- 1Key Laboratory of Biofuels and Shandong Provincial Key Laboratory of Energy Genetics, Qingdao Institute of Bioenergy and Bioprocess Technology – Chinese Academy of Sciences, Qingdao, China

- 2Sinopec Fushun Research Institute of Petroleum and Petrochemicals, Fushun, China

Autolysis is a widespread phenomenon in bacteria. In batch fermentation of Clostridium acetobutylicum ATCC 824, there is a spontaneous large-scale autolysis phenomenon with significant decrease of cell density immediately after exponential phase. To unravel the role of autolysis, an autolysin-coding gene, CA_C0554, was disrupted by using ClosTron system to obtain the mutant C. acetobutylicum lyc::int(72). The lower final cell density and faster cell density decrease rate of C. acetobutylicum ATCC 824 than those of C. acetobutylicum lyc::int(72) indicates that CA_C0554 was an important but not the sole autolysin-coding gene responding for the large-scale autolysis. Similar glucose utilization and solvents production but obvious lower cell density of C. acetobutylicum ATCC 824 comparing to C. acetobutylicum lyc::int(72) suggests that lysed C. acetobutylicum ATCC 824 cells were metabolic inactive. On the contrary, the spore density of C. acetobutylicum ATCC 824 is 26.1% higher than that of C. acetobutylicum lyc::int(72) in the final culture broth of batch fermentation. We speculated that spontaneous autolysis of metabolic-inactive cells provided nutrients for the sporulating cells. The present study suggests that one important biological role of spontaneous large-scale autolysis in C. acetobutylicum ATCC 824 batch fermentation is contributing to generation of more spores during sporulation.

Introduction

Autolysis is a widespread phenomenon in bacteria such as Bacillus subtilis (Lacriola et al., 2013), Escherichia coli (Leduc and Heijenoort, 1980), Lactobacillus helveticus (Lortal et al., 1997). Autolysis of B. subtilis growing cells could be induced by adding chloramphenicol, which caused a significant decrease of OD590 nm in 420 min (Chung et al., 2009). Addition of cephaloridine could induce the autolysis of E. coli grown at 37°C in rich medium, OD600 nm decreased over 80% in 40 min (Leduc et al., 1982). On the other hand, spontaneous autolysis has been reported in Helicobacter pylori and Propionibacterium freudenreichii (Lemée et al., 1995; Fujita et al., 2005). In batch fermentation of H. pylori KZ109, OD600 nm decreased 66% in 12 h (Fujita et al., 2005). In batch fermentation of P. freudenreichii CNRZ 725, up to 88% of OD650 nm decrease was observed after maximal growth (Lemée et al., 1995). Comparing to B. subtilis and E. coli, addition of inducts was not needed and there were no obvious stationary phase in the growth curve of bacteria with spontaneous autolysis.

Spontaneous autolysis phenomenon was also found in Clostridium acetobutylicum. In batch fermentation of C. acetobutylicum ATCC 824, the OD620 nm decreased more than 60% in 15 h immediately after exponential phase (Barber et al., 1979). In batch fermentation of C. acetobutylicum P262, the total cell counts decreased 50% from 35 to 60 h of fermentation (Van der Westhuizen et al., 1982). Minier et al. (1990) carried out C. acetobutylicum batch fermentation, using mineral ultrafiltration membranes to confine the microbial cells in the fermenter while the permeate was subject to heat treatment (70°C for 20 min) before recycling. Under this condition, the activity of autolysins in the fermentation broth was strongly depressed, leading to twofold increase of the maximum OD620 nm (Minier et al., 1990), indicating that autolysins played important roles in the spontaneous autolysis of C. acetobutylicum growing cells.

Autolysins are enzymes that can break down the cell wall of microorganisms (Smith et al., 2000) and have been found in many bacteria, such as E. coli (Heidrich et al., 2001), B. subtilis (Blackman et al., 1998), Enterococcus faecalis (Mesnage et al., 2008), C. acetobutylicum (Croux and García, 1991). The known physiological functions of autolysins include regulation of cell growth, enlargement of the peptidoglycan sacculus, peptidoglycan turnover, production of signaling molecules, recycling of peptidoglycan turnover products, cell separation during cell division, assembly of secretion systems, developmental lysis, biofilm formation (Vollmer et al., 2008). Two enzymes with lytic activity have been purified from the supernatant of C. acetobutylicum ATCC 824 and identified as glycoprotein and amidase, respectively (Webster et al., 1981; García et al., 1988). An extracellular lytic enzyme was purified and characterized as muramidase by Croux et al. (1992) in the same species. Furthermore, two autolysin-coding genes, CA_C0554 (Croux and García, 1991) and SMB_G3117 (Yang et al., 2013), have been characterized in C. acetobutylicum, thereinto CA_C0554 has been functionally verified by expression in E. coli (Croux and García, 1992).

Since spontaneous autolysis usually leads to significant loss of cells, it is interesting to understand the biological role behind this phenomenon. Spontaneous autolysis of H. pylori cells accompanies release of intracellular proteins into the extracellular space, and the intact cells receive the released proteins on the cell surface in order to survive of the adverse environment (Fujita et al., 2005). Though several autolysins have been characterized in C. acetobutylicum, the biological role of spontaneous autolysis in this species is unclear until now. In this study, CA_C0554, one gene contributing to autolysis, was disrupted to study the role of autolysin on the significant decrease of cell density, and to investigate the biological role of spontaneous large-scale autolysis in C. acetobutylicum ATCC 824.

