- Department of Chemical Engineering, Technion – Israel Institute of Technology, Haifa, Israel

We measured the dynamic electrical properties of a spontaneously charged glass surface in an electrolyte solution by using a MHz-level surface acoustic wave (SAW) actuator to introduce a same-frequency mechanical wave into the glass substrate. The mechanical wave vibrated ions in the nanometer-thick electrical double layer (EDL) to appear at the glass/electrolyte interface. The out-of-equilibrium EDL leaked an electrical field, which was modulated by ion vibration frequency to reveal the presence of ions and their dynamic motion. A previous study excited EDLs on the piezoelectric lithium niobate substrate of a SAW actuator in contact with an electrolyte solution, but it remained unclear whether the mechanical or electrical components of the SAW in the piezoelectric substrate dominated the EDL excitation. Here, we isolated the SAW mechanical component in glass and showed that it introduces a similar ion electrokinetic vibration in the excited EDL at the glass/electrolyte interface using sodium nitrate and potassium chloride solutions as electrolytes. The measured electrical field leakage spectra were of similar magnitude to those measured in the previous study and exhibited similar non-monotonic behaviors, taking local maxima where the SAW period (the inverse of its frequency) was synchronized with the ion relaxation times in the EDL. At these frequencies, the synchronization maximized ion vibration displacement, thereby amplifying the electrical field leakage. Our findings may be used to study the electrokinetic properties of solid surfaces and ion dynamics in EDLs. Moreover, SAW-actuated fluidic platforms may support out-of-equilibrium EDLs relevant to ion-selective membranes and the film stability of electrolyte solutions.

1 Introduction

A MHz-level Rayleigh-type surface acoustic wave (SAW), traveling near the surface of a solid substrate, supports an accompanying sub-micrometer-thick evanescent mechanical wave (i.e., a spatiotemporal periodic boundary layer flow) in the neighboring water phase, whether the SAW is a standing (Rayleigh, 1884; Schlichting, 1932) or a traveling wave (Vanneste and Bühler, 2011; Manor et al., 2012). In a piezoelectric substrate, commonly used for SAW actuators, the SAW mechanical component is accompanied by a voltage signal counterpart. Previous theorems have predicted that the SAW mechanical component (Dubrovski and Manor, 2021) and the voltage signal in the piezoelectric substrate (Dietzel and Hardt, 2020) may both introduce electrokinetic effects in an electrolyte solution near the surface of the actuator. The former and the latter displace ions via the accompanying evanescent mechanical wave and the spreading of an electric field in the neighboring electrolyte solution, respectively. Moreover, the voltage signal counterpart of the SAW has been attributed to the electro-catalysis of chemical reactions by SAW actuators (Ahmed et al., 2019; Rezk et al., 2020). SAW actuators have also been used to measure the presence and dynamics of ions in neighboring electrolyte solutions (Aremanda and Manor, 2023). While the contribution of the voltage signal in the piezoelectric substrate of the actuator to electrokinetic effects in the neighboring electrolyte is trivial, it is not clear whether it dominates over contributions from the mechanical component of the SAW. To solve this question, we isolated the mechanical component of the SAW on a glass substrate neighboring an aqueous electrolyte solution. Our measurements confirmed significant electrokinetic effects in the electrical double layer (EDL), which spontaneously appears at the glass/electrolyte interface.

Electrical double layers are the opposing charge layers that spontaneously appear at the surface of a substrate in an electrolyte. The majority of surfaces accumulate spontaneous charge when in contact with an electrolyte due to chemical or physical surface reactions. The charged surface attracts clouds of ions from the electrolyte, some of which will adsorb on the surface. Others, non-adsorbing ions, accumulate in nanometer-thick ion clouds near the charged surface, fully screening the electrical field emanating from the surface charge at equilibrium. EDLs are fundamental to countless natural and artificial systems. Examples of EDL electrokinetic applications include the electrophoretic particle motion, the electroosmotic actuation of flow (Hunter, 2001), and the electrowetting motion of liquid film and drops (Frieder and Jean-Christophe, 2005). Examples of equilibrium applications are energy barriers to particulate coagulation and adsorption (Chan et al., 2008; Homede et al., 2018, 2020), a guiding mechanism for folding structures of proteins (Zhou and Pang, 2018), and the origin of the surface electrical properties in biological (Hong and Okajima, 1986) and artificial membranes (Hoek and Tarabara, 2013).

