- Grassland Science, College of Animal Science and Technology, Shihezi University, Shihezi, China

Maize silage serves as a crucial feed resource for ruminants, yet its quality is frequently compromised during storage by spoilage-associated microbial activity. Clostridium species, particularly Clostridium beijerinckii, are known to induce spoilage by altering fermentation pathways. This study aimed to elucidate the effects of inoculation with C. beijerinckii SHZ-8 on microbial succession, metabolite profiles, and fermentation quality in whole-crop maize silage throughout the spoilage process. Silage samples were prepared with and without C. beijerinckii SHZ-8 inoculation. Microbial community dynamics were assessed via 16S rDNA sequencing, while metabolite alterations were characterized using untargeted metabolomics. Fermentation parameters including nutrient composition, bacterial counts, and organic acid concentrations and ratios were also determined. Correlation analyses between key metabolites and core microbial taxa were conducted. Inoculation with C. beijerinckii SHZ-8 significantly reduced dry matter content by 5.28% (p < 0.01) and lactic acid bacteria counts by 54.51% (p < 0.01), while increasing Clostridium abundance by 3.40 log₁₀ CFU/g FW (p < 0.01). The dominant fermentation mode shifted from homofermentation to heterofermentation, accompanied by an 81.6% decrease in the lactate-to-acetate ratio (p < 0.01). D-galacturonic acid levels exhibited a strong positive correlation with C. beijerinckii SHZ-8 abundance (R2 = 0.87, p < 0.01), suggesting its potential as a biomarker for Clostridium overgrowth. Notably, octanal and D-galacturonic acid emerged as candidate biomarkers in the inoculated group, providing a basis for the development of silage quality monitoring tools. These findings offer valuable insights for improving silage management strategies, enhancing feed preservation, and advancing the sustainability of livestock production.

1 Introduction

Corn silage is a key component of ruminant diets, critically affecting nutrient intake, production performance, and overall health. Its nutritional quality and hygienic safety are largely determined by the succession of microbial communities and their metabolic activities during the ensiling process (Muck, 2010; Pahlow et al., 2015). Under optimal fermentation conditions, lactic acid bacteria (LAB) rapidly convert water-soluble carbohydrates (WSCs) into lactic acid, leading to a swift pH decline that suppresses the growth of undesirable microorganisms and ensures stable, long-term preservation (Kung et al., 2018; Borreani et al., 2018).

However, the activity of certain spoilage-associated bacteria, such as Clostridium beijerinckii SHZ-8, can disrupt this process. These organisms generate undesirable metabolites, including butyric acid, which reduce nutritional value, impair palatability, and potentially pose health risks to livestock (Dunière et al., 2017). Elucidating the ecological role of such spoilage microorganisms in silage fermentation, as well as their interactions with other microbial taxa, is therefore of considerable scientific and practical significance.

Clostridium beijerinckii SHZ-8, a spore-forming and strictly anaerobic bacterium, is frequently associated with silage spoilage. Its metabolic activity—particularly the production of butyric acid—is widely recognized as a hallmark of abnormal fermentation and diminished feed value (Ogunade et al., 2018; Dunière et al., 2017; Vissers et al., 2007). However, early detection of this organism remains difficult due to the complexity of microbial population dynamics and the delayed accumulation of measurable end metabolites during the ensiling process (Sigolo et al., 2023).

Traditional methods for evaluating silage spoilage rely on sensory assessment (e.g., off-odors, discoloration) and physicochemical indicators such as elevated pH, increased ammonia-N content, and accumulation of butyric acid (Kung et al., 2018). Although effective for diagnosing advanced spoilage (Dunière et al., 2013), these indicators typically show marked changes only during the mid-to-late stages of deterioration, limiting their value for early intervention. As a result, recent research has shifted toward identifying specific biological markers (biomarkers) to enable earlier detection and precision management of the fermentation process (Sigolo et al., 2023; Borreani et al., 2018). Such biomarkers may include shifts in microbial community composition, the appearance of distinctive metabolites, or the expression of functional genes closely associated with spoilage development (Ogunade et al., 2018).

Microbial community–based biomarkers have emerged as promising tools for early spoilage detection. Previous studies tracking bacterial and fungal dynamics during fermentation and aerobic deterioration have shown that shifts in the relative abundance of certain taxa can precede visible signs of spoilage (Dunière et al., 2017). Furthermore, recent multi-omics analyses indicate that a decline in Lactobacillus populations—alongside increases in Clostridium spp. and the accumulation of specific amino acid degradation products—may serve as reliable indicators of early-stage deterioration (Ogunade et al., 2018).

Metabolite-based biomarkers have also been widely investigated. Strong correlations have been reported between Clostridium activity and aerobic instability, suggesting that microbial counts may serve as predictive indicators (Dunière et al., 2017). In addition, organic acids, biogenic amines, and specific volatile organic compounds (VOCs) have been proposed as practical markers of deterioration (Sigolo et al., 2023). Amino acid degradation products and selective volatile fatty acids have further been identified as phase-specific spoilage indicators during aerobic exposure (Borreani et al., 2018). Despite these advances, inconsistencies among reported biomarkers—largely attributable to differences in feedstock, ensiling conditions, and analytical methodologies—highlight the need for broader validation, standardized thresholds, and clearly defined detection windows.

In light of the lack of standardized strategies for the early detection of Clostridium beijerinckii SHZ-8–associated spoilage, this study investigated the effects of C. beijerinckii SHZ-8 inoculation on the microbial community structure, metabolite profiles, and fermentation quality of whole-plant corn silage. By combining high-throughput 16S rDNA sequencing with untargeted metabolomics, we aimed to elucidate the microbial and metabolic shifts triggered by this spoilage organism. The findings are expected to advance the mechanistic understanding of C. beijerinckii SHZ-8 in silage fermentation and to provide a theoretical basis for developing early detection methods and targeted control strategies in silage systems.

2 Materials and methods

2.1 Experimental materials

The experiment was conducted using a completely randomized design with two treatments: (1) Clostridium beijerinckii SHZ-8 inoculation (Group I) and (2) control without inoculation (CK). Each treatment included three biological replicates, and all measurements were performed in duplicate (technical replicates) to ensure analytical accuracy. The fermentation period lasted for 60 days, with samples collected on days 1, 7, 15, 30, and 60 for fermentation characteristics, while nutritional composition, microbial diversity, and metabolomic profiling were assessed on day 60.

The Clostridium beijerinckii SHZ-8 strain used in this study was originally isolated and identified in our laboratory from deteriorated whole-plant maize silage through morphological, biochemical, and 16S rRNA gene sequence analyses. The strain is preserved in our laboratory culture collection at −80 °C in 20% (v/v) glycerol stocks. For inoculum preparation, a frozen glycerol stock of C. beijerinckii SHZ-8 was thawed at room temperature, streaked onto enriched clostridial agar plates, and incubated anaerobically at 37 °C for 24 h. A single colony was then transferred into 50 mL of enriched clostridial liquid medium and incubated anaerobically with shaking at 160 rpm and 37 °C for 18 h. Bacterial growth was monitored by measuring optical density at 600 nm (OD₆₀₀). Cells were harvested by centrifugation at 6,000 rpm for 10 min at 4 °C, washed twice, and resuspended in sterile phosphate-buffered saline (PBS, pH 7.4) to achieve a final viable cell concentration of approximately 1.0 × 108 CFU/mL, as determined by plate counting on reinforced clostridial agar.

Whole-plant maize (Zea mays L., cultivar Jinling Silage No. 10) was grown at the Forage Experimental Station of Shihezi University (Xinjiang, China; 44°21′4″N, 85°57′35″E; altitude 420 m), in a temperate continental arid–semiarid climate with annual precipitation of 233 mm and annual sunshine duration of 2,740.6 h. Plants were harvested at the two-thirds milk line (2/3 ML) stage and chopped into 1–2 cm pieces. For the inoculated group, maize was sprayed with C. beijerinckii SHZ-8 suspension at 100 mL/kg fresh weight; the control group (CK) was sprayed with the same volume of sterile water. Approximately 1 kg of fresh material per replicate was packed into polyethylene silage bags (30 × 50 cm), vacuum-sealed, and stored at 26 ± 1 °C.

2.1.1 Determination of nutritional components

Nutritional composition was analyzed following (Li and Li, 2013; Li et al., 2020). Fresh samples were weighed, oven-dried at 105 °C for 30 min to deactivate enzymes, then further dried at 65 °C to constant weight for dry matter (DM) determination. Dried samples were ground and passed through a 1 mm sieve. Crude protein (CP) was determined using a Kjeldahl nitrogen analyzer (K9840, Shandong Haineng Scientific Instrument Co., Ltd., Jinan, China). Neutral detergent fiber (NDF) and acid detergent fiber (ADF) were determined using an automatic fiber analyzer (ST116A, Shandong Shengtai Instrument Co., Ltd., Jinan, China). WSCs were determined using the anthrone method (Cai et al., 2013), and starch content via the enzyme hydrolysis method (Blasel et al., 2006).

