- 1Tecnologico de Monterrey, Institute of Advanced Materials for Sustainable Manufacturing, Vicerrectoría de Investigación y Transferencia de Tecnología, Tecnólogico de Monterrey, Monterrey, México

- 2Tecnologico de Monterrey, School of Engineering and Science, Monterrey, Mexico

- 3Tecnologico de Monterrey, Institute for the Future of Education, Monterrey, Mexico

- 4National Instruments, Austin, TX, United States

- 5ABB, Motion Drives Product (MODP), San Luis Potosí, México

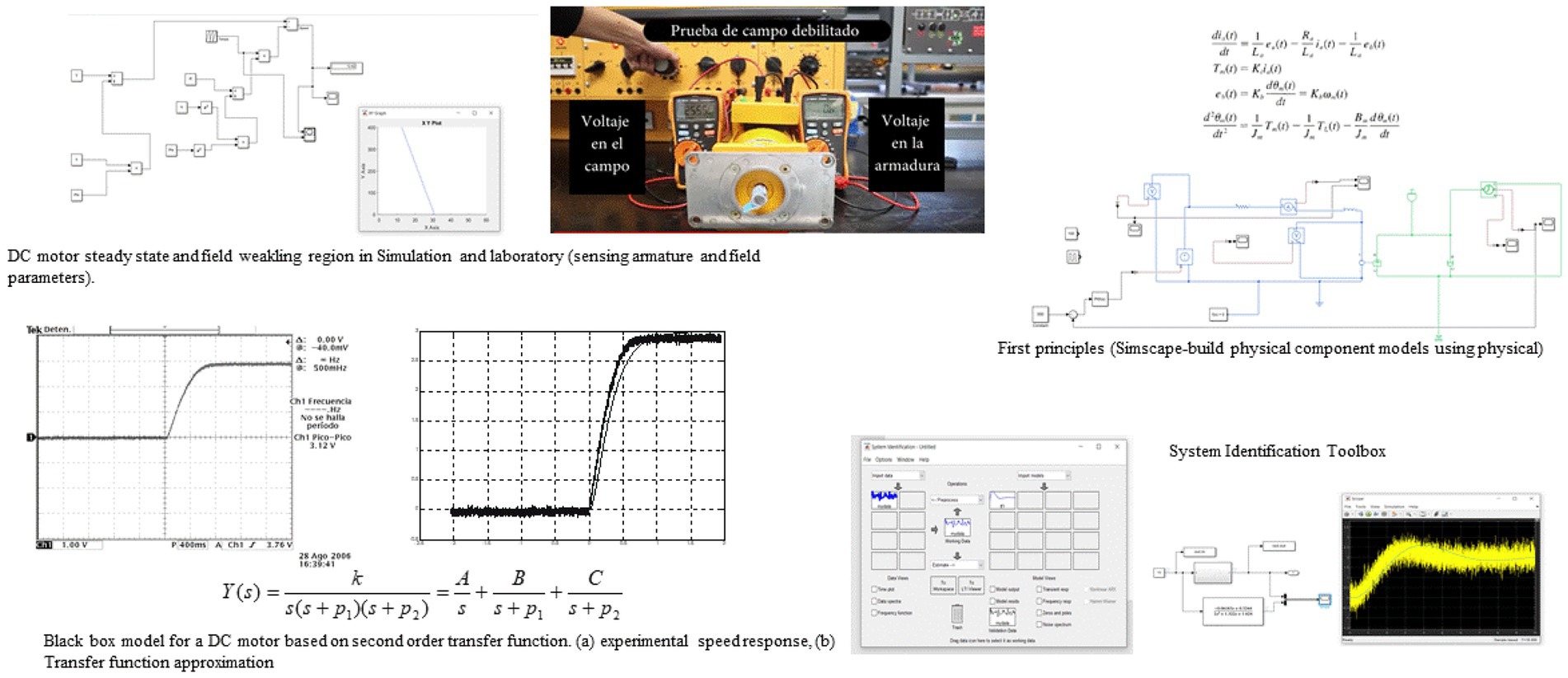

Electric drives have been used in several applications, such as electric vehicles, industry 4.0, and robotics. Thus, it is mandatory to promote updated electric drive courses that allow students to design novel solutions in these engineering areas. However, traditional undergraduate courses that only cover theoretical aspects and do not allow students to interact and produce practical results through experimentation are insufficient today. The students are not exposed to educational innovation, so they have difficulties proposing original solutions. On the other hand, conventional theoretical and laboratory courses in which students follow specific directions for achieving predefined goals do not allow students to create novel solutions and integrate the innovation process as a standard methodology. Moreover, beginning in 2020, the COVID-19 pandemic forced professors to implement digital tools and materials to continue education intensively. This proposed course presents an alternative to promote practical and theoretical knowledge in students. Besides, engineering students must create innovative solutions to increase the quality of life in rural and urban communities, which calls for novel experimental approaches. Electric drives are fundamental elements in electric systems and industrial processes proposed to save energy or control electric machines. In addition, industries urge specialized engineers who can tackle complex industrial problems. The proposed educational methodology can be implemented in manufacturing, agriculture, robotics, and aerospace. Hence, low-cost devices to validate the proposed solutions became used by students to achieve novel solutions using electric drives. This paper describes an undergraduate course called “Digital Control of Electric Machines” (electric drives) and its implementation of the Tec21 Educational Model of Tecnologico de Monterrey, V Model, MATLAB/ Simulink, low-cost hardware, and complex thinking. The content of the course begins with electric machine models and power electronics that allow students to move from the basic to the advanced industrial electric drive problems in a friendly manner. In addition, the V-model and Modelo Tec 21 are used as fundamental pillars of the leading innovative structure of the proposed course. The results showed that students mastered several soft and hard skills to accomplish complex design goals, including controlling an electric rapid prototype vehicle.

Introduction

Since industry and several applications (agriculture and electromobility, for example) require novel electric drives to improve their manufacturing and systems processing, students must have classes that challenge them to propose innovative solutions. Thus, some universities connect their theoretical classes with laboratories that simulate real-world conditions or problems. However, specialized laboratories sometimes have specific schedules and practices that limit their availability and access. Thus, students do not always have exposure to experimental requirements.

On the other hand, students could use low-cost devices to acquire experimental knowledge. Moreover, they can use these devices needed without specific schedules. The Arduino microcontroller board (Banzi and Shiloh, 2022) and MATLAB (MATLAB-SIMULINK (2022)) implement basic and advanced electric drives well. Thus, several applications have used Arduino and MATLAB. For instance, MATLAB and Arduino have been implemented to control a 3-phase inverter with an induction motor, as Zulkifli et al. (2014) presented. Also, Zulkifli et al. (2016) demonstrated that students can implement and use power electronics in experimental work. With the proper selection of low-cost microcontrollers, the students could also develop the PWM switching pattern necessary to drive the converter.

On the other hand, Mi et al. (2005) proposed a continuing course in power electronics that allows students to gain a solid functional understanding of vehicle power electronics, the fundamentals of power semiconductor devices, and the fundamental operation of commonly used power converter circuits. Besides, the students had to solve practical problems such as power device selection and thermal control. This course includes theoretical and experimental content so the students can have an integral vision of the topic. However, when the course is online, low-cost materials must be used. For instance, Asato et al. (2015) showed a low-cost platform to teach mechatronics based on Arduino and a DC drive.

This paper proposes an electric drive course where students learn conventional theoretical concepts and apply them in experimental conditions using low-cost components. One of the proposed course’s main goals is to provide students with product design competencies and skills in electric drives. Thus, students must understand and apply the theoretical concepts in experimental scenarios. The practical scenarios similarly give a broad vision of each course topic’s design limitations and needs. This course covers basic concepts such as graphical programming, modeling DC and AC motors, DC-DC converters, DC – AC converters, PWM techniques, and Motor control (Bose, 1986; Rashid, 2017). This course could benefit different undergraduate degrees since electric drives are used in applications in several areas. The simulations and experiments are performed using Arduino, MATLAB, and Simulink because the necessary time for developing and testing theoretical ideas is as soon as possible. The students have to learn how to create rapid prototypes quickly. If they take too long to create a rapid prototype, they do not get feedback about it to improve the design.

Moreover, they need to gain practical knowledge when designing experimental prototypes, so making mistakes is desirable; they must learn from them. Errors also help them acquire the knowledge they need. If they complete an advanced prototype that requires changes in the design, they spend more money and time adjusting this advanced prototype than modifying a simple one. So the students need to develop rapid prototyping skills at the beginning of the course. They can use low-cost hardware such as Lego robots and Arduino and focus on specific solutions based on software.

In addition, some experimental exercises are implemented in real-time (OPAL-RT, Bian et al., 2015, and MATLAB/Simulink) to achieve a high fidelity model such as a DC-DC or DC-AC converter in power electronics for electric drives. Thus, students understand industrial drives in a friendly manner. Since MATLAB/Simulink is also used by industry, students can continue using these programs in their professional careers. Besides, the conventional simulations based on Simulink blocks for power electronics converters can be implemented in real-time simulation without changes.

The general structure of the proposed course

Low retention rates and students’ decrement of knowledge in specific areas imply that the students need different educational structures to solve complex problems. Moreover, they usually do not connect their courses with the real world (Arthur James, 2015; Tao et al., 2017). Besides, complex thinking requires analyzing specific problems from different perspectives, proposing and assessing several solutions, and being cognitively and emotionally flexible to create innovative solutions (Bartunek and Louis, 1988). To promote complex thinking, this course integrates theoretical concepts, industrial needs, and the creation of rapid prototypes.

