- Hebei Key Laboratory of Flexible Functional Materials, School of Materials Science and Engineering, Hebei University of Science and Technology, Shijiazhuang, China

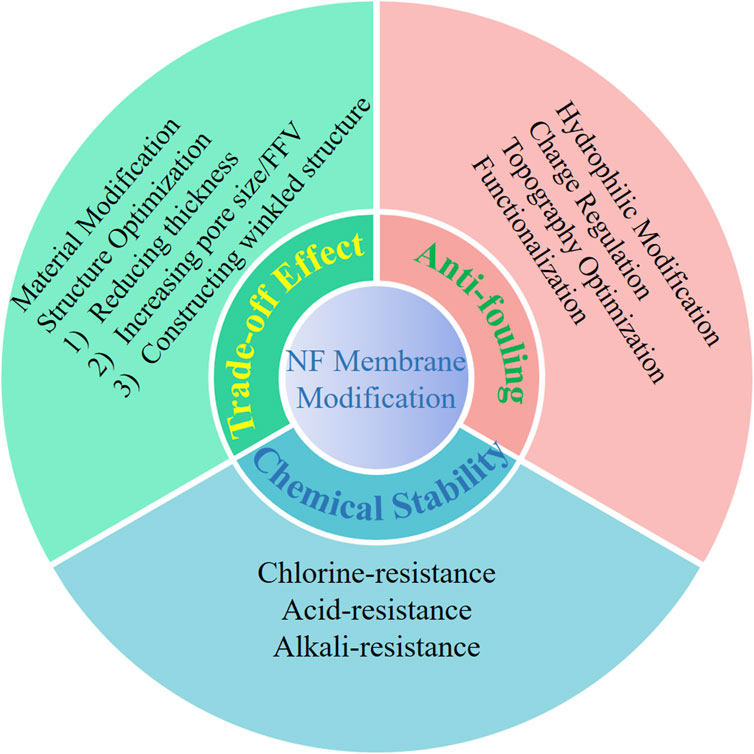

Nanofiltration (NF) membranes are a pressure-driven membrane separation technology that lies between reverse osmosis (RO) and ultrafiltration (UF), featuring selective separation of low-molecular-weight organic compounds, divalent ions, and some monovalent ions. Due to their low operating pressure, low energy consumption, and ability to efficiently desalinate while retaining some beneficial minerals, NF membranes have shown broad application prospects in drinking water purification, wastewater treatment, food and pharmaceutical industries, and resource recovery. This article systematically reviews the existing challenges (including trade-off effect between selectivity and flux, membrane fouling and insufficient chemical stability) and the corresponding countermeasures from the perspectives of material modification and structural design, etc., with the aim of providing references for further research and industrial application of NF membranes.

1 Introduction

With the increasingly severe global water shortage and environmental pollution problems, efficient and energy-saving water treatment technologies have become a research hotspot. Since its development in the 1980s, nanofiltration (NF) technology has been widely applied in several fields, thanks to its unique separation performance (molecular weight cut-off of 200–1,000 Da), relatively low operating pressure (0.5–1.5 MPa), and high selectivity in removing multivalent ions (Zhang et al., 2020; Wieczorek and Ulbricht, 2021; Di et al., 2024; Tan et al., 2025). Compared to reverse osmosis (RO) membranes, NF membranes require less energy for desalination and are capable of retaining certain monovalent ions (e.g., Na+ and K+). These properties make NF membranes particularly suitable for applications where high water quality is desired without the need for complete desalination (Zhang et al., 2020).

Interfacial polymerization (IP) is a commonly employed technique for the fabrication of NF membranes. It involves polymerization occurring at the interface between two immiscible solvents, resulting in the formation of an ultrathin and dense separation layer that exhibits highly efficient retention of small organic molecules and divalent ions (Chen J. et al., 2024; Ding et al., 2024). Despite significant progress in NF technology, the following bottlenecks still exist. 1) The trade-off between selectivity and flux: High rejection rates often come with low flux (Ni et al., 2024). 2) Membrane fouling: Adsorption of pollution leads to performance decline (Liu L. et al., 2025; Tan et al., 2025). 3) Insufficient chemical stability: Extreme pH or oxidative environments can cause membrane degradation (Miao et al., 2024; Wang et al., 2024).

