- 1ICAR-Central Research Institute for Dryland Agriculture (CRIDA), Hyderabad, India

- 2ICAR-National Institute of Abiotic Stress Management, Baramati, India

- 3Indian Farmers Fertiliser Cooperative Limited, IFFCO Sadan, New Delhi, India

Nitrogen (N) is a vital macronutrient for maize productivity, but significant losses under rainfed conditions limit its availability and yield potential. There is a need for energy-efficient and eco-friendly fertilizers along with improved agronomic practices to enhance nutrient use efficiency, crop productivity, and profitability. An experiment was conducted under semi-arid conditions in India in a single location to evaluate the economic and environmental performance of conventional fertilizers at varying nitrogen levels [0, 50, 75, and 100% recommended rate of nitrogen (RDN)] with and without nano-urea in rainfed maize. Application of 100% recommended NPK through conventional fertilizers along with nano-urea spray (N100PK + nano-urea) recorded significantly higher yield (3,026 kg ha-1) and economic returns (US $ 477 ha-1). Notably, the N75PK + nano-urea registered comparable yield over N100PK + nano-urea and N100PK, demonstrating that two foliar sprays of nano-urea could reduce nitrogen input by 25% without yield loss. Additionally, this approach reduced greenhouse gas (GHG) emissions by 25% and energy consumption by 14.9%, highlighting its potential for sustainable maize production. Though the results are encouraging it should be tested across crops and regions.

1 Introduction

Maize (Zea mays L.), popularly known as the “Queen of Cereals,” is the world’s third-largest cereal crop. Its versatility as food, fodder, feed, and fuel makes it highly valuable and demand-driven. Globally, India ranks fourth in maize cultivation area and sixth in production, contributing approximately 4% to the world’s total maize area and 2% to global maize production (Statista, 2024). In India, maize is primarily grown in two seasons, kharif (rainy) and rabi (winter). During 2023–24, maize was cultivated on 11.24 million ha, with 7.57 million ha (67.3%) in kharif (Directorate of Economics and Statistics, 2023-24). More than 70% of kharif maize in India is cultivated under rainfed conditions, making it highly vulnerable to various biotic and abiotic stresses (Anant et al., 2024). As a result, kharif maize yields remain relatively low, averaging 3,100 kg ha-1, compared to rabi maize, which yields an average of 4,163 kg ha-1 under more favorable growing conditions (Directorate of Economics and Statistics, 2022-23). The erratic and uneven distribution of monsoon rains across South and Southeast Asia often leads to intermittent drought, heat stress, or excessive moisture/waterlogging at different crop growth stages, significantly affecting crop productivity. Since plants absorb nutrients in their ionic form dissolved in soil solution, water scarcity directly limits nutrient uptake, further restricting growth and yield (CIMMYT, 2021). Moreover, declining soil organic matter and depleting essential nutrients pose additional constraints in rainfed maize systems (Aakash et al., 2022). Addressing these challenges through improved water and nutrient management strategies is essential for enhancing the resilience and productivity of rainfed maize.

Nitrogen (N) is one of the most essential nutrients for plant growth, and its demand is particularly high in maize, a nitrogen-intensive cereal crop (Mahdi et al., 2012). Nitrogen fertilization plays a crucial role in maize dry matter production by influencing leaf area development and photosynthetic efficiency (Shah et al., 2021a). Additionally, nitrogen is vital for crop development, yield and grain quality, as it is a key component in the synthesis of chlorophyll, enzymes, and other essential biochemical compounds required for plant metabolism and growth (Gheith et al., 2022). However, under rainfed conditions, unpredictable weather patterns especially irregular rainfall and temperature fluctuations lead to significant nitrogen losses through leaching, denitrification, volatilization, and surface runoff. These losses further limit nutrient availability and hinder crop productivity.

In India, the primary source of nitrogen fertilizer is urea. However, its use efficiency in most agricultural fields is only about 30%–40% (Duan et al., 2016), meaning a substantial portion of applied nitrogen remains unutilized and is lost to the environment. Excess urea is released through various pathways, contributing to environmental pollution. It volatilizes as nitrous oxide (N2O), a potent greenhouse gas, and is also emitted as ammonia (NH3), exacerbating global warming and air pollution (Liu et al., 2013). Additionally, nitrate leaching through the soil contaminates groundwater, adversely affecting drinking water quality (Dillard et al., 2015). During the fiscal year 2023–24, India’s urea consumption reached 34.21 million metric tons (FAI, 2024b). A major concern related to urea production and use is its environmental footprint. The greenhouse gas (GHG) emissions associated with both urea production and use are estimated at 5.15 kg CO2-equivalent per kg of urea (Parry et al., 2007), resulting in a massive total emission of approximately 176.2 million tonnes CO2-equivalent during 2023–24. Additionally, production of one tonne of urea requires 12.8 m3 of water and 173.7 kWh of electricity (Fiamelda and Suprihatin, 2020). Consequently, in 2023–24, the production of 34.21 million metric tons of urea resulted in the consumption of approximately 437.9 million cubic meters of water and 5.945 TW-hours (TWh) of electricity. The extensive use of water and electricity, along with massive GHG emissions from urea production, poses serious threats to environmental sustainability. While improving the efficiency of water and energy use in urea production is one possible mitigation strategy, a more impactful and sustainable approach may involve reducing global urea demand altogether by replacing it with energy-efficient and environmentally friendly novel fertilizers (Bartolucci et al., 2022). Scientists, policymakers, industrialists, and farmers are increasingly concerned about these challenges and are actively seeking alternative and innovative nutrient sources to enhance agricultural sustainability (Guardia et al., 2018). One of the promising solution is the use of nano fertilizers (NFs), which improve nutrient use efficiency through precise delivery while minimizing environmental impact due to lower application rates (Arpan and Ayan, 2024). Nanotechnology enables the production of materials significantly smaller than conventional fertilizers, typically below 100 nm, with greater surface area and reactivity (Rehmanullah et al., 2020). These unique properties improve nutrient uptake, minimize losses, and promote sustainable agricultural practices. Unlike conventional fertilizers, which generally exceed 1,000 nm in size, NFs offer superior solubility and dispersion, leading to more efficient nutrient absorption by plants (Gade et al., 2023). Furthermore, NFs help mitigate nutrient losses caused by runoff and leaching while enhancing nutrient retention in the soil. By reducing adsorption and fixation, they ensure improved nutrient availability for plant uptake, ultimately contributing to better crop productivity and environmental sustainability (Thavaseelan and Priyadarshana, 2021; Samuel et al., 2022).

Given these advantages, integrating foliar application of nano fertilizers with conventional soil-applied fertilizers is particularly crucial in rainfed areas, where nutrient availability is often limited by soil moisture fluctuations. In this context, the Indian Farmers Fertilizer Cooperative (IFFCO) has developed nano-urea as an alternative to commercial urea. Nano-urea particles are nanoscale in one dimension (at least 50% of the material), with a physical particle size of 20–50 nm and a hydrodynamic size of 20–80 nm (Kumar et al., 2021a). It contains 4% nitrogen (w/v), has shelf life of approximately 2 years with zeta potential of >30 (Kumar et al., 2021a). Nano-urea is formulated using urea treated with non-ionic surfactants and stabilized in polymer matrices, forming nano clusters of less than 100 nm. When sprayed on leaves, nano urea–liquid (nano nitrogen) fertilizer easily gets absorbed and also enters through stomata due to its nano size (<100 nm). It is distributed to other plant parts through phloem translocation and metabolically assimilated as per the plant’s needs. Nano urea contains nanoscale nitrogen particles (18–30 nm) which have more surface area (10,000 times over 1 mm urea prill) and number of particles (55,000 nano urea–liquid (Nano nitrogen) particles over 1 mm urea prill by mass volume). Nano urea with pore size (20 nm) can easily penetrate through cell wall and reach up to plasma membrane. Large size particles (20–50 nm) can penetrate through stomatal pores. These are also transported via phloem cells through plasmodesmata (40 nm diameter) to other plant parts. These can bind to carrier proteins through aquaporin, ion channels, and through endocytosis and metabolized inside the plant cell (Kumar et al., 2021a). Studies have demonstrated that nano-urea application significantly improves maize yields across various locations (Manikandan and Subramaniam, 2016). Initial findings also indicate its potential to reduce reliance on conventional nitrogen fertilizers while positively influencing soil health and reducing GHG emissions, thereby paving the way for its widespread adoption and lowering overall urea requirements (Upadhyay et al., 2023a; Upadhyay et al., 2023b). Moreover, in rainfed conditions, where conventional fertilizer application is often constrained by inadequate or excessive soil moisture, nano-urea may serve as an effective alternative, applied as a foliar spray at critical crop growth stages. Hence, this study was conducted to evaluate the impact of conventional and nano-urea on maize growth, nitrogen uptake, productivity, profitability, GHG emissions and energy use efficiency under rainfed conditions.