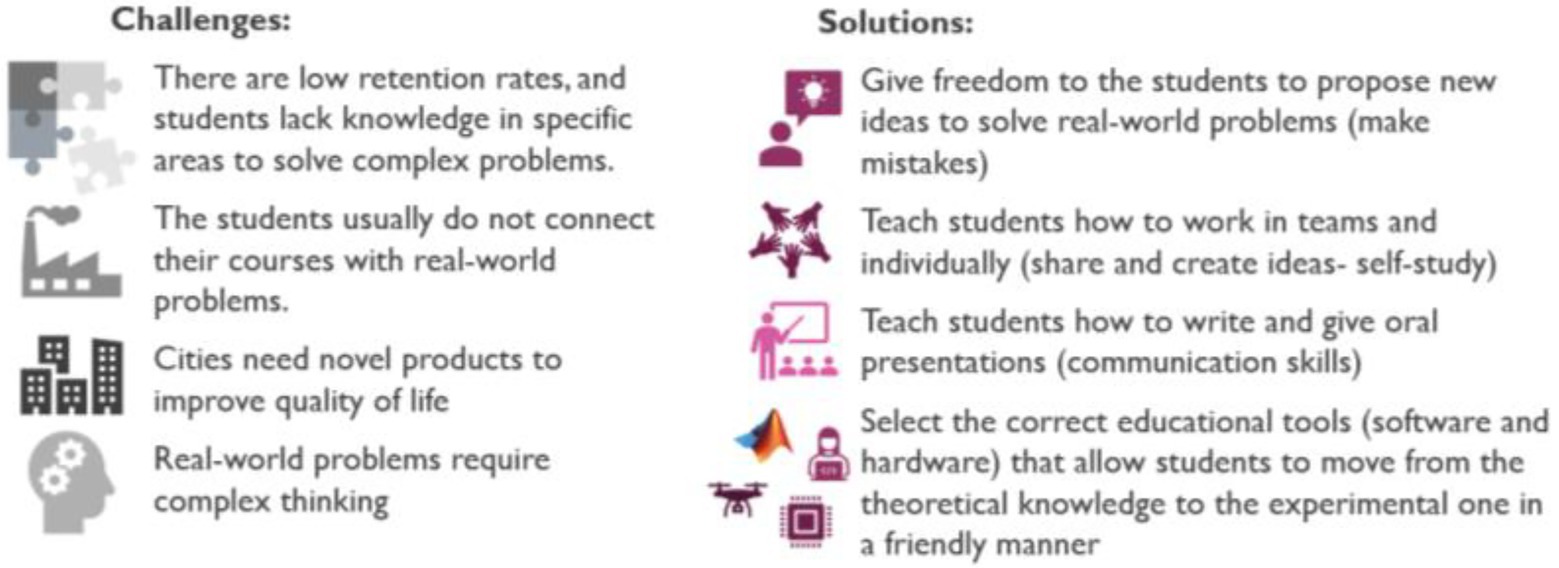

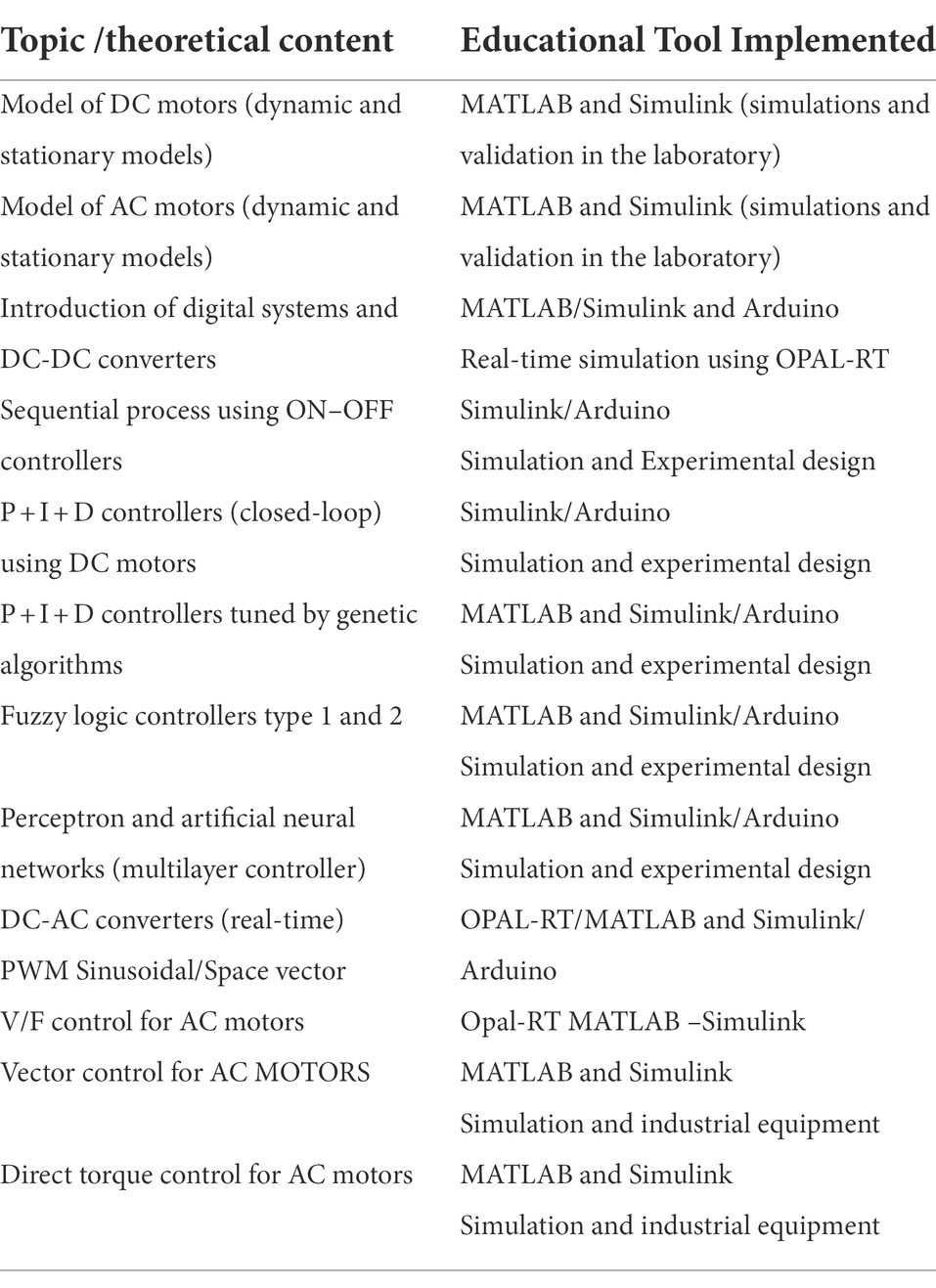

Figure 1 shows the challenges and solutions implemented in this course. This electric drive course has three main components: conventional theory, experimental exercises, and the generation of new solutions (innovation). The conventional theoretical concepts covered in this course are presented in Table 1; the students have to do homework, projects, and exams on each topic.

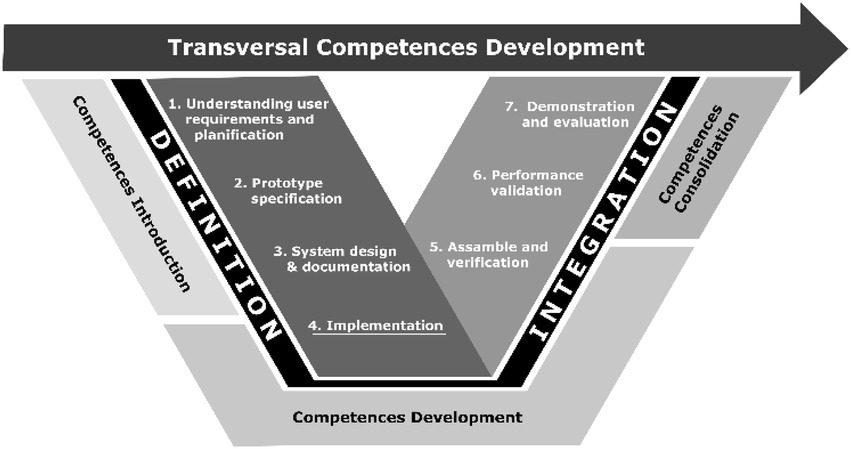

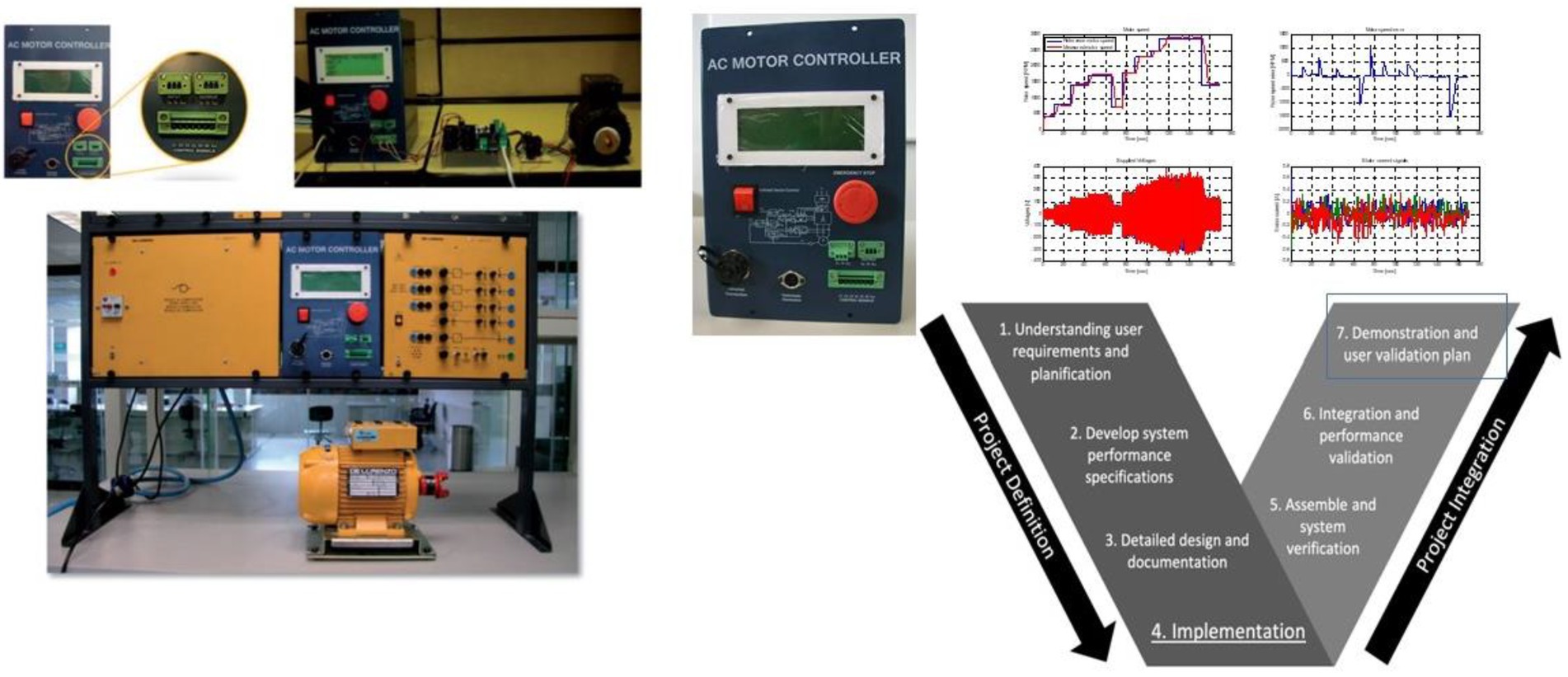

After completing each theoretical section, the student has to run an experimental project connected with a real problem; industry partners usually provide these problems. Thus, the student has to apply the theoretical concepts and develop a rapid prototype using the components implemented in the experimental section of the course to validate the proposed solution. In addition, students have to present their proposals and research document. The undergraduate course was designed to reference the V-Model and the Tec-21 educational model so that the students could create solutions faster than in conventional classes. Figure 2 shows the V-Model in which the design stages for achieving a rapid prototype and the acquired competencies. The presented V-model for education was established as an inherent structure that could be incorporated when real solutions are created.

The Tec21 Educational Model of Tecnologico de Monterrey (Tec 21 Model, 2018) integrates a Challenge-Based-Learning framework that improves course flexibility and tailors the learning experience. Hence, students gain a focused specialty in the professional areas that motivate them [Tec 21 Model]. In addition, the Tec21 model is for Higher Education Institutions that seek more experiential learning and academic motivation and commitment. This paper shows how the educational TEC 21 model1 proposed by Tecnologico de Monterrey and the V model (Shuping and Ling, 2008; Mathur and Malik, 2010) used in industry to develop products are integrated into an undergraduate course promoting complex thinking. It allows students to apply the theoretical concepts in experimentation in a friendly and swift manner using advanced software tools such as MATLAB and Simulink.2

Moreover, at the end of the undergraduate course, the students can solve real problems using complex thinking to combine practical and theoretical knowledge to solve advanced real engineering problems. As presented by Alkhatib (2019) and Ramírez-Montoya et al. (2022), complex thinking allows students to identify and define problems, create solutions, evaluate the outcomes, and satisfy the requirements of “Education 4.0.” Thus, the course material aims to promote complex thinking and combine theoretical and practical knowledge to create solutions.

Figure 2 shows the competencies developed in the V-model. The developed competencies in the Tec 21 model are transversal and disciplinary as follows [Tec 21 model]:

Transversal competencies: self-knowledge and management, innovative entrepreneurship, social intelligence, ethical and citizen commitment, reasoning to face complexity, communication, and digital transformation.

Disciplinary competencies: theoretical knowledge and skills necessary for professional practice in the selected career.

As a result, the V-model and Tec 21 model can be integrated educational tools in a challenge-based learning structure. The course evaluation is based on students’ competencies and knowledge; memorization of concepts is not allowed in the class. This course led students in the following:

• The students are guided to propose innovative solutions.

• They experience active learning.

• The students acquire deep learning.

• They learn backward reasoning.

• The students reflect on their learning.

• They gain research skills.

• They acquire self-directed learning skills.

