- 1Shanxi Ning Guli New Materials Joint Stock Company Limited, Jinzhong, China

- 2School of Civil Engineering, Nanjing Forestry University, Nanjing, China

- 3College of Marine Science and Engineering, Shanghai Maritime University, Shanghai, China

- 4Department of Applied Physics and Electronics, Umeå University, Umeå, Sweden

- 5College of Civil Engineering and Resource Environment, University of Science and Technology Beijing, Beijing, China

Marine soil–structure interfaces are commonly encountered in marine engineering, where they are inevitably subjected to temperature variations and complex stress conditions, including static, dynamic, and creep loads. However, limited studies have addressed the temperature-dependent mechanical behavior of marine soil–structure interfaces under various loading scenarios. This study introduces a self-developed multifunctional large-scale shear apparatus that enables temperature-controlled testing of marine soil interfaces with various structural materials, including concrete, polymer grids, and polymer layers. The apparatus supports static, dynamic, and creep shear testing under precisely controlled thermal conditions. A series of shear tests were conducted on marine soil–concrete, marine soil–polymer grid, and marine soil–polymer layer interfaces to verify the device’s performance. The test results demonstrate that the apparatus can accurately and reliably capture the mechanical responses of marine soil–structure interfaces under different temperatures and loading modes. Furthermore, the results highlight the significant influence of temperature on the shear behavior of these interfaces, emphasizing the necessity of developing such equipment. The findings offer essential insights for the design, evaluation, and long-term stability of marine engineering structures, supporting the development of practical ocean solutions.

1 Introduction

The building of marine engineering projects requires to adopt different types of construction materials, such as cement mortar, concrete and marine soil, etc (Cardile et al., 2021; Xiao et al., 2022; Zhang et al., 2021a, b). It results in there are many marine soil - structure interfaces in marine engineering applications (Shi et al., 2025a, b; Xia et al., 2021). In general, the marine soil - structure interfaces are the weakest component of marine buildings, and the interface mechanical performance determines the stability of engineering facilities (Arulmoly et al., 2021; Chao et al., 2023; Jin et al., 2022; Morsy et al., 2019). Thus, correct evaluation of the interface mechanical properties response between marine soil and structure is vital.

In real-world marine engineering applications, varying thermal conditions—arising from both elevated environmental temperatures and heat-generating facilities—subject the interfaces between marine soil and structures to temperature-induced loading (Hanson et al., 2015; Jueyendah et al., 2021; Sudarsanan et al., 2018; Zhou et al., 2020). For instance, the initial temperature of oil and gas in subsea pipelines can reach up to 80°C, and during transport, heat is continuously transferred to the surrounding marine soil (Rui et al., 2021a, b). In addition, intense solar radiation and high ambient temperatures in coastal regions can cause the surface temperature of marine structures to rise to 70–80°C (Cai et al., 2020; Florentino et al., 2021; Sampa et al., 2021; Yang et al., 2021). In elevated temperature, the mechanical properties of structure, such as cement mortar, concrete, may change, which has non-negligible influence on the mechanical performance of marine soil - structure interfaces (Liu et al., 2023; Qu et al., 2021; Tincopa and Bouazza, 2021). Also, the change of temperature has non-ignorable impact on the mechanical response of marine soil (He et al., 2021; Wang et al., 2021). This can be mainly attributed to the following two reasons. The variation in temperature can change the liquidity of pore water in marine soil to influence pore water pressure, which leads in the fluctuation of effective stress of marine soil (Li et al., 2022; Xia et al., 2023; Zhang et al., 2021a, b); Furthermore, temperature fluctuations can alter the state of pore-filling cementitious materials within marine soil particles, thereby affecting its microstructure. These thermal effects, combined with changes in the mechanical properties of both the clay and the structure, can produce significant coupling interactions, which in turn markedly influence the mechanical behavior at the clay–structure interface (Bilgin and Shah, 2021; Chao and Fowmes, 2022; Frost and Karademir, 2016). It indicates the pressing demand to develop a temperature – controlled mechanical measurement apparatus on marine soil – structure interfaces.

In marine engineering sites, the stress environment of marine engineering applications is complex. The marine soil-structure interfaces are inevitable to experience the static loading resulted from monotonic stress (Filling construction material, etc.), the dynamic loading induced from cyclic stress (Sea wave, etc.) (Ghavam-Nasiri et al., 2019; Liu et al., 2021; Zeng et al., 2023). Also, in general, the service life of marine engineering applications requires at least 10’s of years (Adil et al., 2022; Zadehmohamad et al., 2022; Zhou et al., 2023). During this period, unlike the short-term deformation caused by rapidly applied monotonic or cyclic shear stresses, the marine soil–structure interface is often subjected to long-term creep deformation under sustained shear stress from overlying engineering loads. The mechanical responses of the interface under different types of stress loading—monotonic, cyclic, and creep—differ significantly (Chen et al., 2022; Hou et al., 2022; Tang et al., 2020). In the existing research, the static, dynamic and creep mechanical performance of marine soil – structure interfaces have been investigated by adopting the methods such as cyclic, monotonic and creep interface direct shear tests respectively (Chao and Fowmes, 2021; Chao et al., 2023; Han and Thakur, 2015; Vieira et al., 2013). However, due to the limitation of large temperature – controlled interface shear apparatus, most of the current investigation about the mechanical performance of marine soil – structure interfaces subjected to different types of stress loading does not consider the influence of temperature. It causes the difficulty of simulating the in-situ marine engineering environment during which the changeable temperature influences the short-term monotonic and cyclic as well as long-term creep mechanical properties of interfaces (Chao et al., 2023; Choi et al., 2021; Fowmes et al., 2017). This highlights the urgent need to develop a shear apparatus capable of performing static, dynamic, and creep tests on marine soil–structure interfaces with precise temperature control.

Most current testing methods for marine synthetics are conducted under constant strain rates, fixed normal stresses, and room temperatures, which do not accurately reflect the complex conditions encountered in real-world applications (Chao et al., 2023; Zeng et al., 2023). Although certain advanced devices have been developed, conventional testing often oversimplifies the actual environmental and stress conditions (Chao et al., 2024c, d). There remains a pressing need for more sophisticated apparatus that can replicate realistic stress histories and environmental loads to better evaluate the mechanical behavior of geosynthetic interfaces (Elbaz et al., 2022; Lin et al., 2024). Among these environmental factors, temperature plays a critical role in influencing interface properties (Chao et al., 2025; Xu et al., 2023). Due to the thermal sensitivity of polymer-based marine synthetics, their mechanical characteristics—such as stiffness and surface hardness—can vary considerably with temperature, directly affecting the interaction behavior with surrounding soils. Studies have shown that increasing temperature typically leads to a significant reduction in the peak shear strength at the soil–geosynthetic interface, highlighting the importance of incorporating temperature control in testing protocols.

This study presents a self-developed multifunctional shear apparatus tailored for investigating soil–structure interfaces in marine engineering applications. The apparatus facilitates static, dynamic, and creep shear tests under precisely controlled temperatures ranging from –5°C to 300°C, simulating the complex thermal–mechanical conditions encountered in marine environments. A comprehensive series of shear experiments was conducted to evaluate the performance and reliability of the device under different loading scenarios. Each core function—including temperature control, static loading, dynamic shear, and cyclic shear capabilities—was independently validated, confirming its suitability for advanced research in marine engineering.

2 Motivation and originality

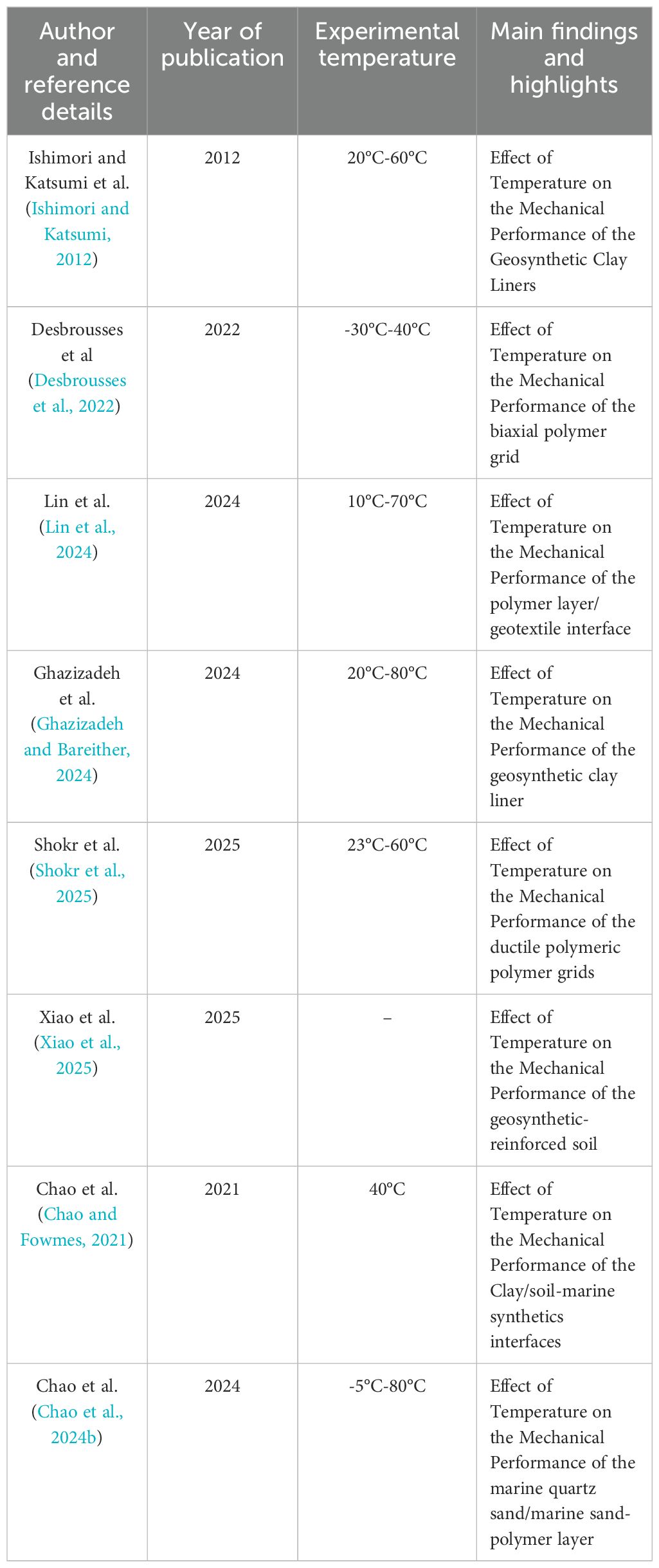

Due to limitations in existing experimental equipment, previous studies have primarily focused on the mechanical behavior of marine soil interfaces under elevated temperatures, while the temperature-dependent responses of sand–geosynthetic interfaces have received comparatively less attention. In fact, both marine soil and sand represent critical geomaterials in marine and coastal engineering, and their interactions with marine synthetics under varying thermal and stress conditions are of great practical importance (Chao and Fowmes, 2022; Chao et al., 2024a, b). In contrast, investigations under low-temperature conditions—especially those involving complex loading scenarios and varying interface stress paths—remain limited. However, in many regions, seasonal fluctuations and extreme climatic events often result in sub-freezing temperatures, posing significant challenges to the mechanical behavior and stability of marine soil. Similarly, the interface performance between marine synthetics and sandy soils under low temperatures is not well understood, despite its relevance to coastal and cold-region infrastructure. More comprehensive studies are needed to capture the thermal-mechanical responses of different geosynthetic–soil interfaces in such environments (Chao and Fowmes, 2021; Chao et al., 2023, 2024d, 2025; Shi et al., 2023). As shown in Table 1, some recent efforts have been made to understand the interface behavior at different temperatures, but comprehensive investigations that consider both mechanical loading and environmental variations are still lacking.