2 Materials and methods

2.1 Experimental site

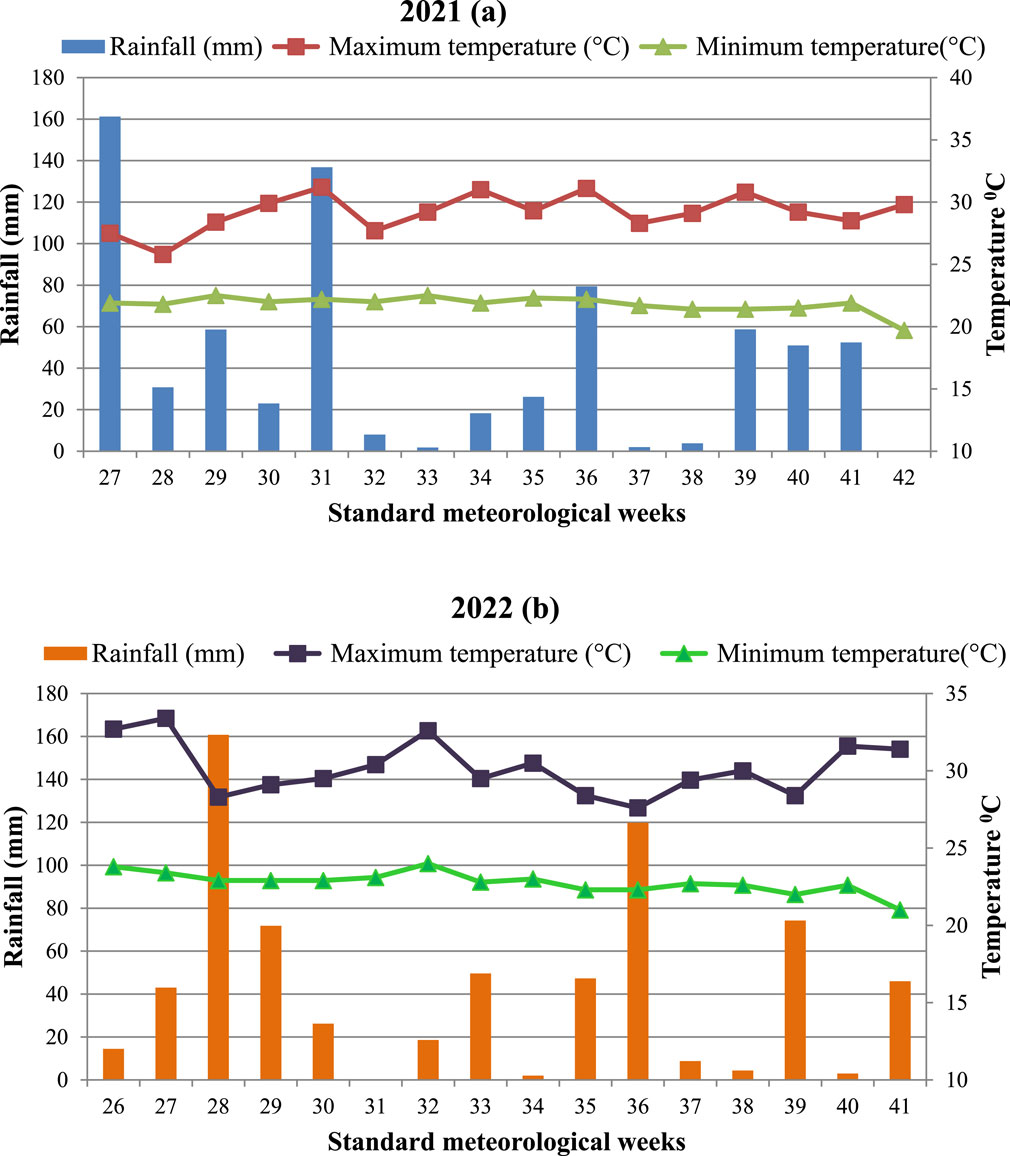

The experiment was conducted at Gungal Research Farm (GRF) of Central Research Institute of Dryland Agriculture, Hyderabad, Telangana, India during rainy season (June to September), 2021 and 2022. Hyderabad is situated at an altitude of 542 m above mean sea level (MSL). It is located at latitude 17.40° N and longitude of 78.47 E. This region has a unique combination of a tropical wet and dry climate that borders on a hot semi-arid climate (Köppen climate classification). The mean weekly minimum and maximum temperature during cropping period ranged from 19.7 to 22.9°C and 22.3–31.2°C during 2021. Whereas, the weekly mean minimum and maximum temperature varied between 21.0 and 24.0°C and 28.3–33.4°C during 2022.An amount of 753.5 and 691.3 mm was received in 45 and 36 rainy days during the crop growth period of 2021 and 2022 (Figures 1a, b). The soil of experimental site was sandy loam, slightly acidic (pH 6.51), EC was in normal range (0.05–0.07 dS m-1), low in organic carbon (0.43%) and available N (179.1 kg ha-1), high in available P (24.7 kg ha-1) and medium in available K (218.1 kg ha-1).

The textural class of the soil was characterized by international pipette method as outlined by Piper (1966). The soil pH was determined by potentiometric method (Piper, 1966), and electrical conductivity was determined using conductivity bridge (Jackson, 1973). Organic carbon content was estimated using the Walkley and Black wet-oxidation method (Jackson, 1973). Available nitrogen was determined following alkaline permanganate method (Subbaiah and Asija, 1956). The available phosphorus and potassium content of the soil was quantified following Bray’s method and Flame photometer, (Jackson, 1973).

2.2 Experimental design

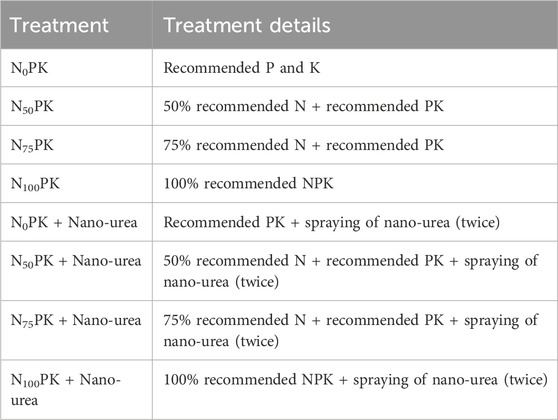

The experiment comprising of eight treatments was laid out in a randomized complete block design (RCBD) with three replications (Table 1). The size of each plot is 5 x 5 m2 To minimize this issue, data collection and sampling were done from the net plot area (4 m × 4 m = 16 m2), excluding one row from each side and 0.5 m from the ends of each plot. In all the treatments, entire dose phosphorus (P) and potassium (K) was applied as basal. Nitrogen (N) was applied in three equal splits viz. Basal, knee high stage and flowering stage of crop. The recommended dose of NPK was 90-45-45 kg N, P2O5 and K2O ha-1. The recommended sources for NPK were prilled urea, single superphosphate and muriate of potash respectively. Nano-urea was foliar applied @ 2 mL L-1 water twice at V6-V8 and V11-V12stages of crop as per the treatment, using a battery operated power sprayer. In other treatments, only water was sprayed. The technical description of IFFCO nano-urea is provided in Supplementary Table S1.