The proposed electric drive course at Tecnologico de Monterrey is associated with the electrical energy program. This course has 48 h provided over 16 weeks. Each class is planned on a 3-h basis, so the topics are distributed among the classes. As mentioned, the V-model structure is implemented in this course to familiarize students with designing rapid prototypes that can be evaluated.

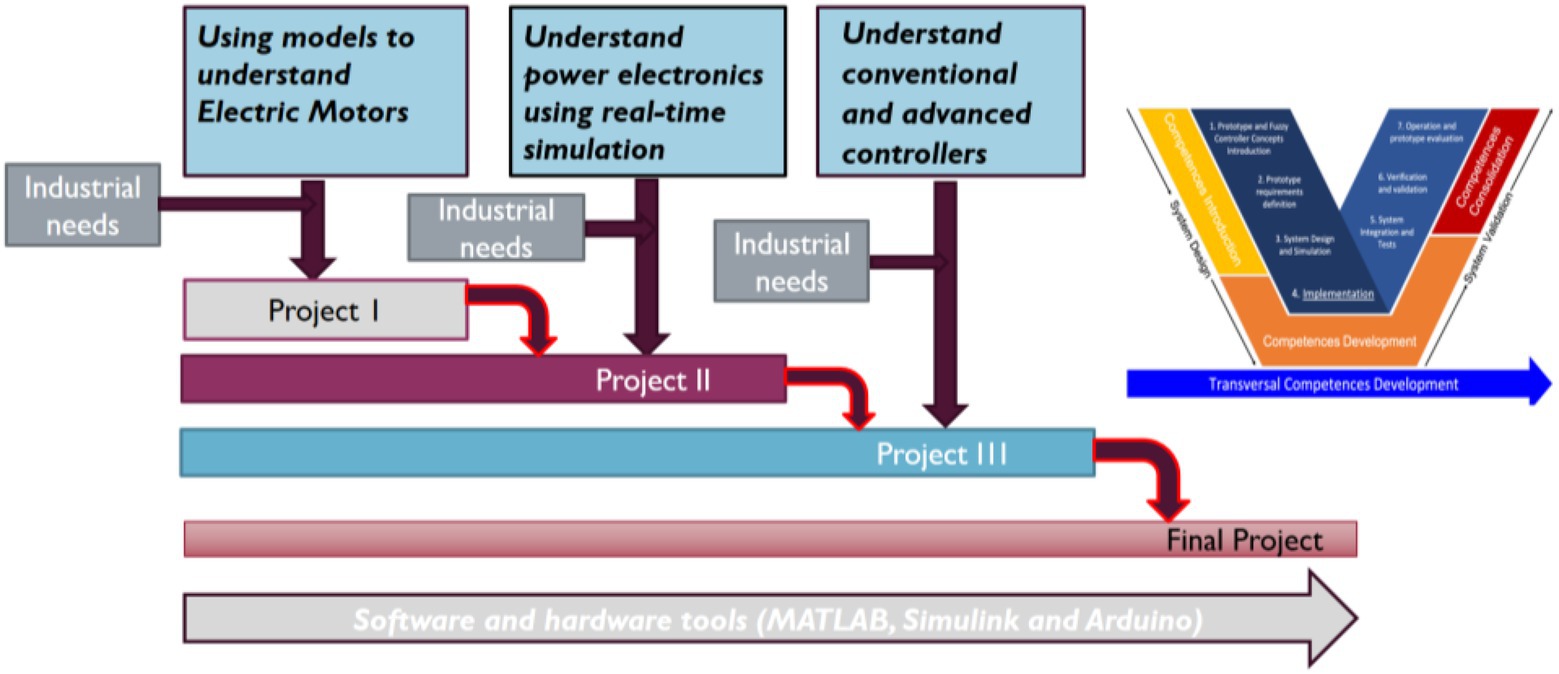

The course content is divided into three main modules. Industries are invited to provide an industrial challenge for students to resolve in each module, so they also get information from their experience with real problems requiring novel solutions (see Figure 3). At the end of each module, the students develop a project connected with an actual application. The final project is the combination of the content of the complete course. Besides, students continuously develop rapid prototypes using software and hardware, allowing them to define and validate complex solutions with low-cost hardware. The primary software programs are MATLAB and Simulink. Figure 4 presents the essential content of the course. The course evaluation is based on projects, homework, and exams. Projects are created in teams of no more than four members who participate in theoretical and practical approaches to each topic. Each team is permitted to propose its emphasis as part of the project description. As a result, several project deliverables with distinct methods emerge. Also, each student is responsible for giving a grade to other pupils (it is a different grade used as feedback for the team). The written report format is based on scientific journals such as IEEE.org. After team members have graded several projects, they can discuss their results concerning ways of improving the projects. As Tlhoaele et al., 2015 suggested, some students learn better from their classmates’ feedback.

Figure 3. Industrial speakers invited to show industrial challenges (electric vehicles and pumping) in the class (National Instruments and ABB).

There are several papers about teaching electric drives in undergraduate courses; however, there is a gap in teaching electric drives using projects based on experimental designs using low-cost hardware to implement complex systems that are linked with industrial needs. Moreover, low-cost hardware can be used to implement advanced controllers that can improve the performance of conventional ones. For example, Arduino is a basic microcontroller that can be used as an acquisition system and running the main control algorithm programmed in Simulink into a conventional PC so advanced controllers can be implemented and evaluated by students. On the other hand, Simulink is a high-level programming language so that students can learn it in a short period of time. This course starts teaching the fundamentals of electric machines and finishes teaching vector control and direct torque control (DTC) using AI, which are advanced topics. It is difficult to teach those topics using conventional educational methodologies; thus, the proposed methodology promotes theoretical and experimental activities so students can learn from these two sources.

On the other hand, this course has been running online since the COVID-19 pandemic forced us to have virtual courses. Students adopted and accepted the course since they could continue getting theoretical and practical knowledge without attending laboratory sessions. One of the main concerns in distance education is experimental knowledge because engineering courses focus on solving real problems, and those experimental exercises are crucial for developing practical skills. It has been demonstrated that simulation-based labs cannot give the complete practical knowledge required in engineering (Borrego et al., 2009; Bielefeldt, 2011). Thus this course provides a solution because the students gain meaningful and relevant experimental knowledge using low-cost material. Also, this course allows students to conduct basic and advanced exercises to solve real problems presented by industry. In general, the skills and knowledge that students gain during the proposed curse are presented below.

- Gain the ability to solve real problems regarding electric drives.

- Understand DC and AC machines.

- Understand basic and advanced industrial controllers for electric drives.

- Gain the ability to design and select hardware components to solve complex problems.

- Conduct real experiments and analyze data.

- Understand clearly the results of the experiment to improve the proposed solution.

- Work in collaborative teams and individually.

- Communicate orally and written effectively.

- Learn the necessary engineering tools regarding electric drives for engineering practice.

On the other hand, the main disadvantage of this methodology is presented below.

Some students do not connect theoretical knowledge completely with practical exercises, so they require more time to complete them during class. Besides, creating support videos is time-consuming for professors; sometimes, the students do not watch the complete video, do not get all the information shown, and ask about topics presented in the supported videos. The cost of the components is low, but the shipping time could be high, so the material has to be shipped before the course starts to avoid a negative impact on the timetable. The complexity of industrial problems must be adjusted to get the correct timetable and complexity, so some industrial projects are partially solved or eliminated from the industrial problem list.

Content of the course and supportive materials

The proposed course includes simulation and experimental exercises that allow students to gain practical experience. Hence, the students can detect specific engineering areas that could be improved in real applications. The first section of the course deals with electrical machine models. These are explained to achieve models based on the first principles, gray box, and black-box models. The second section deals with the design of electric drive controllers, and the third stage covers advanced electric drive controllers using AI controllers. Table 1 shows the main activities developed on each topic.

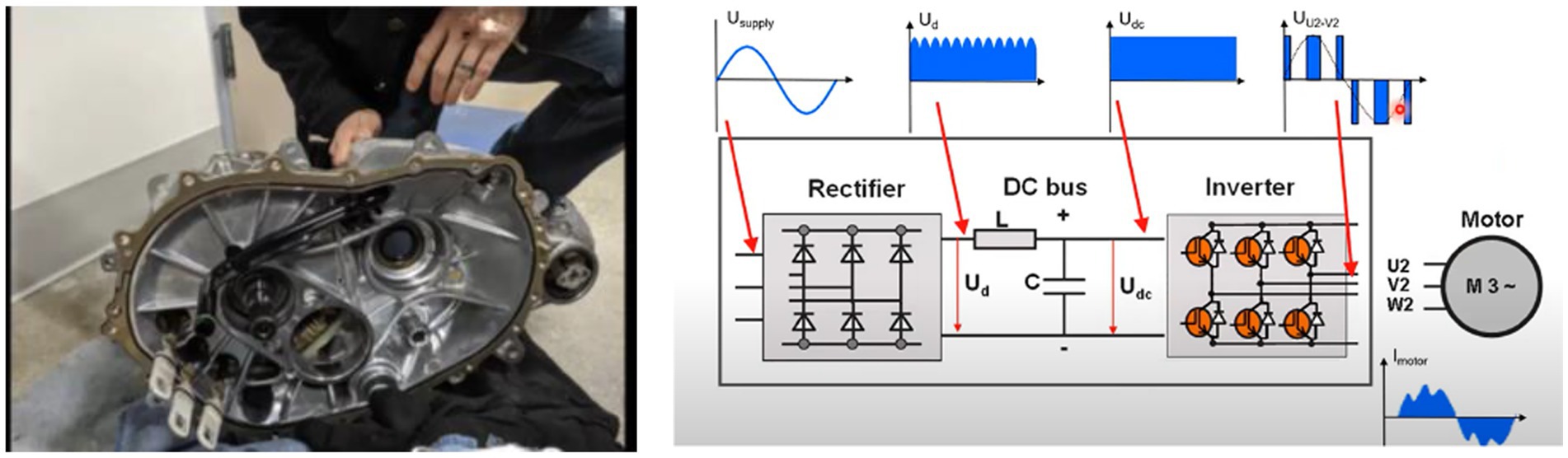

It is essential to mention that short demonstrations and validations of theoretical concepts are also conducted after the end of each section. For instance, when DC motors are explained, steady and dynamic models are covered, and the motor’s performance is demonstrated in the laboratory to confirm the results. Figure 5 shows different DC machine models and the comparison against experimental results from an actual motor. A Simulink diagram for getting the torque and speed curves in a transitory response model and steady stay are deployed. Also, students learn how these models could be used to describe the performance of the DC motor. Some experimental results, such as a field weakling region, are also validated in the laboratory in steady-state and transitory states. As an example, Figure 5 illustrates how a black-box model can be implemented to get a second-order transfer function in MATLAB and how the transfer function can be obtained using the System identification toolbox. For deriving the second-order transfer function of the DC motor, equations from (1) to (12) are used. The input is a step voltage, and the output is the motor speed; the experimental values are collected in the laboratory to find the transfer function. These equations presented below illustrate how a DC motor can be modeled using a simple black box model using a second order transfer function that is possible to implement when the poles p1 and p2 are far enough. Since the main idea of the course is to show basic and advanced models of electric machines, these equations describe a straightforward methodology for modeling DC motors at the beginning of the course as an initial topic in which students go to the laboratory to collect experimental data and use it to determine the transfer function.

Figure 5. DC motor steady-state response, dynamic response, and field weakling operation region in simulation and laboratory (sensing armature and field parameters).

