Abstract

Introduction:

The sustainable valorization of agricultural waste is key to advancing circular economy models and reducing environmental impacts. Banana pseudostem (Musa spp.), an abundant byproduct of tropical agriculture, is evaluated as a renewable raw material for eco-friendly papermaking.

Methods:

Four treatments were applied to banana pseudostem pulp: untreated, naturally fermented, starchenhanced, and mechanically re-homogenized. Key physical and mechanical properties basis weight, caliper, and tear resistance were measured. Data were analyzed using Partial Triadic Analysis (X-STATIS) to assess structural differences and consistency.

Results:

Natural fermentation improved fiber bonding, starch addition significantly increased mechanical strength, and mechanical re-homogenization negatively affected structural integrity. Distinct differences in paper quality were observed among treatments.

Discussion:

Banana pseudostem shows strong potential as a sustainable lignocellulosic resource for papermaking. Optimized treatments improve material properties, supporting agro-industrial waste valorization and contributing to circular bioeconomy practices in tropical regions.

1 Introduction

Due to its significant impact and substantial environmental footprint, the paper industry stands as one of the most globally relevant industrial sectors (Çiçekler and Tutus, 2023). Historically, this sector has played a crucial role in the development of modern civilization by enabling communication, learning, and the preservation of knowledge over centuries (Pastore, 2003; Aithal, 2016). However, its traditional production model, which has prioritized the intensive exploitation of forest resources, has contributed to alarming rates of global deforestation (Ghazoul, 2013). The paper industry is estimated to be responsible for approximately 14% of industrial wood consumption, generating a substantial impact on forest ecosystem degradation and the accelerated loss of biodiversity (Khan et al., 2014; Harrison et al., 2022). In response to the increasing global demand for paper and paper-based products, the scientific and industrial communities have intensified their search for alternative sources of cellulosic fibers, with the primary goal of reducing pressure on forests and minimizing the environmental impact associated with this industry (Małachowska et al., 2021).

In this context, the valorization of agro-industrial waste as alternative raw mate-rials has emerged as a promising strategy, receiving growing attention in recent scientific literature(Singh et al., 2021). The use of non-wood fibers in papermaking has been the subject of numerous studies, with notable examples such as bamboo, rice straw, abacá, and sugarcane bagasse—materials that have already been applied in small-scale commercial operations (Darkwa, 1988; Murthy, 2013). Among these alternatives, banana pseudostem (Musa spp.) stands out as a particularly promising option due to its widespread availability in tropical and subtropical regions, where banana production generates significant volumes of this by-product. Extensive research has demonstrated that the lignocellulosic fibers present in banana pseudostem possess structural characteristics comparable to those of wood, making it a viable source of cellulose to produce quality paper (Barbu et al., 2014; Pereira et al., 2014; de Carvalho et al., 2016). The strategic utilization of these agro-industrial residues not only has the potential to re-duce dependence on forest resources but also to mitigate the environmental impact associated with waste management in the banana industry (Gupta et al., 2022).

Banana pseudostem offers significant advantages as an alternative raw material, including rapid biodegradability and relatively short regeneration cycle—features that make it particularly attractive within the framework of a circular economy (Kumar et al., 2023). However, the efficient conversion of this biomass into high-quality paper presents considerable technical challenges. Research has shown that the physical and mechanical properties of the resulting paper critically depend on multiple variables within the manufacturing process. Factors such as fiber cooking time, the intensity of mechanical refining, the sheet formation method, and the incorporation of modifying additives directly affect essential parameters like strength, texture, and flexibility of the final product (Serrano-Martínez et al., 2024; Park et al., 2015).

Recent research has demonstrated innovative ways to repurpose non-wood lignocellulosic biomass for sustainable papermaking and beyond. Iglesias and Cancela (2025) successfully integrated biomass from Tradescantia fluminensis, an invasive alien species, into commercial pulp formulations, proving its viability as a sustainable alternative in the paper industry (Iglesias and Cancela, 2025). Their work emphasizes the potential of biomass valorization in aligning industrial practices with circular economic principles. Complementing this, Peng et al. (2025) developed a novel strain sensor by engineering cellulosic paper through metal salt treatment and ethanol-assisted processing, highlighting the versatility of paper-based materials in advanced technological applications (Peng et al., 2025). These studies expand the scientific landscape of sustainable and functional paper products, supporting the relevance and innovation of the current research on banana pseudostem pulp.

Data exploration in the context of papermaking from banana pseudostem faces notable challenges, particularly regarding the diversity of variables and the potential lack of complete information. Conventional statistical methods often fail to simultaneously capture the influence of multiple factors—such as fiber cooking time and additive incorporation, limiting a comprehensive understanding of their impact on paper properties. To address these limitations, analytical approaches have been developed that extract complex patterns and describe shared properties in multidimensional datasets, justifying the use of robust statistical methods (Jaén, 2015; Dadvar et al., 2022). In this regard, multivariate analysis methods such as X-STATIS are especially valuable, as they enable the analysis of multiple sets of variables measured on the same observations, even when differing in number or nature. Even in cases of small sample sizes or heterogeneous data, X-STATIS integrates these datasets into an optimal weighted mean and, through dimensionality reduction, reveals the common structure among observations, if the initial factor (k-tables) is well represented (Abdi et al., 2012).

The scientific literature has documented that the strategic incorporation of natural additives particularly starchsignificantly enhances inter-fiber cohesion, thereby improving structural integrity and the mechanical properties of the resulting paper (Khan et al., 2014; Karolia and Malhan, 2005). Similarly, the implementation of semi-industrial processes integrating con-trolled fermentation stages and optimized refining has shown promising results in reducing impurities and improving the quality of the cellulosic pulp (Abdi et al., 2012; Karolia and Malhan, 2005). However, the inherent variability of lignocellulosic materials of agricultural origin necessitates the use of advanced analytical methodologies to systematically evaluate the impact of each process variable on the final paper properties.

In this context, the X-STATIS analysis—or Partial Triadic Analysis (PTA)—emerges as a particularly robust and effective multivariate technique for the evaluation of complex experimental data in industrial process optimization (Jaffrenou, 1978). This methodology, an extension of the STATIS method (Structuration des Tableaux À Trois Indices de la Statistique), allows for the simultaneous analysis of multiple datasets structured under different experimental conditions or temporal blocks, while preserv-ing the underlying relationships among the analyzed variables (Escoufier, 1973; Plantes, 1976). Its application in the present study is especially relevant, as it enables the systematic comparison of different treatments and repetitions in the production of paper from banana pseudostem, allowing the identification of key patterns in the variability of the final product’s physical and mechanical properties.

The ability of X-STATIS to handle matrix-structured data makes it an ideal tool for detecting trends and similarities among treatments, providing critical insights for optimizing the production process (Abdi et al., 2012). The implementation of this analytical methodology supports the identification of optimal manufacturing configurations, contributing significantly to the development of more efficient and environmentally sustainable production strategies.

The main objective of this study is to systematically analyze the impact of four distinct experimental conditions on the production of paper from banana pseudostem, employing X-STATIS analysis as a methodological tool to evaluate variability in key physical and mechanical properties of the final product specifically basis weight (g/m2), caliper (mm), and tear resistance (mN). The findings are expected not only to provide significant scientific contributions to the field of biological materials applied to the paper industry, but also to establish a solid methodological foundation for future re-search focused on the sustainable diversification of raw materials in papermaking, thereby contributing to the transition toward more environmentally friendly production models.