Our analysis is reminiscent of the classic electroacoustic measurements of the interactions between bulk ultrasonic waves and ions in electrolyte solutions (Debye, 1933; Yeager et al., 1949; Dahint et al., 1992) or charged colloids in dispersions (Dukhin and Goetz, 1996; Babchin et al., 1989; Hunter, 1998). These measurements have been employed to analyze ionic species in electrolytes and analyze the electrokinetic properties, most notably the zeta potential, of particle dispersions in electrolytes. In the latter case, the ultrasonic waves interact with the electrical double layers (EDLs) at the interface of particles and electrolytes along the ultrasonic path, which varies the electric potential across the dispersion.

However, the nanometer thickness of EDLs and their nano- to micro-second relaxation times pose a challenge to direct measurements of ion dynamics in an isolated and unique EDL. This challenge is circumvented by exciting an EDL at a flat interface using a MHz-level Rayleigh-type SAW. These are the same type of waves that occur in earthquakes when pressure and shear waves meet near the Earth’s outer crust, forming a large amplitude waves—Rayleigh waves (or equivalently Rayleigh SAWs) that travel—near the crust’s surface. Rayleigh waves travel near the surface of a substrate and support both normal and longitudinal particle motion. In the laboratory, SAWs are generated in the piezoelectric substrate of actuators, where they are accompanied by an electric signal counterpart. The mechanical component of the SAW produces periodic boundary layer flows in the neighboring fluid—the equivalent of an evanescent mechanical wave—close to the surface of the solid (Rayleigh, 1884; Schlichting, 1932; Vanneste and Bühler, 2011; Manor et al., 2012). The leading-order period of the boundary layer flow is similar to the period (the inverse of frequency) of the SAW in the solid; its characteristic thickness—known as the viscous penetration of the SAW into the fluid—is 100 nm in ambient water neighboring a 20-MHz frequency SAW.

In the presence of an SAW in a solid substrate, the EDL at the solid/electrolyte interface is rendered out of equilibrium, leaking an electrical field to the electrolyte bulk. This electrical field leakage is proportional to the zeta potential of the solid surface in the electrolyte solution and is modulated in time by the motion of ions. Thus, the leakage obtains the frequency of the exciting SAW and its harmonics. Moreover, a SAW of MHz-level frequency,

The ratio of the acoustic period and the relaxation time of ion

However, when conducting the measurements directly on the piezoelectric substrate of the SAW actuator, it is unclear whether the mechanical SAW or its electrical counterpart dominated the EDL excitation in the previous experiment. The periodic (AC) voltage

Here, we isolated the contribution of the SAW—that is, of the mechanical vibration—to the leakage of the electrical field off the excited EDL by transferring the SAW from the actuator to a glass slab. The glass slab supports pure mechanical vibration, which excites ions in EDLs at the flat interface between the glass and a drop of electrolyte. We describe our experiment in Section 2, show and discuss our results in Section 3, and summarize and conclude our findings in Section 4.

