedo et al., 2023; Chrysochou et al., 2009; Corallo et al., 2020; Gandino et al., 2009; Martínez-Castañeda and Feijoo, 2023; Pop and Brătulescu, 2018; Vodenicharova, 2020; Vukatana et al., 2016).

QR codes were identified in 13 studies on traceability, particularly for consumer facing transparency and verification of product authenticity in sweets, dairy, cereals, and beverages across Italy, Serbia, Spain, Portugal (Azevedo et al., 2023; Ciasullo et al., 2022; Corallo et al., 2020; Fiore et al., 2024; Ignjatijević et al., 2020; Marchesi et al., 2022; Mascarello et al., 2024; Melissari et al., 2024; Petrontino et al., 2024; Radu et al., 2018; Urtecho et al., 2024; Vukatana et al., 2016; Žurbi and Gregor-Svetec, 2023). QR codes were also linked to food safety (7 studies), mainly through consumer awareness and better risk communication (Azevedo et al., 2023; Corallo et al., 2020; Ignjatijević et al., 2020; Marchesi et al., 2022; Melissari et al., 2024; Urtecho et al., 2024; Vukatana et al., 2016). IoT (10 studies) are increasingly adopted to enhance real-time product monitoring, especially in Southern European environments (Benavides-Espinosa et al., 2023; Ciasullo et al., 2022; Cocco et al., 2021; Fiore et al., 2024; Florez et al., 2021; Gaspar et al., 2021; Martínez-Castañeda and Feijoo, 2023; Scuderi et al., 2022; Urtecho et al., 2024), whereas smart platforms (10 studies on traceability; 5 on food safety) show integration capability by bridging multiple actors along the supply chain (Bahlmann and Spiller, 2009; Corallo et al., 2020; Georgiev & Penov, 2024; Manzini and Accorsi, 2013; Mascarello et al., 2024; Pinto et al., 2006; Scuderi and Timpanaro, 2019; Vodenicharova, 2020; Vukatana et al., 2016; Žurbi and Gregor-Svetec, 2023) Other technologies such as big data, robotics, geographic information systems, and contract-based solutions also played notable roles, although less frequently cited.

These results highlight the increased diversification of digital solutions across a range of a agrifood sectors and regions, with Italy, Spain, Portugal, and Greece emerging as frontrunners, while also reflecting notable uptake across Central and Eastern Europe. While also showing evidence of adoption across Central and Eastern European countries.

Table 3 summarizes the outcomes examined in the studies included in the scoping review. The table focuses on dimensions such as traceability, sustainability, transparency, food safety, and related supply chain impacts.

Discussion

This review mapped the evolving landscape of digitalization tools in the European agri-food supply chain, highlighting a sharp increase in academic engagement from 2018 onwards, with a noted acceleration after 2020. This trend aligns with previous findings that indicate the rise of the digital technologies’ adoption in food supply chains, which is driven by a growing consumer demand for transparency, traceability, and regulatory initiatives (Panigrahi et al., 2025; Saurabh and Dey, 2021; Yadav et al., 2022). The most prolific contribution was made by Italy, which is consistent with prior reviews that showed Southern Europe to be an early hub for digitalization applications in food systems (Sánchez-García et al., 2024).

Blockchain technology was the most investigated technology. The existing literature consistently emphasizes that blockchain is such a disruptive innovation for implementing secure, transparent, and tamper-proof traceability functionalities in a wide range of sectors (Kamilaris et al., 2019). As described in (Hariyani et al., 2025), blockchain is a novel decentralized digital ledger system to secure the transactions through tamper-proof of the data. The blockchain is a foundational technology for creating strong traceability solutions because of this essential feature (Ben Farah et al., 2024; Dutta et al., 2020). The integration of digital tools like RFID, IoT, and QR codes is crucial for advancing digitalization across various sectors. A hybrid approach combining multiple tools is necessary for effective digital traceability and management (Ferdousmou et al., 2024). For instance, in Vietnam’s fine food sector, RFID and IoT devices are deployed as part of a broader strategy focusing on verifiable, technology-driven systems while combining them with other solutions to enhance traceability (Le et al., 2025).

Moreover, big data analytics plays a crucial part in supply chain optimisation, as it allows the analysis of large data sets to predict demand, schedule production in the most efficient way, and manage inventories more effectively. Advanced data analytics enables supply chain managers to make informed decisions, improving operational effectiveness and responsiveness (Florez et al., 2021; Scuderi et al., 2022).