Based on these, this article aims to review the basic design principles of NF membrane and its current research progress in the field of water treatment. Specifically, it provides a comprehensive analysis of the aforementioned challenges associated with NF membranes, as well as their modification approaches from the perspectives of material composition and structural design. Finally, it looks forward to the future development directions of NF technology, providing a reference for related research.

2 Limitations of NF membranes and corresponding countermeasures

Up to now, the problems existing in NF membranes and the corresponding modification strategies are shown in Figure 1. The specific analysis is as follows.

2.1 The trade-off effect between selectivity and flux

2.1.1 Material modification

Introducing nanomaterials, such as metal-organic frameworks (MOFs) (Chen Q. et al., 2024), covalent organic frameworks (COFs) (Xiang et al., 2025), graphene oxide (GO) (Feng et al., 2025b), and carbon nanotubes (CNTs) (Ye et al., 2023), into the separation layer can effectively optimize the membrane’s pore structure and surface properties. For example, MOFs (e.g., ZIF-8 (Xie et al., 2024) and UiO-66 (Huo et al., 2024; Yu et al., 2024) offer uniform channels and enhance molecular sieving capabilities. COFs, with their tunable pore sizes and excellent chemical stability, can improve membrane selectivity (Xiang et al., 2025). The interlayer nanochannels in GO regulate water transport pathways while maintaining a high rejection rate (Feng et al., 2025b). Additionally, incorporating CNTs with low-friction inner surfaces into the separation layer can accelerate water molecule transport and reduce osmotic resistance (Zhao et al., 2023). Inorganic nanoparticles such as SiO2 and TiO2 can also be added into the polyamide (PA) layer to simultaneously enhance mechanical strength and regulate pore size distribution (Yan et al., 2022; Feng et al., 2025a). However, large-scale production of new materials (such as MOFs, COFs, and GO) is challenging due to cost constraints. Besides the above-mentioned nanomaterials, adjusting the membrane surface wettability through block copolymers with hydrophilic/hydrophobic chain can reduce membrane fouling and optimize flux (Wieczorek and Ulbricht, 2021). Embedding artificial water channel proteins in the separation layer can achieve high selectivity and high flux (Song and Kumar, 2019).

2.1.2 Structure optimization

From the perspective of mass transfer, under the premise of ensuring excellent retention performance, reducing the thickness, increasing the pore size/free volume fraction (FFV), or enhancing the effective filtration area of the separation layer can also effectively break the trade-off effect. The IP process was optimized (such as adjusting the monomer concentration and changing the reaction interface) to prepare ultra-thin but dense PA layers, reducing mass transfer resistance (Liu G. et al., 2025). The incorporation of additives into the aqueous phase can also control the IP rate by regulating monomer diffusion, thus enabling the fabrication of a thinner separation layer (Zhang et al., 2022; Zhang et al., 2024; Wang et al., 2025a). In addition to directly controlling the separation layer thickness through aforementioned factors, the substrate can also be pre-modified by depositing a hydrophilic intermediate layer to improve control over the IP process and facilitate optimization of the separation layer structure (Wang et al., 2025b). The hydrophilic surface of the intermediate layer adsorbs amine solution, thereby increasing the local concentration of amine monomers near the reaction interface. This higher amine concentration, combined with the reduced surface pore size of the intermediate layer, helps suppress defect formation in the PA layer and enhances separation performance. Moreover, hydrogen bonding interactions between the intermediate layer and amine molecules can effectively slow down the diffusion of amine monomers, further limiting their supply in the reaction zone and promoting the formation of a thinner PA layer. Nevertheless, achieving a defect-free ultrathin separation layer remains challenging in practical applications.

