- Centre for Robotics and Assembly, Faculty of Engineering and Applied Science, Cranfield University, Cranfield, United Kingdom

The rapid advancement and expanding application of robotics in various sectors necessitate the development of versatile and efficient gripping systems. Robotic grippers, serving as the primary interface between robots and the physical world, are pivotal for the success of robotic applications ranging from industrial automation to delicate tasks in healthcare. This paper delves into the diverse landscape of robotic grippers, examining their design principles, material choices, and the intricate balance between flexibility and strength required to cater to a broad spectrum of operational demands. It further explores the spectrum of actuation mechanisms that empower these grippers, from traditional electric and pneumatic systems to cutting-edge soft robotics technologies that offer unprecedented adaptability and safety. The integration of sensors within grippers, enhancing their intelligence and autonomy, is also scrutinized, alongside a critical evaluation of control strategies that range from conventional PID controllers to sophisticated machine learning algorithms. In addition, this paper emphasizes the significance of real-time control and adaptation in ensuring robots’ ability to respond promptly to environmental changes, leveraging fast data processing and feedback mechanisms for improved performance. The aim of this comprehensive review is not only to provide a foundational understanding of the current state of robotic gripper technology but also to highlight key considerations and emerging trends that will shape the future of robotic manipulation. Through this exploration, the paper seeks to equip designers, engineers, and researchers with the insights needed to innovate and advance the field of robotic gripping systems.

CCS Concepts

• Hardware ∼ Communication hardware, interfaces and storage∼Sensors and actuators

• Hardware ∼ Communication hardware, interfaces and storage∼Electro-mechanical devices

1 Introduction

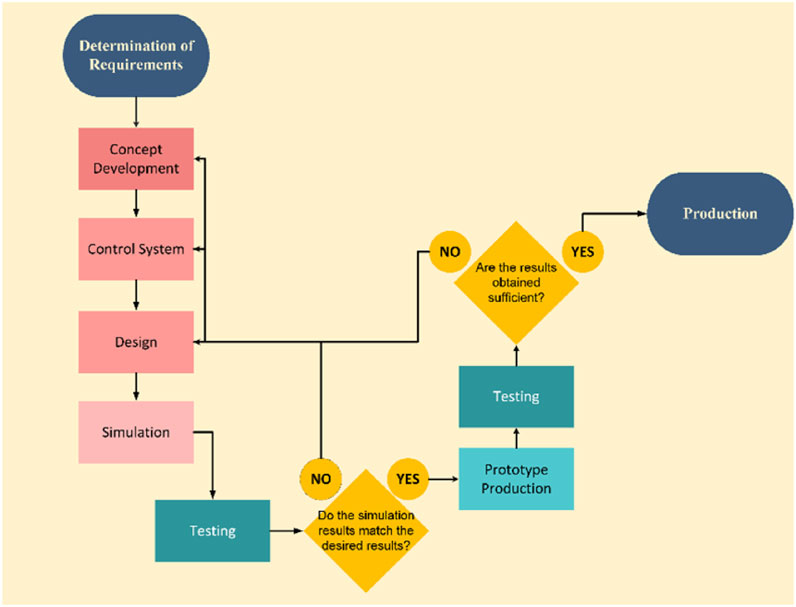

The increasing use of robotics across various sectors has highlighted the importance of robotic grippers, which serve as the critical interface between robots and the physical tasks they perform. This paper provides a comprehensive review of robotic grippers, focusing on their design, actuation mechanisms, sensor integration, and control strategies. Grippers can be used in places that require dynamic movements or grasping tasks (Iida and Laschi, 2011). Robotic grippers find applications in diverse fields, including aviation, assembly industries, shipping, healthcare and agriculture, where their adaptability and precision are crucial (Tai et al., 2016). Numerous materials suitable for use in robotics have been explored in research. Hard materials, notably steel and aluminum, are commonly employed in robotic applications (Mantriota, 2007). Traditional rigid technologies, prevalent in industrial robotics for over 4 decades, continue to perform a variety of tasks (Rossiter and Hauser, 2016). However, there is a growing shift towards flexible grippers, anticipated to gain widespread adoption in sectors where safety is paramount, such as healthcare, and in applications involving direct interaction with humans (Rossiter and Hauser, 2016). The growing emphasis on autonomous grasping, driven by the anticipated expansion of flexible grippers in interactive settings, is further enhanced by the use of soft robotic parts (Rossiter and Hauser, 2016). These components offer added safety in scenarios where unpredictable human movements are likely, making them ideal for environments that facilitate human-machine interaction. This safety feature is crucial for integrating robots into both industrial operations and private spaces (Rossiter and Hauser, 2016). These highlights increasing significance of autonomous grasping, as robots are expected to engage actively with their environments and execute a broad range of tasks (Cao et al., 2021). Consequently, a key aspect of advancing robotic grasping manipulation systems lies in improving the perception of objects to be grasped and effectively addressing uncertainties in their handling (Choi et al., 2018). This paper delves into the advancements and intricacies of robotic grippers, highlighting design variations, actuation methods, sensor integration, and control strategies. Aimed at providing a holistic view, it explores how these elements influence the efficiency, adaptability, and application scope of robotic grippers in industries ranging from automation to healthcare. By dissecting current challenges and projecting future trends, the paper seeks to enrich the knowledge base and stimulate innovation in robotic manipulation technologies. The contributions of this review, in comparison to previous studies, are summarized in Table 1. A Brief Review on Robotic Grippers Classifications (Samadikhoshkho et al., 2019) provides a fundamental classification of robotic grippers, while A Review on Technologies in Robotic Gripper (Chitroda and Patle, 2023) examines grippers from various technological perspectives. In contrast, Soft Manipulators and Grippers: A Review primarily focuses on soft robotic grippers (Hughes et al., 2016). This review, however, expands upon previous works by addressing hybrid and electro-adhesive gripper systems, filling gaps that have not been extensively covered in prior literature. Additionally, a comparative analysis of vacuum, pneumatic, hydraulic, and servo-electric actuation systems is provided, along with a discussion on sensorless sensing techniques, which have received limited attention in existing research. Furthermore, various control strategies, ranging from PID controllers to machine learning-based approaches, are explored to assess their applicability in different scenarios. In this regard, the present review aims to offer a more comprehensive perspective on robotic gripper systems. This paper is underpinned by an analysis of 72 studies that were published within the last 15 years, reflecting the latest advancements and trends in the field of robotic grippers. Informed by extensive research, experience, and analysis, a comprehensive workflow for the design of a robotic gripper was developed, as depicted in Figure 1. The initiation of this process is marked by the determination of project requirements, which includes the identification of the project’s goals, the operational environment of the gripper, and the characteristics of the objects it is intended to handle, such as size, weight, and shape. Following this initial step, concept development is undertaken, where a variety of design ideas are explored, encompassing different types of grippers such as finger-based, suction, and magnetic and the selection of appropriate materials. Upon the establishment of a solid concept, the control strategy for the gripper is determined, along with the selection of the necessary sensors and Actuators. This phase culminates in the formulation of a control algorithm and the planning of movement management strategies. The design phase then follows, where the conceptual framework is translated into tangible designs, detailing the components and mechanisms of the gripper and specifying the power and energy requirements. The completion of the design leads to the simulation phase, where necessary data is inputted to validate the functionality of the design. If the results obtained from the simulation do not meet the set objectives, iterative refinements are made to the design to align the outcome with the goals. Successful simulation results pave the way for the creation of a prototype, which is then subjected to rigorous testing to evaluate its performance, safety, and durability against predefined standards. Discrepancies observed at this stage necessitate further adjustments to the design, control systems, or conceptual underpinnings, ensuring that the final product meets the set criteria. This iterative process is supported by the analysis of 72 contemporary studies, highlighting the commitment to developing a robust and effective robotic gripper. In this paper, the term flexible gripper refers to robotic gripping systems capable of shape adaptation either through soft materials or compliant structural designs. Soft grippers, commonly made from materials such as elastomers or silicone, are considered a subset of this broader definition. Furthermore, this review also includes hybrid gripper systems, which combine both soft and rigid elements. These systems are considered flexible due to their ability to adapt to the shape of the object they are gripping, thanks to compliant components or mechanical designs.

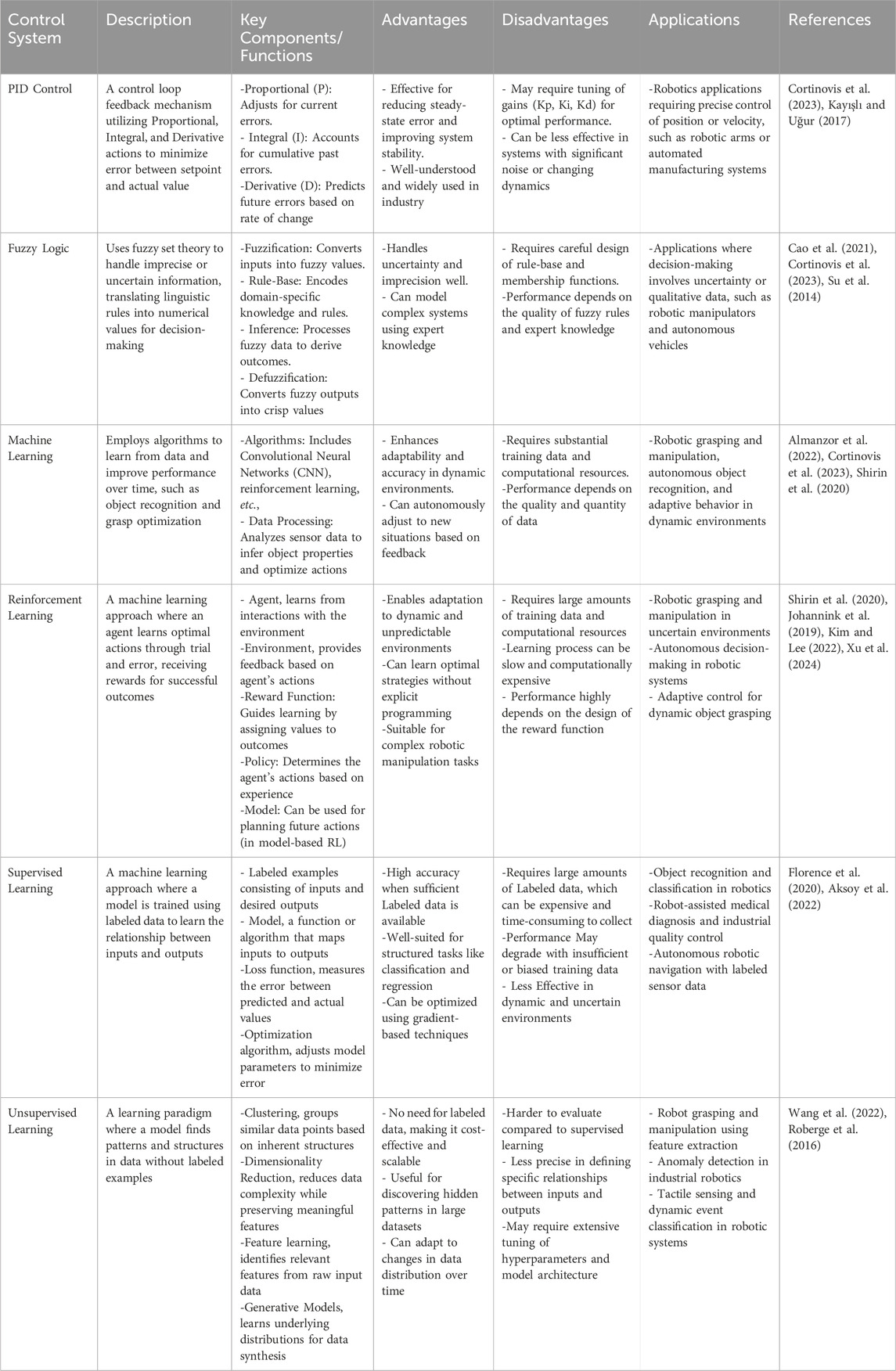

Table 1. A comparison of key aspects covered in previous surveys and the novel contributions of this study.

