- 1School of Life Sciences, Jining Medical University, Jining, China

- 2School of Pharmacy/School of Modern Chinese Medicine Industry, Chengdu University of Traditional Chinese Medicine, Chengdu, China

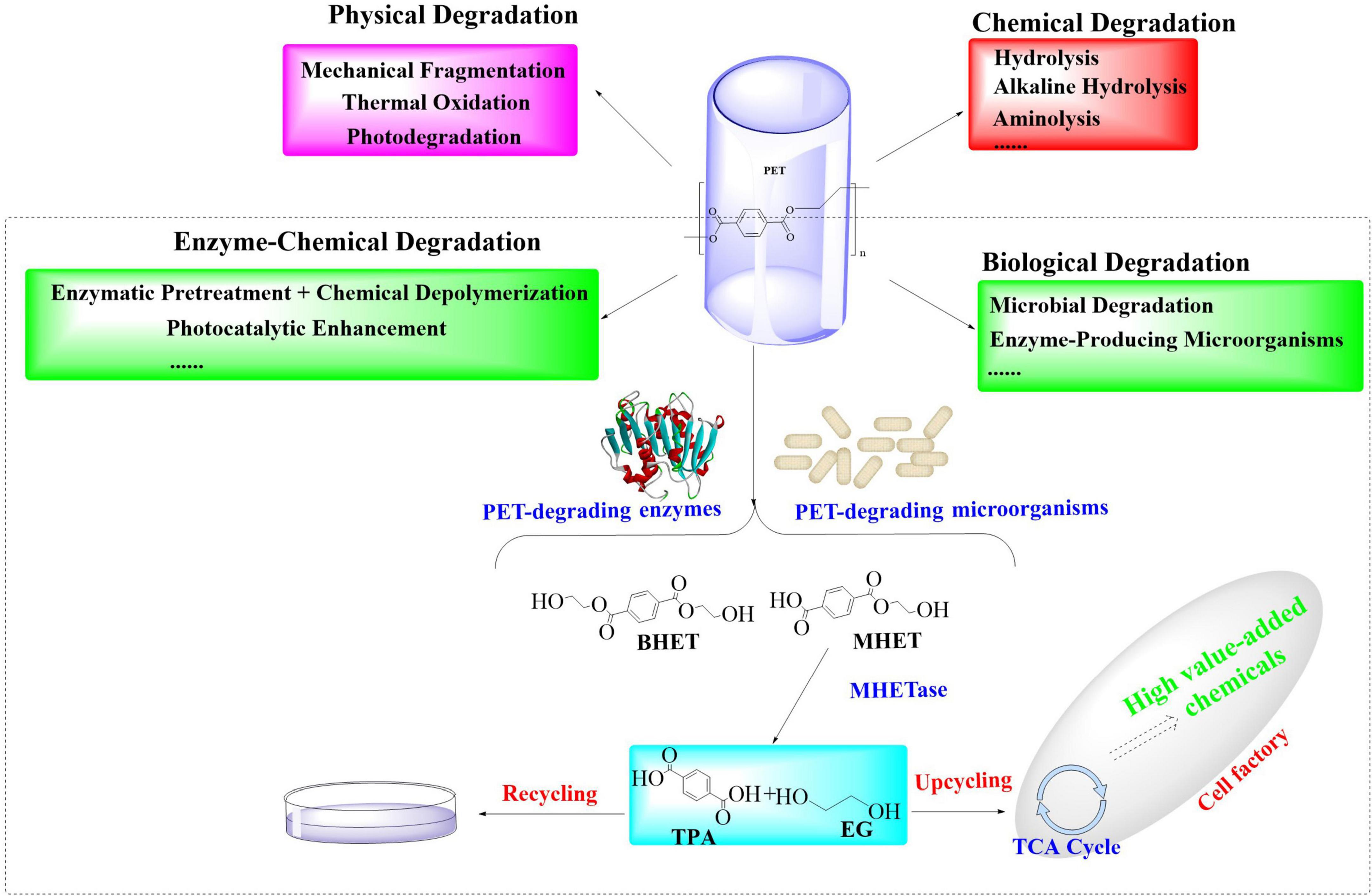

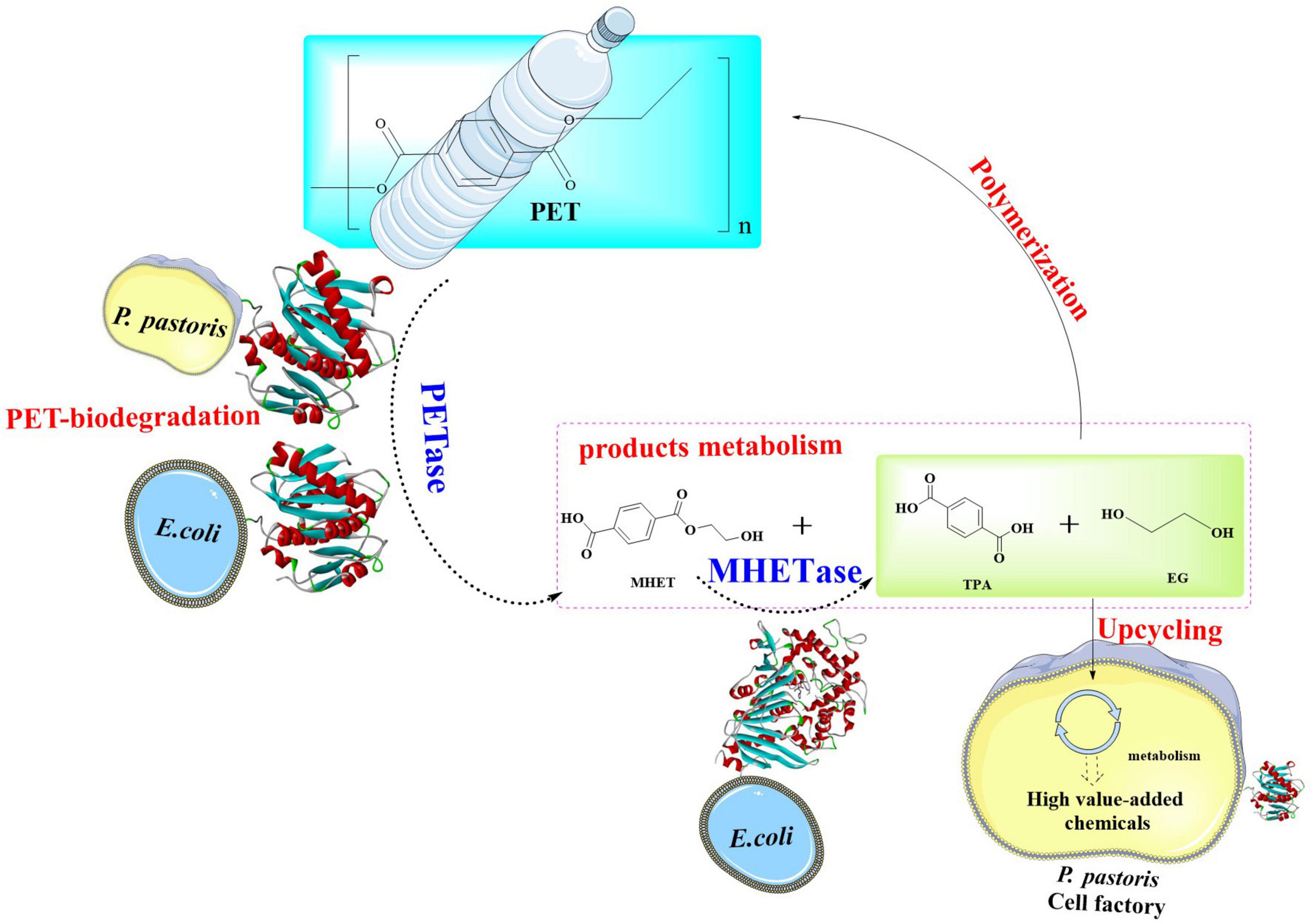

The pervasive accumulation of polyethylene terephthalate (PET) waste has emerged as a critical ecological crisis, which is mainly driven by its recalcitrance to natural degradation and widespread contamination of terrestrial and aquatic ecosystems. In response to this challenge, microbial-mediated PET biodegradation has garnered significant scientific attentions as a sustainable remediation strategy, harnessing the enzymatic cascades of specialized microorganisms to depolymerize PET into bio-assimilable monomers such as terephthalic acid (TPA) and ethylene glycol (EG). In this review, we summarize the extracellular process of PET biodegradation, including microbial attachment, colonization, and direct depolymerization, as well as the metabolic pathways of PET monomers. Strategies for developing PET-degrading chassis cells are also discussed, such as cell surface display, metabolic pathway optimization, and rational design of enzyme-PET interfaces. Microbial-enzyme consortia and molecular engineering of photosynthetic microorganisms also contribute to PET degradation. Although significant progress has been made, challenges remain in enzyme stability, metabolic bottlenecks, industrial scalability, and environmental adaptation. Overall, microbial and enzymatic strategies show great potentials in addressing PET pollution, and future interdisciplinary efforts are needed to overcome these challenges and achieve a sustainable circular plastic economy.

1 Introduction

Polyethylene terephthalate (PET), renowned for its excellent physical and chemical properties, is one of the most extensively used synthetic polymers globally. Owing to its remarkable durability, versatility, and cost-effectiveness, PET has found extensive application across a diverse range of industries, including packaging, textiles, and electronics. However, the widespread use of PET has also led to a significant accumulation of plastic waste in the environment (MacLeod et al., 2021; Santos et al., 2021). PET is highly resistant to natural degradation processes, with a long half-life that can span hundreds of years in landfills, oceans, and other ecosystems (Chu et al., 2022; Zhu et al., 2024). This has given rise to severe environmental concerns, including soil and water pollution, harm to wildlife, and negative impacts on human health (Preda et al., 2024; Li Y. et al., 2024).

Current PET recycling strategies include mechanical recycling and energy-intensive chemical methods (e.g., glycolysis and hydrolysis) (Cao et al., 2022; Mahler et al., 2025; Ragaert et al., 2017), which usually require high temperatures (>200°C) and generate toxic byproducts. While thermal incineration would recover energy, it might emit CO2 and other hazardous pollutants. These approaches would also struggle with scalability, cost, and environmental trade-offs. Additionally, biological PET-degradation, especially the microbial-mediated biodegradation, has emerged as a promising and sustainable solution to address this ecological crisis (Figure 1; Mudondo et al., 2023; Bian et al., 2024). Certain microorganisms could employ endogenous enzymatic cascades to depolymerize PET into monomers (Yip et al., 2024; Yoshida et al., 2021; Barone et al., 2024), which offers a sustainable pathway to mitigate PET pollution. Therefore, understanding the metabolic pathways involved in PET biodegradation is fundamental for harnessing the full potentials of the PET-degrading microorganisms. However, the efficiency of native microbial systems usually remains constrained, such as by suboptimal enzyme activity, substrate accessibility, and inhibitory byproduct accumulation. To address these limitations, enzyme molecular engineering has emerged as a promising approach to enhance PET depolymerization by optimizing the catalytic efficiency of these enzymes (Arnal et al., 2023; Liu F. et al., 2023). Furthermore, the use of synthetic biology and metabolic engineering has further facilitated these processes, leading to significant advancements in PET biodegradation (Bian et al., 2024; Diao et al., 2023). Examples include directed evolution (Shi et al., 2023), dual-enzyme systems (Aer et al., 2024b), surface-display technologies (Xue et al., 2024), and microbial consortia (Salinas et al., 2025), which have demonstrated significant potential in overcoming critical barriers such as intermediate metabolite accumulation and hydrophobic substrate interactions.

Cell factories, the engineered microorganisms with optimized metabolic capabilities, play a crucial role in multiple key aspects (Cho et al., 2022; Qiu et al., 2023; Hussain et al., 2022; Zuo et al., 2024), such as the realm of biotechnology and industrial production, the pharmaceutical industry, the field of environmental remediation, the production of fine chemicals and industrial enzymes. Through metabolic engineering and synthetic biology approaches, the genetic makeup of chassis cells could be modified and optimized, which ensures that the cellular metabolic pathways (metabolic flux) are finely tuned. Equipped with optimal PET hydrolases and optimized metabolic pathways, the engineered cell factories would demonstrate enhanced degradation rates and sustainable utilization of the degradation products (Moog et al., 2021; Dissanayake and Jayakody, 2021; Valenzuela-Ortega et al., 2023; Schneier et al., 2024). Especially, once PET is broken down, the resulting monomers and other small-molecule products would be channeled into the well-designed biosynthetic pathways within the cells (Mubayi et al., 2024; Yang et al., 2024). For instance, the monomers can be used as building blocks for the synthesis of other high-value chemicals (Diao et al., 2024; You et al., 2023), such as specialty solvents, pharmaceutical precursors, or bio-based polymers. This not only reduces the reliance on fossil-based feedstocks but also minimizes the environmental impact associated with conventional plastic production processes. The circular plastic economy seeks to eradicate waste generation through perpetual material recycling into novel products, achieved by implementing innovative strategies for designing efficient metabolic pathways to facilitate monomer conversion. The closed-loop system created by these biological systems ensures that materials are recycled and reused, reducing waste generation and promoting environmental sustainability (Rani et al., 2024; Arijeniwa et al., 2024).

This review analyzes the current state-of-the-art in microbial-mediated PET biodegradation. It is mainly focused on the key enzymes and the metabolic pathways involved in PET degradation, and the strategies for engineering cell factories with enhanced PET degradation efficiency. Additionally, it also explores the upcycling of PET degradation products into valuable chemicals to offer a sustainable approach for plastic waste management. By presenting a detailed overview of these aspects, we hope to provide valuable insights for researchers in this field, and facilitate the development of more effective and environmentally friendly solutions for PET biodegradation.

2 Microbial-mediated degradation of polyethylene terephthalate

2.1 The extracellular process of PET bio-degradation

The process of microbial-mediated degradation of plastic polymers usually encompasses several key steps (Jaiswal et al., 2019), including biodeterioration, bio-fragmentation, assimilation, and mineralization. To achieve optimal microbial utilization for PET biodegradation, a systematic elucidation of metabolic mechanisms must integrate genomic engineering, enzymatic optimization, and ecological synergy. This will guide strategies to engineer microbial platforms with dual catalytic and PET upcycling capabilities, which paves the way for innovative plastic-to-value conversion systems.

2.1.1 The process of microbial attachment and colonization

During the process of microbial-mediated PET biodegradation, microorganisms must firstly be able to adhere to and proliferate on the surface of PET plastic, which is achieved through a combination of biological and physicochemical mechanisms. For example, specific species within the genus Bacillus and Pseudomonas exhibit an affinity for polymers like PET. Moreover, they usually possess the ability to form biofilms on the surfaces of PET materials, which would allow them to persist and colonize surfaces (Skariyachan et al., 2017; Sivan et al., 2006). This is a crucial step in the biodegradation process. In Bacillus species, the formation of biofilms is usually regulated by the two-component signal transduction systems (TCSs) (Ducret et al., 2022), which are typically composed of a sensor histidine kinase (HK) and a response regulator (RR).

Furthermore, it was found that several factors are capable of regulating the surface-attachment process, which can influence how microorganisms or the enzymes interact with surfaces. The hydrophobins (HPs), a kind of small secreted surface-active proteins, could also mediate fungal attachment to hydrophobic surfaces like PET (Terauchi et al., 2022; Sánchez, 2020). In light of this, HPs may serve as effective substrates to enhance microbial adhesion, particularly for strains expressing surface-displayed PET-degrading enzymes, thus significantly improving enzymatic degradation efficiency. Moreover, the implementation of chimeric anchor motifs (e.g., Bacillus subtilis-derived LCI modules) also enables precision immobilization of enzymatic machineries on PET matrices through affinity-driven molecular recognition (Liu Y. et al., 2024). This would establish a bioengineered interface that amplifies substrate-enzyme dynamics and potentiates depolymerization within catalytic microenvironments. Additionally, exopolysaccharides also play roles in the attachment, biofilm adhesion and biodeterioration of plastic polymers (A et al., 2020). Manipulating the levels of the second messenger molecule (cyclic-di-GMP), which regulates biofilm formation, has been demonstrated to significantly enhance the plastic degradation rates (Howard and McCarthy, 2023). The introduction of diguanylate cyclases (DGCs) into Escherichia coli strains expressing PET-degrading enzymes resulted in a notable increase in polyester degradation, which highlights that adjusting biofilm levels can boost enzyme efficacy.

