Abstract

Introduction:

Concrete is widely used in coastal construction, tetrapod armour units as the top layer of breakwaters, which protect rear-side developments by dissipating wave energy. However, concrete poses environmental impacts across its life cycle. There is a remarkable gap in the literature on the Life Cycle Assessment (LCA) of concrete armour units, despite their widespread usage in coastal engineering. To address this, this study evaluates the environmental impact of tetrapod armour over its life cycle.

Methods:

An LCA is undertaken using SimaPro software, applying a cradle-to-gate approach that focuses on production, transportation, and placement stages of tetrapods, concrete and steel for casting. The functional unit (FU) is “5-meter of breakwater.” Due to limited data in the literature, the Life Cycle Inventory (LCI) is mainly obtained from the ecoinvent database available on SimaPro. Energy data for the unit processes is gathered from literature and manufacturers. The Life Cycle Impact Assessment (LCIA) is undertaken using a mid-point approach in the CML-IA method. Additionally, the non-renewable fossil impact category under the Cumulative Energy Demand (CED) method is evaluated, since non-renewable resources are major contributors in tetrapod production.

Results:

The CML-IA results show that cast production emerged as the predominant contributor, comprising over 80% of the total impacts across all categories. Notably, cast production has the highest influence on non-renewable fossil impacts under CED, with a value of 2.62E+06 MJ per FU. This highlights the significant energy burden of steel in tetrapods and underscores the importance of decision-making during the production stage. Additionally, sensitivity analysis revealed that the system has low sensitivity to changes in transportation distance.

Discussion:

The study confirms cast production dominates the total environmental impacts and fossil energy use. Further research is needed to analyze large quarry rocks use for the armour layers, while accounting for regional variables to obtain more reliable results. The findings emphasize the need to explore alternative materials and production methods to reduce the environmental footprint of tetrapods while maintaining their protective effectiveness in coastal construction.

1 Introduction

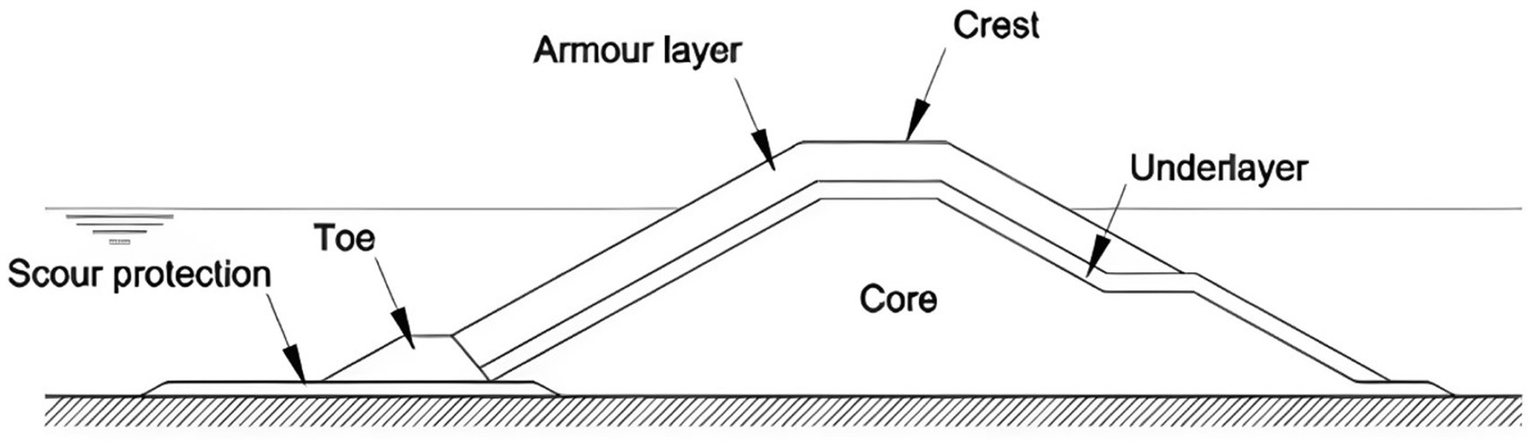

Concrete is one of the most widely used building materials around the world, as reflected in numerous previous studies (Diaferio and Varona, 2024; Wang et al., 2023; Van den Berghe and Verhagen, 2021). Huge environmental concerns are arising from the utilization of concrete in the construction sector (Glanz et al., 2023). In particular, cement production for concrete manufacture generates a high carbon footprint that affects a substantial amount of global CO2 emissions (York, 2021). Consequently, challenges to overcome greenhouse gas emissions and energy consumption in the concrete life cycle are being thoroughly investigated in recent research (Zhang et al., 2018; Xu et al., 2024). Therefore, the aim of this paper is to contribute to the existing literature by carrying out an LCA on concrete armour units, which are extensively used in breakwater applications. On the other hand, concrete has a variety of uses and offers multiple unique functions. One of its uses is the construction of unreinforced concrete armour units for breakwaters to serve as a coastal defense structure (Fookes and Poole, 1981). Breakwaters are marine structures that help break waves and protect against strong waves and currents (Nordstrom, 2014). As shown in Figure 1, a breakwater is made up of five components, including three essential layers: armour, underlayer, and core layers.

Figure 1

Typical breakwater cross section (CIRIA, CUR, and CETMEF, 2007).

The top layer is called the armour layer. While the core and the underlayer are commonly made from relatively smaller rocks, the armour layer can be made up of large rocks from quarries or unreinforced concrete units. Rocks are typically the first option for the armour layer. A breakwater made solely of rocks is called a rubble-mound breakwater. However, when the required rock size is too large, the alternative solution of utilizing a concrete armour unit may be more appropriate (CIRIA, CUR, and CETMEF, 2007). Concrete armour units are unreinforced concrete blocks used primarily for protection against wave action (Park et al., 2019). They come in different shapes and sizes. They can be shaped into concrete cubes, accropodes, stabits, tetrapods, dolos, etc. (Muttray and Reedijk, 2009). Tetrapod is the first irregular shape made for concrete armour units (Natakusumah et al., 2024). It was created in France in the 1950s (Moreau and Gand, 2022). Tetrapods offer a very rough facing for the breakwater as they have high porosity due to 50% voids when staggered (Daniel and Greslou, 1962). This greatly helps dissipate the wave energy. Tetrapods are typically placed as interlocking-type units used in a double layer (CIRIA, CUR, and CETMEF, 2007). They are also capable of standing at a steep slope of 1:3/4 or 1:1.5 (Bakker et al., 2003; Daniel and Greslou, 1962), which may be considered too steep and may be unstable for large quarry rocks. Steep slopes help with shortening the footprint of the breakwater extension. Tetrapods may come in various weights that range from 1.5 to 25 tons (Fibo Intercon, n.d.). They are cast in steel moulds. They can be pre-cast or cast on-site if there is adequate space for casting and storing (Winters, 2024).

A significant amount of concrete is used in a typical tetrapod concrete armour unit. For this reason, considering the new focus on sustainable development and green construction, it is important to consider the sustainability impact of such concrete units over the course of their life cycle. It has been noted from previous and current literature that the usage of LCA helps in identifying environmental impacts associated with a product, from the phase of extraction of raw material to the disposal of the product (Kheiralipour et al., 2024; Finnveden et al., 2009). Although numerous LCA studies have been conducted on other concrete products, such as waste rubber concrete, concrete containing ferrochrome slag and fly ash, recycled e-waste concrete, etc. (Tang et al., 2024; Das et al., 2022; Goh et al., 2022), limited work has been done within the concrete armour units, particularly tetrapods. For instance, a study applied LCA to compare the environmental impact of natural stone and tetrapod breakwaters. All phases during construction were considered. The functional unit considered is 10 m of breakwater, and impact categories are used according to the CML method. Gabi 6 software was used to carry out LCA. The results obtained indicated that concrete production has more impact than natural stone production according to multiple impact categories. For example, a tetrapod breakwater GWP value of 81,700 kg CO2-eq. is more than the natural stone breakwater GWP value of 10,000 kg CO2-eq. In addition, more energy consumption is observed during tetrapod construction than natural stone (Valiyev, 2015). Another study was conducted in Brazil to evaluate the environmental performance of three different types of walls commonly used: ceramic bricks, concrete bricks and cast-in-place reinforced concrete exterior walls. The results were analyzed using SimaPro 7.3 software. The analysis showed that ceramic brick walls have less impact than concrete walls on resource depletion and greenhouse gas emissions (De Souza et al., 2016). Similarly, an LCA of rubble-mound breakwaters with concrete armour units and caisson breakwaters showed that caissons had a smaller carbon footprint, with reinforced concrete being a major contributor to emissions (Broekens et al., 2012). Furthermore, a separate LCA study was performed using SimaPro 7.3 to evaluate alkali-activated blast furnace slag as an alternative binder in concrete mix designs for breakwater structures. Results indicated that sodium silicate-activated slag is a feasible option with low GWP but higher impacts in other categories (Silva et al., 2018).