Smartphones and smart platforms improve consumer satisfaction and engagement during the retail and consumption phases by streamlining in-store procedures, facilitating the customer experience, and offering personalised services (Kosior and Młodawska, 2024; Radu et al., 2018; Vodenicharova, 2020).

Furthermore, emerging technologies, such as geographic information systems (GIS) and digital measurement systems, offer valuable insights into spatial data and supply chain performance indicators, thereby enhancing logistics and production operations (Baralla et al., 2019; Baralla et al., 2020; Medini et al., 2015). The integration of these digital technologies into traditional supply chain models can render businesses more adaptable, responsive, and resilient. The application of these technologies fosters innovation and fundamentally transforms supply chain management, leading to substantial improvements in operational efficiency, precision, and decision-making at every stage of the chain.

The predominance of blockchain and RFID in our analysis aligns with the general trends observed in previous studies on digitalization in the agri-food sector. Blockchain has been repeatedly highlighted as the most studied digital instrument for supply chain traceability, especially due to its immutability, transparency, and ability to generate consumer trust (Casino et al., 2019; Galvez et al., 2018; Kouhizadeh and Sarkis, 2018). RFID has long been recognized as a reliable and cost-effective solution. It is used to monitor logistics and inventory management (Manzini and Accorsi, 2013; Qian et al., 2020). Our results align with this dual trend, indicating that academic interest is due both to technological novelty and the continued use of established tracking instruments. Our finding shows that the majority of studies evaluate technologies in isolation, such as RFID for supply chain control and efficiency (Gandino et al., 2009; Jones et al., 2005; Manzini and Accorsi, 2013), DNA markers for food authenticity (Maldini et al., 2006; Mottola et al., 2014; Scarano et al., 2012), or smart platforms for quality control and coordination (Bahlmann and Spiller, 2009; Pinto et al., 2006). However, the studies reporting broader and more transformative outcomes usually involve multi-technology configurations. For example, Vukatana et al. (2016) described a system that integrates QR codes, smartphones, RFID, and smart platforms in the Albanian wine sector to enhance transparency and competitiveness. Similarly, Perboli et al. (2018). Recent studies (Martínez-Castañeda and Feijoo, 2023; Melissari et al., 2024; Urtecho et al., 2024) have shown that integrating blockchain, IoT sensors, and QR codes can improve traceability, sustainability, and consumer trust in the fresh food supply chain.

The geographical distribution of research, with Italy, Spain, Portugal, and Greece leading in adoption, also aligns with previous research showing that southern Europe is more proactive on digital traceability initiatives. This is reported to be because of the economic importance of high-value traditional food products, i.e., olive oil, wine, and honey, where fraud prevention and authenticity are critical (Lami et al., 2023; Vitaskos et al., 2024). These countries have also experienced a history of food fraud scandals, leading to further investment in traceability technology (Aung and Chang, 2014). Our review also covers Central and Eastern European nations, including Poland, Romania, and Bulgaria, less prominently, which emphasizes earlier research detailing patchy take-up in Europe (Zhou and Xu, 2022). The research by Aung & Chang, (2014) also shows that these regions have suffered repeated food fraud scandals. This has stimulated investment in traceability solutions.

A noteworthy insight is that traceability (provenance tracking) is explicitly targeted in most studies, whereas food safety improvements are typically discussed as a downstream benefit of better traceability, rather than measured directly. This aligns with Charlebois et al. (2024), Ellahi et al. (2024), and Vu et al. (2023), who highlight traceability as a dominant theme, with safety often assumed to improve indirectly. Our review mirrors that trend–few studies provided empirical evidence of reduced contamination or hazards due to digital tools, echoing the gap pointed out by Mbadlisa & Jokonya, (2024) that robust safety outcomes linked to blockchain are rarely documented Food safety is presented more as an indirect benefit than as a clear research goal. Similarly, Dasaklis et al. (2022) and Patel et al. (2023) describe safety improvements as consequences of enhanced traceability systems rather than as primary performance metrics. This is also supported by reviews undertaken by Curto and Gaspar. (2021), Tseng et al. (2022), and Wahyuni et al. (2025), which highlight the practical importance of traceability while mentioning safety only in passing. More critical examinations, like those of Mbadlisa & Jokonya, (2024), highlight the dominance of reviews addressing adoption and technology alongside the scarcity of empirical evidence directly associating blockchain deployment with measurable safety outcomes. The previous work of Ringsberg (2014) is distinguished by the explicit linking of traceability to food safety within a supply chain risk management system, although it does not include empirical measurement of safety effects.