Speed time value:

From the experimental response A and p1, we find:

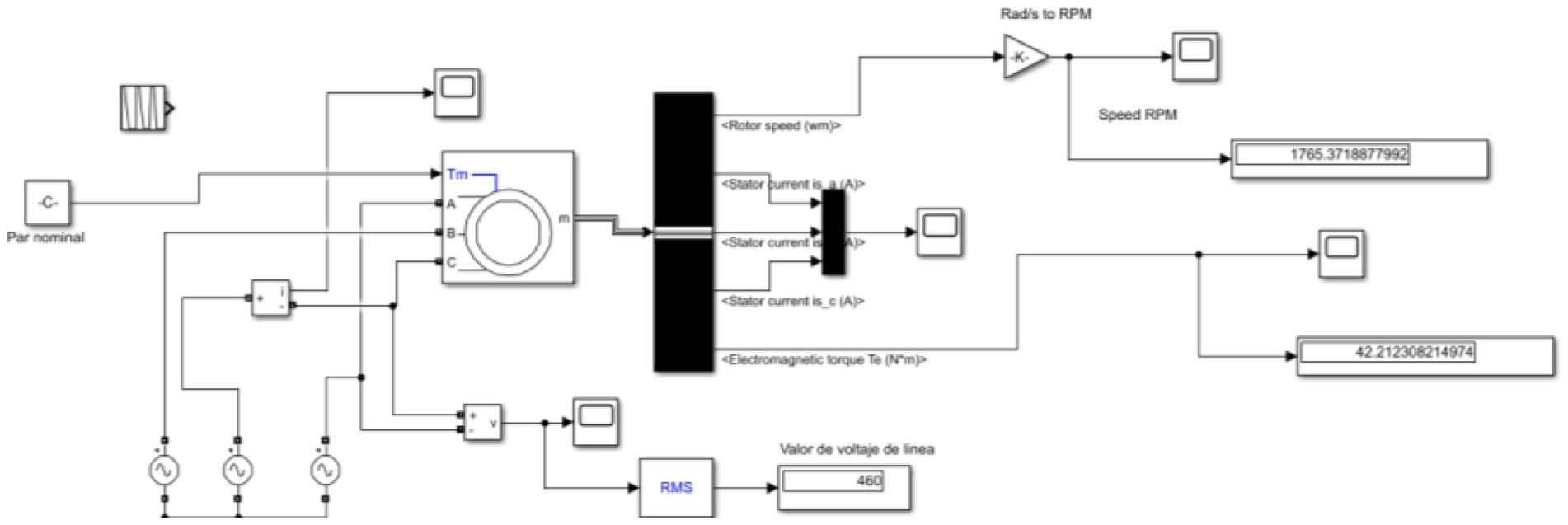

Similarly, AC motors are studied using steady and dynamic models; the students can develop a block diagram of AC machines using a stationary or rotatory reference frame, as shown in Figure 6. Then they can use the model of an AC machine in Simscape [MATLAB]. It is essential to show that students also create models using Simscape/MATLAB. They can build physical component models using physical connections linked with block diagrams to represent the physical elements involved in the system instead of using generic transfer functions only (see Figure 5).

Figure 6. Model of the induction motor using a Simscape induction motor block diagram (stationary reference frame).

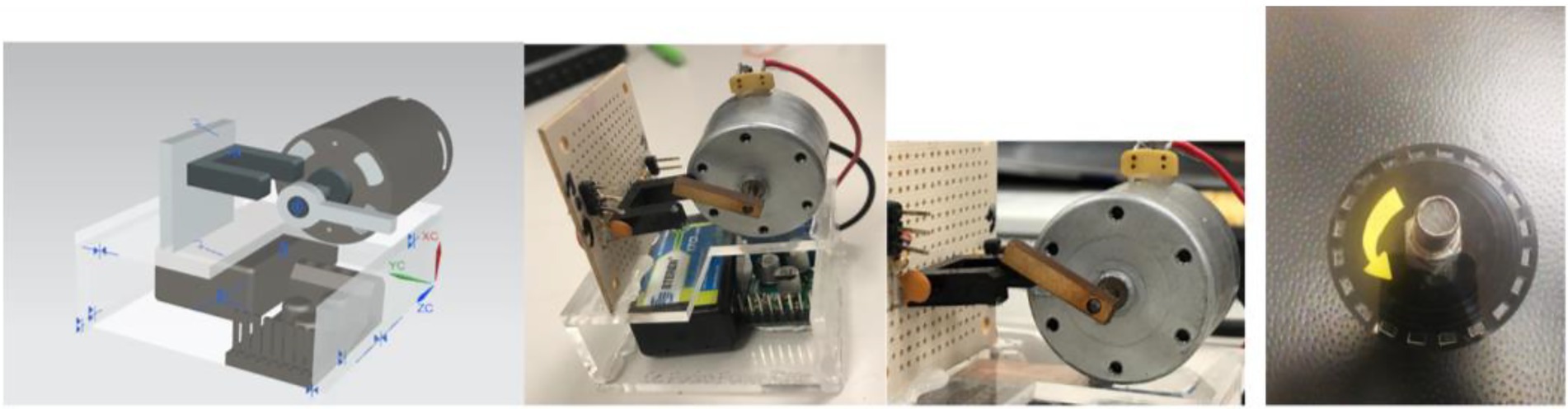

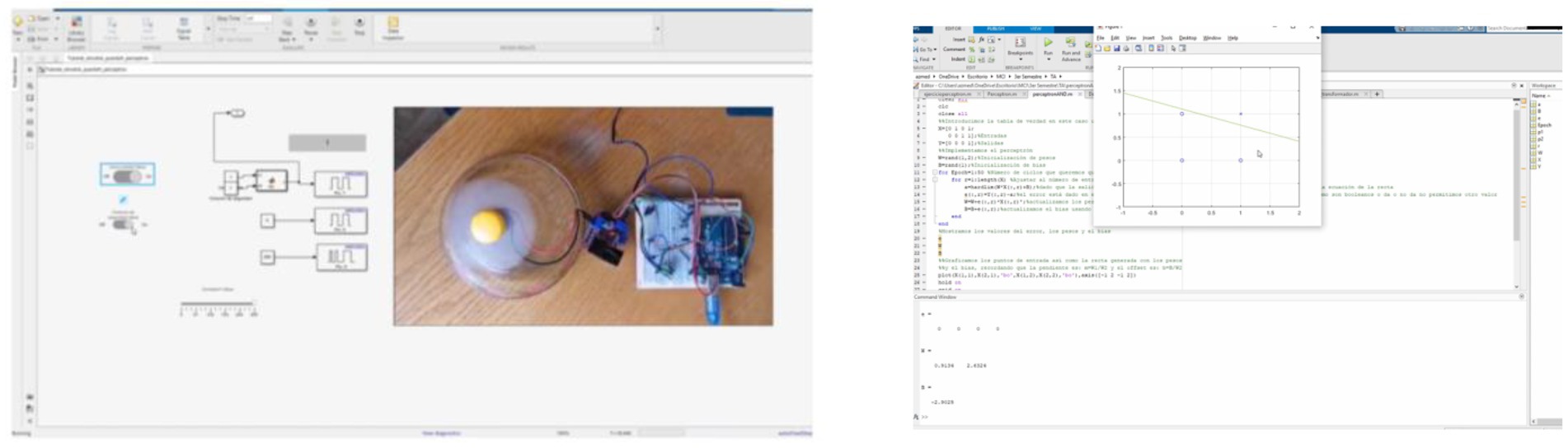

Also, it is noteworthy that students at the beginning of the course do not know how to program in MATLAB or Simulink. Thus, students must run basic models and increment the complexity of the programming tasks as the course moves forward. Additional online resources are reviewed by students, such as MATLAB on Ramp and Simulink on Ramp.3 An Arduino board is one of the students’ first approaches to digital controllers. Since the program is in a graphical language (Simulink), they can move to advanced digital systems such as C2000 micro-controller/Texas Instruments. Students also develop basic sensors to understand how speed and position sensors work in a closed-loop control (see Figure 7).

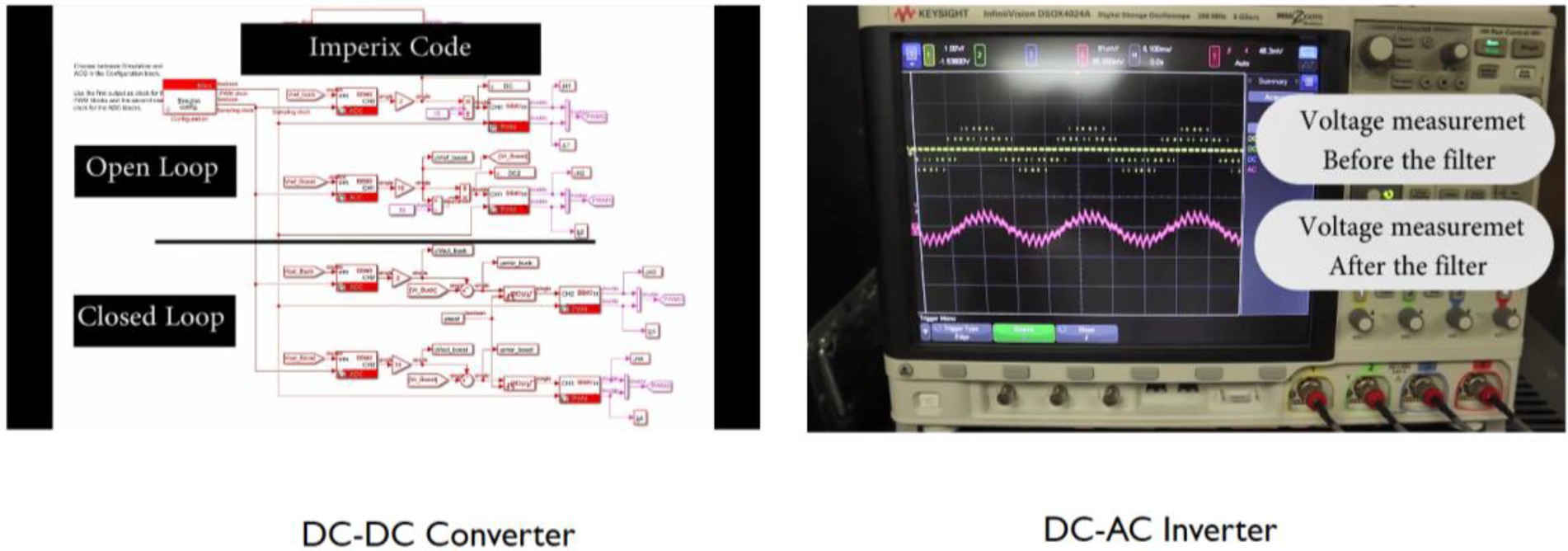

As a result, they can generate advanced electric drives (Rashid, 2017). The power electronics stage (converters DC-DC and DC-AC) is studied using real-time simulation since converters require high fidelity to be modeled. Besides, hardware in the loop can be validated using the same Simulink block diagrams used in a conventional simulation. Figure 8 depicts the real-time simulation running power electronics converters that allows students to accomplish high-fidelity models.

