- 1Università degli Studi di Torino, Dipartimento di Fisica, Torino, Italy

- 2Istituto Nazionale di Fisica Nucleare, Sezione di Torino, Torino, Italy

- 3Fondazione Bruno Kessler, Centro Sensori e Dispositivi, Trento, Italy

- 4Trento Institute for Fundamental Physics and Applications(TIFPA) - INFN, c/o Dip. di Fisica, Università di Trento, Trento, Italy

- 5Consiglio Nazionale delle Ricerche, Istituto Officina dei Materiali, Perugia, Italy

- 6Istituto Nazionale di Fisica Nucleare, Sezione di Perugia, Perugia, Italy

- 7Università del Piemonte Orientale, Dipartimento di Scienze del Farmaco, Novara, Italy

- 8Politecnico di Milano, Dipartimento di Elettronica, Informazione e Bioingegneria, Milano, Italy

- 9Politecnico di Torino, Dipartimento Scienza Applicata e Tecnologia, Torino, Italy

- 10Università degli Studi di Perugia, Dipartimento di Ingegneria, Perigia, Italy

- 11Centre CEA Paris-Saclay, Site de Fontenay-aux-Roses, Saclay, France

This contribution summarises the outcomes of the CSN5 eXFlu research project. In particular, it presents the first exploration of the performance of very thin Low-Gain Avalanche Diode (LGAD) sensors, with a bulk active thickness ranging from 45 µm down to 15 µm. Thin sensors have intrinsically good timing performances, as the non-uniformities of particle charge deposition, which contribute as one of the main components to the timing resolution, are minimised by the thin substrate. A timing resolution of 16.6 ps has been achieved with a 20 µm thick LGAD, which was further reduced to 12.2 ps by combining the timing information from two 20 µm thick sensors. Additionally, various designs of the gain implant, typical of LGAD devices, have been explored. In particular, the beneficial effect of Carbon atoms co-implanted with Boron has been enhanced by the simultaneous annealing of the two elements, resulting in the most radiation-hard LGADs produced by the FBK foundry. The eXFlu sensors have been operated efficiently with almost unchanged performance up to a fluence of 2.5 ✕ 1015 1 MeV equivalent n/cm2. Future developments of the LGAD sensor design to extend its operation to extreme fluences, above 1 ✕ 1017 1 MeV equivalent n/cm2, will be discussed.

1 The EXFLU1 batch

Low-Gain Avalanche Diodes (LGADs) are n-in-p silicon sensors with a high concentration of p+ dopant, typically Boron, close to the n++ electrode (Pellegrini et al., 2014). The p+ implant generates a local increase in the electric field, which leads to a moderate multiplication of charge carriers, on the order of 10–30, easily controlled by the external bias. Thin LGAD sensors, with an active thickness of approximately 50 µm and optimised geometry, have demonstrated excellent timing resolution, down to about 30 ps (Ferrero et al., 2021), opening the way to the usage of silicon sensors as timing detectors for high-energy physics experiments. Still, the full four-dimensional potential of LGAD is being explored by means of diverse designs and R&D lines, such as inverse LGADs (Doblas et al., 2023), trench-isolated LGAD sensors (Bisht et al., 2023), and LGADs with resistive readout, both AC- and DC-coupled (Nakamura et al., 2021; Centis Vignali et al., 2025).

At the end of 2022, Fondazione Bruno Kessler (FBK) released the EXFLU1 batch based on the Low-Gain Avalanche Diode technology. Different advancements in the LGAD concept have been designed (Croci et al., 2022; Croci et al., 2024) and tested (Sola et al., 2023; White et al., 2024) in the EXFLU1 sensors.

