- 1Department of Mechanical Engineering, College of Engineering, Imam Mohammad Ibn Saud Islamic University (IMSIU), Riyadh, Saudi Arabia

- 2Department of Chemistry, Chennai Institute of Technology, Chennai, Tamil Nadu, India

- 3Department of Biomedical Engineering, Karpaga Vinayaga College of Engineering and Technology, Chengalpattu, Tamil Nadu, India

- 4Department of Physics, Dhanalakshmi College of Engineering, Chennai, Tamil Nadu, India

- 5Department of Physics, S. A. Engineering College, Chennai, Tamil Nadu, India

- 6Department of Computer Science and Engineering, Saveetha School of Engineering, SIMATS, Chennai, Tamil Nadu, India

- 7Research Centre for Solar Energy, Department of Integrated Research and Discovery-Physics, Koneru Lakshmaiah Education Foundation, Guntur, Andhra Pradesh, India

This study examines a single-slope corrugated wick solar distillation system enhanced with a hybrid nanocomposite made of zinc oxide (ZnO) nanoparticles and activated carbon (AC) to improve solar radiation capture and maximize photothermal energy conversion. By mediating non-radiative energy exchange between the photonic field and water molecules, Forster Resonance Energy Transfer (FRET) plays a crucial role in enhancing localized thermal interactions at the saline interface. The integration of these nanomaterials promotes better thermal energy coupling. To capture and hold onto solar thermal energy as latent heat during periods of high irradiation, the system also includes a paraffin-based phase change material (PCM), which is positioned strategically beneath the wick absorber. Even in the absence of direct solar input, this stored energy is progressively released over the post-sunset hours, allowing for continued temperature regulation and prolonged nighttime distillate production. Experiments conducted under normal atmospheric and sunlight conditions demonstrate significant improvements over traditional wick-type distillers. With a matching thermal efficiency of 42.53% and an average distillate yield of 5.123 L·m−2·day−1, the new configuration outperformed the control system by 42%. Significantly, on days with constant solar irradiation, the mean evaporative heat transfer coefficient was found to be around 157 W·m−2, demonstrating an effective energy flux between the water layer and wick surface. A combined impact of improved light absorption, greater surface thermal conductivity, and efficient non-contact energy propagation made possible by the FRET mechanism is responsible for the observed improvement in distillation performance. The PCM’s controlled exothermic discharge greatly promotes continuous distillate output during off-peak hours, which helps to maintain the system’s operational continuity and energy autonomy. In addition to redefining the thermal management approach in passive solar desalination systems, the combination of FRET-driven energy dynamics and phase change storage paves the way for next-generation hybrid designs targeted at water-scarce regions with fluctuating sun availability.

1 Overview

The development of sustainable desalination technology is necessary since the shortage of drinkable water has been made worse by global population expansion. Significant progress has been made by researchers worldwide in a variety of distillation procedures, and published findings have improved distillate yields. It has been shown that adding additional absorbents can increase the absorption of solar energy and speed up the rate of evaporation. Solar distillation stands out among these techniques as an economical and environmentally friendly alternative with low maintenance needs. Numerous studies have repeatedly shown that adding nanoparticles to the solar still basin greatly increases evaporation. Furthermore, water production at night, even in the absence of direct solar irradiation, has been made possible by the creative use of phase change materials (PCMs) for thermal energy storage Shanmugan et al. (2013) studied a double-slope wick-type solar still, and the mechanism improved the efficiency of the still to 41.25% with an insulation thickness of 0.05 m beneath the tilted-wick portion and the sides of the still. A comparative analysis of five aluminum can configurations in solar distillation revealed that the diagonal arrangement with an M-shaped absorber (Case 3) offered the best performance (Alasiri and Shanmugan, 2025a), achieving 8.090 kg/m2 distillate and 42.74% thermal efficiency over 24 h. To improve water production and sunlight absorption, Rasachak et al. (2022) examined the effects of tin oxide (SnO2) coatings at different concentrations on solar still absorber plates. Due to potent ultraviolet (UV) and infrared (IR) absorption of SnO2, the results demonstrate that adding 15 weight percent SnO2 to black paint greatly raises surface temperature—up to 101.61°C indoors (53.67% higher than bare plates) and 74.96°C outdoors, which has improved efficiency. To maximize freshwater yield, Elsheikh et al. (2025) examined the integration of machine learning (ML) in solar stills. Intelligent desalination techniques are guided by models such as support vector machine (SVM), adaptive neuro-fuzzy inference system (ANFIS), and hybrid metaheuristics, which improve sustainability, operational efficiency, and prediction accuracy while addressing environmental unpredictability. Sangeetha and Shanmugan (2022) used the Gibbs free energy equation to do a thermodynamic analysis on a U-shaped staircase basin still employing activated carbon made from Mangifera indica and Celosia argentea with ZnO. The results showed a distillate yield of 14.921 L/m2/day at 38.73% efficiency. Additionally, it is coating absorber plates with black paint that contains activated carbon. By concentrating on solar energy-based desalination techniques, Kumar et al. (2023) addressed the worldwide freshwater problem and the rising demand for sustainable solutions. To lessen the impact on the environment and increase energy efficiency, the assessment emphasizes the transition from desalination methods based on fossil fuels to solar thermal technology. It examines both direct and indirect sun desalination methods, new developments such as systems boosted by nanoparticles, and the resuscitation of methods like membrane distillation (MD) for effective freshwater production (Sai et al., 2025). This resulted in a considerable improvement in photothermal conversion, an increase in heat transfer coefficients of 37.20%, and an increase in distillate yield to 4.5 kg/m2 per day. In their thorough analysis, they examined vertically restructured solar stills with wicking systems, resistive heating coils, photovoltaic integration, and optical reflectors. To improve performance, Jathar et al. (2022a) tested a Concave-Type Stepped Solar Still (CTSSS) in Pune, India, employing nanofluids (MgO, AlO3, and TiO2) at concentrations of 0.1 and 0.2%. MgO, Al2O3, and TiO2 nanofluids increased production by 41.35, 28.42, and 19.10%, respectively, at 0.2% concentration. The highest output was recorded at a water depth of 7 mm, indicating an inverse relationship between productivity and water depth. The distilled water is safe to drink according to the World Health Organization (WHO)-2017, Bureau of Indian Standards (BIS)-2010, and Environmental Protection Agency (EPA)-2014 regulations. Solar still–photovoltaic (PV) hybridization was investigated by Shanmugan et al. (2024) as a complementary strategy to alleviate freshwater scarcity and advance renewable energy. Preheating and thermal enhancement are made easier by PV-generated power, which greatly increases distillation efficiency and supports sustainable energy–water nexus methods. Jathar et al. (2022b) examined the growing need for drinking water and its diminishing supply. Although poor productivity remains a significant barrier, solar desalination using solar stills offers a viable alternative. This analysis emphasizes the impact of operational, design, and environmental factors such as absorber plate design, inclination angle, water depth (~1 cm), and ideal solar radiation on performance improvement. Distillate output is further enhanced by methods such as the use of fin-equipped V-corrugated plates, thermal storage materials, reflector plates, a smaller absorber–condensing cover gap, and sun-tracking devices. Recent advances in solar still design and material research serve as a testament to these efforts. Shanmugan et al. (2020) showed improved efficiency of 57.16% in summer and 36.69% in winter by adding TiO2 nanoparticles and Cr2O3 composites to basin liners, as shown by Scanning Electron Microscopy (SEM), Fourier-Transform Infrared spectroscopy (FTIR), and X-ray diffraction (XRD) investigations. These improvements were also reinforced by a multi-criteria analysis of stills using porous activated carbon tubes. To solve the issue of poor productivity, Fayaz et al. (2022) examined the usage of solar stills as an environmentally benign technique for producing freshwater in arid places. To improve solar absorption, this study examines the impact of adding metallic titanium (Ti) particles to black paint in different concentrations on the absorber plate. The maximum surface temperature is 100.39°C indoors at 1,000 W/m2, which is produced by seven weight percent Ti in black paint, according to the results. This is an increase of 11.87% over black paint alone and 54.35% over bare aluminum. Higher concentrations, however, resulted in heat loss. Abed et al. (2022) investigated the use of solar desalination as a solution to freshwater scarcity brought on by climate change. In this study, plain brackish water and dye-dosed water are used to compare single-slope solar stills. According to experimental studies conducted in Tikrit, Iraq, the addition of chemical dyes like thymol blue and methyl orange greatly increases freshwater flow, increasing it by up to 40%. Thymol blue had the highest efficiency, reaching up to 53%. This technique is appropriate for off-grid dry areas because the distilled water satisfies WHO requirements. Abdullah et al. (2025) studied and summarized developments in solar stills boosted by nanomaterials, with a focus on fluids injected with nanoparticles, phase transition materials that are nanoengineered, and nanocoatings. It presents potential research avenues to improve desalination efficiency by nanoscale interventions in solar distillation systems and incorporates thermo-enviro-economic evaluations. In their evaluation of M-shaped solar distillers (SMD) that incorporate Mn2O3–Cu nanocomposites in paraffin RT31 (MCP), Alasiri and Shanmugan (2025b) showed improved nocturnal yield, peak efficiency (42.7%), and greater thermal storage. Seasonal production was greatly increased by 4-chloro-2-methylphenoxyacetic acid (MCPA) integration, suggesting the possibility of sustainable desalination. Double-slope solar stills (DS) supplemented with 30% concentrated strontium zinc nanoparticles (SZNs) were studied. The agricultural sector uses around 70% of the world’s water and is a major source of water pollution, which was the focus of Gorjian et al. Water scarcity is getting worse due to urbanization and climate change, particularly in arid and salt-affected areas. Fossil fuel-based irrigation systems are not environmentally sustainable; however, desalination offers a sustainable substitute. This chapter discusses solar-powered agricultural desalination methods, looking at their technical, financial, and environmental implications as well as international case studies and related difficulties. Ahmed et al. (2025) were able to increase productivity by up to 107% while reducing thermal resistance and spatial footprint. Strategies for future design are described. Awan et al. (2023) examined how the depletion of fossil fuels and the erratic nature of renewable energy sources have increased the significance of thermal management (TM) and energy storage in many industries. Due to their high electrical and thermal conductivity, adjustable chemistry, and light-absorbing capabilities, MXenes, a class of two-dimensional (2D) transition metal carbides and nitrides, exhibit significant promise in TM. The synthesis, characteristics, and various uses of MXene in solar energy, desalination, hybrid PV-T systems, and electronics are highlighted in this paper, with a focus on their potential for effective thermal energy conversion and storage. According to Kumar et al. (2024), adding zinc oxide/polyvinyl chloride/bioactivation (ZPBN) to double-slope basin distillers (DSBD) allows for stable internal heating, increasing production by 126%. ZPBN achieved favorable energy and cost metrics of 4.640 kWh/$ and $83.210, respectively, resulting in a 44% reduction in thermal energy consumption. The combination of photovoltaic (PV) systems, desalination technologies, and artificial intelligence (AI)/ML was examined by Jathar et al. (2024), who emphasized how these technologies work together to improve efficiency, sustainability, and innovation. The study looks at how AI/ML optimizes desalination processes by addressing energy utilization and scalability, while also enhancing PV system performance through predictive maintenance, real-time monitoring, and better operational efficiency. It provides insightful information for researchers, engineers, and politicians by pointing out research gaps, suggesting future directions, and demonstrating that AI can increase freshwater productivity by 10%. Additionally researchers developed in solar desalination using nano-PCM by Almeshaal and Shanmugan (2024), Omara et al. (2024), and Essa et al. (2024) improved the Ball rotation in spherical solar distillation; Mousa et al. (2024) studied the fluorescence resonance energy transfer in solar still. PCM, a parabolic solar concentrator (PSC) (Essa et al., 2022), and nanoparticles were integrated in an experimental study by Abdullah et al. (2021) to increase the efficiency of a tubular solar distillation system (TDSS). These components worked in concert to significantly increase evaporation rates, with the nanoparticle layer enabling a change from film-wise to drop-wise condensation. By directing sunlight onto the drum’s back surface, the PSC increased the amount of solar energy input, and the drum’s spinning speed was adjusted to optimize output. With a significant increase in water output of up to 218% and a thermal efficiency of 63.8%, the redesigned system lowered distillation costs. Palaniappan et al. (2024) explored the application of a solar still integrated with bio-based nano-enhanced phase change materials (Bio-nano-PCM) to improve thermal storage and distillation performance. Additionally, in the recent reviews by Elashmawy et al. (2024), Kabeel et al. (2024), Saleh et al. (2024), and Suresh et al. (2024), they have examined the role of advanced materials in boosting thermal energy utilization. Their research highlights significant advancements in solar thermal technologies, particularly emphasizing the use of nanomaterials, phase change substances, and hybrid thermal storage composites to enhance energy capture and storage efficiency. Sangeetha et al. (2024) examined the integration of ZnO/nZVI nanoparticles for improved solar thermal applications. Kumar et al. (2023) examined the function of nanofluids in enhancing energy system performance, within the context of the energy–exergy–environment (3E) study, additional research carried out by Sangeetha and Shanmugan (2022) focused on activated carbon–zinc oxide (AC/ZnO) composites, and Kumar et al. (2023) investigated the application of bio-based nanoparticles. Furthermore, a thorough analysis of the complementary application of PCMs and nanofluids for improving thermal energy storage was provided by Sangeetha et al. (2023). Additionally, as shown by Nakhaei et al. (2022) and Jang et al. (2019), the Forster Resonance Energy Transfer (FRET) mechanism is essential for elucidating the dynamics of energy and charge transfer in a variety of solar energy technologies, including co-sensitized solar cells.