Materials and Methods

Bacterial Strains and Cultivation Conditions

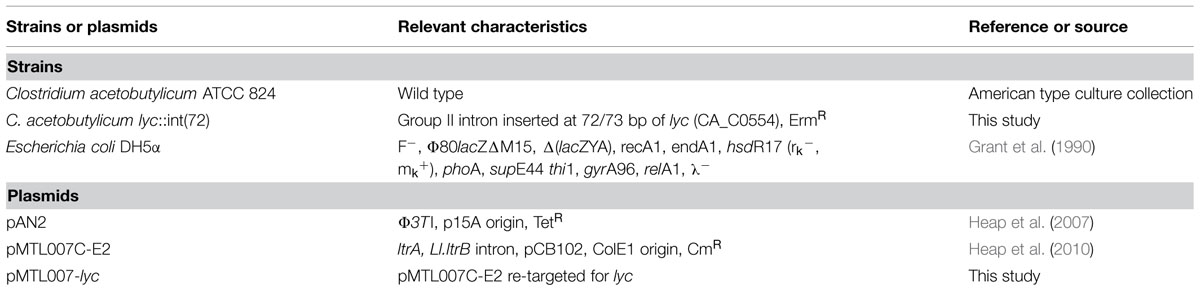

All strains and plasmids used in this study are listed in Table 1. E. coli was cultivated aerobically at 37°C in Luria-Bertani medium containing per liter 10 g tryptone, 5 g yeast extract, 10 g NaCl. Where indicated, appropriate antibiotics were added (chloramphenicol 25 μg ml-1 or tecracycline 10 μg ml-1).

Clostridium acetobutylicum ATCC 824 or its mutant was cultivated anaerobically at 37°C. During the mutagenesis process, clostridial growth medium was used, which contains per liter 0.75 g KH2PO4, 0.75 g K2HPO4, 0.71 g MgSO4⋅7H2O, 0.01 g MnSO4⋅7H2O, 0.01 g FeSO4⋅7H2O, 1 g NaCl, 2 g (NH4)2SO4, 5 g yeast extract, and 2 g asparagine, the pH was adjusted to 6.6 with NH4OH, and glucose was added at a final concentration of 2.5 g l-1 after autoclaving (Roos et al., 1985). While in fermentation, P2 medium (Baer et al., 1987) containing per liter 60 g glucose, 0.5 g K2HPO4, 0.5 g KH2PO4, 2.2 g CH3COONH4, 0.2 g MgSO4⋅7H2O, 0.01 g MnSO4⋅H2O, 0.01 g NaCl, 0.01 g FeSO4⋅7H2O, 1 mg ρ-aminobenzoic acid, 1 mg thiamine, 0.01 mg biotin was used. As an anaerobic indicator, resazurin was added into the clostridial growth medium and P2 medium at a concentration of 1 mg l-1. Where indicated, appropriate antibiotics (e.g., 15 μg ml-1 thiamphenicol or 2.5 μg ml-1 erythromycin) were added in the medium.

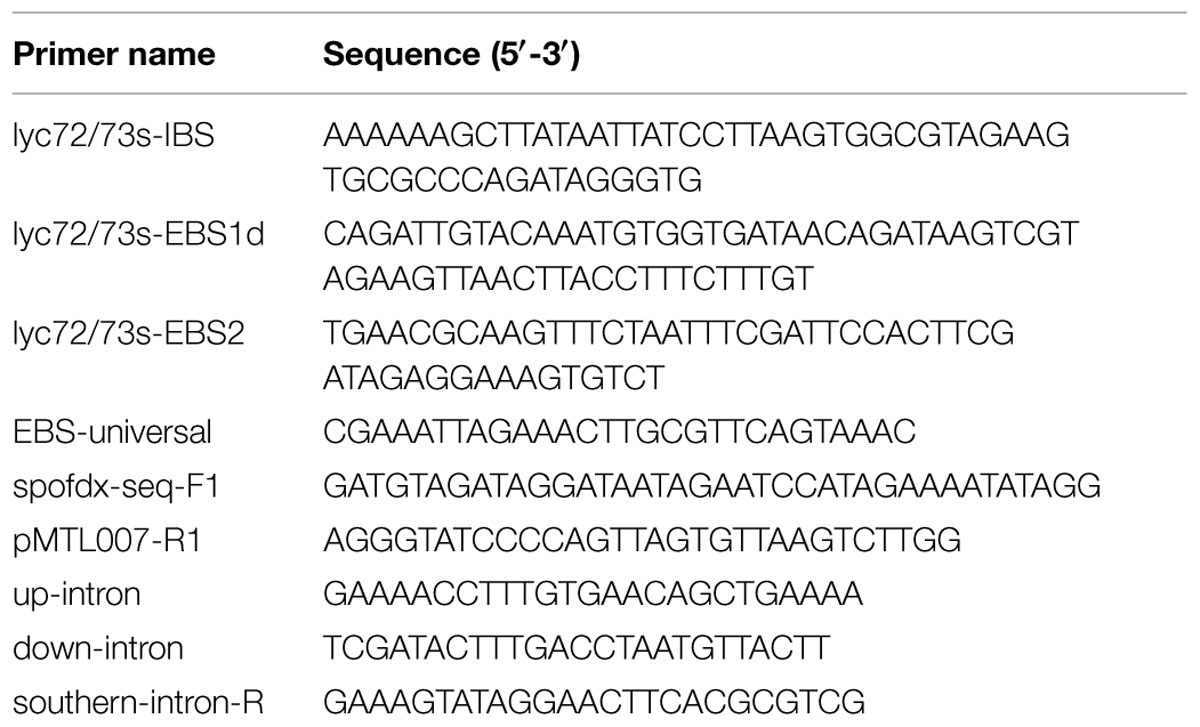

Construction of C. acetobutylicum lyc::int(72)

Generation of the 1,4-β-N-acetylmuramidase (coded by CA_C0554) negative mutant C. acetobutylicum lyc::int(72) was carried out by using the ClosTron system (Heap et al., 2007; Tan et al., 2015). PCR primers for the disruption of the lyc gene (CA_C0554) were designed by using the freely available TargeTron tool at http://www.clostron.com (Perutka et al., 2004). The primers used in this study are listed in Table 2. For retargeting of the intron to CA_C0554, splicing by overlap extension PCR (Warrens et al., 1997) was carried out using lyc72/73s-IBS, lyc72/73s-EBS1d, lyc72/73s-EBS2 and EBS universal primers (Table 2) with a template made by mixing two plasmids pMTL20IT1 and pMTL20IT2 in a ratio of 1:1 (Heap et al., 2010). The purified PCR product was ligated to pEASYTM-E1 and verified by DNA sequencing. After digestion with HindIII and Bsp1407I, the verified fragment was ligated into HindIII/Bsp1407I-restricted pMTL007C-E2. The correct ligation was confirmed by colony (grown on CGM plate containing 25 μg ml-1 chloramphenicol) PCR using the primers spofdx-seq-F1 and pMTL007-R1 (Table 2) with the 548 bp product.

