Abstract

Livestock tracking technologies, particularly virtual fencing systems which confine animals within a designated area without physical fences, have seen significant advancements. However, much of the research focuses on the technology and functionality of these systems, and less attention has been given to the materials used in their design, which are critical to their long-term effectiveness and durability. Specifically, there is a lack of research on optimized materials and designs for cow virtual fencing devices, despite their essential role in ensuring reliable cattle tracking and enhancing animal welfare. Durable, non-toxic materials capable of withstanding harsh environmental conditions are crucial for these applications, yet limited studies have explored suitable material options. This study addresses this gap through a three-pronged approach combining Finite Element Analysis (FEA) simulations, mechanical analysis, and field testing to evaluate two prototype cow ear tag designs—one made from high-speed resin and the other from Nylon 6/66. This study examines their performance under simulated real-world factors, such as chewing forces and environmental exposure. In addition, we conducted field tests at the Cornell University Ruminant Center, a large-scale research dairy facility, to evaluate the prototypes under operational farm conditions. Our findings demonstrate that material choice, and weight significantly affect device longevity, with a reduced size and weight Nylon material offering a 50% improvement in durability compared to resin. Our results emphasize how important material and design choices are in the wider application of sustainable and precision agriculture practices.

1 Introduction

Virtual fencing technology represents a significant innovation in livestock management by removing the need for traditional physical fences. This technology allows for the remote monitoring, tracking, and control of grazing livestock, which offers a more flexible and cost-effective solution for managing large herds in extensive grazing systems (Goliński et al., 2022; Schillings et al., 2024; Musinska et al., 2025). Unlike conventional systems that rely on permanent and costly infrastructure, such as barbed wire fences (Hoag et al., 2025), virtual fencing creates invisible boundaries tracked by collars worn by each animal (Verdon et al., 2024). Commercially available systems include eShepherd, Nofence, Halter, and Vence which use auditory and electrical cues to guide animal movement (Campbell et al., 2020; Aaser et al., 2022; Verdon et al., 2024; Boyd et al., 2022). As animals approach a virtual boundary, the collar emits an auditory warning—typically starting as a continuous tone (~82 dB at 1 m), which may increase in frequency or intensity if the animal continues forward. If the boundary is crossed, a mild electric pulse is delivered, with reported energy values ranging from 0.18 J to 0.2 J and peak voltages up to 3 kV, encouraging the animal to return to the designated area (Aaser et al., 2022; Verdon et al., 2024). This system reduces the need for manual labor and heavy infrastructure, offering operational flexibility and potential cost savings (Hoag et al., 2025). Despite this, the widespread adoption of virtual fencing technology is hindered by concerns regarding the durability and reliability of the collars, particularly under real-world farming conditions (Lee et al., 2018; Goliński et al., 2022; Schillings et al., 2024). For example, one user interviewed in the Hoag et al. (2024) study found that 25% of collars had fallen off within the first five weeks of installment. These collars are subject to a range of harsh environmental conditions, including extreme temperatures, moisture, and physical wear from contact with various objects in the field, such as trees and posts. In addition to these external stresses, they may also need to withstand mechanical forces such as biting and chewing from other cows. Furthermore, comfort and animal welfare are vital considerations in collar design. To minimize the risk of injury or discomfort, collars must be lightweight, ergonomically shaped, and have smooth, rounded edges to prevent chafing or skin lesions—especially around sensitive areas such as the neck and jaw (Herlin et al., 2021; Hofstra et al., 2022). Despite the recognized importance of materials and durability in virtual fencing collars, there is limited research evaluating their wearability and long-term performance under real-world grazing conditions. Recent survey data highlight recurring concerns around collar function, weather resistance, durability, and signal reliability in rugged terrain—particularly among producers unfamiliar with the technology or operating in challenging environments (Hoag et al., 2024). Most studies have focused on the GPS technology of the tracking systems or laboratory-based mechanical testing, overlooking the unique challenges of field use in extensive grazing systems (Dunzendorfer, 2017; Bailey et al., 2018). Furthermore, while existing research has reported failure rates of 5–20% for commercially available cow ear tags (Dunzendorfer, 2017), the specific durability and performance of virtual fencing collars and ear tags—and strategies for improving them—remain largely unexamined. This gap in the literature highlights the need for more comprehensive studies on the long-term reliability and retention of virtual fencing collars, especially when compared to traditional physical fencing systems.

Efforts to enhance the durability of agricultural materials and technologies are well-documented across various domains. For instance, Denisenko et al. (2024) demonstrate how nanomaterials can be used to improve the durability of agricultural machinery components, addressing wear and tear under harsh field conditions. Similarly, Aramide et al. (2021) review surface modification techniques to increase the wear resistance of tillage tools, ensuring their longevity even under abrasive conditions. Trukhanska (2020) highlights technological methods to improve the wear resistance and durability of agricultural parts, contributing to reduced equipment failure rates in demanding environments. In the field of advanced materials, Dhiman et al. (2022) investigated polymer-based engineered materials for sustainable agriculture, highlighting the potential for tailored solutions to address specific environmental and operational challenges. These studies underscore the broader agricultural industry’s commitment to developing robust, long-lasting technologies, mirroring the goals of our material selection process for durable and weather-resistant cow ear tags.

While collars dominate research in virtual fencing, ear tags offer practical advantages—including lower cost, easier attachment, and reduced entanglement risks—which this study investigates by evaluating their material performance through Finite Element Analysis (FEA), mechanical testing, and field-based assessments (Pandey et al., 2021; Ross et al., 2024). Ear tags were chosen for this study over collars due to their simpler design, lower cost, and ease of attachment to livestock, making them more practical for widespread adoption, particularly in resource-limited farming regions. Furthermore, ear tags can be used on calves, whereas collars are unsuitable due to the calves’ growing necks, which could lead to restriction. Ear tags also pose a lower risk of entanglement in vegetation or other obstacles, reducing the likelihood of injury compared to large collars. These advantages are consistent with findings in studies of wearable technology for livestock behavior monitoring, such as those by Ross et al. (2024) and Pandey et al. (2021), which emphasize the practicality and effectiveness of smaller, more manageable devices like ear tags for monitoring animal behavior. Furthermore, a study by Melo-Velasco et al. (2024) reported that improper collar placement compromised the effectiveness of the electric shock in virtual fencing systems, and in one case, 30% of the collars detached on the very first day—highlighting a key reliability challenge that ear tag–based systems may help overcome. Unlike collars, ear tags are quicker to install, require less precision during application, and are less prone to fit-related issues, making them a more consistent and practical option in field conditions.

We designed and manufactured two prototype ear tag designs—one made from high-speed resin and the other from optimized Nylon— which were tested under real-world conditions at the Cornell University Ruminant Center. The study investigates the overall functionality, durability, and comfort of these materials in the field, focusing on their ability to withstand environmental stressors such as chewing forces, physical wear, and weather conditions. The findings aim to inform the development of more durable and effective virtual fencing systems. This research is particularly relevant for low- and middle-income farming regions, where cost-effective and flexible fencing alternatives are crucial for improving livestock management (Marshall et al., 2020).

2 Materials and methods

2.1 Design considerations for virtual fencing ear tags

Virtual fencing applications in livestock management require that the design of ear tags balance durability, weight, and animal comfort. These tags must be resilient enough to withstand the mechanical forces typical in grazing environments, such as biting and chewing of the tags by other cows and impacts with trees, posts, and other obstacles. At the same time, they must endure exposure to environmental elements like sunlight, wind, rain, and temperature fluctuations, all while securely housing the electronic components required for tracking and stimulus delivery. Our design process focused on creating ear tags using materials that can effectively withstand these mechanical stresses and environmental challenges while maintaining functionality and animal welfare. Materials were selected based on their attitude to endure mechanical stress while being lightweight, non-toxic, and resistant to environmental wear. Research highlights that polymer-based materials, such as Nylon, can offer the mechanical strength and environmental resilience required for agricultural applications (Dhiman et al., 2022; Denisenko et al., 2024). These materials are particularly valued for their UV resistance and thermal stability, which are crucial for long-term use in grazing environments (Ramis et al., 2004).” Existing ear tags used for livestock typically weigh between 20g and 40g (Moove1ment GPS Tracking Tags, 2021), however the integration of our electronics for virtual fencing functionality resulted in an increase in the weight of the tags, therefore future optimization should be done to reduce the weight of the electronics.