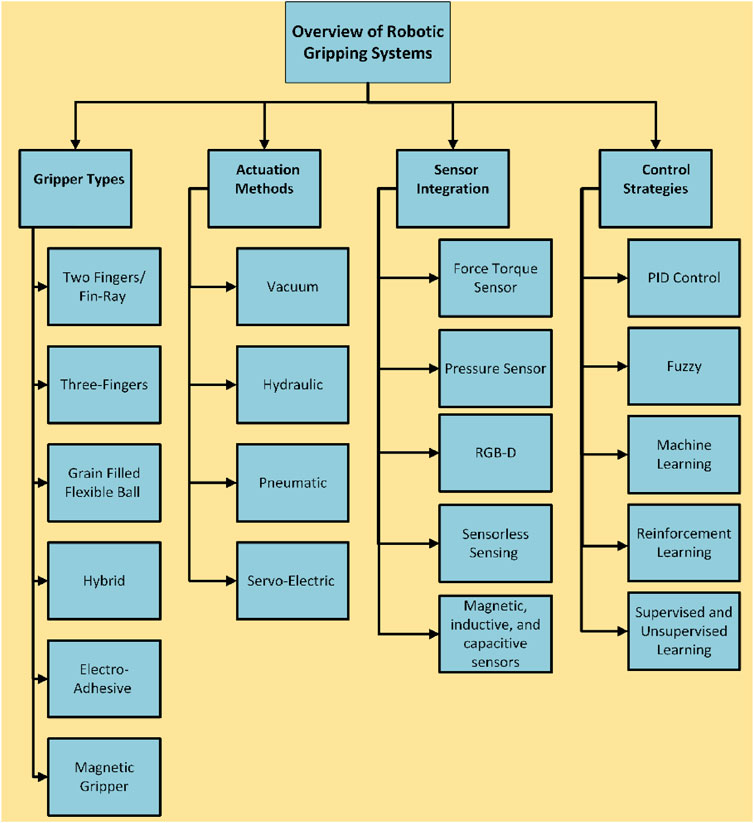

Figure 2 presents a systematic classification of robotic gripping and control strategies. The remainder of this paper is organized as follows: Section 2 discusses gripper types, while Section 3 explores various actuation methods. Section 4 presents sensor integration techniques, and Section 5 covers control strategies. Finally, Section 6 concludes the study with a summary and future research directions.

2 Gripper types

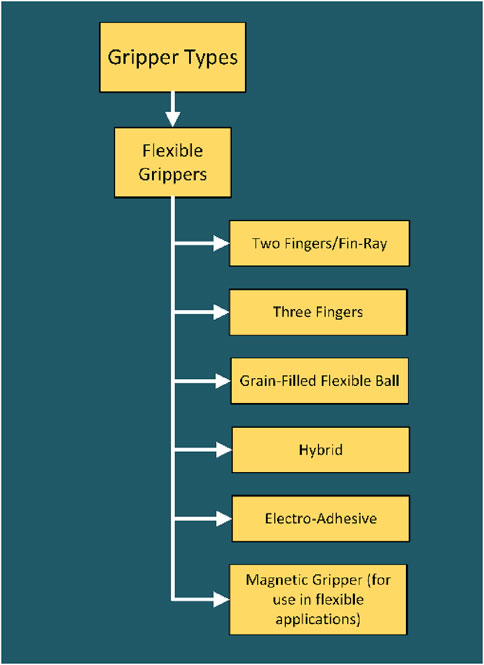

Grippers can be categorized based on their material hardness into two distinct types. While rigid grippers are designed with inflexible joints and links to exert high force, their lack of adaptability makes them less suitable for handling delicate or irregular objects (Samadikhoshkho et al., 2019; Hughes et al., 2016). In contrast, soft grippers, which are the focus of this study, are constructed from pliable materials such as plastic, silicon, and elastomers. Their deformable nature allows them to conform to various object shapes, providing a secure yet gentle grasp without causing damage (Hughes et al., 2016). Due to their adaptability and safety, soft grippers offer significant advantages in applications where traditional rigid grippers may be inadequate (Samadikhoshkho et al., 2019). The classification of different flexible gripper types is illustrated in Figure 3. Following this classification, the subsequent sections delve into different types of grippers in detail, focusing on their working principles, advantages, and application areas. The following subsections examine these designs, highlighting their functionality and suitability for various robotic applications.

2.1 Grain filled flexible ball gripper

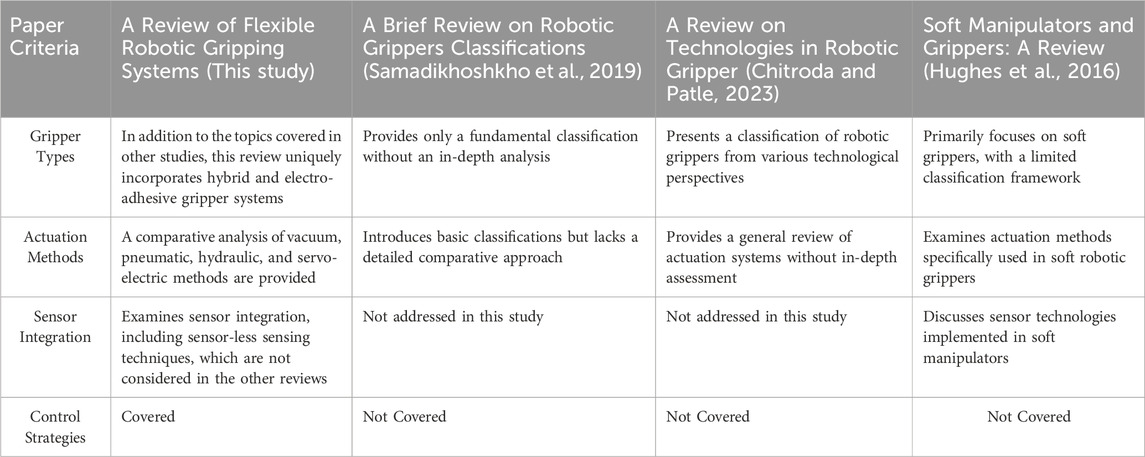

This variant of gripper employs a soft balloon filled with granular substances, such as grains, to encapsulate and secure objects (Samadikhoshkho et al., 2019). Termed as universal grippers, these devices are adept at handling items of varying shapes (Chitroda and Patle, 2023). The operational mechanism of Grain-Filled Flexible Ball Grippers involves the application of both positive and negative pressures to achieve compressive action. The internal granular materials conform passively to the contour of the targeted object upon compression, a process that can be intensified through vacuum assistance. To release the object, positive pressure is applied, which softens the gripper and loosens its grasp. In their investigation, Amen et al. (Amend et al., 2012) innovated a jamming gripper utilizing coffee grains as the granular medium within a flexible envelope, eschewing traditional components like motors, cables, or linkages in favor of a singular pump to regulate airflow. The simplicity of this design, illustrated in Figure 4, underscores its ease of production and cost-effectiveness. Despite its proficiency in handling diverse, lightweight objects (under 1 kg), this gripper might not be the optimal choice for larger, heavier items where mass is a critical factor.

Figure 4. The structure of the designed gripper: 1) Base, 2) External collar, 3) Balloon membrane, 4) Coffee grains, 5) Air filter, 6) Vacuum line port, and 7) High pressure port. Adapted from US Patent No. US 9,120,230 B2 (Amend et al., 2012).

2.2 Hybrid gripper

The actuation of rigid grippers typically necessitates multiple joints and supplementary mechanical connections, each of which often requires independent control. As a result, the control system becomes more complex due to the need for precise coordination of individual actuators and continuous feedback. In contrast, flexible grippers usually operate with simple on-off control logic, significantly reducing control complexity. The growing need for enhanced human-robot interaction is steering the preference towards safer robotic mechanisms, with soft grippers emerging as a prominent solution (Park et al., 2019). Soft grippers are characterized by their ability to deform, thereby providing a larger contact area for gripping and a greater range of motion compared to their rigid counterparts. Despite their advantages, soft grippers suffer from reduced fingertip forces and slower actuation speeds, which limit their ability to lift substantial weights and, consequently, restrict their range of applications. To mitigate these limitations, the development of hybrid grippers is underway. These grippers incorporate rigid materials into soft grippers, augmenting their structural integrity and lifting capacity. In their research, Park et al. engineered such a hybrid gripper and conducted a comparative analysis of its fingertip strength against various soft gripper models, employing a pneumatic actuator for actuation. The comparison, which included Hybrid PneuNet, fast-PneuNet, and fiber-reinforced soft grippers, was facilitated by measuring the applied fingertip force using a force/torque sensor, with actuator movement ranging from 0 to 80 kPa. The findings revealed that the hybrid gripper exhibited 1.5–2 times greater fingertip pressure than the alternative soft gripper designs. This enhancement in performance underscores the efficacy of integrating rigid materials into soft grippers. Notably, the hybrid gripper demonstrated its capability by successfully lifting a basket weighing up to 1.25 kg, showcasing its potential in applications requiring the handling of heavier loads (Park et al., 2019).

2.3 Two fingers/fin-ray robot grippers

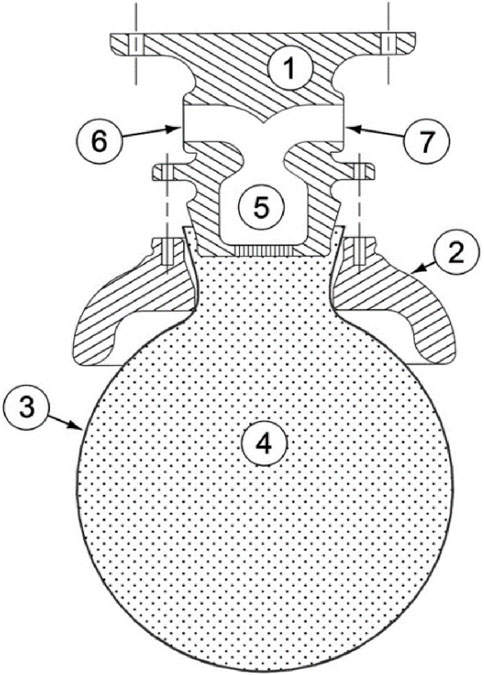

Two-fingered, also known as Fin-Ray, grippers represent a fundamental category within robotic gripping devices, favored for their straightforward design, cost-effectiveness, ease of integration across various domains, and production simplicity. These devices are predominantly employed in the assembly sector for tasks that involve gripping and manipulation (Samadikhoshkho et al., 2019). Ikramul Hasib et al. (2019) introduced an adaptive Fin-Ray gripper, demonstrating notable versatility in handling objects of diverse shapes. Similarly, Almanzor et al. (2022) developed a robotic system for litter collection, leveraging the Fin-Ray gripper’s user-friendliness, minimal operational requirements, and broad object handling capability. This system employs a tendon connected to a servo motor for finger movement, facilitating the opening and closing of the gripper, thereby enabling the identification and collection of lightweight recyclable materials for proper disposal. Further, Cao et al. (2021) utilized a Fin-Ray-style gripper for the detection and securement of objects with indistinct depths. The gripper’s design, characterized by its ability to passively deform in response to environmental conditions and adapt its shape to the objects it engages with, ensures the gentle handling of objects, thereby preserving their integrity while adhering to predetermined manipulation trajectories. Example of two fingers gripper in action is shown in Figure 5c.

