- 1Department of Chemical Sciences, Adekunle Ajasin University, Akungba-Akoko, Ondo, Nigeria

- 2State Key Laboratory of Marine Environmental Health and Department of Chemistry, City University of Hong Kong, Hong Kong, Hong Kong SAR, China

- 3Water Utilization Division, Department of Chemical Engineering, University of Pretoria, Pretoria, South Africa

- 4Department of Physics, Joseph Sarwuan Tarka University Makurdi (Formerly, Federal University of Agriculture Makurdi), Makurdi, Benue, Nigeria

- 5Department of Chemistry, Division of Physical and Computational Sciences, University of Pittsburgh, Bradford, PA, United States

Carbon-based materials are pivotal in next generation energy technologies due to their tunable electronic properties, porosity, and chemical stability. Structural variations from 0D to 3D; graphene, carbon nanotubes, carbon aerogels, and biomass derived activated carbons; enable multifunctional roles as conductive scaffolds, catalysts, adsorbents, and enzyme supports. In biofuel production, they enhance biomass pretreatment, fermentation, and biodiesel synthesis, achieving up to 95% biodiesel yields and 30%–50% faster fermentation. In thermochemical processes, porous carbons improve hydrocarbon cracking, deoxygenation, and tar conversion, boosting selectivity by 20%–40% and reducing byproducts by 25%. For CO2 valorization, carbon nanomaterials enable selective conversion with Faradaic efficiencies >80% and CO2-to-methanol rates up to 0.5 mmol g-1 h-1. In solar and hydrogen technologies, they enhance charge transport, stability, and catalysis, delivering photocurrents of 15–25 mA cm-2, solar-to-hydrogen efficiencies of 12%–18%, and 40% higher H2 yields in biomass gasification. Heteroatom doping and surface functionalization allow precise control over activity and selectivity. Despite scalability and integration challenges, AI-guided design, waste derived carbons, and hybrid architectures promise sustainable, high performance solutions. This review underscores carbon’s role in bridging fundamental science and industrial applications, driving the transition toward a sustainable energy future.

1 Introduction

The accelerating global push toward net-zero emissions has intensified the search for sustainable and scalable energy solutions. Yet, today’s energy market is marked by a fundamental imbalance. On one hand, industry growth, population expansion, and digitalization are projected to increase energy demand in Europe alone by 40% by 2050 (Brugger et al., 2021). On the other hand, fossil fuels still supply ≈80% of the global primary energy mix, pushing atmospheric CO2 levels from 316 ppm in 1959 to 420 ppm in 2023, the highest concentration in three million years, driving climate change at an unprecedented rate of 0.2 °C per decade (Brugger et al., 2021; Smirnov, 2024). While renewable technologies such as solar, wind, and biomass have advanced rapidly, they remain constrained by intermittency, variability, and several technical barriers. Current storage and conversion systems face limited durability, slow reaction kinetics, high material costs, and poor energy densities, making large-scale application challenging (Sayed et al., 2023; Ahiduzzaman and Islam, 2011). Overcoming these bottlenecks requires the development of next-generation materials that can simultaneously deliver efficiency, scalability, and sustainability in energy storage and conversion.

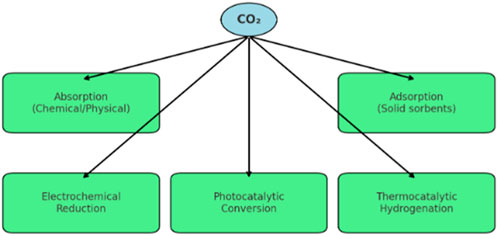

Carbon-based materials have emerged as one of the most promising candidates to meet this challenge (Figure 1). Their unique combination of structural adaptability, tunable electronic properties, chemical stability, and natural abundance enables applications across electrochemical storage, catalytic fuel production, and solar energy conversion (Kothandam et al., 2023; Zhao et al., 2023). From the vast surface area of porous activated carbons to the exceptional conductivity of graphene, engineered carbon architectures have already demonstrated transformative potential across diverse energy technologies (Khalafallah and Zhang, 2024; Amponsah et al., 2014). Nevertheless, despite these advances, several important research gaps remain. First, most studies emphasize the optimization of individual carbon architectures, such as graphene, carbon nanotubes, biochar, or MOF-derived carbons for specific applications (Khalafallah et al., 2019a), but systematic comparisons across these platforms are limited, making it difficult to establish universal design principles. Second, although laboratory-scale demonstrations often report high efficiencies, issues of scalability, cost, and long-term stability under realistic conditions remain underexplored. Third, integration of carbon with semiconductors or 2D frameworks for multifunctional hybrid systems is still in its infancy, with limited understanding of interfacial interactions and synergistic effects (Aldhaher et al., 2024). Fourth, the sustainability dimensions, particularly the use of waste-derived or renewable carbon precursors, have not been sufficiently addressed, despite their relevance for circular energy economies. Finally, there is a lack of comprehensive reviews that holistically evaluate these challenges in tandem and bridge fundamental materials research with industrial applications. However, Carbon-based nano-/microstructured materials provide high surface area and tunable porosity, which enhances transport and storage capacity (Khalafallah et al., 2020; Khalafallah et al., 2021a). Their excellent electrical conductivity facilitates fast charge transfer, improving overall device efficiency. In addition, their chemical stability and structural versatility enable long cycle life and adaptability across diverse energy storage systems.

Figure 1. Various carbon-based materials with vast applications in energy conversion, catalysis, and water treatment.

This review seeks to address these gaps by providing a comprehensive and comparative overview of cutting-edge carbon-based architectures in energy production and conversion. We examine their roles across renewable fuel generation (biofuels, hydrogen, CO2 conversion) and energy conversion platforms (electrocatalysis, photocatalysis, and solar-driven processes). Case studies are included to highlight performance benchmarks, while sustainability considerations—such as waste-derived feedstocks and life-cycle impacts are critically assessed. Finally, we outline future directions that emphasize interdisciplinary approaches, including AI-driven materials discovery and hybrid systems integrating carbon with emerging 2D frameworks like MOFs. By bridging fundamental research with industrial requirements, this review aims to provide a roadmap for the design and deployment of next-generation carbon architectures capable of sustainably meeting global energy demands.

2 Carbon’s versatility: atomic foundations for advanced energy technologies

Carbon holds a unique place in materials science because of its remarkable ability to form diverse structures with tunable properties, a versatility rooted in its electronic configuration and bonding flexibility (Li et al., 2023). With four valence electrons capable of sp, sp2, and sp3 hybridization, carbon forms one-, two-, and three-dimensional structures that range from the insulating diamond (sp3) to highly conductive graphite, graphene, and nanotubes (sp2). Delocalized π-electrons in graphitic systems enable excellent conductivity, while the degree of graphitization dictates electronic performance from semi-metallic graphene to moderately conductive activated carbons (Su and Centi, 2013; Lin et al., 2018; Khalafallah et al., 2021a). This atomic-level tunability explains why carbon serves as both a structural and functional cornerstone of next-generation energy systems.

The family of carbon-based materials spans conventional allotropes (graphite, activated carbons) to engineered nanostructures such as graphene, carbon nanotubes (CNTs), nanofibers, aerogels, and MOF-derived carbons (Madkour, 2024). Each exhibits distinct advantages: graphene provides exceptional mechanical strength, a high surface area, and thermal/electrical conductivity; CNTs combine tensile strength with superior charge transport; and activated carbons, often derived from biomass, offer hierarchical porosity and a large adsorption capacity (Xu et al., 2013; Kalyani and Anitha, 2013). These properties can be tailored at the nanoscale to address specific requirements in energy storage and conversion (Sun et al., 2017). Conductivity is especially critical for high-power devices. Graphene and CNTs reduce resistive losses and are routinely incorporated into composite electrodes for lithium-ion batteries, where they create percolating networks that enable rapid electron transport to active materials such as LiFePO4 and NMC oxides (Wang et al., 2013; Tsai et al., 2020). Similarly, activated carbons, graphitized hierarchical porous carbons and aerogels form highly conductive electrodes for supercapacitors, exploiting vast internal surface areas for charge accumulation (Kaiser and Skákalová, 2011; Khalafallah et al., 2025a). Porosity also underpins carbon’s role as a catalyst support, where high-surface-area carbon derived from MOFs or templating strategies improves reactant dispersion and mass transport in fuel cells (Hu et al., 2023; Su et al., 2009).

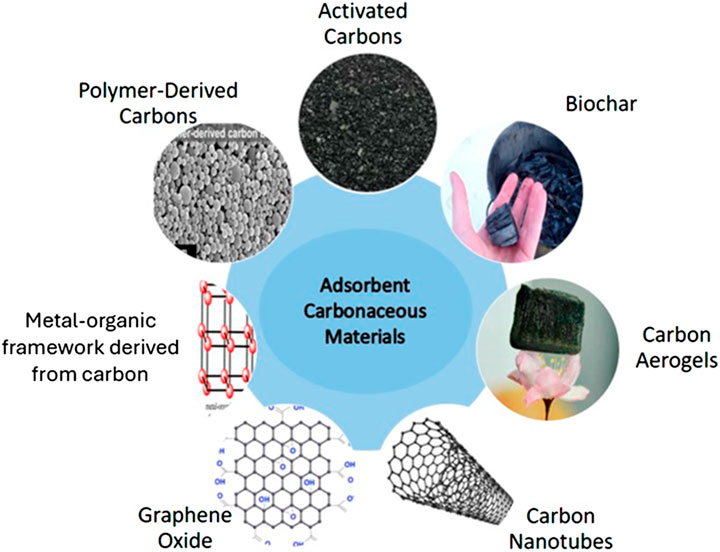

Diamond/graphene (sp3–sp2) interfaces have intermediate carbon bonding states that emerge between three-dimensional diamond and two-dimensional graphene structures (Figure 2). Depending on the crystallographic orientation (e.g., diamond (100) or (111)), the interfacial carbon adopts different geometries, resulting in tunable electronic properties that can switch between insulating (sp3-like) and conductive (sp2-like) states under external stimuli such as light or electric fields. These unique junctions enable photoinduced conductivity and neuromorphic functionalities, including memory and photo-switching behaviors, highlighting their potential for next-generation electronic and brain-inspired devices (Iwane et al., 2024).

Figure 2. Schematic representation of diamond/graphene (sp3–sp2) interfaces illustrating the coexistence of three-dimensional (diamond) and two-dimensional (graphene) carbon structures. The interfacial region is expected to host bonding states intermediate between sp3 and sp2 hybridization, with the resulting structural and electronic properties strongly influenced by the number of graphene layers and the crystallographic orientation of the diamond substrate (Iwane et al., 2024).

