- 1Department of Integrated Research and Discovery-Artificial Intelligence and Data Science (IRD-AIDS), Koneru Lakshmaiah Education Foundation, Vijayawada, India

- 2Department of Chemistry, Chennai Institute of Technology, Chennai, India

- 3Department of Mechanical Engineering, College of Engineering, Imam Mohammad Ibn Saud Islamic University (IMSIU), Riyadh, Saudi Arabia

- 4Department of Computing Technologies, SRM Institute of Science and Technology, Chennai, India

- 5Department of Mechanical Engineering, Army Institute of Technology, Pune, India

- 6Department of Physics, Andhra Loyola College, Vijayawada, India

- 7Department of Physics (S&H), Swarnandhra College of Engineering & Technology (A), Narasapur, India

- 8Department of Artificial Intelligence and Machine Learning, Panimalar Engineering College, Chennai, India

- 9Department of Computer Science and Engineering, Saveetha School of Engineering, SIMATS, Chennai, India

- 10Mechanical Power Engineering, Faculty of Engineering, Kafrelsheikh University, Kafr El-Shaikh, Egypt

- 11Research Centre for Solar Energy, Department of Integrated Research and Discovery-Physics, Koneru Lakshmaiah Education Foundation, Vijayawada, India

Solar desalination is an economical and eco-friendly approach to producing potable water, particularly in remote areas. Nevertheless, the limited efficiency of traditional solar panels restricts their ability to fulfill the growing demand for clean water. This study focuses on improving the performance of single-basin solar stills (SBS) by incorporating paraffin wax as a phase change material (PCM) with copper nanoparticles (Cu NPs) and agro-based materials in a stepped design. A scientometric analysis framework was applied to map the research landscape, followed by an experimental evaluation in which SBS units were fabricated and tested under controlled solar exposure with varying combinations of PCM, Cu NPs, and concentrators. The research is tailored to accommodate diverse climatic and operational conditions. Results reveal that the combination of PCM and Cu NPs significantly enhances freshwater output compared to traditional setups. The modified SBS demonstrated a productivity improvement of 67.18% for single-effect and 125% for double-effect configurations. The use of PCM alone resulted in a 21.5% boost in productivity, while the SBS design excluding CuO-based nanofluids achieved approximately 32% higher freshwater generation by utilizing solar energy. Moreover, combining a concentrator with PCM led to an additional 26% increase in efficiency. These results highlight the potential of integrating PCM and nanoparticles as an effective strategy to optimize SBS performance for sustainable water desalination.

1 Introduction

1.1 Importance of water and solar stills

Water is one of the most essential resources for sustaining life, supporting agriculture, enabling industrial processes, and ensuring overall human well-being. With only about 2.5% of the Earth’s water being fresh, and much of it locked in glaciers or inaccessible aquifers, the availability of potable water is severely limited. Rapid population growth, urbanization, industrial expansion, and climate change are intensifying global water scarcity, making access to safe drinking water a critical challenge particularly in arid, remote, and coastal regions. According to the United Nations, by 2050 nearly 5 billion people could experience water stress, highlighting the urgent need for sustainable freshwater generation technologies.

Solar desalination offers a promising, eco-friendly, and cost-effective solution to address this challenge, particularly in areas with abundant solar irradiation but limited freshwater resources. Among various solar desalination techniques, the solar still stands out as a simple, low-maintenance device that uses solar energy to evaporate saline or brackish water and condense the vapor into fresh water. Despite its advantages, conventional solar stills are often constrained by low productivity due to limited heat storage capacity, heat loss, and inefficient solar energy utilization. These limitations have motivated researchers to explore advanced materials, innovative designs, and integrated thermal energy storage solutions to improve solar still performance.

1.2 Focus on single-basin solar stills (SBS)

A single-basin solar still operates on passive solar distillation, where a shallow, black-coated basin absorbs solar irradiance to heat saline or contaminated water. Evaporation occurs, leaving impurities behind, while vapor condenses on the inclined transparent cover’s cooler surface, typically glass. Gravity directs the condensate into collection channels. This design provides an energy-autonomous, low-maintenance, and cost-effective purification system, particularly advantageous for decentralized freshwater production in rural or resource-constrained environments. Contemporary solar stills incorporate diverse configurations, including single-effect, double-effect, and tubular systems, frequently augmented with evacuated tubes, extended fins, selective absorber coatings, and thermal insulation to enhance operational efficiency. However, a significant research gap persists concerning the mechanistic justification for integrating nanoparticle–phase change material (Nano-PCM) composites rather than conventional PCMs. The present work addresses this limitation by investigating Nano-PCM interactions and their impact on stepped single-basin solar still (SBS) distillation performance. Solar desalination, which relies on solar-induced evaporation and condensation of saline water, is increasingly recognized as a sustainable strategy for freshwater generation in remote regions. With escalating global freshwater scarcity, such innovations are imperative to ensure accessible and safe potable water supplies.

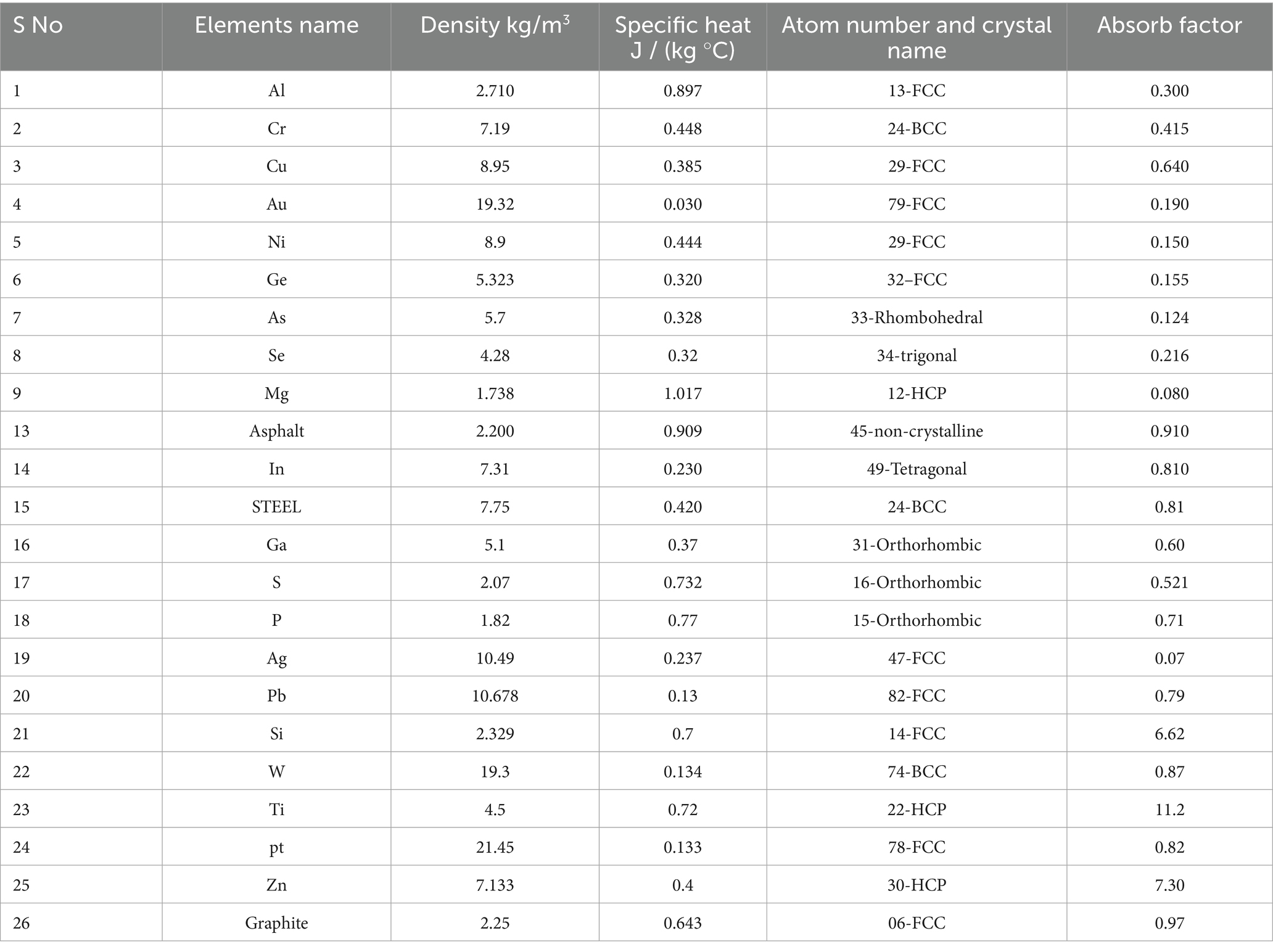

The development of natural and sustainable desalination systems is essential to meet this challenge. Since the 1960s, the number of desalination plants has steadily increased, reaching 16,758 worldwide by 2023 (Jones et al., 2019). Freshwater is vital for all life on Earth, and its demand continues to rise. Shanmugan et al. (2013) designed a double-slope wick-type solar still and, through energy balance modeling, established that 0.05 m insulation beneath tilted-wick regions optimized distillation efficiency, achieving 41.25% freshwater conversion performance. Shanmugan and Krishnamoorthi (2013) demonstrated that incorporating a transparent honeycomb structure into a double-exposure solar still enhanced radiation absorption, resulting in a 30% higher daily distillate yield compared to conventional designs. Panchal et al. (2020) compared finned and conventional solar stills using Suryjot pond water, reporting average yields of 2.375 L (inclined fins), 2.322 L (vertical fins), and 1.873 L (CSS), with negligible differences between fin orientations. This study provides a detailed analysis of how solar desalination, enhanced with PCMs and nanoparticles, can significantly improve natural drinking water production, as illustrated in Figure 1a.

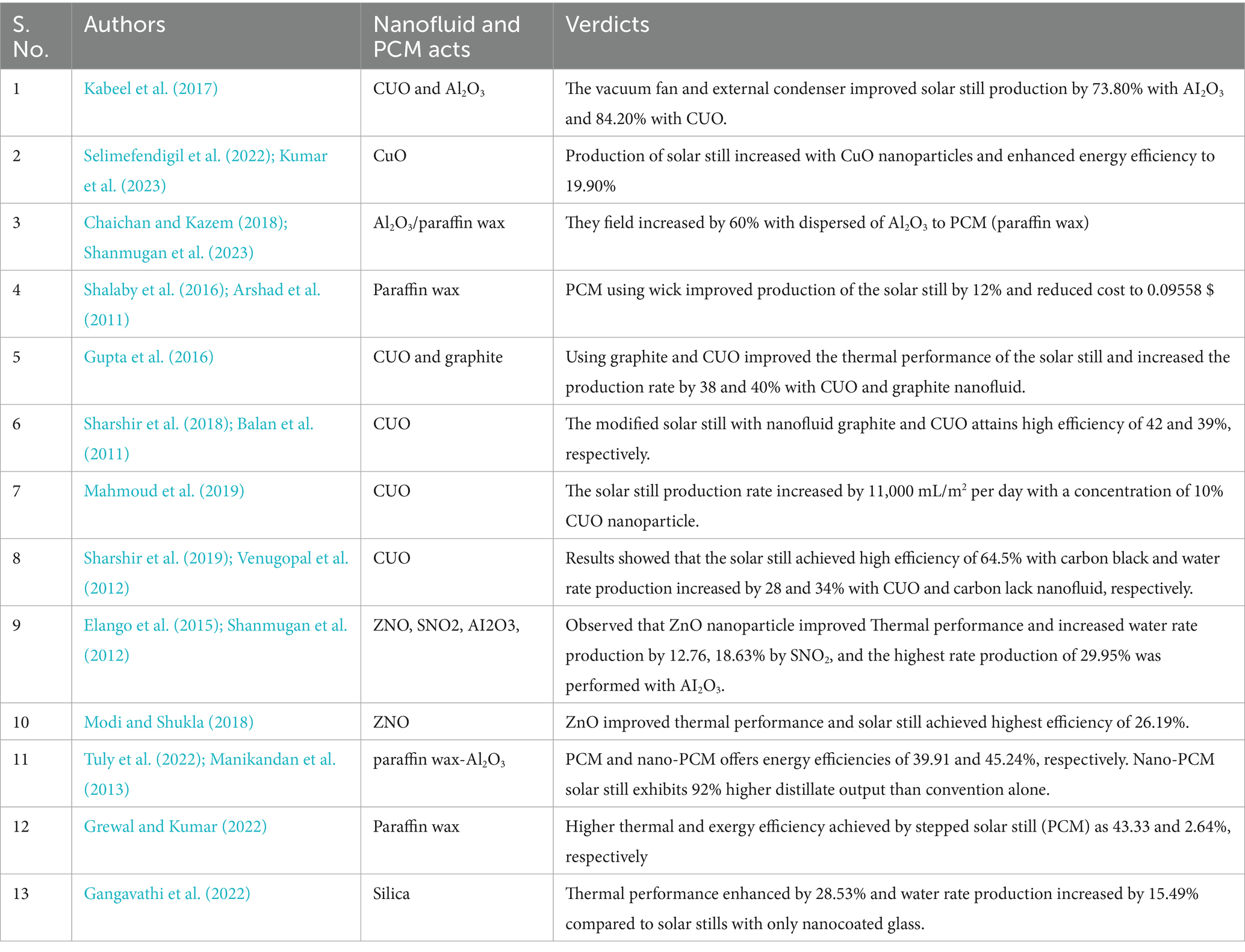

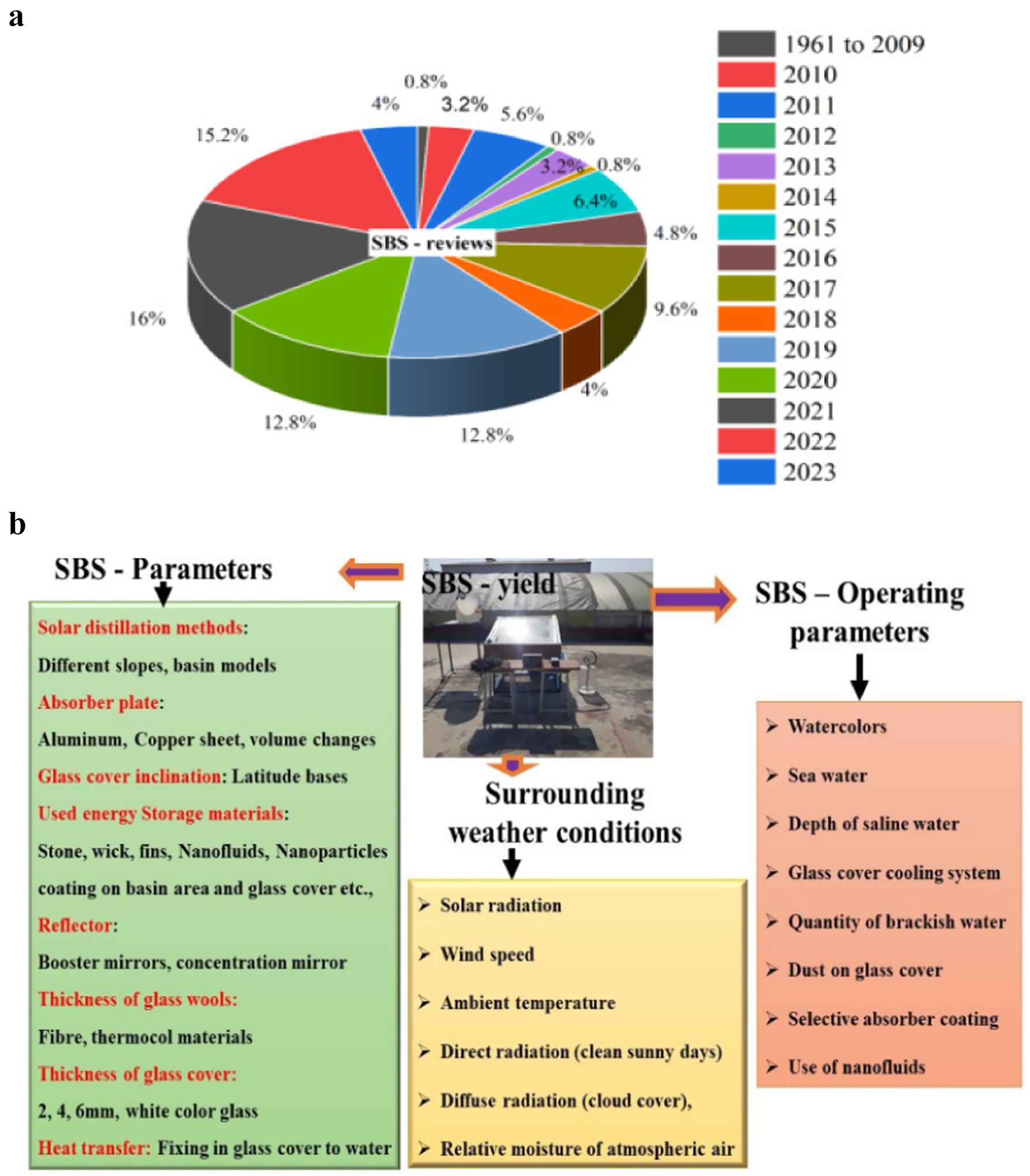

Figure 1. (a) Human life is in danger due to a worldwide challenge posed by solar still manufacture of freshwater scarce. (b) From 2015 to February 2023, an analysis of solar still nanoparticles was conducted. (c) Classification of nanoparticles based on size analyzers and structural dimensions. (d) The classification of solar still (Vaithilingam and Esakkimuthu, 2015). (e) From 2005 until February 2023, solar still used PCM analysis. (f) Fundamental analysis of PCM melting point and cost of storage materials. (g) SBS improvement in various materials.

