- 1Department of Physics, Amrita School of Engineering, Amrita Vishwa Vidyapeetham, Chennai, India

- 2Department of Mechanical Engineering, Amrita School of Engineering, Amrita Vishwa Vidyapeetham, Chennai, India

- 3Department of Chemistry, Amrita School of Engineering, Amrita Vishwa Vidyapeetham, Chennai, India

The global acceptance of additive manufacturing has evolved with time and has proven to provide promising solutions to varied critical requirements of the nuclear industry. The components of a nuclear reactor, when built using additive manufacturing techniques, offer high microstructural control, making them versatile for a range of properties. These properties can be made easily achievable and tailorable by using functionally graded materials. The nuclear components with a wide range of properties are essential, as the environment inside and outside the reactor varies drastically. This study reviews the current progress in additive manufacturing techniques used for manufacturing functionally graded materials for nuclear applications, highlighting the gradient design methodologies and processing techniques. Additive Manufacturing techniques such as selective laser melting uses multiple powder feeders, and mechanical pre-mixing of powders along with controlled process parameters for effectively fabricating functionally graded materials. These materials possess superior mechanical properties (such as microhardness ranging up to 890 H00.5 and compressive strength up to 2040 MPa for FeCrCoNiMo0.5W0.75), thermal conductivity and thermal properties compared to monolithic counterparts. A comparative analysis of the manufacturing capabilities of the additive manufacturing techniques, along with the usage of advanced computational techniques such as AI in optimising process parameters for desirable strength and low defect generation, is also presented. The study emphasises on the need for strategies such as process parameters optimisation and data-driven design to fully utilise the potential of additively manufactured functionally graded materials in the nuclear sector.

1 Introduction

Additive manufacturing (AM), commonly known as 3D printing, is revolutionising various industries, including the nuclear sector. It supports digital design and computer-controlled manufacturing of intricate geometries that were challenging to achieve using conventional techniques. This advanced manufacturing technique offers several advantages over conventional manufacturing techniques, including rapid production time, minimized wastage, and enhanced precision (Huang et al., 2015a; Huang et al., 2015b). More importantly, reducing the impact of structural design significantly contributes to the weight reduction of the components. These qualities not only increase production efficiency but also provide an economical method for large-scale manufacturing. In the nuclear sector, this technology has created specialized, durable, and precise parts critical for nature safety. It also facilitates the synthesis of radiation-resistant materials and equipment for maintenance and repair in radioactive environments by using various materials such as metals, polymers, ceramics, and composites. AM plays a significant role in the production of reactor components, fuel assemblies, and maintenance tools (Lou and Gandy, 2019). AM is expected to become a routine manufacturing, certification, and deployment method over a decade (Mondal et al., 2023; Nelson, 2023).

From an energy point of view, AM supports the advancement of next-generation nuclear reactors by enabling the fabrication of high-performance materials capable of withstanding extreme temperatures and radiation environments. In the major industrial landscape, companies such as GE in aircraft engines and SpaceX in rocket components are already using 3D printing for manufacturing high-precision components (How Additive Manufacturing Helped Launch SpaceX | Kingsbury, https://kingsburyuk.com/how-additive-manufacturing-helped-launch-spacex/.; NASA and Aerojet Rocketdyne Partner to Test AM Hardware - 3Dnatives, https://www.nasa.gov/centers-and-facilities/marshall/3d-printed-rocket-launched-using-innovative-nasa-alloy/.; SpaceX debuts Raptor three engine, further enhanced with metal AM, https://www.3dnatives.com/en/nasa-and-aerojet-rocketdyne-partner-to-test-am-hardware-180520215/#; Through the doors: Inside the AM strategy at GE Aerospace - TCT Magazine, https://www.tctmagazine.com/additive-manufacturing-3d-printing-industry-insights/technology-insights/through-the-doors-inside-the-am-strategy-at-ge-aerospace/). AM has the potential to revolutionize nuclear industries by manufacturing high-performance components efficiently and cost-effectively. Hence, components for the nuclear sector that have higher performance can be manufactured efficiently.

Traditional large light-water nuclear reactors, such as boiling water reactors (BWR) and pressurized water reactors (PWR), have been the strength of nuclear power generation since the late 1950s. However, the global construction of new reactors has been hindered since the 1990s, primarily because of the competition with alternative energy resources. To maintain the nuclear share in the energy portfolio, there is strong interest in smaller, simpler, and more efficient nuclear reactor designs. Several advanced reactor concepts, including small modular reactors (SMR) and GEN IV advanced reactors (e.g., sodium metal fast reactors, molten salt reactors, and gas-cooled reactors), are actively being explored for next-generation solutions for electricity generation (Thompson et al., 2015).

The evolution from conventional materials (steel, aluminum, copper, brass, bronze, and cast iron) and traditional manufacturing methods to AM and, eventually, advancing towards the development of functionally graded materials (FGMs) marks a significant advancement. Initially, manufacturing depended on processes such as casting, forging, and machining, which worked best for producing components from uniform materials with limited design flexibility (Singh et al., 2017; Wohlers et al., 2022). The traditional methods failed to synthesise complex geometries, and component customisation was inadequately met by these approaches, leading to more advanced methods of material synthesis. AM, first with stereolithography and then with fused deposition modelling (FDM) and selective laser sintering (SLS), allowed for direct layer-by-layer fabrication from digital designs, reduced material waste, and increased design options (Singh et al., 2017). Further studies in the optimisation process parameters (layer thickness, printing speed, nozzle or laser power, scan speed, etc.) and computer-aided design modelling (CAD) led to the development of FGM materials with spatially varying properties (NASA, 2016).

FGMs in AM offer significant benefits for nuclear applications, addressing many of the unique challenges posed by extreme operational environments (Reichardt et al., 2021). FGMs enable the creation of components with spatially tailored properties, such as radiation resistance, thermal conductivity, and mechanical strength, which are critical for nuclear reactors, shielding, and waste containment systems. By gradually varying material composition and microstructure, FGMs can optimise performance in specific regions of a component, for example, providing a radiation-resistant surface while maintaining ductility in the core (Zhang et al., 2019; Yoon and Kim, 2024). AM further enhances this capability by allowing precise, layer-by-layer fabrication of complex geometries and material gradients that are difficult or impossible to achieve with traditional methods. This combination reduces material waste, improves design flexibility, and enhances the overall efficiency and safety of nuclear systems. Additionally, AM-enabled FGMs can lead to lighter, more durable components, reducing costs and extending the lifespan of nuclear infrastructure (Li et al., 2020).

The development of FGMs for nuclear and other high-performance applications has been greatly accelerated by recent developments in AM. Complex FGM structure with controlled compositional gradient can be achieved by various AM techniques such as selective laser melting (SLM), wire arc additive manufacturing (WAAM), and laser engineered net shaping (LENS) (Zhang et al., 2019; Sanjeeviprakash et al., 2023; Kumar et al., 2022). These techniques provide high precision, design flexibility, and the ability to locally customise material properties, which are of significance in nuclear reactors that are subjected to hostile environments. However, with these advancements, there is still scope for improvement regarding the reliable production of metal–ceramic and ceramic–ceramic FGMs under nuclear-relevant environments. Thermal mismatch, residual stresses, and microstructural heterogeneity compromise the structural integrity of FGMs when exposed to radiation and high temperatures. Moreover, reproducibility and lack of standardised protocols for testing FGMs in nuclear environments must be addressed (Kumar et al., 2022).