The literature has covered a wide range of LCAs on concrete-based materials, including tetrapod armour units. However, due to limited studies mainly focusing on tetrapods, the literature is left with major gaps that need to be assessed. For instance, Valiyev (2015) proposed a well-structured LCA methodology for tetrapods, contributing significantly to a clearer understanding of the associated challenges. However, the study lacked a comprehensive assessment of key phases of LCA, such as casting, transport, and placement; limited modelling was implemented to thoroughly cover these phases. Also, mid-point indicators like CML-IA and CED were excluded from the study. Furthermore, the existing research relies on outdated data, underscoring the need for updated studies that incorporate advanced methodologies and current databases. Therefore, this research paper is set to cover several gaps from the literature, providing a robust interpretation of tetrapods’ LCA by adopting a cradle-to-gate approach, focusing on production, transportation and placement stages, while excluding the use and disposal phases due to their negligible environmental impact and unpredictable nature (Yadav and Samadder, 2018; Biswas et al., 2017). Thus, delivering a deep understanding to decision-makers. These gaps are filled by conducting casting, transport, and placement modelling together with CML-IA and CED indicators. Moreover, this paper is focused on using an up-to-date database to provide a reliable analysis of the tetrapod LCA. As a result, the ecoinvent v3.8 database, which was recently updated in 2023 (Ecoinvent Association, 2023) is utilized. Additionally, the modelling is performed using SimaPro software, which was adopted due to its high capability to model detailed life cycle stages, advanced integration with ecoinvent database, and support for a wide range of impact assessment methods, as outlined by Su et al. (2020). In this study, the selected unit is a 5 tonne tetrapod with a volume of 2.08 m3, and the casting of this unit is typically made of steel, weighing 1 tonne (Fibo Intercon, n.d.).

2 Materials and methods

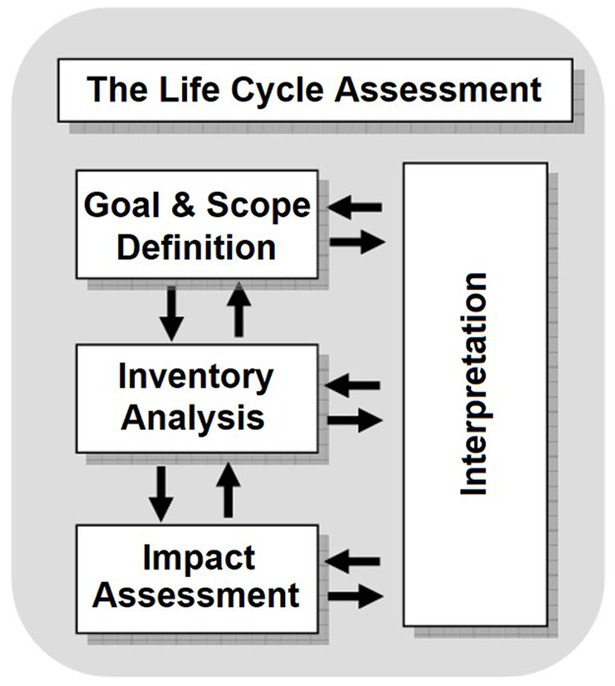

This study employs a standard Life Cycle Assessment approach to assess the potential environmental impacts associated with the life cycle of a concrete coastal armour unit known as a tetrapod. LCA is a thorough assessment method that examines a product’s entire life cycle and incorporates various environmental impacts. These distinctive aspects of LCA help prevent shifting problems from one life cycle stage to another or from one type of environmental impact to another (Finnveden and Potting, 2014). Based on the ISO 14044 standards, which were most recently updated in 2020 (ISO, 2020), the LCA methodology is divided into four phases: the goal and scope definition, the Life Cycle Inventory (LCI) analysis, the Life Cycle Impact Assessment (LCIA) and the interpretation (Pennington et al., 2004). These four phases are illustrated in Figure 2, representing the sequence and interconnections of the steps in the LCA process.

Figure 2

Phases of an LCA (Lee and Inaba, 2004).

The goal of this study is to quantify the environmental impacts of the production, transportation, and placement of tetrapod concrete armour units. The intended purpose of this study is to inform decision-makers, such as contractors, designers, and developers, about the impacts and emissions so they can make decisions on alternatives to be used for coastal protection. This is important as rocks are commonly used for the armour layer. Understanding the impacts of tetrapods may indicate which alternative would be best to use. This study may also aid in policy-making decisions related to casting and transporting concrete for the production of concrete armour units. The functional unit and system boundary are defined in the sub-section below.

2.1 Functional unit and system boundary

The functional unit is necessary for LCA studies to form a reference for the impacts, where the amount of function is quantified and achieved. The functional unit of this study is “5 m of breakwater.” Calculations are made in order to quantify the amount of tetrapod units, volume, and weight within the 5 meters of the breakwater. Several assumptions were made based on available literature and standard engineering practice. Accordingly, the breakwater section is assumed to have a two-layer tetrapod armour unit with a thickness of 2.6 m, as presented by Valiyev (2015). Moreover, the bed level and the top level are taken as −6.0 m and +4.0 m, respectively (Shinde et al., 2017), with a slope ratio of 1:1.5 (Hald et al., 2015).

Table 1 provides a concise overview of every calculation step carried out throughout the analysis. Based on previously mentioned assumptions, the cross-sectional area derived from AutoCAD calculations is approximated to be 50.2 m2 (1–5), and when extended over a 5 m length of breakwater, the calculated volume is 251 m3 (6). Considering a porosity of 50% (Suwannarat et al., 2020), the volume is reduced to 126 m3 (7). As a result, the number of 5 tonne tetrapods with a volume of 2.08 m3 is 61 (8). Finally, the weight of the concrete in 5 m when using 61 tetrapods is 305 tonnes (9).

Table 1

| Description | Equation used | Variable | Calculation | Step No. |

|---|---|---|---|---|

| Thickness of tetrapods (m) |

|

(1) | ||

| Width of crest (m) | (2) | |||

| Crest area (m2) | (3) | |||

| Interface area (m2) |

|

|

(4) | |

| Cross-sectional area (m2) | (5) | |||

| Volume (m3) |

|

(6) | ||

| Adjusted volume (50% porosity) |

|

(7) | ||

| Number of tetrapods required | (8) | |||

| Weight of concrete (tons) | (9) |

Summary of tetrapods calculations.

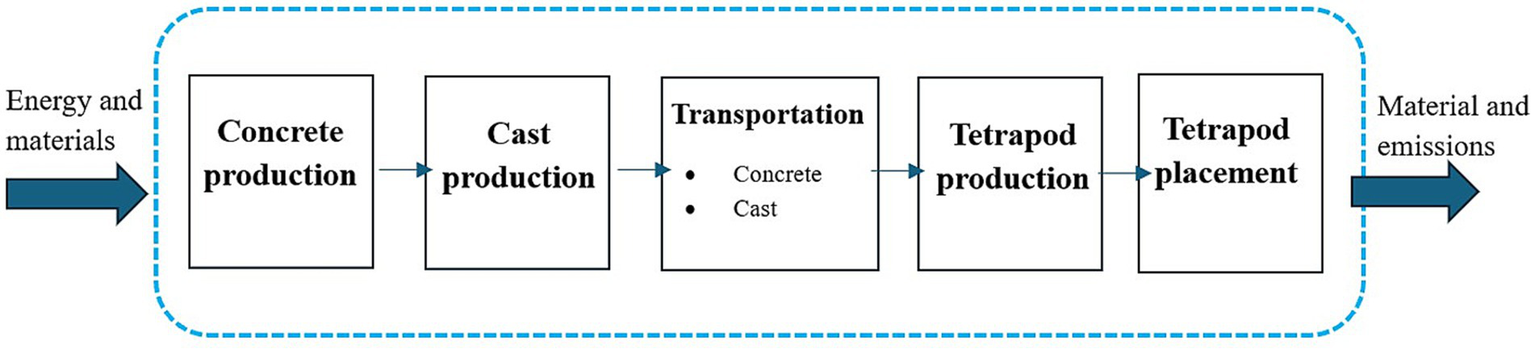

The assessment covers the tetrapod life span from raw materials (concrete and steel cast needed to mould tetrapods) and going up to the placement phase, as depicted in Figure 3. The use and disposal phases are excluded from this LCA. In other words, the study adopts a “cradle to gate” approach, evaluating the stages up to the point where the tetrapods are completed and ready for deployment in coastal projects. This approach was selected to concentrate on the steps with the greatest environmental impacts: production, transportation, and placement. Adding the use and disposal phases would need more parameters that could be highly sensitive to the application of disposal, which are beyond the reach of this research. Hence, this approach provides a thorough understanding of the environmental impacts up to the placement phase.

Figure 3

System boundary from cradle to gate.

