Abstract

Food waste is considered as a critical global issue in food production, leading to environmental and economic consequences. Repurposing food industry by-products for animal feed can reduce waste, lower feed costs, and improve sustainability in aquaculture. Solid-state fermentation (SSF) has emerged as a promising biotechnological approach to enhance the nutritional value of these by-products. SSF employs microorganisms such as fungi, yeasts, and bacteria to convert low-value agro-industrial residues into bioactive-rich, digestible feed ingredients. This process reduces anti-nutritional factors (ANFs) like phytic acid and tannins, commonly found in plant-based meals, while producing beneficial enzymes and organic acids that support gut health and nutrient utilization. Compared to conventional methods, SSF is energy-efficient, produces minimal wastewater, and aligns well with circular bioeconomy principles. Although fishmeal and soybean meal remain dominant protein sources in aquafeed, their sustainability issues call for alternatives. SSF derived ingredients improve feed efficiency, growth, and immunity in aquatic species, offering a viable substitute. However, challenges remain in optimizing microbial strains, fermentation conditions, and substrate safety. This review discusses SSF’s mechanisms, benefits, and applications in aquafeed, highlighting recent advances, current limitations, and future directions for establishing SSF as a sustainable solution in modern aquaculture feed development.

1 Introduction

Food waste presents a major challenge, with about 19% of consumer-available food (approx. 931 million tonnes) wasted in 2024, accounting for 8-10% of global greenhouse gas emissions, $1 trillion in economic losses, and heightened strain on global food systems (Food, Waste Index Report, 2024), contributing to environmental degradation, economic losses, and increased pressure on global food systems (EFFPA, 2018; Economou et al., 2024). Utilizing food industry by-products as alternative raw materials can decrease reliance on global markets, cut costs, and boost the aquaculture sector’s competitiveness, though enhancement of nutritional profiles of aquafeed for potential use in aquafarms. Currently, 5 million tons of raw food are redirected to animal feed, a figure expected to rise to 7 million tons by 2025 (EFFPA, 2018; Ibarruri et al., 2024). Solid-state fermentation (SSF) has gained grip for its remediation potential, transforming underutilized biomass into valuable products, addressing environmental issues from improper waste disposal (EFFPA, 2018). SSF is a heterogeneous process involving three phases, such as solid, liquid, and gas and presents numerous advantages for microbial cultivation in bioprocessing and product development. The resulting products contribute to secondary fermentation within the gastrointestinal tract of livestock, delivering residual bioactive compounds, such as enzymes, organic acids, and peptides, capable of hydrolysing the indigestible dietary components, including complex carbohydrates and fibers. Research has shown improved growth and feed efficiency in animals when SSF-derived products are included in modern aquafeed and poultry diets (Hooge et al., 2010; Hassaan et al., 2017).

Over the past two decades, SSF has attracted considerable interest for industrial applications, primarily because it requires less energy, delivers higher product yields, and generates minimal wastewater, all while reducing the likelihood of bacterial contamination. Moreover, it is environmentally friendly, as it typically employs solid agro-industrial residues as the primary carbon source (Thomas et al., 2013). SSF’s ability to valorize agricultural byproducts aligns with sustainability goals, reducing waste and reliance on costly fishmeal while enhancing the nutritional and functional quality of aquafeed (Thomas et al., 2013; Sadh et al., 2018a,b; Vieira et al., 2023; Ibarruri et al., 2024). This eco-friendly, cost-effective method holds immense potential for aquaculture, addressing nutritional challenges and supporting a more sustainable feed industry (Verduzco-Oliva and Gutierrez-Uribe, 2020). In the aquaculture feed industry, fishmeal and soybean meal remain the dominant protein sources due to their high digestibility and balanced amino acid profiles (Bowyer et al., 2020). However, their limited global availability and unsustainable production call for reduced usage in feeds (Watanabe, 2002; Ibarruri et al., 2024). Although alternatives like animal by-products, plant-based feeds (mainly soya), and single-cell proteins are used (Miles and Chapman, 2006; Yang et al., 2021), they often fall short in amino acid balance, digestibility, and palatability, and may contain antinutrients.

Despite a decent protein content, plant-based meals are constrained by ANFs like phytic acid, trypsin inhibitors, and non-starch polysaccharides (Mandal and Ghosh, 2013; Mandal and Ghosh, 2019). Conventional methods, such as heat treatment, soaking, and germination, often inadequately reduce ANFs but can also result in nutrient losses (Saha and Ray, 2011; Mandal and Ghosh, 2020). From an evolutionary perspective, gut microbiota in herbivorous fish helps to counteract the negative effects of plant-derived ANFs (Xu et al., 2021). Gut microbiota in other fish, incapable of breaking down cellulose, tannins, phytates, and xylans, whereas SSF helps to alleviate ANF impacts, by improving nutrient utilization (Soltani et al., 2019; Ringø et al., 2022). Recent studies have shown that the inclusion of SSFs in fish feed promotes beneficial gut microbiota in various fish species, enhancing host nutrition (Ray et al., 2012; Ringø et al., 2022). Though less studied in aquatic species, in vitro solid-state fermentation (SSF) is considered a promising method to decrease ANFs in plant feed, with microbial enzymes improving nutrient bioavailability in the processed aqua feed.

The global aquaculture industry faces increasing pressure to develop sustainable, cost-effective, and nutritionally optimized feed solutions to meet the rising demand for aquatic products. Solid-state fermentation (SSF) has emerged as a promising technology to address these challenges by enhancing the nutritional quality of aquafeed, reducing ANFs, and promoting environmental sustainability through the utilization of agro-industrial byproducts. By leveraging the enzymatic capabilities of microorganisms such as fungi, yeasts, and bacteria, SSF transforms low-value substrates into nutrient-rich feed ingredients, improving digestibility, gut health, and immune responses in aquatic species. Despite its potential, challenges remain in optimizing fermentation parameters, ensuring the safety of SSF-derived products, and exploring novel substrates and microbial strains for greater efficacy.

Therefore, this review article is targeted to addresses the critical research gaps, including the environmental sustainability of SSF, details its biochemical mechanisms, compares it with other processing methods, and evaluates its applications in aquafeed through case studies on nutritional benefits, growth performance, gut microbiota modulation, and immune system enhancement. This review also critically discusses the limitations of microbial applications in enhancing the nutrient profile of aquafeed ingredients, and highlights the current challenges and future research directions required to advance SSF technology for sustainable aquaculture feed production.

2 Solid-state fermentation

2.1 Principle

Solid-state fermentation (SSF) uses low-water substrates and could be an alternative to conventional aquaculture feed (Betchem et al., 2024). As a bio-process, SSF develops low-value agro-industrial byproducts into high-value feed nutrients while enhancing the nutritional value of aquafeeds by adding microbial growth, enzymatic activity, and bioactive components (Dawood and Koshio, 2020). The added advantage of microbial growth by SSF is that SSF conditions are more favorable than anything conceivable, providing preferential microbial growth that can exist naturally (Betchem et al., 2024). Microbial growth via SSF can improve digestibility, nutrient bioavailability, and feed efficiency in aquaculture (Bowyer et al., 2020). Solid-state fermentation cultivates microorganisms on solid substrates with a low moisture content, usually 40-60% (Bhargav et al., 2008). It is a mode of fermentation that mimics the natural conditions that microbes would encounter when they break down complex organic sources into simpler forms that aquatic organisms can take up (Singhania et al., 2018). Agricultural waste products, such as cassava peel, rice bran, soybean meal, and wheat straw, are typically used as substrates in SSF for aquaculture (Yafetto et al., 2023).