By designing novel monomers for IP, the pore size distribution and FFV of the PA separation layer can be precisely controlled, thereby optimizing the permeability-selectivity balance of NF membranes. Specific strategies can be classified into the following types. 1) Introduction of rigid/distorted monomers: The use of monomers containing bulky groups or non-planar structures can increase the packing defects in the polymer chains, resulting in larger free volume and wider pore size distribution (Liu Y. et al., 2023; Peng et al., 2023; Tang et al., 2023). For instance, the PA network formed by the polymerization of a quaternized-spiro PIP and TMC has a 6% increase in FFV due to the enhanced rigidity of the designed monomer, leading to a higher permeance (∼22 L m-2 h-1 bar-1) (Peng et al., 2023). 2) Using macromolecule to react with TMC. Macromolecules have a relatively high steric hindrance and can react with TMC to increase the FFV of the PA layer (Wang et al., 2025a). For instance, ε-Polylysine/TMC system exhibits a larger FFV (from 15.64% to 38.85%) compared to Lysine/TMC system (Wang et al., 2025a). In addition to modulating the network structure by directly incorporating new monomers into the IP process, post-treatment methods can also be employed to dynamically adjust the network density through the reactive functional groups (e.g., hydroxyl, carboxyl, and amino groups) in monomers or additives (Yu et al., 2022; Mi et al., 2024).

By optimizing the kinetics of IP or introducing external control measures, wrinkled structures can be formed on PA layer surface, thereby significantly increasing the actual active area and simultaneously optimizing the mass transfer pathways. During the IP process, by adding surfactants (such as SDS) or polymers (such as PVA) to regulate the diffusion rate of amine monomers (such as PIP), interfacial instability is induced, resulting in the formation of nano-scale wrinkles or stripe patterns (Tan et al., 2018; Huo et al., 2022). By temporarily supporting the PA layer with removable templates such as Cd(OH)2 nanowires during the IP process, a hollow wrinkled structure is formed after the removal, increasing the effective area (Karan et al., 2015).

2.2 Strategies for improving membrane anti-fouling performance

The improvement of the anti-fouling performance of NF membranes is one of the cores of its application. The key idea of the modification strategy is to change the properties of the membrane surface through physical or chemical methods, thereby weakening the interaction between pollutants and the membrane surface. Specific strategies need to be developed to direct the regulation of membrane surface properties in accordance with the composition of water.

2.2.1 Hydrophilic modification

The specific method involves immobilizing hydrophilic polymers or zwitterionic polymers on membrane surface through surface coating or surface grafting, forming a stable hydration layer on membrane surface as a physical barrier to effectively prevent the adhesion of hydrophobic organic substances (such as proteins, oils), colloids and other contaminants (You et al., 2017; Ding et al., 2021). Among them, zwitterionic polymers have positive and negative charge centers in their molecular structure, which can combine a large number of water molecules through strong ionic hydration to form a super-hydrated layer, and have excellent resistance to various pollutants (Ding et al., 2021). In addition to enhancing hydrophilicity through polymers, as mentioned in Section 3.1.1, some nanomaterials can also improve the hydrophilicity of the membrane surface and endow it with anti-fouling properties.

2.2.2 Surface charge regulation

By altering the charge nature of the membrane surface, electrostatic repulsion (Donnan effect) is utilized to repel contaminants with the same charge (Song et al., 2021; Liu H. et al., 2023; Hui et al., 2025). Most natural organic matter, colloidal particles and microorganisms in natural water bodies carry a negative charge. By sulfonating, carboxylating and other methods to make the membrane surface carry a strong negative charge, these pollutants can be effectively repelled, reducing organic and colloidal pollution. In specific scenarios (such as removing positively charged certain dyes), positively charged NF membranes are also designed. The key lies in the targeted design based on the charge characteristics of the target pollutants.

2.2.3 Surface morphology and roughness optimization

Altering the structure of the membrane surface can affect the way pollutants interact with the membrane and the hydrodynamic behavior. A smooth surface can reduce the anchor points for pollutant deposition, making it less likely for pollutants to adhere and easier for them to be washed away by water flow (Wang et al., 2023; Zhuang et al., 2024). The lotus leaf effect, which involves designing micro-scale patterns on the surface, can not only reduce the actual contact area between pollutants and the membrane surface but also alter the flow field on the membrane surface, generating local turbulence and enhancing shear force, thereby reducing concentration polarization and pollutant deposition.