2.1.2 Determination of fermentation quality

Twenty grams of silage samples collected on days 1, 7, 15, 30, and 60 were mixed with 180 mL deionized water, stored at 4 °C for 24 h, and filtered through four layers of sterile cheesecloth. Filtrate pH was measured immediately using a calibrated pH meter. Organic acids (lactic, acetic, propionic, and butyric acids) were determined by high-performance liquid chromatography (HPLC) (Agilent 1,200, Shandong Jielun Technology Products Co., Ltd., Jinan, China) following Ma et al. (2013). The filtrate was centrifuged (12,000 rpm, 3 min) and supernatants filtered through 0.22 μm aqueous-phase membranes before injection. HPLC conditions: Shodex RSpak KC-811 column (Showa Denko K. K., Tokyo, Japan) (8 mm × 300 mm); mobile phase: 3 mM perchloric acid; column temperature: 50 °C; injection volume: 5 μL; detection wavelength: 210 nm; flow rate: 1 mL/min. Ammonia nitrogen (NH3–N) was measured by the phenol–hypochlorite colorimetric method (Kozloski et al., 2006).

2.2 Experimental methods

2.2.1 Determination of nutritional components

The nutritional composition was determined according to the method described by (Li and Li, 2013; Liu et al., 2021). Immediately after sampling, the fresh weight of the samples recorded. The samples were then dried in a forced-air oven at 105 °C for 30 min deactivate enzymes, followed by further drying at 65 °C until a constant weight wasachieved. DM content was subsequently calculated. DM content was measured by drying fresh whole-plant maize and silage samples at 65 °C for 72 h. After grinding and sieving the samples through a 1 mm screen, CP content was analyzed using a Kjeldahl nitrogen analyzer (K9840, Shandong Haineng Scientific Instrument Co., Ltd., Jinan, China). NDF and ADF contents were measured using an ST116A fiber analyzer (Shandong Shengtai Instrument Co., Ltd., Jinan, China). WSC were determined using the anthrone reagent method (Cai et al., 2013), and starch content was measured by the dual-enzyme hydrolysis method (Chen et al., 2016).

2.2.2 Determination of fermentation quality

20 g of whole-plant corn silage samples collected on fermentation days 1, 7, 15, 30, and 60 were mixed with 180 mL deionized water, refrigerated at 4 °C for 24 h, and filtered through four layers of sterile gauze. The pH of the resulting filtrate was measured immediately using a pH meter. A portion of the filtrate was used to determine the concentrations of lactic acid, acetic acid, propionic acid, and butyric acid using a HPLC (Agilent 1,200, Shandong Jielun Technology Products Co., Ltd., Jinan, China). The filtrate was centrifuged at 12,000 rpm for 3 min, and the supernatant was filtered through an aqueous-phase filter membrane before HPLC analysis. The HPLC conditions were as follows: chromatographic column: Shodex RSpak KC-811 column (Showa Denko K. K., Tokyo, Japan) (8 mm × 300 mm); mobile phase: 3 mol/L perchloric acid solution, filtered and degassed; column temperature: 50 °C; injection volume; 5 μL; detection wavelength: 210 nm; flow rate: 1 mL/min. Another portion of the filtrate was used to measure ammonia nitrogen content using the phenol-sodium hypochlorite colorimetric method (Kozloski et al., 2006).

3 Microbiological indicators

3.1 Determination of microbial viable counts

Twenty grams of fresh whole-plant maize (raw and ensiled) were added to 180 mL of sterile physiological saline and shaken in a shaking incubator (B7 Bo’aosi General Shaking Incubator, Shanghai, China) at 120 rpm for 2 h at 37 °C. The mixture was then allowed to stand. One milliliter of the supernatant was transferred to a test tube containing 9 mL of sterile physiological saline and thoroughly mixed. Serial dilutions were prepared using sterile physiological saline.

A 100 μL aliquot of the 10−6 and 10−7 dilutions was spread onto MRS agar, malt extract agar, nutrient agar (NA), and mold medium (all purchased from Qingdao Haibo Biotechnology Co., Ltd., Qingdao, China), and incubated in an inverted position at 37 °C for 48–72 h. Simultaneously, 100 μL of the same dilutions were spread onto reinforced Clostridial agar medium (Qingdao Haibo Biotechnology Co., Ltd., Qingdao, China), placed in anaerobic gas packs (Mitsubishi Gas Chemical Company, Inc., Tokyo, Japan) with CO2 gas generators (Mitsubishi Gas Chemical Company, Inc., Japan), and incubated in an inverted position in a GH4500 water-jacketed incubator (Tianjin Teste Instrument Co., Ltd., Tianjin, China) at 37 °C for 48–72 h. Each dilution was tested in triplicate.

Colony Counting: Colonies were counted manually. Only plates with clearly distinguishable colonies and counts between 30 and 300 were used for quantification. The number of specific microorganisms per gram of fresh matter (FM), expressed as colony-forming units (CFU), was calculated using the following formula: Microbial count (CFU/g FM) = (Number of colonies × Dilution factor × 1,000 μL)/Volume of diluted sample plated (μL).

3.2 Determination of microbial species diversity

A 0.5 g sample was weighed and ground in liquid nitrogen. Bacterial DNA was extracted using a bacterial genomic DNA extraction kit (DP302, Tiangen Biotech Co., Ltd., Beijing, China). DNA concentration and purity were assessed using a micro nucleic acid quantifier (HM-CWF1, Shandong Hengmei Electronic Technology Co., Ltd., Weifang, China). The nucleic acid concentration was required to exceed 10 ng/μL, with an optimal 260/280 absorbance ratio between 1.8 and 2.0. Qualified DNA samples were used for PCR amplification with universal bacterial primers 27F (5′-AGAGTTTGATCCTGGCTCAG-3′) and 1492R (5′-ACGGTTACCTTGTTACGACTT-3′) (Liu et al., 2024). The PCR reaction mixture contained: 12.5 μL of 2 × Taq Platinum PCR MasterMix, 1 μL of 10 μM forward primer (F), 1 μL of 10 μM reverse primer (R), 10 μL of DNA template (approximately 50–408 ng), and 1.5 μL of ddH2O. The PCR program was as follows: initial denaturation at 94 °C for 2 min; 30 cycles of denaturation at 94 °C for 30 s, annealing at 55 °C for 30 s, and extension at 72 °C for 1.5 min; followed by a final extension at 72 °C for 2 min. The remaining amplification product was stored at −80 °C. PCR products that passed electrophoresis were sent to Sangon Biotech Co., Ltd. (Shanghai, China) for sequencing (Chen et al., 2022).

3.3 Determination of metabolites

Silage samples were oven-dried at 65 °C for 72 h to a constant weight, then ground and sieved to obtain powder with a particle size of <1 mm. Volatile compounds were extracted from the silage samples using a solvent extraction method (e.g., dichloromethane or ethanol). The solvent was removed under reduced pressure using a rotary evaporator, and the extract was concentrated for subsequent analysis.

An aliquot (1–2 μL) of the concentrated extract was injected into a gas chromatography (GC) system equipped with an autosampler in split/splitless inlet mode. GC parameters were as follows: column—polar or non-polar capillary GC column (e.g., DB-5 or DB-35); carrier gas—helium or nitrogen at a flow rate of 1–2 mL/min; oven temperature program—initial temperature 60 °C (1 min hold), ramp to 300 °C at 10 °C/min, final hold for 10 min.

Mass spectrometry (MS) was performed under electron impact (EI) ionization mode, coupled with time-of-flight MS to obtain high-resolution mass spectra (Raut, 2023). Data acquisition was conducted over an m/z range of 50–500, and qualitative and quantitative analyses were based on ion peak data (Liu et al., 2020).

4 Data processing

Nutritional composition, fermentation quality, and viable microbial counts were analyzed using both one-way analyses of variance in SPSS software, version 20.0 (IBM Corp., Armonk, NY, USA). Additional statistical analyses were performed using the stats package (version 4.3.2) in R software (version 4.3.2; R Core Team, Vienna, Austria), and data visualization was conducted with the ggplot2 package (version 3.5.0; Wickham, 2016).