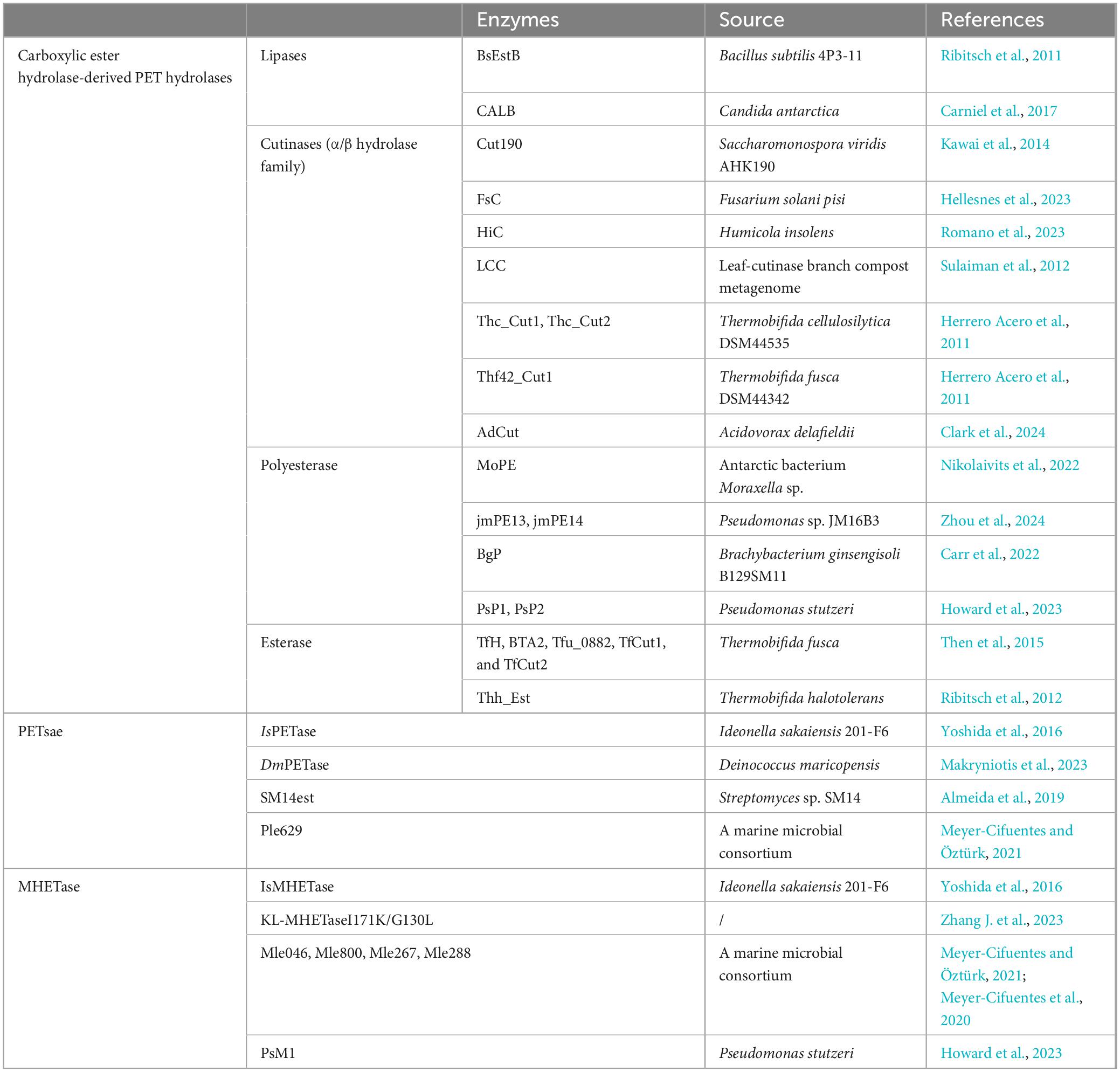

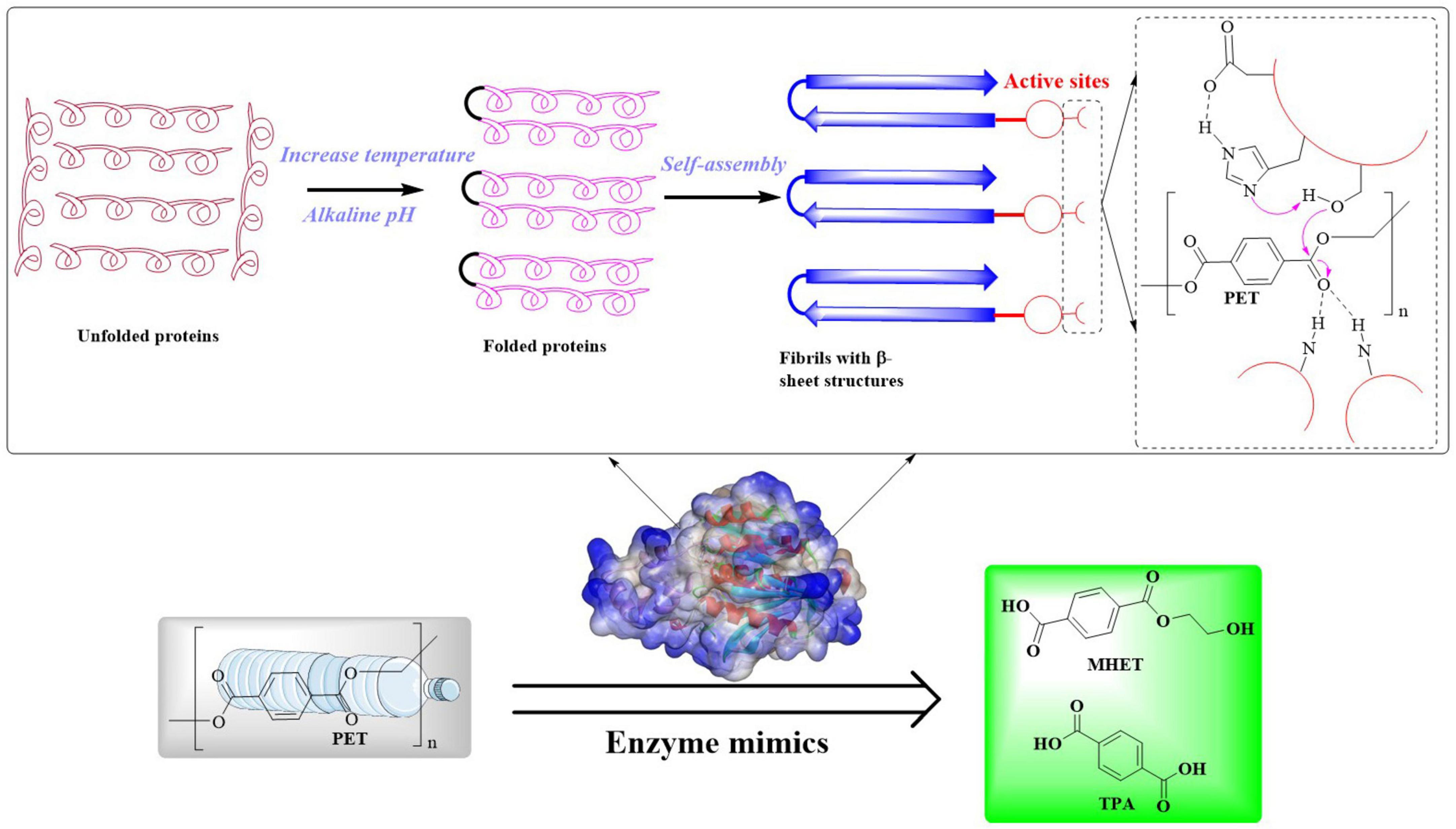

2.1.2 The process of direct PET-depolymerization

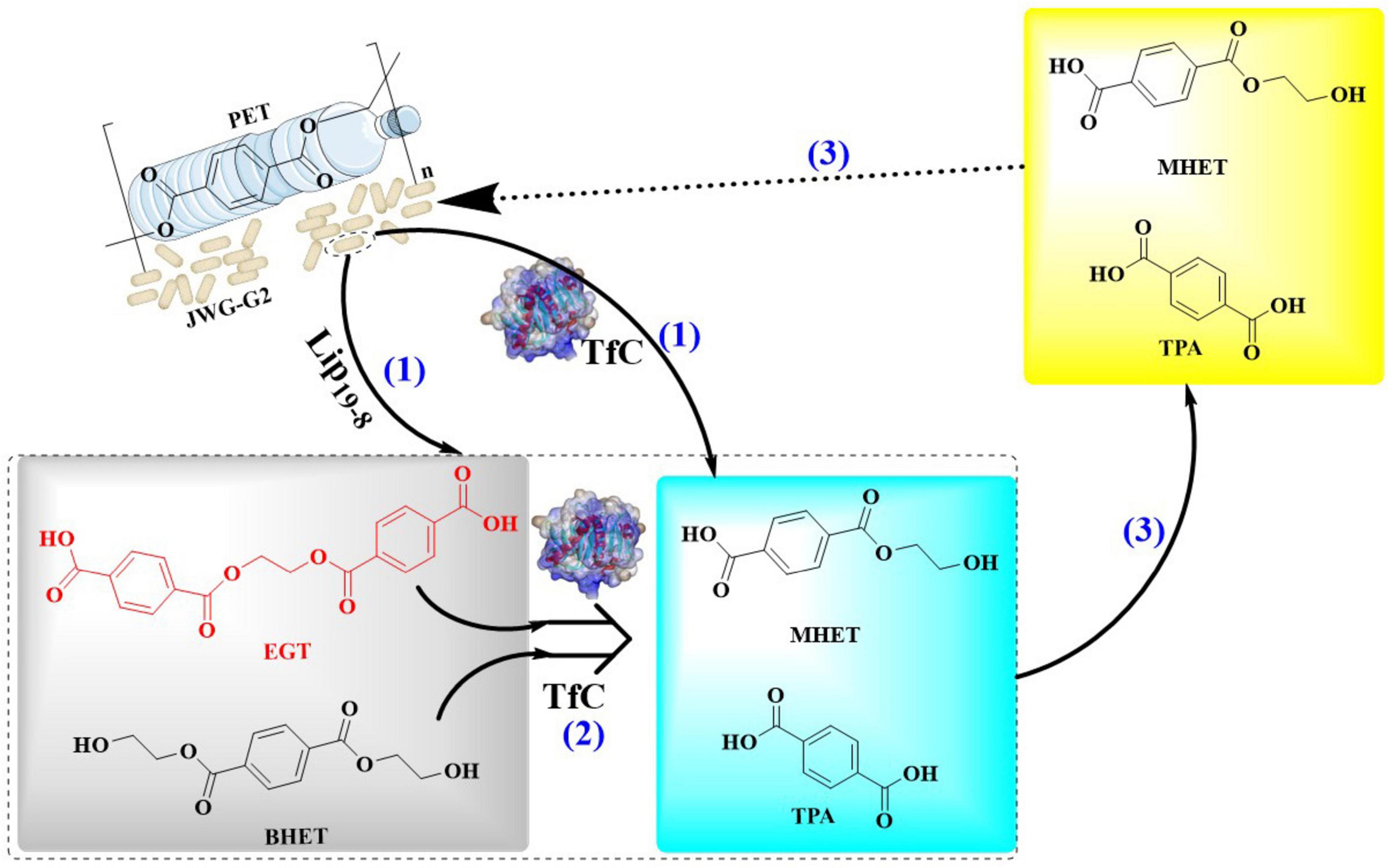

After adhering to the surface and establishing colonization, microorganisms are likely to actively secrete extracellular PET-degrading enzymes specifically bound to PET surfaces, thereby facilitating the biodegradation process. In this stage, two different catalysts would be produced (Table 1) (Kawai et al., 2019): the surface modification enzymes (associated with enzymatic modification of PET to increase the surface hydrophilicity) and the PET-degrading enzymes (capable of directly breaking the ester bonds within the PET polymer releasing monomeric products). PET hydrolases and surface modification enzymes play distinct roles in PET biodegradation. PET hydrolases (e.g., IsPETase) directly cleave ester bonds in PET, depolymerizing it into soluble monomers like terephthalic acid (TPA), ethylene glycol (EG), mono(2-hydroxyethyl) terephthalate (MHET), and Bis(2-hydroxyethyl) terephthalate (BHET). These enzymes usually exhibit catalytic triads (e.g., S160-D206-H237 in IsPETase) and structural adaptations (e.g., disulfide bridges) for substrate binding and hydrolysis. In contrast, surface modification enzymes (e.g., lipases and carboxylesterases) enhance PET hydrophilicity by weakening intermolecular forces, reducing mechanical strength, and increasing water affinity. While hydrolases target chemical bonds, surface modifiers precondition the polymer physically, enabling efficient depolymerization by hydrolases. Lipases, carboxylesterases, and most cutinases exhibit surface modification capabilities that reduce PET strength by weakening intermolecular forces. This would compromise mechanical properties while accelerating degradation susceptibility. For example, lipase from Aspergillus oryzae was used as a catalyst for enzymatic modification of PET fabric combined with polyethylene glycol (PEG), which showed that the water contact angle (WCA) of the treated fabric was significantly reduced from 129.3° to 74.9°, while the moisture regain increased to 3.52% (Liu W. et al., 2024). The lipase from Thermomyces lanuginosus was also successfully used for the biodegradation of PET fabrics/films combined with cutinases from Thermobifida fusca and Fusarium solani (Eberl et al., 2009). In addition to surface-modification, the lipase B from Moesziomyces antarcticus (CALB) was also found to be capable of efficiently converting BHET to MHET and subsequently MHET to TPA and EG (Carniel et al., 2017).

On the contrary, a limited number of cutinases and the PETase have been recognized as the PET-degrading enzymes (or named as PET hydrolases), which are capable of breaking down PET directly into smaller, water-soluble molecules. The cutinase, such as T. fusca cutinase (TfCut2) (Mrigwani et al., 2023), F. solani pisi cutinase (FsC) (Hellesnes et al., 2023), leaf-branch compost cutinase (LCC) (Sulaiman et al., 2012) or their mutants (Tournier et al., 2020; Hong et al., 2023), have all been successfully applied for PET hydrolysis. For instance, the thermostable variant of LCC (LCCICCG) demonstrated exceptional catalytic efficiency, and it was able to degrade 90% of the pretreated PET bottles within 10 h (Tournier et al., 2020). In addition, the recently identified mesophilic IsPETase and MHETase from Ideonella sakaiensis 201-F6 have drawn great attentions (Yoshida et al., 2016), which could catalyze the biodegradation of low-crystallinity (1.9%) PET film at room temperature (30°C). Though IsPETase displays a lower PET-degrading activity than cutinase or cutinase-like PET-degrading enzymes, it provides a more environmentally friendly and energy-saving alternative for PET recycling. On this basis, various PETase mutants have been developed with better catalytic performance, and increased thermostability such as HotPETase (Bell et al., 2022), DuraPETase (Cui et al., 2021), Fast-PETase (Lu et al., 2022), TS-PETase (Zhong-Johnson et al., 2021), ThermoPETase (Francis et al., 2019) and the fused protein with the carbohydrate-binding module (CBM) (Dai et al., 2021; Wang T. et al., 2024) or hydrophobin (HFBI) (Chen et al., 2022).

It is important to highlight that the intermediates and final products of PET degradation (e.g., BHET and MHET) have been identified as competitive inhibitors of PET hydrolases (Barth et al., 2015a). Especially, during the hydrolysis of PET, MHET tends to accumulate to a greater extent than BHET, moreover MHET exhibits a strong affinity for the catalytic site of PET hydrolases (Barth et al., 2015b). Therefore, the accumulation of MHET would significantly impede the efficiency of enzymatic PET depolymerization. Consequently, the ongoing removal of soluble metabolites of PET-degradation is essential for overcoming competitive inhibition (Kushwaha et al., 2022).