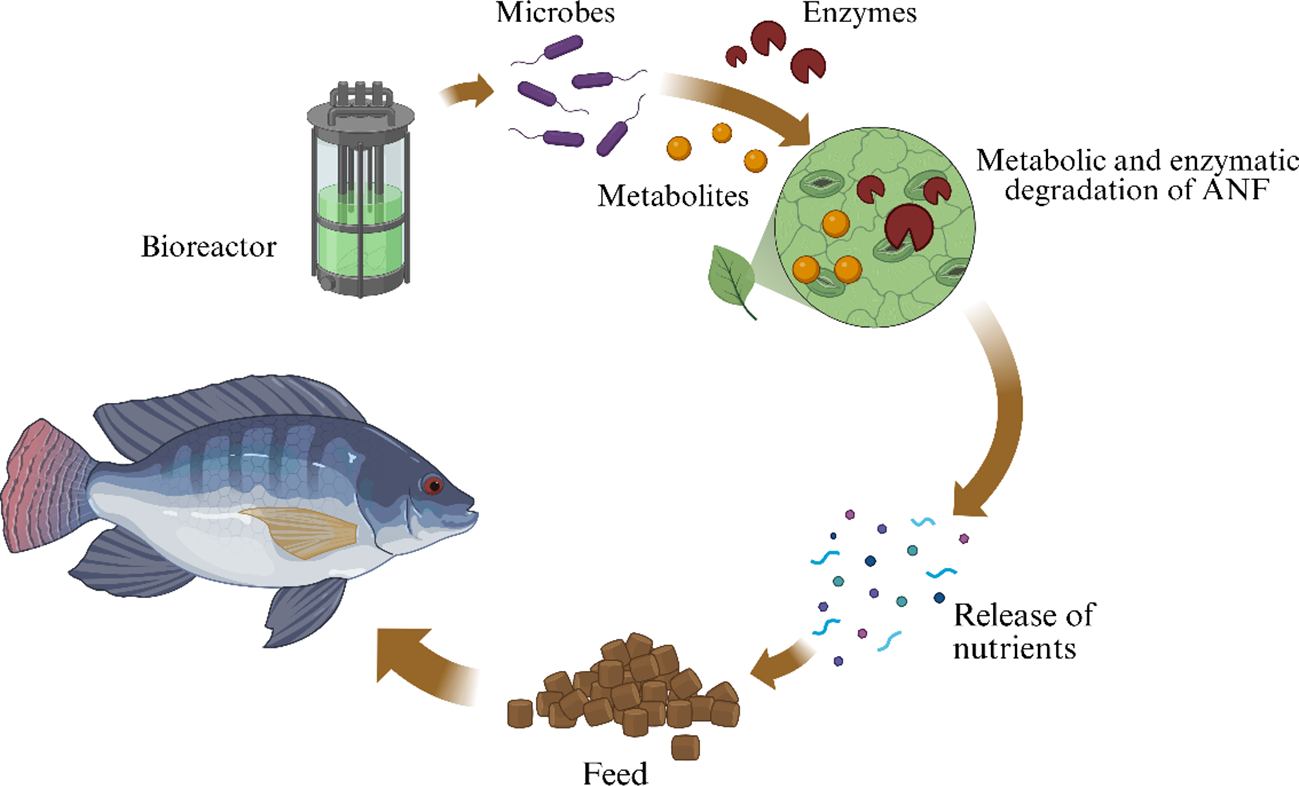

The fermentation process can be controlled by varying temperature, moisture, pH, and aeration parameters. Each parameter must be fine-tuned to ensure the growth of specific microorganisms (Singhania et al., 2017). SSF allows microorganisms to break down a plant material (with agricultural wastes typically having much higher nutrient content), and it enhances the nutritional profile of the substrate, including protein digestibility, and reduces anti-nutritional factors (Sadh et al., 2018a) as shown in Figure 1. In addition, SSF allows for the production of essential enzymes (e.g., proteases, lipases, cellulases, and amylases) that improve the bioavailability of nutrients in aquafeeds (Vieira et al., 2023). SSF also allows for the production of secondary metabolites, such as antimicrobial peptides and bioactive compounds, that could improve fish health and immune responses (Verduzco-Oliva and Gutierrez-Uribe, 2020).

Figure 1

Principle of solid-state fermentation in aquafeed.

2.2 Microorganisms utilized in SSF

Microorganisms employed during SSF are carefully chosen for their enzymatic features, substrate specificity, and ability to grow under low-moisture conditions (El-Bakry et al., 2015). The microorganisms most widely used in SSF for feeding aquaculture include fungi (filamentous fungi and yeasts) and bacteria (Vandenberghe et al., 2021).

2.2.1 Filamentous fungi and yeasts

Common species of fungi employed in SSF, such as Aspergillus niger, Trichoderma reesei, Rhizopus oligosporus, and Pleurotus ostreatus, have been utilized because of the extensive array of enzymes they produce (Feng et al., 2024). As shown in Table 1, fungi produce a wide range of enzymes such as cellulase, xylanase, protease, and lipase, which decompose complex polysaccharides, proteins, and lipids in a variety of plant-based feed materials (El-Gendi et al., 2021). A. niger has been used in SSF for the production of enzyme proteases from aquaculture sludge (Kuan et al., 2024). The enzymatic action of fungi provides improved nutritional value, and their incorporation offers an indirect way to reduce anti-nutritional factors, such as phytate, tannins, and protease inhibitors, which seems to be a major problem in aquaculture systems (Onomu and Okuthe, 2024). Because the requirement utilized in SSF closely resembles the natural habitat of fungi, the growth of these microorganisms can significantly alter the substrate composition they inhabit. Fungi have been shown to enrich lignocellulosic materials with microbial proteins and enzymes. This bioconversion process reduces the crude fiber content while enhancing crude protein levels, protein solubility, and digestibility of both protein and fiber. As a result, the nutritional value of plant-based feedstuffs has improved, making them more suitable for use in aquaculture (Vieira et al., 2023).

Table 1

| Micro-organism | Major enzymes produced | Effects on aquafeed |

|---|---|---|

| Filamentous fungi | Amylase, Protease, Lipase, Cellulase, Phytase, Xylanase, Pectinase, and β-glucanase (Wösten, 2019). | Protease and Amylase: Protein and starch are broken down which increases digestibility. Lipase: Hydrolyses triglyceride ester linkages to produce glycerol and fatty acids, improves fat digestion, and lowers crude fat in fermented foods. Cellulase, xylanase, and β-glucanase: Enhance the digestibility of fiber by breaking down non-starch polysaccharides (NSPs) Phytase: Enhances mineral bioavailability in animal feed by hydrolyzing phytic acid and liberating phosphorus. Pectinase: Enhances the digestion of carbohydrates by breaking down pectin-rich fiber. Lacasses: Oxidate phenolic compounds and lignin. Invertase: also known as sucrase, increases the availability of sugar by converting sucrose to glucose and fructose. |

| Bacteria | Amylase, Protease, Lipase, Cellulase, Phytase, Xylanase, Laccases (Quax, 2013). | |

| Yeast | Amylase, Protease, Invertase (Sucrase), and β-glucanase (Amillano-Cisneros et al., 2025; Sultana et al., 2024) |

Key microorganisms (fungi, yeast, bacteria), their main enzymatic outputs, and their primary effects on aquafeed.

Jannathulla et al. (2017) and (2018) revealed that A. niger fermented guar meal and soybean meal fed to Penaeus vannamei shows fermented meals could be utilized successfully as a potent protein source than the untreated ingredients in the diet of shrimp. Similarly, Kim et al. (2009) and (2010) revealed that Aspergillus oryzae-fermented soybean meal was fed to Oplegnathus fasciatus, and Paralichthys olivaceus enhanced phosphorus absorption and non-specific immune mechanisms in fish. Other commercially available fungal species employed for the fermentation of soybean meal are Candida utilis (Zhou et al., 2011), and Aspergillus niger (Jannathulla et al., 2019), which have been observed to enhance the health status and growth performance of fish. In this regard, Amaral et al. (2023) and Vieira et al. (2023) recorded that A. niger has been used in SSF was fed to European seabass (Dicentrarchus labrax) juveniles showed improved growth performances with excellent survivability. Similarly, Aspergillus ibericus, when employed as an SSF product prepared using a red algae by-product, was fed to D. labrax and was recorded to increase the immune mechanism of fish (Ferreira et al., 2025). Likewise, Aspergillus carbonarius, A. ibericus, and A. uvarum were utilized in the SSF of corn distillers’ dried grains fed to E. labrax to improve its digestibility (Filipe et al., 2023).

In SSF, Saccharomyces cerevisiae, Candida utilis, and Kluyveromyces marxianus are some of the yeasts that can be used to produce single-cell proteins (SCP) that are rich in amino acids, vitamins, and minerals and contribute to aqua-feeding nutrition by supplying bioavailable protein and improving the feed intake of fish (Bilal et al., 2022). Yeast fermentation can also enhance feed stability during storage (Dai et al., 2020). Yeasts can also produce bioactive compounds that are immuno-supportive in aquatic species (Tadioto et al., 2023). Sharawy et al. (2016) noted that Saccharomyces cerevisiae employed in soybean meal was fed to Fenneropenaeus indicus, which shows a 50% replacement of fish meal protein with better growth performance. Similarly, Dossou et al. (2018) reported that S. cerevisiae fermented rapeseed meal fed to Pagrus major resulted in 56.25% fishmeal replacement with better feed utilization and growth performance. Likewise, Plaipetch and Yakupitiyage (2012) found that S. cerevisiae fermented canola meal fed to Lates calcarifer and Oreochromis niloticus revealed that 50% fish meal replacement resulted in excellent growth performance of fish. Wang et al. (2024) reported that common carp (Cyprinus carpio) fed products manufactured using SSF showed increased resistance against springviremia of carp virus. Other commercially available yeast species of Ganodermalucidum fermented mushroom bran hydrolysate and a proportion of 64-80% fishmeal were fed to Carrassius auratus gibelio, which revealed improved growth, digestive enzymes, and antioxidant status of fish (Zhang et al., 2017).

2.2.2 Bacteria

Bacteria, such as Bacillus subtilis, Lactobacillus spp., and Streptomyces, play an essential role during SSF because they produce extracellular enzymes (Table 1) and bioactive compounds, which can promote digestion of feed in fish gut health by increasing beneficial microbiota and producing antimicrobial peptides by reducing pathogenic load (De Villa et al., 2023). Refstie et al. (2005) revealed that when Lactobacillus brevis fermented soybean white flakes were fed Salmo salar, it improved the growth performance of fish, as lactic acid fermentation enhanced the nutritional value of soybean white flakes. Similarly, Yamamoto et al. (2010) reported that Bacillus spp. fermented soybean meal fed Oncorhynchus mykiss enhanced feed digestibility and fish growth performance. Likewise, Wang et al. (2016) observed that when Lactobacillus plantarum PB fermented soybean meal was fed to Scophthalmus maximus L shows 45% fish meal replacement with better feed digestibility. Similarly, C. carpio fed with 0.3 and 0.4 g/kg SSF product of Bacillus velezensis has an improved inflammatory response to gut health and modulates the gut microbiota of species (Chen et al., 2025). Other species of bacteria (Bacillus substilis E20; Shiu et al., 2015, Bacillus subtilis; Lee et al., 2016a, Bacillus subtilis U304; Moniruzzaman et al., 2018, Lactobacillus spp.; Lin and Mui, 2017) were employed to ferment soybean meal shown to improve growth performances of fishes by enhancing health status.

2.3 Substrates used in SSF

The growth of microorganisms and yield of the end product in SSF are significantly influenced by substrates from different sources. Different organisms used in the fermentation mechanism belong to various species, each capable of producing distinct metabolites, such as lactic acid, ethanol, or acetic acid, depending on the substrate employed (Siddik et al., 2024). According to this hypothesis, Lactobacillus species are known to produce lactic acid and citric acid, whereas yeasts primarily generate ethanol and carbon dioxide. Therefore, the substrate was selected to provide a developing culture with nutritional and physical support (Bhargav et al., 2008). The most commonly used solid substrates are cereal grains, such as corn and wheat, and a variety of components and byproducts from plants and animals (fishery byproducts, poultry, and legume seeds) (Šelo et al., 2021). A 25% mixture of rapeseed, soybean, rice bran, and sunflower seed meal has been used as a substrate for SSF feeding of D. labrax (Vieira et al., 2023). In addition, corn starch and soybean protein concentrate were incorporated as substrates in the SSF process for feeding Nile tilapia (O. niloticus) (Bowyer et al., 2020). Fisheries byproducts such as prawn shell powder have also been used in the SSF process for aquaculture effluent treatment (Kuan et al., 2024). The final products of fermentation vary depending on the type and composition of the substrate. It is also noted that the lower water content within the SSF process boosts the process with lower wastewater levels (Chilakamarry et al., 2022). In this regard, many agro-industrial byproducts with high water content, such as pomaces, can be used when no additional water is needed for the substrate. Using natural and agro-based substrates to encourage pigment creation by microorganisms has become a crucial research approach in microbial biotechnology (Venil et al., 2020). For example, in submerged fermentation, various agro-waste substrates have been tested against different bacteria (Sadh et al., 2018b).