2 Materials and methods

2.1 Experimental setup

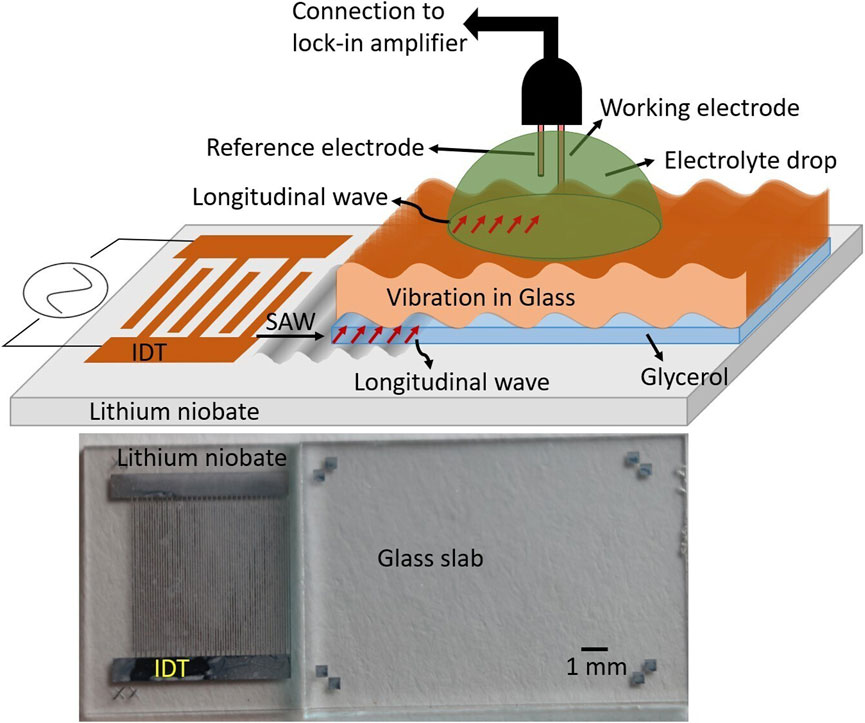

The integrated ultrasonic device in Figure 1 is comprised of a 1-mm-thick glass slab (microscope slides, 1 mm thick, tolerance:

Figure 1. Sketch of the experimental setup and an image (below) of a 1-mm-thick glass slab atop an SAW actuator; interdigital transducer (IDT) comprising electrodes in contact with a piezoelectric substrate is shown to the left. We placed the glass slab atop the actuator, right of the IDT, using a thin layer of glycerol. We illustrate in the sketch the placement of a drop of electrolyte solution atop the glass slab, into which we inserted working and reference electrodes. The excited EDL leaks an electrical field that we measured using the working electrode.

The SAW actuator is comprised of a 5-nm chrome/1,000 nm aluminum interdigital transducer (IDT) consisting of 30 electrode pairs of 50

We dispensed a sessile drop of an electrolyte solution atop the glass substrate. The electrolyte solutions were prepared by dissolving ultrapure salts:

We then positioned the working and reference microelectrodes in the drop. The working electrode was positioned at a separation of 30–40

The electrodes were connected through an active differential voltage probe (RT-ZD02, Rohde & Schwarz, Germany) to an RF lock-in amplifier (SR844, Stanford Research Systems, CA) for measuring the 20 MHz-frequency component of the electrical leakage—the linear (same frequency) response of the EDL to the exciting SAW. We used a BNC T-connector (50