Perhaps the most powerful attribute of carbon is its tunability. Heteroatom doping (N, B, P, S, O) alters local electronic structure, creating active sites for reactions such as the oxygen reduction reaction (ORR) in fuel cells and metal-air batteries (Zhang and Dai, 2015). Nitrogen-doped CNTs, for example, promote O2 adsorption and reduction, providing a sustainable alternative to precious-metal catalysts (Singh et al., 2018). Surface functionalization with groups like –COOH, –OH, or –SO3H further adjusts wettability, ion selectivity, or catalytic activity (Schaetz et al., 2012). These strategies are particularly valuable in capacitive deionization (CDI) systems, where conductivity enables fast charging, porosity governs salt adsorption, and surface chemistry dictates ion specificity. Carbon’s versatility, rooted in its atomic structure and expressed through conductivity, porosity, and tunability, makes it indispensable to advanced energy technologies. From porous electrodes in supercapacitors to conductive networks in batteries, from catalyst supports in fuel cells to engineered nanostructures for CO2 reduction and hydrogen generation, carbon materials underpin nearly every frontier of modern energy science (Khalafallah et al., 2025a; Khalafallah et al., 2019a; Khalafallah and Zhang, 2024). Decades of research into structure–property relationships now provide a robust foundation for precision design, ensuring carbon’s continued central role in meeting the global demand for sustainable, high-performance energy solutions.

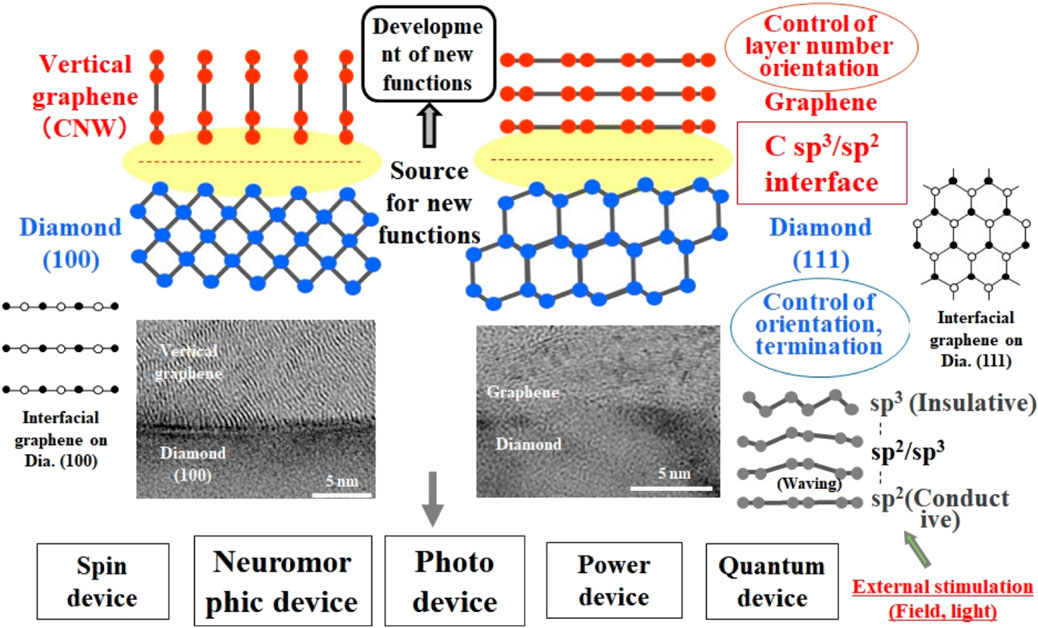

2.1 Carbon-based materials as multifunctional agents in biomass pretreatment, fermentation, and catalysis

Effective pretreatment of lignocellulosic biomass is essential to overcome its structural recalcitrance by disrupting cellulose, hemicellulose, and lignin. However, thermochemical pretreatments often generate inhibitory compounds such as phenolics and furaldehydes, which impair enzymatic hydrolysis and microbial fermentation. Dark fermentation (DF) of lignocellulosic biomass (LB) offers a sustainable pathway for green hydrogen production but is limited by biomass recalcitrance, requiring effective pretreatment (Figure 3). In a recent study, techno-economic analysis highlights how costs are influenced by buffering, productivity, and energy efficiency, with hydrogen yields directly impacting overall feasibility (Zhao et al., 2025).

Figure 3. Lignocellulosic biomass pretreatment for biohydrogen production and various treatment processes (Zhao et al., 2025).

Activated carbons (ACs), owing to their high adsorption capacity and tunable surface chemistry, provide an efficient strategy for hydrolysate detoxification and mitigation of inhibitory effects (Woźniak et al., 2025; Rajesh Banu J et al., 2021). Coconut shell–derived AC selectively removed phenolic inhibitors without affecting sugar content, enhancing enzymatic hydrolysis by 30% and improving fermentation efficiency up to 14-fold (Freitas et al., 2019). Likewise, olive tree pruning residues were valorized as both second-generation (2G) bioethanol feedstock and precursors for AC-based detoxification; optimized activation conditions removed over 50% of toxic compounds, significantly boosting ethanol yields (Arminda et al., 2021). Beyond detoxification, ACs adsorb lignin fragments and soluble phenolics, thereby preventing non-productive enzyme binding and preserving cellulase activity. Their recyclability through thermal or solvent regeneration further strengthens their role as cost-effective auxiliaries in biomass processing.

Sugar fermentation to bioethanol, biobutanol, and related chemicals often suffers from microbial inhibition, slow kinetics, and reduced yields. Graphene oxide (GO), a highly oxidized graphene derivative, offers multifunctional benefits due to its large surface area, abundant oxygenated groups, and electronic conductivity (Kumar et al., 2018; Georgakilas et al., 2016). GO can adsorb toxic inhibitors from fermentation broth, enhance microbial viability, and facilitate electron transfer processes, collectively improving fermentation efficiency (Adeel et al., 2018). Incorporation of GO and carbon nanotube (CNT) composites into ethanol-selective poly(dimethylsiloxane) (PDMS) membranes enabled simultaneous product extraction, alleviated end-product inhibition, and increased bioethanol productivity by up to 115% compared with conventional reactors (Mokaram and Esfahanian, 2024). These findings highlight GO’s potential as a nanomodulator that stabilizes fermentation under inhibitory stress.

Beyond their detoxification and fermentation functions, carbon-based materials act as efficient catalysts in thermochemical and biochemical biomass conversion. Solid acid catalysts derived from de-oiled algal biomass, Jatropha curcas seed cake, rice husk, and other agro-residues exhibit high surface acidity, thermal stability, and reusability in biodiesel production (Roy and Mohanty, 2021; Mardhiah et al., 2017; Rana et al., 2019). These carbon catalysts efficiently esterify free fatty acids and frequently outperform conventional sulfuric acid catalysts in conversion yield and reaction time, demonstrating their promise for scalable green chemistry applications.

3 The pivotal role of carbon catalysts in sustainable biofuel production

The transition to renewable energy demands efficient catalytic processes for converting biomass into viable fuels. Among various alternatives—including electricity, hydrogen, liquefied petroleum gas, natural gas, ethers, and Fischer–Tropsch liquids, biofuels stand out because they can be directly produced from biomass and integrated into existing energy infrastructures (Agarwal et al., 2017; Koçar and Civaş, 2013). Their importance has grown steadily over the past 2 decades, driven by environmental concerns and the depletion of fossil reserves (Arshad et al., 2017). Global biofuel output rose by 17% between 2009 and 2010, reaching 105 billion litres, and today biofuels, primarily ethanol and biodiesel, supply about 2.7% of road transportation fuel worldwide (Koçar and Civaş, 2013). Biofuels are derived from energy-rich compounds in plants and microorganisms through physical, thermochemical, and biochemical pathways (Balat, 2010; Priya et al., 2023). Carbon materials play a pivotal role in advancing biofuel production due to their exceptionally high surface area, tunable porosity, and versatile surface chemistry, which together maximize active site accessibility and mass transport (Zheng et al., 2015). Their structural adaptability allows for tailored catalytic functions across diverse conversion routes, positioning carbon catalysts as indispensable in the shift toward sustainable fuel synthesis.

3.1 Biodiesel production

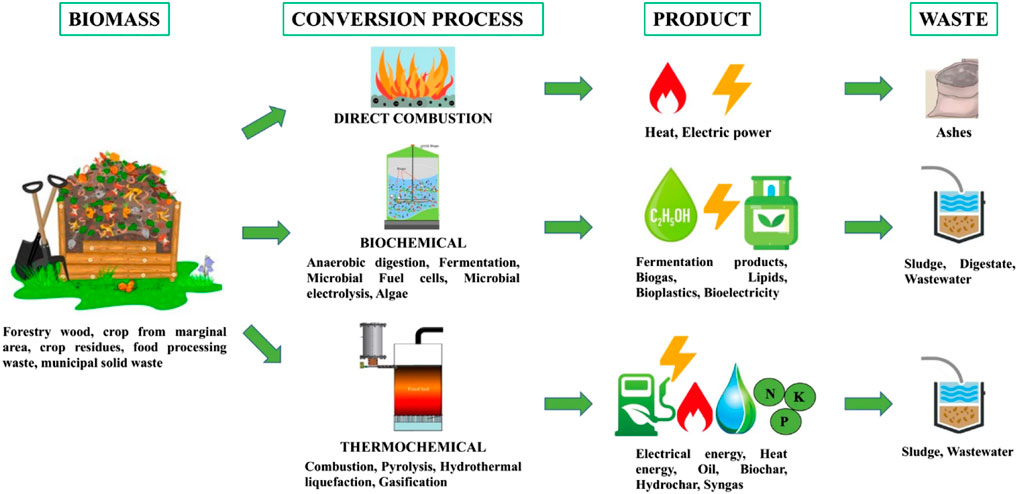

In recent years, biodiesel has gained increasing interest because of its renewable nature, biodegradability, and environmental friendliness. In contrast to traditional chemical catalysis, biochemical catalysis technology has advanced rapidly in the last 10 years, and a significant number of immobilized enzymes are now commercially available to fulfil the demands of the large-scale industrialization of biodiesel (Verma et al., 2012; Zhang et al., 2011). Biomass can be converted into energy and valuable products through several approaches (Figure 4). Direct combustion involves burning biomass in the presence of oxygen at high temperatures (800 °C–1,650 °C) to generate heat, power, and fuel gas, with ash as a byproduct for use in fertilizers or construction, though high costs and low-quality outputs limit its widespread use (Sarker et al., 2024). Biochemical processes include anaerobic digestion, which produces methane-rich biogas and nutrient-rich sludge for agriculture or microalgae cultivation, as well as hydrolysis and fermentation, which break down polysaccharides into sugars that are subsequently converted to ethanol, biogas, or organic acids (Nayeri et al., 2024). Thermochemical processes such as pyrolysis, gasification, and hydrothermal liquefaction (HTL) convert biomass at elevated temperatures and pressures into syngas, bio-oil, char, or hydrochar, with byproducts that can be valorized or further processed (Joshi et al., 2024). Finally, catalytic processes applied to oleaginous feedstocks, including hydrogenation, catalytic cracking, and transesterification, produce high-energy hydrocarbon fuels such as fatty acid methyl esters (FAME), which are biodegradable and suitable as drop-in fuels (Pandit et al., 2023; Khalafallah et al., 2020). Each conversion pathway involves specific operational parameters, temperature, pressure, catalysts, and residence time, that determine product distribution, efficiency, and economic feasibility, highlighting the versatility of biomass as a renewable feedstock (Gugliucci et al., 2024).