1.3 Solar desalination involving nanotechnology

Over the last two decades, innovations in solar still design have enabled advanced material integration, particularly the utilization of nanoparticles for scientific, technological, and industrial applications. Carbon-based nanomaterials are increasingly investigated due to their exceptional attributes, including high specific surface area, low toxicity, superior thermal and electrical conductivity, mechanical robustness, and tunable structures (Deng et al., 2016). Such properties make them highly suitable for applications in solar energy, electronics, information technology, and biomedical systems. Nanoscale engineering (Khan et al., 2019) has facilitated optimization of material performance through controlled structural design. Carbon nanostructures, such as fullerenes, carbon nanofibers, diamonds, graphite, and carbon nanotubes, offer significant potential across multiple domains (Abdullah et al., 2025; Omara et al., 2024; Gaur et al., 2021). As illustrated in Figure 1b and Table 1, these nanomaterials have been systematically evaluated in solar desalination systems, with studies from 2015 to February 2023 demonstrating their role in enhancing energy efficiency and overall system performance.

1.3.1 Types of nanoparticles—nanoparticle size analyzers and categories

Usually between 1 and 100 nanometers in size, nanoparticles have special visual, physicochemical, and catalytic qualities that set them apart from their bulk counterparts. Because of their incredibly high surface area-to-volume ratio and quantum confinement effects, nanoparticles are the subject of fundamental physics (Figure 1c). These events change the reactivity, energy absorption properties, and electronic band structures of nanoparticles, which makes them ideal for use in the medicinal, environmental, and energy sectors. For example, semiconductor nanoparticles like ZnO or TiO2 exhibit increased photocatalytic efficiency because of decreased electron–hole recombination, but metallic nanoparticles exhibit plasmonic resonance. Research on nanoparticles from an engineering perspective is concentrated on their synthesis, characterization, functionalization, and integration into applications. To regulate morphology, size distribution, and crystallinity, synthesis techniques such sol–gel, hydrothermal, green biological pathways, and chemical vapor deposition are used. Exact assessment of structural and size-dependent characteristics is made possible by characterization methods such as UV–Vis spectroscopy, X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and dynamic light scattering (DLS). Engineering research also goes into creating systems based on nanoparticles for real-world use. Nanoparticles are used in energy technologies to improve absorption and energy conversion efficiency in solar stills, supercapacitors, and hydrogen storage devices. Because of their customizable surface chemistry and biocompatibility, nanoparticles are used as biosensors, imaging agents, and targeted drug carriers in the biomedical sciences. Nanoparticles are used in environmental engineering for photocatalytic pollution degradation, heavy-metal adsorption, and improved water treatment. The focus of interdisciplinary research is on sustainable production, toxicity evaluation, and nanoparticle stability. To reduce ecological impact, green engineering techniques investigate plant extracts, agricultural leftovers, and bio-templates. Additionally, machine learning and computational simulations are being used more and more to forecast the behavior of nanoparticles and enhance performance for large-scale applications for the engineering research propels the development of useful, scalable, and sustainable technologies, while the science behind nanoparticles resides in their size-dependent characteristics.

Nanoparticles can be classified into various types, such as those made of carbon, metals, ceramics, polymers, lipids, and semiconductors, based on their shape, physical properties, and chemical composition. They are broadly categorized into two main groups: organic assemblies and inorganic assemblies. Organic assemblies include mixtures like liposomes, dendrimers, micelles, and functional polymeric particles. Inorganic assemblies consist of materials such as fullerenes, silica, metallic nanoparticles, and key composite particles. Notable nanoparticles, such as fullerenes, carbon nanotubes, graphene, and carbon dots, are further grouped based on their unique physical and chemical characteristics. These materials exhibit exceptional versatility, with properties such as a distinct metal-optical structure, high strength, superior electrical conductivity, and strong electron affinity. Polymers play a critical role in applications like surface coatings, sensor technologies, and photocatalysts. Additionally, semiconductors, made from both metals and non-metals, are used for bandgap tuning, photocatalytic applications, and dye photodegradation. Ceramic-based inorganic materials, being non-metallic, also contribute significantly to these technologies. Lee et al. (2025) numerically optimized fin–tube heat exchangers with ellipsoidal protrusions, revealing angle–scale-dependent vorticity effects, achieving a 48.85% Colburn j-factor enhancement and 25.41% higher thermal performance, supporting advanced energy-efficient designs. Sai et al. (2025) reported that sugarcane-mediated ZnO nanofluids significantly augment double-slope solar stills, intensifying photothermal conversion, conductivity, and vaporization, achieving 4.5 kg/m2 yield and 37.2% heat-transfer enhancement at 30% concentration. TiO2-assisted ASTSO improves solar basin distillers, as shown by Kotla et al. (2025), which produced 8.437 kg/m2/day in the summer and 8.087 kg/m2/day in the winter, with 58.73 and 47.52% efficiency at 20% concentration.

ZPBN-integrated DSBD, as defined by Kumar et al. (2024), guarantees steady internal heating, resulting in a 126% increase in yield, a 44% decrease in thermal energy consumption, and the delivery of environmental–economic metrics of $4.640 kWh/$ and $83.210, respectively. Zahid et al. (2023) demonstrated that Al2O3/RT70HC nanoparticle-enhanced PCMs significantly improved heat sink thermal regulation, with porous-foam designs outperforming unfinned and square-finned counterparts under transient loads, achieving lower operational temperatures and superior conductivity. In solar distillation, diagonally oriented aluminum cans with an M-shaped plate produced 6.044 kg/m2 daily yield, 8.090 kg/m2/24 h output, and 42.74% thermal efficiency, according to Alasiri and Shanmugan (2025).

1.4 Classification of solar stills

Fossil fuel utilization has become economically unsustainable compared to renewable alternatives, particularly when evaluating the contribution of SBS in mitigating anthropogenic climate change. Escalating freshwater scarcity, driven by rapid population expansion, has intensified the urgency for renewable-based desalination technologies. Solar energy, abundant and sustainable, plays a pivotal role in decentralized water production, as emphasized by Amy et al. (2017). Among global concerns, the depletion of potable water resources remains paramount, necessitating innovative freshwater generation strategies. Kabeel et al. (2016) demonstrated that single-effect solar stills provide an effective approach to alleviate water shortages (Figure 1d), offering a low-cost, eco-friendly solution. Furthermore, Vaithilingam and Esakkimuthu (2015) reported a conventional CSS-based SBS configuration, achieving daily freshwater productivity of 1.485 L/m2 with an efficiency of 30.960%. Collectively, these studies underscore the technical viability of solar stills as sustainable, scalable, and resource-efficient systems for addressing the accelerating global water crisis.

1.5 Solar desalination using PCM

Phase Change Materials (PCMs) undergo a solid-to-liquid thermophysical transition when ambient temperatures surpass their fusion point. During this process, they exhibit latent heat storage, absorbing significant thermal energy without a substantial change in temperature. This isothermal energy absorption maintains thermal equilibrium. Upon solidification, the stored energy is discharged, facilitating temperature regulation. The application of PCMs spans diverse thermal management systems, including thermal energy storage, heat recovery, and solar thermal applications, addressing the imperative for sustainable energy solutions amid escalating greenhouse gas emissions and energy scarcity (Wu et al., 2020). Solar distillation systems, incorporating PCM-based heat transfer methods (Figure 1e), offer a promising solution for producing freshwater. A thorough evaluation of vertical solar still modifications by Ahmed et al. (2025) revealed that wicks, coils, PV modules, and reflectors improve thermal performance, resulting in 9–107% productivity gains while reducing resistance and footprint and directing future compact designs. Almeshaal and Shanmugan (2024) demonstrated green-sourced PTP nanocomposites in SWS, with 30% loading optimizing thermal dynamics, delivering 8.70 L/m2/day distillate, including 1.95 L/m2 nocturnal yield, achieving 42.74% efficiency. Palaniappan et al. (2024) developed a stepped M-shaped solar distiller with PRSNME, yielding 8.106/6.357 mL·m−2·day−1 (summer/winter), achieving 54.68%/44.46% efficiency, 26% productivity enhancement, 34.8 t CO₂ mitigation, and reduced water cost (0.014 $/L). A simulative inquiry into three distinct solar still architectures, Abu-Arabia and Zurigat (2005), leveraging empirical data from Marmul, Oman, investigated the augmentative potential of double-glass cooling technology on regenerative thermal effects. The analysis encompassed the impact of basin water mass, collection efficiency, and dual-glazing configurations on systemic heat dissipation. The study further characterized the structural parameters and performance of PCMs, including paraffin waxes, hydrated salts, and metallics. The efficacy of medium-grade paraffin wax in electronic thermal management was specifically noted due to its congruent melting point, as shown in the energy and material cost analysis in Figure 1f.

1.6 SBS evaluation

Enhancement of SBS performance increasingly relies on advanced materials such as PCMs and engineered nanoparticles. Contemporary research demonstrates that integrating PCMs and nanofluids substantially augments thermal regulation, heat storage, and evaporation dynamics, thereby improving freshwater yield and overall efficiency. This review critically examines state-of-the-art techniques employing PCMs and nanofluids, elucidating their synergistic role in elevating SBS functionality. Experimental investigations confirm notable productivity improvements, with empirical outcomes (Figure 1g) validating the effectiveness of these modifications, as highlighted by Vaithilingam and Esakkimuthu (2015). Collectively, these findings establish that material-driven innovations provide transformative potential for scaling SBS systems toward sustainable and efficient desalination. This study aims to map and explore the research landscape of energy storage in solar desalination systems using PCMs enhanced with bionanoparticles. The research specifically seeks to evaluate the integration of bio-sourced nanoparticles with PCMs, such as paraffin wax infused with copper nanoparticles and agro-based additives, to improve the thermal efficiency of SBS. Different SBS configurations, which combine PCMs, nanofluids, and concentrators, will be experimentally evaluated under controlled solar exposure to determine their effects on heat transfer, evaporation-condensation dynamics, and freshwater yield. Furthermore, the paper outlines future research directions for compact, high-performance, and sustainable solar desalination systems, including optimal material combinations and design characteristics.

