- 1 Nagaoka University of Technology, Nagaoka, Japan

- 2 Australian Nuclear Science and Technology Organization, Sydney, NSW, Australia

Potassium-based geopolymers were synthesized with varying initial water content (7–10 mol %). Samples were initially cured under tight-lidded conditions at different temperatures (room temperature, 40 °C, and 60 °C) for the initial 24 h and then transitioned to ambient curing without lid. Analysis of the pore size distribution revealed that higher initial water content generally led to larger pores, while higher curing temperatures resulted in smaller pores. Vickers hardness measurements showed a dependence on both initial water content and curing temperature. The electron beam irradiation was processed up to 16 kGy by pulsed linear electron accelerator at Nagaoka University of Technology and up to 992 kGy by electron beam irradiation at the Takasaki Institute of Advanced Quantum Science. The Vickers hardness of a selected sample remained largely unchanged even after electron beam irradiation up to a high dose.

1 Introduction

Cement is one of the candidates for immobilizing radioactive elements and has been used for a time (Rosseel et al., 2016; Kotatkova et al., 2017). However, the production of conventional Portland cement is associated with substantial carbon dioxide (CO2) emissions, contributing to global warming and air pollutants. Furthermore, after the Fukushima Daiichi nuclear accident in 2011, the hydrogen release was emphasized and required to be reduced as low as possible. Some studies have indicated that the radiolysis of pore water within cementitious matrices yields hydrogen gas (Le Caer et al., 2017; Acher et al., 2021). The hydrogen production, G(H2) value, was reported to be linearly proportional to the absorbed gamma-ray dose at ambient temperatures (Kontani et al., 2013). While the decomposition of chemically bound water under gamma irradiation may be limited to a few percent, it has been suggested that this could potentially lead to the degradation of the concrete matrix over extended periods (Khmurovska et al., 2021; Maruyama et al., 2016), raising concerns about the suitability of conventional concrete for long-term storage in decommissioning scenarios. Furthermore, cement is not suitable for immobilization of radioactive aluminum alloys because of hydrogen formation by an aluminum alloys because of hydrogen formation by an aluminum-alkaline solution reaction (Seki et al., 2022).

Geopolymers of aluminosilicate, with their unique properties, have demonstrated a wide range of applications, including in construction (Matsimbe et al., 2022; Das et al., 2024; Verma et al., 2022), water treatment (Elgarahy et al., 2023), especially in waste management (Houhou et al., 2025). In the nuclear industry, geopolymers have earned considerable attention for immobilizing and stabilizing radioactive waste, reducing the potential for radionuclide migration or dispersion into the environment (Mukiza et al., 2023; Kinoshita et al., 2022; Kuenzel et al., 2015; Li et al., 2022). It is also expected to immobilize radioactive aluminum by substituting part of aluminum silicate raw materials. Besides the superior properties compared to Portland cement such as compressive strength, durability, or carbon dioxide (CO2) emission, the low water absorption characteristic is one of the key points to make geopolymer has led to an increasing interest.

Different types of radiation have varying effects on the structure change of geopolymer. Lambertin et al. (2013) investigated the effect of gamma irradiation on metakaolin-based sodium geopolymers. The findings indicated a 10% increase in compressive strength after irradiation up to 1,000 kGy. The radiolytic yield of hydrogen (G(H2)) was reported to be between 0.090 × 10−7 and 0.113 × 10−7 mol.J−1, primarily influenced by the water content. Similarly, Rooses et al. (2013) did the studies on the effect of neutron irradiation on metakaolin-based potassium geopolymer, reporting the hydrogen radiolytic yield ranging from 0.36 × 10−7 to 0.44 × 10−7 mol.J−1, depending on the water content. Furthermore, the study suggested that the G(H2) values were comparable across different dose rates, implying a non-significant dose rate effect on this material.

Both gamma and neutron irradiation could be highly penetrating into materials, while electrons considerably have a shorter penetration range, resulting in effects that are predominantly near-surface. Electron radiation, particularly electron beam irradiation (E-beam), has the potential to modify the properties of geopolymers, possibly enhancing their mechanical strength and radiation shielding effectiveness. Conversely, it can also induce structural damage and material degradation, especially at elevated doses.

Despite these limitations, electron irradiation studies on geopolymers intended for low-level radioactive waste can be valuable for understanding surface degradation mechanisms. Furthermore, these studies could be pertinent for evaluating the effects of beta decay from specific radionuclides such as 60Co, 137Cs, 14C, Tritium, 36Cl, 63Ni, 90Sr and 94Nb that commonly found in low-level waste streams from decommissioning. A challenge in characterizing some of these beta emitters is their easy attenuation, making detection difficult in low-level waste streams. Moreover, even if the waste is considered low-level by its bulk activity, localized damage could be significant due to the concentration of a beta emitter. Therefore, when designing a durable geopolymer for radiation resistance, considering a worst-case scenario from beta damage is a crucial strategy.

Amin et al. (2024) recently presented the direct comparison of the effects of electron beam and gamma-ray irradiation on geopolymer pastes incorporating β-Ni(OH)2. The study examined the changes in compressive strength, surface morphology (using scanning electron microscope (SEM), and phase composition (using XRD and TGA/DTG) following irradiation at varying doses. The result indicated that both electron beam and gamma-ray irradiation led to positive impacts on the compressive strength at the specific dose levels. Mahrous et al. (2024) employed scanning electron microscopy equipped with a backscattered electron detector to analyze surface topographic changes in geopolymer samples post-irradiation, suggesting an analysis of electron interactions with the geopolymer surface.