2.2 Transport of the mechanical field through the integrated device

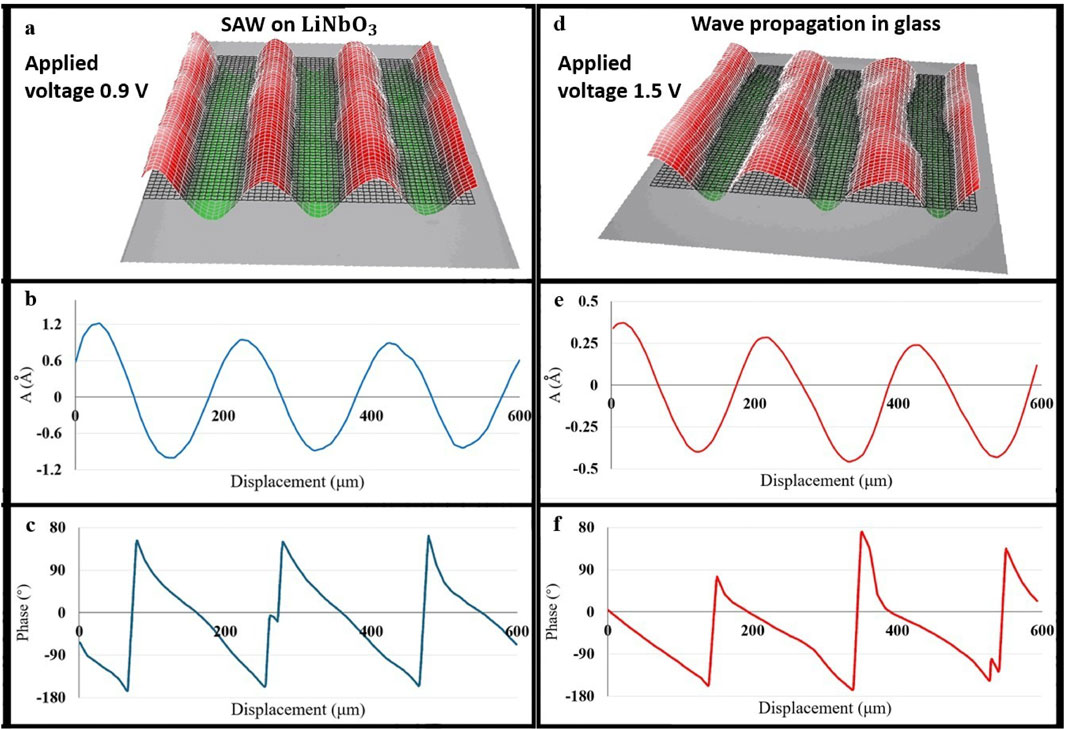

The SAW in an isolated actuator (no glass substrate or glycerol layer) is a propagating Rayleigh wave in the presence of the wave absorber at the edge of the actuator (Figure. 2a-c). In the integrated SAW actuator/glycerol/glass device, the SAW in the actuator translates to a same-frequency mechanical vibration in the glass substrate through the glycerol matching layer via diffraction (Figure 2d,e,f). We observed a propagating mechanical vibration at the glass surface close to the IDT—that is, close to the electrodes on the SAW actuator.

Figure 2. Surface-scanning laser Doppler vibrometer (LDV) measurements of the normal solid displacement on (a) an isolated LN substrate of the SAW actuator (with no additional glass substrate or glycerol atop the SAW actuator) and (d) the glass substrate placed above the actuator (using glycerol for acoustic impedance matching between the substrate), where (b, e) are the corresponding two-dimensional representation of the normal displacement amplitude at the solid surfaces at a specific time and (c, f) are the characteristic sawtooth pattern of the corresponding phase, which indicate that both mechanical waves propagate along the upper surface of both the LN and glass substrates and that both are of similar wavelengths of approximately 200

To realize the transport of mechanical power from the SAW actuator to the glass substrate, we measured the normal vibration at the LN upper surface of the SAW actuator (at the LN/glycerol interface) and at the glass upper surface (at the glass/air interface) of the integrated SAW actuator/glycerol/glass device at separations of 1, 5, 8, and 12 mm from the IDT—see the measurement results in Supplementary Information S3, where we give the corresponding autocorrelation coefficient to compare the two vibration modes on the two substrates that comprise the integrated device. The vibration normal amplitude is similar on both the LN and glass substrate, and both support a similar wavelength of approximately 200

In the absence of a sessile drop of an electrolyte solution, the phase of the mechanical vibration through the integrated device changed with separation from the IDT at the SAW actuator. Moreover, the vibration in the LN and glass substrates appeared synchronized. At separations from the IDT, where the SAW in the actuator is nearly a propagating wave or a combination of a propagating and standing wave, so was the mechanical vibration in the glass substrate directly above. Moreover, the SAW in the actuator did not attenuate by simple diffraction to the glass substrate. Such a simple diffraction would be the case if the glass substrate above the SAW actuator were a half-space of glass. In this case, we would expect the SAW in the actuator to almost fully attenuate at a separation of 1 mm from the point where it propagated under the glycerol film and glass substrate (see Supplementary Information S2 for details). However, our measurements suggest that the vibrations in the LN and glass substrate in the integrated device are intimately connected, suggesting that power is transferred from the SAW actuator to the glass substrate and from the glass substrate back to the LN substrate. This behavior may suggest that the mechanical vibration in the glass substrate is akin to a Lamb wave, in which the mechanical vibration is spread throughout the substrate, continuously absorbing and reflecting power to and from the SAW actuator, respectively.