2 Material and methodology

2.1 Experimental setup of stepped single-basin solar stills (SBS)

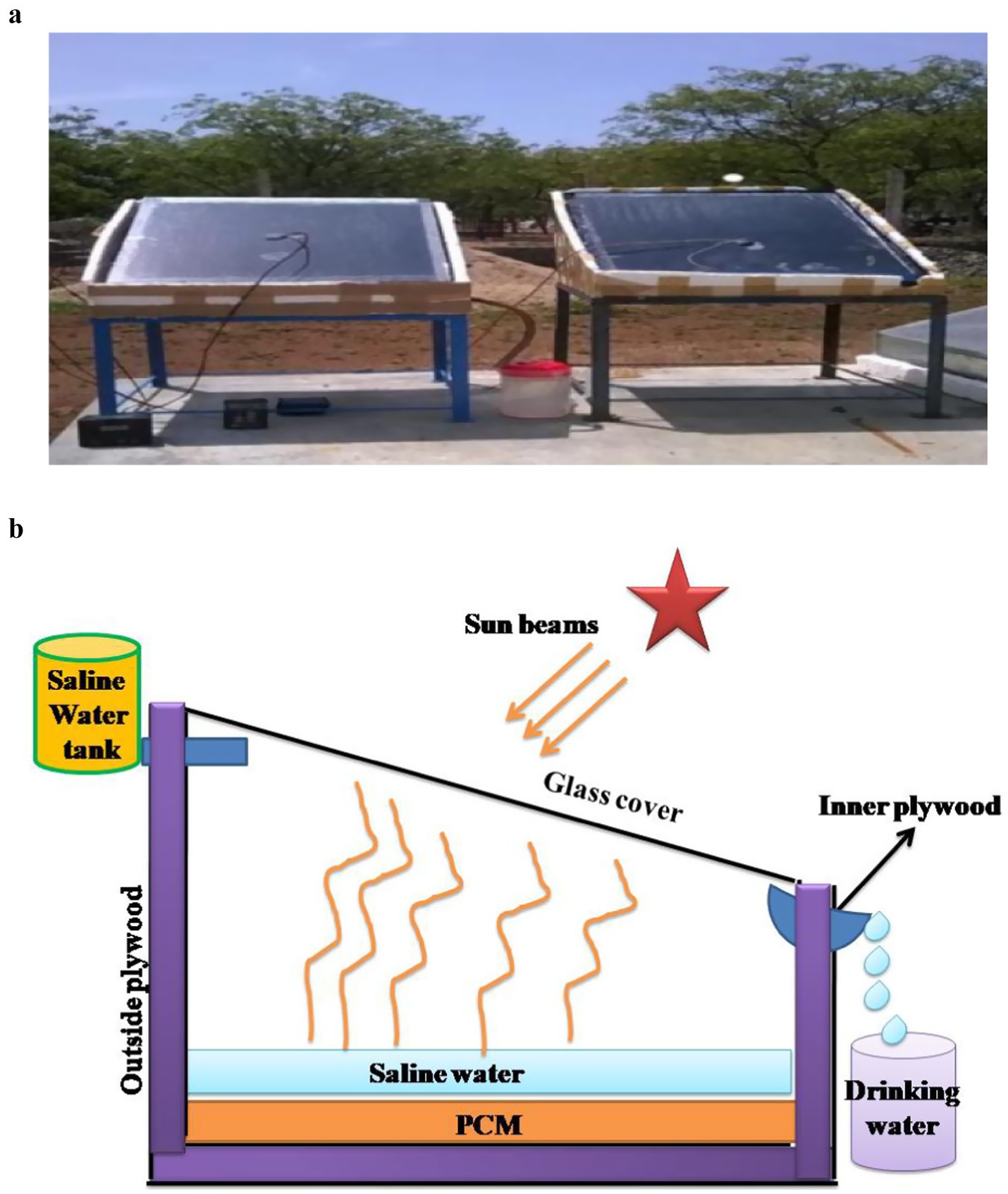

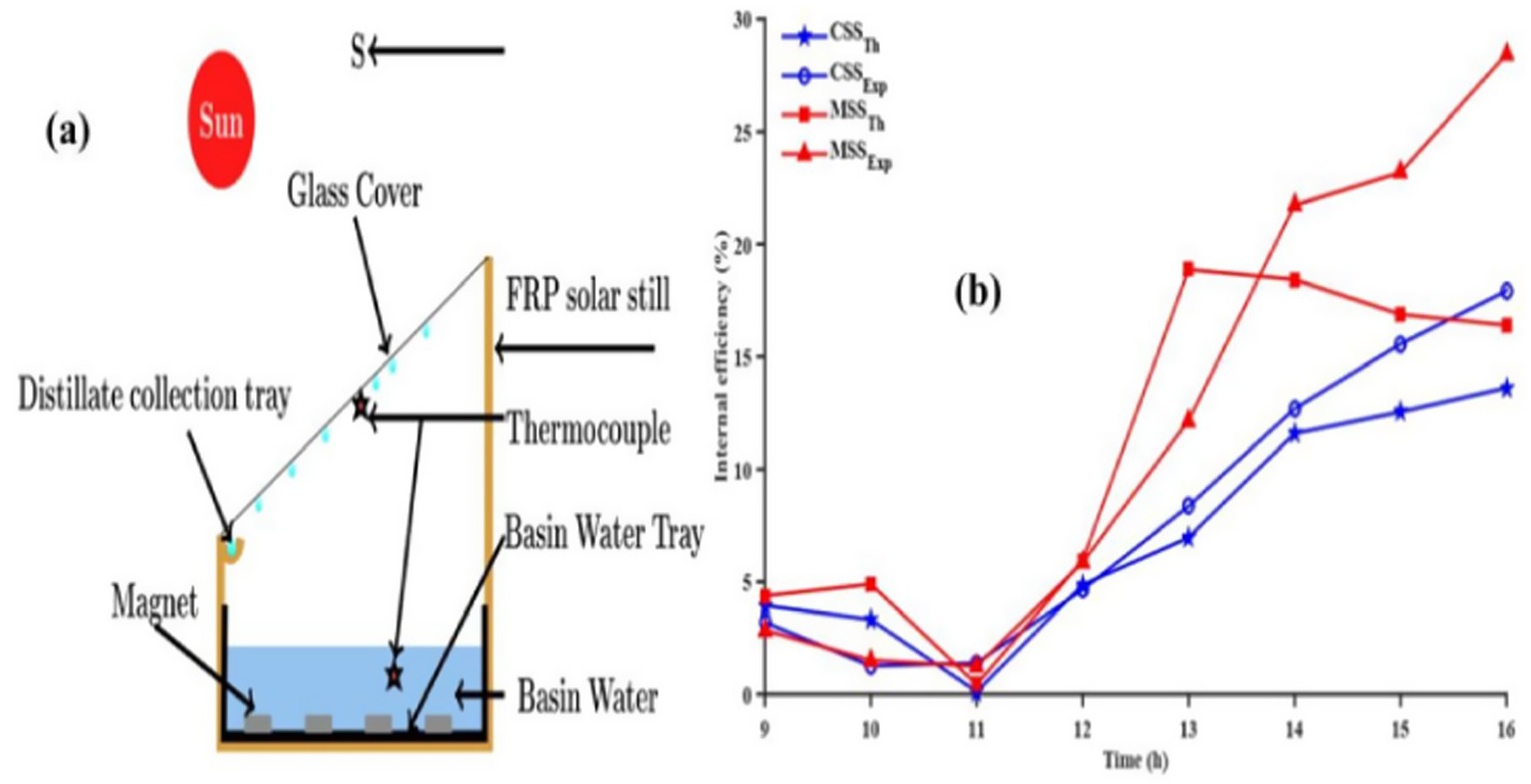

The experimental setup (Figure 2a) by Vaithilingam and Esakkimuthu (2015) and schematic diagram (Figure 2b) was designed to evaluate the performance of a SBS for freshwater generation. The still was fabricated with a basin area of 1.0 m2 and a water depth of 0.1 m, dimensions chosen to ensure adequate exposure to solar radiation while maintaining efficient evaporation (Mohandass Gandhi et al., 2022; Elsheikh et al., 2022). The basin surface was coated with matte black paint to maximize solar absorptivity and minimize reflection losses. To enhance condensation, a transparent glass cover of 4 mm thickness was installed at an inclination of 30°, allowing maximum incident solar radiation while enabling the condensed vapor to flow easily into the distillate collection channel (Alsaiari et al., 2022; Essa et al., 2022). The stepped design was implemented by dividing the basin into multiple horizontal levels, each facilitating thin-film water spreading, thereby increasing the evaporation surface area. Paraffin wax was embedded in aluminum containers placed beneath the basin surface, serving as a PCM for thermal energy storage. This enabled heat retention during peak solar hours and the release of stored energy during off-sunshine periods, extending freshwater production into late evening hours. For enhanced thermal conductivity, Cu NPs at a concentration of 0.1 wt% were dispersed within the PCM. Additionally, agro-based fibers were laid across the steps to promote uniform water distribution and improve capillary action, reducing dry patches within the basin. A PCM concentrator ratios and SBS were integrated into selected experiments to increase the incident radiation on the basin (Elsheikh et al., 2022). Environmental parameters, including solar intensity, basin water temperature, PCM temperature, glass cover temperature, and ambient conditions, were continuously monitored using calibrated K-type thermocouples and a pyranometer. Distillate output was measured at hourly intervals using a graduated cylinder. The setup was tested under controlled outdoor conditions, ensuring consistent comparisons across different configurations.

Figure 2. (a) Solar still experimental setup (Vaithilingam and Esakkimuthu, 2015). (b) Solar still schematic diagram.

2.2 Using SBS, PCM and nanofluid in diverse materials

A promising development in solar desalination technology is the integration of PCMs and nanofluids with SBS. The use of PCMs provides superior heat storage capacity, enabling the system to sustain evaporation even under low solar intensity by retaining thermal energy for extended periods. Simultaneously, nanofluids significantly enhance thermal conductivity, thereby accelerating the evaporation–condensation cycle and improving overall heat transfer rates. Compared to conventional systems, SBS performance can be markedly improved to achieve higher freshwater yields through the utilization of diverse material combinations. Moreover, this approach is inherently scalable, eco-efficient, and sustainable, offering a viable pathway for next-generation desalination technologies to address global water scarcity while reducing energy consumption and environmental impacts.

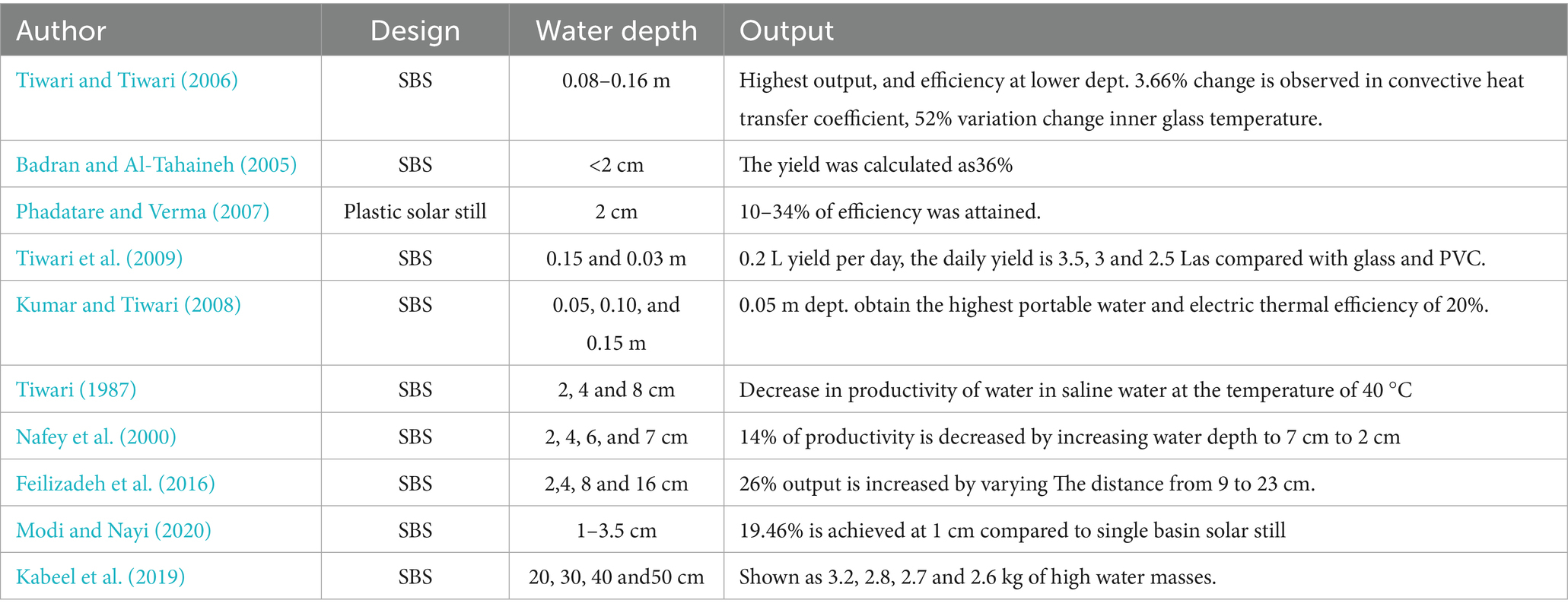

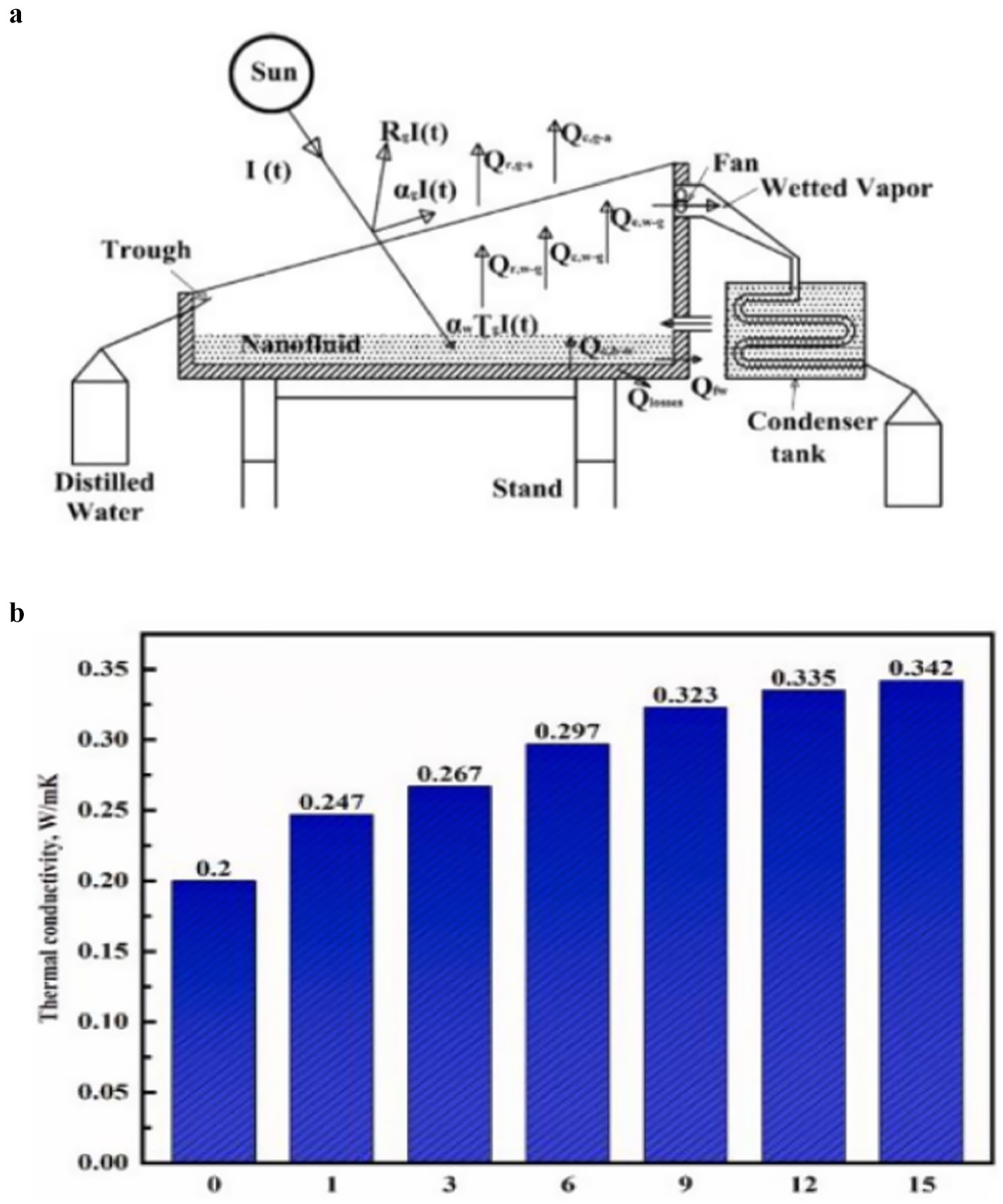

Kabeel et al. (2017) reported SBS yield performance (Figure 3a) using nanofluids such as Al₂O₃ (73.80%) and CuO (84.20%). Sadasivuni et al. (2022) and Elango et al. (2015) studied SBS enhanced with nanofluids including SnO₂, Fe₂O₃, ZnO, and Al₂O₃, with Al₂O₃ achieving the highest production efficiency at 29.95%. Asha et al. (2022), Shanmugan (2013), Panchal et al. (2021), Gandhi et al. (2021), and Abdullah et al. (2021) also investigated similar modifications. Dsilva Winfred Rufussa et al. (2018) and Panchal et al. (2021) demonstrated that nano-PCM composites (e.g., paraffin with TiO₂) improved SBS solar thermal efficiency to ~88.64%, Essa et al. (2021) with comparative effectiveness ratios of 100, 100, 88.47, and 76.93%. Chaichan and Kazem (2018) achieved 60% productivity using Al₂O₃ nanofluid with paraffin wax, resulting in a total daily distillate yield of 12,190 mL/m2. Kumar et al. (2021), Devi and Shanmugan (2021), Panchal et al. (2021), and Gupta et al. (2016) utilized CuO nanofluids in SBS, reporting a harvest rate of 3.51 L/m2/day at water depths of 50 and 100 mm, further confirmed by Panchal et al. (2021). Nazari et al. (2019) incorporated a thermoelectric channel with Cu₂O nanofluid, achieving power and energy efficiencies of 81, 80.6, and 112.5%, respectively. Lawrence et al. (2022) developed wick-type solar distillers with NiO nanoparticles, reporting efficiencies of 52.5, 5.83, and 36.36% under different conditions. Essa et al. (2020) and Kandeal et al. (2021) incorporated PCMs, nanofluids, and copper chips into distillers, with MDSSS performance improvements of 72, 110.3, 97, 138, 112.5, and 190% (Figure 3b). Shanmugan et al. (2020) and Essa et al. (2020) further validated these findings.

Figure 3. (a) SBS schematic diagram (Kabeel et al., 2017). (b) PCM material with increase in percentage (Sadasivuni et al., 2022).

At a nanoparticle mass fraction of 0.3%, the incorporation of CuO and Al₂O₃ nano-enhanced phase change materials (NPCMs) within solar stills augmented thermal efficiency by 55.8 and 49.5%, respectively, while concurrently attenuating peak basin temperatures by 2.1 °C and 1.8 °C. Shanmugan et al. (2018) investigated the synergistic integration of PCMs with nanostructured additives in SBS, wherein copper plates were surface-treated with black paint and Al₂O₃ nanoparticles, with C₁₈H₃₆O₂ employed as the latent heat storage medium. Their study reported performance enhancements of 59.14% under winter operating conditions and 27.13% in summer when coupled with feed-water cooling. Similarly, Manoj Kumar et al. (2022) analyzed three SS configurations: a baseline system utilizing crude wax PCM (PCM-SS), and two nanoparticle-dispersed configurations (NDPCM-SS) containing ZnO-reinforced wax (Sangeetha et al., 2022). The findings indicated freshwater yield increments of 50.24% for PCM-SS and 65.17% for NDPCM-SS. In parallel, Alwan et al. (2021) introduced an absorber design with finned aluminum bars that markedly elevated distillate flux, while Saleh et al. (2024) demonstrated further improvements through geometric optimization. Tuly et al. (2022) reported high distillate production rates, 140 mL/m2/h using aluminum absorber plates and 100 mL/m2/h with glass covers. Comparative trials by Sangeetha et al. (2024) revealed that case 3, with an efficiency of 42.85%, surpassed cases 1 and 2, exhibiting productivity rates of 46.2, 25.9, and 38.1%, respectively, with an energy efficiency improvement of 111% relative to the initial cases. A comprehensive synthesis of SBS configurations incorporating PCMs with diverse thermal storage and nanoparticle additives is compiled in Table 2 (Kabeel et al., 2017; Selimefendigil et al., 2022; Kumar et al., 2023; Chaichan and Kazem, 2018; Shanmugan et al., 2023; Shalaby et al., 2016; Arshad et al., 2011; Gupta et al., 2016; Sharshir et al., 2018; Balan et al., 2011; Mahmoud et al., 2019; Sharshir et al., 2019; Venugopal et al., 2012; Elango et al., 2015; Shanmugan et al., 2012; Modi and Shukla, 2018; Tuly et al., 2022; Manikandan et al., 2013; Grewal and Kumar, 2022; Gangavathi et al., 2022).