Investigating the effects of electron irradiation on geopolymers is essential for understanding the surface degradation mechanisms relevant to low-level radioactive waste immobilization. This study, therefore, examines these effects specifically on a potassium-based geopolymer. In previous studies, potassium-based geopolymer with an Al:Si:K:H2O molar ratio of 1:2:0.8:8 has been successfully synthesized (Yang et al., 2021; Yang et al., 2022). The initial comparison between potassium-based and sodium-based geopolymer samples demonstrated that the potassium-based material was denser and exhibited higher compressive strength. This performance enhancement was directly attributed to the significantly lower viscosity of K2SiO3 compared to Na2SiO3 (Yang et al., 2022; Christophliemk et al., 2022; Lizcano et al., 2012). The reduced viscosity allowed for a lower H2O content in the potassium formulation, which minimized porosity, resulted in a denser matrix and reduced drying shrinkage.

Given that the absorbed dose from the radioactive waste is often highest during the early stages, this investigation focuses on the electron radiation resistance during the initial 7-day curing stage to elucidate the immediate effects of irradiation on the evolving geopolymer matrix. While a comprehensive evaluation of mechanical properties would ideally encompass tensile strength, compressive strength, and fracture toughness, this preliminary investigation centers on Vickers hardness. Analyzing the alterations in Vickers hardness of the geopolymers under irradiation and varying preparation conditions offers valuable initial insights into the material’s surface mechanical behavior and its correlation with porosity.

2 Experiment

2.1 Materials

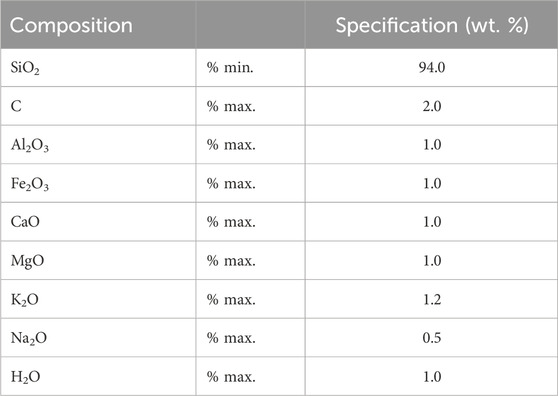

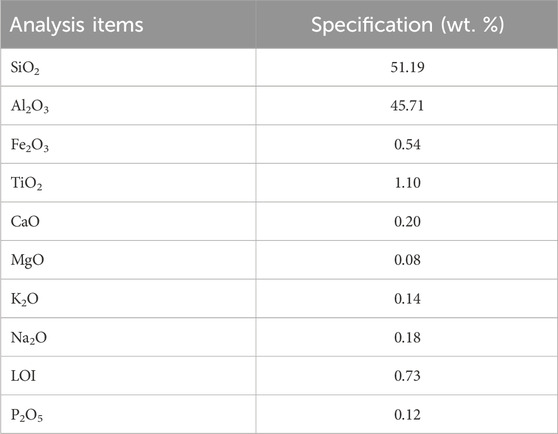

The aluminosilicate precursors for making geopolymer samples consisted of EFACO silica and metakaolin powder. EFACO silica, purchased from Tomoe Engineering Co., Ltd., Japan, comprised primarily SiO2 (up to 94%) with a detailed compositional provided in Table 1. Metakaolin powder, acquired from Imerys-specialties in Japan under the brand name PoleStar450, underwent chemical composition analysis via X-ray fluorescence, with the results presented in Table 2. Based on the results, the molar ratio of Al2O3/SiO2 was determined to be approximately 46/51, assuming the presence of Al2O3・2∼3 SiO2 phases.

The alkaline activators employed were potassium hydroxide and potassium silicate solution. The potassium hydroxide (KOH) was manufactured by UNID.CO.LTD (CAS. No was 1310-58-3) and potassium silicate solution (50% concentration) was sourced from FUJIFILM Wako Pure Chemical Corporation.

2.2 Synthesis of geopolymer

Geopolymer samples were synthesized according to the following procedure: Initially, potassium silicate was mixed with potassium hydroxide powder and distilled water. The water content varied, resulting in four distinct sample groups with the molar ratio of Al: Si: K: H2O = 1:2.1:0.8:x, where x ranged from 7 to 10. In order to discuss the result, the samples were named as W7 to W10.

EFACO silica powder was introduced into the alkaline solution and mechanically stirred at 60 rpm for 1 min. Metakaolin powder was then added, and the mixture continued to stir for a total of 4 min at 60 rpm to ensure homogeneity. The resulting slurry was further homogenized by mixing at 80 rpm for 5 min before being cast into plastic molds.

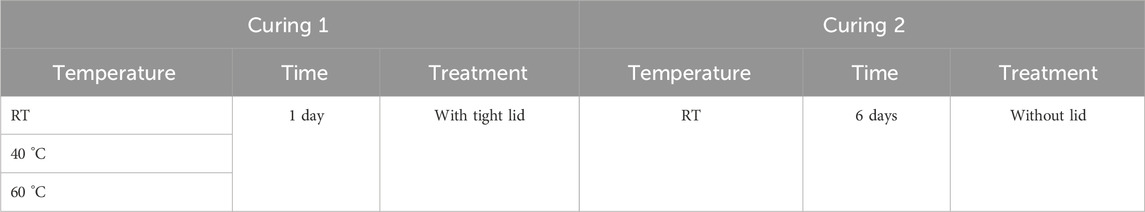

To investigate the influence of early-stage curing conditions on the geopolymer network development and the uniformity of mechanical properties, samples were cured under tight-lidded conditions (with a tight lid) for 24 h (Curing 1) at three different temperatures: room temperature (RT), 40 °C, and 60 °C. The elevated temperatures (40 °C, and 60 °C) aimed to accelerate the geopolymerization process and promote the reduction of free water content within the matrix.

