- 1Department of Agricultural and Biosystems Engineering, North Dakota State University, Fargo, ND, United States

- 2Department of Plant Sciences, North Dakota State University, Fargo, ND, United States

In North Dakota, vegetable production is limited due to cold spring temperatures and a short growing season. High tunnels, also called unheated greenhouses, are commonly utilized to increase air temperature and extend the growing season. Inside high tunnels, optimal irrigation scheduling and precise water management are critical factors to achieve high yields. A remotely controlled drip irrigation system was implemented to deliver precise water amounts based on environmental conditions and crop needs. Irrigation scheduling can be automated by using a soil potential sensor-based drip irrigation system and remotely controlled with real-time data. In this 2022–2023 study, eight tomato (Solanum lycopersicum) and pepper (Capsicum annuum) cultivars were compared inside and outside a high tunnel at the North Dakota State University Horticulture Research Farm near Absaraka, North Dakota. We designed irrigation treatments using management allowable depletion (MAD) at 10% and 30%, and the standard time-based treatment with three replicates. Tomatoes under the 30% MAD treatment showed competitive results both inside (35.97 Mg ha-1) and outside (9.25 Mg ha-1) in 2023. Peppers under the 10% MAD treatment, while not consistently the highest yielding, still yielded respectable results inside (22.23 Mg ha-1) and outside (3.58 Mg ha-1) in 2022. Results also showed that the average fruit diameter and weight were significantly higher under 30% MAD for tomatoes and 10% MAD for green peppers, both inside and outside the high tunnel, respectively. These findings suggest that optimizing irrigation strategies, such as using 30% MAD, can enhance tomato crop productivity and water use efficiency, particularly in controlled environments like high tunnels.

1 Introduction

North Dakota (ND) is an important agricultural state, leading the nation in the production of spring wheat (Triticum aestivum), durum wheat (Triticum durum), dry edible peas (Pisum sativum), dry edible beans (Phaseolus vulgaris), honey, flax (Linum usitatissimum), and canola (Brassica napus) (USDA-NASS, 2024). However, ND’s vegetable production is minimal compared to other states in the United States. It is important to note that vegetable production in ND is highly dependent on weather conditions because the state usually experiences harsh winters and short growing seasons (NDSU NDSCO, 2024). Thus, tomato (Solanum lycopersicum) and pepper (Capsicum annuum) cultivation are extremely limited in ND when compared to other states (USDA-NASS, 2023). Furthermore, vegetable production can vary year to year based on numerous factors such as weather conditions, market demand, and planning decisions made by individual farmers. Therefore, the exact number of hectares for tomato production in ND may vary from year to year.

Peppers and tomatoes are both warm-season crops that require extended frost-free days to mature properly (Adeoye, 2020). Northern states such as ND are not the ideal location for the commercial production of peppers and tomatoes, but profitable pepper and tomato production may be possible in ND with the use of seasonal extension techniques, such as high tunnels. These techniques help to extend the growing season, protect plants from cool temperatures and pests, and create a more favorable microclimate for the crops (Lamont, 2009).

High tunnels, also known as hoop houses or unheated greenhouses, are typically covered with a double layer of 0.15 mm polyethylene greenhouse film in cold and windy locations and are utilized to produce a wide variety of crops directly in the soil (Carey et al., 2009), thus increasing the value of the high tunnel as a tool for season extension and crop protection. High tunnels are enclosed polyethylene, polycarbonate (plastic), or fabric-covered structures utilized to cover and protect crops from sun, wind, excessive rainfall, or cold, and to extend the growing season in an environmentally safe manner (Donovan et al., 2023; Lakhiar et al., 2024a). Carey et al. (2009) underscored the ongoing adoption of high tunnels that resulted in numerous grower innovations and increased university research and extension programs to serve the grower’s needs. Belasco et al. (2013) listed many high tunnel benefits, such as increased yields and quality, extended growing season, and crop protection against extreme weather conditions. Tian et al. (2023) highlighted the role of high tunnels to enhance vegetable production. Splichal (2020) conducted research in ND and found that double-layer high tunnels yielded higher yields and could increase profits for small-scale farmers Sideman (2020) conducted research on the yields of colored bell pepper cultivars grown in high tunnels in northern New England and demonstrated that high tunnels could facilitate the production of ripe colored bell peppers in locations with short growing seasons. Their study also highlighted that cultivars developed for controlled environments produced greater marketable yields than those developed for field production.

Irrigation management is crucial for crops grown in high tunnels, as these structures can significantly alter environmental conditions, particularly temperature. Drost et al. (2021) and Lakhiar et al. (2025) indicated that while temperature control is often the primary focus, water management is equally important to prevent plant stress. Effective irrigation strategies, such as drip irrigation, are recommended to maintain soil moisture, ensuring that water is readily available and plants do not experience water stress. Proper irrigation management can improve growth and productivity in high-tunnel crop production. In a recent study by Rho et al. (2020), the yields, fruit quality, and water use of jalapeno peppers and tomatoes were compared between open field and high tunnel production systems in the Texas High Plains. The high tunnel system significantly increased yield by 30% for peppers and resulted in better color with higher lycopene content for tomatoes compared to open field production. Additionally, tomatoes exhibited 20% higher water use efficiency compared to peppers, and the high tunnel system had 15% lower water use than open field, indicating more efficient water utilization.

Drip irrigation in high tunnels is a highly efficient method for managing water resources for horticultural crops. This emphasizes its suitability for maintaining consistent soil moisture and preventing the stress associated with both over- and under-watering. Zahid et al. (2020) highlighted that drip irrigation, when managed correctly, can lead to improved crop growth and yield. It allows for precise water application directly to the plant roots, minimizing wastage and evaporation loss, ensuring efficient use of water resources, and maximizing water use efficiency. This represents a sustainable approach to high tunnel crop production, ensuring optimal plant growth while conserving water resources.

Irrigation scheduling for vegetable crops is a complex task that has been the subject of extensive research, particularly in the face of climate change. Cahn and Johnson (2017) discussed new approaches for irrigation scheduling and emphasized the integration of advanced sensor technology and web applications to address the challenges posed by imprecise crop coefficients and labor-intensive management of multiple fields. They highlighted the potential of soil moisture sensors, improved public weather station networks, and remote sensing technologies to enhance irrigation efficiency. Pardossi and Incrocci (2011) explored traditional and contemporary methods for irrigation scheduling, focusing on the role of soil moisture sensors and wireless sensor networks in improving water use efficiency and nutrient use efficiency in vegetable cropping systems. These studies underscore the importance of adopting innovative technologies and decision support tools to optimize irrigation practices, ensuring high yields and sustainable water management in agriculture.

The automated drip irrigation system can be an effective way to increase crop yield and water use efficiency in tomatoes because the use of such technology is beneficial for farmers as it can increase profits and conserve water resources (Lakhiar et al., 2024b). The adoption of smart irrigation controllers has increased over the years due to their effectiveness in conserving water and improving irrigation efficiency (Dukes, 2020). These controllers use real-time weather or soil moisture data to determine when and how much water to irrigate the crops, thereby reducing water waste. Vaddevolu et al. (2021) demonstrated the effectiveness of sensor-controlled drip irrigation under mulches for tomato production, emphasizing the role of technology in optimizing water use. Kuslu et al. (2016) provided practical insights from a study in Turkey, suggesting that irrigation can be supplied more frequently at specific intervals during summer and winter to maximize yield. These studies collectively underline the critical interplay between weather conditions and crop production, and the need for strategic management of water resources.

Despite extensive research on irrigation scheduling for open field tomato and pepper production (Suchoff et al., 2018), limited information is available on how different management allowable depletion (MAD) thresholds and time based (TB) strategies perform under the unique microclimatic conditions of high tunnels. In particular, the interactions among soil moisture dynamics, evapotranspiration rates, and water use efficiency across multiple soil depths are still poorly quantified in these protected environments. As a result, growers currently lack evidence-based guidance on which irrigation regime (e.g., 10% or 30% MAD or TB) optimizes water use efficiency (WUE) and yield for tomato and pepper crops grown in high tunnels. This uncertainty can lead to either over-irrigation or under-irrigation, both of which can stress plants and reduce marketable yield.

To date, most studies have focused on open field systems or have evaluated a single irrigation strategy within high tunnels, without directly comparing multiple MAD thresholds across both inside and outside environments (Abdelraouf et al., 2020). By systematically comparing TB, 10% MAD and 30% MAD irrigation treatments in both high tunnel and open field settings over two growing seasons, this study addresses that gap and provides actionable recommendations for sustainable irrigation management in protected agriculture.

A two-year study in ND was conducted to compare the environmental conditions, yield components, and irrigation water management of crops inside high-tunnel and field production systems. The objectives of the current study were to evaluate a remote-controlled soil potential sensor-based drip irrigation system for tomato and pepper production using three different drip irrigation treatments namely, TB irrigation (standard), 10% MAD, and 30% MAD inside and outside a high tunnel to evaluate the effect of these irrigation treatments on fruit yield and quality and WUE for each crop. These three irrigation treatments were chosen to evaluate the effects of soil moisture-based versus fixed-schedule irrigation on crop performance. The 10% MAD represents a conservative threshold aimed at minimizing water stress, whereas the 30% MAD treatment allows for moderate stress to assess potential water-savings. The TB treatment reflects conventional irrigation practices and serves as a baseline for comparison with sensor-based methods. As stated by Shah et al. (2025), the key difference between the 10% MAD and 30% MAD treatments lies in the distribution of irrigation water – 10% MAD involves smaller, more frequent applications, whereas 30% MAD delivers larger amounts of water less frequently.

2 Materials and methods

2.1 Site description

Field experiments were conducted in a high tunnel located at the North Dakota State University Horticulture Research Farm near Absaraka, a small town in Cass County, ND (46°59’28.2” N, 97°21’19.9” W) during the 2022 and 2023 growing seasons. The climate at the research site is typical of a continental climate with cold winters and mild, warm summers (Splichal, 2020). The site has an elevation of 1070 m, with an average monthly high temperature of 27.1 °C in July and a low temperature of -16 °C in January (NDAWN, 2024). The mean annual precipitation is approximately 508 to 660 mm per year, with 935 mm including snow water equivalent. The frost-free period ranges from 110 to 160 days. The average daily mean, maximum, and minimum values of the weather parameters are given below in Table 1. The soil type at the research site is Warsing sandy loam, loamy substratum with 0 to 2 percent slope (NRCS-USDA Web soil survey, 2024).