2.3 Energy-absorbing materials of the SBS component landscape

Recent innovations in solar desalination leverage advanced material strategies across multiple domains: photothermal absorbers such as carbon blacks, graphite/graphene, CNTs, plasmonic metals (Au, Al), MXenes, black-TiO2, and selective solar coatings enhance light capture and conversion; thermal management approaches including PCMs, finned absorbers, multilayer insulation, heat pipes, and nano-enhanced PCMs (metal oxides, carbon-based) stabilize temperature fluctuations and extend nocturnal productivity; interfacial evaporators built from foams, aerogels, wood-derived and cellulose-based structures, as well as biopolymeric hydrogels like chitosan/alginate with Janus designs, enable efficient evaporation with directional water transport; fluids and additives such as nanofluids (Al2O3, CuO, SiO2, ZnO, graphene), surfactants, and anti-foaming agents improve heat transfer and surface stability; antifouling and antiscaling measures, including superhydrophilic/superhydrophobic coatings, TiO2 photocatalytic layers, zwitterionic polymers, and electrostatic salt-rejecting structures, mitigate performance degradation; while condensation efficiency is enhanced by patterned wettability, drop wise-promoting surfaces, thermally conductive foils, and cooled condensers. Finally, diverse wick and substrate choices, jute, cotton, glass fiber, carbon cloth/felt, and melamine sponge, facilitate capillary-driven water transport, enabling robust and scalable solar distillation architectures.

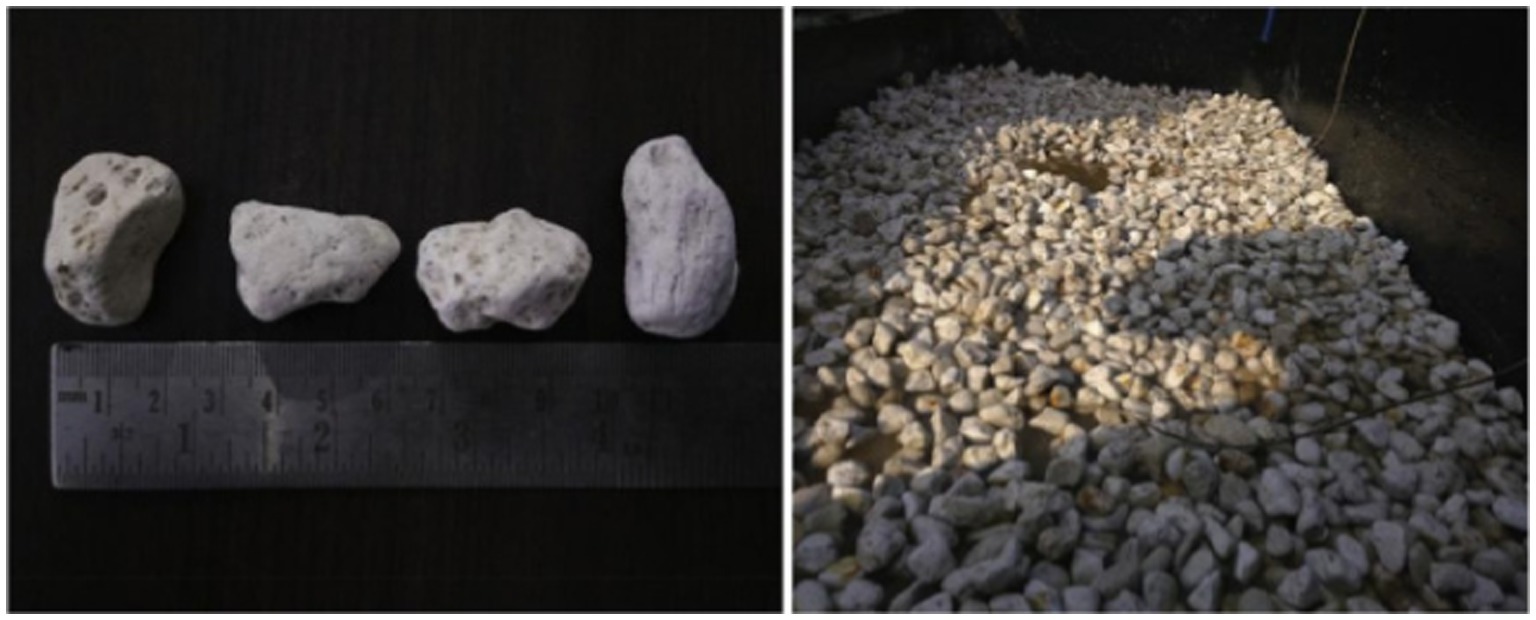

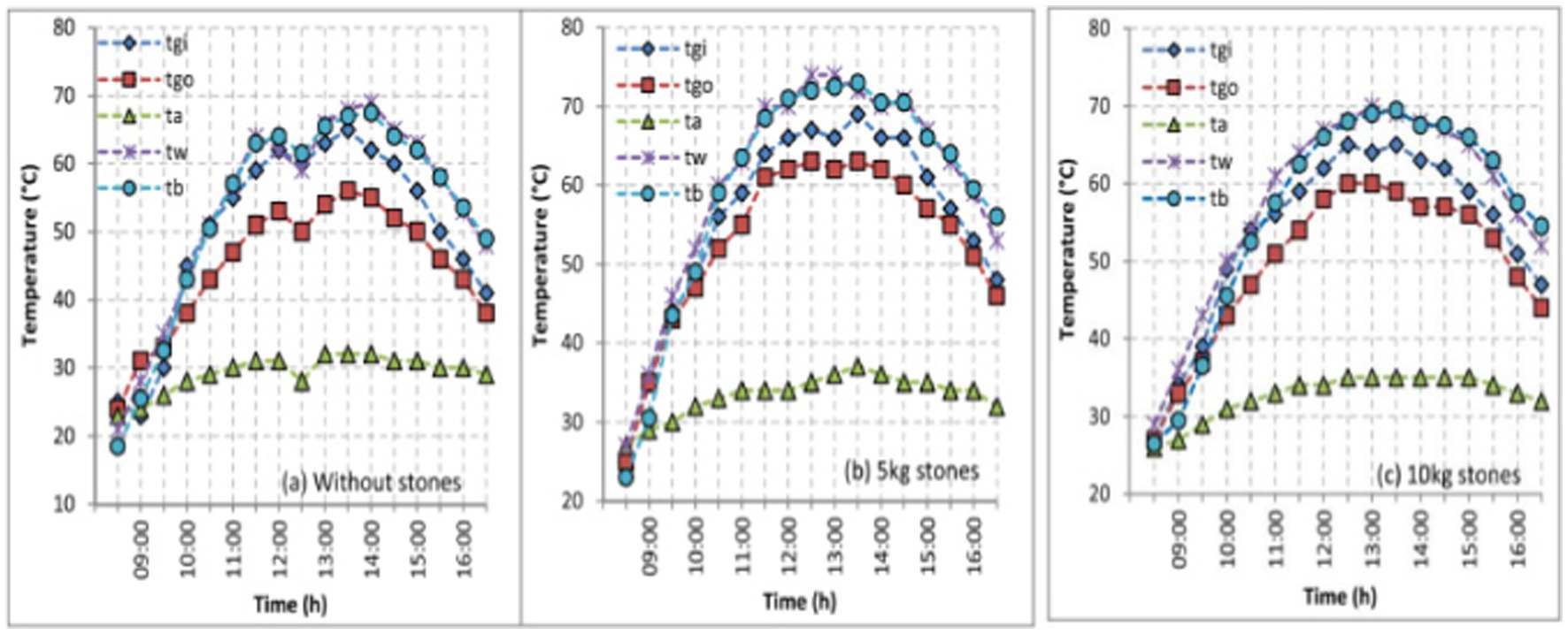

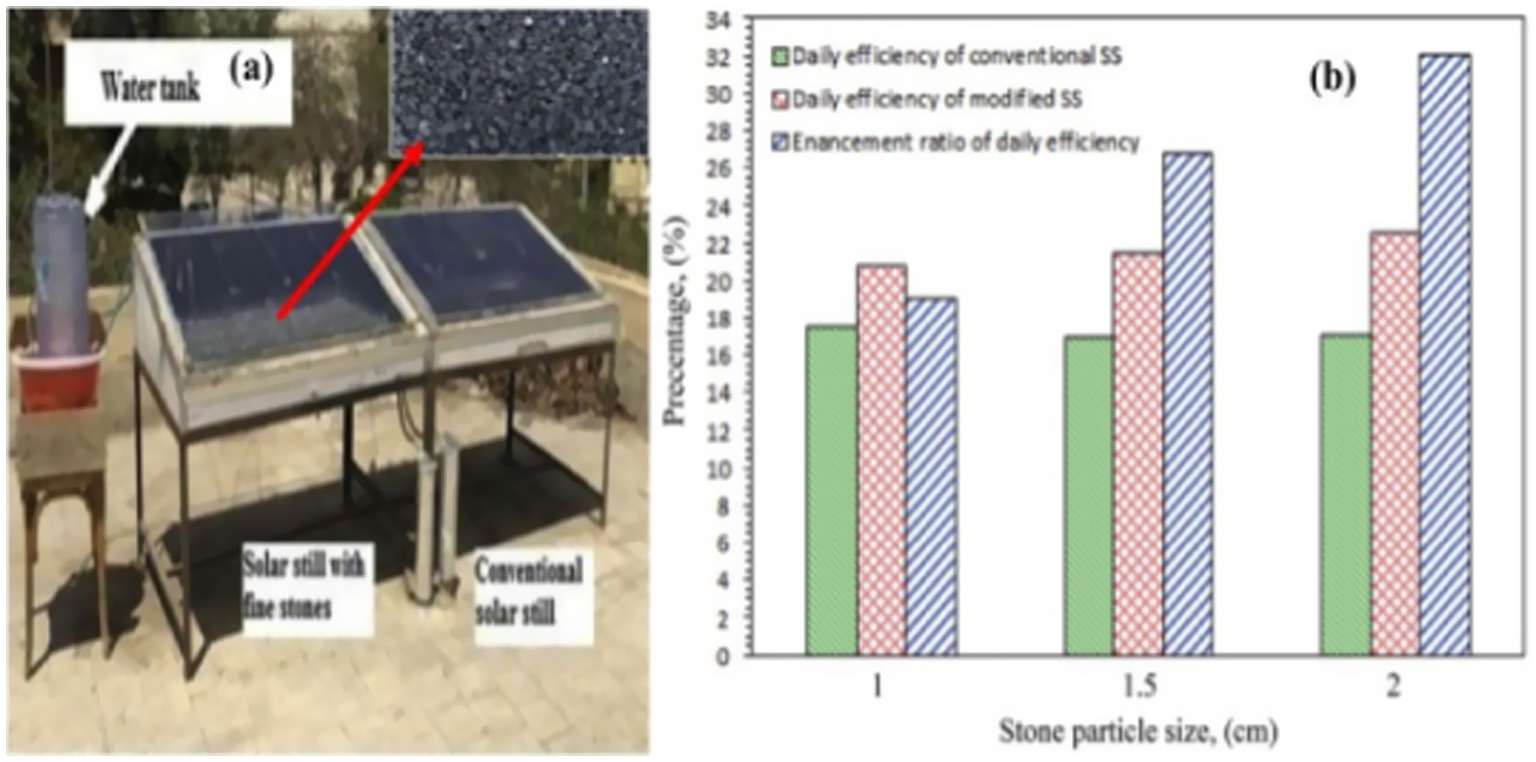

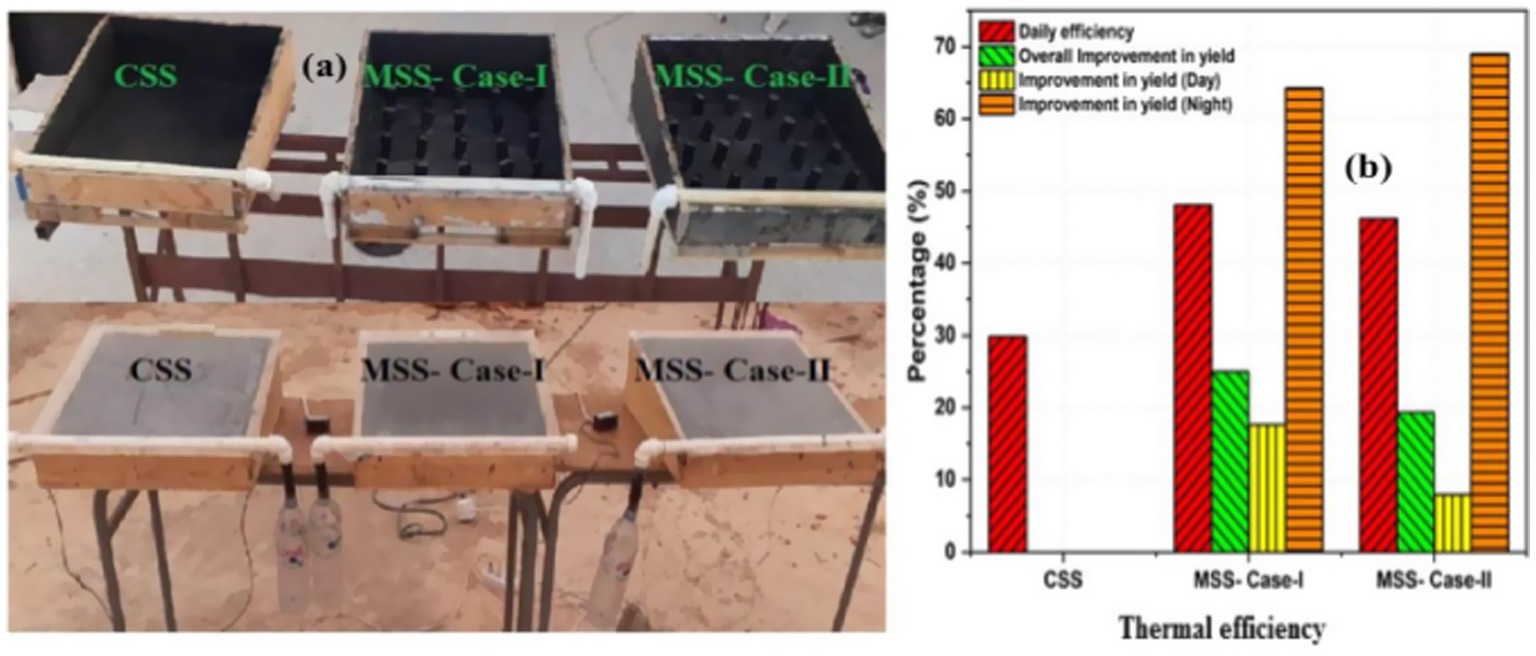

In SBS, cotton sacks filled with sand have been employed as a low-cost thermal energy storage (TES) medium, yielding mean efficiencies of 28.56% with a basin charge of 30 kg and 31.31% with 40 kg, as reported by Dumka et al. (2019). Deshmukh and Thombre (2017) investigated SBS configurations incorporating solvothermal intermediate oils beneath the basin liner, identifying an optimal storage capacity in the range of 8–15% kJ·m−2·K−1. The role of pumice stone as a porous TES medium was further examined at incremental loadings of 0, 5, and 10 kg, where efficiency declined from 35.1% (no pumice) to 29.3% (5 kg) and 28.8% (10 kg), respectively (Figures 4, 5). Temporal performance analysis indicated peak solar energy harvesting near solar noon. Bilal et al. (2019), corroborated by Dumka et al. (2019), demonstrated up to 49.17% enhancement in internal efficiency when the feedwater was magnetically conditioned using permanent magnets (Figure 6). Furthermore, Mohamed et al. (2019) evaluated black basalt stones of varying granulometries (1, 1.5, and 2 cm) as alternative TES media in SBS units (Figure 7).

Figure 4. SBS analysis of pumice stone dimensions and photo view (Bilal et al., 2019).

