- 1Department of Mechanical Engineering, Hangzhou City University, Hangzhou, China

- 2Key Laboratory of Advanced Manufacturing Technology of Zhejiang Province, Zhejiang University, Hangzhou, China

- 3School of Mechanical Engineering, Zhejiang University, Hangzhou, China

Digital transformation is critical for small and medium-sized manufacturing enterprises (SMMEs) in China to enhance competitiveness within the sharing economy, particularly in the production capacity domain, which accounts for 32.75% of the sharing economy market. However, SMMEs face significant technological, financial, organizational, and cultural barriers that hinder their digitalization efforts. This study conducts a comprehensive literature review to analyze barriers to digital transformation and the role of sharing economy platforms. It proposes strategies leveraging chain-centric, industry-brain, and shared service cloud platforms. A case study of Company F, an SMME in the elevator industry, is analyzed using quantitative financial data (2015–2022) and qualitative interviews, employing statistical methods (e.g., regression analysis) and thematic analysis with NVivo to evaluate the impact of a shared service platform provided by Company L. The case study reveals that Company F's digital transformation, facilitated by Company L's shared service platform, significantly improved profitability and operational efficiency. Post-transformation (2019–2022), the mean main business profit margin increased from 32.65% to 45.94%, and total asset turnover rose from 0.64 to 0.84. Regression analysis confirmed significant gains (p < 0.05 for profit margin, p < 0.01 for asset turnover). Qualitative findings highlight enhanced maintenance efficiency, streamlined spare parts management, and increased collaboration, despite a temporary decline in 2020 due to the COVID-19 pandemic. The sharing economy, through data-sharing and collaborative platforms, mitigates SMMEs' resource constraints and fosters digital transformation. These findings underscore the potential of shared platforms to overcome transformation barriers, offering actionable strategies for SMMEs and policymakers. While focused on China, the study suggests broader applicability to other middle-income countries, emphasizing the need for supportive digital ecosystems and regional considerations to ensure equitable transformation.

1 Introduction

The sharing economy, a dynamic and rapidly evolving sector of modern commerce, has become an integral part of China’s economic landscape. This innovative resource allocation approach refers to offering idle items or services with surplus value to others through specialized sharing platforms. This model is set apart because ownership remains unchanged while participants receive material or non-material rewards for their contributions (HE and GU, 2018). The impact of this economic paradigm shift is evident in the impressive figures reported in the “China Sharing Economy Development Report (2023).” According to this authoritative source, China’s share economy market’s scale reached a staggering 3.832 trillion yuan in 2022, demonstrating robust growth with a year-on-year increase of 3.9 percentage points (China Academy of Information and Communications Technology China Telecommunication Technology Labs-Terminals, 2023). Within this thriving ecosystem, the sharing economy market in the production capacity domain has emerged as a particularly significant sector, accounting for 1.2548 trillion yuan. This represents a year-on-year growth of 1.5 percentage points and constitutes 32.75% of the entire sharing economy market, solidifying its position as the second-largest sector in market size (State Information Center--Sharing Economy Research Center, 2023). The consistent and rapid development of the sharing economy in the production capacity domain has created a wealth of new opportunities for transforming and upgrading Chinese manufacturing enterprises. Of note is the rise of sharing manufacturing platforms, primarily established by large manufacturing enterprises, which have become increasingly sophisticated, such as Haier’s COSMOPlat, a platform enabling SMMEs to access advanced manufacturing solutions and collaborate across supply chains, and SANY’s Rootcloud, which provides cloud based industrial IoT services to share equipment data and optimize production processes. These platforms are invaluable assets in supporting the digital transformation journey of small and medium-sized manufacturing enterprises (SMMEs), providing them access to resources and technologies that might otherwise be out of reach. For instance, COSMOPlat integrates SMMEs into a networked ecosystem for customized production, while Rootcloud offers real-time data analytics, reducing the technological and financial barriers faced by smaller firms.

As we delve deeper into the concept of digital transformation, it is important to note that academia has yet to settle on a unified definition for this complex and multifaceted process. However, after an extensive review of related literature, this study proposes a comprehensive understanding of digital transformation: it involves the strategic implementation of innovative digital technologies such as blockchain, cloud computing, and artificial intelligence, coupled with the deployment of digital tools and software to explore and fully leverage the value of digital assets (Kraus et al., 2022). This process goes beyond mere technological adoption; it entails breaking down long-standing data barriers that have traditionally existed between different departments, hierarchical levels, and even among different enterprises within the same industry. This data integration aims to enhance the intelligence quotient across all aspects of a company’s operations, from research and development to design, production, and general operations. By doing so, digital transformation seeks to boost the competitiveness of a company’s products and services, thereby allowing the organization to gain a significant competitive edge in an increasingly digital marketplace. At its most fundamental level, digital transformation represents a profound shift in business and commercial models, driven by the relentless advancement of new-generation information and communication technologies (ICT). This far-reaching transformation encompasses comprehensive changes across all enterprise elements, including supply chain management, product development processes, manufacturing techniques, organizational structures, marketing strategies, and human resource management. The essence of digital transformation lies in its ability to seamlessly combine these new ICT technologies with the existing production elements of an enterprise, fostering unprecedented levels of business innovation and organizational restructuring.

The digital transformation journey typically begins with the integration and sharing of data, progresses to the promotion of business integration and sharing, and ultimately culminates in the efficient sharing of internal and external resources. It is crucial to recognize that digital transformation is not a quick fix for most enterprises but rather a long-term, systematic project. This extended timeline is necessitated by the numerous challenges that must be overcome, including rapid technological iteration, often resistant organizational change, the need for continuous business innovation, and the complex task of cultural reshaping within the organization. Given these multifaceted challenges, it is not uncommon for significant results to only materialize after 3–5 years, or in some cases, even longer (Mahboub and Sadok, 2023). This extended timeline and the complexity of the process make digital transformation a daunting undertaking for many companies, with successful completion often proving elusive.

As a key pillar of China’s national economy, the manufacturing industry is of paramount importance. Its significance to the country’s economic health and global competitiveness cannot be overstated. While the sector has undoubtedly made remarkable strides in recent decades, it faces many challenges threatening its long-term sustainability and global competitiveness (Zhang et al., 2023). Considering these persistent challenges, there is a clear and pressing need for the strategic implementation of digital technologies to facilitate the transformation and upgrading of China’s manufacturing capabilities. In manufacturing, digital transformation can be understood as the process through which manufacturing enterprises harness the power of digital technology to fundamentally reconstruct their production methods, industrial structures, and innovation systems. This comprehensive overhaul optimizes production and manufacturing processes, enhances customer service experiences, and ultimately leads to a complete reconstruction and innovation of the manufacturing industry’s value system. The impetus for this transformation is largely driven by the ever-increasing demand for personalized production and customized services in today’s market. Manufacturing enterprises use digital tools to revolutionize their production methods and organizational models to meet these evolving market demands. This shift propels sweeping changes across the manufacturing industry, particularly in production methods. We are transitioning from traditional combinations of manual and intellectual labor to a new paradigm characterized by human and machine intelligence fusion. Similarly, there is a marked shift from mechanized and automated tools to more sophisticated digital and intelligent tools. The impact of digital transformation extends beyond production methods to drive innovation in the organizational models of the manufacturing industry. This includes a paradigm shift from labor-based to value-based distribution, a transition from primary-secondary relationships to shared cooperative relationships, and a redefinition of organizational boundaries extending beyond individual enterprises’ confines to encompass societal clusters (Kraus et al., 2022). This burgeoning sharing economy presents unprecedented opportunities for the digital transformation of manufacturing enterprises, particularly Small and Medium-Sized Manufacturing Enterprises (SMEs), which form the backbone of China’s industrial sector. This study posits that the sharing economy, through its reliance on digital platforms, data sharing, and collaborative models, can catalyze digital transformation among SMMEs, compelling them to adopt digital technologies and strategies to participate and compete effectively.