Figure 5. Three finger type gripper is shown in (a) (Chitroda and Patle, 2023). Electro-adhesive type gripper is shown in (b). Two finger type gripper is shown in (c).

2.4 Three-fingers robot grippers

Two-fingered grippers are predominantly favored over their three-fingered counterparts due to the adequacy of their performance across a wide spectrum of applications. Nonetheless, each type is designated to specific tasks contingent upon particular requirements. Instances where increased precision in object manipulation or the delicate handling of fragile items is necessary often employ these grippers (Samadikhoshkho et al., 2019). In their research, Choi et al. (2018) explored the efficacy of a three-fingered soft gripper in securing objects that had not been previously encountered. The inherent unpredictability of both the operational environment and the objects themselves presents a unique challenge, one that soft grippers are particularly well-suited to address. Conversely, the deployment of rigid grippers in such scenarios can complicate system control and escalate costs (Choi et al., 2018). Figure 5a shows an example of a three-finger gripper handling an object.

2.5 Electro-adhesive gripper

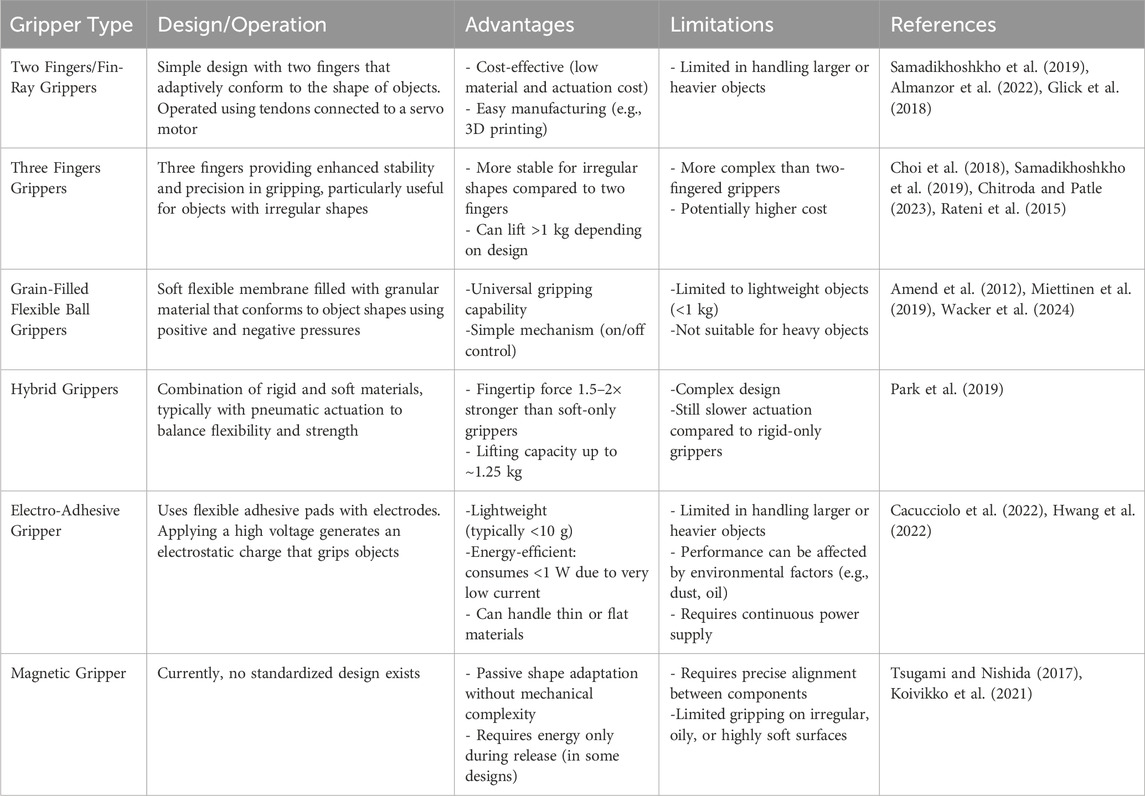

The electro-adhesive gripper is a type of gripper that utilizes electrostatic forces to securely grasp objects, making it a versatile tool for handling various surfaces and materials (Guo et al., 2020). Electro-adhesive grippers consist of adhesive pads, typically made from a flexible material (such as polyurethane, silicone, or polyimide) with electrodes embedded on their surface (Guo et al., 2020; Cacucciolo et al., 2022; Hwang et al., 2022). These electrodes generate an electric field when a specific voltage is applied, and this charged pad creates the adhesive force that allows the gripper to grasp onto objects. The arrangement and structure of the electrodes influence the distribution and strength of the electro-adhesive force (Guo et al., 2020; Cacucciolo et al., 2022; Hwang et al., 2022). In most designs, the electrodes are arranged in parallel plates, but different geometric configurations can also be used. The thin and flexible nature of the electrodes helps maintain the overall flexibility of the gripper, enabling it to grasp a wide range of objects (Guo et al., 2020). Electro-adhesion allows systems to operate with low energy consumption, as only a low passes through the electro-adhesive pad, even though a relatively high voltage (typically in the kilovolt range) is required (Cacucciolo et al., 2019). The functionality of an electro-adhesive gripper, which relies on electrostatic forces to secure objects, is shown in Figure 5b, where a delicate item is grasped without mechanical pressure. Additionally, Table 2 presents a comparison of the robotic gripper types mentioned above across various aspects.

2.6 Magnetic gripper

Magnetic force-based grippers can be designed and controlled as flexible grippers through appropriate material selection and structural design. By integrating deformable elements with magnetic actuation, these systems can provide shape adaptability and compliant gripping behaviour, enabling their use in flexible and adaptive manipulation tasks. The water gripper developed by Tsugami and Nishida consists of an elastic membrane filled with water, with a permanent magnet positioned at the bottom and an electromagnet at the top (Tsugami and Nishida, 2017). When pressed against an object, the membrane conforms to the object’s shape while the magnets attract each other, securing the grip. Releasing is achieved by applying current to the electromagnet, generating a repulsive magnetic field that separates the magnets. In this setup, energy is only consumed during the release phase. The system offers several advantages, including low cost, ease of manufacturing, water resistance, and tolerance to object misalignment (Tsugami and Nishida, 2017). Experimental tests demonstrated that fragile objects such as plastic bottles and quail eggs could be gripped safely without damage (Tsugami and Nishida, 2017). In a similar approach, Koivikko et al. integrated magnetorheological (MR) fluid into the gripper membrane, enabling control of the fluid’s physical properties through magnetic fields (Koivikko et al., 2021). MR fluid is a smart material that behaves like a liquid under normal conditions but rapidly solidifies when exposed to a magnetic field. Before the field is applied, the membrane is soft and easily conforms to the object’s surface. Once the magnetic field is activated, the MR fluid stiffens, causing the membrane to harden and hold the object firmly, as if molded around it. When the field is removed, the fluid becomes liquid again, the membrane softens, and the object is released. This working principle allows the gripper to adjust its stiffness according to the magnetic field. Tests showed an increase in gripping force from 3.8 N to 7.1 N, enabling safe manipulation of both fragile and relatively heavy objects (Koivikko et al., 2021).

In summary, Two-finger/Fin-Ray grippers can be successfully integrated into various fields beyond assembly and sorting tasks due to their lightweight structure, passive adaptation capability, and minimal movement requirements. They are widely used in assistive robotic systems, medical rehabilitation, and delicate object manipulation. Advances in 3D printing technologies, along with flexible materials such as TPU, silicone-based elastomers, and Dragon Skin 30, allow these grippers to be produced cost-effectively and customized for different applications, enabling optimization for various use cases. However, two-finger grippers may face limitations when grasping irregular or large objects. In such cases, three-finger grippers provide a stronger and more stable grip, allowing them to lift heavier objects compared to two-finger grippers. With more contact points and a larger surface area, three-finger designs offer a more reliable solution. Although they can be manufactured using similar materials and 3D printing technologies, three-finger grippers require more material during production, making them more expensive than two-finger models. Grain-Filled Flexible Ball Grippers, like two- and three-finger grippers, are effective in grasping irregular and delicate objects. However, they are not suitable for very small objects, as the vacuum effect may not generate sufficient pressure, leading to inadequate gripping. Additionally, they are less effective than three-finger grippers in handling wide-surfaced objects. While two- and three-finger grippers provide more controlled gripping due to their mechanical structures, Grain-Filled grippers rely on vacuum force, meaning their gripping strength can vary depending on the surface properties of the object. Therefore, when selecting a gripper, factors such as object size, weight, surface texture, and operational requirements should be considered. Hybrid Grippers, with their higher actuation speed and enhanced gripping force, allow for more efficient manipulation of heavy objects. However, because they contain rigid components, they do not offer the same level of flexible adaptation as fully soft grippers. Additionally, their production process is more complex, as it requires the integration of different materials and molding techniques. When selecting a gripper, the object’s weight, surface properties, and operational speed requirements should be considered. Hybrid Grippers, with their strong gripping capability and fast response time, may present a more advantageous option in specific applications compared to two- and three-finger grippers. Electro-Adhesive Grippers, unlike the other grippers mentioned, can grasp delicate and lightweight objects without applying pressure, making them an ideal solution for fragile items. With low energy consumption (less than 1 W) and lightweight construction (as low as 1 g), they are more energy-efficient than two- and three-finger mechanical grippers. However, their requirement for high voltage (1 kV or more) and the fact that their gripping strength depends on surface characteristics can limit their use, particularly on rough surfaces. When choosing the appropriate gripper type, factors such as object size, weight, and surface properties should be considered alongside application requirements such as speed, precision, energy consumption, and production costs.