5 Results

5.1 Effects of Clostridium beijerinckii SHZ-8 inoculation on nutrient components in whole-plant corn silage

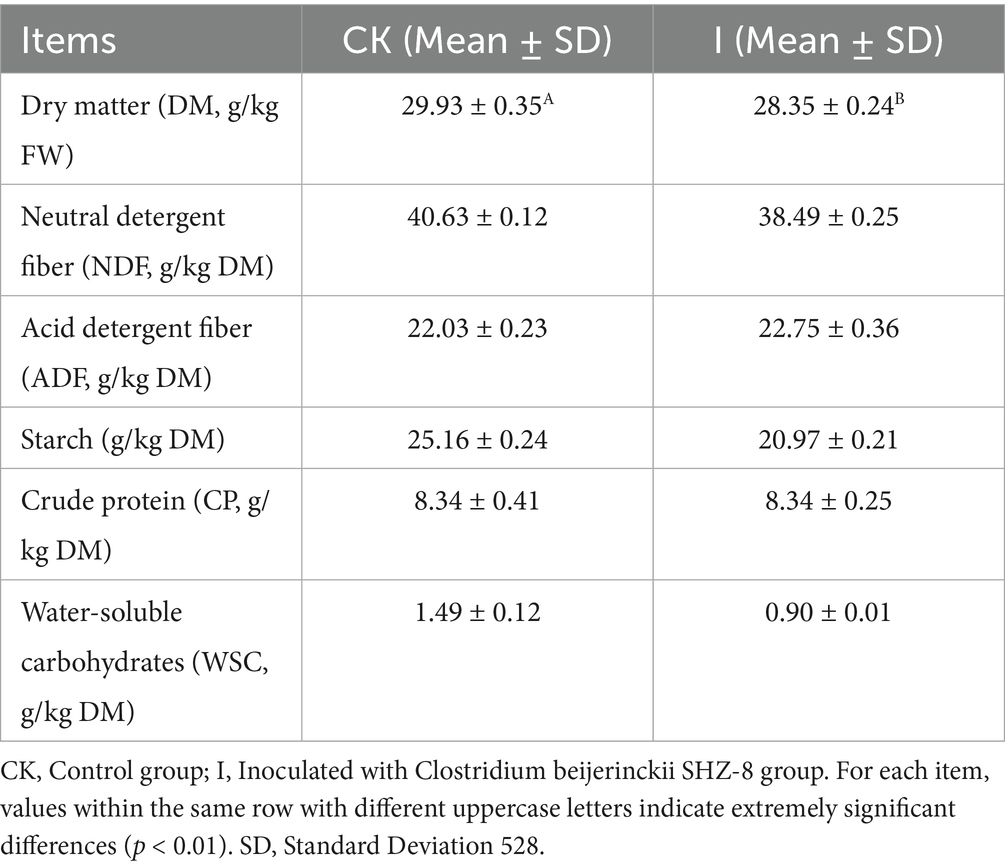

The nutrient composition changes of whole-plant corn silage due to Clostridium beijerinckii SHZ-8 inoculation are detailed in Table 1. Compared to the CK group, DM content in Group I was significantly reduced by 5.28% (p < 0.01). Regarding WSC content, Group I was 40% lower than the CK group (p > 0.05).

Table 1. Effects of Clostridium beijerinckii SHZ-8 inoculation on the nutrient composition of whole-plant maize silage.

5.2 Effects of Clostridium beijerinckii SHZ-8 inoculation on fermentation components in whole-plant corn silage

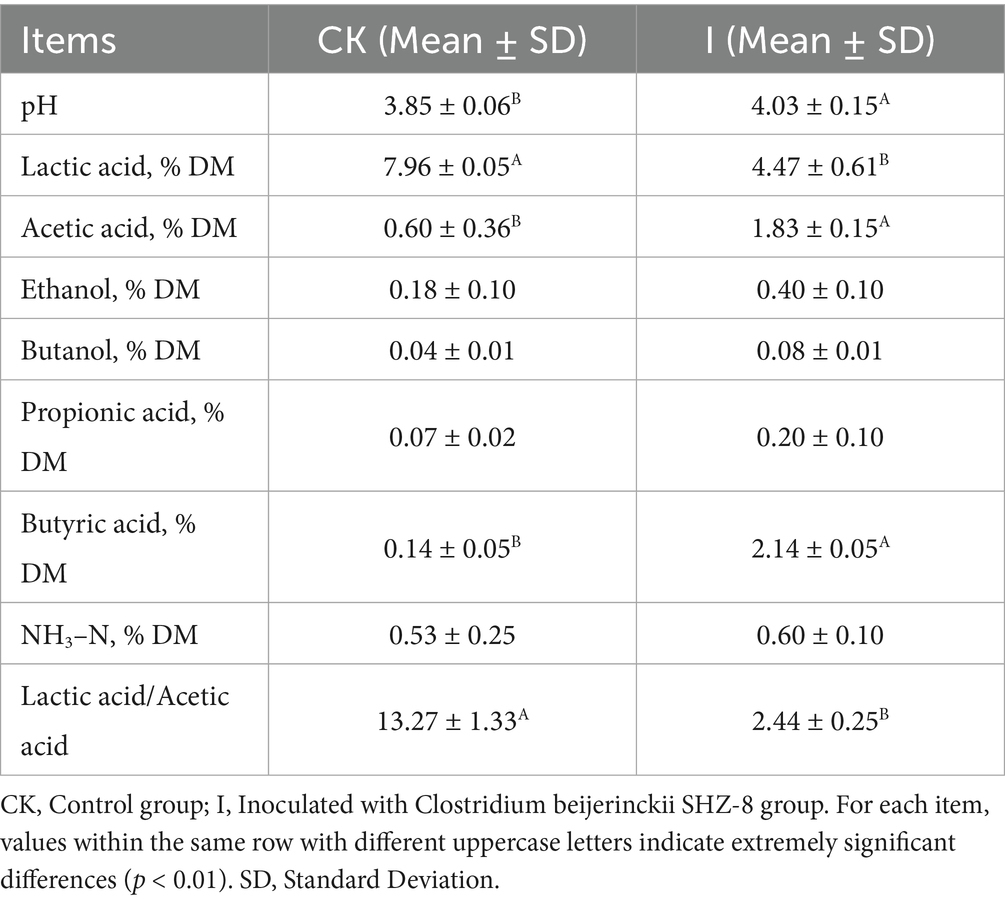

Table 2 summarizes the effects of Clostridium beijerinckii SHZ-8 inoculation on the fermentation quality of whole-plant corn silage. Compared with the CK group, Group I showed a significantly higher pH (4.03 vs. 3.85, p < 0.01), alongside a pronounced reduction in lactic acid content by 43.8% (4.47% DM vs. 7.96% DM, p < 0.01). In contrast, acetic acid concentration increased by 205% in Group I (1.83% DM vs. 0.60% DM, p < 0.01), while butyric acid content rose markedly, showing a 2.00-fold elevation (2.14% DM vs. 0.14% DM, p < 0.01). The lactic acid/acetic acid ratio in Group I was 2.44, representing an 81.6% relative decrease compared with the CK group (13.17, p < 0.01), indicating a clear shift in fermentation pattern from homofermentative to heterofermentative metabolism.

Table 2. Effects of Clostridium beijerinckii SHZ-8 inoculation on the fermentation quality of whole-plant maize silage.