3 Biochemical mechanisms behind nutrient enrichment in SSF

SSF enhances the nutritional profile of plant-based ingredients through microbial action. During SSF, the selected microorganisms grow on the surface of the solid substrate and secrete enzymes through breaking down the complex compounds, reduce ANFs, and produce the essential nutrients. Despite increase in the nutritional profile, SSF also produces microbial metabolites in an environment local to their habitats, contributing to overall feed functionality and digestibility (Ulmer et al., 1981).

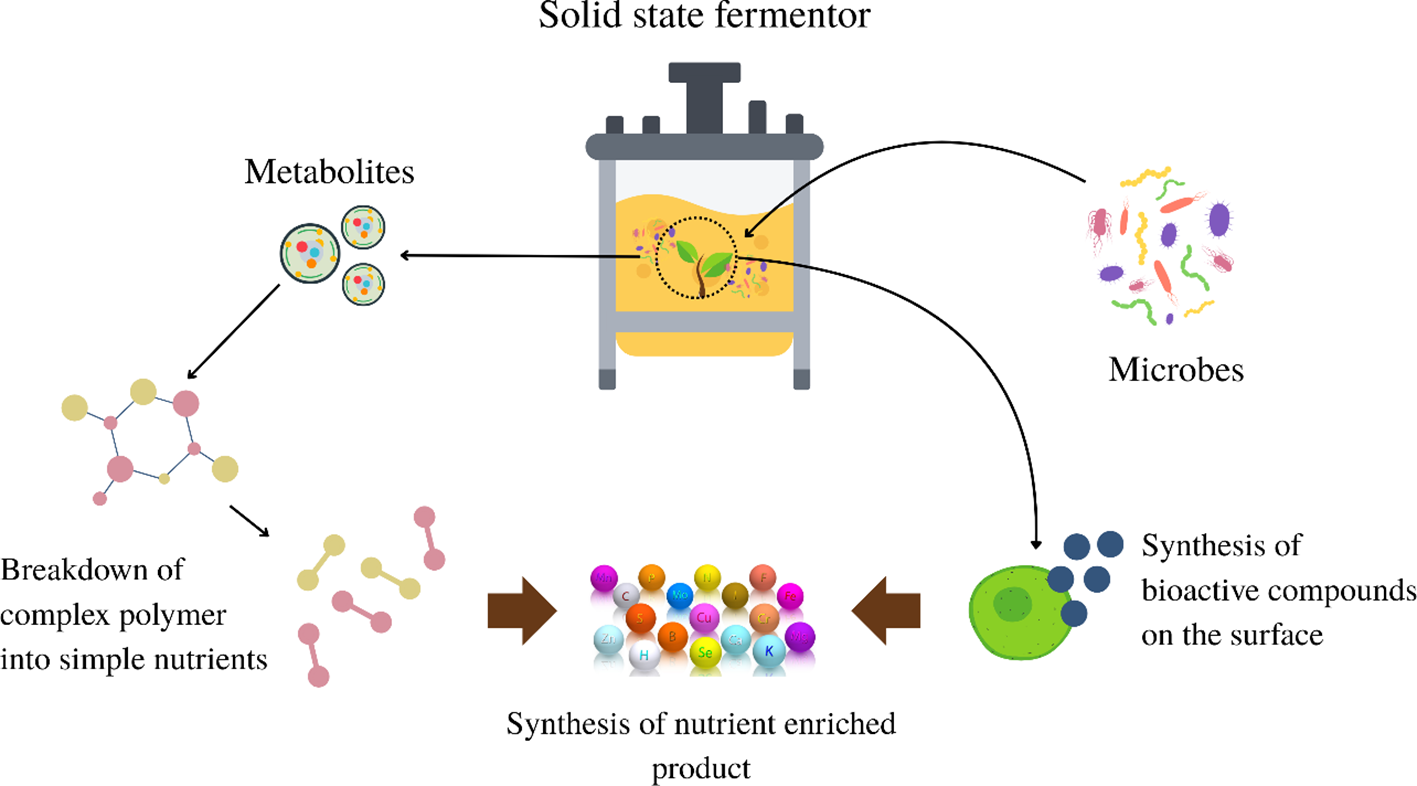

3.1 Metabolites production

Microbial metabolites in solid-state fermentation (SSF) are primarily the result of metabolic activities by microorganisms, such as fungi, bacteria, and yeasts, which grow on solid substrates with minimal free water. These microorganisms enzymatically degrade complex polymers, such as cellulose, starch, and lignin, which serve as both carbon and nutrient sources, into simpler compounds as shown in Figure 2. This process involved several key steps. First, the substrate was selected and inoculated with the desired microorganism, followed by microbial growth either on the surface or within the matrix of the substrate, depending on the organism and substrate porosity. Following colonization, complex macromolecules are hydrolyzed into simple sugars or nutrients, which are then utilized by microbes for growth and maintenance. As microbial activity progresses, especially under controlled SSF conditions (e.g., moisture, temperature, pH, and oxygen), secondary metabolites such as enzymes, organic acids, antibiotics, and other bioactive compounds are synthesized. The efficiency and yield of these valuable metabolites are highly dependent on the optimization of these physicochemical parameters, making SSF a fine-tuned and environmentally sustainable bioprocess (Robinson et al., 2001).

Figure 2

Mechanistic pathways behind the bacterial degradation in Solid-state fermentation.

3.2 Enzyme production

In solid-state fermentation, extracellular enzymes secreted by microorganisms degrade complex insoluble substrates into soluble simpler fragments. Enzymes such as cellulases, amylases, proteases, and ligninases degrade polymers such as cellulose, starch, proteins, and lignin into smaller molecules that can be absorbed and exploited by microbes for growth and metabolism (Graminha et al., 2008). In this process, there are accumulated cellular secreted hydrolytic enzymes that must diffuse through a pore structure to catalyze the hydrolytic degradation of a polymeric substrate into very small water-soluble fragments that diffuse back to the vicinity of the cells for further metabolism. The factors affecting the efficiency of enzymatic degradation are: porosity of the substrates; crystallinity of solid-state substrates; and chemical composition of solid-state substrates, which govern ‘activity’ and the access to enzymes. When the pore structure allows for activity inside the structure, the time to convert polymers into controlled nutrients for cellular grazing by microbes is significantly reduced by providing channels, diffusion paths, and surface area. If the pore structure does not permit the distribution of enzymes, degradation will not occur, and activity will only occur on the surface of the substrate and, in some cases, fall potentially below acceptable levels. Therefore, rapid hydrolysis will not occur as solids remain inaccessible to enzymatic degradation by microbial hydrolytic enzymes secreted into the solid substrate. Accordingly, it is essential to understand how SSF processes allow microorganisms and their secreted enzymes to convert complex insoluble polymers to assimilable soluble nutrients for microbial growth and product formation. As an example of enzymatic degradation that may occur during solid-state fermentation, fungi and bacteria produce cellulases that degrade cellulose (Pandey et al., 1999) as shown in Figure 2.

3.3 Reduction in ANFs

SSF is considered as an effective biotechnological approach for reducing ANFs in plant-derived ingredients, thereby improving their nutritional value for food and feed applications. The reduction in ANFs through SSF occurs through multiple mechanisms. First, enzymatic degradation plays a central role, where specific microbes such as Aspergillus spp., Bacillus subtilis, and Rhizopus oryzae produce enzymes such as proteases, phytases, and tannases that break down ANFs, such as trypsin inhibitors, phytic acid, and tannins. For instance, Aspergillus oryzae-mediated SSF of soybean meal eliminated the protein bands associated with trypsin inhibitors, confirming their breakdown (Hong et al., 2004). Second, microbial metabolism contributes to ANF reduction because microbes utilize ANFs as nutrient sources. A significant reduction in phytate and trypsin inhibitor activities was observed in de-oiled rice bran fermented with Rhizopus oryzae, suggesting that the fungus actively metabolizes these compounds (Ranjan et al., 2019). Third, the synergistic effects of co-culture further enhanced ANF degradation. Co-fermentation using Aspergillus niger, Candida utilis, and Bacillus subtilis in Moringa oleifera leaf meal led to a greater reduction in tannins and phytic acid than single-microbe fermentation (Shi et al., 2020). Finally, SSF reduced ANFs and improved nutrient bioavailability. For example, fermentation of corn-soybean meal with Bacillus subtilis and Enterococcus faecium lowered allergenic proteins, such as glycinin and β-conglycinin, thereby enhancing the nutritional quality of the feed (Shi et al., 2017). Collectively, these mechanisms demonstrate the potential of SSF to transform plant-based materials into more digestible and nutritious forms for sustainable animal nutrition.

3.4 Enhancing nutrient content

SSF technology was also reported to enhance the nutritional profile of plant-based materials through various biological mechanisms. First, the microbial biomass directly contributes to protein enrichment. As microbial communities, primarily bacteria and fungi, proliferate on the substrate during fermentation, their biomass increases crude protein content. For instance, the fermentation of oats with Monascus purpureus increased the protein content from 12.64% to 24.91% (Yu et al., 2025). Second, enzyme-mediated degradation plays a key role. Microbes produce enzymes that break down complex carbohydrates, fibers, and antinutritional components into simpler, more digestible forms. This enzymatic activity improves nutrient availability by reducing molecular barriers that hinder absorption (Jeyakumar and Lawrence, 2022). Third, SSF leads to the synthesis of beneficial bioactive compounds, such as vitamins, organic acids, and antioxidants, which contribute not only to enhanced nutritional value but also to health-promoting properties (Dey et al., 2016; Vandenberghe et al., 2018). Fourth, SSF reduces anti-nutritional factors, such as tannins and phytates, which are known to interfere with mineral and amino acid absorption. This reduction enhances the bioavailability of the essential nutrients (Olukomaiya et al., 2020). Improved digestibility is another vital benefit. Microbial degradation of structural polysaccharides and fibers leads to improved nutrient access. For example, juvenile European seabass (Dicentrarchus labrax) exhibited enhanced digestibility when fed dried distillers’ grains fermented by SSF (Filipe et al., 2023). Together, these mechanisms underscore SSF’s potential of SSF as a sustainable tool for upgrading the feed quality and nutritional efficiency in aquaculture and animal nutrition.