2.2 Life cycle inventory (LCI)

Conducting a representative LCA requires collecting material and energy inputs for each defined unit process within the system boundary. However, given that very few papers have examined the LCA of tetrapods, there is limited data available in the literature. Consequently, this study relied heavily on the ecoinvent database available in SimaPro. Ecoinvent is the world’s leading LCI database, widely regarded as credible, and provides extensive, reliable data on various topics, including building materials, metals, electricity, manufacturing processes, transportation, construction processes, waste management, and water supply (Frischknecht et al., 2005). To determine the amounts of energy or materials needed for each unit process, data were retrieved either from relevant studies in the literature (Valiyev, 2015) or from the manufacturer’s websites (Betonblock®, 2006).

For the concrete production unit process, as with all other material processes included in this study, the data was directly taken from the ecoinvent v3.8 database (Ecoinvent Association, 2023) available in SimaPro 8 (SimaPro, n.d.). This process encompasses the entire manufacturing cycle for producing ready-mixed concrete, including internal processes such as material handling, mixing, and infrastructure. Specifically, the “Concrete, normal {RoW}| production” dataset describes a ready-mix concrete composed of Portland cement, sand, gravel, and water, corresponding to EN 206 grade C 25/30 and exhibiting a compressive strength range of 20–35 MPa (Moreno Ruiz et al., 2021). Regarding the cast production unit process, three main elements were considered: the steel used as the raw material for the cast, the metalworking process for shaping the cast, and the electricity required for welding.

To transport these raw materials to the site, a lorry with a capacity of over 32 metric tons was used. Although, in reality, concrete should be transported using a specialized truck to prevent segregation, the ecoinvent database does not include a specific transport process for concrete. Therefore, the same transport process was applied for both the cast and concrete transportation to the site. A distance of 20 km was applied in both cases, based on typical distances between concrete batching plants and construction sites.

Following the transport of the materials to the site, the tetrapod is assembled or produced on-site. The energy required for pumping the concrete from the truck to the site, the energy needed for vibrating the concrete to remove air spaces between the layers of freshly poured concrete, the water required for curing, as well as the energy needed for water pumping were all taken into account for the tetrapod production process. Lastly, the tetrapods are placed in their designated location using a crane, and the diesel required by the crane is also considered in the inventory. Table 2 shows the detailed life cycle inventory data used in this study, sourced from the Ecoinvent v3.8 database (Ecoinvent Association, 2023):

Table 2

| LCA Phase | Input (process/ materials) | Ecoinvent process/ materials | Unit | Value | Database reference |

|---|---|---|---|---|---|

| Concrete production | Concrete | Concrete, normal {RoW}| production | Alloc Def, S | m3 | 128 | Ecoinvent v3.8 |

| Cast production | Tetrapod cast | Steel, low-alloyed {GLO}| market for | Alloc Def, S | kg | 61,000 | Ecoinvent v3.8 |

| Metal working, average for steel product manufacturing {GLO}| market for | Alloc Def, S | kg | 61,000 | Ecoinvent v3.8 | ||

| Electricity, medium voltage {RoW}| market for | Alloc Def, S | MJ | 16,104 | Ecoinvent v3.8 | ||

| Transportation | Transport of concrete to site | Transport, freight, lorry >32 metric ton, EURO4 {GLO}| market for | Alloc Def, S | tKm | 6,100 | Ecoinvent v3.8 |

| Transport of cast to site | Transport, freight, lorry >32 metric ton, EURO4 {GLO}| market for | Alloc Def, S | tKm | 1,220 | Ecoinvent v3.8 | |

| Tetrapod production | Energy (concrete pumping-diesel) | Diesel {RoW}| market for | Alloc Def, S | kg | 142 | Ecoinvent v3.8 |

| Energy (vibration-electricity) | Electricity, medium voltage {RoW}| market for | Alloc Def, S | MJ | 92 | Ecoinvent v3.8 | |

| Water for curing | Tap water, at user {RoW}| market for | Alloc Def, S | kg | 40,992 | Ecoinvent v3.8 | |

| Energy (water pumping-electricity) | Electricity, medium voltage {RoW}| market for | Alloc Def, S | MJ | 1.4 | Ecoinvent v3.8 | |

| Tetrapod placement | Energy (diesel) for crane | Diesel {RoW}| market for | Alloc Def, S | kg | 5,539 | Ecoinvent v3.8 |

Life cycle inventory.

The design assumes that each tetrapod weighs 5 tonnes, and each will require 2.1 m3 of concrete for construction. Also, the steel cast for a tetrapod of this weight is produced from one tone of the steel. These parameters define the raw materials for the production of the tetrapods for construction purposes.

2.3 Life cycle impact assessment (LCIA)

In this study, all impact categories were assessed using the CML-IA method, a midpoint approach that includes 11 impact categories. The midpoint characterization approach is preferred over the endpoint characterization because it provides a more detailed and accurate evaluation of the environmental impacts associated with a product or process, helping decision-makers better understand the environmental performance of the studied system (Bare et al., 2000).

In addition to the CML-IA impact assessment method, the CED method was also considered, which estimates the primary energy consumed to produce a unit of a given product. The results of this impact assessment method are divided into five categories: 1. non-renewable, fossil, 2. Non-renewable, nuclear, 3. Renewable, biomass, 4. Renewable, wind, solar, geothermal, and 5. Renewable water. Given that non-renewable resources contribute significantly to the materials used in many of the unit processes included in this study, only the results of the non-renewable fossil category will be included. Table 3 shows the impact categories used in this study.

Table 3

| Impact category | Unit |

|---|---|

| Abiotic depletion | kg Sb eq |

| Abiotic depletion (fossil fuels) | MJ |

| Global warming (GWP100a) | kg CO2 eq |

| Ozone layer depletion (ODP) | kg CFC-11 eq |

| Human toxicity | kg 1,4-DB eq |

| Fresh water aquatic ecotox. | kg 1,4-DB eq |

| Marine aquatic ecotoxicity | kg 1,4-DB eq |

| Terrestrial ecotoxicity | kg 1,4-DB eq |

| Photochemical oxidation | kg C2H4 eq |

| Acidification | kg SO2 eq |

| Eutrophication | kg PO4--- eq |

| Non-renewable, fossil | MJ |

Impact categories assessed in this study.

2.4 Sensitivity analysis setup

When performing an LCA, it is essential to factor in uncertainty to maintain the credibility of the findings. Overlooking uncertainty can compromise the assessment’s validity. Therefore, integrating sensitivity analysis during the interpretation phase is crucial (Barahmand and Eikeland, 2022). This analysis examines the stability of the results by identifying key environmental factors. Adjusting input parameters and observing the resulting changes can help pinpoint the most significant influences on environmental performance, aiding in prioritizing actions and investments.

Given that the transportation distance adopted in this study (20 km) was estimated and that it had negligible impact on environmental performance, a sensitivity analysis was performed to examine the impact of varying this distance. The analysis employed a one-factor-at-a-time (OAT) method, where a single parameter is altered while monitoring changes in the response variable (Groen et al., 2014). In this case, the distance was increased by factors of 2 and 3, resulting in distances of 40 km and 60 km, respectively.