Moreover, in the presence of a sessile drop of an electrolyte solution (as in our experiment) atop the glass substrate of the integrated device, the sessile drop absorbs some of the mechanical power in the glass, and hence one should expect that less mechanical power reaches the far end of the integrated device and, hence, a reduced wave reflection off the glass edge far from the IDT. That is, one should expect a more pronounced propagating mechanical wave in the glass substrate. However, measuring the vibration under the drop is a challenge due to its curved free surface and is beyond the scope of the current investigation.

We are predominantly interested in the mechanical vibration at the upper surface of the glass. It is interesting that it is of similar frequency and wavelength to the SAW in the actuator, which determine the frequency of ion excitation in the EDL at the glass/electrolyte interface and the separation between the working electrode and the glass surface that will facilitate the measurement of the electrical field leakage off the EDL, respectively. Our investigation indicates that the similarity between the frequency and wavelength of the vibration in glass and LN should result in a similar (although not the same) mechanical excitation of the ions in our experiment to that previously generated by a direct contact between the electrolyte and the LN substrate of the SAW actuator.

2.3 Transport of the electrical field through the integrated device

The electrical field accompanying the mechanical wave in the piezoelectric LN substrate of the actuator also spread into the glass substrate through the separating glycerol layer. In the absence of charges in the amorphous glass, the electrical potential

The spatiotemporal distribution of the electrical potential in the glass is solved subject to the electrical potential signal accompanying the mechanical wave at the solid surface of the LN substrate at

where

The problem in Equations 1–3 is satisfied by the electrical potential in a half-space of glass,

where

The electrical field accompanying the mechanical vibration in the actuator decays in the glass substrate, reaching a negligible magnitude at the upper surface of the glass. We will show later that the electrical potential measured is three to four orders of magnitude smaller than