Figure 4. Common biomass conversion routes include direct combustion, biochemical processes (anaerobic digestion, hydrolysis, fermentation), and thermochemical processes (pyrolysis, gasification, liquefaction) (Gugliucci et al., 2024).

Catalysis plays a pivotal role in biodiesel production, with transesterification of oils and fats remaining the most cost-effective pathway (Avhad and Marchetti, 2015). Conventional homogeneous catalysts (e.g., NaOH, KOH, H2SO4) deliver high yields but suffer from serious drawbacks, including corrosive waste streams, soap formation, difficult separation, and lack of reusability (Melero et al., 2009). Noble metals such as Pt and Pd are effective in hydrodeoxygenation but are prohibitively expensive and prone to sulfur poisoning. These limitations underscore the need for robust, low-cost, and sustainable heterogeneous alternatives. Carbon-based catalysts have emerged as strong candidates due to their tunable porosity, abundant functionalization, chemical stability, and renewability (Konwar et al., 2014; Khalafallah et al., 2019b). Biomass-derived carbons align with circular-economy principles while offering scalable routes to functional solid catalysts.

Acid-functionalized carbons are among the most effective for biodiesel synthesis. Sulfonated carbons, containing –SO3H, –COOH, and –OH groups, simultaneously catalyze triglyceride transesterification and FFA esterification, making them well-suited for low-quality feedstocks such as waste oils (Geng et al., 2012). They outperform commercial solid acids like Amberlyst-15, often exhibiting higher turnover frequencies and superior FFA tolerance (Hara, 2009). Representative examples include sulfonated biochars, mesoporous carbons, and lignin-derived carbons, all demonstrating high activity and recyclability. Notably, some sulfonated carbons retain catalytic activity in water-rich systems, enabling direct conversion of crude oils without pretreatment. In parallel, basic and heteroatom-doped carbons (e.g., N-doped carbons) have been developed as metal-free solid bases for transesterification, with basic sites such as pyridinic and quaternary N facilitating triglyceride conversion (Anekwe et al., 2025). These materials expand the catalytic landscape by providing bifunctionality and compatibility with condensation-type reactions relevant to fuel upgrading.

Furthermore, carbon-supported composites enhance catalytic performance through synergistic interactions. For instance, Pd–Co nanoparticles on sulfur-modified CNTs displayed superior hydrogenolysis activity, while lignin-derived activated carbons functionalized with phosphorus and sulfur achieved near-complete esterification of oleic acid with excellent reusability (Liao et al., 2019). Overall, carbon-based catalysts combine the advantages of heterogeneous catalysis (recoverability, durability) with renewable feedstock origins and structural tunability. Their demonstrated performance in biodiesel production highlights their potential as sustainable alternatives to conventional catalysts, although further optimization of durability and scalability remains necessary for industrial deployment.

3.2 Enzyme immobilization support for efficient biodiesel production

Biodiesel production via enzymatic (lipase-catalyzed) transesterification offers significant advantages over chemical methods, including mild reaction conditions, tolerance for free fatty acids (FFAs) and water in low-grade feedstocks (such as waste cooking oil and non-edible oils), and minimal waste generation (Kalita et al., 2022). However, the high cost and poor operational stability of free lipases hinder commercialization. Due to the physicochemical properties of carbon materials, superior supports for lipase immobilization, enabling reusable, highly active, and stable biocatalysts critical for economically viable enzymatic biodiesel production have been developed (Bajaj et al., 2010). Carbon’s surface chemistry allows tailored interactions with lipases, profoundly impacting immobilization efficiency, enzyme conformation (and thus activity), and stability (Ma et al., 2025).

Carbon supports significantly enhance lipase stability against denaturing factors prevalent in biodiesel production. Carbon’s chemical inertness protects lipases from denaturation by methanol/ethanol (Sundaramahalingam et al., 2021). Furthermore, carbon’s high thermal conductivity dissipates local heat, while structural rigidity stabilizes the enzyme’s tertiary structure. The rigid carbon structures (AC granules, CNTs) protect enzymes from mechanical shear in stirred reactors (Zhu et al., 2021; Lotti et al., 2018). Lipases that are immobilized on carefully structured carbon supports frequently accomplish >10–20 batch cycles with little loss of activity (Maghraby et al., 2023). On the functionalized activated carbon oxide, lipases were co-immobilized with a maximum immobilized lipase activity of approximately 10,360 U/g matrix. After 20 reuses in the batch system, the activity was kept at around 80%. Within 4 h, over 93% of various oils were converted to biodiesel (Lee et al., 2019).

Enzyme–nanomaterial interactions have a major impact on the catalytic behaviour of enzymes, increasing the catalytic efficiency of lipases by up to 60% and decreasing the esterase by up to 30% (Abdel-Mageed, 2025). Furthermore, the majority of the hydrolases examined showed improved thermal stability as a result of the utilization of CNTs and GO derivatives, particularly those that are amine-functionalized (Pavlidis et al., 2012). In order to combine magnetic qualities with a large surface functionalized with amino groups, a polyamidoamine (PAMAM) dendrimer was grafted onto magnetic multi-walled carbon nanotubes (m-MWCNTs). Rhizomucor miehei lipase (RML) was oriented-immobilized on the resulting m-MWCNTs-PAMAM matrix based on three-dimensional structural (3D) characterization of the enzyme. The immobilized lipase’s recovery activity reached 2,808%, and its equivalent esterification activity was 27 times greater than the free enzyme. In a tert-butanol solvent system, the immobilized enzyme was used to catalyze the manufacture of biodiesel from leftover vegetable oil. Under ideal circumstances, 94% of biodiesel was converted. Furthermore, after ten cycles of reuse, there was no discernible reduction in conversion rates, and the immobilized lipase was readily recovered (Fan et al., 2016).

In conclusion, carbon materials provide an unparalleled platform for lipase immobilization in biodiesel production, synergistically combining high surface area, structural robustness, tunable surface chemistry, and compatibility with diverse reactor configurations. By enabling efficient, reusable, and stable biocatalysts capable of converting low-grade oils into high-quality biodiesel under mild conditions, carbon-supported enzymes represent a cornerstone technology for advancing sustainable and economically competitive enzymatic biodiesel processes (Prajapati et al., 2026). Continued innovation in carbon nanostructure design, surface engineering, and integration with process engineering will further solidify this critical role.

3.3 Pyrolysis and catalytic cracking of heavy hydrocarbons

The catalytic upgrading of heavy hydrocarbon feedstocks, including vacuum residues, heavy crude oils, biomass tars, and waste plastics, remains a major challenge due to coke formation, catalyst deactivation, diffusion barriers, and contaminants such as metals, sulfur, and nitrogen (Kostyniuk et al., 2019). Porous carbon materials, with their high surface area, tunable porosity, intrinsic surface functionalities, and resistance to poisoning, offer distinct advantages as catalysts and supports in these processes (Dutta et al., 2014; Rana et al., 2007). Crude bio-oils from fast pyrolysis are unstable, acidic, and highly oxygenated, requiring upgrading to improve heating value and stability. Activated and sulfonated carbons effectively catalyze esterification of carboxylic acids with alcohol, reducing acidity and improving storage properties (Mostafazadeh et al., 2018). They also act as mild cracking catalysts via decarboxylation and decarbonylation and, when supporting transition metals (Ni, Co, Mo, Ru), enhance dispersion, generate secondary cracking sites, and increase coke resistance compared to oxide supports (Adzahar et al., 2025; Bilge et al., 2023).

The catalytic activity of porous carbons derives from oxygen-containing functional groups and defect sites, which impart weak Brønsted and Lewis acidity (Strapasson et al., 2023). Carboxylic and phenolic groups can protonate hydrocarbons, initiating C–C bond cleavage and facilitating cracking of asphaltenes and resins (Wei et al., 2025). Biomass-derived carbons (e.g., coconut shell, wood, sunflower shells) can be tailored through physical or chemical activation to create hierarchical mesoporosity, improving diffusion of large hydrocarbons and access to active sites (Jain et al., 2015). Sulfonic acid functionalization further strengthens acidity and performance, particularly in esterification and biodiesel production (Niu et al., 2018; Alvear-Daza et al., 2020). Chars and biochars also serve as low-cost adsorbents and catalysts for tar elimination. Rice husk char and its metal-impregnated variants achieved tar conversion efficiencies up to 92.6% by cracking polycyclic aromatics into lighter fractions (Shen, 2014; Guo et al., 2018). Similarly, carbon nanofiber/porous carbon composites with Ni nanoparticles reached 94.8% efficiency due to strong metal–support interactions (Zhang et al., 2020). In coal pyrolysis, Fe- and Ni-modified biochars enhanced mass transfer, hydrogen donation, and selective breakdown of aromatics and heteroatom compounds, boosting light oil yields (Wang et al., 2024).

Overall, porous carbons are indispensable in the thermochemical conversion of heavy hydrocarbons. Their hierarchical porosity enables diffusion of macromolecules, while surface functionalities provide catalytic activity and stability. As supports, they improve metal dispersion and resistance to coking, extending catalyst lifetimes. Advances in nanofabrication and surface modification will further strengthen their role in upgrading heavy feedstocks into cleaner fuels and chemicals.

3.4 Carbon as a catalyst and support in CO2 conversion

The catalytic conversion of CO2 into fuels and chemicals is a key strategy for reducing greenhouse gas emissions and advancing a sustainable energy future (Jia et al., 2022). Carbon-based materials, with their tunable surface chemistry, hierarchical porosity, and high conductivity, function both as active catalysts and as supports for metals in electrochemical reduction, hydrogenation, and photoconversion (Liu et al., 2025). Compared to conventional metal oxides, they offer superior stability, lower cost, and versatile functionalization (Artz et al., 2017). Although CO2 is thermodynamically stable and requires high activation energy (Whang et al., 2019), coupling it with hydrogen-rich compounds enables its transformation into methane, methanol, ethanol, and higher hydrocarbons (Alper and Yuksel Orhan, 2017). Beyond fuels, CO2 also serves as a feedstock for syngas, carbonates, and carboxylic acids. A notable example is dry methane reforming, which consumes both CH4 and CO2 to generate syngas, delivering dual environmental and energy benefits (Whang et al., 2019).