3 Results and discussion

3.1 CML-IA results

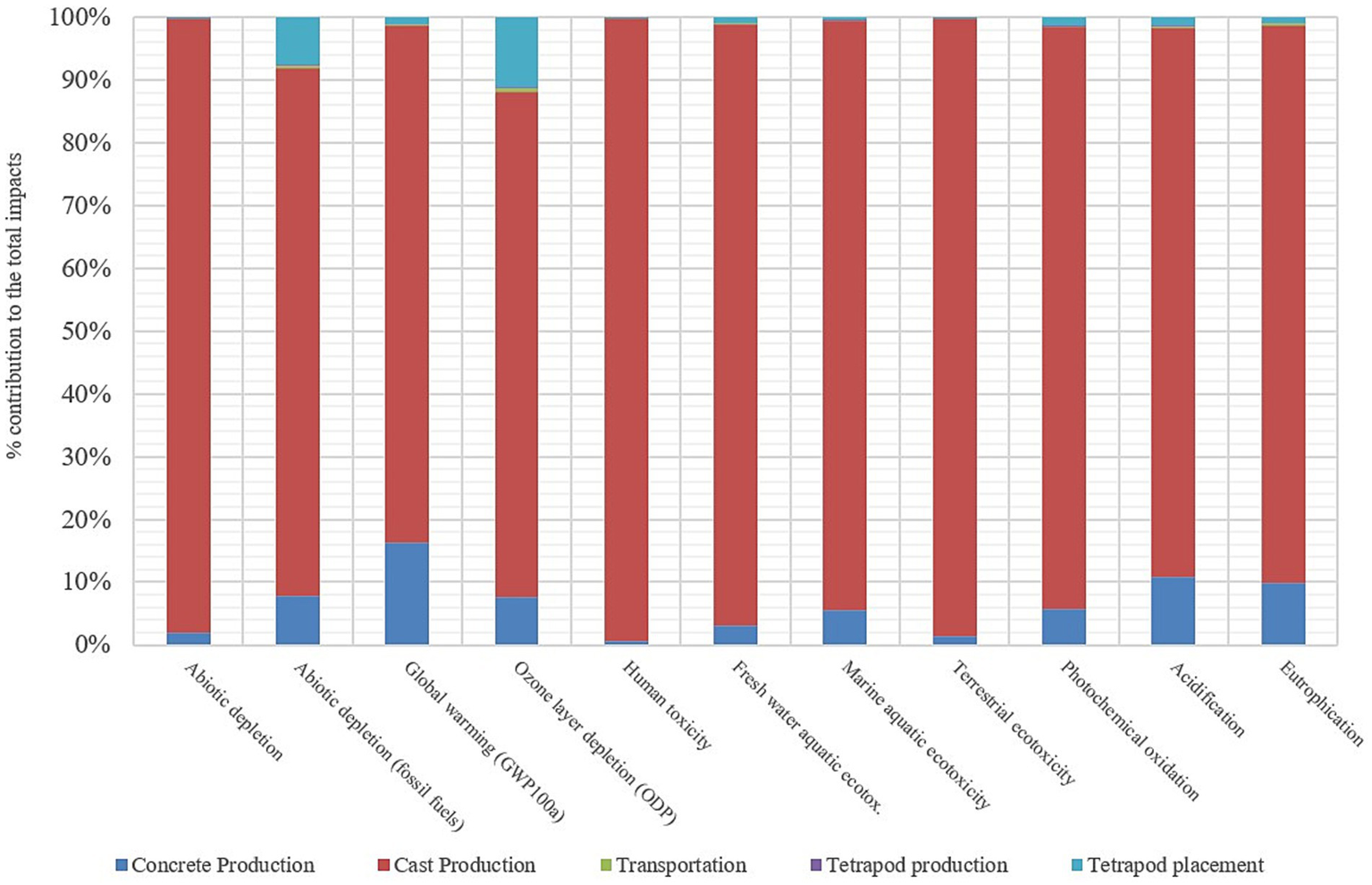

Following the analysis of the CML-IA results, Figure 4 shows that cast production accounted for over 80% of total impacts across all categories. The substantially higher impact of cast production compared to concrete production is due to the energy-intensive nature of steel manufacturing, particularly smelting, refining, and mould fabrication, which requires more resources and generate higher greenhouse gas emissions compared to concrete production (Conejo et al., 2020; Matarrese et al., 2017), which represents 16% of total impacts, attributed mainly to cement manufacturing, a major source of CO2 emissions from the combustion of fossil fuels and calcium carbonate decomposition (Cerchione et al., 2023; Colangelo et al., 2018). These results align with the LCA literature, which consistently identifies material production as a principal environmental hotspot. Table 4 summarizes key LCA findings for relevant materials used around the world:

Figure 4

Contribution of unit processes to different impact categories under CML-IA.

Table 4

| Material studied | Study region | LCA stage with highest impact | Reference |

|---|---|---|---|

| Integrated steel Mill | Germany | Production | Backes et al. (2021) |

| High-speed rail | France | Production | De Bortoli et al. (2020) |

| Portland cement concrete | Lebanon | Production | Semaan et al. (2017) |

| Concrete through air pollutant emissions | Iran | Production | Gheibi et al. (2018) |

| Ordinary portland cement | South Africa | Production | Akintayo et al. (2024) |

| Bio-cementitious materials | Malaysia | Production | Al-Gheethi et al. (2022) |

Studies identifying production as highest LCA impact.

CO2 emissions and energy consumption from resource depletion, such as fossil fuels and water, are the costs of the energy needed for cast production. Fuel extraction and electricity generation require massive quantities of freshwater, and energy production is largely dependent on freshwater (Spang et al., 2014). Apart from CO2 emissions, the production of casting also emits NOx, VOCs, dioxins, and furans, which pollute the air and cause environmental concerns (Conejo et al., 2020). Additionally, the contribution of the tetrapod placement process to impacts within the ozone depletion category is about 11% due to diesel use. NOx emitted from diesel engines reacts with VOCs under sunlight to yield ground-level ozone, contributing indirectly to the destruction of the ozone layer (Hata and Tonokura, 2020). Regarding the transportation and the tetrapod production processes, both had very minimal impacts on the environmental performance of the system studied. Concrete and cast production are the most relevant environmental hotspots. Thus, investigating alternative options for cast production, such as 3D printing with resin materials or the use of sustainable cement substitutes in concrete, can provide promising pathways toward reducing the environmental footprint of tetrapods without compromising their effectiveness in coastal protection.

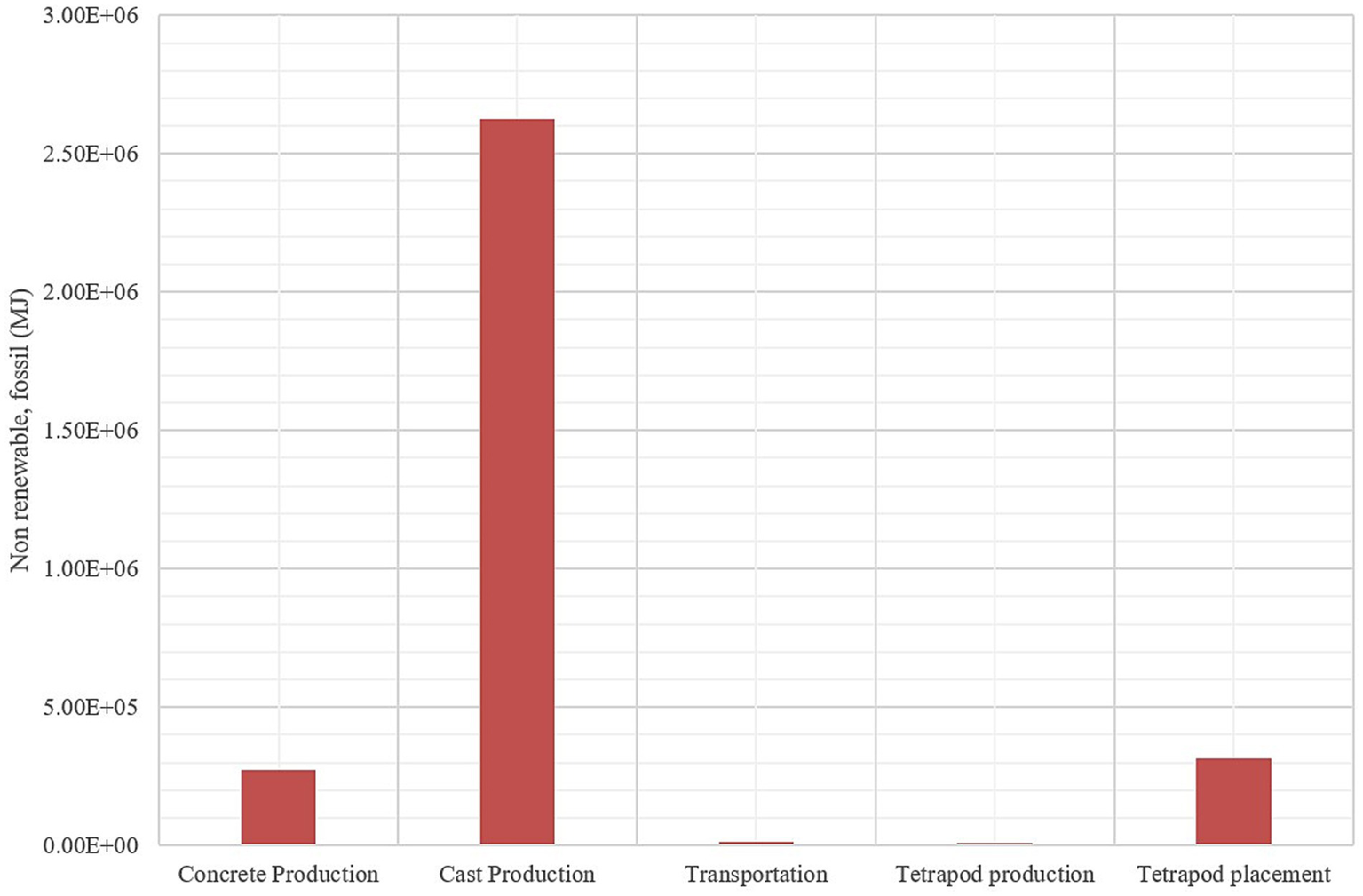

3.2 CED results

The CED results, shown in Figure 5, confirm the CML-IA findings, indicating that cast production consumes the greatest amount of energy at 2.62E+06 MJ per FU, followed by concrete production at 2.73E+05 MJ per FU, this demonstrates that processes with a notable contribution in the global warming impact category also had the greatest impact in the CED category. This aligns with the findings of (Wang and Azam, 2024), which highlight a significant correlation between fossil fuel energy consumption, total greenhouse gas emissions, and the scarcity of natural resources. Fossil fuels significantly contribute to greenhouse gases, increasing global temperatures, and negatively affecting natural resources.