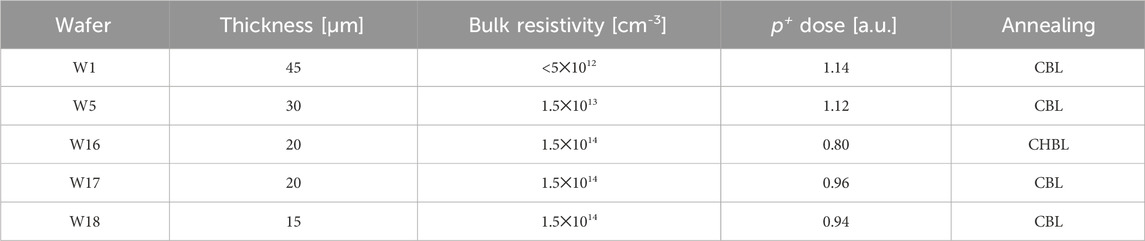

One of the research topics investigated within the EXFLU1 batch is the effect of the thickness on the signal formation and timing resolution of the LGADs. The sensors are made on thin epitaxial layers grown on Czochralski substrates. Only the epitaxial thickness is depleted by applying a reverse bias, constituting the active volume of the sensors. In EXFLU1, the active thickness of the sensors ranges from 45 down to 15 μm, as summarised in Table 1. In thin sensors, the charge is collected fast, and the signal rise time lasts hundreds of picoseconds (Sola et al., 2019). On the other hand, the charge collected by thin sensors is small, and the detector capacitance inversely increases by reducing thickness with the risk of slowing the signal.

In the EXFLU1 batch, the radiation tolerance of the LGAD gain implant has been improved, following an R&D path already investigated by the FBK foundry in previous batches (Ferrero et al., 2021), exploiting the beneficial effect of Carbon co-implantation in the same volume of the Boron implant and annealing the two dopants at the same time (Carbon Boron Low annealing–CBL). A control wafer with a more traditional annealing strategy has also been produced (W16 in Table 1), where Carbon is annealed before the Boron implantation (Carbon High Boron Low annealing–CHBL).

A further optimisation pursued in the EXFLU1 batch concerns the design of the peripheral guard-ring structures on thin sensors (Croci et al., 2024; Sola et al., 2023). It was demonstrated that a design with no floating guard rings ensures a stable operation of the sensors, providing a smooth decrease in the electric field from the sensor active volume to its physical edge.

In the following, timing performances and radiation tolerance of the EXFLU1 sensors will be presented and discussed.

2 Timing resolution from thin LGAD sensors

The main contributions to the timing resolution of the LGAD sensors are the electronic noise, also called jitter, and the non-uniform ionisation resulting from the irregular energy deposition of the particles crossing the sensors, bringing fluctuations on the signal shape, as described in (Ferrero et al., 2021). The jitter inversely scales with the signal-to-noise ratio, which is maximised in LGAD sensors, as the signal increases due to the electron-hole pairs multiplications happening inside the sensors, namely, in the gain layer region. On the other hand, the contribution of the non-uniform energy deposition linearly scales with the thickness and for 20 µm thick sensors is expected to be about 15 ps.

The timing resolution of thin LGAD sensors from the EXFLU1 batch has been tested on a particle beam (Ferrero et al., 2025) at the DESY Test Beam facility (Diener et al., 2019) using electrons with an energy of 4 GeV.

The signals from the EXFLU1 sensors were read out by using single-channel Santa Cruz boards (Ferrero et al., 2021), with a trans-impedance of about 470 Ω, and a second-stage amplification by means of a Cividec C1 broadband amplifier, a general-purpose low-noise current amplifier with an analogue bandwidth of 2 GHz and 20 dB gain. Waveforms acquisition was made through an eight-channel WaveRunner 8208HD Lecroy oscilloscope, with 10 GSa/s sampling and a bandwidth of 2 GHz. By combining the bandwidths of the Cividec amplifier and the oscilloscope, and overall system bandwidth resulted in about 1.4 GHz, limiting the minimum measurable (inverted) signal rise time to about 350 ps. For this reason, the 15 µm sensors from wafer 18 were not tested on the beam, as their expected rise time is faster than the intrinsic limit of the readout chain.

The trigger was set by a 45 µm thick sensor from the EXFLU1 batch with an active surface of approximately 3.6 ✕ 3.6 mm2. The devices under test were placed behind the trigger and followed by a Photonis MCP-PMT used as time reference of the system. The MCP-PMT timing resolution was measured to be (5 ± 2) ps. The active area of the sensors under test ranged from 0.75 ✕ 0.75 mm2 to 1.28 ✕ 1.28 mm2, to limit the sensor capacitance to less than 4 pF. The data-taking of un-irradiated sensors was performed at monitored room temperature, which remained constant at about 18°C.