The environmental aspect of sustainability is only partially supported by the existing body of evidence. While a small number of studies quantify impacts, such as reductions in carbon footprint, energy use, or material inputs, most rely on qualitative claims or consumer perceptions. This suggests that discourse on digital sustainability in agri-food supply chains is still led by strategic and social narratives rather than consistent environmental measurement. Therefore, future empirical work evaluating digital traceability tools should integrate life-cycle assessment, carbon accounting, and resource-efficiency metrics, so that environmental contributions can be verified rather than presumed.

Despite the importance of food safety in the literature on blockchain and digital traceability, the findings suggest that it is generally considered a by-product of traceability rather than a result requiring rigorous testing. Yu et al. (2024) argued that blockchain technology offers promising prospects to enhance traceability of fresh food by promoting safety and consumer access to accurate information. The present study also reveals a gradual trend toward more explicit applications of food safety, particularly with blockchain, RFID, and QR codes. The EU’s “Farm to Fork” and “One Health” strategies, which prioritize integrated approaches to food quality, safety, and sustainability, align with this approach (European Commission, 2020). The results of this study are similar to those mentioned in previous studies. The presence of significant obstacles remains a fact, particularly in heterogeneous agri-food networks where there is a coexistence of different platforms, actors, and standards. This fragmentation hinders continuous data exchange and coordinates workflows. Second, the high initial and continuing costs of implementation, encompassing infrastructure, hardware, and data management, create a financial barrier, especially for smaller firms that lack substantial capital reserves (Amentae and Gebresenbet, 2021; Deral et al., 2024; Obayi et al., 2025; Otter and Sauvée, 2025; Panigrahi et al., 2025). Limited scalability and capacity limits acceptance even further due to the constrained technological infrastructure and insufficient technical and human resources, such as problems with how different systems can work together, very high costs of implementation, and limited ability to grow among the people in the supply chain (Deral et al., 2024; Vimal et al., 2023; Kouhizadeh et al., 2021; Otter and Sauvée, 2025). Although there are indications that trust and ease of use are important factors in adoption (Hald and Kinra, 2019), few studies have examined consumer acceptance of these technologies. While some barriers, such as interoperability and cost, are commonly encountered across contexts, regional specificities also play an important role. Across regions, Europe’s policy framework, supporting instruments, and farm structures create a distinctive backdrop. Therefore, these results should be interpreted as a European snapshot, valuable in its own right, but not directly transferable to regions with different institutional and structural conditions.

Food safety gains were frequently cited as indirect results of improved traceability and transparency. A limited number of studies explicitly linked digitalization to food safety, such as blockchain for contamination tracking and recall management (Azevedo et al., 2023; Commandré et al., 2021; Marchesi et al., 2022; Melissari et al., 2024; Urtecho et al., 2024), RFID for cold-chain monitoring and spoilage prevention (Chrysochou et al., 2009; Corallo et al., 2020; Gandino et al., 2009; Vukatana et al., 2016), and QR codes for consumer risk communication Nonetheless, few studies produced actual empirical evidence of decreased contamination or food safety issues.

Our research shows that integrating digital technologies along the European agri-food supply chain is still in its early stages, with most projects and implementations being conceptual or pilot. While it is clear that significant interest and experimentation in this area exist, only a small number of publications included cases with full operational integration. Large-scale integration of digital technologies into agri-food supply chains and/or smart food systems remains limited. This is also in line with literature suggesting that the rate at which food systems become digitalised is often similar to that of other sectors. This is due to regulatory settings, fragmented supply chains, and technological interoperability challenges (Galvez et al., 2018; Kamilaris et al., 2019).

Variation across sectors and supply chain stages further illustrates this uneven progress. Dairy and meat products, which face strong traceability and safety requirements, showed more balanced adoption levels, including isolated cases of full implementation. By contrast, sectors such as fats, oils, and sugar products were largely confined to the conceptual stage. Similarly, adoption patterns varied geographically. Italy accounted for the largest number of cases across stages, while countries such as Belgium, Germany, and the Netherlands were the main sites of full adoption. This concentration highlights regional disparities, with Western and Southern Europe more active in digitalization initiatives compared to Central and Eastern regions (Apostol and Hernández-Rodríguez, 2024; European Investment Bank, 2022).