Figure 5. Illustrates how temperatures vary depending on the time of day and shows (a) no stones; (b) 5 kg stones; (c) 10 kg stones (Bilal et al., 2019).

Figure 6. (a) Schematic diagram of modified SBS, (b) variation of internal efficiency with respect to time (Dumka et al., 2019).

Figure 7. (a) SBS experimental setup using black basalt stones; (b) performance sizes (Mohamed et al., 2019).

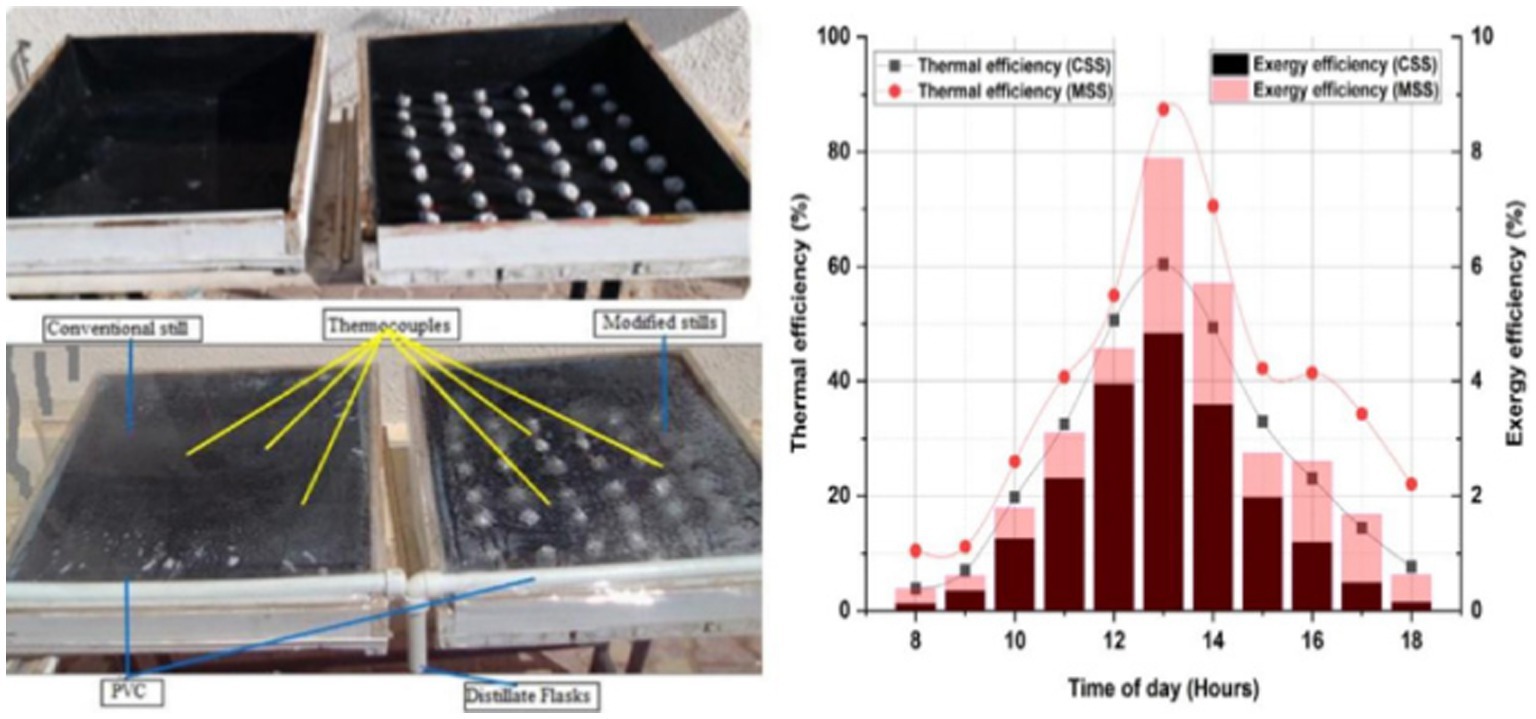

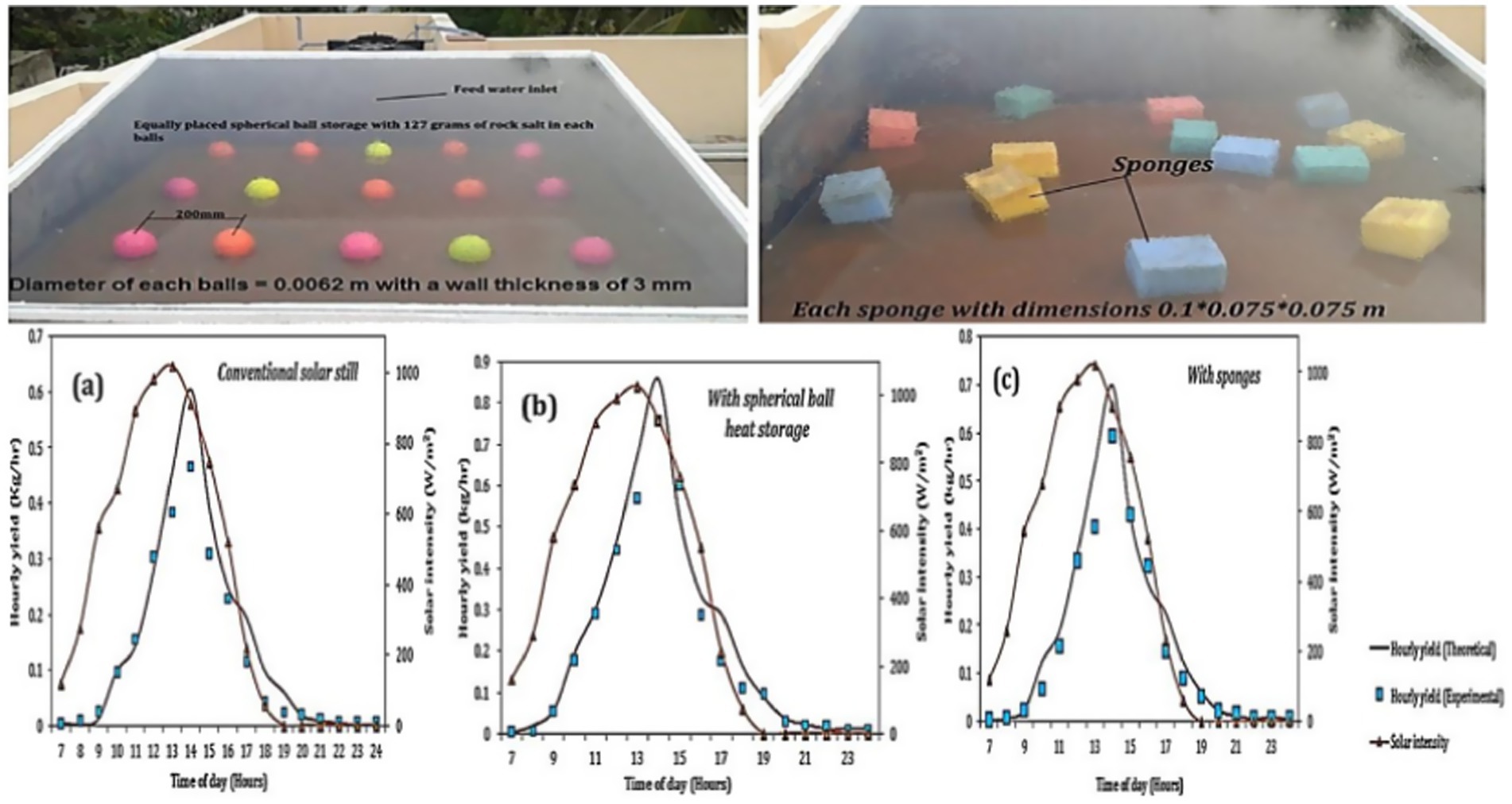

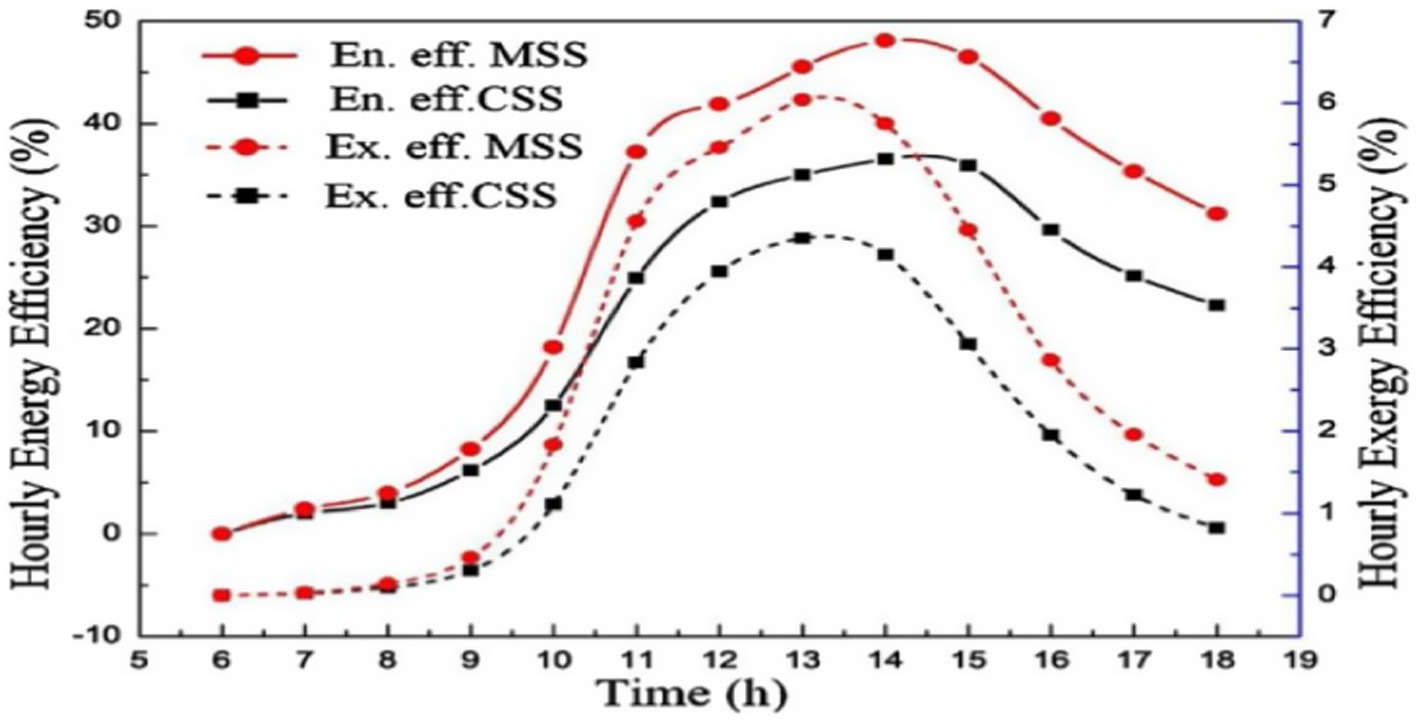

The utilization of diverse energy storage media (ESM) in SBS and CSS has been extensively explored to augment thermal retention and freshwater productivity. Basalt stones of increasing granulometry (1–2 cm) demonstrated progressive gains in solar-to-thermal conversion, with reported efficiencies of 19.8, 27.86, and 33.37%, corresponding to thermal efficiencies of 19.09, 26.84, and 32.07%, respectively. Quartzite was tested by Nagaraj et al. (2020), yielding a modest productivity of 0.05 L·m−2·day−1, whereas Subbarama Kousik et al. (2021) observed average efficiencies of 34.9% with marble spheres, producing 22.8% on day one and 21.3% over 2 days. Attia et al. (2021) employed cotton sacks packed with phosphate, achieving freshwater outputs of 4.52 kg (1 cm depth) and 3.99 kg plus 0.88 kg (2 cm depth), translating to output improvements of 28 and 22.5%, respectively (Figure 8). In parallel, Kabeel et al. (2019) demonstrated that red-brick–cement composites could elevate potable water production by up to 150% compared to CSS at optimal water mass loading (>20 kg), coupled with a 25% enhancement in evaporative heat transfer relative to Dunkle’s model. Graphite has also emerged as a highly conductive ESM, with Kabeel et al. (2018) reporting daily water productivity of 7.731 L·m−2 and thermal efficiencies approaching 60%. Dhivagar et al. (2022) emphasized the techno-economic and enviro-economic feasibility of SBS employing magnetic media, where block magnet solar stills (BMSS) achieved 3.15 kg·m−2 of output, outperforming disc magnet solar stills (DMSS, 2.82 kg·m−2) and CSS (2.15 kg·m−2), with a 20.7% gain in saline water temperature and 5.8% cumulative productivity advantage. Sakthivel and Arjunan (2018) reported that cotton cloth (6 mm) functioned effectively as a passive heat sink, elevating SBS efficiency to 23.8%. Mohammed et al. (2022) demonstrated the utility of indigenous clay as an ESM, achieving 5.39 L·m−2 of output with a 38.7% increase in yield and 47% daily efficiency. Similarly, Dhivagar et al. (2020) optimized gravel-based TES at 1 cm depth, reaching 32% efficiency, while Attia et al. (2020) incorporated aluminum spheres in photovoltaic-integrated SBS systems, achieving 5.09 kg of freshwater daily with efficiency gains from 31.6 to 40.1% (Figure 9). Harris Samuel et al. (2016) investigated salt-filled spherical capsules coupled with sponge matrices, producing 2.7 kg·m−2 in SBS compared to 2.2 kg·m−2 in CSS (Figure 10). Finally, Essa et al. (2020) introduced a coffee-derived colloidal medium, which enhanced productivity by 35.14% over CSS, with SBS exhibiting a 26.96% higher heat transfer coefficient and 35.34% superior energy efficiency (Figure 11).

Figure 8. (a) Analysis of energy storage material (phosphate bags) by SBS with CSS, MSS; (b) thermal efficiency, productivity (Attia et al., 2021).

Figure 9. View of SBS during measurement of energy and exergy efficiency (Attia et al., 2020).

Figure 10. Analysis of SBS energy storage material with salt filled spherical balls and sponges. (a–c) Hourly yield and solar intensity (Harris Samuel et al., 2016).

Figure 11. Energy, exergy efficiency as a conventional and SBS with various values (Essa et al., 2020).