In the landscape of Chinese manufacturing, small and medium-sized manufacturing enterprises (SMMEs) play a crucial role. With over 90% of the total number of manufacturing enterprises in China falling into this category, the digital transformation of SMMEs is paramount for developing China’s digital economy. The sheer number of SMMEs makes them the primary battleground for the digital transformation of the manufacturing industry, and their success or failure in this endeavor will have significant implications for the high-quality development of China’s manufacturing sector. Consequently, studying the digital transformation of SMMEs is not just an academic exercise but a matter of great practical value and significance. The insights gained from such studies can inform policy decisions, guide investment strategies, and help shape the future of China’s manufacturing industry in an increasingly digital world. As China continues to navigate its path toward becoming a global leader in advanced manufacturing, the successful digital transformation of its vast network of SMMEs will be a critical factor in achieving this ambitious goal. This paper contributes to the existing body of knowledge by:

1. Providing a comprehensive analysis of the barriers Chinese SMMEs face in their digital transformation, considering the sharing economy’s influence. This includes exploring technological, organizational, financial, and cultural challenges unique to this context.

2. Proposing actionable strategies for SMMEs to overcome these barriers by leveraging the unique opportunities presented by China’s evolving sharing economy. This includes examining the role of data-sharing, chain-hosting, industry-brain, and shared service cloud platforms.

3. Analyzing a real-world case study of a Chinese SME that successfully underwent a digital transformation by utilizing a sharing service platform. This analysis provides empirical evidence for the proposed strategies and highlights the tangible benefits achievable through this approach.

The findings of this study provide valuable insights for policymakers aiming to promote the digitalization of the manufacturing sector and for SMME managers seeking to navigate the complexities of digital transformation. It underscores the need for a comprehensive and systematic approach to overcome the multifaceted obstacles. It highlights the significant potential of the sharing economy in driving the digital transformation of China’s manufacturing SMMEs. Effectively supporting this transformation is crucial for enhancing the high-quality development of the country’s manufacturing sector and fostering a thriving digital economy.

2 Enabling SMME digital transformation in China: a review of sharing economy solutions

A comprehensive review of existing literature is essential to understand the complex interplay between digital transformation, the sharing economy, and their implications for Chinese manufacturing SMMEs. This section delves into the key themes shaping this dynamic landscape, examining the challenges and opportunities presented by digital transformation in manufacturing, the potential of the sharing economy as an enabler for SMMEs, the specific context of digital transformation in China, the role of data-sharing platforms, and the need to bridge existing research gaps to address the unique needs of Chinese manufacturing SMMEs.

2.1 Digital transformation in manufacturing

The manufacturing landscape is undergoing a profound shift driven by the pervasive adoption of digital technologies. This digital transformation, called Industry 4.0, signifies a transition towards interconnected and intelligent manufacturing systems characterized by data exchange, automation, and cyber-physical systems (Ben-Daya and Bahroun, 2017). This transformation promises significant benefits for manufacturing enterprises, including increased operational efficiency, enhanced agility in responding to market demands, and the ability to offer personalized and customized products (Schumacher et al., 2015).

Despite the evident advantages, the path towards digitalization has challenges. Manufacturing enterprises, especially SMMEs, encounter substantial hurdles in fully realizing the potential of digital technologies. These challenges often stem from limited financial resources to invest in new technologies, a lack of in-house digital expertise, and organizational inertia in adopting new processes and workflows (Li et al., 2018). Furthermore, SMMEs often grapple with legacy IT infrastructure, creating data silos that hinder the seamless flow of information necessary for effective digitalization (Westergren et al., 2024). Beyond these broad challenges, SMMEs often encounter specific technological barriers that hinder their digital transformation. These include the difficulty of integrating legacy systems with new digital tools, lack of in-house expertise to implement and manage advanced technologies (such as AI or IoT), and cybersecurity vulnerabilities due to limited resources for robust security measures. Furthermore, the rapid pace of technological change itself poses a challenge. SMMEs must navigate a landscape where investments in digital tools risk quick obsolescence, demanding constant adaptation and learning to remain competitive.

2.2 The sharing economy as an enabler for SMME digital transformation

Given these challenges, the sharing economy has emerged as a powerful enabler for SMMEs embarking on digital transformation. By fostering collaborative consumption and access over ownership, the sharing economy provides a viable alternative to traditional resource acquisition models, which is particularly beneficial for resource constrained SMMEs (Sutherland and Jarrahi, 2018). Moreover, the inherent structure of the sharing economy, with its reliance on digital platforms, data sharing, and collaborative networks, can drive SMMEs towards digitalization by providing the necessary tools and competitive incentives to adopt new technologies and strategies.

Various sharing economy models hold significant promise for the manufacturing sector. Equipment sharing platforms, for instance, allow SMMEs to access advanced machinery and equipment without significant upfront investment, reducing financial barriers to adopting cutting-edge technologies. Platform-based service exchange models facilitate access to specialized expertise on-demand, addressing the skill gaps often faced by SMMEs in areas like data analytics, cybersecurity, and digital marketing. Data-sharing initiatives enable SMMEs to leverage collective intelligence and insights across the ecosystem, enhancing decision-making and fostering innovation (Durán-Romero et al., 2020).

2.3 Digital transformation in the Chinese context

A proactive and supportive policy environment characterizes China’s pursuit of digital transformation in manufacturing. Recognizing the vital role of digital technologies in driving economic growth and industrial upgrading, the Chinese government has implemented a series of policies and initiatives to accelerate digital adoption across the manufacturing sector, focusing on empowering SMMEs (Guo and Chen, 2022). These efforts encompass financial incentives, infrastructure development, technology transfer programs, and skill development initiatives, creating a fertile ground for digital innovation.

Furthermore, China’s sharing economy exhibits unique characteristics that present opportunities and challenges for SMMEs. The country boasts a vibrant and rapidly expanding sharing economy ecosystem fueled by a massive mobile internet user base, favorable government policies, and a cultural inclination towards collaboration in certain sectors (AlNuaimi et al., 2022). However, navigating the complexities of this evolving landscape requires SMMEs to develop a nuanced understanding of local market dynamics, regulatory frameworks, and competitive forces.

2.4 Data-sharing platforms and their role in SMME digital transformation

Data have become the lifeblood of modern manufacturing, underpinning informed decision-making, process optimization, and the development of innovative products and services. Data-sharing platforms have emerged as essential infrastructure for unlocking the value of data, enabling enterprises to exchange data securely and efficiently within their organizations and across ecosystems. These platforms provide a range of functionalities, including data storage and management, data analytics and visualization tools, and mechanisms for secure data exchange and collaboration (Mosaad et al., 2023).

For SMMEs, participating in data-sharing initiatives offers compelling benefits. Access to larger and more diverse datasets can enhance decision-making, improve demand forecasting, and enable more effective supply chain management. Collaborative data analysis can lead to the development of innovative solutions, optimize production processes, and unlock new revenue streams. However, SMMEs also need to address data security and privacy challenges, ensure interoperability between their systems and the platform, and establish robust data governance frameworks (Xia et al., 2024).