2.2.4 Functionalization

Introducing specific chemical functional groups on membrane surface endows it with special properties (Liu L. et al., 2025). For instance, grafting quaternary ammonium salts, antimicrobial peptides or loading silver nanoparticles (AgNPs), copper nanoparticles can endow the membrane surface with antibacterial properties. However, it should be noted that all the above substances are based on killing bacteria, and secondary pollution caused by dead cells should be prevented. Therefore, preventing the initial adhesion of microorganisms through a highly hydrophilic or zwitterionic surface to avoid pollution caused by dead cells becomes an excellent strategy for enhancing the antibacterial properties of membranes.

2.3 Chemical stability improvement

The chemical stability of membrane materials is insufficient in extreme pH and oxidative environments, which can easily lead to performance degradation or structural damage, restricting their long-term application. In water treatment, the chemical degradation of NF membranes mainly includes hydrolysis reactions and oxidative erosion. The amide bonds within the PA layers are susceptible to hydrolysis under strongly acidic or alkaline conditions, which can lead to the disruption of the cross-linked network structure. Free chlorine (such as sodium hypochlorite) can attack the N-H bonds in the PA layer, forming chloramines or causing chain breaks. The chemical stability of nanofiltration membranes can be enhanced through novel membrane design. For example, developing polyester materials with chlorine-free attack sites (Li et al., 2024), acid-resistant polysulfonamides (Lai et al., 2022), and acid/alkali-resistant polyureas (Wang et al., 2024) not only ensures the long-term stable operation under harsh conditions, but also enables the membrane to withstand more extreme chemical cleaning conditions. However, the improvement of the stability of novel membrane is also only focused on a certain aspect. For instance, although polyester membranes have chlorine resistance, the ester bonds are prone to hydrolysis under alkaline conditions, leading to a sharp decline in performance. Therefore, the chemical stability of NF membranes should be determined by selecting materials and modification strategies based on specific application scenarios.

3 Summary

NF, as an efficient and energy-saving separation technology, holds broad application prospects in the field of water treatment. This paper reviews the main challenges faced by NF membranes and the corresponding improvement strategies. Despite numerous challenges, with the development of new materials and new processes, NF technology is expected to play a greater role in the field of water treatment. Future research should focus on the development of high-performance membrane materials, system optimization and intelligent operation to promote the wider application of NF technology. For example, from the perspective of membrane materials, more regular nanopores can be precisely constructed at atomic level to enable high-speed water molecule transport with near-zero friction and highly selective ion screening. Meanwhile, inorganic-organic hybrid membranes can employ “rigid-flexible integration” strategy by embedding rigid, well-defined channels within a flexible polymer matrix, thereby significantly improving the flux and chemical stability to withstand harsh environments.

Author contributions

MS: Conceptualization, Visualization, Writing – original draft. YZ: Conceptualization, Validation, Writing – original draft. SL: Conceptualization, Investigation, Writing – review and editing. YW: Conceptualization, Investigation, Writing – review and editing. TL: Conceptualization, Investigation, Project administration, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was financially supported by Natural Science Foundation of Hebei Province (E2025208083) and the Science Research Project of Hebei Education Department (BJ2025107).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Chen, J., Pei, H., Zou, Y., Ding, H., Li, Z., Zhang, L., et al. (2024a). Dissecting the impacts of nanobubbles and heat generated in polymerization on polyamide nanofiltration membranes. J. Membr. Sci. 699, 122646. doi:10.1016/j.memsci.2024.122646

Chen, Q., Tang, Y., Ding, Y.-M., Jiang, H.-Y., Zhang, Z.-B., Li, W.-X., et al. (2024b). Synergistic construction of sub-nanometer channel membranes through MOF–polymer composites: strategies and nanofiltration applications. Polym 16 (12), 1653. doi:10.3390/polym16121653

Di, J., Wang, H., Zhang, L., Chen, Z., Zhang, Y., Mamba, B. B., et al. (2024). Recent progress in advanced polyamide nanofiltration membranes via interfacial polymerization for desalination and beyond. Desalination 592, 118167. doi:10.1016/j.desal.2024.118167