The timing resolution is extracted from the distribution of the electron time of arrival inside the sensor under test, using the time of the MCP-PMT as the reference. The time of arrival is evaluated using the constant fraction algorithm, which defines the time of arrival of a particle as the time at which the signal crosses a specific fraction of the total signal amplitude. The 30% of the signal amplitude has been used for the present analysis (Ferrero et al., 2021; Ferrero et al., 2025). The statistical uncertainty contributes less than 2% to each measured point. The MCP-PMT contribution dominates the systematic uncertainty. Other sources of uncertainty, such as the bandwidth of the oscilloscope, reduced to 1 GHz, and the functional form used to fit the signal shape used to set the fractional threshold, varied from Gaussian to Lorentzian and parabolic functions, have been investigated and resulted in a negligible impact of less than 1% on the timing measurements. The total uncertainty results in 0.8 ps for the low-charge points, and down to 0.7 ps for the data points at high collected charge.

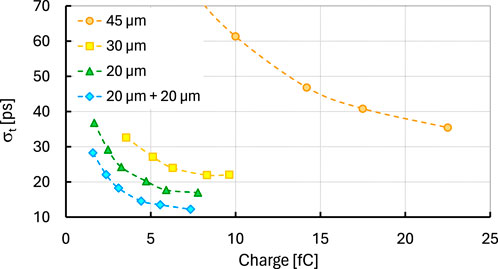

The timing resolutions of 20 and 30 µm thick sensors are shown in Figure 1 as a function of the collected charge. Also, the timing resolution extracted from the combined information of two planes of 20 µm thick sensors is shown, proving that the timing resolution scales by the factor 1/√2 with respect to one plane only. Due to an unexpectedly high level of noise on the test beam data taken on the 45 µm-thick sensors, it was not possible to extract timing information for the highest thickness. Therefore, the results from thin sensors are compared to the timing resolution of a 45 µm thick sensor tested with β-particles from a90Sr source, using the same Photonis MCP-PMT as a time reference, and selecting only the most energetic electrons which result from the 90Y end-point and behave as minimum ionising particles.

Figure 1. Timing resolution as a function of the collected charge from EXFLU1 LGAD sensors with different thicknesses: 45 µm (orange circles), 30 µm (yellow squares), 20 µm (green triangles), and two 20 µm sensors (blue diamonds). The error bars are not displayed.

The comparison of the results from sensors with different active thicknesses demonstrates that the contribution of non-uniform energy deposition to the timing resolution scales with sensor thickness as expected. On the other hand, the jitter contribution only depends on the readout electronics, which remain the same for all the tested sensors. The minimum measured timing resolution is 21.9 ps for the 30 µm thick sensor and 16.6 ps for the 20 µm thick sensor, which reduces to 12.2 ps for a system of 2 planes of 20 µm thick sensors.

The 30-µm thick sensors have been tested after irradiation up to a fluence of 2.5 ✕ 1015 1 MeV equivalent n/cm2, reaching a timing resolution below 22 ps for all tested fluences (Ferrero et al., 2025). The data-taking of irradiated sensors was performed at cold temperatures between −35°C to −42°C and −50°C, using CO2 ice.

3 Radiation hardness of the EXFLU1 sensors

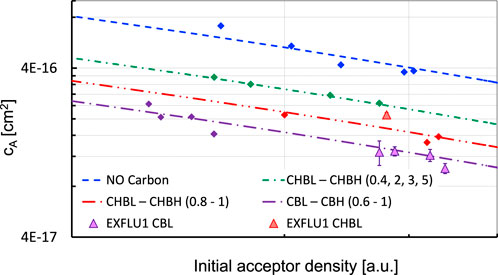

Two different strategies of defect engineering were employed to design the gain implant of the EXFLU1 sensors: Carbon atoms were co-implanted with Boron, using two annealing procedures. For most of the wafers (see Table 1) Carbon and Boron atoms have been activated at the same time with a low thermal budget (CBL). This strategy was proven to be more radiation-hard than previous FBK designs (Ferrero et al., 2021). Still, it requires careful fine-tuning of the concentration of implanted Boron, as just a fraction of the total Boron is activated with annealing. One control wafer has been included in the batch, using a consolidated procedure: the Carbon was implanted and activated with a high thermal budget, subsequently Boron was implanted in the same volume and activated with a low thermal budget (CHBL). In this case, almost every implanted Boron atom is activated.