The retargeted plasmid was transformed into E. coli DH5α together with pAN2 for in vivo methylation (Grant et al., 1990). The methylated plasmid was electroporated into C. acetobutylicum ATCC 824 and selected on the CGM plates containing 15 μg ml-1 thiamphenicol. Verification of correct transformants was carried out by colony PCR using the primers spofdx-seq-F1 and pMTL007-R1 with the 548 bp product. The correct transformants were resuspended in CGM medium and spread onto the CGM plates containing 2.5 μg ml-1 erythromycin. Correct integrants were confirmed by colony PCR using the primers up-intron and down-intron (Table 2) with the ∼2200 bp product, or using the primers up-intron and EBS universal with the 451 bp product. The correct integrant was passaged at least six times on the non-selective medium to lose the ClosTron plasmid lyc-retargeted pMTL007C-E2.

Southern blot analysis was performed to screen the integrants containing a single intron insertion. A lyc intron specific probe (518 bp) was obtained by PCR using primers lyc72/73s-EBS2 and southern-intron-R (Table 2) with genome of an integrant as the template. Genomic DNA of the wild strain and integrants was digested by HindIII, separated in 0.8% agarose gel, then transferred onto a nylon membrane. The hybridization was carried out at 44°C overnight. After incubation with anti-Dig-AP conjugate, the blot was visualized with NBT/BCIP.

Fermentation

Batch fermentation of C. acetobutylicum ATCC 824 or its mutant was carried out in 250-ml bottles containing 50 ml of the P2 medium anaerobically at 37°C. Fresh seeds (5%) were inoculated to start the fermentation. The initial glucose concentration, OD600 nm and pH were 80 g l-1, 0.05-0.1 and 7.0, respectively. Cell-free supernatant samples were stored at -20°C for further analyses.

Spore Density Determination

At the end of fermentation, 100 μl of culture broth was sampled, stayed at 80°C for 10 min to inactivate the vegetative cells (Lehmann et al., 2012), diluted to the 10-1, 10-2, 10-3, 10-4, 10-5, 10-6, and 10-7 fold of the original concentration. The diluted samples were spread onto the P2 plates without antibiotics and incubated at 37°C overnight. The plates with colonies’ number between 100 and 600 were selected to count. The spore density was calculated as follows:

Spore density = Colonies’ number × Dilution fold/100 μl.

Analytical Methods

The optical density (OD) was measured at 600 nm using a 2600 spectrophotometer (Unico Instruments CO., Ltd., Shanghai, China).

The concentration of glucose was determined by high performance liquid chromatography with an Agilent 1260 series, equipped with a Bio-Rad Aminex HI-Plex H column (300 mm × 7.7 mm) and a refractive index detector. Operating conditions were as follows: mobile phase, 5 mM H2SO4; flow rate, 0.6 ml min-1; and column temperature, 65°C.

Acetone, butanol and ethanol were all detected by a GC system (Agilent 7890B) equipped with a flame ionization detector and a column (HP-INNOWAX 19091N-213, 30 m length, 0.32 mm inner diameter). The column temperature was raised from 35 to 45°C at a rate of 2°C min-1, then to 150°C at a rate of 40°C min-1, after which it was maintained at 150°C for 1 min. The injector and detector temperature were 200 and 250°C, respectively. Samples were extracted with threefold volume of ethyl acetate containing ioamyl alcohol as the internal standard, then 1 μl of the organic phase was injected.

Results

Construction of C. acetobutylicum lyc::int(72)