Ding, J., Liang, H., Zhu, X., Xu, D., Luo, X., Wang, Z., et al. (2021). Surface modification of nanofiltration membranes with zwitterions to enhance antifouling properties during brackish water treatment: a new concept of a “buffer layer”. J. Membr. Sci. 637, 119651. doi:10.1016/j.memsci.2021.119651

Ding, H., Liu, Y., Zhang, Z., Cheng, Y., Mo, J., Peng, L. E., et al. (2024). Regulation of interfacial polymerization by organic base for high-permselective nanofiltration. Desalination 573, 117212. doi:10.1016/j.desal.2023.117212

Feng, G., Cui, Z., Hu, X., Mo, K., Zhang, H., and Chen, J. (2025a). Modulating polyamide nanofiltration membrane with silica nanoparticles as aqueous-phase additive for a significant enhancement in surface water treatment. J. Water Process Eng. 77, 108448. doi:10.1016/j.jwpe.2025.108448

Feng, G., Zhang, H., Chen, J., Fang, Z., and Hu, X. (2025b). Modified graphene oxide (GO) embedded in nanofiltration membranes with high flux and anti-fouling for enhanced surface water purification. J. Environ. Chem. Eng. 13 (1), 115172. doi:10.1016/j.jece.2024.115172

Hui, H., Ding, H., Liu, Q., Zhao, H., Hou, J., Zhang, L., et al. (2025). Enhanced nanofiltration membranes for Mg2+/Li+ separation: development of a polyethyleneimine positively charged interlayer. Sep. Purif. Technol. 361, 131337. doi:10.1016/j.seppur.2024.131337

Huo, X., Jing, Z., Wang, H., and Chang, N. (2022). Sodium dodecyl sulfate/C-UIO-66 regulation of nanofiltration membrane with pleated and thin polyamide layer structure. Desalination 538, 115927. doi:10.1016/j.desal.2022.115927

Huo, X., Zhao, Y., Jing, Z., Wang, J., Wang, H., and Chang, N. (2024). Construction of Lewis acid-base via the formation of defective UiO-66 for regulation of the surface nanostructure on nanofiltration membrane. Desalination 582, 117615. doi:10.1016/j.desal.2024.117615

Karan, S., Jiang, Z., and Livingston, A. G. (2015). Sub–10 nm polyamide nanofilms with ultrafast solvent transport for molecular separation. Sci 348 (6241), 1347–1351. doi:10.1126/science.aaa5058

Lai, W., Shan, L., Bai, J., Xiao, L., Liu, L., Wang, S., et al. (2022). Highly permeable and acid-resistant nanofiltration membrane fabricated by in-situ interlaced stacking of COF and polysulfonamide films. Chem. Eng. J. 450, 137965. doi:10.1016/j.cej.2022.137965

Li, J., Peng, H., Liu, K., and Zhao, Q. (2024). Polyester nanofiltration membranes for efficient cations separation. Adv. Mater. 36 (9), 2309406. doi:10.1002/adma.202309406

Liu, H., Song, X., and Zhang, C. (2023a). Tailor-made highly negatively charged nanofiltration membrane prepared by polyphenol derivatives for anionic dye/salt separation. J. Water Process Eng. 54, 104068. doi:10.1016/j.jwpe.2023.104068

Liu, Y., Van Eygen, G., Yuan, S., Wang, H., Chi, M., Xu, D., et al. (2023b). Facile and novel fabrication of high-performance loose nanofiltration membranes for textile wastewater recovery. Sep. Purif. Technol. 308, 122867. doi:10.1016/j.seppur.2022.122867

Liu, G., Wei, M., Xu, Z., Li, D., Liu, M., Huang, J., et al. (2025a). How monomer concentrations influence structures and separation performances of polyamide nanofiltration membranes? J. Membr. Sci. 733, 124334. doi:10.1016/j.memsci.2025.124334

Liu, L., Liu, Y., Huang, J., Chen, X., Feng, S., Wan, Y., et al. (2025b). Strengthening nanofiltration membrane: strategies for enhanced antifouling performance. Chem. Eng. J. 508, 160964. doi:10.1016/j.cej.2025.160964

Mi, B., Sheng, D., Liu, B., Bu, L., Shi, Z., Zhou, S., et al. (2024). Polyamide nanofiltration membrane fabricated via a metal-chelate strategy for high-flux desalination. Desalination 569, 117049. doi:10.1016/j.desal.2023.117049