5.3 Effects of Clostridium beijerinckii SHZ-8 inoculation on microbial community structure in whole-plant corn silage

5.3.1 Effects of Clostridium beijerinckii SHZ-8 inoculation on microbial diversity in whole-plant corn silage

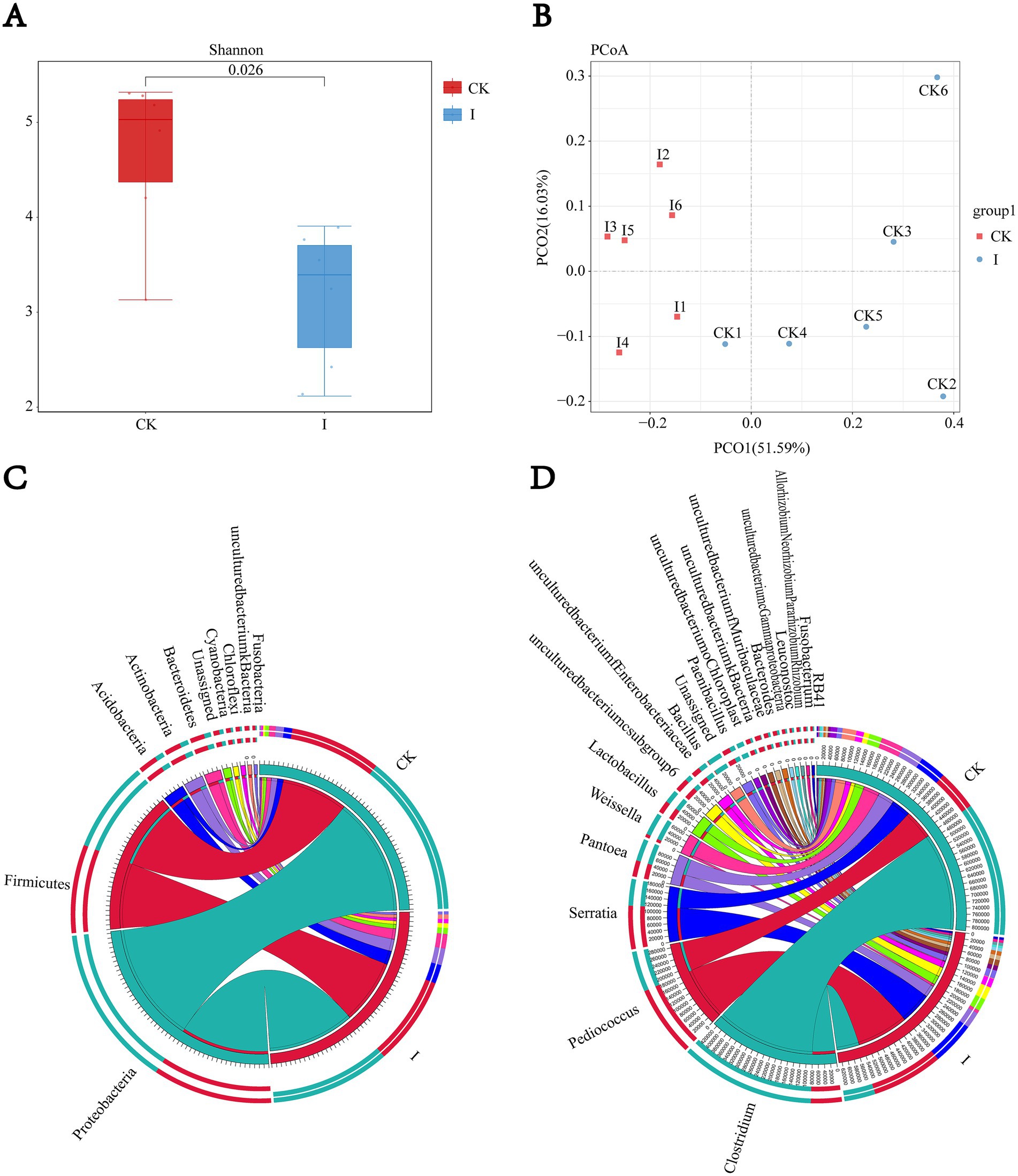

The Shannon index was computed to evaluate microbial diversity, with group I exhibiting a significantly lower bacterial diversity index (3.5 vs. 5.83, p < 0.05) than the CK group. PCoA analysis of beta diversity between CK and group I samples demonstrated notable differences in microbial community structure (p < 0.05; R2 = 0.6891). Analysis at the phylum and genus levels revealed that the microbial compositions ofthe CK and group I were dominated by Proteobacteria, Firmicutes, and Fusobacteria at the phylum level. At the genus level, Gluconobacter, Clostridium, and Pediococcus predominated in group I, while Pediococcus, Serratia, and Pantoea were the dominant genera in the CK group (Figure 1).

Figure 1. Impact of Clostridium beijerinckii SHZ-8 inoculation on the bacterial community structure of whole-crop maize silage. (A) Alpha diversity analysis showing the Shannon diversity index of bacterial communities in the control group (CK) and the C. beijerinckii SHZ-8 inoculated group (I) after 60 days of fermentation. p-value is indicated above the boxplots. (B) Principal Coordinate Analysis (PCoA) plot based on Bray–Curtis dissimilarity, illustrating the separation of bacterial communities between the control group (CK) and the C. beijerinckii SHZ-8 inoculated group (I). The percentage of variance explained by each principal coordinate is indicated on the axes. (C,D) Circos plots illustrating the relative abundance of bacterial taxa at the phylum (C) and genus (D) levels in the control group (CK) and the C. beijerinckii SHZ-8 inoculated group (I). The width of each segment corresponds to the relative abundance of the corresponding taxon.

5.3.2 Effects of Clostridium beijerinckii SHZ-8 inoculation on microbial counts in whole-plant corn silage

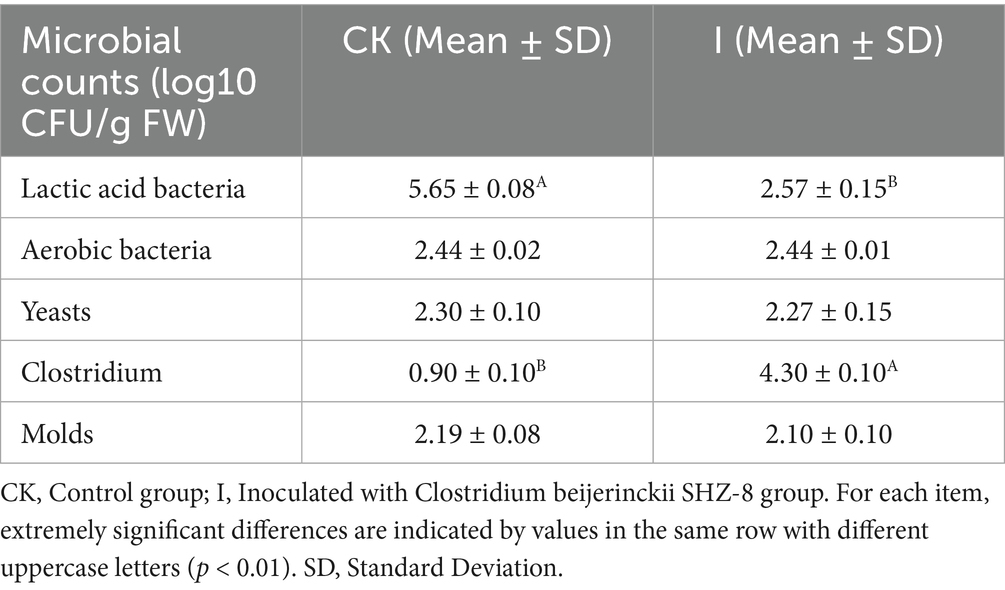

As shown in Table 3, group I had a significantly lower total LAB count than the CK group (2.57 vs. 5.65 log10 CFU/g FW, p < 0.01), representing a 54.51% reduction (p < 0.01). Conversely, the total clostridia count in group I was 3.40-fold higher than in the CK group (4.30 vs. 0.90 log10 CFU/g FW, p < 0.01). This implies that Clostridium beijerinckii SHZ-8 inoculation exerted a significant inhibitory effect on LAB and a promoting effect on clostridia, ultimately causing a shift in the microbial community structure of corn silage.

Table 3. Effects of Clostridium beijerinckii SHZ-8 inoculation on microbial community dynamics in whole-plant maize silage.

5.3.3 Changes in metabolic components in whole-plant corn silage inoculated with clostridium beijerinckii SHZ-8

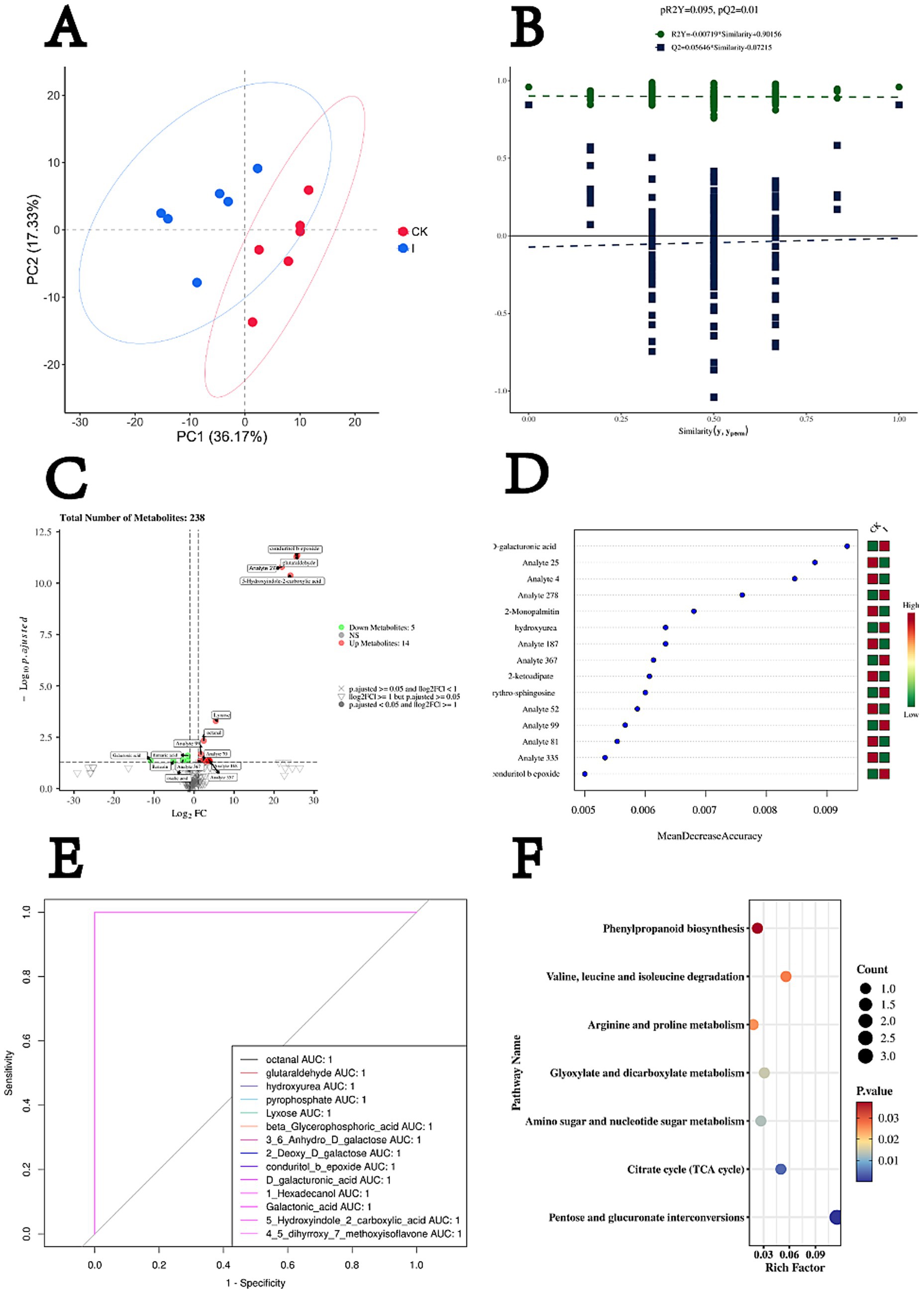

Untargeted metabolomic profiling revealed clear differences between the inoculated treatment group (Group I) and the CK after 60 days of ensiling. Principal component analysis (PCA) (Figure 2A) showed distinct separation of the two groups, with the first (PC1) and second (PC2) principal components explaining 36.17 and 17.33% of the total variance, respectively. Biological replicates within each group clustered tightly, demonstrating high reproducibility of the metabolomic data. Group separation occurred primarily along PC1, indicating substantial divergence in metabolite composition. Orthogonal partial least squares discriminant analysis (OPLS-DA) further confirmed the metabolic distinction between Group I and CK (Figure 2B), yielding model parameters with strong explanatory and predictive power (R2Y and Q2). Model robustness was validated by 200 permutation tests, in which all permuted R2Y values were lower than that of the original model (all <0.9) and most permuted Q2 values fell below zero. The p-values for R2Y and Q2 were 0.095 and 0.01, respectively, confirming the statistical reliability of the model.