2.5 Bridging the gap: addressing the specific needs of Chinese manufacturing SMMEs

While the literature offers valuable insights into digital transformation, the sharing economy, and their convergence, there remains a need for more granular research focusing specifically on the context of Chinese manufacturing SMMEs. Further investigation is required to understand how the unique characteristics of China’s policy landscape, digital ecosystem, and cultural factors influence the adoption and impact of different sharing economy models for digital transformation within this specific context.

This study addresses this gap by delving into the dilemmas Chinese manufacturing SMMEs encounter in their pursuit of digital transformation. It examines how the distinct features of China’s evolving sharing economy can be leveraged to provide practical solutions, enabling these enterprises to overcome their resource constraints, enhance their digital capabilities, and thrive in the increasingly competitive global market. By analyzing a real-world case study of a Chinese SME that has successfully navigated its digital transformation journey through strategic engagement with a sharing service platform, this study provides empirical evidence and practical insights for both policymakers aiming to foster a more supportive environment and SMME managers seeking to harness the transformative power of the sharing economy for digital success.

2.6 Generative AI and its potential for SMME digital transformation

Generative AI, a rapidly advancing field of artificial intelligence, holds significant promise for transforming various aspects of the workplace, including the manufacturing sector. Unlike traditional AI systems that primarily focus on analyzing existing data, generative AI has the unique ability to create new content, designs, and solutions (Capraro et al., 2024). In manufacturing, generative AI can be leveraged for various applications, including accelerating product design processes, optimizing production workflows, predicting equipment failures for proactive maintenance, and personalizing customer interactions. While the potential benefits are substantial, SMMEs may face challenges in adopting generative AI due to the need for significant computing power, large datasets for training AI models, and specialized skills to effectively implement and manage these technologies. However, as generative AI tools become more accessible and integrated into existing platforms, they could significantly lower the barriers to entry for SMMEs seeking to harness the power of AI for digital transformation.

3 Methodology

This study adopts a case study approach to investigate how leveraging the sharing economy can support the digital transformation of Chinese manufacturing SMMEs. The case study methodology is well-suited for examining complex phenomena within real-world contexts, providing a nuanced understanding of a particular case’s specific challenges, strategies, and outcomes (Yin, 2018). This approach allows for an in-depth exploration of the interplay between various factors influencing digital transformation, including technological advancements, organizational structures, market dynamics, and the unique characteristics of China’s evolving sharing economy.

The primary data source for this study is a comprehensive case study of Company F, a Chinese SME operating in the elevator industry that has successfully navigated its digital transformation journey by strategically engaging with a sharing service platform. The data collected for the Company F case study was analyzed using quantitative and qualitative techniques to provide a holistic perspective, with quantitative analysis conducted using Microsoft Excel to process financial records from 2015 to 2022, as presented in Table 2. Specifically, we performed descriptive statistical analyses (including calculation of percentage changes (e.g., growth rate of main business income, net profit growth rate) and averages (e.g., profit margins)) and trend analysis to evaluate the temporal impact of digital transformation on key financial indicators before and after its initiation in 2019, enabling us to quantify improvements in profitability and asset efficiency that supported our conclusions on the sharing economy’s role. The data collected for the Company F case study was analyzed using quantitative and qualitative techniques to provide a holistic perspective. The qualitative analysis involved thematic analysis of interview transcripts and observational notes, conducted using NVivo software (version 12), to identify recurring themes and patterns related to Company F’s digital transformation experience and the role of the sharing service platform. The coding process began with an initial open coding phase, where two researchers independently reviewed the data to assign descriptive codes (e.g., “maintenance efficiency,” “resource access”) to segments reflecting motivations, challenges, and benefits, followed by a collaborative axial coding stage to group these codes into broader categories such as “technological adoption” and “collaborative benefits.” Themes were then refined through iterative comparison with the study’s objectives and theoretical framework (RBV and Dynamic Capabilities Theory), with relationships among data detected based on co-occurrence frequency (e.g., how often “data sharing” linked to “cost reduction” in interviews) and contextual alignment with quantitative outcomes (e.g., profit growth in Table 2), ensuring a robust synthesis of qualitative insights (Yin, 2018). This structured methodology, combining quantitative and qualitative data collection and analysis methods, aimed to provide a comprehensive and nuanced understanding of how the sharing economy can be leveraged to support the digital transformation of Chinese manufacturing SMMEs, drawing valuable lessons from the real-world experience of Company F.

4 The main dilemma of digital transformation in SMMEs

In June 2023, the Ministry of Finance and the Ministry of Industry and Information Technology jointly issued the “Notice on Conducting Pilot Work on Digital Transformation of Small and Medium-sized Enterprises in Cities”. The country has promoted the acceleration of digital transformation of small and medium-sized enterprises through urban pilot work and promoted the deep integration of the digital economy and the real economy. It also identified 16 key industry areas for digital transformation of small and medium-sized enterprises (Ministry of Industry and Information Technology and Ministry of Finance of the People’s Republic of China, 2023). The details are shown in Table 1. From Table 1, the key industry areas supported by the country are basically manufacturing industries, which not only reflects the irreplaceable important position of manufacturing industries in the national economy, but also reflects from the side that the digital transformation of SMMEs is the main direction and key task of digital transformation of small and medium-sized enterprises. In addition, the country has also introduced other policies to increase the assistance for the digital transformation of SMMEs, such as the “14th Five-Year Plan for Promoting the Development of Small and Medium-sized Enterprises” and the “14th Five-Year Plan for Digital Economic Development”, which clearly put forward the strategic deployment to promote the digital transformation of small and medium-sized enterprises. Although the government has issued various policies to vigorously support the digital transformation of small and medium-sized enterprises, the overall digital level of small and medium-sized enterprises is still relatively low, and the road of digital transformation of small and medium-sized enterprises is long and difficult.

According to the “Analysis Report on Digital Transformation of Small and Medium-sized Enterprises (2021)”, 79% of small and medium-sized enterprises are in the exploratory stage of digital transformation, 12% of small and medium-sized enterprises are in the practical stage of digital transformation, and only 9% of small and medium-sized enterprises are in the deep application stage of digital transformation. At present, the overall situation of digital transformation of small and medium-sized enterprises in China is still in the primary stage, and the digital transformation of SMMEs is also in the exploratory stage. Their development still has a long way to go from the expected goal. The situation of digital transformation of SMMEs in China is basically consistent with the overall situation of digital transformation of small and medium-sized enterprises. Small and medium-sized enterprises are the main battlefield for digital transformation in the manufacturing industry, as well as the key focus and challenge of digital transformation in this sector. Compared to large enterprises, small and medium-sized enterprises often have disadvantages such as weak risk resistance, small scale, and limited resources. This has led to various problems that small and medium-sized enterprises may encounter during the transformation process. In the authors opinion, the main difficulties that SMMEs in China face during the transformation process are:

4.1 The leadership lacks sufficient understanding of digital transformation

Digital transformation is a long-term project that cannot provide significant value in a short period of time due to the multi-dimensional changes and restructuring involved in production methods, management models, and business models. Therefore, it requires time to accumulate and precipitate. Transformation is an enduring battle, and enterprises in most cases need 3–5 years to achieve significant results. The ordinary small and medium-sized manufacturing enterprise leaders lack a deep understanding and comprehension of the significance of digital transformation. They are even unsure why sensors should be installed on equipment and what industrial big data is useful for. They prefer to pursue projects that can produce results in a short period of time and coupled with the difficulty of predicting the benefits of transformation at the beginning, it makes the enterprise leadership lack long-term vision for digital transformation.