3.5 High nutrient digestibility

The significant improvement in digestibility caused by SSF is one of its key advantages for both food and feed applications. This enhancement is primarily attributed to microbial enzymatic activity, breakdown of structural barriers, and reduction in ANFs.

-

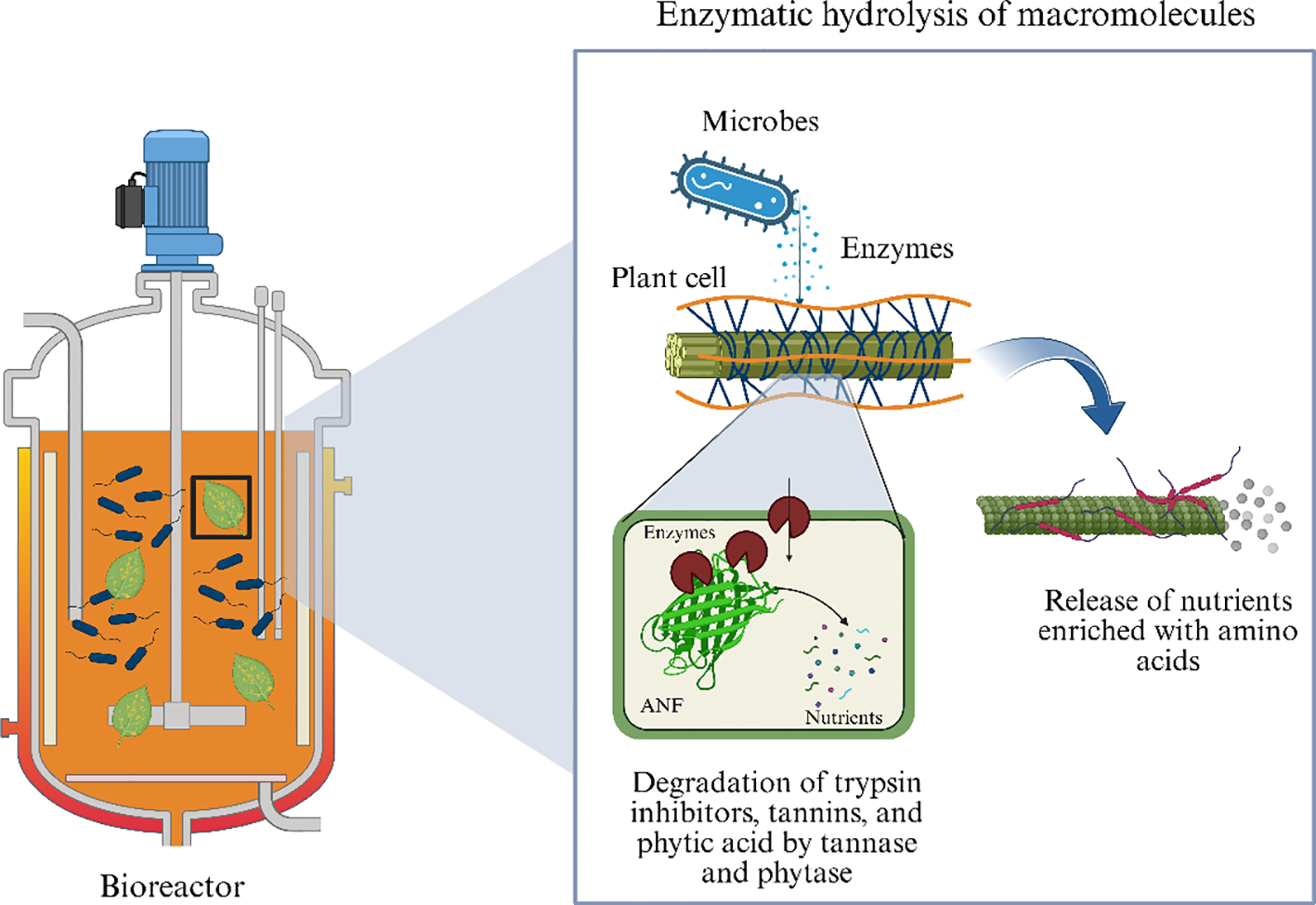

i. Enzymatic Hydrolysis of Macromolecules: Microorganisms used in SSF secrete a variety of enzymes that mimic gastrointestinal digestion. Enzymes, such as amylases, break down starch into simple sugars, proteases hydrolyze proteins into peptides and amino acids, and cellulases and hemicellulases degrade plant cell wall components, releasing entrapped nutrients as shown in Figure 3. This pre-digestion effect increases nutrient bio accessibility, similar to the natural digestive processes of the stomach and intestine (Wang et al., 2024).

-

ii. Reduction of ANFs: SSF also reduces ANFs, such as trypsin inhibitors, tannins, and phytic acid, which are known to impair nutrient absorption. Microbial enzymes, such as tannase and phytase, degrade these compounds, enhancing the bioavailability of key minerals (e.g., calcium, iron, and zinc) and improving the digestibility of proteins and carbohydrates (Adebo et al., 2022).

-

iii. Disruption of Plant Cell Walls: Fungal fermentation is particularly effective in breaking down fibrous plant materials, thereby weakening structural barriers and facilitating the release of intracellular nutrients. This is especially beneficial for fibrous feedstocks, such as oilseed meals, bran, and legumes (Verduzco-Oliva and Gutierrez-Uribe, 2020).

-

iv. Increase in Amino Acid Content: SSF can enhance the amino acid profile of substrates through microbial metabolism. For instance, fermenting soybean meal with Bacillus coagulans for 48 h significantly increased the essential amino acid lysine by 93%, tryptophan by 42%, and valine, isoleucine, and leucine by smaller but notable margins (Imelda et al., 2008).

Figure 3

Microbial enzymatic hydrolysis of plant macromolecules.

4 Solid-state fermentation vs. submerged fermentation

Generally, SSF utilizes solid substrates, like bran, bagasse, and paper pulp. The main advantage of using these substrates is that nutrient-rich waste materials can be easily recycled as substrates. In this fermentation technique, the substrates are utilized very slowly and steadily, so the same substrate can be used for long fermentation periods (Umrao et al., 2024). Hence, this technique supports controlled release of nutrients. SSF is best suited for fermentation techniques involving fungi and microorganisms that require less moisture content. However, it cannot be used in fermentation processes involving organisms that require high aw (water activity), such as bacteria (Dawood and Koshio, 2020). On the other hand, SMF is typically performed using free-flowing liquid substrates such as molasses, wet distillers’ grains, and broths to produce fermented liquid feeds (Sugiharto and Ranjitkar, 2019). The substrates are utilized quite rapidly; hence need to be constantly replaced/supplemented with nutrients. This fermentation technique is best suited for microorganisms such as bacteria that require high moisture content (Subramaniyam and Vimala, 2012). SMF is primarily used in the extraction of secondary metabolites that need to be used in liquid form.

4.1 Nutritional enrichment

SSF is a highly effective technique to enhance the nutritional value of animal feed, particularly in aquaculture (Sun et al., 2023). It significantly improves protein content, both in quantity and quality, by promoting the activity of filamentous fungi, such as Aspergillus spp., which produce proteolytic enzymes that break down complex proteins into more digestible forms (Dai et al., 2020). SSF also enhances amino acid profiles and increases nutrient availability through the action of enzymes such as cellulases, phytases, and proteases (El-Bakry et al., 2015). Additionally, it reduces crude fiber and indigestible polysaccharides, degrades anti-nutritional factors such as phytic acid and tannins, and suppresses harmful pathogens, such as Salmonella, through the production of organic acids and antimicrobial compounds (De Villa et al., 2023). This not only boosts the nutritional and antioxidant properties of feed ingredients, particularly those derived from cereals and legumes, but also improves feed digestibility, fish growth performance, and feed conversion ratios (FCR). SSF is commonly performed using a single type of agro-industrial substrate, which simplifies process control and ensures consistent quality before the fermented product is incorporated into the final feed formulations (Dai et al., 2020). The low-moisture environment of SSF also reduces contamination risks and results in products with a longer shelf life (Krishna, 2005). Nutrient enrichment, particularly protein and fiber breakdown, is less efficient in SMF, although it can be enhanced using specific microbial strains (Cao et al., 2024). However, SMF excels in producing probiotics and bioactive compounds that can support fish immunity and gut health when included in feed (Sørensen, 2022). However, the high moisture content increases the risk of microbial contamination and necessitates further processing steps, such as drying, in addition to operational costs.

4.2 Enzyme production

Fermentation is a fundamental method for producing a wide range of enzymes, and both fungi and bacteria are capable of generating valuable enzymes when cultivated on suitable substrates. Enzymatic production can be performed using either SSF or SMF. SMF is typically used for bacterial enzyme production because of its higher water requirement, whereas SSF is more suitable for fungal enzymes, as fungi thrive in low-moisture environments. The metabolism exhibited by microorganisms is different in SSF and SMF, and the influx of nutrients and efflux of waste materials must be carried out based on these metabolic parameters (Manpreet et al., 2005). Any deviation from optimal parameters can lead to reduced product quality. Notably, enzymes produced via SSF tend to exhibit higher resistance to substrate inhibition and maintain greater stability over a broad range of temperatures and pH levels (Barrios-González, 2012). Traditionally, bacterial enzymes such as amylase, xylanase, L-asparaginase, and cellulase have been produced using SMF. However, emerging research suggests that SSF is more effective in bacterial enzyme production. This shift is largely due to the accumulation of intermediate metabolites in SMF, which can inhibit enzyme activity and reduce the overall productivity. SSF provides a more favorable environment for microbial metabolism, leading to enhanced enzyme yield and activity.