Figure 5

Contribution of unit processes to non-renewable, fossil impacts under CED.

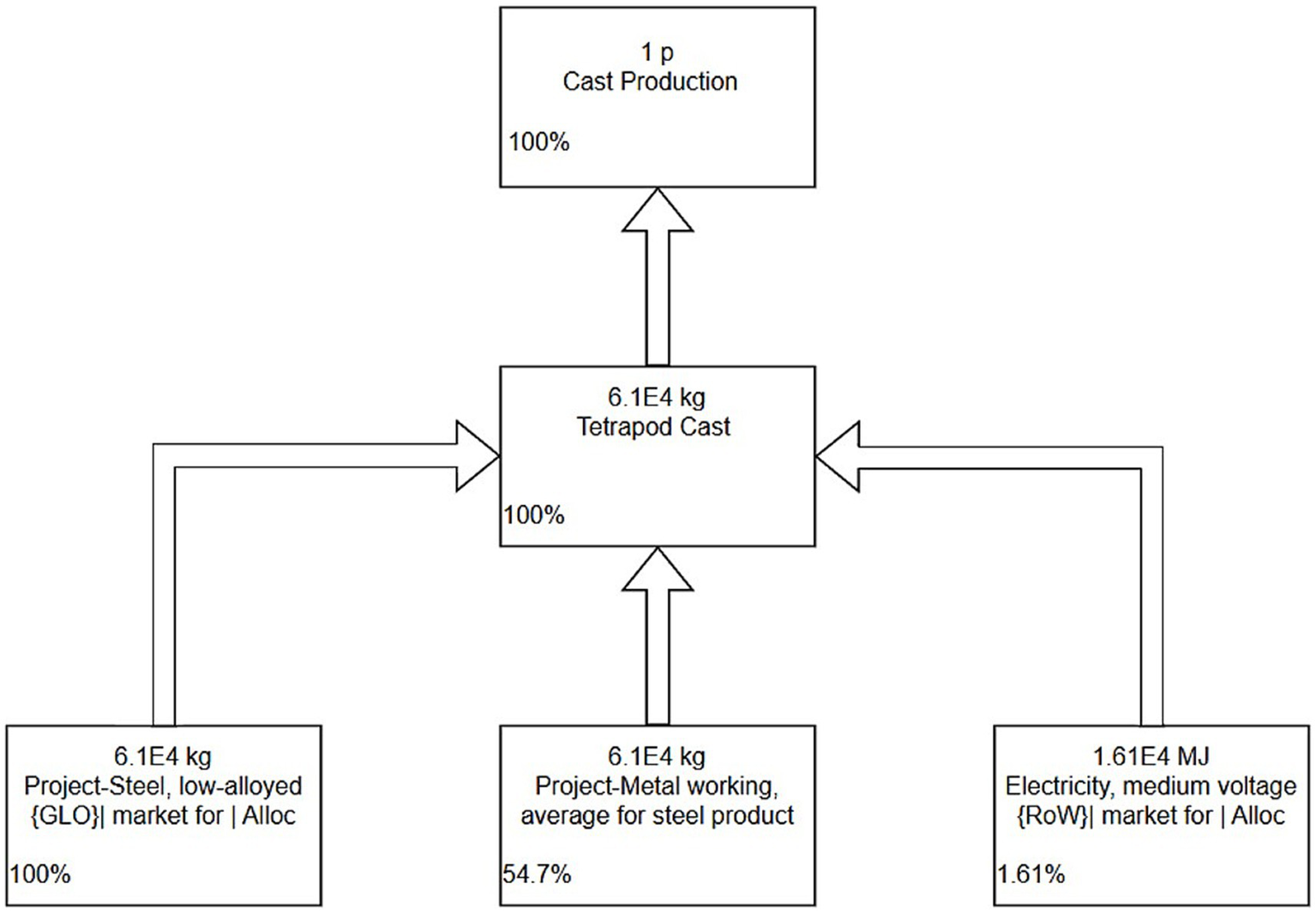

Since cast production dominated CED, a network diagram was used to show the contribution of each process. Figure 6 shows that metalworking represents approximately 55% of the total CED, which is in agreement with the 65% found by Mohsen and Akash (1998). Better environmental performance is possible through the reduction of energy use, increased energy recovery, as well as the substitution of oil and natural gas with renewable energy sources such as biomass, wind, or hydroelectric energy.

Figure 6

Network diagram showing the contribution of different processes to cast production under CED.