In this study, ZnO nanoparticles are synthesized sustainably utilizing green chemistry principles. At the same time, activated carbon is created by thermochemically converting biomass from mango wood, then chemically activating it with NaOH. The resultant nanoparticles are evenly distributed throughout the brine chamber of a solar distillation unit that uses a single-slope wick. Parallel to this, paraffin wax is placed under the corrugated wick absorber in a specific location to act as a PCM and allow for prolonged heat discharge at night. The cumulative freshwater yield during nighttime operation is greatly increased by the latent heat generated during the exothermic phase transition of the PCM. The system undergoes a thorough thermo-optical assessment, with a focus on clarifying how FRET contributes to the thermal energy transfer from the implanted ZnO/activated carbon hybrid to the saline medium. Although nanomaterials and PCMs have been studied separately in the literature to increase the efficiency of solar stills, nothing is known about the combined use of ZnO nanoparticles, activated carbon, and FRET-assisted energy coupling in a single distillation framework. To improve solar absorption, heat retention, and water purification effectiveness, this study presents a novel composite configuration that takes advantage of the complementary qualities of each component: FRET’s non-radiative energy mediation capability, activated carbon’s high surface area and adsorptive potential, and ZnO’s superior photothermal and photocatalytic functionality. The improved method creates a strong foundation for the development of high-efficiency solar thermal water purification technologies in addition to filling a significant research gap in solar desalination.

2 Design of solar distiller

The galvanized steel water tank and the sloping absorber surface of the solar distillers are both firmly fixed inside a plywood framework. The sloping surface is fixed at a 15° tilt angle. Dimensions are 1 × 1 × 0.15 m for the tank and 1 × 0.25 × 0.25 m for the sloping surface. All metallic components are welded and riveted to ensure structural integrity. Glass wool insulation, which has a thermal conductivity of about 0.00038 W/mK, is used to insulate the interstitial area between the external and interior enclosures to reduce conduction heat losses. Thermocol is sewn onto a jute wick to create the corrugated wick structure. Phase change material is then poured into grooves underneath this corrugated structure. A nanocomposite of mat black paint and ZnO/activated carbon is then atomized onto the jute wick, ensuring uniform coating without impeding its inherent capillary action as demonstrated by Saleh et al. (2023) and Abdullah et al. (2023). A tempered glass cover seals the solar still, providing a secure condensing surface with an integrated drainage channel for the collection of distilled water. For accurate temperature monitoring, calibrated iron–constantan thermocouples are positioned thoughtfully around the wick surface at regular intervals. A single thermocouple placed in the center of the condensing glass is sufficient to measure its temperature because of the very small temperature difference across it, as demonstrated by Shanmugan et al. (2023) and Gandhi et al. (2022). The experimental setup, including a solar radiation sensor, is depicted in Figure 1. The paraffin wax utilized in this study has a phase transition temperature of 56–58°C and a specific latent heat of fusion of around 200–220 kJ/kg, which is in close agreement with the temperature window for solar still operation. Extended distillation into the evening is made possible by this temperature range, which enables the PCM to effectively store extra thermal energy during peak solar hours and release it during off-sunshine periods. In contrast to other PCMs frequently used in solar desalination, like stearic acid (~190–200 kJ/kg, 69°C), palmitic acid (~206 kJ/kg, 63°C), and lauric acid (~180–190 kJ/kg, 44°C), paraffin wax exhibits a favorable combination of outstanding material compatibility, cost-effectiveness, appropriate melting range (Ghandourah et al., 2022) and high thermal storage capacity.

Furthermore, depending on formulation, commercial paraffin blends usually provide latent heat values between 170 and 240 kJ/kg. Paraffin wax is a dependable and reproducible thermal storage medium in solar desalination applications because of its minimal supercooling, exceptional thermal cycle stability (Pavithra et al., 2022), and non-corrosive qualities. In light of these characteristics, the chosen paraffin wax has been extensively verified in the literature for passive solar distillation systems. It offers thermal performance that is on par with or better than alternative PCMs. To justify the choice of PCM to improve thermal performance of the solar desalination.

2.1 Study location and climatic conditions

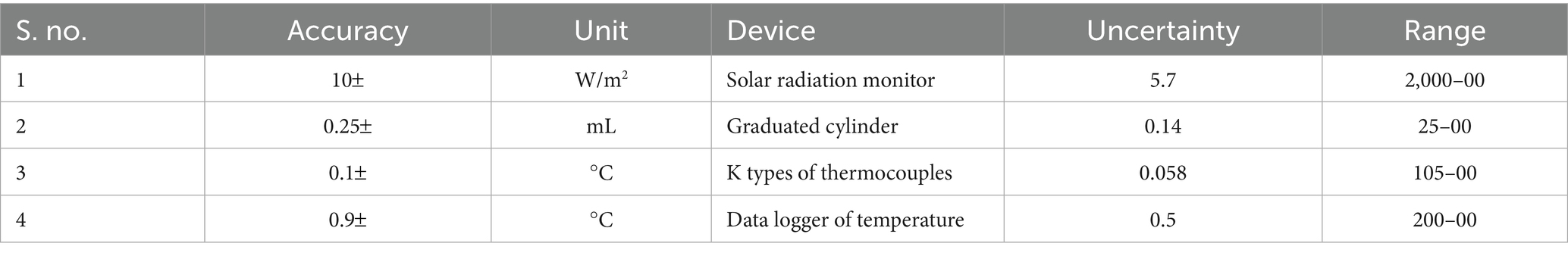

The experimental process was carried out at the Solar Energy Research Laboratory, KLEF University, Vaddeswaram, Guntur District, Andhra Pradesh, India. The site is geographically positioned at approximately 16.4880° N latitude and 80.6480° E longitude. During the observation period (1–30 May 2025), the average solar irradiance was recorded to be around 751 W/m2, using a Kipp and Zonen CMP11 pyranometer for accurate measurement (Abdullah et al., 2022). The mean relative humidity throughout the study duration was about 33%. According to the Köppen climate classification, Vaddeswaram falls under the Tropical Savanna (Aw) category, which is typically marked by clearly defined wet and dry seasons. Experimental error analysis of the solar still is calculated in Table 1.

Table 1. The measurement capabilities, including accuracy, range, and uncertainty, of the instruments utilized in the wick-assisted solar distillation setup.

2.2 Techniques of activated carbon synthesis

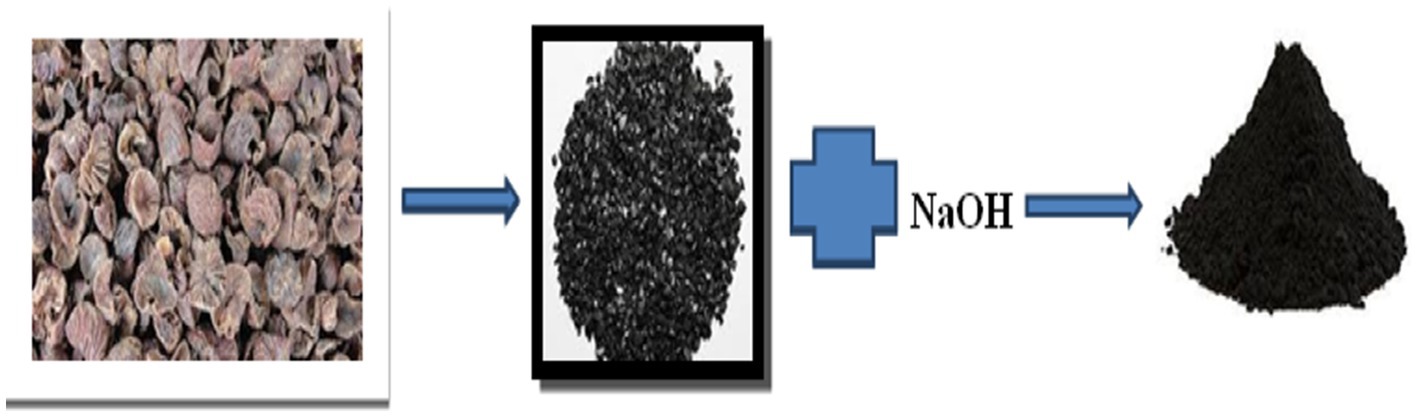

Arecanut shells were collected and air-dried for over 2 days to ensure complete moisture removal. The dried biomass underwent pyrolysis to yield carbonized carbon, confirming complete carbonization. To prevent agglomeration, the carbonized material was pulverized using a mortar and pestle. Chemical activation of the carbonized material was performed using sodium hydroxide (NaOH). An improving the elimination of volatile components and reacting with the carbon matrix, NaOH functions as a potent dehydrating and etching agent during the carbonization process, encouraging the creation of micropores and mesopores. The specific surface area and pore volume of the activated carbon are significantly increased as a result of the formation of a well-connected porous network. Effective solar evaporation depends on both improved water retention and improved interaction with saline water in the wick structure, both of which were supported by the NaOH-activated carbon’s larger surface area in our investigation (Alsaiari et al., 2022). Although KOH is a potent activator as well, it is usually more costly, hygroscopic, and presents more difficulties during post-processing and recovery. However, the main effects of H3PO4 are the introduction of phosphorus-containing surface groups and a distinct pore shape that favors mesopores and macropores, both of which are detrimental to our photothermal application. Therefore, NaOH activation was chosen due to its comparatively easy handling, cheaper processing cost, and less environmental impact, in addition to its capacity to form a large surface area with distinct microporous structures (Essa et al., 2022). Because of these qualities, NaOH is a suitable and environmentally friendly option for creating bio-derived activated carbon that may be used in solar distillation systems.