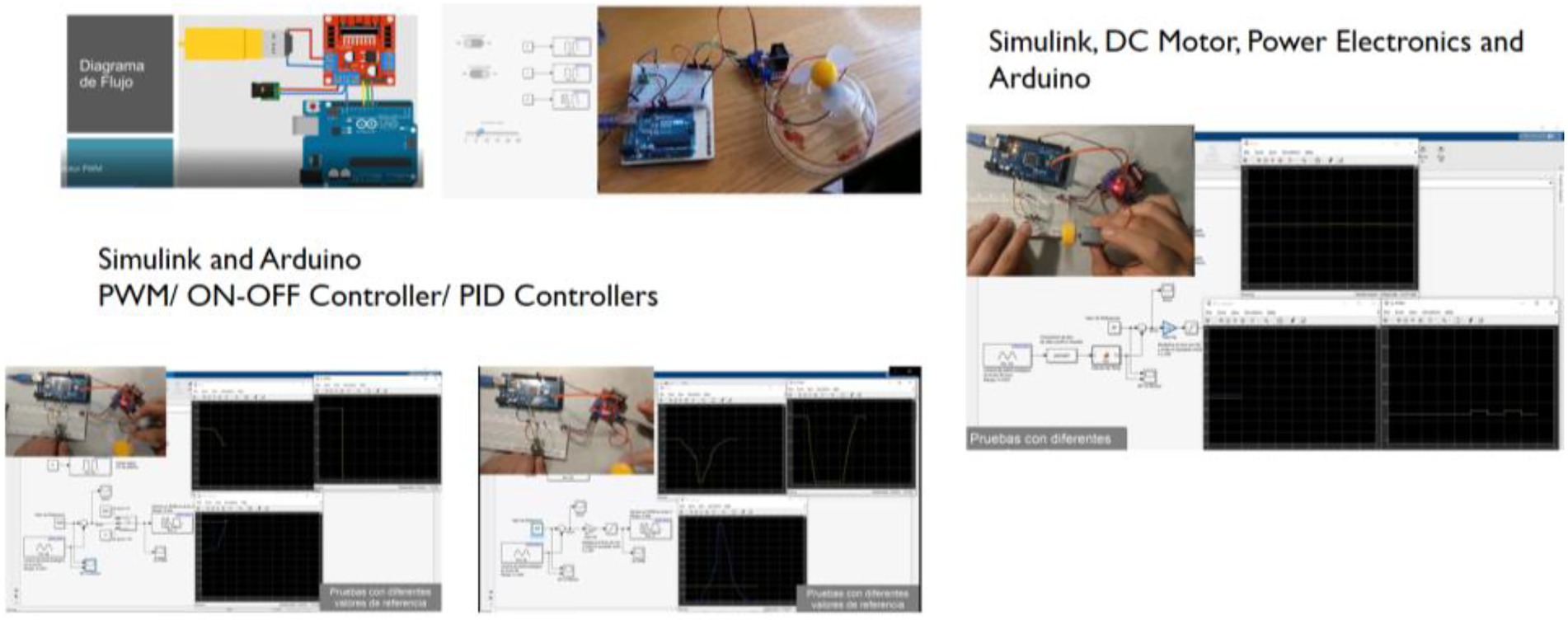

When conventional controllers such as ON–OFF and Proportional+Integral+Derivative controllers are studied (Voda and Landau, 1995), additional material is provided for validating the theoretical concepts during experimental exercises. The students interact with the Arduino board to develop some controllers, and thus, students can get experimental knowledge. Figure 9 illustrates some examples of conventional controllers implemented using MATLAB/Simulink and Arduino. In addition, a series of supporting materials are created to self-study so students can confirm theoretical aspects with experimental ones. Moreover, the students can propose new solutions to practical problems.

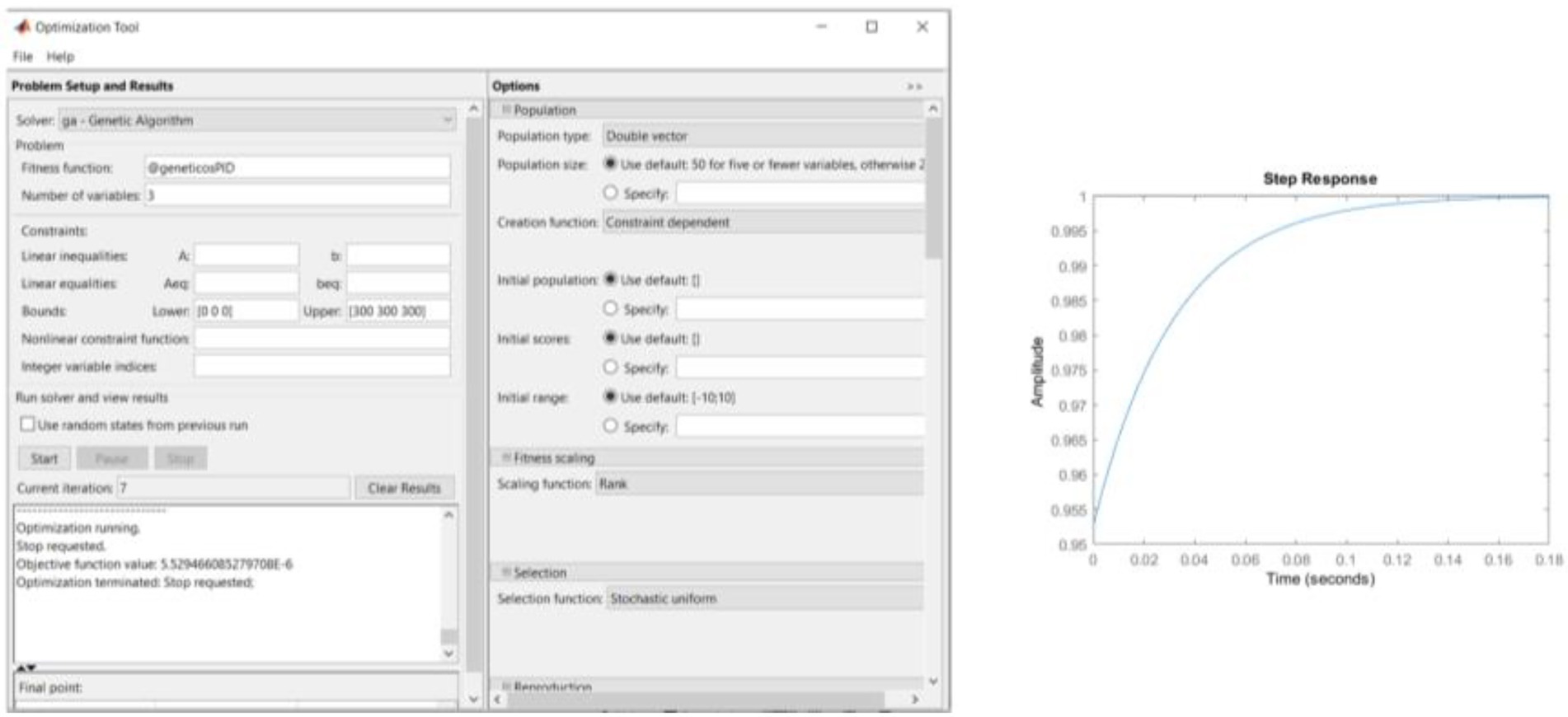

Some additional optimization techniques are also presented in the course, such as genetic algorithms to tune conventional controllers offline (Thomas and Poongodi, 2009). This optimization technique has been used in several applications of electric drives (da Silva et al., 2000; Montazeri-Gh et al., 2006). The optimization editor developed by MATLAB is used, so students do not have to focus on programming the algorithm, and they are focused on creating an optimal solution using the optimization methodology (see Figure 10).