Miao, M.-H., Qiu, J.-K., Xu, Z.-L., Lian, C., Liu, H.-L., Li, J.-H., et al. (2024). Systematic experiments and multiscale simulation calculations reveal chemical stability differences in dry/wet nanofiltration membranes. J. Membr. Sci. 699, 122653. doi:10.1016/j.memsci.2024.122653

Ni, L., Li, M., Guo, X., Song, M., Xie, J., Yang, Y., et al. (2024). Macrocyclic polyamines mediated in situ growth of MOFs for the high permeance of nanofiltration membranes. J. Membr. Sci. 709, 123149. doi:10.1016/j.memsci.2024.123149

Peng, H., Yu, K., Liu, X., Li, J., Hu, X., and Zhao, Q. (2023). Quaternization-spiro design of chlorine-resistant and high-permeance lithium separation membranes. Nat. Commun. 14 (1), 5483. doi:10.1038/s41467-023-41169-x

Song, W., and Kumar, M. (2019). Artificial water channels: toward and beyond desalination. Curr. Opin. Chem. Eng. 25, 9–17. doi:10.1016/j.coche.2019.06.007

Song, Y., Wang, Y., Zhang, N., Li, X., Bai, X., and Li, T. (2021). Quaternized carbon-based nanoparticles embedded positively charged composite membranes towards efficient removal of cationic small-sized contaminants. J. Membr. Sci. 630, 119332. doi:10.1016/j.memsci.2021.119332

Tan, Z., Chen, S., Peng, X., Zhang, L., and Gao, C. (2018). Polyamide membranes with nanoscale Turing structures for water purification. Sci 360 (6388), 518–521. doi:10.1126/science.aar6308

Tan, Q., Zhang, W., Lai, C., Zhi, X., Xia, L., Meng, F., et al. (2025). Resveratrol-interlayered nanofiltration membranes with enhanced permeability and antifouling property via interfacial polymerization. J. Membr. Sci. 735, 124501. doi:10.1016/j.memsci.2025.124501

Tang, S., Chen, Y., Zhang, H., Zhang, T., Wang, P., and Sun, H. (2023). A novel loose nanofiltration membrane with high permeance and anti-fouling performance based on aqueous monomer piperazine-2-carboxylic acid for efficient dye/salt separation. Chem. Eng. J. 475, 146111. doi:10.1016/j.cej.2023.146111

Wang, Q., Lin, W., Chou, S., Dai, P., and Huang, X. (2023). Patterned membranes for improving hydrodynamic properties and mitigating membrane fouling in water treatment: a review. Water Res. 236, 119943. doi:10.1016/j.watres.2023.119943

Wang, Z., Zhang, R., Zhang, S., Li, W., Zhi, K., Su, Y., et al. (2024). Polyurea nanofiltration membranes with extreme-pH stability and high separation performance. J. Membr. Sci. 692, 122286. doi:10.1016/j.memsci.2023.122286

Wang, X., Li, T., Su, M., Li, Z., Zhang, S., Zhang, Y., et al. (2025a). Novel integrated cooperative mechanism for regulating interfacial polymerization to prepare nanofiltration membrane with wrinkled structure. Desalination 615, 119259. doi:10.1016/j.desal.2025.119259

Wang, X., Yang, Y., Li, Z., Li, T., Niu, C., and Wang, R. (2025b). Natural composite hydrogel regulated interface polymerization to prepare high performance nanofiltration membranes with wrinkled structure. J. Membr. Sci. 717, 123567. doi:10.1016/j.memsci.2024.123567

Wieczorek, J., and Ulbricht, M. (2021). Amphiphilic poly(arylene ether sulfone) multiblock copolymers with quaternary ammonium groups for novel thin-film composite nanofiltration membranes. Polym 217, 123446. doi:10.1016/j.polymer.2021.123446