3 Actuation methods

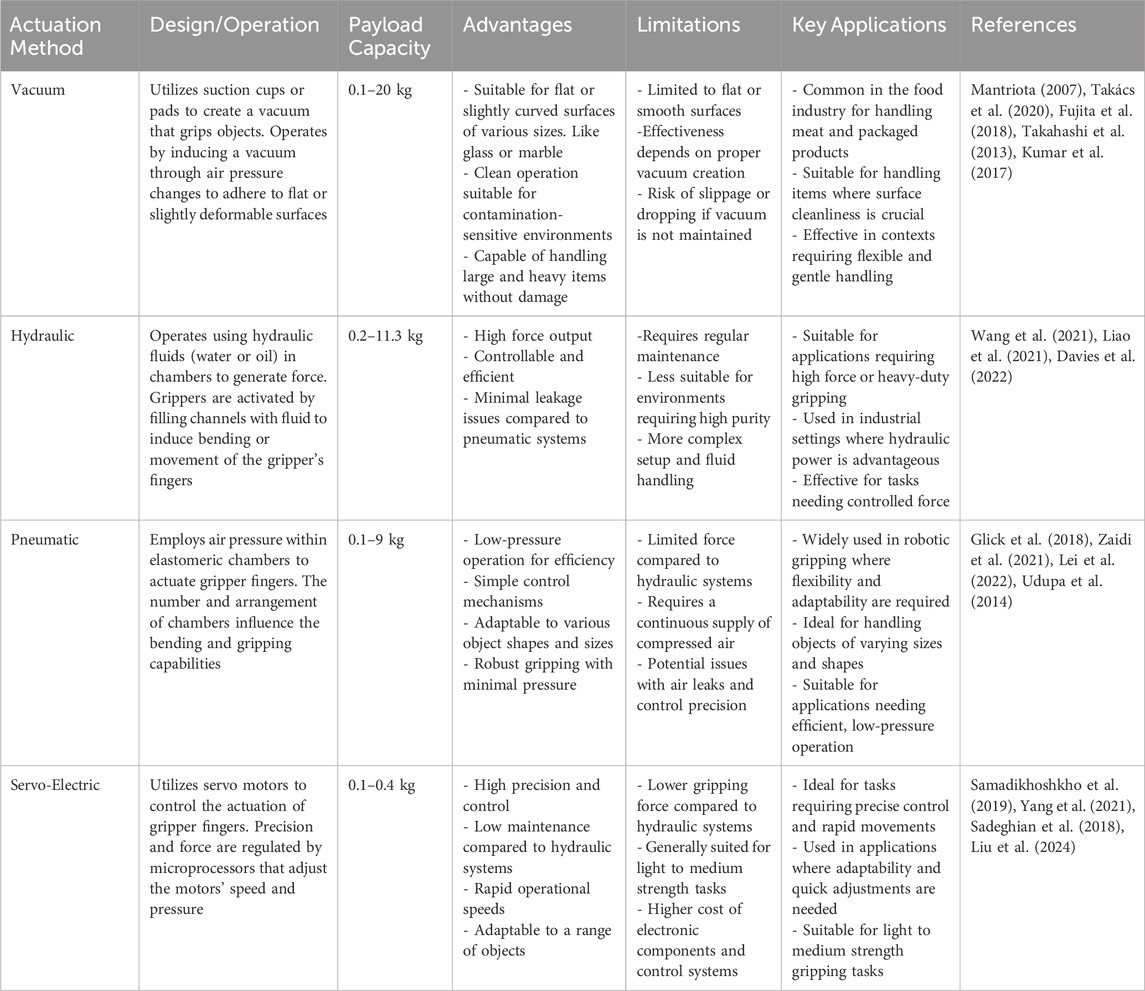

This section categorizes actuation methods used in robotic grippers into four primary types: vacuum, hydraulic, pneumatic, and servo-electric. Each method is analysed based on its working principle, efficiency, adaptability, and application areas. Vacuum grippers rely on suction for object handling, making them ideal for smooth surfaces. Hydraulic grippers utilize liquid-driven actuation, offering high force but requiring regular maintenance. Pneumatic grippers leverage air pressure for flexible and adaptive gripping, particularly in soft robotics applications. Servo-electric grippers, controlled by microprocessors, provide precision and ease of use with adjustable force control. To enhance clarity, a flowchart summarizing these actuation methods is provided, illustrating their classification and highlighting key characteristics. Additionally, Table 3 presents a comparative overview, offering insights into the advantages and limitations of each approach, aiding in the selection of suitable actuation mechanisms for specific robotic applications.

3.1 Vacuum

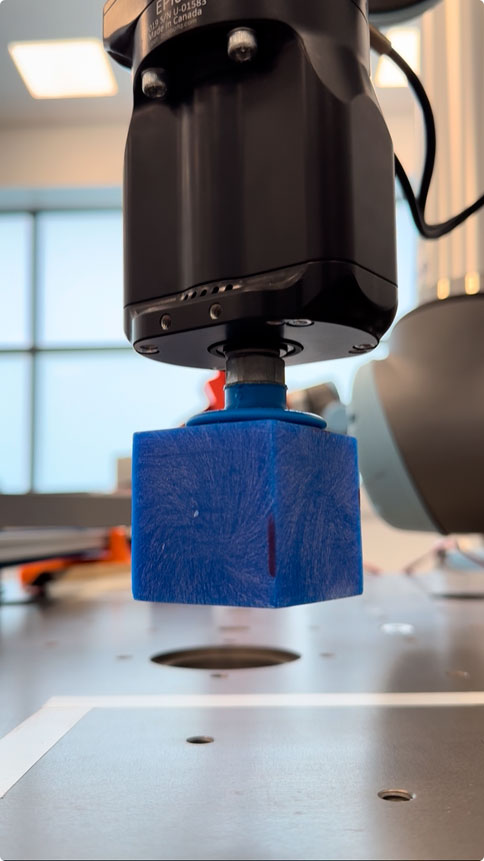

Vacuum grippers are renowned for their versatility and effective gripping capabilities, typically constructed from materials such as polyurethane, rubber or foam (Samadikhoshkho et al., 2019). Their operational principle, reliant on air-induced vacuum, necessitates impeccable vacuum creation, making them particularly adept at handling objects with flat or slightly curved surfaces like marble or glass (Mantriota, 2007), albeit this specificity somewhat narrows the range of suitable objects (Takács et al., 2020). These devices are particularly valued in contexts where contamination avoidance is paramount, as the process involves clean air conveyed through conduits. This makes them suitable for clean environments such as meat cutting facilities or food packaging lines (Takács et al., 2020; Jaiswal and Kumar, 2017). Configurable with one or more suction cups of varying dimensions, vacuum grippers can adapt to the size and shape of the target object, boasting the ability to secure large and hefty items without inflicting damage due to their inherent gentleness (Samadikhoshkho et al., 2019). The suction cups’ load-bearing capacity is directly influenced by the applied pressure force, with incorrect application posing a risk of slippage or dropping of the object (Mantriota, 2007). In a notable application within the food industry, Takács et al. (Takács et al., 2020) employed vacuum grippers for the manipulation of substantial meat pieces and packaged products, opting for suction cups over traditional fingered grippers to enhance safety and load capacity. The simplicity of vacuum grippers, as highlighted by Takács et al., alongside their flexibility in placement, ease of suction cup reconfiguration, and dependency of gripping strength on vacuum pump power, constitutes their primary advantages. However, the effectiveness of suction cups is contingent upon the compatibility with the object’s surface, necessitating the selection of flat or deformable objects to ensure optimal suction, thereby delineating the scope of objects that can be effectively handled by vacuum grippers. A vacuum gripper example is shown in Figure 6.

3.2 Hydraulic

Hydraulic grippers operate through the activation of hydraulic pumps, which enable them to exert considerable force, albeit necessitating regular maintenance to ensure optimal functionality (Samadikhoshkho et al., 2019). Similar to pneumatic grippers, these devices include chambers that are pressurized to produce motion. Pneumatic systems generally use air, whereas hydraulic systems operate with incompressible fluids such as oil. Some studies have also explored the use of water as a hydraulic fluid (Wang et al., 2021). However, since water is conductive, systems that use it must be carefully designed to prevent electrical leakage. In a notable exploration by Wang et al. (2021) In their study, they designed a soft gripper using a hydraulic actuator. The study introduced two distinct configurations: a single-channel design and a more versatile double-channel variant, the latter capable of bending in both inward and outward directions, a feature illustrated in Figure 7. The choice of a hydraulic system was predicated on its controllability, efficiency, and minimal leakage, despite its less frequent application in settings where purity is paramount (Wang et al., 2021). The operational mechanism involves filling the actuator’s channels with the chosen fluid, a process initiated by connecting the channels to a water reservoir and opening the controlling valve. This is followed by the expulsion of air through the reciprocal action of the hydraulic pump, culminating in the disconnection of the system once an adequate volume of fluid is secured within the channels. Throughout the gripping process, the actuation pressure induces the bending of the gripper’s fingers, enhancing the contact force as they engage with the object, thereby facilitating a secure grasp.

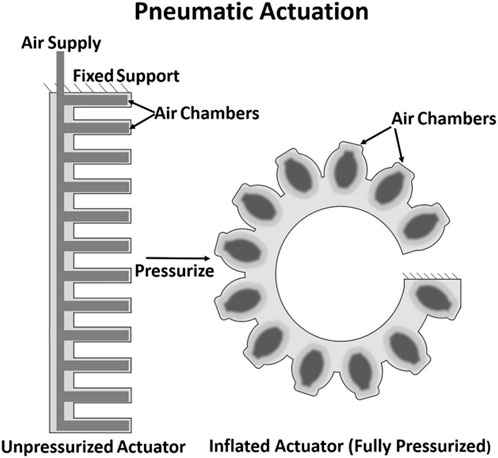

Figure 7. Pneumatic actuation working principle (Zaidi et al., 2021).

3.3 Pneumatic

Pneumatic actuation is a critical component in the field of robotic gripping, where the manipulation of objects is achieved through the controlled bending of fingers via pneumatic means. This actuation method employs hollow elastomeric chambers within the design of the gripper fingers, with the number of chambers tailored to the specific requirements of the application. These chambers are intricately connected to pneumatic tubing, which facilitates the conveyance of gas pressure essential for the actuation process. The internal air pressure is a pivotal factor, dictating the degree of bending of the fingers, thus enabling the gripping action (Zaidi et al., 2021). Glick et al. (2018) have contributed significantly to this domain with the design of a pneumatically actuated elastomeric gripper.

This innovative design aims to ensure robust gripping capabilities at minimal pressure levels, thereby enhancing the gripper’s efficiency in securing objects that exceed its complete grasping capacity. The design’s hallmark is its operation at low pressure, which not only optimizes actuation efficiency but also simplifies control mechanisms. A notable feature of this design is the integration of adhesive materials within the gripper’s interior, augmenting its gripping prowess. The pneumatic actuation principle is illustrated in Figure 7, showcasing the intricate mechanism that underpins this actuation method. The ability to modulate air pressure within the gripper’s fingers presents a versatile approach to robotic gripping, accommodating a wide array of object shapes and sizes (Zaidi et al., 2021). This adaptability, coupled with the simplicity of control, underscores the potential of pneumatic actuation in advancing robotic manipulation technologies.

3.4 Servo-electric grippers

Servo-Electric grippers, akin to their counterparts, are adept at executing a myriad of tasks, particularly in pick-up and placement operations. While they exhibit lower gripping forces in comparison to hydraulic grippers, their capabilities range from light to medium strength (Chitroda and Patle, 2023). Notable advantages of Servo-Electric grippers include ease of control, reduced maintenance expenditures, and rapid operational speeds, The regulation of speed and gripping force in these grippers is accomplished through the use of microprocessors (Chitroda and Patle, 2023), which, coupled with their considerable adaptability, allows them to handle a broad spectrum of objects (Samadikhoshkho et al., 2019). The actuation of the gripper fingers is driven by servo electric motors, enhancing the device’s ability to secure materials of varying properties. This is achieved by employing force sensors to meticulously adjust the applied pressure, ensuring precise control over the gripping process (Chitroda and Patle, 2023). The comparison of the actuation methods mentioned earlier is briefly presented in Table 3.