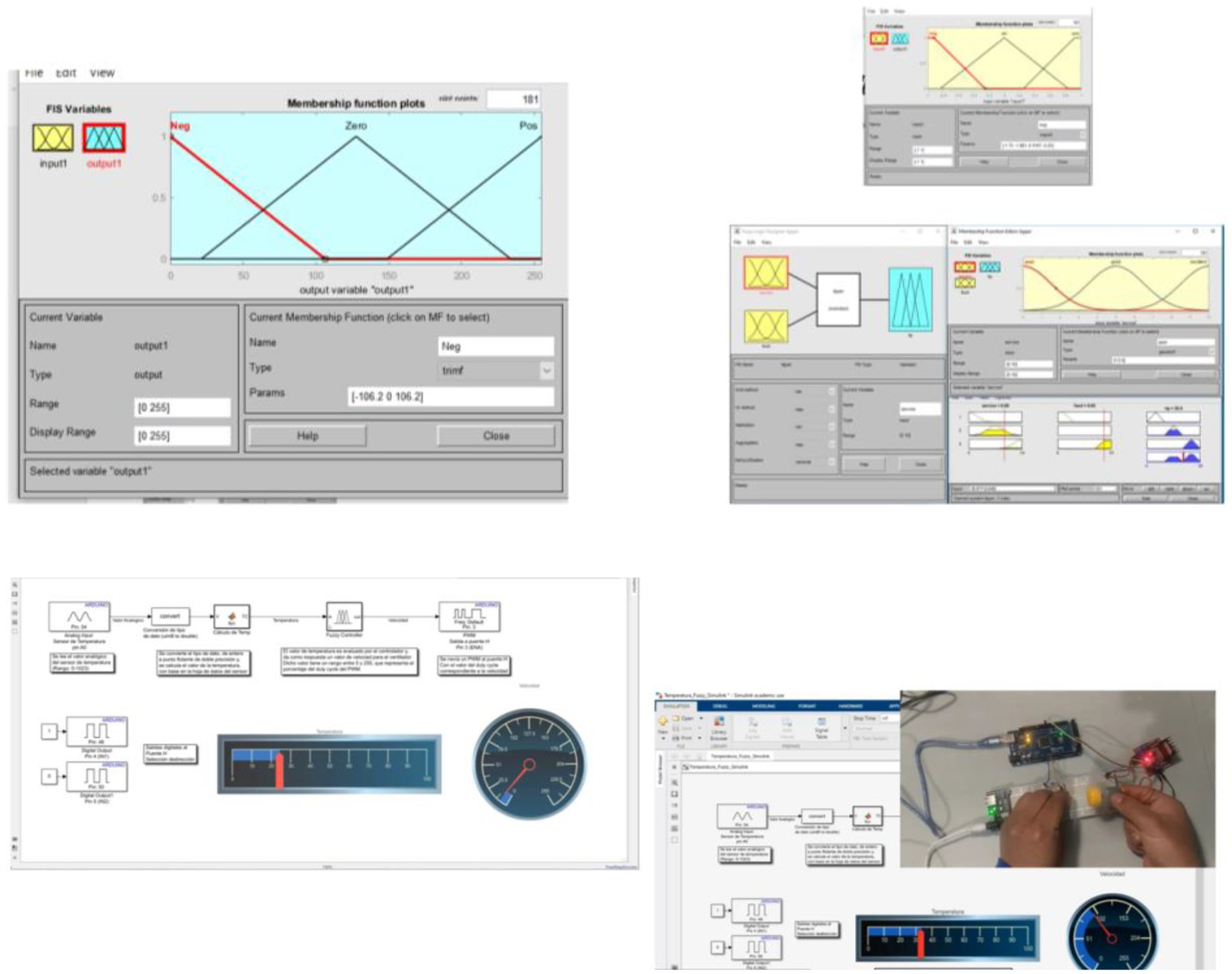

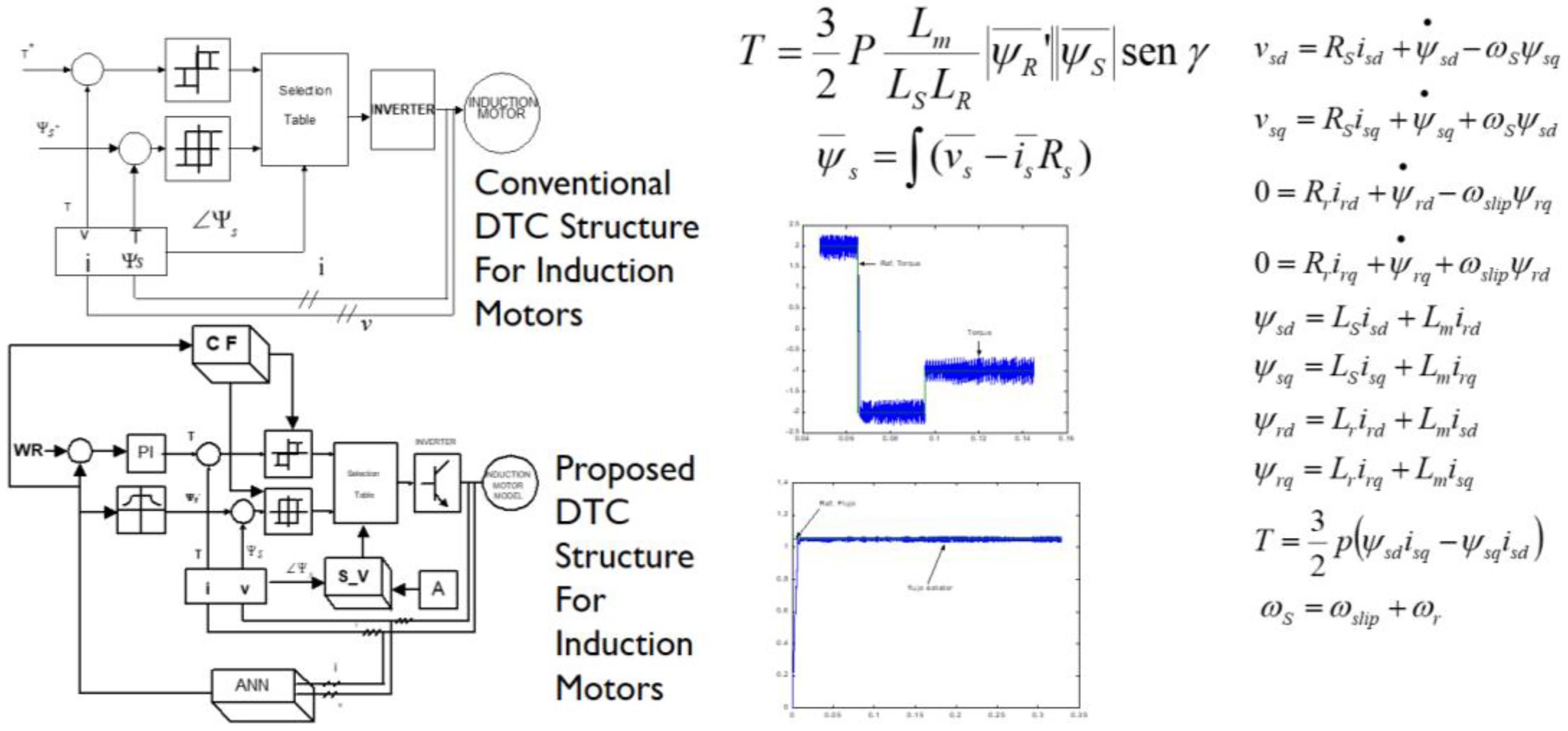

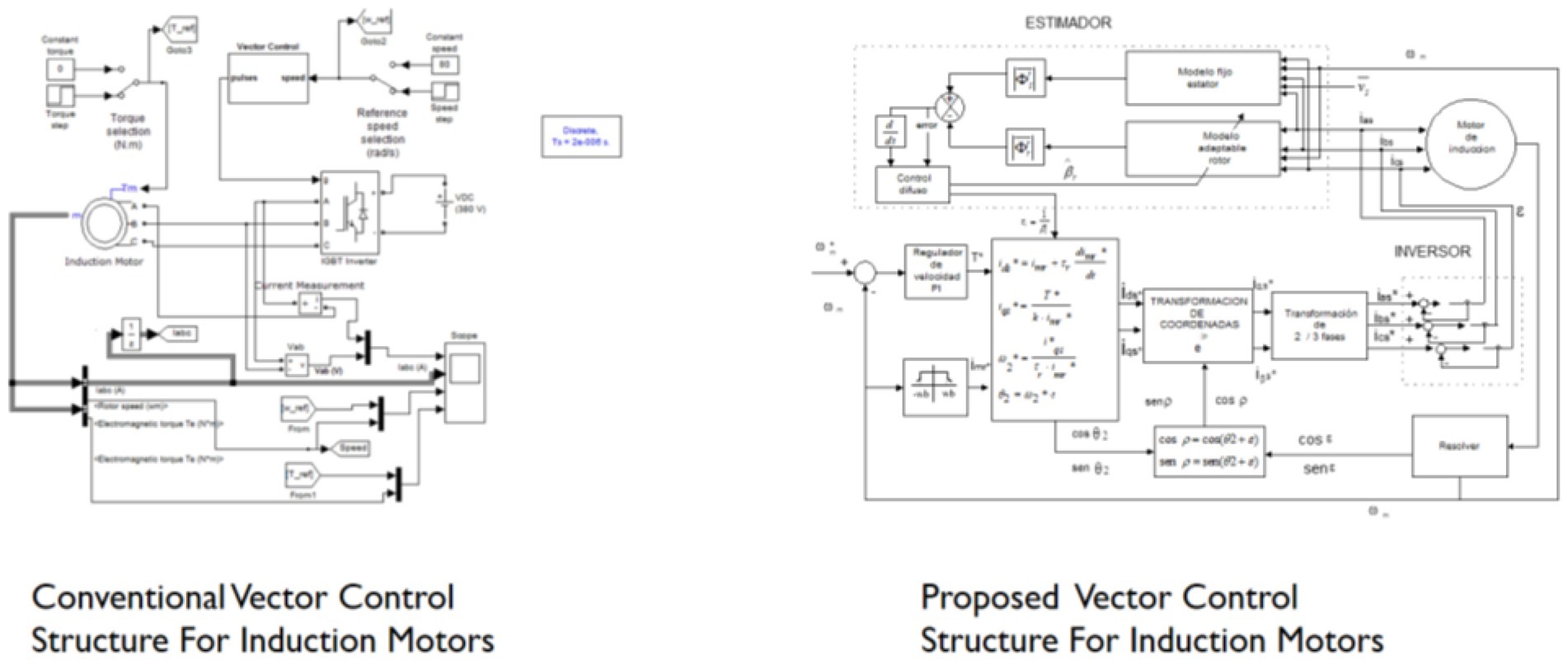

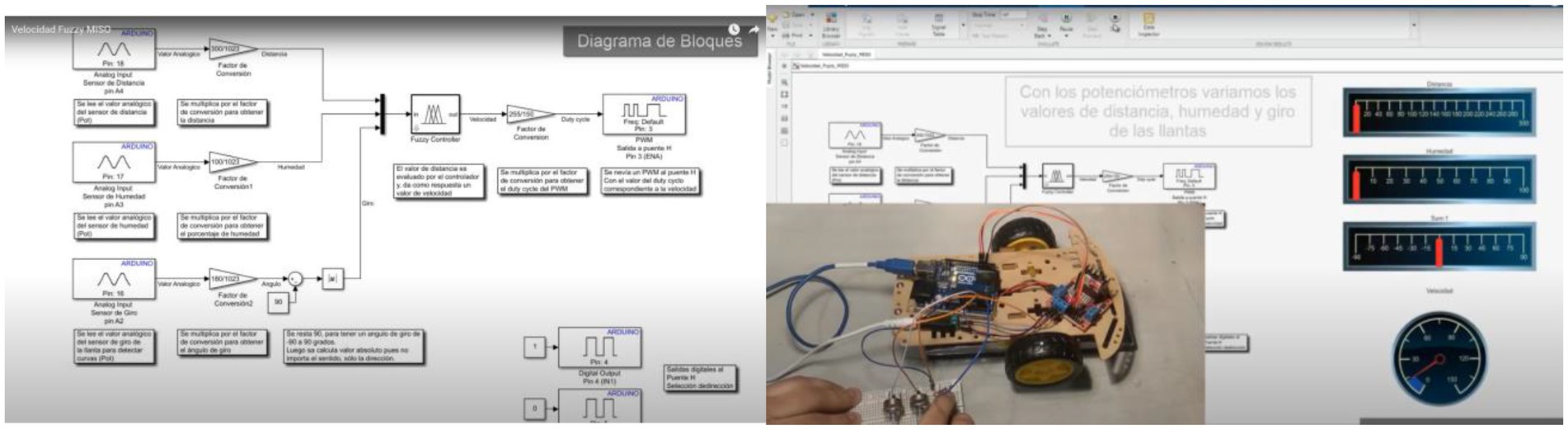

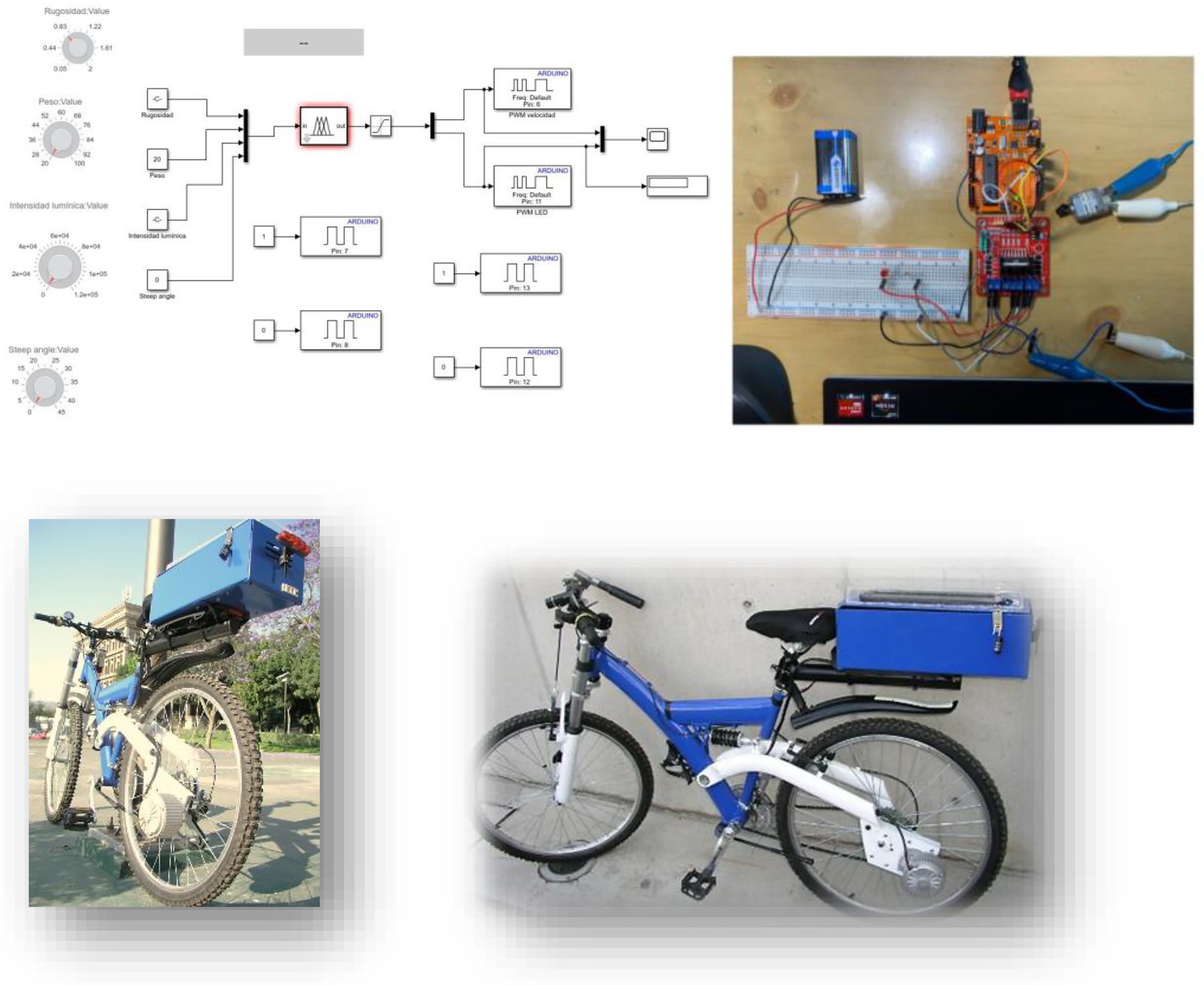

Advanced and conventional control topologies for controlling AC machines are also presented. In the beginning, scalar control (V/F), Peña and Díaz (2016), is studied and analyzed during different industrial applications, and students simulate the electric drive and connect the simulations with real applications (see Figure 11). Students must understand that DTC (El Ouanjli et al., 2019) and vector control are designed to obtain two main control channels, one for the torque and the other for the flux, like a conventional DC drive. Thus students can use the traditional controllers to generate speed or position controllers. These topologies are well known and implemented in several applications. However, some industrial applications improved their performance using artificial intelligence systems. Thus, students need to know intelligent systems to create innovative solutions. When intelligent controllers (Neuro controllers, Fuzzy Logic Controllers, and ANFIS controllers, Vas, 1999; Ponce-Cruz and Ramírez-Figueroa, 2009) are presented, supplementary material is provided to give complete information about the theoretical and practical concepts necessary to implement advanced controllers. Some examples are developed in classes, and advanced exercises are proposed as a solution for industrial applications. The MATLAB editor of Fuzzy logic and artificial neural networks is used ([MATLAB]), so students focus on creating solutions that improve the performance of conventional control structures of electric drives. Figure 12 illustrates the fuzzy editor and a temperature controller using a DC motor (a fan). Figure 13 shows the DTC topology and a proposed scheme to reduce the torque and flux ripple using fuzzy logic controllers and artificial intelligence. Conventional vector control and proposed topology for AC drives are presented in Figure 14.