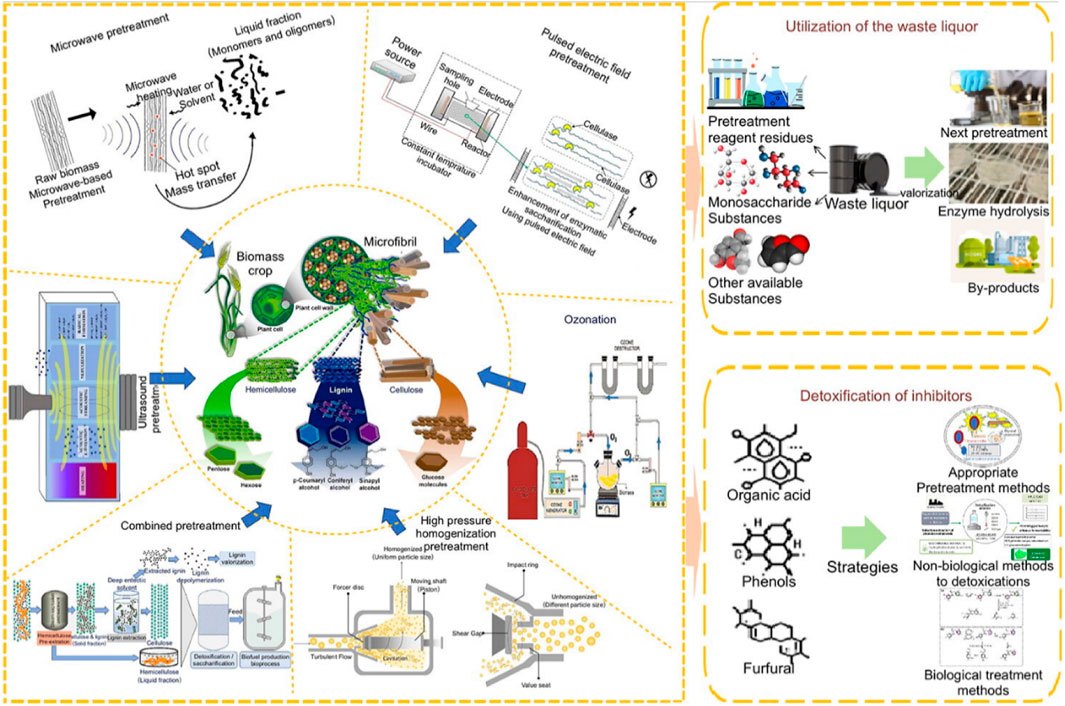

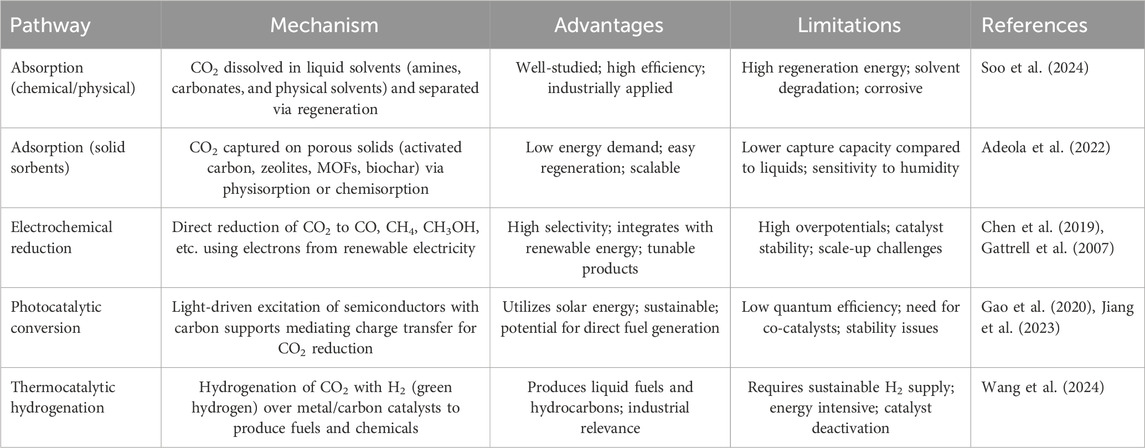

Global management strategies fall into carbon capture and storage (CCS) and carbon capture and utilization (CCU). The integration of carbon capture, utilization, and storage (CCUS) is projected to cut up to 19% of global CO2 emissions by 2050 (Garcia et al., 2022). More recently, reactive carbon capture (RCC) has been introduced, combining capture and direct conversion to enhance efficiency (Barker-Rothschild et al., 2024). CO2 capture and conversion can proceed via absorption, adsorption, membrane separation, electrochemical reduction, thermochemical hydrogenation, and photocatalysis (Garcia et al., 2022; Wu et al., 2022) (Figure 5). Absorption into solvents is well-studied but limited by regeneration costs and solvent degradation (Debbie et al., 2024). Adsorption offers lower energy demand, easier regeneration, and minimal by-products (Dissanayake et al., 2020). Electrochemical methods are attractive for their scalability, controllability, and compatibility with renewable electricity (Zhao and Quan, 2021).

Across these pathways, carbon materials play central roles. Their porosity and surface functionalities boost CO2 uptake, while their conductivity and defect sites enhance performance in electrochemical and thermocatalytic reduction (Wen et al., 2025). Their structural diversity, which ranges from activated carbon to graphene and carbon nanotubes, enables applications as both stand-alone catalysts and versatile support, bridging fundamental challenges with scalable solutions. Table 1 summarizes the mechanisms, advantages, and limitations of each pathway.

Table 1. Summary of major CO2 capture and conversion pathways, including their mechanisms, advantages, and limitations.

3.5 Case studies of CO2 conversion using carbon nanomaterials/composites

Carbon, one of the most abundant and versatile elements on Earth, possesses high surface area, tunable porosity, chemical inertness, and exceptional stability against acids, bases, and thermal stress, distinguishing it from noble metals (Duan et al., 2017; Sundar et al., 2023). These attributes, along with its environmental compatibility and capacity for electronic modification, position carbon as a promising candidate, either as a standalone catalyst or as a support for semiconductors, in the reduction and valorization of CO2.

Electrocatalytic conversion: A growing body of work has demonstrated the ability of carbon-based nanomaterials to drive efficient electrochemical CO2 reduction. Ye et al. (2019) reported a nickel–nitrogen-modified porous carbon/carbon nanotube hybrid (Ni–NPC/CNTs), where the synergy of amorphous carbon and CNTs provided high surface area and rapid electron transfer, yielding 94% CO Faradaic efficiency. Similarly, Zhang et al. (2021) functionalized graphene quantum dots (GQDs) with electron-donating groups (–OH, –NH2), enabling selective CO2-to-CH4 conversion, whereas electron-withdrawing groups suppressed activity. Comparative studies by Yue et al. (2019) ranked the CO2 reduction performance of six carbon allotropes, identifying nitrogen-doped reduced graphene oxide (NRGO) as the most efficient (FECO at −0.9 V). Beyond engineered nanostructures, biomass-derived carbons also show promise. Biochars from mesquite wood chips and chicken manure achieved 78.6% adsorption efficiency within minutes (Dissanayake et al., 2020), while N, S co-doped porous carbons exhibited uptakes of 3.54 mmol g-1 (Shao et al., 2021), underlining the scalability and sustainability potential of biogenic carbons.

Photocatalytic conversion: CO2 reduction uses light-harvesting semiconductors and carbon-based charge mediators to convert CO2 into fuels (Razzaq et al., 2020). Reduced graphene oxide (rGO) has been widely adopted for its superior electron transport (Khalafallah et al., 2025b). Xu et al. (2021) demonstrated that integrating rGO with ZnS/CdS nanosheet heterojunctions enabled multi-interface electron transfer pathways, enhancing both carrier migration and CO2 adsorption. Similarly, Wang et al. (2023) engineered dual-plasma-enhanced 2D/2D/2D g-C3N4/Pd/MoO3–x heterojunctions, where localized surface plasmon resonance extended the optical response into the NIR, yielding highly selective CO production. Carbon nitride nanosheets (CNNS) have also been employed to stabilize TiO2 nanoparticles, creating composites that simultaneously adsorb and reduce CO2 under UV–Vis light without noble-metal co-catalysts, achieving more than a tenfold increase in activity compared to benchmark TiO2 P25 (Crake et al., 2019). In a more recent study by Hossen et al. (2023), the composite photocatalyst incorporating reduced graphene oxide (RGO) and gold (Au) on TiO2 nanotube arrays (TNTAs) demonstrated a significant increase in CO2 photoreduction efficiency (Hossen et al., 2023). Specifically, the yields of CO and CH4 were 29.69 and 2.88 μmol/cm2/h, respectively, which are 12.5 and 7 times higher than those of pure TNTAs. These examples highlight the multifunctionality of carbon frameworks as electron highways, stabilizers, and CO2 adsorption sites in photocatalytic systems.

Hybrid and energy-efficient catalysis: To overcome the limitations of traditional semiconductors like TiO2 and CdS, whose wide band gaps limit visible-light utilization, carbon-based heterojunctions and Z-scheme architectures have been extensively explored (Khalafallah et al., 2018). Lu et al. (2020) demonstrated that BiVO4/g-C3N4 ultrathin nanosheets in a Z-scheme configuration enhanced charge transfer and surface-active sites, leading to nearly fivefold increases in CO and CH4 formation. rGO-based composites further extend photocatalytic activity into the visible spectrum. Carminati et al. (2021) developed rGO/TiO2 and rGO/TiO2/Cu systems in which rGO suppressed charge recombination while Cu provided catalytic sites for CO2 activation. Kandy and Gaikar (2019) reported that nanoporous rGO-coated CdS supported on aluminum achieved methanol production rates of 153.8 μmol g-1 h-1 under solar concentration. Graphitic carbon nitride (g-C3N4), a low-cost, metal-free photocatalyst (band gap ∼2.7 eV), has also emerged as a strong candidate, though its high recombination rate necessitates coupling with carbon structures to enhance visible-light absorption (Li et al., 2020).

These studies demonstrate that carbon nanomaterials are indispensable for efficient CO2-to-fuel conversion. Their tunable structure–property relationships, dictated by doping, defect engineering, porosity, and morphology, enable precise control of reaction pathways and product selectivity. While issues of long-term stability and scalability remain, carbon-based systems offer a compelling and sustainable path toward gigaton-scale CO2 valorization, transforming a greenhouse gas into a resource for renewable fuels.

4 Carbon as a multifunctional amplifier in green energy production and renewables

Carbon materials underpin critical advances in renewable energy technologies due to their tunable electronic properties, hierarchical porosity, and chemical stability. Acting as conductive scaffolds, catalytic sites, and storage media, engineered carbons enhance efficiency, reduce costs, and enable next-generation devices across solar energy conversion, hydrogen production, and biomass-to-fuel technologies. Hydrogen (H2) is a clean energy carrier that releases only water upon combustion. Among several production methods, such as coal gasification, steam reforming, and fossil hydrocarbon reforming, photoelectrochemical (PEC) water splitting and biomass gasification are regarded as the most sustainable routes (Megía et al., 2021).