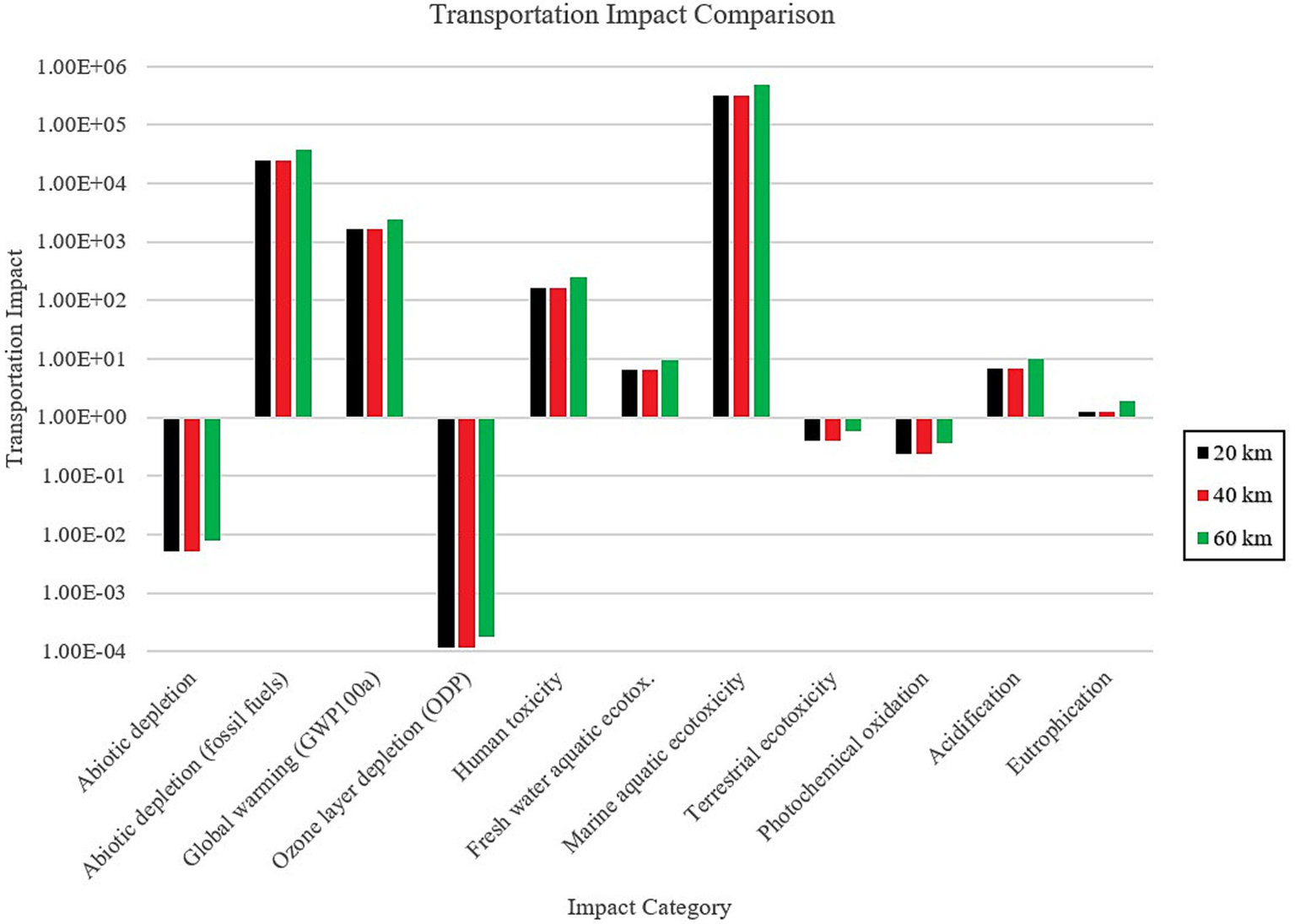

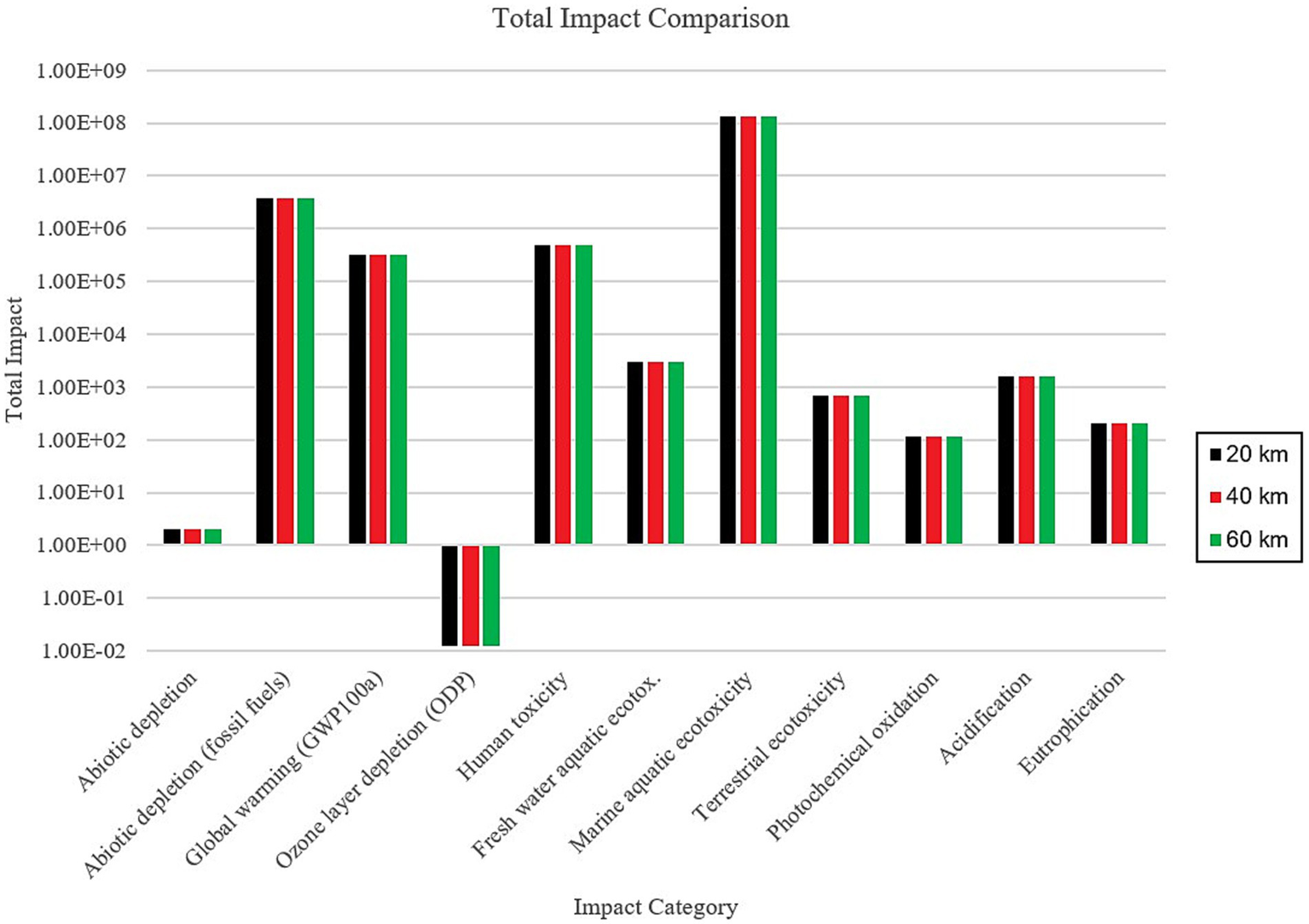

3.3 Sensitivity analysis results

Following the analysis using the CML-IA impact assessment method, varying the transport distance from 20 km to 40 km and 60 km showed a change in the environmental impacts related to the transportation process in both cases. However, these changes were not substantial enough to cause a change in the total environmental impacts, as shown in Table 5. Thus, indicating that the uncertainty in transport distance has minimal impact on the analyzed impact categories.

Table 5

| Transportation distance | 20 km | 40 km | 60 km | ||||

|---|---|---|---|---|---|---|---|

| Impact category | Unit | Total impacts | Transportation | Total impacts | Transportation | Total impacts | Transportation |

| Abiotic depletion | kg Sb eq | 2.04E+00 | 5.14E-03 | 2.04E+00 | 5.14E-03 | 2.04E+00 | 7.70E-03 |

| Abiotic depletion (fossil fuels) | MJ | 3.82E+06 | 2.49E+04 | 3.83E+06 | 2.49E+04 | 3.84E+06 | 3.73E+04 |

| Global warming (GWP100a) | kg CO2 eq | 3.11E+05 | 1.62E+03 | 3.11E+05 | 1.62E+03 | 3.12E+05 | 2.43E+03 |

| Ozone layer depletion (ODP) | kg CFC-11 eq | 1.23E-02 | 1.17E-04 | 1.24E-02 | 1.17E-04 | 1.24E-02 | 1.76E-04 |

| Human toxicity | kg 1,4-DB eq | 4.85E+05 | 1.63E+02 | 4.85E+05 | 1.63E+02 | 4.85E+05 | 2.44E+02 |

| Fresh water aquatic ecotox. | kg 1,4-DB eq | 2.99E+03 | 6.43E+00 | 3.00E+03 | 6.43E+00 | 3.00E+03 | 9.64E+00 |

| Marine aquatic ecotoxicity | kg 1,4-DB eq | 1.34E+08 | 3.22E+05 | 1.34E+08 | 3.22E+05 | 1.35E+08 | 4.83E+05 |

| Terrestrial ecotoxicity | kg 1,4-DB eq | 6.94E+02 | 3.97E-01 | 6.95E+02 | 3.97E-01 | 6.95E+02 | 5.96E-01 |

| Photochemical oxidation | kg C2H4 eq | 1.17E+02 | 2.39E-01 | 1.17E+02 | 2.39E-01 | 1.17E+02 | 3.58E-01 |

| Acidification | kg SO2 eq | 1.60E+03 | 6.81E+00 | 1.61E+03 | 6.81E+00 | 1.61E+03 | 1.02E+01 |

| Eutrophication | kg PO4--- eq | 2.06E+02 | 1.25E+00 | 2.06E+02 | 1.25E+00 | 2.07E+02 | 1.87E+00 |

Sensitivity analysis results.

Additionally, Figure 7 presents the transportation-related impacts resulting from changes in increasing the transport distance. The bar chart compares the three selected scenarios of 20 km, 40 km, and 60 km, highlighting the specific effects on transportation emissions. As shown, there are minor differences in the majority of the impact categories, which reflects the results presenting low sensitivity to change in this parameter.

Figure 7

Sensitivity analysis—transportation impact comparison.

Furthermore, Figure 8 illustrates the total environmental impacts corresponding to the same set of transport distances. The bar chart again compares the 20 km, 40 km, and 60 km scenarios. The result confirms small differences in all types of impacts, again validating the finding that variation in transport distance barely contributes in altering the overall environmental performance.

Figure 8

Sensitivity analysis—total impact comparison.

3.4 Regional variations

In this study, the ecoinvent database was used to reflect the global averages. The ecoinvent process includes specific notations such as {RoW} (rest of the world) and {GLO} (global scope), indicating that the emissions data used is based on global averages rather than data specific to a particular country or region. However, when conducting an LCA for concrete tetrapods, regional variations can play a major role in manipulating results. Although the methodology remains consistent, differences in materials availability, labor efficiency, and other variables are capable of changing the environmental impacts at different stages of the LCA, leading to varied results in each region.

Particularly, the extraction of concrete ingredients and steel differs from one region to another. Countries with rich quarries will produce lower emissions than countries relying on imported materials. Additionally, developed countries implementing high material extraction regulations force environmentally friendly practices, hence reducing impacts compared to third-world countries (Sun and Hasi, 2024; Hunter, 2014). Moreover, the usage of electricity during cement production is a vital variation that must be considered (Nie et al., 2022). Countries relying on coal-based power to produce electricity generate much more emissions than countries using renewable energy sources (Afkhami et al., 2015). On the other hand, stages such as transportation and placement have minimal regional variations. As previously discussed in the sensitivity analysis, an increment in transportation distance produces negligible emissions, reducing the need to focus on the transportation stage for regional variability. Lastly, the placement stage primarily relies on crane operations, which are widely used around the world, making this stage consistent across various regions (Wen et al., 2017), unless the material utilized is significantly heavy, requiring a huge engine size, thus increasing environmental impact (Khan, 2018).

4 Conclusion and recommendations

In this study, LCA is conducted for tetrapods using SimaPro software. The assessment considered the production, transportation, and placement stages of tetrapods, concrete, and steel for casting. The functional unit for the assessment is “5-meter of breakwater.” The inventory data in this study relied heavily on the ecoinvent database available in SimaPro due to limited data availability in the literature. The environmental impacts were assessed using the CML-IA method, a midpoint approach that includes 11 impact categories. Furthermore, CED was also considered, and results showed that cast production accounted for over 80% of the total impacts in all the impact categories. In addition to cast production, concrete production contributed 16% to total impacts, with cement manufacturing being a key driver of CO2 emissions and global warming potential. Similarly, placement activities such as crane usage had a notable influence on ozone layer depletion due to diesel consumption. Moreover, cast production also had the greatest contribution to the non-renewable fossil impacts under CED, showing a value of 2.62E+06 MJ per FU. On the other hand, the results of the sensitivity analysis indicate that the studied system was not sensitive to variations in transportation distance.