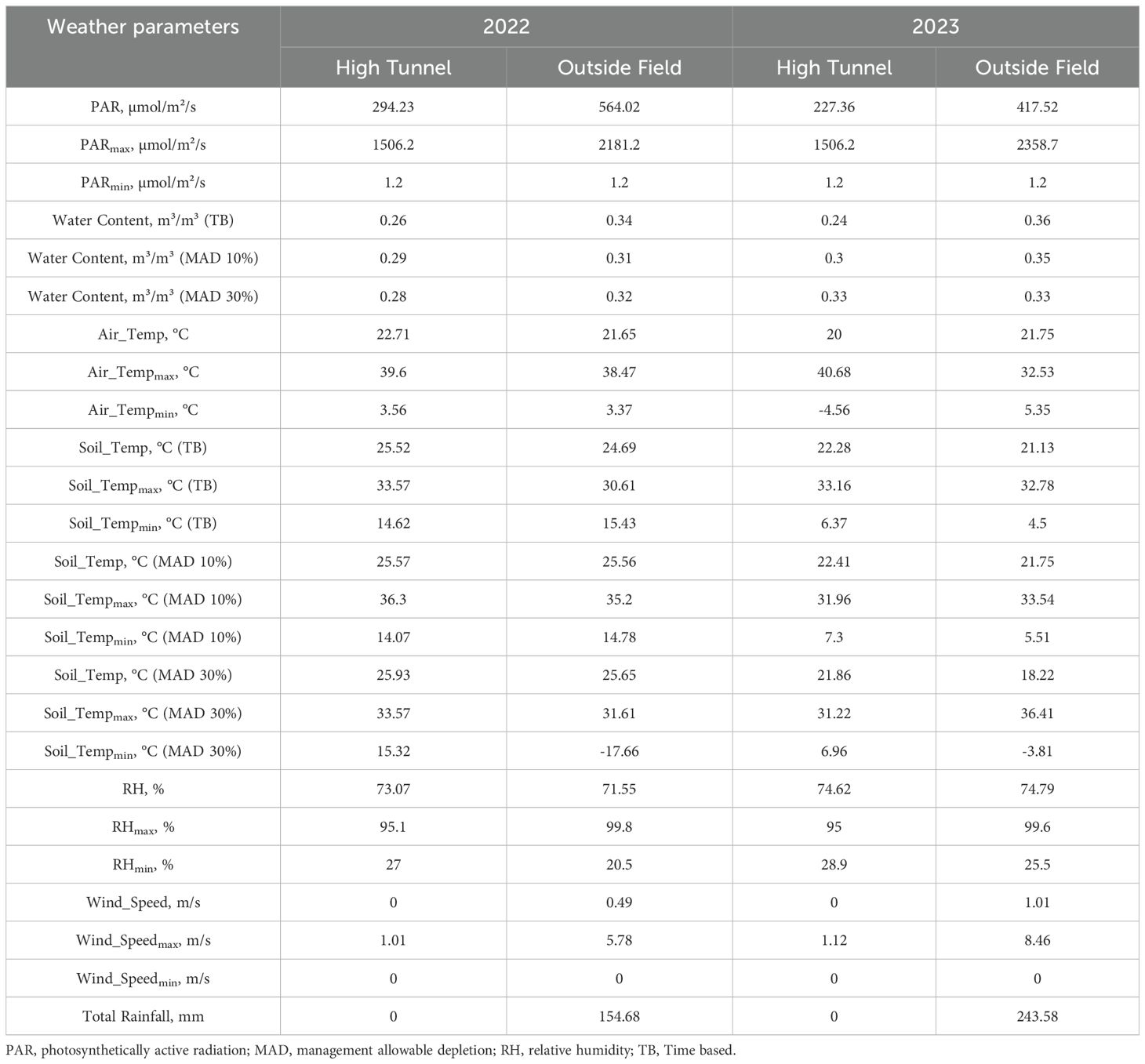

Table 1. Average daily micrometeorological measurements inside the high tunnel (May to October) and in the open field (June to October) in 2022 & 2023.

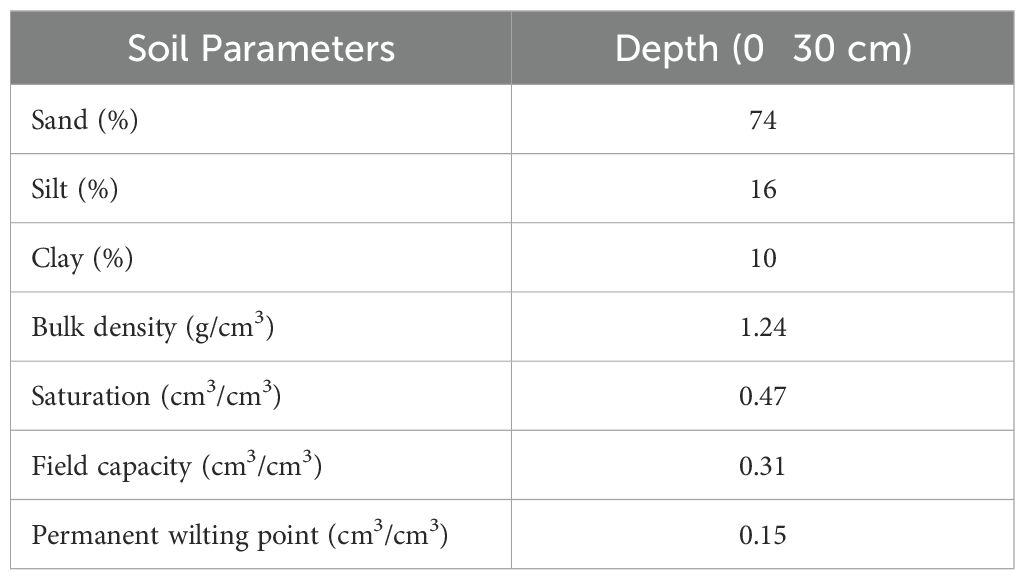

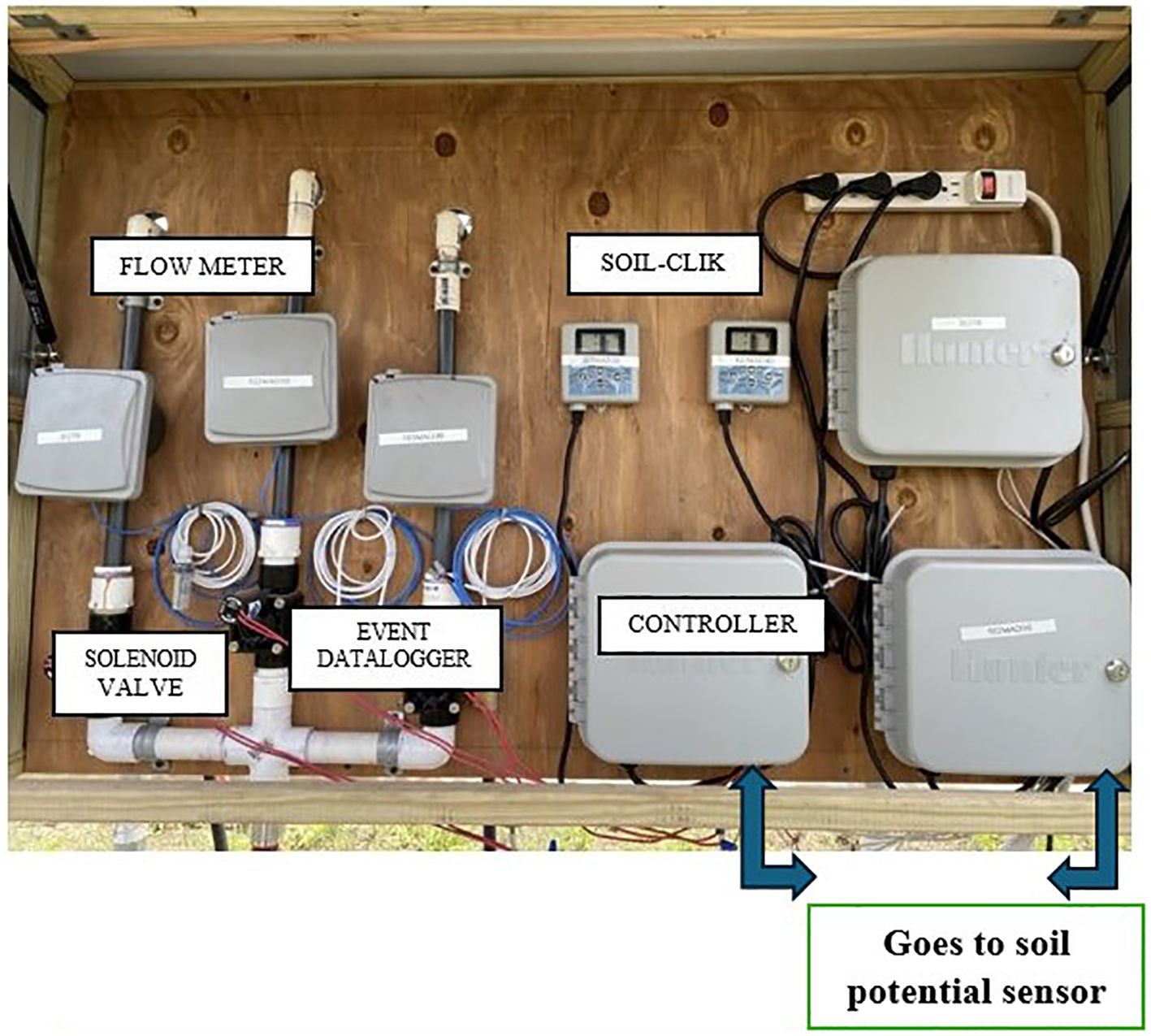

The depth of the water table is about 114 to 152 cm (NRCS-USDA Web soil survey, 2024). The physical soil parameters are given in Table 2. The soil testing (Agvise Laboratories Inc., ND) parameters in 2022 and 2023 were given in Table 3. The soil pH in 2023 was 1.52 units higher than in 2022, which may be caused by the frequent irrigation in 2022, as the irrigation water had a pH of 8.4. The accumulation effects from using high-pH water for irrigation over time can limit nutrient movement in high tunnel and gradually raise root zone pH.