2.2 Ear tag case design and materials

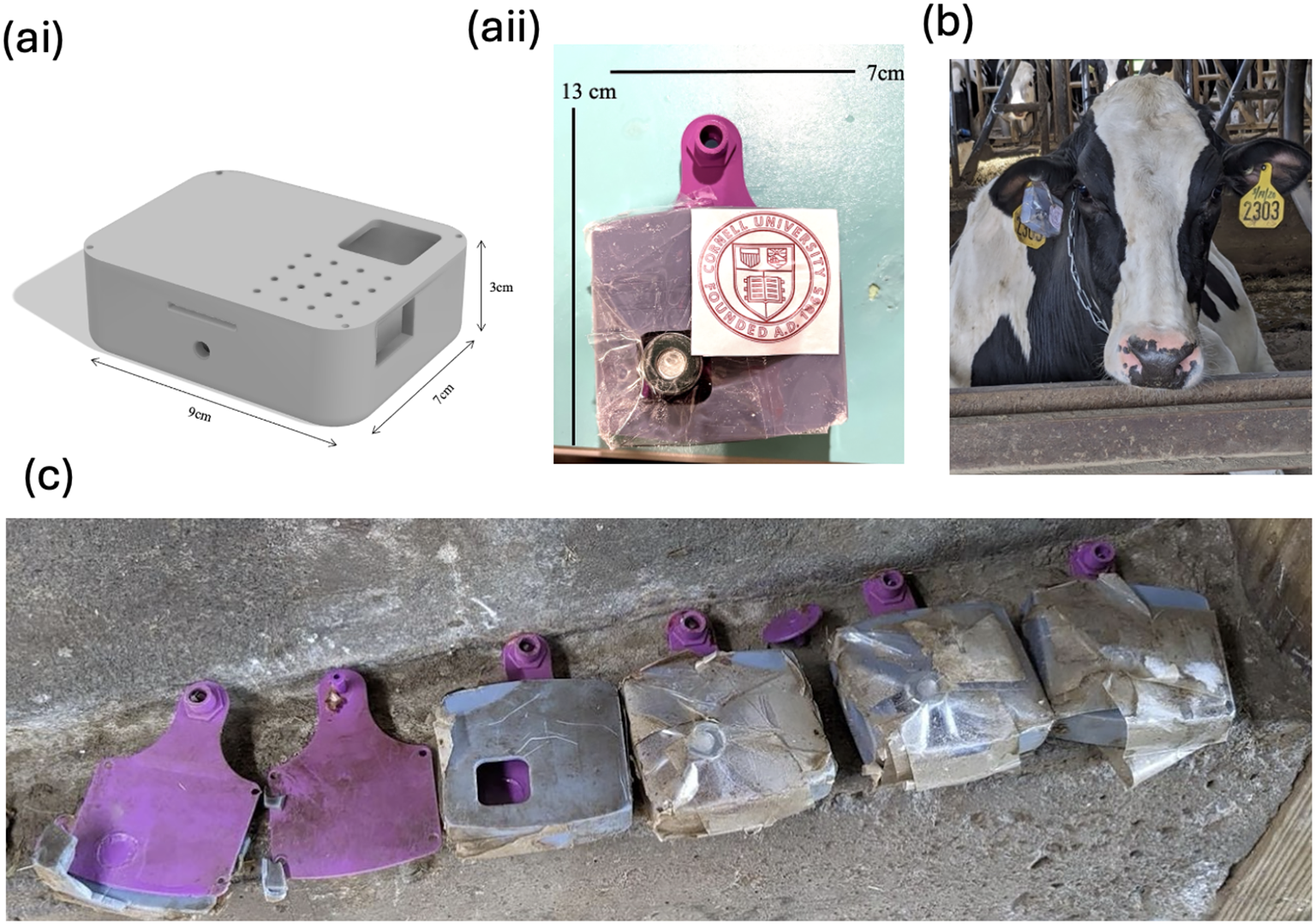

Two versions of the ear tag cases were developed to meet these design requirements: Version 1 (V1) and Version 2 (V2). V1 was constructed from high-speed resin - a material known for its precision and speed in 3D printing. The tag case measured 9 cm x 7 cm x 3 cm, with a wall thickness of 0.35 cm and lid thickness of 0.25 cm. The design incorporated attachment holes for screws to secure the lid to the main body of the case, speaker holes for stimulus sound emission, and a direct view hole for GPS antenna communication (Figure 1). These features were essential for housing the electronic components while maintaining access to satellite signals for GPS tracking.

Figure 1

(ai) CAD design of Version 1 of the cow ear tag case, measuring 9 cm × 7 cm × 3 cm. The enclosure features a wall thickness of 0.35 cm and a lid thickness of 0.25 cm. The design includes screw holes at each corner to secure the lid, speaker perforations to facilitate sound emission, a GPS antenna view port, and an attachment hole for integrating with a rubber ear tag for secure ear placement. (aii) Top-down view of a fully assembled Version 1 tag prior to field testing, showing the overall footprint and attachment components. (b) Photograph of one of the six Version 1 tags attached to a cow during the one-month retention trial. (c) Condition of all six Version 1 cases after removal on day 30. The variation in wear and deformation is attributed to environmental exposure, repeated contact with stall infrastructure, and cow-specific behaviors such as head shaking and side scratching. Several tags show cracks, surface abrasion, or structural distortion—particularly along edges and protruding features. Notably, two tags on the far left have fully broken, leaving only the rubber ear tag attachment component intact.