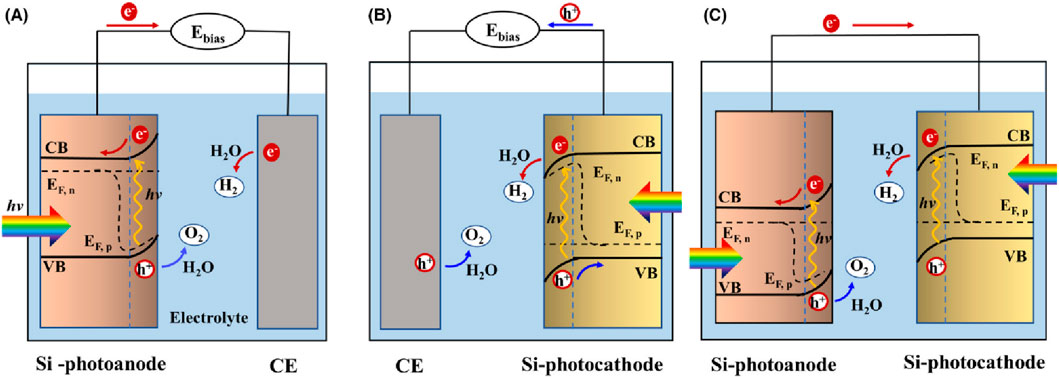

Photoelectrochemical (PEC) Water Splitting: PEC water splitting combines semiconductor photoelectrodes with solar irradiation to drive water electrolysis (Lin et al., 2024). Conventional photoelectrode materials (metal oxides, sulfides, nitrides) often suffer from instability and poor charge transport (Figure 6). Carbon-based materials provide superior conductivity, aqueous stability, and cost advantages compared to noble-metal counter electrodes such as Pt (Yan et al., 2020). Integration of carbon into PEC devices has yielded significant performance gains. For instance, CNT–ZnO heterostructures increased photocurrent density by 33-fold relative to bare ZnO (Alenad et al., 2023). C3N4–TiO2 composites achieved a faradaic efficiency of 88.1%, photocurrent of 4.3 mA cm-2 at 0.6 V (vs. Ag/AgCl), and a hydrogen evolution rate of 26.5 μmol h-1 (Chaulagain et al., 2025). Moreover, carbon-rich photocatalysts such as C3N4 exhibit remarkable pH stability (Peng et al., 2018). Carbon-based electrodes, including graphite rods, have also been validated as low-cost, durable alternatives to Pt in PEC cells (Jilani and Ibrahim, 2025).

Figure 6. PEC water splitting configurations under light: (A) photoanode for OER with a cathode for HER, (B) photocathode for HER with an anode for OER, and (C) dual-photoelectrode performing both OER and HER. CB and VB indicate conduction and valence band edges; EF,n and EF,p are the quasi-Fermi levels; Ebias is the applied voltage (Cheng et al., 2022).

Biomass Gasification: Biomass contains over 40% of its energy in hydrogen, making it an attractive feedstock for thermochemical gasification (Cao et al., 2020). Catalysts are essential for high-yield, selective H2 generation, but conventional ones (e.g., alkaline earth or noble metals) often face cost and efficiency limitations (Lin et al., 2024). Carbon-based materials address these challenges by serving as active catalysts or as support for metals. Recent examples include hierarchical porous carbons modified with NaHCO3/Pt, which delivered a remarkable H2 production rate of 23.8 mL H2/mg Pt during hydrothermal lignocellulose gasification (Hussain et al., 2025). Graphene-supported Pt catalysts have also enhanced gasification efficiency (Bamaca et al., 2021), while CNTs effectively supported Ru catalysts for biomass conversion (Ali et al., 2022). These findings highlight carbon’s dual role in enhancing catalytic activity and reducing precious-metal loadings.

Biomass pyrolysis is an effective thermochemical process for producing hydrogen-rich syngas from plant-based materials (Rathi and Das, 2025). Fast pyrolysis at 800 °C–900 °C can convert ∼60% of biomass into gas, leaving only ∼10% as char, with hydrogen yields increasing at higher temperatures (e.g., 27–41 vol% at 377 °C rising to 41–55 vol% at 752 °C) (Mustapha et al., 2025). Catalysts play a critical role, boosting hydrogen production by enhancing gas yields, promoting tar cracking, and facilitating reforming and water-gas shift reactions (Goren et al., 2025). For example, catalytic pyrolysis of waste paper increased gas output from 54% to 75.6%, while advanced catalysts such as Ni/AlO3 or porous Ni-Al nanosheets produced H2/CO ratios up to ten times higher than non-catalytic processes (Chattopadhyay et al., 2016; Yang et al., 2021). Co-pyrolysis with plastics (e.g., 20 wt% polypropylene) further increased hydrogen yield to 36.1% (10.98 mmol H2 g-1), with gas output of 56.9%, and additional catalytic assistance enhanced both yield and selectivity (Alvarez et al., 2014). Optimizing pyrolysis parameters, including reactor design, heating rates, temperature profiles, and catalyst composition, is key to maximizing hydrogen production and minimizing byproducts, positioning pyrolysis as a promising route for renewable hydrogen generation.

4.1 Carbon-based materials in solar energy conversion

Carbon and its derivatives have become indispensable in advanced technologies such as solar energy conversion, energy storage, sensing, and thermal management, due to their high conductivity, mechanical flexibility, chemical stability, low cost, and environmental compatibility (Gao et al., 2023; Chen et al., 2025; Khan et al., 2020; Khalafallah et al., 2021b). In solar energy systems, carbon materials enhance performance, stabilize devices, and expand applicability across photovoltaic (PV), solar thermal, and integrated solar-thermal/PV technologies.

4.1.1 Photovoltaic applications

Carbon-based materials have been extensively applied across silicon (Si), perovskite, organic, and dye-sensitized solar cells (DSSC). Their tunable morphology, electronic properties, and processability make them ideal for improving efficiency, charge transport, and device stability. Dye-Sensitized Solar Cells (DSSC): Graphene oxide (GO) has been employed as a charge transport layer replacing TiO2, while p-graphene served as a front electrode instead of traditional FTO/ITO, and a C60 derivative (PCBM) combined with PCDTBT acted as a solid electrolyte. This configuration achieved a power conversion efficiency (PCE) of 13.38%, surpassing conventional DSSCs (Islam et al., 2024). Mo-doped carbon rods, MoS2, and cotton-derived carbon fibers have also been used as low-cost, high-performance counter electrodes, rivaling platinum and reducing charge transfer resistance (Upadhyay et al., 2025).

Silicon-based solar cells: Carbon heterostructures with Si improve efficiency and stability while reducing costs. For example, a graphene/Si heterojunction with PMMA as an antireflection layer achieved a PCE of 13.7% (Xiao et al., 2025). Similarly, GO as an interlayer in PEDOT:PSS/n-Si cells enhanced PCE by 3.1% and extended minority carrier lifetimes sevenfold (Sharma et al., 2024). Single-walled carbon nanotubes (SWCNTs) combined with organic passivation layers, such as Nafion, have enabled PCEs up to 23%, replacing metal contacts that often act as recombination centers (Gao et al., 2023; Yan et al., 2021).

Organic Solar Cells (OSCs). Carbon-based materials enhance OSC performance by improving charge transport, exciton dissociation, and interfacial stability across multiple layers, including electrodes, active layers, and transport layers. For instance, CNT-based OSCs in bulk-heterojunction architectures have achieved impressive efficiencies of 19.63%, owing to their high electrical conductivity, large aspect ratio, and ability to form percolation pathways that facilitate efficient electron/hole transport (Maurel et al., 2024). Fullerenes integrated into Y-series electron acceptors in ternary blend OSCs improved exciton separation and reduced non-radiative recombination, resulting in a PCE of 19.22% (Fang et al., 2024). Carbon quantum dots (CQDs) incorporated into the hole transport layer PDOT:PSS not only enhanced interfacial contact and charge collection but also suppressed trap-assisted recombination, increasing the device PCE by 3.9% (Nguyen et al., 2023). Beyond these examples, graphene derivatives, such as reduced graphene oxide (rGO) and functionalized graphene, have also been used as transparent electrodes and interfacial layers to improve carrier mobility and device stability, highlighting the versatility of carbon-based materials in OSCs.

Perovskite Solar Cells (PSCs). PSCs combine high light-harvesting efficiency with solution-processable fabrication, achieving PCE values exceeding 25% (Jiang et al., 2022). Carbon-based materials contribute to PSC performance and stability primarily as counter electrodes, interfacial layers, and additives that reduce ion migration and prevent degradation. The first application of carbon electrodes in CH3NH3PbI3/TiO2 PSCs achieved a PCE of 6.64% (Ku et al., 2013). Subsequent developments using graphite, carbon black, and carbon nanotubes have enhanced electron extraction, improved moisture resistance, and suppressed hysteresis, significantly increasing both efficiency and operational stability (Elseman and Al-Gamal, 2024; Qiu et al., 2025). Hybrid approaches combining carbon with conductive polymers or metal oxides have further optimized charge transport pathways, enabling PSCs to reach near-commercial performance levels while maintaining low-cost and scalable fabrication.

4.1.2 Solar thermal systems and cooling

Localized heating and hot spots in solar modules reduce efficiency, making cooling essential. Carbon-based nanofluids, such as graphene or CNT composites, enhance thermal management. Graphene nanoparticle-based nanofluids demonstrated 42% higher cooling efficiency than water. CNT-CuO nanofluids increased PV power output by 12.07% and energy efficiency by 31.2% (Kargaran et al., 2025). Another solar energy conversion method uses a solar-thermal system to convert solar radiation into heat. This heat can be utilized for a variety of things, including drying and desalinating water, heating and cooling dwellings, and various solar collectors (Tuncer et al., 2024). Nevertheless, there are still many obstacles to overcome to maximize heat transport and storage and increase solar-thermal conversion efficiency. Numerous carbon-based materials have been successfully used in various solar-thermal systems in an effort to address these issues.

Using plasma-enhanced chemical vapour deposition (PECVD), hierarchical vertically grown graphene foam was developed and used as the heating medium in a solar-vapor conversion system (Wu et al., 2019). The effectiveness of solar-thermal conversion was around 93.4% when used externally, and 90% when used in solar-vapor conversion for seawater desalination (Ren et al., 2017). The direct absorption solar-thermal application of graphene oxide-based nanofluids and their binary composites with ZnO and FeO was also compared (Sattar et al., 2025). Since pure graphene oxide has better physicochemical characteristics, conductivity, and stability when dissolved in fluids, it performs better than any other composite systems, demonstrating a 92% solar conversion efficiency (Mushahary et al., 2024). For other carbon-based materials, like carbon nanotubes (Chen et al., 2018) and carbon fibres (Bai et al., 2022), several performance improvements have also been documented in a variety of solar-thermal applications.