4.3 Bioactive compounds

Fermentation has been widely employed to extract various bioactive compounds, including antibiotics, pigments, enzymes, hypocholesterolemic agents, antioxidants, antihypertensive agents, antitumor compounds, biosurfactants, and bioactive peptides (Sadh et al., 2018a; Chai et al., 2020). Numerous studies have demonstrated the successful production of these compounds through microbial fermentation. Despite this, there is limited research comparing the efficiency and effectiveness of different fermentation methods, specifically solid-state and submerged fermentation, for the production of such bioactive substances. Antibiotics are one of the most significant categories of bioactive compounds derived from microorganisms via fermentation. The first commercially produced antibiotic, penicillin, was extracted from Penicillium notatum as early as the 1940s using both SSF and SMF (Arumugam et al., 2013). Since then, a wide range of antibiotics, including cyclosporins, tetracyclines, surfactins, streptomycin, and cephalosporins, have been successfully produced using fermentation techniques (Subramaniyam and Vimala, 2012).

Initially, the SMF was the predominant method used for antibiotic production. However, with advancements in substrate development, SSF has gained increasing popularity because of its advantages in terms of yield and compound stability. Recent studies have indicated that SSF often results in higher antibiotic production and improved product stability compared to SMF, primarily because of the reduced accumulation of inhibitory intermediate metabolites (Barrios-González and Miranda, 2012; Barrios-González, 2012). Despite these benefits, the choice between SSF and SMF largely depends on the specific microbial strain involved, as some microorganisms perform better in one system than in the other. In addition, the efficiency of SSF is heavily influenced by the physical and chemical properties of the substrate, which can limit its application (Pandey et al., 2000; Thomas et al., 2013). Therefore, it is essential to evaluate a broad range of substrate materials during the development phase to optimize the fermentation process and maximize antibiotic yield.

4.4 Economic feasibility and resource efficiency

The overall economic viability of a fermentation process is influenced by several key factors including the availability and cost of substrates, scalability of the process, energy requirements, and complexity of downstream processing. SSF is often considered more cost-effective because it utilizes low-cost agricultural residues, requires minimal water and energy inputs, and generates less wastewater (Karimi et al., 2021). However, maintaining optimal environmental conditions and ensuring consistent substrate quality pose operational challenges. In contrast, SMF is easier to automate and scale for industrial production but typically involves higher operational expenses because of its greater demand for water, energy, and more intensive waste management (Holker and Lenz, 2005; Thomas et al., 2013). Consequently, choosing the most economically feasible method depends on balancing the production efficiency with resource use and sustainability.

In recent decades, SSF has attracted considerable attention as an alternative to SMF, largely because of its cost-effectiveness and its ability to replicate the natural environment of many microorganisms. SSF offers several key advantages over SMF, including the use of minimal moisture, reduced risk of bacterial contamination, improved oxygen flow, simpler fermentation media, lower capital investment, higher productivity, and decreased energy consumption (Holker and Lenz, 2005; Pandey et al., 2000; Olukomaiya et al., 2019). Additionally, SSF typically does not require strict control of fermentation conditions and involves less effort in downstream processing (Olukomaiya et al., 2019). Due to its low-tech equipment requirements and cost-effectiveness, SSF is considered a more suitable and widely applicable method for the feed industry. This technique has been extensively applied in various sectors for the production of enzymes, biofuels, food, animal feed, and secondary metabolites such as antibodies and immunological drugs. However, one of the main limitations of SSF is the difficulty in controlling certain operational parameters, particularly agitation, which restricts its broader industrial use. Despite this, recent advances in bioreactor design show promise in overcoming these challenges, paving the way for improved agitation control and scalability in industrial applications.

4.5 Environmental sustainability

The environmental benefits of SSF stem from its operation without free-flowing water, leading to minimal water usage and low wastewater generation (Pandey et al., 2000). This eliminates the need for antifoaming agents and allows some SSF processes to be carried out under semi-sterile conditions (Hernandez et al., 1992). Since SSF occurs at water activity levels below 1, the risk of contamination by bacteria and yeasts is significantly reduced, potentially removing the need for energy-intensive sterilization procedures (Thomas et al., 2013). Moreover, SSF is eco-friendly because it often utilizes agricultural waste as a source of carbon and energy (Vandenberghe et al., 1999; Pandey et al., 2000). This is especially common in the production of enzymes and organic acids, where plant residues are used as substrates and inducers. Additional advantages of SSF include decreased water usage, reduced wastewater output, the potential for greater volumetric productivity and higher product concentrations, enhanced consistency in results, and more space-efficient operations. This is largely due to the lower moisture content in SSF, which enables greater substrate loading in smaller, more compact fermentation units. Furthermore, contamination control is easier, and the fermentation media are typically simpler (Gowthaman et al., 2001; Durand, 2003; Thomas et al., 2013).

In contrast, SMF has a higher environmental burden due to its reliance on large volumes of water and energy-intensive operations. SMF systems require continuous agitation, aeration, and temperature control, all of which contribute to increased electricity consumption (Holker and Lenz, 2005; Thomas et al., 2013). The production process also generates significant quantities of liquid waste, which must be treated before disposal, thereby adding to environmental management costs. Moreover, SMF often uses refined substrates, which may involve upstream resource-intensive processing. Although SMF offers advantages in process scalability and control, its environmental sustainability is lower than that of SSF unless integrated with efficient waste treatment and energy recovery systems (Pandey et al., 2000; Thomas et al., 2013). Therefore, from an ecological standpoint, SSF holds a clear advantage as a low-impact, eco-efficient method for fermentation-based feed enhancement.

5 Advantages of solid-state fermentation over radiation and chemical methods

SSF offers several key advantages over radiation and chemical methods in the enhancement of aqua feed. Unlike radiation techniques, which are often energy-intensive and carry safety risks due to exposure, SSF utilizes natural microbial processes that are environmentally friendly and free from hazardous residues. In contrast to chemical fermentation, where synthetic additives or harsh reagents can leave residues potentially harmful to aquatic animals and ecosystems, SSF employs beneficial microorganisms to degrade complex substrates and improve nutrient profiles, offering a safer and more sustainable alternative. According to Karimi et al. (2021), SSF provides considerable economic and environmental benefits in the conversion of agro-industrial waste into valuable products like bioethanol and animal feed, outperforming chemical and irradiation methods that require costly materials and infrastructure. Moreover, the mild operational conditions of SSF help preserve thermolabile bioactive components such as antioxidants, vitamins, and enzymes, which are often diminished during chemical or radiation-based processing (Pandey et al., 2000). Despite growing evidence of SSF’s effectiveness in enhancing feed quality, direct comparative studies assessing its superiority over radiation and chemical methods remain limited and warrant further investigation.

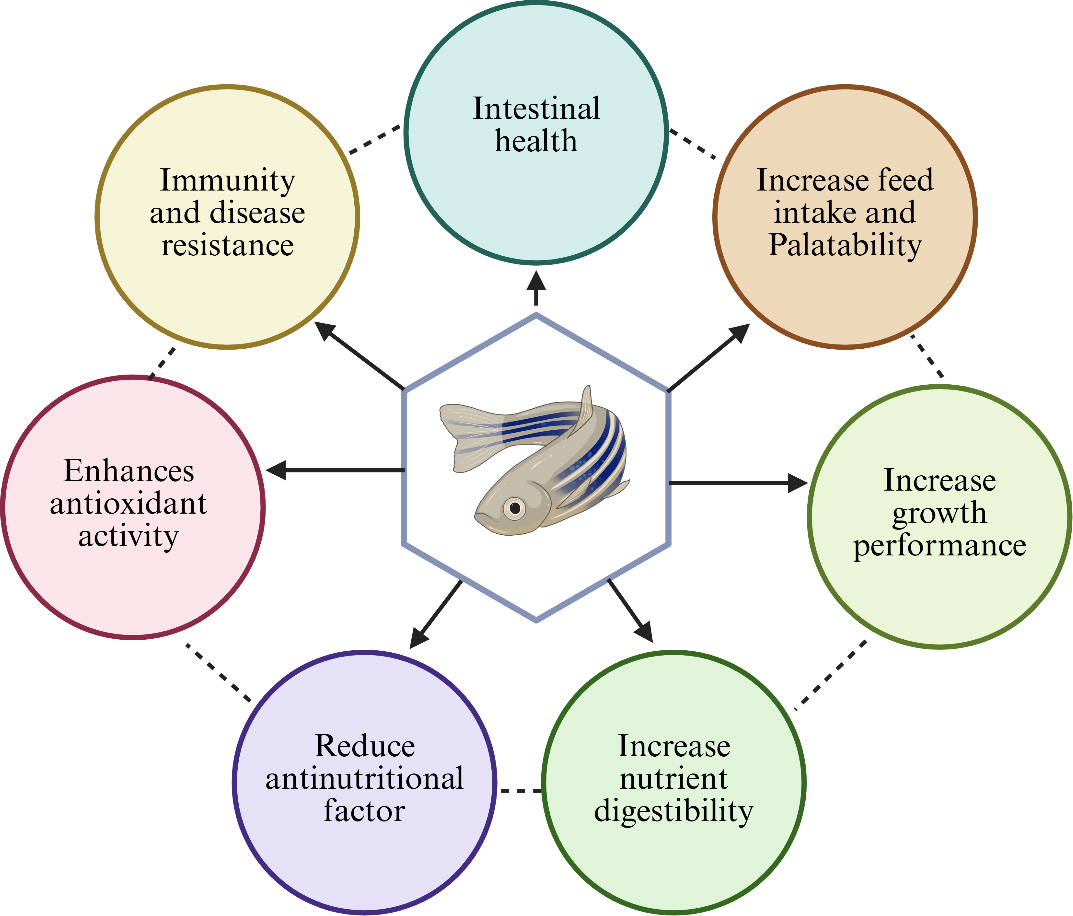

6 SSF technology in fish feed

As mentioned above, SSF enhances the nutritional quality of feed by increasing enzyme activity and improving the bioavailability of proteins and carbohydrates, while simultaneously reducing anti-nutritional factors such as phytic acid and tannins (Figure 4). This leads to better digestibility and nutrient absorption, resulting in improved growth performance, including higher weight gain and more efficient feed conversion. SSF also enriches feeds with beneficial microbial metabolites and immunostimulants like β-glucans, which boost the fish’s non-specific immune response and enhance disease resistance. Moreover, it promotes a healthier gut microbiota and increases antioxidant enzyme activity, helping fish withstand environmental and physiological stress (Siddik et al., 2024). Overall, SSF-based diets not only support better health and survival in fish but also offer a sustainable, cost-effective alternative to traditional feed ingredients. However, there are limited studies despite the multiple benefits of SSF in fish feeds. Hence, in the following section we will emphasize on exploring more about the fermented ingredients incorporated diets to provide deeper insight into the potential of SSF.