Table 3 provides a structured comparison of robotic gripper actuation methods, each with distinct advantages and limitations depending on the intended application. The choice of actuation method should be guided by application-specific requirements, including force output, response speed, adaptability, and environmental constraints. Pneumatic actuators offer high compliance and adaptability, making them ideal for handling delicate objects; however, they require an external air supply and typically have slower response times compared to hydraulic systems. In contrast, hydraulic actuators provide greater gripping force and precision but tend to be bulkier and require complex fluid management to prevent leakage. Vacuum-based grippers excel at adhering to flat and smooth surfaces but struggle with irregular or porous objects and require continuous suction to maintain grip. Servo motors, commonly used in soft grippers, offer high precision, fast response times, and programmability; however, their gripping force depends on the efficiency of the mechanical system and is generally lower than that of hydraulic or pneumatic systems. Moreover, servo-based systems tend to be mechanically more complex due to additional components such as cables and pulleys. In conclusion, while servo motors provide advantages in precision and programmability, their direct force output is more limited, making hydraulic and pneumatic systems preferable for applications requiring high gripping force. Pneumatic systems offer lightweight and flexible gripping, whereas vacuum-based grippers depend heavily on surface conditions. Ultimately, the most suitable actuation method should be selected based on the specific requirements of the application. Future advancements in actuation technologies are expected to focus on improving energy efficiency, reducing system complexity, and enhancing control precision to meet the evolving demands of robotic gripping applications.

4 Sensor integration

4.1 Force torque sensor

In the realm of robotic manipulation, the roles of force and torque are paramount, with their accurate quantification being critical to the success of such applications (Glick et al., 2018). Typically, a Force/Torque (F/T) sensor is strategically positioned between the robot’s wrist and the gripper to measure these parameters (Collins et al., 2023). Among the available six degrees of freedom (6-DoF) force/torque sensing technologies—capacitive, piezoresistive, and piezoelectric—the piezoresistive variant is most commonly employed (Lin et al., 2019). Piezoresistive sensors consist of structures that deform under applied force or torque, causing a proportional change in the sensor’s electrical resistance (Fiorillo et al., 2018). This resistance change is typically measured using a Wheatstone bridge circuit and converted into an electrical signal (Fiorillo et al., 2018). Piezoelectric sensors, on the other hand, rely on the property of certain crystal or ceramic materials to generate an electric charge under mechanical stress; they produce an electrical signal directly proportional to the magnitude of the applied force or torque (Fiorillo et al., 2018). Capacitive force/torque sensors, on the other hand, determine the applied forces or torques by exploiting the principle of capacitance, which involves the storage of electrical energy in an insulator positioned between two conductive plates (Kim et al., 2013). Any force or torque applied alters the plates’ separation distance, thereby modifying the measured capacitance value, from which the applied force or torque can subsequently be inferred (Kim et al., 2013). The primary aim of using a force-torque (F/T) sensor in robotic systems is to enable the robot to interact intelligently and adaptively with its environment by perceiving external forces and torques applied at its end-effector. In conventional industrial robots, motion is typically controlled through pre-programmed trajectories using position and velocity feedback. However, such systems lack adaptability when unplanned physical interactions occur. The integration of a force-torque sensor overcomes this limitation by providing real-time feedback on interaction forces, thereby allowing dynamic and compliant responses. As described by Loske and Biesenbach, one practical application of F/T sensors is in hand-guided robot motion, where an operator can manually guide a robot to desired positions, and the sensor ensures smooth and safe cooperation between human and robot (Loske and Biesenbach, 2014). The recorded positions can be saved to generate automated motion sequences (Loske and Biesenbach, 2014). Another significant use is in sensor-guided motion, where a robot maintains a constant applied force (e.g., during assembly or polishing) even as it moves along a surface (Loske and Biesenbach, 2014). Furthermore, F/T sensors play a critical role in advanced fields such as robot-assisted surgery (Muscolo and Fiorini, 2023). These sensors provide haptic feedback to surgeons or offer information about tissue properties by measuring the applied force (Muscolo and Fiorini, 2023). Muscolo and Fiorini emphasize that these capabilities are particularly valuable in educational settings, helping novice surgeons develop sensitivity and reducing the likelihood of excessive force application (Muscolo and Fiorini, 2023). This, in turn, enhances safety and minimizes the risk of tissue damage.

4.2 Pressure sensor

In robotic arm applications, particularly those involving gripping and manipulation, a fundamental requirement is the establishment of precise and smooth physical contact between the object and the gripper (Almassri et al., 2015a). To ensure the regulation of this contact, pressure sensors have been innovatively designed (Almassri et al., 2015a). Pressure, fundamentally, is the force exerted per unit area, with the general relationship delineated as below:

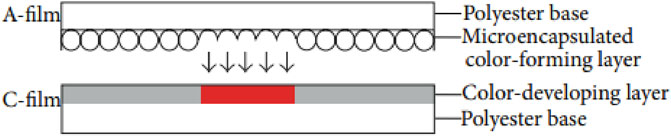

In Equation 1, P denotes pressure, F the applied force, and A the surface area in contact. To find the average pressure, the applied force is divided by the area (Almassri et al., 2015b). Upon the interaction of multiple objects, force is mutually exerted, necessitating the computation of average pressure by dividing the total applied force by the contact area. However, the distribution of surface contact pressure is not uniformly consistent, often requiring the calculation of peak pressure in certain instances (Almassri et al., 2015b). To address these variabilities, technologies such as load cells, pressure indicating film, and tactile pressure sensors have been developed (Almassri et al., 2015b). Load cells, integrated within the system, provide feedback on the compression force exerted on the object. Pressure Indicating Film, which employs fragile microcapsules covering one of the contact surfaces, visually represents pressure intensity through the dispersion of ink from ruptured capsules under pressure, as depicted in Figure 8 (Almassri et al., 2015b). The intensity of the ink’s color serves as an indicator of the pressure magnitude, with darker hues signifying higher pressures, making this technique suitable for applications requiring visual representation of peak pressure or for single-use scenarios (Cacucciolo et al., 2019). Conversely, tactile pressure sensors quantify the pressure through direct contact with the object, enabling the extraction of multiple parameters from the resultant signal, such as the location of the contact area, the object’s shape, and the spatial distribution of applied pressure (Almassri et al., 2015b).

Figure 8. Pressure indicating film design (Almassri et al., 2015b).

4.3 RGB-D

In the domain of robotic gripping, the precise localization of the target object is imperative for successful manipulation (Ringdahl et al., 2019). This entails acquiring depth information to ascertain the object’s coordinates in real-world scenarios, a task facilitated by RGB-D sensors. These sensors are distinguished by their ability to measure an object’s depth in conjunction with capturing imagery in the red, green, and blue color spectrums (Vit and Shani, 2018). Adar Vit and Guy Shani undertook an evaluative study of four distinct RGB-D sensors, comparing their efficacy (Vit and Shani, 2018). A critical aspect of gripping endeavors involves the accurate determination of the robotic hand and fingers’ positioning (Martinez-Martin et al., 2017). It is important to detect this because for a successful grasping process, the object to be grasped must be approached at a correct angle and when the appropriate position is formed, this can be detected, and the grasping process can be realized (Martinez-Martin et al., 2017). The application structure of RGB-D sensors can be categorized into two main components: gripper recognition and grasp validation (Muscolo and Fiorini, 2023). Gripper recognition refers to the process of identifying and localizing the gripper within the environment by distinguishing it from surrounding objects (Martinez-Martin et al., 2017). Additionally, depth data may be utilized to extract the object’s contours, which assists in aligning the gripper accurately during the grasping process. The subsequent Grasping Check phase evaluates the success of the gripping action and monitors for any slippage during object transport. This evaluative mechanism leverages depth and edge information to verify the precision of the gripper’s contact with the object, thereby optimizing the gripping process and reducing the duration of operations.