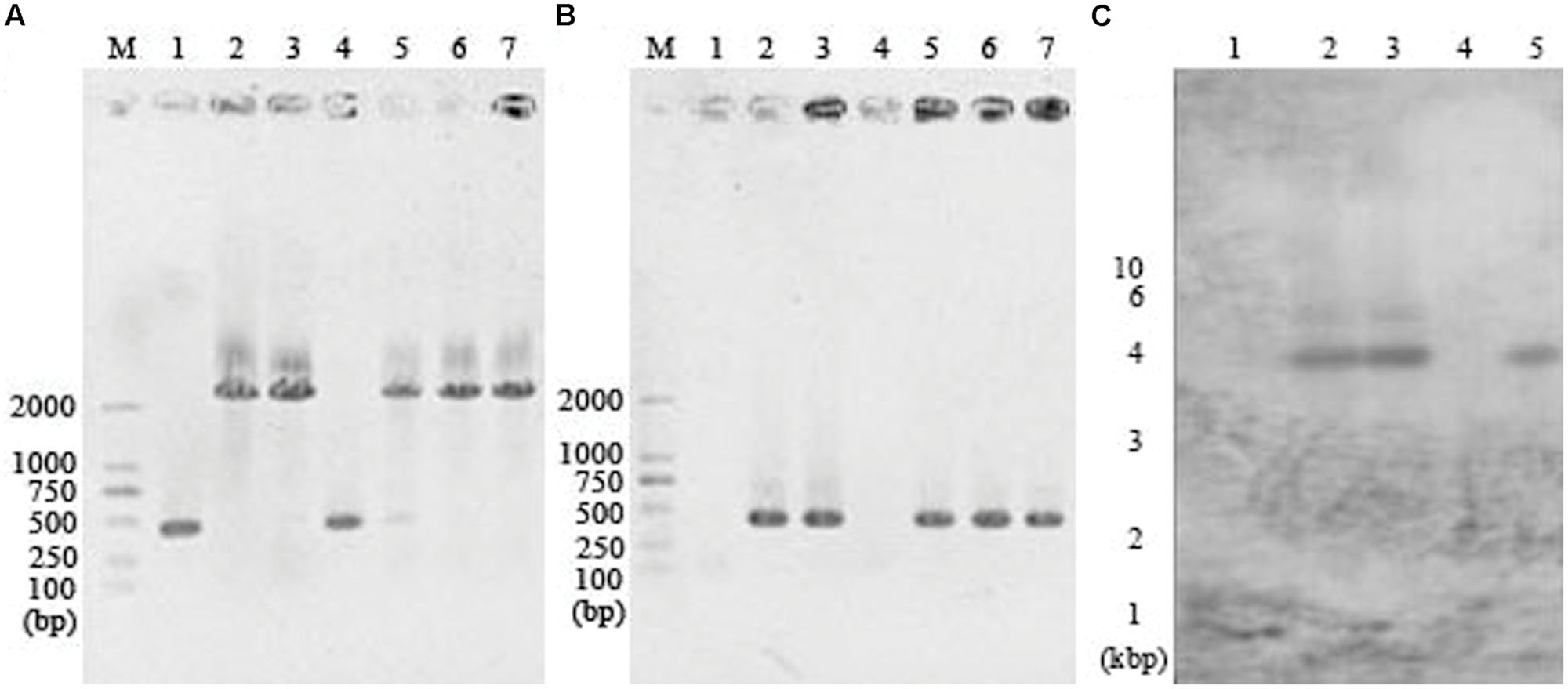

CA_C0554, one of the autolysin-coding genes found in C. acetobutylicum ATCC 824, was disrupted by ClosTron system to investigate the role of autolysin on the spontaneous large-scale autolysis. Putative integrants were screened by colony PCR from the erythromycin-resistant colonies. Using primers up-intron and down-intron, a product of ∼2200 bp was obtained with a putative integrant as template, while a product of 425 bp was obtained with the wild strain as template (Figure 1A). Using primers up-intron and EBS universal, a product of 451 bp was obtained with a putative integrant as template, while no product was obtained with the wild strain as template (Figure 1B). Five putative integrants were screened and four of them were verified by southern blot analysis with a lyc intron specific probe. As shown in Figure 1C, the integrant in lane 5 with only one hybridized belt was verified as the correct CA_C0554 disrupted mutant and named as C. acetobutylicum lyc::int(72).

FIGURE 1. Confirmation of the CA_C0554 disruption mutant C. acetobutylicum lyc::int(72) by colony PCR and southern blot analysis. Screening of putative integrants was performed by colony PCR with primers up-intron and down-intron (A) or primers up-intron and EBS universal (B). M, marker; 1, C. acetobutylicum ATCC 824; 2-7, erythromycin-resistant clones. Verification of the correct integrants with a single intron insertion was carried out by southern blot analysis (C). M, marker; 1, C. acetobutylicum ATCC 824; 2-5, putative integrants screened by colony PCR.