2.3 Activated carbon synthesis from arecanut shells

A widely available and environmentally beneficial agricultural waste material, arecanut shells, was used in the manufacture of activated carbon. To guarantee that all surface and intrinsic moisture content was removed, fresh arecanut shells were first gathered and allowed to air-dry for 2 days. For pyrolysis to be effective and to produce a high-quality carbon output, this drying stage is essential. After drying, pyrolysis, a thermal breakdown process carried out without oxygen, was applied to the shells. For roughly 2–3 h, the pyrolysis was carried out in a controlled muffle furnace at temperatures between 400 and 500°C. This caused the volatile organic chemicals to break down, resulting in the formation of carbonized material. Complete carbonization was verified by a structural and optical examination, as evidenced by the material’s uniform black color and friability. The carbonized arecanut shells were manually crushed and ground into a fine powder using a mortar and pestle to decrease the particle size and avoid aggregation. The resultant powder was appropriate for adsorption-based applications due to its high surface area and porous structure. Chemical activation, a crucial process to increase the carbon’s surface area and porosity, was the following stage. Since sodium hydroxide (NaOH) effectively creates micropores (Asha et al., 2022), it was chosen as the activating agent. To guarantee uniform mixing, a NaOH solution was added to the fine carbon powder in a 1:3 weight ratio (carbon: NaOH) and thoroughly mixed. To allow for complete chemical interaction and pore development, this mixture was left at room temperature for 12 h. Following soaking, the mixture underwent a second heat treatment (activation) for 2 h at about 700°C in a muffle furnace, which enhanced surface activation and promoted additional porosity growth. After cooling, the activated carbon was regularly cleaned with 0.1 M HCl and deionized water to remove any remaining chemicals and balance the pH. The finished product was kept in airtight containers for later use after being dried overnight at 110°C in a hot air oven.

2.4 ZnO nanoparticle synthesis

Zinc acetate dihydrate was used as the precursor in a straightforward solution-based technique to create zinc oxide (ZnO) nanoparticles. A standard process involved dissolving 0.1 M zinc acetate in deionized water while stirring constantly at room temperature. Sodium hydroxide (NaOH) solution was gradually added dropwise while being constantly stirred until the pH reached around 10–11 to promote the creation of nanoparticles. To encourage ZnO nanoparticle nucleation and development, the solution was kept between 60 and 70°C for 2 h. The successful production of ZnO was shown by the creation of a white precipitate (Abdullah et al., 2021). Centrifugation was used to collect this precipitate, which was then repeatedly cleaned with ethanol and deionized water to get rid of any unreacted ions before being dried for 6 h at 100°C. To improve crystallinity and eliminate any organic residues, the resultant powder was calcined for 2 h at 450°C.

2.5 ZnO–activated carbon composite preparation

The ZnO–Activated Carbon (ZnO–AC) composite was made by physically mixing the synthesized ZnO nanoparticles with the activated carbon in various weight ratios (1:1, 1:2, and 2:1) to examine the impact of composition on performance. A ball mill or the magnetic stirring methods were used for the physical mixing (Panchal et al., 2021). To guarantee that the ZnO particles were evenly distributed throughout the carbon matrix, the appropriate amounts of ZnO and activated carbon were dissolved in ethanol and constantly agitated for four to 6 h (Kumar et al., 2021). The resulting slurry was mixed, filtered, dried at 100°C, and then finely powdered. The ZnO–AC nanocomposite was utilized for additional characterizations, including SEM, XRD, Energy-Dispersive X-ray Analysis (EDAX) spectroscopy, and adsorption or photocatalytic performance investigation, after being kept in a desiccator to stop moisture absorption. As shown in Figure 2, the conversion of carbonized biomass into activated carbon entails a notable decrease in particle size and an increase in porosity, both of which are critical for raising the material’s adsorption efficiency. In water purification applications, the activation process increases the surface area and pore volume by introducing physical and chemical changes that make it easier to capture contaminants. This is especially crucial for treating saline water since dissolved contaminants must be removed using efficient adsorption processes.

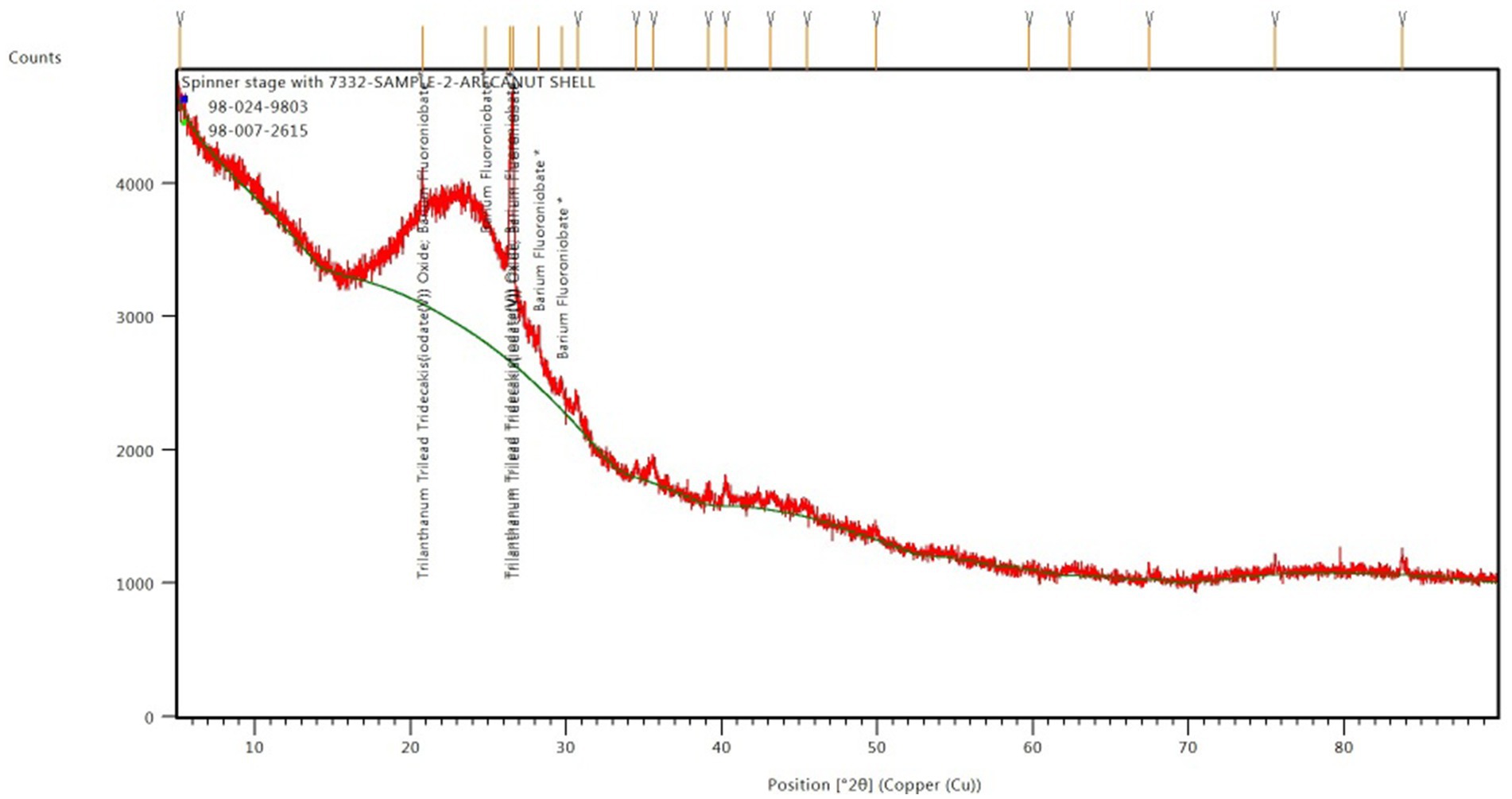

The structural characteristics of the synthesized activated carbon were characterized by X-ray diffraction (XRD) analysis, as illustrated in Figure 3. The amorphous or semi-crystalline structure of the observed broad diffraction peak, which is centered at 2Ɵ = 24°, is characteristic of carbonaceous materials that have undergone thermal treatment. A disorderly arrangement of carbon atoms, which is advantageous for adsorption because it contains more active sites, is implied by the absence of distinct peaks (Shanmugan et al., 2020). The average crystallite dimension was determined using the Debye–Scherrer equation, which links peak broadening with crystallite size. Using a form factor (K) of 0.9, the crystallite size was determined to be roughly 89.7 nm, supporting the assumption that the carbon structure remains amorphous, yet exhibits nanoscale characteristics.

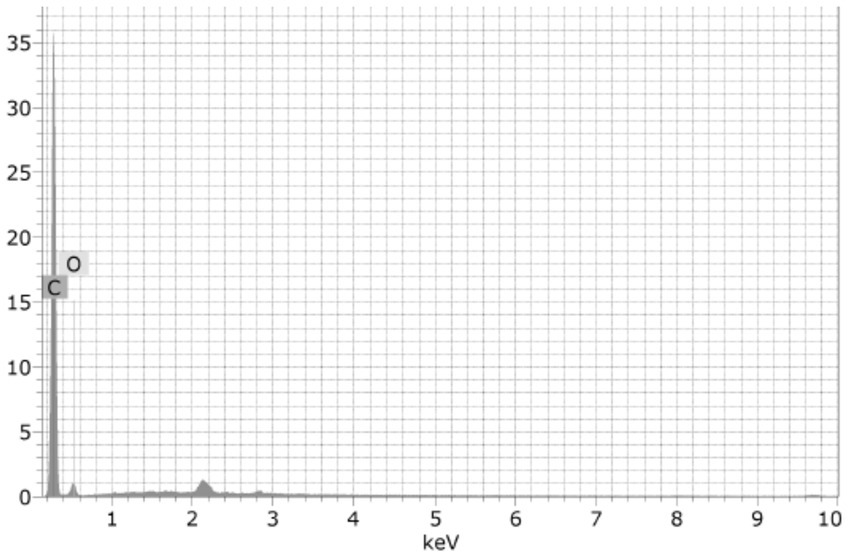

The elemental analysis of the activated carbon is provided by Energy-Dispersive X-ray Spectroscopy (EDX), which is shown in Figure 4. This confirms that carbon predominates with little oxygen present. Surface functional groups like hydroxyl, carbonyl, or carboxyl moieties added after chemical activation with sodium hydroxide (NaOH) may be responsible for the trace oxygen level (Essa et al., 2020). These functional groups can promote adsorption through electrostatic interactions and hydrogen bonding, hence enhancing the affinity of the material toward various ionic or polar pollutants in saline water.