The acceptor removal coefficient was extracted by comparing the amount of active Boron before irradiation and up to a fluence of 1.5 ✕ 1015 1 MeV equivalent n/cm2. In sensors with higher irradiation, the defects in the bulk become non-negligible, affecting the investigation of the gain implant properties. The fraction of active Boron has been measured through capacitance-voltage (C-V) characterisation of the sensors to access the bias point at which the gain layer is depleted, referred to as VGL. All C-V measurements were performed at a temperature of +20°C and an optimised frequency, ranging between 1k Hz and 2k Hz. Four different methods were used to extract VGL, as described in Ferrero et al. (2021); Altamura et al. (2025).

1. The bias corresponding to the interaction point between two linear fits, considering the initial flat part of the C-V curve and the subsequent drop due to the depletion of the sensor bulk.

2. The bias value associated with a fixed value of capacitance, which geometrically corresponds to a fixed depleted volume, hence depth, of the gain layer.

3. The bias at which the derivative of the curve 1/C2-V reaches its maximum.

4. The bias matching the maximum measured resistance, considering the sensor as modelled by the parallel of a capacitor and a resistor.

The values of acceptor removal coefficients, cA, of the EXFLU1 sensors result from the average of cA independently obtained from each of the four methods described above and are summarised in Figure 2, compared to the coefficient from previous productions of LGAD sensors from FBK. The values of the initial acceptor density have been assessed experimentally from the profiles of active dopants extracted by the C-V curves.

Figure 2. The acceptor removal coefficients (cA) from the EXFLU1 sensors (triangles) compared to the ones resulting from previous FBK productions (diamonds). Four different parametrisations of the acceptor removal mechanism are superimposed to the data, according to the design and the defect engineering of the gain implant (Ferrero et al., 2001).

The EXFLU1 sensors demonstrated the best tolerance to radiation compared to all the FBK sensors produced so far.

4 The eXFlu outcomes

The EXFLU1 sensors demonstrated that thin LGADs have excellent intrinsic timing capabilities. Sensors with an active thickness of 20 µm reach a timing resolution well below 20 ps, and, with the combined information from two planes of sensors, it is possible to achieve a timing resolution of about 12 ps, with a charge collected by the sensors between 5 and 8 fC (Ferrero et al., 2025).

It is necessary to consider that reducing the sensor thickness leads to an increase in capacitance and a decrease in the delivered charge. The results presented here were obtained with fast custom-made electronics with a wide bandwidth and high power consumption. The EXFLU1 sensors still have to prove their performance once coupled to low-power ASICs optimised for timing measurements.

Regarding radiation tolerance, the EXFLU1 sensors are the most radiation-hard LGADs produced by FBK and can operate with almost unchanged performance up to a fluence of 2.5 ✕ 1015 1 MeV equivalent n/cm2 (Altamura et al., 2025).

Still, to operate LGAD sensors for 4D tracking in future high-energy and high-intensity hadron colliders, a new design of the gain implant needs to be adopted. Compensated LGADs represent the key evolution for efficiently operating LGAD sensors at fluences above 1017 1 MeV equivalent n/cm2 (Sola et al., 2024). Their innovative design results from the compensation of two dopant elements of different types, namely, p- and n-type, implanted in the same volume. Both dopants, commonly Boron and Phosphorus, are deactivated by irradiation, but if properly engineered, their difference remains constant with irradiation. The compensated LGADs represent the radiation-hard frontier of LGAD sensors for 4D tracking at the extreme fluences.

Data availability statement

The data analyzed in this study is subject to the following licenses/restrictions: The data that support the findings of this study are available on request from the corresponding author. Requests to access these datasets should be directed to Valentina Sola, dmFsZW50aW5hLnNvbGFAdW5pdG8uaXQ=.