The results of this study can be used to aid the stakeholders involved in construction using tetrapods in defining mitigation measures to combat the negative environmental impacts resulting from the usage of tetrapods. It can also help policymakers define rules and laws to limit those negative impacts.

In order to further advance the research, it is recommended to consider regional variations when carrying out LCA on concrete tetrapods. Future research should account for variations in material extraction and cement production, as these factors can significantly influence results across different regions. In contrast, transportation and placement may be neglected due to their minimal influence on regional variation. Furthermore, undertaking an LCA on utilizing large quarry rocks for the armour layer is capable of providing meaningful comparisons of the impacts that can be made between tetrapods and rocks, which would facilitate the selection of a more environmentally friendly option.

Statements

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

EM: Conceptualization, Visualization, Investigation, Formal analysis, Methodology, Writing – original draft. NY: Software, Methodology, Investigation, Writing – original draft. MA: Formal analysis, Data curation, Writing – original draft, Conceptualization. AT: Validation, Writing – review & editing. SA: Supervision, Validation, Writing – review & editing, Conceptualization, Resources, Project administration. MM: Writing – review & editing, Supervision, Visualization, Validation.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. The work in this paper was supported, in part, by the Open Access Program from the American University of Sharjah. This paper represents the opinions of the authors and does not mean to represent the position or opinions of the American University of Sharjah (No: OPFY25-3152-OE2593).

Acknowledgments

The authors would like to express their gratitude to the American University of Sharjah for providing resources for this research.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1

Afkhami B. Akbarian B. Beheshti N. Kakaee A. H. Shabani B. (2015). Energy consumption assessment in a cement production plant. Sustain Energy Technol Assess10, 84–89. doi: 10.1016/j.seta.2015.03.003

2

Akintayo B. D. Olanrewaju O. A. Olanrewaju O. I. (2024). Life cycle assessment of ordinary Portland cement production in South Africa: mid-point and end-point approaches. Sustain. For.16:3001. doi: 10.3390/su16073001

3

Al-Gheethi A. A. Memon Z. A. Balasbaneh A. T. Al-Kutti W. A. Mokhtar N. Othman N. et al . (2022). Critical analysis for life cycle assessment of bio-cementitious materials production and sustainable solutions. Sustain. For.14:1920. doi: 10.3390/su14031920

4

Backes G. J. Julian S. Pauliks N. Neugebauer S. Traverso M. (2021). Life cycle assessment of an integrated steel mill using primary manufacturing data: actual environmental profile. Sustain. For.13:3443. doi: 10.3390/su13063443

5

Bakker P. van den Berge A. Hakenberg R. Klabbers M. Muttray M. Reedijk B. et al . (2003). “Development of concrete breakwater Armour units” in Proceedings of the 1st coastal estuary and offshore engineering specialty conference of the Canadian Society for Civil Engineering (Moncton, NB, Canada), 4–7.

6

Barahmand Z. Eikeland M. S. (2022). Life cycle assessment under uncertainty: a scoping review. WORLD3, 692–717. doi: 10.3390/world3030039

7

Bare J. C. Hofstetter P. Pennington D. W. Udo de Haes H. A. (2000). Midpoint versus endpoints: the sacrifices and benefits. Int. J. Life Cycle Assess.5:326. doi: 10.1007/BF02978665

8

Betonblock® (2006). Tetrapods/moulds. Available online at: https://betonblock.com/en/products/tetrapods (Accessed March 10, 2025).

9

Biswas W. K. Alhorr Y. Lawania K. K. Sarker P. K. Elsarrag E. (2017). Life cycle assessment for environmental product declaration of concrete in the Gulf states. Sustain. Cities Soc.35, 1–38. doi: 10.1016/J.SCS.2017.07.011

10

Broekens R. Escarameia M. Cantelmo C. Woolhouse G. (2012). “Quantifying the carbon footprint of coastal construction–a new tool HRCAT” in Innovative coastal zone management: Sustainable engineering for a dynamic coast (London: ICE Publishing), 253–262.

11

Cerchione R. Colangelo F. Farina I. Ghisellini P. Passaro R. Ulgiati S. (2023). Life cycle assessment of concrete production within a circular economy perspective. Sustain. For.15:11469. doi: 10.3390/su151411469

12

CIRIA, CUR, and CETMEF (2007). “The rock manual” in The use of rock in hydraulic engineering. 2nd ed (London: C683, CIRIA).

13

Colangelo F. Forcina A. Farina I. Petrillo A. (2018). Life cycle assessment (LCA) of different kinds of concrete containing waste for sustainable construction. Buildings8:70. doi: 10.3390/buildings8050070

14

Conejo A. N. Birat J.-P. Dutta A. (2020). A review of the current environmntal challenges of the steel industry and its value chain. J. Environ. Manag.259:109782. doi: 10.1016/j.jenvman.2019.109782

15

Daniel P. Greslou L. (1962). THE "TETRAPOD". Costal Eng. Proceed.1:27. doi: 10.9753/icce.v8.27

16

Das P. Cheela V. R. S. Mistri A. Chakraborty S. Dubey B. Barai S. V. (2022). Performance assessment and life cycle analysis of concrete containing ferrochrome slag and fly ash as replacement materials–a circular approach. Constr. Build. Mater.347:128609. doi: 10.1016/j.conbuildmat.2022.128609

17

De Bortoli A. Bouhaya L. Feraille A. (2020). A life cycle model for high-speed rail infrastructure: environmental inventories and assessment of the Tours-Bordeaux railway in France. Int. J. Life Cycle Assess.25, 814–830. doi: 10.1007/s11367-019-01727-2

18

De Souza D. M. Lafontaine M. Charron-Doucet F. Chappert B. Kicak K. Duarte F. et al . (2016). Comparative life cycle assessment of ceramic brick, concrete brick and cast-in-place reinforced concrete exterior walls. J. Clean. Prod.137, 70–82. doi: 10.1016/j.jclepro.2016.07.069

19

Diaferio M. Varona F. B. (2024). Concrete structures: latest advances and prospects for a sustainable future. Appl. Sci.14:3803. doi: 10.3390/app14093803

20

Ecoinvent Association . (2023). Ecoinvent Database Version 3.8. Ecoinvent Association. Available online at: https://www.ecoinvent.org. (Accessed April 25, 2025).

21

Fibo Intercon . (n.d.). Sea Defense Production. Available online at: https://fibointercon.com/wp-content/uploads/2020/03/Tetrapod-Brochure.pdf (Accessed May 12, 2025).

22

Finnveden G. Hauschild M. Z. Ekvall T. Guinee J. Heijungs R. Hellweg S. et al . (2009). Recent developments in life cycle assessment. J. Environ. Manag.91, 1–21. doi: 10.1016/j.jenvman.2009.06.018

23

Finnveden G. Potting J. (2014). “Life cycle assessment” in Encyclopedia of toxicology. ed. WexlerP.. 3rd edn. (Cambridge: Academic Press), 74–77.

24

Fookes P. G. Poole A. B. (1981). Some preliminary considerations on the selection and durability of rock and concrete materials for breakwaters and coastal protection works. Q. J. Eng. Geol.14, 97–128. doi: 10.1144/GSL.QJEG.1981.014.02.03

25

Frischknecht R. Jungbluth N. Althaus H. J. Doka G. Dones R. Heck T. et al . (2005). The ecoinvent database: overview and methodological framework. Int. J. Life Cycle Assess.10, 3–9. doi: 10.1065/lca2004.10.181.1

26

Gheibi M. Karrabi M. Shakerian M. Mirahmadi M. (2018). Life cycle assessment of concrete production with a focus on air pollutants and the desired risk parameters using genetic algorithm. J. Environ. Health Sci. Eng.16, 89–98. doi: 10.1007/s40201-018-0302-x

27

Glanz D. Sameer H. Göbel D. Wetzel A. Middendorf B. Mostert C. et al . (2023). Comparative environmental footprint analysis of ultra-high-performance concrete using Portland cement and alkali-activated materials. Front. Built Environ.9:1196246. doi: 10.3389/fbuil.2023.1196246

28

Goh P. G. Maghfouri M. Onn C. C. Loo S. C. (2022). Life cycle assessment on recycled e-waste concrete. Case Stud. Constr. Mater.17:e01412. doi: 10.1016/j.cscm.2022.e01412

29

Groen E. A. Bokkers E. A. Heijungs R. de Boer I. (2014). Sensitivity analysis in life cycle assessment. Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector, San Francisco, 23, 482–488

30

Hald T. Torum A. Holm-Karlsen T. (2015). Design of rock armoured single layer rubble mound breakwaters. Proceed. Coastal Eng. Conf.2, 1800–1813. doi: 10.1061/9780784404119.134

31

Hata H. Tonokura K. (2020). Impact of next-generation vehicles on tropospheric ozone estimated by chemical transport model in the Kanto region of Japan. Sci. Rep.10:2382. doi: 10.1038/s41598-020-59300-z

32

Hunter T. (2014). The role of regulatory frameworks and state regulation in optimising the extraction of petroleum resources: a study of Australia and Norway. Extr. Ind. Soc.1, 48–58. doi: 10.1016/j.exis.2014.02.001

33

ISO (2020). Environmental management. Life cycle assessment. Requirements and guidelines. Amendment 2. Geneva: International Organization for Standardization.