2.3 Crop management

The land was initially ploughed for primary tillage, followed by secondary tillage using a cultivator to ensure fine tilth. Finally, leveling with a rotavator was done for optimal crop establishment. Sowing was done with tractor-drawn seed drill at a spacing of 60 cm × 20 cm. Maize hybrid DHM 111 with duration of 90–95 days and yield potential of 6.25–7.5 tha-1 was selected in this study. It is known for its high yield potential, responsiveness to nutrients, tolerance to lodging, and stay-green characteristics. Thinning and gap filling was done at 10–15 days after sowing (DAS), as required. Atrazine 50% WP @ 2.5 kg ha-1 was sprayed at 2 DAS as pre-emergence spray followed by Tembotrione 42% SC @ 286 mL ha-1 at 15–20 DAS or four leaf stage as post emergence to control the growth of weeds. Intercultivation was done once at 35DAS to control late emerging weeds. For the control of fall army worm, Carbofuran 3Ggranules @ 7.5 kg ha-1 was placed in leaf whorls at 25–30 DAS. Spraying of Emamectin benzoate 5% SG @ 0.4 g L-1 was done as required during the crop growth period. Crop was harvested manually at physiological maturity stage and aboveground biomass was removed from the plots.

2.4 Observations on crop

Five plants from each net plot area were randomly selected and tagged for recording observations on plant growth characteristics such as plant height (cm). The mean of height of these five tagged plants were computed and used for statistical analysis. Leaf area index (LAI) was determined by using following formula (Watson, 1952).

Dry matter production was recorded by following the destructive sampling technique. Five plants per plot from the net plot in all the replications were uprooted to avoid the border row effect, roots were clipped off and kept in labelled brown paper bag and allowed for partial sun drying for 2–3 days. Later samples were oven dried at 65–70°C till a constant weight was obtained. Five cobs were randomly selected from each net plot area to evaluate length of the cob (cm), single cob weight (g) and number of grains cob-1. For 100 grain weight, all the cobs from each net plot were threshed and one hundred grains were counted from the yield of each net plot and then weighed. Cobs harvested from each net plot were sun-dried until the moisture content reached 14%, after which they were threshed using a maize thresher, and the grain yield was recorded. After removing the cobs, leftover plant material, including the husk, was sun dried and weighed for stover yield.

2.5 Nitrogen uptake

Nitrogen (N) content in plant samples was estimated by modified Kjeldhal method (Jackson, 1967) using Automatic Kelplus distillation unit after digesting the plant sample in conc. H2SO4 and H2O2 (Piper, 1966). N uptake by grain and stover of maize crop was calculated by using the following formula.

2.6 Available soil nitrogen

After the crop harvest in 2022, the soil samples were collected from all the treatments (0–15 cm depth) in polythene bags. The soil samples were dried under shade, ground with pestle and mortar and sieved through 2 mm sieve. The processed soil samples were analyzed for available soil N by using alkaline potassium permanganate method (Subbaiah and Asija, 1956).

2.7 Economic analysis

The economic analysis included studying the cost of cultivation, gross returns, net returns, and benefit: cost (B:C) ratio in different treatments. The cost of cultivation was calculated for all treatments with the prevailing market prices of inputs (Supplementary Table S3) and worked out by considering all the expenses incurred in the crop cultivation and summed up with the common costs of various operations and inputs. Gross returns were calculated by multiplying the grain and straw yield with the prevailing market prices of grain and straw, respectively. Net returns were calculated by subtracting the total cost of cultivation from the gross returns (US $ ha−1). BC ratio was calculated as the ratio of gross return to the cost of cultivation. Further, economic analysis was also carried out by considering the cost of non-subsidized urea (US $ 0.61kg−1) as against the subsidized cost (US $ 0.07 kg−1) (FAI, 2024a).

2.8 Energy use efficiency

All inputs (fertilizers, seeds, fuel, human, agro-chemicals, implements, machine, etc.) and outputs (main and by-product) were considered for energy budgeting. Physical unit of inputs were translated into energy units by multiplying with energy equivalents (Supplementary Table S2) for the estimation of energy inputs. Similarly, energy output was calculated by multiplying the amount of grain and stover yield by its corresponding energy equivalents. The net energy and energy use efficiency were calculated as described below (Hatirli et al., 2006).

2.9 GHG emissions

The emissions from maize crop under different N treatments come under direct GHG emissions. The indirect GHG emissions comprise farm management practices (sowing, tillage, irrigation, and harvesting) as well as the production and transportation of agricultural materials (seeds, fertilizer, and pesticides) (Huayun et al., 2023). In the present study, direct GHG emissions from different treatments were calculated using reference values: 5.15 kg CO2-eq per kg of product (including urea production and use) as reported by Parry et al. (2007), and 0.248 kg CO2-eq per liter of product, based on the steam and power consumption of a nano-urea plant, as reported by Upadhyay et al. (2023b).

2.10 Statistical analysis

The data was subjected to analysis of variance (ANOVA) of a RCBD and tested at 5% level of significance using SPSS. Post-hoc mean separation was done using Duncan’s Multiple Range Test.

3 Results

3.1 Crop growth

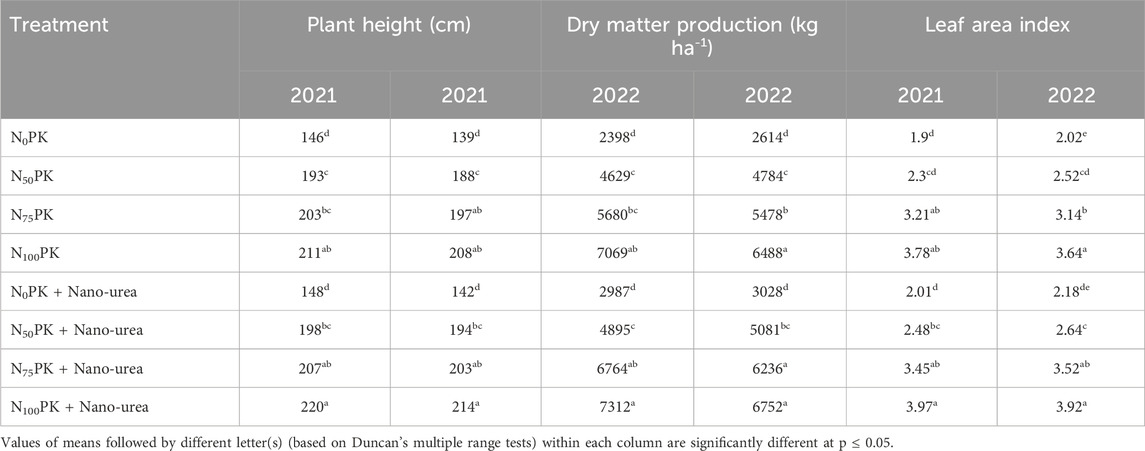

Foliаr аpplicаtion of nаno-fertilizers significantly influenced the growth parameters of maize (Table 2). Combined application of 100% N and recommended PK along with foliar spray of nano-urea (N100PK + Nano-urea) recorded higher plant height (220 and 214 cm) during the year 2021 and 2022, respectively. However, the treatments N100PK and N75PK + Nano-urea were found to be on par with N100PK + Nano-urea. Similarly, the highest dry matter production was recorded with N100PK + Nano-urea, which was statistically comparable to N100PK and N75PK + Nano-urea. A similar trend was observed for the leaf area index, where N100PK + Nano-urea recorded the highest values (3.45 and 3.52 during first and second years, respectively). However, these values were statistically on par with N100PK and N75PK + Nano-urea. The lowest plant height, dry matter production and leaf area index were observed in N0PK and N0PK + Nano-urea during both years of study.