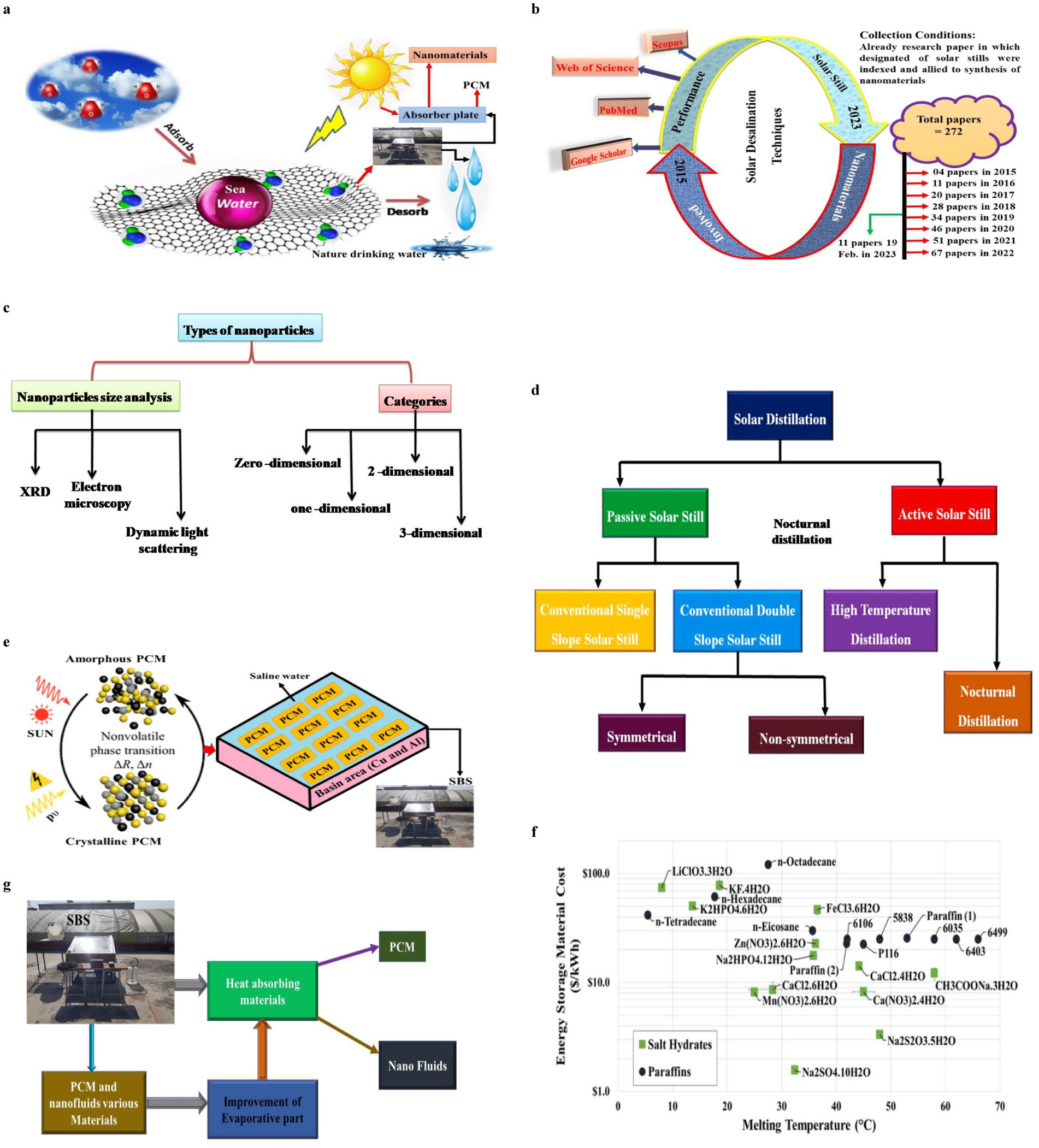

Table 3 (Tiwari and Tiwari, 2006; Badran and Al-Tahaineh, 2005; Phadatare and Verma, 2007; Tiwari et al., 2009; Kumar and Tiwari, 2008; Tiwari, 1987; Nafey et al., 2000; Feilizadeh et al., 2016; Modi and Nayi, 2020; Kabeel et al., 2019) displays the cooling and water depth analysis for SBS. Energy Storage of Bio-Nanoparticle-Enhanced PCM for Solar Desalination does not directly analyze the engineering scalability of SBS systems. However, the bibliometric insights reveal emerging research on modular thermal storage, hybrid configurations, and techno-economic optimization, which collectively indicate potential pathways for future large-scale and community-based implementations. In this study, the focus is on mapping the scientometric landscape rather than conducting direct experimental synthesis. However, the reviewed literature highlights the incorporation of bio-nanoparticles such as ZnO, TiO2, Al2O3, SiO2, and carbon-based nanostructures within organic and inorganic PCMs to improve thermal conductivity, latent heat storage, and stability. These nanoparticles are often surface-functionalized or dispersed using biopolymer stabilizers (e.g., chitosan, cellulose) to enhance compatibility and reduce agglomeration. The scientometric analysis reveals that ZnO- and Al2O3-based bio-nanoparticle composites are most frequently reported for solar desalination, owing to their superior thermal conductivity, photothermal conversion efficiency, and cost-effectiveness. Thus, our framework contextualizes how these nanoparticle-enhanced PCMs are advancing energy storage for solar desalination, even though experimental validation is beyond the scope of this work.

2.4 Mapping the research landscape: solar desalination

Research on solar desalination has evolved from simple conventional solar stills (CSS) toward advanced passive, active, and hybrid configurations aimed at overcoming low productivity and efficiency challenges. Passive designs include single- and double-slope basin stills, stepped and wick-type systems, while active and hybrid systems integrate flat plate collectors, evacuated tube collectors, PV/T units, or waste-heat recovery to enhance thermal energy input. Recent studies emphasize nanomaterials, photothermal coatings, and PCMs to improve heat absorption, thermal storage, and nocturnal productivity. Interfacial evaporators such as carbon-based foams, aerogels, and hydrogels, along with nano-enhanced PCMs (Al2O3, CuO, ZnO, graphene), are widely explored for boosting evaporation and maintaining stability under varying solar intensity. Parallel developments target condensation enhancement using hydrophobic/hydrophilic surface patterning, dropwise promoters, and subcooling techniques to increase distillate recovery. Advanced systems such as humidification–dehumidification (HDH), membrane distillation (MD), and solar-driven RO hybrids extend the technology landscape toward higher output and scalability. Performance is typically reported in terms of daily freshwater yield (L·m−2·day−1), thermal/exergy efficiency, water quality compliance, and levelized cost of water (LCW). However, the field still faces gaps in standardization, long-term outdoor stability, fouling and scaling resistance, and economic viability. Emerging trends highlight salt-rejecting evaporator structures, dropwise condensation surfaces, nano-enhanced PCMs, and AI-driven optimization as promising solutions for reliable 24-h productivity. Despite progress, further research is required in scaling control, brine management, and durable low-cost materials, especially for community-scale deployment in water-stressed regions.

Hydrogel/aerogel evaporators with broadband absorption and self-salt-excretion; advanced condensation strategies like patterned wettability and heat-pipe-assisted cooling; salt-rejecting architectures that enable continuous purging; nano-enhanced PCMs for nocturnal yield and thermal stability; and hybrid solar desalination systems that combine energy and water production are all examples of how state-of-the-art solar desalination is progressing. Bottlenecks continue to exist despite encouraging laboratory results because of a lack of standardised test procedures, a dearth of long-term field testing, difficulties managing brine and scaling, the stability of condensation in humid environments, and limitations related to cost and manufacturing. Uniform feed water and weather conditions, multi-day outdoor testing with cloudy periods, and open reporting of yields, temperatures, salt balances, uncertainties, and manufacturing details are all important components of comparative reporting. Future prospects include low-cost condenser upgrades, community-scale hybrid solar still systems with storage, PCM-used basin area retrofits for historic stills, long-lasting salt-rejecting IPE systems verified over >90 days.

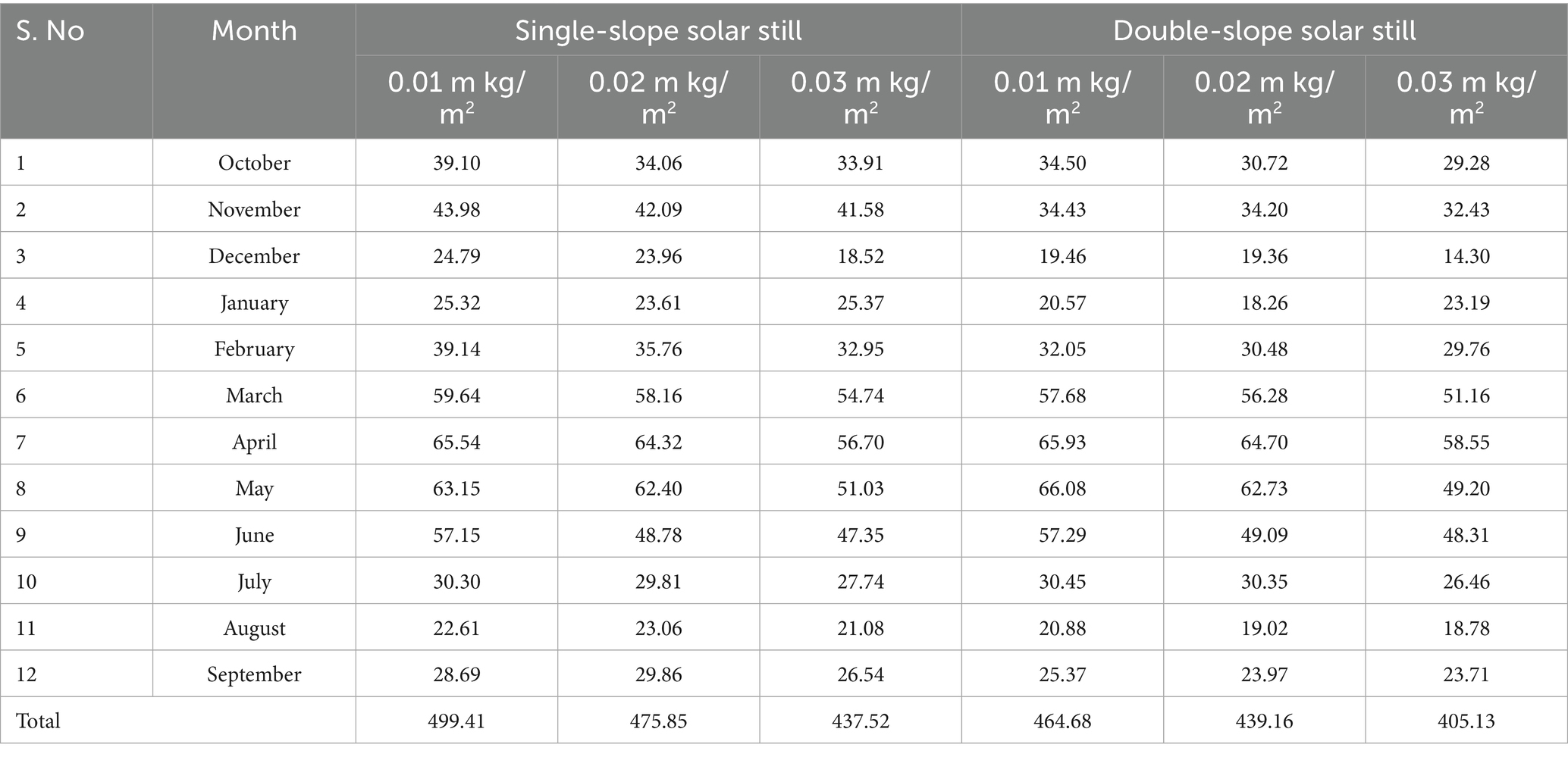

3 Solar still comparative studies with single and double slopes

When a single distiller is utilized, the average daily revenue is 1.629, and 1.44 kg of the bowl area is produced by a double slope solar still. According to solar distillers, the highest water temperatures measured were 60 °C and 61 °C, respectively. Using PCM and nanofluids, the effects of an increase in inner intensity on a produced convective stream in the double slope basin region were investigated. The average daily revenue for a solar still is 1.629; for a double distiller, it is 01.440 kg. Water temperatures, absorber plate have 60 °C, 61 °C, correspondingly. Three SBS pictures of double and single slope distillers employing fiber-reinforced plastic (FRP) material have been approved to this day by Tiwari et al. (1986) and Abdullah et al. (2022). The study found that dual distillers worked better in the long run than single stills in both summer and winter weather conditions. Rubio et al. (2000) started with experimental results from the summer and winter in Table 4 and used factual modelling to calculate volume stream levels. In response, we have compared of our solar still dimensions with those commonly reported in the literature. The fabricated SBS in this study had a basin area of actual dimension, 1 m2, which falls within the typical range of 0.5–1.5 m2 reported for laboratory and pilot-scale SBS systems, Malik et al. (2021), Panchal et al. (2020) have been used basin areas of 0.8 m2 and 1.2 m2, respectively, achieving productivity gains comparable to our results when similar enhancement techniques were applied. Our design thus represents a standard laboratory-scale unit, ensuring that the results are directly comparable with existing literature and scalable for field applications.

Table 4. Comparative study on monthly water production reports from year-over-year examination of single- and double-slope solar stills (Rubio et al., 2000).

The shallow stills findings, including the water and glass cover temperatures, were found to be accurately predicted by the model, with no appreciable variations between single and double slope circumstances. Altarawneh et al. (2017) looked at a once-yearly act on pyramid-shaped as a basin types distiller units (single and double slope). The proposed annual optimal angle views are approximately 30.3°, 45.0°, and 65.0° when applied to solar stills with single, double, or pyramidal geometries that face south. The output of the SBS has been increased by 28%. For 35°, it was discovered that the summertime performance was just slightly better than the other stills. In order to explain the fluctuating energy balance equations created by Mohandass Gandhi et al. (2022), Pavithra et al. (2022) employed MATLAB by a solar distiller with a machine learning. As a result of many PCM (paraffin) and insulation options, the lowest total annual cost (TAC) of 71.67 dollars was attained (glass wool). According to the scheme of phenolic foam, the maximum distillation production (9.421) was reported by Suresh and Shanmugan (2019). The Multi Objective Optimization (MOO) was examined using a PCM research of aggressive and economical performance by Malik et al. (2021), Panchal et al. (2020) wick type solar distiller. A mass of PCM variables has four parameters, which both treat TAC and full aggressive efficiency as objective functions. Applied MOO shows that, in comparison to the non-optimized system, the annual distilled water improvement is 4.35% and the energy efficiency gain is 1.47% when the PCM mass is approximately 1 kg. The two solar still desalination systems were studied by Angappan et al. (2022). Figure 12a shows how the Dielectric Barrier Discharge (DBD) on the condensation surface affects the cold plasma layer. The wettability and hydrophobicity of the condensation surface are influenced by the cold plasma coating, as demonstrated by environmental conditions. Applying plasma coating will increase the angle at which water droplets make contact with the glass surface, increasing the hydrophobicity of the surface, as seen in Figure 12b. According to research, the production of freshwater is increased by 25.7% by plasma coating when compared to an uncoated system, different PCM, and nanofluids.

Figure 12. (a) Yearly research articles reviewed by this work (Angappan et al., 2022). (b) Factors affecting distillate output (Angappan et al., 2022).

The recent works on solar stills using hybrid materials by Vijayakumar and Karthick (2025) demonstrated that Glauber salt–graphene oxide nanocomposite PCM exhibited superior productivity, achieving peak energy (43.06%), exergy (2.47%), and minimum water distillation cost ($0.024) and enhanced exergy methods. Modeled a modified solar still with TiO2–SiO2 hybrid nanofluid using Atangana–Baleanu fractional derivatives, demonstrating seasonal performance gains, 4.65% prediction error, enhanced efficiencies, and reduced economic–environmental impacts of exergy and energy approaches, MSS reduced CO2 by 22 and 29.6% more during the winter. The results of this study demonstrate that the integration of PCMs with Cu NPs and concentrators in SBS can substantially enhance freshwater productivity. In practical applications, this implies that communities in water-scarce or off-grid regions can benefit from a reliable, low-cost, and sustainable desalination solution. The 67.18 and 125% improvements in single- and double-effect SBS configurations, respectively, highlight the scalability of the approach for both small domestic units and larger decentralized desalination plants (Angappan et al., 2022). The use of paraffin wax as a PCM ensures energy storage during peak solar hours, enabling extended water production even under fluctuating solar intensity. Similarly, the incorporation of Cu NPs enhances thermal conductivity, reducing start-up times and maximizing evaporation rates. The findings also indicate that agro-based and eco-friendly materials can replace expensive commercial additives, lowering costs and enhancing environmental sustainability. Overall, the results provide a practical pathway for translating laboratory-scale innovations into community-scale desalination systems that can address potable water shortages in arid and coastal regions.

The main contribution of this paper is twofold: (i) it presents a scientometric framework that maps global research trends in bio-nanoparticle-enhanced PCMs for solar desalination, identifying key gaps and opportunities, and (ii) it experimentally validates a novel stepped single basin solar still design using paraffin wax PCM, copper nanoparticles, and concentrators, achieving up to 125% higher freshwater productivity. Together, these contributions advance both the research landscape and practical applications for sustainable water desalination. The novelty of this work lies in its societal scope, which explicitly highlights the integration of bio-based, agro-waste-derived nanoparticles with PCMs to enhance the thermal storage and freshwater productivity of SBS. This is presented through a dual scientometric–experimental framework that compares bio-based nanoparticles with conventional metallic ones and addresses underexplored research areas. The societal benefits are substantial, as the proposed system contributes to water security in resource-limited regions, promotes waste valorisation by reusing agro-waste, reduces environmental risks from metallic nanoparticle leaching, and offers a low-cost, sustainable desalination method.