Table 1. Recent studies have investigated the influence of temperature on the mechanical performance of interfaces.

In marine environments, marine soil is subjected to a combination of monotonic loads (e.g., overburden and surface surcharge) and cyclic loads induced by traffic, wave forces, and seismic disturbances. Although the shear behavior of marine soil is generally strain-controlled, most existing experimental studies still utilize shear apparatuses based on displacement-controlled loading. Research using dynamic direct shear and ring shear devices has shown that under cyclic loading, marine soil tends to fail at lower shear stresses compared to monotonic conditions. Similarly, geosynthetic–sand interfaces, which are widely used in reinforced foundation systems, also exhibit complex shear responses under repeated and sustained loading. However, most current testing systems lack temperature control, limiting their ability to simulate real-world environmental conditions such as seasonal freezing or thawing. Since both marine soil and sand in geosynthetic-reinforced systems often remain under long-term service conditions, they may experience not only short-term deformation but also time-dependent shear creep. Traditional displacement-controlled systems are insufficient to capture these long-term behaviors, especially under variable thermal and stress conditions. Therefore, there is an increasing demand for advanced shear testing equipment that integrates both load and temperature control to enable a comprehensive evaluation of the mechanical performance of clay and sand–geosynthetic interfaces under realistic environmental and loading scenarios.

3 Development of the apparatus

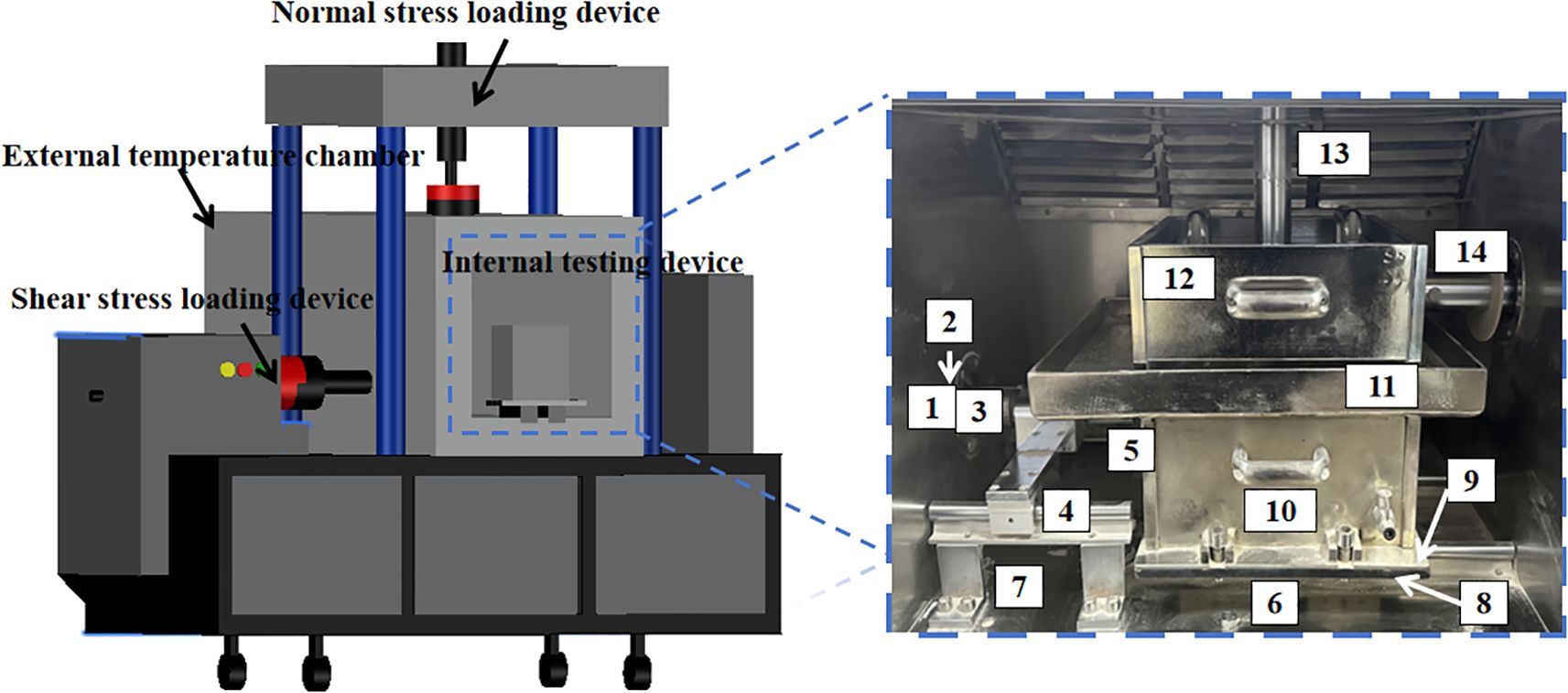

The following section provides a detailed overview of the key components of the self-developed multifunctional, temperature-controlled large-scale interface shear apparatus as shown in Figure 1.

The temperature-controlled large interface dynamic shear apparatus comprises the following key components: (1) a shear loading servo control device for precise control of the loading process; (2) a shear load cell to measure applied shear forces; (3) a horizontal steel shear rod that transmits the shear load; (4) a horizontal sliding block connector linking the shear rod to the moving parts; (5) a horizontal displacement sensor for real-time monitoring of shear displacement; (6) a sliding block and (7) slide rail that guide the shear box movement; (8) a bottom horizontal support and (9) an additional slide rail for structural stability; (10) a bottom shear box and (12) upper shear box forming the main shear interface; (11) a water bath to regulate testing temperature; (13) a normal pressure loading rod to apply vertical stress; and (14) a horizontal block rod for alignment and reinforcement. This integrated system enables accurate and reliable dynamic shear testing of soil–structure interfaces under varying thermal and loading conditions.

The present apparatus demonstrates several clear innovations and unique features compared with previously reported shear testing systems. Unlike conventional devices, it integrates static, dynamic, and long-duration creep testing within a single platform under precisely controlled thermal conditions, enabling comprehensive investigation of marine soil–structure interfaces. The system offers an extended temperature range that allows simulation of diverse marine environmental conditions, and it supports combined loading protocols that have rarely been achieved in earlier studies. Furthermore, the apparatus is designed to accommodate different interface materials—including concrete, polymer grids, and polymer layers—demonstrating its versatility and adaptability. Systematic comparison with existing systems highlights that these features collectively provide a higher level of experimental flexibility, reliability, and functionality, thereby representing a significant advancement in laboratory simulation of temperature-dependent soil–structure behavior.

3.1 Shear load application system

The shear loading system can impose monotonic, cyclic and creep shear stress on marine soil -structure interfaces, which is primarily composed by upper and bottom shear box, horizontal slide rail, and shear loading servo control system. The upper shear box holds the marine soil sample, while the upper surface of the bottom shear box secures the structure using a clamping bar. During testing, the upper shear box remains stationary, and the shear loading servo control system applies stress- or displacement-controlled shear loading to the bottom shear box. In the displacement - controlled shear loading method, the bottom shear box can conduct horizontal movement at a constant displacement velocity along monotonic or cyclic directions, which can impose static or dynamic shear loading on marine soil - structure interfaces; In the stress - controlled shear loading method, the bottom shear box can be imposed shear stress in a certain value for a long duration, which can apply creep shear loading on marine soil - structure interfaces.

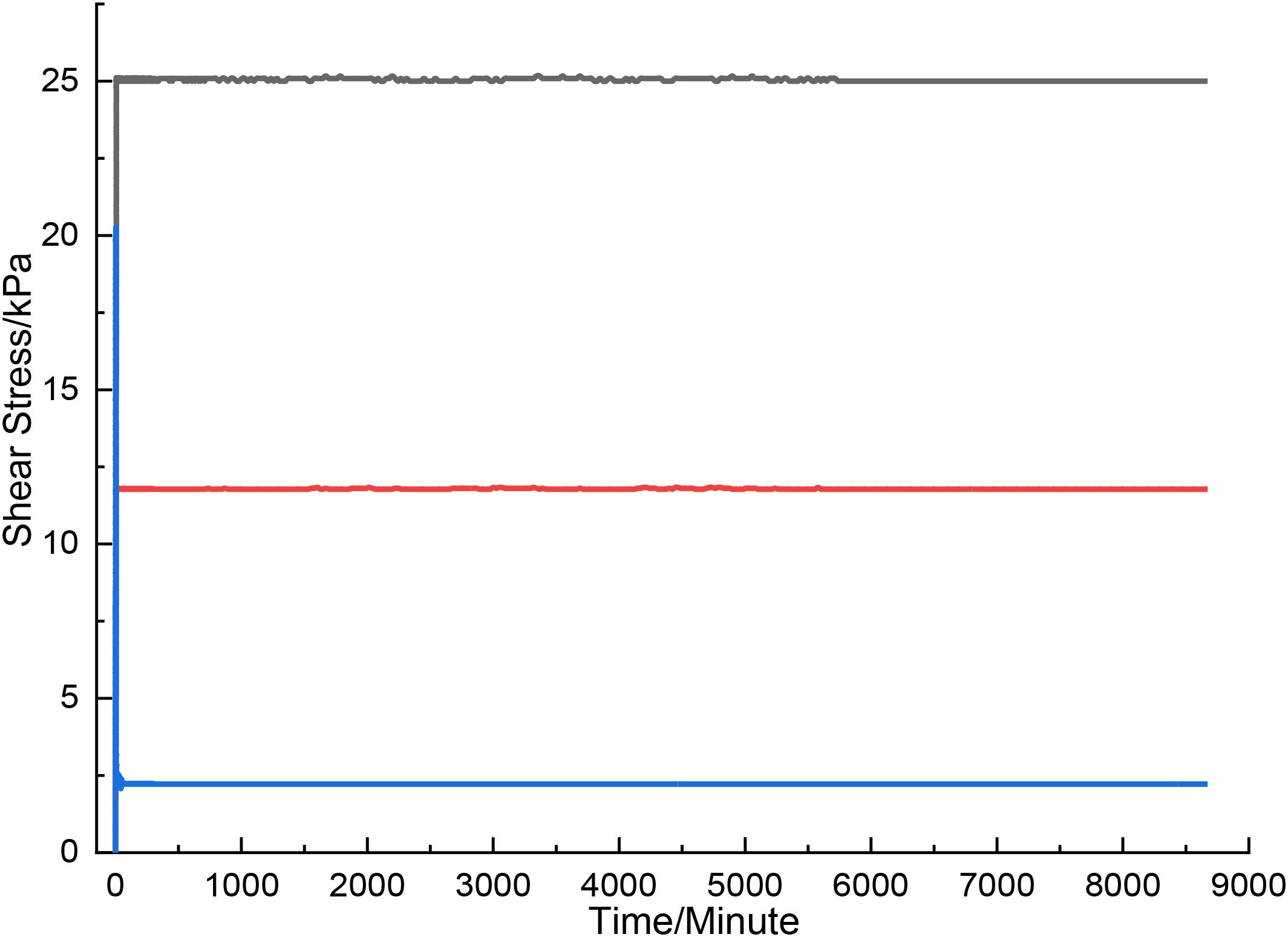

In this research, three different shear stress levels were applied on marine soil - structure interfaces for 6 days in the temperature of 60°C to verify the effectiveness of the shear stress loading system, and the test results are presented in Figure 2.

According to Figure 2, the imposed shear stress keeps stable at the expected value in elapsed time for about 9000 minutes (About 6 days) in the temperature of 60°C. The test results fully validate the functional effectiveness of the shear stress loading system, with preciously controlling the shear stress value during a long time.