4.4 Sensorless sensing

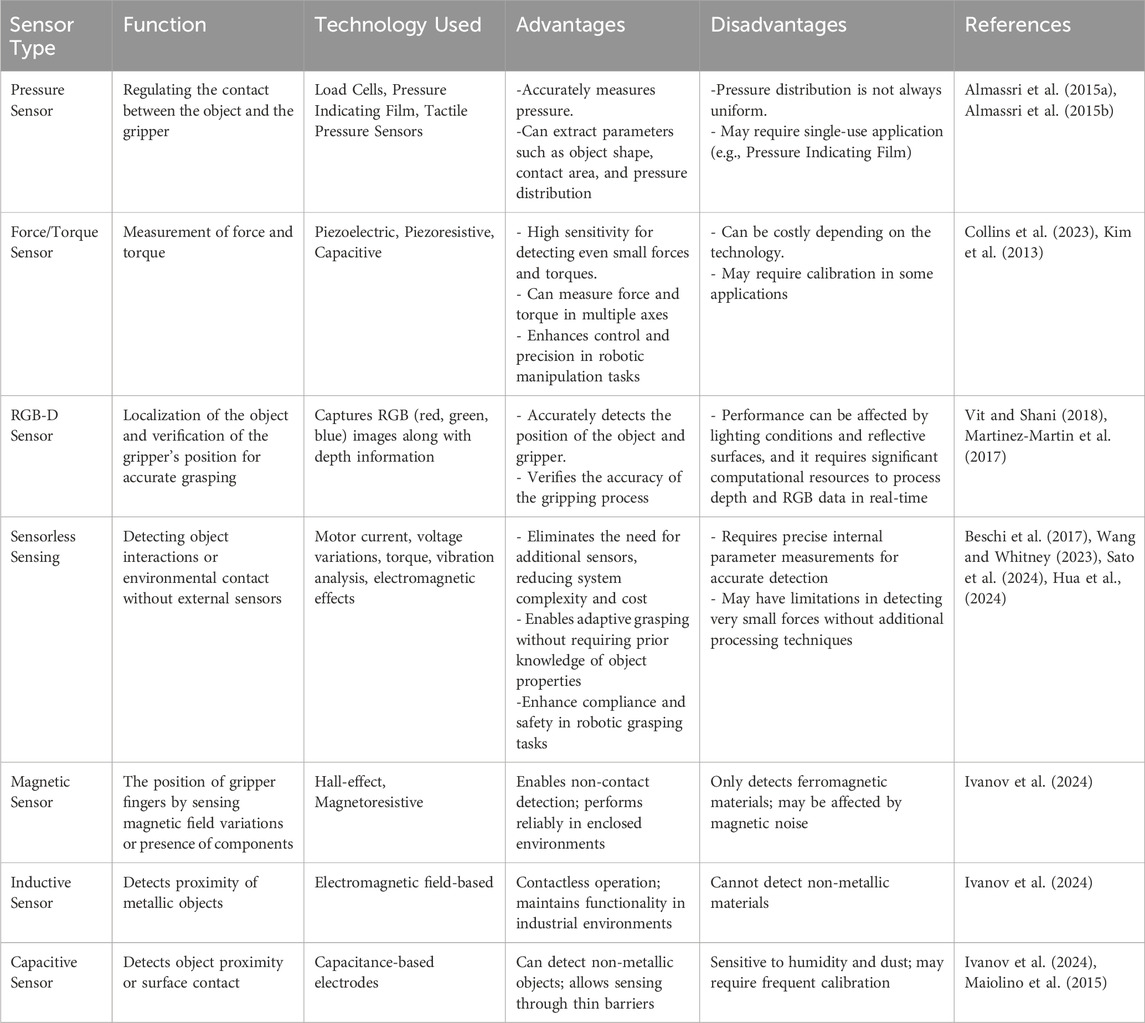

Sensorless sensing technologies detect object interactions or environmental contact without using external sensors by measuring the system’s internal parameters. Contact detection can be achieved through internal measurements such as motor current, voltage variations, torque, vibration analysis, and electromagnetic effects. Beschi et al. introduced a sensorless object-detection approach for an underactuated robotic hand, relying solely on actuator position and current measurements instead of external sensors (Beschi et al., 2017). Their method integrates a joint impedance control scheme with a state observer, which estimates the kinematic configuration of the fingers using a probabilistic approach. By continuously adjusting the position set-points based on the estimated contact state, the system enables adaptive grasping, eliminating the need for prior knowledge of the object’s material or shape. This ensures stable and flexible grasping, preventing damage to delicate objects while maintaining firm control over various shapes and materials (Beschi et al., 2017). Experimental validation with a three-finger adaptive gripper demonstrated the method’s effectiveness in grasping objects with different stiffness levels and shapes, outperforming traditional force-threshold-based control by ensuring all fingers reach a stable final configuration before stopping movement (Beschi et al., 2017). Similarly, Wang & Whitney proposed a sensorless contact detection method for motorized hydraulic actuators, leveraging internal fluid pressure measurements instead of external force sensors (Wang and Whitney, 2023). Their approach employs a disturbance observer, which estimates external forces by analyzing deviations in internal pressure, enabling precise contact detection without endpoint sensing. This strategy enhances low-impedance sensitivity while maintaining high-bandwidth force control, making it particularly suitable for human-robot interaction and remote hydraulic actuation. Experimental validation with a 2-DOF hydraulic gripper demonstrated reliable contact detection with a 0.2 N sensitivity, ensuring robust performance across various interaction scenarios (Wang and Whitney, 2023). Sato et al. developed a sensorless parallel gripper that achieves sub-Newton level grasping force using linear servomotors and a low-friction mechanical design, eliminating the need for external force sensors (Sato et al., 2024). Their system ensures delicate object handling by leveraging the inherent back-drivability of the motor, allowing precise force control without additional sensing hardware. Likewise, Hua et al. proposed a sensorless grasping force control method for a pneumatic underactuated robotic gripper, utilizing pneumatic pressure variations and a state-based actuation model to estimate and regulate grasping forces without direct force measurements (Hua et al., 2024). This approach enhances adaptive grasping capabilities, enabling accurate and non-destructive grasping in soft robotics applications. The comparison of the sensors is presented in Table 4.

In addition to force, pressure, and vision-based sensors, magnetic, inductive, and capacitive sensors are also integrated into robotic gripping systems to address specific functional requirements. Magnetic sensors, such as Hall-effect types, are used to detect the position of internal moving components like pistons in pneumatic actuators, providing reliable, compact, and contactless feedback (Ivanov et al., 2024). Inductive sensors particularly proximity-based designs are effective for detecting the presence of metallic parts by sensing disturbances in electromagnetic fields, which makes them suitable for industrial environments requiring robust, non-contact sensing (Ivanov et al., 2024). Capacitive sensors, by contrast, can detect both proximity and contact with soft or non-metallic objects by monitoring capacitance variations, although their performance may be influenced by environmental conditions such as humidity and dust (Maiolino et al., 2015).

In robotic applications, sensor integration is a critical factor that determines a system’s interaction with its environment. Sensors play a key role in fundamental functions such as object detection, grip force regulation, and positioning. However, it is not only the presence of a sensor but also its accuracy that directly affects system performance. For instance, force/torque sensors must provide precise measurements to ensure stable gripping and prevent delicate objects from being exposed to excessive force. However, factors such as non-linear responses, crosstalk, and hysteresis can lead to measurement errors, necessitating a careful calibration process. Similarly, pressure sensors are used to regulate grip force, but their effectiveness largely depends on sensitivity and response time. Piezoresistive sensors, for example, may exhibit drift over prolonged use, compromising their accuracy. RGB-D sensors are commonly used for object recognition and depth estimation; however, variations in lighting conditions, surface reflectivity, and sensor resolution can pose challenges in terms of accuracy. These limitations may result in positioning errors, leading to unsuccessful grasps or misaligned objects. Conversely, sensorless detection methods that estimate contact forces through motor currents or impedance models introduce additional uncertainty due to their reliance on indirect measurements.

A comprehensive approach to sensor selection and integration should not only assess the theoretical accuracy of sensors but also evaluate their performance under real-world operating conditions. This involves analysing error margins, reviewing calibration methods, and assessing the suitability of different sensor types for specific applications. Future research should aim to establish standard accuracy criteria and testing protocols to evaluate sensor performance in alignment with the requirements of robotic manipulation tasks.

5 Control strategy

Grippers, functioning as dynamic end-effectors, are required to respond in real time to variations in object characteristics, interaction forces, and operational demands. This section examines how general control methods such as PID, fuzzy logic, and machine learning can be adapted and applied to the control of gripper systems. These strategies cover aspects such as managing finger movements, regulating grasping force, and enabling adaptive behaviors during manipulation. In this context, control is not limited to robot motion alone; it also involves the coordinated operation of the gripper together with sensors and actuators within the entire system. To fully implement these strategies, it is essential to understand the broader framework of robotic control systems, which are designed to regulate the movements, functionalities, and overall behaviors of robots.

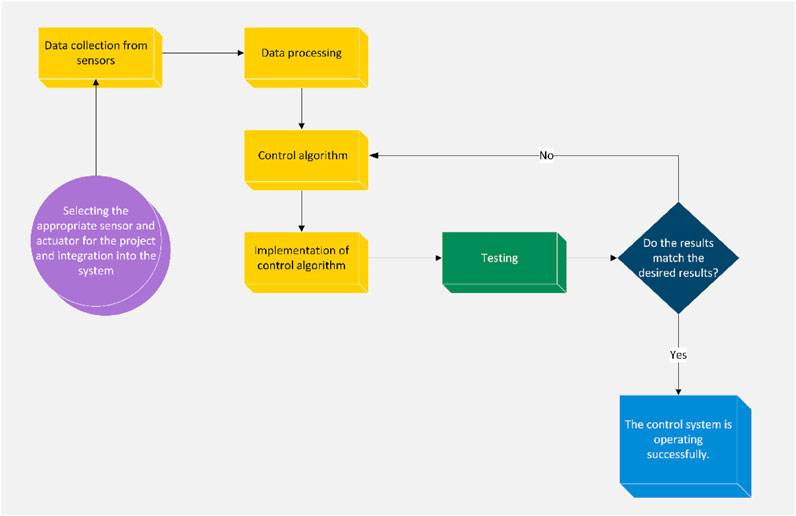

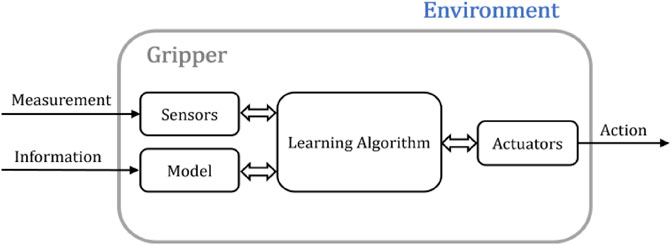

Integral to these systems is a fusion of algorithms, logical constructs, and control strategies, which collectively empower robots with the ability to autonomously make decisions. This decision-making process is informed by the interpretation of data gathered from a diverse suite of sensors interconnected with robot (Jaiswal and Kumar, 2017). The algorithms central to this system are crucial for the activation of motion-enabling actuators, ensuring that the robot’s movements and tasks are meticulously aligned with predetermined goals and desired outcomes (Cortinovis et al., 2023). The block diagram illustrating the control system process is shown in Figure 9.

5.1 Selection of sensors and actuators

In robotic gripper applications, the determination of the position of the object and its grasping are performed by sensors and actuators (Hughes et al., 2016). In order to select appropriate sensors according to the robot’s task, environmental factors must first be determined (e.g., distance, temperature, light level) (Zhang et al., 2020). When choosing a sensor, keep the following things in mind: Robotic systems often require real-time data processing, so having fast response times from sensors increases the system’s ability to respond (Zhang et al., 2020). The sensitivity of the data provided by the sensors affects the performance of the system. In applications requiring high sensitivity, higher quality sensors should be selected. The environmental conditions (temperature, humidity, dust, etc.) where the sensors will be used can affect sensor selection (Zhang et al., 2020). For example, sensors that will operate at high temperatures must be heat resistant.

Along with sensors, actuators are an indispensable part of grippers. The movements of the grippers are controlled by actuators. At the same time, by adding various sensors (such as position, acceleration, force) to these systems, the data from these sensors can be monitored instantly and controlled precisely (Zhang et al., 2020). The actuators selected must be compatible with the existing system and sensors. In order for the control algorithms to work properly, it is important that the system components are integrated with each other. Actuators working in harmony with the data provided by the sensors increases the overall efficiency of the system (Boyraz et al., 2018). The energy consumption of the actuators affects the mobility and efficiency of the robot. Energy consumption can be controlled according to the required force and torque values (Boyraz et al., 2018). The response time of the actuators affects the overall performance of the system. For robotic arms that need to move quickly, actuators with fast response should be selected (Boyraz et al., 2018).

5.2 Control algorithms

5.2.1 PID control

PID control systems, prevalent in contemporary industry, embody the principles of proportional, integrative, and derivative functions. These systems employ a feedback mechanism that addresses discrepancies between the initial and desired states, adjusting outputs to mitigate such errors (Cortinovis et al., 2023). In Equation 2 the error, denoted as e(t), is calculated by the difference between the setpoint and the current value (Asif and Webb, 2015). The control gains are defined as Kp for proportional, Ki for integral, and Kd for derivative actions, which collectively influence the system’s output signal to expedite the attainment of the setpoint by reducing system errors, where τ represents the integral component and t signifies the present time (Asif and Webb, 2015).

The proportional component addresses immediate errors by adjusting for current deviations. The integral part accumulates historical errors, assessing cumulative discrepancies over time. The derivative segment anticipates future errors by evaluating the rate of error change, facilitating preemptive corrections.

