- 1Tobacco Research Institute of Hubei Province, Wuhan, China

- 2College of Resources and Environment, Huazhong Agricultural University, Wuhan, China

- 3Xiangyang Tobacco Company of Hubei, Xiangyang, China

- 4Enshi Tobacco Company of Hubei Province, Enshi, China

- 5Shiyan Tobacco Company of Hubei Province, Shiyan, China

Introduction: Cigar filler tobacco, as the core component of cigars, determines combustion uniformity and smoking smoothness through its combustion performance.

Methods: To investigate the effects of calcium (Ca) fertilizers on the yield, quality, and combustion properties of filler tobacco leaves, the experiment used the cigar filler cultivar CX-14 (Chuxue No. 14) as the material, with sugar alcohol chelated Ca fertilizer as the Ca source. The field experiment included five Ca levels, with application rates (calculated as CaO) of 0 (CaO0), 40 (CaO40), 80 (CaO80), 120 (CaO120), and 160 kg/ha (CaO160). Thermogravimetric analysis was performed using a Q600 (TA-DSC) in an air atmosphere to study the weight loss and heat release behaviors of the tobacco leaves, and the Coats-Redfern integral method was applied to calculate the activation energy of the tobacco leaves.

Results and Discussion: The results showed that, compared to the control without Ca fertilizer, the yields of CaO40 and CaO80 treatments increased by 11.6% and 5.4%, respectively, and the proportion of premium tobacco leaves increased by 20.6% and 14.5%, respectively. The ash content of the tobacco leaves in the CaO40 and CaO80 treatments decreased by 31.9% and 27.5%, respectively. Ca fertilization primarily enhanced overall combustion performance by improving pyrolytic reactivity during Stage III (400-510°C) of the combustion process. During the III stage, compared to untreated tobacco, the activation energy of the tobacco leaves in the CaO40 treatment decreased by 5.6%, and the frequency factor increased by 73.2%; in the CaO80 treatment, the activation energy decreased by 3.1%, and the frequency factor increased by 23.5%. The combustion stability index and the comprehensive combustion characteristics index of the tobacco leaves treated with CaO80 were optimal, increasing by 34.5% and 33.9%, respectively, compared to the control. Based on the integrated effects on yield, economic value, and combustion performance, the optimal application rate of sugar alcohol-chelated Ca fertilizer (as CaO) is recommended to be between 40 and 80 kg/ha.

1 Introduction

As a typical representative of natural tobacco products, cigars’ unique flavor profile and combustion quality are highly dependent on the physicochemical properties of the tobacco leaves used. A cigar consists of three parts: the filler, the binder, and the wrapper, with the filler as the core component that directly determines the product’s flavor complexity and combustion performance (Chen et al., 2019; Li et al., 2024a). Despite China being the largest tobacco producer in the world (Jiao et al., 2024), domestic cigar tobacco has long faced key issues such as a shortage of high-quality raw materials and insufficient combustion properties, which have allowed traditional regions like Cuba and the Dominican Republic to dominate the high-end cigar market (Cai et al., 2019; Yan et al., 2021). Overcoming the combustion performance limitations of filler tobacco has become a core requirement for enhancing the competitiveness of China’s cigar industry.

The combustion properties of tobacco leaves directly impact the sensory quality and consumer experience of tobacco products. The combustion process releases aromatic compounds through thermal decomposition, with the sufficiency and coordination of this release directly influencing the smoothness of the smoke, ash morphology, and irritation levels. Combustibility defects not only limit aroma release but also tend to cause issues such as the presence of off-flavors and ash carbonization, significantly reducing industrial usability (Yan et al., 2001; Chen et al., 2019; Li et al., 2024b). However, current approaches to improving tobacco leaf combustion mainly involve adding exogenous substances during processing to regulate combustibility. These include the addition of combustion aids (such as potassium (K) salts) to improve combustion (Wang et al., 2021), spraying glycerol to reduce the activation energy of component decomposition and volatile production, thereby increasing weight loss (Yan et al., 2001; Chen et al., 2019; Li et al., 2024b), or applying pectinase, α-amylase, and other substances before fermentation to regulate combustion properties (Fan et al., 2018). Although these methods yield short-term results, they may compromise the natural aroma components of the tobacco leaves, making it difficult to meet the stringent requirements for natural flavor in high-end cigars.

Compared to methods that regulate combustion performance by adding external substances, fertilization to regulate the intrinsic physicochemical properties of tobacco provides a new approach to improving both combustion performance and natural quality. Ca is a crucial nutrient for tobacco growth, and its concentration in tobacco leaves is considerably higher than that of phosphorus (P), often surpassing even K and nitrogen (N) (Zou and Xiong, 2010). Adequate Ca nutrition promotes tobacco plant growth and development, increases leaf yield, and balances the content of substances such as potassium, nicotine, and sugars, which affect leaf quality (Yang et al., 1999; Yao et al., 2017; Feng et al., 2021). As a structural element in plant cell walls, Ca significantly influences leaf cell wall rigidity and ash content through the cross-linking interaction between Ca and pectin (Hepler and Winship, 2010). Within a certain range, the Ca content in tobacco leaves positively correlates with combustibility ratings in sensory quality assessments (Xu, 1987; Xiao, 2013; Liu et al., 2022). However, existing studies largely rely on indirect indicators such as sensory ratings or K/chlorine (Cl) ratios to assess combustibility (Mo et al., 2016; Tang et al., 2019; Wu et al., 2022), making it difficult to quantify the dynamic characteristics of the combustion process (e.g., ignition difficulty, heat release rate, combustion stability, etc.). Although the positive correlation between the K/Cl ratio and combustibility has been confirmed (Ge et al., 2012), the mechanism by which Ca influences combustion phase transitions and heat release characteristics remains unclear, limiting the development of precise regulation strategies.

Building on Ca’s dual role in tobacco growth and combustion regulation, this study established field trials using sugar-alcohol chelated Ca fertilizer as Ca source. A synchronous thermal analyzer was used to analyze the thermal weight loss process, heat release, and combustion kinetics of tobacco leaves, aiming to provide theoretical and technical support for the precise regulation of combustion performance in high-quality filler tobacco.

2 Materials and methods

2.1 Experimental site

The field experiment was conducted from March to August 2022 at the Xinghua Village Experimental Base in Xijiadian Town, Danjiangkou City, Shiyan, Hubei Province (32°47′7″N, 111°10′57″E). This region experiences hot, rainy summers and mild, dry winters, with an average annual temperature of 21.6°C and annual precipitation ranging from 750 mm to 900 mm. The terrain in the cigar-growing area is characterized by gently sloping hills, with long hours of sunshine, which is favorable for the cultivation of cigar tobacco filler varieties (Ren et al., 2023). The soil is yellow-brown soil, and the basic physical and chemical properties of the plow layer are as follows: pH 6.77, organic matter 5.47 g/kg, alkaline N 64.17 mg/kg, available P 21.50 mg/kg, available K 280.44 mg/kg, exchangeable magnesium (Mg) 0.30 g/kg, and exchangeable Ca 4.76 g/kg.

2.2 Experimental materials

The tobacco variety used for the experiment was ‘Chu Xue 14’ (CX-14), provided by the Hubei Tobacco Research Institute. The fertilizers applied included ammonium nitrate phosphate (N 30%, P2O5 4%), single superphosphate (P2O5 12%), K sulfate (K2O 50%, S 17.5%), and sugar alcohol chelated Ca fertilizer (Ca ions ≥ 180 g/L).

2.3 Experimental design

Five treatment levels of sugar alcohol chelated Ca fertilizer (expressed as CaO) were applied, as follows: (1) control treatment (CaO0: 0 kg/ha); (2) CaO40: 40 kg/ha; (3) CaO80: 80 kg/ha; (4) CaO120: 120 kg/ha; (5) CaO160: 160 kg/ha. Each treatment was replicated three times in a randomized block design. The experimental plot area was 32.4 m2, with four rows per plot and 15 plants per row. The row spacing was 1.2 m and the plant spacing was 0.45 m.

For all treatments, the N, P, and K fertilizers were applied in the following quantities: N 187.50 kg/ha, P2O5 281.25 kg/ha, and K2O 562.50 kg/ha. Fifty percent of the N and potassium fertilizers, along with all the superphosphate, were applied as base fertilizers before transplanting using a banded method. After base fertilization, ridges were formed and plastic film was laid. The remaining 50% of the N and potassium fertilizers, along with the chelated Ca fertilizer, were applied as a root drench during the growing season, after being diluted with water. Other field operations and management followed the local standards for high-quality cigar tobacco leaf production.