Following this initial curing phase, all samples were further cured at room temperature (RT) without a lid for an additional 6 days to release the water (Curing 2), totaling 7 days of curing. The detailed curing treatment conditions are summarized in Table 3. Throughout the curing process, the weight of the geopolymer samples was monitored to track water release. Pore size measurements were performed using the Hitachi TM3000 scanning electron minis cope (SEM).

2.3 Electron irradiation

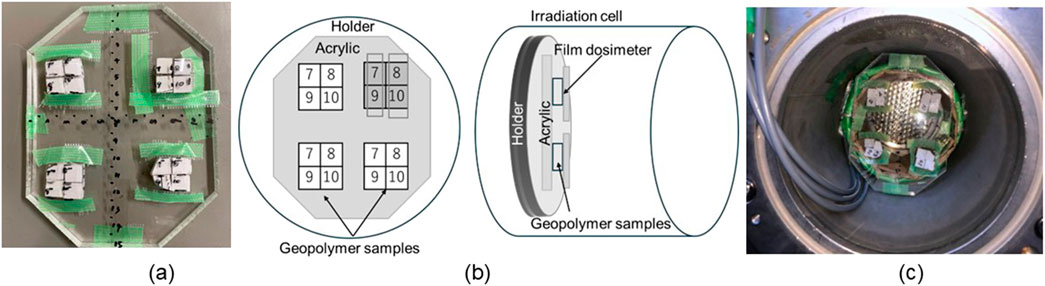

The potassium and metakaolin-based geopolymer samples were underwent low absorbed dose electron beam irradiation by using a pulsed linear electron accelerator (ETIGO-III) at the Nagaoka University of Technology, Nagaoka city, Japan (Tokuchi et al., 1998). The operating was at a peak voltage of 2 MeV, a current of 5 kA, and a pulse with of 100 ns. Each sample was sectioned into four pieces and subsequently affixed to a polymethyl methacrylate, as depicted in Figure 1. Each experimental group comprised four samples, each with a different initial water content. A film dosimeter reference was placed on top of each sample. Following the first irradiation shot, one group of samples along with the film dosimeter, was removed. Subsequently, after each subsequent shot (second, third, and fourth), another group of samples was removed. Consequently, the final group of samples received a total of four irradiation shots.

Figure 1. (a) Samples on a polymethyl methacrylate plate, (b) target installation diagram, (c) samples in the ETIGO-III.

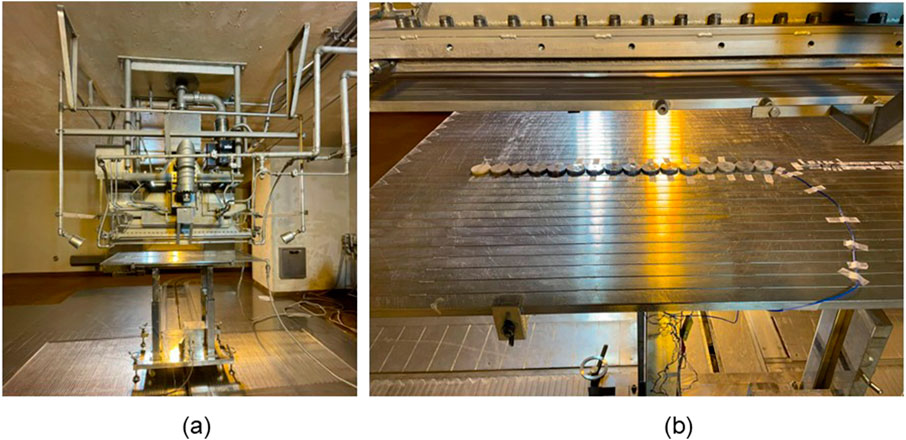

To achieve higher absorbed doses, separate irradiation experiments were conducted up to 1,000 kGy (actual measured dose was 992 kGy) using a Cockcroft-Walton accelerator at the Takasaki Institute for Advanced Quantum Science in Takasaki city, Japan. The methodology for dose determination in this experiment was consistent with that employed in Nagaoka University of Technology study. The irradiation was directed onto the surface of the geopolymer samples to observe surface modifications following different irradiation exposures. Figure 2 illustrates the arrangement of samples within the accelerator. The Vicker hardness before and after irradiation were tested with the Mitutoyo HV-115, applying 1 kgf load for 15 s at 12 distinct points on each sample surface.

Figure 2. (a) Electron irradiation by the Cockcroft Walton accelerator, (b) schematic illustrating the sample loading.