Author contributions

VS: Conceptualization, Funding acquisition, Investigation, Methodology, Project administration, Resources, Supervision, Writing – original draft. MB: Methodology, Project administration, Supervision, Writing – review and editing. FM: Conceptualization, Methodology, Supervision, Writing – review and editing. AA: Data curation, Formal Analysis, Writing – review and editing. RA: Writing – review and editing. GB: Conceptualization, Writing – review and editing. NC: Conceptualization, Methodology, Writing – review and editing. MC: Software, Writing – review and editing. TC: Investigation, Software, Writing – review and editing. MD: Formal Analysis, Writing – review and editing. FF: Data curation, Writing – review and editing. AF: Formal Analysis, Writing – review and editing. SGa: Formal Analysis, Writing – review and editing. GG: Data curation, Formal Analysis, Writing – review and editing. SGi: Writing – review and editing. OA: Data curation, Writing – review and editing. LL: Writing – review and editing. LM: Writing – review and editing. AM: Software, Writing – review and editing. DP: Methodology, Writing – review and editing. GP: Conceptualization, Investigation, Methodology, Software, Writing – review and editing. FS: Writing – review and editing. MT: Data curation, Formal Analysis, Writing – review and editing. RW: Data curation, Formal Analysis, Investigation, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work has received funding from the INFN CSN5 through the eXFlu research project (Italy) and from the European Union’s Horizon 2020 Research and Innovation programme under Grant Agreements Nos 101004761 (AIDAinnova) and 101057511 (EURO-LABS).

Acknowledgments

The authors thank the RD50 Collaboration (CERN), now DRD3, for hosting discussions on common challenges and exchange of ideas and points of view, representing the fruitful environment where the eXFlu research has grown. The development of the periphery of the thin LGAD sensors has been possible thanks to the design and work done by Gian Franco Dalla Betta and Lucio Pancheri on previous FBK batches. Part of the measurements leading to the timing resolution results have been performed at the Test Beam Facility at DESY Hamburg (Germany), a member of the Helmholtz Association (HGF).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The handling Editor VG declared that they were involved in the decision to grant INFN funding to the authors.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Altamura, A. R., Anderlin, L., Arcidiacono, R., Borghi, G., Boscardin, M., Sola, V., et al. (2025). “Radiation-resistant thin LGADs for enhanced 4D tracking,” in Wien (AT) the 17th Vienna conference on instrumentation. Available online at: https://indico.cern.ch/event/1386009/contributions/6279047/.

Bisht, A., Borghi, G., Boscardin, M., Centis Vignali, M., Ficorella, F., Ali, O. H., et al. (2023). Characterization of novel trench-isolated LGADs for 4D tracking. Nucl. Inst. Meth. A, 167929. doi:10.1016/j.nima.2022.167929

Centis Vignali, M., Bisht, A., Boscardin, M., Cavazzini, L., Ficorella, F., Hammad Ali, O., et al. (2025). Development and waferlevel characterization of the first production of DC-RSD sensors at FBK. J. Instrum. 20, C07037. doi:10.1088/1748-0221/20/07/C07037

Croci, T., Fondacci, A., White, R. S., Durando, M., Galletto, S., Borghi, G., et al. (2024). Measurements and TCAD simulations of guard-ring structures of thin silicon sensors before and after irradiation. Nucl. Inst. Meth. A, 169801. doi:10.1016/j.nima.2024.169801

Croci, T., Morozzi, A., Moscatelli, F., Sola, V., Borghi, G., Paternoster, G., et al. (2022). TCAD simulations of non-irradiated and irradiated low-gain avalanche diodes and comparison with measurements. J. Instrum. 17, C01022. doi:10.1088/1748-0221/17/01/C01022

Diener, R., Dreyling-Eschweiler, J., Ehrlichmann, H., Gregor, I. M., Kötz, U., Krämer, U., et al. (2019). The DESY II test beam facility. Nucl. Inst. Meth. A (922), 265–286. doi:10.1016/j.nima.2018.11.133

Doblas, A., Flores, D., Hidalgo, S., Moffat, N., Pellegrini, G., Quirion, D., et al. (2023). Inverse LGAD (iLGAD) periphery optimization for surface damage irradiation. Sensors 23, 3450. doi:10.3390/s23073450

Ferrero, M., Altamura, A. R., Arcidiacono, R., Borghi, G., Boscardin, M., Cartiglia, N., et al. (2025). “Timing resolution of thin LGAD sensors for high radiation environments,” in Trento (IT) 20th anniversary “Trento” workshop on advanced silicon radiation detectors. Available online at: https://indico.cern.ch/event/1455346/contributions/6323206/.