4.2 Lack of digital talent

Digital transformation is a highly technical task, and SMMEs need to rely on professional digital talents and technologies to achieve their transformation goals. In fact, China’s digital talent reserves are generally insufficient. The average digital-related talent in each enterprise accounts for only 20% of the total human resources (Montero Guerra et al., 2023), and most of these digital talents are concentrated in relatively strong large enterprises. The talents remaining in small and medium-sized enterprises can be said to be very few. SMMEs have small scales and lack funds. They cannot provide generous salary packages to attract excellent digital talents, nor do they have the funds to cultivate their own employees. This leads to a lack of digital talents in SMMEs.

4.3 Weak foundation for transformation

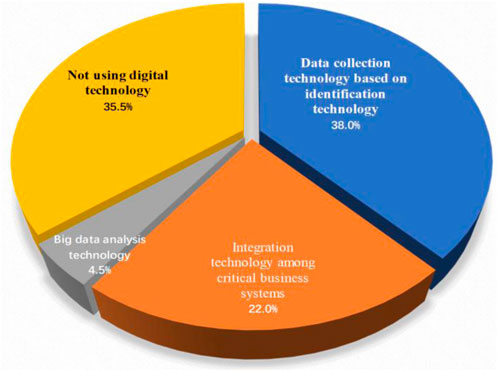

The digital transformation foundation level of SMMEs in China is generally low, and many factories have not even completed basic informatization, nor can they achieve automated data acquisition for production. According to incomplete statistics, only 38% of SMMEs have adopted identification technologies such as barcodes and RFID for data acquisition, 22% of enterprises have integrated and shared key business systems using system integration technology, and only 4.5% of enterprises have used big data analysis technology to guide their production and manufacturing work. For more details, please refer to Figure 1.

It can be found that the proportion of digital technology usage in SMMEs in China is not high, and the foundation of digital transformation is relatively weak, especially the utilization rate of some advanced digital technologies and equipment is low, which cannot ensure a good infrastructure environment for digital transformation.

4.4 Lack of sufficient transformation funds

SMMEs generally have small asset scales and difficulties in financing, and their reserve funds for transformation are far less sufficient than large enterprises. Some enterprises may have invested a large amount of funds in digital transformation at the beginning, but due to their insufficient self-generation ability, it is difficult for them to obtain special funds. Therefore, it is difficult for them to continue to bear the high cost of transformation. These enterprises often show weak performance in the middle and later stages of transformation and ultimately fail to transform successfully.

4.5 Lack of awareness and ability in collaborative sharing

Many SMMEs started as workshops, and at that time, the manufacturing process level of these enterprises was generally low, with rough production and operation methods and lagging management concepts. The impact of inter-enterprise collaboration on the profitability of the enterprise itself was not significant. This made many small and medium-sized manufacturing enterprise owners habitually choose to go it alone, and rarely collaborate and share resources with other enterprises. With the development of new-generation ICT technologies such as artificial intelligence, big data, cloud computing, and blockchain, the business, manufacturing methods, management models, and business models of enterprises have undergone tremendous changes. It is unrealistic for small and medium-sized enterprises to rely on going it alone to achieve sustainable profit growth. If enterprises continue to stick to the old rules and conventions, they will be eliminated by society sooner or later. The millions of small and medium-sized enterprises that have gone bankrupt in the past 3 years are good examples.

The majority of SMMEs lack sufficient collaborative and sharing capabilities. They rarely use digital technology to integrate procurement, research and development, production, marketing, and service information across the enterprise. Data and information are not shared across different departments, leading to the emergence of “information islands” within the enterprise (Peng and Tao, 2022). Most SMMEs lack reliable digital equipment and data acquisition methods, making it difficult to achieve digital control of the production process and automate the collection of product production process data. Not to mention sharing the latest data with partner units in a timely manner, which greatly reduces the efficiency of collaborative management and joint decision-making between enterprises (Zhou and Li, 2023). In response to the difficulties, I propose solutions from the perspective of the sharing economy to escape the predicament. Sharing economy platforms often bring together various excellent resources such as talents, equipment, technology, and data, which can precisely address the urgent needs of SMMEs. Specifically, the following measures can be taken:

(1) To address the lack of awareness among leadership regarding digital transformation, enterprises can leverage shared manufacturing platforms to obtain high-quality digital talent, services, or digital construction solutions at a fair price and create more production or business benefits in a short period of time. This allows the enterprise leadership to see the enormous value of digital transformation and voluntarily adhere to the path of digital transformation.

(2) To address the shortage of digital talent, enterprises can first join a shared manufacturing platform established by industry leaders to find the required digital talent, which can be shared and used by multiple enterprises.

(3) To address the weak foundation for transformation, enterprises can post their needs on a shared service cloud platform built based on industrial internet, which provides digital infrastructure construction plans and cloud services to help enterprises establish a good digital infrastructure and enhance their digital foundation.

(4) To address the lack of sufficient transformation funds, enterprises can post their digital service needs on shared manufacturing platforms. After the supply-demand matching is completed, capable individuals or organizations on the platform will provide corresponding services, and the shared service prices are often relatively inexpensive, alleviating the financial difficulties of SMMEs.

(5) To address the lack of collaborative and sharing awareness and ability, enterprises can join a shared manufacturing platform (or other shared platforms) for a period and experience the invisible benefits brought by the sharing economy. At the same time, with the support of shared manufacturing platforms, SMMEs will also strengthen their collaborative and sharing abilities with the help of new generation information technologies such as IoT and cloud computing.

4.6 Theoretical framework

This study draws upon two prominent theoretical lenses to understand how the sharing economy can support SMMEs’ digital transformation journey: the Resource-Based View (RBV) and the Dynamic Capabilities Theory. The RBV posits that a firm’s competitive advantage stems from its access to valuable, rare, inimitable, and non-substitutable resources (Barney, 1991). Through platforms offering access to advanced technologies, specialized expertise, and data resources, the sharing economy can provide SMMEs with valuable resources they might not possess internally. This access can enable them to overcome resource constraints, a common barrier to digital transformation (TEECE, 2014). Dynamic Capabilities Theory complements the RBV by focusing on a firm’s ability to sense, seize, and reconfigure resources to maintain competitiveness in dynamic environments (Teece et al., 1997). Engaging with sharing platforms can enhance an SMME’s sensing capabilities by providing access to real-time market information and emerging trends. These platforms can also facilitate seizing opportunities by rapidly accessing required resources and expertise. Additionally, the flexible nature of sharing economy models supports reconfiguring resources to adapt to evolving technological and market demands.

This study contributes to both theoretical perspectives by providing empirical evidence for the sharing economy’s role in enhancing resource access and dynamic capabilities among Chinese SMMEs. The research aims to demonstrate how the sharing economy can be leveraged to overcome digital transformation challenges and create a more competitive and resilient manufacturing sector by analyzing a real-world case study.