2.2 Experimental design

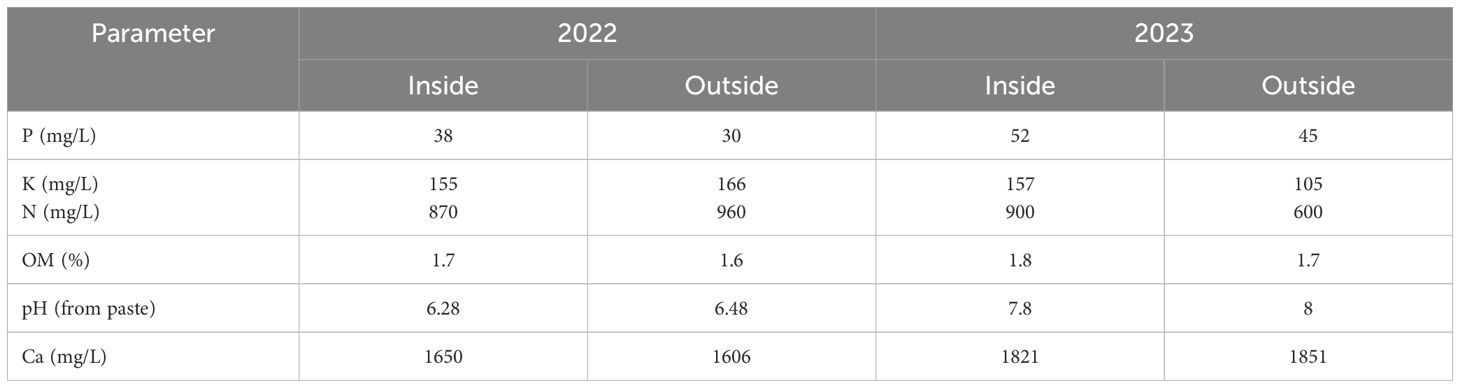

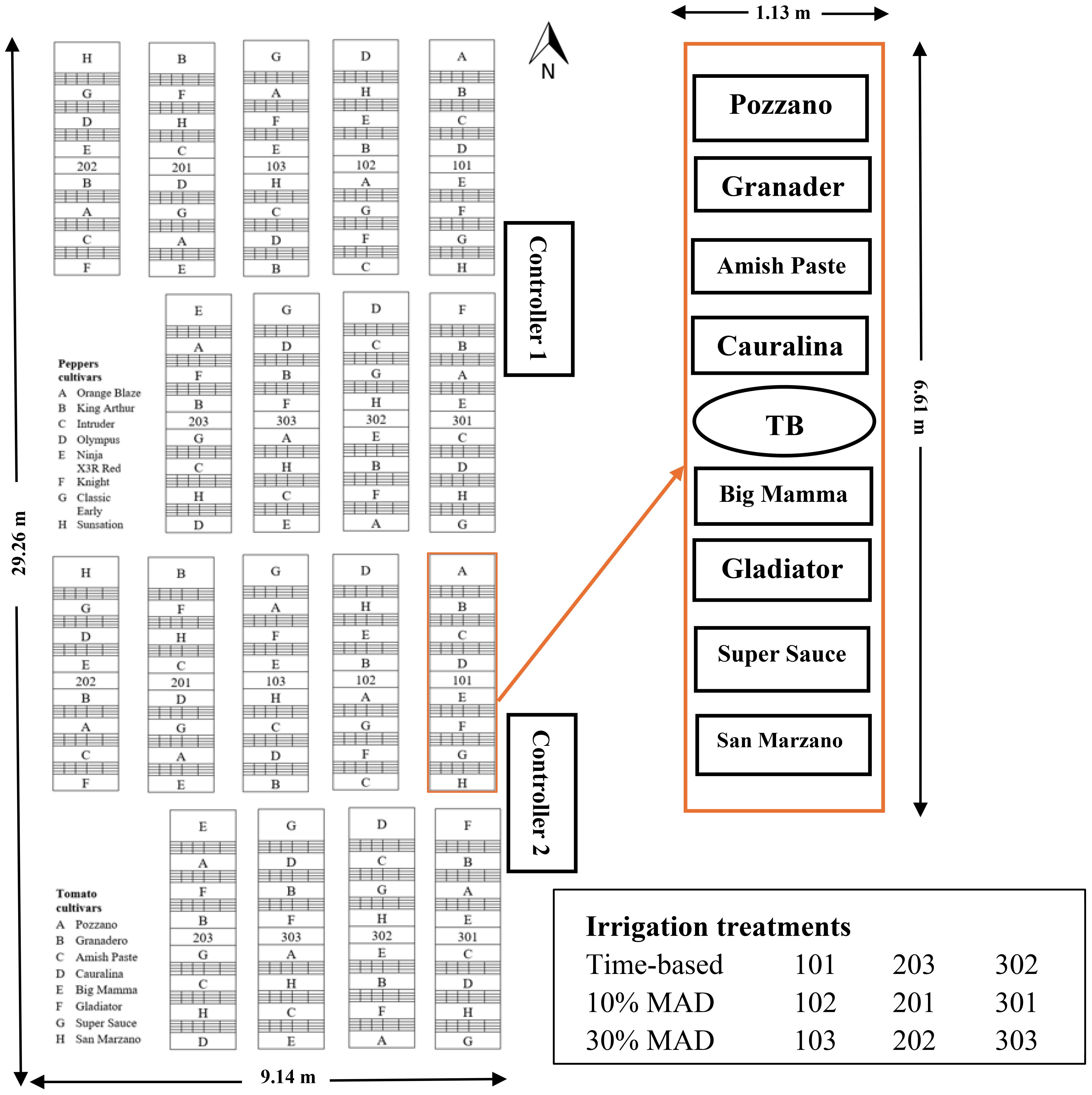

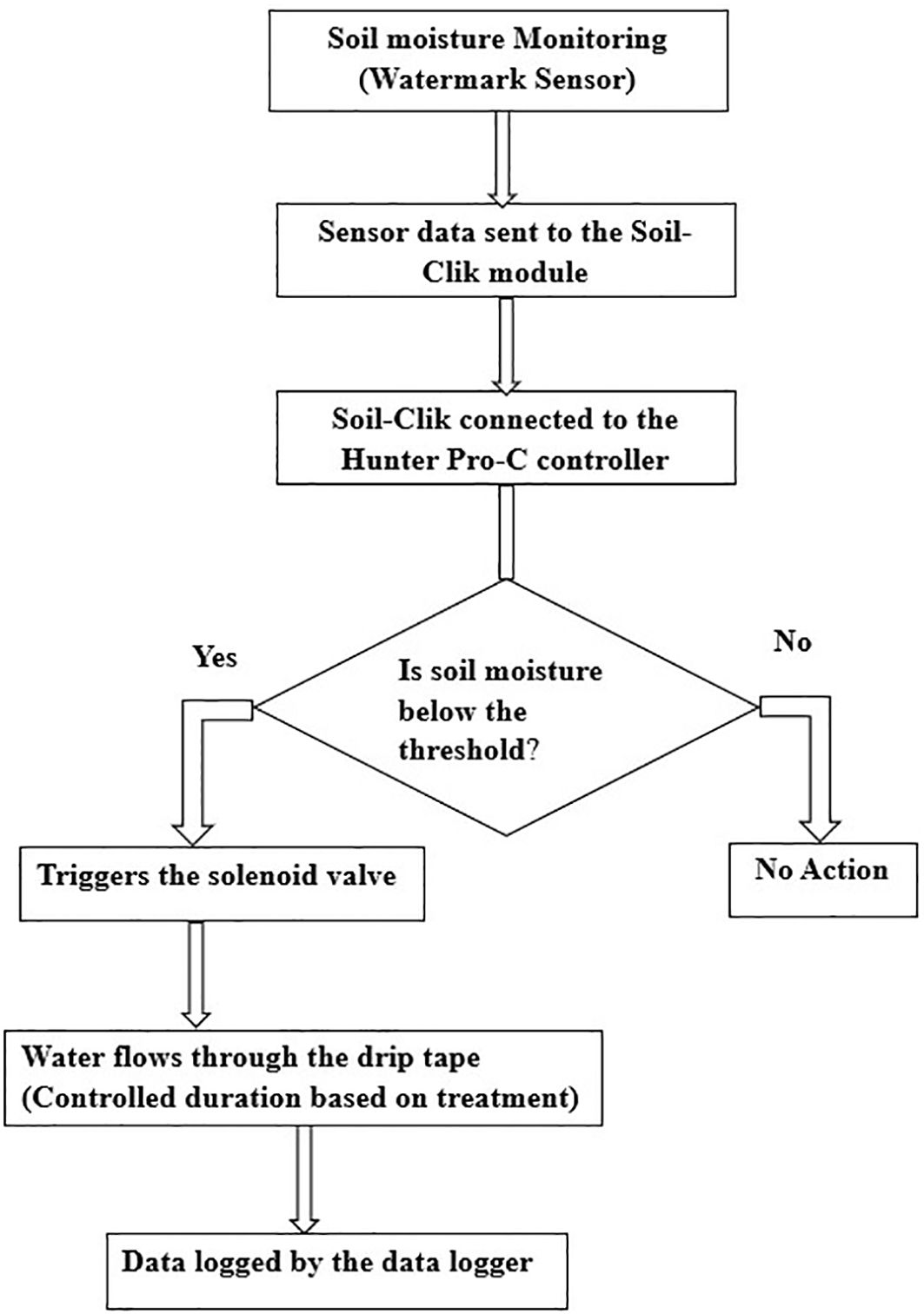

The experiment was conducted with a split-plot complete randomized block design with the three irrigation treatments (TB, 10% MAD, and 30% MAD) as the main plot, and eight cultivars as the sub-plot with three replicates. Each irrigation treatment was applied to three beds (main plots) as a whole, and within each bed, eight cultivars per crop were arranged in rows as subplots, ensuring equal distribution and replication across treatments. The complete layout of the experiment was mirrored inside and outside the high tunnel (Figure 1). The front view of one of the four controller boxes is given in Figure 2. The flow chart showing the operation of the remotely controlled drip irrigation system is given in Figure 3. A more detailed explanation of the remote automation system can be found in Shah et al. (2025). Tomatoes and peppers were planted in separate beds; however, both were grown in the same soil type at the experimental site, and the soil was uniform across the plots. The ground was prepared to form raised beds (1.13 m width x 0.1 m height). Eighteen raised beds were established inside the high tunnel and outside the field to grow peppers (nine raised beds) and tomatoes (nine raised beds). The design allowed the evaluation of eight cultivars under each of the three irrigation treatments, within the limitation of nine beds per crop, while maintaining appropriate replication and randomization. The area inside and outside the high tunnel was subdivided into two zones (blocks) for each crop. In each zone, there were nine plots (6.61 m length x 1.13 m width each per plot) for each crop. Plants were manually transplanted at a 0.6 m spacing for both peppers and tomatoes. The growing degree days from transplanting to final harvest ranged from 1117 for the high tunnel and 974 for the outside field in 2022. In 2023, this ranged from 1425 for high tunnel and 1192 for outside field.

2.3 High tunnel

The Nor’easter style high tunnel (Rimol Greenhouse Systems, Inc., Hooksett, NH) was used in the study with 29.26 m length x 9.14 m width x 4.26 m height and a total of 267.44 m² of area. The area outside the high tunnel was the same as inside the high tunnel. The covering material of the high tunnel was a 0.2 mm-thick double polycarbonate sheet (Rimol Greenhouse Systems, Inc., Hooksett, NH). During the study period, the high tunnel’s sidewalls were automatically rolled up when the air temperature inside the high tunnel was above 24 °C to dissipate accumulated daytime heat within the tunnel. The roll-upside walls were automatically controlled by a low-voltage DC motor and triggered by an air temperature sensor suspended in the middle of the high tunnel. Black plastic mulch (Dubois Agri. Inc., QC, Canada) with a thickness of 0.02 mm was used for both inside the high tunnel and outside the field on the top of the raised beds. The width of the mulch was 0.9 m, while the two edges of the mulch were buried by soil during the field operation. There was 0.7 m of width exposed to the atmosphere. The raised bed’s construction, drip tape installation, and mulch layout were all finished in one operation by a small bedder (Mechanical Transplanter Co., Holland, MI). According to previous research, the use of black plastic mulch has been shown to significantly enhance tomato yields (Vaddevolu et al., 2021).

2.4 Seeding and transplant

The pepper cultivars were Orange Blaze, King Arthur, Intruder, Olympus, Ninja, X3R Red Knight, Classic, and Early Sensation. The paste tomato cultivars were Pozzano, Granadero, Amish Paste, Cauralina, Ninja, Big Mama, Gladiator, and San Marzano. In 2022 and 2023, the peppers and tomatoes were directly seeded in 10.16 cm x 8.89 cm (LxW) plastic trays (Carlin Horticulture Supplies Inc., St. Paul, MN) and placed in a greenhouse. The growing medium utilized to germinate the seeds and grow the seedlings was a peat-based, general-purpose growing medium (Pro-Mix, Premier Tech., Quakertown, PA). The seedlings for the high tunnel and field were grown in a greenhouse at 27°C until acclimated to the outdoor environment at a semi-protected area for approximately one week before transplanting. During the final week before transplanting, the plants were placed outdoors to acclimate them to external environmental conditions.

2.5 Drip irrigation

The surface drip irrigation system was installed with drip tapes (Drip Works Inc., Sanhedrin Circle Willits, CA) in each plot with 0.30 m (12 inch) emitter spacing, and 1.89 L min-1 flow rate per 30.48 m (100 ft) drip length at a pressure range of 69–103 kPa (10–15 psi). Two drip tapes, spaced 30.48 cm apart, were installed in the middle of each raised bed where the plants were between the two drip lines. Two control boards were installed, both inside and outside the high tunnel, to host various instruments and sensors to guide the irrigation scheduling. One soil potential sensor was connected with a Soil-Clik (Hunter Industries, Inc., San Marcos, CA), and the Soil-Clik was connected to a controller (Hunter PRO–C, Hunter Industries, Inc., San Marcos, CA) for each irrigation treatment. A solenoid valve was utilized to trigger the irrigation. A flowmeter (Midwest Instruments and Controls, Rice Lake, WI) and datalogger (Onset, HOBO Inc., Bourne, MA) were utilized to record the irrigation amount. Two more flowmeters were mounted at the headline to measure the total flow amount inside and outside the high tunnel. Based on the soil release curve measured using HYPROP and WP4 (Roy et al., 2018), level 2 at -10 kPa was set up for 10% MAD (measured as -14.1 kPa or 30.7%) and level 3 at -20 kPa is set up for 30% MAD (measured as -24 kPa or 26.1%). Irrigation was needed when the soil potential reached 10% and 30% below the moisture content between the field capacity and the permanent wilting point. Based on the drip tubing flow rate, the irrigation time was calculated as 24 min (1.5 cm) for TB, 10 min (0.6 cm) for 10% MAD and 20 min (1.3 cm) for 30% MAD inside and outside the high tunnel, assuming only half of the area (50 cm) was wetted. Whenever the water potential reached level 2 for 10% MAD and level 3 for 30% MAD, the Soil-Clik triggered, and the solenoid valve opened to allow the irrigation to start. The management of the irrigation was operated through the manufacturer-provided application Hydra-wise®. The application was installed on mobile phones to remotely control the irrigation scheduling. The two controllers were connected to Mi-Fi (Verizon Jetpack MiFi 8800 L, Basking Ridge, NJ) because the high tunnel did not have internet access. The Mi-Fi was placed in the middle between the inside and outside HT, so the signal can cover the area both inside and outside the high tunnel, and only one Mi-Fi unit is needed.