2 Materials and methods

2.1 Study area

The present study was conceived as an exploratory and analytical investigation aimed at evaluating the production of paper from banana pseudotallus. The plant material was collected in the locality of Matilde Esther, located in the province of Los Ríos, Ecuador (1°50′40″S, 79°29′36″O), during the month of October 2024, in full harvest season. Climatic conditions during harvest were representative of a humid tropical climate, with an average temperature of approximately 27 ± 2°C. Pseudotallus belonging to two varieties widely cultivated in the region, Cavendish and Gross Michelm of the Musa acuminata species (group AAA), were selected for their high availability and recognized aptitude for vegetable fiber extraction. Physiological maturity was determined by visual criteria, such as uniform tissue coloration, absence of rot or mechanical damage, and by assessing the structural firmness of the pseudostem. These parameters guaranteed the homogeneity of the sample and improved the reproducibility of the experimental treatments.

2.2 Experimental design

The pseudostems were cut into sections of approximately 30 cm and subjected to a cleaning process to remove surface impurities. The following steps were then performed:

Cooking: The pseudostem sections were boiled in water at 90°C for 60 min using a 2% hydrogen peroxide solution as a bleaching agent to facilitate fiber separation. This process was carried out in a stainless steel container under controlled temperature and time conditions.

Rinsing: After cooking, the fibers were rinsed with distilled water to remove any bleaching agent residues and other impurities.

Grinding: A high-speed industrial blender was used to pulp the cooked fibers, producing a homogeneous aqueous pulp with a pulp-to-water ratio of 1:3. This pulp served as the common base for all experimental conditions.

From this base pulp, four differentiated experimental conditions were established, referred to as Tests 1 to 4. These variations were designed to evaluate the effects of physical, fermentative, and natural additive treatments on the paper’s properties:

Test 1 (Untreated): The freshly prepared base pulp was used without additives or fermentation. The mixture was filtered using wooden frames covered with microperforated fabric and sun-dried. This untreated condition established a benchmark for evaluating how subsequent physical and chemical treatments would affect the structural integrity and mechanical properties of the final paper sheets.

Test 2 (Fermented): The same base pulp was subjected to natural fermentation for three days before being filtered and dried under the same conditions as Test 1. The purpose of this treatment was to evaluate the effects of fermentation on fiber structure and paper quality. Fermentation was carried out at tropical ambient temperature (27 ± 2°C), with an initial pulp-to-liquid ratio of 1:3. No inoculum was added; microbial activity depended on the native microbiota. The pH decreased from 6.8 to approximately 4.3 on the third day, indicating metabolic activity and mild acidification. This protocol was selected based on previous artisanal trials that showed improved fiber softness and separation without visible degradation.

Test 3 (Fermented + Starch): Using the previously fermented pulp from Test 2, approximately 20 grams of cornstarch (equivalent to four tablespoons) were added per 6 liters of aqueous pulp, with the aim of enhancing inter-fiber cohesion through a natural additive. The subsequent formation and drying process was identical to the previous tests. This corresponds to a starch concentration of 3.33 g/L, a proportion supported by prior studies on oil palm and Sesbania pulps which demonstrated enhanced strength without compromising sheet flexibility (Low et al., 2021; Boon et al., 2024).

Test 4 (Fermented + Homogenized): Finally, a portion of the same fermented pulp was blended again (approximately 4 liters) for five minutes to achieve greater fiber homogenization before forming the sheets under the same conditions as the previous tests. Mechanical homogenization aimed to improve fiber dispersion and bonding efficiency, as supported by reports indicating reduced porosity and increased surface contact in starch-treated non-wood pulp sheets (Suzuki et al., 1997).

These four experimental conditions generated a diverse and representative dataset, which was subsequently analyzed using the X-STATIS multivariate technique. To ensure process consistency, all sheets were formed using the same standardized method. Approximately 200 mL of pulp (with a 1:3 pulp-to-water ratio) was poured into wooden frames measuring 25 cm × 30 cm, lined with micro-perforated cotton fabric to allow for water drainage and fiber mat formation.

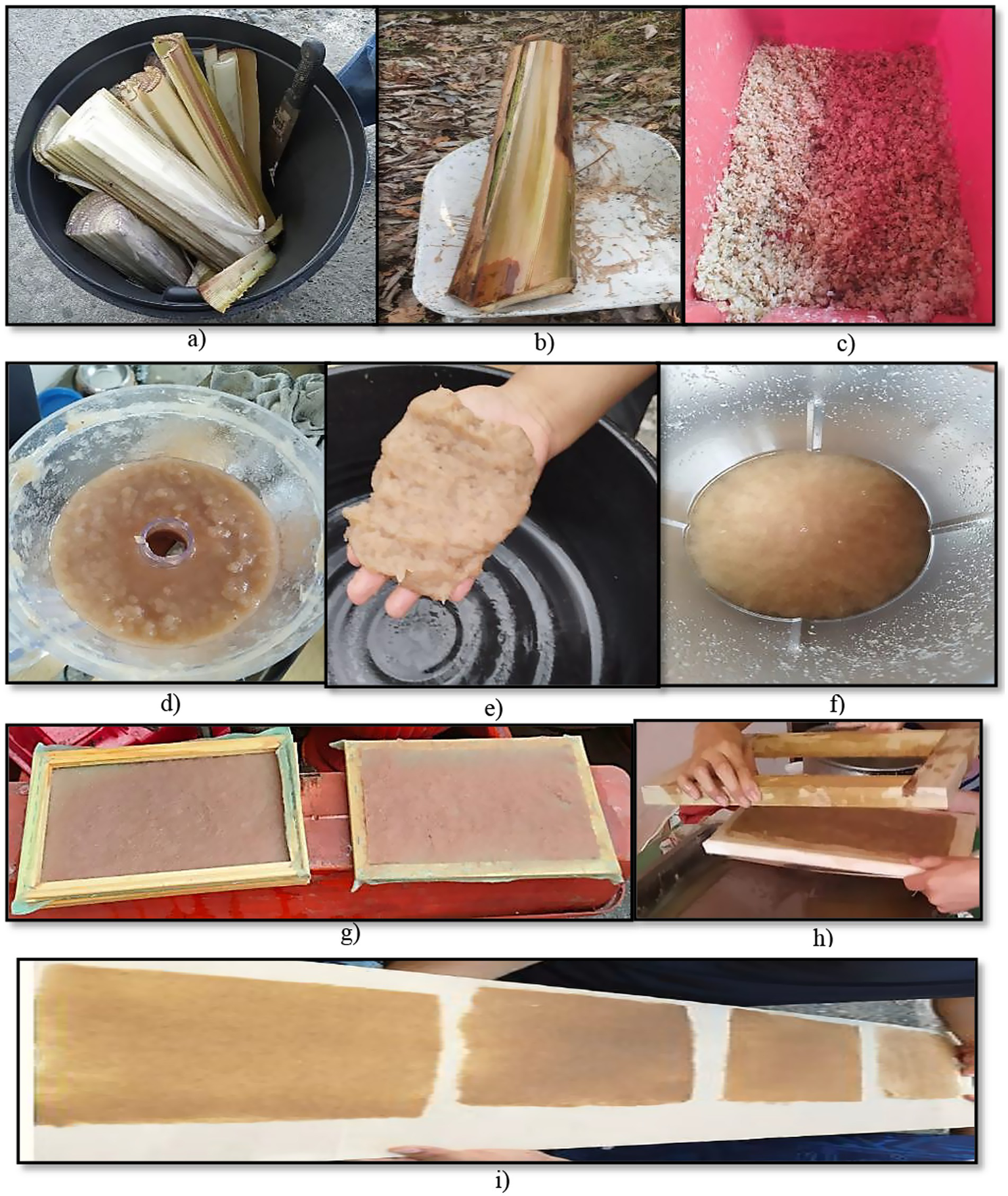

After pouring, the pulp was manually leveled using a wooden spatula to ensure even distribution. Once the water drained by gravity, “the former sheet was gently pressed using a hand roller weighing approximately 1.2 kg for 30 s to remove excess moisture and promote inter-fiber bonding.” The pressed sheets were dried under direct sunlight for approximately 5 to 6 h, depending on ambient conditions (average temperature: 28 ± 2°C; relative humidity: 60–70%). Once dried, sheets were conditioned for 24 h in a dry room before physical and mechanical testing. A photographic overview of the artisanal papermaking workflow is shown in Figure 1.