3 Results

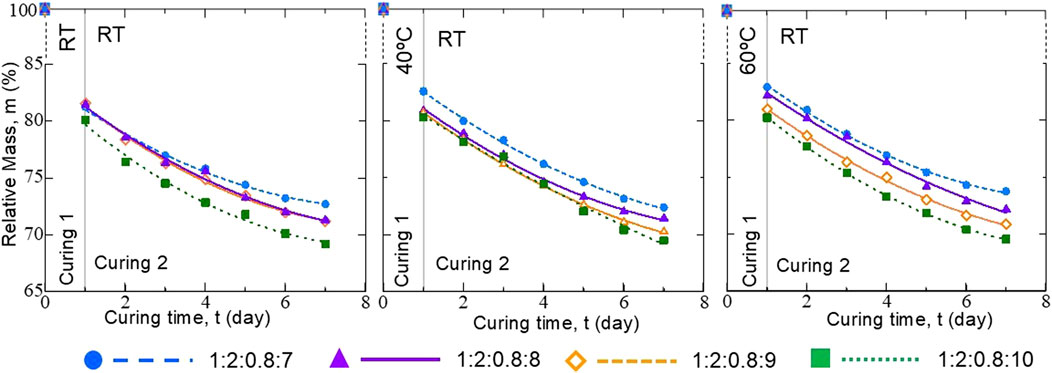

Figure 3 illustrates the cumulative mass change of the geopolymer samples after a total period of 7 days (1 day in Curing 1 followed by 6 days in Curing 2). The data clearly demonstrates that the initial water content influenced the total mass loss across all sample groups. Specifically, the total mass loss was lowest for sample W7 and highest for sample W10. Focusing on the initial phase (Curing 1, 24 h), the mass loss in samples cured at elevated temperatures (40 °C and 60 °C) was lower than that of the samples cured at RT, although the difference was relatively small. After the 5-day period in Curing 2, no significant difference in total mass loss was observed across all sample groups sharing the same initial water content. The lower mass loss of W7 suggests that water is more effectively retained within the geopolymer matrix. Water retention implies tighter structural compactness, which may contribute to a higher volume of H2 gas production.