3.2 Yield attributes and yield

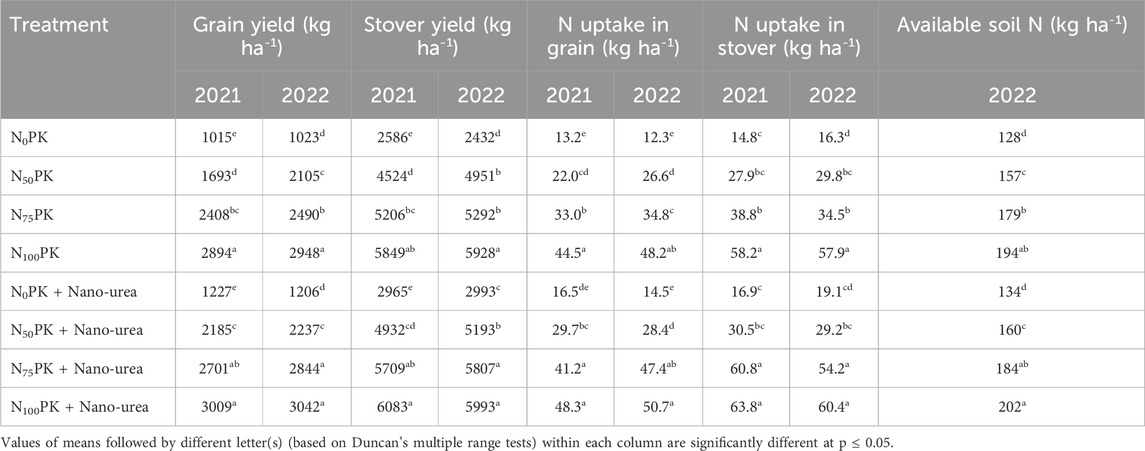

Application of conventional fertilizer with foliar spray of nano-urea had a significant impact on yield attributes and maize yield (Tables 3, 4). The highest cob length, number of grains per cob, cob weight, and 100-grain weight were recorded with application of 100% RDF along with foliar sprays of nano-urea (N100PK + Nano-urea). These values were statistically comparable to those recorded under N100PK and N75PK + Nano-urea. In contrast, the lowest yield attributes were observed in treatments without nitrogen application (N0PK and N0PK + Nano-urea), regardless of nano-urea spray, during both years of the study.

The grain yield ranged from 1,019 to 3,026 kg ha-1 across all treatments based on the mean data, as the crop was entirely grown under rainfed conditions, receiving 753.5 mm of rainfall in 2021 and 691.3 mm in 2022. During the crop growth period in both seasons, weekly rainfall varied significantly, reaching up to 162 mm in some meteorological standard weeks, while during other weeks, it was as low as 2 mm. Significantly higher grain and stover yields were recorded with N100PK + Nano-urea, with grain yields of 3,009 kg ha-1 in 2021 and 3,042 kg ha-1 in 2022, and stover yields of 6,083 kg ha-1 and 5,993 kg ha-1, respectively. The treatments N100PK and N75PK + Nano-urea produced statistically comparable grain and stover yields in both cropping seasons. The application of 100% RDF through soil, combined with foliar sprays of Nano-urea, resulted in a 66.4% increase in grain yield and a 58.5% increase in stover yield compared to the treatment without N fertilizer application. In contrast, treatments receiving only 50% of the recommended N, regardless of nano-urea application, resulted in significantly lower yields by 27% and 37% compared to N100PK + Nano-urea. The lowest grain and stover yields were observed in N0PK treatment during both the years.

3.3 Nitrogen uptake

Nitrogen uptake (kg ha-1) by grain and stover showеd significant rеsults with application of nano urea along with convеntional fеrtilizеrs (Table 4). Significantly higher nitrogen uptake by grain and stover were observed with application of 100% recommended NPK with foliar spray of Nano-urea (N100PK + Nano-urea) which were at par with N75PK + nano-urea and N100PK during both years. The lowest nitrogen uptake values by grain and stover were obtained in N0PK treatment during 2021 and 2022.

3.4 Post-harvest available soil nitrogen

Recommended NPK application along with nano-urea spray (N100PK + Nano-urea) registered significantly highest values of available soil N over other treatments in post-harvest soil samples compared to other treatments except N100PK and N75PK + nano-urea (Table 4). Treatments with 50% recommended N doses registered significantly lower available N compared with recommended NPK application. Treatment without soil and foliar N application (N0PK), registered 35% lower available N compared with N100PK + nano-urea.

3.5 Profitability

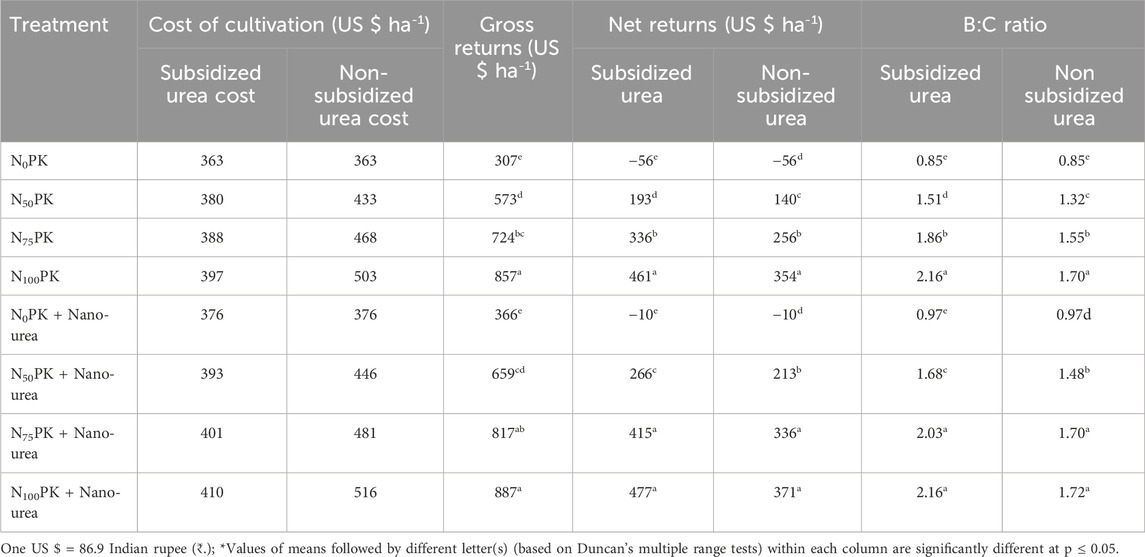

The cost of cultivation with subsidized urea was comparatively lower than unsubsidized urea while net returns and B:C were high (Table 5). The cost of cultivation of rainfed maize was highest under N100PK + nano-urea compared to other treatments (US $ 410 ha-1 with and US $ 516 ha-1 without subsidized urea). Higher gross returns, net returns and B:C ratio (with and without subsidized urea) were registered with N100PK + nano-urea treatment, and was on par with N75PK + nano-urea and N100PK. Significantly lower gross returns, net returns and B:C ratio were recorded with N0PK + nano-urea and N0PK.

3.6 Energetics

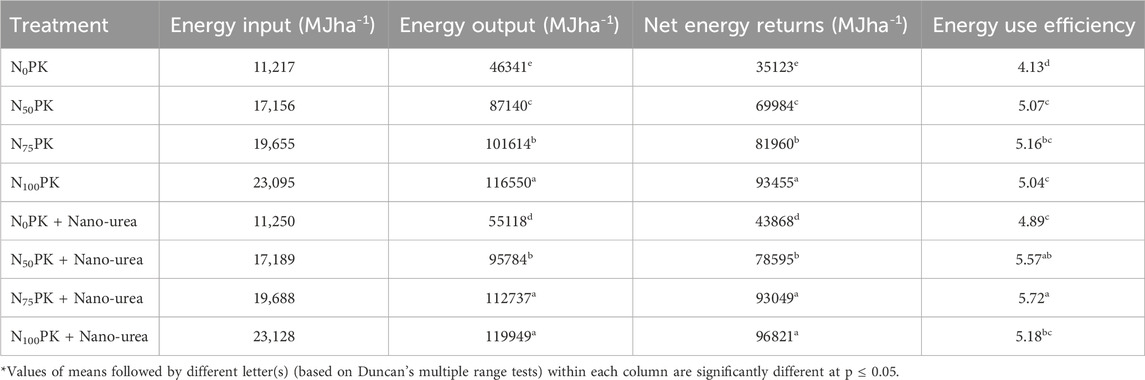

Based on the energy equivalents (Supplementary Table S3), energy input, energy output, net energy returns and energy use efficiency (Table 6) were calculated. Among all treatments, N100PK + Nano-urea recorded the highest energy input (23,128 MJ ha-1), energy output (119,949 MJ ha-1), and net energy returns (96,821 MJ ha-1). However, these values were statistically on par with those of N100PK and N75PK + Nano-urea. The highest energy use efficiency (5.72) was observed under N75PK + Nano-urea, which was significantly superior to all other treatments, indicating better conversion of input energy into output energy. Conversely, the treatment without any nitrogen application (N0PK) recorded the lowest energy output (46,341 MJ ha-1), net energy returns (35,123 MJ ha-1), and EUE (4.13).

