- 1Department of Chemical and Environmental Engineering, The University of Nottingham Ningbo China, Ningbo, China

- 2Nottingham Ningbo China Beacons of Excellence Research and Innovation Centre, Ningbo, China

- 3State Key Laboratory of Advanced Environmental Technology, Institute of Urban Environment, Chinese Academy of Sciences, Xiamen, China

- 4Ningbo Key Laboratory of Urban Environmental Pollution Control, Chinese Academy of Science (CAS) Haixi Industrial Technology Innovation Center in Beilun, Ningbo, China

- 5Ningbo Helong New Material Co., LTD, Ningbo, China

The escalating issue of marine plastic pollution demands urgent and innovative solutions to mitigate its detrimental impacts on ecosystems, human health, and global economies. This paper provides a comprehensive review of mechanical recycling and upcycling technologies for marine macro- and microplastics, addressing the challenges and future directions in their sustainable management. The study systematically examines the processes of collection, cleaning, separation, and melt processing, highlighting advancements and limitations in current methodologies. Recent advancements in marine plastic recycling technologies have addressed the challenges of macroplastic collection and separation, further research into more cost-effective and scalable processes remains imperative for its recycling and upcycling. The recycling of microplastics is much more challenging because of the difficulties in efficient collection and separation. The comprehensive methodologies for the segregation of both macroplastics and microplastics were discussed. The policy framework and technical pathway for marine plastics management was proposed. The paper concludes with actionable recommendations for stakeholders, emphasizing the need for standardized monitoring, improved separation techniques, and global collaboration to combat marine plastic pollution effectively.

1 Introduction

The ocean covers nearly 71% of Earth’s surface, making it potentially the most extensive repository of waste on our planet. The pervasive issue of marine plastic pollution poses a significant threat to the health of our oceans and has far-reaching implications for ecosystems, economies, and global policies. Mismanaged waste plastics enter the ocean primarily via river systems and activities related to marine fisheries (Van Emmerik et al., 2019; Nelms et al., 2021; Meijer et al., 2021; Thushari and Senevirathna, 2020). The endangerment of ocean ecosystems by plastic pollution from marine sources is a substantial concern, where non-biodegradable plastics constitute 73% of the debris present in various aquatic ecosystems worldwide (Cocchi et al., 2023). Waste marine plastics pose a threat to marine wildlife through entanglement and ingestion, as well as to human marine activities through interaction with ships (Law, 2017; Ibrahim et al., 2024). The toxic substances in marine plastics, especially monomer residues, plasticisers, coloring agents, flame retardants, and others, cause ecotoxicological and combined pollution (Gong and Xie, 2020; Worm et al., 2017). Furthermore, chemical pollutants, which include pharmaceuticals and personal care products, pesticides, polycyclic aromatic hydrocarbons, polychlorinated biphenyls, trace heavy metals, ultraviolet filters (UV-filters), organophosphorus flame retardants (OPFR), as well as polybrominated diphenyl ethers (PBDEs) derived from marine plastic debris, possess the capacity to promote trophic transfer and bioaccumulation within the ecological food web, thereby presenting a considerable threat to human health (Worm et al., 2017; Râpă et al., 2024; Aragaw, 2020). Moreover, specific minuscule plastic microparticles may leach their chemical additives, such as bisphenol A (BPA), bis(2-ethylhexyl) phthalate (DEHP), and dibutyl phthalate (DBP), consequently exacerbating the potential risks to both aquatic life forms and human health (Dimassi et al., 2023).

As plastics accumulate in marine environments, they not only disrupt marine life but also lead to economic burdens through the degradation of coastal communities and industries such as fisheries and tourism. Calculating the accurate economic impact of marine plastics is challenging. Beaumont et al. (2019) estimate that marine plastic pollution could reduce global marine ecosystem service (benefits provided to human by marine ecosystem (Barbier, 2017)) delivery by 1–5% annually, equivalent to an economic loss of $500–$2500 billion per year (based on 2011 values). Given the estimated 75–150 million tons of plastic in the ocean in 2011, this translates to an annual cost of $3300–$33,000 per ton of marine plastic in terms of diminished marine natural capital (Beaumont et al., 2019). Although an accurate quantitative assessment of the economic impact of marine plastics on the entire ecosystem is not possible, the financial losses attributable to marine plastics can be quantified in certain sectors, such as fisheries and tourism (Newman et al., 2015). Mcilgorm et al. (2022) studied the direct economic loss incurred in the sectors of fisheries, aquaculture, maritime transportation and marine tourism, the economic loss in Asia Pacific Economic Cooperation (APEC) and on global scale amounted to $10.82 billion and $18.3 billion, respectively. In the absence of changes in plastic production or waste management policies, the global economic loss associated with marine plastics can reach $ 731 billion by 2050 (Mcilgorm et al., 2022).

In response to this crisis, various countries have implemented policies and initiatives aimed at mitigating the impact of plastic waste and promoting sustainable practices. The EU Marine Strategy Framework Directive (Directive 2008/56/EC) and the Waste Directive (Directive 2008/98/EC) established the requirements for monitoring and reducing marine plastics and waste treatment hierarchy, respectively (Penca, 2018). In 2020, the Save Our Seas 2.0 Act, a bipartisan effort in the United States, was enacted to fortify domestic initiatives targeting marine debris, bolster international engagement in combatting marine waste, and enhance local systems to mitigate marine litter (S.1982 - 116TH CONGRESS, 2019-2020). The United States’ policy inclination is directed towards diminishing the utilization of disposable plastic bags (Wagner, 2017) and stopping the use of plastic microbeads for cosmetic products (Bakaraki Turan et al., 2021). China has also established a stricter waste plastic management framework, while policy development and scientific research on marine plastics have accelerated in recent years. In 2017, the State Oceanic Administration (SOA) established the Marine Litter and Microplastics (MPs) Research Center, focusing on monitoring technologies and global governance strategies (Fu et al., 2020). At the provincial level, the Fujian government promulgated a strategic action plan aimed at enhancing the integrated management of floating garbage in the sea in 2020, which constituted the first document specifically developed to address marine waste cleanups, including plastic waste (Fürst and Feng, 2022). The predominant focus of these policy frameworks is on the mitigation of plastic waste entering the oceans, with limited attention directed towards the recycling and repurposing of marine plastic materials. Current estimates indicate that over 150 million tons of plastics already pollute our oceans, with an additional 4.8–12.7 million metric tons entering marine ecosystems each year (Agenda, 2016; Jambeck et al., 2015). Given this escalating crisis, developing specialized recycling methodologies for marine plastics has become an urgent priority.

The challenges for marine plastics mechanical recycling and upcycling mainly arises from three aspects. First, pre-processing marine plastics presents additional difficulties compared to municipal waste. Large-scale collection systems for marine plastics are lacking, and the unique marine environment introduces contaminants such as salt, marine organisms, and sand. These factors prevent the direct application of conventional land-based sorting techniques to marine plastics (Mendoza et al., 2024). Second, marine environments accelerate plastic degradation due to mechanical forces (e.g., waves, currents) and prolonged UV exposure. This degradation negatively impacts both mechanical recycling and upcycling, though its full effects remain understudied (Law, 2017). Third, the current low economic viability of marine plastic recycling indicates that technological solutions alone are insufficient. Addressing plastic pollution requires collaborative efforts from multiple stakeholders, including policymakers (Schmaltz et al., 2020).

Despite growing literature on marine plastic pollution (Cole et al., 2011; Simul Bhuyan et al., 2021; Li et al., 2016; Yang et al., 2021b; Iñiguez et al., 2016; Auta et al., 2017), critical gaps persist in scalable recycling solutions. First, existing reviews focus predominantly on environmental impacts (Aragaw, 2020b) or policy frameworks (Wu, 2022),with limited integration of technical pathways. Second, while macroplastic collection technologies have advanced (Schmaltz et al., 2020), cost-effective microplastic retrieval remains unexplored at scale. Third, degradation studies (Iniguez et al., 2018) rarely address recyclability thresholds for marine-weathered plastics. This review bridges these gaps by synthesizing marine plastics sources, recycling challenges and mechanical recycling technologies with actionable policy and economic insights. While this review focuses on mechanical recycling and upcycling, we acknowledge that challenges in collection, cleaning, and separation apply broadly to chemical, thermal, and biological recycling. However, because mechanical recycling is the dominant method in current industry practice and requires stricter pre-processing standards due to its sensitivity to contaminants, polymer degradation, and economic viability constraints, we will therefore limit our discussion of pre-processing stages to mechanical recycling (Muzata et al., 2024; Ragaert et al., 2017).

1.1 Sources of marine plastics

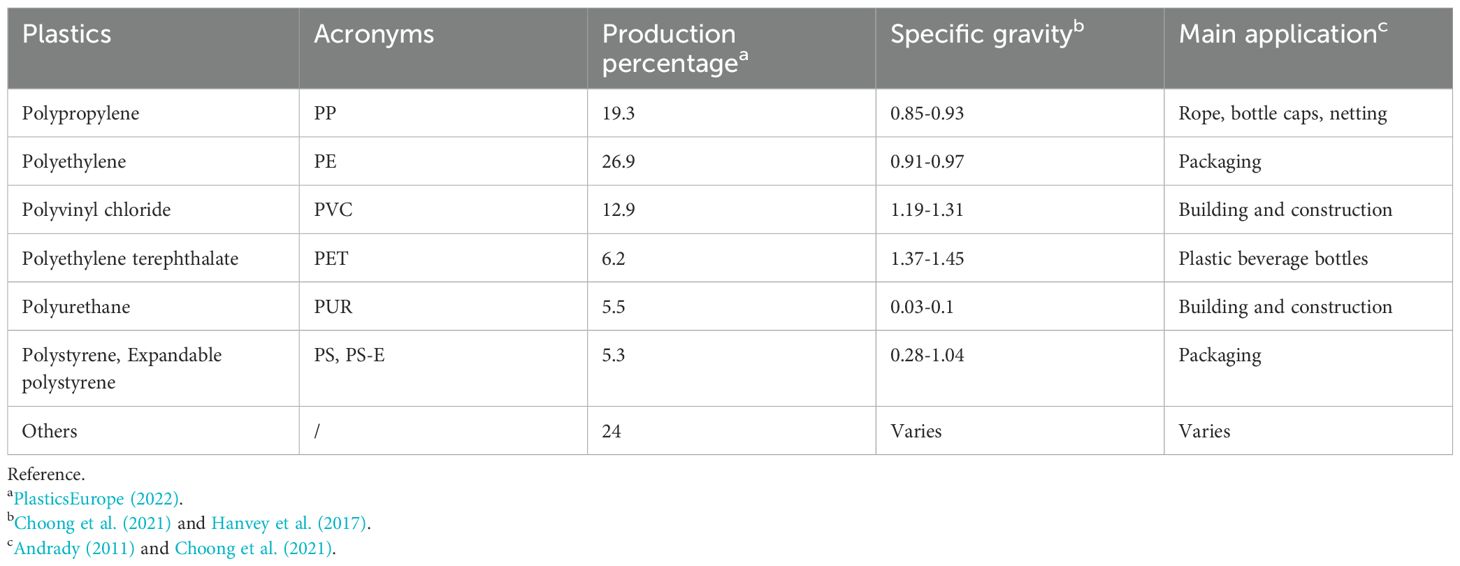

In 2021, the worldwide production of plastic reached 390.7 million tons (PlasticsEurope, 2022). Table 1 lists the production data for the major types of plastics.