2.4 Sample collection and processing

Soil samples were collected before base fertilizer application using a five-point sampling method. The soil was taken at a depth of 0–20 cm, mixed from five points, and then reduced to 1 kg using the quartering method. The soil was placed in sample bags, air-dried in a cool place, and ground. The samples were sieved through 10-mesh and 100-mesh screens for nutrient content analysis.

Cigar tobacco leaves were collected from the middle section of air-cured cigars, with 1 kg of tobacco sampled per plot. The tobacco leaves were processed according to the tobacco industry standard YC/T 31-1996 (“Preparation of Tobacco and Tobacco Product Samples and Determination of Moisture Content—Oven Drying Method”) for chemical composition and combustion property analysis.

2.5 Measurements and methods

2.5.1 Economic traits of tobacco leaves

Tobacco leaves were harvested using an under-ripe method, starting with the lower leaves and progressing to the upper leaves. Harvesting began on June 24, 2022, with every 7 days a collection of 3 to 4 leaves. The bottom 2 to 3 leaves were left intact. After harvest, the tobacco leaves were bundled by treatment area and hung for uniform curing. After curing, the leaf moisture was balanced. The leaves were graded and weighed according to the Chinese Hubei Province Local Standard “DB42/T1549-2020 Cigar Tobacco Leaf Grading and Quality Standards.” The yield of tobacco leaves, categorized into wrapper, binder, and filler grades, was recorded for each treatment. Tobacco leaf value was calculated based on the 2022 Hubei Province cigar tobacco purchase prices.

2.5.2 Soil nutrient and tobacco leaf chemical composition analysis

Soil organic matter, alkaline hydrolyzable N, available P, available K, and effective trace elements were determined using the methods outlined in “Soil Agricultural Chemical Analysis” (Bao, 2013).

The content of major elements in tobacco leaves was determined by digesting the samples with H2SO4-H2O2 and measuring the N and P content using a flow injection analyzer. K content was measured using a flame photometer. The content of trace elements in tobacco leaves was determined by digesting the samples with HNO3-HClO4 (4:1) and analyzing the Ca content with atomic absorption spectrometry (AAS). The total sugar and reducing sugar content in tobacco leaves were determined according to the current Chinese industry standard YC/T 159-2002; tobacco starch content was measured following the YC/T 216-2007 standard; nicotine content was determined according to YC/T 160-2002.

2.5.3 Combustibility test and evaluation method of cigar tobacco leaves

The combustion characteristics of tobacco leaves were analyzed using a Q600 synchronous thermal analyzer (TA-DSC) under the following conditions: air atmosphere, approximately 10 mg of sample (screened through a 65-mesh sieve) placed in a ceramic crucible, with an initial temperature of 30°C and a heating rate of 20°C/min until 590°C, obtaining a curve showing the change in sample weight with temperature.

In this study, the combustion starting temperature of the tobacco leaves was determined using the TG-DTG joint definition method (Ma et al., 2006), based on the thermal gravity (TG) curve and the differential thermal gravity (DTG) curve during the combustion process. The combustion process of tobacco leaf samples is complex. To better evaluate the combustibility of cigar tobacco leaves, the ignition index (), combustion stability index (), and comprehensive combustion characteristic index () were used to analyze the combustion performance among different treatments. has been confirmed as an effective indicator for assessing the combustion performance of tobacco (Zhong, 2014). Specifically, the ignition performance of the sample is positively correlated with , which reflects the fuel’s flammability and reactivity. is mainly used to evaluate the combustion stability of the sample during the process; a higher value indicates greater combustion stability. A higher value indicates better overall combustion performance of the sample (Ni et al., 2023).

The formulas used for calculating these indices are as follows:

Ignition Index:

Combustion Stability Index:

Overall Combustion Characteristics Index:

Mean Combustion Rate:

In equations (1), (2), (3), and (4), represents the maximum combustion rate (maximum weight loss rate), %/min; represents the average combustion rate, %/min; is the ignition temperature, °C; is the temperature at the maximum combustion rate, °C; and is the burnout temperature, °C. is the temperature at which combustion is completed without further weight loss (corresponding to a combustion rate of less than 1%/min). is the heating rate, °C/min; is the remaining mass fraction of the sample when the temperature reaches the ignition temperature , %; is the remaining mass fraction of the sample when the temperature reaches the burnout temperature , %.

2.5.4 Tobacco leaf pyrolysis kinetics model

Kinetic parameters (E and A) are critical indicators for evaluating heterogeneous reactions. The thermal decomposition reaction in biomass combustion can be regarded as a gas-solid reaction, expressed as: A (solid) + B (gas) → C (solid). Previous studies have made significant contributions to the kinetic research on biomass oxidation reactions (Diblasi, 2008; Hameed et al., 2019; Mian et al., 2020), proposing various methods for solving activation energy, estimating pre-exponential factors, and determining the most suitable form of the reaction mechanism function. This study uses the Coats-Redfern integral method to calculate the chemical reaction kinetics of tobacco leaf pyrolysis (Gao et al., 2013; Wang, 2022).

Coats-Redfern Integral Method:

For typical reaction temperature ranges and most activation energy (E) values, 2RT/E ≪ 1, so equation (5) can be rewritten as:

In these equations, is the pre-exponential factor (min-¹); is the apparent activation energy (kJ/mol); is the universal gas constant (8.314 J·mol-1·K-1); is the constant heating rate (K/min); is the temperature (K); is the conversion rate of the tobacco leaf at temperature ,. .; is the initial mass (before weight loss, %); is the mass at the end of weight loss (%); and is the mass at time (%).

At a constant heating rate, the thermal analysis data were substituted into a commonly used solid-state reaction mechanism function (Supplementary Table S2) (Yang et al., 2018). The results were plotted and fitted with a straight line. Based on the high linear correlation coefficient R2, the mechanism function G(α) was determined, and the linear relationship between and was established. The activation energy () was calculated from the slope of the line, while the pre-exponential factor (A) was obtained from the intercept .

2.6 Data processing

The raw data were processed using Excel 2021, while SPSS 19.0 was used for analysis of variance and Pearson correlation analysis. Significance was tested at a level of P< 0.05 using the Least Significant Difference (LSD) method, and graphs were generated using Origin 2022.

3 Results

3.1 Yield and value of cigar leaf filler tobacco leaves

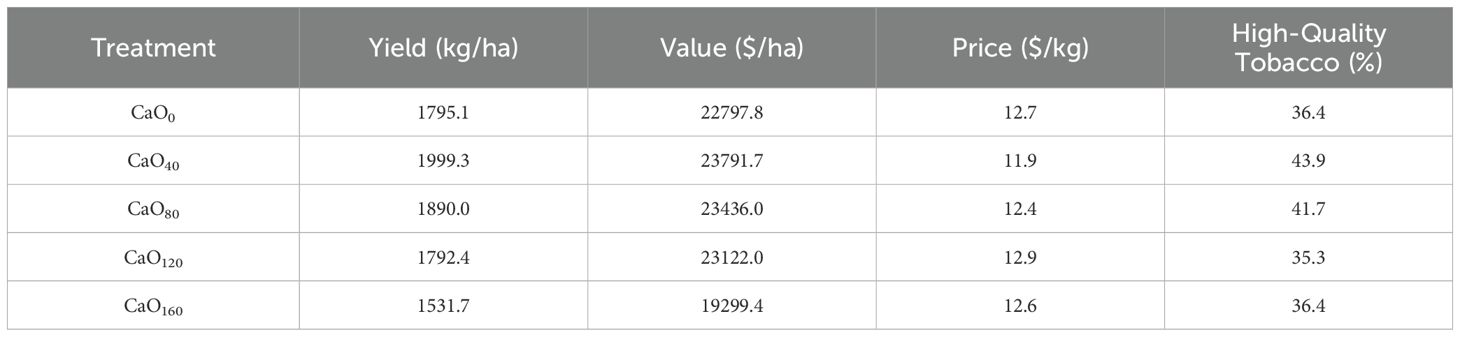

The cigar tobacco yield, output value, and proportion of premium-grade leaves exhibited an initial increase followed by a decrease with increasing Ca fertilizer application. The highest values for these parameters were observed at a Ca fertilizer rate of 40 kg/ha (Table 1). Compared with the control (CaO0), the CaO40 and CaO80 treatments increased yield by 11.4% and 5.3%, respectively, while enhancing the premium-grade leaf proportion by 7.5% and 5.3%. This demonstrates that Ca fertilizer application within 40-80 kg/ha can effectively improve both yield and economic returns of cigar tobacco. Compared to the CaO0, the yield increased by 11.4% and 5.3%, and the proportion of high-quality tobacco increased by 7.5% and 5.3% for the CaO40 and CaO80 treatments, respectively. This indicates that applying Ca fertilizer within the range of 40-80 kg/ha can enhance both the yield and value of cigars. However, when application rates exceeded 80 kg/ha, significant reductions in both yield and premium-grade leaf proportion were observed, indicating that excessive Ca fertilization adversely affects both productivity and leaf quality.