3.7 Greenhouse gas emissions (GHG)

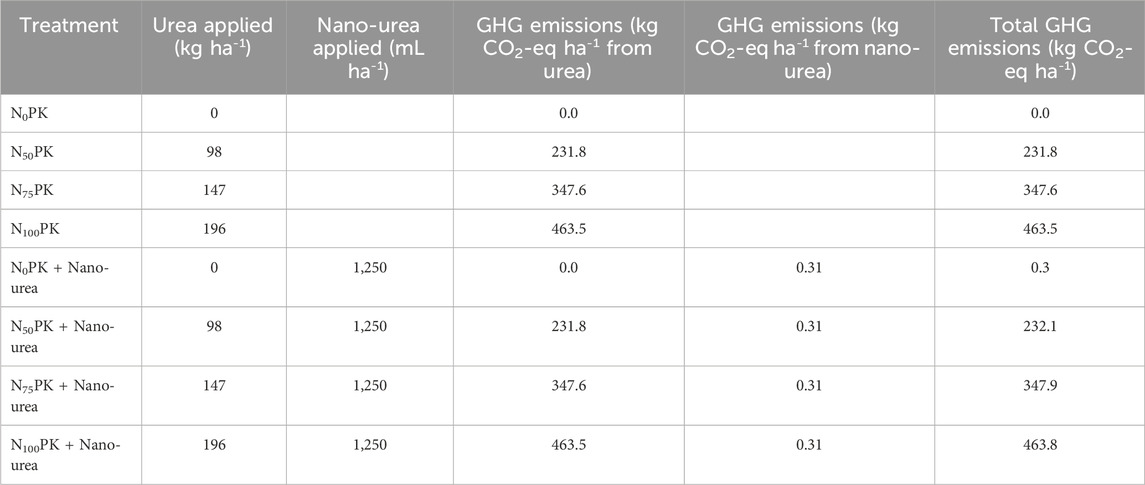

Among the treatments, the highest GHG emissions were recorded under N100PK (463.5 kg CO2-eq ha-1) and N100PK + Nano-urea (463.8 kg CO2-eq ha-1) than other treatments (Table 7). The additional emissions due to foliar application of nano-urea were minimal, at only 0.3 kg CO2-eq ha-1. However, a 25% reduction in the nitrogen dose combined with nano-urea application (N75PK + Nano-urea) resulted in lower GHG emissions (347.9 kg CO2-eq ha-1) compared to the N100PK treatment.

4 Discussion

4.1 Crop growth

A significant increase in plant height with the combined application of 100% recommended NPK supplemented by two foliar sprays of nano-urea (N100PK + Nano-urea) can be attributed to the enhanced penetration of nanoparticles through the stomata, leading to increased nitrogen availability, as reported by Abdel-Aziz et al. (2018). Additionally, foliar application of nano-urea, in combination with soil-applied nitrogen, improved nitrogen uptake (Table 2), promoting enhanced cell division, metabolism, and overall cell growth. These findings align with those of Jigyasa et al. (2023), who also reported increased plant height in maize with application of nano-urea alongside conventional fertilizers. Application of nano-fertilizers ensures a controlled and precise nutrient release, allowing crops to receive nutrients in optimal proportions for enhanced growth and development (DeRosa et al., 2010). Millan et al. (2008) highlighted that NH4+ ions retained within the internal channels of zeolite are gradually released, enabling progressive nutrient absorption by crops and ultimately enhancing dry matter production. Additionally, nano-fertilizers have been reported to exhibit a synergistic effect when combined with conventional fertilizers (Rathnayaka et al., 2018).

In the present study, the combined application of 100% recommended NPK through conventional fertilizers, supplemented by two foliar sprays of nano-urea (N100PK + Nano-urea), resulted in significantly higher dry matter accumulation. This can be attributed to improved nutrient availability, as nano-urea enhances nitrogen uptake efficiency through foliar absorption, complementing soil-applied nitrogen. Higher biomass production in kharif maize under the combined application of 75% RDF + nano-urea was also reported by Kundu and Chhabra (2024). The comparable performance of N100PK, N75PK + Nano-urea, and N100PK + Nano-urea treatments may be due to efficient nitrogen utilization facilitated by nano-urea, which enhanced foliar absorption and compensated for the reduced soil-applied nitrogen in N75PK + Nano-urea. In the N100PK treatment, nitrogen availability might have already been optimal, resulting in no significant advantage from additional nano-urea. These findings align with those of Zia et al., (2025), who reported higher dry matter production in finger millet with nano-urea application.

The higher leaf area index (LAI) under the N100PK, N75PK + Nano-urea, and N100PK + Nano-urea treatments may be attributed to the combined effect of optimum soil nitrogen and nano-urea, which enhances nitrogen availability and uptake, thereby promoting improved LAI. The increase in LAI with nano-urea application could be due to its nanoscale formulation, which ensures efficient foliar absorption, better nitrogen utilization, and enhanced leaf expansion and canopy development (Anushka et al., 2023). Similarly, Sharma et al. (2022) reported that nano-urea application improves LAI in pearl millet by facilitating better nutrient penetration and uptake efficiency.

4.2 Yield attributes and yield

A significаnt increаse in various yield attributes with the application of 100% RDF along with foliаr аpplicаtion of nаno-urea (N100PK + Nano-urea) might be due to fаster growth rаte аnd photosynthetic аssimilаtion rаte as a result of improved аvаilаbility аnd trаnslocаtion of nutrients. The availability of nutrients further encouraged а greаter pаrtitioning of photosynthаtes leading to better yield attributes (Zia et al., 2025). Similar improvement in yield attributes due to application of nano-fertilizer has been reported by Choudhary et al. (2019) in corn. Improved yield attributes by аpplying conventionаl fertilizer in combinаtion with nаno-fertilizer were also reported by Kundu and Chhabra (2024). Application of 100% recommended dose of N + PK along with two sprays of nano-urea recorded higher grain and straw yield which were statistically at par with N75PK + nano urea and N100PK during both the years. These findings indicate that up to 25% of the recommended nitrogen dose can be curtailed without any yield penalty when supplemented with nano-urea.

In the present study, nano-urea was applied as a foliar spray, enabling direct penetration through stomatal pores and subsequent transport via plasmodesmata. Due to its nanoscale size and unique surface properties, nano-urea efficiently infiltrates plant tissues, ensuring a controlled and sustained nitrogen release within the plant system (Kumar et al., 2021b). This smart-release mechanism provides a steady nitrogen supply, which supports dry matter accumulation, chlorophyll biosynthesis, plant growth, and ultimately, higher yields (Sun et al., 2020). Additionally, nano-urea exhibits a prolonged release period, whereas conventional urea, applied in soil, releases nutrients within 2–7 days (Seleiman et al., 2021). A major drawback of conventional urea is its high loss through leaching and volatilization, accounting for over 70% of applied nitrogen, leaving less than 20% available for plant uptake (Kahrl et al., 2010). In contrast, nano-urea releases nitrogen 12 times slower than conventional urea, ensuring sustained metabolic interactions, which contribute to increased grain yield (Saurabh et al., 2019). Our findings also align with Kumar et al. (2021a) and Kundu and Chhabra (2024), who reported that foliar application of nano-fertilizers at critical crop growth stages, either alone or in combination with conventional fertilizers, significantly improves crop yield. This underscores the potential of nano-urea as an efficient nitrogen source, enabling sustainable nutrient management while maintaining or even enhancing crop productivity, even at reduced conventional nitrogen application rates.