3 Results and discussion

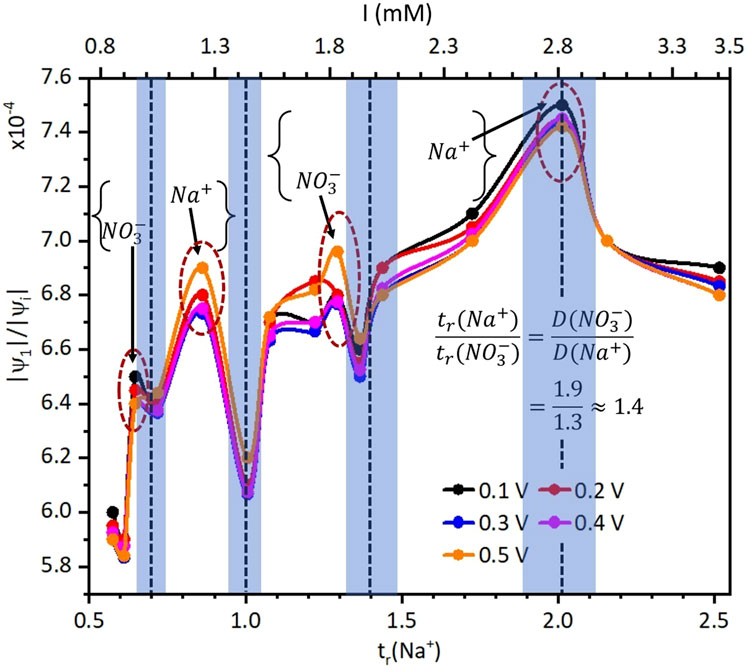

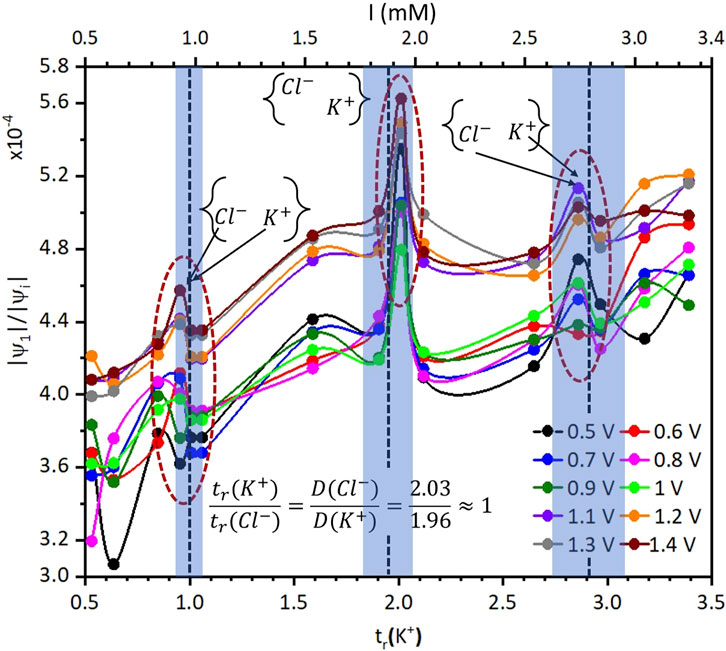

In Figures 3, 4 we show the ionic strength variations of the measured electrical field leakage in terms of a voltage spectrum, which we obtained for different magnitudes of the applied voltage to the SAW actuator

Figure 3. Ionic strength

Figure 4. Ionic strength

In our current experiments, we eliminated the electrical signal in the SAW actuator by transferring the mechanical component of the SAW to a mechanical vibration in the neighboring glass substrate. The intensity of the SAW in the actuator was linearly proportional to

The choice of electrolyte solutions is such that one

The electrical field leakage measured as an electrical potential spectra is the response of the EDL to the MHz-level mechanical vibration in glass that is in contact with

The excitation of the EDL at the glass–electrolyte interface in our measurement was solely mechanical. It is useful to compare our results to Aremanda and Manor (2023), where the excitation of the EDL at the SAW actuator/electrolyte interface comprised both a mechanical vibration component (Rayleigh SAW) and its electrical potential counterpart in the piezoelectric LN substrate of the actuator. We observed three points of comparison. (a) We measured peaks of the voltage leakage,

The first point of comparison—the measured

Moreover, the measured voltage peaks to originate from the

A second point of comparison was the similar magnitude of the measured voltage,

The third point was about the scaling of the measured voltage,

4 Conclusion

A previous direct measurement of the dynamic electrokinetic properties of an isolated and unique EDL system (Aremanda and Manor, 2023) overcame the challenges in observing the dynamics of ions therein by using MHz-level SAWs, which render the EDL out of equilibrium and cause the leakage of electrical fields. The electrical field leakage baseline is connected to the EDL zeta potential and is modulated by the ion mechanical vibration. The leakage undergoes local maxima levels, where the exciting SAW temporal period synchronizes with the ion relaxation time in the EDL. However, the EDL was measured at the interface between the electrolyte and the piezoelectric LN substrate of the SAW actuator, which supports both a Rayleigh-type SAW—a mechanical vibration—and a voltage signal counterpart. The relative contributions of the two mechanisms to the EDL excitation were not investigated, although Dubrovski and Manor (2021) hinted at a greater contribution from the SAW.

Here, we answered this question by isolating the mechanical vibration in glass. The glass substrate—a dielectric—attenuated the electrical field counterpart of the SAW in the actuator piezoelectric substrate due to the SAW finite wavelength. The thickness of the glass substrate was five times the SAW wavelength, and hence attenuated the electrical field emanating from the actuator to a level many orders of magnitude smaller than the measured electrical field leakage off the EDL at the glass/electrolyte interface. We studied similar electrolyte systems to those measured previously atop the SAW actuator, using ion mixtures of different and similar diffusion coefficients; the ion diffusion coefficient alongside the EDL Debye length determined the corresponding EDL relaxation time. We thus showed that the mechanical vibration alone is sufficient to introduce measurable electrokinetic effects in an EDL, that this component introduces at least the same magnitude of electrical field leakage off the EDL, and that the scaling that collapses the measured electrical field (voltage) curves,