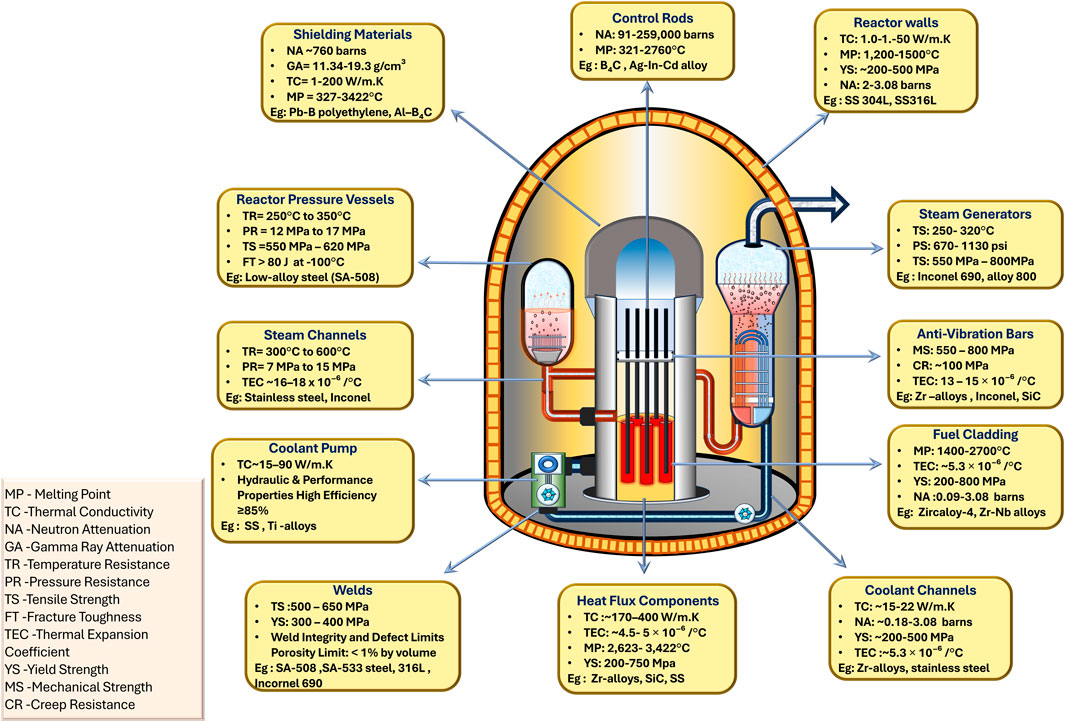

The ability to produce parts quickly and domestically, reduces dependence on complex supply chains, and further improves sustainability and reduces the carbon footprint associated with transportation and logistics. The development of next-generation reactors, including small modular reactors (SMRs) and advanced fission reactors, requires new innovative manufacturing approaches such as gradient based AM (Sun et al., 2021; Liao et al., 2024). AM has the potential for rapid prototyping and repeated testing, accelerating the design and development of advanced reactors. The flexibility of AM also allows engineers to experiment with new materials and design concepts, which can lead to innovation in reactor technology with high safety concerns. The major components of a nuclear reactor include the reactor core, fuel rods and assemblies, moderator, control rods, pressure vessel, steam generator, and cooling system, demonstrated in Figure 1, along with specific properties of each component. AM enables the incorporation of high-performance materials and design elements, such as optimized cooling channels, improved radiation shielding, and long-lasting protective coatings, which are major components of nuclear reactors. These innovations improve the overall safety and lifespan of nuclear reactors, addressing critical concerns such as design flexibility, safety features, production time, cost-effectiveness, strengthened structural integrity, localized and on-demand manufacturing, reactor lifespan, and sustainability and waste reduction with traditional manufacturing methods (Kang et al., 2021; Bergeron and Crigger, 2018). Nuclear projects are often associated with high costs and extended lifetimes, but by incorporating AM, production costs and time can be reduced, making nuclear energy projects more economically viable. Additionally, the ability to manufacture components locally saves on delays associated with long supply chains and logistics, further lowering costs and project timelines (Thomas, 2016).

Figure 1. Schematic diagram of a typical nuclear reactor showing its components and the necessary material properties of the same.

2 Economics of AM and current market

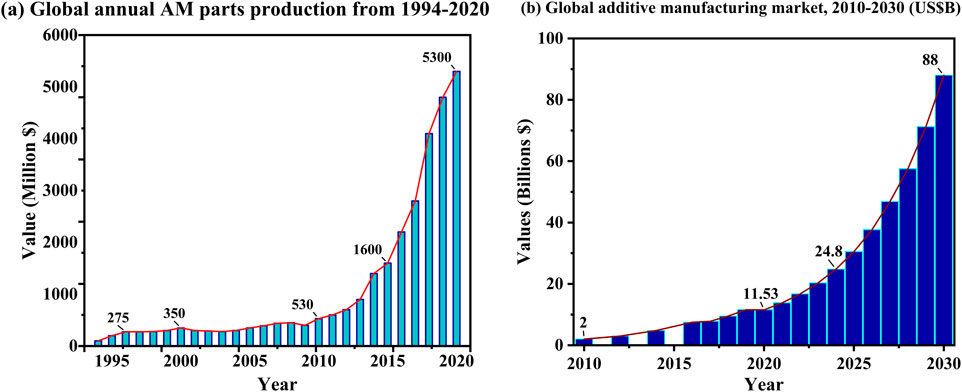

The global additive manufacturing market size was valued at USD 20.37 billion in 2023 and is expected to grow at a CAGR of 23.3% from 2023 to 2030. A total of 2.2 million units of 3D printers were shipped globally in 2021, and the unit shipments are expected to reach 21.5 million units by 2030. Figures 2a,b illustrates the global AM market and parts production. The growing demand for prototyping applications in healthcare, automotive, aerospace and defence industries have encouraged aggressive research and development in AM and thereby drove the growth of the market (Hensley et al., 2021).

Figure 2. (a) Global annual AM parts production from 1993 to 2020, (b) Global AM market from 2010 to 2030.

Innovation in materials, precision engineering, and applications in critical industries underpins the market’s growth. In the nuclear sector, these innovations are unlocking new possibilities for component design, efficiency, and sustainability. The integration of AM in nuclear applications is expected to grow as the technology evolves and regulatory frameworks adapt. AM plays a pivotal role in advancing small modular reactors (SMRs). SMRs (Liao et al., 2024) fusion energy systems, and next-generation reactor designs. In conclusion, the synergy between the expanding global AM market and the nuclear sector highlights its potential to revolutionise the industry by enhancing efficiency, safety, and sustainability while contributing to the broader growth of advanced manufacturing technologies (Bergeron and Crigger, 2018; Kang et al., 2021; Liao et al., 2024).

3 AM processes for nuclear applications

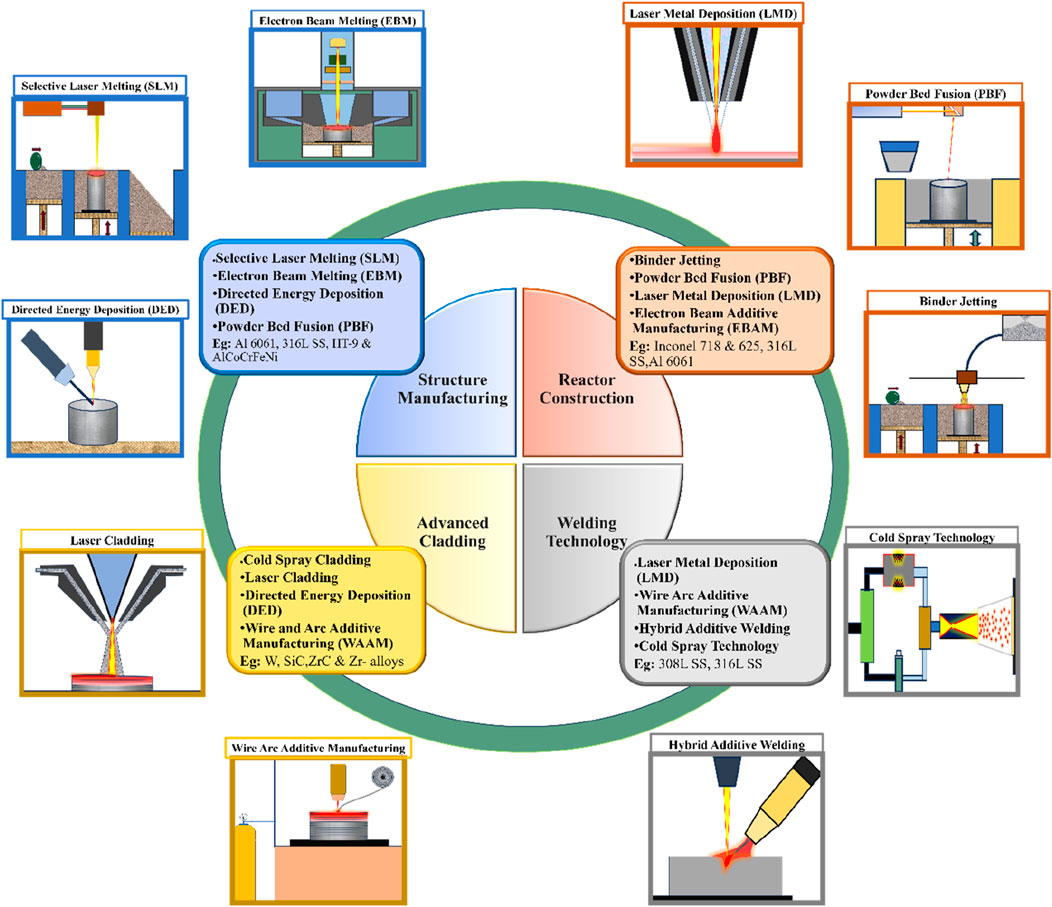

AM has emerged as an advanced manufacturing technique that offers precise control over spatial resolution and enables layer-by-layer deposition of multi-materials. It provides control over the compositional and microstructural features in localised regions across different dimensions. These characteristics of AM make it suitable for the fabrication of FGM, whose properties can be tailored for various extreme condition environments such as nuclear reactors. As the nuclear reactor components have to withstand mechanical stresses, high temperatures, and radiation exposure, the strategic control over the AM process parameters can lead to the formation of multi-dimensional gradient structures. Such advancements in AM can enable the next-generation systems for nuclear applications in terms of efficiency, longevity, and safety of the components. A range of AM techniques that can be deployed for the development of materials for the nuclear reactor have been shown in Figure 3.