4.3 Nitrogen uptake

Application of 100% recommended NPK with foliar spray of nano-urea (N100PK + Nano-urea) resulted in significantly higher nitrogen uptake by grain and stover over other treatments, except N75PK + Nano-urea and N100PK, which correlates with the statistically similar yield levels observed under these treatments. This indicates that nano-urea foliar application effectively triggers nutrient uptake mechanisms, leading to efficient nitrogen utilization. The higher nitrogen uptake observed with increased nitrogen levels can be attributed to improved nutrient availability in the root zone, leading to enhanced absorption and higher dry matter production, as reported by Prakasha et al. (2017). The positive effect of nano-fertilizer use on nutrient uptake could be due to its higher surface area compared to conventional fertilizers, which ensures controlled release and reduced nutrient fixation (Rani et al., 2019). Foliar application of nano-urea enables rapid nutrient absorption due to its nanoparticle size (<50 nm), which is smaller than the pore size of leaves, facilitating efficient penetration into plant tissues and enhancing nutrient uptake (Rathnayaka et al., 2018). Similar findings were reported by Upadhyay et al. (2023b) in maize, wheat, and pearl millet, where the combined application of conventional urea and controlled-release nano-urea improved nutrient uptake.

4.4 Available soil nitrogen

The available nitrogen (N) in post-harvest soil samples from the N100PK + Nano-urea, N100PK, and N75PK + nano-urea treatments remained statistically similar. This suggests that up to 25% of the recommended nitrogen dose can be curtailed through nano-urea application in rainfed maize. The comparable available N levels between the N100PK and N75PK + nano-urea treatments indicate that nutrient mining did not occur during either cropping season, likely due to the supplementary nitrogen provided by nano-urea. However, the highest soil available N levels were observed with the recommended nitrogen application combined with nano-urea spray. In contrast, reducing nitrogen application to 50% of the recommended dose resulted in a depletion of soil available N, regardless of nano-urea supplementation. Furthermore, treatments without any nitrogen application exhibited significantly lower available N across seasons, even with nano-urea spray. Therefore, applying at least 75% of the recommended nitrogen dose through conventional urea with nano-urea spray is essential to prevent nitrogen mining. Similar findings were also reported by Upadhyay et al. (2023a).

4.5 Profitability

The cost of cultivation using unsubsidized urea was significantly higher compared to subsidized urea, resulting in lower net returns and benefit-cost (B:C) ratios (Table 6). This is attributed to the high market price of unsubsidized urea (US $27.2 per 45 kg bag) compared to the subsidized price (US $3.06 per 45 kg bag) provided by the Government of India (GoI). The incorporation of nano-urea in the N75PK + nano-urea treatment incurred an additional cost of US $4 per hectare over the N100PK treatment under subsidized conditions. This cost increase was primarily due to the substantial subsidy offered on conventional urea. However, when evaluated based on the price of unsubsidized urea, the use of N75PK along with two foliar sprays of nano-urea led to a cost saving of US $21.9 per hectare. This highlights the economic advantage of nano-urea when traditional subsidies are excluded.

Government provides subsidies on fertilizers, to make them more accessible and affordable for farmers. Historically, these subsidies have promoted fertilizer use, contributing to significant yield increases. However, recent studies (Kishore et al., 2021) indicate that their impact on agricultural growth and poverty reduction has diminished over time, while the fiscal burden continues to grow. Furthermore, fertilizer subsidies have led to the overuse of urea and the under application of phosphorus (P), potassium (K), micronutrients, and organic amendments, especially in India and Nepal. This imbalance contributes to soil degradation, groundwater contamination, and greenhouse gas emissions. Moreover, these subsidies can discourage innovation in fertilizer development and crowd out investments in agricultural research and development (Gulati and Banerjee, 2015).

According to Fertilizer Statistics 2023–24, the total national requirement of urea was 38.45 million tons, with 31.41 million tons produced domestically and 7.04 million tons imported, incurring an import expenditure of USD 2.6 billion. This underscores the need to enhance urea-use efficiency or adopt novel alternatives such as nano-fertilizers to alleviate the growing economic burden on both the government and farmers. Economically, the gross returns, net returns, and B:C ratio under N100PK + nano-urea were higher than most other treatments, with the exception of N75PK + nano-urea and N100PK alone. This demonstrates that two foliar sprays of nano-urea can effectively reduce the nitrogen requirement by up to 25% without compromising profitability. Based on this potential, approximately 9.6 million tons of urea or 25% of India’s total urea requirement could be replaced with nano-urea, potentially saving up to USD 3.4 billion in subsidized costs. The enhanced yields in nano-urea treatments were due to improved biomass accumulation and nutrient translocation to reproductive parts, leading to higher monetary returns and improved B:C ratios. Overall, the combined use of nano-fertilizers with conventional fertilizers emerged as a cost-effective and profitable nutrient management strategy. These findings are in agreement with studies by Upadhyay et al. (2023a), Tripathi and Venkatesh (2025), and Zia et al. (2025), which also reported maximum economic returns and higher benefit–cost ratios with foliar application of nano-fertilizers.

4.6 Energetics

Energy input was highest for N100PK + nano-urea treatment followed by N100PK and the difference between these two treatments was only 43 MJ ha-1 due to addition of nano-urea. This suggests that nano-urea production requires relatively low energy, making it an energy-efficient technology. The energy equivalent for producing 1 L of nano-urea is 4.26 MJ (Upadhyay et al., 2023b), whereas the energy requirement for producing 1 kg of conventional nitrogen is 60.6 MJ (Devasenapathy et al., 2009). Thus, reducing 25% of the nitrogen requirement in maize through nano-urea application represents a highly efficient energy-saving strategy. Energy output and net energy returns were higher under N100PK + nano-urea and were statistically at par with N100PK and N75PK + nano-urea which was mainly due to statistically similar yields. While, higher energy use efficiency was recorded under N75PK + nano urea over rest of the treatments which was due to the reduction of 25% dose of N and statistically similar yields with that of N100PK + nano-urea and N100PK treatments. Based on these findings, N75PK + nano-urea emerge as the most energy-efficient alternative compared to N100PK-based treatments. Upadhyay et al. (2023b), also reported higher energy use efficiency under N75PK + nano-urea in maize, wheat, and pearl millet.

4.7 Greenhouse gas emissions (GHG)

Though the results are based on secondary assumptions, the results provided a deep insight on the understating of GHG emissions in each treatment. The tradeoff between yield and reduction in GHG emissions was observed with N75PK + Nano-urea treatment, primarily due to 25% reduction in nitrogen application compared to N100PK treatments. This reduction in nitrogen input contributed to lower GHG emissions, while maintaining comparable yield levels. Since urea production emits significantly more GHG kg-1 compared to nano-urea, replacing a portion of conventional urea with nano-urea effectively lowered overall emissions, demonstrating its potential role in mitigating the environmental impact of nitrogen fertilization (Upadhyay et al., 2023b; Tripathi and Venkatesh, 2025).

5 Conclusion

We conclude, based on a 2-year study that integrating nano-urea with conventional fertilizers significantly enhances growth, yield, nutrient uptake and economic returns while reducing GHG emissions in rainfed maize. Application of 75% RDN + recommended PK along with two foliar sprays of nano-urea (1,250 mL ha-1) resulted in grain yield comparable to the full recommended nitrogen dose with or without nano-urea spray (N100PK + Nano-urea and N100PK). Furthermore, application of 75% recommended N with foliar spray of nano-urea gave statistically similar net returns and B:C ratio, indicating that nitrogen application can be reduced by 25% without compromising on yield or profitability. Additionally, energy use efficiency was greater for N75PK + nano-urea treatment compared to other treatments. Notably, the N75PK + nano-urea treatment recorded lower GHG emissions than N100PK treatment, primarily due to the 25% reduction in conventional nitrogen fertilizer use. The integrated use of conventional and nano-fertilizers thus offers a promising strategy to optimize productivity, improve resource-use efficiency, and promote environmental sustainability. Adoption of this approach could reduce the national subsidy burden on the Government of India, lower GHG emissions from urea production and use, and decrease water and electricity consumption in fertilizer manufacturing. However, long-term studies are needed to assess the impacts of nano-fertilizer use on soil health, crop quality, and sustainability, and the results should be validated across different crops and agro-ecological zones before being translated into policy.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding authors.