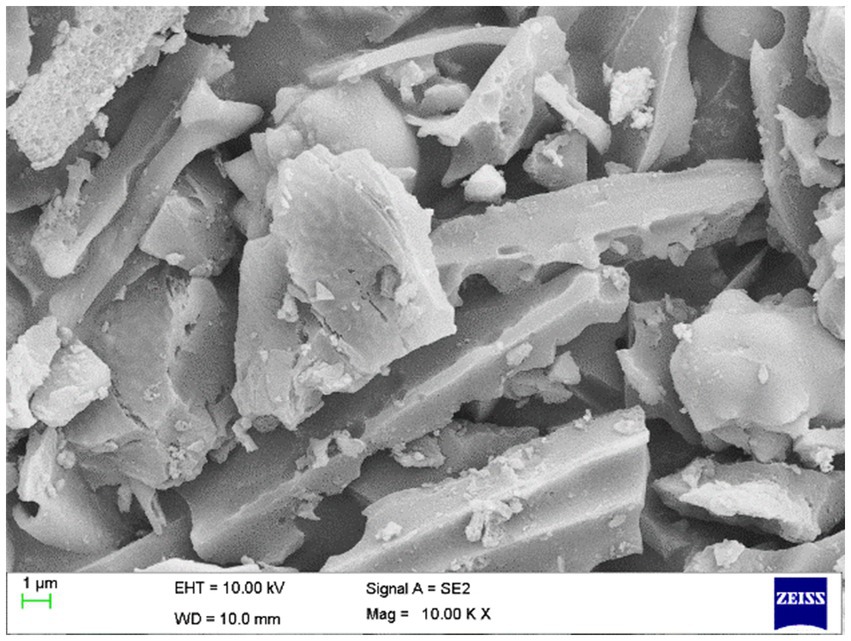

The morphological properties of the activated carbon are further supported by Scanning Electron Microscopy (SEM) pictures (Figure 5). The pictures show an uneven, flaky surface with a lot of porosity, which shows that a micro- and mesoporous structure was successfully formed during activation. These pores increase the material’s adsorption capacity by giving contaminating molecules multiple paths and binding sites. Additionally, mechanical resilience is suggested by the shape, which is beneficial for recurrent use in water treatment systems (Panchal et al., 2021). It is found that the successful synthesis of activated carbon with a large surface area, amorphous microstructure, and advantageous chemical properties is confirmed by the combined XRD, SEM, and EDX investigations. These characteristics are essential for creating economical and effective adsorbents for environmental remediation applications, especially in water purification and desalination systems.

2.6 ZnO nanoparticles

ZnO nanoparticles with a main particle size of 89 nm and a bandgap of 3.9 eV were purchased from Sigma Aldrich. These nanoparticles exhibit remarkable photocatalytic activity due to their exceptionally large specific surface area. An equimolar ZnO/activated carbon nanocomposite was made by carefully blending ZnO nanoparticles with activated carbon. The overall performance of the single-slope wick-type solar still is significantly enhanced by the combined impacts of the activated carbon’s adsorptive/absorptive properties and the nanoparticles’ photocatalytic properties.

ZnO nanoparticles and activated carbon were combined in a 1:1 weight ratio in the updated process. To get rid of any remaining moisture, both materials were first dried for 6 h at 80°C. To create a consistent first blend, the powders were mechanically combined in a ball mill set at 200 rpm for 30 min after drying. The combination was suspended in analytical-grade, 99.9% pure ethanol at a solid-to-solvent ratio of 1 g to 20 mL to improve dispersion and avoid agglomeration. Because it dissolves surface impurities and lowers van der Waals tensions between nanoparticles, ethanol was chosen. After that, the suspension was ultrasonically stirred for 30 min in pulse mode (5 s on, 5 s off) using a probe sonicator (750 W, 20 kHz). Clusters of nanoparticles are broken up in this stage, which also strengthens the interfacial contacts between ZnO and activated carbon. To guarantee even mixing and enhance binding, the suspension was magnetically agitated for 4 h at 500 rpm after sonication. Following extensive mixing, Gandhi et al. (2021) used Whatman filter paper (Grade 41) to filter the mixture, and a hot air oven was used to dry the solid nanocomposite overnight at 80°C. The dry material was then stored in airtight receptacles for future use after being carefully mashed with a mortar and pestle. This thorough technique guarantees reproducibility and facilitates the efficient use of the ZnO–activated carbon nanocomposite in photocatalytic or environmental remediation procedures.

2.7 Improving solar desalination using ZnO-AC

Activated carbon (AC) and ZnO nanoparticles both contribute to improved system performance in solar desalination in different but complementary ways. ZnO nanoparticles efficiently transform solar energy into heat by increasing the temperature at the evaporative surface and speeding up water evaporation because of their broad band gap (~3.3 eV) and strong absorption. ZnO also has photocatalytic action when exposed to sunlight, producing reactive oxygen species that break down organic contaminants and help purify water. When distributed across the wick surface, it also improves heat transfer and evaporation rates by increasing surface roughness and thermal conductivity (Sadasivuni et al., 2020). Activated carbon, on the other hand, greatly increases thermal energy input by absorbing a wide range of solar light due to its highly porous structure and black coloring. In addition to serving as a filtration medium by adsorbing dissolved organics and contaminants, it improves capillary action, guaranteeing constant water delivery to the evaporative surface. Additionally, by reducing heat loss from the wick surface, AC enhances system performance by providing thermal insulation. Even when used separately, these materials are quite effective in solar desalination applications because they each target distinct mechanisms, such as photothermal conversion, adsorption, and thermal regulation.

3 Findings and conversation

3.1 The FRET mechanism, experiment methodology, and climatic parameters

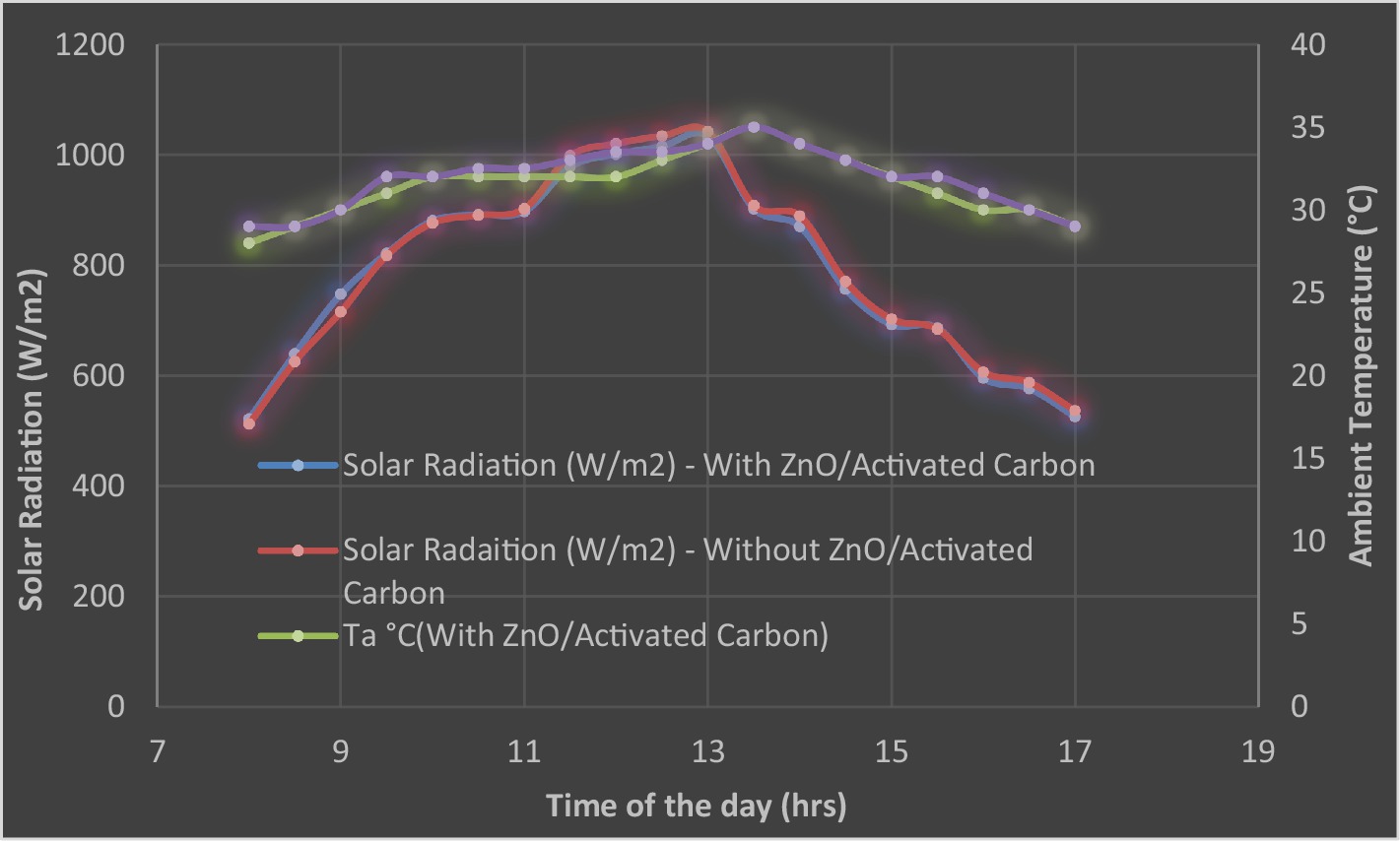

This experimental study, conducted in Andhra Pradesh during May 2025, evaluated a novel solar still designed in two configurations: with and without a ZnO/activated carbon nanocomposite. Throughout the summer period, ambient temperature was continuously monitored using a digital thermometer, while solar irradiance was simultaneously recorded with an Emcon solar radiation monitor. To demonstrate the effectiveness of the FRET mechanism, observational data from 11 May 2025 and 20 May 2025—two representative days encompassing trials both with and without the nanocomposite—were chosen for detailed analysis. Figure 6 visually depicts the recorded environmental parameters, clearly illustrating consistent climatic conditions across trials performed during periods of peak solar radiation.