Figure 4

Advantages of incorporation of solid-state fermented ingredients in aquafeeds.

6.1 Feed intake and palatability

Feed intake is a critical parameter for assessing the effectiveness of fermented ingredients in aquaculture. A deficiency in essential amino acids, particularly common in alternative protein sources, such as plant-based proteins, has been identified as a potential cause of reduced feed intake (Gómez-Requeni et al., 2004; Kader and Koshio, 2012). Supplementing fermented soybean meal-based diets deficient in methionine (an essential amino acid) and taurine (an essential nutrient) has been shown to improve the amino acid balance and increase feed intake (Lee et al., 2016a). Overall, feed intake in fish is primarily governed by the energy content of the diet, as fish tend to eat until their energy requirements are fulfilled (Cho, 1992). Azarm and Lee (2014) found an inverse relationship between the daily feed intake and digestible energy content of formulated diets in juvenile black sea bream. Other studies have also reported decreased feed intake in response to diets with higher digestible energy levels (Van Vo et al., 2020a,b). Feed intake can be modulated by nutritional management practices, including feeding frequency and regimen, which are often species-specific in their effectiveness and response (Gilannejad et al., 2019; Sirakov et al., 2023). Furthermore, hybrid striped bass consuming diets formulated with either fermented or traditional soybean meal exhibited a significant decrease in feed consumption relative to fish fed a control diet containing 30% fishmeal (Rombenso et al., 2013). This improved response is likely linked to the removal of feed intake inhibitors, especially oligosaccharides, which are substantially reduced through fermentation (Rombenso et al., 2013).

A study on animal-derived proteins found that freshwater carp (Labeo bata) readily consumed aquafeeds containing fermented fish offal (Mondal et al., 2011).The increased feed intake suggests that fermentation enhances the palatability of the diet. In contrast, partially replacing fishmeal with a fermented mulberry leaf and fish offal blend in L. rohita diets has no significant effect on feed intake (Kaviraj et al., 2013). Espe et al. (1992) reported that, the Atlantic salmon also consumes high level of fish silage containing diets. In contrast, the European sea bass had lower affinity towards the feed intake of fish silage prepared by fermentation using apple pomase, molasses, formic acid and Lactobacillus plantarum (Davies et al., 2020). The nutritional quality of fish silage may be compromised by inadequate drying procedures, which can degrade key nutrients and reduces the palatability to fish. Additionally, different variables such as source and makeup of ingredients, changes occurring during processing, microorganisms used, and conditions under which fermentation takes place affect the palatability of feed and reduces the dietary intake of fish. Subsequently, the feed intake also gets affected by the feed ingredients quality, formulation, fish species and water quality. Although diets vary across studies on substrates, microbial communities, and moisture levels, the fermentation process consistently breaks down nutrients and food particles, enhancing their digestibility compared with unfermented alternatives. However, fermentation elevates free amino acid and small peptide content, improves feed taste, and promotes better nutrient uptake in fish.

6.2 Growth performance

In recent years, different research has provided newer insights in aquatic species receiving feeds formulated with fermented components compared with those given non-fermented alternatives (Meng et al., 2023). The observed increase in growth may stem from fermentation-induced enhancements in protein quality and amino acid balance coupled with the breakdown of anti-nutritional compounds, and carbohydrates (Olukomaiya et al., 2019). The probiotics used in the fermentation process synthesizes different metabolites which breakdown the antinutritional compounds into simple sugars and nutrients (Nagarajan et al., 2022). These metabolites support gut health and enhance digestive efficiency, and the quality of the ingredients chosen for the feed formulation. Additionally, the microbes synthesizes different enzymes such as amylase, cellulase and protease to catabolize the complex mixture into bioactive compounds (Tamang et al., 2016). Altering feed components through fermentation can improve nutrient absorption, and in turn, promote better growth in fish. However, studies on plant-based proteins have suggested that fermented variants can only be included in fish diets up to a certain limit, beyond which growth performance may decline.

Zhou et al. (2011) reported that substituting up to 20% of fishmeal protein with fermented soybean meal in juvenile black sea bream (Sparus macrocephalus) diets did not adversely affect the growth performance. However, substituting more than 20% of fishmeal protein with fermented soybean meal resulted in a decreased feed efficiency and hindered growth. Similarly, Lee et al. (2016a) observed that replacing up to 20% of fishmeal protein with fermented soybean meal in juvenile rockfish (Sebastes sp.) diets did not negatively affect growth performance. However, feeding black sea bream with 24% fermented cottonseed meal resulted in a significant decline in its growth performance, which is due to the reduction in the lysine bioavailability by the high level of fermented cottonseed meal in the diet. Similarly, the tilapia fed with 16% fermented cottonseed meal resulted in the reduction in its growth performance (Lim and Lee, 2011). Subsequently, a higher level of inclusion of fermented soybean up to 30-40% in the diet of black seabream often associated with poor growth performance (Zhou et al., 2011). Similar findings were reported in the study of Rinchard et al. (2003) in Onchorynchus mykiss and Oreochromis niloticus by El-Saidy and Saad (2011). Consequently, direct comparisons among these studies are challenging owing to diet formulations with fermented cotton seed meal.

A few studies reported that, the partial replacement of fish meal with unfermented ingredients resulted in improved growth performance without causing negative effects. For example, fishmeal replacement levels of up to 60% in sharp snout sea bream, 50% in red sea bream (ranging from 5% to 50%), and 50% in gilthead sea bream (ranging from 20% to 50%) have been shown to have no adverse effects on growth performance (Martínez-Llorens et al., 2007). Similarly, evidence suggests that raw soybean protein can serve as a viable alternative to fishmeal in rainbow trout diets, supporting both nutrient absorption and growth without adverse effects (Luo et al., 2006). Numerous studies have used formulated feeds containing synthetic amino acids, most notably lysine and methionine, which likely contributed to a more balanced nutrient composition and permitted a higher degree of fishmeal replacement (Chaklader et al., 2020; Lim and Lee, 2009). For instance, when taurine, along with essential amino acids such as lysine and methionine, is included, fermented soybean protein can substitute up to 40% of fish-derived protein in young black sea bream diets without negatively affecting growth outcomes (Azarm and Lee, 2014).

6.3 Nutrient digestibility and anti-nutritional factor reduction

The fish fed with fermented plant ingredients have shown better digestibility and improved growth performance compared to unfermented plant diets. This is owing to changes in the proximate composition of the diet after fermentation, which improved the nutritional value of plant ingredients. The European seabass fed with corn distellers grain fermented with Aspergillus carbonarius, A. ibericus, and A. uvarum improved the level of soluble proteins, reduced the fiber content and enhances the production of lignocellulolytic enzymes (Filipe et al., 2023). According to Ngandzali et al. (2011), incorporating soybean protein concentrate into the diet of black sea bream improves the efficiency of protein digestion. This improvement may be partly attributed to the addition of phytase to soybean meal, which helps mitigate the adverse effects of phytic acid, a known anti-nutritional compound (Ngandzali et al., 2011). Nonetheless, decreased nutrient digestibility has been reported at elevated inclusion rates of fermented plant ingredients in the diets of juvenile black sea bream (Sun et al., 2015) and rainbow trout (Luo et al., 2006). Additionally, the higher-level inclusion of fermented soybean meal up to 30% in the diet of black sea bream significantly affected the apparent digestibility of the nutritional value of the ingredients (Zhou et al., 2011). Similar results were obtained in the study of Nguyen et al. (2015), where the soybean-derived compounds (oligosaccharides and lectins), affected the digestibility of lipids and absorption by inhibiting the release of pancreatic lipase and bile acids which aid in digestion and the fermented cotton seed meal affected the digestibility of proteins and lipids in the black sea bream by lowering its apparent digestibility (Sun et al., 2015). Reduced protein digestibility in fermented cottonseed meal may be due to antinutritional factors, such as free gossypol and phytic acid, as well as an imbalanced amino acid profile (Zhou and Yue, 2012). Fish species differ in their ability to utilize plant proteins in their diets, which is influenced by their varying tolerances to anti-nutritional factors present in these ingredients (Francis et al., 2001).Moreover, smaller fish generally tolerate lower inclusion levels of plant proteins than larger fish, which tends to be less sensitive to the antinutritional factors found in plant ingredients (Martínez-Llorens et al., 2007). Lim et al. (2004) found that larger juvenile rockfish could replace up to 30% of the dietary fishmeal with dehulled soybean meal without negatively affecting growth performance. However, exceeding the maximum dietary inclusion level of soybean meal leads to decreased feed utilization efficiency, which can be attributed to factors such as imbalanced amino acid profiles, presence of antinutritional factors, poor protein digestibility, higher levels of indigestible carbohydrates, and reduced feed palatability (Francis et al., 2001). Improving fish performance can be achieved by minimizing anti-nutritional factors such as phytic acid and tannins, decreasing crude fiber levels, and enhancing the availability of low-molecular-weight peptides and fatty acids (Ramachandran and Ray, 2007).