The difference between classic electroacoustic studies and this one is that in classic electroacoustics, bulk ultrasonic waves generate an electrical potential difference across a volume of electrolyte solution or a colloidal suspension in electrolyte. Here, we excited ions in an isolated EDL emanating from a flat solid surface in contact with electrolytes by generating an ultrasonic vibration in the solid. Our work shows that future studies in this field may measure the static and dynamic electrokinetic properties of flat solid surfaces, provided that the solid substrate supports a corresponding mechanical vibration. For example, silica-based glass substrates, such as the one in our experiment, are widely used for surface chemistry manipulation, and hence is a versatile platform to study the dynamic motion of ions in EDLs generated by different surface chemistries in contact with an electrolyte, which may be used, for example, for membranes, batteries, and supercapacitors.

Moreover, we highlighted that a mechanical vibration traveling along a solid substrate in an electrolyte solution introduces electrokinetic effects. Ions vibrate in the EDL at the frequency of the mechanical vibration. Thus, out-of-equilibrium EDLs must be accounted for, especially in micro- and nano-fluidic systems that are actuated by mechanical vibration, such as SAWs. For example, on such platforms, EDLs that govern ion transport through ion-sensitive membranes or govern the stability of liquid films may not be at equilibrium and hence may possess different electrical properties from equilibrium EDLs; out-of-equilibrium EDLs may alter the membrane ion screening properties and the stability of the liquid films.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Author contributions

SA: formal analysis, investigation, methodology, validation, writing – original draft, and writing – review and editing. YL: investigation and writing – review and editing. GO: investigation, validation, and writing – review and editing. OM: conceptualization, formal analysis, funding acquisition, methodology, project administration, supervision, and writing – original draft.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was supported by the Ministry of Innovation, Science & Technology of the State of Israel, grant number 1001827275, and by the Israel Science Foundation, grant number 520/24.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The authors declare that no generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/facou.2025.1568083/full#supplementary-material

References

Ahmed, H., Rezk, A. R., Richardson, J. J., Macreadie, L. K., Babarao, R., Mayes, E. L. H., et al. (2019). Acoustomicrofluidic assembly of oriented and simultaneously activated metal-organic frameworks. Nat. Commun. 10, 2282. doi:10.1038/s41467-019-10173-5

Aremanda, S., and Manor, O. (2023). Measurements of ion dynamics and electro-mechanical resonance in an electrical double layer near a surface acoustic wave. J. Phys. Chem. C 127, 20911–20918. doi:10.1021/acs.jpcc.3c05063

Babchin, A., Chow, R., and Sawatzky, R. (1989). Electrokinetic measurements by electroacoustical methods. Adv. Colloid Interface Sci. 30, 111–151. doi:10.1016/0001-8686(89)80005-3

Chan, D. Y., Manor, O., Connor, J. N., and Horn, R. G. (2008). Soft matter: from shapes to forces on the nanoscale. Soft Matter 4, 471–474. doi:10.1039/b712924f

Dahint, R., Grunze, M., Josse, F., and Andle, J. (1992). Probing of strong and weak electrolytes with acoustic wave fields. Sensors Actuators B Chem. 9, 155–162. doi:10.1016/0925-4005(92)80209-G

Debye, P. (1933). A method for the determination of the mass of electrolytic ions. J. Chem. Phys. 1, 13–16. doi:10.1063/1.1749213

Dietzel, M., and Hardt, S. (2020). Electroosmotic flow in small-scale channels induced by surface-acoustic waves. Phys. Rev. Fluids 5, 123702. doi:10.1103/physrevfluids.5.123702

Dubrovski, O., and Manor, O. (2021). Revisiting the electroacoustic phenomenon in the presence of surface acoustic waves. Langmuir 37, 14679–14687. doi:10.1021/acs.langmuir.1c02414

Dukhin, A. S., and Goetz, P. J. (1996). Acoustic and electroacoustic spectroscopy. Spectroscopy 12, 4336–4344. doi:10.1021/la951086q

Frieder, M., and Jean-Christophe, B. (2005). Electrowetting: from basics to applications. J. Phys. 17, R705–R774. doi:10.1088/0953-8984/17/28/r01

Gu, Y., and Li, D. (2000). The zeta-potential of glass surface in contact with aqueous solutions. J. Colloid Interface Sci. 226, 328–339. doi:10.1006/jcis.2000.6827

Hoek, E. M. V., and Tarabara, V. V. (2013). Encyclopedia of membrane science and technology. Hoboken, NJ: Wiley Online Library.