3.2 Changes in the chemical composition of filler tobacco leaves

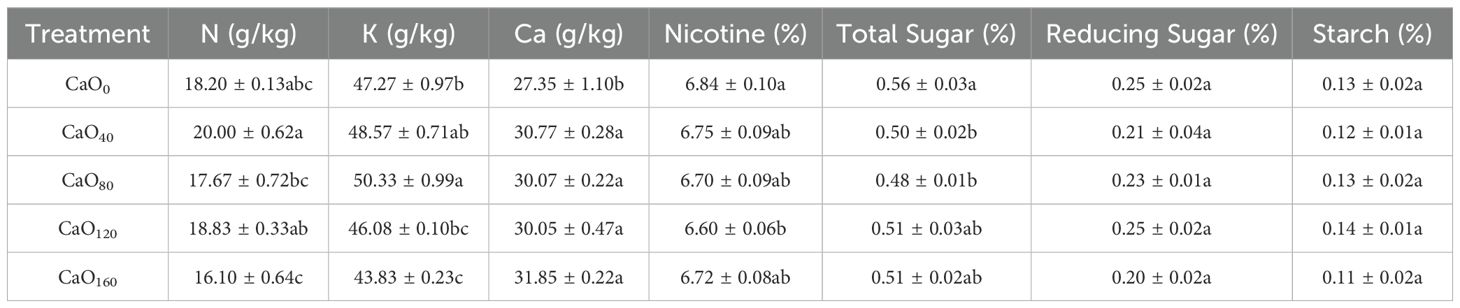

The application of Ca fertilizer significantly increased the Ca content in cigar leaves compared to the control group (Table 2). Among all treatments, the CaO160 application resulted in a 16.5% increase in Ca content compared to the control. Furthermore, as the Ca fertilizer application increased, the K content in the leaves initially rose and then declined. The CaO80 treatment led to a 6.5% increase in K content. However, the application of Ca fertilizer resulted in a reduction in nicotine, total sugar, and reducing sugar content in the leaves.

Table 2. Chemical composition of filler tobacco leaves under different Ca fertilizer application rates.

3.3 Pyrolysis behavior analysis of filler tobacco leaves

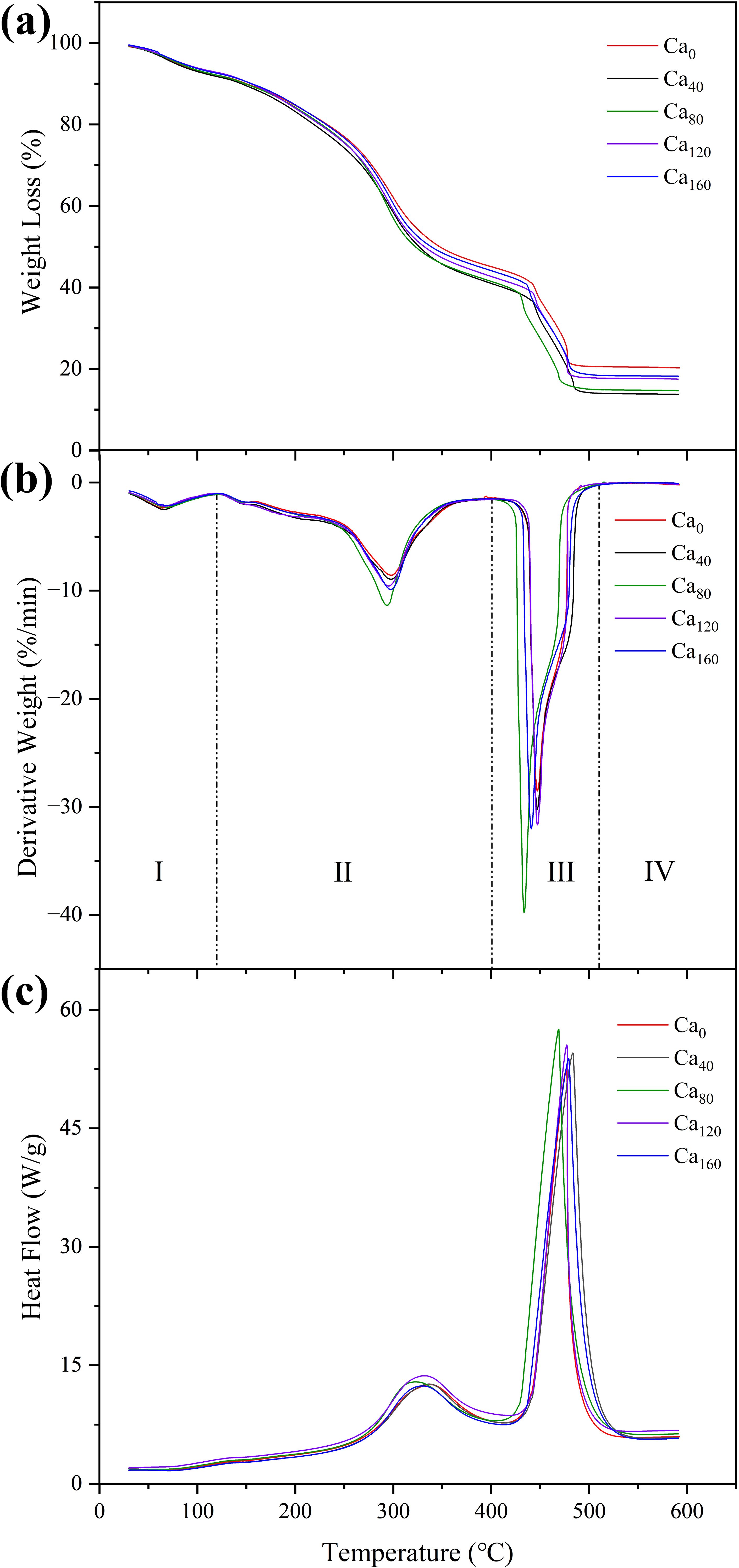

The TG and DTG curves showed that the pyrolysis processes of filler tobacco leaves under different Ca fertilizer levels were similar (Figures 1a, b). As the temperature increased, the pyrolysis process of tobacco leaves was divided into four stages of weight loss. Stage I (30-120°C) was the drying phase, where free water and bound water within the tobacco leaves evaporated. This stage accounted for approximately 9% of the total weight loss. Stage II (120-400°C) was the main stage of pyrolysis and combustion of volatile components, with the largest weight loss, accounting for approximately 59% of the total weight loss. During this stage, as pyrolysis progressed, the weight loss rate of tobacco leaves exhibited a “slow-fast-slow” trend. After 250°C, the weight loss rate increased rapidly, but after 350°C, the weight loss rate gradually decreased with rising temperature. This can be attributed to the initial decomposition of a small amount of low-boiling organic compounds, followed by the thermal decomposition of hemicellulose, pectin, and the release of nicotine after 250°C (Wang, 2022). This is accompanied by the combustion of volatile components, leading to rapid mass loss. After 350°C, the main decomposition of macromolecules like cellulose produced char and caused gas-phase to solid-phase diffusion (Yang et al., 2007; Islam et al., 2016), preparing for the intense combustion in Stage III. Stage III (400-510°C) was the combustion phase of carbonized material, accounting for approximately 31% of the total weight loss. The weight loss rate increased rapidly, and the pyrolysis reaction rate significantly accelerated. The formed charcoal reacted strongly with oxygen, producing methane, with large amounts of CO2 and water vapor released during combustion. Stage IV (510-590°C) was the burnout phase, during which the weight loss rate slowed (≤0.09%/min). This stage mainly involved the slow pyrolysis of a small amount of lignin or the slow oxidation of residual carbon (Ma et al., 2018), accounting for approximately 1% of the total weight loss.