When the aforementioned plastic products reach the end of their lifecycle, an estimated 4.8 to 12.7 million metric tons of improperly managed plastic waste is annually deposited into the ocean (Jambeck et al., 2015). Consequently, it is projected that the total amount of plastic waste in the marine ecosystem will reach approximately 100 to 250 million metric tons by the year 2025 (Jambeck et al., 2015).

Plastic waste can be categorized into macroplastics (>0.5 cm) and microplastics (<0.5 cm) (Lebreton et al., 2019). Other researchers have a more precise classification based on the plastic dimensions: mega-debris (>100 mm), macro-debris (20–100 mm), meso-debris (5–20 mm), micro-debris (0.1μm and 5 mm) (Barnes et al., 2009), and nano-debris (<0.1μm) (GESAMP, 2016). The types and sizes of marine plastics vary across distinct geological regions. Polyethylene (PE), polypropylene (PP), and polystyrene (PS) are the most commonly found waste plastics in marine environments (Perumal and Muthuramalingam, 2022). Eo et al. (2018) investigated the waste plastic compositions of sand beaches in South Korea and found that 95% of the large microplastics (1–5 mm) expanded PS, whereas PE and PP accounted for 49% and 38% of the small microplastics (0.02–1 mm), respectively. Based on a meta-analysis, Erni-Cassola et al. (2019) further concluded that low-density PP and PE (0.89-0.94 g/cm3)accounted for 25% and 42% of the sea surface sample, and the content decreased to 3% and 2% in the deep sea, polyesters and acrylics (1.10-1.40 g/cm3), which are dense polymers, account for 77% of the plastics found in deep-sea environments.

Marine plastics originate from land-based pollution and marine activities. Research has shown that 80% of marine plastic waste comes from land (Andrady, 2011). Southeast Asia is proposed to be the primary source of plastic emissions from terrestrial to marine environments, predominantly originating from river systems (Van Emmerik et al., 2019). Meijer et al. (2021) examined the origins of marine plastics from rivers, and their findings reveal that over 1000 rivers contribute to 80% of the total global riverine plastic discharge into the marine environment. 0.8 million to 2.7 million metric tons of plastics enter the ocean from these 1000 rivers annually. It was estimated that the Yangtze River catchment in China contributes the largest annual plastic load to the ocean, discharging 0.33 million tons (range: 0.31–0.48) into the East China Sea. The Ganges River catchment ranks second, with an estimated input of 0.12 million tons per year (range: 0.10–0.17) (Lebreton et al., 2017). Nelms et al. (2021) studied the plastic pollution in the Ganges River, a 2500 km river in India that sustains over 655 million people, finding that the major source of plastic pollution is discarded fishing gear in such large rivers. Marine plastic emissions were found to be strongly associated with fishing activities. Deville et al. (2023) conducted a study on marine plastic emissions within the Peruvian Economic Exclusive Zone, revealing that an estimated 2,715–5,584 metric tons of plastic material were discharged into this region in 2018. Notably, discarded, lost, or abandoned fishing equipment contributed significantly, accounting for 56–96% of the total plastic release.

Compare to macroplastics, the identification and quantification of microplastics present significantly greater challenges. The microplastics infiltrate the marine environment via various pathways, such as riverine systems, coastlines, urban sewage outflows, storm runoffs, inappropriate disposal methods, intentional dumping, unintended releases from marine operations, and atmospheric deposition (Wang et al., 2018). The primary sources of microplastics include plastic pellets, microbeads, and glitters (Fatima and Chihhao, 2022). The secondary sources are effluent from water and wastewater treatment plants, wear and tear from normal plastic use, and airborne dust (Yang et al., 2021a; GESAMP, 2016). Macroplastics may also be further degraded to secondary microplastics after exposure to the marine environment (Hasan Anik et al., 2021; Wang et al., 2018). The investigation of microplastics in beach and marine bottom sediments in the southern Baltic Sea showed that wastewater treatment plant effluents, maritime transport, and tourism are major sources of microplastic pollutants (Graca et al., 2017). Given the diverse sources and widespread presence of marine microplastics, significant attention has been directed towards monitoring their distribution and abundance in aquatic environments. The National Oceanic and Atmospheric Administration (NOAA), National Centers for Environmental Information (NCEI) provide open access to global marine microplastic data through a user-friendly GIS web map and data porta, facilitating the continuous monitoring of microplastic distribution on a worldwide scale (Nyadjro et al., 2023).

1.2 Challenges for recycling marine plastic wastes

A systemic perspective is crucial for understanding the challenges associated with the management of marine plastic waste (Schneider et al., 2018). Although numerous studies have focused on policies to reduce plastic waste before it enters the ocean (Willis et al., 2018; Wu, 2022; Kamaruddin et al., 2022), the substantial quantity of existing marine debris necessitates the development of sustainable recycling and treatment technologies. Key challenges in managing marine plastic waste arise from the collection, separation, and recycling processes because of technical and economic considerations.

The collection of marine plastic waste presents significant logistical and economic challenges (Juan et al., 2021). Current methods for collecting marine plastic waste typically include: 1) manual retrieval from coastal areas, 2) surface trawling operations, 3) deployment of retention booms to capture floating marine debris at the sea surface, 4) bottom trawling, and 5) underwater diving collection (Schneider et al., 2018). Current marine plastic collection methods face significant limitations. Manual retrieval, especially through underwater diving, is notably expensive, while the effectiveness of surface or bottom trawling depends heavily on the local concentration of plastic waste. Although these methods are effective for collecting macroplastics, they are less suited for microplastics, which are rarely addressed by existing technologies. Owing to the technical and economic constraints of collection technologies, nonprofit organizations have become primary contributors to marine plastic collection initiatives. As the volume of collected ocean plastics increases, the challenge of treating and recycling this waste has become increasingly pressing.

Following collections, marine plastics must be properly separated to enable high-value recycling application. Similar to municipal plastic waste, the inherent immiscibility of different plastic types complicates recycling efforts (Hopewell et al., 2009). For macroplastics, manual sorting remains a practical separation approach. In contrast, microplastic separation demands more sophisticated methodologies, including filtration, density-based flotation, centrifugation, and magnetic separation techniques (Kurniawan et al., 2021). The complex composition of waste streams and degradation of plastics after reprocessing are major challenges for mechanical recycling (Vogt et al., 2021). Before melt processing, waste marine plastics must be sorted to achieve a certain purity level prior to the reprocessing process, such as extrusion. However, even low levels of contaminants can be difficult to remove and compromise the performance of recycled plastic products processed by mechanical separation (Roosen et al., 2020).

Plastic degradation in marine environments further complicates recycling. Previous research indicates that ultraviolet (UV) degradation dominates the breakdown of marine plastics, with biodegradation, thermo-oxidative degradation, thermal degradation, and hydrolysis playing comparatively minor roles (Andrady, 2011). UV exposure leads to the photo-initiated oxidative degradation of polyethylene (PE), polypropylene (PP), and polystyrene (PS), resulting in reduced molecular weight and the generation of carboxylic functional groups. These changes can significantly deteriorate the mechanical performance of recycled marine plastics. Iniguez et al. (2018) studied the recyclability of four common plastics, Nylon, PE, PP and PET, in marine environments. After 6.5 months of UV exposure, the study found that all materials exhibited surface degradation, with PP showing visible cracks. All materials become less elastic and more rigid. However, quantifying the degradation rate of marine plastics remains challenging because of the presence of different types of additives, as well as potential shielding by water or biofilms (Gewert et al., 2015). Consequently, characterizing the recyclability of marine plastics is critical before mechanical recycling can be undertaken.

2 Mechanical recycling of marine plastics

Mechanical recycling is the most common approach for recycling waste plastics and involves a series of sequential processes: collection/segregation, cleaning, drying, chipping/sizing, coloring/agglomeration, pelletization/extrusion, and manufacturing (Li et al., 2022).

Mechanical recycling refers to a series of physical processes designed to recover plastic materials for reuse. As the most widely adopted method for plastic waste recycling, this approach typically involves sequential operations including separation and sorting, baling, washing, grinding, compounding/pelletizing (Ragaert et al., 2017).

However, recycling marine plastics presents unique challenges compared with land-based plastic waste, primarily because of the following factors:

1. The collection of marine plastics presents significantly greater challenges compared to municipal waste, primarily due to the complexities associated with detecting marine plastics and retrieving microplastics (Ibrahim et al., 2024).

2. Difficulty in eliminating pollutants in marine plastics, such as salt, sand, shell, algae and marine plants (Ronkay et al., 2021).

3. Some marine plastic debris present challenges for mechanical recycling owing to their complex structures, multilayered compositions, or heterogeneous material properties (Ibrahim et al., 2024). Existing separation techniques may be inadequate for processing these macro- and microplastics.

The subsequent discussion elucidates the existing techniques and challenges of the aforementioned procedures within the context of marine plastic waste cycling.