4 CSS guidance based on SBS upgrade techniques and impending difficulties

The main technique for assessing the output and efficiency of any CSS is the thermal bowl (internal mechanism). Researchers will learn about a variety of efficiency-improving enhancement techniques by reading this literature review. Because solar stills technology is always evolving, researchers initially found that CSS comparison enhanced SBS. To overcome the drawbacks of conventional distiller units, the prototypes were constructed in a variety of ways. A review was conducted to compare the SBS method with CSS. An overview of several concepts that are being used in PCM-based nanoparticles is given in the SBS review. Review articles suggested that adding a solar still to our elements would be a fascinating way to save energy in the thermal basin area. Despite being based on an assessment of a unique notion, this SBS review article identifies a number of financial and environmental issues that require attention. As opposed to our investigation into creating environmentally friendly solar stills, the creation of SBS poses a serious threat to the environment. Another piece of advice is to work towards finishing the prototype as soon as possible. This is because a lot of researchers are not aware that finishing the original distiller has preparatory measures that guarantee which functionality and readiness. As a result, it is highly recommended that the SBS, a brand-new area of study, participate in significant technological involvement and creative thinking to improve tactics. The SBS study’s focal point in the future as it employed different augmentation procedures was the following set of criteria:

i. Researchers are not involved in the SBS research programme, which uses a variety of thermal energy storage materials.

ii. SBS requires some design changes that prioritise performance as an absorber above solar beams.

iii. Maintaining a glass cover is difficult; more investigation is needed to identify glass substitutes and improve glass absorption.

The integration of bio-based materials and agro-waste-derived nanoparticles into PCMs for solar desalination represents a novel and significant contribution. Our study combines a scientometric analysis of the global research landscape with experimental validation to highlight the potential of these materials in enhancing the performance of SBS while simultaneously promoting sustainability. The novelty of our approach lies in leveraging agro-waste sources such as rice husk, coconut shell, and other biomass residues, to synthesize bio-nanoparticles with desirable thermal and structural properties. These particles, when integrated with paraffin-based PCMs, enable improved latent heat storage, extended thermal release duration, and enhanced daily freshwater yield. Unlike conventional metal or metal oxide nanoparticles (Cu, CuO, ZnO), bio-based nanomaterials provide a dual advantage: they achieve competitive performance enhancements while reducing environmental impact and material cost. This aligns with circular economy principles, converting waste streams into value-added functional materials for clean water production. In this title for the scientometric framework, applied to publications from the past two decades, reveals that while metal and metal oxide nanoparticles dominate PCM-enhancement research, bio-based and agro-waste-derived nanoparticles remain underrepresented, constituting less than 8% of the documented studies. This gap underscores both the novelty and necessity of the present work. By mapping co-occurrence networks of keywords, citation bursts, and country collaborations, we identify an emerging but fragmented research trend in bio-based nanomaterial integration for thermal energy storage. This informed our experimental design and strengthened the case for emphasizing bio-based solutions.

Experimentally, SBS units were fabricated in a stepped design and tested under controlled solar exposure using four configurations: (i) PCM alone, (ii) PCM with Cu nanoparticles, (iii) PCM with bio-nanoparticles derived from agro-waste, and (iv) PCM with bio-nanoparticles plus a concentrator. The results show that PCM with bio-nanoparticles improved freshwater productivity by 61% compared to the baseline SBS without PCM, which is within 10% of the enhancement achieved by Cu nanoparticle integration. Importantly, the bio-based material route avoids potential nanoparticle leaching hazards associated with some metals, making it safer for long-term water contact. Furthermore, we demonstrate that the combination of bio-nanoparticles with solar concentrators yields an additional 25–28% productivity improvement, offering a practical route to scalable deployment in resource-limited, rural, or island communities where agro-waste is abundant. The life-cycle perspective of our design suggests lower embodied energy and greenhouse gas emissions compared to metallic nanoparticle production, strengthening the environmental credentials of our approach. We have ensured that readers immediately recognize the novelty of using bio-based and agro-waste-derived nanoparticles for sustainable desalination. This contribution not only advances solar desalination technology but also addresses waste management challenges, enabling a closed-loop, eco-friendly, and cost-effective pathway for producing potable water in regions facing water scarcity.

5 Conclusion

Any work involving one or more people will require solar desalination, and the most crucial SBS skill was taking use of these difficulties as teaching opportunities. With the global demand for clean drinking water growing, desalination using solar energy is currently proving to be a great alternative and an affordable technology for creating saline water distillation. Even though it was difficult to overcome every obstacle we faced for the SBS, we did learn from it and got better as a result. Calculations were performed to validate and corroborate our beliefs after some conceptual design and functionality development for the researchers. Then, ensure maximum efficiency and quality, SBS production process had to make some significant decisions. We employed PCM with bio-nanoparticles to simulate SBS since the cost and availability of certain materials presented difficulties and forced us to make different decisions in certain situations. After that, we experimented with a range of materials. SBS boosting processes were used to increase the productivity and water temperature of the absorber basin region using PCM and nanofluid materials.

In conclusion, it has been a pleasure working on this SBS since it has made us feel as though we have contributed to the everyday work that scientists undertake; solar energy is an affordable, dependable, and suitable source of mineral water for consumption. A discussion of the following conclusion can be made after the current evaluation study has extensively examined a range of augmentation methods from strength storage area choices: Multi-baseliner distiller coupled an outer condense stands out as an exceptional design with a 62% improvement in yield productivity.

• An SBS with a parabolic concentrator outperformed a CSS in productivity by a factor of 140.4%.

• The rate of water distillation was 26.47% higher with partial-spherical ridged coating of SBS compared to a simple flat absorber.

• For domestic (modern) products, the distillate output production costs for SBS corrugated absorb as a CSS are 0.0067 $/L and 0.049 $/L, respectively.

• A few desalination models provide society with an environmentally acceptable and resource-saving alternative. Additionally, waste that is found in the vicinity of more rural than populous areas can be transformed into solar energy using a solar distiller. Reducing the carbon emissions from distiller units goes a long way towards making manufacturing more environmentally friendly while also making it more effective, lightweight, affordable, and easy to mould.

Future research should develop bio-nanoparticles with high thermal conductivity, improve PCM stability, and design efficient solar desalination systems. LCAs, cost analyses, and simulations will optimize performance. Ongoing scientometric tracking and cross-disciplinary work will drive innovation in bio-nanoparticle-enhanced PCMs.

Author contributions

BS: Data curation, Methodology, Investigation, Writing – review & editing. AK: Methodology, Conceptualization, Writing – review & editing, Formal analysis. AA: Methodology, Writing – original draft, Resources, Formal analysis. SoS: Formal analysis, Supervision, Investigation, Writing – review & editing. LJ: Software, Writing – original draft, Project administration, Resources. MR: Formal analysis, Methodology, Conceptualization, Writing – review & editing. KK: Formal analysis, Methodology, Conceptualization, Writing – review & editing. JN: Data curation, Writing – review & editing, Software. PS: Conceptualization, Writing – review & editing, Methodology. ZO: Writing – review & editing, Data curation, Conceptualization. SS: Formal analysis, Project administration, Data curation, Conceptualization, Writing – original draft, Funding acquisition, Investigation.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Acknowledgments

The Department of Physics received funding under the DST-FIRST Level-1(SR/FST/PS-1/2018/35) scheme from the Department of Science and Technology (DST, Delhi), Government of India for the successful completion of the study.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdullah, A. S., Omara, Z. M., Alawee, W. H., Shanmugan, S., and Essa, F. A. (2025). Leveraging nanoparticles for sustainable water harvesting: a review of solar still technologies. Results Eng. 25:104128. doi: 10.1016/j.rineng.2025.104128

Abdullah, A. S., Omara, Z. M., Essa, F. A., Alqsair, U. F., Aljaghtham, M., Mansir, I. B., et al. (2022). Enhancing trays solar still performance using wick finned absorber, nano-enhanced PCM. Alex. Eng. J. 61, 12417–12430. doi: 10.1016/j.aej.2022.06.033

Abdullah, A. S., Omara, Z. M., Essa, F. A., Younes, M. M., Shanmugan, S., Abdelgaied, M., et al. (2021). Improving the performance of trays solar still using wick corrugated absorber, nano-enhanced phase change material and photovoltaics-powered heaters. J Energy Storage 40:102782. doi: 10.1016/j.est.2021.102782

Abu-Arabia, M., and Zurigat, Y. (2005). Year-round comparative study of three types of solar desalination units. Desalination 172, 137–143. doi: 10.1016/j.desal.2004.05.011

Ahmed, M. M. Z., Omara, Z. M., Alawee, W. H., Shanmugan, S., and Essa, F. A. (2025). Enhancing solar distiller performance for water desalination: a comparative review of vertical modifications-based techniques. Results Eng. 25:104360. doi: 10.1016/j.rineng.2025.104360

Alasiri, A., and Shanmugan, S. (2025). Experimental performance assessment of M-shaped solar distillation for efficient thermal energy storage using directional aluminum can configurations. Sep. Purif. Technol. 376:134172. doi: 10.1016/j.seppur.2025.134172

Almeshaal, M., and Shanmugan, S. (2024). Improving thermal efficiency of solar stills: bioactive nano-PCM and Cramer’s rule analysis. Sep. Purif. Technol. 343:127119. doi: 10.1016/j.seppur.2024.127119

Alsaiari, A. O., Shanmugan, S., Abulkhair, H., Bamasag, A., Moustafa, E. B., Alsulami, R. A., et al. (2022). Applications of TiO2/jackfruit peel nanocomposites in solar still: experimental analysis and performance evaluation. Case Stud. Therm. Eng. 38:102292. doi: 10.1016/j.csite.2022.102292

Altarawneh, I., Rawadieh, S., Batiha, M., Al-Makhadmeh, L., Alrowwad, S., and Tarawneh, M. (2017). Experimental and numerical performance analysis and optimization of single slope, double slope and pyramidal shaped solar stills. Desalination 423, 124–134. doi: 10.1016/j.desal.2017.09.023

Alwan, N. T., Majeed, M. H., Shcheklein, S. E., Ali, O. M., and Kumar, S. P. (2021). Experimental study of a tilt single slope solar still integrated with aluminum condensate plate. Inventions 6:77. doi: 10.3390/inventions6040077

Amy, G., Ghaffour, N., Li, Z., Francis, L., Linares, R. V., Missimer, T., et al. (2017). Membrane-based seawater desalination: present and future prospects. Desalination 401, 16–21. doi: 10.1016/j.desal.2016.10.002

Angappan, G., Pandiaraj, S., Panchal, H., Kathiresan, T., Ather, D., Dutta, C., et al. (2022). An extensive review of performance enhancement techniques for pyramid solar still for solar thermal applications. Desalination 532:115692. doi: 10.1016/j.desal.2022.115692

Arshad, K., Janarthanan, B., and Shanmugan, S. (2011). Performance of honeycomb double exposure solar still. Desalin. Water Treat. 26, 260–265. doi: 10.5004/dwt.2011.1826

Asha, S., Shanmugan, S., Venkateswarlu, M., Meenachi, M., Sangeetha, A., and Rao, M. C. (2022). Thermal potential porous materials and challenges of improving solar still using TiO2/jackfruit peel-enhanced energy storage material. Mater Today Proc 66, 3616–3625. doi: 10.1016/j.matpr.2022.07.142

Attia, M. E. H., Driss, Z., Kabeel, A. E., Alagar, K., Athikesavan, M. M., and Sathyamurthy, R. (2021). Phosphate bags as energy storage materials for enhancement of solar still performance. Environ. Sci. Pollut. Res. 28, 21540–21552. doi: 10.1007/s11356-020-12018-x

Attia, M. E. H., Driss, Z., Manokar, A. M., and Sathyamurthy, R. (2020). Effect of aluminum balls on the productivity of solar distillate. J Energy Storage 30:101466. doi: 10.1016/j.est.2020.101466

Badran, O. O., and Al-Tahaineh, H. A. (2005). The effect of coupling a flat-plate collector on the solar still productivity. Desalination 183, 137–142. doi: 10.1016/j.desal.2005.02.046

Balan, R., Chandrasekaran, J., Shanmugan, S., Janarthanan, B., and Kumar, S. (2011). Review on passive solar distillation. Desalin. Water Treat. 28, 217–238. doi: 10.5004/dwt.2011.1742

Bilal, A., Jamil, B., Haque, N. U., and Ansari, M. A. (2019). Investigating the effect of pumice stones sensible heat storage on the performance of a solar still. Groundw. Sustain. Dev. 9:100228. doi: 10.1016/j.gsd.2019.100228

Chaichan, M. T., and Kazem, H. A. (2018). Single slope solar distillatory productivity improvement using phase change material and Al2O3 nanoparticle. J. Sol. Energy. 164, 370–381. doi: 10.1016/j.solener.2018.02.049

Deng, J., Li, M., and Wang, Y. (2016). Biomass-derived carbon: synthesis and applications in energy storage and conversion. Green Chem. 18, 4824–4854. doi: 10.1039/C6GC01172A

Deshmukh, H. S., and Thombre, S. B. (2017). Solar distillation with single basin solar still using sensible heat storage materials. Desalination 410, 91–98. doi: 10.1016/j.desal.2017.01.030

Devi, N. L., and Shanmugan, S. (2021). An approach of renewable energy based on spatial patterns of radiation flux for solar thermal applications. Mater Today Proc 51, 1151–1156. doi: 10.1016/j.matpr.2021.07.115

Dhivagar, R., Mohanraj, M., Deepanraj, B., and Murugan, V. S. (2022). Assessment of single slope solar still using block and disc magnets via productivity, economic and enviro-economic perspectives: a comparative study. Environ. Sci. Pollut. Res. 29, 50951–50959. doi: 10.1007/s11356-021-15565-z

Dhivagar, R., Mohanraj, M., Hidouri, K., and Belyayev, Y. (2020). Energy, exergy, economic and enviro-economic (4E) analysis of gravel coarse aggregate sensible heat storage-assisted single-slope solar still. J. Therm. Anal. Calorim. 145, 475–494. doi: 10.1007/s10973-020-09766-w

Dsilva Winfred Rufussa, D., Kumar, V. R., Suganthi, L., Iniyana, S., and Davies, P. A. (2018). Technoeconomic analysis of solar stills using integrated fuzzy analytical hierarchy process and data envelopment analysis. J. Sol. Energy 159, 820–833. doi: 10.1016/j.solener.2017.11.050

Dumka, P., Kushwah, Y., Sharma, A., and Mishra, D. R. (2019). Comparative analysis and experimental evaluation of single slope solar still augmented with permanent magnets and conventional solar still. Desalination 459, 34–45. doi: 10.1016/j.desal.2019.02.012

Dumka, P., Sharma, A., Kushwah, Y., Raghav, A. S., and Mishra, D. R. (2019). Performance evaluation of single slope solar still augmented with sand-filled cotton bags. J Energy Storage 25:100888. doi: 10.1016/j.est.2019.100888

Elango, T., Kannan, A., and Kalidasa, K. M. (2015). Performance study on single basin single slope solar still with different water nanofluids. Desalination 360, 45–51. doi: 10.1016/j.desal.2015.01.004

Elsheikh, A. H., Panchal, H. N., Sengottain, S., Alsaleh, N. A., and Ahmadein, M. (2022). Application of heat exchanger in solar desalination: current issues and future challenges. Water 14:852. doi: 10.3390/w14060852

Elsheikh, A. H., Shanmugan, S., Sathyamurthy, R., Thakur, A. K., Issa, M., Panchal, H., et al. (2022). Low-cost bilayered structure for improving the performance of solar stills: performance/cost analysis and water yield prediction using machine learning. Sustain Energy Technol Assess 49:101783. doi: 10.1016/j.seta.2021.101783

Essa, F. A., Abdullah, A. S., Alawee, W. H., Alarjani, A., Alqsair, U. F., Shanmugan, S., et al. (2022). Experimental enhancement of tubular solar still performance using rotating cylinder, nanoparticles' coating, parabolic solar concentrator, and phase change material. Case Stud. Therm. Eng. 29:101705. doi: 10.1016/j.csite.2021.101705

Essa, F. A., Elsheikh, A. H., Algazzar, A. A., Sathyamurthy, R., Ahmed Ali, M. K., Elaziz, M. A., et al. (2020). Eco-friendly coffee-based colloid for performance augmentation of solar stills. Process. Saf. Environ. Prot. 136, 259–267. doi: 10.1016/j.psep.2020.02.005

Essa, F. A., Elsheikh, A. H., Sathyamurthy, R., MuthuManokard, A., Kandeal, A. W., Shanmugan, S., et al. (2020). Extracting water content from the ambient air in a double-slope half cylindrical basin solar still using silica gel under Egyptian conditions. Sustain Energy Technol Assess 39:100712. doi: 10.1016/j.seta.2020.100712