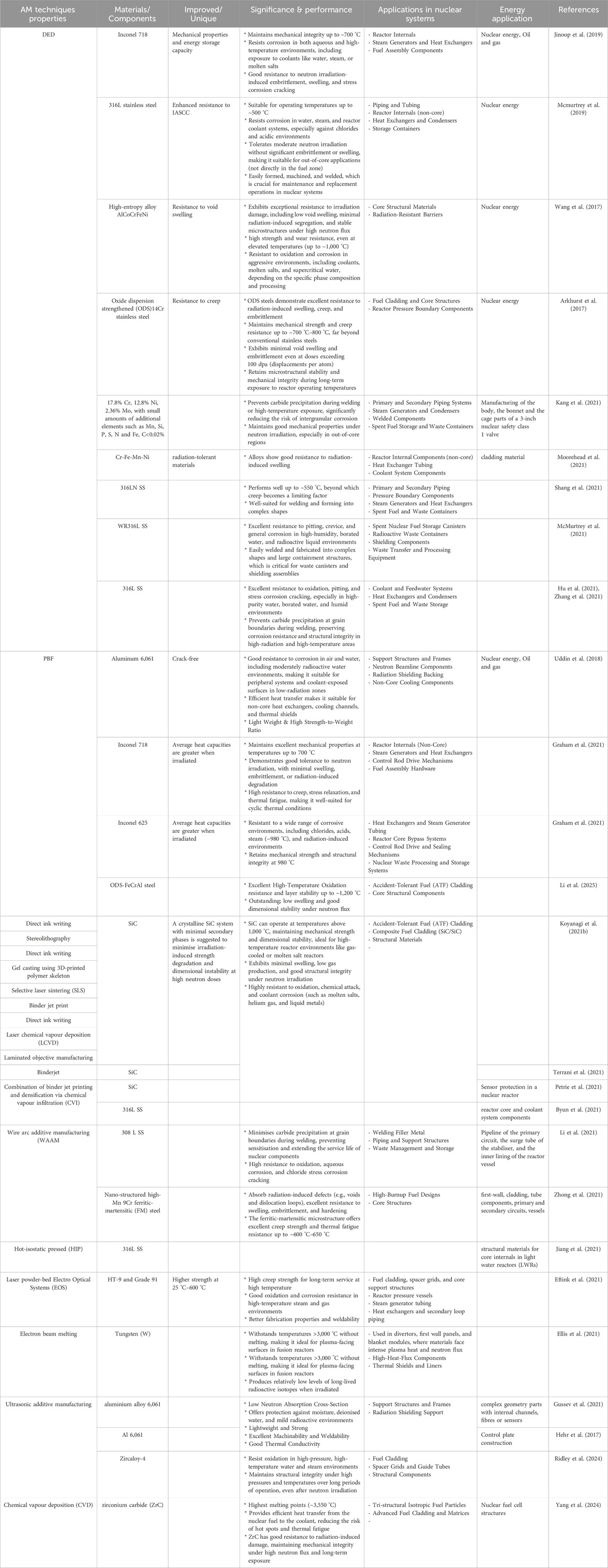

Table 1 summarizes the AM based techniques for nuclear sector materials. Laser DED and PBF are the most commonly used AM techniques in nuclear applications due to their superior advantages, such as being capable of fabricating large and complex parts with graded material compositions, high-resolution and near-net-shape production with minimal post-processing (Xie et al., 2021; Downey, 2023). These two methods address the key challenges, such as porosity, residual stresses, and anisotropic mechanical properties. In the case of DED, it offers high accuracy and the capability for repair, rebuild, and fabrication of complex components. Its capability to deposit material layer by layer ensures effective utilization of material and part customization necessary for utilisation of material and part customisation necessary for the rigorous demands of nuclear systems. On the other hand, PBF provides unmatched detail and homogeneity, making it ideal for producing components with complex geometries and excellent mechanical properties (Uribe-lam et al., 2021; Singh and Singh, 2018). The precise control over the fusion process ensures high-quality and defect-free parts, which is crucial for reliability in nuclear environments. The dominance of laser DED and PBF lies in their ability to meet the demands of the nuclear industry, including durability, resistance to aggressive environments, and consistent performance over time, which is essential for maintaining the reliability and safety of nuclear reactors.

Several other AM techniques available are Laser Chemical Vapour Deposition (LCVD) (Miyagishi et al., 2025), Wire Arc Additive Manufacturing (WAAM) (Chen et al., 2021), etc., are not preferred in nuclear applications due to limitations in scalability, precision, or material compatibility when compared to L-DED and PBF.

Various studies related to the printing of compositionally graded FGMs using primarily Laser DED, also known as laser engineered net shaping (LENS) technique, have been reported. This technique uses a laser heat source for melting the powders and the substrate, along with a coaxial nozzle for printing the 3D component. Yoon and Kim (2024) developed an approach to replace the dissimilar metal welds in the nuclear reactors with FGM fabricated through the DED technique. The work focuses on utilising the potential of FGM to reduce the primary water stress corrosion cracking, which is the major concern in nuclear reactors due to the residual stress caused by the dissimilar welds. The study analyses the potential of FGM comprising low alloy steel and stainless steel in terms of mechanical performance and its behaviour under temperature variations. The DED fabricated FGM showed enhanced mechanical and thermal performance, which is essential for the structural integrity and safety of the nuclear reactors. However, the optimum compositional ratio and impact on the material under a corrosive environment for long-term application can further explore the possibilities of achieving tailored microstructures and mechanical properties. Jinoop et al. (2019) explored the process window for fabricating thin-walled Inconel 718 structures using the DED technique, established an optimum range of laser energy per unit length (105 kJ/m to 210 kJ/m) and powder feed rates per unit length (4 g/m to 12.5 g/m) for structural integrity. A significant effect of the post-heat treatment on the mechanical performance of the fabricated structures was reported in terms of reduction in tensile residual stress (50%) and enhancement in ductility (62.5%) and energy storage capacity (2.4 times). The study suggested the potential of DED for fabricating lightweight, durable components with tailored characteristics for nuclear applications. However, a few concerns remain unaddressed. With further exploration of the process and property relationship, the behaviour of these components under cyclical loading conditions and the influence of the variable microstructure along the layers for long-term application can be examined to determine the optimum manufacturing conditions. Mcmurtrey et al. (2019) compared the irradiation damage and irradiation-assisted stress corrosion cracking (IASCC) susceptibility of AM 316L stainless steel and wrought 316L stainless steel. The work demonstrates a lower susceptibility of AM 316L stainless steel to IASCC than wrought 316L, which is essential for nuclear applications. It also explores the microstructural features of AM 316L, which depicts a lower density of voids in AM 316L as compared to wrought 316L, resulting in reduced localised deformation. This work establishes the initial understanding of the relation between microstructures and AM materials’ performance. However, exploring the post-processing treatments of AM components can further lead to improving the safety and performance of the nuclear reactor components. Moorehead et al. (2021) worked on developing compositionally complex alloys (Cr-Fe-Mn-Ni) for nuclear applications by utilising high-throughput methodology in combination with AM. This study addresses the limitations of the ASME-qualified materials codes for advanced nuclear reactor design. The AM-DED technique was employed to fabricate the compositional array of unary, binary, ternary, and quaternary alloys (Cr-Fe-Mn-Ni). With further implementation of synthesis, irradiation, and characterisation methodology, a significant reduction in fabrication time was observed in comparison to conventional methods. In addition, some studies also reported the wire-DED technique, i.e., the combination of wire and powder-fed DED for printing larger FGM components.

In PBF, different types of heat sources are used to fuse the powdered raw material and form a 3D component. Based on these heat sources (laser, electron), PBF can build 3D components with different types of fusion techniques, such as laser fusion and electron beam fusion. The laser fusion technique can further be classified as selective laser melting (SLM) and selective laser sintering (SLS). During the process, the laser scans the X-Y plane along the uniformly distributed powdered bed, which is fitted with a roller over a construction griddle. The interaction of the laser beam with the powdered material layer allows the beam to melt or sinter the particles together to form a solid layer. After the printing of the first layer, the powder bed steps down, and the roller spreads the powder uniformly over the bed for the next laser scan. SLS and SLM are the two commonly used PBF techniques used to manufacture FGM (Uribe-lam et al., 2021; Singh and Singh, 2018; Uddin et al., 2018). AA6061 components by laser-based PBF technique with assisted high-temperature powder bed heating. The cracking due to the solidification was eliminated by the optimised process parameters and preheating, which altered the thermodynamic conditions. This laser PBF technique for manufacturing AA6061 showed enhanced mechanical performance as compared to the conventionally manufactured material. The yield strength of the heated AA6061 was increased up to 280 MPa as compared to the as-fabricated AA6061 samples. The ultimate strength was recorded as 310 MPa in preheated AA6061 samples as compared to the as-built AA6061, which was recorded as 130 MPa (Uddin et al., 2018).

Unlike DED, where multiple hoppers for feedstock are provided, the fabrication of the gradient structure in SLM requires alternate strategies. Various studies reported different strategies for achieving a gradient microstructure. Demir and Previtali (2017) used a multiple powder feeder system for the fabrication of Fe/Al-12Si multi-material, where two separate material hoppers and a lower mixing hopper were used. The upper hopper was operated during single-material processing, and the lower hopper was used for mixing the materials. Though the approach was not standard, it allowed for achieving a similar composition as in DED. Similarly, C. Han et al. (Han et al., 2018) adopted the strategy of mixing the powder of different compositions (Ti/HA powder mixtures with varying HA content) using mechanical mixing by a planetary ball milling apparatus. After mixing, each composition was fed to the powder feeder, and a layer of 2 mm thickness was formed. Additionally, PBF processes can also manufacture gradient materials by gradually controlling the thermal cycles, cooling rates, or laser parameters during the SLM process (Parhizkar et al., 2023).