2.6 Measurements

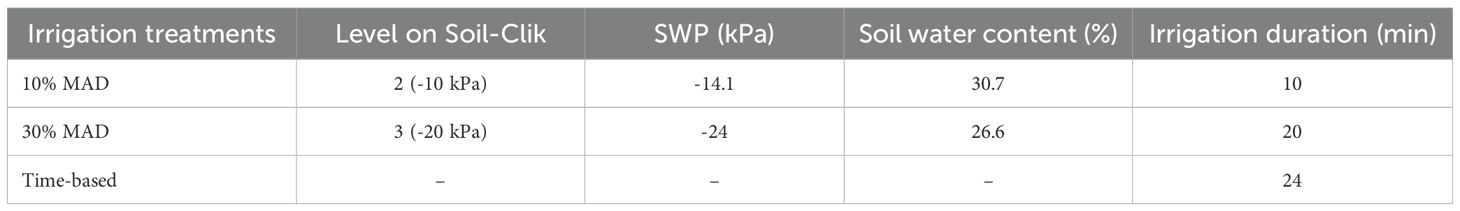

Soil water potential (SWP) sensors (Watermark, model 200SS, Irrometer Co. Inc., Riverside, CA) and soil temperature sensors (Type – T thermocouple, TC Measurement and Control Inc., Berkeley, IL) were installed in the raised beds adjacent to the sensor for irrigation control to measure soil water potential and temperature. Two soil water potential sensors and two temperature sensors at 15 and 30 cm depths, respectively, were buried in the center of the 2nd replicate for each irrigation treatment of both crops. All soil water potential and soil temperature sensors were connected to a datalogger (CR1000, Campbell Sci. Inc., Logan, UT), and a multiplexer (AM16/32B, Campbell Sci. Inc., Logan, UT) with a 12 V battery, and the data were recorded at 15-min intervals. One additional water potential sensor was installed at 15 cm depth, next to the monitoring sensors, but was connected to the controller (Hunter PRO–C, Hunter Industries, Inc., San Marcos, CA) to guide the irrigation for 10% MAD and 30% MAD treatments. The TB treatment irrigates the crops for 24 min on Monday, Wednesday, and Friday. The 10% MAD and 30% MAD treatments are scheduled to trigger the irrigation three times each day if needed. The three replications were connected and irrigated at the same time and amounts. The levels of soil water potential and Soil-Clik levels for the different irrigation treatments are given in Table 4.

Table 4. Soil water potential (SWP) and manageable allowable depletion (MAD) for irrigation treatments.

Micrometeorological measurements were collected inside and outside the high tunnel. Each weather station (Onset Corporation, Pocasset, MA) measured the Photosynthetic Active Radiation (PAR) with a PAR sensor, wind speed and direction were measured by a three-cup anemometer, and relative humidity and air temperature were measured by the ATMOS 14 sensor (METER Group, Pullman, WA). Reference evapotranspiration (ET0) was measured using an automatic ETgage (ETgage Co., Loveland, CO, USA) and recorded by a HOBO event datalogger (Onset Computer Corporation, 1996), installed inside and outside the high tunnel. Data was continuously retrieved using software provided by the manufacturer. All the sensors were installed at a height of 1.2 m above the ground. Two web cameras (S10–4G U Box, RUIBOSI Electronic Co., LTD, Shenzhen, China) were installed inside and outside the high tunnel for live monitoring of the plants. Soil moisture sensors (Decagon Devices, Pullman, WA) were installed in the three treatments for both peppers and tomatoes, inside and outside the high tunnel, to measure the soil moisture contents at 15 cm depth. Data was downloaded and analyzed on a weekly schedule. An automatic tipping bucket rain gauge (Productive Alternatives Inc., Fergus Falls, MN) was installed to measure the rainfall outside the high tunnel.

2.7 Yield data collection

In both 2022 and 2023, peppers and tomatoes were transplanted earlier inside the high tunnel than outside in the open field. Transplanting inside the high tunnel occurred on 2nd May in 2022 and 1st May in 2023, whereas transplanting outside the tunnel took place on 1st June in 2022 and 12th June in 2023. Weekly plant observations and harvesting were conducted beginning in mid-June inside the high tunnel and mid-July outside for both years. Harvesting continues weekly for both crops at both locations throughout the season. Harvesting was initiated once pepper fruits reached at least 80% of the marketable size with a dark green color, and when tomatoes reached the “pink to red” stages classified according to USDA maturity standards (7 CFR § 51.1904) and the unofficial visual aid from the USDA Marketing Service Fruit and Vegetable Division and the United Fresh Fruit and Vegetable Association (United States Department of Agriculture, 1981). Fruits were hand-harvested and weighed immediately after collection. The total number and marketable yield were recorded based on visible biological defects. During peak production, harvesting frequency increased to twice per week for crops inside the high tunnel, while harvesting remained once per week for crops grown outside the field.

2.8 Water use efficiency

WUE is the key metric that measures the crop yield produced per unit of water consumed and can be calculated from Equation 1 (Stanhill, 1986):

2.9 Statistical analysis

All yield data collected from the study were analyzed and compiled using the SAS version 9.4 (Statistical Analysis System Institute, Carey, NC). A two-way analysis of variance (ANOVA) was applied to study the impact of irrigation treatment on marketable fruit yield with Tukey’s mean separation test. The cultivars were all averaged because individual cultivar comparisons were not the study’s objective.

3 Results and discussions

3.1 Climatic and environmental conditions during the study period

There were significant differences in environmental conditions between the high tunnel and the outside field. The average daily mean, maximum, and minimum air temperatures were all higher inside the high tunnel than outside. The average daily mean, maximum, and minimum RH were higher inside the high tunnel than outside the high tunnel. The high tunnel significantly reduced the average wind speed compared with the field. Incoming PAR was also greatly decreased in the high tunnel when compared with the field. The diurnal PAR values on a cloud-free day (07/15) in 2022 and 2023 were measured both inside and outside the high tunnel. The PAR inside the high tunnel was lower compared to the outside field due to the double polycarbonate sheet, which partially blocks incoming radiation. The ET values were slightly lower inside the high tunnel than in the field. The consistently higher ET outside the high tunnel than inside was likely due to greater exposure to environmental factors like wind and direct sunlight, which elevate water loss in the outside field. It is important to note that the data presented in this study reflect conditions specific to the experimental site and may not represent the general environmental or agronomic conditions of the broader area.

The ET outside displayed sharper fluctuations in 2022 while it steadily increased in 2023, indicating daily and seasonal weather variation, with a peak around mid-summer (July), when temperature and solar radiation were the highest. Inside the high tunnel, the ET was lower and more stable, reflecting a controlled environment that minimized extreme fluctuations. This stability in the high tunnel suggests potential benefits for water conservation and irrigation efficiency because crops would likely require less frequent irrigation compared to an outside field. The seasonal decline in ET after July for both environments correspond to cooling temperatures as summer transitions to fall. This comparison highlights how high tunnels can moderate climate impacts, offering a more consistent growing environment and possibly improving water use efficiency. The controlled environment within high tunnels helps to maintain optimal temperature and humidity levels, which are crucial for pepper and tomato growth. For instance, maintaining daytime temperatures between 24-30°C (75-86°F) and nighttime temperatures between 18-21°C (64-70°F) is ideal for tomato growth. Similarly, peppers thrive in slightly warmer conditions, with optimal temperatures ranging from 25-30°C (77-86°F) during the day and 20-24°C (68-75°F) at night (Rho et al., 2020).