4.1.3 Integrated systems

In recent years, there has also been a widespread adoption of integrated solar conversion systems, which combine PV and solar-thermal technology (Togun et al., 2025). While the thermal system generates heat, the photovoltaic units of these integrated systems transform solar energy into renewable power (AL-Elanjawy and Yilmaz, 2024). The thermal unit may generate heat for practical uses while concurrently cooling the PV module to increase its PCE and longevity. Additionally, integrated PV/solar-thermal systems have been developed with the use of carbon-based nanomaterials (Kazem et al., 2023). According to a recent study, using graphene-based ionanofluids as a heat transfer medium in a hybrid PV/thermal system increased energy efficiency by 5% when compared to using the ionic liquid alone (Moulefera et al., 2025). A hybrid nanofluid of multiwall carbon-silicon carbide was used in a simulated study and yielded an average thermal and electrical energy efficiency of 56.55% and 13.85%, respectively, in another illustration of the successful application of carbon-based materials in PV/thermal systems (Kazemian et al., 2022).

5 Challenges and limitations

Despite substantial progress, several challenges remain in the development and application of carbon-based materials for catalysis and biofuel production. Catalyst synthesis and reproducibility remain critical issues, as achieving uniform dispersion of active sites, consistent properties, and adequate thermal stability is difficult, particularly for heterogeneous catalysts derived from bio-based precursors, with variability in synthesis methods directly impacting catalytic activity and selectivity (Adeola et al., 2022; Osman et al., 2024). Scalability and cost present additional barriers because high-temperature carbonization, activation, and doping procedures increase production expenses and energy consumption, while some approaches using agricultural waste impose practical and environmental limitations (Sravan et al., 2026). Catalyst recovery and operational stability are also concerns, as separation in industrial processes, such as filtration or centrifugation, can result in significant material loss, and long-term performance may be compromised by leaching of active sites (Mehdi et al., 2025). Furthermore, integration in bioprocesses requires optimization to combine adsorption, catalysis, and regeneration effectively within consolidated bioprocessing schemes for biofuels (Boodhoo et al., 2022).

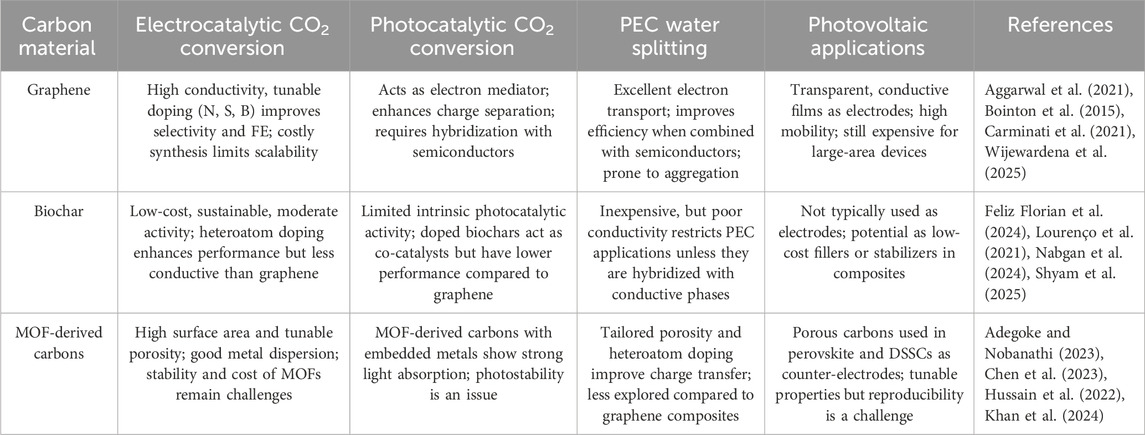

A critical comparison of graphene, biochar, and metal–organic framework (MOF)-derived carbons reveal distinct advantages and limitations across key energy applications (Table 2). Graphene offers exceptional electrical conductivity and high surface area, making it particularly effective in electrocatalytic CO2 conversion and energy storage devices (Samara et al., 2025). Biochar is cost-effective and environmentally benign, with surface functionalities that favor adsorption-driven processes but often suffer from lower conductivity (Adeola et al., 2024; Sambo et al., 2024; Shyam et al., 2025). MOF-derived carbons provide tunable porosity and heteroatom doping, enhancing catalytic activity in photocatalysis and photoelectrochemical water splitting, yet their synthesis can be complex and resource-intensive (Wang et al., 2025). Evaluating these materials across applications highlights the limitations between performance, scalability, and sustainability, offering guidance for selecting the optimal carbon-based material for a given energy conversion or storage technology.

Table 2. Critical comparison of graphene, biochar, and MOF-derived carbons across key energy applications.

To address these limitations, future research should focus on advanced catalyst design through the development of hierarchical and multifunctional carbons, including ordered mesoporous carbons and carbon aerogels, with optimized pore architecture, diffusion pathways, and integrated catalytic and adsorptive activity. Precision engineering of active sites, including tailored dopants, single-atom catalysts, and co-functionalized surfaces, can enhance activity, selectivity, and stability in complex reactions (Wang and Yan, 2025). Sustainable synthesis strategies should employ energy-efficient, low-cost, and environmentally benign methods for converting biomass and waste into high-performance carbon catalysts. Integration with AI and machine learning can guide optimization of carbon structure-property relationships, dopant configurations, and hierarchical designs for lower overpotentials, higher Faradaic efficiencies, and multifunctional performance (Khalafallah et al., 2025c; Olawade et al., 2025).

Life cycle assessment (LCA) studies are essential to compare biomass-derived carbons with conventional sources and ensure environmental sustainability in green biorefineries (Hussin et al., 2023; Khandelwal et al., 2025). Finally, process intensification strategies that combine adsorption, catalysis, and regeneration in single-step or continuous operations can maximize efficiency while minimizing energy consumption (Hoff and Eisenacher, 2025), providing a pathway toward more economically viable and sustainable carbon-based catalytic systems.

6 Conclusion

Carbon materials are central to next-generation renewable energy and biofuel technologies due to their tunable surface chemistry, porosity, stability, and sustainable sourcing potential. In solar energy systems, they enhance the stability, efficiency, and lifetime of PSCs, DSSCs, OSCs, and Si-based devices. In hydrogen production, carbon nanomaterials facilitate cost-effective water splitting and biomass gasification, achieving photocurrents of 15–25 mA cm-2, solar-to-hydrogen efficiencies of 12%–18%, and up to 40% higher H2 yields in thermochemical processes. In biofuel production, carbon-based catalysts and supports improve biomass pretreatment, fermentation, and biodiesel synthesis, enabling yields as high as 95% for biodiesel and accelerating fermentation rates by 30%–50%. Likewise, in thermochemical conversion, porous carbons significantly boost hydrocarbon cracking, deoxygenation, and tar conversion, improving product selectivity by 20%–40% while reducing unwanted byproducts by 25%. For CO2 valorization, advanced carbon nanomaterials achieve Faradaic efficiencies greater than 80% and CO2-to-methanol rates of up to 0.5 mmol g-1 h-1, highlighting their ability to drive selective, energy-efficient transformations.

Beyond application-specific performance, carbon materials serve multifunctional roles: as catalysts for deoxygenation and tar cracking, as adsorbents for detoxifying inhibitory streams, as support for stabilizing enzymes and microbes, and as engineered nanomaterials enabling photocatalytic and electrochemical conversion pathways. Their inherent tunability—through porosity, doping, and surface functionalization, offers precise control over reaction pathways, selectivity, and multifunctionality. Recent advances in atomic-scale engineering, such as single-atom catalysts (SACs) and doped heterostructures, have further enhanced catalytic activity and stability. Carbon materials are not merely alternatives but often superior solutions for key transformations in renewable energy and biofuel production. From enabling biodiesel production from waste oils to upgrading complex bio-oils, detoxifying hydrolysates, and conditioning syngas, engineered carbon architectures leverage fundamental material properties to overcome critical bottlenecks.

Carbon-based materials hold strong potential for large-scale commercialization due to their abundance, versatility, and outstanding performance in energy storage applications. Large-scale commercialization of carbon-based materials can be achieved through the development of cost-effective synthesis routes, scalable fabrication techniques, and easy integration into existing energy infrastructures. However, challenges persist regarding performance consistency, long-term stability, environmental sustainability, and navigating complex regulatory frameworks, all of which must be carefully addressed to ensure successful industrial transition and widespread adoption. Looking forward, machine learning and AI-guided optimization of dopant configurations/synthesis, pore architectures, and surface chemistries promise unprecedented performance gains in renewable energy and bio-refinery applications within the next decade. Continued innovations in the design, synthesis, and integration of carbon materials will be essential to realize their full potential in advancing the global renewable energy transition and fostering a circular bioeconomy.

Author contributions

AA: Conceptualization, Formal analysis, Software, Writing – original draft, Writing – review and editing. DTA: Software, Investigation, Writing – original draft, Formal Analysis. DOA: Formal Analysis, Writing – original draft, Investigation. PK: Writing – original draft, Visualization, Conceptualization. AO: Formal Analysis, Writing – original draft. AI: Writing – original draft, Writing – review and editing. FO: Writing – review and editing, Writing – original draft.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdel-Mageed, H. M. (2025). Frontiers in nanoparticles redefining enzyme immobilization: a review addressing challenges, innovations, and unlocking sustainable future potentials. Micro Nano Syst. Lett. 13, 7. doi:10.1186/s40486-025-00228-2

Adeel, M., Bilal, M., Rasheed, T., Sharma, A., and Iqbal, H. M. N. (2018). Graphene and graphene oxide: functionalization and nano-bio-catalytic system for enzyme immobilization and biotechnological perspective. Int. J. Biol. Macromol. 120, 1430–1440. doi:10.1016/j.ijbiomac.2018.09.144

Adegoke, K. A., and Maxakato, N. W. (2023). Electrocatalytic CO2 conversion on metal-organic frameworks derivative electrocatalysts. J. CO2 Util. 69, 102412. doi:10.1016/j.jcou.2023.102412

Adeola, A. O., Abiodun, B. A., Adenuga, D. O., and Nomngongo, P. N. (2022). Adsorptive and photocatalytic remediation of hazardous organic chemical pollutants in aqueous medium: a review. J. Contam. Hydrology 248, 104019. doi:10.1016/j.jconhyd.2022.104019

Adeola, A. O., Oyedotun, K. O., Waleng, N. J., Mamba, B. B., and Nomngongo, P. N. (2024). Onion skin–derived sorbent for the sequestration of methylparaben in contaminated aqueous medium. Biomass Convers. Biorefinery 14, 22909–22920. doi:10.1007/s13399-023-04332-4

Adzahar, N. A., AbdulKareem-Alsultan, G., Lee, H. V., and Taufiq-Yap, Y. H. (2025). Advances in supported monometallic and bimetallic catalysts towards green aviation fuels: a review. Energy Adv. 4, 966–1005. doi:10.1039/d5ya00078e

Agarwal, A. K., Agarwal, R. A., Gupta, T., and Gurjar, B. R. (2017). Introduction to biofuels. In: Agarwal, A., Agarwal, R., Gupta, T., Gurjar, B. (eds), Biofuels. Green Energy and Technology. Singapore: Springer, 3–6. doi:10.1007/978-981-10-3791-7_1

Aggarwal, M., Basu, S., Shetti, N. P., Nadagouda, M. N., and Aminabhavi, T. M. (2021). Photocatalytic conversion of CO2 into valuable products using emerging two-dimensional graphene-based nanomaterials: a step towards sustainability. Chem. Eng. J. 425, 131401. doi:10.1016/j.cej.2021.131401

Ahiduzzaman, M., and Islam, A. K. M. S. (2011). Greenhouse gas emission and renewable energy sources for sustainable development in Bangladesh. Renew. Sustain. Energy Rev. 15 (9), 4659–4666. doi:10.1016/j.rser.2011.07.086

AL-Elanjawy, Y. A. H., and Yilmaz, M. (2024). Integrated systems of a solar thermal energy driven power plant. J. Adv. Res. 38, 157–177.