Figure 2. Metabolomic profiling reveals key metabolic alterations associated with Clostridium beijerinckii SHZ-8 inoculation in whole-crop maize silage. (A) PCA score plot illustrating the separation of metabolic profiles between the control group (CK) and the C. beijerinckii SHZ-8 inoculated group (I) after 60 days of fermentation, based on PC1 (36.17%) and PC2 (17.33%). (B) Permutation test results for OPLS-DA model validation, showing the distribution of R2Y and Q2 values from permuted datasets, with the original model’s R2Y and Q2 values indicated (pR2Y = 0.095, pQ2 = 0.01). (C) Volcano plot displaying differentially abundant metabolites between the C. beijerinckii SHZ-8 inoculated group (I) and control group (CK). Red points indicate significantly upregulated metabolites, green points indicate significantly downregulated metabolites (p-adjusted < 0.05 and |log2FC| > = 1). (D) Feature importance ranking from random forest analysis, identifying top metabolites contributing to the separation between groups based on MeanDecreaseAccuracy. D-galacturonic acid is highlighted. (E) Receiver ROC curves for selected metabolites, demonstrating their ability to discriminate between the C. beijerinckii SHZ-8 inoculated group (I) and the control group (CK) based on their AUC values. Octanal and D-galacturonic acid are highlighted with AUC = 1. (F) KEGG pathway enrichment analysis of differentially abundant metabolites, highlighting significantly enriched metabolic pathways. The size of the circle indicates the number of metabolites enriched in the pathway, and the color indicates the p-value.

The primary variation was captured along the predictive component, reflecting metabolites directly associated with group classification. Volcano plot analysis (Figure 2C) identified 19 significantly altered metabolites (adjusted p < 0.05, |log₂FC| ≥ 1), of which 14 were upregulated and 5 were downregulated in Group I compared with CK. Notably elevated metabolites included lyxose, octanal, conduritol B epoxide, glutaraldehyde, and 5-hydroxyindole-2-carboxylic acid, whereas galactonic acid, fumaric acid, benzoic acid, and oxalic acid were significantly reduced. Random Forest classification (Figure 2D) identified D-galacturonic acid as the top discriminatory metabolite, followed by 2-monopalmitin and other features. Consistently, heatmap visualization revealed a higher relative abundance of D-galacturonic acid in Group I than in CK. Receiver operating characteristic (ROC) curve analysis (Figure 2E) further demonstrated strong discriminatory capacity, with 14 metabolites achieving perfect group classification (AUC = 1.0). Representative metabolites included octanal, xyurea, lyxose, β-glycerophosphoric acid, and D-galacturonic acid. By integrating differential metabolite profiling, Random Forest–based feature importance ranking, and ROC curve evaluation, this study identified metabolites of potential monitoring relevance. Among them, lyxose and octanal exhibited both robust statistical significance and perfect classification performance (AUC = 1.0), qualifying as potential metabolic biomarkers. In contrast, although D-galacturonic acid ranked highest in feature importance and attained an AUC of 1.0, it did not meet the statistical significance threshold and is therefore considered a candidate biomarker.

KEGG pathway enrichment analysis (Figure 2F) revealed significant metabolic divergence between Group I and CK, with seven pathways enriched (p < 0.05). The most prominent enrichment occurred in pentose and glucuronate interconversions (map00040; Rich factor = 0.115, count = 3, p = 2.10 × 10−5), involving D-galacturonic acid (C00181) and lyxose (C01680). The citrate cycle (TCA cycle) (map00020; Rich factor = 0.050, count = 1, p = 0.0042) was represented by fumaric acid (C00122). Amino sugar and nucleotide sugar metabolism (map00520; Rich factor = 0.027, count = 1, p = 0.0128) also included D-galacturonic acid (C00181). Glyoxylate and dicarboxylate metabolism (map00630; Rich factor = 0.031, count = 1, p = 0.0145) was linked to fumaric acid (C00122). Arginine and proline metabolism (map00330; Rich factor = 0.018, count = 1, p = 0.0253) was enriched in detected intermediates, while valine, leucine, and isoleucine degradation (map00280; Rich factor = 0.056, count = 1, p = 0.0268) was represented by glutaraldehyde (C00638). Additionally, phenylpropanoid biosynthesis (map00940; Rich factor = 0.023, count = 1, p = 0.0374) was identified as a significantly enriched pathway.

5.3.4 Joint analysis of differential microorganisms and metabolites in whole-plant corn silage inoculated with clostridium beijerinckii SHZ-8