5 Sharing economy helps SMMEs in digital transformation

5.1 The ways in which sharing platforms empower digital transformation of SMMEs

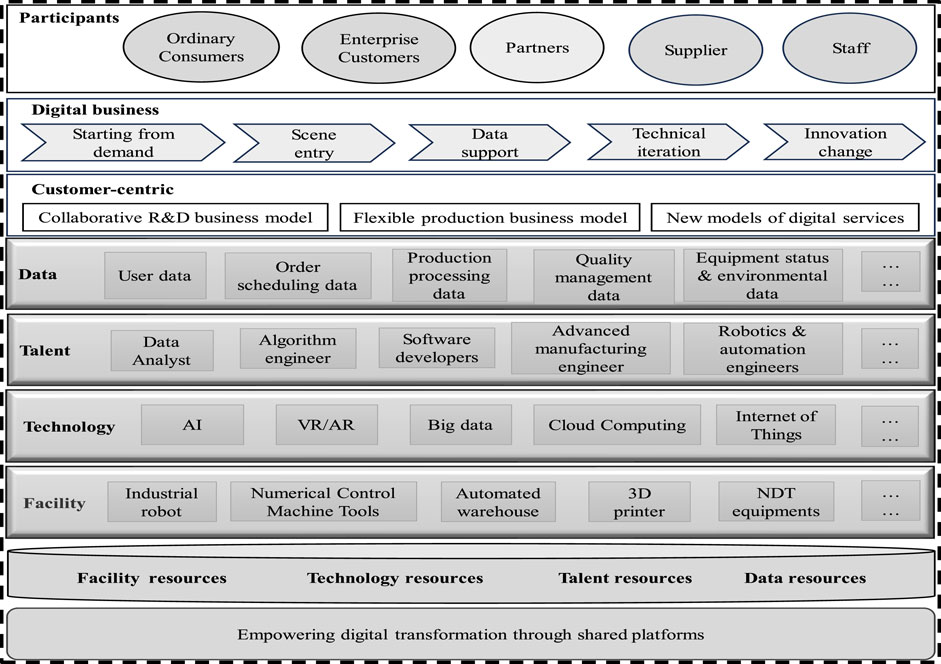

SMMEs often face difficulties such as weak network infrastructure, insufficient funds, technology, and talent reserves. By leveraging sharing economy platforms, enterprises can share various resources, reducing transformation costs and optimizing production models and business processes, with multiplier effects that extend beyond China to invigorate economies worldwide. These platforms (such as chain-hosting shared manufacturing platforms, industry-brain-like collaborative sharing platforms, and shared service cloud platforms) enable SMMEs to access advanced technology, professional digital talent, and valuable data resources at relatively low time and economic costs, as outlined in Figure 2, fostering not only local industrial upgrading but also serving as a scalable model for other countries to enhance SMME competitiveness, stimulate job creation, and drive sustainable economic growth in manufacturing sectors globally (Sutherland and Jarrahi, 2018; de Paula et al., 2023; Ceipek et al., 2021; Liu et al., 2023; George and Schillebeeckx, 2022). For instance, the chain-hosting model improves collaboration efficiency across industrial chains, a strategy that could be adapted in regions like Southeast Asia or Europe to bolster SMME integration into global supply chains. At the same time, the shared service cloud platform’s low-cost digital solutions could empower resource constrained SMMEs in middle-income countries to leapfrog technological barriers. Figure 2 is the basic framework of the shared platform empowering digital transformation. Through the shared platform, SMMEs can share advanced technology, professional digital talent, and valuable data resources with relatively low time and economic costs. This reduces transformation costs, optimizes their production models and business processes, and improves the production and management efficiency of the enterprise. This study advances the specialized literature by introducing an innovative framework that integrates the sharing economy’s collaborative models (chain-hosting shared manufacturing platforms, industry-brain-like collaborative sharing platforms, and shared service cloud platforms) with SMMEs’ digital transformation, offering a pioneering approach tailored to the Chinese context and extensible globally. This research uniquely bridges the Resource-Based View (RBV) and Dynamic Capabilities Theory with empirical evidence from China’s sharing economy, demonstrating how these platforms provide SMMEs with access to critical resources (e.g., technology and expertise) and enhance dynamic capabilities (e.g., sensing market trends and reconfiguring operations), as validated by the case of Company F and supported by Figure 2 and Table 2 (Barney, 1991; TEECE, 2014; Teece et al., 1997). Unlike prior studies that broadly address digital transformation or the sharing economy separately, our work innovatively synthesizes these domains to propose actionable, platform-specific strategies that mitigate SMMEs’ resource constraints and cultural barriers, contributing a nuanced understanding of how data-sharing ecosystems and industry-specific collaboration can drive high-quality development in manufacturing sectors worldwide. There are three ways for sharing economy platforms to empower the digital transformation of SMMEs:

- The first is a chain-hosting shared manufacturing platform, which is built based on leading enterprises in the industry, can improve the collaboration efficiency of the upstream and downstream of the industrial chain and drive SMMEs to integrate into the digital application scenario. With the shared manufacturing industrial chain of this platform, the collaboration and sharing of the complete industrial chain from raw material procurement, R&D design, production and manufacturing, logistics and distribution, marketing, and sales to after-sales service can be realized. Through the collaboration and sharing of the industrial chain, SMMEs can share information and collaborate with upstream and downstream enterprises to improve the efficiency of procurement, production, and other links; they can also break down departmental barriers, realize the interconnection and data sharing of equipment, optimize the business processes between various links, and improve the overall operation and production efficiency of enterprises (de Paula et al., 2023; Ceipek et al., 2021). The chain-hosting shared manufacturing platform greatly reduces the transformation threshold of SMMEs and promotes them to better carry out digital transformation.

- The next is an industry-brain-like collaborative sharing platform built on industries within a region that have significant advantages and good development prospects. It can leverage platform effects to drive the digital transformation of industrial clusters within the region, especially facilitating the transformation of SMMEs with weaker capabilities. Through the “industry brain-sharing platform,” the sharing and interoperability of industrial chain data within the region are achieved, enhancing the transparency of the industrial chain within the region, promoting the collaborative development of various production and manufacturing enterprises within the region (Liu et al., 2023; George and Schillebeeckx, 2022). At the same time, the industry brain platform provides services such as talent training and technological innovation, assisting enterprises in the region in achieving digital transformation and upgrading.

- Lastly, there is a shared service cloud platform built on the industrial Internet, which can provide excellent digital solutions for SMMEs. The shared service cloud platform combines cloud computing with the industrial Internet, opens platform interfaces for SMMEs, and provides high-quality, low-cost microservices and computing power in a cloud-based manner, enabling them to “go to the cloud” and “use the cloud.” Industrial Internet companies mainly offer general SaaS products, characterized by high standardization, and have accumulated a wealth of experience in providing solutions to customers over the years. Through integration with other systems, the shared service cloud platform fully leverages the advantages of industrial Internet companies and cloud networks to achieve intelligent interconnection of devices and data sharing, providing optional solutions for personalized customized services to users, enhancing the digital capabilities of enterprises.

Digital service providers can also use this platform to develop easily deployable, low-cost digital solutions or applications for SMMEs, reducing the cost of enterprise transformation.