34

Khan M. A. (2018). A comparative life cycle analysis of new and old designs of crane truck frames: case study at Vemservice. (Bachelor’s thesis, Mid Sweden University).

35

Kheiralipour K. Brandão M. Holka M. Choryński A. (2024). A review of environmental impacts of wheat production in different agrotechnical systems. Resources13:93. doi: 10.3390/resources13070093

36

Lee K.-M. Inaba A. (2004). Life cycle assessment: best practices of International Organization for Standardization (ISO) 14040 series. Life Cycle Assessment: Best Practices of International Organization for Standardization (ISO) 14040 Series.

37

Matarrese P. Fontana A. Sorlini M. Diviani L. Specht I. Maggi A. (2017). Estimating energy consumption of injection moulding for environmental-driven mould design. J. Clean. Prod.168, 1505–1512. doi: 10.1016/j.jclepro.2017.07.144

38

Mohsen M. S. Akash B. A. (1998). Energy analysis of the steel making industry. Int. J. Energy Res.22, 1049–1054. doi: 10.1002/(SICI)1099-114X(19981010)22:12<1049::AID-ER422>3.0.CO;2-W

39

Moreau J. D. Gand G. (2022). New data on the Permian ecosystem of the Rodez Basin: ichnofauna (traces of protostomians, tetrapods and fishes), jellyfishes and plants from Banassac-Canilhac (Lozère, southern France). Geodiversitas44, 975–987. doi: 10.5252/geodiversitas2022v44a31

40

Moreno Ruiz E. Fitz Gerald D. Symeonidis A. Ioannidou D. Müller J. Valsasina L. et al (2021). Documentation of changes implemented in ecoinvent database v3.8. ecoinvent Association, Zürich, Switzerland.

41

Muttray M. Reedijk B. (2009). Design of concrete Armour layers. Hansa Int. Marit. J.6, 111–118. doi: 10.34218/IJCIET.12.6.2021.005

42

Natakusumah D. K. Achiari H. Nugroho E. O. Adinata F. Hidayatulloh S. Ishakputra J. A. (2024). Pentapod: a new type of concrete armor for coastal protection. Results Eng.22:102069. doi: 10.1016/j.rineng.2024.102069

43

Nie S. Zhou J. Yang F. Lan M. Li J. Zhang Z. et al . (2022). Analysis of theoretical carbon dioxide emissions from cement production: methodology and application. J. Clean. Prod.334:130270. doi: 10.1016/j.jclepro.2021.130270

44

Nordstrom K. F. (2014). Living with shore protection structures: a review. Estuar. Coast. Shelf Sci.150, 11–23. doi: 10.1016/j.ecss.2013.11.003

45

Park Y. H. Oh Y. M. Ahn S. M. Han T. H. Kim Y. T. Suh K. D. et al . (2019). Development of a new concrete armor unit for high waves. J. Coast. Res.35, 719–728. doi: 10.2112/JCOASTRES-D-17-00224.1

46

Pennington D. W. Potting J. Finnveden G. Lindeijer E. Jolliet O. Rydberg T. et al . (2004). Life cycle assessment Part 2: Current impact assessment practice. Environ. Int.30, 721–739. doi: 10.1016/j.envint.2003.12.009

47

Semaan P. Massih M. A. Chalouhy M. Ghanimeh S. Jawad D. (2017). Life cycle assessment of concrete industry in developing nations. International Conference on Sustainable Infrastructure 2017 (pp. 197–206). doi: 10.1061/9780784481196.018

48

Shinde S. Ukalkar M. A. Tambe M. A. Prakash M. A. (2017). Design of breakwaters for the development of fishery harbour - a case study. Int. Res. J. Eng. Technol.4, 2043–2047.

49

Silva M. G. Gomes V. Saade M. R. (2018). The contribution of life-cycle assessment to environmentally preferable concrete mix selection for breakwater applications. Ambiente Construído18, 413–429. doi: 10.1590/s1678-86212018000200262

50

SimaPro . (n.d.). SimaPro software (Version 8) [Computer software]. Available online at: https://simapro.com/ (Accessed April 29, 2025).

51

Spang E. S. Moomaw W. R. Gallagher K. S. Kirshen P. H. Marks D. H. (2014). The water consumption of energy production: an international comparison. Environ. Res. Lett.9:105002. doi: 10.1088/1748-9326/9/10/105002

52

Su D. Ren Z. Wu Y. (2020). “Guidelines for selection of life cycle impact assessment software tools” in Sustainable product development. ed. SuD. (Cham: Springer).

53

Sun L. Hasi M. (2024). Effects of mining sector FDI, environmental regulations, and economic complexity, on mineral resource dependency in selected OECD countries. Resources Policy89:104651. doi: 10.1016/j.resourpol.2024.104651

54

Suwannarat W. Kositgittiwong D. Ekkawatpanit C. Sukjan R. (2020). A study of the energy reduction of flow through concrete and natural rubber tetrapods. The 25th National Convention on Civil Engineering (pp. WRE05-1–WRE05-8). Chonburi, Thailand.

55

Tang B. Wu H. Wu Y. F. (2024). Evaluation of carbon footprint of compression cast waste rubber concrete based on LCA approach. J. Build. Eng.86:108818. doi: 10.1016/j.jobe.2024.108818

56

Valiyev V. (2015). Life cycle assessment of natural stone and tetrapod utilization on breakwaters (Master’s thesis). Istanbul Technical University, Coastal Sciences and Engineering programme.

57

Van den Berghe K. B. Verhagen T. J. (2021). Making it concrete: analysing the role of concrete plants’ locations for circular city policy goals. Front. Built Environ.7:748842. doi: 10.3389/fbuil.2021.7488422021

58

Wang J. Azam W. (2024). Natural resource scarcity, fossil fuel energy consumption, and total greenhouse gas emissions in top emitting countries. Geosci. Front.15:101757. doi: 10.1016/j.gsf.2023.101757

59

Wang L. Zhang P. Golewski G. Guan J. (2023). Editorial: fabrication and properties of concrete containing industrial waste. Front. Mater.10:1169715. doi: 10.3389/fmats.2023.1169715

60

Wen B. Jin Q. Huang H. Tandon P. Zhu Y. (2017). Life cycle assessment of quayside crane: a case study in China. J. Clean. Prod.148, 1–11. doi: 10.1016/j.jclepro.2017.01.146

61

Winters D. (2024). Engineering and scaling cement-based carbon storage systems (Doctoral dissertation, Colorado State University).

62

Xu Y. Yao Z. Wang J. Fang Y. Ding Z. Huang X. (2024). Mechanical properties and energy evolution of drilling shaft lining concrete under hydro-mechanical coupling. Constr. Build. Mater.419:135548. doi: 10.1016/j.conbuildmat.2024.135548

63

Yadav P. Samadder S. R. (2018). Environmental impact assessment of municipal solid waste management options using life cycle assessment: a case study. Environ. Sci. Pollut. Res.25, 838–854. doi: 10.1007/s11356-017-0439-7

64

York I. N. (2021). Concrete needs to lose its colossal carbon footprint. Nature597, 593–594. doi: 10.1038/d41586-021-02612-5

65

Zhang C. Hu M. Dong L. Xiang P. Zhang Q. Wu J. et al . (2018). Co-benefits of urban concrete recycling on the mitigation of greenhouse gas emissions and land use change: a case in Chongqing metropolis, China. J. Clean. Prod.201, 481–498. doi: 10.1016/j.jclepro.2018.07.238

Summary

Keywords

life cycle assessment, tetrapod, concrete armour, sustainability, ecoinvent, SimaPro

Citation

Mikhail E, Younes N, Al Adab M, Tarnini AB, Atabay S and Mortula MM (2025) Life cycle assessment of tetrapod concrete armour units. Front. Sustain. Cities 7:1592987. doi: 10.3389/frsc.2025.1592987

Received

13 March 2025

Accepted

29 May 2025

Published

18 June 2025

Volume

7 - 2025

Edited by

Gustavo Henrique Nalon, Universidade Federal de Juiz de Fora, Brazil

Reviewed by

Yoon Seong Chang, National Institute of Forest Sicence (NIFoS), Republic of Korea

Sunita Kumari, Deenbandhu Chhotu Ram University of Science and Technology, India

Vittoria Borghese, Netherlands Organisation for Applied Scientific Research, Netherlands

Updates

Copyright

© 2025 Mikhail, Younes, Al Adab, Tarnini, Atabay and Mortula.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Serter Atabay, satabay@aus.edu

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.