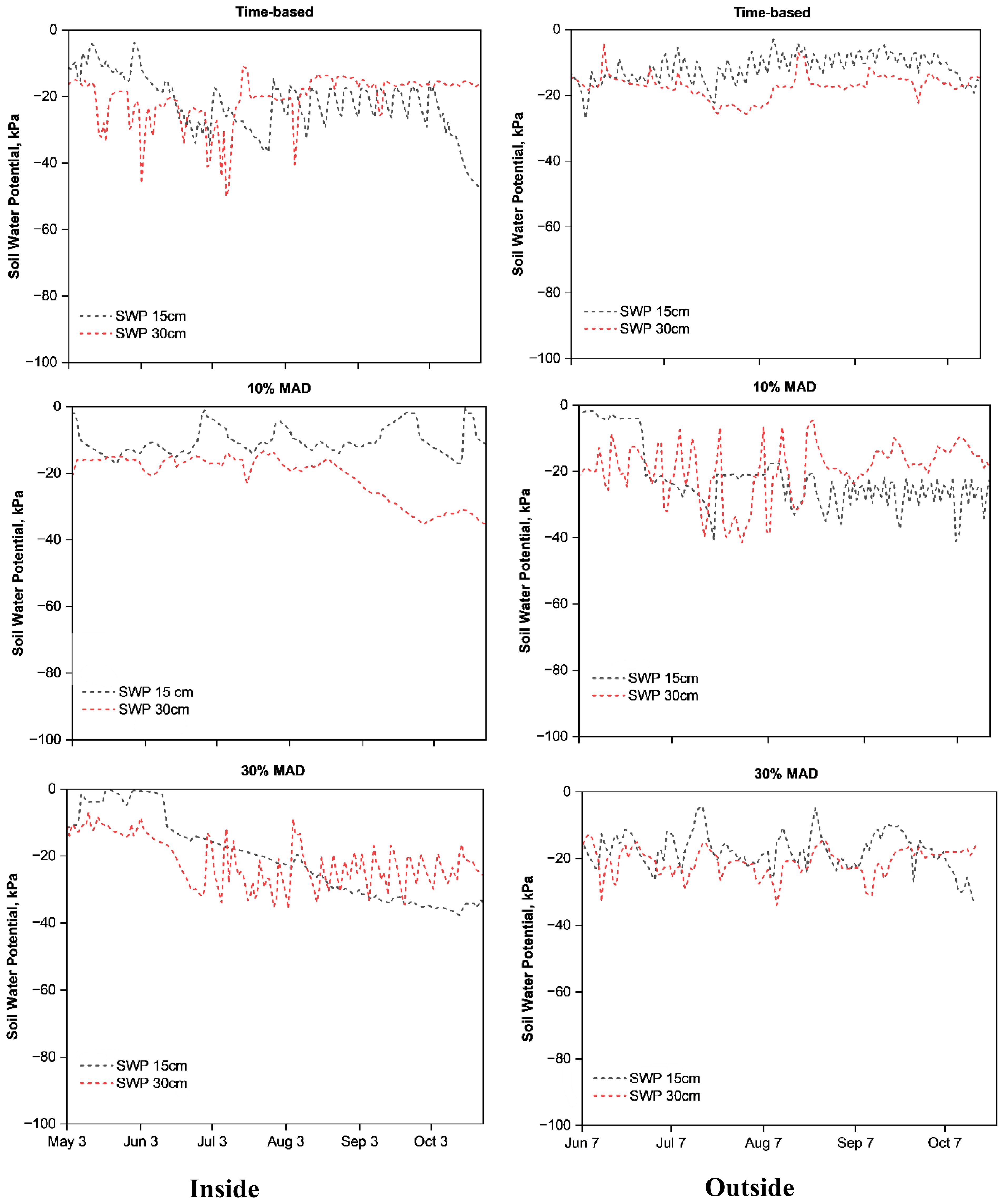

3.2 Temporal variation in soil water potential

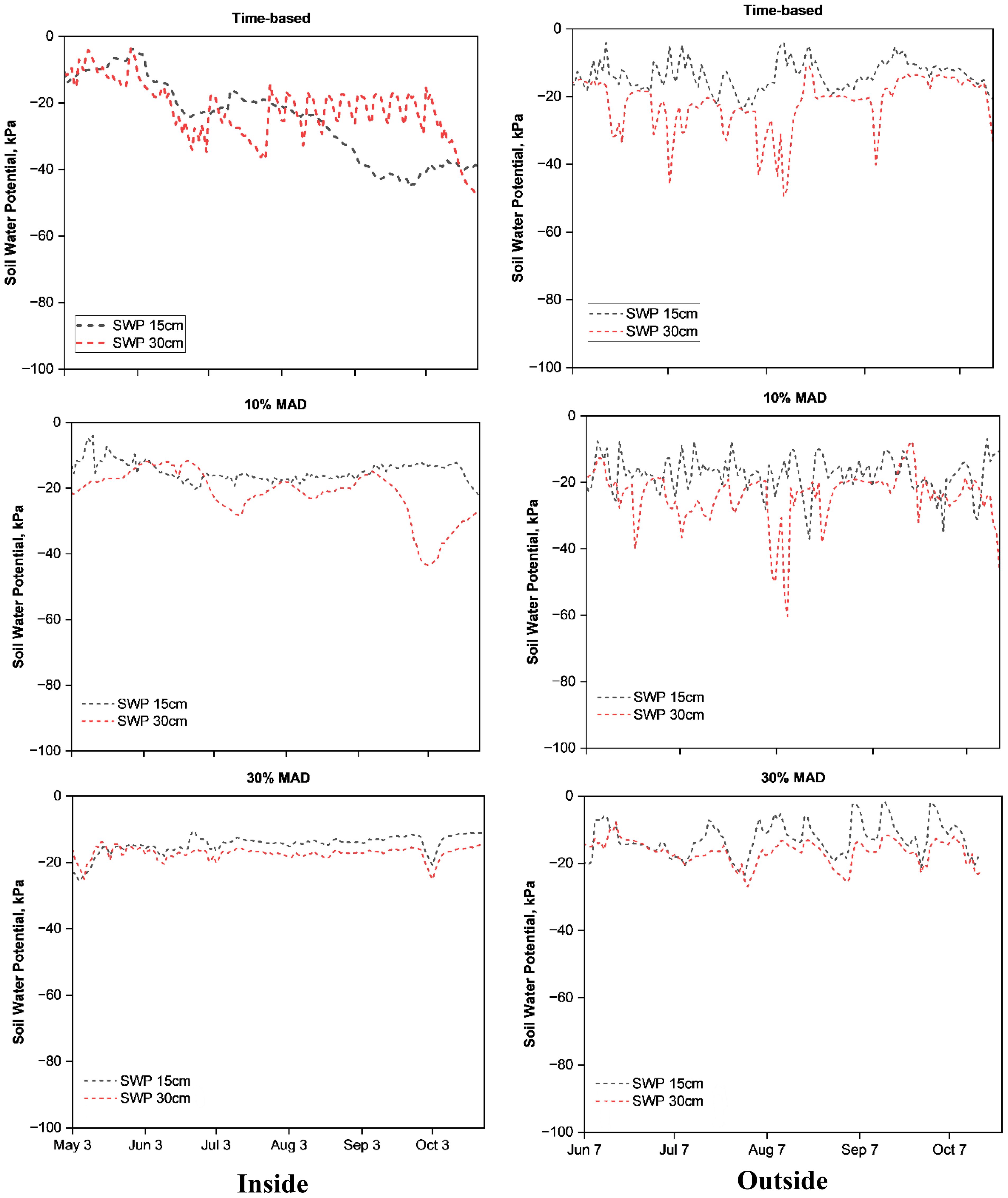

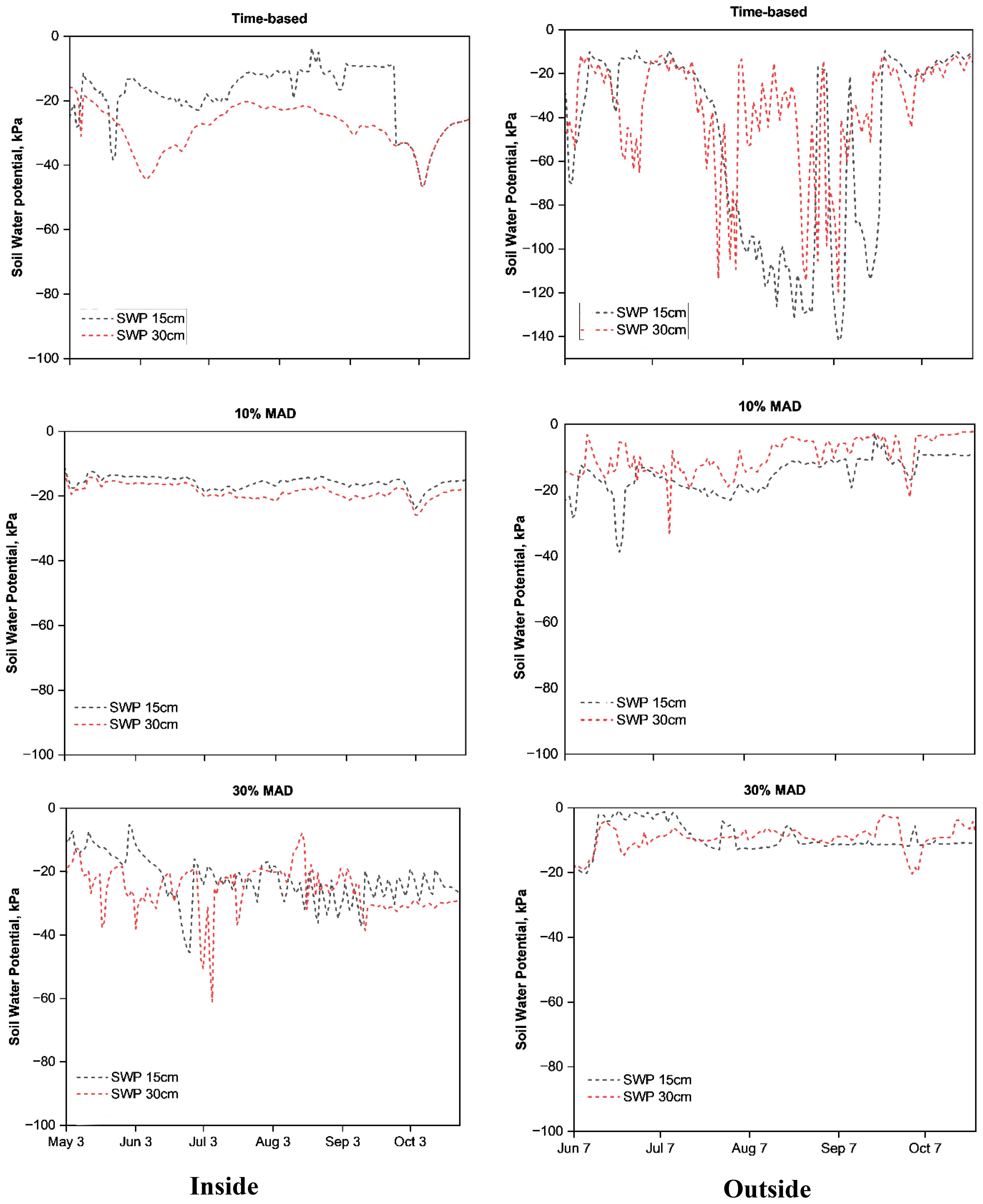

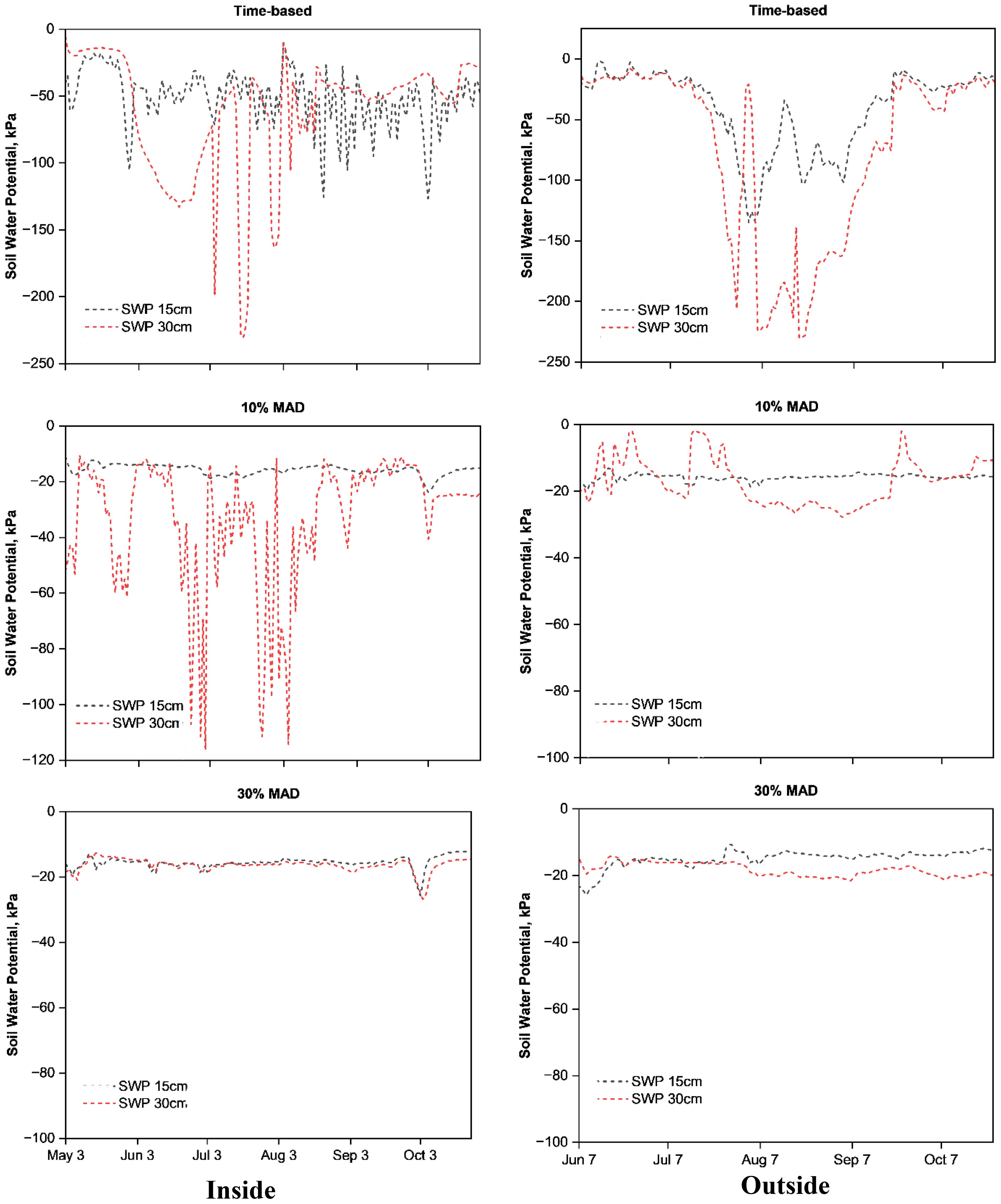

In both years and across nearly all irrigation treatments, SWP at 15 cm depth was generally higher than at the 30 cm depth inside the high tunnel for both peppers and tomatoes (Figures 4-7). This indicated that the soil was wetter at 15 cm depth than the 30 cm depth. There were frequent irrigations that occurred in all the MAD irrigation treatments due to the sandy loam soil type, which has a smaller water holding capacity (He et al., 2021). Also, the evaporation from the surface soil was less because of the black plastic mulch. Thus, the soil at 15 cm depth was generally wetter when compared to the 30 cm depth. In some cases, soil water infiltrates deeper layers, leading to a dry surface layer and a wet bottom layer. The SWP at 15 cm and 30 cm depths indicates the SWP at which water is held in the soil, with lower (more negative) values suggesting drier conditions. These irrigation treatments reflect the percentage of allowable soil moisture depletion before irrigation was triggered. Inside the high tunnel, the curves generally show less fluctuation, indicating more stable moisture levels due to controlled environmental conditions. Outside, the curves exhibit greater variability, reflecting the influence of external weather conditions.

Figure 4. Daily average soil water potential (SWP) at 15 and 30 cm depth in pepper plots in 2022 under different drip irrigation treatments inside and outside the high tunnel.

Figure 5. Daily average soil water potential (SWP) at 15 and 30 cm depth in tomato plots in 2022 under different drip irrigation treatments inside and outside the high tunnel.

Figure 6. Daily average soil water potential (SWP) at 15 and 30 cm depth in pepper plots in 2023 under different drip irrigation treatments inside and outside the high tunnel.

Figure 7. Daily average soil water potential (SWP) at 15 and 30 cm depth in tomato plots in 2023 under different drip irrigation treatments inside and outside the high tunnel.