In the binder jetting (BJ) process, the powder particles are fused by selectively depositing the liquid bonding agent onto the powder bed (Koyanagi et al., 2021a; She et al., 2024). The print head drops the bonding agent onto the powder platform, and the particles are bonded together through the process of adhesion or chemical reaction. The support structures for the printed objects are facilitated by the surrounding powder materials, which are removed on the completion of the printing process. The required level of printing quality is achieved through post-processing processes such as sintering, infiltration, and hot-isostatic processing. The major advantages of BJ include large build volume, high printing speed, and low printing cost. In view of this, Zhao et al. (2023) fabricated 316L-toughened porous Al2O3-based functionally graded ceramic using a binder jetting technique. The printed parts were further subjected to sintering from 1,200 °C to 1,450 °C for 2 h at a heating rate of 5 °C/min in a vacuum atmosphere. This approach leads to achieving tailored properties of the material for complex applications such as high-temperature and nuclear reactors. The work explores a low-temperature toughening mechanism by utilising 1% CuO and 4% TiO2 as sintering aids and 0%–40% Al2O3, which enhances the densification process and mechanical properties of the component. However, further exploring the incorporation of metal alloys as toughening phases could lead to the development of materials with enhanced performance for various applications (Srivastava et al., 2024). The printed parts using BJ techniques are typically porous and require certain post-processing, such as sintering or infiltration, to enhance their mechanical properties and functional performance. The post-infiltration of the printed or sintered parts involves the filling of the porous structure with molten alloys, epoxy or precursors to enhance the sintered density of the structure (Chen et al., 2022). However, the extent and spatial distribution of infiltration can be varied by changing the orientation, capillarity and the time of infiltration, which is responsible for achieving gradient structures. Chen et al. (2022) studied the effect of multi-infiltration operations in alumina parts. It was observed that the ceramic suspension infiltrated the skeleton under the effect of gravity, which resulted in density heterogeneities of the parts. Therefore, BJ can offer the flexibility of fabricating graded structures through the post-infiltration technique.

Stainless steel alloys like 316LN, 308L SS, and WR316L are well known for their excellent mechanical strength, corrosion resistance, and ability to withstand high temperatures and radiation. Their durability and reliability make them essential for critical components like reactor pressure vessels, piping, and core structures. Similarly, zirconium carbide (ZrC) has outstanding thermal conductivity, a high melting point, and resistance to neutron irradiation. These properties make ZrC a key material in fuel cladding and protective coatings. These properties help improve reactor efficiency while enhancing safety by preventing fuel degradation and reducing radiation exposure. By combining these advanced materials, the nuclear industry ensures the structural integrity and longevity of reactors, meeting the demanding performance and safety requirements.

Combining AM techniques to fabricate FGM demonstrates significant potential in nuclear sector. Superalloys such as Inconel 718 and 625 are already AM-compatible for complex reactor components and provide exceptional resistance to corrosion and high temperatures (Jinoop et al., 2019; Graham et al., 2021). Well-known in AM, austenitic stainless steels like 316L and 316LN are perfect for graded structures with improved surface qualities (Shang et al., 2021; Mcmurtrey et al., 2019). Although ODS variants present processing challenges, HEAs (like AlCoCrFeNi) and ODS steels (like 14Cr and ODS-FeCrAl) offer radiation and creep resistance appropriate for fuel cladding and structural internals (Li et al., 2025; Wang et al., 2017). For core applications that demand corrosion and radiation tolerance, ferritic-martensitic steels such as HT-9 and Grade 91 benefit from FGMs (Eftink et al., 2021). Despite the fabrication challenges, ceramics like SiC and ZrC are being incorporated into AM and FGM processes because they are perfect for components that face plasma and are related to fuel (Petrie et al., 2021; Yang et al., 2024). For accident-tolerant designs, FGMs can improve zirconium-based alloys, such as Zircaloy-4, which are essential in Light Water Reactors (LWRs) (Ridley et al., 2024). Aluminium 6,061 is perfect for non-core and instrumentation roles because of its low neutron absorption and ease of AM fabrication, particularly using ultrasonic AM (Gussev et al., 2021). While tungsten is challenging to process, it is necessary for fusion applications when graded with steels to manage thermal mismatch (Ellis et al., 2021). Specialised stainless alloys, such as Cr-Fe-Mn-Ni variants, support containment and reprocessing applications (Moorehead et al., 2021). When combined with AM and FGM methods, these materials mark a substantial improvement in nuclear system performance and design.

4 Properties of nuclear reactor materials

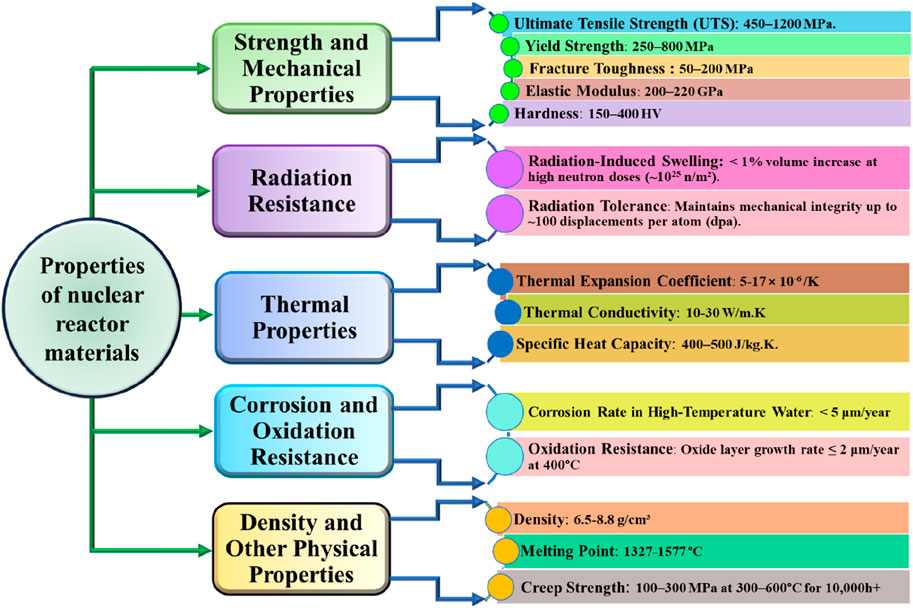

Nuclear reactor materials are specifically engineered to withstand extreme conditions, such as high temperatures, radiation exposure, oxidation, and corrosive environments, ensuring the safety and efficiency of the nuclear reactor (Was, 2007). Figure 4 shows the structural and functional property requirements of nuclear reactor materials. These materials are exceptionally strong, with yield strengths ranging from 250 to 800 MPa and ultimate tensile strengths between 450 and 800 MPa. They also have high fracture toughness (50–200 MPa) and hardness (150–400 HV), making them highly resistant against mechanical stresses with delayed failure (Hehr et al., 2017; Lou and Gandy, 2019). The resistance to radiation is a key property, as these materials must maintain their structural integrity under high levels of neutron irradiation (∼1025 n/m2). They must resist swelling, with volume increasing typically limited to less than 1%. The materials need to be resistant to radiation damage up to ∼100 displacements per atom (dpa). Corrosion rates in high-temperature water are limited below 5 μm/year and oxide layer growth rates below 2 μm/year. The thermal properties optimised for reactor conditions, with thermal conductivity ranging from 10 to 30 W/mK and specific heat capacities between 400 and 500 J/kg·K. These materials also have high melting points (1,327 °C–1,577 °C) and low thermal expansion coefficients (5-17 × 10−6/K), ensuring stability under thermal cycling. Furthermore, they exhibit excellent creep strength, resisting deformation under stresses of 100–300 MPa at 300 °C–600 °C for over 10,000 h (Frost and Ashby, 1982) (Thermophysical Properties of Materials for Nuclear Engineering: A Tutorial and Collection of Data, 2009). Combined, these set of critical properties make nuclear reactor materials highly durable and reliable, essential for the safe and efficient operation of nuclear power plants.

5 Materials for nuclear applications

Nuclear materials should be able to sustain harsh conditions like high temperatures, neutron radiation, corrosive media, and mechanical stress. Inconel 718 and 625 are two examples of alloys that have high mechanical strength and are resistant to corrosion at temperatures up to 980 °C. They also have strong resistance to radiation, which makes them perfect for use in interior components of the reactor, heat exchangers, and steam generator tubing (Jinoop et al., 2019; Graham et al., 2021). Stainless steels such as 316L and 316LN SS are also common in non-core reactor parts because they can be shaped and welded easily and can withstand moderate amounts of radiation. They find applications starting from piping systems to containers for spent fuel (Shang et al., 2021; Mcmurtrey et al., 2019). Advanced stainless steels like ODS 14Cr are highly resistant to creep and swelling up to 800 °C. This is important in high-radiation areas like fuel cladding and core structures (Li et al., 2025; Arkhurst et al., 2017).