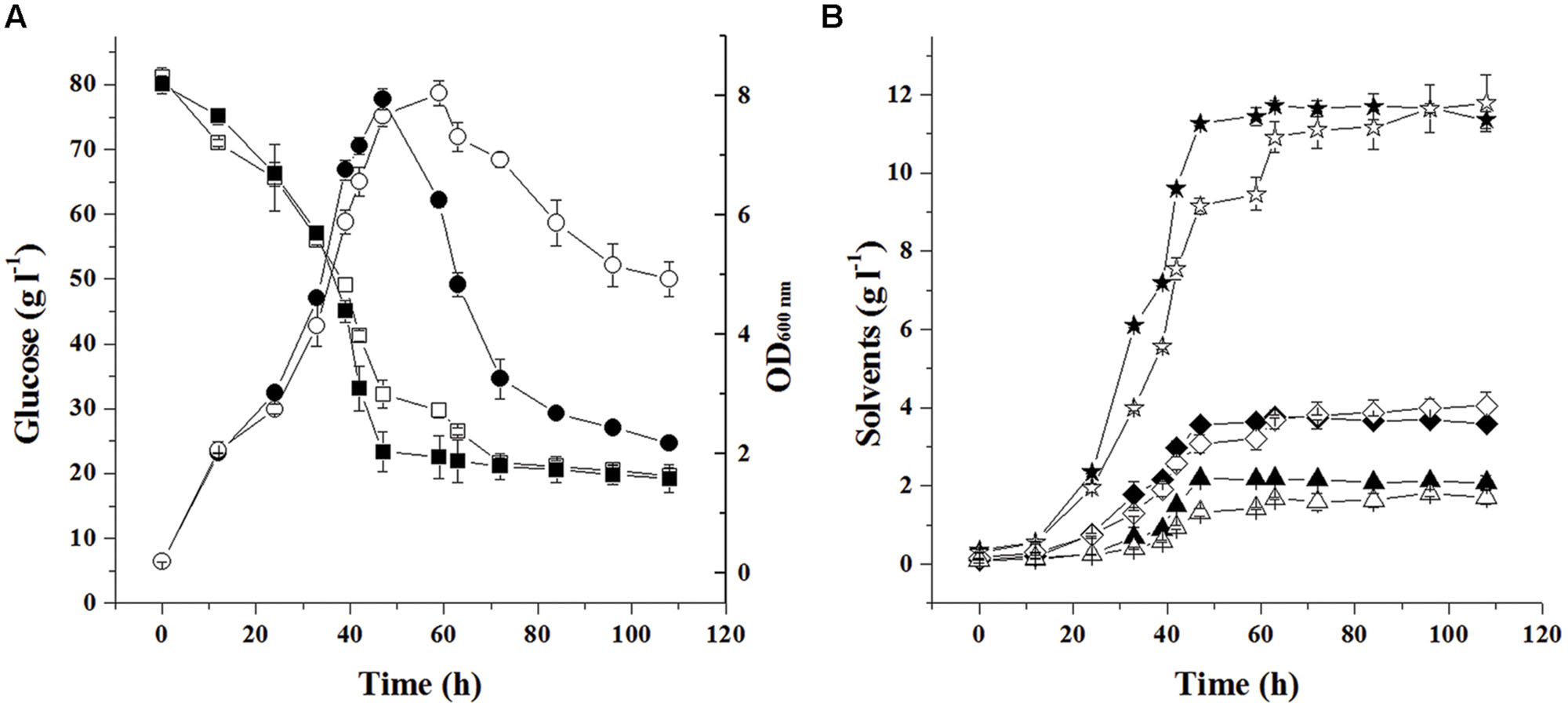

Effect of CA_C0554 Disruption on Metabolism

The effect of CA_C0554 disruption was investigated. Firstly, batch fermentation of C. acetobutylicum ATCC 824 and C. acetobutylicum lyc::int(72) was compared. As shown in Figure 2, during the exponential phase (0-47 h), the cell growth of the 2 strains were similar. In fermentation of C. acetobutylicum ATCC 824, OD600 nm decreased 72.5% (7.94 ± 0.18 to 2.18 ± 0.04) from 47 to 108 h, which was similar with the previous reports (Barber et al., 1979; Lehmann and Lütke-Eversloh, 2011; Lehmann et al., 2012). On the other hand, during fermentation of C. acetobutylicum lyc::int(72), OD600 nm decreased 35.6% (7.66 ± 0.19 to 4.93 ± 0.30) in the same phase (47–108 h). The OD600 nm decrease rate (0.094 h-1) of C. acetobutylicum ATCC 824 is 2.09 fold of that (0.045 h-1) of. C. acetobutylicum lyc::int(72), which means CA_C0554 plays an important role in the cell density decrease in the batch fermentation of C. acetobutylicum ATCC 824. On the other hand, since there was still 35.6% decrease of cell density in the batch fermentation of C. acetobutylicum lyc::int(72), it seems that besides CA_C0554, there are other autolysins responsible for the cell density decrease in the batch fermentation of C. acetobutylicum ATCC 824. In another word, CA_C0554 was an important but not the sole gene coding for autolysins responsible for the spontaneous large-scale autolysis.

FIGURE 2. Time course of batch fermentation with glucose as substrate by C. acetobutylicum ATCC 824 and C. acetobutylicum lyc::int(72). ATCC 824-glucose (■), ATCC 824-OD (•), ATCC 824-butanol (★), ATCC 824-acetone (⧫), ATCC 824-ethanol (▲), lyc::int(72)-glucose (□), lyc::int(72)-OD600 nm (○), lyc::int(72)-butanol (☆), lyc::int(72)-acetone (◇), lyc::int(72)-ethanol (△). Data are presented as the average ± standard deviation values of three parallel replicates.

In batch fermentation of C. acetobutylicum ATCC 824, the consumed glucose was 60.84 ± 0.77 g l-1, which was very similar to that (60.45 ± 1.02 g l-1) consumed in batch fermentation of C. acetobutylicum lyc::int(72). The final concentration of acetone (3.58 ± 0.08 g l-1 vs. 4.05 ± 0.36 g l-1), butanol (11.36 ± 0.22 g l-1 vs. 11.79 ± 0.73 g l-1), and ethanol (2.08 ± 0.18 g l-1 vs. 1.71 ± 0.18 g l-1) were also comparable between the batch fermentation of C. acetobutylicum ATCC 824 and that of C. acetobutylicum lyc::int(72), respectively. This suggests that the obvious change of cell density did not influence the overall metabolic level of the CA_C0554 disrupted mutant C. acetobutylicum lyc::int(72).