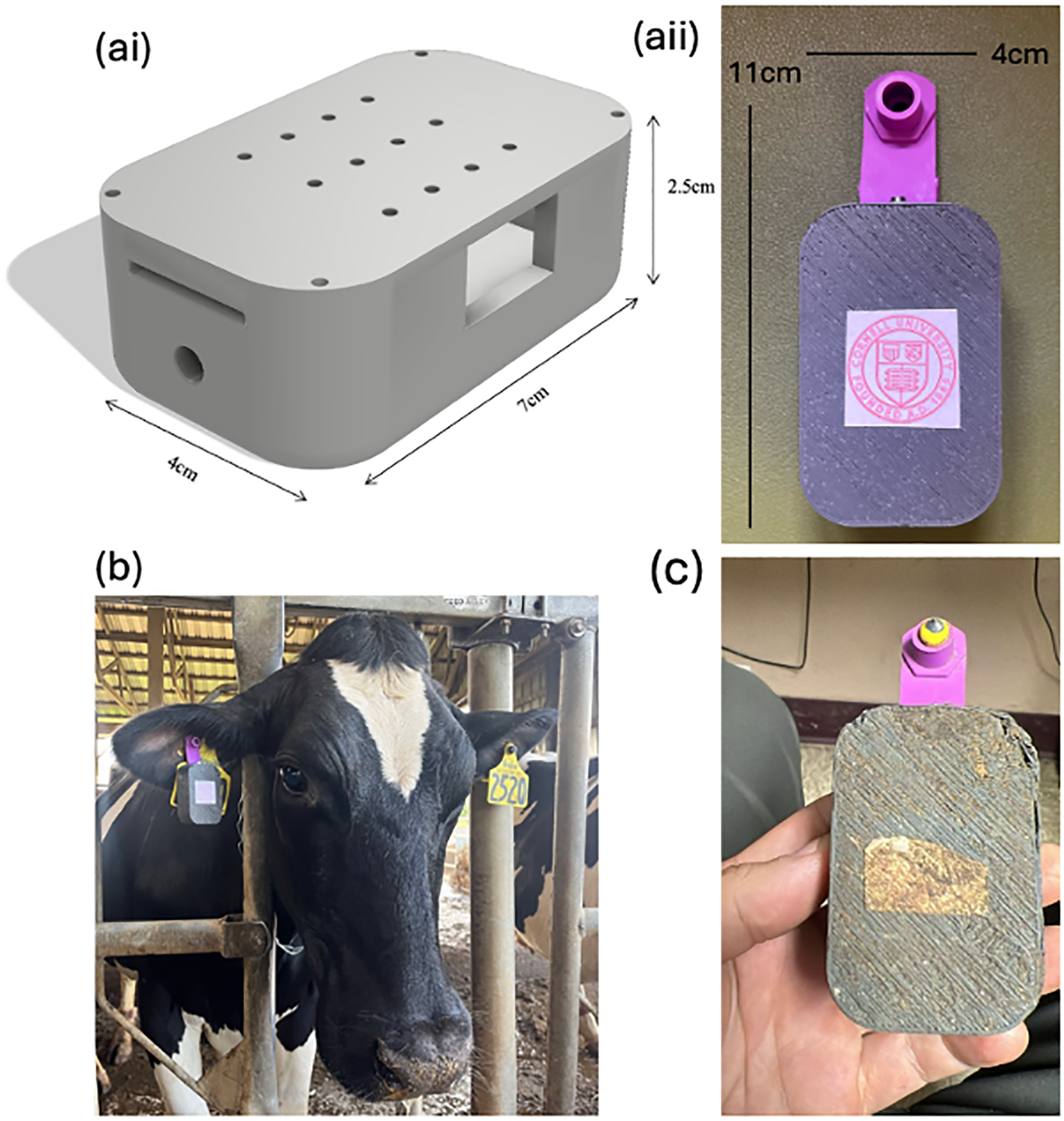

Despite its ability to produce highly detailed prints, resin was found to have limitations in long-term durability, as only three out of the six cases deployed on cows survived at the end of the 30 days trial. In response to these durability concerns, V2 was designed using Nylon 6/66, a material known for its superior resistance to mechanical stress, temperature fluctuations, and long-term wear (Mukhopadhyay, 2009). Nylon 6/66 was chosen for Version 2 due to its superior combination of tensile strength, stiffness (Young’s modulus), low water absorption, and UV resistance compared to other candidates, as shown in Supplementary Figure S1. While Nylon 610 offered comparable or better mechanical performance, it was excluded due to high cost and limited availability. Nylon 11 and Nylon 12 lacked the necessary strength and stiffness, making Nylon 6/66 the most practical and durable option for field use. V2 is smaller in size (7 cm × 4 cm × 2.5 cm) compared to V1, with similar wall and lid thicknesses of 0.35 cm and 0.25 cm, respectively. A key design modification in V2 was the omission of the GPS view hole, as testing demonstrated that the GPS antenna could successfully communicate with satellites through the Nylon material, eliminating the need for a direct view hole (Figure 2).

Figure 2

(ai) Version 2 of the cow ear tag case, with dimensions of 7cm x 4cm x 2.5cm. The enclosure features wall thickness of 0.35cm and a lid thickness of 0.25cm. The design includes space at each of the four corners for screws to secure the lid, speaker holes to facilitate sound emission, and an attachment hole for the rubber ear tag to ensure secure piercing onto the ear. A GPS hole was no longer needed as it was determined that the antenna can still access the satellites through plastic. (aii) Top-down view of a fully assembled Version 2 tag prior to deployment, showing its compact footprint and attachment interface. (b) Day 1 of V2 placed on cow 2520. Seven other tags were placed on seven additional cows. (c) The condition of one of the V2 cases after being removed from a cow on day 30.

3 Results

3.1 Field testing

Field testing of the ear tags was conducted to evaluate their real-world performance, retention, and structural integrity over a 30-day period at the dairy unit of the Cornell University Ruminant Center at the Cornell Agricultural System Testbed (CAST). All procedures with animals were approved by the Animal Care and Use committee of Cornell university (protocol #2023-0132). Cows used for testing were adult lactating or dry Holstein cows housed in free-stall barns with ad-libitum access to feed and water. Barns had either two or three row deep sand-bedded stalls with metallic stall loops. Self-locking headgates (i.e., headlocks) were placed in the feed lane. During testing, the V1 and V2 ear tags were monitored for retention, comfort, and any signs of failure. Inspections were performed daily from days 0 to 7, every other day from days 7 to 15, and once per week from days 15 to 30. The larger size and heavier weight of the resin based V1 ear tags led to significant discomfort for the cows, with structural failures occurring in 50% of the V1 tags after one month of use, as shown in Figure 1c. This highlighted the material’s susceptibility to failure when exposed to prolonged physical stress under field conditions. Figure 1b shows a photo of one of the six V1 tags placed on a cow for the one-month retention test, providing a visual reference of the tag’s real-world application.

In contrast, The V2 Nylon tags achieved 100% retention (vs. 50% for resin; Figure 2c), attributable to their mechanical resilience (Figure 3), which enabled them to withstand prolonged field stress without structural failure. The enhanced retention was attributed to the superior mechanical properties of Nylon 6/66 and the smaller, more compact design, which allowed the tags to maintain their integrity even under prolonged physical stress. Fewer cows experienced discomfort or irritation, with only three instances of minor signs of ear inflammation (i.e., redness, swelling, serous exudation) in the area surrounding the ear-piercing, compared to the widespread discomfort seen with V1, where all cows experienced mild signs of inflammation in the area surrounding the ear piercing. All cases were monitored and resolved without the need for veterinary intervention. Figure 2b shows the initial deployment of the V2 ear tag on cow 2520, with seven additional V2 tags placed on seven other cows. This image provides context for the setup of the retention test and demonstrates the ease of integration of the V2 tags into a real-world dairy farm environment.