3.2 Normal stress loading system

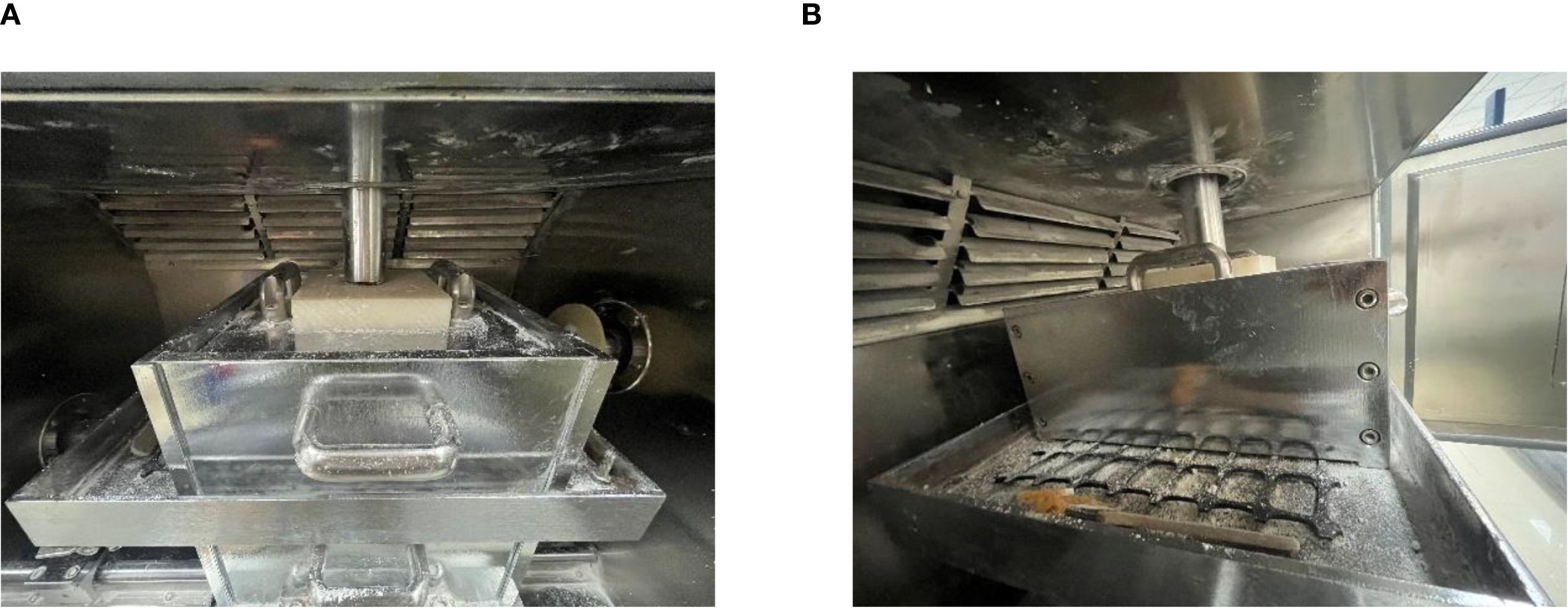

The normal stress loading system is designed to precisely apply and regulate normal stresses on the marine soil–structure interface through a servo-controlled actuator combined with a high-accuracy normal displacement gauge. This dual-feedback system enables the application of normal loads in either displacement-controlled or stress-controlled modes, providing flexibility to simulate different field loading conditions. The system can impose normal displacements up to 200 mm and generate normal stresses up to 40 kN, covering a wide range of stress states relevant to marine geotechnical engineering. The accurate control and measurement capabilities of the system ensure consistent loading conditions during tests, which is essential for capturing the true mechanical response of marine soil interfaces under various normal stress scenarios, as shown in Figure 3.

3.3 Temperature conditioning system

The temperature controlling system is mainly composed of a heating plate, power cable, temperature sensor cable, temperature-adjusting device. The heating plate is inside the bottom shear box underneath the marine soil-structure interface, and the power cable is connected to the temperature - adjusting device. The temperature probe of temperature sensor cable is placed inside the interlayer of structure, and the temperature - adjusting device can real-timely adjust the temperature of heating plate based on the measured interface temperature transferred by the temperature sensor cable. The automatic temperature controlling system can adjust the temperature of marine soil - structure interfaces to keep stable at a certain value (-5°C~300°C) for a long duration (7 days) and the control accuracy within 0.1 °C.

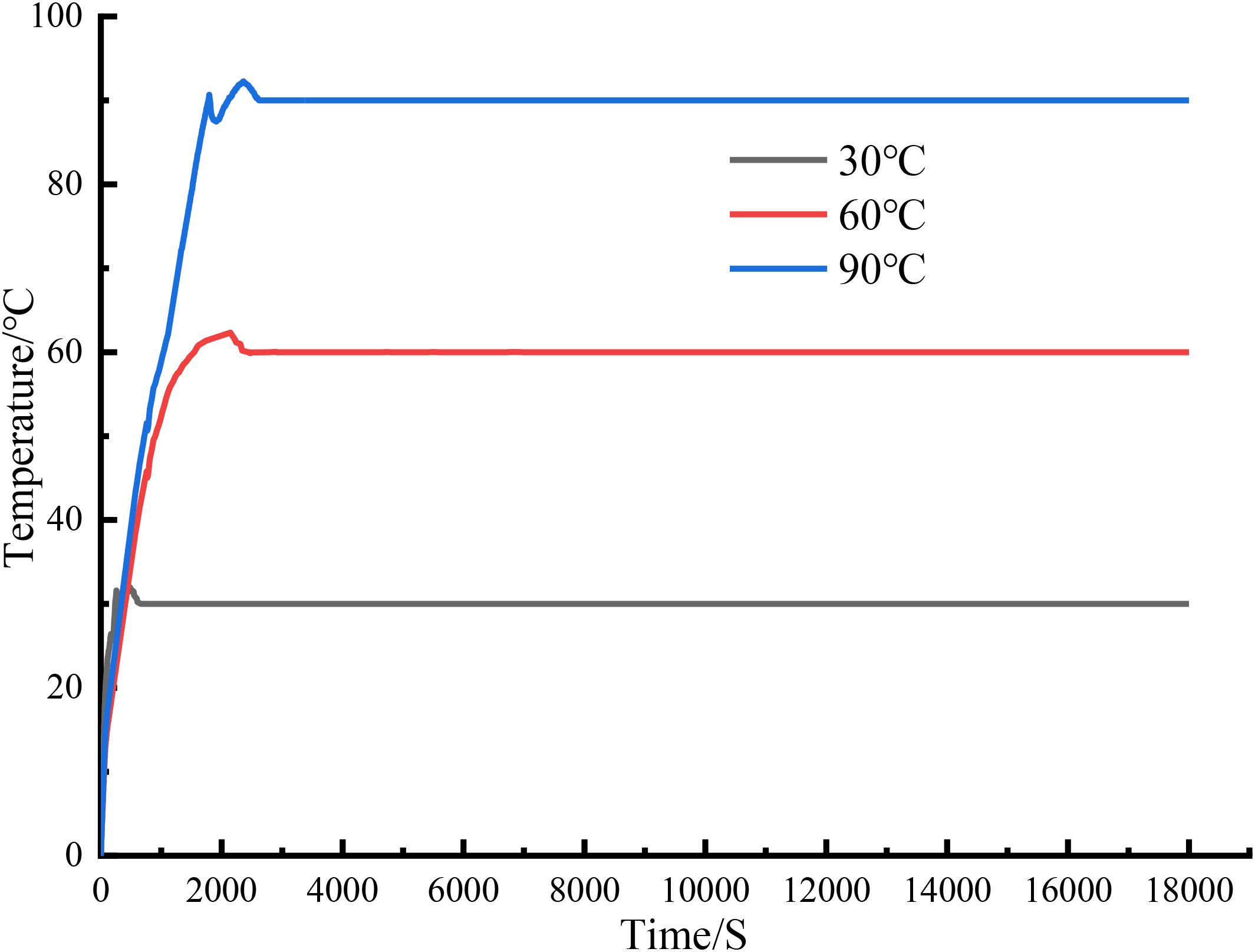

In this study, the temperature of marine soil–structure interfaces were maintained at three stable levels (30°C, 60°C, and 90°C) for seven days to verify the reliability of the automatic temperature control system. The test results are shown in Figure 4.

According to Figure 4, the automatic temperature - controlled system can adjust the experimental temperature at the expected value (30°C, 60°C, 90°C) for a long duration (About 7 days). The fluctuation of temperature is controlled within 0.2°C. The test results strongly validate the functional effectiveness of the automatic temperature - controlled system.

3.4 System for data acquisition and test management

The System for data acquisition and test management is designed to continuously record real-time test parameters—including horizontal and vertical shear displacement and stress, as well as temperature—while managing the entire test procedure. This system primarily consists of horizontal and normal shear displacement gauges, horizontal and normal shear stress sensors, temperature transducers, and integrated data processing and test control software. The displacement gauges have a maximum measurement range of 100 mm with a resolution of 0.002 mm, enabling highly precise displacement monitoring. The temperature sensors cover a measurement range from 15°C to 150°C, with an accuracy of 0.01°C, ensuring reliable thermal data acquisition. Shear stress sensors can measure up to 40 kN with a precision of 0.1 kN, allowing accurate stress recording. Together, these components enable comprehensive monitoring and precise control of the shear tests, which is critical for obtaining valid and reproducible experimental results.

3.5 Overall function

The self-developed large interface shear apparatus is specifically designed to simulate and evaluate the mechanical behavior of marine soil–structure interfaces under complex loading and environmental conditions. It can accurately apply monotonic, cyclic, and creep shear stresses while maintaining precise temperature control across a wide range from -5°C to 300°C. This capability enables comprehensive testing of interface responses under static, dynamic, and long-term creep conditions, which are critical for understanding the performance and durability of marine engineering structures. The apparatus accommodates various interface types commonly encountered in marine geotechnical applications, including cement mortar–marine soil, concrete–marine soil, and steel plate–marine soil interfaces. Its robust design and versatile loading functions provide a reliable platform for investigating the coupled effects of mechanical loading and temperature variations, offering valuable insights to improve the design and safety assessment of marine infrastructure.

4 Experimental program

4.1 Experimental materials

Using the cement mortar–marine soil interface as a case study, a series of static, dynamic, and creep shear tests were conducted at various temperatures to thoroughly evaluate the functionality and stability of the self-developed apparatus. In these tests, the marine soil had a density of 1.75 g/cm³ and an optimum water content of 9.65%.

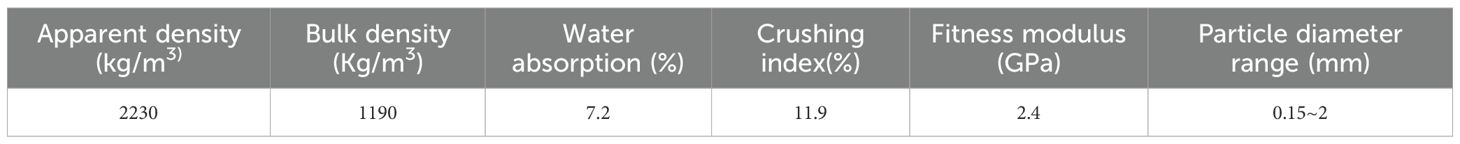

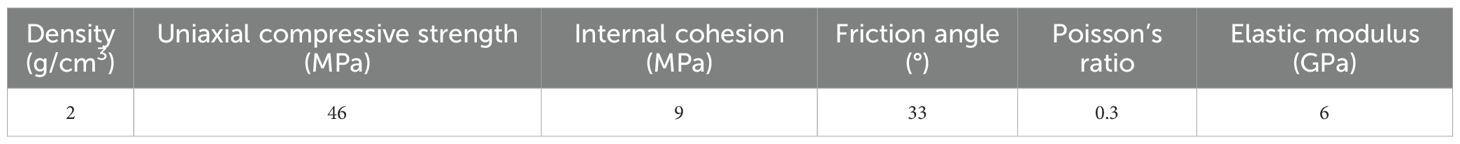

In this study, sustainable cement mortar was used with a full (100%) replacement ratio. The sustainable aggregate was sourced from recycled concrete waste. The sustainable aggregate is prepared by the following procedure: (1) The intact cement mortar block with the strength grade of C30 was prepared; (2) The intact cement mortar block was broken up; (3) The cement mortar particles with the diameter ranging from 0.15 mm to 2 mm were sieved; (4) The sieved cement mortar particles were adopted as the sustainable aggregates for the cement mortar. The basic parameters of the sustainable cement mortar particles are listed in Table 2. No.52.5 Portland cement, water and the prepared sustainable aggregates were mixed together, with the mass ratio of 0.6:0.3: 1, to prepare the sustainable cement mortar. The basic properties of the prepared sustainable cement mortar are demonstrated in Table 3.