Ferrero, M., Arcidiacono, R., Mandurrino, M., Sola, V., and Cartiglia, N. (2021). An introduction to ultra-fast silicon detectors. Boca Raton (FL: CRC Press, 184. doi:10.1201/9781003131946

Nakamura, K., Kita, S., Ueda, T., Hara, K., and Suzuki, H. (2021). First prototype of finely segmented Hpk aclgad detectors. JPS Conf.Proc. 34, 010016. doi:10.7566/JPSCP.34.010016

Pellegrini, G., Fernández-Martínez, P., Baselga, M., Fleta, C., Flores, D., Greco, V., et al. (2014). Technology developments and first measurements of Low Gain Avalanche Detectors (LGAD) for high energy physics applications. Nucl. Inst. Meth. A (765), 12–16. doi:10.1016/j.nima.2014.06.008

Sola, V., Arcidiacono, R., Cartiglia, N., Ferrero, M., Siviero, F., Tornago, M., et al. (2019). Next-generation tracking system for future hadron colliders. PoS, 034. doi:10.22323/1.373.0034

Sola, V., Fondacci, A., Morozzi, A., Passeri, D., Moscatelli, F., Borghi, G., et al. (2023). “Characterisation of the EXFLU1 batch from FBK,” in Tivat (MNE) 42st RD50 workshop. Available online at: https://indico.cern.ch/event/1270076/contributions/5450195/.

Sola, V., Paternoster, G., Morozzi, A., Arcidiacono, R., Barozzi, M., Borghi, G., et al. (2024). The first batch of compensated LGAD sensors. Nucl. Inst. Meth. A, 169453. doi:10.1016/j.nima.2024.169453

Keywords: solid state radiation sensors, LGAD, thin sensors, precise timing, radiation hardness, 4D tracking

Citation: Sola V, Boscardin M, Moscatelli F, Altamura AR, Arcidiacono R, Borghi G, Cartiglia N, Centis Vignali M, Croci T, Durando M, Ficorella F, Fondacci A, Galletto S, Gioachin G, Giordanengo S, Hammad Ali O, Lanteri L, Menzio L, Morozzi A, Passeri D, Paternoster G, Siviero F, Tornago M and White RS (2025) Thin LGAD sensors for 4D tracking in high radiation environments: state of the art and perspectives. Front. Sens. 6:1648102. doi: 10.3389/fsens.2025.1648102

Received: 16 June 2025; Accepted: 21 July 2025;

Published: 01 August 2025.

Edited by:

Vincenzo Guidi, University of Ferrara, ItalyReviewed by:

Gaetano Barone, Brown University, United StatesCopyright © 2025 Sola, Boscardin, Moscatelli, Altamura, Arcidiacono, Borghi, Cartiglia, Centis Vignali, Croci, Durando, Ficorella, Fondacci, Galletto, Gioachin, Giordanengo, Hammad Ali, Lanteri, Menzio, Morozzi, Passeri, Paternoster, Siviero, Tornago and White. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: V. Sola, dmFsZW50aW5hLnNvbGFAdW5pdG8uaXQ=

V. Sola

V. Sola M. Boscardin

M. Boscardin F. Moscatelli

F. Moscatelli A. R. Altamura1,2

A. R. Altamura1,2 G. Borghi

G. Borghi N. Cartiglia

N. Cartiglia M. Centis Vignali

M. Centis Vignali T. Croci

T. Croci M. Durando

M. Durando A. Fondacci

A. Fondacci S. Giordanengo

S. Giordanengo A. Morozzi

A. Morozzi D. Passeri

D. Passeri G. Paternoster

G. Paternoster