3.2 Energy transduction via Forster resonance energy transfer

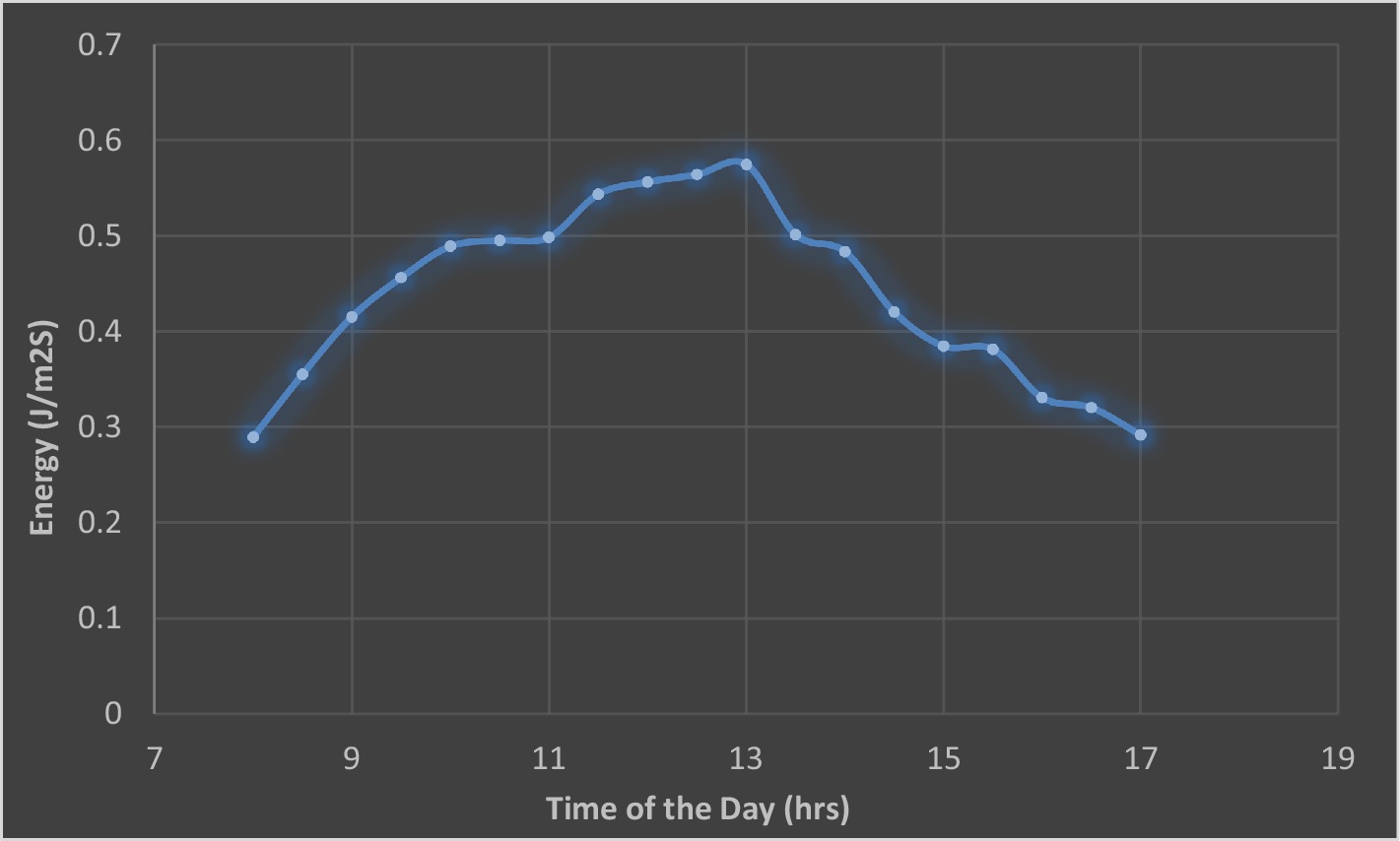

The ZnO nanoparticles and activated carbon, strategically integrated within the wick’s evaporative surface, efficiently capture and assimilate the impinging solar irradiance that permeates the transparent glass cover. Concurrently, the activated carbon component functions as an adsorbent for dissolved ionic species present in the saline feed water, thereby significantly improving the distillate’s purity. Figure 7 delineates the aggregate radiative uptake and adsorption characteristics of the ZnO and activated carbon nanocomposite. Maximal energy assimilation was recorded during a 30-min temporal window, specifically from 12:30 to 1:00 p.m. simultaneously; the FRET mechanism orchestrates efficient energy transduction within the system (Elsheikh et al., 2022). This enables the ZnO nanoparticles to harvest photonic energy both directly from the incident solar flux and indirectly via energy transfer from the proximally located activated carbon.

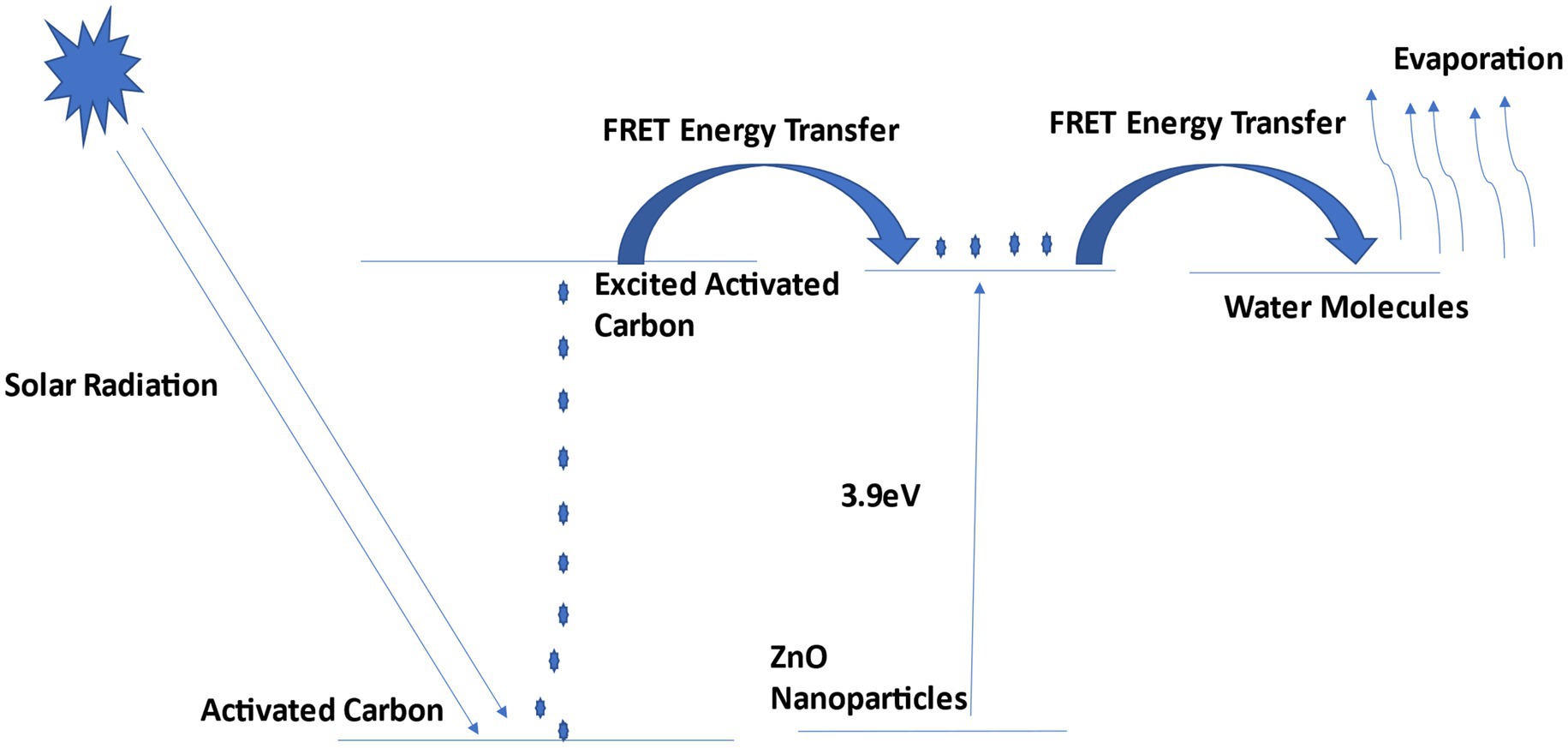

The cascade energy transfer irrigates molecules residing within inclined, balanced, wicking outside and is then mediated through the FR-ET device. Figure 8 shows a schematic illustration of this mechanism. The combined adsorption and solar photothermal absorption capabilities of the ZnO/activated carbon nanocomposite profoundly impact the evaporation kinetics (Elsheikh et al., 2022). The activated carbon effectively sequesters waterborne contaminants, concurrently facilitating energy transfer to ZnO. Additionally, the underlying PCM, which is positioned strategically beneath the corrugated wick and in touch with the tank’s water surface, receives heat energy from the ZnO/activated carbon composite. This energy is continuously used for the paraffin wax’s endothermic phase transition at times of peak isolation. Conversely, exothermic phase change of the paraffin wax in the evening releases stored thermal energy, which is then re-utilized to drive nocturnal water evaporation, thereby extending the distillation cycle.

Because of their superior photoluminescence qualities and potent light absorption, ZnO nanoparticles act as energy donors in the FRET mechanism. ZnO becomes photo-excited and absorbs high-energy photons when exposed to sunlight, which moves electrons from the valence band to the conduction band. Excitons, or electron–hole pairs, are created as a result of this excitation. These excitons then relax and release energy in the form of near-visible fluorescence. The energy acceptor is AC, which has a defect-rich structure and a broad light absorption curve. Non-radiative dipole–dipole energy transfer from ZnO to AC is made possible by the spectral overlap between the emission band of ZnO and the absorption band of AC. This energy is delivered directly to the AC surface and transformed into localized heat rather than being reemitted as light (Panchal et al., 2021). The effectiveness of photothermal conversion is greatly increased by this localized thermal amplification at the water–wick interface. Additionally, the nanocomposite guarantees that ZnO and AC particles are in close proximity to one another, usually less than 10 nm, which is necessary for effective FRET. This closeness maximizes heat localization and reduces energy dissipation. Our findings show that the synergistic interaction increases distillate yield by speeding up the excitation and vaporization of water molecules. ZnO serves as a photoexcited donor in this situation, transferring solar energy that has been absorbed to AC, which serves as an effective heat sink. The enhanced performance of the solar distillation system is largely due to this donor–acceptor interaction.

Using a mix of mechanical stirring and ultrasonication, we made sure that the ZnO nanoparticles were well distributed throughout the PCM matrix. To improve distribution and break up any agglomerates, the nanoparticles were first pre-dispersed in a tiny volume of ethanol using ultrasonication for 30 min. To guarantee homogeneity, this dispersion was then gradually added to the molten PCM while being continuously stirred by magnetic stirring for an hour at a regulated temperature (usually between 70 and 80°C). As a surfactant, a small quantity of polyvinylpyrrolidone (PVP) was used to improve stability and stop re-agglomeration. PVP was selected because of its demonstrated efficacy in steric stabilization and its compatibility with ZnO and PCM nanoparticles (Essa et al., 2021). Effective dispersion and long-term stability of the nanocomposite were demonstrated by the absence of phase separation or sedimentation during heat cycling.

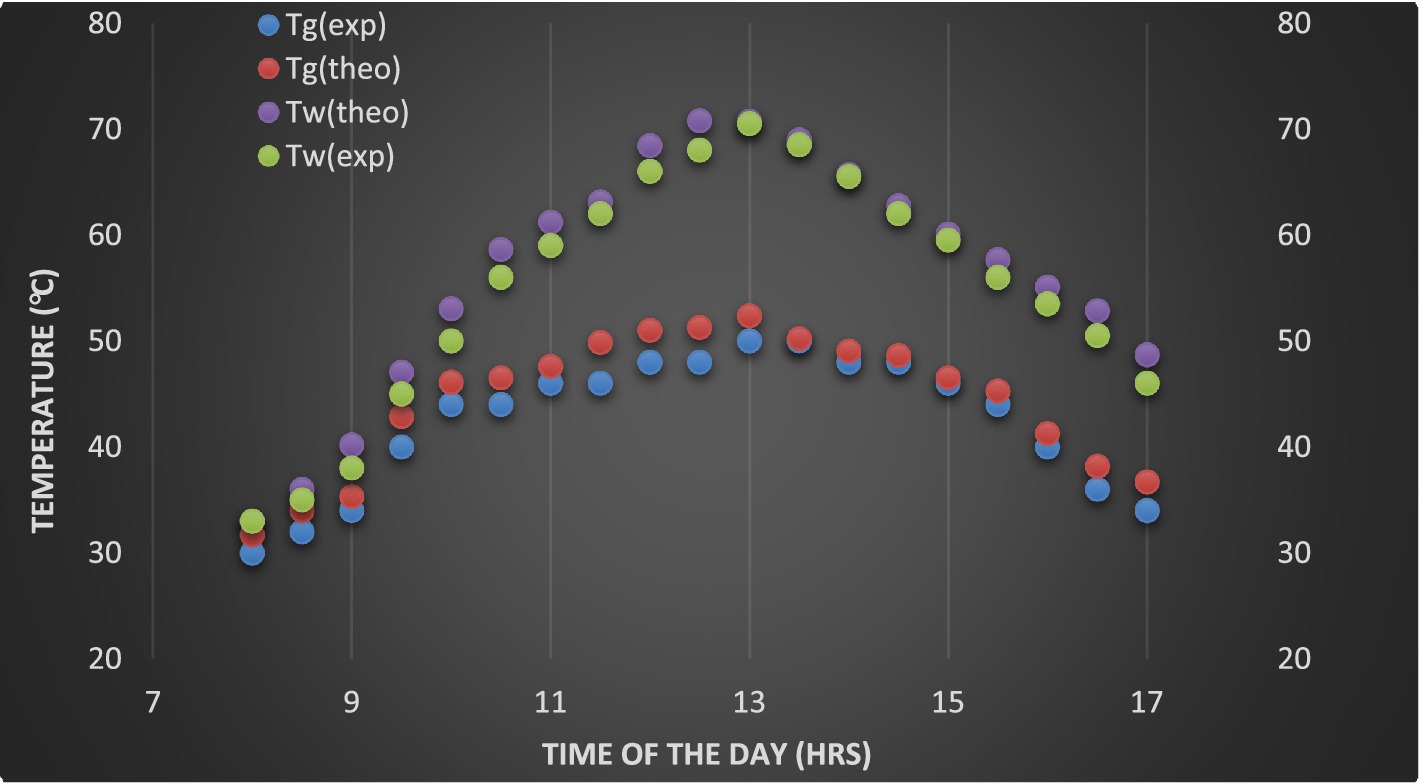

Analytical solution for the Tw − Tg inside angled; floating wick surfaces is shown in Figure 9. This theoretical model has been rigorously validated against experimental observations, demonstrating a strong conjoint trend and minimal discrepancy. This congruence substantiates the model’s suitability for predictive simulations in solar still applications operating under analogous climatic conditions.