Aldhaher, A., Rabiee, N., and Iravani, S. (2024). Exploring the synergistic potential of MXene-MOF hybrid composites: a perspective on synthesis, properties, and applications. Hybrid. Adv. 5, 100131. doi:10.1016/j.hybadv.2023.100131

Alenad, A. M., Taha, T. A., Zayed, M., Gamal, A., Shaaban, M., Ahmed, A. M., et al. (2023). Impact of carbon nanotubes concentrations on the performance of carbon nanotubes/zinc oxide nanocomposite for photoelectrochemical water splitting. J. Electroanal. Chem. 943, 117579. doi:10.1016/j.jelechem.2023.117579

Ali, M. A. M., Inoue, S., and Matsumura, Y. (2022). Carbon nanotube as catalyst support in supercritical water. J. Supercrit. Fluids 190, 105755. doi:10.1016/j.supflu.2022.105755

Alper, E., and Yuksel Orhan, O. (2017). CO2 utilization: developments in conversion processes. Petroleum 3 (1), 109–126. doi:10.1016/j.petlm.2016.11.003

Alvarez, J., Kumagai, S., Wu, C., Yoshioka, T., Bilbao, J., Olazar, M., et al. (2014). Hydrogen production from biomass and plastic mixtures by pyrolysis-gasification. Int. J. Hydrogen Energy 39, 10883–10891. doi:10.1016/j.ijhydene.2014.04.189

Alvear-Daza, J. J., Pasquale, G. A., Rengifo-Herrera, J. A., Romanelli, G. P., and Pizzio, L. R. (2021). Mesoporous activated carbon from sunflower shells modified with sulfonic acid groups as solid acid catalyst for itaconic acid esterification. Catal. Today 372, 51–58. doi:10.1016/j.cattod.2020.12.011

Amponsah, N. Y., Troldborg, M., Kington, B., Aalders, I., and Hough, R. L. (2014). Greenhouse gas emissions from renewable energy sources: a review of lifecycle considerations. Renew. Sustain. Energy Rev. 39, 461–475. doi:10.1016/j.rser.2014.07.087

Anekwe, I. M. S., Akpasi, S. O., Tetteh, E. K., Joel, A. S., Mustapha, S. I., and Isa, Y. M. (2025). Progress in heterogeneous catalysis for renewable energy and petrochemical production from biomass. Fuel Process. Technol. 276, 108267. doi:10.1016/j.fuproc.2025.108267

Arminda, M., Josúe, C., Cristina, D., Fabiana, S., and Yolanda, M. (2021). Use of activated carbons for detoxification of a lignocellulosic hydrolysate: statistical optimisation. J. Environ. Manag. 296, 113320. doi:10.1016/j.jenvman.2021.113320

Arshad, M., Zia, M. A., Shah, F. A., and Ahmad, M. (2017). An overview of biofuel. Springer EBooks, 1–37. doi:10.1007/978-3-319-66408-8_1

Artz, J., Müller, T. E., Thenert, K., Kleinekorte, J., Meys, R., Sternberg, A., et al. (2017). Sustainable conversion of carbon dioxide: an integrated review of catalysis and life cycle assessment. Chem. Rev. 118 (2), 434–504. doi:10.1021/acs.chemrev.7b00435

Avhad, M. R., and Marchetti, J. M. (2015). A review on recent advancement in catalytic materials for biodiesel production. Renew. Sustain. Energy Rev. 50, 696–718. doi:10.1016/j.rser.2015.05.038

Bai, Y., Lin, F., Liu, X., Feng, J., Zhu, X., Huang, Z., et al. (2022). Directional chitosan/carbon fiber powder aerogel supported phase change composites for effective solar thermal energy conversion and hot compression. J. Energy Storage 56, 105980. doi:10.1016/j.est.2022.105980

Bajaj, A., Lohan, P., Jha, P. N., and Mehrotra, R. (2010). Biodiesel production through lipase catalyzed transesterification: an overview. J. Mol. Catal. B Enzym. 62 (1), 9–14. doi:10.1016/j.molcatb.2009.09.018

Balat, M. (2011). Potential alternatives to edible oils for biodiesel production – a review of current work. Energy Convers. Manag. 52 (2), 1479–1492. doi:10.1016/j.enconman.2010.10.011

Banu J, R., Sugitha, S., Kavitha, S., Kannah R, Y., Merrylin, J., and Kumar, G. (2021). Lignocellulosic biomass pretreatment for enhanced bioenergy recovery: effect of lignocelluloses recalcitrance and enhancement strategies. Front. Energy Res. 9, 646057. doi:10.3389/fenrg.2021.646057

Barker-Rothschild, D., Chen, J., Wan, Z., Renneckar, S., Burgert, I., Ding, Y., et al. (2025). Lignin-based porous carbon adsorbents for CO2 capture. Chem. Soc. Rev. 54, 623–652. doi:10.1039/d4cs00923a

Bilge, S., Donar, Y. O., Ergenekon, S., Özoylumlu, B., and Sinağ, A. (2023). Green catalyst for clean fuel production via hydrodeoxygenation. Turkish J. Chem. 14, 2088.

Bointon, T. H., Russo, S., and Craciun, M. F. (2015). Is graphene a good transparent electrode for photovoltaics and display applications? IET Circuits, Devices and Syst. 9, 403–412. doi:10.1049/iet-cds.2015.0121

Boodhoo, K. V. K., Flickinger, M. C., Woodley, J. M., and Emanuelsson, E. A. C. (2022). Bioprocess intensification: a route to efficient and sustainable biocatalytic transformations for the future. Chem. Eng. Process. - Process Intensif. 172, 108793. doi:10.1016/j.cep.2022.108793

Brugger, H., Eichhammer, W., Mikova, N., and Dönitz, E. (2021). Energy efficiency vision 2050: how will new societal trends influence future energy demand in the European countries? Energy Policy 152, 112216. doi:10.1016/j.enpol.2021.112216

Cao, L., Yu, I. K. M., Xiong, X., Tsang, D. C. W., Zhang, S., Clark, J. H., et al. (2020). Biorenewable hydrogen production through biomass gasification: a review and future prospects. Environ. Res. 186, 109547. doi:10.1016/j.envres.2020.109547

Carminati, S. A., Rodríguez-Gutiérrez, I., de Morais, A., da Silva, B. L., Melo, M. A., Souza, F. L., et al. (2021). Challenges and prospects about the graphene role in the design of photoelectrodes for sunlight-driven water splitting. RSC Adv. 11, 14374–14398. doi:10.1039/d0ra10176a

Chattopadhyay, J., Pathak, T. S., Srivastava, R., and Singh, A. C. (2016). Catalytic co-pyrolysis of paper biomass and plastic mixtures HDPE (high density polyethylene), PP (polypropylene) and PET (polyethylene terephthalate) and product analysis. Energy 103, 513–521. doi:10.1016/j.energy.2016.03.015

Chaulagain, N., Alam, K. M., Garcia, J. C., Vrushabendrakumar, D., Heger, J. E., Pan, G., et al. (2025). Heteroepitaxial growth of narrow band gap carbon-rich carbon nitride using in situ polymerization to empower sunlight-driven photoelectrochemical water splitting. J. Am. Chem. Soc. 147 (13), 11511–11532. doi:10.1021/jacs.5c01824

Chen, Y., Zhang, Q., Wen, X., Yin, H., and Liu, J. (2018). A novel CNT encapsulated phase change material with enhanced thermal conductivity and photo-thermal conversion performance. Sol. Energy Mater. Sol. Cells 184, 82–90. doi:10.1016/j.solmat.2018.04.034

Chen, Z., Wang, X., and Liu, L. (2019). Electrochemical reduction of carbon dioxide to value-added products: the electrocatalyst and microbial electrosynthesis. Chem. Rec. 19, 1272–1282. doi:10.1002/tcr.201800100

Chen, B., Yang, Z., Jia, Q., Ball, R. J., Zhu, Y., and Xia, Y. (2023). Emerging applications of metal-organic frameworks and derivatives in solar cells: recent advances and challenges. Mater. Sci. Eng. R Rep. 152, 100714. doi:10.1016/j.mser.2022.100714

Chen, M., Wang, N., Bai, D., Li, Y., Yang, S., Wang, Z., et al. (2025). Revolutionizing perovskite solar cells with carbon electrodes: innovations and economic potential. Adv. Funct. Mater. 35, 2422020. doi:10.1002/adfm.202422020

Cheng, C., Zhang, W., Chen, X., Peng, S., and Li, Y. (2022). Strategies for improving photoelectrochemical water splitting performance of Si-based electrodes. Energy Sci. and Eng. 10, 1526–1543. doi:10.1002/ese3.1087

Crake, A., Christoforidis, K. C., Godin, R., Moss, B., Kafizas, A., Zafeiratos, S., et al. (2019). Titanium dioxide/carbon nitride nanosheet nanocomposites for gas phase CO2 photoreduction under UV-visible irradiation. Appl. Catal. B Environ. 242, 369–378. doi:10.1016/j.apcatb.2018.10.023

Dissanayake, P. D., Choi, S. W., Igalavithana, A. D., Yang, X., Tsang, D. C. W., Wang, C.-H., et al. (2020). Sustainable gasification biochar as a high efficiency adsorbent for CO2 capture: a facile method to designer biochar fabrication. Renew. Sustain. Energy Rev. 124, 109785. doi:10.1016/j.rser.2020.109785

Duan, X., Xu, J., Wei, Z., Ma, J., Guo, S., Wang, S., et al. (2017). Metal-free carbon materials for CO2Electrochemical reduction. Adv. Mater. 29 (41), 1701784. doi:10.1002/adma.201701784

Dutta, S., Bhaumik, A., and Wu, K. C.-W. (2014). Hierarchically porous carbon derived from polymers and biomass: effect of interconnected pores on energy applications. Energy Environ. Sci. 7 (11), 3574–3592. doi:10.1039/c4ee01075b

Dzifack Kenfack, G. M., Tchangnwa Nya, F., and Laref, A. (2024). Organic solar cell efficiency improvement through architecture engineering by integrating carbon nanoring – SCAPS 1D modelling. Mater. Chem. Phys. 324, 129713. doi:10.1016/j.matchemphys.2024.129713