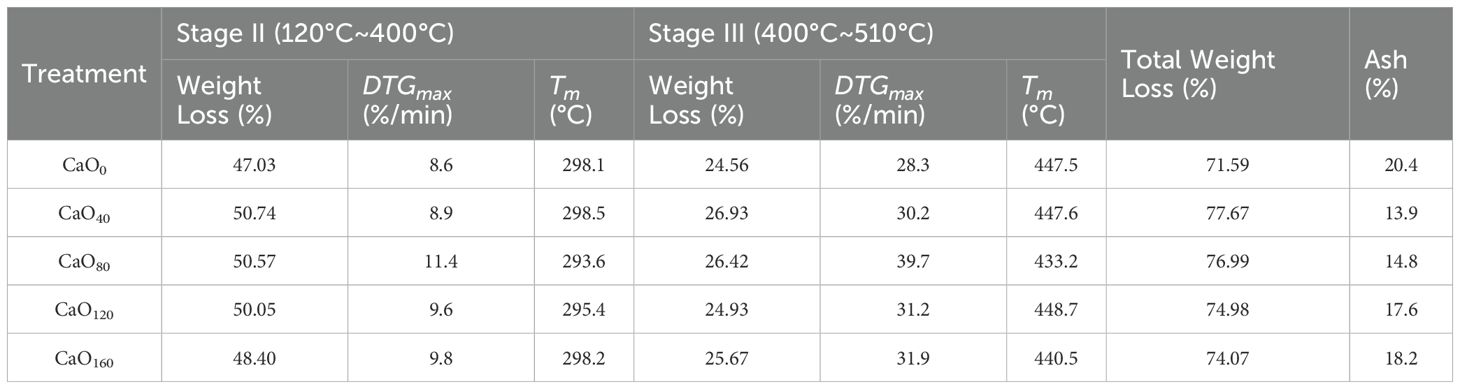

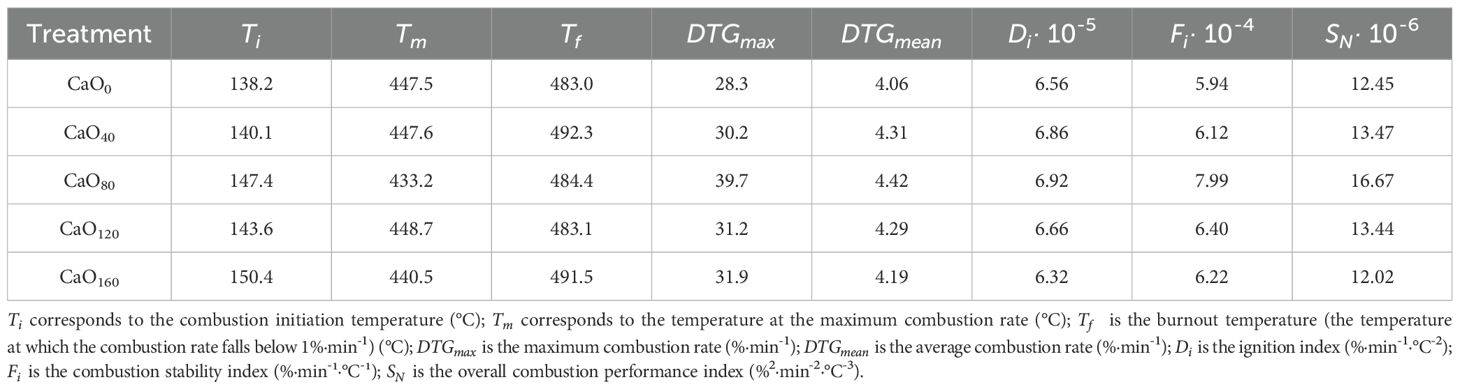

As the Ca fertilizer application increased, the total weight loss rate and maximum combustion rate of filler tobacco leaves in stages II and III showed a trend of first increasing and then decreasing (Table 3). In the CaO40 and CaO80 treatments, the total weight loss rate in stages II and III increased by 8.49% and 7.54%, respectively, compared to the control. For the CaO80 treatment, the maximum combustion rate in stages II and III significantly increased by 32.56% and 40.28%, respectively, while the combustion peak temperature decreased by1.5% and 3.2%. As the Ca fertilizer application increased, the ash content of tobacco leaves first decreased and then increased. The ash content after pyrolysis for the CaO40 and CaO80 treatments was reduced by 31.9% and 27.5%, respectively, compared to the control, indicating that the leaves treated with CaO40 and CaO80 underwent more complete oxidation during combustion than those treated with other fertilizer levels.

Table 3. Pyrolysis parameters and mass loss of filler tobacco leaves in stages II and III under different Ca fertilizer application rates.

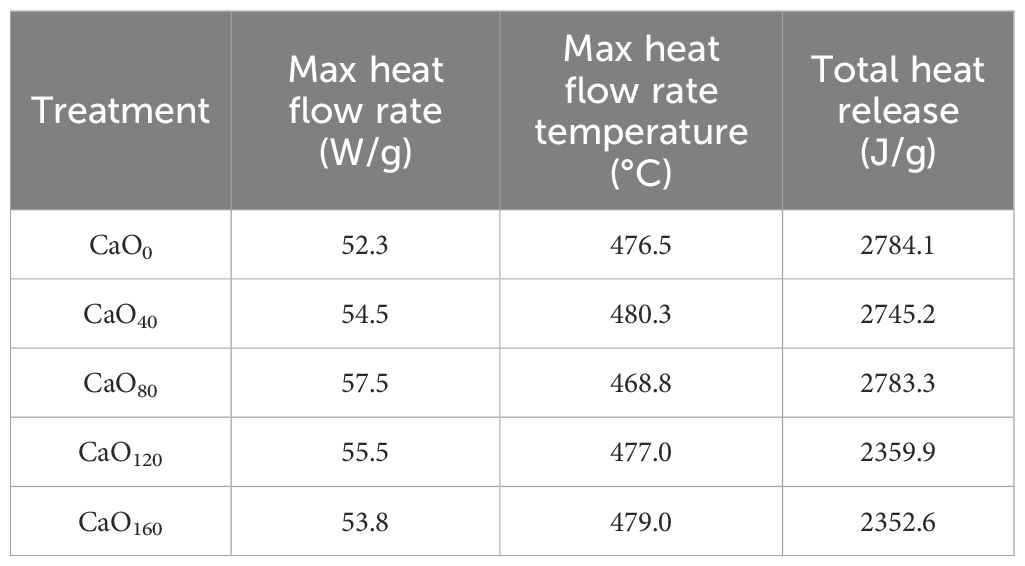

The heat release of filler tobacco leaves occurs primarily between 400°C and 550°C under different Ca fertilizer application rates, indicating that rapid combustion of the leaves takes place within this temperature range. With increasing Ca fertilizer application, the heat release is shifted toward higher temperatures, widening the temperature range of heat release (Figure 1c). As the Ca fertilizer application rate increases, the total heat release during combustion decreases, while the maximum heat flux initially increases and then decreases. Compared to the control, the maximum heat flux in the CaO80 treatment increased by 9.9%, while the total heat release in the CaO120 and CaO160 treatments decreased by 15.2% and 15.5%, respectively. This suggests that when the CaO application rate exceeds 80 kg/ha, the temperature at which the maximum heat flux occurs shifts to higher temperatures, and the total heat release decreases (Table 4).

Table 4. Heat flux curve parameters of filler tobacco leaves under different Ca fertilizer applications.