Figure 11. Industrial applications solved using an industrial drive (Altivar-58) and the Simulink block diagram designed by students to understand and propose new solutions.

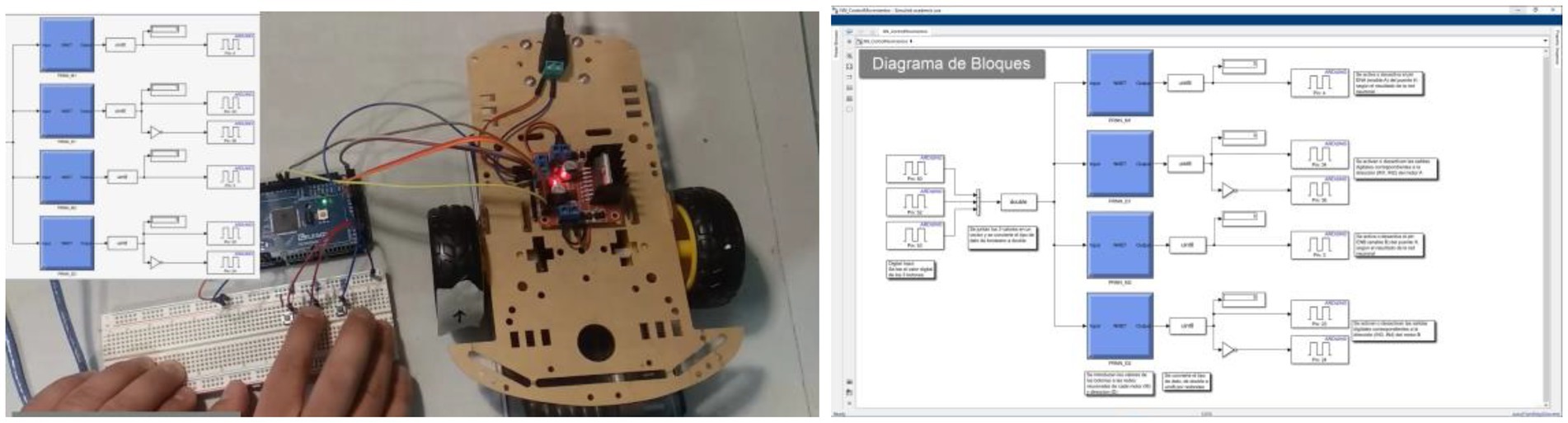

Electric vehicle rapid prototype

Students use low-cost materials to develop a proposed rapid prototype of an electric vehicle, which is a complex problem. The main goal is to develop solutions that improve the performance of the electric vehicle in specific operating conditions such as navigation or parking (Chan, 1993; Wirasingha and Emadi, 2010). Sometimes, students propose using intelligent controllers like artificial neural networks or fuzzy logic controllers. The rapid prototype is not entirely functional since it is only used to validate the specific performance during an operation. Potentiometers, like analog inputs, implement different sensors, so students can add the number of sensors they require without spending money. After the students validate the rapid prototype, some continue developing a complete version of the functional prototype. In this stage, students understand the models and the conventional control algorithms for DC and AC electric drives and power electronics deployed in electric drives. Figure 15 presents a Mamdani-type fuzzy logic controller designed for parking, and Figure 16 illustrates a perceptron that is the primary element in a neural network topology. An artificial neural network controller (based on a multilayer structure) designed to avoid obstacles during navigation is presented in Figure 17. The fuzzy logic and neural network controller are created using a primary hardware platform of DC motors, so the students only validate the specific operation of the electric vehicle.

However, the DC drive can be changed to an AC drive when a DTC or vector control is implemented since these techniques mimic the performance of DC drives using two channels, one for the torque and the other for the flux. Figure 18 illustrates how students can move from the rapid prototype to the complete functional prototype of an electric bicycle. This electric bicycle was developed using solar panels to charge the battery pack in the DC drive. Students assessed different control topologies in the Arduino board and created a functional prototype. These project assessments determine the progress level in the V model as a reference so students can realize how far they are from producing a commercial product. It is essential to mention that some projects achieve only the first stages in the V model. Nevertheless, the students understand, define, and propose a solution for a real complex problem that could be implemented. Figure 19 shows a field-oriented controller for an induction motor that achieves the last stage in the V model. It is important to mention that there are some drawbacks when the hardware is implemented. These drawbacks are explained below. Figure 20 illustrates the evolution of an educational training module to teach electric drives. It is essential to observe how the prototypes are changing according to the end user’s feedback, so the final version of the prototype achieves all the end user’s requirements.

To implement low-cost hardware systems, students have to break down a whole system into basic components to detect fault conditions or improve performance, but they are unfamiliar with breaking down a whole system. Moreover, the selection of specific hardware components for solving an application is unclear when the curse starts.

Besides, some students are unfamiliar with digital systems, so advanced digital systems cannot be taught at the beginning of the course. This is the main reason that Arduino is a good starting point regarding digital systems. In addition, real-time simulation is evaluated in the power electronics section, so students have to learn about FPGAs and DSPs. This course only gives information for understanding the essential information about advanced digital systems, but it does not cover all the technological and practical issues about advanced digital systems.

There is a general introduction about the hardware at the beginning of the course, but the students must independently deal with more advanced problems. The professor has to deal with a short period of time to cover the material, so additional activities are crucial in this curse; additionally, specific homework is assigned to students with less knowledge about digital systems.