Thermostable cutinases like LCCICCG exhibit exceptional thermostability and display improved catalytic efficiency on semi-crystalline PET, which made them ideal for the industrial-scale processes requiring high-temperature pretreatment. In contrast, mesophilic PETase (e.g., IsPETase) are found to be capable of being operated at ambient temperatures (30°C) but suffered from low activity and poor stability, which might limit its industrial viability. However, its energy-saving potential makes it environmentally advantageous for in situ remediation (Mrigwani et al., 2023). Advanced PETase mutants (e.g., DuraPETase and Fast-PETase) now enable gap closure through optimized mesophilic functionality (35°C) coupled with 4.2-fold increased degradation rates compared to wild-type enzymes.

2.2 Microbial-mediated biodegradation pathway of PET

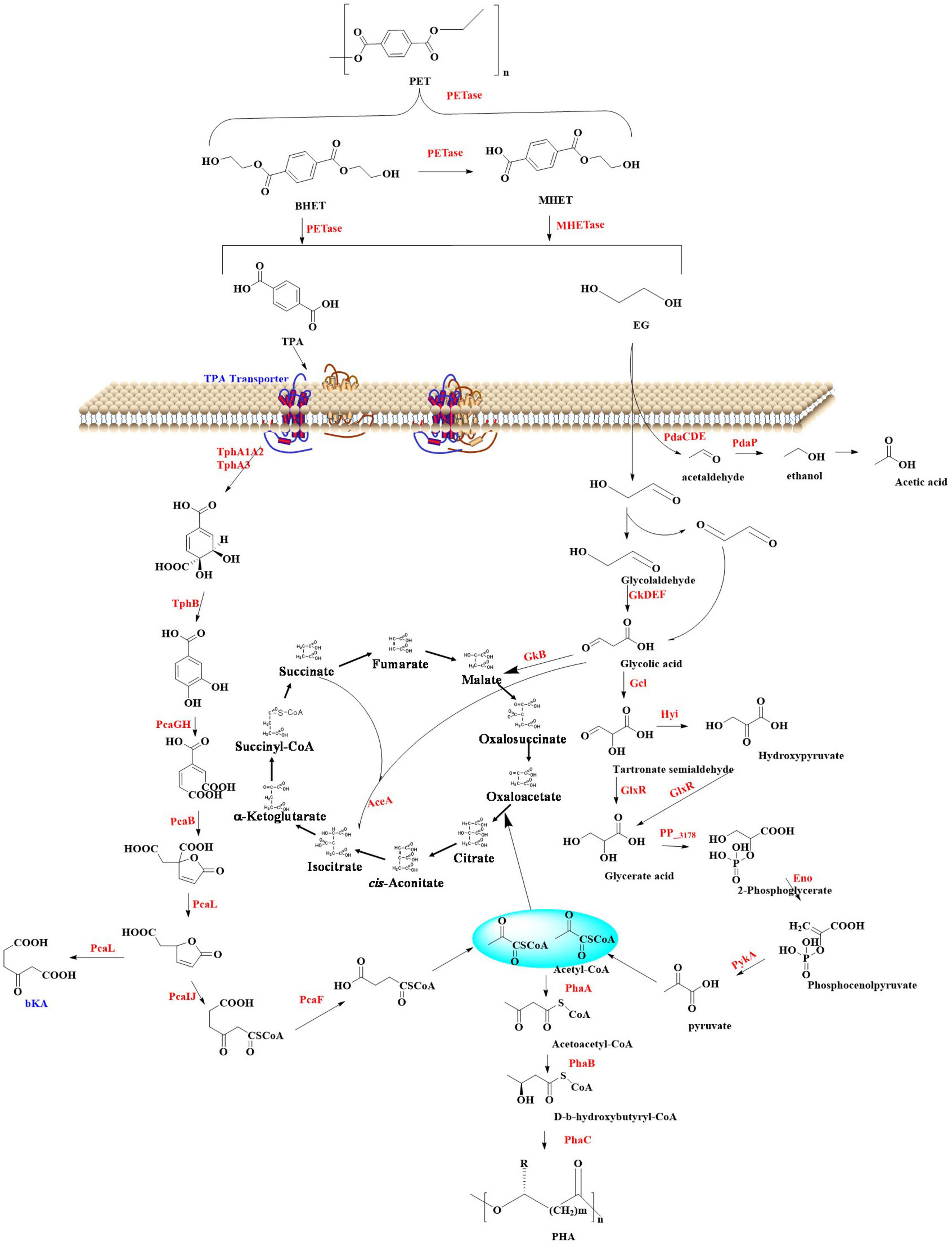

The extracellular enzymatic hydrolysis of PET begins with the cleavage of ester bonds through enzymatic action, yielding aromatic intermediates such as TPA, BHET, MHET, and EG. This initial depolymerization phase constitutes the kinetic bottleneck in PET decomposition. The released depolymerization products (primarily TPA and EG) undergo sequential internalization and catabolism through microbial peripheral metabolic pathways (Kushwaha et al., 2022; Gao et al., 2022; Qi et al., 2021b). This process drives cellular proliferation by redirecting carbon flux within metabolic networks, ultimately sustaining biomass synthesis through optimized carbon allocation strategies. Ultimately, biodegradation achieves complete mineralization through coordinated metabolic pathways. In this process, organic substrates are fully oxidized into inorganic end-products (CO2 and H2O) via the tricarboxylic acid (TCA) cycle and associated intracellular redox mechanisms. This process could be illustrated by Figure 2 (Kushwaha et al., 2022; Gao et al., 2022; Qi et al., 2021b).

Figure 2. Polyethylene terephthalate metabolic pathways and its conversion into high value chemicals.

2.2.1 The metabolic pathways of TPA

Terephthalic acid is taken up by microorganisms through specific transporters such as the MucK in Acinetobacter baylyi ADP1 (Pardo et al., 2020). Once inside the cell, TPA would be catabolized via the protocatechuate (PCA) 4,5-cleavage pathway (Sasoh et al., 2006; Fukuhara et al., 2008). In this process, genes responsible for TPA degradation are situated within two nearly identical clusters: tphRICIA2IA3IBIA1I and tphRIICIIA2IIA3IIBIIA1II. The genes (tphR, tphC, tphA2, tphA3, tphB, and tphA1) are anticipated to encode for the IclR-type transcriptional regulator, the TPA binding receptor, the large subunit of the oxygenase component of TPA 1,2-dioxygenase (TPADO), the small subunit of the oxygenase component of TPADO, a 1,2-dihydroxy-3,5-cyclohexadiene-1,4-dicarboxylate dehydrogenase (DCDDH), and a reductase component of TPADO, respectively. The TPADO is capable of converting TPA into 1,2-dihydroxy-3,5-cyclohexadiene-1,4-dicarboxylate, which would be further converted into protocatechuic acid (PCA) catalyzed by DCDDH. The PCA is then ring-cleaved by PCA 3,4-dioxygenase (P34Os) (Guzik et al., 2014), and the resulting products are further metabolized into acetyl-CoA entering the TCA cycle for further oxidation and energy production. Some microorganisms (e.g., Blastobotrys (Arxula) adeninivorans) is capable of decarboxylating PCA by the gallic acid decarboxylase (Agdc1p) (Meier et al., 2017). The catechol-1,2-dioxygenase (Acdo1p) in Blastobotrys raffinosifermentans is determined to be associated with the catabolism of PCA (Meier et al., 2022). It was also found that overexpression of catechol-1,2-dioxygenase (ACDO1) in B. raffinosifermentans resulted in a faster conversion of catechol to cis,cis-muconic acid, which revealed that ACDO1 is probably associated with the PCA degradation. Furthermore, aromatic compounds such as PCA are primarily metabolized through the β-ketoadipate pathway in microorganisms. This pathway facilitates the sequential conversion of PCA into acetyl-CoA and succinyl-CoA, which serve as key intermediates for integration into the TCA cycle to drive energy production and biosynthetic processes. Representative microbial species capable of executing this metabolic route include Rhodococcus opacus PD630 (Navas et al., 2021) and Aspergillus niger (Sgro et al., 2023), both of which exhibit robust aromatic degradation capacities with potential applications in bioremediation and bio-industrial synthesis. Specially, in Rhodococcus jostii RHA1, a second degradation pathway for PCA was identified, which leads to the formation of hydroxyquinol (benzene-1,2,4-triol) (Spence et al., 2020). The gene cluster (ro01857-ro01860) is crucial for the degradation of PCA and it is predominantly composed of genes that encode for hydroxyquinol 1,2-dioxygenase and maleylacetate reductase. The former catalyzes the ring-cleavage of hydroxyquinol to produce maleylacetate, while maleylacetate reductase further converts maleylacetate into 3-oxoadipate. Additionally, in this cluster another two genes are hypothesized to encode a mono-oxygenase (ro01860) and a decarboxylase (ro01859).

2.2.2 The metabolic pathways of EG

For EG, it could be directly metabolized into the Krebs cycle by certain microorganisms such as Pseudomonas putida via isocitrate (Li et al., 2019; Hosseinpour et al., 2016). In P. putida, this is a multi-step process, including the following critical steps: initial oxidation step, conversion to glycolic acid, generation of glyoxylic acid, and finally entry into the Krebs cycle. The alcohol dehydrogenase (ADH) plays a crucial role in the oxidation of EG, which is capable of oxidizing EG to glycolaldehyde (GA), a more reactive aldehyde intermediate. Then, GA will be catalyzed into glycolic acid catalyzed by the aldehyde dehydrogenase (ALDH). Subsequently, glycolic acid is converted to glyoxylic acid, a precursor for entry into the Krebs cycle, which is catalyzed by glycolate oxidase (GOX). Finally, the glyoxylic acid enters the Krebs cycle through the glyoxylate shunt, and this process is mainly facilitated by isocitrate lyase and malate synthase. Isocitrate lyase is capable of cleaving isocitrate (a Krebs cycle intermediate) to form glyoxylate and succinate, and the malate synthase then combines glyoxylate with acetyl-CoA to generate malate. This enzymatic process allows EG to be incorporated into the central metabolic pathway, where it would be further oxidized and utilized to generate energy in the form of ATP and reducing equivalents (e.g., NADH and FADH2).

Escherichia coli also has the capability of metabolizing EG (Shimizu and Inui, 2024). In E. coli, EG is firstly oxidized to GA catalyzed by propanediol oxidoreductase encoded by the fuco gene. Then, GA is further oxidized to glycolic acid by glycolaldehyde dehydrogenase with NAD and NADP as coenzymes. Subsequently, the glycolic acid would be metabolized via the glycolate pathway generating the final product glyoxylic acid, which mainly catalyzed by the glycolate oxidase. Finally, the glyoxylic acid will enter the Krebs cycle through the glyoxylate shunt similar to that found in the P. putida.

3 Strategies for the development of promising chassis cells for PET-degradation

3.1 Cell surface display utilized for PET-biodegradation

Cell surface display technology is a robust genetic engineering approach that facilitates the targeted anchoring of functional proteins or peptides onto microbial cell membranes through genetic engineering approaches, with applications spanning both prokaryotic and eukaryotic organisms. Its versatility stems from the ability to maintain the structural integrity and biological activity of displayed biomolecules while enabling direct interaction with extracellular environments, which makes it particularly valuable for applications ranging from whole-cell biocatalysis to environmental bioremediation and biomedical engineering. Consequently, this section highlights the strategic integration of cell surface display systems in engineering microbial catalysts for enhanced PET biodegradation, establishing this approach as a versatile platform bridging fundamental research and industrial applications.

3.1.1 Application of the surface-displayed PETase in E. coli

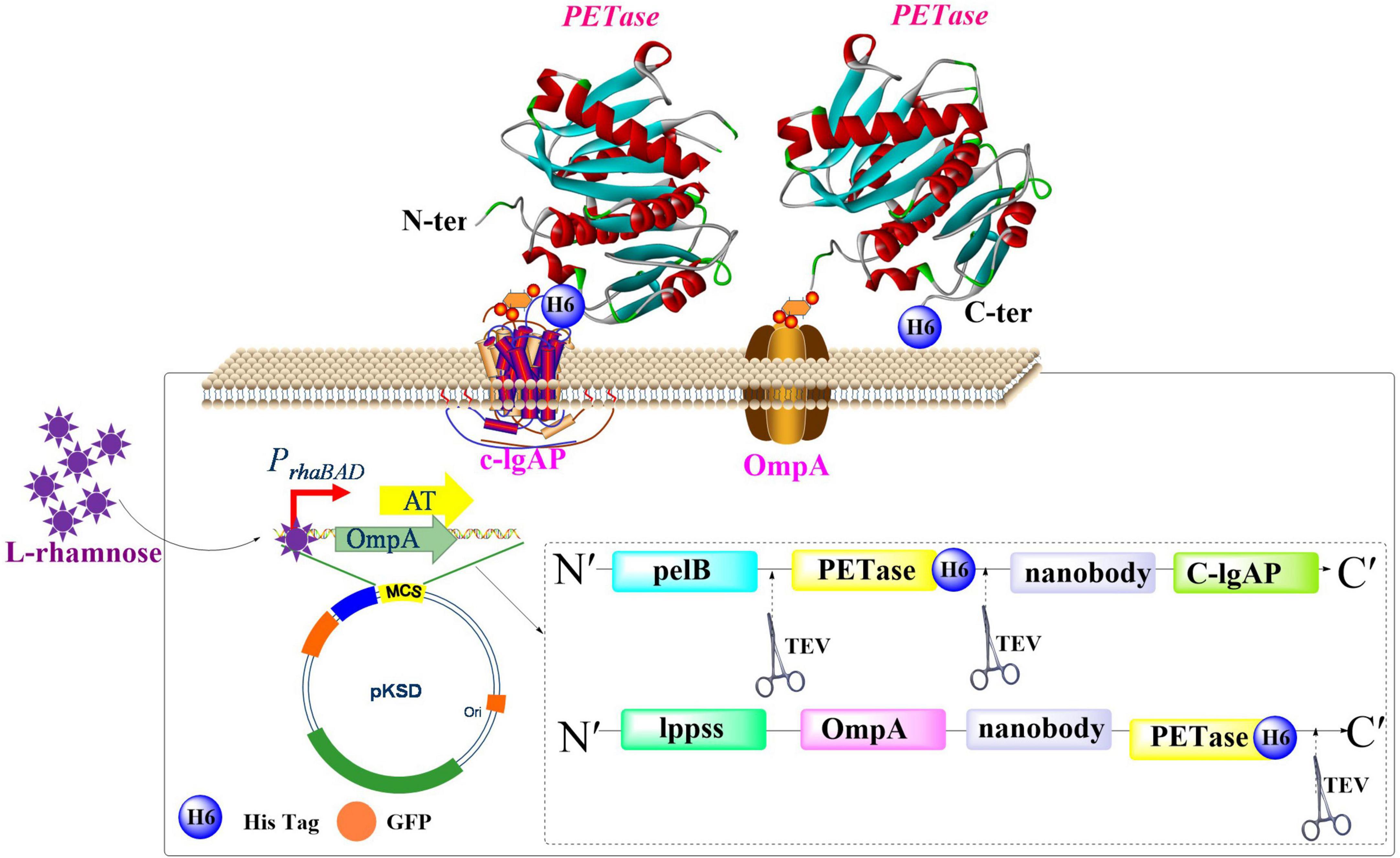

Heyde et al. (2021) proposed an efficient screening method for identifying enzymes that act on PET with surface display technology utilized in E. coli (Figure 3). Performance of two different membrane anchors were investigated for displaying IsPETase: C-IgAP from Neisseria gonorrhoeae and an Lpp-OmpA fusion protein from E. coli. Results indicated that Lpp-OmpA was more effective for displaying IsPETase, which displayed a PET-degrading activity comparable to 20 nM free IsPETaseAustin. Furthermore, the fused GFP-nanobody, acting as a surrogate marker for assessing enzyme activity on the cell surface, significantly improves the efficiency of high-throughput screening strategies for identifying PET-degrading enzyme. In a separate investigation, researchers engineered E. coli to co-display HotPETase and a β-glucan-specific carbohydrate-binding module (BaCBM) through a truncated outer membrane hybrid protein (FadL) anchoring system, which creates regenerable whole-cell biocatalysts with enhanced operational stability for PET biodegradation (Wang T. et al., 2024). This system showed enhanced PET-degradation efficiency, reusability and stability, which could produce 1.03 mM of water-soluble products, retain activity after ∼100 h at 40°C, and maintain ∼54.6% of its initial activity after nine cycles.