Throughout 2022, for peppers and tomatoes, the SWP at 15 cm and 30 cm depths showed distinct seasonal trends (Figures 4, 5). From May to June, during the flowering stage, both depths maintained relatively stable SWP values, indicating effective initial irrigation. However, during the hotter months of July and August, the SWP at 15 cm depth became more negative, reflecting increased soil dryness due to higher evapotranspiration and plant water uptake, while the 30 cm depth showed less pronounced fluctuations, retaining moisture better. As temperatures cooled from September to October, the SWP at 15 cm depth slowly recovered, indicating improved moisture levels, whereas the 30 cm depth remained stable, consistently providing a reliable water source. The 15 cm depth showed more pronounced fluctuations in SWP compared to the 30 cm depth, indicating a quicker response to irrigation events. For the TB treatment, SWP at 15 cm depth exhibits frequent peaks and troughs, reflecting regular irrigation intervals. In contrast, 10% MAD treatment maintained a relatively stable SWP at both depths, with minor fluctuations, suggesting more efficient water management. The 30% MAD treatment showed larger fluctuations at 15 cm depth, indicating less frequent but more substantial irrigation events, while 30 cm depth remained relatively stable. Overall, the data suggest that the 10% MAD treatment provided the most consistent soil moisture levels, particularly at 30 cm depth, which is crucial for optimal tomato and pepper growth.

During 2023, the SWP in the pepper and tomato plots exhibited notable fluctuations, particularly inside the high tunnel at 15 cm and 30 cm depths, where values frequently exceeding –10 kPa and –20 kPa, respectively (Figures 6, 7). These depths correspond to the primary root zone, where soil moisture is highly responsive to irrigation and plant water uptake. The pronounced fluctuations inside the tunnel are likely due to increased evapotranspiration driven by the enclosed microclimate, coupled with intermittent irrigation and active root water uptake, especially by tomatoes. Additionally, the soil’s texture and structure may also contribute to rapid drainage and water redistribution, further amplifying moisture variability at these depths. The TB irrigation treatment resulted in similar SWP trends inside and outside the high tunnel in both years. In contrast, the 10% MAD treatment maintained relatively stable SWP values, with only minor fluctuations above –10 kPa at 15 cm and consistent stability at 30 cm, suggesting effective water management. The 30% MAD treatment, however, showed larger fluctuations, with SWP values occasionally exceeding –10 kPa at 15 cm and –20 kPa at 30 cm depth, indicating less frequent but more intensive irrigation events.

Outside the high tunnel, the SWP at 15 cm depth exhibited more pronounced fluctuations compared to inside, again exceeding –10 kPa, while at 30 cm depth values fluctuated around –20 kPa. Under the 10% MAD treatment, SWP remained relatively stable with minor variations above –10 kPa at both depths. The 30% MAD treatment outside the tunnel showed more variability at 15 cm, while remaining moderately stable at 30 cm, with values sometimes falling below –20 kPa. Soil water potential values nearing -30 kPa indicate that the soil is beginning to dry, though it still retains moisture sufficient for plant uptake. While this level is generally acceptable for most crops, including peppers, it suggests a need for attention. At –40 kPa, plants begin to experience mild water stress, requiring more frequent irrigation to maintain health. Values at –50 kPa or lower indicate significant stress that can compromise plant growth and yield (Ma et al., 2022). Additionally, SWP values higher than –20 kPa at depths beyond 30 cm inside the root zone may reflect subsoil compaction, which can impede water infiltration and root expansion.

3.3 Irrigation scheduling and water application efficiency

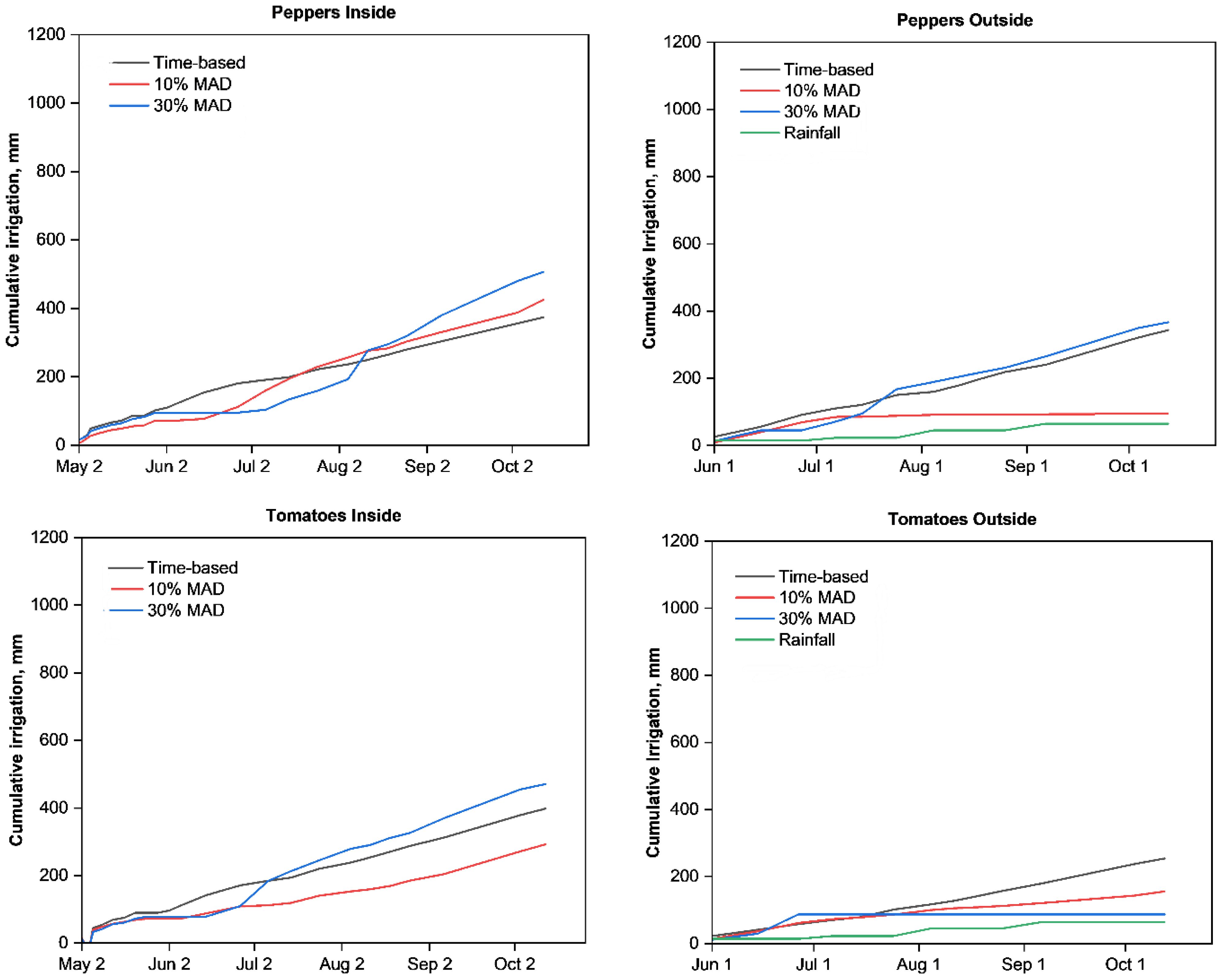

Since rainfall is excluded inside the high tunnel, the water requirement for the plants solely depends on irrigation (Montri and Biernbaum, 2009). The irrigation controller was programmed to turn on the irrigation system when the soil potential level falls below a certain level. This ensures that the plants receive the appropriate amount of water and prevents overwatering (Vaddevolu and Jia, 2024; Ibrahim et al., 2023). The total amount of rainfall that occurred for the growing season of 2022 was 154.68 mm. The cumulative irrigation and monthly rainfall for peppers and tomatoes grown inside and outside the high tunnel under TB, 10% MAD and 30% MAD irrigation treatments in 2022 are shown in Figure 8. Across all the treatments, irrigation demand was consistently higher for crops grown inside the high tunnel compared to outside, where natural rainfall provided some supplementary irrigation. The 30% MAD treatment showed the steepest irrigation curves for both peppers and tomatoes, reflecting the need for more frequent irrigation due to maintaining a lower soil moisture depletion threshold. In contrast, TB and 10% MAD treatments exhibited more conservative irrigation levels, especially outside, where rainfall reduced the need for additional watering. Rainfall outside for both crops contributed minimally to the overall irrigation needs, as indicated by the flatter lines compared to cumulative irrigation. The high tunnel environment resulted in stable but higher irrigation demands, whereas outside conditions allowed for more variability through the interaction of irrigation and rainfall. This comparison highlights the significant influence of the high tunnel environment on increasing the water requirements.

Figure 8. Cumulative irrigation and monthly cumulative rainfall (mm) in 2022 under different drip irrigation treatments inside and outside the high tunnel for peppers and tomatoes.

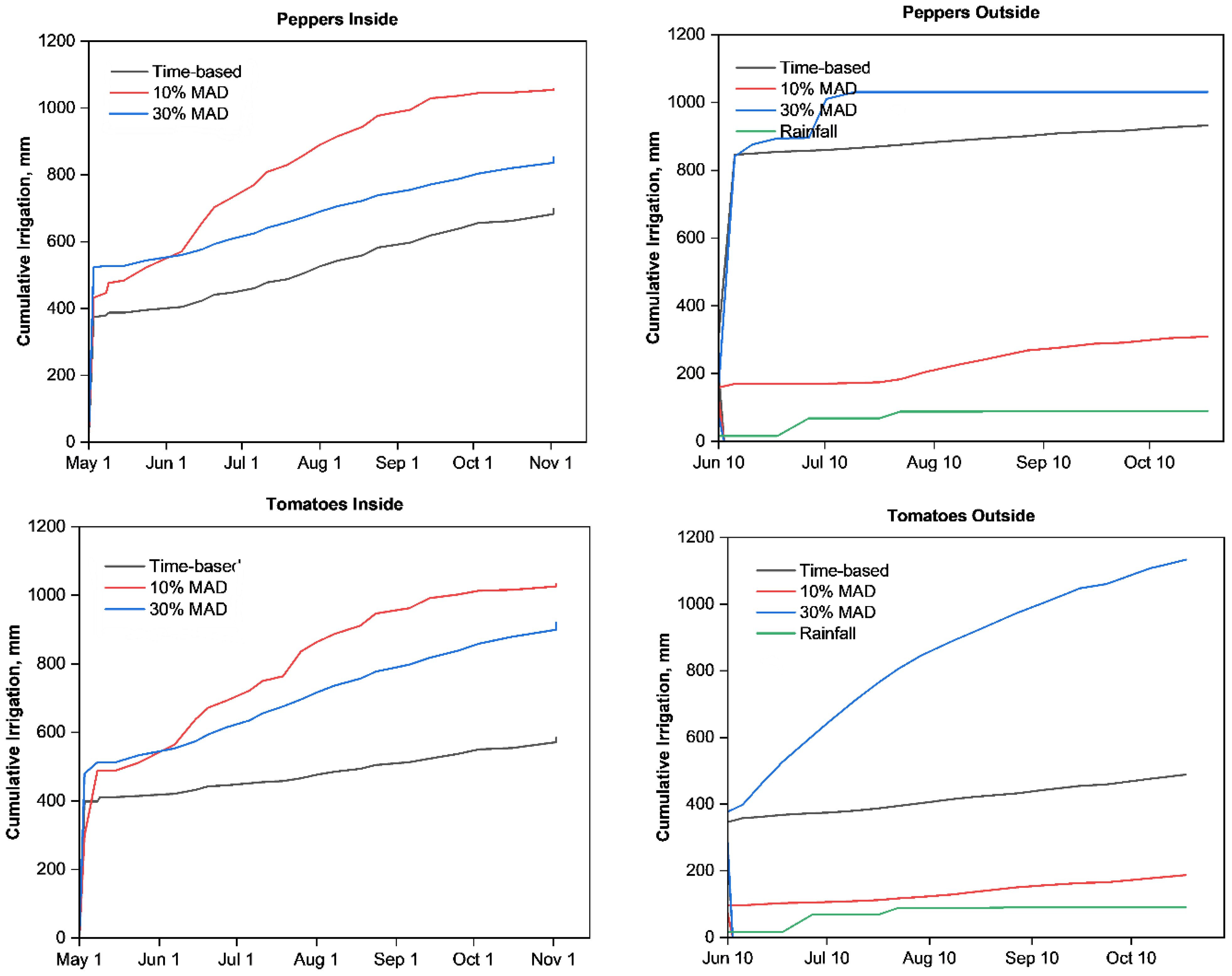

The cumulative irrigation for peppers and tomatoes grown inside and outside the high tunnel under TB, 10% MAD and 30% MAD irrigation treatments in 2023 are shown in Figure 9. For peppers inside, the 30% MAD curve showed a gradual and steady increase in irrigation, whereas the 10% MAD applied significantly more water. Peppers grown outside had a steeper curve of 30% MAD, with the TB resulting in the highest water use early on and then stabilizing later. For tomatoes inside, the cumulative irrigation under TB increased more rapidly compared to MAD treatments, with 10% MAD again consuming more water than 30% MAD. Similar trends were observed for tomatoes outside, though 10% MAD had a sharper increase compared to TB irrigation, which was more gradual. Rainfall contributed minimally to the outdoor scenarios, as shown by the relatively flat green curve, emphasizing the reliance on irrigation. In comparison, TB irrigation consistently over-irrigated compared to the MAD treatments, with 30% MAD being the most efficient water supply across all scenarios.