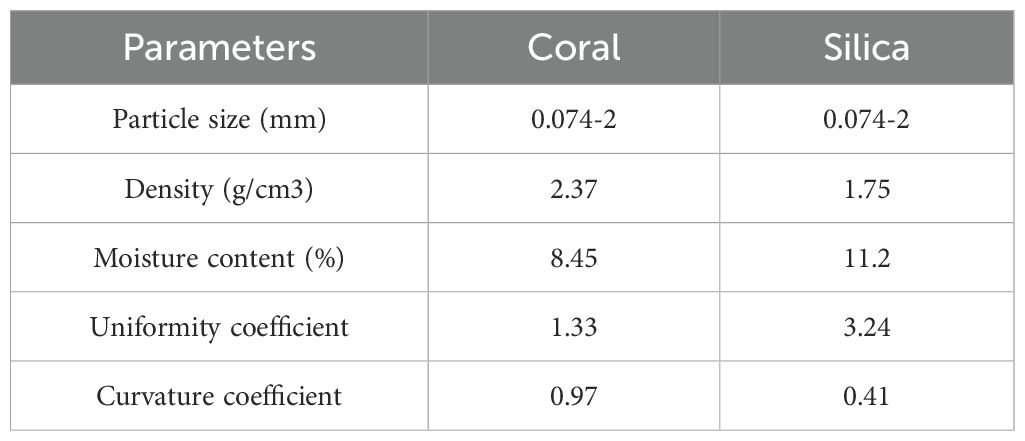

To evaluate the performance of the developed apparatus, a series of shear tests were carried out using different configurations involving three types of marine synthetics in contact with marine coral sand and marine silica sand, including polymer layers and polymer grids. The fundamental properties of the selected marine synthetics and soils used in the experimental program are summarized in Tables 4, 5, respectively.

4.2 Preparation of samples

The cement mortar sample was cut to 460 mm by 280 mm and secured to the bottom shear box with a clamp. The upper shear box was positioned above the mortar and filled with marine soil, prepared at optimal moisture and density, up to 75 mm height. During testing, the upper box remained fixed while shear was applied by moving the bottom box, creating shear stress at the marine soil–cement mortar interface.

The geosynthetic specimen, cut to 460 mm × 280 mm according to ASTM D6072, was clamped onto the bottom shear box using a fixing bar. The upper shear box was then positioned above it, leaving a 2 mm gap between the two boxes. Soil was placed in the upper box in three equal layers (each 25 mm thick), compacted lightly 16 times per layer at optimum moisture content and density following Proctor test standards. Shearing was achieved through the relative movement of the two shear boxes. To minimize frictional interference, the side walls of the upper box along the shear direction included 4 mm gaps, allowing the geosynthetic to pass without contact. The perpendicular side walls remained closed to prevent soil leakage. The shearing rate was determined based on specific test conditions.

4.3 Experimental scheme

This study conducted three types of temperature-controlled shear tests—static, dynamic, and creep—on marine soil–cement mortar interfaces to evaluate their mechanical responses under varying thermal and loading conditions. In addition, similar shear tests were performed on two typical geosynthetic–soil interfaces: polymer grid–marine coral sand and polymer layer–marine silica sand. These configurations represent common interface types in marine and coastal engineering applications. The tests aimed to investigate the temperature-dependent behavior of each interface type and assess the influence of soil type and geosynthetic characteristics on interface shear performance under different stress conditions. The selection of experimental parameters, including temperature range and normal stress, is supported by previous studies (Chao et al., 2024b, d, 2025; Chen et al., 2023; Lin et al., 2024; Xu et al., 2023), ensuring that the chosen values are consistent with widely accepted practices in marine engineering.

4.3.1 Temperature-controlled static direct shear test

Temperature-controlled monotonic direct shear tests on marine soil–cement mortar interfaces were carried out under normal stresses of 25, 50, and 100 kPa, following a consolidated undrained shear procedure. The interface temperature was maintained constant at 40°C, 100°C, or 200°C throughout each test. The procedure involved installing the marine soil and cement mortar samples, stabilizing the interface temperature, and consolidating the interface under normal stress for 12 hours. Next, undrained shearing was carried out at a steady displacement rate of 1 mm/min until reaching a shear displacement of 100 mm. These tests were designed to confirm the device’s ability to control temperature and apply monotonic shear loading.

Temperature-controlled monotonic direct shear tests were conducted on the interface between polymer grid and marine coral sand under normal stresses of 50 and 150 kPa. The interface temperatures were maintained constant at -5°C, 20°C, 60°C, or 80°C throughout each test. The testing procedure included preparing and installing the polymer grid and coral sand specimens, stabilizing the target interface temperature, and applying the selected normal stress for a 4-hour consolidation period. Subsequently, undrained monotonic shearing was performed at a constant displacement rate of 2 mm/min until the shear displacement reached 120 mm. These tests aimed to evaluate the interface shear behavior under different thermal and stress conditions, and to verify the performance of the apparatus in maintaining temperature stability and applying monotonic shear loading.

4.3.2 Dynamic direct shear tests conducted under controlled temperature conditions

Dynamic direct shear tests conducted under controlled temperature conditions on marine soil–cement mortar interfaces were performed under normal stresses of 50, 100, and 150 kPa, with temperatures set at 40°C, 100°C, and 200°C respectively, following a consolidated undrained shear protocol. The test procedure was as follows: first, the cement mortar and marine soil samples were assembled; next, the interface temperature was set to the target value and maintained throughout the test; then, the interface was consolidated under the applied normal stress for 12 hours; finally, shear loading was applied at a constant displacement rate of 1 mm/min until reaching 3 mm displacement in one direction, followed by shearing in the opposite direction with the same parameters. This is one shear cycle. Total 10-time shear cycles were conducted. The temperature-controlled dynamic shear experiments were to test the functionality of temperature - controlling and cyclic shear loading for the developed apparatus.

Dynamic direct shear tests under controlled temperature conditions were conducted on polymer layer–marine siliceous sand interfaces, subjected to normal stresses of 50 and 150 kPa, with interface temperatures set at -5°C, 20°C, 60°C, and 80°C. The tests followed a consolidated undrained shear protocol. The procedure included the following steps: first, the polymer layer and marine siliceous sand specimens were prepared and installed; second, the interface temperature was adjusted to the target level and kept stable throughout the test; third, the interface was consolidated under the applied normal stress for 8 hours; finally, cyclic shear loading was applied at a constant displacement rate of 0.5 mm/min until reaching a displacement of 5 mm in one direction, followed by reverse shearing under the same parameters. Each test involved a total of 20 shear cycles. These temperature-controlled dynamic shear tests were performed to validate the apparatus’s capability in maintaining thermal stability and enabling repeated shear loading.

4.3.3 Temperature-regulated creep shear tests

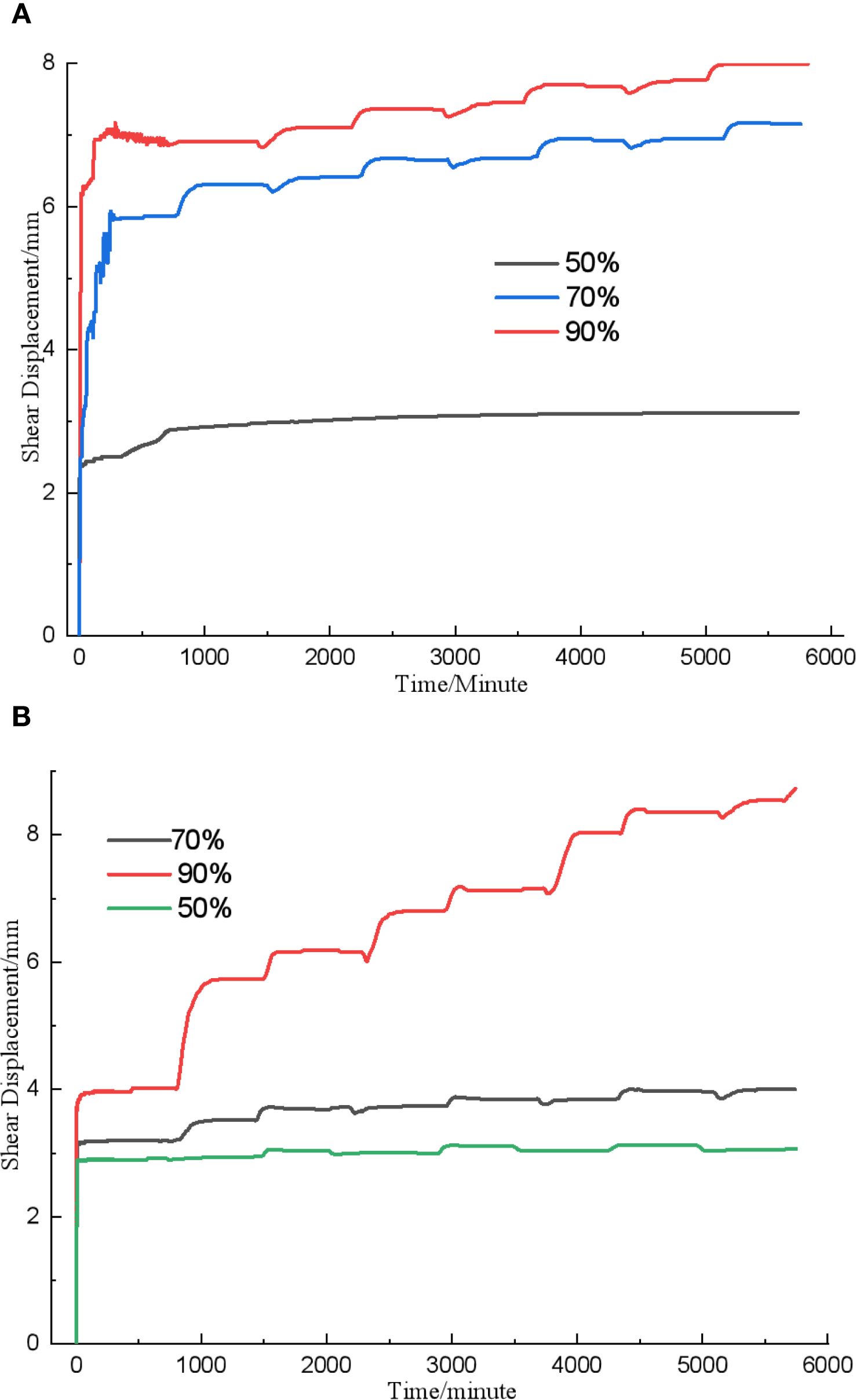

Temperature-controlled creep shear tests on marine soil–cement mortar interfaces were conducted under a normal stress of 25 kPa. The creep shear stress levels were set at 50%, 70%, and 90% of the monotonic peak shear strength corresponding to 25 kPa normal stress, with temperatures maintained at 60°C and 200°C. The procedure included installing the cement mortar and marine soil samples, stabilizing the interface temperature at the target value, consolidating under 25 kPa normal stress for 12 hours, then applying and maintaining a constant shear stress throughout the test. The tests continued until interface failure or a maximum duration of 6 days. These creep shear tests verify the temperature control and creep loading capabilities of the developed apparatus.