The FRET mechanism’s governing Equation 1 is as follows:

3.3 Enhanced evaporation kinetics and heat transfer

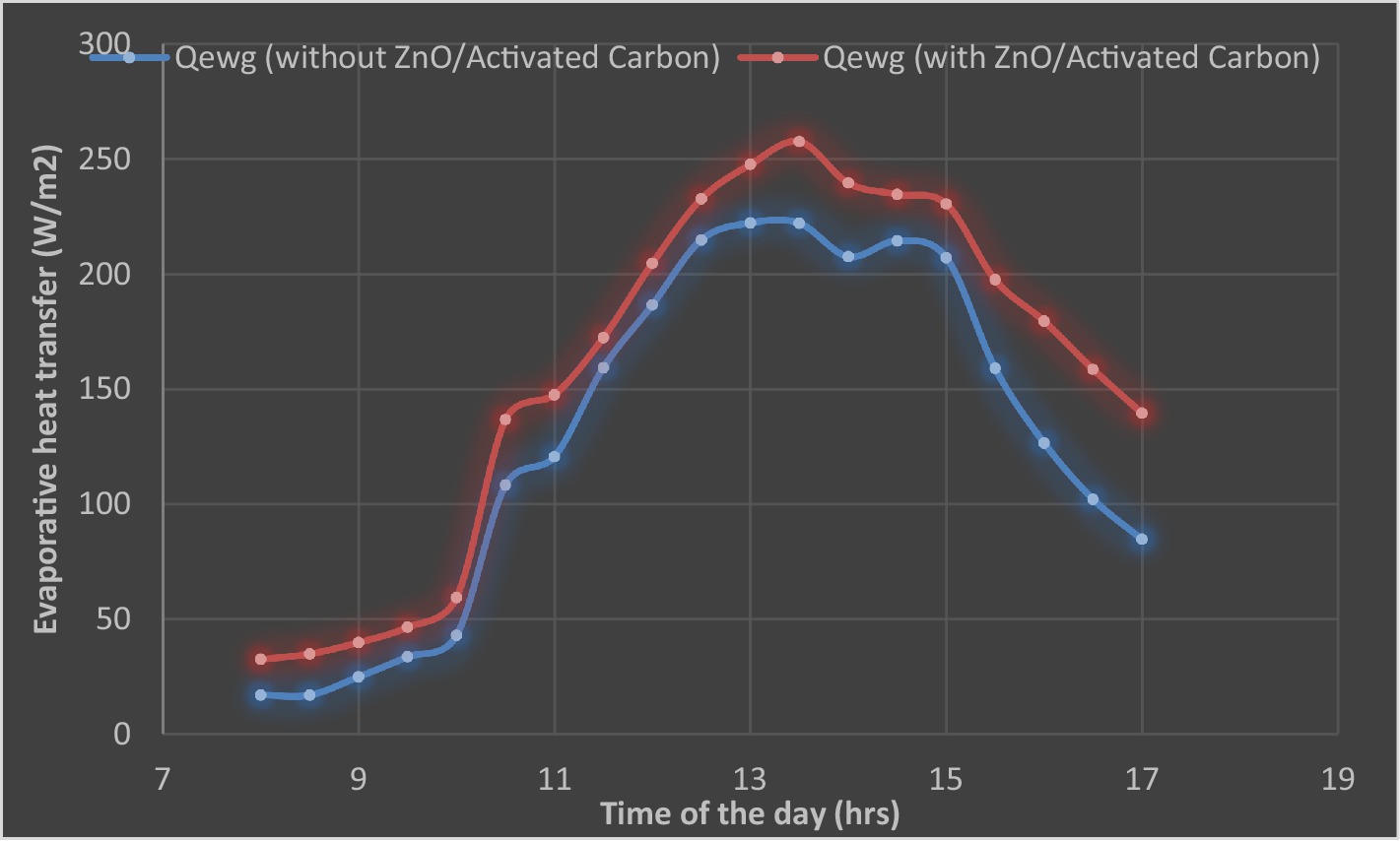

The energy transduced to water molecules accelerates evaporation, notably surpassing the rate observed in control stills lacking ZnO or activated carbon augmentation. Figure 10 quantitatively depicts the evaporative heat transfer coefficient for both the nanocomposite-integrated and control solar stills. The data unequivocally demonstrate a substantially elevated evaporative heat transfer throughout the operational daylight hours in the nanocomposite-enhanced still, Lawrence et al. (2022). The synergistic energy transfer mechanisms responsible for this notable improvement are direct solar absorption by the water molecules and additional energy flux from the integrated ZnO/activated carbon composite irrigating molecules within inclined, balanced wicking outside, which is mediated through the FR-ET phenomenon. Consequently, the presence of the ZnO/activated carbon nanocomposite augments the overall evaporative flux from the distillation unit.

3.4 Enhanced performance metrics and operational dynamics

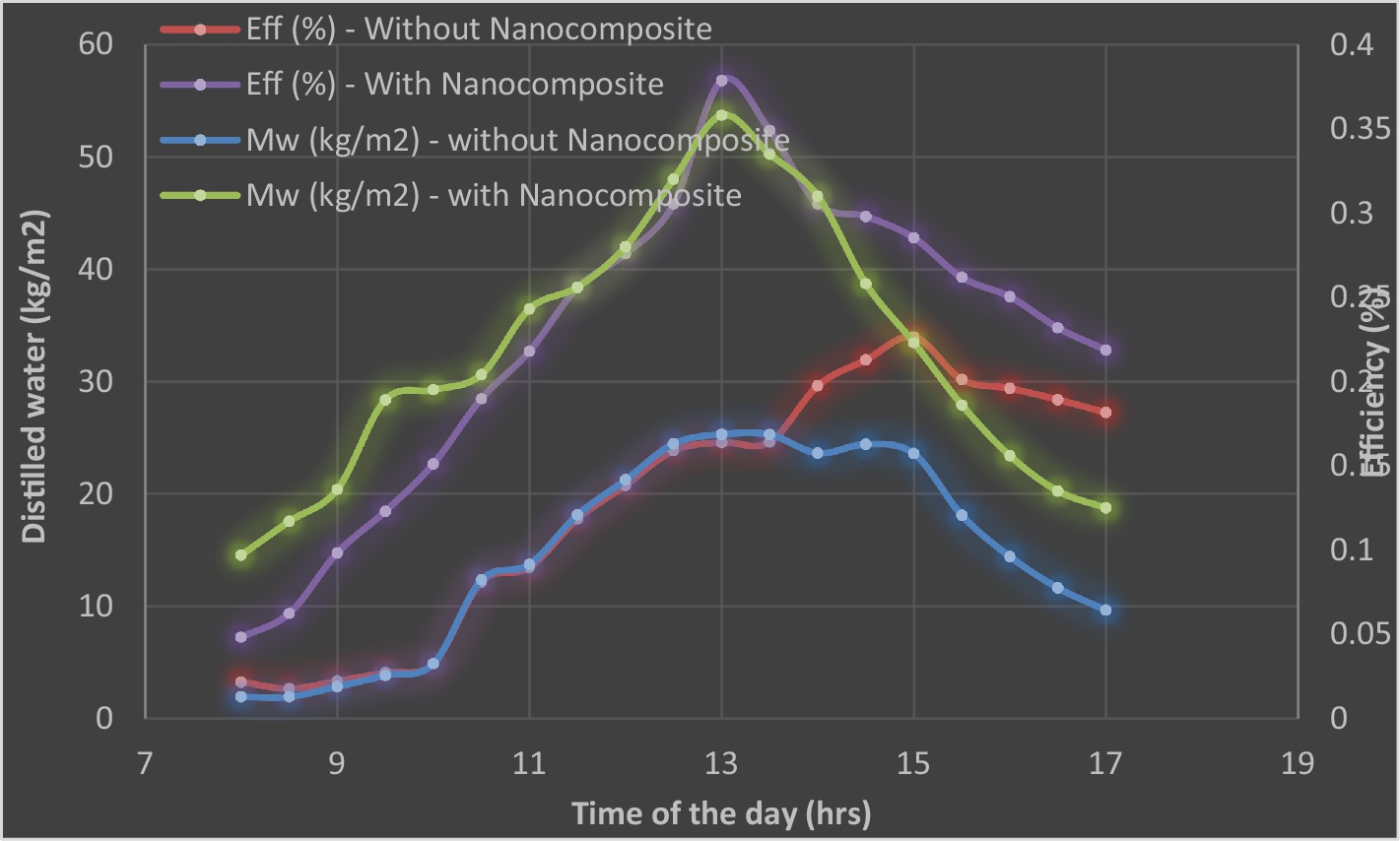

Figure 11 illustrates the superior performance metrics and operational advantages of the nanocomposite-augmented solar still, particularly its immediate concentrate production and enhanced conversion efficiency compared to a conventional control unit. Maximal instantaneous distillate flux was quantified at approximately 0.358 kg/m2 and 0.335 kg/m2 during the 30-min intervals peaking at 13:00 and 13:30 h, respectively. These values consistently surpassed the output of the control, still, underscoring the augmented system’s enhanced productivity. Over a complete 24-h operational cycle, the system achieved a total daily distillate yield of 5.123 L/m2. Notably, approximately 1 L of this output was generated during nocturnal hours, Essa et al. (2020). This nocturnal distillate production is directly attributable to the latent heat of fusion released during the exothermic phase transition of the integrated paraffin Phase Change Material (PCM). The ZnO/activated carbon solar still, specifically when incorporating paraffin wax, demonstrated an impressive average daily efficiency of 42.53%.

The efficiency (η%) was calculated using the following Equation 2:

The optimized implementation of the FRET process within the solar still critically mediates effective energy transduction. This mechanism facilitates the transfer of energy from the AC component toward the ZnO irradiated molecules, thereby profoundly influencing the kinetics of evaporative heat transfer. Additionally, the corrugated morphology of the wick surface, positioned within the water tank, plays a pivotal role in the sequestration of dissolved impurities during the initial phase of the evaporative process. This multi-faceted approach collectively contributes to the system’s superior distillate quality and overall operational robustness.