Homede, E., Abo Jabal, M., and Manor, O. (2020). Connecting surface-forces-based energy barriers to nonhomogeneous colloidal structures to appear from volatile binary mixtures of same size nanoparticle species. Adv. Func. Mater. 30, 2005486. doi:10.1002/adfm.202005486

Homede, E., Zigelman, A., Abezgauz, L., and Manor, O. (2018). Signatures of van der Waals and Electrostatic Forces in the Deposition of Nanoparticle Assemblies. Phys. Chem. Lett. 9, 5226–5232. doi:10.1021/acs.jpclett.8b02052

Hong, F. T., and Okajima, T. L. (1986). Electrical double layers in pigment-containing biomembranes. Boston, MA: Springer US, 129–147. doi:10.1007/978-1-4684-8145-7_10

Hunter, R. J. (1998). Review Recent developments in the electroacoustic characterisation of colloidal suspensions and emulsions, 30.

Hunter, R. J. (2001). Foundations of colloid science/Robert J. Hunter. 2nd Edn. Oxford University Press, 375–378.

Manor, O., Yeo, L. Y., and Friend, J. R. (2012). The appearance of boundary layers and drift flows due to high-frequency surface waves. J. Fluid Mech. 707, 482–495. doi:10.1017/jfm.2012.293

Morse, P., and Ingard, K. (1986). “Theoretical acoustics,” in International series in pure and applied physics. Princeton University Press.

Rayleigh, L. (1884). On the circulation of air observed in kundt’s tubes, and on some allied acoustical problem. Phil. Trans. Roy. Soc. 175, 1–21.

Rezk, A. R., Ahmed, H., Brain, T. L., Castro, J. O., Tan, M. K., Langley, J., et al. (2020). Free radical generation from high-frequency electromechanical dissociation of pure water. Phys. Chem. Lett. 11, 4655–4661. doi:10.1021/acs.jpclett.0c01227

Royer, D., Lyle, S., and Dieulesaint, E. (1999). “Elastic waves in solids II: generation, acousto-optic interaction, applications,” in Advanced texts in physics. Berlin Heidelberg: Springer.

Salzmann, E., and Dransfeld, K. (1967). Elastic surface waves in quartz at 316 MHz. Appl. Phys. Lett. 10, 3.

Vanneste, J., and Bühler, O. (2011). Streaming by leaky surface acoustic waves. Proc. R. Soc. A 467, 1779–1800. doi:10.1098/rspa.2010.0457

Yeager, E., Bugosh, J., Hovorka, F., and McCarthy, J. (1949). The application of ultrasonic waves to the study of electrolytic solutions II. The detection of the Debye effect. J. Chem. Phys. 17, 411–415. doi:10.1063/1.1747269

Keywords: surface acoustic wave, acoustic streaming, electroacoustics, electrokinetics, electrical double layer, electrolytes, relaxation time, bulk acoustic wave

Citation: Aremanda S, Li Y, Onuh G and Manor O (2025) Measurement of dynamic electrokinetic effects at the glass/electrolyte interface using a mega-Hertz-level mechanical wave. Front. Acoust. 3:1568083. doi: 10.3389/facou.2025.1568083

Received: 28 January 2025; Accepted: 10 April 2025;

Published: 05 June 2025.

Edited by:

James Friend, University of California, San Diego, United StatesReviewed by:

John Sharer Allen, University of Hawaii at Manoa, United StatesAthanasios Athanassiadis, Heidelberg University, Germany

Copyright © 2025 Aremanda, Li, Onuh and Manor. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ofer Manor, bWFub3JvQHRlY2huaW9uLmFjLmls

Sudeepthi Aremanda

Sudeepthi Aremanda Yifan Li

Yifan Li Gideon Onuh

Gideon Onuh Ofer Manor

Ofer Manor