Temperature-controlled creep shear tests on polymer grid–marine siliceous sand interfaces were conducted under normal stresses of 50 and 150 kPa. The creep shear stress levels were set at 50%, 70%, and 90% of the monotonic peak shear strength corresponding to each normal stress, with interface temperatures maintained at -5°C, 20°C, 60°C, and 80°C. The test procedure involved assembling the polymer grid and marine siliceous sand specimens, stabilizing the interface temperature at the target value, consolidating under the applied normal stress for 4 hours, and then applying and maintaining a constant shear stress throughout the test duration. The tests were continued until interface failure or a maximum duration of 2 days was reached. These creep shear tests were designed to verify the temperature control and creep loading functions of the developed apparatus.

The detailed experimental plan is presented in Table 6.

5 Results analysis

5.1 Temperature-regulated monotonic direct shear test

Figure 5 shows the results of the temperature-controlled monotonic direct shear tests conducted on marine soil–structure (cement mortar) interfaces.

Figure 5. Temperature-controlled interface monotonic direct shear test results. (A) Normal Pressure 25 kPa. (B) Normal Pressure 50 kPa. (C) Normal Pressure 100 kPa.

Figure 5 clearly demonstrates that temperature plays a critical role in influencing the shear stress–displacement behavior of marine soil–cement mortar interfaces. Under identical normal stress conditions, the static mechanical response of the interface varies noticeably with changes in temperature. Generally, an increase in temperature leads to a reduction in the peak shear strength. For instance, at a normal stress of 25 kPa, the peak shear strength decreases from 23.6 kPa at 40 °C to 15.9 kPa at 100 °C, reflecting a substantial weakening effect. This pronounced sensitivity to temperature emphasizes the necessity of employing a temperature-controlled shear testing system to accurately characterize interface behavior under varying thermal conditions, which is especially important for marine and marine engineering applications where temperature fluctuations are common.

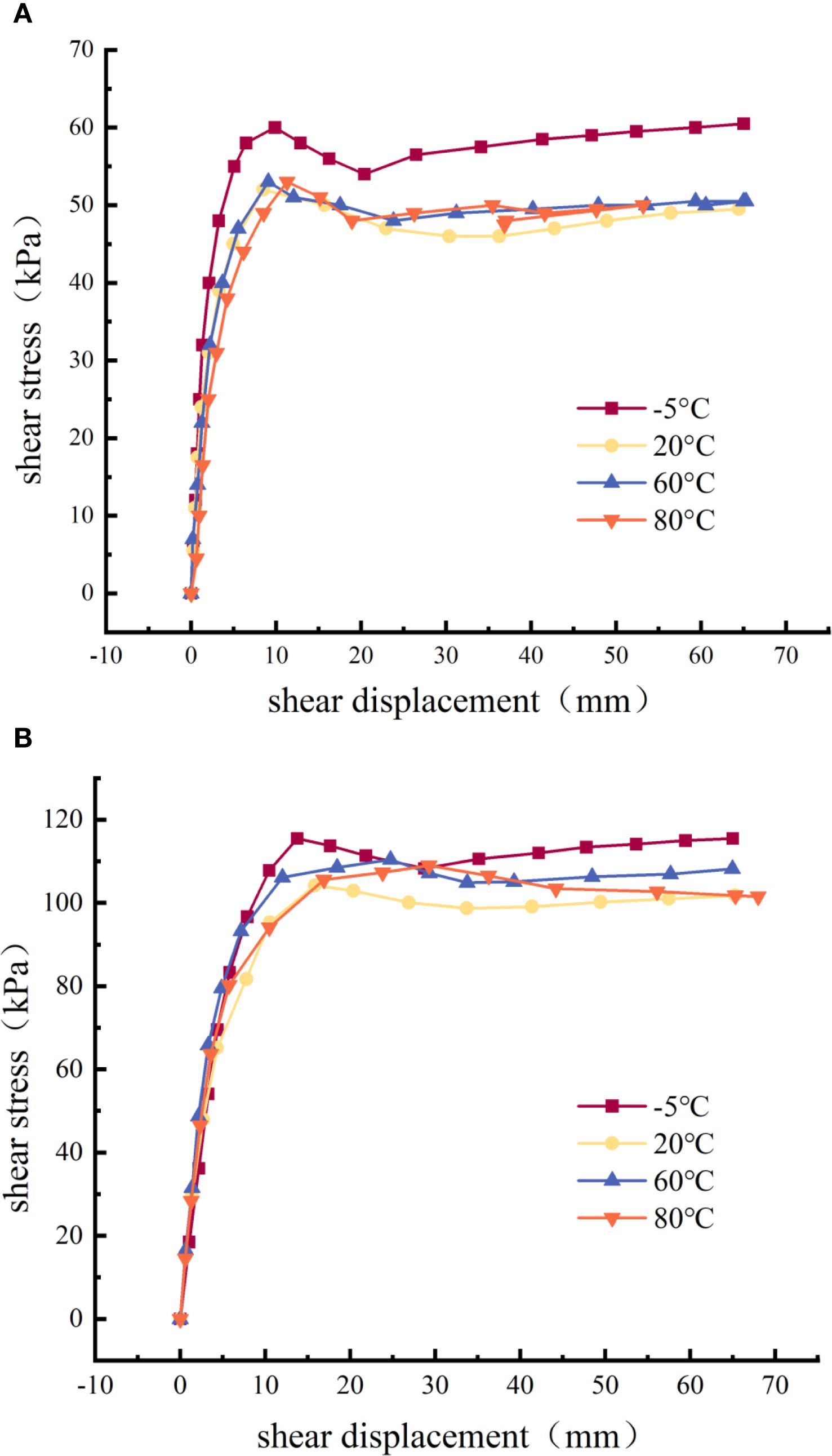

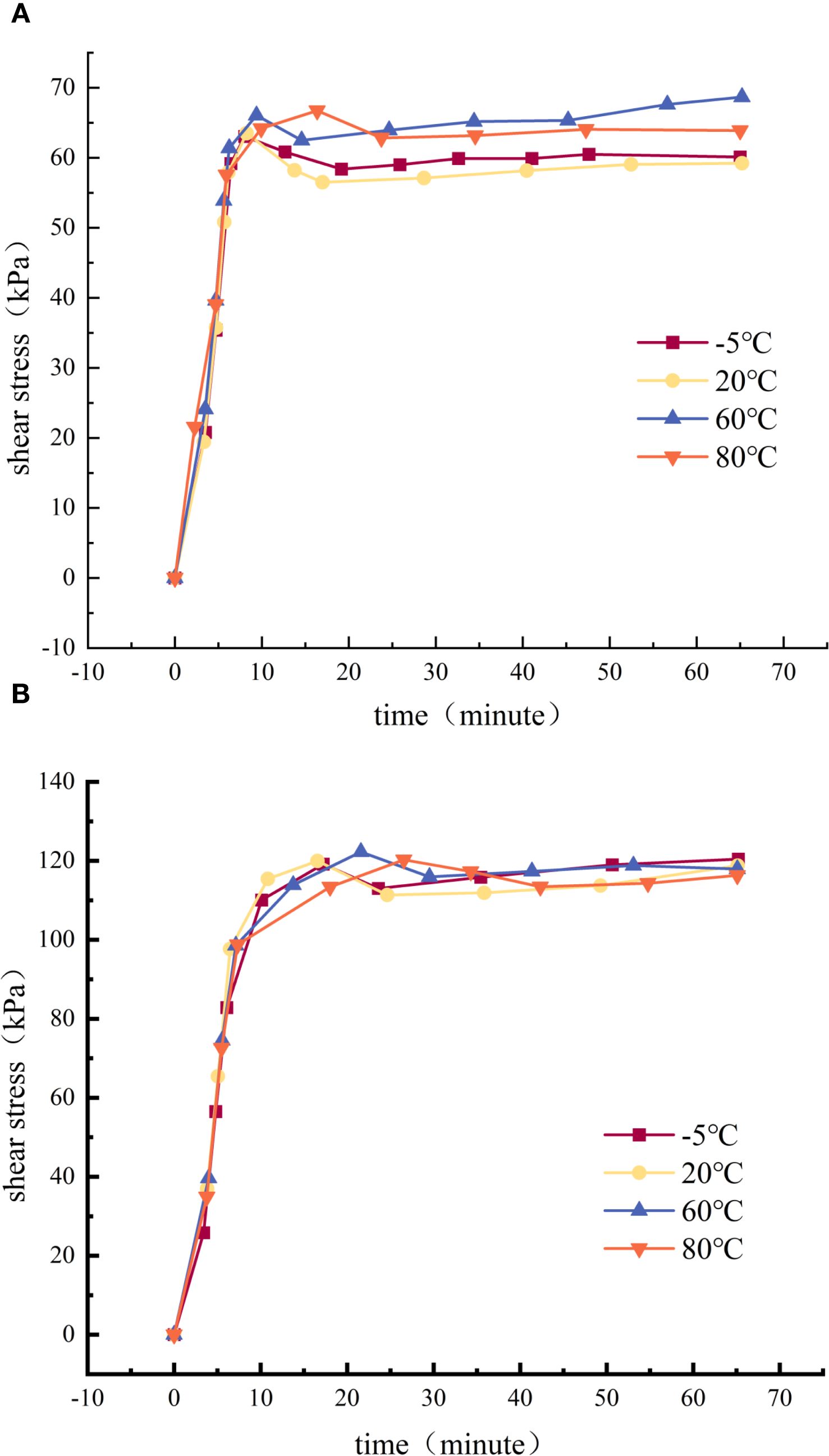

Figure 6 shows the temperature-controlled direct shear tests of polymer grid and marine coral sand.

Figure 6. Temperature-controlled interface direct shear test results of polymer grid and marine coral sand. (A) 50kPa. (B) 150 kPa.

Figure 6 demonstrates that temperature has a pronounced effect on the shear stress–displacement response of polymer grid–marine coral sand interfaces. At a constant normal stress, the static shear behavior varies noticeably with temperature. In general, rising temperatures lead to a reduction in peak shear strength. This temperature sensitivity underscores the necessity of using a temperature-controlled shear apparatus to accurately characterize interface behavior under varying thermal conditions, which is essential for marine and coastal engineering applications where temperature changes are common.