5.2 The ways in which the data middle platform promotes the digital transformation of SMMEs

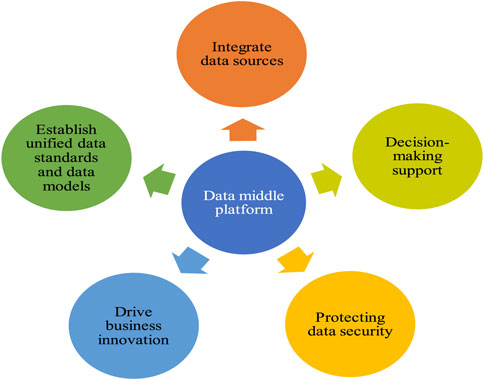

The data middle platform is an important part of the sharing economy, serving as an enterprise-level sharing service platform with the core idea of data sharing. The data middle platform acts as a bridge connecting supply and demand, providing data sharing, exchange, and trading services for both parties. SMMEs face challenges such as difficulty in obtaining data, ensuring data security, lack of standardized data, poor data quality, and heterogeneous data sources during the digital transformation process. The data middle platform addresses these issues by providing standardized data services, enabling data circulation, and sharing among different business departments, breaking down information barriers between departments, and promoting business collaboration within the enterprise. Additionally, the data middle platform provides a unified data service interface, integrating internal and external data resources of the enterprise, eliminating data silos to achieve data consistency between different systems, improving data quality and reliability, and providing data support for the enterprise’s digital transformation. As a foundational technological platform for the digital transformation of manufacturing enterprises (Wu and Li, 2024), the data middle platform first digitizes the core business of the enterprise and deposits data to achieve business data. It then connects data from different business systems, establishes unified data standards, and accomplishes data convergence, development, and secure management, forming the enterprise’s data assets. Furthermore, it connects and encapsulates the reusable capabilities of multiple scenarios with the core elements spanning the entire industry chain at the middle platform layer, providing data sharing services to the outside world. Finally, it assists enterprises in establishing a unified data service system, standardizing the management of data APIs, enabling data reuse in multiple business scenarios, and activating the business value of data. The data middle platform is a significant driving force for the digital transformation of manufacturing enterprises, assisting SMMEs in digital transformation in several aspects, as detailed in Figure 3.

(1) Integration of data sources: SMMEs have numerous internal and external data sources, including various business systems, sensor devices, and public data open platforms. The data middle platform can integrate and consolidate these data sources to form a relatively complete data ecosystem, laying a comprehensive and accurate data foundation for the digital transformation of SMMEs.

(2) Establishment of unified data standards and data models: Through the data middle platform, manufacturing enterprises can standardize various data, establish unified data models, facilitating the management, analysis, and sharing of data. This avoids issues such as data format confusion and conflicts between different departments or data sources.

(3) Decision support: The data middle platform provides real-time and accurate data support, assisting enterprises in making data-driven decisions. Through the analysis and exploration of key data, SMMEs can better grasp market demand and optimize production processes.

(4) Promoting business innovation: The data middle platform not only supports existing business operations but also promotes business innovation in manufacturing enterprises by providing new data services and applications. For example, using the intelligent analysis tools provided by the data middle platform, manufacturing enterprises can develop new products or processes that better meet market demands.

(5) Ensuring data security: While sharing data, it is essential to ensure data security and privacy protection, taking necessary measures to prevent risks. The data middle platform provides a secure data storage and management mechanism, ensuring data integrity and security, thus providing reliable support for the digital transformation of enterprises.

In conclusion, as part of the sharing economy, the data middle platform provides strong support and guarantees for the digital transformation of SMMEs, accelerating the digital transformation process for these enterprises.

6 Case analysis

This study selects Company L as the research object for three main reasons: 1) This enterprise is recognized as a “specialized, refined and innovative” small giant enterprise by the Ministry of Industry and Information Technology and is a typical representative of the successful digital transformation of countless small and medium-sized enterprises in China today. 2) This enterprise has constructed a shared service platform for the elevator industry based on the industrial internet, providing digital solutions for small and medium-sized enterprises in the elevator industry and supporting their digital transformation. 3) The enterprise has relatively smooth channels for obtaining digital-related information.

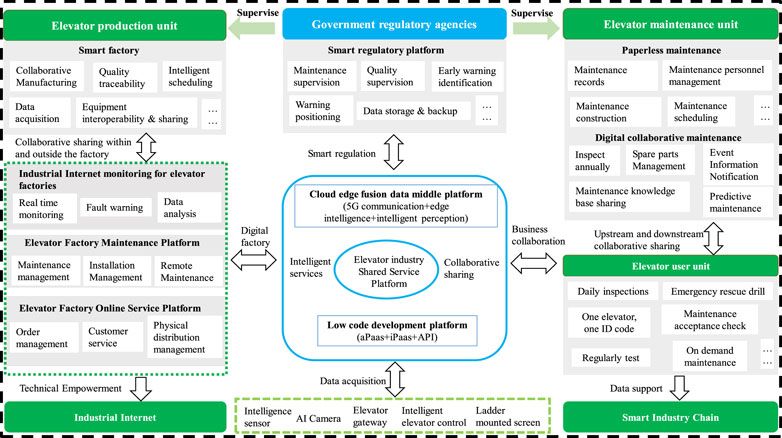

6.1 A digital collaborative sharing scheme for shared service platforms in the elevator industry

Company L is an industrial internet-based enterprise that specializes in providing intelligent services for small and medium-sized elevator enterprises. By relying on key technologies such as the Internet of Things, intelligent perception, cloud intelligence, and 5G edge computing, and combining with its own experience in the elevator industry for many years, the company has constructed a shared service platform for the elevator industry based on the industrial internet. This platform enables digital collaborative sharing in the entire industrial chain of elevator intelligent manufacturing, intelligent supervision, and maintenance services. Figure 4 is the digital collaborative sharing solution of the elevator industry shared service platform. It can be seen from the figure that Company L can provide various services to enterprise customers through the shared service platform. For example, through the industrial internet platform, enterprise customers can monitor elevators remotely, enable digitalization and intelligence in elevator maintenance, and improve elevator management efficiency. Through IoT devices such as smart sensors, smart elevator gateways, and AI cameras, enterprise customers can collect elevator status data and elevator maintenance information online. After analyzing the collected elevator data, the platform issues an early warning notice to determine the possible time and location of elevator failures and arranges personnel to rush to the scene for maintenance in a timely manner to avoid failures. Through the low-code development platform, business departments of enterprise customers can build application platforms by dragging and dropping, greatly reducing the application building threshold, reducing the iterative communication process with the IT department, and shortening the project development cycle. At the same time, the low-code platform supports cross-platform deployment of applications, and data between different departments or systems of enterprise customers can be shared, which helps customers to achieve digital transformation.

Figure 4. Digital collaborative sharing schemes for shared service platform in the elevator industry.

6.2 Analysis of the effect of digital transformation

Over the years, Company L has been dedicated to the digitalization of the elevator industry, assisting numerous enterprises in their digital transformation efforts with notable success. For case analysis, we selected Company F, an SME in City F specializing in elevator sales, installation, and maintenance. The study analyzed its financial performance from 2015 to 2022 (Table 2) using advanced statistical methods to test two hypotheses: H1 (Digital transformation via a sharing service platform significantly increases profitability (measured by main business profit margin), and H2) Digital transformation enhances operational efficiency (measured by total asset turnover). Using Microsoft Excel, we calculated means and standard deviations for key financial indicators pre- (2015–2018) and post-transformation (2019–2022): the mean main business profit margin rose from 32.65% (SD = 2.72) to 45.94% (SD = 13.63), and the mean total asset turnover increased from 0.64 (SD = 0.04) to 0.84 (SD = 0.12), indicating improved profitability and efficiency with greater variability post-transformation. A simple linear regression analysis further confirmed these effects, with time (pre- vs. post-2019) as the independent variable: for profit margin, the regression yielded a significant positive slope (β = 13.29, R2 = 0.62, p < 0.05), supporting H1, and for total asset turnover, a positive slope (β = 0.20, R2 = 0.74, p < 0.01), supporting H2, demonstrating that digital transformation, facilitated by Company L’s platform, statistically enhanced Company F’s performance despite a temporary dip in 2020 due to the COVID-19 pandemic. Company F identified two pressing issues: firstly, low efficiency in elevator maintenance, where the company faced challenges in timely responding to elevator malfunctions and scheduling maintenance personnel for on-site repairs due to limited maintenance staff and the dispersed locations of elevators. Secondly, there is difficulty in spare parts management, where traditional warehouse models incur high storage costs and significant manpower for parts management. Complementing the quantitative findings, qualitative thematic analysis of interview transcripts with Company F’s digitalization head and technical staff, alongside observational notes from site visits, was conducted using NVivo (version 12) to derive conclusions about the sharing platform’s role, following a structured procedure: initial open coding identified recurring concepts (e.g., “real-time monitoring,” “cost savings”) from 15 interview segments and 10 observation entries, which were then grouped into categories (e.g., “operational improvements,” “resource access”) during axial coding, and refined into three key themes (enhanced maintenance efficiency, streamlined spare parts management, and increased collaboration) based on their frequency (e.g., “real-time monitoring” appeared in 80% of interviews) and alignment with quantitative gains (Table 2). These themes led to the conclusion that Company L’s sharing service platform mitigated technological and financial barriers by enabling predictive maintenance and lean inventory practices, as staff emphasized the platform’s role in “anticipating failures before they happen” and “reducing warehouse clutter,” directly supporting the study’s proposition that sharing economy platforms facilitate SMMEs’ digital transformation (Yin, 2018).