2.1 Marine plastic collection

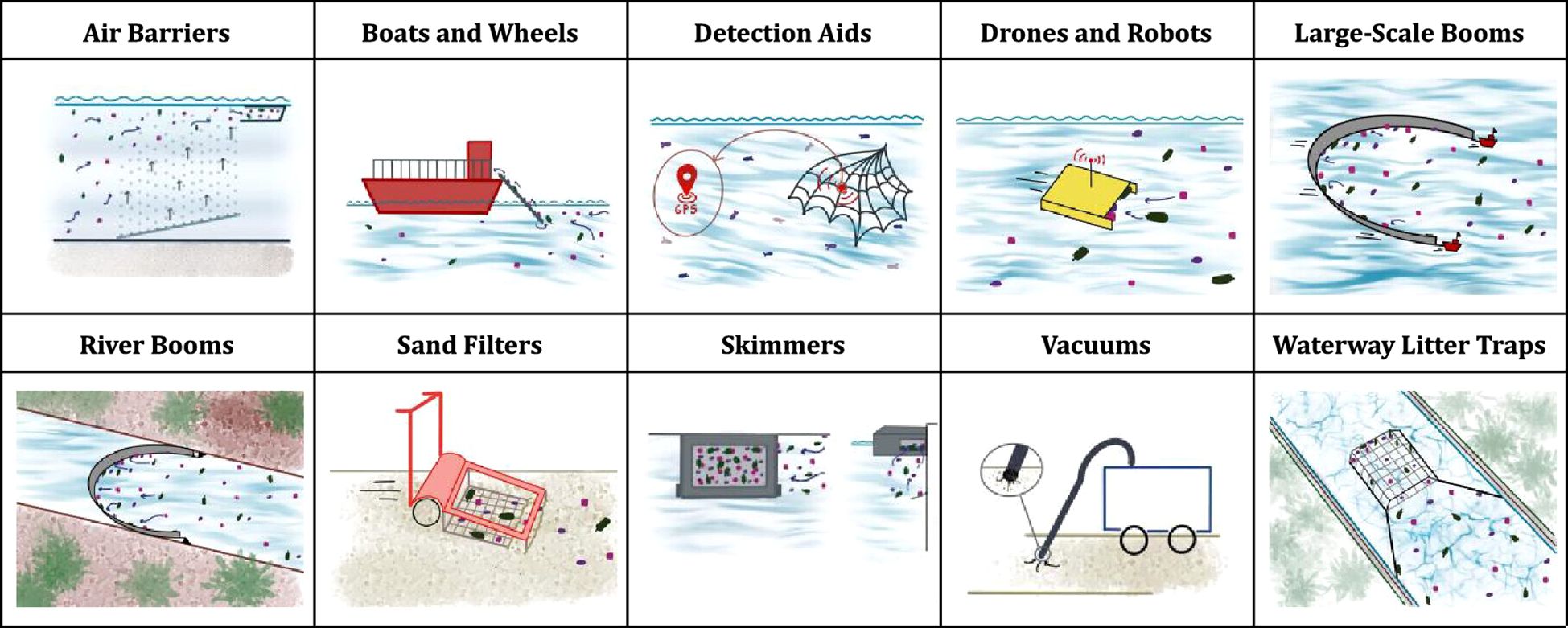

Schmaltz et al. (2020) provided a comprehensive overview the current marine and riverine plastics collection technologies, as shown in Figure 1.

Figure 1. Graphical depictions of waste plastic collection technologies (Falk-Andersson et al., 2023).

These technologies can be divided into two categories: 1) prevention technologies and 2) clean-up technologies (Schmaltz et al., 2020). Prevention technologies aim to reduce marine plastic pollution by intercepting plastics before they enter the ocean, often targeting rivers as the primary pathways. An example of this technology is the Mr. Trash Wheel, a device powered by both solar and hydro energy, strategically positioned at the mouth of rivers or streams to capture floating debris and use a conveyor system to transfer the accumulated waste into designated dumpsters (Mr. Trash Wheel, ). Another example is the “Great bubble barrier”, which uses a tube with holes installed on the riverbed, which is pumped through the tube and pushes the plastic to the water surface to be collected (UNESCO, 2022).

In contrast, cleanup technologies focus on retrieving plastics that are already present in marine environments. However, owing to high costs and limited effectiveness, only a few institutions and businesses are actively engaged in marine plastic retrieval. Operations that focus on both floating and underwater marine plastic recycling have been reported. One notable example of a floating plastic operation is the Seabin Project, which originated in Australia. A pool skimmer and a garbage bin were combined near the shoreline to establish a system for gathering marine debris. In 2022, this initiative managed to collected 32.9 tons of marine litter in Sydney and 3.34 tons in Los Angeles (Seabin, 2023). For large-scale operations, The Ocean Cleanup initiative stands out as a pioneering effort aimed at reducing marine plastic pollution in large accumulation zones, such as the Great Pacific garbage patch. The Ocean Cleanup has developed a massive (three meters in depth) U-shaped floating net-like barrier to capture plastic debris in open ocean environments. This innovative structure is gradually towed by two ships to gather floating marine plastics, which are then transported to shore for recycling (Renee cho, 2022). Despite these efforts, collection activities in areas with low plastic density remain limited. Detect-aid collection systems have been proposed to address this issue. A research team from Xiamen University developed a sea-floating litter prediction system that monitors and identifies floating marine litter, predicts its trajectory, and determines the optimum interception points (Zhang, 2020). For underwater marine plastics, although Broere et al. (2021) reported successful submerged macroplastic detection using imaging sonar, the high costs associated with seafloor plastic retrieval have hindered large-scale applications. Currently, most underwater plastic collection relies on trawling by fishermen or manual retrieval by scuba and snorkel divers, which are labor-intensive and costly (Madricardo et al., 2020).

Due to technological and economic constraints, the collection of microplastics is even more challenging and was primarily conducted for research purposes. The Non-profit Organization, ‘Microplastic Removal System’, uses a static charge filtration screen to remove the microplastics from beaches, often relying on volunteers from developed regions, such as the US, UK, Australia and Hong Kong (Microplastic Removal Systems, ). Air barriers (or bubble barriers) can also be used for the collection of microplastics as small as 1 mm in size (The Great Bubble Barrier, ).

Overall, to address the collection limitations noted in Section 1.2, passive systems (e.g., Bubble Barriers, Seabins) reduce operational costs compared to manual retrieval but remain depth-limited (<5 m). Detect-aid systems (e.g., trajectory prediction) improve efficiency in low-density zones, though scalable solutions for benthic macroplastics are absent. Microplastic collection, however, remains economically unviable and source control is currently more feasible than retrieval.

2.2 Marine plastic cleaning

Compared to terrestrial waste plastics, marine plastic waste often contains additional contaminants such as sand, salt, shells, algae, and marine plants (Ronkay et al., 2021). Density separation can effectively isolate sand and shells from plastic materials. Conventionally, cleaning processes involve purification and desiccation procedures, where cold or hot water is used to remove impurities, and chemical cleaning agents, such as caustic soda and surfactants, are employed to detach adhesives from plastics (Al-Salem et al., 2009). Such methods are highly effective and capable of removing over 99% of the initial organic contaminants in RPET bottles. These cleaning processes are often integrated into the sorting process; for example, shredding is combined with a sink-float sorting step (Lange, 2021).

However, conventional wet cleaning processes are resource intensive and require significant amounts of water, energy for drying, and additional wastewater treatment. To address these challenges, various dry cleaning processes have been developed to reduce the use of water and energy, as well as wastewater treatment costs. Xia and Zhang (2018) developed a dry system employing particle collision and abrasion to clean waste plastics within a gas-solid medium. They systematically investigated the effects of the superficial gas velocity, bed height, thermal conditions, agitation velocity, and cleaning duration in an agitated fluidized bed containing Geldart B silica sand. Geng et al. (2022) also proposed a similar waterless process for waste plastic cleaning, which involves three main steps: 1) detachment of soil and small sand through the friction of the sand medium, 2) separation of sand and plastics by a wind sorting device, and 3) removal of dust on the plastic piece surface by high-speed air. This dry cleaning process can achieve a cleaning efficiency of over 90% and offers economic benefits, with resource consumption of 88.64 RMB/ton and net income of 311.36 RMB/ton (Geng et al., 2022).

2.3 Marine plastic separation

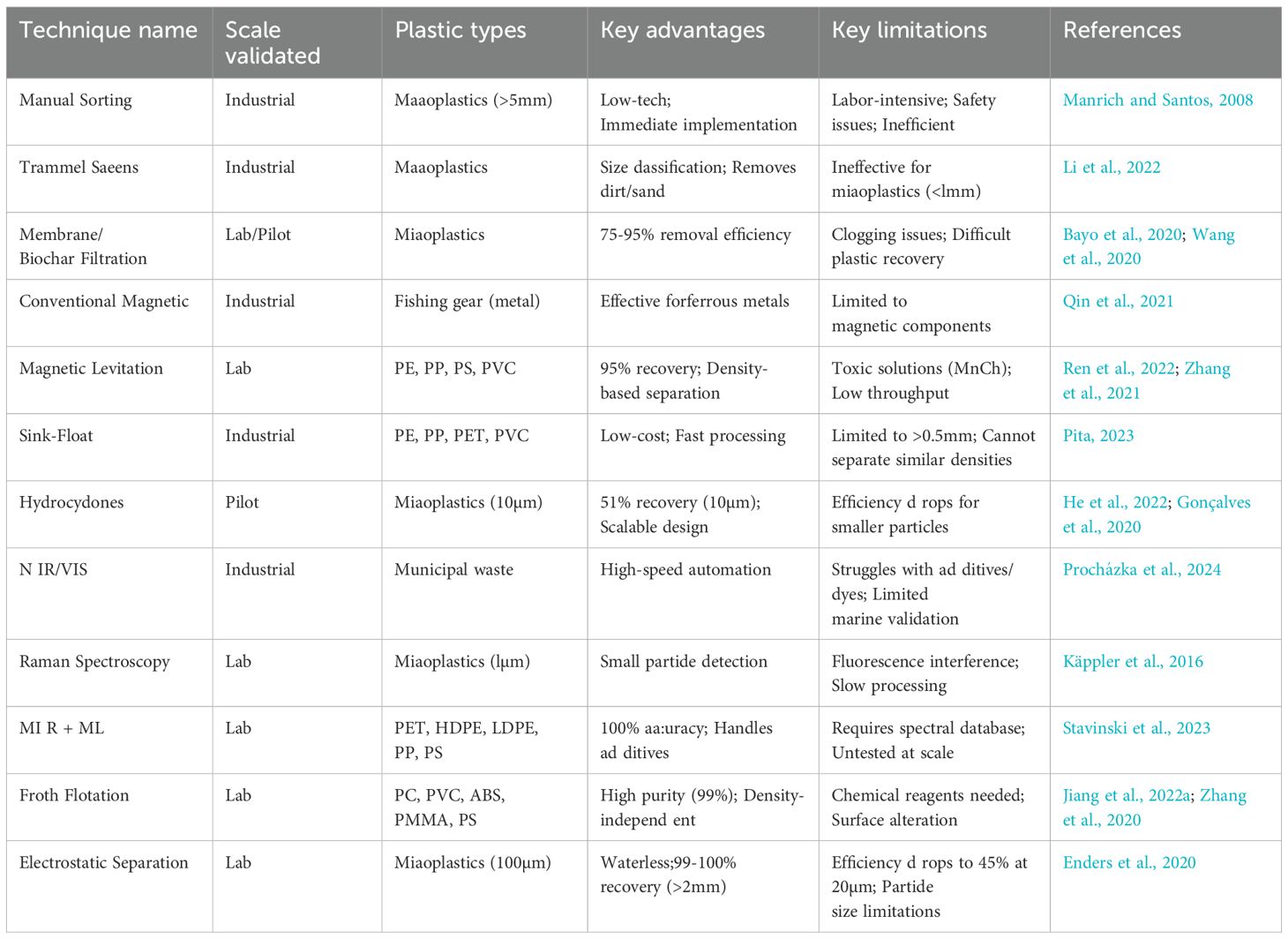

Table 2 summarized the plastic separation techniques covered in this section. The table outlines the scale at which the technique has been validated, types of plastics suitable for each technique, along with their respective advantages and limitations.