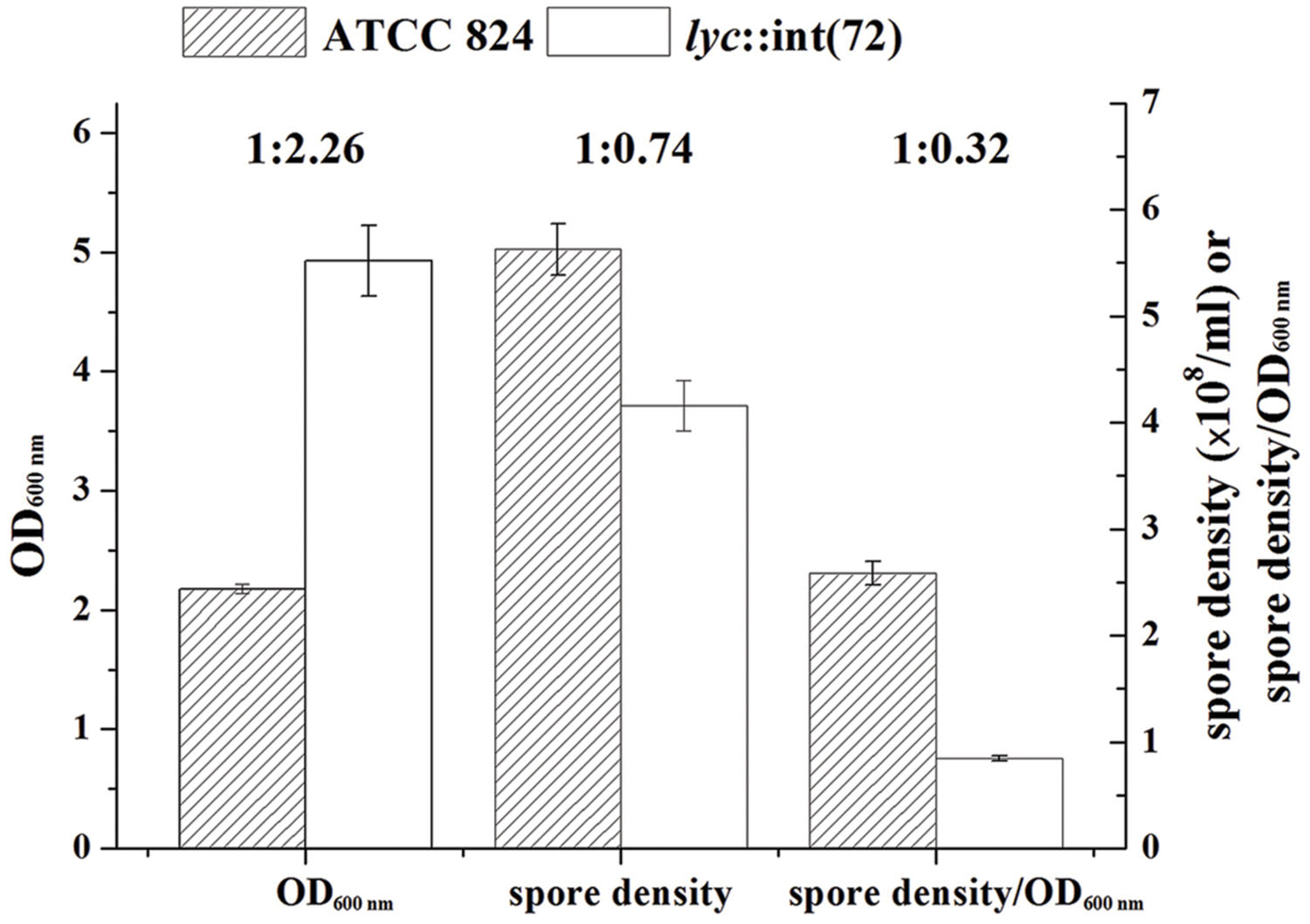

Effect of CA_C0554 Disruption on Sporulation

To investigate the effect of CA_C0554 disruption on sporulation, the spore density of the final culture in batch fermentation was determined. In the end (108 h) of batch fermentation, the spore density of C. acetobutylicum lyc::int(72) (4.16 ± 0.24 × 108/ml) was 26.1% lower than that of C. acetobutylicum ATCC 824 (5.63 ± 0.24 × 108/ml; Figure 3). On the other hand, the OD600 nm (4.93 ± 0.30) of C. acetobutylicum lyc::int(72) at 108 h was 2.26 fold of that (2.18 ± 0.04) of C. acetobutylicum ATCC 824 (Figure 3). OD600 nm represents the whole biomass including metabolic-inactive cells, vegetative cells and spores, hence the ratio of spore density to OD600 nm could represent the ratio of spores in the whole biomass. As shown in Figure 3, the ratio of spore density to OD600 nm of C. acetobutylicum lyc::int(72) at 108 h was 0.32 fold of that of C. acetobutylicum ATCC 824. This indicates that the significant decrease of spore ratio in the whole biomass for the mutant was caused by disruption of CA_C0554, an important autolysin-coding gene.

FIGURE 3. Comparison of cell density and spore density in final (108 h) culture of batch fermentation of C. acetobutylicum ATCC 824 and C. acetobutylicum lyc::int(72). Data are presented as the average ± standard deviation values of three parallel replicates.

Discussion

C. acetobutylicum ATCC 824 is an anaerobic, Gram-positive strain, which is one of the important strains for biobutanol production (Liu et al., 2010; Tracy et al., 2011; Zhang et al., 2012). As a spore-forming strain, the sporulation process of C. acetobutylicum ATCC 824 has been widely investigated in recent years (Bi et al., 2011; Al-Hinai et al., 2014). In this study, an autolysin-coding gene, CA_C0554, was disrupted to study the biological role of spontaneous large-scale autolysis in C. acetobutylicum ATCC 824.

In batch fermentation of CA_C0554 disrupted mutant C. acetobutylicum lyc::int(72), the OD600 nm decrease rate was only 47.8% of that in C. acetobutylicum ATCC 824 batch fermentation. This suggests CA_C0554 was an important but not the sole gene coding for autolysins responsible for the large-scale autolysis. In an earlier study, an autolysis-deficient mutant C. acetobutylicum lyt-1 has been isolated by ethyl methane sulfonate mutagenesis using C. acetobutylicum P262 as parent (Allcock et al., 1981). In C. acetobutylicum P262 batch fermentation, 50% OD600 nm decrease has been observed after exponential phase, but no obvious OD600 nm change was found in C. acetobutylicum lyt-1 batch fermentation (Van der Westhuizen et al., 1982). This was because on one hand C. acetobutylicum lyt-1 produced less autolysin than the parent P262 strain, which was similar to this study, on the other hand C. acetobutylicum lyt-1 had an altered cell wall which was more resistant to autolysins (Allcock et al., 1981).

The trends of glucose utilization and solvents (acetone, butanol, and ethanol) production were similar between the batch fermentation of C. acetobutylicum ATCC 824 and that of C. acetobutylicum lyc::int(72). This suggests that the significant change of cell density did not influence the substrate utilization and products formation of the CA_C0554 disrupted mutant C. acetobutylicum lyc::int(72). Similar phenomenon has been reported by Minier et al. (1990), in which autolysins in the broth were subject to heat treatment (70°C for 20 min) before recycling, while cells were confined by mineral ultrafiltration membranes in the batch fermentation of C. acetobutylicum ATCC 824.

Since increased cell density did not lead to increased substrate utilization and product formation in mutant C. acetobutylicum lyc::int(72), it is speculated that the increased cells in C. acetobutylicum lyc::int(72) batch fermentation, namely, the cells lysed by autolysins in C. acetobutylicum ATCC 824 batch fermentation were metabolic inactive. It indicated that the spontaneous large-scale autolysis is selective in the batch fermentation of C. acetobutylicum ATCC 824, in other words, the cells without metabolic activity were lysed. After disruption of CA_C0554, less metabolic-inactive cells were lysed, meanwhile less spores formed, which suggests the autolysis of metabolic-inactive cells could benefit the sporulation. We speculated that metabolic-inactive cells were lysed by autolysins to release nutrients on which the sporulating cells could feed. A killing factor has been characterized in B. subtilis, by which part of cells were lysed to release nutrients that could be fed on by sporulating cells (González-Pastor et al., 2003).

Spore forming bacteria initiate the sporulation process to survive of environments unfavorable for growth, while in the environments suitable for vegetative growth, germination of spores happened (Nicholson et al., 2000; Yang et al., 2009). The more spores, the larger survival probability. Hence during sporulation, C. acetobutylicum would form spores as more as possible. Normally, the metabolic-inactive cells are considered useless to the sporulation process. However, a large quantity of metabolic-inactive cells were lysed by autolysins such as the protein coded by CA_C0554. Nutrients released by lysed cells were utilized by sporulating cells. Therefore, providing nutrients for sporulation to form more spores under the unfavorable environment is an important biological role of spontaneous large-scale autolysis in the batch fermentation of C. acetobutylicum ATCC 824.

In summary, an important autolysin-coding gene, CA_C0554, was disrupted to obtain C. acetobutylicum lyc::int(72), the mutant of C. acetobutylicum ATCC 824. In the final culture of batch fermentation, though the OD600 nm of C. acetobutylicum lyc::int(72) was 126% higher than that of C. acetobutylicum ATCC 824, the utilization of substrate and solvents formation were similar between mutant and wild strain. This suggested that the lysed cells of C. acetobutylicum ATCC 824 were metabolic inactive. In addition, the spore density of C. acetobutylicum ATCC 824 is 26.1% higher than that of C. acetobutylicum lyc::int(72), suggesting the lysed metabolic-inactive cells could provide nutrients for the sporulating cells to form more spores. In conclusion, one important biological role of spontaneous large-scale autolysis in C. acetobutylicum ATCC 824 batch fermentation is contributing to generation of more spores during sporulation.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

The authors thank Nigel P. Minton and John T. Heap, University of Nottingham, for kindly providing the ClosTron plasmids. The work was supported by the Shandong Province Natural Science Funds for Distinguished Young Scholar (JQ201507), the Promotive Research Fund for Excellent Young and Middle-aged Scientists of Shandong Province (BS2013SW018), and the China Petrochemcial Corporation (Sinopec).