Figure 3. Schematic illustration of the surface display modules for heterogeneous IsPETase expression.

To achieve the purpose of efficient display of PETase, identification and design of powerful anchoring motifs is highly important. To date, several passenger proteins have been shown to be suitable for surface display of target protein. For example, PgsA, from B. subtilis, was shown to be capable of presenting active PETase on the cell surface of E. coli (Yamashita et al., 2024). YeeJ, a new inverse autotransporter in E. coli, has also been successfully utilized for surface display of PETase in E. coli UT5600 (Gercke et al., 2021). Moreover, it was found that the cell-displayed PETase in combination with externally supplied rhamnolipids displayed improved PET-degrading performance (increased by ∼16-fold) compared with the free PETase. Notably, the system demonstrated efficient degradation of highly crystalline post-consumer PET bottles (initial crystallinity: 34.4%), which results in a remarkable reduction to 8% residual crystallinity within 3 days under mild conditions (25°C). The whole-cell biocatalyst system featuring surface co-display of high-affinity adhesive proteins (cp52k from the stalked barnacle Pollicipes pollicipes and mfp-3) and Fast-PETase has been successfully constructed in E. coli to enhance PET biodegradation efficiency (Hu and Chen, 2023). The ice nucleation protein (INP), a structurally characterized outer membrane protein derived from Pseudomonas syringae, has also been extensively employed as an anchoring scaffold to enable effective surface display of fused functional proteins (Ramezani Khorsand et al., 2024). This application leverages its modular architecture comprising N-terminal membrane-anchoring domains, repetitive central β-helical motifs for water interaction, and C-terminal aggregation interfaces.

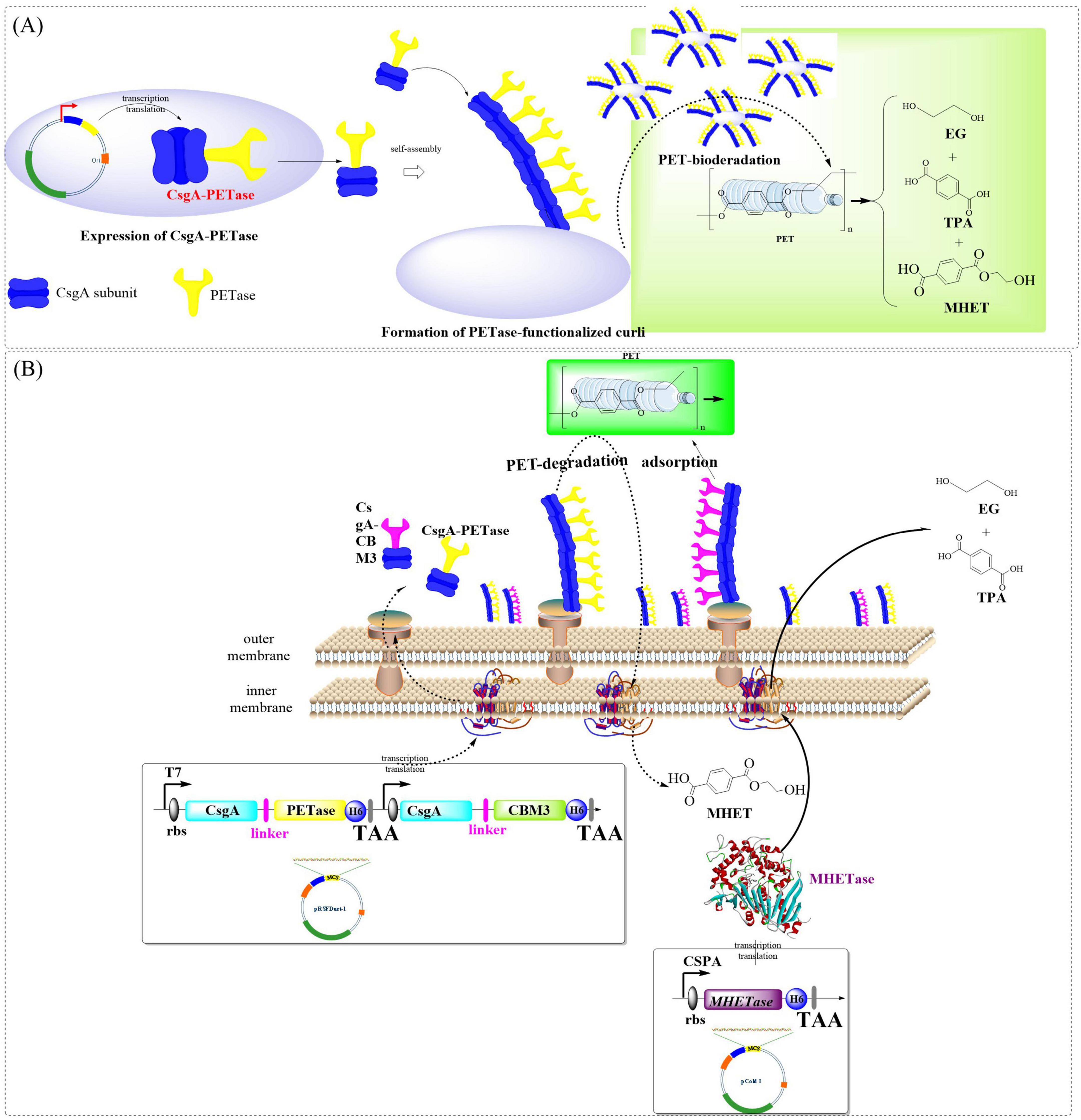

Curli, composed of self-assembling CsgA monomers, is capable of forming β-sheeted nanofibers covering the bacteria, which might be also utilized to facilitate the secretion and display of catalytic enzymes (Sleutel et al., 2023; Zhang X. et al., 2023). Recently, a proposal has been put forward to engineer the curli of E. coli by fusing CsgA with IsPETase for PET degradation (Zhu et al., 2022). The fused CsgA-PETase was capable of forming functional PETase-coated curli nanofibers on the surface of E. coli PHL628, which resulted in the formation of whole-cell biocatalyst (BIND-PETase, Figure 4A). BIND-PETase exhibited an impressive activity of 966 ± 29 U/g and demonstrated remarkable stability even after 30 days at both 4°C and room temperature. However, it is worth noting that its activity dropped to 55% after only three cycles. BIND-PETase could effectively degrade PET microplastics in wastewater and depolymerize post-consumer PET releasing TPA and MHET (total of 4.3 mM after 15 days, and 3.3 mM after 7 days, respectively). Especially, the degrading performance could be further improved by 22.1% with addition of 0.02% STS. Similarly, fusing CsgA and PETases to E. coli Nissle 1917 (EcN) resulted in a 10-fold increase in PET-degrading activity (Wang C. et al., 2024) compared to that from Zhu et al. (2022). Among the obtained whole-cell catalysts, EC-FastPETase shows the highest activity in PET film degradation [3.0 ± 0.073 mg/(d × cm2)] with a total product of 11.4 ± 0.3 nM. Especially, co-display of CBM3 and EC-FastPETase significantly promoted biofilm formation and cell adsorption resulting a 35% increase in degrading activity (3.4 ± 0.148 mg/(d × cm2), yield 1.5 ± 0.1 mM). This reaction system was also capable of effectively degrading PET film and microplastics, releasing 12.7 ± 0.2 mM TPA and 1.65 ± 0.05 mM MHET. In addition, it could catalyze the transformation of 10 and 100 μm PET microplastics into TPA (11.14 ± 0.12 and 8.38 ± 0.1 mM), with degradation efficiencies of 21.40% and 16.09%, respectively. The improved catalytic efficiency could be partially attributed to the enhanced secretory capacity of extracellular proteins. More significantly, the strategic intracellular co-expression of MHETase coupled with surface-displayed CBM3 synergistically enhanced both substrate accessibility and metabolic processing of PET polymers (Figure 4B). This integrated enzymatic configuration demonstrated remarkable catalytic enhancement, achieving a 10- to 20-fold greater degradation efficiency for BHET compared to the conventional free enzyme systems.

Figure 4. Schematic illustration of the engineered curli of E. coli by fusing CsgA with IsPETase for PET degradation. (A: Construction of the whole-cell biocatalyst BINDPETase; B: strategic intracellular co-expression of PETase coupled with surface-displayed CBM3).

3.1.2 Application of the surface-displayed PETase in yeast cells

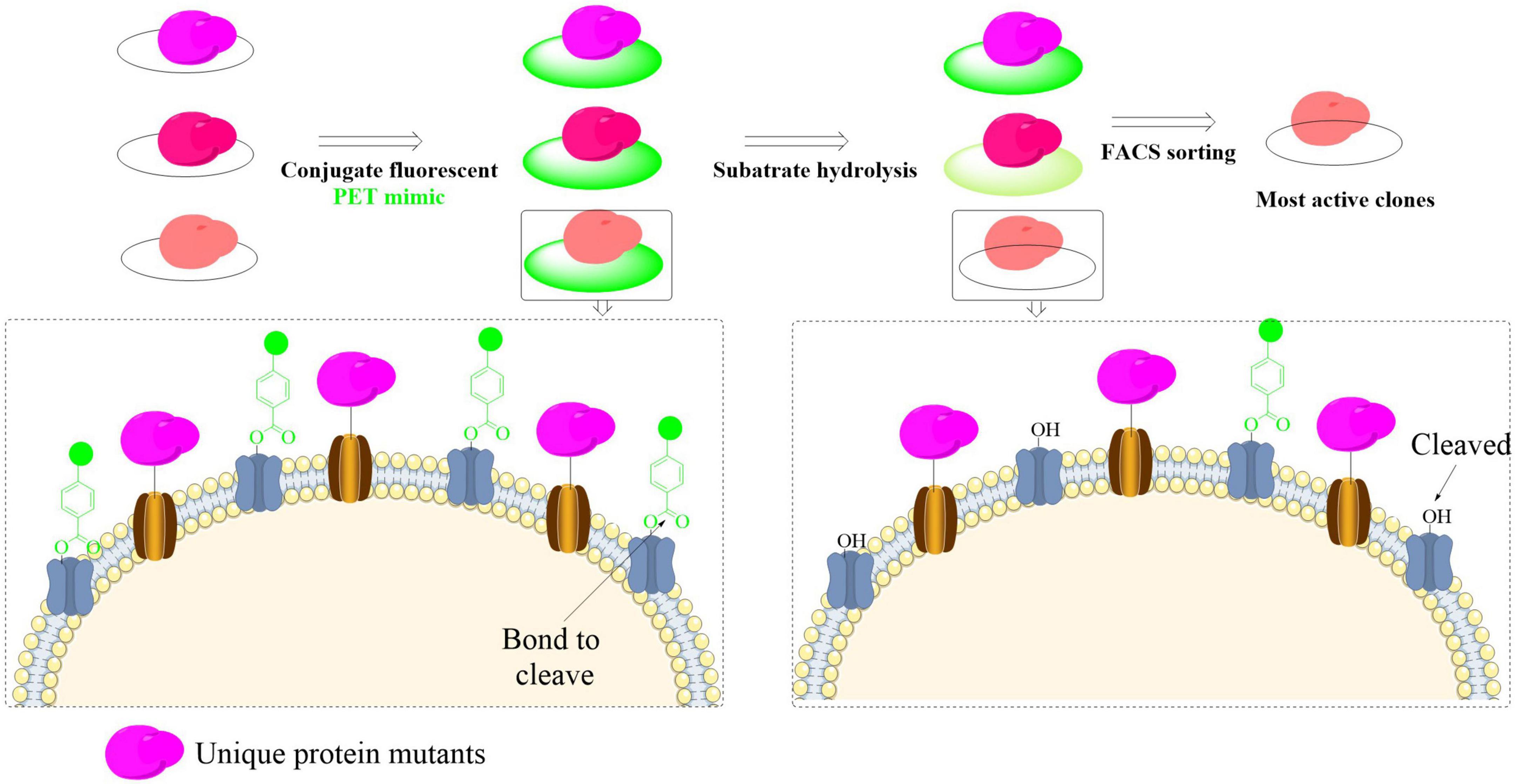

A state-of-the-art yeast surface display system with ultra-high-throughput capabilities has recently been engineered to streamline the discovery and functional characterization of PET-hydrolyzing enzymes (Cribari et al., 2023). The system demonstrates exceptional efficiency in enzyme evaluation through simultaneous display of multiple enzyme variants on yeast cell surfaces, allowing quantitative assessment of binding interactions and catalytic performance without requiring protein purification. It involves three critical steps: design of a PET-mimicking probe for yeast surface display, utilization of fluorescent streptavidin to label unhydrolyzed probes, and use of the fluorescence activated cell sorting (FACS) to identify and obtain high-activity catalysts (Figure 5). Using this method, a library of 2.7 million yeast clones was screened, especially it was found that mutations at H218 could enhance PET-degrading activity. This was further confirmed by the mutant H218Y with significantly increased PET degradation (by approximately twofold). The observed improvement arose via two synergistic effects: (1) direct non-covalent interactions of Y218 with the PET substrate, and (2) the subsequent enhancement in enzyme-substrate binding affinity. However, while surface-displayed PETase demonstrates remarkable catalytic turnover enhancement, studies have revealed critical limitations in practical implementation of whole-cell catalysts that exhibit optimal functionality only at extremely low concentrations (typically < 0.1 mg/L) (Chen et al., 2020). This concentration-dependent performance constraint, particularly evident in heterogeneous catalytic systems, poses significant challenges for scaling up PET biodegradation processes in real-world environments where high catalyst loading and operational stability are essential. Overall, this strategy could efficiently address critical limitations in traditional PETase screening methods that often rely on surrogate soluble substrates. Moreover, it also enables precise control over enzyme-substrate ratios through cell-surface engineering strategies.

Figure 5. Schematic illustration of the high-throughput yeast surface display platform for efficient identification and evaluation of PET-degrading enzymes.

It must be noted that the N-linked glycosylation might pose negative effects on the P. pastoris-expressed recombinant protein (Han et al., 2020; Huang et al., 2013). It was estimated that N-glycosylations in eukaryotic expression systems could interfere with the bio-activity of prokaryotic genes. This is extremely true for the recombinant IsPETase and BurPL expressed in P. pastoris, although the decreased catalytic activities could be further restored by de-glycosylation treatment or mutagenesis (Chen et al., 2021). Similarly, it was also found that N-glycosylation at N181 in CtPL-DM, a PET-degrading enzyme from Caldimonas taiwanensis, would significantly reduce its catalytic activity when expressed in P. pastoris (Li et al., 2023b). This might result in a putative N-glycosylation site N181, which restrained the conformational change of the substrate-binding Trp. However, the catalytic activity could also be restored by removing the N-glycosylation such as through the N181A mutation. Further de-glycosylation at additional sites (N181A, N220A, and N261A) show little effect on the performance of N181A, which further underscores the importance of the residue N181. Based on these findings, performance of N181A was further enhanced via molecular engineering. The resulting CC mutant (CtPL-DMR230C/S284C) and the CtPL-DMN181A/F235L mutant showed over 60% and ∼20% increased PET-degrading activity at 60°C, respectively. Notably, CC variant demonstrated higher catalytic activity at elevated temperatures, with a 2.5-fold increase at 70°C compared to 60°C. After 5 days, the CtPL-DMN181A/F235L-mediated degradation of amorphous GfPET film and reinforced PET resulted in a total of monomeric products of ∼5 mM and 0.8 mM at 50°C, respectively.

The structural incompatibility between yeast glycosylation machinery and bacterial enzymes poses functional challenges in heterologous expression systems. Specifically, yeast platforms (e.g., Yarrowia lipolytica) exhibit yeast-specific N-glycosylation patterns that might disrupt the folding and catalytic activity of bacterial-derived PET hydrolases like IsPETase. The industrial-scale implementation of microbial PET degradation systems also encounters significant technical challenges, primarily stemming from ineffective maintenance of extracellular pH levels that severely impair enzymatic functionality and catalytic stability. This issue could be compounded by undesirable metabolic flux diversion toward ethanol accumulation and non-productive byproduct biosynthesis pathways. To address these challenges, codon optimization, utilization of glycosylation-reduced strains, and fed-batch fermentation strategies optimized for PETase production would be prioritized.