2.3.1 Manual sorting

Manual sorting is a simple and labor-intensive sorting method, the recyclable materials were selectively sorted by the “waste pickers” (Li et al., 2022). Manual sorting can be applied to visible marine macroplastics, but this process depends entirely on the experience of the workers responsible for identifying and sorting the plastics (Manrich and Santos, 2008). Although manual sorting is inexpensive, it has been proven to be unsafe and inefficient in some developing countries, such as China (Ji et al., 2022). The safety concerns predominantly arise from 1) an insufficiency of personal protective equipment; 2) the prevalent condition of workers being financially disenfranchised, lacking stable housing, and not receiving adequate community assistance; 3) the inability of workers to access sufficient medical care; 4) the absence of comprehensive safety regulations pertaining to waste management; and 5) a deficiency in safety training and awareness (Chandrappa and Das, 2012).

2.3.2 Sieving

Trommel screens, also referred to as rotary screens, are cylindrical rollers that are positioned at an incline and feature perforations along their surfaces, which can be utilized for either primary or final size classification (Li et al., 2022). The small holes first screen out fine dirt and small objects; therefore, macroplastics with the desired size can be separately collected (Ji et al., 2022). The factors influencing the efficiency of a trommel include the dimensions of the screen apertures, the diameter of the trommel, the rate of rotation, the classification of the trommel, the quantity of baffles, and the angle of inclination of the cylinder (Li et al., 2022). For microplastics, once they are collected, on-site sieving can be applied to isolate large microplastics (>1 mm) for later visual processing. However, this technique is not applicable to small microplastics (<1 mm) and requires further laboratory extraction processes (Hanvey et al., 2017). Filtration is a commonly used method for separating and collecting microplastics. Bayo et al. (2020) compared the efficiency of membrane bioreactor and rapid sand filtration on the removal of microplastics, the results indicated these two types of filtration obtained similar performance, the removal efficiency is 79.01% and 75.49%, respectively. Researchers have endeavored to identify the primary controlling variables and enhance the effectiveness of filtration processes. In a study conducted by Zhu (2015), an elutriation apparatus was developed with a focus on optimizing the flow rate and column diameter to attain the targeted filtration efficiency for microplastics. To further improve the filtration performance, Wang et al. (2020) used corn straw biochar and hardwood biochar as filtration media and achieved a removal efficiency of more than 95% for the microplastic spheres. The problem with the filtration technique is that it is difficult to extract and recycle the microplastics accumulated in the filtration medium. To overcome this problem, Rhein et al. (2019) proposed a magnetic-seeded filtration process that involved hetero-agglomeration and magnetic separation steps. Fe3O4 was used as a magnetic seed to agglomerate with the non-magnetite microplastics to form hetero-agglomerates, and the tank was subjected to a magnetic field to process the separation. This process can also achieve a separation efficiency of 95% (Rhein et al., 2019). Subsequent work by the research group further evaluated three hetero-agglomerate processing approaches: thermal, chemical, and mechanical breakup methods. These investigations revealed consistent performance across all strategies, with high magnetic seed recovery rates exceeding 90%, maintained separation efficiency through multiple operational cycles, and effective recovery of non-magnetic fractions when applicable (Rhein et al., 2021).

2.3.3 Magnetic separation

Magnetic separation is a common method for separating magnetic and non-magnetic materials (Qin et al., 2021). It is usually followed by eddy current and density segregation methodologies to separate ferrous metals, non-ferrous metals, and non-metallic materials (Adhiwiguna et al., 2025). Consequently, metals in marine plastics (mixed macroplastics), such as fishing gear, can be effectively separated using this technique. For microplastics, a technique called magnetic levitation separation has been developed and used in various applications (Xia et al., 2023; Zhang et al., 2021; Ren et al., 2022). The magnetic levitation of plastic is achieved by the balance of the gravitational force, buoyancy force and the magnetic buoyancy force on the object, the levitated height of the object is affected by the magnetic field and material density (Zhao et al., 2018). An important advantage of magnetic levitation is that it can separate mixed plastics rather than the two types of plastics in most of the extant separation processes (Zhang et al., 2019). Ren et al. (2022) designed a magnetism-assisted density gradient separation device, by adjusting the density of the MnCl2 solution, the PE with different densities (0.98-1.35 g cm-3) was also selectively separated. Although microplastics can be accurately separated using this technique, their processing capacity is still low. Zhang et al. (2021) proposed a magnetic projection device with an automatic feeding module to improve the automation of the process, and six types of plastics were successfully separated, with a recovery rate of over 95%. To increase the operating space and processing capacity, Xia et al. (2023) developed radial magnetic levitation with an open structure of two ring magnets, making the addition and removal of samples and medium easier, with good visualization, and no limitation on the height of the container. The challenge for magnetism-assisted separation is that the microplastic feed into the system needs to be properly controlled in terms of size and impurities. Another problem is that manganese chloride, used as a solution in the process, is toxic and may harm the aquatic environment, which means that the industry incurs extra costs for plastic cleaning and wastewater treatment.

2.3.4 Density separation (sink-float separation)

Plastics with different densities can be placed in a liquid of intermediate density; the denser plastic will sink and separate from the floating plastics (Pita, 2023). Due to its low cost and fast separation efficiency, density separation is the most feasible and applicable method for application in various contaminated environments (Kurniawan et al., 2021), and medium density plays a key role in affecting the separation efficiency of mixed plastics (Fu et al., 2017). Water, calcium chloride solution (CaCl2), sodium chloride solution (NaCl), and ethyl alcohol solution (C2H5OH) are commonly used separation media (Wang et al., 2019; Fu et al., 2017). However, non-aqueous media present post-separation challenges, as residual solutes must be thoroughly removed from recovered plastics. In this regard, water-soluble salts like NaCl are particularly advantageous due to their ease of removal through simple rinsing and lower environmental impact compared to heavy metal salts. Duong et al. (2022) tested the separation efficiency of microplastics (PS, PE, PVC, PET, PP, and HDPE) using different salt solutions (NaCl, NaI, CaCl2, and ZnCl2), and the results revealed that NaCl is the best option by considering the separation efficiency, cost, environmental effects, and ease of post-separation cleanup.

Nevertheless, for plastic particles that possess dimensions smaller than 0.5 mm, the traditional density separator proves to be impractical; but the technique of hydrocyclone separation may be employed (Zhang et al., 2023). The hydrocyclone, also referred to as a cyclone, is a widely applied separation device in the coal industry, which utilizes centrifugal force to accelerate the setting rate of slurry particles and separate particles according to their shape, size, and density (Lu, 2015). However, because this method is gravity-based, plastics with similar densities cannot be separated by this method (Pita and Castilho, 2017). Hydrocyclones have been applied for the separation of different types of plastics (Gent et al., 2018; Zhang et al., 2023; Malcolm Richard et al., 2011). Malcolm Richard et al. (2011) presented a method for the separation of plastics with different densities by using density media separation (DMS) techniques. The efficiency of DMS cyclones is influenced by various factors such as viscosity, particle size distribution, flow rate, pressure of the separation media, diameter, length, feed and exit port size, cyclone configurations, and particle size distributions (Malcolm Richard et al., 2011). To enhance the geometric characteristics of hydrocyclones and optimize their performance, computational fluid dynamics simulations were utilized to replicate and study the intricate mechanisms involved in the centrifugal separation process. This approach involves the application of advanced numerical methods to model fluid flow patterns, forces, and interactions within the hydrocyclone system, providing valuable insights into the underlying physics and enabling the identification of potential areas for improvement and optimization. Based on a database of 60 hydrocyclones with different geometric dimensions, Gonçalves et al. (2020) used numerical and experimental studies to change the design of hydrocyclones, leading to a 22% higher processing capacity, 9% higher efficiency, and 33% reduction in energy consumption.

The concentration of microplastics and the viscosity of the solution also affect the overall performance. He et al. (2022) investigated the performance of mini-hydrocyclones in separating microplastics, 10 μm microplastics achieved a recovery rate of 51%, with a maximum concentration ratio of 2.16. Han et al. (2019) improved the extraction efficiency of microplastics in flotation techniques by using a NaCl-NaI mix to replace the commonly used NaCl solution and used air flotation rather than stirring. Yuan et al. (2022) also used air flotation to remove the microplastics from water in a mini-hydrocyclone, the separation efficiency improved by 5% to 15% within a split ratio range of 0.04 to 0.23.

As mentioned above, the efficiency of hydrocyclones in separating plastics depends on the inherent properties of microplastics, selection of the separation medium, and geometry of the cyclones. However, the properties of microplastics in different geological regions may vary, which means that the design of the separation process must be optimized accordingly.

2.3.5 Optical sorting

There are some commonly used spectroscopic methods (optical techniques) to separate municipal waste plastics, including near-infrared (NIR), Raman, Laser-induced breakdown spectroscopy (LIBS), and X-ray fluorescence spectroscopy (XRF). The process of optical sorting relies on the application of artificial illumination to the stream of waste materials, which is subsequently identified by highly sensitive sensors, followed by the pneumatic ejection of the identified materials to their predetermined locations; among the various methodologies employed, near-infrared/visual spectroscopy (NIR/VIS) scanning is the most commonly used technique (Procházka et al., 2024). However, current optical sorting methods are mainly designed for separating mixed municipal solid waste, and the effectiveness of optical sorting for marine plastics still requires further investigation. Mendoza et al. (2024) evaluated the performance of municipal solid waste optical sorters (NIR/VIS) for separating marine plastics, the results showed the chemical differences of the marine plastics will not affect the efficiency of the automatic sorting system. The NIR/VIS wavelengths may however present additional difficulties in the characterization of post-consumer plastics due to the excessively absorbent spectral bands originating from various additives such as dyes. Furthermore, environmental weathering (e.g., mechanical abrasion and photodegradation) alters polymer surface chemistry, causing spectral shifts that reduce identification accuracy. For example, photodegradation generates carbonyl groups (C=O), creating new FTIR absorption peaks at 1710–1740 cm-1 (Iniguez et al., 2018; Gewert et al., 2015), while mechanical abrasion increases surface roughness, scattering incident light and broadening spectral bands in NIR (Käppler et al., 2016). To overcome these problems, a technique using mid-infrared spectroscopy and machine learning was developed for the classification of post-consumer plastic waste (Stavinski et al., 2023). Their approach utilized a spectral database containing 835 real-world plastic items (yielding 2505 spectra) across five major resin types (PET #1, HDPE #2, LDPE #4, PP #5, PS #6). They applied autoencoders—an unsupervised machine learning algorithm—to pre-process spectral data before classification using several models: Random Forest (RF), k-Nearest Neighbors (KNN), Support Vector Machine (SVM), and Logistic Regression (LR). Notably, the RF model achieved perfect accuracy (100.0%) in both the C–H stretching region (2990–2820 cm-1) and the molecular fingerprint region (1500–650 cm-1). There are many other optical identification methods have been devised in recent decades and implemented for the segregation of plastics. Raman spectroscopy can be used to obtain the molecular structure by analyzing the scattering spectrum at different frequencies from the incident light (Neo et al., 2022). LIBS employs a laser to heat polymer micro regions, leading to ablation, atomic decomposition, plasma formation, and subsequent characteristic radiation for data analysis (Zhang et al., 2023). XRF uses X-ray photons to impact a targeted material and detect the movements of electrons, followed by the emission of X-rays (Rybarczyk et al., 2020). The smallest measurable sample sizes of NIR, LIBS, and XRF are 1 cm, 1 mm, and 1 cm, respectively, making these techniques suitable for separating macroplastics (Michel et al., 2020). Raman spectroscopy, with the smallest sample sizes of 1 μm, is more appropriate for microplastics (Käppler et al., 2016).