References

Al-Hinai, M. A., Jones, S. W., and Papoutsakis, E. T. (2014). σK of Clostridium acetobutylicum is the first known sporulation-specific sigma factor with two developmentally separated roles, one early and one late in sporulation. J. Bacteriol. 196, 287–299. doi: 10.1128/JB.01103-13

Allcock, E. R., Reid, S. J., Jones, D. T., and Woods, D. R. (1981). Autolytic activity and an autolysis-deficient mutant of Clostridium acetobutylicum. Appl. Environ. Microbiol. 42, 929–935.

Baer, S. H., Blaschek, H. P., and Smith, T. L. (1987). Effect of butanol challenge and temperature on lipid composition and membrane fluidity of butanol-tolerant Clostridium acetobutylicum. Appl. Environ. Microbiol. 53, 2854–2861.

Barber, J. M., Robb, F. T., Webster, J. R., and Woods, D. R. (1979). Bacteriocin production by Clostridium acetobutylicum in an industrial fermentation process. Appl. Environ. Microbiol. 37, 433–437.

Bi, C., Jones, S. W., Hess, D. R., Tracy, B. P., and Papoutsakis, E. T. (2011). SpoIIE is necessary for asymmetric division, sporulation, and expression of σF, σE, and σG but does not control solvent production in Clostridium acetobutylicum ATCC 824. J. Bacteriol. 193, 5130–5137. doi: 10.1128/JB.05474-11

Blackman, S. A., Smith, T. J., and Foster, S. J. (1998). The role of autolysins during vegetative growth of Bacillus subtilis 168. Microbiology 144, 73–82. doi: 10.1099/00221287-144-1-73

Chung, J., Yoon, H. E., Shin, H. C., Choi, E., and Byeon, W. (2009). Induction of growth phase-specific autolysis in Bacillus subtilis 168 by growth inhibitors. J. Microbiol. 47, 50–59. doi: 10.1007/s12275-008-0256-2

Croux, C., Canard, B., Goma, G., and Soucaille, P. (1992). Purification and characterization of an extracellular muramidase of Clostridium acetobutylicum ATCC 824 that acts on non-N-acetylated peptidoglycan. Appl. Environ. Microbiol. 58, 1075–1081.

Croux, C., and García, J. L. (1991). Sequence of the lyc gene encoding the autolytic lysozyme of Clostridium acetobutylicum ATCC 824: comparison with other lytic enzymes. Gene 104, 25–31. doi: 10.1016/0378-1119(91)90460-S

Croux, C., and García, J. L. (1992). Reconstruction and expression of the autolytic gene from Clostridium acetobutylicum ATCC 824 in Escherichia coli. FEMS Microbiol. Lett. 95, 13–20. doi: 10.1111/j.1574-6968.1992.tb05336.x

Fujita, Y., Yamaguchi, K., Kamegaya, T., Sato, H., Semura, K., Mutoh, K., et al. (2005). A novel mechanism of autolysis in Helicobacter pylori: possible involvement of peptidergic substances. Helicobacter 10, 567–576. doi: 10.1111/j.1523-5378.2005.00364.x

García, J. L., García, E., Sánchez-Puelles, J. M., and López, R. (1988). Identification of a lytic enzyme of Clostridium acetobutylicum that degrades choline-containing pneumococcal cell walls. FEMS Microbiol. Lett. 52, 133–138. doi: 10.1111/j.1574-6968.1988.tb02584.x

González-Pastor, J. E., Hobbs, E. C., and Losick, R. (2003). Cannibalism by sporulating bacteria. Science 301, 510–513. doi: 10.1126/science.1086462

Grant, S. G. N., Jessee, J., Bloom, F. R., and Hanahan, D. (1990). Differential plasmid rescue from transgenic mouse DNAs into Escherichia coli methylation-restriction mutants. Proc. Natl. Acad. Sci. U.S.A. 87, 4645–4649. doi: 10.1073/pnas.87.12.4645

Heap, J. T., Kuehne, S. A., Ehsaan, M., Cartman, S. T., Cooksley, C. M., Scott, J. C., et al. (2010). The ClosTron: mutagenesis in Clostridium refined and streamlined. J. Microbiol. Methods 80, 49–55. doi: 10.1016/j.mimet.2009.10.018

Heap, J. T., Pennington, O. J., Cartman, S. T., Garter, G. P., and Minton, N. P. (2007). The ClosTron: a universal gene knock-out system for the genus Clostridium. J. Microbiol. Methods 70, 452–464. doi: 10.1016/j.mimet.2007.05.021

Heidrich, C., Templin, M. F., Ursinus, A., Merdanovic, M., Berger, J., Schwarz, H., et al. (2001). Involvement of N-acetylmuramyl-L-alanine amidases in cell separation and antibiotic-induced autolysis of Escherichia coli. Mol. Microbiol. 41, 167–178. doi: 10.1046/j.1365-2958.2001.02499.x

Lacriola, C. J., Falk, S. P., and Weisblum, B. (2013). Screen for agents that induce autolysis in Bacillus subtilis. Antimicrob. Agents Chemother. 57, 229–234. doi: 10.1128/AAC.00741-12

Leduc, M., Kasra, R., and Van Heijenoort, J. (1982). Induction and control of the autolytic system of Escherichia coli. J. Bacteriol. 152, 26–34.