3.1.3 Application of the co-display systems in engineered cells

Recently, a novel strategy was proposed involving the surface co-display of engineered PETase variants and MHETase on both E. coli and P. putida platforms (Figure 6; Xue et al., 2024). Fluorescence quantification identified YfaL as the most efficient autotransporter among the tested variants (YfaL, YeeJ, Aom, and EstP), which exhibits a 4.2-fold higher signal intensity compared with that of YeeJ. It is further confirmed that the engineered strains co-displaying DuraPETase and MHETase exhibited enhanced biocatalytic activity against both BHET and PET substrates, especially the strain PD5 achieves exceptional BHET degradation rates over 1 mM/h. Especially, critical evaluation of catalytic kinetics revealed DuraPETase as the rate-limiting enzyme governing PET depolymerization efficiency in the dual-enzyme cascade system. Therefore, to enhance the surface display of DuraPETase, two distinct strategies were implemented. The initial experimental setup involved two genetically engineered bacterial strains: UTD1 (lacking the outer membrane protease OmpT, a key virulence factor implicated in host cell adhesion and antimicrobial peptide degradation) and ELD1 (with an inactivated lpp gene to promote enhanced outer membrane vesicle production, a modification associated with compromised envelope integrity). Second, molecular chaperones were co-expressed under inducible promoters in strains ECD1 and ELCD1. These strategies significantly improved the PET-degrading activities, especially co-expression of chaperones in ECD1 resulted in the highest catalytic activity, achieving 1.82 mM/h on BHET and 0.302 mM/day on PET powder. However, combining all strategies in strain ELCD1 did not yield higher activity as expected, which highlights the complexity of optimizing surface display efficiencies. Based on these, engineering of the YeeJ translocator domain resulted in mutant E9D1 (YeeJI42F/K105N/K106N/D116G/S294G/N78S/E293V) and E33D1 (YeeJI42F/K105N/K106N/D116G/S294G/N197K/D358C), which displayed significantly higher PET degradation rates. It is suggested that reduced chain length and interaction forces were capable of facilitating secretion efficiency. For example, disruption of the salt bridge (N78S/E293V) in E9D1 increased β-barrel conformational entropy to enhance substrate threading, while charge-swap mutations (N197K/D358C) in E33D1 electrostatically dilated the translocation pore by 2.1 Å. These synergistically optimized the secretory flux. Especially, strain EC9F exhibited a remarkable PET degradation rate of 3.85 mM/day, with a 51-fold increase over the initial strain ED1. Under the optimal conditions, this dual-enzyme cascade system achieved the highest reported PET degradation rate of 4.95 mM/day.

Figure 6. Graphic representation of surface co-display platforms with engineered PETase and MHETase on both E. coli and P. putida.

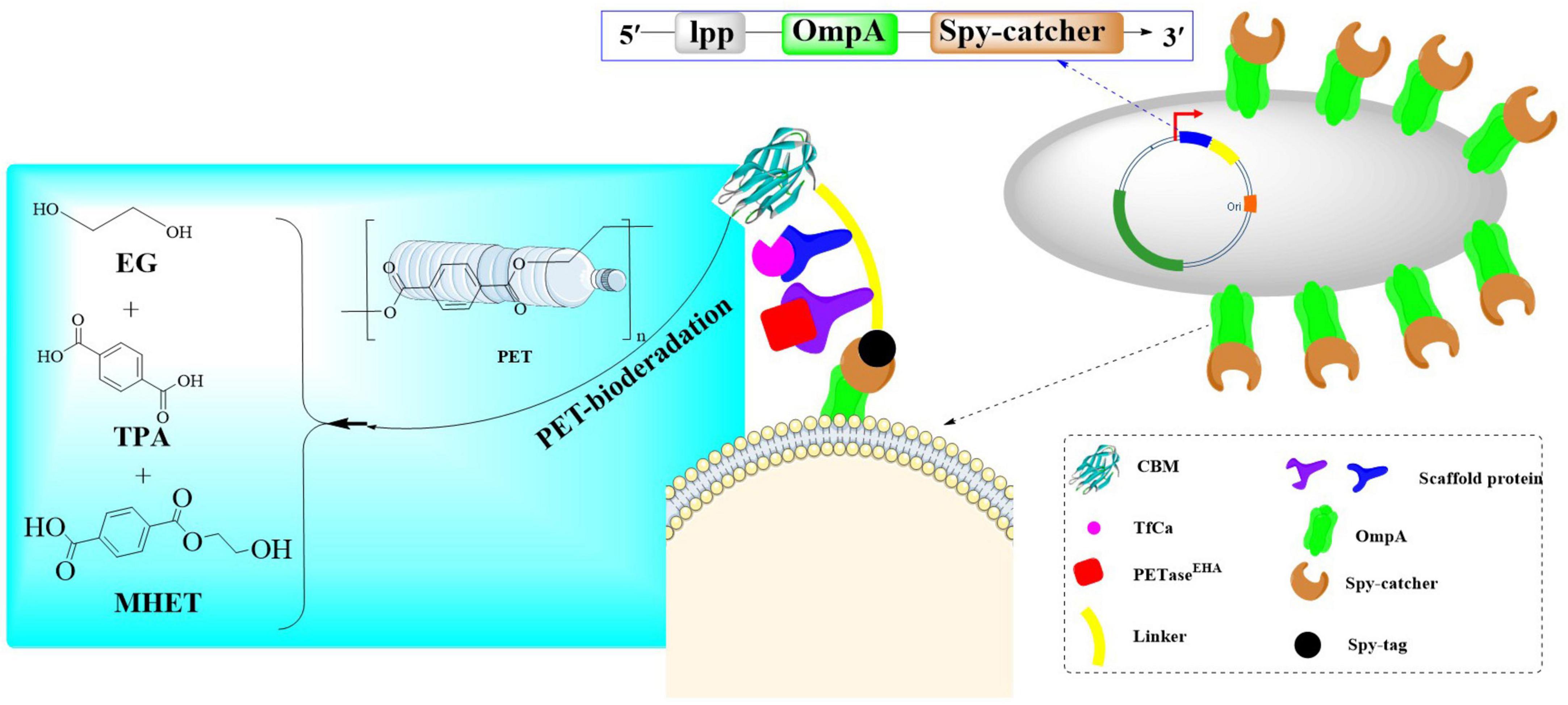

Recently, a PT-EC enzymatic consortium was engineered in E. coli BL21(DE3) through a modular assembly strategy incorporating the dual-mutant LCCF242A/D238C variant, TfCa carboxylesterase, and crystalline cellulose-binding module CBM3, which exhibits a 2.7-fold enhancement in polyethylene terephthalate (PET) depolymerization efficiency compared to conventional enzymatic systems (Aer et al., 2024a). The system strategically employs a biomimetic cellulosome-inspired scaffolding architecture, which combines a chimeric cohesin-TB hybrid scaffold with heterologous dockerin domains to establish a spatially organized multi-enzyme assembly. This design is able to enhance the proximity-driven catalytic synergism through optimized spatial arrangement of enzymatic components. In this way, a <2 nm inter-enzyme spacing within the scaffolded complex could be developed, and a 3.8-fold increase in PET-to-TPA conversion efficiency could be achieved. Finally, the PT-EC biocatalytic complexes (Figure 7) were precisely anchored on the E. coli surface via coordinated Lpp-OmpA membrane fusion and SpyCatcher/SpyTag covalent immobilization. The developed whole-cell biocatalyst exhibited remarkable thermal stability and solvent adaptability, maintaining over 80% of its original catalytic activity even after prolonged incubation at 50°C, while demonstrating exceptional tolerance to a wide range of organic solvents including polar and non-polar systems. At 40°C and pH 7.4, PT-ECEHA achieved 16.5 ± 1.2 mM TPA accumulation within 48 h, which significantly surpassed that of PETaseEHA (1.0 ± 0.3 mM). Furthermore, the surface-displayed PT-ECEHA further exhibited a PET film mass loss rate of 2.3 mg/cm2/day, a 20-fold improvement over the free enzyme system. In a 7-day evaluation at 40°C, PT-ECEHA demonstrated exceptional catalytic efficiency with a 4.3 mM increase in product release. While PT-ECZPE exhibited significantly lower degradation activity on PET films (≤5% surface erosion), it demonstrated markedly enhanced performance with amorphous PET powder substrates. Notably, the hydrolytic products (TPA/EG) showed sustained linear release kinetics during 7-day incubation, reaching cumulative yields of 11.56 mM (R2 = 0.98). This dichotomy directly demonstrates that substrate crystalline structure and enzyme accessibility are critical limiting factors in enzymatic PET depolymerization processes. Finally, through combinatorial mutagenesis screening, a thermostable variant TfCaI69W/L281Y was identified, which demonstrated a 2.5-fold enhancement in the accumulation of products (TPA/EG). Notably, it could maintain >90% residual activity after 8 h at 65°C (t1/2 = 15.3 h) with specific activity reaching 38.7 U/mg. This clearly revealed MHET intermediate accumulation could be effectively alleviated during extended degradation processes.

Figure 7. Diagrammatic representation of a robust whole-cell biocatalyst constructed with the PT-EC biocatalytic complexes displayed on the E. coli surface via coordinated Lpp-OmpA membrane fusion and SpyCatcher/SpyTag covalent immobilization.

Escherichia coli platforms (e.g., with Lpp-OmpA-anchored IsPETase) excel in rapid engineering, scalability, and compatibility with synthetic biology tools. However, proteolytic degradation (e.g., OmpT-mediated cleavage) and insufficient glycosylation limit their long-term stability. Yeast systems (e.g., P. pastoris displayed PETase) bypass protease issues and enable eukaryotic post-translational modifications. However, unintended N-glycosylation (e.g., at residue N181 in CtPL-DM) might result in the reduced catalytic activity unless mitigated via mutagenesis (e.g., N181A). In conclusion, E. coli remains preferable for scalable whole-cell biocatalyst production, while yeast systems are better suited for eukaryotic enzyme optimization.

3.2 Optimizing the metabolic pathways of the host for PET biodegradation

3.2.1 Metabolic engineering of P. putida

Recent breakthroughs in synthetic biology have enabled the development of P. putida strains with dual catalytic capabilities: (1) efficient assimilation of PET monomers via customized metabolic pathways, and (2) robust extracellular secretion of functional PET hydrolases through engineered secretion systems (Brandenberg et al., 2022). This integrated approach leverages modular genetic circuits for monomer metabolism while employing Type II secretion machinery to achieve coordinated enzyme production and extracellular release. It started with chromosomal integration of the tphII operon from Comamonas sp. E6 into P. putida KT2440 driven by a constitutive promoter. Subsequent optimization of TA assimilation was achieved through adaptive laboratory evolution (ALE) coupled with targeted mutagenesis of the MhpT transporter system. To address transcriptional repression mediated by the GclR regulator on glycolate (Gcl) and glyoxylate (GlxR) metabolism, parallel ALE campaigns were also conducted. P. putida TA7-EG with a nonsense mutation in gclR (PP_4283) resulted in truncated GclR protein and de-repressed C2 metabolism. P. putida TA7-BD acquiring a missense mutation in PP_2046 (putative transcriptional regulator) shows significantly enhanced 1,2-butanediol (BD) utilization efficiency. Building upon this foundation, a modular surface display system was engineered using different membrane anchors (EhaA secretion system, InaV ice nucleation protein, and OprF porin) for extracellular PET hydrolase presentation. In addition, the chimeric architecture also contained: (1) OprF signal peptide for periplasmic translocation; (2) catalytic domains (HiC, LCC, or IsPETase mutants); (3) flexible glycine-serine linker (G4SGGS(G4S)3); and (4) C-terminal transmembrane anchor. These are all under the regulation of rhamnose-inducible PrhaB promoter. Results revealed P. putida TA7-EG transformants exhibited 1.3–2.5-fold enhanced esterolytic activity, and the OprF-HiC chimera demonstrated peak performance as 2.68 ± 0.15 U/ml. Notably, rhamnose-induced expression triggered significant growth defects (30%–45% biomass reduction), particularly in LCC-expressing strains, which might highlight the enzyme-specific cytotoxicity. Moreover, to achieve temperature-responsive transcriptional regulation of heterologous expression, two thermoregulated systems were engineered: (1) the λ phage-derived cI857/PL system employing a thermosensitive repressor, and (2) a synthetic PIbpA variant incorporating Pseudomonas aeruginosa IbpA-5′UTR modifications. It was shown that the engineered PIbpA enabled robust PET hydrolase production (0.92 ± 0.08 mg/L extracellular protein) with minimal growth compromise (12% biomass reduction). The pLo-PIbpA-EhaA-LCC recombinant system exhibited temperature-responsive activation kinetics, achieving a 104-fold increase in esterolytic activity (212.4 ± 8.7 U/mg) at 30°C, which is a 37% improvement over λ PL-regulated counterparts. Notably, this performance was optimized through a controlled temperature gradient protocol (25–30°C for 6 h), which effectively mitigated proteotoxic stress-induced biomass loss from 45% to 12% while preserving extracellular PET hydrolase activity at 212.4 ± 8.7 U/mg. This temperature-modulated expression strategy aligns with recent advancements in enzyme thermal stability engineering, where gradual thermal adaptation has been shown to enhance both catalytic efficiency and cellular viability in heterologous expression systems. The optimized method demonstrated remarkable efficacy in protein aggregation control, achieving a 2.3-fold reduction in misfolded protein accumulation. Moreover, it effectively maintained cellular viability at over 85%, while simultaneously addressing the growth defects characteristic of LCC-expressing strains through direct intervention in aggregation-related pathways. Based on these, chromosomal integration of PIbpA-PET hydrolase expression cassettes in the engineered P. putida strains was achieved. While this genomic integration strategy effectively balanced hydrolase expression with cellular viability, it resulted in a concomitant reduction in overall enzyme production levels. Notably, P. putida KT2440 carrying the PIbpA-bglx-HiC construct achieved a 25% mass reduction in PBAT-starch-PLA copolymer films within 6 days. When extended to a 4-week incubation period, the engineered strain P. putida TA7-BD expressing the same enzyme system mediated approximately 40% depolymerization efficiency for the copolymer substrate. Although the PET upcycling cell factory constructed in this study demonstrated limited autotrophic efficiency, it uncovered critical challenges in engineering robust microbial chassis systems for industrial-scale applications. The study revealed three key engineering challenges in heterologous hydrolase expression systems, including (1) growth impairment caused by metabolic burden, (2) host protease-dependent enzyme degradation, and (3) suboptimal transmembrane transport of polymeric substrate degradation intermediates. The enduring challenges inherent in microbial metabolic networks highlight fundamental limitations demanding systematic investigation, particularly focusing on: (1) carbon flux maldistribution during the integration of heterologous pathways, (2) insufficient regeneration capacity of energy currencies (ATP/NADPH) under suboptimal metabolic states, and (3) redox imbalance triggered by exogenous enzymatic systems.