2.3.6 Froth flotation

The key concept of froth flotation relies on the preferential adhesion of particles to air bubbles, governed by their surface energy and resulting hydrophobic or hydrophilic properties (Kökkiliç et al., 2022). In plastic flotation, multiple bubbles adhere to a single particle, forming aggregates where clusters of plastic particles are held together by bubbles (Wang et al., 2015).The froth flotation efficiency is affected by various chemical and physical variables. Physical variables include physical properties, such as particle size and composition, and chemical variables mainly aim to control the hydrophilic and hydrophobic states of the materials (Wills et al., 2015). Hydrophobic materials can attach to air bubbles and float (Kökkiliç et al., 2022). Froth flotation is limited to fine plastics due to the insufficient adhesion between larger particles and bubbles, leading to bubble rupture (Wills and Finch, 2015). Therefore, froth flotation cannot be applied to macroplastics. Froth flotation separates fine particles from aqueous suspensions by the selective attachment of particles to air bubbles (Pawlik, 2022). Because of this mechanism, froth flotation can separate plastics with different densities; however, the reagents introduced in the process may require further wastewater treatment.

Jiang et al. (2022a) conducted a study into the impact of microplastic properties, flotation conditions, and the presence of various aqueous species on the efficacy of froth flotation separation. The findings revealed that variables such as pH, temperature, microplastic size, and concentration did not have any significant influence on the efficiency of separation. However, it has been observed that the selection of specific aqueous species is crucial to attaining the desired recovery rate for distinct microplastics (Jiang et al., 2022a). To further improve separation efficiency, Zhang et al. (2020) used chlorine dioxide for the surface treatment of polyvinyl chloride (PVC) and polycarbonate (PC). This process successfully increased the hydrophilization of PC, and the recovery rate and purity of the separated PC were 97% and 99%, respectively (Zhang et al., 2020). Wang et al. (2023) also tried to improve the hydrophilization of PC by using Fe(VI), which successfully separates PC from multi-plastic mixtures (PC, ABS, PVC, PMMA and PS). However, this process changed the surface functional groups of PC, and the effects of the surface treatment on the properties of PC still require further investigation.

2.3.7 Electrostatic separation

Electrostatic separation is a promising method for separating various types of waste plastics (Silveira et al., 2018; Park et al., 2008). The underlying principle of this technology lies in the distinct electrical properties exhibited by various types of plastics, which result in discrepant charges (Li et al., 2017; Rybarczyk et al., 2020). Consequently, these charged particles undergo various electrostatic forces within the electric field and are separated into different pure fractions. It has a minimum treatment particle size of 100 µm (Kurzweg et al., 2022). While excessively large particles may be too heavy to be effectively moved by the electric field, a universally defined threshold for “too large” remains unavailable in the literature. However, studies suggest that electrostatic separation can achieve a separation efficiency of ∼60–100% for particles ranging from 450 µm to 4 mm, making it particularly suitable for microplastic separation (Enders et al., 2020). A notable advantage of this method is that it does not require wastewater treatment or drying processes (Pita and Castilho, 2017).

Felsing et al. (2018) pioneered the application of the Korona-Walzen-Scheider (KWS) electrostatic separator for microplastic (MP) separation. Their study evaluated four distinct matrices—quartz sand, freshwater suspended particulate matter, freshwater sediment, and beach sand—each spiked with MPs ranging from 0.063 to 5 mm in size. Remarkably, this method achieved recovery rates approaching 100% across all tested materials. Building on this work, Enders et al. (2020) assessed the reliability of the KWS system for extracting MPs of varying sizes from beach sediments. Their results revealed a strong dependence of separation efficiency on MP size, with recovery rates (RR) as follows: MP ≥2 mm, RR=99-100%; 63<MP<450 µm, RR≈60-95%; MP=20 µm, RR≈45% (Enders et al., 2020). Kurzweg et al. (2022) further improved the separation process by combining electrostatic separation with density separation by using potassium iodide solution, followed by differential scanning calorimetry to determine the recovery rate. While their scaled-up electrostatic separation achieved recovery rates comparable to small-scale processes, the study highlighted the need for further refinement of Differential Scanning Calorimetry (DSC) protocols to improve measurement accuracy in MP quantification (Kurzweg et al., 2022).

3 Thermomechanical recycling of marine plastics

After cleaning and separation, marine plastics can be extruded and pelletized for further processing. The pellets were subsequently processed using resin-molding techniques to form new products. There are five typical resin molding techniques: extrusion molding, injection molding, blow molding, vacuum molding and inflation molding (Al-Salem et al., 2009). However, the efficacy of mechanical recycling is heavily dependent on the purity of the waste stream, and different types of fillers in recycled plastics, such as contaminants and additives, can compromise the material quality (Lange, 2021). For high-value-added applications with strict properties requirements, recycled marine plastic should have no significant decrease in chemical, physical, and mechanical properties compared to virgin materials (Râpă et al., 2024). Furthermore, stringent regulations restrict the use of recycled marine plastics in certain applications, such as food packaging, owing to the potential presence of toxic impurities (Lange, 2021). For instance, in the US, the Food and Drugs Administration(FDA) evaluates recycled plastics for food contact on a case-by-case basis through its Food Contact Notification (FCN) or Threshold of Regulation (ToR) processes. Obtaining approval is particularly challenging for marine plastics due to the difficulty in identifying and removing complex environmental contaminants like persistent organic pollutants or heavy metals absorbed during ocean exposure (FDA, 2021).

4 Upcycling of macroplastics and microplastics

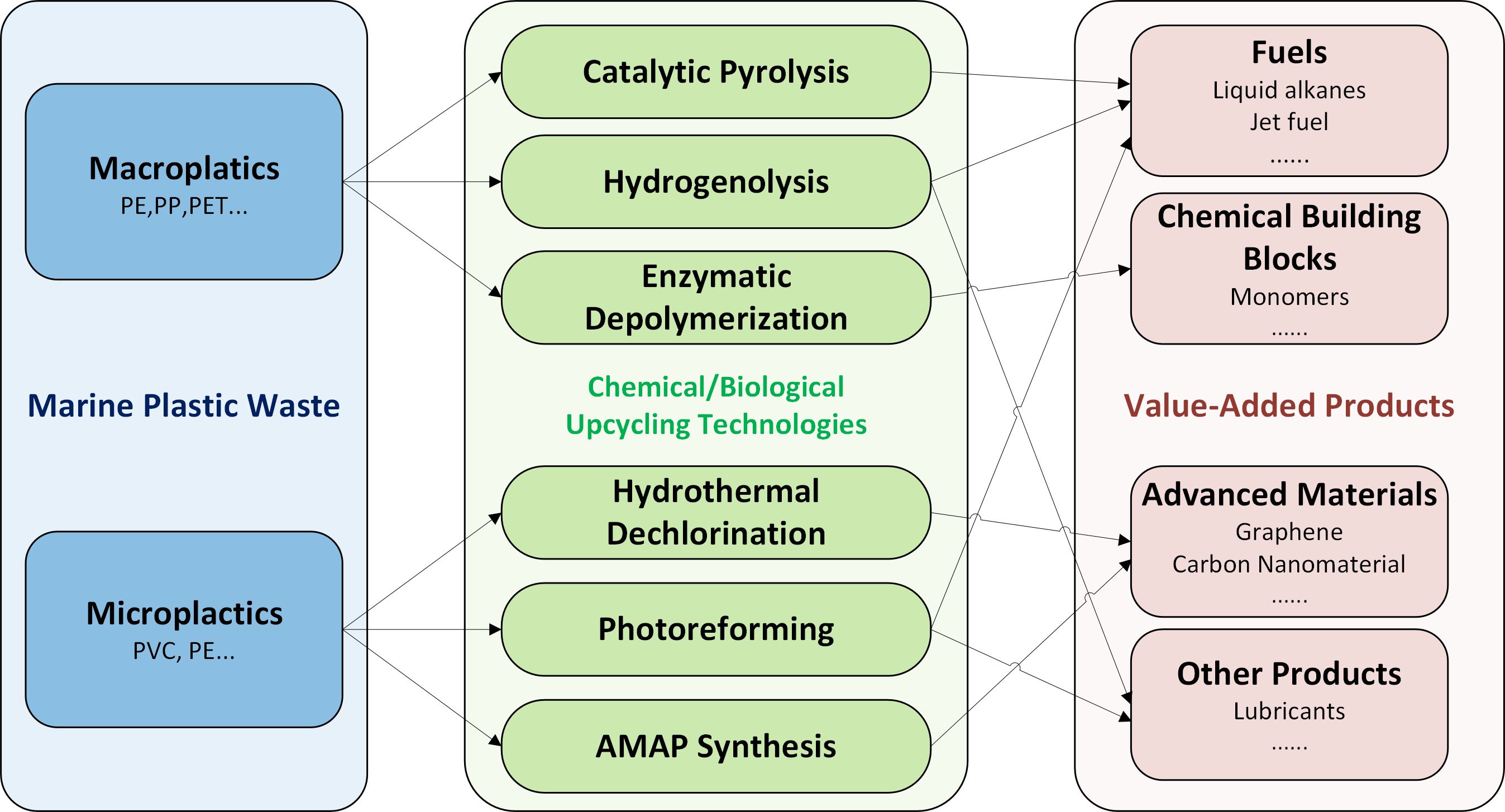

Upcycling marine plastic waste offers a promising pathway for transforming environmental pollutants into high-value products, combining sustainability with innovation to address the global plastic crisis. In this review, ‘upcycling’ encompasses two distinct pathways: (1) Mechanical upcycling, referring to the physical reprocessing of waste plastics into higher-value products, and (2) Chemical and biological upcycling, denoting the molecular transformation of plastic polymers into value-added feedstocks or fuels through chemical or biological processes.