Author contributions

KG: Investigation, Writing – review and editing, Visualization, Formal Analysis. VK: Investigation, Writing – original draft. VS: Writing – review and editing, Visualization. AS: Writing – review and editing. KR: Visualization, Writing – review and editing. SK: Writing – review and editing, Investigation. BB: Writing – review and editing. BR: Formal Analysis, Writing – original draft. NL: Writing – original draft. PC: Writing – original draft. BS: Writing – original draft. MK: Writing – review and editing, Funding acquisition, Resources. TS: Resources, Writing – review and editing, Funding acquisition.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was funded by Indian Farmers Fertilizer Cooperative Limited (IFFCO), New Delhi, India. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article, or the decision to submit it for publication.

Conflict of interest

Authors MK and TS were employed by Indian Farmers Fertiliser Cooperative Limited, IFFCO Sadan.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fnano.2025.1617500/full#supplementary-material

References

Aakash, K., Thakur, N. S., Singh, M. K., Bhayal, L., Meena, K., Choudhary, S. K., et al. (2022). Sustainability in rainfed maize (Zea mays L.) production using choice of corn variety and nitrogen scheduling. Sustain 14, 3116. doi:10.3390/su14053116

Abdel-Aziz, H. M., Hasaneen, M. N. A., and Omar, A. M. (2018). Foliar application of nano chitosan NPK fertilizer improves the yield of wheat plants grown on two different soils. Egypt. J. Exp. Biol. (Bot.). 14, 63–72. doi:10.5455/egyjebb.20180106032701

Anant, K., Rashmee, Y., Ankur, J., and Vikas, B. (2024). Varietal evaluation of maize crop for better production in district Auraiya, Uttar Pradesh. Int. J. Agric. Ext. Soc. Dev. 7, 30–32. doi:10.33545/26180723.2024.v7.i4Sa.521

Anushka, A. S., Senthil Kumar, N., Sritharan, S., Radhamani, S., and Maragatham, S. (2023). Studies on the effect of nano-urea o ngrowth, yield and nutrient use efficiency in transplanted rice. Int. J. Environ. Clim. 13, 1547–1554. doi:10.9734/ijecc/2023/v13i102810

Arpan, D., and Ayan, S. (2024). Molecular mechanisms of plant productivity enhancement by nano fertilizers for sustainable agriculture. Plant Mol. Biol. 114, 128. doi:10.1007/s11103-024-01527-9

Bartolucci, B., Scognamiglio, V., Antonacci, A., and Fraceto, L. F. (2022). What makes nanotechnologies applied to agriculture green? Nano Today 43, 101389–5. doi:10.1016/j.nantod.2022.101389

Choudhary, R. C., Kumaraswamy, R. V., Kumari, S., Sharma, S. S., Ajay, P., Ramesh, R., et al. (2019). Zinc encapsulated chitosan nanoparticle to promote maize crop yield. Int. J. Biol. Macromol. 127, 126–135. doi:10.1016/j.ijbiomac.2018.12.274

CIMMYT (2021). Improving rainfed (kharif) maize productivity. Available online at: https://www.cimmyt.org/projects/improving-rainfed-kharif-maize-productivity/.

DeRosa, M. C., Monreal, C., Schnitzer, M., Walsh, R., and Sultan, Y. (2010). Nanotechnology in fertilizers. Nat. Nanotechnol. 5, 91. doi:10.1038/nnano.2010.2

Devasenapathy, P., Senthilkumar, G., and Shanmugam, P. M. (2009). Energy management in crop production. Indian. J. Agron. 54, 80–90. doi:10.59797/ija.v54i1.4771

Dillard, S. L., Wood, C. W., Wood, B. H., Feng, Y., Owsley, W. F., and Muntifering, R. B. (2015). Effects of nitrogen fertilization on soil nutrient concentration and phosphatase activity and forage nutrient uptake from a grazed pasture system. J. Environ. Manag. 154, 208–215. doi:10.1016/j.jenvman.2015.02.035

Directorate of Economics and Statistics (2022). Agricultural statistics at a glance. Department of Agriculture and Farmers Welfare, Ministry of Agriculture and Farmers Welfare, New Delhi: Government of India.

Directorate of Economics and Statistics (2023). Agriculture statistics at a glance. Government of India, Ministry of Agriculture.

Duan, Y., Xu, M., Gao, S., Liu, H., Huang, S., and Wang, B. (2016). Long-term incorporation of manure with chemical fertilizers reduced total nitrogen loss in rain-fed cropping systems. Sci. Rep. 6, 33611. doi:10.1038/srep33611

FAI. (2024a). Fertilizer statistics 2023-24. 69th Edition, Newe Delhi, India: The Fertilizer Association of India.

Fiamelda, L., Suprihatin, P., and Purwoko, P. (2020). Analysis of water and electricity consumption of urea fertilizer industry: case study PT. X. Earth Environ. Sci. 472, 012034. doi:10.1088/1755-1315/472/1/012034

Gade, A., Ingle, P., Nimbalkar, U., Mahendra, R., Rajesh, R., Mahesh, V., et al. (2023). Nanofertilizers: the next generation of agrochemicals for long-term impact on sustainability in farming systems. Agrochem 2, 257–278. doi:10.3390/agrochemicals2020017

Gheith, E. M. S., Ola, Z., Sobhi, F. L., Hayssam, M., Siddiqui, M. H., Ghareeb, R. Y., et al. (2022). Maize (Zea mays L.) productivity and nitrogen use efficiency in response to nitrogen application levels and time. Front. Plant Sci. 13, 941343. doi:10.3389/fpls.2022.941343

Guardia, G., Sanz-Cobena, A., Sanchez-Martin, L., Fuertes-Mendizabal, T., Gonzalez-MuruabJose, C. A., lvarez, J. M., et al. (2018). Urea-based fertilization strategies to reduce yield-scaled N oxides and enhance bread making quality in a rainfed Mediterranean wheat crop. Agric. Ecosyst. Environ. 265, 421–431. doi:10.1016/j.agee.2018.06.033

Gulati, A., and Banerjee, P. (2015). Rationalising fertiliser subsidy in India: key Issues and policy options. Available online at: https://www.think-asia.org/bitstream/handle/11540/11017/Working_Paper_307.pdf?sequence=1.

Hatirli, S. A., Ozkan, B., and Fert, C. (2006). Energy inputs and crop yield relationship in greenhouse tomato production. Renew. Energy. 31, 427–438. doi:10.1016/j.renene.2005.04.007

Huayun, H., Qi, Hu., Feifei, P., and Xuebiao, P. (2023). Evaluating nitrogen management practices for greenhouse gas emission reduction in a maize farmland in the North China plain: adapting to climate change. Agron. MDPI. 12, 3749. doi:10.3390/plants12213749

Jackson, M. L. (1967). Soil chemical analysis. New Delhi: Prentice Hall of India Pvt. Ltd., 115–150.

Jackson, M. L. (1973). Soil chemical analysis. New Delhi: Prentice Hall of India Pvt. Ltd., 151–153.

Jigyasa, N., Victor, D., Renuka, B., and Meena, R. K. (2023). Response of zinc and nano urea on growth and yield of maize (Zea mays L.). Int. J. Environ. Clim. 13, 1046–1052. doi:10.9734/ijecc/2023/v13i92326

Kahrl, F., Li, Y., Su, Y., Tennigkeit, T., Wilkes, A., and Xu, J. (2010). Greenhouse gas emissions from nitrogen fertilizer use in China. Environ. Sci. Policy. 138, 688–694. doi:10.1016/j.envsci.2010.07.006

Kishore, A., Muzna, A., Timothy, J., and Krupnik, K. (2021). Development of balanced nutrient management innovations in South Asia: perspectives from Bangladesh, India, Nepal, and Sri Lanka. Glob. food Secur. 28, 100464. doi:10.1016/j.gfs.2020.100464

Kumar, Y., Singh, T., Raliya, R., and Tiwari, K. N. (2021a). Nano fertilizers for sustainable crop production, higher nutrient use efficiency and enhanced profitability. Indian J. Fert. 17, 1206–1214.