Figure 1

Visual workflow of the artisanal paper production process from banana pseudostem fibers. (a) Selection of pseudostem sections; (b) Cross-sectioned harvested stalks; (c) Cooked and rinsed fibers before pulping; (d) Pulping stage using an industrial blender; (e) Fermented pulp after three days (Test 2); (f) Starch-enhanced pulp (Test 3); (g) Homogenized pulp (Test 4); (h) Pouring pulp into wooden frame molds; (i) Manual pressing with a hand roller; (j) Sun drying of the handmade paper sheets.

The grammage (basis weight) of each sheet was calculated using square samples of 10 × 10 cm, which were weighed on an analytical balance and scaled to g/m2. Each test condition was replicated four times to ensure statistical robustness.

To clarify this design in greater detail, each repetition (RP1 to RP4) refers to an independent execution of the same treatment under identical conditions. For each of the four experimental treatments (Tests 1 to 4), four separate repetitions were carried out on different days using new pulp prepared from the same initial batch of banana pseudostem. This approach was designed to evaluate the internal consistency and variability of the process. In each repetition, a new set of paper sheets was formed, dried, and measured following the same protocol, generating a total of sixteen data points (4 repetitions × 4 treatments) for subsequent statistical and multivariate analysis. Although individual experimental repetitions (RP1 to RP4) were performed to ensure process stability and reproducibility, the observed variability across different treatments prevents meaningful aggregation of their data into a single statistical group. As such, all statistical analyses and interpretations are presented at the treatment level (Test 1 to Test 4), which preserves the integrity of the comparisons and avoids misleading dispersion of metrics caused by structural heterogeneity between experimental configurations.

Although direct measurements of banana pseudostem fiber morphology were not performed in this study due to the artisanal nature of the process and the limitations of the equipment, the specialized literature reports relevant morphological parameters for this material. According to Pereira et al. (2014), the average length of the fibers in banana pseudostem (Musa sp. cv. Pacovan) ranges from 1.13 to 2.41 mm, with a typical width of 15 to 25 μm and an approximate wall thickness of 3.6 μm. These dimensions are considered suitable for papermaking, especially when combined with treatments that improve inter-fiber bonding, such as fermentation and the incorporation of natural additives such as starch. In addition, studies by Małachowska et al. (2021) highlight the high flexibility and collapsibility of non-wood fibers, such as banana pseudostem, which positively influence sheet formation and mechanical strength. Although this study did not include direct morphological characterization, the observed physico-mechanical performance of the paper suggests adequate inter-fiber cohesion, probably supported by the structural characteristics described in previous research. It is recommended that future research complement these findings by microscopic analysis (e.g., SEM or fiber image analysis) to validate the fiber morphology and better relate it to the behavior of the final product.

The paper sheets obtained in this study are considered prototypes intended mainly for the characterization of the physico-mechanical properties and the validation of process concepts. Due to their structural properties, the heterogeneity inherent to the handmade manufacturing process and the non-optimization of the final production conditions, these sheets do not meet the requirements for their use as a writing support or with commercialization standards. Instead, they are oriented to research applications, such as sustainable packaging, biological materials for structural uses or components in property evaluation processes for future product development.

2.3 Statistical analysis using X-STATIS

The exploratory data analysis in the production of paper from banana pseudostem is essential to understanding the variations in the physical and mechanical properties of the resulting paper. In this context, X-STATIS emerges as a multivariate exploratory data analysis technique, based on linear algebra particularly within Euclidean vector spaces. The name X-STATIS originates from the French expression “Structuration des Tableaux à Trois Indices de la Statistique,” which translates as “structuring of tripartite statistical tables” (Taleat et al., 2021).

X-STATIS (Partial Triadic Analysis) was selected for its suitability in handling multiblock data structures, particularly when comparing patterns across multiple treatments and variables. This multivariate approach has been increasingly applied in materials science and agro-industrial research to discern subtle treatment effects even in small experimental designs (Van Deun et al., 2009; Llobell et al., 2020).

To support the dataset resulting from the evaluation of the properties of the paper produced from banana pseudostem during the study period, three types of measurements were considered: Basis Weight (g/m2), Caliper (mm), and Tear Resistance (mN). The selection of these variables was based on their relevance in characterizing paper quality and the reliability of the measurement methods used.

To ensure the reliability of mechanical property measurements, all physical and mechanical tests were conducted under controlled environmental conditions. The laboratory maintained a temperature of 23 ± 2°C and a relative humidity of 50 ± 5%, following the guidelines recommended by the TAPPI T402 standard and ISO 187:1990. These conditions were monitored using a calibrated digital thermo-hygrometer throughout the testing period. Maintaining consistent atmospheric conditions is essential, as both humidity and temperature significantly influence paper behavior particularly in tear resistance and caliper measurements (Iglesias and Cancela, 2025; International Organization for Standardization (ISO), 1990).

The dataset used for the X-STATIS analysis was constructed from the physical and mechanical properties measured in each of the four experimental treatments (Tests 1 to 4), each replicated four times (Repetitions RP1 to RP4), resulting in a total of 16 experimental units. For each unit, three quantitative variables were recorded: basis weight (g/m2), caliper (mm), and tear resistance (mN). These 16 combinations were grouped into four separate data blocks (one per treatment), each containing its four repetitions and associated measurements. This multiblock structure formed the basis for the X-STATIS analysis, where the objective was to identify shared patterns across treatments and evaluate the reproducibility and structural coherence of the data. The matrix configuration followed the classical three-mode format: objects (repetitions), variables (physical properties), and conditions (experimental treatments), which is compatible with the requirements of the STATIS method and its extension to partial triadic analysis.

2.3.1 Data structuring

The data were organized into a tripartite table comprising:

Objects (n): These refer to the different treatments applied to the banana pseudostem, including varieties, cooking conditions, and other relevant factors. This categorization allows for the assessment of how each treatment in-fluences the properties of the resulting paper.

Variables (p): The physical and mechanical properties of the paper were measured through the following variables:

Basis Weight (g/m2): This measures the mass of paper per unit area. It is determined by weighing a paper sample of known dimensions and calculating the weight per square meter. Basis weight is a key indicator of paper quality and its suitability for various applications.

Caliper (mm): This refers to the thickness of the paper, evaluated using a micrometer. This variable is crucial for determining paper quality and applicability, as it influences both user perception and performance in downstream processes.

Tear Resistance (mN): This measures the paper’s resistance to tearing, assessed using a standardized tear test. It quantifies the force required to tear a sample, providing insight into the durability and strength of the paper—critical aspects for its use in final products. Tear strength was evaluated with an Elmendorf tester (model 65–16, Thwing-Albert Instrument Co., USA), following the ISO 1974:2012 standard method for determining the tear strength of paper. This ensured consistency and comparability with international paper performance standards.

Temporal Dimension (k): Different time intervals were established for performing the measurements, allowing the observation of how the properties of the paper may vary over time and under different treatment conditions.

The organization of data into this tripartite structure not only facilitates analysis using X-STATIS but also enables the exploration of a shared global structure across multiple tables. This is particularly relevant in the context of this study, which seeks to identify complex patterns and relationships between the applied treatments and the properties of the paper produced. The ability of X-STATIS to handle multidimensional data ensures that significant interactions can be captured—interactions that might not be apparent through unidimensional analyses.