Elias Bamaca Saquic, B., Irmak, S., Wilkins, M., and Smith, T. (2021). Effect of precursors on graphene supported platinum monometalic catalysts for hydrothermal gasification of biomass compounds to hydrogen. Fuel 290, 120079. doi:10.1016/j.fuel.2020.120079

Elseman, A. M., and Al-Gamal, A. G. (2024). Multiwalled carbon nanotubes as hole collectors in inverted perovskite solar cells. ACS Appl. Nano Mater. 7 (8), 8792–8803. doi:10.1021/acsanm.4c00262

Fan, Y., Wu, G. L., Su, F., Li, K., Xu, L., Han, X., et al. (2016). Lipase oriented-immobilized on dendrimer-coated magnetic multi-walled carbon nanotubes toward catalyzing biodiesel production from waste vegetable oil. Fuel 178, 172–178. doi:10.1016/j.fuel.2016.03.071

Fang, H., Chen, Q., Lin, Y., Xu, X., Wang, J., Li, M., et al. (2024). Fullerene-hybridized fused-ring electron acceptor with high dielectric constant and isotropic charge transport for organic solar cells. Angew. Chem. Int. Ed. 64, e202417951. doi:10.1002/anie.202417951

Feliz Florian, G., Ragoubi, M., Leblanc, N., Taouk, B., and Abdelouahed, L. (2024). Biochar production and its potential application for biocomposite materials: a comprehensive review. J. Compos. Sci. 8, 220. doi:10.3390/jcs8060220

Freitas, J. V., Nogueira, F. G. E., and Farinas, C. S. (2019). Coconut shell activated carbon as an alternative adsorbent of inhibitors from lignocellulosic biomass pretreatment. Industrial Crops Prod. 137, 16–23. doi:10.1016/j.indcrop.2019.05.018

Gao, Y., Qian, K., Xu, B., Li, Z., Zheng, J., Zhao, S., et al. (2020). Recent advances in visible-light-driven conversion of CO2 by photocatalysts into fuels or value-added chemicals. Carbon Resour. Convers. 3, 46–59. doi:10.1016/j.crcon.2020.02.003

Gao, Q., Yan, J., Li, H., Chen, J., Yang, X., Bai, Y., et al. (2023). Commercial carbon nanotube as rear contacts for industrial p-type silicon solar cells with an efficiency exceeding 23%. Carbon 202, 432–437. doi:10.1016/j.carbon.2022.11.020

Garcia, J. A., Villen-Guzman, M., Rodriguez-Maroto, J. M., and Paz-Garcia, J. M. (2022). Technical analysis of CO2 capture pathways and technologies. J. Environ. Chem. Eng. 10 (5), 108470. doi:10.1016/j.jece.2022.108470

Gattrell, M., Gupta, N., and Co, A. (2007). Electrochemical reduction of CO2 to hydrocarbons to Store renewable electrical energy and upgrade biogas. Energy Convers. Manag. 48, 1255–1265. doi:10.1016/j.enconman.2006.09.019

Geng, L., Yu, G., Wang, Y., and Zhu, Y. (2012). Ph-SO3H-modified mesoporous carbon as an efficient catalyst for the esterification of oleic acid. Appl. Catal. A General 427–428, 137–144. doi:10.1016/j.apcata.2012.03.044

Georgakilas, V., Tiwari, J. N., Kemp, K. C., Perman, J. A., Bourlinos, A. B., Kim, K. S., et al. (2016). Noncovalent functionalization of graphene and graphene oxide for energy materials, biosensing, catalytic, and biomedical applications. Chem. Rev. 116 (9), 5464–5519. doi:10.1021/acs.chemrev.5b00620

Goren, A. Y., Temiz, M., Erdemir, D., and Dincer, I. (2025). The role of effective catalysts for hydrogen production: a performance evaluation. Energy 315, 134257. doi:10.1016/j.energy.2024.134257

Gugliucci, W., Pepe, O., and Ventorino, V. (2024). Biomass conversion strategies and wastewater reuse: a deep focus on hydrothermal liquefaction as a circular economy approach. Chem. Biol. Technol. Agric. 11, 177. doi:10.1186/s40538-024-00710-w

Guo, F., Li, X., Liu, Y., Peng, K., Guo, C., and Rao, Z. (2018). Catalytic cracking of biomass pyrolysis tar over char-supported catalysts. Energy Convers. Manag. 167, 81–90. doi:10.1016/j.enconman.2018.04.094

Hara, M. (2009). Environmentally benign production of biodiesel using heterogeneous catalysts. ChemSusChem 2 (2), 129–135. doi:10.1002/cssc.200800222

Hoff, K. L., and Eisenacher, M. (2025). Process intensification strategies for esterification: kinetic modeling, reactor design, and sustainable applications. Int. J. Mol. Sci. 26, 7214. doi:10.3390/ijms26157214

Hossen, M. A., Khatun, F., Ikreedeegh, R. R., Muhammad, A. D., Abd Aziz, A., Leong, K. H., et al. (2023). Enhanced photocatalytic CO2 reduction to CH4 using novel ternary photocatalyst RGO/Au-TNTAs. Energies 16 (14), 5404. doi:10.3390/en16145404

Hu, X., Yang, B., Ke, S., Liu, Y., Fang, M., Huang, Z., et al. (2023). Review and perspectives of carbon-supported platinum-based catalysts for proton exchange membrane fuel cells. Energy and Fuels 37 (16), 11532–11566. doi:10.1021/acs.energyfuels.3c01265

Hussain, M. Z., Yang, Z., Xia, Y., van der Linden, B., Heinz, W. R., Bahri, M., et al. (2022). MOF-derived multi-heterostructured composites for enhanced photocatalytic hydrogen evolution: deciphering the roles of different components. Energy and Fuels 36 (19), 12212–12225. doi:10.1021/acs.energyfuels.2c02319

Hussain, S., Irmak, S., and Farid, M. U. (2025). Developing N, S-doped hierarchical porous carbon-supported Pt catalysts for hydrothermal gasification of woody biomass to hydrogen. Next Energy 8, 100257. doi:10.1016/j.nxener.2025.100257

Hussin, F., Hazani, N. N., Khalil, M., and Aroua, M. K. (2023). Environmental life cycle assessment of biomass conversion using hydrothermal technology: a review. Fuel Process. Technol. 246, 107747. doi:10.1016/j.fuproc.2023.107747

Islam, M. N., Chowdhury, M. R. H., Chowdhury, M. H. D., Islam, M. J., Rahaman, M. L., and Chowdhury, M. I. B. (2024). “A high-efficiency dye-sensitized solar cell using PCDTBT:PCBM as solid electrolyte and graphene oxide as hole transport layer,” in 2024 6th international conference on electrical engineering and information andamp; communication technology (ICEEICT), 933–938. doi:10.1109/iceeict62016.2024.10534413

Iwane, H., Saito, G., Muto, S., and Ueda, K. (2024). Diamond/Graphene (carbon sp3-sp2) heterojunctions for neuromorphic device applications. J. Mater. Res. 39, 2107–2114. doi:10.1557/s43578-024-01395-5

Jain, A., Xu, C., Jayaraman, S., Balasubramanian, R., Lee, J. Y., and Srinivasan, M. P. (2015). Mesoporous activated carbons with enhanced porosity by optimal hydrothermal pre-treatment of biomass for supercapacitor applications. Microporous Mesoporous Mater. 218, 55–61. doi:10.1016/j.micromeso.2015.06.041

Jia, S., Ma, X., Sun, X., and Han, B. (2022). Electrochemical transformation of CO2 to value-added chemicals and fuels. CCS Chem. 4, 3213–3229. doi:10.31635/ccschem.022.202202094

Jiang, Q., Tong, J., Xian, Y., Kerner, R. A., Dunfield, S. P., Xiao, C., et al. (2022). Surface reaction for efficient and stable inverted perovskite solar cells. Nature 611 (7935), 278–283. doi:10.1038/s41586-022-05268-x

Jiang, Y., Wang, K., Wang, Y., Liu, Z., Gao, X., Zhang, J., et al. (2023). Recent advances in thermocatalytic hydrogenation of carbon dioxide to light olefins and liquid fuels via modified fischer-tropsch pathway. J. CO2Util. 67, 102321. doi:10.1016/j.jcou.2022.102321

Jilani, A., and Ibrahim, H. (2025). Development in photoelectrochemical water splitting using carbon-based materials: a path to sustainable hydrogen production. Energies 18, 1603. doi:10.3390/en18071603

Joshi, N. C., Sinha, S., Bhatnagar, P., Nath, Y., Negi, B., Kumar, V., et al. (2024). A concise review on waste biomass valorization through thermochemical conversion. Current research in microbial sciences. Curr. Res. Microb. Sci. 6, 100237. doi:10.1016/j.crmicr.2024.100237

Kaiser, A. B., and Skákalová, V. (2011). Electronic conduction in polymers, carbon nanotubes and graphene. Chem. Soc. Rev. 40 (7), 3786. doi:10.1039/c0cs00103a

Kalita, P., Basumatary, B., Saikia, P., Das, B., and Basumatary, S. (2022). Biodiesel as renewable biofuel produced via enzyme-based catalyzed transesterification. Energy Nexus 6, 100087. doi:10.1016/j.nexus.2022.100087

Kalyani, P., and Anitha, A. (2013). Biomass carbon and its prospects in electrochemical energy systems. Int. J. Hydrogen Energy 38 (10), 4034–4045. doi:10.1016/j.ijhydene.2013.01.048

Kandy, M. M., and Gaikar, V. G. (2019). Continuous photocatalytic reduction of CO2 using nanoporous reduced graphene oxide (RGO)/cadmium sulfide (CdS) as catalyst on porous anodic alumina (PAA)/aluminum support. J. Nanosci. Nanotechnol. 19 (8), 5323–5331. doi:10.1166/jnn.2019.16817

Kargaran, M., Goshayeshi, H. R., Azarberahman, S., and Chaer, I. (2025). Advanced cooling of photovoltaic panels using hybrid nanofluids incorporating graphene oxide and carbon nanotubes. Int. J. Energy Res. 2025 (1), 4345236. doi:10.1155/er/4345236

Kazem, H. A., Al-Waeli, A. A., Chaichan, M. T., Sopian, K., Ahmed, A. A., and Wan Nor Roslam, W. I. (2023). Enhancement of photovoltaic module performance using passive cooling (fins): a comprehensive review. Case Stud. Therm. Eng. 49, 103316. doi:10.1016/j.csite.2023.103316

Kazemian, A., Salari, A., Ma, T., and Lu, H. (2022). Application of hybrid nanofluids in a novel combined photovoltaic/thermal and solar collector system. Sol. Energy 239, 102–116. doi:10.1016/j.solener.2022.04.016

Khalafallah, D., and Zhang, Q. (2024). Dual-metal hydroxide heterojunction and chayote fruit biomass–derived hierarchical porous carbon for augmenting the performance of hybrid supercapacitors. J. Energy Storage 95, 112621. doi:10.1016/j.est.2024.112621