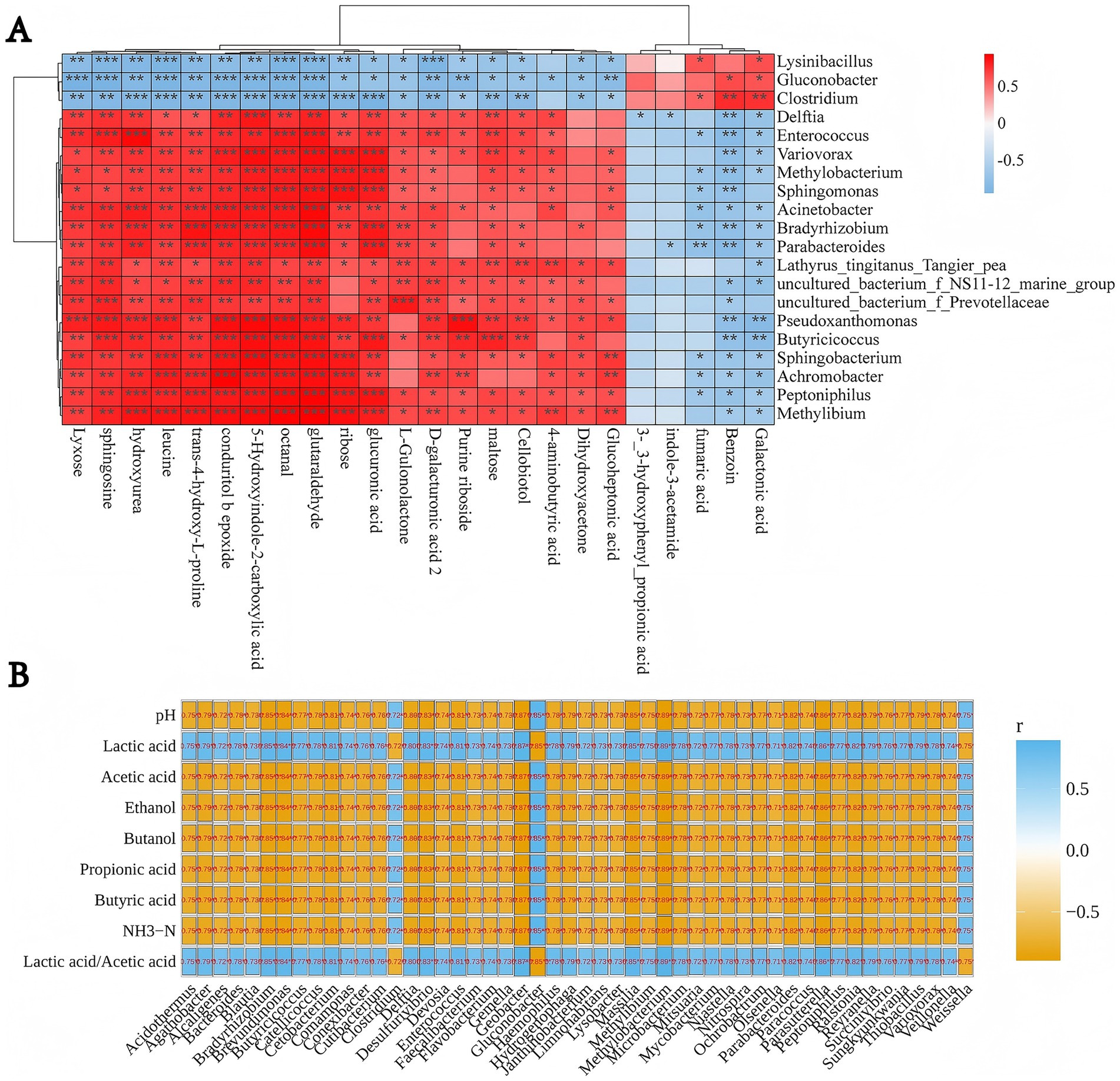

As shown in Figure 3, Clostridium displayed a robust positive correlation with galactaric acid (R2 = 0.87) and benzaldehyde (R2 = 0.77) (both p < 0.01), hinting at its metabolic role in converting complex carbohydrates into galactaric acid. It also generates aromatic compounds such as benzaldehyde through fermentative metabolic pathways. A notable positive correlation with fumaric acid (R2 = 0.67; p < 0.05) and negative correlations with ribose (R2 = 0.92; p < 0.001), leucine (R2 = 0.91; p < 0.001), and sphingosine (R2 = 0.88; p < 0.01) were identified. Clostridium exhibited inverse correlations with lactic acid and the lactic acid/acetic acid ratio, yet displayed positive correlations with pH (R2 = 0.75), acetic acid (R2 = 0.72), ethanol (R2 = 0.70), butanol (R2 = 0.74), propionic acid (R2 = 0.73), butyric acid (R2 = 0.72), and ammonia nitrogen (R2 = 0.75) (all p < 0.01). This suggests that lactic acid has an inhibitory effect on the growth of Clostridium; thus, as lactic acid concentration increases, the abundance or activity of Clostridium decreases, resulting in a negative correlation. Conversely, the increased concentrations of acetic acid, propionic acid, ethanol, butanol, and butyric acid, which are intermediate or end products of Clostridium metabolism, reflect an active metabolic state of Clostridium.

Figure 3. Correlation among key metabolites, microbial genera, and fermentation parameters in whole-crop maize silage inoculated with Clostridium beijerinckii SHZ-8. (A) Spearman’s heatmap shows associations between microbial relative abundance and metabolite profiles, where red denotes positive and blue denotes negative correlations; significance is indicated (*p < 0.05, **p < 0.01, ***p < 0.001). (B) Spearman’s heatmap presents correlations between microbial taxa and fermentation quality traits (pH, organic acids, ethanol, butanol, NH3–N, and lactic/acetic acid ratio), with orange for negative and blue for positive associations. Numerical values in the maps indicate correlation coefficients (r).

6 Discussion

6.1 Effect of Clostridium beijerinckii SHZ-8 inoculation on microbial community structure and quality of whole-plant corn silage

The results of this study indicated that inoculation with Clostridium beijerinckii SHZ-8 significantly altered the nutritional composition, fermentation quality, and metabolic end-products of whole-plant corn silage. A complex and dynamic relationship exists among microbial community succession (Zhu et al., 2025), changes in nutrient composition(Bian et al., 2022), and the production of fermentation metabolites (Zhong et al., 2018; Tian et al., 2021; Ding et al., 2023), which is influenced by both intrinsic microbial interactions and external environmental conditions, forming a multi-layered ecological network(Passos et al., 2003).

The observed reduction in LAB abundance in the SHZ-8-inoculated group can be explained by the competitive and inhibitory activities of C. beijerinckii. First, C. beijerinckii competes with LAB for available fermentable carbohydrates, particularly soluble sugars, thereby reducing the substrate pool for LAB metabolism. Second, under anaerobic conditions, C. beijerinckii can directly utilize lactic acid produced by LAB via secondary fermentation, converting it into acetic acid, butyric acid, CO₂, and H₂ (2 Lactic acid → Butyric acid + 2 CO₂ + 2 H₂; Lactic acid → Acetic acid + CO₂ + H₂). The consumption of lactic acid deprives LAB of its primary metabolic product, disrupting its ecological advantage. Third, the metabolic activity of C. beijerinckii leads to elevated silage pH due to the replacement of stronger lactic acid (pKₐ ≈ 3.8) with weaker acids such as acetic acid and butyric acid (pKₐ ≈ 4.8). This pH shift reduces the acidic stress that typically suppresses the growth of competing spoilage-associated anaerobes, while simultaneously diminishing the acid-tolerant fitness of LAB (Shu et al., 2021). Additionally, certain metabolites, including butyric acid and solventogenic by-products, may exert direct inhibitory effects on LAB growth.

Regarding metabolite accumulation, C. beijerinckii SHZ-8 promotes the synthesis of butyric acid, aldehydes, and alcohols through distinct but interconnected metabolic pathways. Butyric acid production primarily occurs through the acetyl-CoA–butyrate fermentation pathway, in which acetyl-CoA (derived from saccharides or from acetic acid via the reverse β-oxidation pathway) is converted to butyryl-CoA and subsequently to butyric acid. Aldehyde and alcohol formation is associated with the solventogenic phase of C. beijerinckii metabolism, often termed ABE (acetone–butanol–ethanol) fermentation during this process, acetyl-CoA is reduced to aldehydes by aldehyde dehydrogenase and subsequently to alcohols by alcohol dehydrogenase under reduced redox potential. For example, butyraldehyde is produced from butyryl-CoA and then reduced to butanol; similarly, acetaldehyde is reduced to ethanol. Aldehydes may also arise as transient intermediates prior to solvent conversion, and their transient accumulation, along with butanol production, is characteristic of clostridial fermentation under nutrient-limiting or redox-balanced conditions. The production of acetic acid may additionally involve the Wood–Ljungdahl pathway, enabling C. beijerinckii to fix CO₂ under anaerobic conditions.

Collectively, these metabolic activities lead to a decrease in lactic acid and LAB populations, while promoting the accumulation of butyric acid, aldehydes, and alcohols, resulting in elevated pH, altered organic acid profiles, and undesirable flavor compounds. These changes ultimately compromise silage quality, stability, and palatability (Lima et al., 2017; Henderson and Giddens, 1977).

6.2 Metabolomic and microbial correlation analyses reveal the remodeling effect of Clostridium beijerinckii SHZ-8 on the fermentation network of whole-crop maize silage

Metabolomic profiling combined with microbial correlation analysis revealed that Clostridium beijerinckii SHZ-8 exerts profound and multifaceted effects on the metabolite composition of whole-crop maize silage. Multivariate statistical analyses (PCA and OPLS-DA) demonstrated clear separation between the inoculated group (I) and the CK, highlighting the extent of metabolic reprogramming induced by Clostridium activity. These findings align with previous reports indicating that members of the genus Clostridium disrupt lactic acid–dominated fermentation by redirecting substrate fluxes toward amino acid putrefaction and alternative lipid-associated metabolic pathways (Borreani et al., 2018; Ogunade et al., 2018).

Integration of Random Forest analysis, ROC curve evaluation, and volcano plots identified a set of potential metabolic biomarkers. Both xylose and octanal emerged as core discriminative features distinguishing the inoculated group (I) from the CK, showing significant differences and perfect classification accuracy (AUC = 1.0) across statistical models, thereby qualifying as robust candidate biomarkers. Although D-galacturonic acid did not reach statistical significance in univariate analyses, it ranked highest in the Random Forest model and achieved an AUC of 1.0, underscoring its potential as a key candidate biomarker. As a functional component of plant cell walls, D-galacturonic acid may serve as an early indicator of structural degradation, providing a signal of impending spoilage before visible symptoms appear (Ochoa-Villarreal et al., 2012).

The metabolic origins of these candidate biomarkers warrant particular attention and can be broadly classified into two categories: (i) metabolites directly generated through Clostridium metabolism, and (ii) metabolites released from plant cell wall degradation. Octanal exemplifies the first category, as it is a key intermediate in the fatty acid chain-elongation and acyl-CoA reduction pathways of Clostridium metabolism (Das et al., 2020). In this study, octanal was strongly and positively correlated with C. beijerinckii SHZ-8 abundance in whole-crop maize silage. Its pronounced lipophilicity facilitates rapid diffusion within the silage matrix and partitioning into microbial membranes, where it disrupts membrane integrity, increases permeability, dissipates proton motive force, and induces leakage of intracellular contents. These membrane-active properties selectively suppress acid-tolerant LAB while promoting the proliferation of more resilient spoilage-associated anaerobes such as Clostridium sporogenes (Omoigberale, 2021). Beyond membrane disruption, octanal can react with amino groups in proteins and nucleic acids to form Schiff bases, impairing enzymatic activity and altering gene expression. Collectively, these biochemical and ecological effects accelerate the decline of beneficial microbial populations, drive community restructuring toward a clostridial-dominant state, and contribute to elevated pH, reduced palatability, and cytotoxicity at high concentrations (Kung et al., 2018). Although traditionally regarded as a transient metabolic intermediate (Hafner et al., 2013), the stable accumulation of octanal under specific fermentation conditions underscores its dual role as both a quality-deteriorating agent and a process-related biomarker of Clostridium solventogenesis.