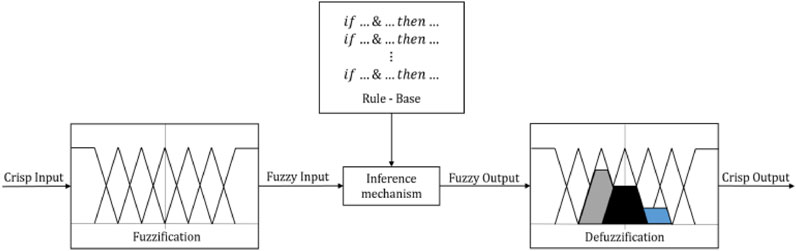

5.2.2 Fuzzy

Fuzzy logic extends beyond the binary true-false or 0–1 paradigm by incorporating intermediate values, thereby offering a robust framework for addressing situations characterized by uncertainty (Kayışlı and Uğur, 2017). This computational approach facilitates the quantification of linguistic uncertainties, translating subjective statements into precise numerical values. The design of such systems often leverages domain-specific expertise to interpret and encode these nuanced expressions (Kayışlı and Uğur, 2017). Essentially, fuzzy logic provides a methodological bridge between verbal articulations and their numerical counterparts, as depicted in the schematic representation in Figure 10. Fuzzification transforms distinct inputs into fuzzy numerical values ranging between 0 and 1, employing an IF-THEN rule structure based on expert-derived knowledge within the Rule-Base block, which encapsulates all potential system scenarios (Su et al., 2014). The absence of any expected probability in the rule-base triggers system errors. The inference mechanism processes this fuzzy data to derive outcomes, while the defuzzification phase converts these fuzzy outputs back into concrete values applicable to real-world tasks (Cortinovis et al., 2023). An application of fuzzy control in a robotic manipulator, detailed in (Su et al., 2014), demonstrates the use of fuzzy logic to categorize the object for manipulation based on its physical properties, highlighting the nuanced decision-making process enabled by fuzzy control.

Figure 10. Diagram of fuzzy system (Cortinovis et al., 2023).

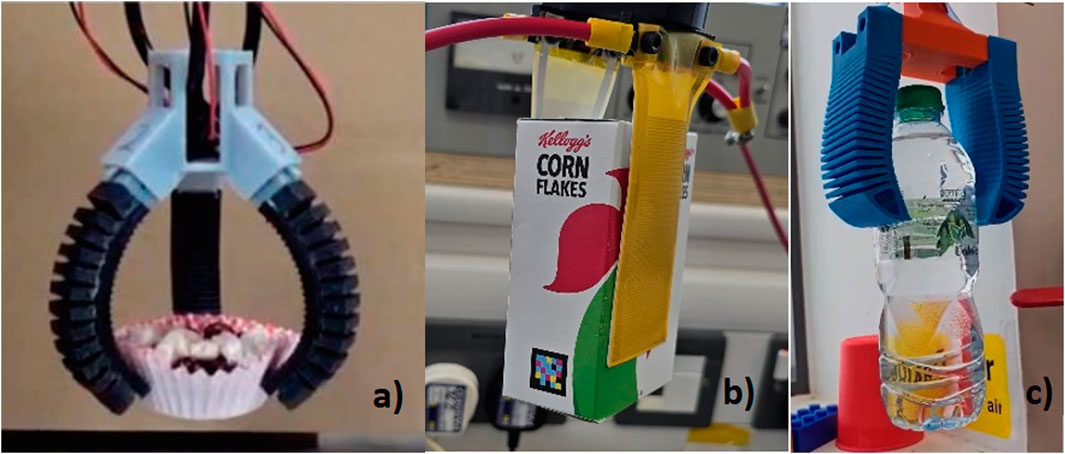

5.2.3 Machine learning

Recent advancements in robotic grasping have increasingly incorporated machine learning (ML) techniques to enhance functionality (Cortinovis et al., 2023). Key objectives of ML in this context include accurately determining object locations, estimating postures, and formulating grasp strategies for effective manipulation. Grippers equipped with diverse sensors gather essential data which ML algorithms then analyze to discern the object’s characteristics, such as shape, size, and color. This process enables autonomous object recognition and the determination of optimal gripping angles. Post-manipulation, the ML system assesses the grip’s efficacy through feedback, which informs adjustments in grip strength, operational speeds, and other parameters to optimize performance. Figure 11 shows the block diagram of Machine Learning’s gripper applications. For instance, ML algorithms can preemptively modify gripping strategies to mitigate the risk of dropping objects or adapt to changing requirements due to variations in object properties or detection and collection utilizing Convolutional Neural Networks (CNN), a deep learning algorithm frequently applied in image processing (Almanzor et al., 2022). This method processes visual input to identify and classify features across various layers, enabling the system to recognize target objects. The study specifically employed Mask Region Convolutional Neural Network for object segmentation and classification, leveraging the COCO dataset for enhanced accuracy (Almanzor et al., 2022). Parallelly, a separate study employed reinforcement learning for robotic grasping, emphasizing a trial-and-error approach where the system iteratively refines its actions based on feedback to achieve predefined objectives (Shirin et al., 2020). This method underscores the importance of adaptive behavior in robotics, allowing for the optimization of actions to maximize rewards and efficiency in task execution (Shirin et al., 2020). The comparison of the control methods mentioned in Table 5 has been made.

Figure 11. Machine learning diagram for gripper (Cortinovis et al., 2023).

5.2.4 Reinforcement learning

Reinforcement Learning (RL) is a machine learning method that enables an artificial intelligence agent to interact with its environment and learn the most optimal actions based on a reward-cost balance (Shirin et al., 2020). While traditional control systems rely on predefined models, RL dynamically learns from environmental data, offering more flexible and adaptive solutions. This feature provides a significant advantage, especially in controlling nonlinear and complex systems. The use of RL in flexible robotic grippers has great potential for optimizing grasping strategies by adapting to different object types and environmental variations. RL approaches combined with Finite Element Analysis (FEA) help determine optimal grasping points, minimizing stress and deformation on objects during grasping (Römer et al., 2024). Additionally, the use of RL in residual control mechanisms allows for modeling non-linear dynamics, friction, and contact forces, where traditional control systems fall short, ensuring a more reliable and stable grasp (Johannink et al., 2019). RL has been shown to outperform classical PID or model-based control methods by learning unknown contact forces and environmental variations, ultimately improving system performance. The flexibility of RL in robotic systems extends beyond grasping processes, also playing a crucial role in task scheduling and optimization in manufacturing lines (Kim and Lee, 2022). Particularly in complex robotic systems such as dual-gripper mechanisms, RL-based scheduling algorithms enable robots to adapt to variable processing times and achieve maximum efficiency within minimal time. In recent years, Deep Reinforcement Learning (DRL) techniques have expanded the capabilities of RL by incorporating deep neural networks, allowing robots to adapt more quickly to environmental factors (Shirin et al., 2020). Advanced DRL architectures such as the Grasp-Q-Network process data from multiple cameras and sensors to determine the most suitable grasping strategies, thereby improving the success rate of robotic grasping (Shirin et al., 2020). The implementation of Deep Q-Learning and Double Deep Q-Learning algorithms enables robotic systems to learn the most efficient grasping movements in dynamic environments. In particular, DRL methods supported by visual feedback mechanisms allow robots to detect object positions in real-time and develop the most appropriate grasping strategies (Shirin et al., 2020).

In conclusion, the integration of RL into flexible robotic gripper systems offers great potential for optimizing grasping strategies and enhancing overall efficiency in robotic systems. The combination of FEA and RL helps grippers determine more precise and efficient grasping points, while residual RL approaches reduce error margins in contact interactions and make the system more adaptable (Römer et al., 2024; Johannink et al., 2019). The application of DRL in grasping processes improves robots’ ability to learn from visual feedback, enabling the development of more flexible and reliable gripper systems (Shirin et al., 2020). These advancements pave the way for the widespread and effective use of flexible robotic grippers in industrial manufacturing processes.

5.2.5 Supervised and unsupervised learning

Supervised learning is a machine learning approach in which models are trained using a dataset where each data sample has a predefined correct answer (label). In other words, the dataset used for learning includes an expected output (label) corresponding to each input. The model learns from these examples and becomes capable of making predictions for new, previously unseen data. For instance, in the study conducted by Florence et al. (2020), a learning process was implemented to enable a robot to distinguish grasped objects from the background by recognising its own manipulator (arm). In this process, the robot first created a dataset containing images of its manipulator from different angles and learned to identify whether a given image belonged to its own structure. It then used this acquired knowledge to separate and identify the objects it grasped from its manipulator. In this method, supervised learning enabled the robot to train a model using self-generated labelled datasets. Similarly, in another study conducted by Aksoy et al. (2022), deep learning-based supervised models were used to plan the movement of a robotic hand and adjust its gripping force. In this research, pressure and motion data were collected while the robotic hand grasped different objects, and these data were labelled to train a machine learning model. Based on this training, the model was able to predict the optimal grasping angle and force for new objects.

Unsupervised learning is a method in which the data used for training the model is unlabelled, meaning that the meaning of each data point is not predefined. Instead, the model itself attempts to identify patterns, differences, and hidden structures within the data. This process can be likened to a person examining a book written in an unfamiliar language. If the meanings of the words were provided from the outset, the person could directly learn what each word meant (supervised learning). However, in unsupervised learning, no such information is given. Instead, the person tries to deduce meanings by analysing repeated words, their frequency within sentences, and relationships between words. Machine learning models follow a similar approach, analysing data and identifying natural groupings and structures within it. For example, Wang et al. (2022) developed an unsupervised learning approach to enable a robot to grasp different objects. In this method, the robot learned common features among similar objects, allowing it to successfully grasp objects it had never encountered before. As a result, the robot acquired a general grasping ability without requiring specific training for each individual object. Similarly, Roberge et al. (2016) proposed an unsupervised learning method that enables robots to analyse data from tactile sensors and determine whether an object is slipping. This approach allowed the robot to automatically detect slippage, helping it to securely hold objects without the need for predefined rules.

5.3 Integration testing of control system

Integration testing is used to check whether all components, such as sensors, actuators, control algorithms, and feedback mechanisms, are working together in harmony to achieve the desired operational objectives (Ramasubramanian et al., 2022). For these tests, simulations are used in the initial stages to observe the behavior of the control system. Simulations allow the system to go through various test scenarios, including extreme cases, and help identify potential defects before real-world implementation (Ramasubramanian et al., 2022). Once the system performs satisfactorily in the simulation, real-world testing begins. During these tests, it is crucial to verify the accuracy of sensor data and the responses of actuators. During integration testing, sensor inputs are compared to expected values, and the system’s responses through actuators are observed. Any discrepancies between expected and actual performance, such as incorrect sensor readings or delayed actuator responses, are reviewed and corrected (Ramasubramanian et al., 2022). In summary, integration testing verifies that all components of a robotic control system work together, ensuring that the robot can effectively and reliably perform its intended tasks in both simulation and real-world scenarios.

5.4 Realtime control and adaptation

Real-time control is used to optimize the performance of robotic systems and quickly adapt to environmental conditions (Rosenberger et al., 2021). Robots must process sensor data obtained instantaneously to adapt to environmental changes and task requirements. In this process, fast data processing and low latency are critical; any delay can prevent robotic systems from achieving the desired outcomes (Rosenberger et al., 2021). Real-time control systems enable the robot to adjust itself continuously based on feedback data. Feedback-controlled systems like PID reduce errors, allowing the robot to move more accurately and stably. In environments where obstacles are continuously moving or environmental conditions are constantly changing, such adaptive algorithms help robots detect these changes and respond immediately, enabling them to perform tasks more reliably and accurately.

In adaptation processes, machine learning algorithms can be used. Robots can detect the physical properties of objects and adjust their strategies accordingly (Rosenberger et al., 2021). For example, a robot can adjust the torque it applies when tightening screws during assembly, depending on the size and thread characteristics of each screw, rather than applying the same force to every screw. This prevents screws from being over-tightened, which could cause damage, or from being too loose, which could lead to safety issues. This adaptive behavior of the robot makes the assembly process more efficient and reliable. Real-time control and adaptation enable robots to provide both high performance and flexibility, allowing them to operate successfully in complex and dynamic environments.