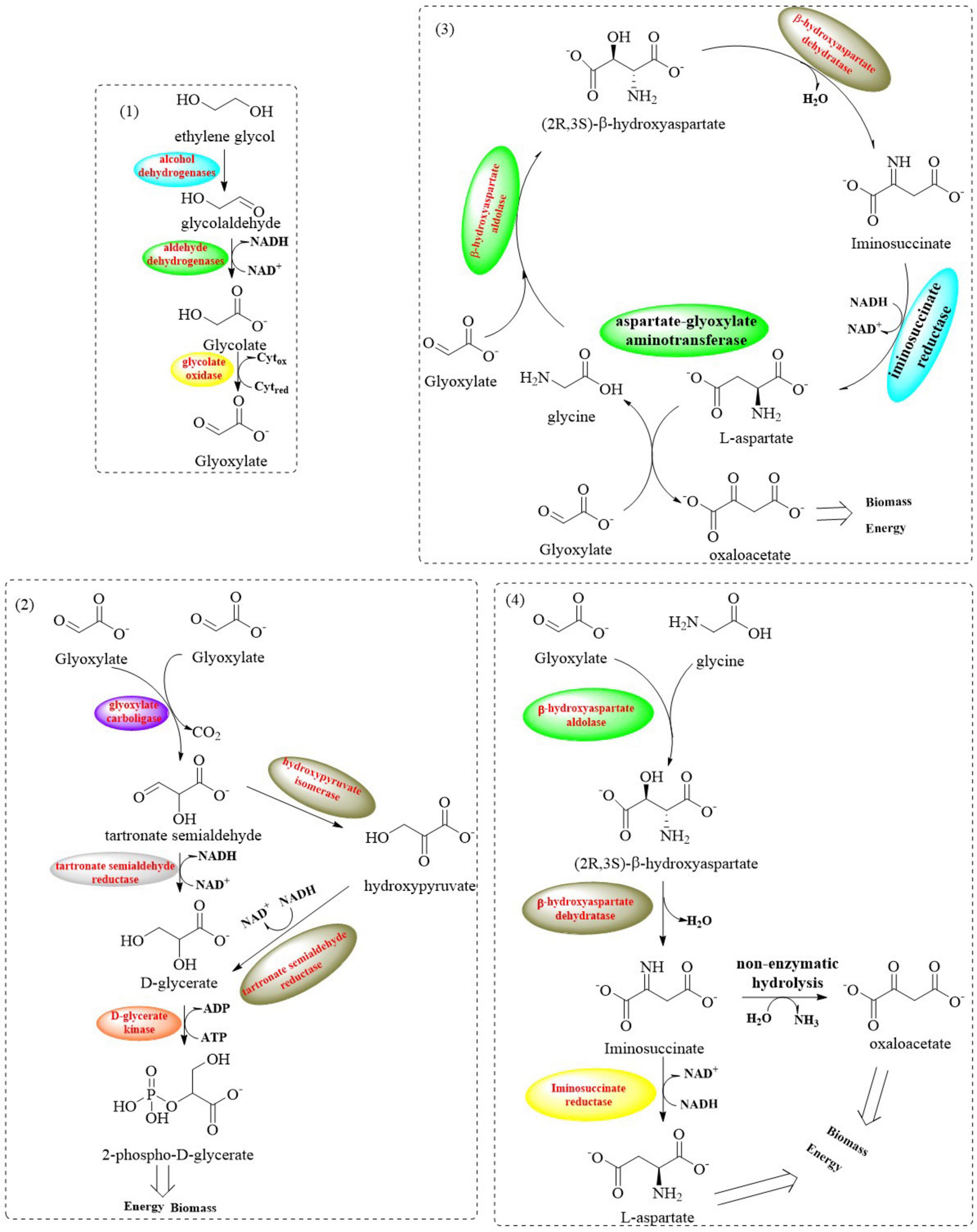

Extensive biochemical studies have established that most microbial systems employ the canonical glycerate pathway for EG assimilation (Mückschel et al., 2012; Franden et al., 2018; Werner et al., 2021). This oxidative metabolic route involves sequential enzymatic conversions through intermediates like glycolaldehyde (GA) and glyoxylate, ultimately yielding CO2 as the terminal oxidation product with suboptimal carbon efficiency. However, this process necessitates supplementary reducing equivalents (NADH/FADH2) and ATP, which poses critical industrial bottlenecks through three interconnected mechanisms: (1) growth arrest triggered by redox cofactor depletion, (2) pathway flux oscillations induced by energy deficits, and (3) cumulative metabolic stress from auxiliary enzyme overexpression. Recent advances in synthetic metabolism have revealed the β-hydroxyaspartate cycle (BHAC) as a biochemically streamlined route that bypasses decarboxylation steps while preserving carbon fidelity (Figure 8; Schada von Borzyskowski et al., 2019; Roell et al., 2021). It involves a coordinated system comprising four key enzymes encoded by the Bhc gene cluster: the PLP-dependent aminotransferase (BhcA), serine/threonine dehydratase (BhcB), β-hydroxyaspartate aldolase (BhcC), ornithine cyclodeaminase (BhcD), and along with an IclR-family transcriptional regulator. This multi-enzyme complex catalyzes the efficient conversion of two glyoxylate molecules into oxaloacetate through an energy-conserving mechanism that requires only one NADH equivalent while maintaining complete carbon retention (without CO2 release) (Schada von Borzyskowski et al., 2019).

Figure 8. Graphical representation of metabolic pathways involved in EG assimilation (1: oxidative reactions from EG to glyoxylate; 2: the glycerate pathway: it converts two glyoxylate molecules into two – phosphoglycerate and CO2; 3: the BHAC: a cyclic pathway where four enzymes transform two glyoxylate molecules into one oxaloacetate molecule; 4: the BHA shunt: it convertes glyoxylate and glycine into aspartate).

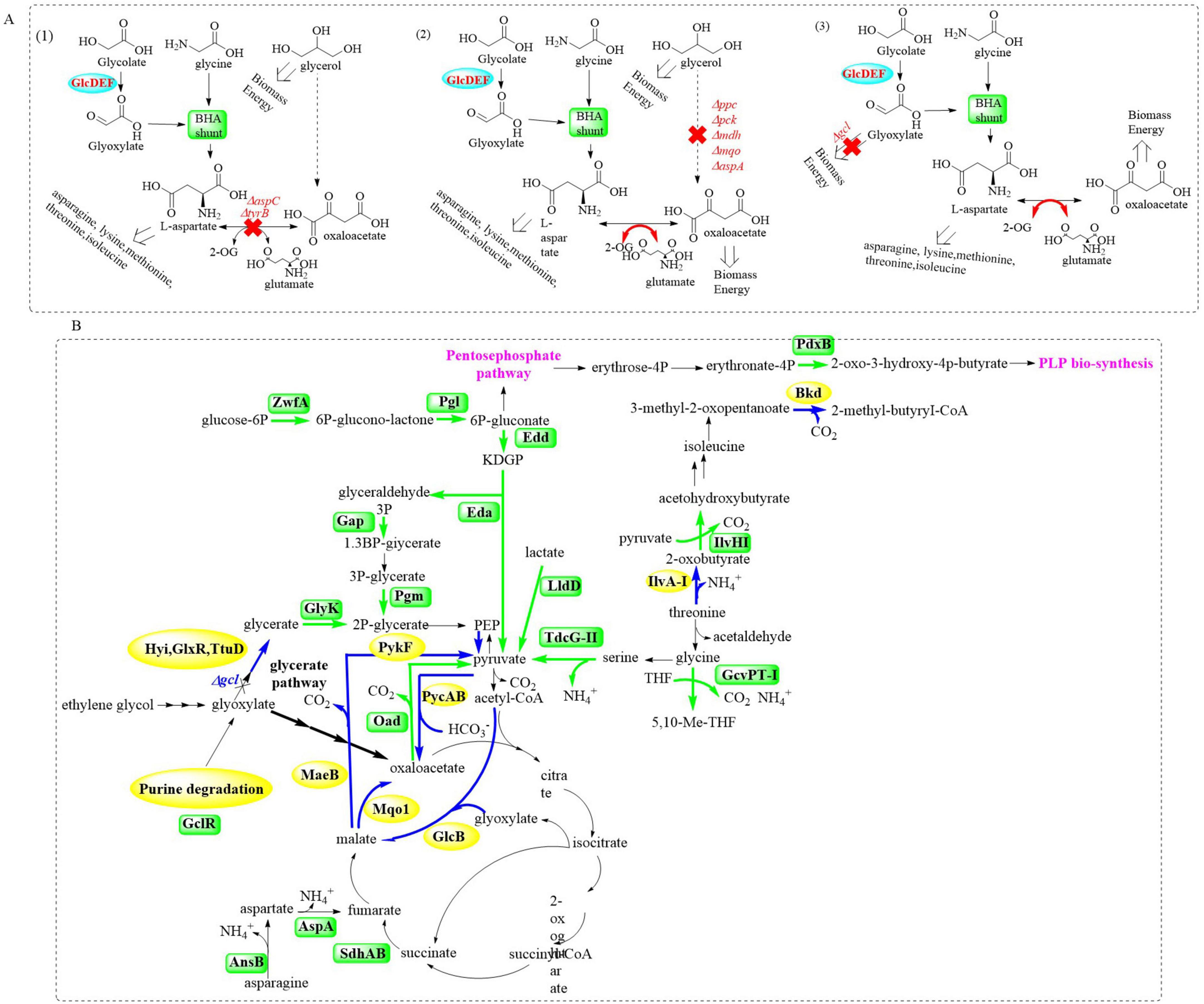

Based on these mechanistic insights, the potential of implementing the BHAC pathway in P. putida KT2440 was investigated through strategic engineering of glycerate metabolism (Schada von Borzyskowski et al., 2023). Core enzymes (BhcC/BhcB/BhcD) were first tested in E. coli chassis strains with incremental metabolic demands (Figure 9A). Glycolate was selected over toxic glyoxylate, leveraging endogenous conversion capacity. In aspartate-auxotrophic ΔaspC/ΔtyrB E. coli grown on glycerol/glycolate/glycine, the full BHA shunt enabled growth (18.2 ± 0.4 h doubling), whereas pathway-deficient controls failed. Tyrosine limitation was identified as the bottleneck, alleviated by 1 mM supplementation (13.0 ± 0.4 h doubling), which indicates precursor flux redirection might compensate the auxotrophy.

Figure 9. Graphical representation of the strategic engineering for glycerate metabolism by introducing the BHAC pathway in E. coli (A) and P. putida KT2440 (B).

Based on the initial testing in E. coli, structure-guided engineering of P. putida KT2440 was employed to replace native glycerate metabolism with the BHAC pathway aiming to enhance PET degradation capabilities while maintaining the metabolic robustness. Upon integration of the complete BHAC pathway into P. putida KT2440 Δgcl (Figure 9B), the engineered strain P. putida Δgcl + BHAC demonstrated immediate growth initiation on EG-containing medium, bypassing the adaptive lag phase required by its counterpart. Enzymatic assays revealed activities of the heterologous BHAC pathway components at ∼0.5 and 10 U/mg, which highlights the distinct catalytic efficiencies between key enzymes. Furthermore, the BHAC-equipped strain exhibited a 5%–10% increase in growth rate compared to P. putida KT2440 E6.1, a derivative previously optimized via ALE to metabolize EG through the native glycerate pathway. This enhancement underscores the metabolic superiority of the synthetic BHAC route over the naturally evolved glycerate-dependent system in terms of carbon utilization efficiency and kinetic performance.

Proteomic profiling of the strain P. putida Δgcl + BHAC uncovered a systemic metabolic rewiring, which is characterized by the following points. (1) The downregulation of glycolytic/gluconeogenic nodes (PycAB, Mqo1, and MaeB) coupled with upregulation of oxaloacetate decarboxylase (Oad), which establish oxaloacetate as the predominant entry point for TCA cycle influx. (2) Diverting carbon flux from glyoxylate shunt through decreased malate synthase (GlcB) activity and elevated succinate dehydrogenase (SdhAB) levels. This reveals preferential routing of acetyl-CoA through canonical TCA oxidation rather than bypass mechanisms. (3) Aspartate-to-TCA rechanneling via upregulated aspartate transaminases, which enables nitrogen-efficient α-ketoglutarate synthesis. (4) Activation of glycine salvage pathways is achieved through enhanced glycine cleavage system components, which is capable of facilitating serine/pyruvate interconversion to maintain redox balance. (5) Cofactor provisioning via PdxB-mediated pyridoxal 5′-phosphate (PLP) biosynthesis is associated with creating a self-reinforcing loop to sustain BHAC enzyme activity and biomass accretion. This multipronged adaptation highlights the metabolic prioritization of BHAC-mediated EG assimilation over native routes, which would achieve energy and redox balance through streamlined carbon funneling into the TCA cycle.

Finally, to further optimize chassis performance, ALE was applied to P. putida KT2440 Δgcl + BHAC. The evolved strain demonstrated a 35% increase in specific growth rate (μ = 0.42 ± 0.03 h–1) and 20% higher maximum biomass density (OD600 8.7 ± 0.2) under 20 mM EG. Genomic analysis identified subtle mutations in the bhcABCD expression module and key genomic adaptations. It mainly involve: (1) regulatory adjustments caused by a LysR-family transcriptional regulator (lldR) mutation and altered expression of lactate utilization and glycolate metabolism regulators (regB); (2) redox rebalancing resulting from the upregulated lldD (lactate dehydrogenase) and dld2 (D-lactate dehydrogenase), driven by the lldR mutation capable of modulating pyruvate-lactate interplay; (3) systemic optimization including the enhanced RegAB (redox sensors) and CioA (cytochrome oxidase) expression, the remodeling of electron transport chain and the fine-tuned central carbon/amino acid metabolism. These multi-tiered adaptations synergistically enhanced redox homeostasis and substrate channeling into the TCA cycle, maximizing EG assimilation. This work establishes a chassis with engineered metabolic robustness for PET-derived EG upcycling, bridging biodegradation and sustainable chemical synthesis.