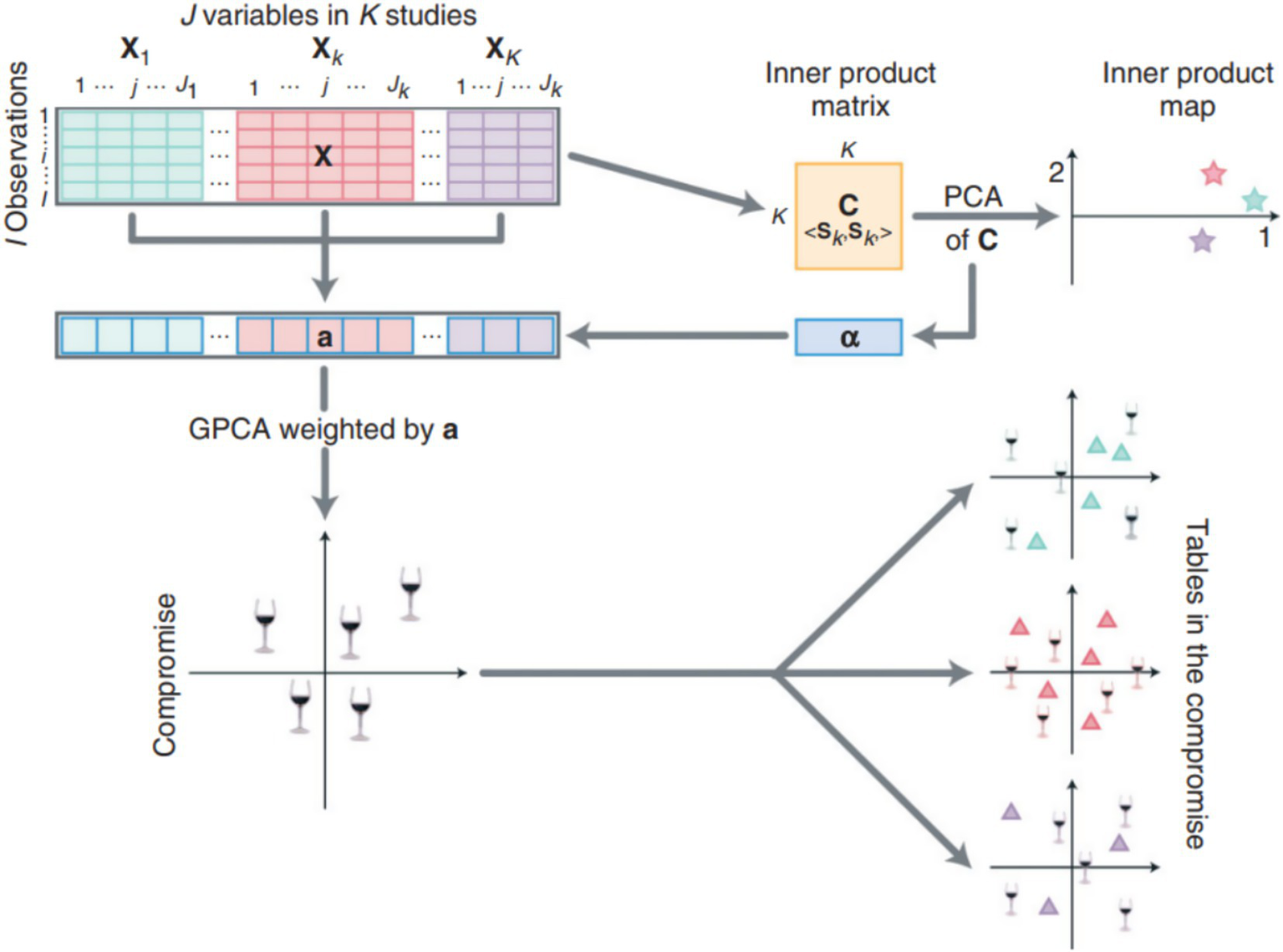

The analysis is carried out in three fundamental stages, allowing for both the de-composition and synthesis of the information contained within the data. In the first phase, known as interstructure, relationships among the different datasets are examined using similarity measures such as the scalar product between tables. This preliminary analysis helps identify interrelations among individual configurations and supports the establishment of meaningful comparisons (Abdi et al., 2012).

The second phase, referred to as Compromise, combines the datasets into a unified representation, calculated as an optimal weighted average of the individual configurations. This global representation, known as the Compromise, is then subjected to further analysis through Principal Component Analysis (PCA) to uncover the common structure among observations, maximizing the correlation with each original configuration (Abdi et al., 2012; Vivien and Sune, 2009).

Finally, in the third phase, known as Intrastructure or Trajectories, the original datasets are projected onto the Compromise. This procedure enables the investigation of both the similarities and differences between the original configurations, offering a deeper understanding of the interactions among variables.

The diagram reproduced from Abdi et al. (2012) clearly illustrates this process (see Figure 1). It shows how observations and variables are organized across multiple studies, and how the inner product matrix is calculated. From this matrix, a Principal Component Analysis (PCA) is conducted to identify patterns in the data. The final representation in the compromise space facilitates the visualization of relationships between the tables, which is essential for the interpretation of results.

All mathematical procedures involved in this statistical method including two-dimensional representations, component extraction, and the computation of coordinates corresponding to the applied treatments—were performed using the “ade4” package within the R environment, version 4.3.2 (2025) (Dray and Dufour, 2007). This methodological approach enabled a comprehensive and detailed analysis of the data, facilitating the detection of complex patterns and relationships in the paper production process using banana pseudostem.

3 Results

The results obtained in this study provide a detailed and rigorous analysis of the physical and mechanical properties of paper produced from banana pseudostem, evaluated under various controlled experimental conditions. The quality of the paper was specifically assessed using three critical parameters widely recognized in the pa-permaking industry: Basis Weight (g/m2), Caliper (mm), and Tear Resistance (mN). These variables were evaluated through multiple replicated tests to ensure statistical robustness, reproducibility, and consistency of the findings.

The initial results for basis weight, measured in grams per square meter (g/m2), showed notable variability. In Test 1, the basis weight was 84.25 ± 11.18 g/m2, while in Test 2 it increased to 95 ± 4.9 g/m2. However, in Tests 3 and 4, the values were significantly lower, at 60.75 ± 0.96 g/m2 and 65.75 ± 2.5 g/m2, respectively. This variability suggests that both processing conditions and the quality of the raw material greatly influence the basis weight of the paper.

The caliper of the paper, measured in millimeters (mm), also exhibited significant variation. The caliper values mirrored those of the basis weight, with 0.88 ± 0.08 mm in Test 1 and 1.04 ± 0.25 mm in Test 2. Tests 3 and 4 recorded values of 0.6 ± 0.05 mm and 0.97 ± 0.06 mm, respectively. These results indicate that paper thickness is sensitive to manufacturing conditions, which may impact its applicability in various contexts.

The caliper values measured, notably in Test 2 (1.04 ± 0.25 mm), are unusually high for handsheets of similar basis weight (~95 g/m2). Such thickness implies a low apparent density and elevated porosity, which is likely due to insufficient compaction during sheet formation consistent with outcomes obtained via artisanal papermaking methods without hydraulic pressing. Indeed, handmade papers often exhibit increased caliper variability and thickness when uniform formation and sufficient mechanical pressure are not applied (Quintana et al., 2024). Moreover, studies of traditional handmade paper indicate that increased thickness and porosity correlate with lower density, as shown in caliper ranges of 90–700 μm and corresponding apparent densities of 0.2–0.4 g/cm3(Aryal et al., 2022). While this may limit dimensional control, it accurately reflects production conditions in decentralized or rural environments, where process simplicity takes precedence over industrial standardization.