5.2 Temperature-regulated dynamic direct shear tests

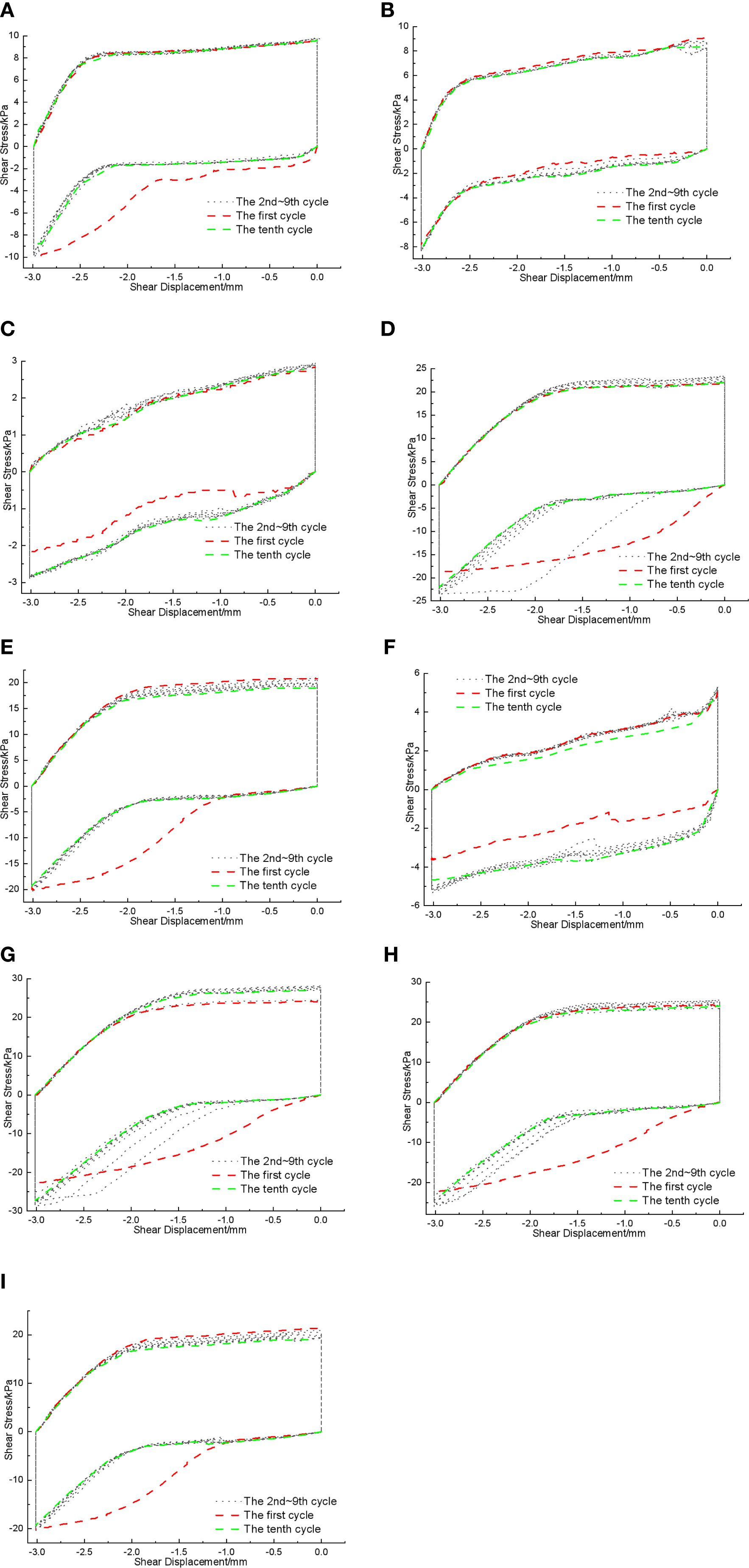

The results of Dynamic direct shear tests under temperature control on marine soil - cement mortar interfaces are presented in Figure 7.

Figure 7. The temperature-controlled interface dynamic shear tests. (A) Normal Pressure 50 kPa and Temperature 40°C. (B) Normal Pressure 50 kPa and Temperature 100°C. (C) Normal Pressure 150 kPa and Temperature 200°C. (D) Normal Pressure 100 kPa and Temperature 40°C. (E) Normal Pressure 100 kPa and Temperature 100°C. (F) Normal Pressure 100 kPa and Temperature 200°C. (G) Normal Pressure 150 kPa and Temperature 40°C. (H) Normal Pressure 150 kPa and Temperature 100°C. (I) Normal Pressure 150 kPa and Temperature 200°C.

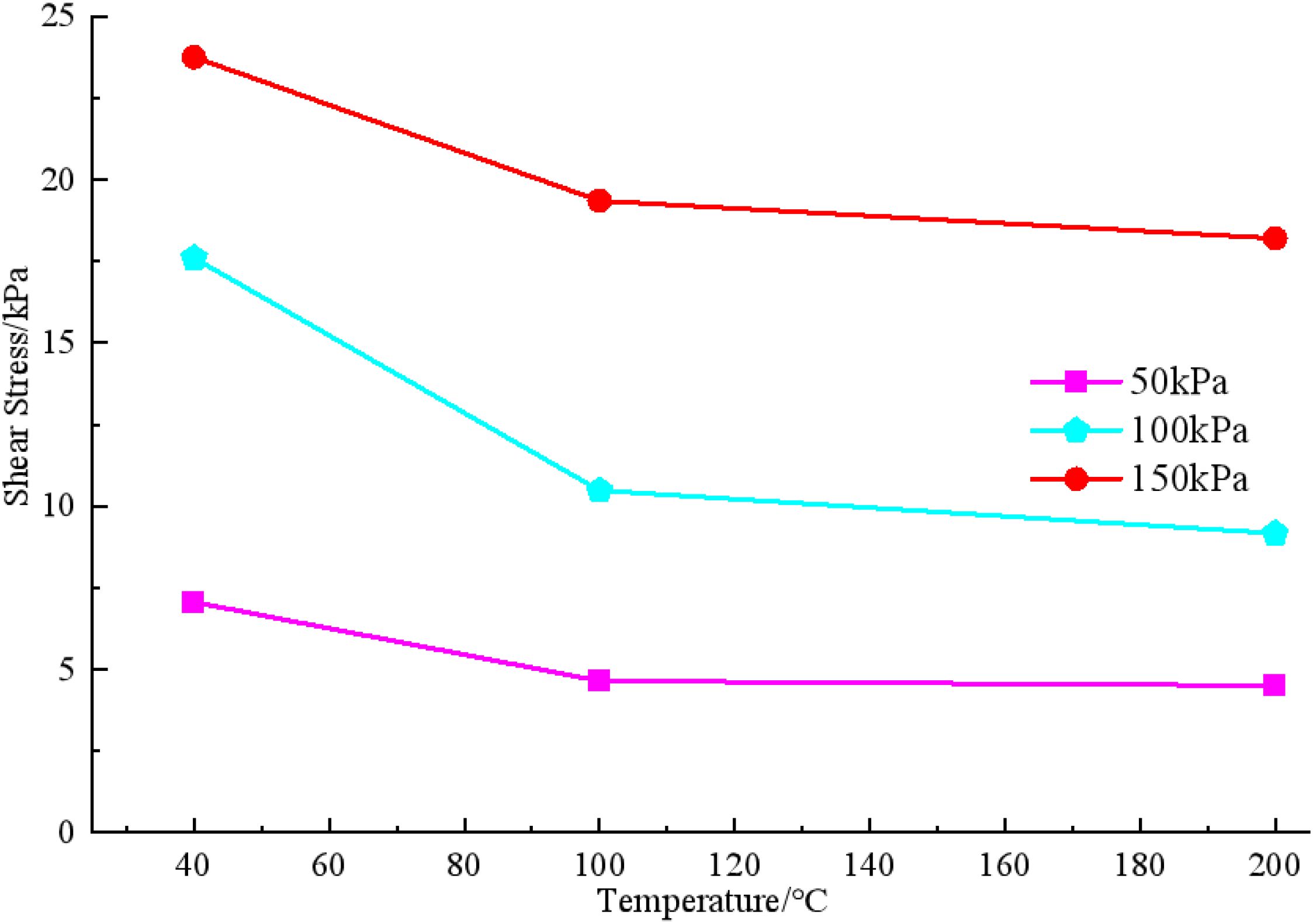

Figure 7 demonstrates that, across various normal stress levels, the dynamic mechanical behavior of marine soil–cement mortar interfaces exhibit noticeable variation with changes in temperature. These finding highlights temperature as a key factor influencing the interface’s dynamic response under cyclic loading conditions commonly encountered in marine environments. To quantitatively evaluate this effect, the dynamic peak shear strength is defined as the average of the maximum shear stresses recorded during cyclic shearing in both opposing directions. The resulting relationship between dynamic peak shear strength and temperature is detailed in Figure 8, providing insight into how thermal variations can degrade or alter the interface’s load-bearing capacity during dynamic events.

Figure 8. Curves showing the relationship between interface dynamic peak shear strength and temperature.

As illustrated in Figure 8, the dynamic peak shear strength of the marine soil–structure interface exhibits a clear declining trend with increasing temperature. Specifically, at a normal stress level of 50 kPa, the peak shear strength decreases from 24 kPa at 40°C to 20 kPa at 100°C, corresponding to a reduction of approximately 16.67%. This significant decrease underscores the pronounced effect of temperature on the interface’s dynamic mechanical behavior, which is critical for assessing the performance and stability of marine structures subjected to varying thermal conditions.

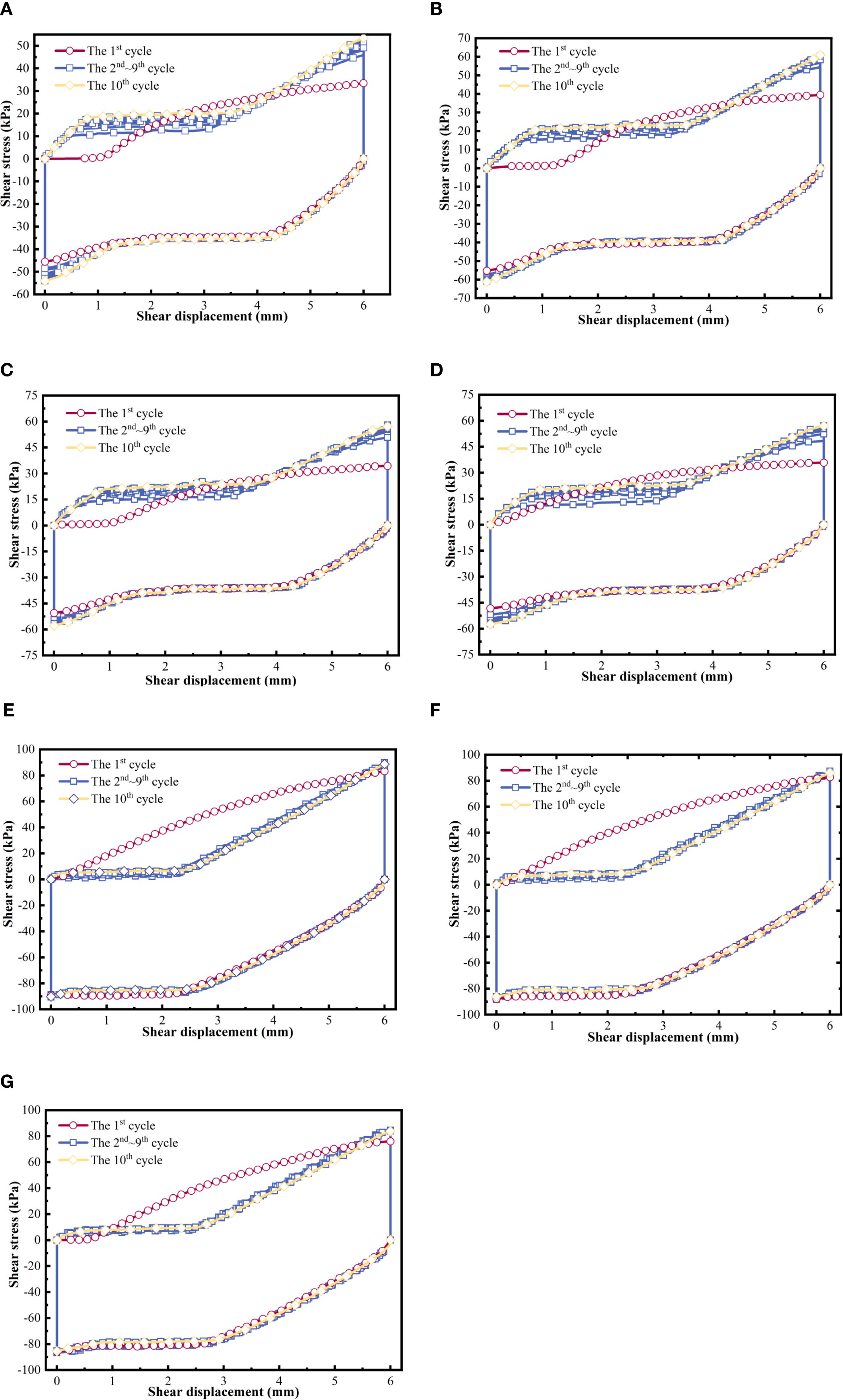

The results of dynamic direct shear tests under temperature control on polymer layer–marine silica sand interfaces are presented in Figure 9.