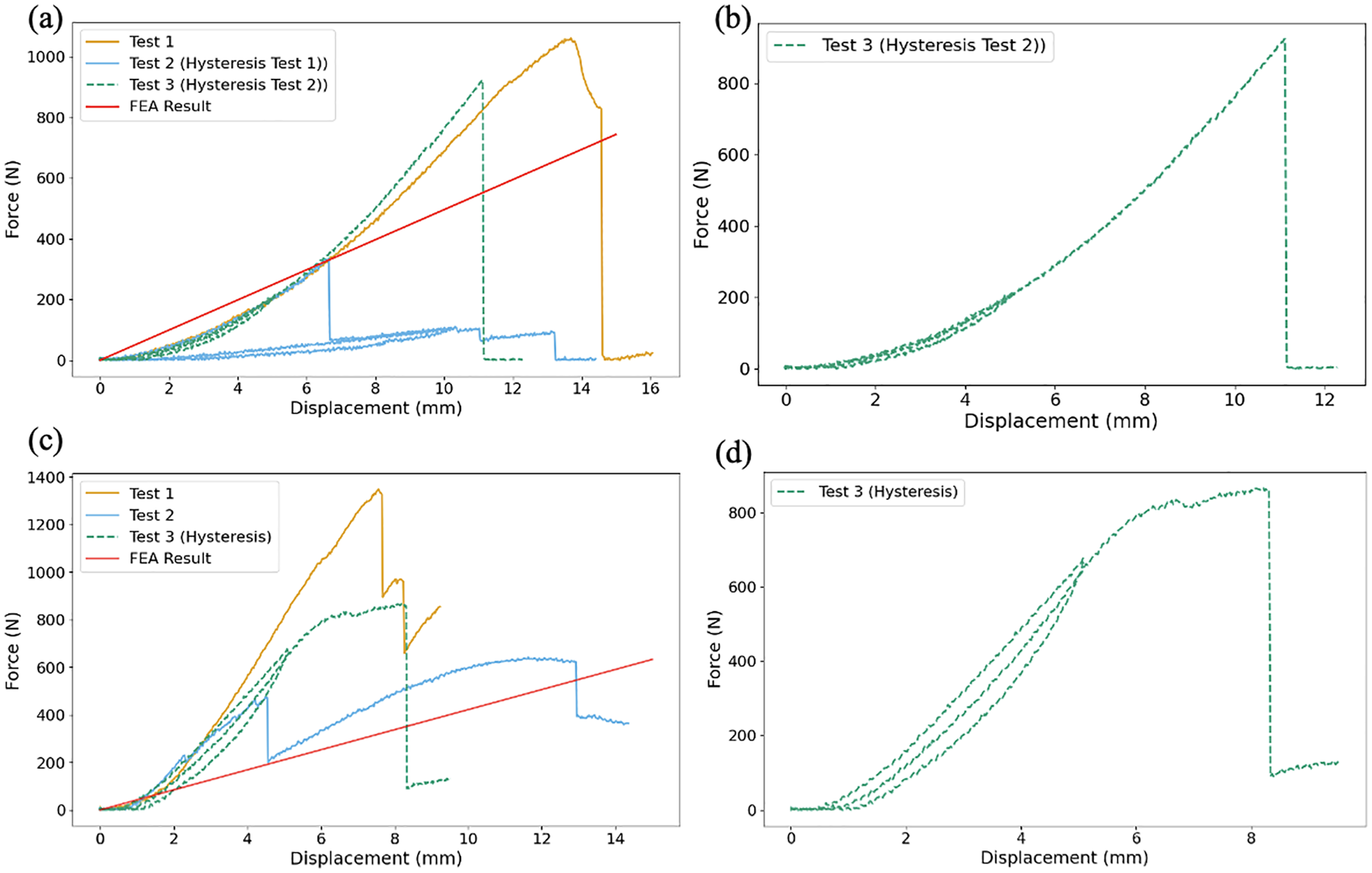

Figure 3

Mechanical testing results for High-Speed Resin and Nylon 6/66 ear tag housings. (a) Force–displacement curves for High-Speed Resin from static compression tests, including two hysteresis cycles and a comparison to FEA-predicted response under 800 N. (b) High-Speed Resin isolated hysteresis loop showing nonlinear elastic behavior and partial energy dissipation. (c) Force–displacement curves for Nylon 6/66 from static compression tests, including one hysteresis cycle and comparison to FEA-predicted response under 800 N. (d) Nylon 6/66 isolated hysteresis loop from cyclic loading showing progressive deformation.

3.2 Mechanical compression test

To characterize the mechanical behavior of the 3D-printed ear tag housings, we conducted static compression tests using a servo-hydraulic testing machine. All tests were performed in a 20,000 lbf capacity digitally controlled, servo-hydraulic testing machine (Instron series 1320, with MTS TestStar II controller). Static tests were performed in displacement control, simply ramping up the displacement until the part failed. Fatigue tests were performed under force control. These tests provided force–displacement and stress–strain data used to evaluate stiffness, yield strength, and post-yield deformation for both case materials. The results are shown in Figures 3 and 4. Force is reported in Newtons (N), and material properties such as stress and modulus are presented in Megapascals (MPa) and Gigapascals (GPa).

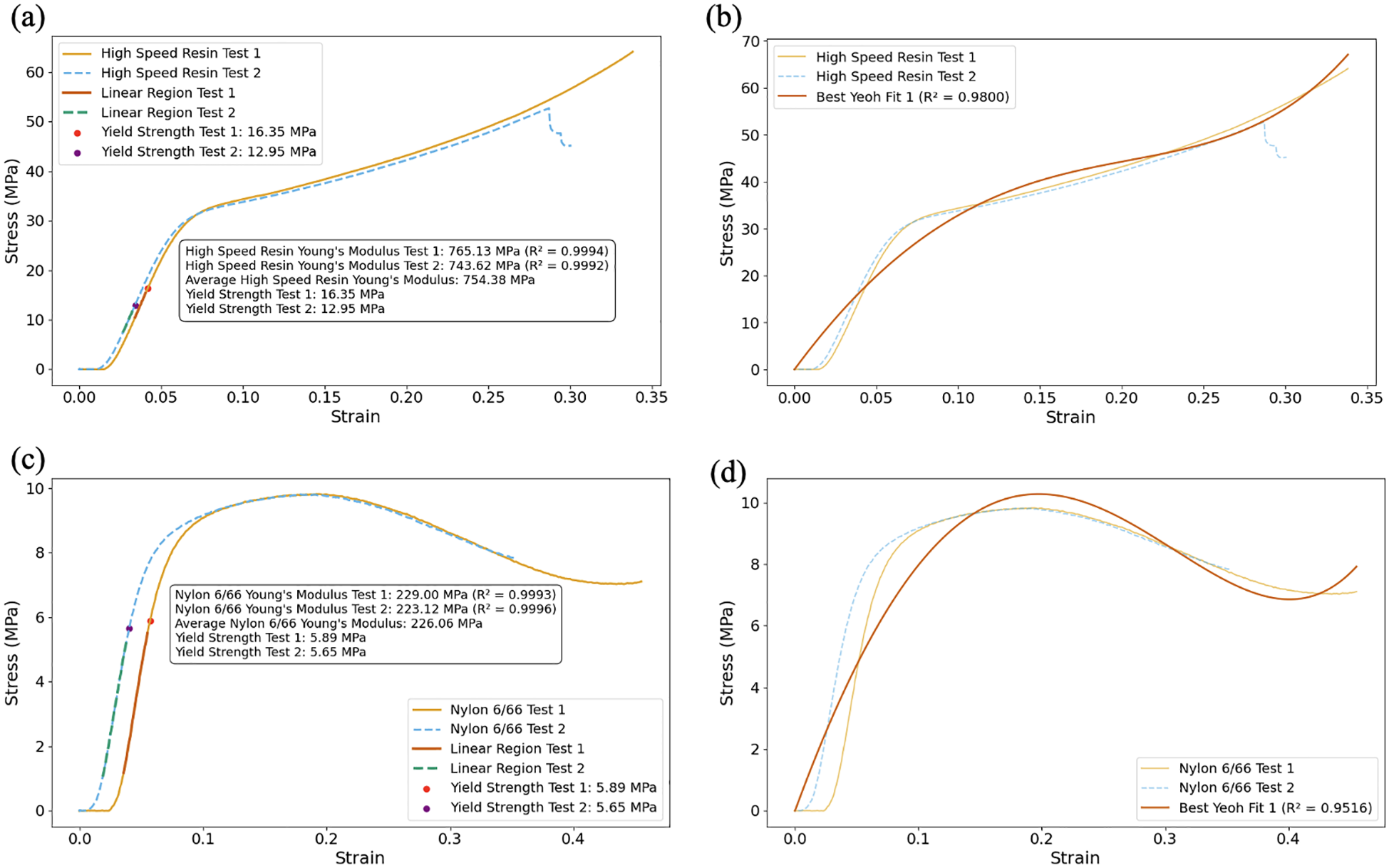

Figure 4

Stress strain plots for high-speed resin and nylon 6/66. (a) Stress–strain curves from two samples, with an average Young’s modulus of 754.38 MPa and yield strengths of 16.35 MPa and 12.95 MPa, calculated from linear elastic regions. (b) Best-fit Yeoh model curve for Test 1 data, showing strong agreement with nonlinear response (R² = 0.9800). Model parameters: C1 = 1142.02, C2 = –404.38, C3 = 61.58. (c) Stress–strain curves from two tests, with an average Young’s modulus of 226.06 MPa and yield strengths of 5.89 MPa and 5.65 MPa. (d) Optimized Yeoh model fit for Test 1, capturing the nonlinear response with good agreement (R² = 0.9516). Model parameters: C1 = 186.42, C2 = –59.81, C3 = 7.89.

The force–displacement curves in Figures 3a, c show that High-Speed Resin exhibits greater initial stiffness and reaches peak force around 1000 N but fails abruptly with limited deformation—characteristic of brittle behavior. In contrast, the Nylon 6/66 cases, particularly in Test 1, demonstrate higher load capacity (over 1300 N) and undergo greater deformation before failure. While Nylon 6/66 achieved a higher peak load than High-Speed Resin in Test 1, Tests 2 and 3 resulted in lower maximum forces, underscoring the variability typical of 3D-printed components. Furthermore, rather than fracturing suddenly, the Nylon parts exhibit progressive damage, as seen in the dips along the curve. Both materials display variability in peak force and displacement, highlighting the variability among complex 3D printed parts. When comparing the hysteresis curves, Nylon 6/66 (Figure 3d) exhibits a broader loop than High-Speed Resin (Figure 3b), indicating greater energy absorption and higher ductility. This further supports the conclusion that High-Speed Resin behaves in a more brittle manner than Nylon 6/66.