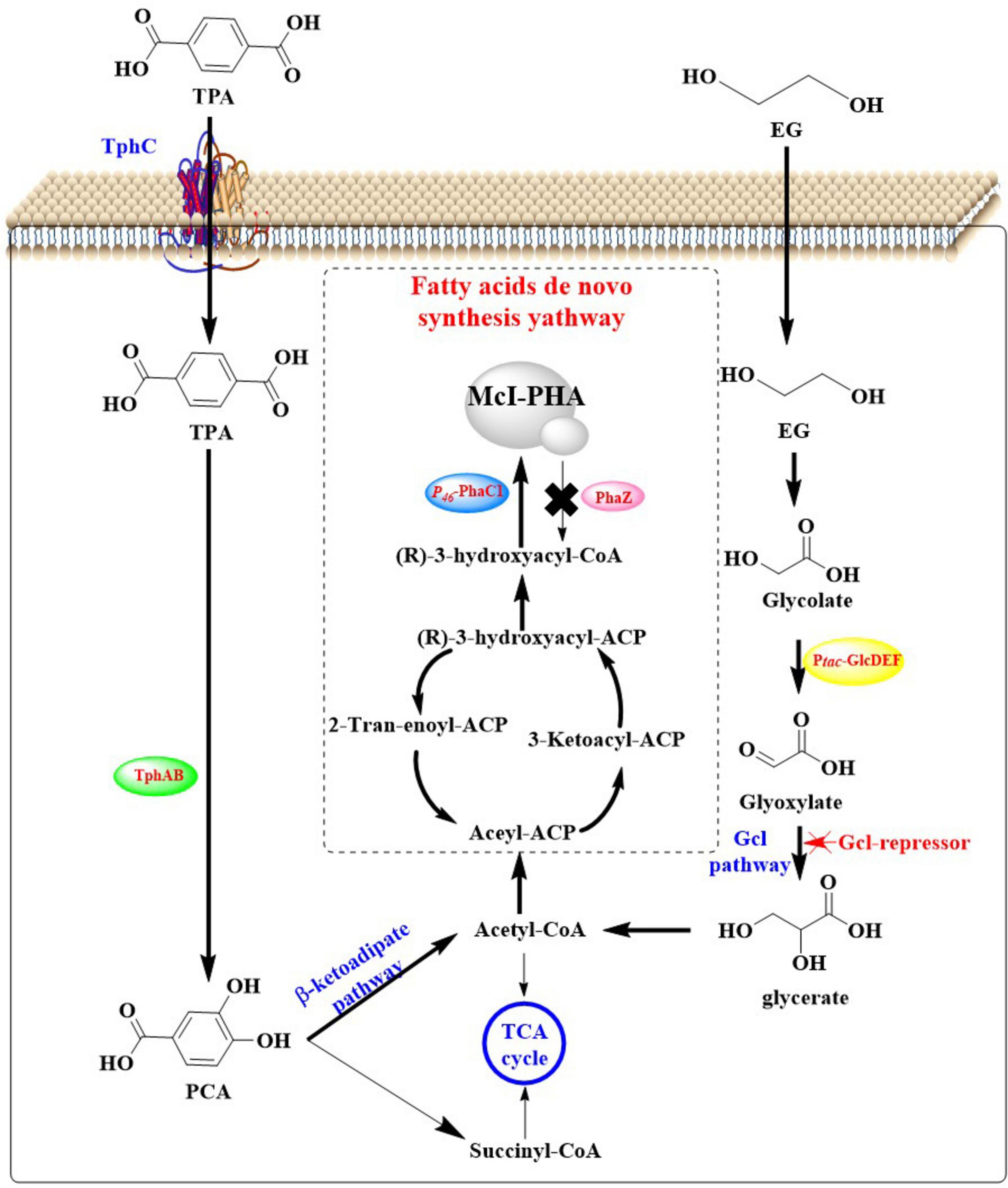

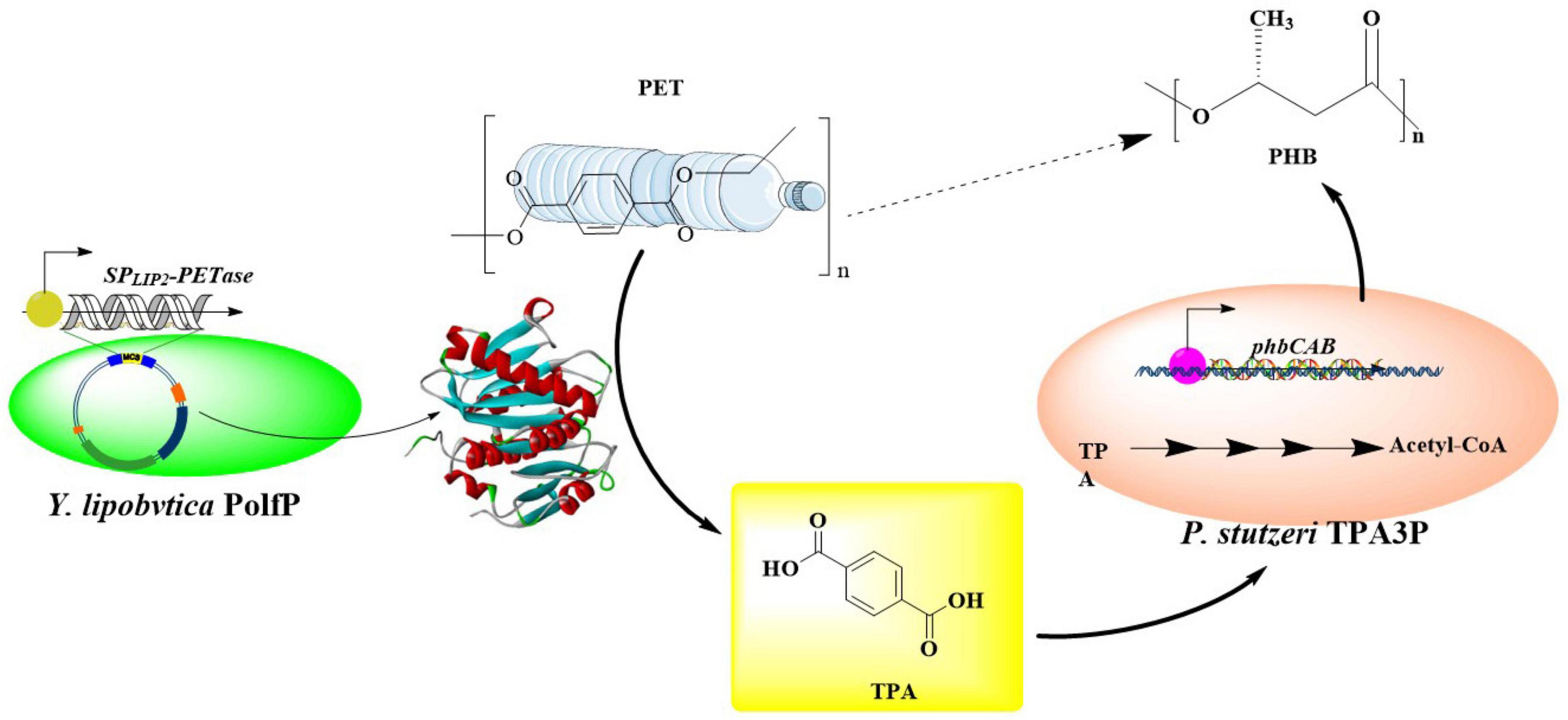

Recent scientific advances have demonstrated an innovative closed-loop strategy for plastic waste valorization through biocatalytic cascade reactions (Tiso et al., 2021). The post-consumer PET was successfully converted into two structurally distinct biodegradable polymers: microbial-derived polyhydroxyalkanoates (PHAs) and a novel bio-based poly(amide urethane) (bio-PU) synthesized through chemoenzymatic modification. The integrated biorecycling process begins with enzymatic depolymerization of post-consumer PET films using an engineered LCC variant in a thermostated stirred-tank reactor (70°C). Kinetic analysis showed peak TPA and EG production rates of 4.1 ± 0.3 and 2.1 ± 0.2 mM⋅h–1, respectively, within the first 24 h. Gravimetric and HPLC analyses confirmed 47.2% ± 2.1% depolymerization efficiency with near-complete surface erosion (92%–95%), while bulk crystallinity remained stable (Xc > 0.45) over 120 h. However, an 18.7% efficiency decline was observed between 24 and 120 h, which was attributed to synergistic factors: (1) arrhenius-driven thermal deactivation of LCC (Ea = 58.2 kJ⋅mol–1) and (2) TPA-induced acidification (ΔpH 1.8) causing non-competitive inhibition, as evidenced by 3.2-fold Km increase and 68% Vmax reduction. These results enabled development of two distinct metabolic pathways in Pseudomonas species for bioplastic monomer biosynthesis. Firstly, it was confirmed that that PET hydrolyzate showed no growth inhibition on P. putida KT2440 and Pseudomonas umsongensis GO16, moreover the latter showed enhanced growth possibly caused by the capability of utilizing TPA as an additional carbon source. The metabolic engineering of P. umsongensis GO16 for enhanced EG utilization was accomplished through carbon source-directed ALE under EG-limiting conditions. The optimized strain KS3 exhibited remarkable performance, achieving complete EG assimilation (1.7 ± 0.2 g/L) within 9 h while demonstrating a maximum specific growth rate (μmax) of 0.32 h–1. Upscaling to 5-L bioreactors revealed distinct substrate utilization patterns, achieving complete TPA depletion within 23 h (qTPA = 0.45 g/gCDW/h) compared to extended EG consumption (qEG = 0.13 g/gCDW/h). The process yielded 2.3 g/L biomass, with nitrogen limitation inducing PHA accumulation reaching 0.15 g/L (6.5% cell dry weight). The final yield reached 0.21 g CDW/g substrate, with the C8–C12 PHA profile closely matching that of the TPA-fed controls, which thereby confirmed the metabolic fidelity. Furthermore, it was elucidated that EG might be primarily routed to de novo fatty acid synthesis due to its high redox potential, while TPA required complementary pentose phosphate/TCA pathways. Then, the genetically engineered P. umsongensis GO16 KS3 was used to produce HAAs, reaching a concentration of 35 mg/L. The strain preferentially synthesized HAAs from TPA and utilized EG for growth, with a production rate of 5 mg/L/h and a yield of 0.01 gHAA/gTPA. The obtained HAAs were confirmed to be a mixture of four congeners with hydroxydecanoate as the main hydroxy fatty acid. This process is believed to not only diverts PET from waste streams but also produces a bioplastic with diverse applications, showcasing an effective circular economy approach.

In a similar study, PET oligomers derived from chemical recycling were fully converted into monomers through bio-depolymerization, which were then utilized for the production of PHAs by a co-culture of two genetically modified microbes (Liu P. et al., 2023). Firstly, E. coli BL21 (DE3)-LCCICCG was used as the chassis cell to express the PET hydrolase LCCICCG capable of degrading the PET oligomers into monomers, and the continuous metabolism of these produced oligomers. It was shown that BL21(DE3)-LCCICCG is able to depolymerize 76.9% of the PET oligomers into 0.61 g/L MHET, 5.48 g/L TPA, and 2.87 g/L EG after 72 h of cultivation at 30°C. Especially, within 24 h, BHET could be fully degraded.

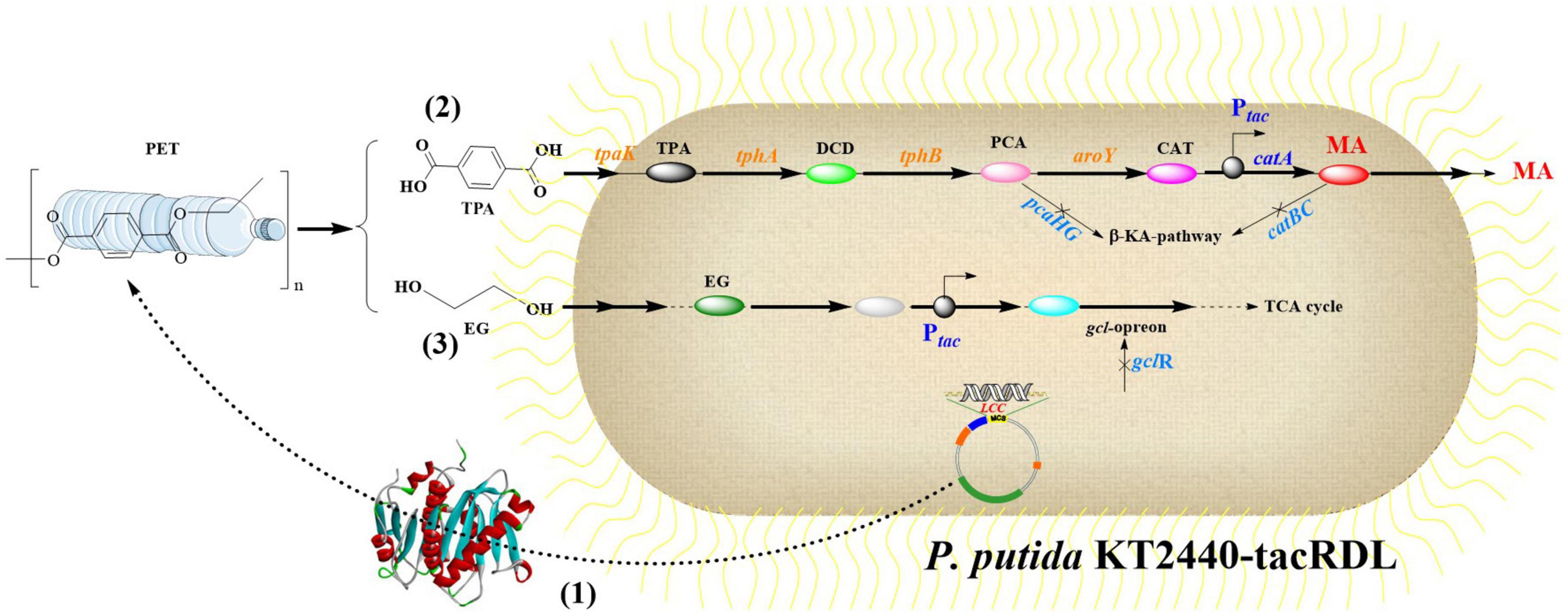

Given that MHET was determined to be an inhibitor for LCC in the PET degradation (Barth et al., 2016), the helper enzyme IsMHETase was therefore expressed in P. putida KT2440 to accelerate the hydrolysis of MHET into TPA and EG. Moreover, the native EG metabolic pathways of P. putida KT2440 were improved by the deletion of gclR gene, the overexpression of glycolate oxidase gene and the insertion of tph gene cluster. The resulting stain P. putida KT2440-ΔRDt (Figure 10) could grow rapidly with TPA and EG as the only carbon sources, and the OD600 reached 14.77 after 74 h. By this strain, 16.67 g/L TPA could be completely metabolized within 74 h with a catabolic rate of 0.22 g/(L⋅h). About 1.37 g/L PHA could be obtained from 16.67 g/L TPA and 6.08 g/L EG, furthermore the yield could be increased to 1.53 g/L after deletion of the endogenous PHA depolymerase gene phaZ (forming P. putida KT2440-ΔRDt-ΔZ). Moreover, overexpression of PHA synthase (phaC1) under the control of P46 revealed that the obtained P. putida KT2440-ΔRDt-ΔZP46C is able to catalyzed the formation of 1.90 g/L PHA. Then, the two engineered host were applied for the biosynthesis of PHA from PET oligomers in one pot, and a low level of MHET (0.28 g/L) was detected at 12 h during the co-cultivation process. The yield of PHA was 1.10 g/L with a conversion rate of 0.11 gPHA/goligomer, and the products were mainly consisted of 3-hydroxydecanoate (60.88%) and 3-hydrox-yoctanoate (23.67%). This conversion rate might be the currently highest level for the biosynthesis of utilizing PET or PET monomers as substrate.

Figure 10. Graphical representation of the co-culture of genetically modified E. coli BL21 (DE3)-LCCICCG and P. putida KT2440-ΔRDt-ΔZP46C for the biodegradation and up-cycling of PET.

3.2.2 The application of synthetic biology in the construction of chassis cells for PET up-recycling

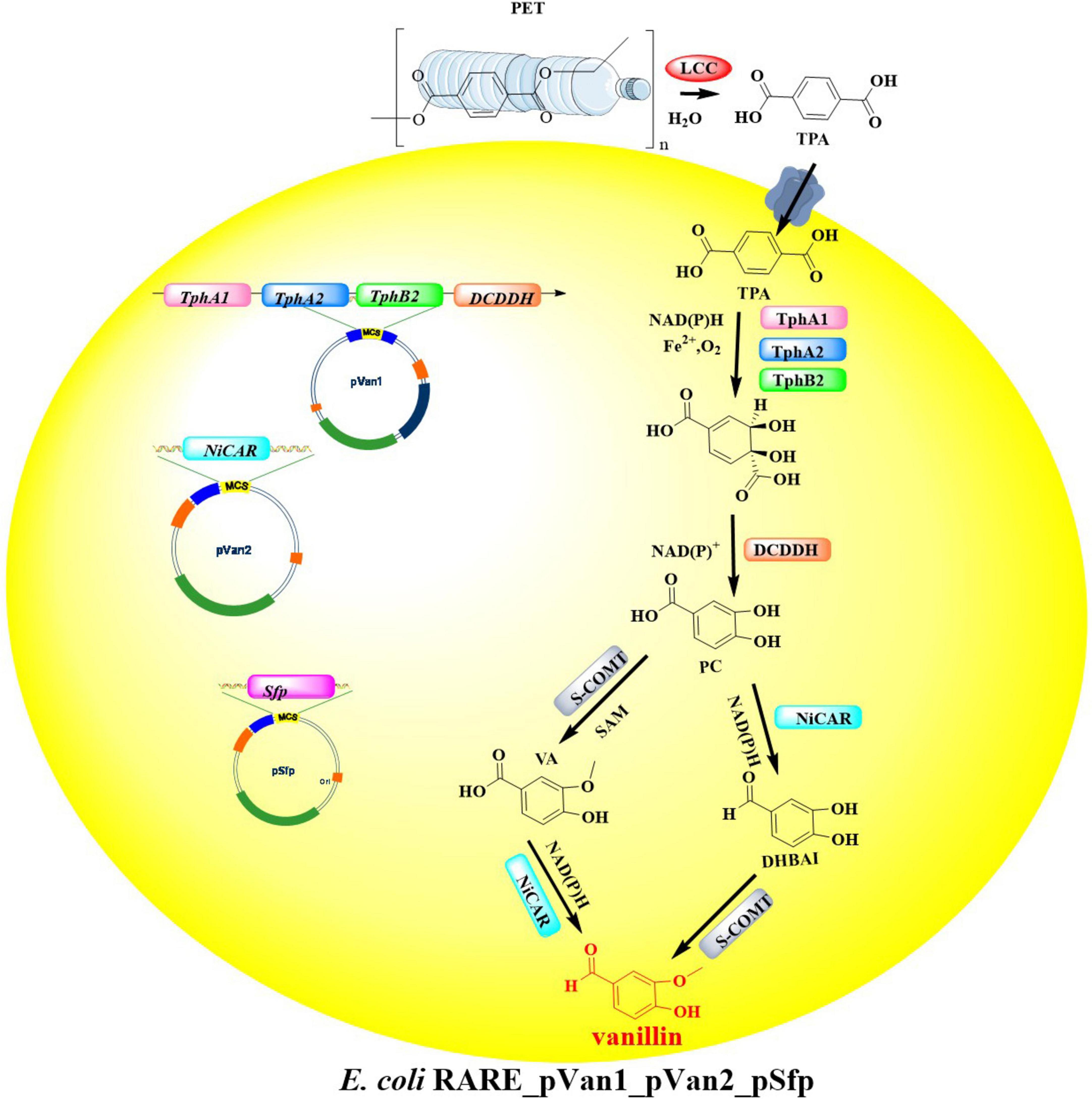

Integrated with emerging PET degradation and recycling technologies, the strategic repurposing of recovered monomers for synthesizing new PET materials or high-value derivatives presents a promising sustainable solution. To advance circular economy objectives in plastic waste management, a biosynthetic platform in engineered E. coli MG1655 RARE was developed that enables direct biological conversion of PET-derived TPA into vanillin-a commercially significant flavor compound and chemical precursor (Sadler and Wallace, 2021). In this engineered metabolic pathway, four key enzymes are essential for the bioconversion process (Figure 11): terephthalate 1,2-dioxygenase (TPADO), dihydroxy-3,5-cyclohexadiene-1,4-dicarboxylic acid dehydrogenase (DCDDH), carboxylic acid reductase (CAR), and catechol O-methyltransferase (COMT). For the biotransformation of TPA to vanillin, recombinant E. coli strains were engineered to co-express three essential plasmids: pVan1 (encoding TPADO), pVan2 (harboring the Nocardia iowensis CAR gene, NiCAR), and pSfp (containing the phosphopantetheinyl transferase gene required for CAR activation). Results showed that with added TPA (5 mM), a much lower yield of vanillin (5 μM, <1% conversion) was achieved. Notably, in this process the intermediates protocatechuate, dihydroxybenzaldehyde, and vanillic acid are also detected with the yields of 18, 10, and 2 μM, respectively. After optimization of the protein expression, reaction conditions and the cell membrane permeabilization of TPA, the conversion rate achieved was as high as 79% increased by ∼157-fold. Finally, biotransformation of post-consumer PET bottle into vanillin was investigated by coupling this metabolic pathway with LCCWCCG-catalyzed PET hydrolysis (Tournier et al., 2020). Results showed that the yield of vanillin reached to 68 μM, when the two stepwise reactions finished after 24 h. Though this strategy demonstrates potentials in the biological upcycling of post-consumer plastic waste into special value-added chemicals, great attentions should be paid to further improving the lower TPA concentrations. This is believed to be the rate-limiting step for a circular and sustainable bio-PET economy.