Figure 9. Cumulative irrigation and monthly cumulative rainfall (mm) in 2023 under different drip irrigation treatments inside and outside the high tunnel for peppers and tomatoes.

In 2022, the TB and 10% MAD treatments exhibited more conservative irrigation levels, primarily due to horizontal seepage from surrounding areas into the high tunnel in spring. This additional supplement moisture reduced the need for frequent irrigation, even under stricter thresholds, such as the 10% MAD. The growing season in 2022 was also shorter due to an early frost in September, which further contributed to the lower cumulative irrigation compared to 2023. Additionally, rainfall contributed some supplemental moisture to crops grown outside the high tunnel, further reducing irrigation demand for these treatments. In contrast, during the 2023 season, cumulative irrigation was notably higher under the 10% MAD treatment compared to the 30% MAD treatment, particularly inside the high tunnel for both peppers and tomatoes. This difference is because of the more sensitive nature of the 10% MAD threshold, which triggers irrigation more frequently to maintain soil moisture within a narrow allowable depletion range. Under the warmer and drier microclimate inside the high tunnel, more frequent irrigation was necessary to avoid crop stress, leading to significantly higher water use under the 10% MAD treatment compared to the less sensitive 30% MAD, which allowed greater soil drying before irrigation was triggered.

Interestingly, for crops grown outside the tunnel in 2023, the 30% MAD treatment exhibited the highest cumulative irrigation. This can be explained by the less controlled environmental conditions outside the tunnel, including wind, temperature fluctuations, and inconsistent rainfall. In such settings, allowing deeper soil layers to dry under the 30% MAD threshold often resulted in larger, more infrequent irrigation events. These larger irrigation pulses, combined with higher evaporation and drainage losses, cumulatively resulted in greater water use compared to more frequent but smaller irrigations under the 10% MAD treatment. This pattern reflects the complex interaction among irrigation strategy, environmental exposure, and soil water dynamics under different growing environments. The substantial differences in cumulative irrigation between the 2022 and 2023 growing season for both crops were attributed to several key environmental and agronomic factors. Notably, the 2023 growing season was both longer and significantly drier, with higher average temperatures that in 2022. These conditions increased crop evapotranspiration demand, necessitating more frequent and higher-volume irrigation events to maintain adequate soil moisture, particularly during critical growth stages. The peak in cumulative irrigation observed in August 2023 aligns with the period of maximum water demand, driven by both crop maturity stages and intensified heat stress under high tunnel conditions. The higher irrigation frequency also reflects a deliberate management strategy to prevent plant water stress, particularly under the 30% MAD treatment, which allows for greater soil drying before triggering irrigation. Together with variations in soil water-holding capacity, irrigation scheduling, and crop canopy development, these factors contributed to the significant increase in water application during the 2023 season.

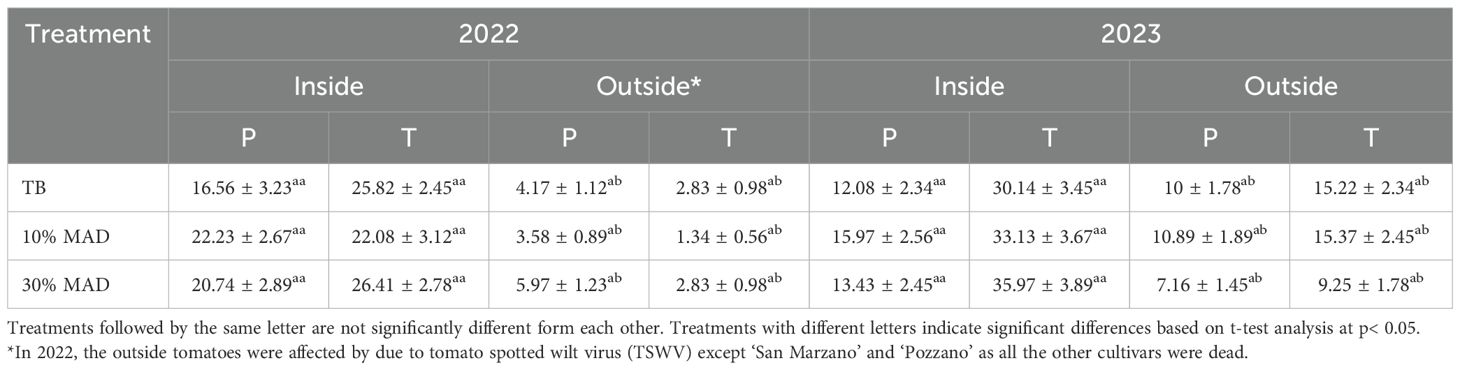

3.4 Crop yield under different treatments

Inside the high tunnel in 2022, peppers were harvested 35 days after transplanting (DAT), and tomatoes were harvested at 52 DAT. Outside the high tunnel, peppers were harvested at 52 DAT and tomatoes were harvested at 55 DAT. In 2023, both peppers and tomatoes were harvested 72 DAT inside the high tunnel and 75 DAT for peppers and tomatoes outside the high tunnel. In 2022, nearly all outside cultivars suffered significant losses due to an outbreak of Tomato Spotted Wilt Virus (TSWV), a serious viral disease affecting crops. Among the cultivars, only San Marzano and Pozzano demonstrated notable resilience, surviving the TSWV impact that devastated other cultivars; thus, the yield was less for tomatoes outside the high tunnel. Table 5 highlights the results that showed significant differences between treatments based on t-test analysis at p< 0.05. Mean separation refers to the process of determining which group means are statistically different from each other after the analysis of variance (ANOVA). The statistical analysis revealed no significant differences among the three irrigation treatments (TB, 10% MAD, and 30% MAD) within the same environment (inside or outside the high tunnel). However, there was a statistically significant difference between yields inside and outside the high tunnel across both crops and years. For peppers, the highest yields inside the tunnel were generally associated with the 10% MAD treatment, whereas for tomatoes, the highest yields inside were associated with 30% MAD. Outside the high tunnel, 10% MAD resulted in the highest yields for tomatoes, particularly in 2023. Notably, the outside plots in 2022 suffered from a viral disease, which led to considerably lower yields for tomatoes, particularly under the 10% MAD treatment. Despite these fluctuations, yields were consistently higher inside the high tunnel compared to outside, highlighting the role of protected cultivation in improving productivity. These results suggest that while irrigation treatments influenced yield trends, environmental conditions, particularly those provided by the high tunnel, had a more significant impact on overall crop performance.

Table 5. Average pepper (P) and tomato (T) yield (Mg ha-1) and standard deviation under time-based (TB), 10% management allowable depletion (MAD), and 30% MAD irrigation treatments in 2022 and 2023.

In 2022, pepper yields inside the high tunnel were highest under 10% MAD treatment at 22.23 ± 2.67 Mg ha-1, which was approximately 34% greater than the TB treatment yield of 16.56 ± 3.23 Mg ha-1; however, these differences were not statistically significant. Tomato yields inside the tunnel in 2022 ranged from 22.08 ± 3.12 Mg ha-1 (10% MAD) to 26.41 ± 2.78 Mg ha-1 (30% MAD), with no significant differences between treatments. Outside the tunnel in 2022, both pepper and tomato yields were significantly lower compared to inside. For example, pepper yields outside ranged from 3.58 ± 0.89 Mg ha-1 under 10% MAD to 5.97 ± 1.23 Mg ha-1 under 30% MAD, representing an approximately 70-75% reduction compared to inside yields. Tomato yields outside in 2022 were even lower, between 1.34 ± 0.56 Mg ha-1 and 2.83 ± 0.98 Mg ha-1, indicating the high tunnel provided a substantial yield advantage. In 2023, a similar pattern emerged inside the tunnel, tomato yields were highest under 30% MAD at 35.97 ± 3.89 Mg ha-1, representing a 19% increase compared to TB at 30.14 ± 3.45 Mg ha-1, although these differences were not statistically significant. Pepper yields inside the tunnel in 2023 ranged from 12.08 ± 2.34 Mg ha-1 (TB) to 15.97 ± 2.56 Mg ha-1 (10% MAD) with no significant differences between treatments. Outside the tunnel, yields for both crops were significantly lower than inside, with all treatments as not significantly different. For instance, tomato yield under 30% MAD outside was 9.25 ± 1.78 Mg ha-1, approximately 74% lower than the corresponding inside yield, while pepper yield outside under TB was 10.00 ± 1.78 Mg ha-1, which is nearly 34% lower than inside TB treatment.

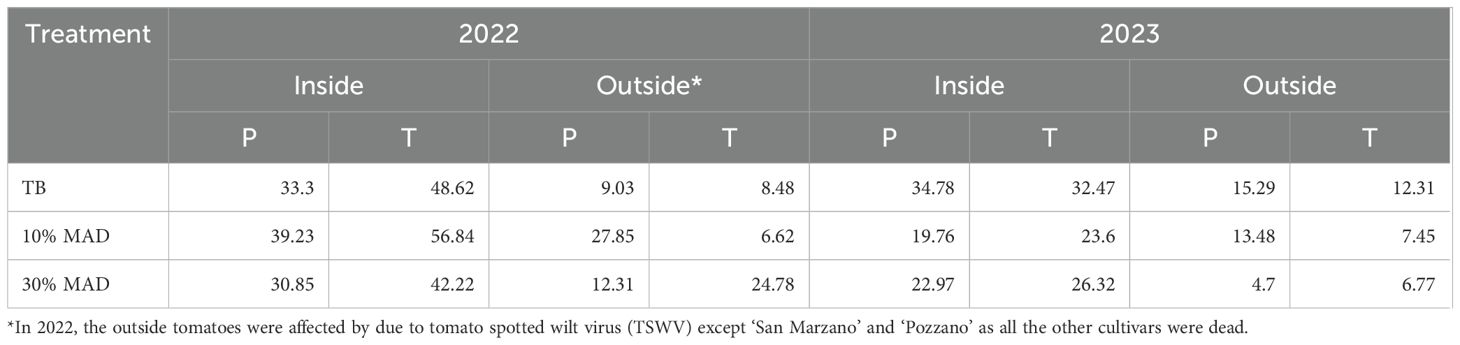

3.5 Water use efficiency

Irrigation treatments for peppers and tomatoes inside and outside the high tunnel significantly influenced WUE values in 2022. For both peppers and tomatoes inside the high tunnel in 2022, 10% MAD achieved the highest WUE at 39.23 kg m-3 and 56.84 kg m-3, respectively, followed by TB and 30% MAD (Table 6). Outside the high tunnel in 2022, peppers under 10% MAD exhibited significantly higher WUE (27.85 kg m-3) compared to TB and 30% MAD. For tomatoes outside the high tunnel in 2022, 30% MAD had the highest WUE (24.78 kg m-3). In the 2023 field experiments, both peppers and tomatoes under the TB irrigation treatments had the highest WUE. In 2022, for both peppers and tomatoes, 10% MAD irrigation resulted in higher WUE inside than outside. The results show the importance of selecting appropriate irrigation practices to optimize water use efficiency based on crop type and growing conditions. The results of the ANOVA tests, calculated using SAS 9.4, especially the Pr(>F) values, were used to examining the significance of irrigation treatment effects on WUE for peppers and tomatoes across different growing conditions and years. Based on the statistical analysis of WUE for tomatoes and peppers grown inside and outside the high tunnel during the 2022 and 2023 growing seasons, significant differences were observed in several treatments at the 0.05 probability level. For peppers, significant differences in WUE were found inside the high tunnel (p = 0.015) and outside (p = 0.006) in 2022, indicating the treatment had a statistically significant effect on WUE during these periods. However, no significant differences were observed in 2023 either inside (p = 0.068) or outside (p = 0.738) the high tunnel. Similarly, for tomatoes, significant differences in WUE were observed inside the high tunnel (p = 0.035) and outside (p = 0.013) in 2022, suggesting that the irrigation treatments significantly influenced WUE during this period. In contrast, no significant differences were detected in 2023, either inside (p = 0.387) or outside (p = 0.147) the high tunnel.