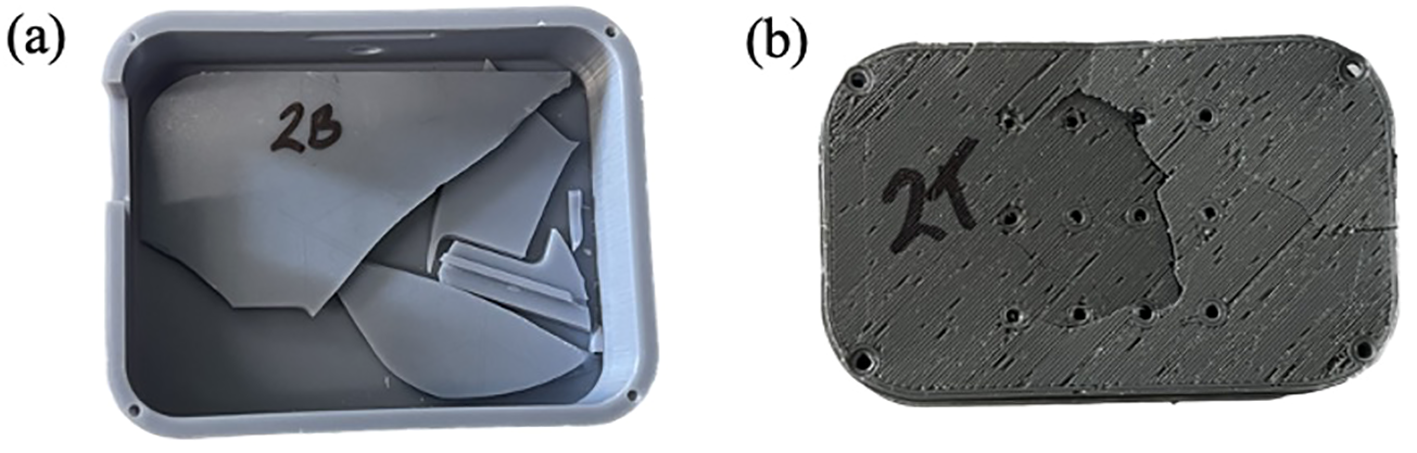

The stress–strain curves for High-Speed Resin and Nylon 6/66 are shown in Figure 4. These experiments were conducted to determine the Young’s modulus and yield strength of each material for use in our FEA material models. Since the manufacturer does not provide these parameters for High-Speed Resin, it was necessary to obtain them experimentally. Additionally, 3D-printed materials often behave differently from their injection-molded counterparts due to factors such as anisotropy, internal defects, and interlayer bonding. To account for this variability, we directly measured the mechanical properties of our printed samples. For reference, Nylon 6/66 is typically reported to have a Young’s modulus ranging from 0.210 to 4.10 GPa and a yield strength between 25.0 and 90.0 MPa (MatWeb, Nylon 6/66)2. To quantify said properties, a python script was written to detect the linear elastic region via a sliding window approach, applying linear regression to each segment and selecting the window with the highest R² value. The slope of this best-fit line represents the Young’s Modulus (Lord and Roebuck, 1997), while the yield strength is defined as the stress at which the actual strain exceeds the linear elastic projection by more than 5% (Christensen, 2011). Using the linear region indicated in the stress–strain curve, High-Speed Resin exhibits a significantly higher average Young’s Modulus (754.38 MPa), indicating greater stiffness, and higher yield strengths (16.35 MPa and 12.95 MPa), meaning it can withstand greater stress before permanent deformation, compared to Nylon 6/66, which shows a lower Young’s Modulus (226.06 MPa) and yield strengths (5.89 MPa and 5.65 MPa). Yeoh model fitting—a hyperelastic material model used to describe nonlinear stress–strain behavior in rubber-like polymers—was applied to characterize the nonlinear response of each material (Yarin et al., 2020). High-Speed Resin showed strong agreement with the model (R² = 0.9800), with best-fit parameters C1 = 1142.02, C2 = –404.38, and C3 = 61.58. Nylon 6/66 had slightly lower agreement (R² = 0.9516) and lower coefficient values (C1 = 186.42, C2 = –59.81, C3 = 7.89), consistent with its lower stiffness and resistance to strain. Comparatively, the higher C1 value for High-Speed Resin reflects its greater stiffness, while the more negative C2 and larger C3 values indicate greater resistance to strain and a capacity to sustain larger deformations before significant stress changes. Overall, while High-Speed Resin is stiffer and stronger in the linear region, Nylon 6/66 exhibits enhanced ductility and strain capacity, making it more resilient under large deformation conditions. These results highlight the stiffer but more brittle nature of High-Speed Resin compared to the more ductile behavior of Nylon 6/6. Figure 5 further emphasizes this, as it can be seen that the High-Speed Resin case lid shatters at failure, whereas the Nylon 6/66 case just cracks where the load is applied.

Figure 5

Post-test images of 3D-printed ear tag housings. (a) High Speed Resin case showing brittle fracture and complete fragmentation following failure. (b) Nylon 6/6 case exhibiting ductile cracking and partial structural integrity. The distinct failure modes visually support the differences observed in mechanical and stress–strain testing.

Based on the mechanical results, Nylon 6/66 is more suitable for cow virtual fencing ear tag cases. While High-Speed Resin demonstrates superior stiffness and higher yield strength—making it appropriate for rigid, load-bearing applications—its brittle nature and limited deformation capacity present a risk of sudden failure under the repeated impacts, bending, or torsional forces common in field conditions. In contrast, Nylon 6/66 offers greater flexibility and ductility, allowing it to absorb and recover from daily mechanical stresses without cracking. This compliance helps reduce discomfort for the animal and extends the durability of the tag in a dynamic, high-movement environment. Therefore, despite its lower strength, the toughness and resilience of Nylon 6/66 make it a more practical and animal-friendly choice for wearable livestock devices.

3.3 FEA

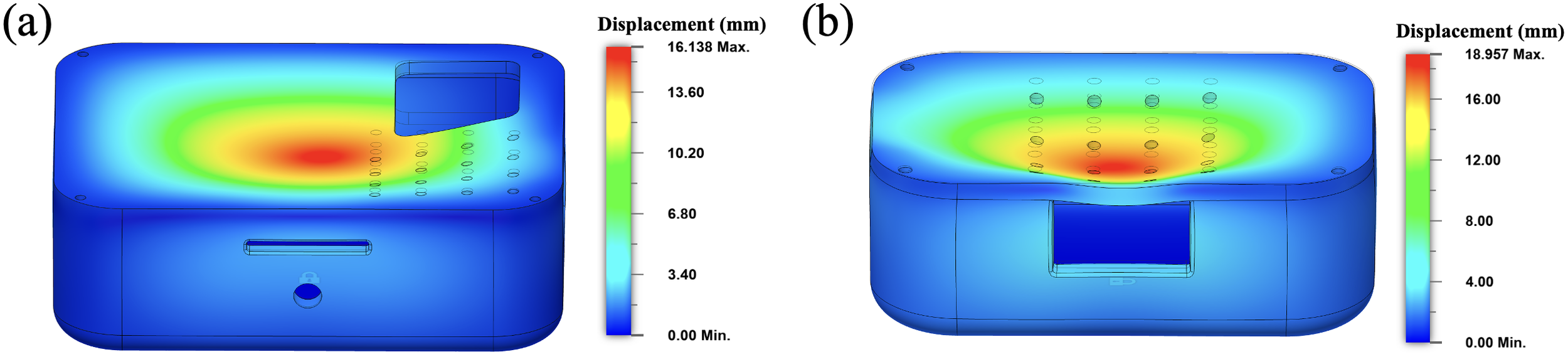

In addition to the mechanical tests, to further understand the deformation behavior of the ear tag cases, finite element analysis (FEA) was run using the material parameters extracted from the mechanical tests, shown in Figure 4. The results of the two ear tag cases under 800N of force is shown in Figure 6. We replicated the mechanical tests so applied the force using a 25.4mm diameter centered on the middle of the case.