High-entropy alloys (like AlCoCrFeNi) and ceramics, SiC and ZrC, are new types of materials that are pushing the boundaries of nuclear material science. High-entropy alloys are capable of resisting void swelling and damage caused by radiation, making them potential materials for core structural parts that are exposed to high neutron flux (Wang et al., 2017). Both SiC and ZrC are excellent options for accident-tolerant fuel cladding and gas-cooled reactor applications because they can work at temperatures over 1,000 °C and have excellent thermal stability and resistance to oxidation (Koyanagi et al., 2021a; Yang et al., 2024; Petrie et al., 2021; Terrani et al., 2021). Refractory materials are crucial for nuclear reactor applications because they can keep their shape even when exposed to very high temperatures and radiation. Tungsten, as well as Zr-4 alloys, are key materials in plasma-facing components as they can withstand temperatures over 3,000 °C and have low long-term radioactivity (Ridley et al., 2024; Ellis et al., 2021).

6 Functionally graded materials: role of properties and microstructures

Functionally graded materials exhibit a hierarchical arrangement at the microstructural level, which caters to the nuclear sector prominently. Due to the demand for graded properties in nuclear materials, FGM is a popular choice for the above. Properties of FGM in the nuclear industry, grouped under various requirements, include dissimilar welds in components such as nuclear walls. The additive manufacturing industry is instrumental in meeting the demands of the graded property arrangement in FGMs (Mahamood and Akinlabi, 2017). Ti-6Al-4V/Ni-20Cr FGM has been shown to have combined effects of heat and corrosion resistance of both alloys, which is appropriate for the nuclear wall developed using DED (Yakovlev et al., 2005). The laser power optimisation during DED led to a crack-free interface. The nuclear wall has a high demand for versatile and dynamic properties, wherein tungsten is an integral part of the former as it helps in providing superior thermal protection to the stainless-steel wall. The above FGM is achieved using cold gas spraying, where the coarser tungsten particles show efficient peening, rendering it an efficient thermal barrier. The diffusivity and conductivity properties exhibited by the W/316L FGM are an average of both systems, which were engineered using a radio frequency inductively coupled system (Kim et al., 2019). The hierarchical microstructure rendered by the virtue of FGM can be attributed to the robust nature of additive manufacturing, which provides an avenue for optimizing process parameters selectively to obtain the former (Dash et al., 2020).

Microstructure plays a vital role in enhancing prosperities of FGMs such as mechanical strength, tensile strength, ductility, wear resistance, thermal stability and resistance to extreme corrosion environment and other characteristics (Chen et al., 2022). FGMs can achieve high mechanical strength by controlling the distributions and morphology of grains and tuning of phases. For instance, grain refinement and phase distribution gradients can make the material vulnerable to dislocations formation which renders the material with high strength and fracture toughness. Microstructural gradients can aid in formation of passive oxide layers or lowering the susceptibility localised galvanic reactions, which makes the material more resistant to corrosion. Also, the controlled change in microstructure can lower residual stresses and stop cracks from spreading (Chen et al., 2022).

Conventional materials such as metals, alloys, polymers, and ceramics have uniform or homogeneous compositions. Therefore, their physical, mechanical, thermal, and chemical properties are the same throughout the structure. In the case of FGMs, properties are varied in a gradient manner through the thickness of the material. In terms of mechanical properties, Ti-based alloys possess tensile strength ranging from 210 MPa to 1,380 MPa and Young’s modulus of 120 GPa. Compared to the homogenous Ti-alloys, their FGM counterpart exhibits higher range of tensile strength and Young’s modulus (Yin et al., 2018; Hu et al., 2021; Alarifi, 2024). FGM made of stainless steel has tensile strengths between 515 and 625 MPa and a higher Young’s modulus of 190 GPa. The tailored FGM counterpart material gradient makes these materials less stress-concentrated and improves the resistance against crack formation and propagation under load conditions. Alternatively, standard wrought Ti6Al4V alloys usually have a uniform tensile strength of around 950 MPa and a Young’s modulus of about 110 GPa (Yin et al., 2018; Alarifi, 2024). Similarly, Al2O3–ZrO2 systems, can combine the 260 MPa strength of alumina with the enhanced fracture toughness of zirconia (ZrO2). Homogeneous alumina alone has a Young’s modulus of up to 413 GPa but is prone to brittle failure (Wu et al., 2022).

The thermal property of FGM have the ability to create a thermal gradient in bulk material for efficient heat management. For instance, Al-based FGMs can work at melting temperatures of about 660 °C, and their thermal conductivities can be altered depending on the gradient composition, which is not possible in non-FGM Al alloys (Zhang et al., 2021; Su et al., 2023). Ceramic-based FGMs, like alumina/zirconia systems, show a range of Vickers hardness values, from 18.4 GPa (pure alumina) to 15.0 GPa with a 50% zirconia blend (Li et al., 2020; Li et al., 2021; Zhang et al., 2021). As the porosity in the gradient FGMs move from a dense core to a porous outer layer, their thermal conductivities drop from typical metal values (∼20–50 W/m·K) to insulating ceramic values (<5 W/m·K). Homogeneous ceramics often suffer from thermal shock and brittleness. FGMs mitigate these by gradually changing from an area with high thermal conductivity to low thermal conductivity. This makes them more durable in high-temperature environments (Zhang et al., 2021).

7 Microstructural gradient in FGMs

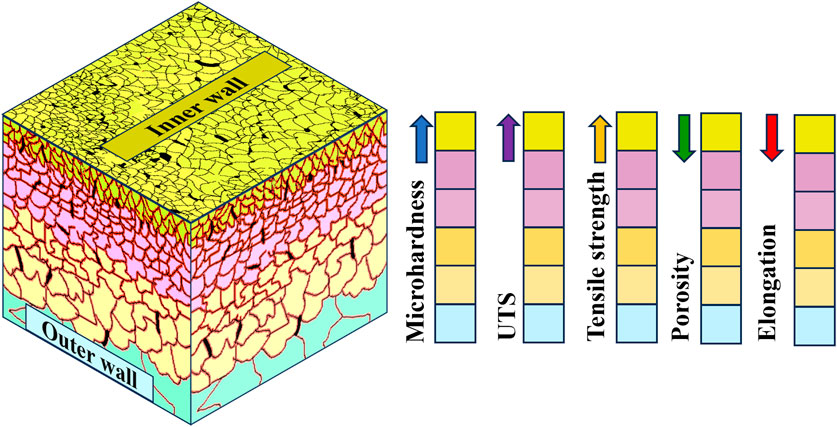

FGMs can be classified into three main types based on their gradient characteristics. Chemical Composition Gradient FGMs, where the material composition gradually transitions, optimise properties such as corrosion resistance, thermal conductivity, and mechanical strength for applications in aerospace and biomedical implants. Porosity Gradient FGMs, where porosity varies throughout the material to enhance thermal insulation, reduce weight, or improve bone integration in medical implants. Microstructure Gradient FGMs, where phase distribution, grain size, or crystallinity changes gradually, enhancing mechanical strength, wear resistance, porosity, and elongation (Mahamood and Akinlabi, 2017). Figure 5. shows the microstructure gradient FGM and the change in properties across the cross-section. This gradient in microstructure helps reduce defects caused by radiation exposure which minimises thermal stresses and enhance creep and corrosion resistance. As a result, these materials can withstand extreme nuclear environments, ensuring long-term performance and safety, making them suitable for nuclear applications (Duan et al., 2023). Microstructural gradation can be achieved during the solidification process by controlling the cooling rate and controlled heat treatment techniques. The microstructure gradient FGMs traditionally rely on conventional synthesis methods such as powder metallurgy, diffusion bonding, and plasma spraying, which often struggle with achieving precise gradients and complex geometries. However, 3D printing techniques, such as Direct Energy Deposition (DED), Selective Laser Melting (SLM), and Binder Jetting, offer significant advantages, including fine control over gradient transitions, complex shape fabrication, material efficiency, and reduced processing time (Singh et al., 2017). Compared to conventional methods, 3D printing enables superior customisation, better microstructural integrity, and optimised performance, making it a transformative approach for advanced FGM applications in the energy sector (Alarifi, 2024; Kumar et al., 2022).

8 Computational approaches

Artificial intelligence (AI) and machine learning (ML) are incorporated with AM, especially in the area of process optimisation, defect prediction, and property enhancement for FGMs. Artificial Neural Networks (ANNs), Decision Trees (DTs), Support Vector Machines (SVMs), and Convolutional Neural Networks (CNNs) are some of the most popular machine learning algorithms. Predicting mechanical defects such as surface morphology and dimensional accuracy, these models have helped minimise production errors and optimise process parameters. ANN has been used to predict surface roughness in BJ and to estimate build time in L-PBF. CNNs have successfully classified built quantity in L-PBF, achieving accuracy up to 89%. Meanwhile, CNNs in BJT applications showed ML’s precision manufacturing capabilities by accurately predicting dimensional deviations in dental crowns (Jin et al., 2020; Raza et al., 2022; Babu et al., 2023; Ukwaththa et al., 2024).