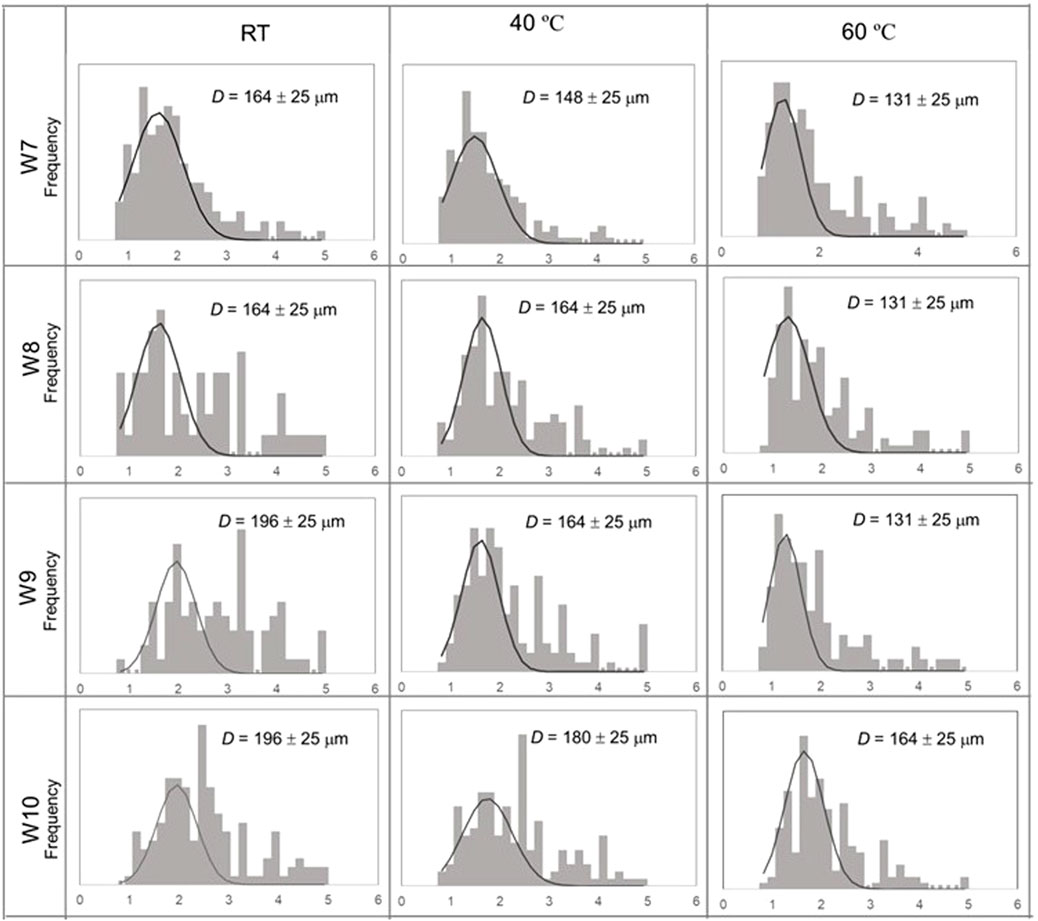

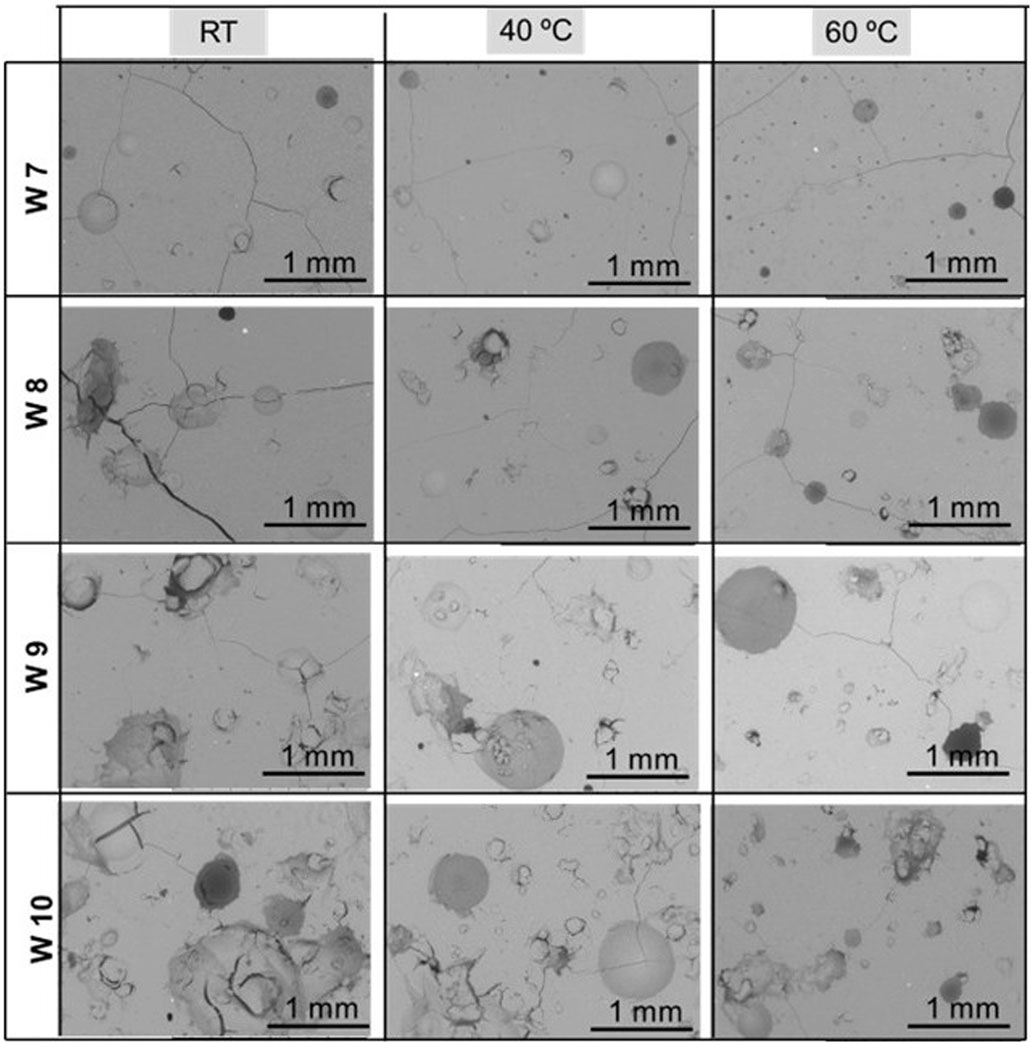

Figure 4 shows the pore size distribution of the samples under different synthesizing conditions. Generally, at a given curing temperature, a higher initial water content resulted in larger pore sizes. This is likely due to the increased amount of water trapped within the geopolymer matrix, which subsequently forms voids upon evaporation. Furthermore, comparing samples with the same initial water content but different Curing 1 temperatures, a slight influence of temperature on the pore size distribution was revealed (Figure 5). Analysis of this distribution indicated that higher Curing 1 temperatures led to a refinement of the pore structure, with the distribution shifting towards smaller pore sizes as the curing temperature increased from RT to 60 °C. This suggests that elevated temperatures promote a denser microstructure.

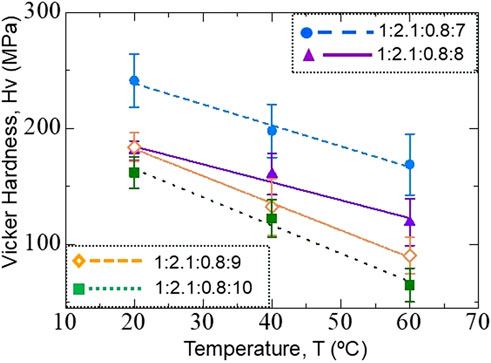

Figure 6 illustrates the Vickers hardness of the geopolymer samples across all the synthesis conditions. The initial water content clearly influenced the Vickers hardness. For Curing 1 at RT, the sample W7 exhibited the highest Hv, while the sample W10 showed the lowest. However, the Hv values for W8, W9 samples were relatively similar and not so different to W10, suggesting that the RT curing provides a more stable or less sensitive hardness response to variations in higher water content within that range. In contrast, for Curing 1 temperatures of 40 °C and 60 °C, a much distinct trend was observed, the Hv decreased consistently with increasing the water content. Furthermore, when comparing samples with the same initial water content, the Hv tended to be highest for those cured at RT and lowest for those cured at 60 °C of Curing 1.