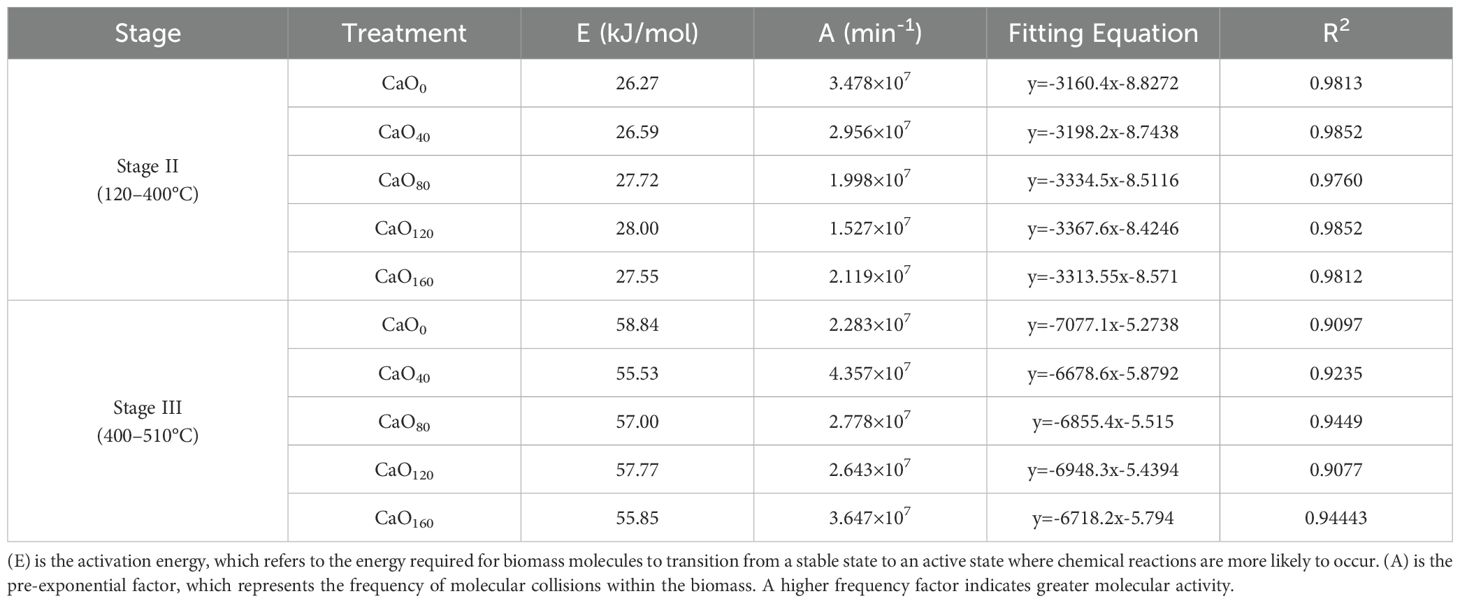

3.4 Pyrolysis kinetic analysis of filler tobacco leaves

The activation energy and frequency factor for each stage at different Ca fertilizer dosages were determined by fitting the Coats-Redfern method to stages II and III of the filler tobacco leaves combustion process (Table 5). In stage II (120-400°C), the one-dimensional diffusion model (G(α) = α²) was identified as the most suitable model for describing the pyrolysis of filler tobacco leaves. As the Ca fertilizer amount increased, the activation energy of filler tobacco leaves showed a trend of initially increasing and then decreasing, while the frequency factor exhibited the opposite trend. Notably, the CaO0 treatment resulted in the lowest activation energy (26.27 kJ/mol) and the highest frequency factor (3.478×107 min-1), indicating a lower proportion of non-volatile substances in the CaO0 treatment, easier devolatilization, and a faster chemical reaction rate. Compared to the control group, the application of Ca fertilizer resulted in an increase in activation energy and a decrease in frequency factor for filler tobacco leaves, suggesting that more energy is required for the pyrolytic combustion of tobacco leaves in the 120-400°C range, leading to a slower reaction rate. In stage III (400-510°C), the reaction mechanism shifted from one-dimensional diffusion to a more complex four-dimensional diffusion model (G(α) = (1-2α/3) - (1-α)2/3). Compared to the control group, all Ca fertilizer treatments reduced the activation energy and increased the frequency factor of tobacco leaves. Specifically, the CaO40 treatment reduced the activation energy by 5.6% and increased the frequency factor by 72.3%, indicating that the application of Ca fertilizer lowered the activation energy required for the pyrolytic combustion of filler tobacco leaves in the 400-510°C range, thereby accelerating the chemical reaction rate.

Table 5. Pyrolysis kinetic parameters of filler tobacco leaves under different Ca fertilizer applications.

3.5 Analysis of the combustion characteristics of filler tobacco leaves

As the application rate of Ca fertilizer increased, the combustion parameters of filler tobacco leaves initially increased and then decreased (Table 6). Compared to the control, the filler tobacco leaves treated with CaO80 exhibited the , , , , and , which increased by 40.28%, 8.86%, 5.49%, 34.51%, and 33.89%, respectively. The CaO40 treatment ranked second in all parameters, indicating that CaO80 treatment resulted in the optimal ignition performance, thermal reactivity, combustion stability, and overall combustion characteristics, with CaO40 following closely behind. However, the application of Ca fertilizer increased the of filler tobacco leaves. Specifically, the CaO180 treatment showed the most significant increase in , rising by 8.8% compared to the control, followed by a 6.7% increase in the CaO80 treatment. This suggests that the application of Ca fertilizer reduces the content of low-boiling, easily decomposable organic components (such as nicotine, reducing sugars, and total sugars, as shown in Table 3), leading to an increase in the combustion initiation temperature. Overall, while the application of Ca fertilizer improved certain combustion parameters, the use of excessive Ca fertilizer (e.g., CaO180 treatment) may lead to an excessively high combustion initiation temperature, thereby negatively affecting the combustion characteristics.

Table 6. Characteristics of filler tobacco leaves pyrolysis under different Ca fertilizer application rates.