Figure 9. The temperature-controlled interface dynamic shear tests of polymer layer–marine silica sand interfaces. (A) Normal Pressure 50 kPa and Temperature -5°C. (B) Normal Pressure 50 kPa and Temperature 20°C. (C) Normal Pressure 50 kPa and Temperature 60°C. (D) Normal Pressure 50 kPa and Temperature 80°C. (D) Normal Pressure 150 kPa and Temperature -5°C. (E) Normal Pressure 150 kPa and Temperature 20°C. (F) Normal Pressure 150 kPa and Temperature 60°C. (G) Normal Pressure 150 kPa and Temperature 80°C.

As shown in Figure 9, the dynamic peak shear strength of the polymer layer–marine silica sand interface decreases consistently with increasing temperature. This trend indicates that temperature has a significant effect on the interface’s dynamic shear behavior. Such thermal sensitivity must be considered when assessing the long-term stability and mechanical performance of geosynthetic-reinforced marine structures exposed to fluctuating temperature conditions.

5.3 Temperature-controlled creep shear tests

Figure 10 presents the results of temperature-controlled creep shear tests conducted on marine soil–cement mortar interfaces.

Figure 10. Temperature-controlled interface creep shear tests. (A) Temperature 200 °C. (B) Temperature 60°C.

Figure 10 indicates that the magnitude of creep shear stress significantly affects the creep behavior of the interfaces. Under the same loading duration, higher creep shear stress results in greater interface creep displacement compared to lower stress levels. Additionally, temperature plays an important role in the creep mechanical performance; similar to short-term temperature effects, elevated temperatures lead to increased creep shear displacement. For instance, at 90% of the peak shear strength and at 3000 minutes of loading, the interface creep displacement at 200°C reaches 7.2 mm, which is 4.19% greater than the 6.9 mm displacement observed at 60°C. These findings suggest that temperature variations may critically influence the long-term safety of civil engineering structures.

Figure 11 presents the results of temperature-controlled creep shear tests conducted on polymer grid–marine silica sand interfaces.

Figure 11. Temperature-controlled interface creep shear tests of polymer grid–marine silica sand interfaces. (A) 50 kPa. (B) 150 kPa.

Figure 11 demonstrates that the magnitude of creep shear stress has a pronounced effect on the creep behavior of the polymer grid–marine silica sand interface. Under identical loading durations, higher stress levels induce noticeably greater creep displacements. Additionally, temperature is a key factor influencing creep response, with elevated temperatures leading to increased deformation—consistent with trends observed in short-term shear behavior. These findings highlight the importance of accounting for thermal effects when evaluating the long-term stability of polymer grid-reinforced marine systems.

6 Conclusion

This study introduces a self-developed large-scale interface shear apparatus designed to support advanced ocean engineering research and provide innovative ocean solutions. The apparatus is capable of performing monotonic, cyclic, and creep shear tests on structure–marine soil interfaces over a broad temperature range (-5°C to 300°C), allowing simulation of realistic marine environmental conditions. To verify the device’s performance, a series of temperature-controlled shear experiments were conducted, including static direct shear tests on polymer grid–marine coral sand interfaces, dynamic shear tests on polymer layer–marine silica sand interfaces, and creep tests on polymer grid–marine silica sand interfaces. These tests were performed at temperatures ranging from –5°C to 80°C, reflecting common thermal conditions in marine settings. The experimental results confirmed the apparatus’s robust functionality, thermal stability, and loading accuracy across various interface types and loading modes, making it a valuable tool for marine geotechnical studies and engineering applications aimed at sustainable ocean development.

The findings demonstrate that the developed apparatus reliably achieves precise temperature regulation and shear loading control, delivering consistent and accurate measurements under diverse testing conditions. The results further indicate that temperature has a significant influence on the static, dynamic, and creep mechanical behaviors of cement mortar–marine soil interfaces. Similarly, the shear behavior of geosynthetic–marine sand interfaces is also markedly affected by temperature variations. Elevated temperatures generally lead to reduced peak shear strength and increased creep deformation across different interface types. These observations highlight the critical importance of such a multifunctional, temperature-controlled shear testing system in the field of marine geotechnical engineering. It offers essential experimental support for understanding temperature-dependent interface behavior, which is crucial for the design, stability assessment, and long-term performance of marine structures. This work contributes to the development of robust ocean solutions by addressing the challenges posed by complex thermal–mechanical coupling in marine environments.

7 Limitation

The primary limitation of the present study lies in the scope of experimental validation. While the apparatus has been applied to three representative marine soil–structure interfaces (concrete, polymer grid, and polymer layer) under controlled thermal conditions, field-scale and long-term validations are still needed to fully capture the variability and complexity of in-situ marine environments. Additionally, although mechanistic links between temperature, pore pressure response, and interface shear behavior have been established, further investigation is required to quantify these effects under more complex loading and environmental scenarios. Moreover, controlling soil water content during long-term, high-temperature tests remains a challenge and will be a key focus for future improvements of the apparatus.

Moreover, the apparatus itself contains several functionalities that remain to be explored. For instance, it could be adapted to simulate high-salinity and high-humidity conditions, enable high-speed micromechanical recording during tests, or integrate real-time visualization to better capture interface processes. These capabilities were beyond the scope of the current study but offer promising directions for future research to deepen mechanistic understanding and enhance the practical relevance of marine soil–structure interface investigations.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material. Further inquiries can be directed to the corresponding author.

Author contributions

BY: Conceptualization, Data curation, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – review & editing. KX: Data curation, Formal Analysis, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing – original draft. KT: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Project administration, Software, Supervision, Validation, Writing – review & editing. PC: Conceptualization, Data curation, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Writing – review & editing. XF: Data curation, Funding acquisition, Methodology, Project administration, Resources, Validation, Writing – review & editing.

Funding

The author(s) declare financial support was received for the research and/or publication of this article. The authors would like to acknowledge the consistent support of Failure Mechanics and Engineering Disaster Prevention, Key Lab of Sichuan Province: No FMEDP202209; Shanghai Sailing Program: No 22YF1415800, No 23YF1416100; Shanghai Natural Science Foundation: No 23ZR1426200; Project funded by China Postdoctoral Science Foundation: No 2023M730929; The Shanghai Soft Science Key Project: No 23692119700; Funded by Key Laboratory of Ministry of Education for Coastal Disaster and Protection, Hohai University, No 202302; Funded by Key Laboratory of Estuarine & Coastal Engineering, Ministry of Transport, No KLECE202302.

Conflict of interest

Author BY was employed by Shanxi Ning Guli New Materials Joint Stock Company Limited.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adil W., Rahman F. U., Abdullah G. M., Tayeh B. A., and Zeyad A. M. (2022). Effective utilization of textile industry waste-derived and heat-treated pumice powder in cement mortar. Construct. Building. Mater. 351, 128966. doi: 10.1016/j.conbuildmat.2022.128966

Arulmoly B., Konthesingha C., and Nanayakkara A. (2021). Performance evaluation of cement mortar produced with manufactured sand and offshore sand as alternatives for river sand. Construct. Building. Mater. 297, 123784. doi: 10.1016/j.conbuildmat.2021.123784

Bilgin Ö. and Shah B. (2021). Temperature influence on high-density polyethylene geomembrane and soil interface shear strength. Int. J. Geosynthetics. Ground. Eng. 7, 66. doi: 10.1007/s40891-021-00311-9

Cai H., Zhang Q., and Ye G. (2020). Numerical simulation on undrained cylic triaxial test of soft marine clay considering end restrictions of soil specimen. Ocean. Eng. 216, 108100. doi: 10.1016/j.oceaneng.2020.108100

Cardile G., Pisano M., Recalcati P., and Moraci N. (2021). A new apparatus for the study of pullout behaviour of soil-geosynthetic interfaces under sustained load over time. Geotextiles. Geomembr. 49, 1519–1528. doi: 10.1016/j.geotexmem.2021.07.001

Chao Z. and Fowmes G. (2021). Modified stress and temperature-controlled direct shear apparatus on soil-geosynthetics interfaces. Geotextiles. Geomembr. 49, 825–841. doi: 10.1016/j.geotexmem.2020.12.011

Chao Z. and Fowmes G. (2022). The short-term and creep mechanical behaviour of clayey soil-geocomposite drainage layer interfaces subjected to environmental loadings. Geotextiles. Geomembr. 50, 238–248. doi: 10.1016/j.geotexmem.2021.10.004

Chao Z., Li Z., Dong Y., Shi D., and Zheng J. (2024a). Estimating compressive strength of coral sand aggregate concrete in marine environment by combining physical experiments and machine learning-based techniques. Ocean. Eng. 308, 118320. doi: 10.1016/j.oceaneng.2024.118320

Chao Z., Liu H., Wang H., Dong Y., Shi D., and Zheng J. (2024b). The interface mechanical properties between polymer layer and marine sand with different particle sizes under the effect of temperature: Laboratory tests and artificial intelligence modelling. Ocean. Eng. 312, 119255. doi: 10.1016/j.oceaneng.2024.119255

Chao Z., Shi D., Fowmes G., Xu X., Yue W., Cui P., et al. (2023). Artificial intelligence algorithms for predicting peak shear strength of clayey soil-geomembrane interfaces and experimental validation. Geotextiles. Geomembr. 51, 179–198. doi: 10.1016/j.geotexmem.2022.10.007

Chao Z., Shi D., and Zheng J. (2024c). Experimental research on temperature–Dependent dynamic interface interaction between marine coral sand and polymer layer. Ocean. Eng. 297, 117100. doi: 10.1016/j.oceaneng.2024.117100

Chao Z., Wang H., Zheng J., Shi D., Li C., Ding G., et al. (2024d). Temperature-dependent post-cyclic mechanical characteristics of interfaces between geogrid and marine reef sand: experimental research and machine learning modeling. J. Mar. Sci Eng. 12, 1262. doi: 10.3390/jmse12081262

Chao Z., Zhou J., Shi D., and Zheng J. (2025). Particle size effect on the mechanical behavior of coral sand–geogrid interfaces. Geosynthetics. Int. 1–17. doi: 10.1680/jgein.24.00143

Chen J.-F., Akosah S., Ma C., and Gidigasu S. S. (2023). Large-scale triaxial tests of reinforced coral sand with different grain size distributions. Mar. Georesour. Geotechnol. 41, 544–554. doi: 10.1080/1064119X.2022.2068462

Chen H., Chu J., Guo W., and Wu S. (2022). Use of suction caissons for seawall construction. Ocean. Eng. 266, 112632. doi: 10.1016/j.oceaneng.2022.112632

Choi J., Jang B.-S., Ju H., and Han S. (2021). Undrained bearing capacity of spudcan in soft-over-stiff clay after penetration. Ocean. Eng. 235, 109369. doi: 10.1016/j.oceaneng.2021.109369

Desbrousses R., Meguid M., and Bhat S. (2022). Effect of temperature on the mechanical properties of two polymeric geogrid materials. Geosynthetics. Int. 29, 326–336. doi: 10.1680/jgein.21.00032a

Elbaz Y., Naeem M., Leblouba M., and Arab M. G. (2022). Cyclic Performance of 3D-Printed Snakeskin-Bioinspired Interfaces 2022 Advances in Science and Engineering Technology International Conferences (ASET) (USA: IEEE), 1–6.