In 2020, facing the unforeseen circumstances brought by the pandemic, Company F, lacking experience in dealing with such situations, saw a decline in main business profit margin and net profit growth rate by 32.98% and 117.85%, respectively, compared to 2019. However, Company F’s leadership swiftly adjusted the company’s strategy to minimize the impact of the pandemic, collaborated with Company L to formulate a new digital transformation plan and process, and maintained rapid growth in main business income and net profit over the next 2 years. As the digital transformation progresses, Company F’s return on net assets and asset turnover rate steadily increase each year, leading to a continuous improvement in the company’s profitability and asset operational capabilities. While China’s government has demonstrated a strong commitment to driving digital transformation across its manufacturing sector, it is crucial to acknowledge that this transformation is not occurring within a homogenous landscape. Significant regional disparities exist within China, impacting the adoption and impact of digital initiatives on SMMEs. Coastal provinces, for instance, often possess more developed digital infrastructure, stronger economies, and a more established culture of technological adoption compared to inland regions. These disparities can create an uneven playing field, where SMMEs in more digitally advanced areas may disproportionately benefit from government policies and readily access resources within the sharing economy. Recognizing these variations is thus essential for policymakers, as targeted interventions are needed to ensure a more inclusive and equitable digital transformation journey for all Chinese manufacturing SMMEs.

6.3 Extending the frameworks: applicability to other contexts

While this study centers on the Chinese context, it is crucial to acknowledge that digital transformation and the sharing economy are global phenomena impacting SMMEs worldwide. The challenges SMMEs face, such as limited resources and expertise, resonate across diverse settings, as do the potential benefits of leveraging sharing platforms for access to technology, knowledge, and cost reduction. However, directly applying the frameworks presented here to other countries requires careful consideration of contextual variations. Factors such as the policy environment, market maturity of the sharing economy, and cultural factors will influence the adaptation and effectiveness of these strategies. Future research exploring the applicability of these frameworks within different national and regional contexts, considering these nuances, would be valuable for advancing our understanding of how the sharing economy can best support global SMME digitalization.

7 Conclusion

This study focuses on how the sharing economy can support small, medium, and micro-enterprises (SMMEs) in digital transformation within the manufacturing industry. It examines the primary challenges SMMEs face in digital transformation and proposes methods to help them overcome these challenges using sharing economy platforms. The study introduces the sharing economy’s support for SMMEs in digital transformation relying on data hubs and three types of sharing economy platforms. These platforms include the chain-centric sharing manufacturing platform, the industry-brain-style collaborative sharing platform, and the sharing service cloud platform. These platforms aim to reduce the cost and threshold of digital transformation for enterprises by providing technical innovation, data sharing, and other services. While the study is based on the Chinese context, its findings offer valuable insights for policymakers in other middle-income countries aiming to empower their SMMEs through digital transformation. It emphasizes the importance of creating a supportive ecosystem, including investing in digital infrastructure, promoting digital literacy and skills development programs for SMMEs, and establishing regulatory sandboxes to foster innovation within the sharing economy.

The study also discusses the case of Company L assisting Company F in digital transformation using a digital collaborative sharing solution for the elevator industry’s sharing service platform. It analyzes the effects of digital transformation on Company F and demonstrates that digital transformation effectively enhances enterprises’ profitability and asset operational capabilities. This research contributes to theory by advancing the integration of the sharing economy with the Resource-Based View (RBV) and Dynamic Capabilities Theory, demonstrating empirically through Company F’s case (Table 2) how access to shared resources (e.g., technology, data) enhances SMMEs’ competitive advantage and dynamic capabilities like sensing and reconfiguring, thus extending these frameworks beyond traditional firm-centric models. Practically, it offers actionable strategies for SMMEs (such as leveraging chain-hosting platforms, industry-brain collaborations, and shared service clouds) to overcome digital transformation barriers, as validated by Company F’s improved profitability and efficiency (e.g., 20.97% income growth in 2022), while providing policymakers with a blueprint to foster digital ecosystems that support economic resilience and industrial upgrading, applicable not only in China but also in other manufacturing-driven economies. These contributions underscore the transformative potential of shared platforms, bridging theoretical insights with real-world applicability for enhancing SMMEs’ digital maturity. The study concludes by highlighting the transformative potential of shared platforms for Chinese SMMEs and emphasizes the need for companies to integrate these platforms into a holistic digital transformation strategy. It suggests considering investments in process re-engineering, product innovation, and organizational cultural shifts to leverage the opportunities of the digital age fully.

8 Limitations and future research

It is important to acknowledge that this study offers a limited timeframe for evaluating the full impact of digital transformation. While Company F’s positive results from 2019 to 2022 are promising, observing long-term trends is essential to assess these benefits’ sustainability and evolving nature. Future research should employ a longitudinal approach, tracking SMMEs over a more extended period (e.g., 5–10 years) to understand how the benefits and challenges of digital transformation, particularly those facilitated through the sharing economy, unfold, and change over time. This would also allow for a more nuanced analysis of factors influencing sustained success in digital adoption and its impact on overall competitiveness.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Author contributions

JX: Formal Analysis, Methodology, Writing – original draft, Writing – review and editing. ZH: Investigation, Validation, Writing – original draft, Writing – review and editing. ZJ: Project administration, Writing – original draft, Writing – review and editing. KA-B: Validation, Writing – original draft, Writing – review and editing. AW: Funding acquisition, Project administration, Supervision, Writing – original draft, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research is partially supported by the National Natural Science Foundation of China (52372420), the Baima Lake Laboratory Joint Fund of the Zhejiang Provincial Natural Science Foundation of China (LBMHZ25F030002), Offshore Wind Power Joint Fund of Guangdong Basic and Applied Basic Research Foundation (2024A1515240073), Scientific Research Foundation of Hangzhou City University (X-202404), Zhejiang Province Key research project (2024C01039), and Ningbo's Key Technology Breakthrough Program of KeChuang Yongjiang 2035 (2024Z177).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

AlNuaimi, B. K., Singh, K., Ren, S., Budhwar, P., and Vorobyev, D. (2022). Mastering digital transformation: the nexus between leadership, agility, and digital strategy. J. Bus. Res. 145, 636–648. doi:10.1016/j.jbusres.2022.03.038

Barney, J. (1991). Firm resources and sustained competitive advantage. J. Manag. 17, 99–120. doi:10.1177/014920639101700108

Ben-Daya, H., and Bahroun, Z. (2017). Internet of things and supply chain management: a literature review. Int. J. Prod. Res. 57 (15–16), 4719–4742. doi:10.1080/00207543.2017.1402140