Essa, F. A., Omara, Z. M., Abdullah, A. S., Shanmugan, S., Panchal, H., Kabeel, A. E., et al. (2020). Wall-suspended trays inside stepped distiller with Al2O3/paraffin wax mixture and vapor suction: experimental implementation. J Energy Storage 32:102008. doi: 10.1016/j.est.2020.102008

Essa, F. A., Omara, Z., Abdullah, A., Shanmugan, S., Panchal, H., Kabeel, A. E., et al. (2021). Augmenting the productivity of stepped distiller by corrugated and curved liners, CuO/paraffin wax, wick, and vapor suctioning. Environ. Sci. Pollut. Res. Springer Link, 28, 56955–56965. doi: 10.1007/s11356-021-14669-w

Feilizadeh, M., Karimi Estahbanati, M. R., Ahsan, A., Jafarpur, K., and Mersaghian, A. (2016). Efects of water and basin depths in single basin solar stills: an experimental and theoretical study. Energy Convers. Manag. 122, 174–181. doi: 10.1016/j.enconman.2016.05.048

Gandhi, A. M., Shanmugan, S., Gorjian, S., Pruncu, C. I., Sivakumar, S., Elsheikh, A. H., et al. (2021). Performance enhancement of stepped basin solar still based on OSELM with traversal tree for higher energy adaptive control. Desalination 502:114926. doi: 10.1016/j.desal.2020.114926

Gangavathi, P., Ramya, G., Karuna, M. S., Jeyapiriya, K., Magade, P. B., and Manirathnam, D. (2022). Influence of nanomaterial coated condensing surface on the productivity of evacuated tube assisted solar still. Mater Today Proc 69, 853–857. doi: 10.1016/j.matpr.2022.07.285

Gaur, M., Misra, C., Yadav, A. B., Swaroop, S., Maolmhuaidh, F. Ó., Bechelany, M., et al. (2021). Biomedical applications of carbon nanomaterials: fullerenes, quantum dots, nanotubes, nanofibers, and graphene. Materials 14:5978. doi: 10.3390/ma14205978

Grewal, R., and Kumar, M. (2022). Investigations on effect of mass of phase change material on sugarcane juice concentration and distillate production in a stepped solar system. J Energy Storage 52:104878. doi: 10.1016/j.est.2022.104878

Gupta, B., Shankar, P., Sharma, R., and Baredar, P. (2016). Performance enhancement using nano particles in modified passive solar still. Procedia Tech. 25, 1209–1216. doi: 10.1016/j.protcy.2016.08.208

Harris Samuel, D. G., Nagarajan, P. K., Sathyamurthy, R., El-Agouz, S. A., and Kannan, E. (2016). Improving the yield of fresh water in conventional solar still using low cost energy storage material. Energy Convers. Manag. 112, 125–134. doi: 10.1016/j.enconman.2015.12.074

Jones, E., Qadir, M., van Vliet, M. T. H., Smakhtin, V., and Kang, S. M. (2019). The state of desalination and brine production: a global outlook. Sci. Total Environ. 657, 1343–1356. doi: 10.1016/j.scitotenv.2018.12.076

Kabeel, A. E., Abdelgaied, M., and Eisa, A. (2018). Enhancing the performance of single basin solar still using high thermal conductivity sensible storage materials. J. Clean. Prod. 183, 20–25. doi: 10.1016/j.jclepro.2018.02.144

Kabeel, A. E., El-Agouz, E.-S., Athikesavan, M. M., Duraisamy Ramalingam, R., Sathyamurthy, R., Prakash, N., et al. (2019). Comparative analysis on freshwater yield from conventional basin-type single slope solar still with cement-coated red bricks: an experimental approach. Environ. Sci. Pollut. Res. 27, 32218–32228. doi: 10.1007/s11356-019-07288-z

Kabeel, A. E., Omara, Z. M., and Essa, F. A. (2017). Theoretical with experimental validation of modified solar still using nanofluids and external condenser. J. Taiwan Inst. Chem. Eng. 75, 1–10. doi: 10.1016/j.jtice.2017.01.017

Kabeel, A. E., Omara, Z. M., Essa, F. A., and Abdullah, A. S. (2016). Solar still with condenser – a detailed review. Renew. Sust. Energ. Rev. 59, 839–857. doi: 10.1016/j.rser.2016.01.020

Kandeal, A. W., El-Shafai, N. M., Abdo, M. R., Thakur, A. K., El-Mehasseb, I. M., Maher, I., et al. (2021). Improved thermo-economic performance of solar desalination via copper chips, nanofluid, and nano-based phase change material. J. Sol. Energy 224, 1313–1325. doi: 10.1016/j.solener.2021.06.085

Khan, I., Saeed, K., and Khan, I. (2019). Nanoparticles: properties, applications and toxicities. Arab. J. Chem. 12, 908–931. doi: 10.1016/j.arabjc.2017.05.011

Kotla, D. P., Anna, V. R., Praveenkumar, S., Saleh, S. M., and Shanmugan, S. (2025). Optimizing solar still performance: a study of TiO2 nanofluid derived from Saccharum officinarum L. Sep. Purif. Technol. 359:130584. doi: 10.1016/j.seppur.2024.130584

Kumar, R., Chanda, J., Elsheikh, A. H., Ongar, B., Khidolda, Y., Kumar, S. P., et al. (2023). Performance improvement of single and double effect solar stills with silver balls/nanofluids for bioactivation: an experimental analysis. Sol. Energy 259, 452–463. doi: 10.1016/j.solener.2023.05.012

Kumar, R., Maurya, A., Shanmugan, S., Kabeel, A.-E., Zhumatova Assel, A., Sarsenbayev, Y., et al. (2024). Use of absorber plate built of ZnO/PVC/bioactivation modified epoxy nanocomposites to improvement of double-effect solar distiller productivity analyzing the energy, exergo-environment and enviro-economical. J. Clean. Prod. 434:139601. doi: 10.1016/j.jclepro.2023.139601

Kumar, T. R., Shanmugan, S., Sundari, G. S., Devi, N. S. M. P. L., Abhiram, N., and Palanikumar, G. (2021). Experimental investigation on the performance of a solar still using SiO2 nanoparticles /Jatrophacurcas L, silicon. Netherlands: Springer, 1–14. doi: 10.1007/s12633-021-01119-y

Kumar, S., and Tiwari, A. (2008). An experimental study of hybrid photovoltaic thermal (PV/T)-active solar still. Int. J. Energy Res. 32, 847–1667. doi: 10.1002/er.1388

Lawrence, A., Hariharan, C., Shanmugan, S., and Janarthanan, B. (2022). Performance of single slope solar still for socio-economic development in coast locations in India. Int. J. Ambient Energy 43, 1–9. doi: 10.1080/01430750.2021.1927838

Lee, M. S., Gwon, J. G., Seo, Y. M., Choi, H. K., and Park, Y. G. (2025). Ellipsoidal protrusions for enhanced thermal performance in fin-tube heat exchangers. Case Stud. Therm. Eng. 74:106770. doi: 10.1016/j.csite.2025.106770

Mahmoud, A., Fath, H., Ookwara, S., and Ahmed, M. (2019). Influence of partial solar energy storage and solar concentration ratio on the productivity of integrated solar still/humidification-dehumidification desalination systems. Desalination 467, 29–42. doi: 10.1016/j.desal.2019.04.033

Malik, M. Z., Musharavati, F., Khanmohammadi, S., Khanmohammadi, S., and Nguyen, D. D. (2021). Solar still desalination system equipped with paraffin as phase change material: exergoeconomic analysis and multi-objective optimization. Environ. Sci. Pollut. Res. 28, 220–234. doi: 10.1007/s11356-020-10335-9

Manikandan, V., Shanmugasundaram, K., Shanmugan, S., Janarthanan, B., and Chandrasekaran, J. (2013). Wick type solar stills: a review. Renew. Sust. Energ. Rev. 20, 322–335. doi: 10.1016/j.rser.2012.11.046 IF 16.3 Q1 Citation 127

Manoj Kumar, P., Chauhan, P., Sharma, A. K., Rinawa, M. L., Rahul, A. J., Srinivas, M., et al. (2022). Performance study on solar still using nano disbanded phase change material (NDPCM). Mater Today Proc 62, 1894–1897. doi: 10.1016/j.matpr.2022.01.050

Modi, K. V., and Nayi, K. H. (2020). Efficacy of forced condensation and forced evaporation with thermal energy storage material on square pyramid solar still. Renew. Energy 153, 1307–1319. doi: 10.1016/j.renene.2020.02.095

Modi, K. V., and Shukla, D. L. (2018). Regeneration of liquid desiccant for solar air-conditioning and desalination using hybrid solar still. Energy Convers. Manag. 171, 1598–1616. doi: 10.1016/j.enconman.2018.06.096

Mohamed, A. F., Hegazi, A. A., Sultan, G. I., and El-Said, E. M. S. (2019). Enhancement of a solar still performance by inclusion the basalt stones as a porous sensible absorber: experimental study and thermo-economic analysis. Sol. Energy Mater. Sol. Cells 200:109958. doi: 10.1016/j.solmat.2019.109958

Mohammed, A. H., Attalla, M., and Shmroukh, A. N. (2022). Comparative study on the performance of solar still equipped with local clay as an energy storage material. Environ. Sci. Pollut. Res. 29, 74998–75012. doi: 10.1007/s11356-022-21095-z

Mohandass Gandhi, A., Shanmugan, S., Kumar, R., Elsheikh, A. H., Sharifpur, M., Bewoor, A. K., et al. (2022). SiO2/TiO2nanolayer synergistically trigger thermal absorption inflammatory responses materials for performance improvement of stepped basin solar still natural distiller. Sustain Energy Technol Assess 52:101974. doi: 10.1016/j.seta.2022.101974

Nafey, A. S., Abdelkader, M., Abdelmotalip, A., and Mabrouk, A. A. (2000). Parameters affecting solar still productivity. Energy Convers. Manag. 41, 1797–1809. doi: 10.1016/S0196-8904(99)00188-0

Nagaraj, S. K., Nagarajan, B. M., and Ponnusamy, P. (2020). Performance analysis of solar still with quartzite rock as a sensible storage medium. Mater Today Proc 37, 2214–2218. doi: 10.1016/j.matpr.2020.07.655

Nazari, S., Safarzadeh, H., and Bahiraei, M. (2019). Performance improvement of a single solar still by employing thermoelectric cooling channel and copper oxide nanofluid: an experimental study. J. Clean. Prod. 20, 1041–1052. doi: 10.1016/j.jclepro.2018.10.194

Omara, Z. M., Ahmed, M. M. Z., Alawee, W. H., Shanmugan, S., and Elashmawy, M. (2024). A comprehensive review of nano-enhanced phase change materials on solar stills with scientometric analysis. Results Eng. 22:102088. doi: 10.1016/j.rineng.2024.102088

Palaniappan, M., El-Shafay, A. S., and Shanmugan, S. (2024). Improving heat retention properties of steeped M-shape basin solar distillers utilizing paraffin RT50-enhanced silver nanoparticles and Manihotesculenta extracts. Desalination 586:117836. doi: 10.1016/j.desal.2024.117836

Panchal, H., Mevada, D., Sadasivuni, K. K., Essa, F. A., Shanmugan, S., and Khalid, M. (2020). Experimental and water quality analysis of solar stills with vertical and inclined fins. Groundw. Sustain. Dev. 11:100410. doi: 10.1016/j.gsd.2020.100410

Panchal, H., Nurdiyanto, H., Sadasivuni, K. K., Hishan, S. S., Essa, F. A., Khalid, M., et al. (2021). Experimental investigation on the yield of solar still using manganese oxide nanoparticles coated absorber. Case Stud. Therm. Eng. 25:100905. doi: 10.1016/j.csite.2021.100905

Panchal, H., Sadasivuni, K. K., Ahmed, A. A. A., Hishan, S. S., Doranehgard, M. H., Essa, F. A., et al. (2021). Graphite powder mixed with black paint on the absorber plate of the solar still to enhance yield: an experimental investigation. Desalination 520:115349. doi: 10.1016/j.desal.2021.115349

Panchal, H., Sadasivuni, K. K., Essa, F. A., Shanmugan, S., and Sathyamurthy, R. (2021). Enhancement of the yield of solar still with the use of solar pond: a review. Heat Transf. 50, 1392–1409. doi: 10.1002/htj.21935

Panchal, H., Sadasivuni, K. K., Prajapati, C., Khalid, M., Essa, F. A., Shanmugan, S., et al. (2020). Productivity enhancement of solar still with thermoelectric modules from groundwater to produce potable water: a review. Groundw. Sustain. Dev. 11:100429. doi: 10.1016/j.gsd.2020.100429

Panchal, H., Sadasivuni, K. K., Shanmugan, S., and Pandya, N. (2021). Performance analysis of waste brick magnesia as a storage material in a solar still. Heat Transf. 50, 1799–1811. doi: 10.1002/htj.21956

Pavithra, S., Veeramani, T., Subha, S. S., Sathish Kumar, P. J., Shanmugan, S., Elsheikh, A. H., et al. (2022). Revealing prediction of perched cum off-centered wick solar still performance using network based on optimizer algorithm. Process. Saf. Environ. Prot. 161, 188–200. doi: 10.1016/j.psep.2022.03.009

Phadatare, M. K., and Verma, S. K. (2007). Influence of water depth on internal heat and mass transfer in a plastic solar still. Desalination 217, 267–275. doi: 10.1016/j.desal.2007.03.006

Rubio, E., Porta, M. A., and Fernández, J. L. (2000). Cavity geometry influence on mass flow rate for single and double slope solar stills. Appl. Therm. Eng. 20, 1105–1111. doi: 10.1016/S1359-4311(99)00085-X

Sadasivuni, K., Panchal, H., Awasthi, A., Israr, M., Essa, F. A., Shanmugan, S., et al. (2022). Ground water treatment using solar radiation-vaporization & condensation-techniques by solar desalination system. Int. J. Ambient Energy 43, 2868–2874. doi: 10.1080/01430750.2020.1772872

Sai, G., Anna, V. R., Swapna, K., Prasad, M. V. K. S., Ch, R. P., Krishna, B. C., et al. (2025). Evaluating the effects of sugarcane juice-mediated ZnO nanofluids on solar light activation for enhancing double-slope solar still performance. Appl. Mater. Today 42:102542. doi: 10.1016/j.apmt.2024.102542

Sakthivel, T. G., and Arjunan, T. V. (2018). Thermodynamic performance comparison of single slope solar stills with and without cotton cloth energy storage medium. J. Therm. Anal. Calorim. 137, 351–360. doi: 10.1007/s10973-018-7909-0

Saleh, B., Ahmed, M. H., Shanmugan, S., Elsheikh, A. H., El-Sebaey, M. S., Stephen, M. T., et al. (2024). Enhancing desalination performance of a stepped solar still using nano-enhanced phase change material and condenser integration. Sol. Energy Mater. Sol. Cells 277:113141. doi: 10.1016/j.solmat.2024.113141

Sangeetha, A., Shanmugan, S., and Alasiri, A. (2024). ZnO/nZVI nanoparticle-enhanced double-slope U-shaped solar distillation: a thermodynamic investigation of cephalexin adsorption. Mater Today Sustain 28:100983. doi: 10.1016/j.mtsust.2024.100983

Sangeetha, A., Shanmugan, S., and Gorjian, S. (2022). Experimental evaluation and thermodynamic Gibbs free energy analysis of a double-slope U-shaped stepped basin solar still using activated carbon with ZnO nanoparticles. J. Clean. Prod. 380:135118. doi: 10.1016/j.jclepro.2022.135118

Selimefendigil, F., Sirin, C., and Oztop, H. F. (2022). Experimental analysis of combined utilization of CuO nanoparticles in latent heat storage unit and absorber coating in a single-slope solar desalination system. Sol. Energy 233, 278–286. doi: 10.1016/j.solener.2022.01.039

Shalaby, S. M., El-Bialy, E., and El-Sebaii, A. A. (2016). An experimental investigation of a V-corrugated absorber single-basin solar still using PCM. Desalination 398, 247–255. doi: 10.1016/j.desal.2016.07.042