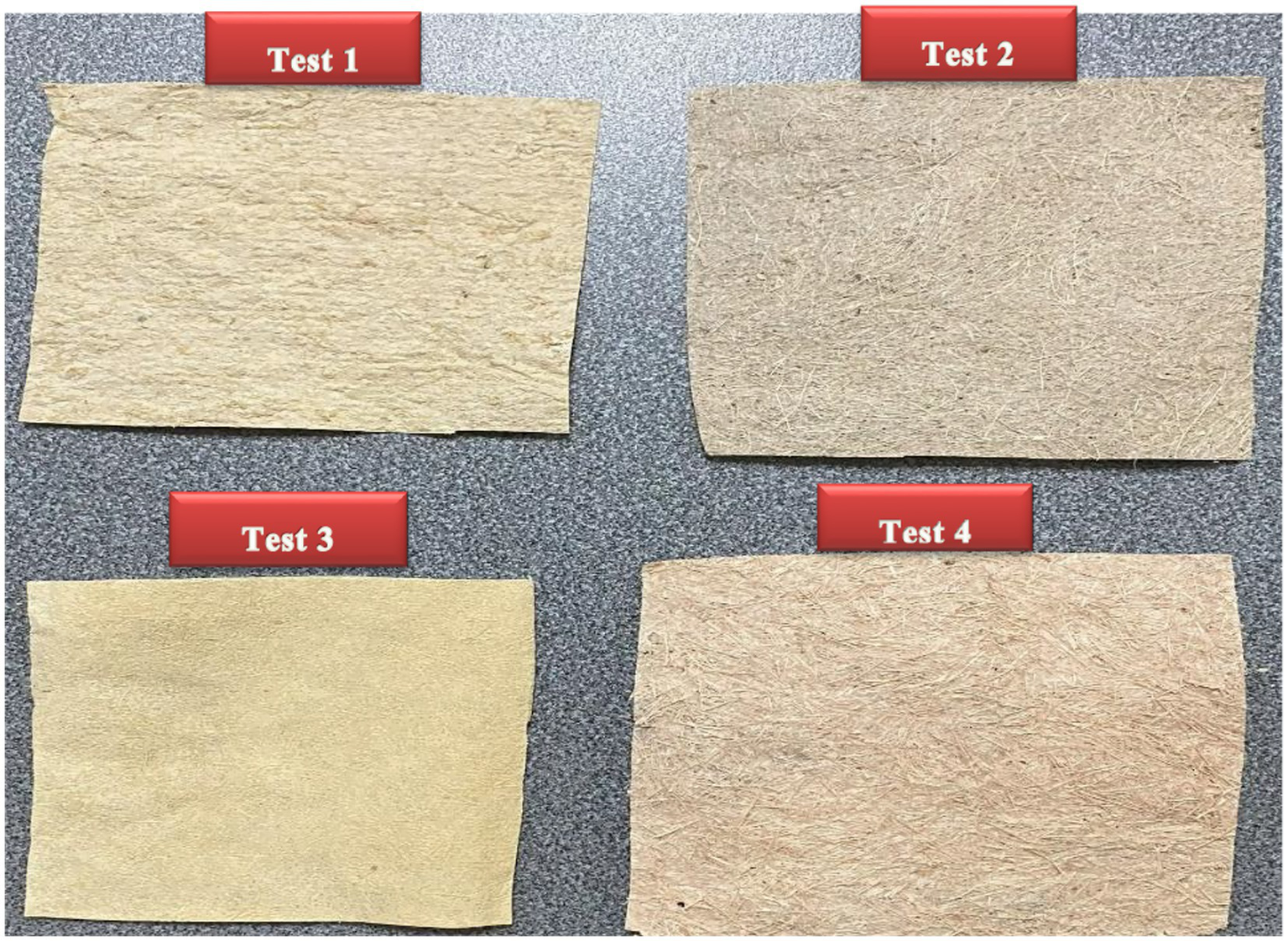

The Figure 2 presents a visual comparison of the final sheets of paper obtained from each experimental treatment applied to banana pseudostem fibers. The untreated sample (Test 1) exhibits a rough texture with uneven fiber distribution and low compactness, consistent with its moderate tear resistance and basis weight. The fermented sample (Test 2) shows a visibly more fibrous and open structure, with less compacted fibers, which may explain its increased caliper and improved bonding compared to Test 1. Test 3 (fermented + starch) displays a notably smoother and more uniform surface, with better fiber cohesion and reduced porosity, reflecting its improved mechanical performance despite a lower basis weight. Finally, the sample from Test 4 (fermented + homogenized) presents a coarse texture, with fibers distributed in a random pattern, likely due to excessive mechanical homogenization. This treatment appears to have reinforced inter-fiber contacts, aligning with the unusually high tear resistance reported. These visual observations support the quantitative data shown in Table 1 and reinforce the interpretation of structural and functional effects associated with each processing condition.

Figure 2

Comparación visual de las hojas de papel finales producidas a partir de pseudotallo de banano.

Table 1

| Tests | Basic weight (g/m²) | Caliber (mm) | Tear (mN) |

|---|---|---|---|

| Test 1 (Untreated) | 84.25 ± 11.18 | 0.88 ± 0.08 | 601.5 ± 134.8 |

| Test 2 (Fermented) | 95 ± 4.9 | 1.04 ± 0.25 | 711.25 ± 215.02 |

| Test 3 (Fermented + Starch) | 60.75 ± 0.96 | 0.6 ± 0.05 | 371.25 ± 125.97 |

| Test 4 (Fermented + Homogenized) | 65.75 ± 2.5 | 0.97 ± 0.06 | 5129.75 ± 1518.98 |

Descriptive statistics of tests.

Regarding tear resistance, measured in millinewtons (mN), the tests revealed contrasting behavior. Test 1 achieved a mean tear resistance of 601.5 ± 134.8 mN, and Test 2 improved to 711.25 ± 215.02 mN. In Test 3, the value dropped to 371.25 ± 125.97 mN, while Test 4 presented an unusually high tear resistance of 5,129.75 ± 1,518.98 mN. This striking increase in Test 4 may be attributed to unexpected fiber restructuring caused by excessive homogenization, highlighting the need to better understand the mechanical effects of this processing step.

The abnormally high tear resistance observed in Test 4 (>5,000 mN) may be attributed to the additional mechanical homogenization applied to the fermented pulp. This process likely enhanced fiber dispersion and increased the number of contact points between fibers, thereby improving bonding efficiency. Similar effects have been reported for non-wood pulps, where intensive fiber processing reduced porosity and improved fiber interlacing, contributing to higher tear strength (Pannala and Karunarathne, 2022). While these results exceed typical values for handmade paper, they suggest that fiber interactions in Test 4 were optimized by the processing conditions.

While the results for grammage, caliper and tear strength are clearly presented, the study lacks a direct comparison with commercial papers (e.g., office printing paper, recycled paper) or standardized handmade variants, making it difficult to assess practical competitiveness. By way of context, standard office printing paper (~80 g/m2) typically has caliper values of between 0.09 and 0.11 mm and an Elmendorf tear strength of between 500 and 800 mN, according to ISO 1974 methodology(International Organization for Standardization, 2012). In contrast, banana-based papers reported in the literature, while exhibiting lower tensile strength, often show comparable or slightly higher tear strength due to longer fibers and better fiber bonding(Khan et al., 2014). In addition, sustainable packaging papers made from banana pulp have achieved tear strength that meets or exceeds commercial standards (e.g., KEBS EAS 859:2017)(Musombi et al., 2024). Therefore, their Test 4 formulation, with an abnormally high tear strength (>5,000 mN), suggests unique fiber interactions and bonding effects. However, without parallel measurements on industrially produced office or recycled papers under the same test conditions, it remains difficult to define competitive positioning. Future work should include reference samples of commercial and recycled printing papers, tested in parallel according to ISO 1974, to corroborate claims about their market-relevant performance.