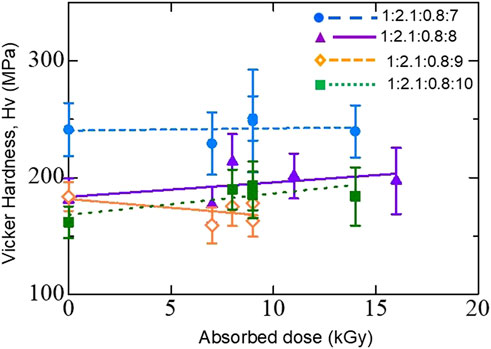

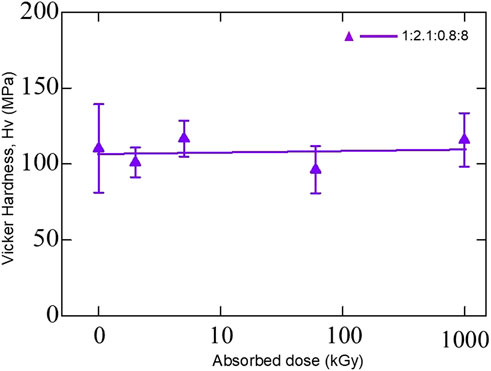

Although demonstrating comparable water retention across all Curing 1 conditions, the sample cured at RT resulted in a higher Vickers hardness, suggesting a more optimized structural matrix. Therefore, the RT-cured group was selected to investigate the effect of electron irradiation. Figure 7 illustrates the Vickers hardness of these samples after irradiation using the ETIGO-III accelerator. Consistent with the data presented in Figure 4 for RT curing, the sample W7 exhibited the highest Vickers hardness, while the Hv values for the W8, W9, and W10 samples were not significantly different. Notably, Figure 7 confirms that the Hv of all samples was not affected by electron irradiation up to an absorbed dose of 16 kGy. For the subsequent high-dose irradiation experiment, the optimization process focused on selecting the samples with considering two factors the mechanical stability and low defect potential. Sample W7 was eliminated from consideration due to the potential for H2 gas production stemming from high retained water (Figure 3). Similarly, samples W9 and W10 were excluded for their lower mechanical strength, which was suggested by having larger pore sizes (Figure 5). In contrast, the highest Vickers hardness was observed for sample W8 which was cured at RT (Figure 6), implying the denser structural condition was best suited for the investigation into the high-dose effects of electron irradiation. Subsequently, the absorbed dose was increased up to 992 kGy for the W8 sample. As shown in Figure 8, there was no significant change in Hv was observed, indicating remarkable stability of the surface hardness of this specific geopolymer composition under electron irradiation, at least up to these dose levels.

4 Discussion

The observed influence of initial water content on the Vickers hardness aligns with existing literature on geopolymer mechanical properties. These observations suggest that the amount of initial water plays a significant role on the influence of development of mechanical strength. Lahoti et al. (Lahoti et al., 2017) have pointed out that the compressive strength decreased with the water/solid ratio. The sample of Lahti was cured at RT, giving similar results in this study. However, there were variations in compressive strength observed particularly with water/solids at 0.52 wt%, indicating that the compressive strength of alkali-activated geopolymers was not completely affected by the water/solid ratio. Similarly, in this study, the Hv was not complete affected by water content from 8 to 10 mol % (25–32 wt%) at RT. Our findings, showing a peak in hardness at a specific lower water content, likely reflect this balance between the necessity of water for the reaction and the detrimental effect of excessive water on the final density and strength.

The effect of Curing 1 temperature on the mechanical properties of geopolymer, particularly hardness, is complex. While some studies have shown that compressive strength can increase with higher curing temperatures or longer curing times (Rovnanik, 2010; Hardjito and Rangan, 2005), the decrease in hardness observed in this study might be related to the moisture conditions during curing. Although a tight lid was used to retain moisture, potentially preventing rapid drying and promoting a more complete reaction, it might have also contributed to the formation of a less cohesive matrix over time, thereby reducing hardness. Given that the curing time was fixed at 24 h in this study, further investigation into the interplay of curing temperature, initial water content, and moisture levels is necessary to definitively explain the observed decrease in hardness.

The effect of electron beam irradiation on the Vickers hardness of a potassium-based geopolymer (8% initial water content, cured at room temperature for Curing 1) was investigated up to an absorbed dose of 992 kGy. The results, however, appear contrary to some literature reporting that electron beam irradiation affects the compressive strength of geopolymers (Amin et al., 2024; Mahrous et al., 2024). The localized nature of E-beam effects, along with potential influences from factors such as cross-linking, chain scission, polymerization (Yang et al., 2021), and surface modifications by moisture (Ashfaq et al., 2020), may contribute to the observed stability. Given the limited existing research on the specific effects of electron beam irradiation on geopolymer hardness, these results highlight the potential resilience of potassium-based geopolymers to this type of radiation. Nevertheless, to draw more definitive conclusions and fully elucidate the underlying mechanisms for this stability, further comprehensive studies are warranted, encompassing a wider range of geopolymer compositions, irradiation parameters, and mechanical properties.

5 Conclusion

The effect of electron beam irradiation on the Vickers hardness of the potassium-based geopolymer with varying initial water content was investigated. The Vickers hardness showed no significant change when samples were irradiated up to 992 kGy dose, suggesting a stability of this geopolymer to electron irradiation under the tested conditions. The initial water added into the geopolymer was found to influence the Vickers hardness, with higher contents generally leading to lower hardness values. The curing temperature during the initial 24 h (Curing 1 with a tight lid) also affected the Vickers hardness, indicating its importance in the development of the geopolymer mechanical properties. These findings contribute to the growing understanding of how synthesis parameters impact the Vickers hardness of geopolymer and provide a preliminary indication of their stability under electron beam irradiation, warranting further investigation into the effects on other mechanical properties.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

T-M-DD: Writing – review and editing, Writing – original draft. YY: Writing – review and editing, Formal Analysis, Data curation. TK: Methodology, Writing – review and editing. TN: Writing – review and editing, Conceptualization. GT: Writing – review and editing, Conceptualization. HS: Writing – review and editing, Project administration.