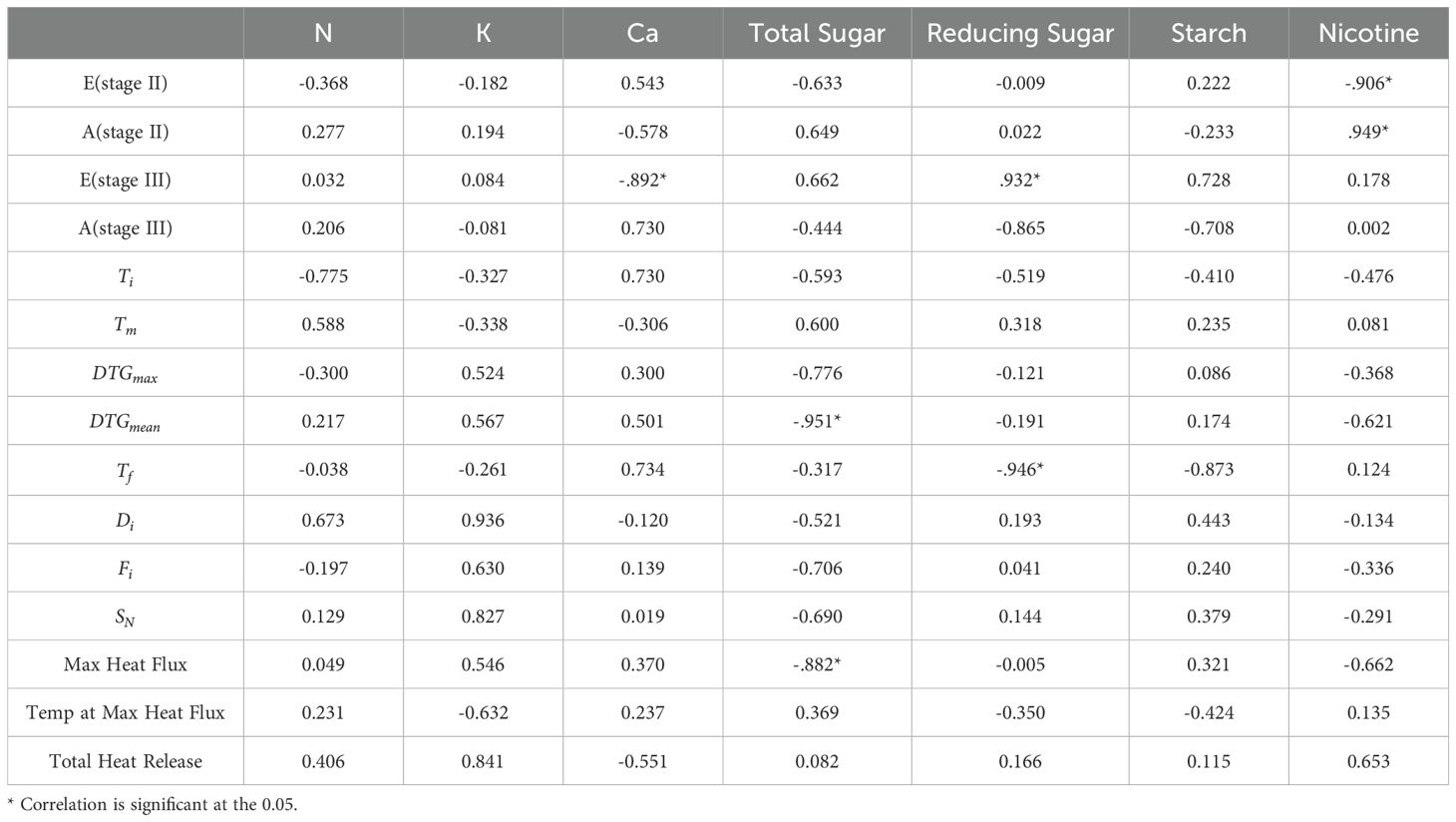

3.6 Correlation analysis of pyrolysis parameters and chemical composition of filler tobacco leaves

In this study, Pearson correlation analysis was systematically used to explore the relationships between the chemical composition of filler tobacco leaves (such as N, K, Ca, total sugars, reducing sugars, and nicotine) and pyrolysis characteristics (including activation energy, frequency factor, combustion rate, and combustion characteristics) (Table 7). The results showed that the activation energy during the pyrolysis of tobacco leaves in stage III was significantly negatively correlated with Ca content (r = -0.892, P< 0.05) and significantly positively correlated with reducing sugar content (r = 0.932). This suggests that an increase in Ca content may catalytically promote the pyrolysis of certain components, thereby reducing the activation energy. On the other hand, reducing sugars may increase the energy demand for decomposition reactions during pyrolysis at higher temperatures. In stage II of pyrolysis, activation energy and frequency factor were significantly negatively correlated (r = -0.906) and significantly positively correlated (r = 0.949) with nicotine content, respectively. This may be attributed to the lower temperature required for nicotine decomposition, which is accompanied by energy release, thus lowering the activation energy requirement (Liang et al., 2022; Yin et al., 2022). Additionally, the correlation trends between total sugars, N, and potassium content in tobacco leaves and the activation energy and frequency factor in stage II were consistent with those for nicotine. This is consistent with the findings of Zhang et al. (2018), who observed that higher levels of total sugars, nicotine, and total N in tobacco leaves were associated with lower activation energy for low-temperature pyrolysis reactions. This finding suggests that high concentrations of these chemical components enhance the reactivity of the low-temperature pyrolysis process to some extent. However, the study found that total sugars had a negative effect on combustion rate and energy release during pyrolysis. The maximum combustion rate was strongly negatively correlated with total sugar content (r = -0.776), while the average combustion rate showed a significant negative correlation (r = -0.952) with total sugar content. Additionally, the maximum heat flux was also significantly negatively correlated with total sugar content (r = -0.882). These results suggest that the macromolecular structure of sugars may only effectively decompose under high-temperature conditions, thereby inhibiting the increase in combustion rate and energy release during pyrolysis. Notably, the potassium content in tobacco leaves showed a strong positive correlation (r > 0.5) with combustion rate, ignition index, combustion stability index, overall combustibility index, and total heat release, indicating that potassium plays a crucial role in enhancing the rate stability and pyrolysis efficiency of tobacco combustion, thus optimizing the overall combustion performance.

Table 7. Correlation between combustion characteristics and chemical composition of filler tobacco leaves.

4 Discussion

This study shows that when CaO application is within the range of 40-80 kg/ha, the yield, value, and proportion of high-quality cigar tobacco increase significantly (Table 1). However, when the application exceeds 120 kg/ha, it has a negative effect on yield and value. Compared to the control, the application of Ca fertilizer reduced total sugar, reducing sugar, and nicotine content in the middle leaves. When CaO was applied at 40-80 kg/ha, Ca content in the tobacco leaves increased by 9.94%-12.50%, while potassium content increased by 2.75%-6.47% (Table 2), which is consistent with the findings of Li, Zou, Qiang, and others (Qiang et al., 2001; Li et al., 2005; Zou and Xiong, 2012). Furthermore, after Ca fertilizer application, total sugar, reducing sugar, and nicotine content in the middle leaves decreased, but the changes remained within a reasonable range, contributing synergistically to quality improvement. The sugar alcohols and organic compounds in sugar alcohol-chelated Ca fertilizers enhance plant stress resistance (Gul et al., 2017; Issa et al., 2020). Additionally, chelated Ca may reduce Ca fixation in the phloem and promote its transport and conversion within the plant (Shen et al., 2016), which may be a key factor in improving cigar tobacco yield and quality. This study also found that the application of sugar alcohol-chelated Ca fertilizer lowered the soil pH by 0.3-0.4 units, bringing the soil into the optimal pH range for tobacco growth (5.5-6.5) (Supplementary Table S1) (Yan et al., 2023). This pH adjustment may also be an important mechanism for enhancing tobacco plant growth. Notably, no studies have been reported on the application of sugar alcohol-chelated Ca fertilizer in soil. However, in this study, the positive effects of soil irrigation with a certain concentration of sugar alcohol-chelated Ca fertilizer on tobacco leaf yield and quality were consistent with foliar application reports for other crops, including peanuts (Li et al., 2022), potatoes (Li et al., 2020; Wang et al., 2023), eggplant (Wu et al., 2013), and cherry tomatoes (Ding et al., 2015). These results suggest that sugar alcohol-chelated Ca fertilizer has high applicability in improving cigar tobacco yield and quality.

Although previous studies have reported a close relationship between Ca content in tobacco leaves and both yield quality and sensory evaluation parameters (Xiao, 2013), there is currently no direct evidence indicating that Ca content in tobacco leaves affects the thermal weight loss process, heat release, and combustion kinetic characteristics. The results of this study indicate that Ca fertilizer primarily improves the pyrolytic reactivity in Stage III of the combustion process, thereby enhancing the overall combustion process of the filler tobacco leaves. Specifically, the response of filler tobacco leaves to Ca fertilizer varies across different pyrolysis stages, particularly in terms of activation energy and frequency factor, showing stage-specific changes. The application of Ca fertilizer reduced the content of low molecular organic compounds in the tobacco leaves (such as a decrease in nicotine and reducing sugars, see Table 2), resulting in an increase in activation energy and a decrease in frequency factor during the second pyrolysis stage, thereby hindering the initial combustion reaction of this stage. Interestingly, the application of Ca fertilizer enhanced the pyrolytic reactivity in stage III. Specifically, the maximum combustion rate in Stage III significantly increased (by 6.7%-40.3%), activation energy decreased (by 1.8%-5.6%), and the frequency factor increased (by 15.9%-73.2%). This phenomenon may be closely related the enhancement of mass transfer during carbon combustion and the increase in Ca content in the tobacco leaves. During the combustion of charcoal, oxygen diffuses to the active sites through chemisorption, where it reacts with the carbonized components, and gaseous products (such as CO2) then diffuse away from the active sites. This mass transfer process is one of the key mechanisms that promotes combustion reactions (Islam et al., 2016). On one hand, after applying Ca fertilizer, the combustion peak temperature in Stage II shifted to lower temperatures (Figure 1B), and the reaction time shortened, indicating an earlier onset of lower-temperature pyrolysis (<350°C), which allowed the pyrolytic reaction to enter the charcoal formation stage earlier (350-400°C), thereby extending the time for oxygen to diffuse to the active sites of the charcoal through chemisorption. This provides sufficient oxygen supply for the combustion of char in Stage III, further promoting the shift of the combustion peak to lower temperatures and significantly increasing the weight loss rate and pyrolysis efficiency (Yuzbasi and Selçuk, 2011; Peng et al., 2021).

On the other hand, the increase in Ca content in tobacco leaves promoted pyrolysis in Stage III. After the reaction in Stage II, the released Ca was converted into Ca salts, which inhibited condensation reactions during pyrolysis and catalyzed the pyrolysis of hemicellulose in the tobacco leaves (Wang et al., 2015), thereby promoting rapid combustion in Stage III. Moreover, after the application of Ca fertilizer, the Ca content in the tobacco leaves did not increase excessively (3.0%-3.2%) and remained within the optimal range for high sensory combustibility ratings (2.5%-3.5%) (Xiao, 2013). Furthermore, the Ca content showed a significant negative correlation with the activation energy during the III pyrolysis stage (r = −0.892, P<0.05), further confirming the promoting effect of increased Ca content on the pyrolysis during this stage.

This study also found that the combustion characteristics index was optimal when the Ca fertilizer application was within the range of 40-80 kg/ha (Table 6). However, when the CaO application rate reached 160 kg/ha, the comprehensive combustion characteristic index was lower than that of the control group, indicating a decline in tobacco leaf combustion performance. This may be related to the toxic effects of excessive Ca fertilizer application on plant physiology, leading to the excessive formation of Ca pectate in the leaves (Almeida et al., 2016). The accumulation of Ca pectate increases the rigidity of the cell walls beyond normal strength, hindering the release of flammable substances. It also reduces the content of low molecular weight organic compounds and easily pyrolyzed components, resulting in the need for more energy during tobacco leaf pyrolysis. Under these conditions, the catalytic effect of Ca salts on pyrolysis is insufficient to offset the negative effects of Ca toxicity, leading to a decrease in the overall combustion performance of the tobacco leaves compared to the control group.