3.1 Interstructure analysis

The interstructure analysis among the tests revealed significant correlations. It was observed that Test 1 maintained a correlation of 0.6467 with Test 2, and a correlation of 0.4966 with Test 3. These correlations indicate that the physical and mechanical properties of the paper are interrelated and that the treatments applied may have cumulative effects on the final characteristics of the product.

It is worth highlighting the high correlation observed between Tests 2 and 3 (r = 0.9016), indicating the presence of significant common elements in their experimental configurations. The low correlation of Test 4 with the other conditions suggests substantial variability in its operational parameters, emphasizing the importance of optimizing processing conditions to achieve greater consistency.

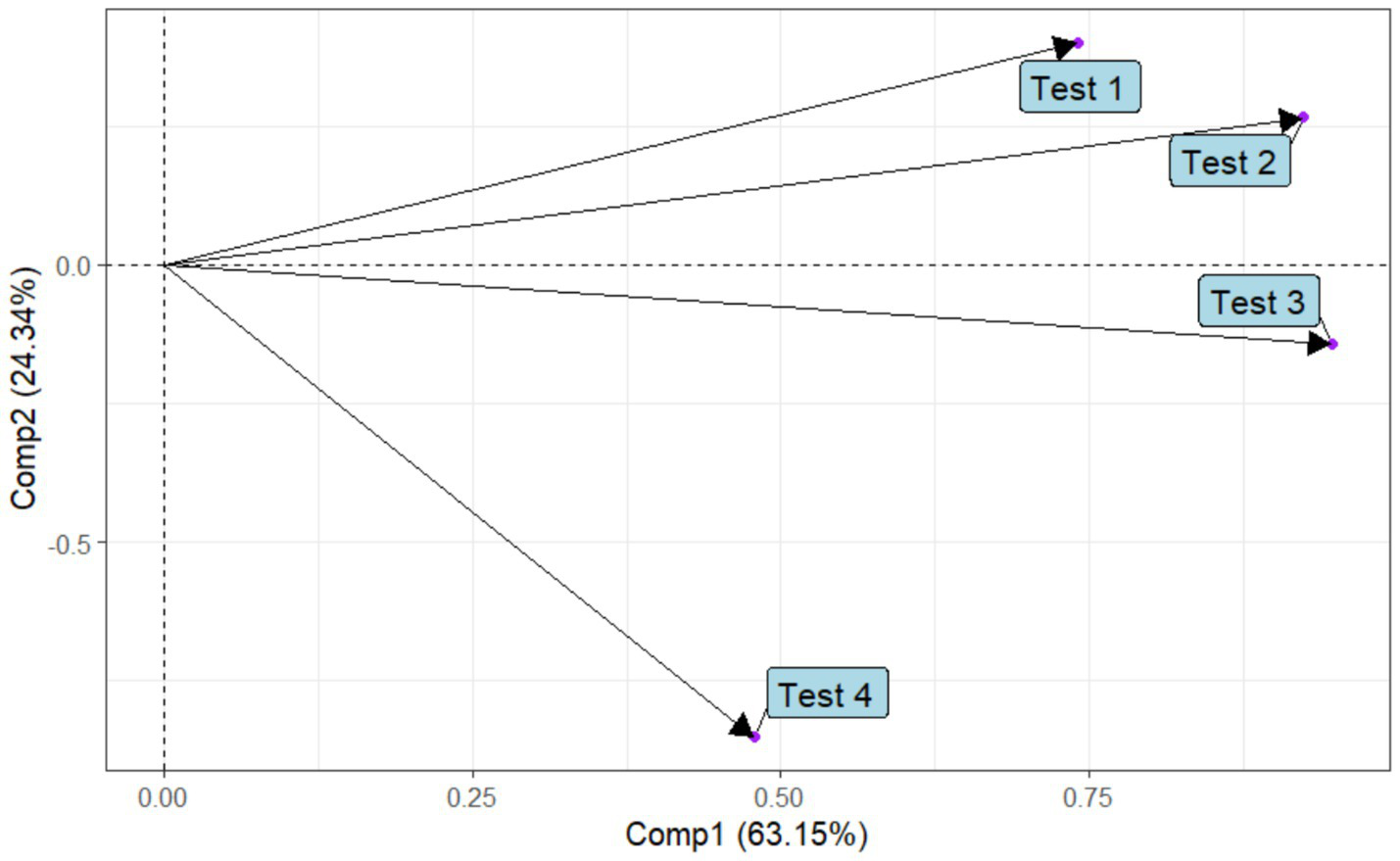

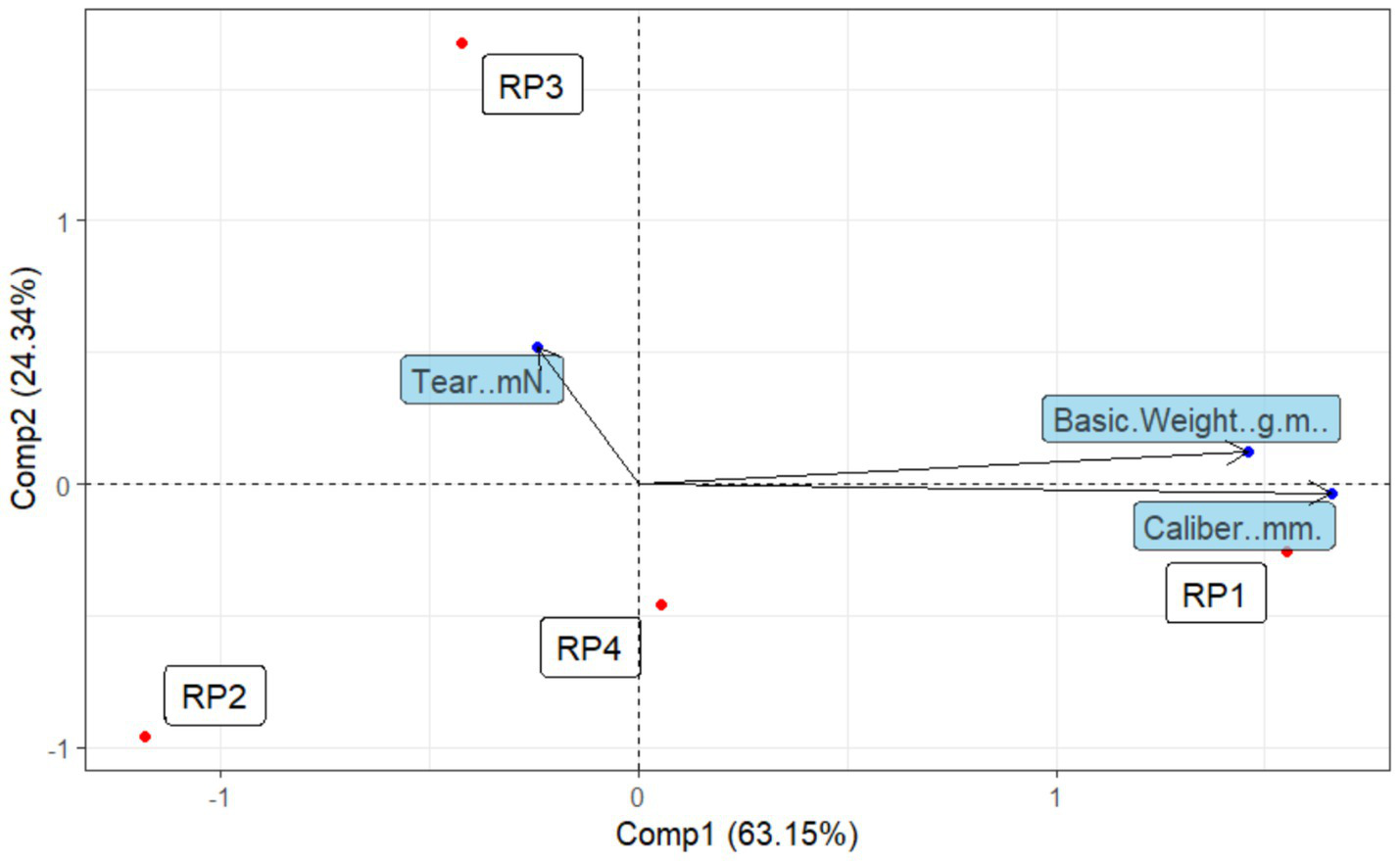

As shown in Figure 3, the vectors corresponding to the experimental tests are projected in the Euclidean space defined by the first two principal components (Comp1: 63.15% and Comp2: 24.34%), which together explain 87.49% of the total variability. The angular distances between the vectors indicate the degree of structural similarity among the tests.