Figure 6

Finite element analysis (FEA) simulations of 3D-printed ear tag housings under a static 800 N compressive load. (a) V1 case simulated using Tough 2000, a stand-in material with similar mechanical properties to High-Speed Resin (which is not directly available in Fusion 360’s material library) with material parameters: Young’s modulus = 0.754 GPa, yield strength = 14.65 MPa. (b) V2 Nylon 6/6 case with material parameters: Young’s modulus = 0.226 GPa, yield strength = 5.77 MPa. Both materials were selected from the Fusion 360 Additive Manufacturing material library. Displacement contours are shown with exaggerated deformation for visualization purposes. Tough 2000 exhibited a peak displacement of 16.14 mm, while Nylon 6/6 peaked at 18.957 mm.

The FEA simulations for High-Speed Resin and Nylon 6/66 used the experimentally measured Young’s moduli and yield strengths. In both cases, the FEA model closely followed the initial slope of the experimental force–displacement curves (Figure 3), accurately capturing elastic stiffness. For High-Speed Resin (Figure 3a), the FEA results aligned well with the test data up to around 300 N, but then continued to rise linearly, missing the sharp drop that occurred in the physical test due to brittle fracture. In the case of Nylon 6/6 (Figure 3c), the FEA simulation captures the elastic behavior well, but underestimates the force required to reach larger displacements, particularly beyond the yield point, as it assumes plastic deformation occurs at a constant stress, while the real material shows strain hardening. The FEA peak displacements of 16.14 mm for High-Speed Resin and 18.96 mm for Nylon 6/6, as shown in Figure 6, are reasonably close to the values observed in physical testing, though they slightly overestimate the measured displacements. The real-world mechanical test data showed more complex deformation patterns, which weren’t linear like the FEA model assumed. Overall, the FEA models provided a good baseline for elastic behavior but struggled to capture the full complexity of failure in 3D-printed materials, suggesting that more advanced modeling approaches will be needed in future work.

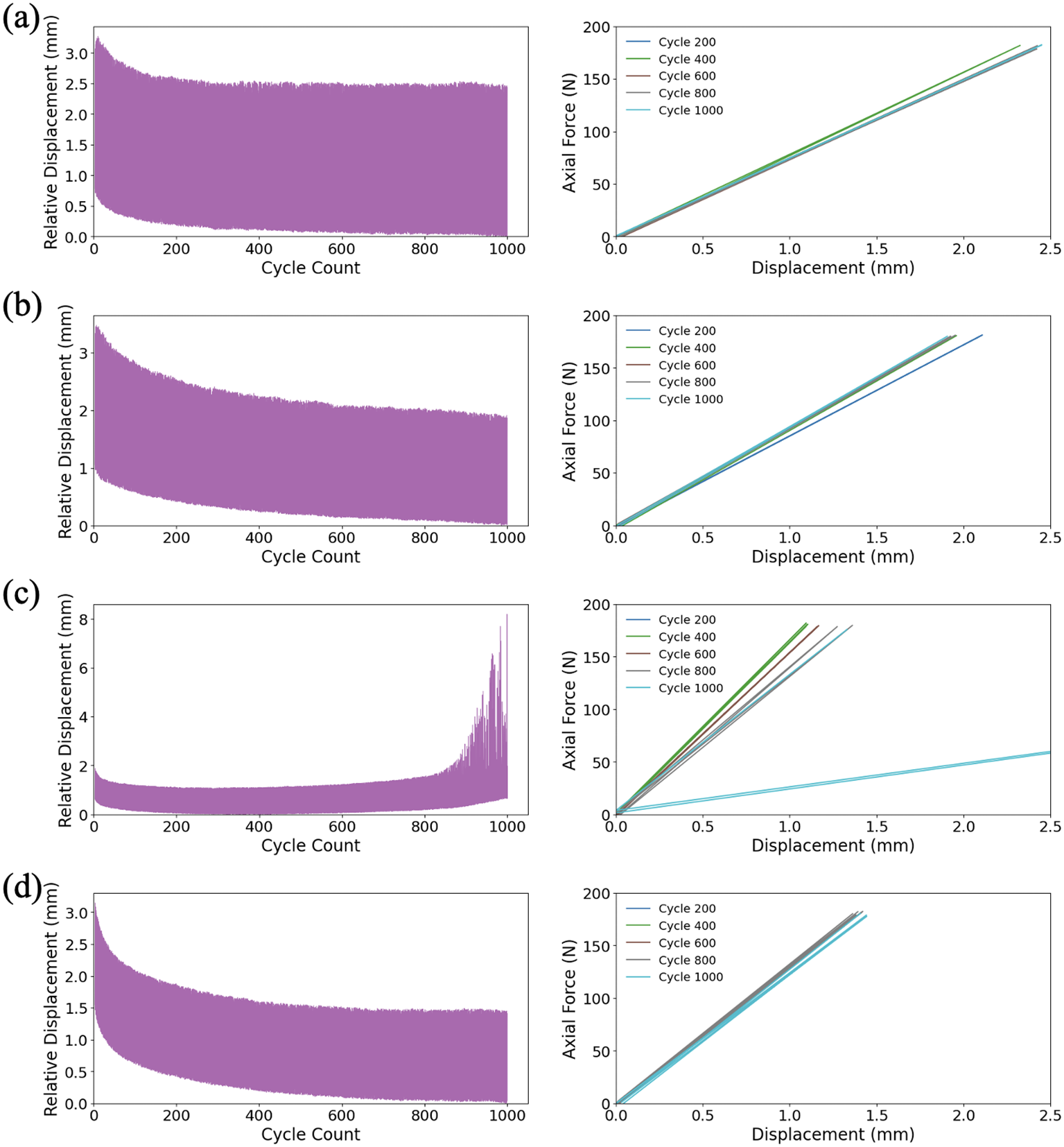

3.4 Fatigue test

To simulate real-world exposure and assess cyclic loading behavior, four cases were tested—two Version 1 (V1) High-Speed Resin and two Version 2 (V2) Nylon 6/66. Figure 7 has been divided between resin cases (7a and 7b) and Nylon cases (7c and 7d). The left-hand plots show relative displacement over 1000 cycles, while the right-hand plots show hysteresis loops at selected cycle intervals. The resin cases (7a and 7b) maintain stable displacement throughout the test, with tightly clustered hysteresis loops indicating minimal energy loss, low plastic deformation, and strong fatigue resistance. In contrast, the Nylon cases show greater variability. Figure 7c exhibits a sharp increase in displacement after 800 cycles, suggesting structural degradation. The widening of the hysteresis loops further indicates permanent deformation. Figure 7d performed better than 7c, maintaining more consistent behavior, but still showed slightly wider hysteresis loops and larger displacement drift compared to the resin cases, suggesting incomplete recovery between cycles. Overall, the High-Speed Resin cases show better mechanical stability under repeated loading up to 1000 cycles of 200N, which is to be expected as from Figure 4 it is seen that Nylon 6/66 as a lower Young’s modulus and thus behaves more elastically. Finally, as shown in Figure 5, when the Resin cases fail, they tend to shatter completely, whereas the Nylon 6/66 cases are more likely to bend or fracture without fully breaking. This suggests that although Nylon 6/66 exhibits lower mechanical stability under cyclic loading, it may offer a more ductile failure mode, reducing the likelihood of total structural failure when the material’s limit is reached.

Figure 7

Mechanical fatigue performance of 3D-printed ear tags under cyclic loading. Left column: Relative displacement over cycle count. Right column: Hysteresis loops at selected cycles (200–1000). (a, b) correspond to two V1 High-Speed Resin cases. (c) and (d) correspond to two V2 Nylon 6/66 cases.Supplementary Figure S1. Comparison of mechanical and environmental properties (tensile strength, Young’s modulus, elongation at break, water absorption, and Shore hardness) for six 3D printing materials: Nylon 6, Nylon 66, Nylon 11, Nylon 12: Variants of polyamide polymers differing in molecular structure and performance; Nylon 6 and 66 are known for high strength and stiffness, while Nylon 11 and 12 offer better flexibility. PLA (Polylactic Acid): A biodegradable polymer derived from renewable resources, known for ease of printing but lower mechanical durability. ABS (Acrylonitrile Butadiene Styrene): A petroleum-based thermoplastic valued for strength and toughness. Values are normalized from MatWeb² material property data. Error bars are not shown as the values represent single averaged entries without reported variability.