4.1 Mechanical upcycling

In recent years, numerous companies have successfully upcycled mechanically recycled marine macroplastics into commercial products, including shoes, sunglasses, bags, athletic shorts, and furniture (Dorfman, 2020; Winkler, 2024). In 2019, The Ocean Cleanup (n.d.) project transformed plastics collected from the Great Pacific Garbage Patch into sunglasses. In 2021, Sabic and Microsoft collaborated to produce Microsoft Ocean Plastic Mouse, which contained 20 wt. % recycled ocean plastic (Heather, 2021). Similarly, Adidas partnered with Parley to produce shoes from recycled marine plastic bottles (Adidas, 2021). The environmental benefits of these initiatives have been validated by life cycle assessments (LCAs) conducted by researchers. Cañado et al. (2022) gathered discarded polyamide fishing nets and employed 3D printing techniques to fabricate new products. By conducting a cradle-to-grave LCA investigation, the utilization of marine plastic waste as a primary resource demonstrated enhanced efficacy in environmental impacts compared to virgin bioplastics sourced from renewable sources. Tippett (2023) conducted an investigation into the ecological ramifications associated with the manufacturing of recycled plastic granulate derived from discarded ropes, which originate from the fishing or aquaculture sectors, and LCA demonstrated that the recycled material exhibits markedly reduced impacts on global warming potential, acidification potential, and eutrophication potential compared to conventional materials.

Although macroplastics have seen successful commercial upcycling, the upcycling of marine microplastics remains largely hypothetical due to the absence of operational facilities. The mechanical upcycling of microplastics are rarely reported. Some researchers reported the chemical upcycling method for transform the carbon in low value polyolefins to high value organics (Vogt et al., 2021; Jiang et al., 2022b). These innovative approaches highlight the potential for future advancements in microplastic upcycling, although significant technical and logistical challenges remain.

4.2 Chemical and biological upcycling

Chemical and biological upcycling depolymerizes marine plastics into molecular building blocks (e.g., monomers, oligomers, or hydrocarbons) for reconstitution into higher-value products, overcoming limitations of mechanical reprocessing for degraded polymers. Exemplary chemical and biological upcycling routes are shown in Figure 2.

Key technologies include catalytic pyrolysis, which converts polyolefins (PE/PP) into liquid alkanes for fuels. For instance, Cai et al. (2021)demonstrated that PP plastic waste can be transformed into hydrogen and liquid fuels using Fe/Al2O3 and Fe/ZSM-5 catalysts, respectively. Similarly), Cocchi et al. (2023) validated this approach using marine plastic litter (52 wt% PE, 45 wt% PP) collected during beach cleanups, confirming catalytic pyrolysis as a viable upcycling pathway for valuable organic products. Beyond pyrolysis, hydrogenolysis offers another route; Jia et al. (2021) reported a liquid-phase catalytic process that efficiently converts high-density PE to jet-fuel and lubricant hydrocarbons under mild conditions using Ru catalysts. Enzymatic depolymerization also shows significant promise. Lu et al. (2022)utilized FAST-PETase for ambient degradation of macroplastics, achieved near-complete depolymerization of untreated postconsumer-PET from 51 thermoformed products within one week. This enzyme further demonstrated efficacy on amorphous sections of commercial water bottles and entire thermally pretreated bottles at 50°C, enabling closed-loop PET recycling via monomer recovery and resynthesis.

Though mechanical upcycling of microplastics were rarely reported, chemical upcycling show promise for microplastics; recent work demonstrates hydrothermal dechlorination of PVC microparticles into carbon nanomaterials for energy storage applications (Zhang et al., 2025). Photoreforming offers a low-energy route for transforming microplastic waste into fuel and chemicals. Uekert et al. (2019) employed an inexpensive carbon nitride/nickel phosphide (CNx|Ni2P) photocatalyst to photoreform polyester microfibers, generating H2 and organics. Atmospheric pressure microwave plasma (APMP) synthesis provides a one-step, environmentally friendly method to convert microplastics into valuable graphene. Zafar and Jacob (2024) demonstrated efficient transformation of polyethylene microplastics from waste dropper bottles using this technique.

While offering a transformative pathway, scaling chemical and biological upcycling to address the immense challenge of marine plastics, particularly persistent microplastics, requires breakthroughs in handling complex contaminant mixtures and improving process energy efficiency.

5 Policy frameworks and technical pathways for marine plastic waste management

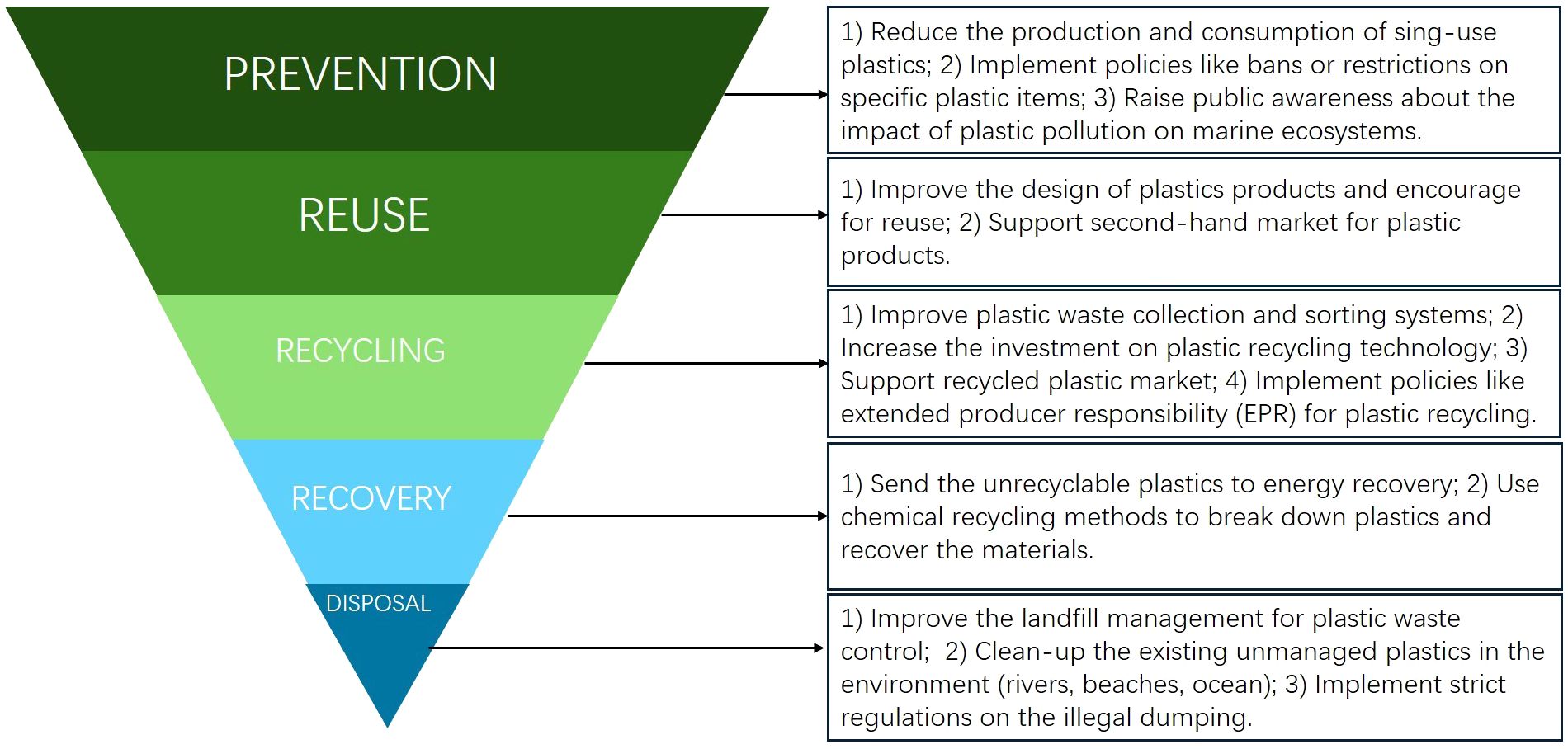

Building upon the technical routes and challenges of marine plastic recycling identified in previous sections, this section establishes how policy frameworks enable viable waste management pathways through the waste hierarchy (prevention > reuse > recycling > recovery > disposal). We align solutions with this hierarchy from the EU Marine Strategy Framework Directive (2008/56/EC) and Waste Directive (2008/98/EC) (European Commission, 2008), proposing an integrated technical route shown in Figure 3.

Strict regulations on single-use plastics (e.g., China’s 2025 phase-out plan, EU Directive 2019/904) primarily serve prevention by mitigating plastic leakage at source (National Development and Reform Commission, 2020). For existing marine plastics, the core focus shifts to recycling and recovery, where this review’s examined technologies apply most directly. Macroplastic recycling leverages separation techniques like density-based hydrocyclones and NIR/VIS optical sorting to achieve material purity for mechanical upcycling—processes commercially implemented in products from Adidas shoes to Ocean Cleanup sunglasses. These align with policies mandating recycled content (e.g., EU’s 25-30% targets for bottles) but require enhanced collection systems and extended producer responsibility schemes.

Recovery provides pathways for non-recyclable plastics: catalytic pyrolysis (Section 4.2) converts degraded PE/PP into fuels, while emerging chemical upcycling methods target microplastics through hydrothermal dechlorination or photoreforming. Though less mature, these technologies offer value extraction where mechanical recycling fails, supported by policy incentives for chemical recovery. For microplastics, separation methods like froth flotation and magnetic levitation bridge recycling and recovery but face scalability limitations.

Finally, disposal manages residuals from recycling/recovery processes—such as contaminated microplastics or pyrolysis chars—through regulated landfilling or energy recovery. This least-preferred tier requires stringent controls to prevent secondary pollution. Global collaboration must prioritize scaling feasible separation technologies while advancing monitoring systems like NOAA’s microplastic database. The integrated pathway in Figure 3 demonstrates how policy frameworks activate technical solutions across the hierarchy, with prevention reducing new inputs and recycling/recovery addressing legacy waste.

6 Research gap and future direction

Despite the significant advancements in mechanical recycling technologies for marine plastics, several critical research gaps and challenges remain. Addressing these gaps is essential for enhancing the efficiency, scalability, and sustainability of recycling processes while aligning with global and regional policy frameworks. The existing marine plastics pose significant threats to marine ecosystems, human health, and economic activities. The current marine plastic collection and transportation processes are labor-intensive and costly (Râpă et al., 2024). To address this issue, some non-profit organizations and research facilities have developed collection technologies for recycling waste plastics from rivers, beaches, and regions at various ocean depths. However, many of these technologies still struggle with cost effectiveness, which limits the large-scale treatment of marine plastics. Passive collection systems, such as Seabin and Ocean Cleanup interceptors, may be an effective solution to reducing the operating cost. However, these techniques are mainly designed for collecting floating macroplastics, and the collection of high-density marine plastics remains challenging. Future research should focus on improving the cost-effectiveness of current collection technologies and extending their applicability to more plastic types.