Xiang, P., Liu, Y. X., Qin, N., Zhang, Y. Y., Xu, L. N., Huang, X., et al. (2025). Preparation of PEI/COFs-NH2PES composite nanofiltration membranes via polyelectrolyte polyethyleneimine-mediated assembly and their study on dye/salt separation. J. Membr. Sci. 718, 123652. doi:10.1016/j.memsci.2024.123652

Xie, Q., Chen, Z., Jin, W., Yu, T., Lin, J., Hong, Z., et al. (2024). Tannic acid etched ZIF-8 incorporated thin-film nanocomposite nanofiltration membrane with enhanced performance. Appl. Surf. Sci. 660, 159975. doi:10.1016/j.apsusc.2024.159975

Yan, X.-Y., Wang, Q., Wang, Y., Fu, Z.-J., Wang, Z.-Y., Mamba, B., et al. (2022). Designing durable self-cleaning nanofiltration membranes via sol-gel assisted interfacial polymerization for textile wastewater treatment. Sep. Purif. Technol. 289, 120752. doi:10.1016/j.seppur.2022.120752

Ye, L., Wang, L., Wei, Z., Zhou, S., Yao, Z., Fan, F., et al. (2023). Thin film composite nanofiltration membrane with tannic acid-Fe(III) complexes functionalized CNTs interlayer toward energy efficient remediation of groundwater. Desalination 552, 116438. doi:10.1016/j.desal.2023.116438

You, X., Ma, T., Su, Y., Wu, H., Wu, M., Cai, H., et al. (2017). Enhancing the permeation flux and antifouling performance of polyamide nanofiltration membrane by incorporation of PEG-POSS nanoparticles. J. Membr. Sci. 540, 454–463. doi:10.1016/j.memsci.2017.06.084

Yu, L., Li, K., Zhang, Y., Wang, J., and Zhang, G. (2022). Improved permeability of tight acid resistant nanofiltration membrane via citric acid post-treatment. J. Membr. Sci. 648, 120381. doi:10.1016/j.memsci.2022.120381

Yu, Q., Zhou, Y., and Gao, C. (2024). UiO-66 regulated thin-film nanocomposite membranes for water treatment. Desalination 587, 117917. doi:10.1016/j.desal.2024.117917

Zhang, H., He, Q., Luo, J., Wan, Y., and Darling, S. B. (2020). Sharpening nanofiltration: strategies for enhanced membrane selectivity. ACS Appl. Mater. Interfaces 12 (36), 39948–39966. doi:10.1021/acsami.0c11136

Zhang, M., You, X., Xiao, K., Yin, Z., Yuan, J., Zhao, J., et al. (2022). Modulating interfacial polymerization with phytate as aqueous-phase additive for highly-permselective nanofiltration membranes. J. Membr. Sci. 657, 120673. doi:10.1016/j.memsci.2022.120673

Zhang, L., Hu, M., Zhang, Y., Hou, J., Zhang, M., Gao, C., et al. (2024). Phytic acid and ferric chloride compound additives-regulated interfacial polymerization for high-performance nanofiltration membrane. J. Membr. Sci. 693, 122386. doi:10.1016/j.memsci.2023.122386

Zhao, C., Liu, C., Wang, W., Zhang, Z., Yang, X., Tian, J., et al. (2023). Interfacial polymerization layer with CNT providing fast water channels under electric field for efficient desalination of nanofiltration membranes. Desalination 565, 116825. doi:10.1016/j.desal.2023.116825

Keywords: nanofiltration, water treatment, trade-off effect, membrane fouling, chemical stability

Citation: Su M, Zhang Y, Liu S, Wang Y and Li T (2025) Challenges and solutions for nanofiltration membranes in water treatment. Front. Chem. Eng. 7:1695014. doi: 10.3389/fceng.2025.1695014

Received: 29 August 2025; Accepted: 12 September 2025;

Published: 03 October 2025.

Edited by:

Guiliang Li, Chinese Academy of Sciences (CAS), ChinaReviewed by:

Zhenyu Cui, Tianjin Polytechnic University, ChinaHongchang Pei, Shandong University of Technology, China

Copyright © 2025 Su, Zhang, Liu, Wang and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Tiantian Li, bGl0aWFudGlhbjY2OUAxNjMuY29t

Minghan Su

Minghan Su Tiantian Li

Tiantian Li