Figure 3

Statis process. Figure reproduced from Abdi et al. (2012).

Tests 2 and 3 exhibit a nearly parallel and closely aligned orientation, clearly demonstrating a strong similarity in their data structures. Similarly, Test 1 appears near them, although with a slight angular deviation, suggesting a certain level of affinity but with some distinct differences. In contrast, Test 4 is projected in an opposite and more distant direction, reflecting a substantially different configuration compared to the other three tests. This spatial dispersion supports the results of the RV coefficient matrix (Table 2), where the highest correlations are observed between Tests 2 and 3, and the lowest correlation is found between Test 4 and the other experimental conditions.

Table 2

| Comparison | Test 1 | Test 2 | Test 3 | Test 4 |

|---|---|---|---|---|

| Test 1 (Untreated) | 1 | |||

| Test 2 (Fermented) | 0.6466737 | 1 | ||

| Test 3 (Fermented + Starch) | 0.4966152 | 0.9016402 | 1 | |

| Test 4 (Fermented + Homogenized) | 0.1312104 | 0.1609485 | 0.5117483 | 1 |

Correlations statistics of repetitions.

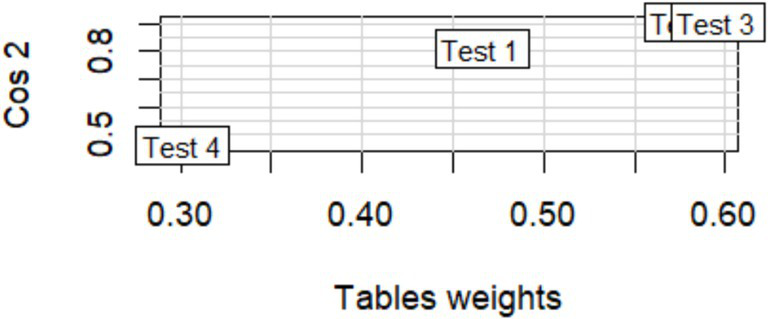

The quantitative evaluation of the compromise, supported by the weighting coefficients (α-k) and the structural quality indices (cos2), allows for a precise identification of the relevance and homogeneity of each test in constructing the common structure. According to the results presented in Figure 4, Test 3 exhibits the highest contribution to the compromise, with a weighting coefficient α-k of 0.5957, indicating that this experimental configuration shares a high degree of structural similarity with the other data tables in the analysis. It is followed by Test 2 (α-k = 0.5809) and Test 1 (α-k = 0.4658), which also demonstrate substantial participation in the formation of the over-all compromise structure.

Figure 4

X- STATIS Interstructure analysis represented by tests according to the evaluated model.

In contrast, Test 4 reflects the lowest relative contribution (α-k = 0.3010), suggesting a weaker alignment with the predominant structural configuration of the data. Regarding the structural quality index (cos2), once again, Test 2 stands out with the highest value (0.9051), closely followed by Test 3 (0.9030), highlighting their strong in-ternal coherence and close relationship with the common structure identified in the dataset. On the other hand, Test 4 presents the lowest cos2 value (0.4609), indicating a configuration that diverges more markedly from the others.

These results reinforce the notion that those tests exhibiting greater structural similarity (i.e., higher α-k and cos2 values) contribute more significantly to the construction of the compromise. Consequently, the experimental configurations represented by Tests 2 and 3 appear to reflect more homogeneous conditions in terms of the physical and mechanical properties evaluated, whereas Test 4 stands out due to its di-vergence—potentially attributable to uncontrolled experimental variability or substantial differences in the processing conditions applied.

3.2 Compromise analysis

Figure 4 presents the projection of the physical and mechanical variables of the paper produced from banana pseudostem. In the subspace generated by the Compro-mise matrix, the variables “Basis Weight” (g/m2), “Caliper” (mm), and “Tear Resistance” (mN) are represented in a way that encapsulates the information collected from the various treatment repetitions. The first two axes of the Compromise analysis explain 87.49% of the total inertia, which provides sufficient robustness to uncover the main patterns related to the physical and mechanical properties of the paper.

In the visualization provided by the Compromise biplot, the first axis, which captures 63.15% of the variability, is predominantly associated with the variables “Basis Weight” and “Caliper,” both positioned at the extreme of this axis. Meanwhile, the second axis, accounting for 24.34% of the inertia, is more closely related to “Tear Resistance,” which is located along this axis. The Compromise results reveal a clear distinction in the principal component space: experimental configurations RP1 and RP4, which are positioned closer to the variables for weight and caliper, differ significantly from RP2 and RP3, which exhibit more moderate values and are located nearer to the origin.

This interpretation allows the identification of two main groups of experimental configurations, distinguished more by the evaluated physical and mechanical properties (basis weight and caliper versus tear resistance) than by specific procedural differences in each test. Therefore, this finding contributes to a deeper understanding of how each treatment impacts the final characteristics of the paper and provides guidance for potential adjustments in the manufacturing processes to optimize the desired properties.