Currently, marine microplastic collection is mainly carried out for research purposes rather than recycling. Compared to macroplastics, the economic benefits of recycling microplastics are minor unless a large-scale cost-effective collection system can be developed. Based on the current situation, source control is the most acceptable control method for microplastics (Ruan et al., 2018). To reduce microplastic pollution, three important aspects must be considered: 1) recycling of macroplastics to reduce plastic fragmentation (Julienne et al., 2019); 2) reducing the use of single-use plastics (Xanthos and Walker, 2017); and 3) reducing the use of microbeads and synthetic microfibers (Lindeque et al., 2020).

To motivate investment in marine plastic recycling, government support in the following aspects is crucial: 1.Designing effective solid waste management strategies to prevent plastic leakage into marine environments.2. Providing tax subsidies and financial incentives to make recycling operations economically viable. 3. Enhancing public education on marine plastic pollution and expanding the market for recycled marine plastic products. Marine plastic pollution is a global issue that requires coordinated international effort. Although some countries have initiated projects to address this problem, marine plastic pollution remains underappreciated in many regions (Kurniawan et al., 2021). Strengthening global collaboration, sharing best practices, and raising awareness are essential for achieving meaningful progress in combating marine plastic pollution.

7 Conclusion

Although marine plastic pollution has attracted public attention in recent years, there remains a lack of large-scale waste management systems and reliable commercial solutions for the treatment of existing marine plastics. Recycling of marine plastics, especially macroplastics, has become an urgent issue because they can break up into microplastics, which are almost impossible to completely remove from the ocean. Marine plastic pollution is a typical global problem that requires all stakeholders (government, product manufacturers, scientists, NGOs, and the general public) to make joint efforts to solve this problem. To improve the upcycling or recycling of marine plastics, this review systematically reviews the mechanical techniques for recycling marine macroplastics and microplastics. The main mechanical recycling technologies involved in marine plastic collection, cleaning, separation, and melt processing were discussed. However, current mechanical recycling technologies still have some limitations. Many techniques are still in the laboratory stage and have not yet been industrialized. Some of the technologies mentioned in this paper may perform well in a small lab-scale experiment but may face cost-effectiveness issues in large-scale processes. As a result, there is an urgent need to establish a reliable marine plastic monitoring system, set up standard plastic collection, separation, and melt processing steps, and establish domestic and international cooperation to solve this problem.

Author contributions

YT: Writing – original draft, Writing – review & editing. YiZ: Writing – original draft. ZhW: Funding acquisition, Writing – review & editing, Project administration. ZeW: Writing – review & editing. HH: Writing – review & editing. HZ: Writing – review & editing. JD: Writing – original draft. YM: Writing – review & editing. YuZ: Writing – review & editing. PH: Funding acquisition, Project administration, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was supported by Ningbo Science & Technology Innovation 2025 Major Project (Grant ID:2022Z157) and the Ningbo International Science &Technology Cooperation Program (Grant ID:2023H005).

Conflict of interest

Author YuZ was employed by the company Ningbo Helong New Material Co., LTD.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Glossary

ABS: Acrylonitrile Butadiene Styrene

APEC: Asia Pacific Economic Cooperation

ARIS: Adaptive Resolution Imaging Sonar

ATR: Attenuated Total Reflectance

BPA: Bisphenol A

DBP: Dibutyl Phthalate

DEHP: Bis(2-Ethylhexyl) Phthalate

DMS: Density Media Separation

DSC: Differential Scanning Calorimetry

LCA: Life Cycle Assessment

LIBS: Laser-Induced Breakdown Spectroscopy

LS-TENG: Liquid-Solid Triboelectric Nanogenerator

MP: Microplastics

NCEI: National Centers For Environmental Information

NDRC: National Development And Reform Commission

NIR: Near-Infrared Reflectance

NIR/VIS: Near-Infrared/Visual Spectroscopy

NOAA: National Oceanic And Atmospheric Administration

OPFR: Organophosphorus Flame Retardants

PBDEs: Polybrominated Diphenyl Ethers

PC: Polycarbonate

PE: Polyethylene

PET: Polyethylene Terephthalate

PMMA: Polymethyl Methacrylate

PP: Polypropylene

PS: Polystyrene

PS-E: Expandable Polystyrene

PUR: Polyurethane

PVC: Polyvinyl Chloride

Py-GC/MS: Pyrolysis-Gas Chromatography-Mass Spectrometry

RR: Recovery Rate

SOA: State Oceanic Administration

SRS: Stimulated Raman Scattering

SSS: Side-Scan Sonar

UV: Ultraviolet

XRF: X-Ray Fluorescence

References

Adhiwiguna I. B. G. S., Ramalingam K., Becker K.-H., Khoury A., Warnecke R., and Deike R. (2025). Extended material recovery from municipal solid waste incinerator bottom ash using magnetic, eddy current, and density separations. Recycling 10. doi: 10.3390/recycling10010016

Adidas (2021). How We Turn Plastic Bottles into Shoes: Our Partnership with Parley for the Oceans. Available online at: https://www.adidas.com/us/blog/639412-how-we-turn-plastic-bottles-into-shoes-our-partnership-with-parley-for-the-oceans (Accessed 6 October 2024).

Agenda I. (2016). The new plastics economy rethinking the future of plastics (Geneva, Switzerland: The World Economic Forum).

Al-Salem S. M., Lettieri P., and Baeyens J. (2009). Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manage. 29, 2625–2643. doi: 10.1016/j.wasman.2009.06.004

Andrady A. L. (2011). Microplastics in the marine environment. Mar. pollut. Bull. 62, 1596–1605. doi: 10.1016/j.marpolbul.2011.05.030

Aragaw T. A. (2020). Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. pollut. Bull. 159, 111517. doi: 10.1016/j.marpolbul.2020.111517

Auta H. S., Emenike C. U., and Fauziah S. H. (2017). Distribution and importance of microplastics in the marine environment: A review of the sources, fate, effects, and potential solutions. Environ. Int. 102, 165–176. doi: 10.1016/j.envint.2017.02.013

Bakaraki Turan N., Sari Erkan H., and Onkal Engin G. (2021). Current status of studies on microplastics in the world’s marine environments. J. Cleaner Production 327, 129394. doi: 10.1016/j.jclepro.2021.129394

Barbier E. B. (2017). Marine ecosystem services. Curr. Biol. 27, R507–R510. doi: 10.1016/j.cub.2017.03.020

Barnes D. K., Galgani F., Thompson R. C., and Barlaz M. (2009). Accumulation and fragmentation of plastic debris in global environments. Philos. Trans. R. Soc. B: Biol. Sci. 364, 1985–1998. doi: 10.1098/rstb.2008.0205

Bayo J., López-Castellanos J., and Olmos S. (2020). Membrane bioreactor and rapid sand filtration for the removal of microplastics in an urban wastewater treatment plant. Mar. pollut. Bull. 156. doi: 10.1016/j.marpolbul.2020.111211

Beaumont N. J., Aanesen M., Austen M. C., Borger T., Clark J. R., Cole M., et al. (2019). Global ecological, social and economic impacts of marine plastic. Mar. pollut. Bull. 142, 189–195. doi: 10.1016/j.marpolbul.2019.03.022

Broere S., Van Emmerik T., González-Fernández D., Luxemburg W., De Schipper M., Cózar A., et al. (2021). Towards underwater macroplastic monitoring using echo sounding. Front. Earth Sci. 9. doi: 10.3389/feart.2021.628704

Cai N., Xia S., Li X., Xiao H., Chen X., Chen Y., et al. (2021). High-value products from ex-situ catalytic pyrolysis of polypropylene waste using iron-based catalysts: the influence of support materials. Waste Manage. 136, 47–56. doi: 10.1016/j.wasman.2021.09.030

Cañado N., Lizundia E., Akizu-Gardoki O., Minguez R., Lekube B., Arrillaga A., et al. (2022). 3D printing to enable the reuse of marine plastic waste with reduced environmental impacts. J. Ind. Ecol. 26, 2092–2107. doi: 10.1111/jiec.13302

Chandrappa R. and Das D. B. (2012). Solid waste management: principles and practice (Berlin, Heidelberg: GERMANY, Springer Berlin/Heidelberg).

Choong W. S., Hadibarata T., and Tang D. K. H. (2021). Abundance and distribution of microplastics in the water and riverbank sediment in Malaysia—A review. Biointerface Res. Appl. Chem. 11, 11700–11712. doi: 10.33263/BRIAC114.1170011712

Cocchi M., Cafiero L., De Angelis D., Falasconi M. B., Piemonte V., Tuffi R., et al. (2023). Conversion of marine plastic litter into chemicals and fuels through catalytic pyrolysis using commercial and coal fly ash-synthesized zeolites. ACS Sustain. Chem. Eng. 11, 3644–3656. doi: 10.1021/acssuschemeng.2c06130

Cole M., Lindeque P., Halsband C., and Galloway T. S. (2011). Microplastics as contaminants in the marine environment: a review. Mar. pollut. Bull. 62, 2588–2597. doi: 10.1016/j.marpolbul.2011.09.025

Deville A., Vazquez-Rowe I., Ita-Nagy D., and Kahhat R. (2023). Ocean-based sources of plastic pollution: An overview of the main marine activities in the Peruvian EEZ. Mar. pollut. Bull. 189. doi: 10.1016/j.marpolbul.2023.114785

Dimassi S. N., Hahladakis J. N., Yahia M. N. D., Ahmad M. I., Sayadi S., and Al-Ghouti M. A. (2023). Effect of temperature and sunlight on the leachability potential of BPA and phthalates from plastic litter under marine conditions. Sci. Total Environ. 894. doi: 10.1016/j.scitotenv.2023.164954

Dorfman J. (2020). 13 stunning recycled ocean plastic products. Available online at: https://lazyenvironmentalist.com/recycled-ocean-plastic-products/ (Accessed 24 September 2024).

Duong T. T., Le P. T., Nguyen T. N. H., Hoang T. Q., Ngo H. M., Doan T. O., et al. (2022). Selection of a density separation solution to study microplastics in tropical riverine sediment. Environ. Monit. Assess. 194. doi: 10.1007/s10661-021-09664-0

Eo S., Hong S. H., Song Y. K., Lee J., Lee J., and Shim W. J. (2018). Abundance, composition, and distribution of microplastics larger than 20 mum in sand beaches of South Korea. Environ. pollut. 238, 894–902. doi: 10.1016/j.envpol.2018.03.096

Erni-Cassola G., Zadjelovic V., Gibson M. I., and Christie-Oleza J. A. (2019). Distribution of plastic polymer types in the marine environment; A meta-analysis. J. Hazard Mater 369, 691–698. doi: 10.1016/j.jhazmat.2019.02.067

European Commission (2008). Waste framework directive. Available online at: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en (Accessed 25 October 2024).