Figure 11. Diagrammatic illustration of the engineered metabolic pathway for the bioconversion process of TPA.

In another study, a novel artificial microbial system was developed for efficient biodegradation of PET, which was constituted of R. jostii, P. putida and two metabolically engineered B. subtilis (Qi et al., 2021a). Firstly, the two-step PET-degrading metabolic pathways were achieved with two metabolically engineered B. subtilis. The first strain was engineered to heterologously express Bs_PETase, mediating the depolymerization of PET to MHET. The second strain was designed to express Bs_MHETase, enabling hydrolytic cleavage of MHET into TPA and EG. This functional segregation optimizes catalytic efficiency by spatially separating the sequential enzymatic reactions within specialized microbial chassis. Results demonstrated enhanced depolymerization efficiency in this dual-species microbial system, which achieved complete hydrolysis of 2 g/L BHET within 22 h, with concurrent degradation of 13.6% (weight loss) of amorphous PET films over 7 days. However, inhibitory effects from TPA and EG were also observed during BHET degradation, especially the released TPA significantly suppressed host cell proliferation. To address this limitation, R. jostii RHA1, a strain renowned for its robust aromatic compound catabolism, was integrated, which resulted in complete degradation of 2 g/L TPA within 28 h. This strategy effectively alleviated the TPA-mediated growth inhibition, and enabled a tripartite microbial consortium to hydrolyze 2 g/L BHET within 20 h. Especially, the optimized system achieved 31.2 ± 2.2% weight loss of PET within 7 days, representing a 17.6% enhancement. Finally, P. putida KT2440 was introduced with the purpose of relieving the inhibitory effect caused by EG, which is capable of transforming EG into acetaldehyde. However, it was shown that the growth of the other three bacteria would be strongly inhibited by P. putida when co-cultivated in nutrient-rich media. This was finally tackled with a selective medium species (inorganic salt media, W) with the addition of ammonium sulfate and potassium nitrate, and sucrose and glucose as dual carbon sources. In this way, BHET (2 g/L) could be completely degraded within 20 h catalyzed by the four-species microbial system without detectable accumulation of TPA and EG. Following optimization, the PET film demonstrated a weight loss of 7.9 ± 0.78 mg within 7 days, and the depolymerization rate reached as high as 23.2 ± 2.3%. However, the degradation rate of the four-species microbial system was lower than that obtained with the three-species system (31.2 ± 2.2%), which might be caused by the nutrient-poor medium. Overall, this study highlights a novel idea for efficient biodegradation of PET in a greener way catalyzed with the artificial microbial consortia. However, a thorny issue still needs to be resolved that is how to address the issue of achieving appropriate growth rates among different microbial strains during the co-fermentation process.

3.2.3 Dual enzyme system for PET recycling

Recently, a thermophilic carboxylesterase (Est30) was engineered for efficient PET-depolymerization by relieving the inhibitory effect caused by the accumulated MHET (Zhang J. et al., 2023). It was mainly focused on (1) establishing a hydrogen-bonding network to stabilize transition-state conformations through carboxyl terminus binding, and (2) enhancing hydrophobic interactions surrounding the MHET benzene ring. Initial computational screening identified 11 out of 14 variants with improved MHET hydrolysis efficiency at 50°C (pH 7.5), among which M8 (Est30I171K/G130L), M13, and M14 (Est30I171K/M127S/G130L) exhibited remarkable catalytic enhancements of 36. 0-, 62. 1-, and 96.3-fold, respectively. Structural analysis demonstrated conserved active-site architecture (RMSD = 0.62 Å) and oxyanion hole geometry relative to the wild-type enzyme, while variant M14 exhibited a unique lid domain reorientation toward the hydrolase domain. Molecular dynamics (MD) simulations revealed that engineered mutations preserved critical hydrogen bonding and hydrophobic stacking interactions, demonstrating their role in transition-state stabilization. The thermostable variant M8 (Tm = 67.58°C, designated as KL-MHETase) demonstrated optimal activity under FAST-PETase-compatible conditions. Then a dual-enzyme system combining KL-MHETase and FAST-PETase (2:6 ratio) achieved 2.6-fold faster PET depolymerization and 1.64-fold higher TPA yield (99.5% purity) compared to FAST-PETase alone. However, the initial reaction kinetics revealed competitive binding between KL-MHETase and FAST-PETase, which suggests the need for spatial optimization. To address this limitation, researchers developed fusion enzymes using flexible (Gly-Ser)n linkers to connect FAST-PETase with M14 (KLS-MHETase). The engineered mutant KL36F demonstrated enhanced catalytic synergy via an efficient MHET channeling system, achieving 82.9% PET conversion (1.12-fold increase), 82.5% TPA yield (1.64-fold enhancement), and 99.5% product purity (1.47-fold improvement) under standard reaction conditions. Linker flexibility enabled proper orientation of active sites for direct MHET transfer, effectively preventing intermediate accumulation. At 0.35 μM loading, KL36F sustained MHET levels below inhibitory thresholds (<0.5%), while suboptimal enzyme dosing underscored the need for MHETase refinement. In industrial-scale trials (100 g/L PET), KL36F achieved >90% depolymerization efficiency, yielding 89.0% TPA with >99% purity, demonstrating robust scalability, and commercial viability. Comparative studies with other dual-enzyme systems, such as PETase/ΔBsEst and PETase/ΔChryBHETase (producing 663.1 and 617.6 μM TPA, respectively), further confirm the general efficacy of cascade enzymatic strategies. Collectively, these advancements demonstrate potential to establish sustainable plastic circularity through enzyme-driven valorization processes, while achieving operational cost reductions via streamlined downstream processing.

Similar studies further validate the efficacy of cascade enzymatic systems for PET depolymerization. Engineered BHETase variants (ΔBsEst and ΔChryBHETase) with 3.5-fold improved catalytic efficiency (kcat/KM) were incorporated into synergistic systems with PETase (Li et al., 2023a). The PETase/ΔBsEst and PETase/ΔChryBHETase combinations demonstrated exceptional performance, producing 663.1 and 617.6 μM TPA within 24 h, which represents a 7.0- and 6.5-fold increases, respectively over PETase monotherapy (95 μM). This enhancement mechanism parallels the KL36F system, where coordinated actions between PET-degrading and intermediate-processing enzymes prevents metabolic bottlenecks. The observed TPA yields (82.5%–89.0%) and purities (>99%) across different dual-enzyme systems further highlight its generalizability for industrial-scale plastic valorization. These findings corroborate the broader applicability of dual-enzyme cascades in establishing closed-loop PET recycling paradigms.

Recent advancements in enzymatic PET degradation have also led to the development of an innovative dual-enzyme system that operates through signal peptide-independent secretion (Aer et al., 2024b). This system employs a bifunctional chimeric enzyme (designated TfH-FPE), which is created by fusing FAST-PETase with TfH, a phospholipase capable of modifying cell membrane permeability. The TfH component facilitates extracellular secretion of the fusion enzyme while simultaneously enhancing substrate accessibility through membrane modulation. Results showed that this synergistic design significantly improves the bio-depolymerization efficiency of PET compared to single-enzyme approaches. The engineered TfH-FPE chimeric enzyme achieved a secretion yield of 104 ± 5.2 mg/L under optimized conditions, representing a 32.5-fold enhancement over conventional signal peptide-dependent systems. The enhanced secretory efficiency directly underpinned superior PET depolymerization efficacy, with TfH-FPE demonstrating sixfold increased product titer relative to standalone FAST-PETase and twofold elevated yield vs. equimolar discrete enzyme cocktails under identical operational parameters. In addition, kinetic characterization revealed substantial functional improvements in the fusion enzyme, including a 4.7-fold increase in hydrolysis rate constant (kcat/Km) and 4.1-fold enhanced substrate adsorption affinity toward PET films at 50°C. Time-course analyses demonstrated temperature-dependent degradation profiles, and the product accumulation reached saturation (8.9 ± 0.3 mM) within 48 h at 50°C, while exhibiting sustained linear release kinetics over 7 days at 40°C. Notably, despite showing 1.5-fold greater cumulative product yields than FAST-PETase at 40°C, TfH-FPE displayed counterbalanced kinetic properties with a threefold reduction in hydrolysis rate but 4.1-fold higher PET binding affinity. The decoupled catalytic kinetics and substrate adsorption profiles reveal the bifunctional merits of the fusion architecture, including prolonged operational stability through strengthened substrate binding, and the attenuated product inhibition achieved via spatial segregation of hydrolytic domains.

Moreover, the TfH-FPE fusion enzyme also exhibited superior PET depolymerization kinetics across all experimental conditions, which is capable of achieving maximal efficiency at 50°C with 12.2 ± 0.9 mM product release, a twofold greater than equimolar mixtures of standalone FAST-PETase and TfH. This might be mechanistically linked to enzyme colocalization effects, where spatial proximity between the phospholipase and PETase domains minimizes substrate diffusion barriers and enables cooperative catalysis. Importantly, this study establishes two paradigm-shifting innovations in enzymatic PET recycling. The autonomous secretion framework, a signal peptide-independent secretory mechanism, would enable efficient extracellular delivery of multi-domain biocatalysts (104 ± 5.2 mg/L yield). The synergistic interfacial catalysis mechanism integrates TfH-driven membrane permeabilization for enhanced substrate accessibility with FAST-PETase-mediated processive hydrolysis, which would establish a dual-functional cascade that optimizes both catalytic initiation and chain-scission efficiency. This tandem action achieved 4.7-fold faster PET film deconstruction compared to monofunctional systems. Collectively, these advantages position the TfH-FPE system as a paradigmatic framework for next-generation biocatalyst design: (1) autonomous platforms circumventing upstream protein engineering constraints through self-sufficient catalysis; (2) spatially optimized cascade architectures bypassing diffusion barriers via enzyme colocalization; and (3) thermostable systems preserving functional integrity across industrial processing temperatures (40–50°C).

The integration of PETase and MHETase into dual-enzyme systems effectively mitigates intermediate product inhibition (e.g., MHET accumulation), thereby achieving significantly enhanced PET degradation efficiency through synergistic catalytic action. In contrast, single-enzyme systems (e.g., free LCCICCG) usually required exogenous MHETase supplementation to alleviate inhibition, which might complicate the process design. Dual-enzyme consortia outperformed single systems by 50-fold in PET-to-TPA conversion due to synchronized depolymerization and intermediate metabolism (Diao et al., 2023).

3.3 Metabolic engineering of Yarrowia lipolytica

Yarrowia lipolytica (Cao et al., 2023; Park and Ledesma-Amaro, 2023; Liu Y. et al., 2024) is of great significance in the biotech field as it can efficiently produce a variety of valuable metabolites like lipids and polyols, and has been widely applied in the food, cosmetic and biofuel industries. As a premier microbial model, it enables mechanistic dissection of metabolic networks and cellular dynamics, serving as a translational platform bridging basic research in core biological principles with applied innovations in industrial biotechnology.

3.3.1 Direct heterologous expression of PET-degrading enzymes in Y. lipolytica

Recent advances have demonstrated successful heterologous expression of a codon-optimized PETase gene in Y. lipolytica for direct PET degradation (Kosiorowska et al., 2022b). The PETase coding sequence (GenBank: GAP38373.1) was codon-optimized for yeast expression and placed under the transcriptional control of the native XPR2 secretion signal to facilitate enzyme extracellular secretion. The optimized expression cassette was subsequently integrated into the genome of Y. lipolytica strain AJD2, generating the engineered strain AJD 2 pAD PET_IS. Functional characterization revealed successful secretory production of active PETase without causing significant growth defects. However, during PET degradation assays, both the engineered strain and AJD2 control failed to assimilate TPA monomers, and this contrasted with previous observations by Costa et al. (2020), where the Y. lipolytica derivatives demonstrated TPA utilization. This phenotypic discrepancy may be attributed to differences in cultivation conditions or strain-specific metabolic capabilities. Notably, both strains exhibited EG assimilation capacity, and the engineered AJD 2 pAD PET_IS strain achieved complete hydrolysis of MHET to TPA within 96 h. When applied to PET degradation, TPA accumulation became detectable in AJD 2 pAD PET_IS culture supernatants for 120 h, whereas neither TPA nor BHET were observed in AJD2 controls. These metabolic profiles differ significantly from the TPA utilization patterns reported by Costa et al. (2020), which suggests potential strain-specific differences in aromatic compound metabolism or variations in experimental conditions. Further optimization revealed that supplementation with specific metal ions markedly enhanced PET depolymerization efficiency. The addition of 2.5 mM MnSO4 and 1 mM CuSO4 increased TPA yields to 75 mg⋅L–1 (7.5-fold enhancement) and 62 mg⋅L–1 (6.2-fold enhancement), respectively. Most remarkably, incorporation of 1% (w/v) olive oil into the culture medium achieved a maximum TPA of 124 mg⋅L–1. This synergistic effect likely stems from the dual function of olive oil as both a hydrophobic surface-modifying agent and an inducer of endogenous lipase production, which may collaboratively enhance PET accessibility and enzymatic hydrolysis through interfacial activation mechanisms. Intriguingly, cultivation in 0.3-L Erlenmeyer flasks revealed growth inhibitory effects associated with salt supplementation, which could be potentially linked to suboptimal oxygen transfer efficiency and altered cellular proliferation kinetics. This contrasts with improved biomass accumulation observed in scaled bioreactor systems, where enhanced aeration and nutrient distribution likely mitigated the ionic stress effects documented in flask-scale experiments. Notably, olive oil supplementation induced pronounced physicochemical changes in PET substrates, including the accelerated surface corrosion, and substantial polymer mass reduction (53.05% ± 2.1% of initial mass). These alterations correlated with enhanced biodegradation efficiency, potentially through amphipathic compound-mediated biofilm formation and increased polymer surface hydrophilicity. This integrated approach demonstrates substantial potential for synergistic PET bioremediation during yeast cultivation, where microbial proliferation and enzymatic depolymerization proceed concurrently. The scale-dependent parameter optimization highlights the necessity for bioreactor-specific condition tailoring to maximize degradation efficiency while maintaining culture viability.

3.3.2 Metabolic engineering and fermentation engineering of Y. lipolytica for PET-cycling