Table 6. Water use efficiency (kg m-3) obtained for time-based (TB), management allowable depletion (MAD) at 10% and 30% MAD irrigation treatments during the 2022 and 2023 field experiments for tomatoes (T) and peppers (P) inside and outside the high tunnel.

4 Conclusions

In conclusion, our study evaluated the effectiveness of different irrigation treatments on tomato and pepper cultivars grown inside and outside a high tunnel under North Dakota’s challenging climate. The integration of a remote-controlled drip irrigation system significantly enhanced both water use efficiency and crop yield. The ability to monitor and adjust irrigation remotely provides farmers with greater flexibility and convenience, reduces labor demands, and minimizes the need for constant physical presence in the field – making it a practical and efficient solution for specialty crop production in northern regions.

In 2023, tomatoes under the 30% MAD treatment showed competitive performance, resulting in 35.97 Mg ha-1 inside the high tunnel and 9.25 Mg ha-1 outside. Although peppers under the 10% MAD treatment did not consistently achieve the highest yields, they still produced respectable yields inside (22.23 Mg ha-1) and outside (3.58 Mg ha-1) of the high tunnel in 2022. For both peppers and tomatoes grown inside the high tunnel in 2022, the 10% MAD treatment achieved the highest WUE, at 39.23 kg m-3 and 56.84 kg m-3, respectively, followed by the TB and 30% MAD treatments. Outside the high tunnel in 2022, peppers under the 10% MAD treatment exhibited significantly higher WUE (27.85 kg m-3) compared to the TB and 30% MAD treatments. For tomatoes outside the high tunnel in 2022, the 30% MAD treatment had the highest WUE (24.78 kg m-3).

These findings suggest that optimizing irrigation strategies such as using 10% MAD can enhance crop productivity and water use efficiency, particularly in controlled environments like high tunnels. The consistent performance of this conservative irrigation threshold highlights its potential for improving resource efficiency in specialty crop production. Further research is recommended to refine these strategies and explore their applicability across diverse climatic conditions, soil types, and crop species, thereby supporting adoption in sustainable agricultural systems.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

SSSV: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Software, Validation, Writing – original draft, Writing – review & editing. XJ: Conceptualization, Investigation, Methodology, Funding acquisition, Project administration, Resources, Supervision, Writing – review & editing. IMG: Data curation, Writing – review & editing. HHV: Funding acquisition, Project administration, Resources, Supervision, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This project was supported by the North Dakota Department of Agriculture Specialty Crop Block Grant (#21-346), the North Dakota Water Resources Research Institute (NDWRRI), and the North Dakota Agricultural Experiment Station. Additional support was provided by the USDA National Institute of Food and Agriculture, Hatch Project Number ND01482 and ND01511.

Acknowledgments

We would like to thank all those who contributed to the successful completion of the laboratory and field experiments, including Dr. Thomas Scherer, Dr. Dongqing Lin, and Mr. Colin Auwarter. We also extend our sincere appreciation to the reviewers and the associate editor for their valuable comments.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdelraouf R. E., Ghanem H. G., Bukhari N. A., and El-Zaidy M. (2020). Field and modeling study on manual and automatic irrigation scheduling under deficit irrigation of greenhouse cucumber. Sustain For 12, 1–20. doi: 10.3390/su12239819

Adeoye I. B. (2020). Factors affecting efficiency of vegetable production in Nigeria: A review. Agric. Econom 1, 14. doi: 10.5772/intechopen.92702

Belasco E., Galinato S., Marsh T., Miles C., and Wallace R. (2013). High tunnels are my crop insurance: An assessment of risk management tools for small-scale specialty crop producers. Agric. Res Econom Rev. 42, 403–418. doi: 10.1017/S1068280500004445

Cahn M. D. and Johnson L. F. (2017). New approaches to irrigation scheduling of vegetables. Horticulturae 3, 28. doi: 10.3390/horticulturae3020028

Carey E. E., Jett L., Lamont W. J., Nennich T. T., Orzolek M. D., and Williams K. A. (2009). Horticultural crop production in high tunnels in the United States: A snapshot. HortTechnology 19, 37–43. doi: 10.21273/horttech.19.1.37

Donovan M., Ruiz-Menjivar J., Coolong T., and Swisher M. E. (2023). A scientometric review of the peer-reviewed research on high tunnels in the United States. Renewable Agric. Food Syst. 38, e48. doi: 10.1017/s1742170523000443

Drost D., Black B., and Stock M. (2021). Irrigation Management in High Tunnels. Utah state university cooperative extension. Available online at: https://digitalcommons.usu.edu/extension_curall/2173/ (Accessed June 29, 2023).

Dukes M. D. (2020). Two decades of smart irrigation controllers in US landscape irrigation. Trans. ASABE 63, 1593–1601. doi: 10.13031/trans.13930

He D., Oliver Y., and Wang E. (2021). Predicting plant available water holding capacity of soils from crop yield. Plant Soil 459, 315–328. doi: 10.1007/s11104-020-04757-0

Ibrahim G. R. F., Rasul A., and Abdullah H. (2023). Assessing how irrigation practices and soil moisture affect crop growth through monitoring Sentinel-1 and Sentinel-2 data. Environ. Monit. Assess. 195, 1262. doi: 10.1007/s10661-023-11871-w

Kuslu Y., Sahin U., Kiziloglu F. M., and Sengul M. (2016). Yield and quality responses of drip-irrigated spinach to different irrigation quantities in a semi-arid region with a high altitude. J. Cent. Eur. Agric. 17, 763–777. doi: 10.5513/jcea01/17.3.1774

Lakhiar I. A., Yan H., Zhang J., Wang G., Deng S., Bao R., et al. (2024a). Plastic pollution in agriculture as a threat to food security, the ecosystem, and the environment: an overview. Agronomy 14, 548. doi: 10.3390/agronomy14030548

Lakhiar I. A., Yan H., Zhang C., Wang G., He B., Hao B., et al. (2024b). A review of precision irrigation water-saving technology under changing climate for enhancing water use efficiency, crop yield, and environmental footprints. Agriculture 14, 1141. doi: 10.3390/agriculture14071141

Lakhiar I. A., Yan H., Zhang C., Zhang J., Wang G., Deng S., et al. (2025). A review of evapotranspiration estimation methods for climate-smart agriculture tools under a changing climate: vulnerabilities, consequences, and implications. J. Water Climate Change 16, 249–288. doi: 10.2166/wcc.2024.048

Lamont W. J. (2009). Overview of the use of high tunnels worldwide. HortTechnology 19, 25–29. doi: 10.21273/hortsci.19.1.25

Ma Y., Liu H., Yu Y., Guo L., Zhao W., and Yetemen O. (2022). Revisiting soil water potential: Towards a better understanding of soil and plant interactions. Water 14, 3721. doi: 10.3390/w14223721

Montri A. and Biernbaum J. A. (2009). Management of the soil environment in high tunnels. HortTechnology 19, 34–36. doi: 10.21273/HORTTECH.19.1.34

NDAWN (2024). North Dakota Agricultural Weather Network. Available online at: http://ndawn.ndsu.nodak.edu/ (Accessed October 4, 2024).

NDSU NDSCO (2024). North Dakota State Climate Office: Climate Summaries. Available online at: https://www.ndsu.edu/ndsco/climate_summaries/ (Accessed June 29, 2023).

NRCS-USDA (2024). Web soil survey. Available online at: https://websoilsurvey.nrcs.usda.gov/app/ (Accessed August 24, 2024).

Pardossi A. and Incrocci L. (2011). Traditional and new approaches to irrigation scheduling in vegetable crops. HortTechnology 21, 309–313. doi: 10.21273/HORTTECH.21.3.309

Rho H., Colaizzi P., Gray J., Paetzold L., Xue Q., Patil B., et al. (2020). Yields, fruit quality, and water use in jalapeno pepper and tomatoes under open field and high-tunnel production systems in the Texas high plains. HortScience 55, 1632–1641. doi: 10.21273/hortsci15143-20

Roy D., Jia X., Steele D. D., and Lin D. (2018). Development and comparison of soil water release curves for three soils in the red river valley. Soil Sci. Soc. America J. 82, 568–577. doi: 10.2136/sssaj2017.09.0324

Shah B., Hatterman-Valenti H., Vaddevolu U., and Jia X. (2025). Remote-controlled automatic drip irrigation for specialty horticultural crop productions. J. ASABE 68, 421–436. doi: 10.13031/ja.16144

Sideman R. G. (2020). Colored bell pepper yields from cultivars grown in high tunnels in Northern New England. HortTechnology 30, 456–462. doi: 10.21273/HORTTECH04577-20

Splichal K. L. (2020). High tunnels extend the growing season in warm season crops tomato, cucumber and bell pepper (Doctoral dissertation, North Dakota State University) Fargo, ND: North Dakota State University.

Suchoff D. H., Schultheis J. R., Kleinhenz M. D., Louws F. J., and Gunter C. C. (2018). Rootstock improves high-tunnel tomato water use efficiency. HortTechnology 28, 344–353. doi: 10.21273/HORTTECH04015-18

Tian S., Zhao X., Vincent I. R., Gong T., Ray Z. T., Legaspi J., et al. (2023). Using high tunnels to enhance organic vegetable production in florida: an overview: HS1466/HS1466, 9/2023. EDIS 2023. doi: 10.32473/edis-hs1466-2023

United States Department of Agriculture (1981). Fruit and vegetable division report. USDA Marketing Service & United Fresh Fruit and Vegetable Association.

USDA-NASS (2023). Census of horticulture (North Dakota). United States Department of Agriculture, National Agricultural Statistics Service. Available online at: https://www.nass.usda.gov/Surveys/Guide_to_NASS_Surveys/Census_of_Horticultural_Specialties/index.

USDA-NASS (2024). Census of horticulture (North Dakota). United States Department of Agriculture, National Agricultural Statistics Service. Available online at: https://www.nass.usda.gov/Surveys/Guide_to_NASS_Surveys/Census_of_Horticultural_Specialties/index.php.

Vaddevolu U. and Jia X. (2024). Testing a soil moisture sensor-based irrigation controller in both laboratory and field conditions for Fargo Silty Clay soils. Appl. Eng. Agric. 40, 41–50. doi: 10.13031/aea.15777

Vaddevolu U. B. P., Lester J., Jia X., Scherer T. F., and Lee C. W. (2021). Tomato and watermelon production with mulches and automatic drip irrigation in North Dakota. Water 13, 1991. doi: 10.3390/w13141991

Keywords: remote control, soil potential sensors, deficit irrigation, high tunnel agriculture, water use efficiency

Citation: Vishnumolakala SSS, Jia X, Goodspeed IM and Hatterman-Valenti H (2025) Evaluating irrigation strategies and cultivar response of tomato and pepper under automated drip systems in high tunnel and open field environments in North Dakota. Front. Agron. 7:1540521. doi: 10.3389/fagro.2025.1540521

Received: 05 December 2024; Accepted: 17 June 2025;

Published: 21 July 2025.

Edited by:

Michael O. Adu, University of Cape Coast, GhanaReviewed by:

Tamer A. Elbana, National Research Centre, EgyptImran Ali Lakhiar, Jiangsu University, China

Copyright © 2025 Vishnumolakala, Jia, Goodspeed and Hatterman-Valenti. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xinhua Jia, eGluaHVhLmppYUBuZHN1LmVkdQ==

Sai Sri Sravya Vishnumolakala

Sai Sri Sravya Vishnumolakala Xinhua Jia

Xinhua Jia Ivy Mary Goodspeed

Ivy Mary Goodspeed Harlene Hatterman-Valenti

Harlene Hatterman-Valenti