Lehmann, D., Hönicke, D., Ehrenreich, A., Schmidt, M., Weuster-Botz, D., Bahl, H., et al. (2012). Modifying the product pattern of Clostridium acetobutylicum, physiological effects of disrupting the acetate and acetone formation pathways. Appl. Microbiol. Biotechnol. 94, 743–754. doi: 10.1007/s00253-011-3852-8

Lehmann, D., and Lütke-Eversloh, T. (2011). Switching Clostridium acetobutylicum to an ethanol producer by disruption of the butyrate/butanol fermentative pathway. Metab. Eng. 13, 464–473. doi: 10.1016/j.ymben.2011.04.006

Lemée, R., Lortal, S., and Van Heijenoort, J. (1995). Autolysis of dairy propionibacteria: isolation and renaturing gel electrophoresis of the autolysins of Propionibacterium freudenreichii CNRZ 725. Lait 75, 345–365. doi: 10.1051/lait:19954-526

Liu, Z. Y., Ying, Y., Li, F. L., Ma, C. Q., and Xu, P. (2010). Butanol production by Clostridium beijerinckii ATCC 55025 from wheat bran. J. Ind. Microbiol. Biotechnol. 37, 495–501. doi: 10.1007/s10295-010-0695-8

Lortal, S., Lemée, R., and Valence, F. (1997). Autolysis of thermophilic lactobacilli and dairy propionibacteria: a review. Lait 77, 133–150. doi: 10.1051/lait:199719

Mesnage, S., Chau, F., Dubost, L., and Arthur, M. (2008). Role of N-acetylglucosaminidase and N-acetylmuramidase activities in Enterococcus faecalis peptidoglycan metabolism. J. Biol. Chem. 283, 19845–19853. doi: 10.1074/jbc.M802323200

Minier, M., Soucaille, P., Blanc-Ferras, E., Izard, A., and Goma, G. (1990). Inactivation of lytic enzymes by heat treatment in ultrafiltration-coupled acetonobutylic fermentation. Appl. Microbiol. Biotechnol. 33, 274–279. doi: 10.1007/BF00164521

Nicholson, W. L., Munakata, N., Horneck, G., Melosh, H. J., and Setlow, P. (2000). Resistance of Bacillus endospores to extreme terrestrial and entraterrestrial environments. Microbiol. Mol. Biol. Rev. 64, 548–572. doi: 10.1128/MMBR.64.3.548-572.2000

Perutka, J., Wang, W., Goerlitz, D., and Lambowitz, A. M. (2004). Use of computer designed group II introns to disrupt Escherichia coli DExH/D-box protein and DNA helicase genes. J. Mol. Biol. 336, 421–439. doi: 10.1016/j.jmb.2003.12.009

Roos, J. W., McLaughlin, J. K., and Papoutsakis, E. T. (1985). The effect of pH on nitrogen supply, cell lysis, and solvent production in fermentations of Clostridium acetobutylicum. Biotechnol. Bioeng. 27, 681–694. doi: 10.1002/bit.260270518

Smith, T. J., Blackman, S. A., and Foster, S. J. (2000). Autolysins of Bacillus subtilis: multiple enzymes with multiple functions. Microbiology 146, 249–262. doi: 10.1099/00221287-146-2-249

Tan, Y., Liu, Z. Y., Liu, Z., Zheng, H. J., and Li, F. L. (2015). Comparative transcriptome analysis between csrA-disruption Clostridium acetobutylicum and its parent strain. Mol. Biosyst. 11, 1434–1442. doi: 10.1039/C4MB00600C

Tracy, B. P., Jones, S. W., Fast, A. G., Indurthi, D. C., and Papoutsakis, E. T. (2011). Clostridia: the importance of their exceptional substrate and metabolite diversity for biofuel and biorefinery applications. Curr. Opin. Biotechnol. 23, 1–18. doi: 10.1016/j.copbio.2011.10.008

Van der Westhuizen, A., Jones, D. T., and Woods, D. R. (1982). Autolytic activity and butanol tolerance of Clostridium acetobutylicum. Appl. Environ. Microbiol. 44, 1277–1281.

Vollmer, W., Joris, B., Charlier, P., and Foster, S. (2008). Bacterial peptidoglycan (murein) hydrolases. FEMS Microbiol. Rev. 32, 259–286. doi: 10.1111/j.1574-6976.2007.00099.x

Warrens, A. N., Jones, M. D., and Lechler, R. I. (1997). Splicing by overlap extension by PCR using asymmetric amplification: an improved technique for the generation of hybrid proteins of immunological interest. Gene 186, 29–35. doi: 10.1016/S0378-1119(96)00674-9

Webster, J. R., Rein, S. J., Jones, D. T., and Woods, D. R. (1981). Purification and characterization of an autolysin from Clostridium acetobutylicum. Appl. Environ. Microbiol. 41, 371–374.

Yang, L., Bao, G., Zhu, Y., Dong, H., Zhang, Y., and Li, Y. (2013). Discovery of a novel gene involved in autolysis of Clostridium cells. Protein Cell 4, 467–474. doi: 10.1007/s13238-013-3025-x

Yang, W. W., Crow-Willard, E. N., and Ponce, A. (2009). Production and characterization of pure Clostridium spore suspensions. J. Appl. Micorbiol. 106, 27–33. doi: 10.1111/j.1365-2672.2008.03931.x

Keywords: autolysis, sporulation, Clostridium acetobutylicum, ClosTron, autolysin

Citation: Liu Z, Qiao K, Tian L, Zhang Q, Liu Z-Y and Li F-L (2015) Spontaneous large-scale autolysis in Clostridium acetobutylicum contributes to generation of more spores. Front. Microbiol. 6:950. doi: 10.3389/fmicb.2015.00950

Received: 14 July 2015; Accepted: 27 August 2015;

Published: 09 September 2015.

Edited by:

Weiwen Zhang, Tianjin University, ChinaReviewed by:

Zhidan Liu, China Agricultural University, ChinaXu Fang, Shandong University, China

Guokui Qin, Massachusetts Institute of Technology, USA

Copyright © 2015 Liu, Qiao, Tian, Zhang, Liu and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) or licensor are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Fu-Li Li, Key Laboratory of Biofuels and Shandong Provincial Key Laboratory of Energy Genetics, Qingdao Institute of Bioenergy and Bioprocess Technology – Chinese Academy of Sciences, Qingdao 266101, China,bGlmbEBxaWJlYnQuYWMuY24=

Zhen Liu

Zhen Liu Kai Qiao2

Kai Qiao2 Fu-Li Li

Fu-Li Li