3.5 Environmental data analysis of wick-type solar stills

Total Dissolved Solids (TDS) were measured using a TDS meter and found to be <10 ppm, indicating high purity. The Electrical Conductivity (EC) was <20 μS/cm. The pH, measured using a pH meter, was in the range of 6.5–7.5. These values comply with the drinking water standards specified by the WHO guidelines and the Indian Standard IS 10,500. The feed water used for the experiments was seawater (Sadasivuni et al., 2020). The initial salinity, measured using a refractometer, was found to be 35,000 ppm for seawater. Systems using PCMs, advanced nanomaterials (Al2O3, CuO, and SiO2), and hybrid additions such as surface coatings, heat storage media, and multi-stage designs are included in this comparison (Panchal et al., 2020). In particular, we point out that even while some of these systems have higher peak productivity, their scalability and cost-efficiency are often compromised by intricate fabrication procedures, pricey components, or multi-step integration. With a thermal efficiency of 42.53% and a daily output of 5.123 L/m2, our system exhibits competitive performance using inexpensive, sustainable ingredients, specifically paraffin wax, activated carbon obtained from biomass, and zinc oxide made using green chemistry. The cost of raw materials is greatly decreased by using mango wood, an agricultural waste product, as a precursor for activated carbon. Additionally, the integration technique eliminates the need for a large structural redesign of traditional solar stills. In the updated manuscript, we have also added a first economic analysis. Based on material cost, manufacturing time, and operational longevity, this research calculates the cost per liter of distilled water (Balan et al., 2011). Over the course of its anticipated three to 4-year operational life, the redesigned solar still is expected to cost between INR 2,500 and 3,000 (about $30 to $35 USD) in total, or INR 0.2–0.3 per liter of freshwater (Suresh and Shanmugan, 2019). In contrast to more intricate nanocomposite systems and traditional solar stills, our concept provides a good balance between cost-effectiveness and performance improvement. This additional economic and comparative analysis, in our opinion, strengthens the system’s practicality and supports its potential for implementation in areas with limited resources and water.

4 Findings

The modified solar still’s thermal and evaporative dynamics were greatly improved by the addition of paraffin-based PCM and a ZnO/activated carbon nanocomposite. This resulted in an impressive distillate output of roughly 5.123 L·m−2·day−1 and an overall thermal efficiency of 42.53%. When compared to the baseline (unmodified) solar still without either nanocomposites or latent heat storage materials, a thorough thermophysical examination that included evaporative heat flow, instantaneous water production rate, and system efficiency consistently showed significantly better performance. The functional importance of FRET as a crucial non-radiative energy relay mechanism that promotes effective photothermal coupling between the saline water interface and the nanomaterial matrix is supported by this notable improvement. To accelerate phase transition rates under solar exposure, the system makes use of the photonic interaction and energy relay channels created by FRET to provide effective thermal gradients. The system’s thermal input capacity was also significantly increased by the use of commercially available ZnO nanoparticles and paraffin wax together with bio-sourced activated carbon made from processed arecanut shells. In addition to increasing thermal conductivity and solar absorptivity, this combination encourages localized heat retention within the ideal temperature range for water vaporization. Crucially, dipole–dipole interactions that promote a collision less, non-radiative energy transfer are how the FRET-mediated mechanism works. In contrast to conduction-based systems, this guarantees continuous stimulation of the saline medium without causing thermal losses or physical resistance. Water molecules are therefore efficiently stimulated within the desired temperature range, encouraging both prolonged and faster etherealization over the course of the day.

Nomenclature

• η = distillation efficiency (%)

• m = mass of distillate collected (kg)

• hfg = latent heat of vaporization of water (kJ/kg)

• I = average solar irradiance (W/m2)

• A = area of the basin (m2)

• t = time duration of operation (s)

• Eads.ac = Absorptions of energy as AC

• Eabs ZnO = Energy absorption of ZnO

• Etrans = Mass of energy transition ZnO-AC

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

MP: Data curation, Project administration, Investigation, Writing – review & editing. NA: Data curation, Conceptualization, Resources, Writing – review & editing. AK: Formal analysis, Writing – review & editing, Conceptualization, Methodology. TS: Validation, Conceptualization, Data curation, Writing – review & editing. NK: Data curation, Investigation, Writing – original draft. RU: Methodology, Validation, Writing – original draft, Software. PS: Methodology, Writing – review & editing, Investigation. SS: Supervision, Formal analysis, Investigation, Methodology, Software, Writing – original draft, Resources, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was supported and funded by the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) (grant number IMSIU-DDRSP2503).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdullah, A. S., Alawee, W. H., Shanmugan, S., and Omara, Z. M. (2023). Techniques used to maintain minimum water depth of solar stills for water desalination–a comparative review. Results Eng. 19:101301. doi: 10.1016/j.rineng.2023.101301

Abdullah, A. S., Omara, Z. M., Alawee, W. H., Shanmugan, S., and Essa, F. A. (2025). Leveraging nanoparticles for sustainable water harvesting: a review of solar still technologies. Results Eng. 25:104128. doi: 10.1016/j.rineng.2025.104128

Abdullah, A. S., Omara, Z. M., Essa, F. A., Alqsair, U. F., Aljaghtham, M., Mansir, I. B., et al. (2022). Enhancing trays solar still performance using wick finned absorber, nano- enhanced PCM. Alex. Eng. J. 61, 12417–12430. doi: 10.1016/j.aej.2022.06.033

Abdullah, A. S., Omara, Z. M., Essa, F. A., Younes, M. M., Shanmugan, S., Abdelgaied, M., et al. (2021). Improving the performance of trays solar still using wick corrugated absorber, nano-enhanced phase change material and photovoltaics-powered heaters. J Energy Storage 40:102782. doi: 10.1016/j.est.2021.102782

Abed, F. M., Ahmed, A. H., Hasanuzzaman, M., Kumar, L., and Hamaad, N. M. (2022). Experimental investigation on the effect of using chemical dyes on the performance of single-slope passive solar still. Sol. Energy 233, 71–83. doi: 10.1016/j.solener.2021.12.060

Ahmed, M. M. Z., Omara, Z. M., Alawee, W. H., Shanmugan, S., and Essa, F. A. (2025). Enhancing solar distiller performance for water desalination: a comparative review of vertical modifications-based techniques. Results Eng. 25:104360. doi: 10.1016/j.rineng.2025.104360

Alasiri, A., and Shanmugan, S. (2025a). Experimental performance assessment of M-shaped solar distillation for efficient thermal energy storage using directional aluminum can configurations. Sep. Purif. Technol. 376:134172. doi: 10.1016/j.seppur.2025.134172

Alasiri, A., and Shanmugan, S. (2025b). The role of Mn2O3-cu NanoPCM in aluminum cans for enhancing thermal performance and freshwater yield of M-shaped basin solar desalination system: an experimental analysis. Sep. Purif. Technol. 377:134267. doi: 10.1016/j.seppur.2025.134267

Almeshaal, M., and Shanmugan, S. (2024). Improving thermal efficiency of solar stills: bioactive nano-PCM and Cramer’s rule analysis. Sep. Purif. Technol. :127119. doi: 10.1016/j.seppur.2024.127119

Alsaiari, A. O., Shanmugan, S., Abulkhair, H., Bamasag, A., Moustafa, E. B., Alsulami, R. A., et al. (2022). Applications of TiO2/jackfruit peel nanocomposites in solar still: experimental analysis and performance evaluation. Case Stud. Therm. Eng. 38:102292. doi: 10.1016/j.csite.2022.102292

Asha, S., Shanmugan, S., Venkateswarlu, M., Meenachi, M., Sangeetha, A., and Rao, M. C. (2022). Thermal potential porous materials and challenges of improving solar still using TiO2/jackfruit peel-enhanced energy storage material. Mater Today Proc 66, 3616–3625. doi: 10.1016/j.matpr.2022.07.142

Awan, H. T. A., Kumar, L., Wong, W. P., Walvekar, R., and Khalid, M. (2023). Recent progress and challenges in MXene-based phase change material for solar and thermal energy applications. Energies 16:1977. doi: 10.3390/en16041977

Balan, R., Chandrasekaran, J., Shanmugan, S., Janarthanan, B., and Kumar, S. (2011). Review on passive solar distillation. Desalin. Water Treat. 28, 217–238. doi: 10.5004/dwt.2011.1742

Elashmawy, M., Ahmed, M. M. Z., Alawee, W. H., Shanmugan, S., and Omara, Z. M. (2024). Scientometric analysis and review of materials affecting solar still performance. Results Eng. 23:102574. doi: 10.1016/j.rineng.2024.102574

Elsheikh, A., Faqeha, H., Hammoodi, K. A., Bawahab, M., Fujii, M., Shanmugan, S., et al. (2025). Integrating predictive and hybrid machine learning approaches for optimizing solar still performance: a comprehensive review. Sol. Energy 295:113536. doi: 10.1016/j.solener.2025.113536

Elsheikh, A. H., Panchal, H. N., Sengottain, S., Alsaleh, N. A., and Ahmadein, M. (2022). Applications of heat exchanger in solar desalination: current issues and future challenges. Water 14:852. doi: 10.3390/w14060852

Elsheikh, A. H., Shanmugan, S., Sathyamurthy, R., Thakur, A. K., Issa, M., Panchal, H., et al. (2022). Low-cost bilayered structure for improving the performance of solar stills: performance/cost analysis and water yield prediction using machine learning. Sustain Energy Technol Assess 49:101783. doi: 10.1016/j.seta.2021.101783

Essa, F. A., Abdullah, A. S., Alawee, W. H., Alarjani, A., Alqsair, U. F., Shanmugan, S., et al. (2022). Experimental enhancement of tubular solar still performance using rotating cylinder, nanoparticles’ coating, parabolic solar concentrator, and phase change material. Case Stud. Therm. Eng. 29:101705. doi: 10.1016/j.csite.2021.101705

Essa, F. A., Elsheikh, A. H., Sathyamurthy, R., MuthuManokard, A., Kandeal, A. W., Shanmugan, S., et al. (2020). Extracting water content rom the ambient air in a double-slope halfcylindrical basin solar still using silica gel under Egyptian conditions. Sustain Energy Technol Assess 39:100712. doi: 10.1016/j.seta.2020.100712

Essa, F. A., Omara, Z. M., Abdullah, A. S., Shanmugan, S., Panchal, H., Kabeel, A. E., et al. (2020). Wall-suspended trays inside stepped distiller with Al2O3/paraffin wax mixture and vapor suction: experimental implementation. J Energy Storage 32:102008. doi: 10.1016/j.est.2020.102008

Essa, F. A., Omara, Z., Abdullah, A., Shanmugan, S., Panchal, H., Kabeel, A. E., et al. (2021). Augmenting the productivity of stepped distiller by corrugated and curved liners, CuO/paraffin wax, wick, and vapor suctioning. Environ. Sci. Pollut. Res. 28, 56955–56965. doi: 10.1007/s11356-021-14669-w

Essa, F. A., Omara, Z. M., Elsheikh, A. H., Shanmugan, S., Abdullah, A. S., and El-Sebaey, M. S. (2024). Innovative configurations for spherical solar distillation: ball rotation and preheating for improved productivity. Case Stud. Therm. Eng. 59:104489. doi: 10.1016/j.csite.2024.104489

Fayaz, H., Rasachak, S., Ahmad, M. S., Kumar, L., Zhang, B., Selvaraj, J., et al. Improved surface temperature of absorber plate using metallic titanium particles for solar still application. Sustain Energy Technol Assess 52, Part A, (2022):102092. doi: 10.1016/j.seta.2022.102092

Gandhi, A. M., Shanmugan, S., Gorjian, S., Pruncu, C. I., Sivakumar, S., Elsheikh, A. H., et al. (2021). Performance enhancement of stepped basin solar still based on OSELM with traversal tree for higher energy adaptive control. Desalination 502:114926. doi: 10.1016/j.desal.2020.114926

Gandhi, A. M., Shanmugan, S., Kumar, R., Elsheikh, A. H., Sharifpur, M., Bewoor, A. K., et al. (2022). SiO2/TiO2 nanolayer synergistically trigger thermal absorption inflammatory responses materials for performance improvement of stepped basin solar still natural distiller. Sustain Energy Technol Assess 52:101974. doi: 10.1016/j.seta.2022.101974

Ghandourah, E. I., Sangeetha, A., Shanmugan, S., Zayed, M. E., Moustafa, E. B., Tounsi, A., et al. (2022). Performance assessment of a novel solar distiller with a double slope basin covered by coated wick with lanthanum cobalt oxide nanoparticles. Case Stud. Therm. Eng. 32:101859. doi: 10.1016/j.csite.2022.101859