In summary, when the application rate of Ca fertilizer is between 40–80 kg/ha, it not only increases the yield and value of tobacco leaves but also improves their combustion properties. These findings provide scientific data and theoretical support for the precise regulation of cigar tobacco combustion properties through Ca fertilizer application. Furthermore, they offer guidance for nutrient management in other crops, contributing to the promotion of sustainable agriculture and the achievement of public health goals.

5 Conclusions

In conclusion, an appropriate amount of sugar alcohol-chelated Ca fertilizer can promote the growth of cigar filler tobacco, regulate nicotine, “two sugars,” and K content, enhance tobacco yield, value, and the proportion of high-quality tobacco, and improve combustion characteristics. When the application of sugar alcohol-chelated Ca fertilizer is 40 kg/ha, the yield and value of filler tobacco leaves reach their highest levels, at 1999.3 kg/ha and 23,791.7 USD/ha, respectively. The yield and value are slightly lower at 80 kg/ha. In addition, the ash content of tobacco leaves in the 40 kg/ha and 80 kg/ha treatments was significantly reduced by 31.86% and 27.5%, respectively, compared to the control. At an application rate of 80 kg/ha, the tobacco leaves show the highest ignition index, combustion stability index, and overall combustion characteristics index, with the 40 kg/ha rate showing the second-best results. Based on the combined results of different sugar alcohol chelated Ca fertilizer application rates on the yield, value, and combustion properties of cigar filler tobacco, the optimal Ca fertilizer application range (calculated as CaO) is 40-80 kg/ha.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material. Further inquiries can be directed to the corresponding author.

Author contributions

JS: Resources, Writing – review & editing. LZ: Methodology, Visualization, Writing – review & editing. HT: Project administration, Writing – review & editing. YC: Investigation, Project administration, Writing – original draft. BQ: Data curation, Writing – review & editing. YF: Investigation, Project administration, Writing – review & editing. TC: Supervision, Writing – review & editing. RX: Formal Analysis, Writing – review & editing. YZ: Project administration, Writing – review & editing. YR: Conceptualization, Writing – review & editing. LC: Supervision, Writing – review & editing. XS: Funding acquisition, Resources, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by the Science and Technology Project of China National Tobacco Corporation Hubei Province Company, grant number 027Y2022-022.

Acknowledgments

We thank Professor Cao Hongliang from the College of Engineering at Huazhong Agricultural University for providing the instrument (Q600, TA-DSC), and Dr. Yang Zhengming for assisting with its use.

Conflict of interest

The authors declare that this research was funded by the scientific and technological project of Hubei Company of China National Tobacco Corporation, with the project number 027Y2022-022. The funder had the following involvement in the study: providing experimental farmland, tobacco seedlings, and participating in part of the data collection.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fagro.2025.1574895/full#supplementary-material

References

Almeida P. H., Mógor Á.F., Ribeiro A. Z., Heinrichs J., Amano E. (2016). Increase in lettuce (Lactuca sativa L.) production by foliar calcium application. Aust. J. Basic Appl. Sci. 10, 161–167.

Cai B., Geng Z., Gao H., Lin B., Xing L., Hu X., et al. (2019). Research progress of production technologies of cigar tobaccos in China. Acta Tabacaria Sin. 25, 110–119. doi: 10.16472/j.Chinatobacco.2019.T00013

Chen D., Li M., Wang R., Li L., Li X., Shi X. (2019). Progress of the domestic cigar filler tobacco. J. Yangzhou University(Agricultural Life Sci. Edition) 40, 83–90. doi: 10.16872/j.cnki.1671-4652.2019.01.015

Diblasi C. (2008). Modeling chemical and physical processes of wood and biomass pyrolysis. Prog. Energy Combustion Sci. 34, 47–90. doi: 10.1016/j.pecs.2006.12.001

Ding S., Li Y., Yuan L., Zhao B., Lin Z., Li J., et al. (2015). Effects of small molecular organics chelated calcium fertilizer on cherry tomato yield, quality and nutrients absorption. Soil Fertilizer Sci. China 5, 61–66. doi: 10.11838/sfsc.20150511

Fan W., Gao J., Zhang J. (2018). Effect of enzyme on aroma quality and combustion properties of flue-cured tobacco leaves. Southwest China J. Agric. Sci. 31, 948–957. doi: 10.16213/j.cnki.scjas.2018.5.013

Feng X., Huang Y., Wu G., Gou J., Peng Y. (2021). Effects of different calcium concentrations on growth and magnesium absorption of flue-cured tobacco. Crops 03, 190–194. doi: 10.16035/j.issn.1001-7283.2021.03.029

Gao W., Chen K., Xiang Z., Yang F., Zeng J., Li J., et al. (2013). Kinetic study on pyrolysis of tobacco residues from the cigarette industry. Ind. Crops Products 44, 152–157. doi: 10.1016/j.indcrop.2012.10.032

Ge W., Zhang H., Gu J. (2012). Correlation between chemical compositions and combustion characteristic of tobacco leaves. Fire Sci. Technol. 31, 1032–1035.

Gul H., Farman M., Hussain A., Irshad M. (2017). Exogenously applied sorbitol alleviates the salt stress by improving some biochemical parameters in spinach (Spinacia oleracea L.). Int. J. Biol. Biotechnol. 14, 677–686.

Hameed S., Sharma A., Pareek V., Wu H., Yu Y. (2019). A review on biomass pyrolysis models: Kinetic, network and mechanistic models. Biomass Bioenergy 123, 104–122. doi: 10.1016/j.biombioe.2019.02.008

Hepler P. K., Winship L. J. (2010). Calcium at the cell wall-cytoplast interface. JIPB 52, 147–160. doi: 10.1111/j.1744-7909.2010.00923.x

Islam M., Auta M., Kabir G., Hameed B. H. (2016). A thermogravimetric analysis of the combustion kinetics of karanja (Pongamia pinnata) fruit hulls char. Bioresource Technol. 200, 335–341. doi: 10.1016/j.biortech.2015.09.057

Issa D. B., Alturki S. M., Sajyan T. K., Sassine Y. N. (2020). Sorbitol and lithovit-guano25 mitigates the adverse effects of salinity on eggplant grown in pot experiment. 18, 113–126. doi: 10.15159/AR.20.075

Jiao Y., Chen Q., Guo X., Li H., Chen X., Men K., et al. (2024). Effect of potassium fulvate on continuous tobacco cropping soils and crop growth. Front. Plant Sci. 15. doi: 10.3389/fpls.2024.1457793

Li J., Rong S., Qin Y., Zhou J., Zeng D., Zhong Q., et al. (2024a). Analysis of chemical composition and quality difference in different sections of cigar filler and wrapper leaves. J. Henan Agric. Sci. 53, 62–69. doi: 10.15933/j.cnki.1004-3268.2024.01.007

Li L., Wang R., Shi Y., Pan Y., Liu L., Wang J. (2024b). Study on the correlation between grey whiteness and conventional chemical composition of cigar tobacco. J. Anhui Agric. Sci. 52, 165–169. doi: 10.3969/j.issn.0517-6611.2024.09.037

Li T., Wei Q., Sun W., Tan H., Cui Y., Han C., et al. (2022). Spraying sorbitol-chelated calcium affected foliar calcium absorption and promoted the yield of peanut (Arachis hypogaea L.). Front. Plant Sci. 13. doi: 10.3389/fpls.2022.1075488

Li Y., Yang G., Li F., Bai L., Huang M., Liu K., et al. (2020). Effects of sugar alcohol chelated calcium fertilizer on yield, quality and nutrient uptake of potato. Soils 52, 773–780. doi: 10.13758/j.cnki.tr.2020.04.017

Li J., Zhang M., Lin Q., Chen Z., Xie G., Peng J., et al. (2005). Effects of interaction of potassium,Calcium and magnesium on flue-cured tobacco growth and nutrient absorption. J. Anhui Agric. Univ. 32, 125–129. doi: 10.13610/j.cnki.1672-352x.2005.04.027

Liang M., Zhao G., Ge H., Yin X., Zhang B., Li R., et al. (2022). Study on thermogravimetric characteristics and product release behavior of nicotine salts based on thermogravimetric-mass spectrometry(TG-MS). Acta Tabacaria Sin. 28, 8–15. doi: 10.16472/j.Chinatobacco.2022.T0009

Liu L., Wang J., Shi Y., Hu J., Tan Z., Zhu J., et al. (2022). Analysis on the relationship between mineral elements and sensory quality of cigar tobacco leaves in Laifeng County. Hubei Agric. Sci. 61, 100–102 + 158. doi: 10.14088/j.cnki.issn0439-8114.2022.18.017