6.4 Antioxidant activity

The fish experience oxidative stress due to internal metabolism and external mediators, hence the antioxidative enzymes plays a main role in maintaining the homeostasis (Ding et al., 2015). Antioxidant enzymes, such as catalase, glutathione peroxidase (GPx), and superoxide dismutase (SOD), are well-established biomarkers of antioxidant status and are commonly used to assess the impact of different dietary protein sources on fish health (Siddik et al., 2022). Dietary inclusion of 160 g/kg fermented soybean meal in juvenile black sea bream results in elevated liver glutathione peroxidase (GPx) and SOD activities (Azarm and Lee, 2014). Studies have shown that fermenting soybean meal with A. oryzae enhances the bioavailability of key antioxidant compounds, such as isoflavones and flavones, thereby improving the antioxidant activity in fish (Kim et al., 2010). Lee et al. (2016a) reported that high levels of fermented soybean meal in rockfish diets did not negatively affect feeding behavior or overall health, indicating that these inclusion levels may boost antioxidant enzyme activity and protect against oxidative stress induced by increased concentrations of antinutritional factors in plant-based proteins (Zheng et al., 2017). The dietary incorporation of dried fermented soybeans (meju) in olive flounder between 3 to 6% increased the SOD activity. At higher level, it enhances the nitro-blue tetrazolium (NBT) reduction activity and liver SOD activity. This is due to the higher bioavailability of bioactive polyphenol compounds in the diet (Kim et al., 2010). Aspergillus oryzae serves as the key microorganism in fermenting commercial meju, contributing to its enhanced antimutagenic and antioxidative effects (Lin et al., 2006).

However, the antioxidant properties of the diets is exhibited by the microbes or by the metabolites or the enzymes such as α-amylase, cellulose-degrading enzymes, phytase, and carboxypeptidase is remains unclear. Soybean meal, which is rich in isoflavones and flavones, is well known for its positive effects on antioxidant activity and immune function in organisms. The bioavailability of isoflavones and flavones is influenced by their chemical structure, vulnerability to microbial breakdown, and hydrophobicity (Birt et al., 2001). Soy isoflavones in their glycoside-conjugated form are not readily utilized by fish, as they require hydrolysis by enzymes, such as glucuronidase or sulfatase, to become bioavailable. Usually, the enzymes such as Bacillus subtilis and Aspergillus oryzae had the properties to convert the unsoluble isoflavone glycosides to readily soluble isoflavone aglycones. In addition, it enhances the flavonoids and polyphenol compounds in the meju which attributed to the elevation in the liver SOD activity of olive flounder (Li et al., 2019; Kim et al., 2010).

6.5 Immunity and disease resistance

The fermentation process usually involves the external addition of microbes to improve the nutritional value of the ingredients. Lactic acid bacteria (LAB), a common beneficial microbes used in the process, however feeding the fish with fermented feed ingredients formulated diets enhances the proliferation of LAB population in the gut, which determines the health of intestinal flora and also plays a key role in digestion and absorption. In addition, the LAB population enhance the immune function of the host (Zhang et al., 2020). However, the underlying mechanism in elevating the immune response is still remains unclear. It is believed that, LAB activates immune cells and promote cytokine production, both of which are essential for initiating and regulating the immune response. Lutful Kabir (2009) reported that lactic acid bacteria, particularly Lactobacillus species, enhance the production of Th2 cytokines such as interleukins IL-4 and IL-10, which support B cell development and immunoglobulin class switching, both critical for antibody generation. Fermented feed boosts systemic antibody production and mucosal immune responses in fishes (Dossou et al., 2018). In recent studies, metabolites produced during the fermentation process is involved in elevating the immunoglobulin (Ig) levels in fish (Tang et al., 2012; Zhuo et al., 2021). Additionally, the fermented plant based ingredients were known to strength the non-specific immunity, which is an essential defense mechanism against infections and diseases (Lee et al., 2016b, 2013). However, the results are inconsistent; while some studies on fermented soybean meal show no significant impact on innate immunity (Ding et al., 2015; Katya et al., 2014), others have reported that it stimulates or enhances nonspecific immune responses, thereby improving fish disease resistance (Siddik et al., 2019b; Abdul Kader et al., 2012). Lysozyme activity is widely regarded as a key indicator of nonspecific immunity and is an essential part of the immune system, playing a crucial role in defending the body against microbial invasion (Katya et al., 2014). Lysozyme, a key enzyme modulates the immune response in causing disease resistance against the pathogens (Katya et al., 2014). It is evident in the study of Siddik et al. (2019a), where the Asian seabass juvenile fed with fermented poultry by-product meal added with fish hydrolysate enhanced the lysozyme activity to defend against the Vibrio harveyi infection. These studies provided newer insights of the fermentation process associated with immune modulation in the fishes.

6.6 Gastrointestinal morphology

Proper intestinal development is vital, because intestinal function is strongly associated with fish growth performance and overall health (Siddik et al., 2019a, 2020). The intestinal mucosa is essential for nutrient digestion and absorption, and its structural morphology provides a reliable measure of fish health status (Siddik et al., 2020). Longer mucosal folds and taller villi are indicators of good health and enhanced nutrient absorption, whereas shorter folds and reduced villus height suggest impaired nutrient uptake and decreased fish growth performance (Siddik et al., 2018; Dimitroglou et al., 2011). A study by Siddik et al. (2019b) revealed the effect of changes in the intestinal morphology of the juvenile Asian seabass fed with fermented poultry by-product meal added with fish hydrolysate. It is noted that complete replacement of fish meal with fermented poultry by-product meal added with fish hydrolysate increased the fold length and villus height in the distal intestine. Similarly, the fold length and lamina propria height were remain unaffected with the dietary supplementation of corn fermented protein-soluble meals in the diet of Atlantic salmon (Hossain et al., 2023). These findings suggest that fermented diets may stimulate the proliferation of intestinal epithelial cells, expand absorptive surface area, and enhance the overall efficiency of nutrient utilization in fish.

The peptides produced during fermentation process also modulated the morphology of the intestine and also provided beneficial effects (Van Vo et al., 2020b; Tang et al., 2012). Studies on non-fish species have demonstrated that fermented diets enhance intestinal structure and promote better health (Xu et al., 2012), largely because of (1) the close relationship between gut microbiota and the digestive process, which facilitates improved nutrient absorption. (2) An increased population of LAB can suppress harmful pathogens that damage gut tissue and structure, (3) fermentation breaks down complex polysaccharides into smaller peptides, and (4) fermentation reduces ANFs, improving overall gut health. The dietary supplementation of fermented ingredients not only served as an alternative protein rich sources but also added an advantage over enhancing the performance and the intestine health, as it is serve as a vital organ in regulating the absorption of vital nutrients, growth and immune response against the harmful pathogens. Numerous studies have provided insights into the fermentation process associated bacteria as it contribute to greater tolerance of environmental factors in the fish gastrointestinal tract by supporting optimal oxygen levels as well as stabilizing pH and temperature (Dawood and Koshio, 2020). Such favorable conditions promote the proliferation of beneficial bacteria while inhibiting the growth of potential pathogens, thereby creating an environment that supports improved fish health (Dawood and Koshio, 2020).

Fermented diets can promote the proliferation of beneficial bacteria, leading to higher colonization of probiotic microbes on mucous membranes, which helps prevent pathogens from adhering to the intestinal lining. Furthermore, probiotic bacteria generate antimicrobial peptides, such as bacteriocins, which help suppress the growth of harmful pathogens in the intestine. Few studies specified that the intestinal microbes facilitate the movement of different solutes and compounds by regulating the proteins at the juncture of the epithelial cell membrane, which shielded from the effect of infectious microbes (Gareau et al., 2010). Additionally, probiotic bacteria can stimulate intestinal epithelial cells to release cytokines that regulate immune cells, including dendritic, T, and B cells, and enhance the capacity of lipopolysaccharides to trigger TNF-α gene transcription in animal models (Chiang et al., 2009).

6.7 Intestinal microflora

Gut microbiota is crucial for various physiological functions in fish, including supporting digestion, lowering intestinal pH, maintaining the integrity of the mucosal barrier, limiting enterobacterial colonization, interacting with the immune system, and enhancing disease resistance (Dimitroglou et al., 2011; Romero et al., 2014). Fermented diets may help to maintain a healthy gastrointestinal environment in fish because of their low pH, abundant lactobacilli, high lactic acid content, and reduced levels of enterobacteria (Catalán et al., 2018). The host fish intestine serves as the substrate for the proliferation of the beneficial microbes, which modulates the absorption of the dietary compounds (Ringø et al., 2006). These beneficial microbes produce metabolites and outcompetes the growth of pathogenic microbes in the intestine (Meng et al., 2023). Juvenile turbot fed Enterococcus faecium-fermented soybean meal showed a significant increase in beneficial bacteria, such as Lactobacillus and the anti-inflammatory Faecalibaculum, while the presence of Vibrio was reduced compared to those fed unfermented soybean meal (Li et al., 2020). This is mainly attributed to the properties fermented meals in creating acidic environment in the gut, which favors the growth of beneficial microbes and reduces the harmful pathogenic microbes especially Vibrio sp (Li et al., 2020). Additionally, the proliferation of Fusobacteriota and Cetobacterium in the gut of zebra fish were improved by feeding the fish with fermented rice bran and soybean meal using Bacillus subtilis (Wang et al., 2022). Similarly, the Asian seabass diets incorporated with the fermented poultry by-product meals improved the proliferation of LAB in the gut (Siddik et al., 2020). Hence, these studies have underscored the insights of fermentation process in improving the beneficial microbes’ population and also in modulating the immune response and enhancing the growth performance of the fishes.

7 Limitations of microbial applications in enhancing the nutrient profile of aquafeed ingredients

Although SSF has various benefits in enhancing the nutritional quality of feed by increasing enzyme activity and improving the bioavailability of proteins and carbohydrates, along with reducing anti-nutritional factors such as phytic acid and tannins, several studies have reported the nutrient loss during fermentation due to microbial utilization. However, the mechanistic role behind the nutrient utilization by various microbes during fermentation was limited. A concise overview of how microbial fermentation can negatively influences the nutrient profile of various feed ingredients is presented below:

7.1 Amino acid

While fermentation often improves protein quality, some microbial strains can decrease amino acid levels in aquafeed ingredients Lactobacillus spp. fermentation sometimes led to reduced levels of specific amino acids such as phenylalanine, lysine, and leucine, suggesting active microbial metabolism of these substrates during fermentation (Refstie et al., 2005). Similarly, studies using Bacillus spp. or A. oryzae have reported losses in sulfur-containing amino acids like cysteine and methionine under certain fermentation conditions (Song et al., 2008). Soybean meal fermented with S. cerevisiae showed significant reduction in crude protein (Sharawy et al., 2016). Additionally, Shi et al. (2022) found that SSF of Moringa oleifera leaf meal with mixed strains of A. Niger, C. utilis and B. subtilis led to major reductions in amino acids. Thus, the influence of microbial fermentation on the amino acid profile of plant proteins largely depends on factors such as substrate composition, type of microorganism, incubation temperature, pH, moisture level, and fermentation duration (Lim and Lee, 2011).