Among the significantly upregulated metabolites, xylose was strongly linked to the hydrolysis of structural polysaccharides. Derived primarily from hemicellulose degradation, its accumulation may indicate enhanced activity of Clostridium-associated polysaccharide-degrading pathways (Weimer, 2022). However, because xylose is not exclusively produced by Clostridium (Broeker et al., 2018), its specificity as a diagnostic marker is lower than that of octanal in complex microbial communities. Accordingly, xylose is better suited as an auxiliary indicator of Clostridium metabolic activity rather than a standalone, specific biomarker.

D-Galacturonic acid, a direct product of homogalacturonan degradation in plant cell wall pectin, is primarily generated in silage through the activity of microbial pectinolytic enzymes—most notably pectate lyases (PL1, PL9) and polygalacturonases—which cleave the α-(1 → 4)-linked galacturonic acid backbone (Leschine, 2005). Under anaerobic conditions, such enzymes are predominantly associated with Clostridium spp. (e.g., C. beijerinckii) and a limited number of other microorganisms (ten Have et al., 2002). Genome annotations of C. beijerinckii and related clostridia have identified polysaccharide utilization loci (PULs) encoding PL1, PL9, α-L-arabinofuranosidase, and β-xylosidase (Huang et al., 2022; Huang et al., 2025). These enzymes act synergistically to remove arabinan and xylan side chains, expose the homogalacturonan backbone, and release both D-galacturonic acid and xylose. KEGG pathway enrichment links these activities to the “Pentose and glucuronate interconversions” pathway, which channels liberated D-galacturonic acid into uronate isomerase– and dehydrogenase-mediated reactions, producing pyruvate and glyceraldehyde-3-phosphate for fermentation metabolism (Seveso et al., 2024). Because pectin is among the earliest cell wall polymers targeted during anaerobic spoilage—and pectinolytic activity is common in clostridia but rare in LAB—D-galacturonic acid represents a highly specific early-stage signal of clostridial pectinolysis. Its release precedes extensive cellulose degradation, thereby providing early warning of structural carbohydrate loss and potential nutrient depletion. In this study, D-galacturonic acid concentration exhibited a strong positive correlation with Clostridium relative abundance (R2 = 0.87), reinforcing its potential as an early-warning biomarker of clostridial-driven deterioration.

Correlation analyses revealed that the observed metabolic shifts closely reflected a transition from lactic acid–dominated to butyric acid–dominated fermentation—a hallmark of Clostridium overgrowth. Significant positive correlations were observed among butyric acid, propionic acid, ethanol, butanol, ammonia-N, and pH, indicating a metabolic deviation from lactic acid–driven acidification toward proteolytic and solvent-producing pathways. In contrast, lactic acid concentration and the lactate/acetate ratio were significantly negatively correlated, suggesting delayed or impaired lactic acid production. This reduction weakened a critical ecological barrier against Clostridium expansion, thereby creating favorable conditions for C. beijerinckii SHZ-8 to dominate the silage microbiome. The resulting metabolic shift exerted a dual impact at ecological and biochemical levels: (i) hydrolysis of plant cell wall polysaccharides disrupted fiber structure, releasing soluble sugars that fueled Clostridium metabolism while depleting structural carbon reserves and causing irreversible nutrient loss; and (ii) these sugars drove the production of butyric acid, aldehydes, and alcohols, which in turn elevated pH, promoted protein degradation with ammonia-N release, and accelerated spoilage progression.

Metabolomic–microbial correlation analyses demonstrated that Clostridium beijerinckii SHZ-8 profoundly reconfigures the metabolic network of whole-crop maize silage, with octanal and D-galacturonic acid emerging as key indicators of fatty acid reduction and pectin degradation, respectively. These metabolites mark the transition from lactic acid–dominated fermentation to butyric acid-, alcohol-, and aldehyde-rich fermentation. This shift compromises the fermentation barrier, accelerates nutrient loss, elevates pH, and increases hygienic risks. Concurrent monitoring of these metabolites alongside conventional indicators offers a robust early-warning framework for controlling Clostridium overgrowth. Looking ahead, validation under farm-scale conditions—where environmental heterogeneity, forage composition, and management practices vary—will be critical. Progress will also depend on developing rapid, field-deployable assays that balance analytical specificity with the sensitivity required to detect low-abundance early-stage markers. Integrating such portable, user-friendly platforms into routine farm operations would enable real-time monitoring and precision interventions, ultimately advancing silage preservation strategies.

7 Conclusion

This study shows that inoculation with Clostridium beijerinckii SHZ-8 significantly accelerates nutrient loss and increases spoilage risk in whole-crop maize silage, characterized by marked reductions in DM content and LAB counts, extensive proliferation of Clostridium, and a clear shift in fermentation from homofermentation to heterofermentation. Integrated metabolomic and microbiome analyses identified galacturonic acid as an early-stage metabolic biomarker of silage deterioration. These insights establish a scientific basis and practical framework for early spoilage detection and the development of targeted preservation strategies, offering substantial value for quality control and risk management in silage production.

Data availability statement

The sequencing data generated in this study have been deposited in the NCBI Sequence Read Archive (SRA) under the BioProject accession number PRJNA1338828.

Author contributions

FY: Writing – original draft, Writing – review & editing, Investigation. DF: Investigation, Writing – review & editing. XY: Supervision, Conceptualization, Writing – review & editing. JL: Conceptualization, Supervision, Writing – review & editing. CM: Data curation, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Visualization, Writing – original draft, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was funded by the Ministry of Finance and the Ministry of Agriculture and Rural Affairs through the National Modern Agricultural Industry Technology System Project (grant number CARS-34). The Article Processing Charge (APC) was also funded by CARS-34.

Acknowledgments

The authors would like to express their heartfelt gratitude to all co-authors for their invaluable assistance and steadfast support throughout the research endeavor.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bian, X., Chen, J. R., Fan, J., Yang, Y., Yu, D. H., Ren, L. K., et al. (2022). Microbial and genes diversity analysis: relationship between starch conversion and carbohydrate metabolism during Niandoubao fermentation via the glutinous proso millet (GPM) process. Food Contr. 140:109154. doi: 10.1016/j.foodcont.2022.109154

Blasel, H. M., Hoffman, P. C., and Shaver, R. D. (2006). Degree of starch access: an enzymatic method to determine starch degradation potential of corn grain and corn silage. Anim. Feed Sci. Technol. 128, 96–107. doi: 10.1016/j.anifeedsci.2005.08.018

Borreani, G., Tabacco, E., Schmidt, R. J., Holmes, B. J., and Muck, R. E. (2018). Silage review: factors affecting dry matter and quality losses in silages. J. Dairy Sci. 101, 3952–3979. doi: 10.3168/jds.2017-13837

Broeker, J., Mechelke, M., Baudrexl, M., Mennerich, D., Hornburg, D., Mann, M., et al. (2018). The hemicellulose-degrading enzyme system of the thermophilic bacterium Clostridium stercorarium: comparative characterisation and addition of new hemicellulolytic glycoside hydrolases. Biotechnol. Biofuels 11:229. doi: 10.1186/s13068-018-1228-3

Cai, K. K., Huang, Z. W., Shen, Z. Y., and Sun, C. T. (2013). Study on enzymatic hydrolysis of rice bran starch by double enzymes. J. Chin. Cereals Oils Assoc. 18, 17–23.

Chen, B., Feng, S. L., Hou, J. F., Zhu, Y., Bao, F., Han, H. L., et al. (2022). Genome-wide transcriptome analysis revealing the genes related to sugar metabolism in kernels of sweet corn. Meta 12:1254. doi: 10.3390/metabo12121254

Chen, J. Y., Wu, W. F., Cheng, R. M., Yin, H. M., and Xi, Y. B. (2016). Comparison of two methods for determination of free starch in potato. Agric. Technol. 36:27–28.