3.5 Weight comparison and comfort

As mentioned, the size of the tags affected retention rates, and weight also plays a significant role. Table 1 presents the weight comparison between the V1 resin case and the V2 Nylon case. The V2 design, which uses Nylon 6/66 and more compact electronics, resulted in a significant weight reduction, contributing to improved comfort for the cows. The weight reduction in V2 tags was a key factor in the improved retention and comfort observed during the field tests.

Table 1

| Version | Material | Case, g | Electronics, g | Total, g |

|---|---|---|---|---|

| V1 | Resin | 80 | 50 | 130 |

| V2 | Nylon | 19 | 20 | 39 |

Comparison of weight between V1 3D printed resin case and V2 3D printed nylon case.

4 Discussion

The transition from high-speed resin (V1) to Nylon 6/66 (V2) in the design of cow ear tags for virtual fencing systems represents a meaningful improvement in both mechanical performance and animal welfare. Previous studies have emphasized the critical role of material selection in agricultural applications (Scarascia-Mugnozza et al., 2011; Alves et al., 2009), and this study provides robust evidence that Nylon 6/66 outperforms traditional materials such as PLA (polylactic acid) and resin in terms of both durability and biocompatibility. In particular, the enhanced tensile strength and reduced displacement under applied stress observed in Nylon 6/66 suggests that it offers superior resistance to physical damage, which is a common issue with resin-based materials. This improved mechanical performance can mitigate the breakage and damage often seen with other materials, thereby enhancing the longevity of the tags. Furthermore, these findings align with the growing body of research advocating for the reduction of tag size and weight to improve animal comfort and welfare (Pandey et al., 2021). The smaller, lighter design of the V2 Nylon tag effectively addresses concerns related to discomfort associated with heavier, bulkier devices. The reduction in weight not only decreases the risk of skin irritation and infections but also helps prevent disruptive impacts from the tags during feeding, grooming, lying down, or interactions with other animals. Such concerns have been highlighted in previous studies evaluating the welfare impacts of livestock tracking devices, underscoring the importance of ergonomic design in minimizing stress on animals (Pereira et al., 2023; Džermeikaitė et al., 2023).

Field testing provided additional insight into the real-world performance of the V2 Nylon ear tags. In controlled dairy barn environments - where the tags were subjected to interactions with concrete surfaces, headlocks, and close-quarter contact with other animals -, the V2 tags exhibited a 100% retention rate after 30 days of use, a significant improvement over the V1 resin tags, which showed a 50% failure rate over the same period. This enhanced retention rate demonstrates Nylon 6/66’s ability to withstand the prolonged mechanical stresses that are typical in field environments, ensuring the long-term viability of the tags. However, further studies are needed to assess the performance of the V2 tags in more variable field conditions, such as in free-range or paddock environments, where mechanical and environmental stresses may differ. Despite the promising results, several challenges were encountered during the development and testing of the tags. Early attempts to print with Nylon 6/66 faced technical challenges, primarily due to the lack of standardized printing guidelines for this material. This required extensive trial and error, leading to inconsistent print quality and delays in the development process. While Nylon’s inherent flexibility may improve its impact resistance, there are concerns about the long-term durability of the material, particularly if the tag design is not carefully optimized to balance flexibility with structural integrity. Though PLA remains a more straightforward material to print and offers certain advantages in ease of use, the superior resilience of Nylon 6/66 makes it a more suitable material for cow ear tags, especially when considering long-term durability (3D Meta 2025)3. Therefore, future research should focus on further optimizing the printing process for Nylon, as well as refining tag designs to maximize both comfort and durability. Additionally, exploring hybrid composite materials that combine Nylon’s mechanical properties with enhanced biocompatibility could offer even better outcomes for animal welfare in virtual fencing applications.

5 Conclusion

To conclude, this study underscores the critical role of material selection in the design of 3D-printed ear tags for virtual fencing systems. Compared to high-speed resin, Nylon 6/66 demonstrated superior durability, retention, and animal comfort in both laboratory and field evaluations. While resin cases exhibited greater stiffness, they were prone to brittle failure under load. In contrast, the V2 Nylon 6/66 tags achieved a 100% retention rate over 30 days and resulted in fewer signs of discomfort, offering a more reliable and welfare-friendly solution.

Beyond mechanical performance, these results contribute to the broader goals of sustainable and precision livestock farming. By enhancing comfort and durability, the improved design reduces the need for frequent tag replacement, minimizes stress-induced behaviors, and supports better health outcomes for animals. This work lays the groundwork for future innovations that balance technological function with the ethical imperative of animal welfare.

Statements

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material. Further inquiries can be directed to the corresponding author.

Ethics statement

The animal study was approved by Cornell University Institutional Animal Care and Use Committee (IACUC), Cornell University, Ithaca, NY, United States. The study was conducted in accordance with the local legislation and institutional requirements.

Author contributions

HJ: Conceptualization, Methodology, Writing – review & editing, Investigation, Validation, Writing – original draft, Formal Analysis, Visualization. CR: Writing – review & editing, Supervision, Methodology, Data curation, Investigation. DH: Writing – review & editing, Investigation, Data curation. JT: Data curation, Investigation, Writing – review & editing. TN: Writing – review & editing, Investigation, Conceptualization, Data curation. JB: Investigation, Conceptualization, Writing – review & editing. JG: Resources, Writing – review & editing, Funding acquisition, Project administration. DE: Writing – review & editing, Funding acquisition, Resources, Project administration.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. We thank the Bezos Earth Fund for providing financial support for this project. This research was also supported by the USDA National Institute of Food and Agriculture (NIFA) Farm of the Future project # 2023-77038-38865.

Acknowledgments

Finally, we would like to thank Professor Alan Zehnder for his invaluable support and guidance with running the static loading tests.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that Generative AI was used in the creation of this manuscript. Generative AI was used in the preparation of this manuscript for language editing, clarity enhancement, and formatting guidance. No content was generated by AI without author oversight, and all scientific claims, analyses, and conclusions were developed and verified by the authors. The AI tool used was ChatGPT (OpenAI, GPT-4, 2025).

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fanim.2025.1643958/full#supplementary-material

Supplementary Figure 1Comparison of mechanical and environmental properties (tensile strength, Young’s modulus, elongation at break, water absorption, and Shore hardness) for six 3D printing materials: Nylon 6, Nylon 66, Nylon 11, Nylon 12: Variants of polyamide polymers differing in molecular structure and performance; Nylon 6 and 66 are known for high strength and stiffness, while Nylon 11 and 12 offer better flexibility. PLA (Polylactic Acid): A biodegradable polymer derived from renewable resources, known for ease of printing but lower mechanical durability. ABS (Acrylonitrile Butadiene Styrene): A petroleum-based thermoplastic valued for strength and toughness. Values are normalized from MatWeb² material property data. Error bars are not shown as the values represent single averaged entries without reported variability.

Supplementary Table 1Comparison of candidate materials based on mechanical demands and environmental stressors, with reference to normalized performance shown in Supplementary Figure S1.

Footnotes

1.^Moovement. GPS ear tags for cattle. Available at: https://www.moovement.com [Accessed 6 June 2025].

2.^MatWeb, LLC. Nylon 6/66 (PA 6/66), unreinforced – Material Property Datasheet. Available at: https://www.matweb.com/search/datasheet_print.aspx?matguid=26386631ec1b49eeba62c80a49730dc4 [Accessed 6 June 2025].

3.^3D META. (2025, February 6). PLA+ or Nylon for Durability?https://www.3dmeta.com.au/blogs/news/pla-or-nylon-for-durability.