7.2 Lipid and fatty acids

Refstie et al. (2005) observed a decrease in the lipid content of soybean meal following fermentation with L. acidophilus. Also, Gao et al. (2020) reported that SSF of rapeseed cake with Pichia pastoris led to a reduction in saturated (SFAs) and unsaturated fatty acids (UFAs), along with an increase in polyunsaturated fatty acids (PUFAs), compared to the unfermented counterpart Similarly, Siddik et al. (2019a) reported that fermentation of poultry by-product meal with S. cerevisiae and L. casei resulted in an increase in PUFAs, accompanied by a reduction in SFAs and UFAs. Conversely, fermentation of fish silage with L. plantarum and Streptococcus thermophilus has been reported to reduce PUFA levels compared to raw poultry by-products (Özyurt et al., 2016). Also, it has been reported that Shewanella spp. fermentation of soybean meal increased crude protein but caused a significant decrease in crude lipid (Li et al., 2019), indicating possible metabolic use of other nutrients. The variation in raw materials, microbial strains, and fermentation conditions may account for these conflicting findings.

7.3 Crude fiber and carbohydrate

Soybean meal subjected to fermentation with S. cerevisiae exhibited a significant decrease in fiber content compared to its commercial counterpart (Sharawy et al., 2016). They suggested that the secretion of various fiber-degrading enzymes during fermentation may be responsible for the reduced fiber content in fermented soybean meal. In another study, fermentation of grass pea (Lathyrus sativus) seeds with Bacillus spp. resulted in a significant reduction in crude fiber content (Ramachandran et al., 2005). Similar reductions were also reported by Zhou et al. (2011) in C. utilis-fermented soybean meal and by Kim et al. (2016) in Bacillus-fermented soybean meal. Ahmed et al. (2014) and Hassaan et al. (2015) found that Canola meal upon fermentation with L. salivarius and sunflower meal with S. cerevisiae, B. subtilis revealed reduction in crude fiber content. In another study involving Moringa oleifera leaf flour upon fermentation (SSF) with A. niger, C. utilis and B. subtilis led to 70% reduction in crude fiber, 30% decrease in fat content, as well as marked reductions in total reducing sugars (12-2% decrease) indicating microbial consumption of energy substrates rather than enhancing feed value (Shih et al., 2021). Additionally, soybean meal fermented with L. plantarum led to reduction of non-digestible carbohydrates such as stachyose, raffinose and sucrose (Wang et al., 2016).

7.4 Minerals

Controlled SSF experiments have shown decline in mineral content with increasing fermentation time and under conditions that expose substrates to oxygen or heat. In fenugreek seed SSF with A. awamori, mineral concentrations (Fe, Zn, Ca, Cu, Na) and antioxidant markers rose during early fermentation but declined after extended incubation (after day 5) indicating a clear time dependence where prolonged fermentation can reverse initial mineral gains (Dhull et al., 2021). However, there is limited information available on the reduction of minerals in aquafeed ingredients during microbial fermentation, as most studies primarily focus on improving nutrient bioavailability and reducing antinutritional factors rather than assessing potential nutrient losses.

8 Challenges and limitations

Although SSF supports important bioprocessing activities, setting precise control of moisture, temperature, pH, and airflow is still very challenging. A lack of moisture in fermenters causes solid materials to resist heat flow, which may result in the accumulation of heat, inhibiting both microbial growth and other product reactions (Manan and Webb, 2017). An inappropriate climate may lead to substrate moisture reduction, disruption of microbial life, food mold, and allow nutrients to escape (Alp and Bulantekin, 2021). Because different parts of a solid substrate may have differing amounts of pH, nutrients, and oxygen, it is challenging to stay throughout the fermentation process (Raimbault, 1998). Because there are not enough real-time monitoring systems for solid-state fermentation, SSF requires more effort and is less reliable than SMF (Jin et al., 2024). Ensuring the safety of SSF-derived products is critical, especially when using agro-industrial by-products as substrates that may introduce pathogens or mycotoxins if not properly managed. The use of unsuitable microbes or poor growth conditions may lead to mycotoxin development by filamentous fungi, which are hazardous to both livestock and humans (Egbuta et al., 2017). The regular removal of ANFs is necessary to maintain unsafe amounts of residual compounds that harm nutrient absorption (Abu Hafsa et al., 2022). Because safety standards are not standardized, commercial growth in the industry is restrained, underlining the importance of rigorous post-fermentation studies (Sabahi et al., 2023). If good optimization is not used in fermentation, important nutrients, mainly vitamins and amino acids, might be lost from production (Chavan et al., 1989). Heat problems, longer fermentation periods, and high moisture in the grain can degrade critical nutrients, making finished animal feed less valuable (Mukherjee et al., 2015). Remaining stable through storage is a major issue, as continuing growth by microbes can lead to the gradual loss of nutrients and quality in the food over time (Leistner and Gould, 2002). Scaling up SSF from the laboratory to the industrial level is logistically complex (Mitchell et al., 2006). Designing a good bioreactor is necessary to provide proper heat and mass transfer, sufficient aeration, and complete mixing of the substrate while supporting the growth of microbes (Mitchell et al., 2000). SSF often requires the use of tray or rotary drum bioreactors, which are costly and challenging to operate (Singhania et al., 2018). As agro-industrial waste materials vary greatly, it is difficult to achieve equal product results and maintain consistency in the process (Hoque and Devi, 2025). Furthermore, it is difficult to monitor and control SSF because its substrate is naturally heterogeneous. Because advanced sensors are lacking, it is more difficult to control the behavior of the growing bacteria (Molin and Givskov, 1999). As fermentation progresses, it becomes more difficult to measure and control the pH, nutrients, and metabolite levels (Chai et al., 2022). Although not using sterile procedures may be cheaper, it makes it much easier for contamination to occur and for the process to vary, which affects how much is produced and how reproducible it is (Kumar, 1998).

A key problem with most static bed SSF systems is that there is not enough oxygen transferred unless air is forced. As the particle size of the system increases, the availability of oxygen at the surface becomes more important (Raghavarao et al., 2003). Therefore, effective heat management is a key issue. The energy produced during fermentation in solid substrates is difficult to remove, which may cause the substrate to dry out and slow the growth of microbes. Large systems have lower heat release efficiency through conduction and convection (Casciatori and Thoméo, 2018). Mixing in SSF systems can be complicated because the process tends to use a large amount of energy and may damage sensitive microbial structures. The presence of surfaces for internal heat transfer may lead to weaker mixing, and this tendency increases with increasing size, causing uneven temperature and nutrient zones (Zhang et al., 2018). It is also necessary to maintain the water activity at the proper level because high evaporation for refrigeration can drastically reduce water activity, preventing microbes from multiplying. Consequently, growers need precise control of aeration and humidity throughout the process (Krishna, 2005). Scaling up SSF does not always run smoothly. Only identical geometries fail to maintain balanced local conditions, because longer transfer paths become less effective. In addition, the lack of sufficient pressure drops, air access, and efficient ways to handle solids negatively affects large-scale SSSF reactors (Mitchell et al., 2006).

9 Future prospects and research directions

The exploration of novel substrates, including agro-industrial byproducts and food waste, is a promising direction for sustainable SSF. Rice bran, soybean meal, brewery spent grain, seaweed, fruit pomace, and vegetable residues supply a variety of nutrients that can be easily found (Šelo et al., 2021). Merging ingredients and finding efficient pretreatment processes (mechanical or enzymatic) can improve microbial activity and nutrition, which supports the aims of a circular economy (El-Bakry et al., 2015). Improvements in nutrient conversion and the reduction of substances harmful to nutrition during SSF heavily depend on the proper selection and engineering of microbes. Aspergillus, Trichoderma, and certain Bacillus and Lactobacillus species have been used over the years because of their strong enzyme-producing abilities (Raimbault, 1998). New findings have also brought attention to Streptomyces species that produce strong and durable enzymes, and Debaryomyces hansenii, which ferments high-salt agro-industrial materials (Martin et al., 2010; Jain et al., 2021). Furthermore, non-traditional eukaryotic organisms, such as protists and microalgae, are gaining attention for their potential in the synthesis of bioactive compounds and degradation of complex feedstock components (Burleson, 2012). Combining genetic engineering with synthetic biology allows scientists to develop custom microbial strains that enhance their enzymes, improve the use of different materials, and minimize the risk of toxin production (Boukid et al., 2023). Technically integrating these microorganisms with SSF results in higher process reliability, more secure products, and an environmentally conscious approach, mainly in the production of aquafeeds and various other bioproducts. In addition, examining probiotic traits and beneficial metabolites in SSF-based diets supports the production of good nutritional feeds.

Innovations in bioreactor design and process monitoring are essential for overcoming scalability and control challenges. The use of sensors for parameters such as pH, temperature, and moisture in automated systems allows precise control and a substantial decrease in manual tasks (Bellon-Maurel et al., 2003). New bioreactor methods, such as Reusable Immobilized Temporary Immersion (RITA), have increased mass transfer in cultures and help them to remain stable by putting less strain on microbes, leading to greater performance and consistency in production (Kaya et al., 2018). In addition, combining AI and machine learning in fermentation provides strong capabilities to improve the fermentation process. These methods can be used to predict the outcomes of SSF, ensure accuracy in repeated experiments, and increase the overall SSF dependability (Vinestock et al., 2024). Developing standardized protocols for safety and nutritional quality assessments is a research priority. The production of safe and high-quality SSF-derived products depends on the development of guidelines for selecting strains, pre-processing substrates, and testing after fermentation. Such guidelines are intended to confirm that pathogens, toxins, and residual antinutritional factors are not present in food (Alhomodi, 2022). With the help of advanced analytical tools, it is easier to observe how microbial communities perform and which metabolites they produce, providing essential information about the safety and function of the process (Singh and Shyu, 2024).