Das, M., Patra, P., and Ghosh, A. (2020). Metabolic engineering for enhancing microbial biosynthesis of advanced biofuels. Renew. Sust. Energ. Rev. 119:109562. doi: 10.1016/j.rser.2019.109562

Ding, X. H., Yang, W. J., Du, X. B., Chen, N., Xu, Q. Y., Wei, M. H., et al. (2023). High-level and -yield production of L-leucine in engineered Escherichia coli by multistep metabolic engineering. Metab. Eng. 78, 128–136. doi: 10.1016/j.ymben.2023.06.003

Dunière, L., Sindou, J., Chaucheyras-Durand, F., Chevallier, I., and Thévenot-Sergentet, D. (2013). Silage processing and strategies to prevent persistence of undesirable microorganisms. Anim. Feed Sci. Technol. 182, 1–15. doi: 10.1016/j.anifeedsci.2013.04.006

Dunière, L., Xu, S., Long, J., Elekwachi, C. O., Wang, Y., Turkington, K., et al. (2017). Bacterial and fungal core microbiomes associated with small grain silages during ensiling and aerobic spoilage. BMC Microbiol. 17:50. doi: 10.1186/s12866-017-0947-0

Hafner, S. D., Howard, C. C., Muck, R. E., Franco, R. B., Montes, F., Green, P. H. R., et al. (2013). Emission of volatile organic compounds from silage: compounds, sources, and implications. Atmos. Environ. 77, 827–839. doi: 10.1016/j.atmosenv.2013.04.076

Henderson, P. J. F., and Giddens, R. A. (1977). 2-deoxy-d-galactose, a substrate for the galactose-transport system of Escherichia coli. Biochem. J. 168, 15–22. doi: 10.1042/bj1680015

Huang, G. T., Su, D. X., Lee, Y. K., Zou, X. Q., Dong, L. H., Deng, M., et al. (2025). Accumulation of water-soluble polysaccharides during lychee pulp fermentation with Lactiplantibacillus plantarum involves endoglucanase expression. J. Agric. Food Chem. 73, 3669–3679. doi: 10.1021/acs.jafc.4c08859

Huang, H. Q., Zheng, Z. G., Zou, X. X., Wang, Z., Gao, R., Zhu, J., et al. (2022). Genome analysis of a novel polysaccharide-degrading bacterium Paenibacillus algicola and determination of alginate lyases. Mar. Drugs 20:388. doi: 10.3390/md20060388

Kozloski, G. V., Senger, C. C. D., Perottoni, J., and Sanchez, L. B. (2006). Evaluation of two methods for ammonia extraction and analysis in silage samples. Anim. Feed Sci. Technol. 127, 336–342. doi: 10.1016/j.anifeedsci.2005.09.005

Kung, L., Shaver, R. D., Grant, R. J., and Schmidt, R. J. (2018). Silage review: interpretation of chemical, microbial, and organoleptic components of silages. J. Dairy Sci. 101, 4020–4033. doi: 10.3168/jds.2017-13909

Leschine, S. (2005). Degradation of polymers. Boca Raton, Florida, USA: CRC Press eBooks, 101–131 (19.pt2).

Li, X. X., and Li, X. Z. (2013). Optimization of anthrone colorimetric method for determination of soluble sugar content in sweet corn. Storage Process 17, 24–27.

Li, M., Zhang, L. D., Zhang, Q., Zi, X. J., Lv, R. L., Tang, J., et al. (2020). Impacts of citric acid and malic acid on fermentation quality and bacterial community of cassava foliage silage. Front. Microbiol. 11:595622. doi: 10.3389/fmicb.2020.595622

Lima, S., Milstien, S., and Spiegel, S. (2017). Sphingosine and sphingosine kinase 1 involvement in endocytic membrane trafficking. Biol. Chem. 292, 3074–3088. doi: 10.1074/jbc.m116.762377

Liu, J., Jia, X. Y., Yan, W. M., Zhong, Y. Q. W., and Shangguan, Z. P. (2020). Changes in soil microbial community structure during long-term secondary succession. Land Degrad. Dev. 31, 1151–1166. doi: 10.1002/ldr.3505

Liu, Y., Wang, G. G., Wu, H., Meng, Q. X., Khan, M. Z., and Zhou, Z. M. (2021). Effect of hybrid type on fermentation and nutritional parameters of whole plant corn silage. Animals 11:1587. doi: 10.3390/ani11061587

Liu, X. D., Wang, A. F., Zhu, L. Q., Guo, W., Guo, X. J., Zhu, B. C., et al. (2024). Effect of additive cellulase on fermentation quality of whole-plant corn silage ensiling by a bacillus inoculant and dynamic microbial community analysis. Front. Microbiol. 14:1330538. doi: 10.3389/fmicb.2023.1330538

Ma, R., Ou Yang, J., Li, X., Lian, Z. N., and Cai, C. (2013). Simultaneous determination of organic acids and saccharides in lactic acid fermentation broth from biomass using high performance liquid chromatography. Chin. J. Chromatogr. 30, 62–66. doi: 10.3724/sp.j.1123.2011.09033

Muck, R. E. (2010). Silage microbiology and its control through additives. Rev. Bras. Zootec. 39, 183–191. doi: 10.1590/S1516-35982010001300021

Ochoa-Villarreal, M., Aispuro-Hernández, E., Vargas-Arispuro, I., and Martínez-Téllez, M. Á. (2012). “Plant cell wall polymers: function, structure and biological activity of their derivatives” in Polymerization. IntechOpen.

Ogunade, I. M., Jiang, Y., Pech Cervantes, A. A., Kim, D. H., Oliveira, A. S., Vyas, D., et al. (2018). Bacterial diversity and composition of alfalfa silage as analyzed by Illumina MiSeq sequencing: effects of Escherichia coli O157:H7 and silage additives. J. Dairy Sci. 101, 2048–2059. doi: 10.3168/jds.2017-12876

Omoigberale, M. (2021). Evaluating the impact of alternative antimicrobials on biofilms formed by Clostridium Perfringens. [doctoral dissertation]. University of Lincoln.

Pahlow, G., Muck, R. E., Driehuis, F., Elferink, S. J. W. H. O., and Spoelstra, S. F. (2015). Microbiology of ensiling. Agron. Monogra. 42, 31–93. doi: 10.2134/agronmonogr42.c2

Passos, F. V., Fleming, H. P., Hassan, H. M., and McFeeters, R. F. (2003). Effect of malic acid on the growth kinetics of Lactobacillus plantarum. Appl. Microbiol. Biotechnol. 63, 207–211. doi: 10.1007/s00253-003-1375-7

Raut, B. (2023). Gas chromatography mass spectrometry: principle, instrumentation, advantages, and 10 reliable applications—chemistry notes. Chemist Notes. Available online at: https://chemistnotes.com/analytical_chemistry/gas-chromatography-mass-spectrometry-principle-instrumentation-advantages-and-10-reliable-applications/ (Accessed January 2, 2024).

Seveso, A., Mazurkewich, S., Banerjee, S., Poulsen, J. C. N., Leggio, L. L., and Larsbrink, J. (2024). Polysaccharide utilization loci from Bacteroidota encode CE15 enzymes with possible roles in cleaving pectin-lignin bonds. Appl. Environ. Microbiol. 90:e0176823. doi: 10.1128/aem.01768-23

Shu, D. T., Guo, Y. Q., Zhang, B. G., Zhang, C. F., Van, J. D., Lin, Y. B., et al. (2021). Rare prokaryotic sub-communities dominate the complexity of ecological networks and soil multinutrient cycling during long-term secondary succession in China’s loess plateau. Sci. Total Environ. 774:145737. doi: 10.1016/j.scitotenv.2021.145737

Sigolo, S., Fancello, F., Ghilardelli, F., Mosconi, M., Prandini, A., Masoero, F., et al. (2023). Survey on the occurrence of silage volatile organic compounds in the Po valley–Italy. Anim. Feed Sci. Technol. 297:115593. doi: 10.1016/j.anifeedsci.2023.115593

ten Have, A., Tenberge, K. B., Benen, J. A., Tudzynski, P., Visser, J., and van Kan, J. A. L. (2002). The contribution of cell wall degrading enzymes to pathogenesis of fungal plant pathogens. Berlin, Heidelberg, Germany: Springer eBooks, 341–358.

Tian, H. C., Wang, Y., Liu, Z. C., Hu, Z. Y., Guo, Y. Q., Deng, M., et al. (2021). Effects of malic acid and sucrose on the fermentation parameters, CNCPS nitrogen fractions, and bacterial community of Moringa oleifera leaves silage. Microorganisms 9:2102. doi: 10.3390/microorganisms9102102

Vissers, M. M. M., Driehuis, F., Giffel, M. C. T., Jong, P. D., and Lankveld, J. M. G. (2007). Concentrations of butyric acid bacteria spores in silage and relationships with aerobic deterioration. J. Dairy Sci. 90, 928–936. doi: 10.3168/jds.s0022-0302(07)71576-x

Weimer, P. J. (2022). Degradation of cellulose and hemicellulose by ruminal microorganisms. Microorganisms 10:2345. doi: 10.3390/microorganisms10122345

Wickham, H. (2016). “Data analysis” in In ggplot2: elegant graphics for data analysis (Cham: Springer International Publishing), 189–201.

Zhong, Y. Q. W., Yan, W. M., Wang, R. W., Wang, W., and Shangguan, Z. P. (2018). Decreased occurrence of carbon cycle functions in microbial communities along with long-term secondary succession. Soil Biol. Biochem. 123, 207–217. doi: 10.1016/j.soilbio.2018.05.017

Keywords: Clostridium beijerinckii SHZ-8, metabolomics analysis, microbial diversity, silage, whole-plant corn

Citation: Yang F, Fu D, Yu X, Lv J and Ma C (2025) Research on the spoilage characteristics of whole-plant corn silage inoculated with Clostridium beijerinckii SHZ-8. Front. Microbiol. 16:1640283. doi: 10.3389/fmicb.2025.1640283

Edited by:

Ashwani Kumar, University of Allahabad, IndiaReviewed by:

Ping Li, Guizhou University, ChinaShuai Du, Inner Mongolia Agricultural University, China

Copyright © 2025 Yang, Fu, Yu, Lv and Ma. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Chunhui Ma, eWFuZ3lhbmdfc2h6XzEwMTlAMTI2LmNvbQ==

Fan Yang

Fan Yang Dongqing Fu

Dongqing Fu