References

1

Aaser M. F. Staahltoft S. K. Korsgaard A. H. Trige-Esbensen A. Alstrup A. K. O. Sonne C. et al . (2022). Is virtual fencing an effective way of enclosing cattle? Personality, herd behaviour and welfare. Animals12, 842. doi: 10.3390/ani12070842

2

Alves C. Freitas M. Silva A. J. Luz S. M. Alves D. E. (2009). Sustainable design procedure: The role of composite materials to combine mechanical and environmental features for agricultural machines. Materials Design30, 4060–4068. doi: 10.1016/j.matdes.2009.05.015

3

Aramide B. Pityana S. Sadiku R. Jamiru T. Popoola P. (2021). Improving the durability of tillage tools through surface modification—a review. Int. J. Advanced Manufacturing Technol.116, 83–98. doi: 10.1007/s00170-021-07487-4

4

Bailey D. W. Trotter M. G. Knight C. W. Thomas M. G. (2018). Use of GPS tracking collars and accelerometers for rangeland livestock production research. Trans. Anim. Sci.2, 81–88. doi: 10.1093/tas/txx006

5

Boyd C. S. O’Connor R. Ranches J. Bohnert D. W. Bates J. D. Johnson D. D. et al . (2022). Virtual fencing effectively excludes cattle from burned sagebrush steppe. Rangeland Ecol. Manage.81, 55–62. doi: 10.1016/j.rama.2022.01.001

6

Campbell D. L. Ouzman J. Mowat D. Lea J. M. Lee C. Llewellyn R. S. (2020). Virtual fencing technology excludes beef cattle from an environmentally sensitive area. Animals10, 1069. doi: 10.3390/ani10061069

7

Christensen R. M. (2011). Defining yield stress and failure stress (Strength). Theory Materials Failure, 118–132.

8

Denisenko M. Deviatko O. Kanivets N. Mushtruk N. Tuziuk M. (2024). “Application of Nanomaterials and Nanotechnologies to Increase the Durability of Agricultural Machinery Working Bodies,” in Design, Simulation, Manufacturing: The Innovation Exchange (Springer Nature, Switzerland), 371–381. doi: 10.1007/978-3-031-63720-9_32

9

Dhiman A. Sharma A. K. Agrawal G. (2022). Polymer based engineered materials for sustainable agriculture. ACS Agric. Sci. Technol.2, 693–711. doi: 10.1021/acsagscitech.1c00278

10

Dunzendorfer P. (2017). Application of product development methodologies for injection moulded components of an animal monitoring device. Universität Linz, Johannes Kepler University Linz.

11

Džermeikaitė K. Bačėninaitė D. Antanaitis R. (2023). Innovations in cattle farming: Application of innovative technologies and sensors in the diagnosis of diseases. Animals13, 780. doi: 10.3390/ani13050780

12

Goliński P. Sobolewska P. Stefańska B. Golińska B. (2022). Virtual fencing technology for cattle management in the pasture feeding system—a review. Agriculture13, 91. doi: 10.3390/agriculture13010091

13

Herlin A. Brunberg E. Hultgren J. Högberg N. Rydberg A. Skarin A. (2021). Animal welfare implications of digital tools for monitoring and management of cattle and sheep on pasture. Animals11, 829. doi: 10.3390/ani11030829

14

Hoag D. L. Reuter R. Mooney D. F. Vitale J. Ritten J. DeLay N. et al . (2025). The economic fundamentals of virtual fencing compared to traditional fencing. Rangelands47, 92–101. doi: 10.1016/j.rala.2024.05.006

15

Hoag D. Vorster A. G. Ehlert K. Evangelista P. Edwards-Callaway L. Mooney D. F. et al . (2024). Beef cattle producer perspectives on virtual fencing. Rangeland Ecol. Manage.96, 143–151. doi: 10.1016/j.rama.2024.06.004

16

Hofstra G. Roelofs J. Rutter S. M. van Erp-van der Kooij E. de Vlieg J. (2022). Mapping welfare: Location determining techniques and their potential for managing cattle welfare—A review. Dairy3, 776–788. doi: 10.3390/dairy3040053

17

Lee C. Colditz I. G. Campbell D. L. (2018). A framework to assess the impact of new animal management technologies on welfare: A case study of virtual fencing. Front. Veterinary Sci.5. doi: 10.3389/fvets.2018.00187

18

Lord J. D. Roebuck B. (1997). Recommended methods for determining Young’s modulus for tensile tests.

19

Marshall K. Salmon G. R. Tebug S. Juga J. MacLeod M. Poole J. et al . (2020). Net benefits of smallholder dairy cattle farms in Senegal can be significantly increased through the use of better dairy cattle breeds and improved management practices. J. Dairy Sci.103, 8197–8217. doi: 10.3168/jds.2019-17334

20

Melo-Velasco J. Wilson K. R. Heimsoth J. Myers R. L. (2024). There will always be collars in my future”; Exploring US ranchers’ and company representatives’ perspectives of virtual fencing for livestock. Smart Agric. Technol.9, 100632. doi: 10.1016/j.atech.2024.100632

21

Mukhopadhyay S. K. (2009). “Manufacturing, properties and tensile failure of nylon fibres,” in Handbook of tensile properties of textile and technical fibres (Woodhead Publishing, Swaston, U.K), 197–222. doi: 10.1533/9781845696801.2.197

22

Musinska J. Skalickova S. Nevrkla P. Kopec T. Horky P. (2025). Unlocking potential, facing challenges: A review evaluating virtual fencing for sustainable cattle management. Livestock Sci., 295, 105693. doi: 10.1016/j.livsci.2025.105693

23

Pandey S. Kalwa U. Kong T. Guo B. Gauger P. C. Peters D. J. et al . (2021). Behavioral monitoring tool for pig farmers: Ear tag sensors, machine intelligence, and technology adoption roadmap. Animals11, 2665. doi: 10.3390/ani11092665

24

Pereira E. Araújo Í. Silva L. F. V. Batista M. Júnior S. Barboza E. et al . (2023). RFID technology for animal tracking: A survey. IEEE J. Radio Frequency Identification7, 609–621. doi: 10.1109/JRFID.2023.3334952

25

Ramis X. Cadenato A. Salla J. M. Morancho J. M. Valles A. Contat L. et al . (2004). Thermal degradation of polypropylene/starch-based materials with enhanced biodegradability. Polymer Degradation Stability86, 483–491. doi: 10.1016/j.polymdegradstab.2004.05.021

26

Ross T. R. Thiemann G. W. Kirschhoffer B. J. Kirschhoffer J. York G. Derocher A. E. et al . (2024). Telemetry without collars: performance of fur-and ear-mounted satellite tags for evaluating the movement and behaviour of polar bears. Anim. Biotelemetry12, 18. doi: 10.1186/s40317-024-00373-2

27

Scarascia-Mugnozza G. Sica C. Russo G. (2011). Plastic materials in European agriculture: actual use and perspectives. J. Agric. Eng.42, 15–28. doi: 10.4081/jae.2011.3.15

28

Schillings J. Holohan C. Lively F. Arnott G. Russell T. (2024). The potential of virtual fencing technology to facilitate sustainable livestock grazing management. animal18, 101231. doi: 10.1016/j.animal.2024.101231

29

Trukhanska O. (2020). Technological methods of increasing wear resistance and durability of details. Machinery Energy Transport Agro-Industrial Complex4, 109–115. doi: 10.37128/2520-6168

30

Verdon M. Hunt I. Rawnsley R. (2024). The effectiveness of a virtual fencing technology to allocate pasture and herd cows to the milking shed. J. Dairy Sci.107, 6161–6177. doi: 10.3168/jds.2023-24537

31

Yarin A. L. Sankaran A. An S. Pourdeyhimi B. (2020). Constitutive modeling of polymers accounting for their hyperelasticity, plasticity, creep and viscoelastic relaxation. Polymer Testing85, 106444. doi: 10.1016/j.polymertesting.2020.106444

Summary

Keywords

precision livestock technology, 3D-printed wearables, agricultural materials engineering, nylon durability, fatigue testing

Citation

James H, Rial C, Hull D, Taylor J, Nikolaou T, Boza J, Giordano J and Erickson D (2025) Improved durability of 3D-printed ear tags for virtual fencing in cattle: mechanical and field performance. Front. Anim. Sci. 6:1643958. doi: 10.3389/fanim.2025.1643958

Received

09 June 2025

Accepted

28 July 2025

Published

18 August 2025

Volume

6 - 2025

Edited by

Archibold Bakare, Fiji National University, Fiji

Reviewed by

Andrea Bragaglio, Council for Agricultural Research and Agricultural Economy Analysis | CREA, Italy

Ishaya Usman Gadzama, The University of Adelaide, Australia

Updates

Copyright

© 2025 James, Rial, Hull, Taylor, Nikolaou, Boza, Giordano and Erickson.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: David Erickson, de54@cornell.edu

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.