Funding

The authors declare that financial support was received for the research and/or publication of this article. This work was partly supported by KAKENHI 20H04611.

Acknowledgements

A part of the electron irradiation was carried out with the help of Koichi Hirota and Shota Yamazaki at National Institutes for Quantum Science and Technology.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that Generative AI was used in the creation of this manuscript. English refinement.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Acher, L., Noirfontaine, M. N., Chartier, D., Gorse-Pomonti, D., Courtial, M., Tusseau-Nenez, S., et al. (2021). H2 production under gamma irradiation of a calcium aluminate cement: an experimental study on both cement pastes and its stable hydrates. Radiat. Phys. Chem. 189, 109689. doi:10.1016/j.radphyschem.2021.109689

Amin, M. S., Mohsen, A., Deghiedy, N. M., Abu-Drief, A. M., Ahmed, H. A., Huange, H., et al. (2024). Impact of electron-beam and gamma-ray on the compressive strength, surface features and phase composition of β-Ni(OH)2-impregnating-geopolymer pastes. Case Stud. Constr. Mater. 20, e02841. doi:10.1016/j.cscm.2023.e02841

Ashfaq, A., Clochard, M. C., Coqueret, X., Dispenza, C., Driscoll, M. S., Ulanski, P., et al. (2020). Polymerization reactions and modifications of polymers by ionizing radiation. Polymers 12 (12), 2877. doi:10.3390/polym12122877

Christophliemk, M. P., Pikkarainen, A. T., Heponiemi, A., Tuomikoski, S., Runtti, H., Hu, T., et al. (2022). Preparation and characterization of porous and stable sodium- and potassium-based alkali activated material (AAM). Appl. Clay Sci. 230, 106697. doi:10.1016/j.clay.2022.106697

Das, D., Gotabiewska, A., and Rout, P. K. (2024). Geopolymer bricks: the next generation of construction materials for sustainable environment. Constr. Build. Mater. 445, 137876. doi:10.1016/j.conbuildmat.2024.137876

Elgarahy, A. M., Maged, A., Eloffy, M. G., Zahran, M., Kharbish, S., Elwakeel, K. Z., et al. (2023). Geopolymers as sustainable eco-friendly materials: classification, synthesis routes, and applications in wastewater treatment. Sep. Purif. Technol. 324, 124631. doi:10.1016/j.seppur.2023.124631

Hardjito, D., and Rangan, B. V. (2005). Development and properties of low-calcium fly ash based geopolymer concrete. Perth, Australia: Curtin University of Technology. Available online at: http://www.geopolymer.org/fichiers_pdf/curtin-flyash-GP-concretereport.pdf.

Houhou, M., Leklou, N., Ranaivomanana, H., Penot, J. D., and Baros, S. D. (2025). Geopolymers in nuclear waste storage and immobilization: mechanisms, applications, and challenges. Discov. Appl. Sci. 7, 126. doi:10.1007/s42452-025-06536-x

Khmurovska, Y., Stemberk, P., Sikorin, S., Němeček, J., Jozwiak-Niedzwiedzka, D., Dolezelova, M., et al. (2021). Effects of gamma-ray irradiation on hardened cement mortar. Int. J. Concr. Struct. Mater. 15, 17. doi:10.1186/s40069-020-00452-7

Kinoshita, N., Yoda, Y., Nakashima, H., Asada, M., Kiyomura, S., Sasaki, Y., et al. (2022). Physical and adsorption characteristics of geopolymers prepared using 1-5 M NaOH solution for immobilization of radioactive wastes. J. Nucl. Radiochem. Sci. 22, 7–13. doi:10.14494/jnrs.22.7

Kontani, O., Sawada, S., Maruyama, I., Takizawa, M., and Sato, O. (2013). “Evaluation of irradiation effects on concrete structure—Gamma-ray irradiation tests on cement paste,” in Proceedings of the ASME 2013 power conference: power2013, 2013, July 29 - august 1 (Boston. New York: American Society of Mechanical Engineers). doi:10.1115/POWER2013-98099

Kotatkova, J., Zatloukal, J., Reiterman, P., and Kolar, K. (2017). Concrete and cement composites used for radioactive waste deposition. J. Environ. Radioact. 178-179, 147–155. doi:10.1016/j.jenvrad.2017.08.012

Kuenzel, C., Cisneros, J. F., Neville, T. P., Vandeperre, L. J., Simons, S. J. R., Bensted, J., et al. (2015). Encapsulation of Cs/Sr contaminated clinoptilolite in geopolymers produced from metakaolin. J. Nucl. Mater. 466, 94–99. doi:10.1016/j.jnucmat.2015.07.034

Lahoti, M., Narang, P., Tan, K. H., and Yang, E. H. (2017). Mix design factors and strength prediction of metakaolin-based geopolymer. Ceram. Int. 43, 11433–11441. doi:10.1016/j.ceramint.2017.06.006

Lambertin, D., Boher, C., Dannoux-Papin, A., Galliez, K., Rooses, A., and Frizon, F. (2013). Influence of gamma ray irradiation on metakaolin based sodium geopolymer. J. Nucl. Mater. 443 (1-3), 311–315. doi:10.1016/j.jnucmat.2013.06.044