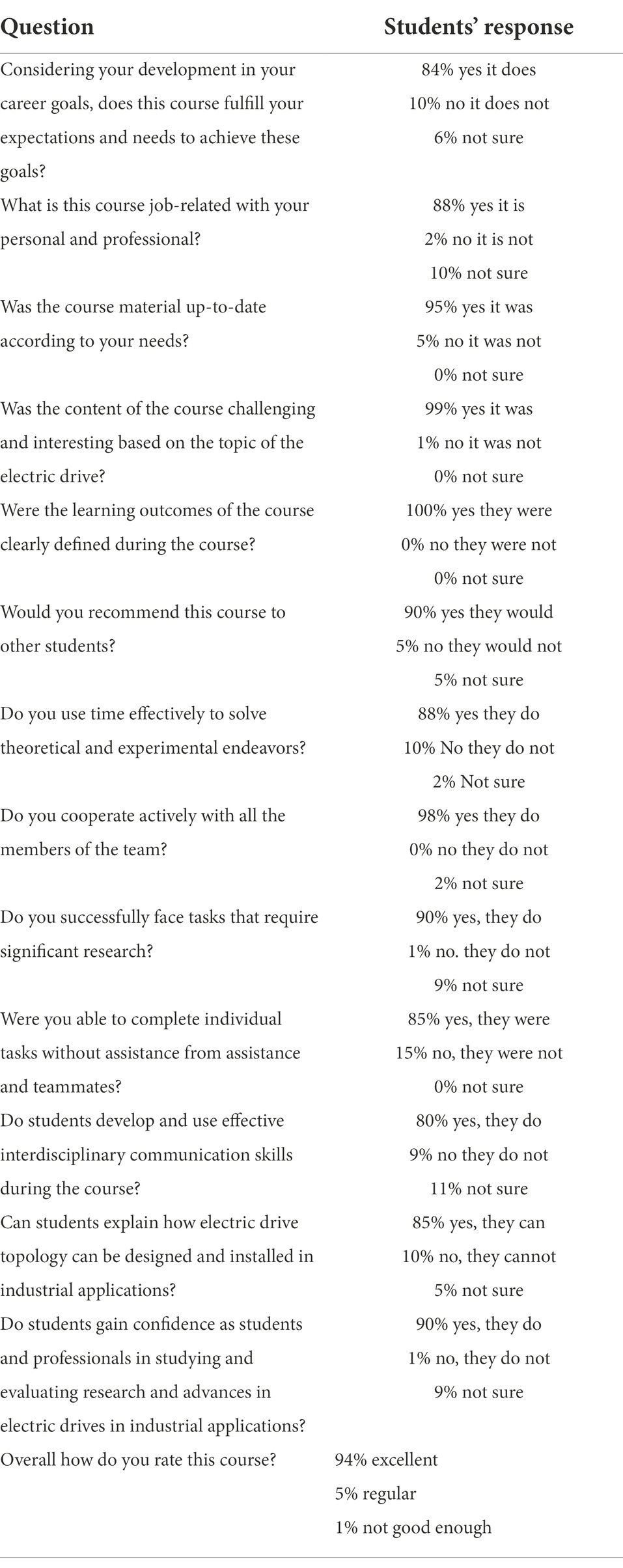

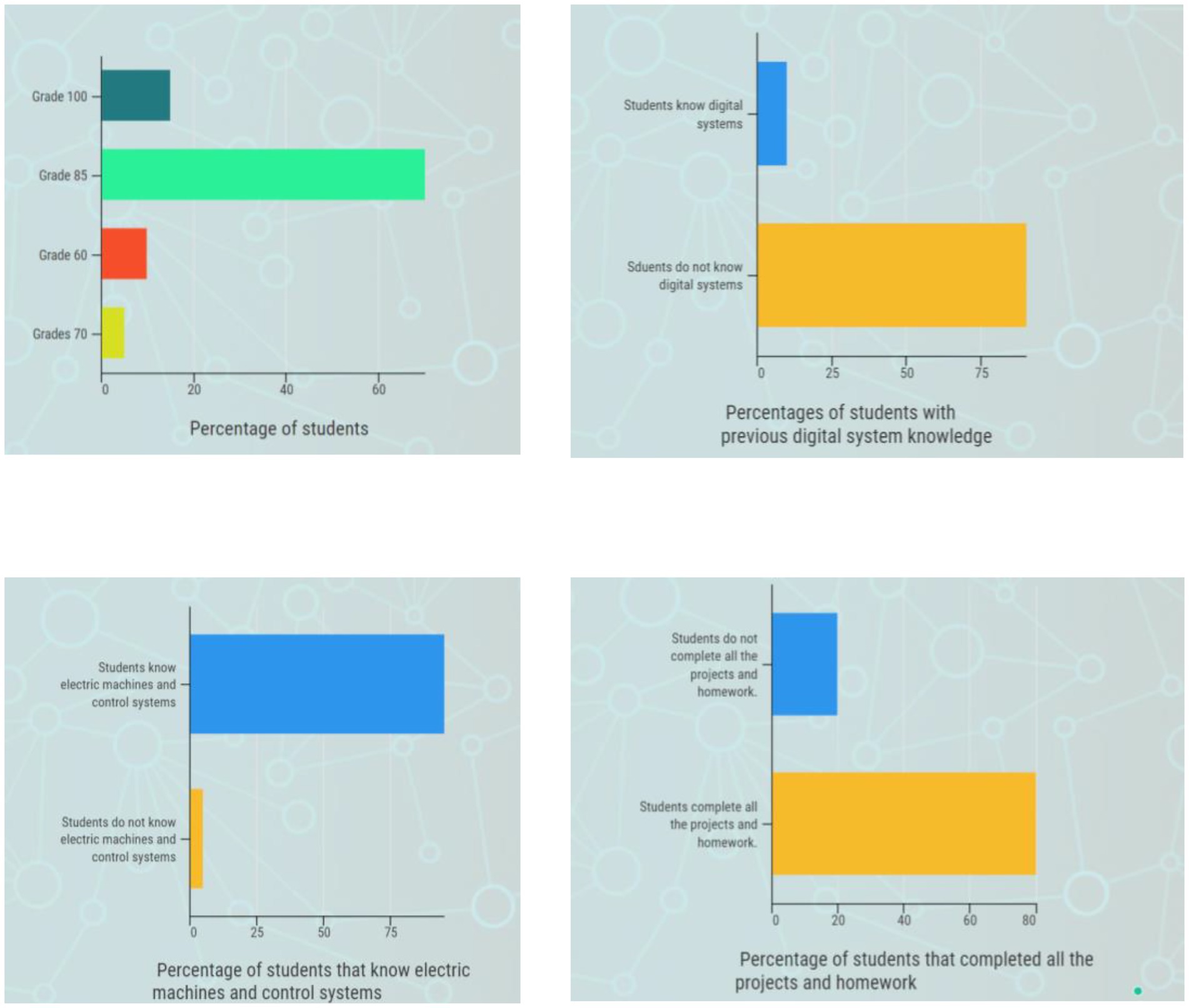

The experimental examples have a time limit of 2 h, so some students require more time because they have to detect fault conditions. However, at the end of the course, all the students can finish the experimental exercises in time. If low-cost hardware is implemented as an embedded system, the memory and processing time could be limited in the implementation. However, they can be replaced to implement advanced electric drives. In addition, a sample of 95 students who took the course answered the survey presented in Table 2. It is essential to mention that the survey results show that students accepted and adopted the course of this electric drive. Moreover, the course helps develop their career goals. Finally, Figure 20 shows the general results obtained in the course. It is essential to comment that there are some limitations from the previous advanced digital systems knowledge since the students did not take a course on this topic previously. Thus, during the course, specific topics are covered. Besides, the percentage of students that get a final grade equal to 60/100 is low compared to students that get a grade of 85/100 points; the minimum grade to pass the course is equal to 70/100. Similarly, the number of students that course previous electric machines and control system topics is high (see Figure 21). The grades and feedback regarding the written report were evaluated based on the following elements (Scoles et al., 2000; Gibson, 2001; Ihsan et al., 2012): general appearance, title page, table of content, figures and tables, section heading, subheadings, introductions, development, conclusions, and references.

Conclusion

This undergraduate course structure allows students to propose original solutions to complex problems and develop transversal and multidisciplinary competencies using complex thinking in electric drives. Moreover, this course confronts the students with real scenarios where they have to create rapid prototypes to assess ideas to improve the performance of electric drives in several applications. Thus, the students can get feedback from end-users. The students begin this undergraduate course by developing basic DC motor models. Finally, they can create a rapid electric vehicle prototype and assess the results. Besides, they can connect the experimental results to gain valuable experience in creating practical electric drives.

This paper shows how students can learn not only theoretical concepts of electric drives but also propose solutions to real complex problems and combine information from industry and academia using the Tec 21 Educational Model and the V model. In this structure, industry partners provide real problems to students in each course section to resolve as challenges. Thus, students must develop and propose innovative solutions to improve the performance of electric drive applications. The students become familiar with industrial problems and how the industry tries to solve them. The students begin with theoretical concepts and move to practical results using MATLAB, Simulink, and OPAL-RT, which are excellent educational tools. Initially, some students do not know how to program in MATLAB and Simulink, but they can learn those quickly. These educational tools are used with Arduino during the entire course.

This course is accepted by students and also improved their knowledge about practical and theoretical issues regarding electric drives. Since electric drives are extremely useful technology, they can apply their gained knowledge to solve practical problems in several areas. Besides, the students can construct a solution and validate it using rapid prototyping based on model V and Tec 21 model. Thus, the proposed structure helps them to develop and organize a practical solution.

This educational proposal could be implemented in engineering courses to increase students’ practical knowledge. This course is not designed to substitute for a laboratory course in electric drives; it is a new approach at Tecnologico de Monterrey for teaching theory and its applications in undergraduate programs.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Funding

This study was funded by Writing Lab, Institute for the Future of Education, Tecnologico de Monterrey, Mexico.

Acknowledgments

We wish to show their appreciation to MATLAB, National Instruments, and ABB for supporting this educational research project. Specially to Esperanza Linares from MATLAB. We acknowledge the technical and financial support of Writing Lab, Institute for the Future of Education, Tecnologico de Monterrey, Mexico, in the production of this work.

Conflict of interest

BM was employed by company National Instruments. MA was employed by ABB.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Footnotes

References

Alkhatib, O. J. (2019). “A framework for implementing higher-order thinking skills (problem-solving, critical thinking, creative thinking, and decision-making) in engineering & humanities” in Advances in science and engineering technology international conferences (ASET) (Dubai, United Arab Emirates: IEEE), 1–8.

Arthur James, S. (2015). Student usage of a learning management system at an open distance learning institute: a case study in electrical engineering. Int. J. Electr. Eng. Educ. 52, 142–154. doi: 10.1177/0020720915575925

Asato, K., Asato, K., Nagado, T., and Tamaki, S. (2015). “Development of low-cost educational material for learning fundamentals of mechatronics” in International conference on intelligent informatics and biomedical sciences (ICIIBMS) ed. Patrick Di Justo (IEEE), 454–456.

Banzi, M., and Shiloh, M. (2022). Getting started with Arduino. United States of America: Maker Media, Inc.

Bartunek, J. M., and Louis, M. R. (1988). The Design of Work Environments to stretch Managers' capacities for complex thinking. Hum. Resour. Plan. 11.

Bian, D., Kuzlu, M., Pipattanasomporn, M., Rahman, S., and Wu, Y. (2015). “Real-time co-simulation platform using OPAL-RT and OPNET for analyzing smart grid performance” in IEEE power & energy society general meeting (Dubai, United Arab Emirates: IEEE), 1–5.

Bielefeldt, A. R. (2011). Incorporating a sustainability module into first-year courses for civil and environmental engineering students. J. Prof. Issues Eng. Educ. Pract. 137, 78–85. doi: 10.1061/(ASCE)EI.1943-5541.0000050

Borrego, M., Douglas, E. P., and Amelink, C. T. (2009). Quantitative, qualitative, and mixed research methods in engineering education. J. Eng. Educ. 98, 53–66. doi: 10.1002/j.2168-9830.2009.tb01005.x

Chan, C. C. (1993). An overview of electric vehicle technology. Proc. IEEE 81, 1202–1213. doi: 10.1109/5.237530

da Silva, W. G., Acarnley, P. P., and Finch, J. W. (2000). Application of genetic algorithms to the online tuning of electric drive speed controllers. IEEE Trans. Ind. Electron. 47, 217–219. doi: 10.1109/41.824145

El Ouanjli, N., Derouich, A., El Ghzizal, A., Motahhir, S., Chebabhi, A., El Mourabit, Y., et al. (2019). Modern improvement techniques of direct torque control for induction motor drives-a review. Prot. Control Mode. Power Syst. 4, 1–12. doi: 10.1186/s41601-019-0125-5

Gibson, I. S. (2001). Group project work in engineering DesignÐLearning goals and their assessment*. Int. J. Eng. Educ. 17, 261–266.

Ihsan, A. K. A. M., Taib, K. A., Talib, M. Z. M., Abdullah, S., Husain, H., Wahab, D. A., et al. (2012). Measurement of course evaluation for lecturers of the Faculty of Engineering and Built Environment. Procedia Soc. Behav. Sci. 60, 358–364.

Mathur, S., and Malik, S. (2010). Advancements in the V-model. Int. J. Com. Appl. 1, 30–35. doi: 10.5120/266-425

MATLAB-SIMULINK. (2022). Available at: https://www.mathworks.com/products/matlab.html

Mi, C., Shen, Z. J., and Ceccarelli, T. (2005). Continuing education in power electronics. IEEE Trans. Educ. 48, 183–190. doi: 10.1109/TE.2004.837038

Montazeri-Gh, M., Poursamad, A., and Ghalichi, B. (2006). Application of genetic algorithm for optimization of control strategy in parallel hybrid electric vehicles. J. Franklin Inst. 343, 420–435. doi: 10.1016/j.jfranklin.2006.02.015

Peña, J. M., and Díaz, E. V. (2016). “Implementation of V/f scalar control for speed regulation of a three-phase induction motor” in IEEE ANDESCON (Arequipa, Peru: IEEE), 1–4.

Ponce-Cruz, P., and Ramírez-Figueroa, F. D. (2009). Intelligent control systems with LabVIEWTM. Springer London: Springer Science & Business Media.

Ramírez-Montoya, M. S., Castillo-Martínez, I. M., Sanabria-Z, J., and Miranda, J. (2022). Complex thinking in the framework of education 4.0 and open innovation—a systematic literature review. J. Open Innov. 8:4. doi: 10.3390/joitmc8010004

Scoles, K., Bilgutay, N., and Good, J. (2000). A new course evaluation process. IEEE Trans. Educ. 43, 125–131. doi: 10.1109/13.848063

Shuping, L., and Ling, P. (2008). “The research of V model in testing embedded software” in International conference on computer science and information technology (Singapore: IEEE), 463–466.

Tao, J., Han, H., Wen, X., and Tang, J. (2017). Entering the world of electrical engineering: a gateway course for first-year students at Wuhan University, China. Int. J. Electr. Eng. Educ. 54, 131–140.

Tec 21 Model (2018). Available online at: https://tec.mx/es/modelo-tec21#section2 (Accessed on March 2022).

Thomas, N., and Poongodi, D. P. (2009). “Position control of DC motor using genetic algorithm-based PID controller” in Proceedings of the world congress on engineering, vol. 2, 1–3.

Tlhoaele, M., Suhre, C., and Hofman, A. (2015). Using technology-enhanced, cooperative, group project learning for student comprehension and academic performance. Eur. J. Eng. Educ. 41, 263–278. doi: 10.1080/03043797.2015.1056102

Vas, P. (1999). Artificial-intelligence-based electrical machines and drives: Application of fuzzy, neural, fuzzy-neural, and genetic-algorithm-based techniques. Vol. 45. (New York, NY, United States: Oxford university press), 656.

Voda, A. A., and Landau, I. D. (1995). A method for the auto-calibration of PID controllers. Automatica 31, 41–53. doi: 10.1016/0005-1098(94)00067-S

Wirasingha, S. G., and Emadi, A. (2010). Classification and review of control strategies for plug-in hybrid electric vehicles. IEEE Trans. Veh. Technol. 60, 111–122. doi: 10.1109/TVT.2010.2090178

Zulkifli, S. A., Hussin, M. N., and Saad, A. S. (2014). “MATLAB-Arduino as a low-cost microcontroller for 3 phase inverter” in IEEE student conference on Research and Development (Penang, Malaysia: IEEE), 1–5.

Zulkifli, S. A., Ramli, F. N. F., and Razali, S. (2016). “Undergraduate student experience in the development of a ZVS power converter for voltage control with a low-cost microcontroller” in IEEE international conference on automatic control and intelligent systems (I2CACIS) (Selangor, Malaysia: IEEE), 55–60.

Keywords: Electric drives, model Tec21, V model, complex thinking, electric vehicle, educational innovation, undergraduate education, rapid prototype

Citation: Ponce P, Ramirez R, Ramirez MS, Molina A, MacCleery B and Ascanio M (2022) From understanding a simple DC motor to developing an electric vehicle AI controller rapid prototype using MATLAB-Simulink, real-time simulation and complex thinking. Front. Educ. 7:941972. doi: 10.3389/feduc.2022.941972

Edited by:

Celina P. Leão, University of Minho, PortugalReviewed by:

Atif Iqbal, Qatar University, QatarNikolay Hinov, Technical University, Sofia, Bulgaria

Copyright © 2022 Ponce, Ramirez, Ramirez, Molina, MacCleery and Ascanio. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Pedro Ponce, cGVkcm8ucG9uY2VAdGVjLm14

Pedro Ponce

Pedro Ponce Ricardo Ramirez

Ricardo Ramirez Maria Soledad Ramirez

Maria Soledad Ramirez Arturo Molina1

Arturo Molina1