Falk-Andersson J., Rognerud I., De Frond H., Leone G., Karasik R., Diana Z., et al. (2023). Cleaning Up without Messing Up: Maximizing the Benefits of Plastic Clean-Up Technologies through New Regulatory Approaches. Environ. Sci. Technol. 57, 13304–13312. doi: 10.1021/acs.est.3c01885

Fatima H. and Chihhao F. (2022). “Microplastics in the marine environment: A review of their sources, formation, fate, and ecotoxicological impact,” in Marine pollution. Eds. Monique M., Mohamed H. H. A., Teresa B., and Ahmed A. A. (IntechOpen, Rijeka).

FDA (2021). Guidance for industry: use of recycled plastics in food packaging (Chemistry considerations) (Maryland: FDA).

Felsing S., Kochleus C., Buchinger S., Brennholt N., Stock F., and Reifferscheid G. (2018). A new approach in separating microplastics from environmental samples based on their electrostatic behavior. Environ. pollut. 234, 20–28. doi: 10.1016/j.envpol.2017.11.013

Fu D., Chen C. M., Qi H., Fan Z., Wang Z., Peng L., et al. (2020). Occurrences and distribution of microplastic pollution and the control measures in China. Mar. pollut. Bull. 153. doi: 10.1016/j.marpolbul.2020.110963

Fu S., Fang Y., Yuan H., Tan W., and Dong Y. (2017). Effect of the medium’s density on the hydrocyclonic separation of waste plastics with different densities. Waste Manage. 67, 27–31. doi: 10.1016/j.wasman.2017.05.019

Fürst K. and Feng Y. (2022). China’s regulatory respond to plastic pollution: Trends and trajectories. Front. Mar. Sci. 9, 982546. doi: 10.3389/fmars.2022.982546

Geng X., Song N., Zhao Y., and Zhou T. (2022). Waste plastic resource recovery from landfilled refuse: A novel waterless cleaning method and its cost-benefit analysis. J. Environ. Manage. 306. doi: 10.1016/j.jenvman.2022.114462

Gent M., Sierra H. M., Álvarez M. M., and Mcculloch J. (2018). An evaluation of hydrocyclones and the LARCODEMS cylindrical cyclone for the separation of waste plastics of proximate densities. Waste Manage. 79, 374–384. doi: 10.1016/j.wasman.2018.08.004

GESAMP (2016). Sources, fate and effects of microplastics in the marine environment: part two of a global assessment (London: IMO), 220.

Gewert B., Plassmann M. M., and Macleod M. (2015). Pathways for degradation of plastic polymers floating in the marine environment. Environ. Science: Processes Impacts 17, 1513–1521. doi: 10.1039/C5EM00207A

Gonçalves S. M., Kyriakidis Y. N., Ullmann G., Barrozo M. A. D. S., and Vieira L. G. M. (2020). Design of an optimized hydrocyclone for high efficiency and low energy consumption. Ind. Eng. Chem. Res. 59, 16437–16449. doi: 10.1021/acs.iecr.0c02871

Gong J. and Xie P. (2020). Research progress in sources, analytical methods, eco-environmental effects, and control measures of microplastics. Chemosphere 254, 126790. doi: 10.1016/j.chemosphere.2020.126790

Graca B., Szewc K., Zakrzewska D., Dołęga A., and Szczerbowska-Boruchowska M. (2017). Sources and fate of microplastics in marine and beach sediments of the Southern Baltic Sea—a preliminary study. Environ. Sci. pollut. Res. 24, 7650–7661. doi: 10.1007/s11356-017-8419-5

Han X., Lu X., and Vogt R. D. (2019). An optimized density-based approach for extracting microplastics from soil and sediment samples. Environ. pollut. 254. doi: 10.1016/j.envpol.2019.113009

Hanvey J. S., Lewis P. J., Lavers J. L., Crosbie N. D., Pozo K., and Clarke B. O. (2017). A review of analytical techniques for quantifying microplastics in sediments. Analytical Methods 9, 1369–1383. doi: 10.1039/C6AY02707E

Hasan Anik A., Hossain S., Alam M., Binte Sultan M., Hasnine M. D. T., and Rahman M. M. (2021). Microplastics pollution: A comprehensive review on the sources, fates, effects, and potential remediation. Environ. Nanotechnology Monit. Manage. 16. doi: 10.1016/j.enmm.2021.100530

He L., Ji L., Sun X., Chen S., and Kuang S. (2022). Investigation of mini-hydrocyclone performance in removing small-size microplastics. Particuology 71, 1–10. doi: 10.1016/j.partic.2022.01.011

Heather C. (2021). Sabic and microsoft create mouse made from ocean plastic. Available online at: https://www.ptonline.com/news/sabic-and-microsoft-create-mouse-made-from-ocean-plastic:~:text=Sabic%20is%20providing%20a%20new%20Xenoy%20resin%20for (Accessed 6 October 2024).

Hopewell J., Dvorak R., and Kosior E. (2009). Plastics recycling: challenges and opportunities. Philos. Trans. R. Soc. B: Biol. Sci. 364, 2115–2126. doi: 10.1098/rstb.2008.0311

Ibrahim I. A., Rawindran H., Alam M. M., Leong W. H., Sahrin N. T., Ng H.-S., et al. (2024). Mitigating persistent organic pollutants from marine plastics through enhanced recycling: A review. Environ. Res. 240. doi: 10.1016/j.envres.2023.117533

Iñiguez M. E., Conesa J. A., and Fullana A. (2016). Marine debris occurrence and treatment: A review. Renewable Sustain. Energy Rev. 64, 394–402. doi: 10.1016/j.rser.2016.06.031

Iniguez M. E., Conesa J. A., and Fullana A. (2018). Recyclability of four types of plastics exposed to UV irradiation in a marine environment. Waste Manag 79, 339–345. doi: 10.1016/j.wasman.2018.08.006

Jambeck J. R., Geyer R., Wilcox C., Siegler T. R., Perryman M., Andrady A., et al. (2015). Plastic waste inputs from land into the ocean. Science 347, 768–771. doi: 10.1126/science.1260352

Ji T., Fang H., Zhang R., Yang J., Fan L., and Li J. (2022). Automatic sorting of low-value recyclable waste: a comparative experimental study. Clean Technol. Environ. Policy 25, 949–961. doi: 10.1007/s10098-022-02418-7

Jia C., Xie S., Zhang W., Intan N. N., Sampath J., Pfaendtner J., et al. (2021). Deconstruction of high-density polyethylene into liquid hydrocarbon fuels and lubricants by hydrogenolysis over Ru catalyst. Chem. Catalysis 1, 437–455. doi: 10.1016/j.checat.2021.04.002

Jiang J., Shi K., Zhang X., Yu K., Zhang H., He J., et al. (2022b). From plastic waste to wealth using chemical recycling: A review. J. Environ. Chem. Eng. 10. doi: 10.1016/j.jece.2021.106867

Jiang H., Zhang Y., Bian K., Wang H., and Wang C. (2022a). Insight into the effect of aqueous species on microplastics removal by froth flotation: Kinetics and mechanism. J. Environ. Chem. Eng. 10. doi: 10.1016/j.jece.2022.107834

Juan R., Domínguez C., Robledo N., Paredes B., Galera S., and García-Muñoz R. A. (2021). Challenges and opportunities for recycled polyethylene fishing nets: towards a circular economy. Polymers 13. doi: 10.3390/polym13183155

Julienne F., Delorme N., and Lagarde F. (2019). From macroplastics to microplastics: Role of water in the fragmentation of polyethylene. Chemosphere 236. doi: 10.1016/j.chemosphere.2019.124409

Kamaruddin H., Maskun, Patittingi F., Assidiq H., Bachril S. N., and Al Mukarramah N. H. (2022). Legal aspect of plastic waste management in Indonesia and Malaysia: addressing marine plastic debris. Sustainability 14. doi: 10.3390/su14126985

Käppler A., Fischer D., Oberbeckmann S., Schernewski G., Labrenz M., Eichhorn K.-J., et al. (2016). Analysis of environmental microplastics by vibrational microspectroscopy: FTIR, Raman or both? Analytical Bioanalytical Chem. 408, 8377–8391. doi: 10.1007/s00216-016-9956-3

Kökkiliç O., Mohammadi-Jam S., Chu P., Marion C., Yang Y., and Waters K. E. (2022). Separation of plastic wastes using froth flotation – An overview. Adv. Colloid Interface Sci. 308. doi: 10.1016/j.cis.2022.102769

Kurniawan S. B., Abdullah S. R. S., Imron M. F., and Ismail N. I. (2021). Current state of marine plastic pollution and its technology for more eminent evidence: A review. J. Cleaner Production 278, 123537. doi: 10.1016/j.jclepro.2020.123537

Kurzweg L., Schirrmeister S., Hauffe M., Adomat Y., Socher M., and Harre K. (2022). Application of electrostatic separation and differential scanning calorimetry for microplastic analysis in river sediments. Front. Environ. Sci. 10. doi: 10.3389/fenvs.2022.1032005

Lange J.-P. (2021). Managing plastic waste─Sorting, recycling, disposal, and product redesign. ACS Sustain. Chem. Eng. 9, 15722–15738. doi: 10.1021/acssuschemeng.1c05013

Law K. L. (2017). Plastics in the marine environment. Ann. Rev. Mar. Sci. 9, 205–229. doi: 10.1146/annurev-marine-010816-060409

Lebreton L., Egger M., and Slat B. (2019). A global mass budget for positively buoyant macroplastic debris in the ocean. Sci. Rep. 9. doi: 10.1038/s41598-019-49413-5

Lebreton L. C. M., Van Der Zwet J., Damsteeg J.-W., Slat B., Andrady A., and Reisser J. (2017). River plastic emissions to the world’s oceans. Nat. Commun. 8, 15611. doi: 10.1038/ncomms15611

Li H., Aguirre-Villegas H. A., Allen R. D., Bai X., Benson C. H., Beckham G. T., et al. (2022). Expanding plastics recycling technologies: chemical aspects, technology status and challenges. Green Chem. 24, 8899–9002. doi: 10.1039/D2GC02588D

Li J., Gao K., and Xu Z. (2017). Charge-decay electrostatic separation for removing Polyvinyl chloride from mixed plastic wastes. J. Cleaner Production 157, 148–154. doi: 10.1016/j.jclepro.2017.03.233

Li W. C., Tse H. F., and Fok L. (2016). Plastic waste in the marine environment: A review of sources, occurrence and effects. Sci. Total Environ. 566-567, 333–349. doi: 10.1016/j.scitotenv.2016.05.084

Lindeque P. K., Cole M., Coppock R. L., Lewis C. N., Miller R. Z., Watts A. J. R., et al. (2020). Are we underestimating microplastic abundance in the marine environment? A comparison of microplastic capture with nets of different mesh-size. Environ. pollut. 265. doi: 10.1016/j.envpol.2020.114721

Lu L. (2015). Iron ore: mineralogy, processing and environmental sustainability (San Diego, United Kingdom: Elsevier Science & Technology).