Jang, Y. J., Kawaguchi, D., Yamaguchi, S., Lee, S., Lim, J. W., Kim, H., et al. (2019). Enhancing the organic solar cell efficiency by combining plasmonic and Förster resonance energy transfer (FRET) effects. J. Power Sources 438:227031. doi: 10.1016/j.jpowsour.2019.227031

Jathar, L. D., Ganesan, S., and Palanimuthu, L. (2022a). Performance assessment of concave-type stepped desalination unit with nanoparticles and varying water depth: an experimental approach. Int. J. Ambient Energy 43, 5041–5054. doi: 10.1080/01430750.2021.1933589

Jathar, L. D., Ganesan, S., Shahapurkar, K., Soudagar, M. E. M., Mujtaba, M. A., Anqi, A. E., et al. (2022b). Effect of various factors and diverse approaches to enhance the performance of solar stills: a comprehensive review. J. Therm. Anal. Calorim. 147, 4491–4522. doi: 10.1007/s10973-021-10826-y

Jathar, L. D., Nikam, K., Awasarmol, U. V., Gurav, R., Patil, J. D., Shahapurkar, K., et al. (2024). A comprehensive analysis of the emerging modern trends in research on photovoltaic systems and desalination in the era of artificial intelligence and machine learning. Heliyon 10:e25407. doi: 10.1016/j.heliyon.2024.e25407

Kabeel, A. E., Algazzar, A. M., Essa, F. A., et al. (2024). Geothermal and solar energy in water desalination and power generation: comprehensive review. Energy Systems. doi: 10.1007/s12667-024-00685-5

Kumar, R., Chanda, J., Elsheikh, A. H., Ongar, B., Khidolda, Y., Kumar, S. P., et al. (2023). Performance improvement of single and double effect solar stills with silver balls/nanofluids for bioactivation: an experimental analysis. Sol. Energy 259, 452–463. doi: 10.1016/j.solener.2023.05.012

Kumar, R., Maurya, A., Shanmugan, S., Kabeel, A.-E., Zhumatova, A. A., Sarsenbayev, Y., et al. (2024). Use of absorber plate built of ZnO/PVC/bioactivation modified epoxy nanocomposites to improvement of double-effect solar distiller productivity analyzing the energy, exergo-environment and enviro-economical. J. Clean. Prod. 434:139601. doi: 10.1016/j.jclepro.2023.139601

Kumar, T. R., Shanmugan, S., Sundari, G. S., Devi, N. S. M. P. L., Abhiram, N., and Palanikumar, G. (2021). Experimental investigation on the performance of a solar still using SiO2 nanoparticles /Jatrophacurcas L, silicon. Netherlands: Springer.

Kumar, L., Soomro, J., Khoharo, H., and Assad, M. E. H. (2023). A comprehensive review of solar thermal desalination technologies for freshwater production. AIMS Energy 11, 293–318. doi: 10.3934/energy.2023016

Kumar, R., Tripathi, P., Ongar, B., Khidolda, Y., Omara, Z. M., Abdullah, A. S., et al. (2023). Experimental study on double effect solar distiller using bioactivity nanoparticles with analysis of thermo-economic and enviro-economical. Case Stud. Therm. Eng. 47:103045. doi: 10.1016/j.csite.2023.103045

Lawrence, A., Hariharan, C., Shanmugan, S., and Janarthanan, B. (2022). Performance of single slope solar still for socio-economic development in coast locations in India. Int. J. Ambient Energy 43, 5175–5183. doi: 10.1080/01430750.2021.1927838

Mousa, G., Basem, A., Shanmugan, S., Karmiris-Obratański, P., Faqeha, H., Alshareef, R. S., et al. (2024). Harnessing fluorescence resonance energy transfer for improved solar still performance with zinc oxide nanoparticles and activated carbon. Appl. Mater. Today 38:102196. doi: 10.1016/j.apmt.2024.102196

Nakhaei, R., Razeghizadeh, A., Shabani, P., Ganji, J., and Tabatabaee, S. S. (2022). Combination of co-sensitization and Förster resonance energy transfer in natural-synthetic dye sensitized solar cells. Opt. Mater. 131:112690. doi: 10.1016/j.optmat.2022.112690

Omara, Z. M., Ahmed, M. M. Z., Alawee, W. H., Shanmugan, S., and Elashmawy, M. (2024). A comprehensive review of nano-enhanced phase change materials on solar stills with scientometric analysis. Results Eng. 22:102088. doi: 10.1016/j.rineng.2024.102088

Palaniappan, M., El-Shafay, A. S., and Shanmugan, S. (2024). Improving heat retention properties of steeped M-shape basin solar distillers utilizing paraffin RT50-enhanced silver nanoparticles and Manihotesculenta extracts. Desalination 586:117836. doi: 10.1016/j.desal.2024.117836

Panchal, H., Nurdiyanto, H., Sadasivuni, K. K., Hishan, S. S., Essa, F. A., Khalid, M., et al. (2021). Experimental investigation on the yield of solar still using manganese oxide nanoparticles coated absorber. Case Stud. Therm. Eng. 25:100905. doi: 10.1016/j.csite.2021.100905

Panchal, H., Sadasivuni, K. K., Ahmed, A. A. A., Hishan, S. S., Doranehgard, M. H., Essa, F. A., et al. (2021). Graphite powder mixed with black paint on the absorber plate of the solar still to enhance yield: an experimental investigation. Desalination 520:115349. doi: 10.1016/j.desal.2021.115349

Panchal, H., Sadasivuni, K. K., Prajapati, C., Khalid, M., Essa, F. A., Shanmugan, S., et al. (2020). Productivity enhancement of solar still with thermoelectric modules from groundwater to produce potable water: a review. Groundw. Sustain. Dev. 11:100429. doi: 10.1016/j.gsd.2020.100429

Panchal, H., Sadasivuni, K. K., Shanmugan, S., and Pandya, N. (2021). Performance analysis of waste brick magnesia as a storage material in a solar still. Heat Transfer, Wiley Online Library 50, 1799–1811. doi: 10.1002/htj.21956

Pavithra, S., Veeramani, T., Subha, S. S., Kumar, P. J. S., Shanmugan, S., Elsheikh, A. H., et al. (2022). Revealing prediction of perched cum off-centered wick solar still performance using network based on optimizer algorithm. Process. Saf. Environ. Prot. 161, 188–200. doi: 10.1016/j.psep.2022.03.009

Rasachak, S., Khan, R. S. U., Kumar, L., Zahid, T., Ghafoor, U., Selvaraj, J., et al. (2022). Effect of tin oxide/black paint coating on absorber plate temperature for improved solar still production: a controlled indoor and outdoor investigation. Int. J. photoenergy 2022, 1–12. doi: 10.1155/2022/6902783

Sadasivuni, K. K., Pancha, H., Awasthi, A., Israr, M., Essa, F. A., Shanmugan, S., et al. (2020). Ground water treatment using solar radiation-vaporization & condensation-techniques by solar desalination system. Int. J. Ambient Energy 4:1772872. doi: 10.1080/01430750.2020.1772872

Sai, G., Anna, V. R., Swapna, K., Prasad, M. V. K. S., Ch, R. P., Krishna, B. C., et al. (2025). Evaluating the effects of sugarcane juice-mediated ZnO nanofluids on solar light activation for enhancing double-slope solar still performance. Appl. Mater. Today 42:102542. doi: 10.1016/j.apmt.2024.102542

Saleh, B., Ahmed, M. H., Shanmugan, S., Elsheikh, A. H., El-Sebaey, M. S., Stephen, M. T., et al. (2024). Enhancing desalination performance of a stepped solar still using nano-enhanced phase change material and condenser integration. Sol. Energy Mater. Sol. Cells 277:113141. doi: 10.1016/j.solmat.2024.113141

Saleh, B., Essa, F. A., Omara, Z. M., Ahmed, M. H., El-Sebaey, M. S., Stephen, M. T., et al. (2023). Using direct solar energy conversion in distillation via evacuated solar tube with and without nanomaterials. PRO 11:1734. doi: 10.3390/pr11061734

Sangeetha, S., and Shanmugan, S. (2022). Gorjian, experimental evaluation and thermodynamic Gibbs free energy analysis of a double-slope U-shaped stepped basin solar still using activated carbon with ZnO nanoparticles. J. Clean. Prod. 380, Part 2:135118. doi: 10.1016/j.jclepro.2022.135118

Sangeetha, A., Shanmugan, S., and Alasiri, A. (2024). ZnO/nZVI nanoparticle-enhanced double-slope U-shaped solar distillation: a thermodynamic investigation of cephalexin adsorption. Mater Today Sustain 28:100983. doi: 10.1016/j.mtsust.2024.100983

Sangeetha, A., Shanmugan, S., Alrubaie, A. J., Jaber, M. M., Panchal, H., Attia, M. E. H., et al. (2023). A review on PCM and nanofluid for various productivity enhancement methods for double slope solar still: future challenge and current water issues. Desalination 551:116367. doi: 10.1016/j.desal.2022.116367

Shanmugan, S., Djuansjah, J., Ahmadein, M., Alsaleh, N. A., Parsa, S. M., and Elsheikh, A. H. (2023). Chemical potential of different phases inside the pyramid stepped basin solar still through Gibbs free energy. Case Stud. Therm. Eng. 49:103277. doi: 10.1016/j.csite.2023.103277

Shanmugan, S., Essa, F. A., Gorjian, S., Kabeel, A. E., Sathyamurthy, R., and MuthuManokar, A. (2020). Experimental study on single slope single basin solar still using TiO2 nano layer for natural clean water invention. J Energy Storage 30:101522. doi: 10.1016/j.est.2020.101522

Shanmugan, S., Hammoodii, K. A., Eswarlal, T., Selvaraju, P., Bendoukha, S., Barhoumi, N., et al. (2024). A technical appraisal of solar photovoltaic-integrated single slope single basin solar still for simultaneous energy and water generation. Case Stud. Therm. Eng. 54:104032. doi: 10.1016/j.csite.2024.104032

Shanmugan, S., Saminathan, P., and Anandh, R. (2013) Thermal modeling of double slope wick-type solar still with different thickness insulation absorption of wick surface, International Conference on Energy Efficient Technologies for Sustainability IEEE.

Suresh, C., Chithambaram, V., Muthucumaraswamy, R., Praveenkumar, S., Saleh, S. M., Rao, M. C., et al. (2024). Transformative nanofluid solutions: elevating solar still performance for enhanced output. Ain Shams Eng. J. 15:103088. doi: 10.1016/j.asej.2024.103088

Keywords: activated carbon, ZnO nanoparticles, paraffin, FRET mechanism, thermo performa

Citation: Palaniappan M, Alrasheedi NH, Kavitha A, Sangeetha T, Keerthika N, Usha RJ, Selvaraju P and Shanmugan S (2025) Enhanced solar energy absorption in PCM-integrated corrugated wick distillers using ZnO nanoparticles and activated carbon. Front. Water. 7:1651002. doi: 10.3389/frwa.2025.1651002

Edited by:

Laveet Kumar, University of Malaya, MalaysiaReviewed by:

Rubina Bahar, Tunku Abdul Rahman University, MalaysiaSagar Dnyaneshwar Shelare, Priyadarshini College of Engineering, India

Copyright © 2025 Palaniappan, Alrasheedi, Kavitha, Sangeetha, Keerthika, Usha, Selvaraju and Shanmugan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: S. Shanmugan, cy5zaGFubXVnYW0xOTgyQGdtYWlsLmNvbQ==

†Deceased

Murugesan Palaniappan1

Murugesan Palaniappan1 A. Kavitha

A. Kavitha S. Shanmugan

S. Shanmugan