Furthermore, the integration of explainable AI (XAI) methods into these ML models enhances transparency, interpretability, and user trust. A case study explained how design parameters, such as strut thickness and node radius, affect the Poisson ratio in hexachiral structure FGMs by combining Gaussian process regression (GPR) with SHapley Additive exPlanations (SHAP). Similarly, in L-PBF, SHAP analysis has been utilised to interpret how laser power and feed rate affect the geometry and porosity of Fe-Ni alloys, allowing more confident process optimisation (Ladani, 2021; Ukwaththa et al., 2024; Pancholi et al., 2025).

9 Limitations, challenges and considerations

FGM’s synthesised through AM offer significant advantages due to their gradient composition and customizable properties. However, maintaining their structural integrity comes with challenges such as delamination, cracking, porosity, anisotropic behaviour, material inconsistencies, and thermal stress. It is vital to understand this process variation, since it could otherwise be a limiting factor in the use of AM in mission-critical components. One of the major issues of 3D printing is delamination, which occurs primarily at interface zones due to thermal fluctuation, poor interlayer bonding, thermal stresses, melt-pool behaviour, or differences in material properties. Delamination in AM can lead to structural weaknesses, reduced mechanical properties, and potential failure of the printed component. Delamination is attributed to residual stresses and thermal gradients that occur during printing. However, optimising printing parameters can help mitigate this issue (Flavin et al., 1992; Negi et al., 2013; Frazier, 2014; Thompson et al., 2015; Lou and Gandy, 2019). Similarly, cracking is another common problem, primarily caused by the residual stresses that accumulate during the rapid heating and cooling cycles and post-processing stages. These stresses leads to differential expansion and contraction between the layers. To mitigate this issue, computational models have been developed to predict crack formation, while hybrid AM techniques, including ultrasonic additive manufacturing (UAM), preheating strategies, and heat treatments, are being used to reduce stress buildup and improve material stability. Porosity is another common issue, arising from incomplete fusion or gas entrapment, balling, and keyhole effects, reducing mechanical strength of the components. Studies suggest that optimising powder particle size, energy input, and scanning strategies can help minimise porosity and enhance material density (Zhang et al., 2019; Reichardt et al., 2021; Yoon and Kim, 2024).

Anisotropic behaviour is a major challenge in AM-based FGMs due to the layer-wise deposition process, which introduces mechanical and thermal property variations across different build directions. These microstructural differences affect the functional properties, such as fatigue resistance, mechanical strength, and material performance. Fibre-reinforced and metal matrix composites highlight the impact of material orientation and reinforcement distribution, emphasising the need for large-scale, optimised scanning patterns and post-processing treatments to address anisotropy. Material inhomogeneity is another issue arising from variations in composition and structural inconsistencies within individual layers (Li et al., 2020; Sun et al., 2021; Liao et al., 2024). Improper powder mixing and deposition irregularities can cause mechanical property variations, influencing hardness, ductility, and structural performance. There are some AM techniques, such as multi-material fused filament fabrication (FFF) and laser engineered net shaping (LENS), that have been explored to improve compositional grading and structural uniformity (Kang et al., 2021).

Challenges in AM of FGM material compatibility, process stability, and microstructural control differences in thermal expansion, bonding characteristics, and phase transformations can lead to defects such as cracks, delamination, or porosity. Process stability is another challenge, including optimising printing parameters to achieve consistent material gradients while ensuring defect-free strong layer adhesion and maintaining structural and mechanical integrity under varying conditions. Additionally, at the microscopic level, controlling the material’s microstructure is equally important, since uneven phase distribution or internal voids can weaken performance. Research suggests that preheating or post-heat treatment processes, optimised laser parameters, and real-time thermal monitoring can significantly reduce thermal distortions, enhancing the stability and repeatability of AM processes. Addressing these structural issues through advanced manufacturing techniques, smarter process design, and process optimisations is crucial for the successful application of FGMs in engineering applications, from aerospace to biomedical devices (Thomas, 2016; Bergeron and Crigger, 2018).

10 Manufacturing of FGM using AM: future prospects

The future of FGMs manufactured using AM is influenced by emerging trends. One major prospect in hybrid manufacturing, which combines AM with conventional machining and heat treatment to enhance the structural performance. Currently, advanced materials like ceramics, polymers, and composites are being used in AM, thereby expanding their potential applications. Apart from that, AI and ML play a crucial role in optimising printing parameters and predicting material behaviour for improved performance. Sustainability initiatives focus on minimising material waste and developing recyclable FGMs. However, several challenges must be addressed, including material compatibility, process optimisation, cost-effectiveness, and the establishment of industry standards.

Advancements in FGMs using AM will require interdisciplinary collaboration, incorporating numerous fields such as metallurgy, material science, nanotechnology, computational modelling, and materials engineering. In AM, improvements in feedstock material development, process enhancements, and integration with smart materials and sensors will lead to stronger, more resilient, and adaptable FGMs. Improvements in process, such as real-time monitoring, AI-aided parameter control, and modifications, will increase the precision and quality. Through continued research and innovation, the next-generation of FGMs will offer superior performance, reliability, scalability, and adaptability, making them a valuable asset across various industries.

Author contributions

AS: Data curation, Writing – original draft, Writing – review and editing, Validation. MS: Conceptualization, Data curation, Investigation, Validation, Writing – original draft, Writing – review and editing. KD: Writing – review and editing, Conceptualization, Data curation, Writing – original draft.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alarifi, I. M. (2024). Revolutionising fabrication advances and applications of 3D printing with composite materials: a review. Virtual Phys. Prototyp. 19, e2390504. doi:10.1080/17452759.2024.2390504

Arkhurst, B. M., Park, J. J., Lee, C. H., and Kim, J. H. (2017). Direct laser deposition of 14Cr oxide dispersion strengthened steel powders using Y2O3 and HfO2 dispersoids. J. Korean Inst. Metals Mater. 55, 550–558. doi:10.3365/KJMM.2017.55.8.550

Babu, S. S., Mourad, A. H. I., Harib, K. H., and Vijayavenkataraman, S. (2023). Recent developments in the application of machine-learning towards accelerated predictive multiscale design and additive manufacturing. Virtual Phys. Prototyp. 18, e2141653. doi:10.1080/17452759.2022.2141653

Bergeron, A., and Crigger, J. B. (2018). Early progress on additive manufacturing of nuclear fuel materials. J. Nucl. Mater. 508, 344–347. doi:10.1016/j.jnucmat.2018.05.058

Byun, T. S., Garrison, B. E., McAlister, M. R., Chen, X., Gussev, M. N., Lach, T. G., et al. (2021). Mechanical behavior of additively manufactured and wrought 316L stainless steels before and after neutron irradiation. J. Nucl. Mater. 548, 152849. doi:10.1016/j.jnucmat.2021.152849

Chen, X., Kong, F., Fu, Y., Zhao, X., Li, R., Wang, G., et al. (2021). A review on wire-arc additive manufacturing: typical defects, detection approaches, and multisensor data fusion-based model, 707–727.

Chen, Q., Juste, E., Lasgorceix, M., Lefebvre, G., Tenailleau, C., Duployer, B., et al. (2022). Post-infiltration to improve the density of binder jetting ceramic parts. J. Eur. Ceram. Soc. 42, 7134–7148. doi:10.1016/j.jeurceramsoc.2022.08.005

Dash, K., Yazar, K. U., Chattopadhyay, K., and Suwas, S. (2020). Graded microstructure and texture in ultrafine grained multi-layered immiscible bimetallic system. Mater. (Oxf) 13, 100830. doi:10.1016/j.mtla.2020.100830

Demir, A. G., and Previtali, B. (2017). Multi-material selective laser melting of Fe/Al-12Si components. Manuf. Lett. 11, 8–11. doi:10.1016/j.mfglet.2017.01.002

Downey, C. (2023). Development of advanced coating technologies using powder-blown directed energy deposition (DED) additive manufacturing for advanced nuclear reactor applications. Idaho: ProQuest Dissertations and Theses Global. Available online at: https://www.proquest.com/dissertations-theses/development-advanced-coating-technologies-using/docview/2825771582/se-2.

Duan, X., Wang, S., Yang, H., Wang, G., Liu, W., and Xiao, Z. (2023). Microstructure and mechanical properties of functional gradient materials of high entropy alloys prepared by direct energy deposition. J. Mater. Res. Technol. 26, 1677–1696. doi:10.1016/j.jmrt.2023.07.276

Eftink, B. P., Vega, D. A., El Atwani, O., Sprouster, D. J., Yoo, Y. S. J., Steckley, T. E., et al. (2021). Tensile properties and microstructure of additively manufactured grade 91 steel for nuclear applications. J. Nucl. Mater. 544, 152723. doi:10.1016/j.jnucmat.2020.152723

Ellis, E. A. I., Sprayberry, M. A., Ledford, C., Hankwitz, J. P., Kirka, M. M., Rock, C. D., et al. (2021). Processing of tungsten through electron beam melting. J. Nucl. Mater. 555, 153041. doi:10.1016/j.jnucmat.2021.153041

Frost, H. J., and Ashby, M. F. (1982). Deformation-mechanism maps: the plasticity and creep of metals and ceramics. Pergamon Press.