Ma P., Chen S., Wu Z., Xing X., Zhang X. (2018). Combustion characteristics and dynamic analysis of three biomass components and straw briquette. Acta Energiae Solaris Sin. 39, 837–843. doi: 10.19912/j.0254-0096.2018.03.038

Ma B.-G., Li X.-G., Xu L., Wang K., Wang X.-G. (2006). Investigation on catalyzed combustion of high ash coal by thermogravimetric analysis. Thermochimica Acta 445, 19–22. doi: 10.1016/j.tca.2006.03.021

Mian I., Li X., Dacres O. D., Wang J., Wei B., Jian Y., et al. (2020). Combustion kinetics and mechanism of biomass pellet. Energy 205, 117909. doi: 10.1016/j.energy.2020.117909

Mo J., Wang H., Du J., Yao F., Xu S., Shi X. (2016). Impact of dosage of magnesium fertilizer on cigar wrapper quality and the combustibility. Tianjin Agric. Sci. 22, 33–37. doi: 10.3969/j.issn.1006–6500.2016.06.008

Ni Z., Song Z., Bi H., Jiang C., Sun H., Qiu Z., et al. (2023). The effect of cellulose on the combustion characteristics of coal slime: TG-FTIR, principal component analysis, and 2D-COS. Fuel 333, 126310. doi: 10.1016/j.fuel.2022.126310

Peng Y., Hao X., Qi Q., Tang X., Mu Y., Zhang L., et al. (2021). The effect of oxygen on in-situ evolution of chemical structures during the autothermal process of tobacco. J. Analytical Appl. Pyrolysis 159, 105321. doi: 10.1016/j.jaap.2021.105321

Qiang J., Wang H., Li F., Wu S., Xu S. (2001). Effect of various levels of calium fertilizer on caand K absorption by flue-cured tobacco. J. Yunnan Agric. University(Natural Science) 16, 120–123. doi: 10.16211/j.issn.1004-390x(n).2001.02.013

Ren H., Xia J., Du S., Liu S., Zeng F., Shen Y., et al. (2023). Analysis of affecting meteorological factors in two cigar growing areas in Danjiangkou City. J. Shaanxi Meteorol. 03, 55–58.

Shen X., Yuan L., Li Y., Zhao B., Lin Z., Li J., et al. (2016). Application of small molecular organics chelated calcium fertilizer. Soil Fertilizer Sci. China 03, 87–92. doi: 10.11838/sfsc.20160314

Tang H., Zeng Z., Zhang Y., Li X., Wang J., Liu L., et al. (2019). Leaf quality, nitrogen uptake and nitrogen use efficiency of tobacco under combination of chemical nitrogen fertilizer with organic fertilizer. Acta Agriculturae Boreali-Sinica 34, 183–191. doi: 10.7668/hbnxb.201751264

Wang A. (2022). Characterization of cigar combustion state and study on pyrolysis and combustion characteristics of tobacco leaf (Zhengzhou, China: Henan Agricultural University). doi: 10.27117/d.cnki.ghenu.2021.000541

Wang C., Bai L., Diao C. (2015). Effect of metallic salts of potassium, calcium and magnesium on biomass pyrolysis. J. Tianjin Univ. Sci. Technol. 30, 33–37 + 42. doi: 10.13364/j.issn.1672-6510.20140092

Wang A., Cai B., Fu L., Liang M., Shi X., Huang F., et al. (2021). Pyrolysis and combustion characteristics and kinetics of typical cigar tobacco leaves. Tobacco Sci. Technol. 54, 75–82. doi: 10.16135/j.issn1002-0861.2020.0432

Wang Y., Qin T., Pu Z., Dekomah S. D., Yao P., Sun C., et al. (2023). Foliar Application of Chelated Sugar Alcohol Calcium Improves Photosynthesis and Tuber Quality under Drought Stress in Potatoes (Solanum tuberosum L.). IJMS 24, 12216. doi: 10.3390/ijms241512216

Wu W., Liu Y., Li P., Zhao Y., Mou G. (2013). Effects of sugar alcohol complex calcium on eggplant growth, yield and quality. China Vegetables 24, 46–48.

Wu C., Shi Y., Pan Y., Wang J., Hu J., Jia M., et al. (2022). Effect of fertilizer application rate of maifanite on quality of Laifeng cigar tobacco leaf. Soil Fertilizer Sci. China 5, 116–123. doi: 10.11838/sfsc.1673-6257.21009

Xiao Y. (2013). Status of Soil-Tobacco Calcium contents and its Influence on Tobacco Quality in Qujing (Zhengzhou, China: Henan Agricultural University).

Xu Y. (1987). Factors and substances that determine the flammability of tobacco leaves. Tobacco Sci. Technol. 2, 37–40. doi: 10.16135/jissn1002–0861.1987.02.014

Yan J., Shi R., Wang C., Li D., Li J., Xu R., et al. (2023). Effects of different amendments on soil acidity and tobacco growth in acidic tobacco field. Soils 55, 612–618. doi: 10.13758/j.cnki.tr.2023.03.019

Yan X., Wang Y., Lei J., Zhou J., Pan Y., Hu X., et al. (2021). Classification of domestic cigars and its practical application. Acta Tabacaria Sin. 27, 100–109. doi: 10.16472/j.Chinatobacco.2021.T0029

Yan K., Wang J., Qu J., Li X. (2001). Correlation between smoking quality and physical/chemical parameters of flue-cured tobacco in Henan province. Tobacco Sci. Technol. 10, 5–9.

Yang Y., Cui G., Huang B., Zhang J., Fang L. (1999). Effect of ca2+on yield, quality and botanical characteristics of tobacco. J. Yunnan Agric. Univ. 2, 27–31. doi: 10.16211/j.issn.1004-390x(n).1999.02.007

Yang Y., Deng J., Zhang Y., Wang W. (2018). Oxidation characteristics of coal by STA-FTIR experiment. J. China Coal Soc. 43, 1031–1040. doi: 10.13225/j.cnki.jccs.2017.0751

Yang H., Yan R., Chen H., Lee D. H., Zheng C. (2007). Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86, 1781–1788. doi: 10.1016/j.fuel.2006.12.013

Yao F., Mo J., Wang H., Xu S., Du J., Shi X. (2017). Effects of quick lime application on growth and fermentation quality of Hainan cigar wrapper. J. Shanxi Agric. Sci. 45, 237–241. doi: 10.3969/j.issn.1002-2481.2017.02.24

Yin X., Zhao G., Deng C., Huang P., Liang M., Ge H., et al. (2022). Thermal pyrolysis characteristics and kinetic study of different nicotine salts. Chem. Res. Appl. 34, 2598–2609.

Yuzbasi N. S., Selçuk N. (2011). Air and oxy-fuel combustion characteristics of biomass/lignite blends in TGA-FTIR. Fuel Process. Technol. 92, 1101–1108. doi: 10.1016/j.fuproc.2011.01.005

Zhang Y., Li G., Huang C., Li Q. (2018). Kinetic study on pyrolysis reaction of tobacco leaf in different regions. J. Light Industry 33, 55–62. doi: 10.3969/j.issn.2096-1553.2018.02.009

Zhong X. (2014). Study on combustion characteristics of tobacco (Kunming, China: Kunming University Of Science And Technology).

Zou W., Xiong D. (2010). Effects of available calcium in soil on growth of flue-cured tobacco. Fujian J. Agric. Sci. 25, 96–99. doi: 10.19303/j.issn.1008-0384.2010.01.019

Keywords: cigar, sugar alcohol-chelated calcium, yield, quality, kinetics, combustion characteristics

Citation: Sun J, Zhai L, Tian H, Chang Y, Qiao B, Fan Y, Chen T, Xu R, Zhang Y, Rao Y, Chai L and Sun X (2025) Sugar alcohol-chelated calcium fertilizer enhances yield, quality and combustion performance in filler tobacco leaves. Front. Agron. 7:1574895. doi: 10.3389/fagro.2025.1574895

Received: 11 February 2025; Accepted: 18 March 2025;

Published: 15 April 2025.

Edited by:

Hanuman Singh Jatav, Sri Karan Narendra Agriculture University, IndiaReviewed by:

Arkaprava Roy, National Institute of Biotic Stress Management, IndiaVipendra Kumar, Punjab Agricultural University, India

Copyright © 2025 Sun, Zhai, Tian, Chang, Qiao, Fan, Chen, Xu, Zhang, Rao, Chai and Sun. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xuecheng Sun, c3hjY25AbWFpbC5oemF1LmVkdS5jbg==

Jingguo Sun1

Jingguo Sun1 Lindun Zhai

Lindun Zhai Xuecheng Sun

Xuecheng Sun