Capraro, V., Lentsch, A., Acemoglu, D., Akgun, S., Akhmedova, A., Bilancini, E., et al. (2024). The impact of generative artificial intelligence on socioeconomic inequalities and policy making. PNAS Nexus 3 (6), pgae191. doi:10.1093/pnasnexus/pgae191

Ceipek, R., Hautz, J., Petruzzelli, A. M., De Massis, A., and Matzler, K. (2021). A motivation and ability perspective on engagement in emerging digital technologies: the case of Internet of Things solutions. Long. Range Plan. 54 (5), 101991. doi:10.1016/j.lrp.2020.101991

China Academy of Information and Communications (Technology China Telecommunication Technology Labs-Terminals) (2023). Research report on the development trend of enterprise digital transformation technology (2023). Beijing: China Academy of Information and Communications Technology. Available online at: http://www.caict.ac.cn.

de Paula, D., Marx, C., Wolf, E., Dremel, C., Cormican, K., and Uebernickel, F. (2023). A managerial mental model to drive innovation in the context of digital transformation. Industry Innovation 30 (1), 42–66. doi:10.1080/13662716.2022.2072711

Durán-Romero, G., López, A. M., Beliaeva, T., Ferasso, M., Garonne, C., and Jones, P. (2020). Bridging the gap between circular economy and climate change mitigation policies through eco-innovations and Quintuple Helix Model. Technol. Forecast. Soc. Change 160, 120246. doi:10.1016/j.techfore.2020.120246

George, G., and Schillebeeckx, S. J. (2022). Digital transformation, sustainability, and purpose in the multinational enterprise. J. World Bus. 57 (3), 101326. doi:10.1016/j.jwb.2022.101326

Guo, X., and Chen, X. (2022). The impact of digital transformation on manufacturing-enterprise innovation: empirical evidence from China. Sustainability 15 (4), 3124. doi:10.3390/su15043124

He, J., and Gu, X. (2018). Value analysis of shared warehousing system based on Web. Comput. Integr. Manuf. Syst. 24 (09), 2322–2328. doi:10.13196/j.cims.2018.09.020

Kraus, S., Durst, S., Ferreira, J. J., Veiga, P., Kailer, N., and Weinmann, A. (2022). Digital transformation in business and management research: an overview of the current status quo. Int. J. Inf. Manag. 63, 102466. doi:10.1016/j.ijinfomgt.2021.102466

Li, L., Su, F., Zhang, W., and Mao, Y. (2018). Digital transformation by SME entrepreneurs: a capability perspective. Inf. Syst. J. 28 (6), 1129–1157. doi:10.1111/isj.12153

Liu, M., Li, C., Wang, S., and Li, Q. (2023). Digital transformation, risk-taking, and innovation: evidence from data on listed enterprises in China. J. Innovation and Knowl. 8 (1), 100332. doi:10.1016/j.jik.2023.10033

Mahboub, H., and Sadok, H. (2023). Implementing enterprise digital transformation: a contribution to conceptual framework design. Nankai Bus. Rev. Int. 14 (1), 35–50. doi:10.1108/NBRI-06-2022-0067

Ministry of Industry and Information Technology and Ministry of Finance of the People's Republic of China (2023). Notice of the Ministry of Finance, the Ministry of Industry, and Information Technology on carrying out the pilot work of digital transformation of small and medium sized enterprises in cities [EB/OL]. Available online at: https://www.miit.gov.cn/jgsj/qyj/wjfb/art/2023/art_f1ed2173b4c04cc4866046437afc6e18.html.

Montero Guerra, J. M., Danvila-del-Valle, , and Méndez-Suárez, M. (2023). The impact of digital transformation on talent management. Technol. Forecast. Soc. Change 188, 122291. doi:10.1016/j.techfore.2022.122291

Mosaad, M., Benoit, S., and Jayawardhena, C. (2023). The dark side of the sharing economy: a systematic literature review of externalities and their regulation. J. Bus. Res. 168, 114186. doi:10.1016/j.jbusres.2023.114186

Peng, Y., and Tao, C. (2022). Can digital transformation promote enterprise performance? —from the perspective of public policy and innovation. J. Innovation and Knowl. 7 (3), 100198. doi:10.1016/j.jik.2022.100198

Schumacher, A., Erol, S., and Sihn, W. (2015). A maturity model for assessing industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP 52, 161–166. doi:10.1016/j.procir.2016.07.040

State Information Center--Sharing Economy Research Center (2023). China's sharing economy development report. Beijing: State Information Center.

Sutherland, W., and Jarrahi, M. H. (2018). The sharing economy and digital platforms: a review and research agenda. Int. J. Inf. Manag. 43, 328–341. doi:10.1016/j.ijinfomgt.2018.07.004

Teece, D. J. (2014). The foundations of enterprise performance: dynamic and ordinary capabilities in an (economic) theory of firms on JSTOR. Acad. Manag. Perspect. 328, 43822373.

Teece, D. J., Pisano, G., and Shuen, A. (1997). Dynamic capabilities and strategic management. Strategic Manag. J. 18 (7), 509–533. doi:10.1002/(SICI)1097-0266(199708)18:7<509::AID-SMJ882>3.0.CO;2-Z

Westergren, , Mähler, V., and Jadaan, T. (2024). Enabling digital transformation: organizational implementation of the internet of things. Inf. and Manag. 61 (6), 103996. doi:10.1016/j.im.2024.103996

Wu, Q., and Li, S. (2024). Decarbonization by digits: how data factors drive nonlinear sustainable dynamics in manufacturing. Appl. Energy 374, 123967. doi:10.1016/j.apenergy.2024.123967

Xia, L., Baghaie, S., and Mohammad Sajadi, S. (2024). The digital economy: challenges and opportunities in the new era of technology and electronic communications. Ain Shams Eng. J. 15 (2), 102411. doi:10.1016/j.asej.2023.102411

Yin, R. K. (2018). Case study research and applications: design and methods. Sixth Edition. Thousand Oaks, CA: COSMOS Corporation, SAGE Publications, Inc, 352. Available online at: https://collegepublishing.sagepub.com/products/case-study-research-and-applications-6-250150.

Zhang, X., Xu, Y. Y., and Ma, L. (2023). Information technology investment and digital transformation: the roles of digital transformation strategy and top management. Bus. Process Manag. J. 29 (2), 528–549. doi:10.1108/BPMJ-06-2022-0254

Keywords: digital transformation, sharing economy, SMMEs, manufacturing, data sharing, shared service platform, China, industry 4.0

Citation: Xiaosheng J, Hua Z, Jin Z, AL-Bukhaiti K and Wan A (2025) Overcoming digital transformation barriers: Chinese SMMEs in the sharing economy. Front. Manuf. Technol. 5:1495840. doi: 10.3389/fmtec.2025.1495840

Received: 13 September 2024; Accepted: 14 April 2025;

Published: 25 April 2025.

Edited by:

Osden Jokonya, University of the Western Cape, South AfricaReviewed by:

Otilia Manta, Romanian Academy, RomaniaWillard Munyoka, University of Venda, South Africa

Copyright © 2025 Xiaosheng, Hua, Jin, AL-Bukhaiti and Wan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhang Jin, Y2ljYWRhQHpqdS5lZHUuY24=; Khalil AL-Bukhaiti, ZW5nLmtoYWxpbDY3MEBob3RtYWlsLmNvbQ==

Ji Xiaosheng1

Ji Xiaosheng1 Khalil AL-Bukhaiti

Khalil AL-Bukhaiti