Graham, M. W., King, J. C., Pavlov, T. R., Adkins, C. A., Middlemas, S. C., and Guillen, D. P. (2021). Impact of neutron irradiation on the thermophysical properties of additively manufactured stainless steel and inconel. J. Nucl. Mater. 549, 152861. doi:10.1016/j.jnucmat.2021.152861

Gussev, M. N., Sridharan, N., Babu, S. S., and Terrani, K. A. (2021). Influence of neutron irradiation on Al-6061 alloy produced via ultrasonic additive manufacturing. J. Nucl. Mater. 550, 152939. doi:10.1016/j.jnucmat.2021.152939

Han, C., Li, Y., Wang, Q., Cai, D., Wei, Q., Yang, L., et al. (2018). Titanium/Hydroxyapatite (Ti/HA) gradient materials with quasi-continuous ratios fabricated by SLM: material interface and fracture toughness. Mater. Des. 141, 256–266. doi:10.1016/j.matdes.2017.12.037

Hehr, A., Wenning, J., Terrani, K., Babu, S. S., and Norfolk, M. (2017). Five-axis ultrasonic additive manufacturing for nuclear component manufacture. JOM 69, 485–490. doi:10.1007/s11837-016-2205-6

Hensley, C., Sisco, K., Beauchamp, S., Godfrey, A., Rezayat, H., Mcfalls, T., et al. (2021). Qualification pathways for additively manufactured components for nuclear applications. J. Nucl. Mater. 548, 152846. doi:10.1016/j.jnucmat.2021.152846

Hu, X., Lach, T. G., and Terrani, K. A. (2021). Deuterium permeation and retention in 316L stainless steel manufactured by laser powder bed fusion. J. Nucl. Mater. 548, 152871. doi:10.1016/j.jnucmat.2021.152871

Huang, Y., Leu, M. C., Mazumder, J., and Donmez, A. (2015a). Additive manufacturing: Current state, future potential, gaps and needs, and recommendations. J. Manuf. Sci. Eng. 137, 014001.

Huang, Y., Leu, M. C., Mazumder, J., and Donmez, A. (2015b). Additive manufacturing: current state, future potential, gaps and needs, and recommendations. J. Manuf. Sci. Eng. 137, 014001. doi:10.1115/1.4028725

Jiang, L., Song, M., Yang, L., Yang, J., Du, D., Lou, X., et al. (2021). A comparison study of void swelling in additively manufactured and cold-worked 316L stainless steels under ion irradiation. J. Nucl. Mater. 551, 152946. doi:10.1016/j.jnucmat.2021.152946

Jin, Z., Zhang, Z., Demir, K., and Gu, G. X. (2020). Machine learning for advanced additive manufacturing. Matter 3, 1541–1556. doi:10.1016/j.matt.2020.08.023

Jinoop, A. N., Paul, C. P., Mishra, S. K., and Bindra, K. S. (2019). Laser additive manufacturing using directed energy deposition of Inconel-718 wall structures with tailored characteristics. Vacuum 166, 270–278. doi:10.1016/j.vacuum.2019.05.027

Kang, S. H., Suh, J., Lim, S. Y., Jung, S., Jang, Y. W., and Jun, I. S. (2021). Additive manufacture of 3 inch nuclear safety class 1 valve by laser directed energy deposition. J. Nucl. Mater. 547, 152812. doi:10.1016/j.jnucmat.2021.152812

Kim, D. K., Woo, W., Kim, E. Y., and Choi, S. H. (2019). Microstructure and mechanical characteristics of multi-layered materials composed of 316L stainless steel and ferritic steel produced by direct energy deposition. J. Alloys Compd. 774, 896–907. doi:10.1016/j.jallcom.2018.09.390

Kingsbury (2010). How Additive Manufacturing Helped Launch SpaceX. Kingsbury. Available online at: https://kingsburyuk.com/how-additive-manufacturing-helped-launch-spacex/(Accessed May 21, 2025).

Koyanagi, T., Terrani, K., Harrison, S., Liu, J., and Katoh, Y. (2021a). Additive manufacturing of silicon carbide for nuclear applications. J. Nucl. Mater. 543, 152577.

Koyanagi, T., Terrani, K., Harrison, S., Liu, J., and Katoh, Y. (2021b). Additive manufacturing of silicon carbide for nuclear applications. J. Nucl. Mater. 543, 152577. doi:10.1016/j.jnucmat.2020.152577

Kumar, P., Sharma, S. K., and Singh, R. K. R. (2022). Recent trends and future outlooks in manufacturing methods and applications of FGM: a comprehensive review. Mater. Manuf. Process. 38 (9), 1033–1067. doi:10.1080/10426914.2022.2075892

Ladani, L. J. (2021). Applications of artificial intelligence and machine learning in metal additive manufacturing. JPhys Mater. 4, 042009. doi:10.1088/2515-7639/ac2791

Li, Y., Feng, Z., Hao, L., Huang, L., Xin, C., Wang, Y., et al. (2020). A review on functionally graded materials and structures via additive manufacturing: from multi-scale design to versatile functional properties. Adv. Mater Technol. 5, 1900981. doi:10.1002/admt.201900981

Li, Y., Luo, Y., Li, J., Song, D., Xu, B., and Chen, X. (2021). Ferrite formation and its effect on deformation mechanism of wire arc additive manufactured 308 L stainless steel. J. Nucl. Mater. 550, 152933. doi:10.1016/j.jnucmat.2021.152933

Li, J. S., Wang, Y. F., Chai, J., Gong, W., and Wang, X. Z. (2025). Additive manufactured ODS-FeCrAl steel achieves high corrosion resistance in lead-bismuth eutectic (LBE). J. Nucl. Mater. 604, 155516. doi:10.1016/j.jnucmat.2024.155516

Liao, H., Zhang, T., Li, C., Tang, C., Li, Y., and Chen, P. (2024). Advancements in the research of high-temperature gas-cooled reactor fuel via additive manufacturing techniques. Int. J. Adv. Nucl. React. Des. Technol. 6, 14–20. doi:10.1016/j.jandt.2024.05.005

Lou, X., and Gandy, D. (2019). Advanced manufacturing for nuclear energy. JOM 71, 2834–2836. doi:10.1007/s11837-019-03607-4

Mahamood, R. M., and Akinlabi, E. T. (2017). “Types of functionally graded materials and their areas of application,” in Topics in mining, metallurgy and materials engineering, 9–21. doi:10.1007/978-3-319-53756-6_2

McMurtrey, M. D., O’Brien, R. C., Sun, C., Shiau, C.-H., and Teng, F.Idaho National Laboratory (2019). Irradiation damage and IASCC of printed 316L for use as fuel cladding. 19th Int. Conf. Environ. Degrad. Mater. Nucl. Power Syst. – Water React. Available online at: https://www.osti.gov/biblio/1811539.

McMurtrey, M., Sun, C., Rupp, R. E., Shiau, C. H., Hanbury, R., Jerred, N., et al. (2021). Investigation of the irradiation effects in additively manufactured 316L steel resulting in decreased irradiation assisted stress corrosion cracking susceptibility. J. Nucl. Mater. 545, 152739. doi:10.1016/j.jnucmat.2020.152739

Miyagishi, T., Kondo, S., Katsui, H., Yabuuchi, K., Usukawa, R., Ogino, Y., et al. (2025). Effects of irradiation on interfacial strength and microstructure of double-layer mullite and alumina coating on SiC. J. Nucl. Mater. 603, 155410. doi:10.1016/j.jnucmat.2024.155410

Mondal, K., Karkkainen, R., Martinez, O., Sikkema, I., Mathur, M., Hollifield, S., et al. (2023). Advanced manufacturing technologies for enhancing security in nuclear and radiological materials transport. Int. J. Adv. Nucl. React. Des. Technol. 5, 144–150. doi:10.1016/j.jandt.2024.01.001

Moorehead, M., Nelaturu, P., Elbakhshwan, M., Parkin, C., Zhang, C., Sridharan, K., et al. (2021). High-throughput ion irradiation of additively manufactured compositionally complex alloys. J. Nucl. Mater. 547, 152782. doi:10.1016/j.jnucmat.2021.152782

NASA (2016). Aerojet rocketdyne partner to test AM hardware - 3dnatives. Available online at: https://www.3dnatives.com/en/nasa-and-aerojet-rocketdyne-partner-to-test-am-hardware-180520215/#! (Accessed May 21, 2025).