Kumar, Y., Tiwari, K. N., Singh, T., and Raliya, R. (2021b). Nanofertilizers and their role in sustainable agriculture. Ann. plant soil Res. 23, 238–255. doi:10.47815/apsr.2021.10067

Kundu, A. K., and Chhabra, V. (2024). Effect of application of nano-urea on maize (C-1415 Variety) growth and yield under Punjab conditions. Eco. Env.& Cons. 29, 1604–1607. doi:10.53550/EEC.2023.v29i04.023

Liu, X., Zhang, Y., Han, W., Tang, A., Shen, J., Cui, Z., et al. (2013). Enhanced nitrogen deposition over China. Nature 494, 459–462. doi:10.1038/nature11917

Mahdi, S. S., Hasan, B., and Singh, L. (2012). Influence of seed rate, nitrogen and zinc on fodder maize (Zea mays) in temperate conditions of western Himalayas. Indian J. Agron. 57, 85–88. doi:10.59797/ija.v57i1.4604

Manikandan, A., and Subramaniam, K. S. (2016). Evaluation of zeolite-based nitrogen Nano-fertilizers on maize growth, yield and quality on inceptisol and alfisols. Int. J. Plant Soil Sci. 9, 1–9. doi:10.9734/IJPSS/2016/22103

Millan, G., Agosto, F., Vazquez, M., Botto, L., Lombardi, L., and Juan, L. (2008). Uso de clinoptilolita como un vehículo de fertilizantes nitrogenados en un suelo de la región Pampeana de Argentina. Cienc. Investig. Agrar. 35, 293–302. doi:10.4067/s0718-16202008000300007

Parry, M. L., Canziani, O. F., Palutik, J. P., Linden vander, P. J., and Hanson, C. E. (2007). Impacts, adaptation and vulnerability, climate change, contribution of working group II to the fourth assessment report of the intergovernmental panel on climate change, IPCC. Cambridge: Cambridge University Press, 976.

Prakasha, G., Kalyana Murthy, K. N., RohaniMeti, N., Jagadish, J., and Prathima, A. S. (2017). Nutrient uptake and economics of finger millet (Eleusinecoracana(L.)Gaertn.) under guni method of planting in eastern dry zone of Karnataka. Int. J. Pure App. Biosci. 5, 144–151. doi:10.18782/2320-7051.5472

Rani, B., Zalawadia, N. M., Buha, D., and Rushang, K. (2019). Effect of different levels of chemical and nano urea nitrogenous fertilizers on content and uptake of N, P, K by sorghum crop Cv. Gundari. J. Pharmacogn. Phytochem. 8, 454–458.

Rathnayaka, R., Iqbal, M. N. N., and Rifnas, L. M. (2018). Influence of urea and nano-urea nitrogen fertilizers on the growth and yield of rice (Oryza sativa L.). Int. J. Res. Publ. Rev. 5, 1–8. doi:10.13140/RG.2.2.14315.59684

Rehmanullah, M. Z., Inayat, N., and Majeed, A. (2020). Application of nanoparticles in agriculture as fertilizers and pesticides: challenges and opportunities. Front. Stress Manag. Dur. Agri. doi:10.1007/978-981-15-1322-0_17

Samuel, M. S., Ravikumar, M., John, J., Selvarajan, E., Patel, H., Chander, P. S., et al. (2022). A review on green synthesis of nanoparticles and their diverse biomedical and environmental applications. Catal 12, 459. doi:10.3390/catal12050459

Saurabh, K., Manjaiah, K. M., Datta, S. C., Thekkumpurath, A. S., and Kumar, R. (2019). Nanoclay polymer composites loaded with urea and nitrification inhibitors for controlling nitrification in soil. Arch. Agron. Soil Sci. 65, 478–491. doi:10.1080/03650340.2018.1507023

Seleiman, M. F., Suhaibani, N., Ali, N., Akmal, M., Alotaibi, M., Refay, Y., et al. (2021). Drought stress impacts on plants and different approaches to alleviate its adverse effects. Plants 10, 1–25. doi:10.3390/plants10020259

Shah, A. N., Tanveer, M., Abbas, A., Yildirim, M., Shah, A. A., Ahmad, M. I., et al. (2021a). Combating dual challenges in maize under high planting density: stem lodging and kernel abortion. Front. Plant Sci. 12, 699085. doi:10.3389/fpls.2021.699085

Sharma, S. K., Sharma, P. K., Mandeewal, R. L., Sharma, V., Chaudhary, R., Pandey, R., et al. (2022). Effect of foliar application of nano-urea under different nitrogen levels on growth and nutrient content of pearl millet Pennisetumglaucum L. Int. J. Plant and Soil Sci. 34, 149–155. doi:10.9734/ijpss/2022/v34i2031138

Statista (2024). Statista. Available online at: https://www.statista.com/statistics/254292/global-corn-production-by-country/.

Subbaiah, B. V., and Asija, G. L. (1956). A rapid procedure for estimation of available nitrogen in the soil. Cur Sci. 25, 258–260.

Sun, J., Li, W., Li, C., Chang, W., Zhang, S., Zeng, Y., et al. (2020). Effect of different rates of nitrogen fertilization on crop yield, soil properties and leaf physiological attributes in banana under subtropical regions of China. Front. Plant Sci. 11, 613760. doi:10.3389/fpls.2020.613760

Thavaseelan, D., and Priyadarshana, G. (2021). Nanofertilizer use for sustainable agriculture. J. Res. Technol. Eng. 2, 41–59.

Tripathi, S. C., Kumar, N., and Venkatesh, K. (2025). Nano urea’s environmental edge and economic efficacy in boosting wheat grain yield across diverse Indian agro-climates. Sci. Rep. 15, 3598. doi:10.1038/s41598-024-83616-9

Upadhyay, P. K., Abir, D., Singh, V. K., Dwivedi, B. S., Singh, T., Rajanna, G., et al. (2023b). Conjoint application of nano-urea with conventional fertilizers: an energy efficient and environmentally robust approach for sustainable crop production. PLoS One 18, e0284009. doi:10.1371/journal.pone.0284009

Upadhyay, P. K., Singh, V. K., Rajanna, G. A., Dwivedi, B. S., Dey, A., Singh, R. K., et al. (2023a). Unveiling the combined effect of nano fertilizers and conventional fertilizers on crop productivity, profitability, and soil well-being. Fron. Sustain. Food Syst. 7, 1260178. doi:10.3389/fsufs.2023.1260178

Watson, D. J. (1952). The physiological basis of variation in yield. Adv. Agron. 4, 101–145. doi:10.1016/S0065-2113(08)60307-7

Keywords: greenhouse gas emissions, energy, maize, nano urea, nitrogen, rainfed farming

Citation: Gopinath KA, Kumari VV, Singh VK, Shanker AK, Reddy KS, Kundu S, Bhargavi B, Rajkumar B, Lavanya N, Chandana P, Sunitha B, Krupashankar MR and Singh T (2025) Impact of conventional and nano fertilizers on rainfed maize yield, profitability and soil nitrogen. Front. Nanotechnol. 7:1617500. doi: 10.3389/fnano.2025.1617500

Received: 24 April 2025; Accepted: 27 May 2025;

Published: 11 June 2025.

Edited by:

Jayanta Kumar Patra, Dongguk University Seoul, Republic of KoreaReviewed by:

Melvin Samuel, University of Wisconsin–Milwaukee, United StatesNikolaos Katsenios, Hellenic Agricultural Organization – ELGO, Greece

Copyright © 2025 Gopinath, Kumari, Singh, Shanker, Reddy, Kundu, Bhargavi, Rajkumar, Lavanya, Chandana, Sunitha, Krupashankar and Singh. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: V. Visha Kumari, dmlzaGEudmVudWdvcGFsQGdtYWlsLmNvbQ==; V. K. Singh, dmt1bWFyc2luZ2hfMDFAeWFob28uY29t

K. A. Gopinath

K. A. Gopinath V. Visha Kumari

V. Visha Kumari V. K. Singh

V. K. Singh A. K. Shanker

A. K. Shanker K. Sammi Reddy

K. Sammi Reddy S. Kundu1

S. Kundu1 B. Bhargavi

B. Bhargavi N. Lavanya

N. Lavanya P. Chandana

P. Chandana Tarunendu Singh

Tarunendu Singh