Le Caer, S., Dezerald, L., Boukari, K., Laine, M., Taupin, S., Kavannagh, R. M., et al. (2017). Production of H2 by water radiolysis in cement paste under electron irradiation: a joint experimental and theoretical study. Cem. Concr. Res. 100, 110–118. doi:10.1016/j.cemconres.2017.05.022

Li, L., Xu, Z., Li, H., Li, J., Hu, D., Xian, Y., et al. (2022). Immobilization of strontium and cesium by aluminosilicate ceramics derived from metakaolin geopolymer-zeolite A composites via 1100°C heating treatment. Ceram. Int. 48 (11), 15236–15242. doi:10.1016/j.ceramint.2022.02.054

Lizcano, M., Kim, H. S., Basu, S., and Radovic, M. (2012). Mechanical properties of sodium and potassium activated metakaolin-based geopolymers. J. Mater. Sci. 47, 2607–2616. doi:10.1007/s10853-011-6085-4

Mahrous, M. A., Trindade, A. C. C., and Aboukhatwa, M. (2024). Investigating irradiation effects on metakaoline-based geopolymer. Constr. Build. Mater. 437, 136837. doi:10.1016/j.conbuildmat.2024.136837

Maruyama, I., Haba, K., Sato, O., Ishikawa, S., Kontani, O., and Takizawa, M. (2016). A numerical model for concrete strength change under neutron and gamma-ray irradiation. J. Adv. Concr. Technol. 14 (4), 144–162. doi:10.3151/jact.14.144

Matsimbe, J., Dinka, M., Olukanni, D., and Musonda, I.(2022). Geopolymer: a systematic review of methodologies. 15, 6852. doi:10.3390/ma15196852

Mukiza, E., Phung, Q. T., Fredericks, L., Jacques, D., Seethamram, S., and De Schutter, G. (2023). Co-immobilization of cesium and strontium containing waste by metakaolin-based geopolymer: microstructure, mineralogy and mechanical properties. J. Nucl. Mater. 585, 154639. doi:10.1016/j.jnucmat.2023.154639

Rooses, A., Steins, P., Dannoux-Papin, A., Lambertin, D., Poulesquen, A., and Frizon, F. (2013). Encapsulation of Mg-Zr alloy in metakaolin-based geopolymer. Appl. Clay Sci. 73, 86–92. doi:10.1016/j.clay.2012.09.023

Rosseel, T. M., Maruyama, I., Pape, Y. L., Kontani, O., Giorla, A. B., Remec, I., et al. (2016). Review of the current state of knowledge on the effects of radiation on concrete. J. Adv. Conc. Tech. 14 (7), 368–383. doi:10.3151/jact.14.368

Rovnanik, P. (2010). Effect of curing temperature on the development of hard structure of metakaolin based geopolymer. Constr. Build. Mater. 24, 1176–1183. doi:10.1016/j.conbuildmat.2009.12.023

Seki, M., Fujita, Y., Fujihara, Y., Zhang, J., Yoshinaga, H., Sano, T., et al. (2022). Development of stabilization treatment technology for radioactive aluminum waste. J. Nucl. Fuel Cycle Environ. 29 (1), 2–9. doi:10.3327/jnuce.29.1_2

Tokuchi, A., Ninomiya, N., Yatsui, K., Imada, G., Zhu, Q., Jiang, W., et al. (1998). Development of high energy induction accelerator, “ETIGO-III”, 12th international conference on high-power particle beams. BEAMS'98. Proceedings (Cat. No.98EX103). doi:10.1109/BEAMS.1998.822410

Verma, M., Dev, N., Rahman, I., Nigam, M., Ahmed, M., and Mallick, J. (2022). Geopolymer concrete: a material for sustainable development in Indian construction industries. Crystals 12 (4), 514. doi:10.3390/cryst12040514

Yang, Y., Le, T. C. D., Kudo, I., Do, T. M. D., Niihara, K., Suematsu, H., et al. (2021). Pore-forming process in dehydration of metakaolin-based geopolymer. Int. J. Ceram. Eng. Sci. 3, 211–216. doi:10.1002/ces2.10100

Keywords: geopolymer, metakaolin, potassium, irradiation, Vicker hardness, nuclear waste, decommissioning

Citation: Do T-M-D, Yaru Y, Kikuchi T, Nakayama T, Thorogood GJ and Suematsu H (2025) Electron irradiation effects on Vickers hardness of potassium-based geopolymers: the role of water content. Front. Nucl. Eng. 4:1699785. doi: 10.3389/fnuen.2025.1699785

Received: 05 September 2025; Accepted: 03 November 2025;

Published: 19 November 2025.

Edited by:

Hammad Raza Khalid, Northumbria University, United KingdomReviewed by:

Sajid Iqbal, Korea Advanced Institute of Science and Technology (KAIST), Republic of KoreaSotya Astutiningsih, University of Indonesia, Indonesia

Copyright © 2025 Do, Yaru, Kikuchi, Nakayama, Thorogood and Suematsu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Thi-Mai-Dung Do, bWFpZHVuZ0B2b3MubmFnYW9rYXV0LmFjLmpw

Thi-Mai-Dung Do

Thi-Mai-Dung Do Yang Yaru1

Yang Yaru1 Takashi Kikuchi

Takashi Kikuchi Gordon James Thorogood

Gordon James Thorogood