Nelson, A. T. (2023). Prospects for additive manufacturing of nuclear fuel forms. Prog. Nucl. Energy 155, 104493. doi:10.1016/j.pnucene.2022.104493

Pancholi, S., Gupta, M. K., Bartoszuk, M., Vashishtha, G., Ross, N. S., Korkmaz, M. E., et al. (2025). Transforming additive manufacturing with artificial intelligence: a review of current and future trends. Netherlands: Springer. doi:10.1007/s11831-025-10283-y

Parhizkar, H., Taddei, P., Weziak-bialowolska, D., Mcneely, E., Spengler, D., Guillermo, J., et al. (2023). Objective indoor air quality parameters and their association to respiratory health and well-being among office workers. Build. Environ. 246, 110984. doi:10.1016/j.buildenv.2023.110984

Petrie, C. M., Schrell, A. M., Leonard, D. N., Yang, Y., Jolly, B. C., and Terrani, K. A. (2021). Embedded sensors in additively manufactured silicon carbide. J. Nucl. Mater. 552, 153012. doi:10.1016/j.jnucmat.2021.153012

Raza, A., Deen, K. M., Jaafreh, R., Hamad, K., Haider, A., and Haider, W. (2022). Incorporation of machine learning in additive manufacturing: a review. Int. J. Adv. Manuf. Technol. 122, 1143–1166. doi:10.1007/s00170-022-09916-4

Reichardt, A., Shapiro, A. A., Otis, R., Dillon, R. P., Borgonia, J. P., McEnerney, B. W., et al. (2021). Advances in additive manufacturing of metal-based functionally graded materials. Int. Mater. Rev. 66, 1–29. doi:10.1080/09506608.2019.1709354

Ridley, M., Parker, C., Helmreich, G., Massey, C., Nelson, A., and Pint, B. (2024). Interface stability of ultrasonic additively manufactured Zircaloy-4 during hydrothermal corrosion. J. Nucl. Mater. 603, 155376. doi:10.1016/j.jnucmat.2024.155376

Sanjeeviprakash, K., Kannan, A. R., and Shanmugam, N. S. (2023). Additive manufacturing of metal-based functionally graded materials: overview, recent advancements and challenges. Springer Berlin Heidelberg. doi:10.1007/s40430-023-04174-1

Shang, Z., Fan, C., Ding, J., Xue, S., Gabriel, A., Shao, L., et al. (2021). Heavy ion irradiation response of an additively manufactured 316LN stainless steel. J. Nucl. Mater. 546, 152745. doi:10.1016/j.jnucmat.2020.152745

She, Y., Tang, J., Wang, C., Wang, Z., Huang, Z., and Yang, Y. (2024). Preparation of high-density green body based on binder jetting 3D printing using spheroidized SiC powder. Ceram. Int. 50, 32412–32419. doi:10.1016/j.ceramint.2024.06.049

Singh, R., Bhavar, V., Kattire, P., Thakare, S., Patil, S., and Singh, R. K. P. (2017). A review on functionally gradient materials (FGMs) and their applications. IOP Conf. Ser. Mater Sci. Eng. 229, 012021. doi:10.1088/1757-899X/229/1/012021

Singh, N., Singh, R., and Ahuja, I. P. S. (2018). On development of functionally graded material through fused deposition modelling assisted investment casting from Al 2 O 3/SiC reinforced waste low density polyethylene. Trans. Indian Inst. Metals 71, 2479–2485. doi:10.1007/s12666-018-1378-9

SpaceX debuts (2021). Raptor 3 engine, further enhanced with metal AM. Available online at: https://www.metal-am.com/spacex-debuts-raptor-3-engine-further-enhanced-with-metal-additive-manufacturing/(Accessed May 21, 2025).

Srivastava, M., Jayakumar, V., Udayan, Y., M, S., S M, M., Gautam, P., et al. (2024). Additive manufacturing of titanium alloy for aerospace applications: insights into the process, microstructure, and mechanical properties. Appl. Mater Today 41, 102481. doi:10.1016/j.apmt.2024.102481

Sun, C., Wang, Y., McMurtrey, M. D., Jerred, N. D., Liou, F., and Li, J. (2021). Additive manufacturing for energy: a review. Appl. Energy 282, 116041. doi:10.1016/j.apenergy.2020.116041

TCT (2015). Through the doors: inside the AM strategy at GE aerospace - TCT magazine. Available online at: https://www.tctmagazine.com/additive-manufacturing-3d-printing-industry-insights/technology-insights/through-the-doors-inside-the-am-strategy-at-ge-aerospace/(Accessed May 21, 2025).

Terrani, K. A., Jolly, B. C., Trammell, M. P., Vasadevamurthy, G., Schappel, D., Ade, B., et al. (2021). Architecture and properties of TCR fuel form. J. Nucl. Mater. 547, 152781. doi:10.1016/j.jnucmat.2021.152781

Thermophysical Properties of Materials (2009). Thermophysical properties of materials for nuclear engineering: a tutorial and collection of data. International Atomic Energy Agency.

Thomas, D. (2016). Costs, benefits, and adoption of additive manufacturing: a supply chain perspective. Int. J. Adv. Manuf. Technol. 85, 1857–1876. doi:10.1007/s00170-015-7973-6

Thompson, S. M., Bian, L., Shamsaei, N., and Yadollahi, A. (2015). An overview of direct laser deposition for additive manufacturing; part I: transport phenomena, modeling and diagnostics. Addit. Manuf. 8, 36–62. doi:10.1016/j.addma.2015.07.001

Uddin, S. Z., Murr, L. E., Terrazas, C. A., Morton, P., Roberson, D. A., and Wicker, R. B. (2018). Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing. Addit. Manuf. 22, 405–415. doi:10.1016/j.addma.2018.05.047

Ukwaththa, J., Herath, S., and Meddage, D. P. P. (2024). A review of machine learning (ML) and explainable artificial intelligence (XAI) methods in additive manufacturing (3D printing). Mater. Today Commun. 41, 110294. doi:10.1016/j.mtcomm.2024.110294

Uribe-lam, E., Treviño-quintanilla, C. D., Cuan-urquizo, E., Uribe-lam, E., and Cuan-urquizo, E. (2021). Use of additive manufacturing for the fabrication of cellular and lattice materials: a review review. Mater. Manuf. Process. 36, 257–280. doi:10.1080/10426914.2020.1819544

Vastola, G., Zhang, G., Pei, Q. X., and Zhang, Y. (2016). Modeling the microstructure evolution during additive manufacturing of TI6AL4V: a comparison between electron beam melting and selective laser melting. J. Metals 68 (5), 1370–1375. doi:10.1007/s11837-016-1890-5

Wang, R., Zhang, K., Davies, C., and Wu, X. (2017). Evolution of microstructure, mechanical and corrosion properties of AlCoCrFeNi high-entropy alloy prepared by direct laser fabrication. J. Alloys Compd. 694, 971–981. doi:10.1016/j.jallcom.2016.10.138

Xie, J., Lu, H., Lu, J., Song, X., Wu, S., and Lei, J. (2021). Additive manufacturing of tungsten using directed energy deposition for potential nuclear fusion application. Surf. Coatings Technol. 409, 126884. doi:10.1016/j.surfcoat.2021.126884

Yakovlev, A., Trunova, E., Grevey, D., Pilloz, M., and Smurov, I. (2005). Laser-assisted direct manufacturing of functionally graded 3D objects. Surf. Coat. Technol. 190, 15–24. doi:10.1016/j.surfcoat.2004.07.070

Yang, G., Xiang, Y., Poirier, T., Malmir, N., Yao, T., Churi, N., et al. (2024). Extrusion-based additive manufacturing of zirconium carbide for nuclear fuel cell structures. Ceram. Int. 51, 252–258. doi:10.1016/j.ceramint.2024.10.438

Yoon, J. H., and Kim, J. H. (2024). Characteristics of 3d printed functionally graded material for replacement of dissimilar metal weld in nuclear reactor. Archives Metallurgy Mater. 69, 45–48. doi:10.24425/amm.2024.147782

Zhang, C., Chen, F., Huang, Z., Jia, M., Chen, G., Ye, Y., et al. (2019). Additive manufacturing of functionally graded materials: a review. Mater. Sci. Eng. A 764, 138209. doi:10.1016/j.msea.2019.138209

Zhang, X., Kenesei, P., Park, J. S., Almer, J., and Li, M. (2021). In situ high-energy X-ray study of deformation mechanisms in additively manufactured 316L stainless steel. J. Nucl. Mater. 549, 152874. doi:10.1016/j.jnucmat.2021.152874

Zhao, W., Liu, W., Wu, J., Wei, Q., and Ye, C. (2023). 316L-toughened porous Al2O3-based ceramic functionally graded materials using binder jetting. Ceram. Int. 49, 39760–39770. doi:10.1016/j.ceramint.2023.06.039

Keywords: additive manufacturing, functionally graded material, nuclear component, gradient microstructure, machine learning

Citation: Sasi A, Srivastava M and Dash K (2025) Role of additive manufacturing in developing functionally graded materials for nuclear applications. Front. Nucl. Eng. 4:1603437. doi: 10.3389/fnuen.2025.1603437

Received: 31 March 2025; Accepted: 28 July 2025;

Published: 21 August 2025.

Edited by:

Mohan Sai Kiran Kumar Yadav Nartu, Pacific Northwest National Laboratory (DOE), United StatesReviewed by:

Saisree Varahabhatla, University of Pittsburgh, United StatesKrishna Kamlesh Verma, University of North Texas, United States

Copyright © 2025 Sasi, Srivastava and Dash. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: K. Dash, ZF9raHVzaGJ1QGNoLmFtcml0YS5lZHU=

Amal Sasi

Amal Sasi Madhulika Srivastava

Madhulika Srivastava K. Dash

K. Dash