Based on the review of various control methodologies, we propose the following recommendations for selecting an optimal control strategy for robotic grippers in different application scenarios. PID controllers remain a reliable choice for structured environments where system dynamics are well-defined, offering precise position and velocity control. However, their sensitivity to parameter tuning and difficulty in adapting to changing conditions make them less suitable for complex and dynamic settings. Fuzzy logic controllers, as demonstrated in robotic gripper applications, offer greater adaptability in handling uncertainties and imprecise data. They are particularly advantageous in scenarios where traditional mathematical modelling is challenging, such as grasping deformable or irregularly shaped objects. Meanwhile, machine learning-based approaches, including reinforcement learning (RL), have shown significant potential in optimising grasping strategies by learning from real-time interactions with the environment. These methods, especially deep reinforcement learning (DRL), enable robotic grippers to autonomously refine their grasping techniques based on feedback, making them ideal for unstructured environments or applications requiring high adaptability. Moreover, supervised learning provides high accuracy and reliability as it is trained on labelled datasets, making it effective in recognising predefined objects and estimating grasping force. However, applications requiring large-scale labelled data may face data storage challenges. Additionally, it may struggle when encountering previously unseen objects. In contrast, unsupervised learning enables robots to autonomously identify patterns, offering advantages in grasping unknown objects and detecting slippage without relying on predefined rules. However, as it is based on self-organising patterns, it may produce unpredictable outcomes and lead to higher computational costs. Given these insights, a hybrid approach that integrates classical control methods with AI-driven adaptability could provide a balanced solution, leveraging the stability of traditional controllers alongside the flexibility of intelligent systems. These findings emphasize the importance of intelligent control strategies and advanced material selection in shaping the future of robotic grippers. As research continues to evolve, it is essential to integrate these technological advancements into real-world applications to enhance efficiency, adaptability, and safety.

6 Discussion

The shifting from rigid to flexible and hybrid grippers highlights the need for more adaptable and efficient gripping solutions. Two-fingered grippers remain a cost-effective choice, while three-fingered designs offer enhanced stability and precision for delicate handling. Hybrid grippers, combining rigid and soft materials, demonstrate 1.5x to 2x greater fingertip force, enabling better lifting capacity up to 1.25 kg (Park et al., 2019), whereas electroadhesive grippers stand out for their low energy consumption (<1 W) but require high-voltage operation (>1 kV). Different actuation methods offer varying levels of efficiency. Pneumatic actuators offering high compliance but requiring an external air supply, hydraulic systems providing greater force at the cost of complex maintenance, servo-electric actuators excelling in precision but featuring a more mechanically complex design, and vacuum-based systems providing strong gripping capability for lifting heavy objects but being limited by surface conditions and airtight sealing requirements. Sensor integration is also important for optimized performance, with RGB-D sensors excelling in object localization but requiring high computational power, force/torque sensors enhancing precision at additional cost, and sensorless sensing offering a cost-effective alternative through internal system monitoring. Control strategies significantly impact gripping performance. PID controllers are effective in structured environments, but fuzzy logic controllers (FLCs) provide better adaptability by handling uncertainty and imprecise sensor data. Fuzzy logic enhances grip force regulation and object adaptability but does not possess the learning capability of reinforcement learning (RL). Studies show that RL-based Center-of-Mass (CoM)-based grasping strategies achieve a 98.8% success rate in regrasping tasks, enabling robots to autonomously optimize grasp poses and improve stability (Wang et al., 2024). Additionally, integrating trajectory prediction with RL enhances dynamic object grasping, increasing the success rate up to 83% by allowing robots to anticipate object movement and adjust grasping actions accordingly (Xu et al., 2024).

7 Conclusion

The expansive review of robotic gripping manipulation systems presented in this paper elucidates the rapid advancements and multidisciplinary innovations that are shaping the field. As we stand at the cusp of what could be a transformative era in robotic manipulation, it's imperative to delve deeper into the confluence of material science, actuation technologies, sensor integration, and sophisticated control strategies that are driving these advancements. The evolution from traditional, rigid grippers to more adaptable, soft, and hybrid systems highlights a paradigm shift towards robotic systems that are not only efficient and versatile but also safe for human interaction. This transition is critical in diverse applications, from industrial automation to delicate tasks in healthcare and service industries, where the interaction between humans and robots is becoming increasingly prevalent. The integration of sophisticated sensors and the application of artificial intelligence and machine learning algorithms have notably enhanced the autonomy, adaptability, and precision of these systems. This technological evolution is not merely augmenting existing capabilities but is also broadening the scope of robotic applications, pushing the frontiers of what can be achieved in robotic manipulation. The introduction of a comprehensive workflow for the design of robotic grippers, as highlighted in the discussion of Figure 1. This workflow outlines a systematic approach that begins with the identification of project requirements and spans concept development, control strategy formulation, and the eventual testing of prototypes. This structured process ensures that each gripper is tailor-made to meet specific operational demands, incorporating the right mix of materials, sensors, and control mechanisms to optimize performance. Despite these advancements, challenges remain in optimizing payload capacity, improving energy efficiency, and enhancing adaptability for complex tasks.

8 Future work

Future research will focus on the design, fabrication, and performance evaluation of electroadhesive grippers and 3D-printed flexible finger-type grippers. While these gripper types offer significant advantages in energy efficiency, adaptability, and safe object handling, further research is needed to optimize their payload capacity and operational efficiency. In the development of electroadhesive grippers, efforts will be directed towards enhancing adhesion force, surface adaptability, and power efficiency, while addressing key challenges such as high-voltage requirements and surface dependency. Performance evaluations will focus on factors such as gripping force, energy consumption, and reliability across different surfaces. Current research on flexible grippers primarily focuses on objects weighing 1 kg or less. However, Future research will aim to increase the payload capacity of flexible grippers, ensuring that they can handle heavier objects while maintaining adaptability and compliance. This will involve material optimization, reinforcement techniques, and structural modifications to improve gripping force and mechanical durability. As part of this research, 3D printing technology will be utilized to design and manufacture flexible grippers, which will then undergo experimental testing. Performance evaluations will be based on metrics such as load-bearing capacity, deformation response, and grasping stability under various conditions. This future research aims to contribute to the development of flexible robotic grippers with higher payload capacities through systematic performance evaluations, thereby expanding their application in industrial automation and complex manipulation tasks. The findings will provide critical insights for the development of next-generation adaptive gripping solutions.

Author contributions

BT: Writing – original draft, Supervision, Visualization. SA: Supervision, Writing – review and editing, Conceptualization. PW: Supervision, Writing – review and editing. MC: Supervision, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Acknowledgments

The authors express their sincere gratitude to Jamie Rice and Daniel Oakley, Lab Technicians, and James Fowler, Senior Technical Officer at the Intelligent Automation Lab, for their invaluable support and technical expertise, which were essential for the project’s success. BT would also like to acknowledge the Ministry of National Education of Türkiye for their support through the YLSY scholarship program, which enabled the pursuit of this doctoral research.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aksoy, B., Özsoy, K., Yücel, M., Ekrem, Ö., and Salman, O. K. M. (2022). Motion control of the robot arm manufactured with a three-dimensional printer and hardness detection of objects. Bilişim Teknol. Derg. 15 (3), 289–300. doi:10.17671/gazibtd.1059378

Almanzor, E., Anvo, N. R., Thuruthel, T. G., and Iida, F. (2022). Autonomous detection and sorting of litter using deep learning and soft robotic grippers. Front. Robot. AI 9 (Dec), 1064853. doi:10.3389/frobt.2022.1064853

Almassri, A. M., Wan Hasan, W. Z., Ahmad, S. A., Ishak, A. J., Ghazali, A. M., Talib, D. N., et al. (2015b). Pressure sensor: state of the art, design, and application for robotic hand. London: Hindawi Publishing Corporation. doi:10.1155/2015/846487

Almassri, A. M., Wanhasan, W. Z., Ahmad, S. A., Ishak, A. J., Serdang, U., and Wada, C. (2015a). “Optimisation of grasping object based on pressure sensor measurement for robotic hand gripper,” in 2015 9th International Conference on Sensing Technology (ICST), Auckland, New Zealand, 08-10 December 2015, 795–798. doi:10.1109/icsenst.2015.7438505

Amend, J. R., Brown, E., Rodenberg, N., Jaeger, H. M., and Lipson, H. (2012). A positive pressure universal gripper based on the jamming of granular material. IEEE Trans. Robotics 28 (2), 341–350. doi:10.1109/TRO.2011.2171093

Beschi, M., Villagrossi, E., Tosatti, L. M., and Surdilovic, D. (2017). Sensorless model-based object-detection applied on an underactuated adaptive hand enabling an impedance behavior. Robot. Comput. Integr. Manuf. 46, 38–47. doi:10.1016/j.rcim.2016.11.005

Boyraz, P., Runge, G., and Raatz, A. (2018). An overview of novel actuators for soft robotics. Basel: MDPI AG. doi:10.3390/act7030048

Cacucciolo, V., Shea, H., and Carbone, G. (2022). Peeling in electroadhesion soft grippers. Extreme Mech. Lett. 50 (Jan), 101529. doi:10.1016/j.eml.2021.101529

Cacucciolo, V., Shintake, J., and Shea, H. (2019). “Delicate yet strong: characterizing the electro-adhesion lifting force with a soft gripper,” in 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea (South), 14-18 April 2019 (IEEE).

Cao, H., Huang, J., Li, Y., Zhou, J., and Liu, Y. (2021). “Fuzzy-depth objects grasping based on FSG algorithm and a soft robotic hand,” in IEEE international conference on intelligent robots and systems (Prague: Institute of Electrical and Electronics Engineers Inc.), 3948–3954. doi:10.1109/IROS51168.2021.9636173

Chitroda, M., and Patle, Dr. B. K. (2023). A review on technologies in robotic gripper. Int. J. Adv. Eng. Nano Technol. 10 (5), 1–5. doi:10.35940/ijaent.C7232.0511523

Choi, C., Schwarting, W., Delpreto, J., and Rus, D. (2018). Learning object grasping for soft robot hands. IEEE Robot. Autom. Lett. 3 (3), 2370–2377. doi:10.1109/LRA.2018.2810544

Collins, J. A., Grady, P., and Kemp, C. C. (2023). “Force/torque sensing for soft grippers using an external camera,” in Proceedings - IEEE international conference on robotics and automation (London: Institute of Electrical and Electronics Engineers Inc.), 2620–2626. doi:10.1109/ICRA48891.2023.10161257

Cortinovis, S., Vitrani, G., Maggiali, M., and Romeo, R. A. (2023). Control methodologies for robotic grippers: a review. Basel: Multidisciplinary Digital Publishing Institute. doi:10.3390/act12080332

Davies, J., Phan, P. T., Huang, D., Hoang, T. T., Low, H., Thai, M. T., et al. (2022). “Hydraulically actuated soft tubular gripper,” in Proceedings - IEEE international conference on robotics and automation (Philadelphia: Institute of Electrical and Electronics Engineers Inc.), 6144–6150. doi:10.1109/ICRA46639.2022.9811983