Florentino B., Cheng Q., Call D. F., and Barlaz M. A. (2021). Evidence of thermophilic waste decomposition at a landfill exhibiting elevated temperature regions. Waste. Manage. 124, 26–35. doi: 10.1016/j.wasman.2021.01.014

Fowmes G. J., Dixon N., Fu L., and Zaharescu C. A. (2017). Rapid prototyping of geosynthetic interfaces: investigation of peak strength using direct shear tests. Geotextiles. Geomembr. 45, 674–687. doi: 10.1016/j.geotexmem.2017.08.009

Frost J. and Karademir T. (2016). Shear-induced changes in smooth geomembrane surface topography at different ambient temperatures. Geosynthetics. Int. 23, 113–128. doi: 10.1680/jgein.15.00036

Ghavam-Nasiri A., El-Zein A., Airey D., and Rowe R. K. (2019). Water retention of geosynthetics clay liners: Dependence on void ratio and temperature. Geotextiles. Geomembr. 47, 255–268. doi: 10.1016/j.geotexmem.2018.12.014

Ghazizadeh S. and Bareither C. A. (2024). Effect of temperature on critical strength of geosynthetic clay liner/textured geomembrane composite systems. Geotextiles. Geomembr. 52, 12–26. doi: 10.1016/j.geotexmem.2023.08.005

Han J. and Thakur J. K. (2015). Sustainable roadway construction using recycled aggregates with geosynthetics. Sustain. Cities. Soc. 14, 342–350. doi: 10.1016/j.scs.2013.11.011

Hanson J., Chrysovergis T., Yesiller N., and Manheim D. (2015). Temperature and moisture effects on GCL and textured geomembrane interface shear strength. Geosynthetics. Int. 22, 110–124. doi: 10.1680/gein.14.00035

He S.-H., Shan H.-F., Xia T.-D., Liu Z.-J., Ding Z., and Xia F. (2021). The effect of temperature on the drained shear behavior of calcareous sand. Acta Geotech. 16, 613–633. doi: 10.1007/s11440-020-01030-7

Hou R.-Y., Zheng J.-J., Fang H., and You L. (2022). An analytical model for dynamic response of geosynthetic reinforced embankment system under traffic load. Comput. Geotech. 142, 104555. doi: 10.1016/j.compgeo.2021.104555

Ishimori H. and Katsumi T. (2012). Temperature effects on the swelling capacity and barrier performance of geosynthetic clay liners permeated with sodium chloride solutions. Geotextiles. Geomembr. 33, 25–33. doi: 10.1016/j.geotexmem.2012.02.005

Jin H., Guo L., Sun H., Shi L., and Cai Y. (2022). Undrained cyclic shear strength and stiffness degradation of overconsolidated soft marine clay in simple shear tests. Ocean. Eng. 262, 112270. doi: 10.1016/j.oceaneng.2022.112270

Jueyendah S., Lezgy-Nazargah M., Eskandari-Naddaf H., and Emamian S. (2021). Predicting the mechanical properties of cement mortar using the support vector machine approach. Construct. Building. Mater. 291, 123396. doi: 10.1016/j.conbuildmat.2021.123396

Li S., Wang C., Yang J., Lai Y., Jiang Q., and Wan X. (2022). Thermo-hydro-mechanical process and damage mechanism of a cold-region canal under coupled wetting–drying and freezing–thawing cycles. Acta Geotech. 17, 4655–4665. doi: 10.1007/s11440-022-01531-7

Lin H., Gong X., Zeng Y., and Zhou C. (2024). Experimental study on the effect of temperature on HDPE geomembrane/geotextile interface shear characteristics. Geotextiles. Geomembr. 52, 396–407. doi: 10.1016/j.geotexmem.2023.12.005

Liu H., Han J., and Parsons R. L. (2023). Numerical analysis of geosynthetics to mitigate seasonal temperature change-induced problems for integral bridge abutment. Acta Geotech. 18, 673–693. doi: 10.1007/s11440-022-01614-5

Liu C., Huang X., Wu Y.-Y., Deng X., and Zheng Z. (2021). The effect of graphene oxide on the mechanical properties, impermeability and corrosion resistance of cement mortar containing mineral admixtures. Construct. Building. Mater. 288, 123059. doi: 10.1016/j.conbuildmat.2021.123059

Morsy A., Zornberg J., Han J., and Leshchinsky D. (2019). A new generation of soil-geosynthetic interaction experimentation. Geotextiles. Geomembr. 47, 459–476. doi: 10.1016/j.geotexmem.2019.04.001

Qu F., Li W., Wang K., Tam V. W., and Zhang S. (2021). Effects of seawater and undesalted sea sand on the hydration products, mechanical properties and microstructures of cement mortar. Construct. Building. Mater. 310, 125229. doi: 10.1016/j.conbuildmat.2021.125229

Rui S., Wang L., Guo Z., Cheng X., and Wu B. (2021a). Monotonic behavior of interface shear between carbonate sands and steel. Acta Geotech. 16, 167–187. doi: 10.1007/s11440-020-00987-9

Rui S., Wang L., Guo Z., Zhou W., and Li Y. (2021b). Cyclic behavior of interface shear between carbonate sand and steel. Acta Geotech. 16, 189–209. doi: 10.1007/s11440-020-01002-x

Sampa N. C., Schnaid F., Rocha M. M., Cudmani R., and dos Santos Amaral C. (2021). Vertical and horizontal pullout capacity of mooring lines embedded in very soft clays. Ocean. Eng. 234, 109229. doi: 10.1016/j.oceaneng.2021.109229

Shi D., Chen X., and Shao W. (2023). Modeling of bidirectional chloride convection-diffusion for corrosion initiation life prediction of RC square piles under drying-wetting cycle. Appl. Ocean. Res. 141, 103789. doi: 10.1016/j.apor.2023.103789

Shi D., Xu K., Chao Z., and Cui P. (2025a). Experimental Study on Mechanical Properties of Triaxial Geogrid Reinforced Marine coral sand-Clay Mixture Based on 3D Printing Technology. Front. Mar. Sci 12, 1660611. doi: 10.3389/fmars.2025.1660611

Shi D., Xu K., Yu X., Cui P., and Chao Z. (2025b). Strength estimation of textured polymer layer-reinforced materials in practical marine engineering based on physical experiments and artificial intelligence modelling. Front. Mar. Sci 12. doi: 10.3389/fmars.2025.1653741

Shokr M., Meguid M., Bhat S., and Malomo D. (2025). Experimental and numerical investigations of slab-on-grade reinforced with stiff and ductile geogrids. Int. J. Geosynthetics. Ground. Eng. 11, 1–17. doi: 10.1007/s40891-025-00621-2

Sudarsanan N., Karpurapu R., and Amrithalingam V. (2018). An investigation on the interface bond strength of geosynthetic-reinforced asphalt concrete using Leutner shear test. Construct. Building. Mater. 186, 423–437. doi: 10.1016/j.conbuildmat.2018.07.010

Tang Y., Xiao S., and Yang Q. (2020). The behaviour of geosynthetic-reinforced pile foundation under long-term dynamic loads: model tests. Acta Geotech. 15, 2205–2225. doi: 10.1007/s11440-019-00890-y

Tincopa M. and Bouazza A. (2021). Water retention curves of a geosynthetic clay liner under non-uniform temperature-stress paths. Geotextiles. Geomembr. 49, 1270–1279. doi: 10.1016/j.geotexmem.2021.04.005

Vieira C. S., Lopes M., and Caldeira L. M. (2013). Sand-geotextile interface characterisation through monotonic and cyclic direct shear tests. Geosynthetics. Int. 20, 26–38. doi: 10.1680/gein.12.00037

Wang J., Dai M., Cai Y., Guo L., Du Y., Wang C., et al. (2021). Influences of initial static shear stress on the cyclic behaviour of over consolidated soft marine clay. Ocean. Eng. 224, 108747. doi: 10.1016/j.oceaneng.2021.108747

Xia W., Wang Q., Yu Q., Yao M., Sun D., Liu J., et al. (2023). Experimental investigation of the mechanical properties of hydrophobic polymer-modified soil subjected to freeze–thaw cycles. Acta Geotech. 18, 3623–3642. doi: 10.1007/s11440-023-01804-9

Xia H., Zhou X., Zhou M., Niu F., and Zhang X. (2021). Capacity of caissons in stiff-over-soft clay under combined V–HM loadings. Ocean. Eng. 229, 109007. doi: 10.1016/j.oceaneng.2021.109007

Xiao C., Han H., Ding L., and Gao S. (2025). Prediction on lateral deformation of GRS walls using a creep-temperature coupled constitutive model of geosynthetics. Acta Geotech. 20, 891–913. doi: 10.1007/s11440-024-02409-6

Xiao S., Zhou J., and Tang Y. (2022). Centrifuge model test on the behavior of geosynthetic-reinforced pile foundations under simulated train loads. Acta Geotech. 17, 4131–4144. doi: 10.1007/s11440-022-01530-8

Xu L., Wang R., Liu Q., Chen J., Wang X., and Meng Q. (2023). Effect of particle size distribution on monotonic direct shear characteristics of geotextile/geogrid-calcareous sand interface. Appl. Ocean. Res. 137, 103601. doi: 10.1016/j.apor.2023.103601

Yang S., Ren Y., and Andersen K. H. (2021). Effects of thixotropy and reconsolidation on the undrained shear characteristics of remoulded marine clays. Ocean. Eng. 239, 109888. doi: 10.1016/j.oceaneng.2021.109888

Zadehmohamad M., Luo N., Abu-Farsakh M., and Voyiadjis G. (2022). Evaluating long-term benefits of geosynthetics in flexible pavements built over weak subgrades by finite element and Mechanistic-Empirical analyses. Geotextiles. Geomembr. 50, 455–469. doi: 10.1016/j.geotexmem.2022.01.004

Zeng W.-x., Ying M.-j., and Liu F.-y. (2023). Investigation on the cyclic shear response of stereoscopic geogrid-reinforced coarse-grained soil interface. Transport. Geotech. 38, 100905. doi: 10.1016/j.trgeo.2022.100905

Zhang X., Du M., Fang H., Shi M., Zhang C., and Wang F. (2021b). Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Construct. Building. Mater. 299, 124290. doi: 10.1016/j.conbuildmat.2021.124290

Zhang Q., Fang T., Ye G., Liu G., Wang R., and Tian Y. (2021a). Effect of sitting time on the breakout force of mat foundation on soft marine clay seabed. Ocean. Eng. 234, 108770. doi: 10.1016/j.oceaneng.2021.108770

Zhou W., Guo Z., Wang L., Li J., and Rui S. (2020). Sand-steel interface behaviour under large-displacement and cyclic shear. Soil Dynamics. Earthquake. Eng. 138, 106352. doi: 10.1016/j.soildyn.2020.106352

Keywords: marine soil, marine engineering, interface, temperature, static and dynamic

Citation: Yang B, Xu K, Tan K, Cui P and Feng X (2025) A large temperature-controlled static and dynamic mechanical testing apparatus on marine soil-structure interfaces for marine engineering. Front. Mar. Sci. 12:1671265. doi: 10.3389/fmars.2025.1671265

Received: 22 July 2025; Accepted: 12 September 2025;

Published: 25 September 2025.

Edited by:

Debabrata Karmakar, National Institute of Technology, Karnataka, IndiaReviewed by:

Shengjie Rui, National University of Singapore, SingaporeJingjie Wei, Missouri University of Science and Technology, United States

Copyright © 2025 Yang, Xu, Tan, Cui and Feng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Peng Cui, Y3VpLnBlbmdAdW11LnNl; Xianhui Feng, ZmVuZ3hpYW5odWlAdXN0Yi5lZHUuY24=

†These authors have contributed equally to this work

Bowen Yang1†

Bowen Yang1† Peng Cui

Peng Cui