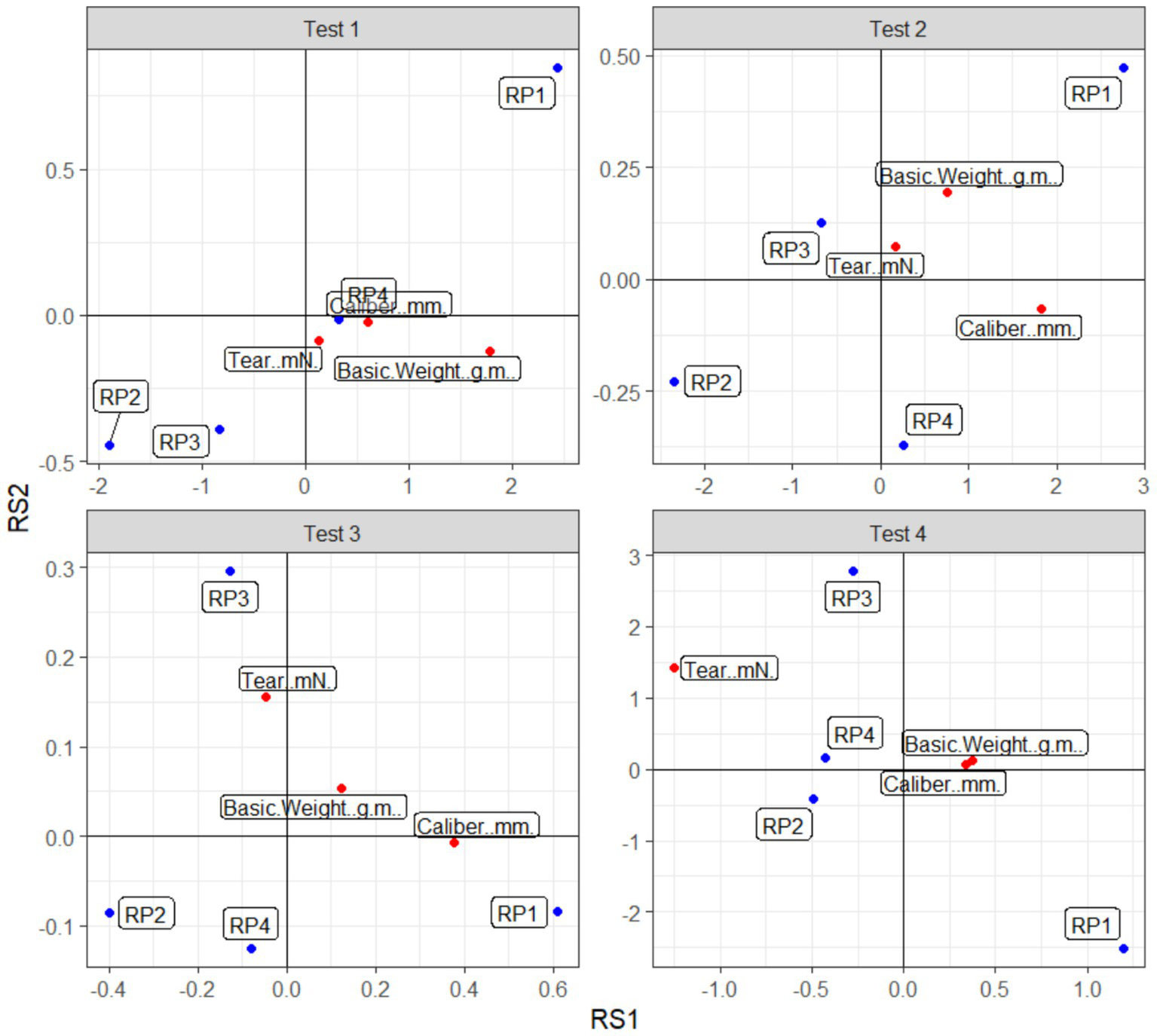

3.3 Intrastructure analysis

The reproducibility analysis of the compromise structure, known as Intrastructure, enables the examination of internal coherence among experimental repetitions and their correspondence with the physical and mechanical properties of paper produced from banana pseudostem. In this phase, the rows and columns of each of the four initial tables are projected onto the factorial space defined by the Compromise matrix (Figure 4). This allows for the assessment of the temporal stability of the samples within each repetition interval and their alignment with the common spatiotemporal pattern extracted through X-STATIS. This projection facilitates the identification of overlapping variables, particularly those occupying similar positions in the factorial plane an indication of shared structural patterns across repetitions and experimental conditions (Figure 5).

Figure 5

Typological value.

In Test 1, the high dispersion observed among repetitions RP1, RP2, and RP3 in relation to the variables “Basis Weight,” “Caliper,” and “Tear Resistance” reflects notable variability in the experimental responses, possibly attributable to inconsistencies in processing parameters or heterogeneity in the raw material. This dispersion under-scores the need for stricter control of operating conditions to achieve more stable results. In Test 2, repetitions RP1 and RP4 are projected peripherally, suggesting atypical or differentiated behaviors, while RP3 aligns closely with the variable “Basis Weight,” indicating a direct influence of this property on the corresponding repetition potentially linked to specific adjustments made during the fiber treatment process (Figure 6).

Figure 6

Projection of physical-mechanical variables of paper based on banana pseudostem according to consensus structure.

In Test 3, greater homogeneity was observed among RP2, RP3, and RP4, which clustered around the origin of the factorial plane, indicating consistency in the evaluated properties. RP1, on the other hand, was projected in isolation, which may reflect a specific deviation, either due to variability in the raw material or alterations in the papermaking process. In the case of Test 4, a clear differentiation was noted among the repetitions: RP1 and RP4 tended to be associated with “Basis Weight,” while RP2 and RP3 were projected closer to the variable “Caliper,” highlighting how different aspects of the process influence the structural properties of the paper in distinct ways (Figure 7).

Figure 7

Reproducibility analysis of the commitment structure (Intrastructure). Each red dot corresponds to a physical-mechanical variable, and the abbreviations RP indicate the projected repetitions according to the commitment.

It is worth noting that although X-STATIS prioritizes the extraction of dominant patterns across the dataset which may entail some loss of information regarding in-dividual observations—this limitation is mitigated through complementary descriptive analyses (see Table 1), which help recover specific insights into the behavior of variables. Nevertheless, this Intrastructure phase is essential for validating the reproducibility of the experimental configurations and understanding how each repetition contributes to the underlying common structure. In this way, the technique offers valuable tools for identifying sources of variability and designing continuous improvement strategies in papermaking processes, with a view toward their standardization and sustainability.

4 Discussion

This study aimed to explore the sustainable valorization of banana pseudostem through the optimization of papermaking treatments and the application of multivariate analysis using X-STATIS, also known as Partial Triadic Analysis (PTA). The results confirm that the goal was achieved, providing insights into how different treatments influence the material’s physical and mechanical properties and offering valuable information for developing sustainable production processes.

Controlled fermentation (Test 2) improved fiber cohesion and flexibility, leading to higher basis weight and caliper compared to untreated pulp (Test 1). These findings align with previous research showing that biological pretreatments like fermentation can facilitate lignin reduction, improving fiber separation and bonding (Taleat et al., 2021; Melesse et al., 2022). Furthermore, the incorporation of starch in Test 3 significantly enhanced tear resistance, reinforcing the paper’s structural integrity. This result supports earlier findings by Hubbe (2006) and Tian et al. (2017), which highlight starch as an effective natural additive to strengthen inter-fiber bonds, particularly in non-wood pulp-based papers.

However, Test 4, which applied additional mechanical homogenization, did not provide significant benefits and resulted in structural inconsistencies, particularly in tear resistance. This suggests that over-processing may damage fiber integrity, weakening the matrix and reducing mechanical performance, as noted in previous studies on fiber over-refinement (Lucia et al., 2003).

Comparative analysis revealed that while Tests 1 and 2 yielded balanced mechanical properties, Test 3 demonstrated the most notable improvement in tear resistance despite a lower basis weight. This highlights the effectiveness of starch as a reinforcement agent. In contrast, the structural weakening observed in Test 4 underscores the risks of excessive mechanical treatment. These results illustrate the complex interplay between chemical and physical interventions, where some combinations, like fermentation and starch addition, act synergistically to enhance performance, while others, like over-homogenization, may have adverse effects.

The application of X-STATIS (PTA) proved to be a methodological strength of this study, allowing the integration of multiple datasets and the identification of consensus patterns across treatments and repetitions. This multiblock analysis enabled robust evaluation despite the limited sample size and experimental variability, providing a holistic view of the data structure. However, it is recognized that focusing on global patterns may obscure specific individual behaviors, which is why descriptive statistics (Table 1) were also presented to offer a complementary perspective.

This research not only evaluated the technical feasibility of using banana pseudostem as a raw material for papermaking but also identified key process variables that can be optimized to improve product quality. Nevertheless, limitations such as the small sample size, natural variability of the raw material, and lack of controlled drying conditions should be considered when interpreting the results.

The findings support the viability of banana pseudostem as a renewable and eco-friendly lignocellulosic resource, contributing to circular economy strategies by transforming agricultural waste into value-added products. Practices such as natural fermentation and starch addition demonstrated their potential to improve the mechanical performance of paper, offering low-cost, low-energy solutions suitable for rural and decentralized production systems.

Beyond the technical outcomes, this study highlights the potential for implementing small-scale or community-based papermaking initiatives in tropical regions. The simplicity and scalability of the treatments evaluated make them accessible for artisanal production models, as demonstrated in countries like India, Colombia, and Kenya. By promoting the local valorization of agricultural waste, these approaches can support rural entrepreneurship, reduce environmental impacts, and contribute to diversifying raw material sources in the global paper industry, advancing sustainable development and circular bioeconomy practices.

4.1 Social and environmental impact

This study contributes to advancing sustainable development goals by promoting the local valorization of agricultural waste in tropical regions. By converting banana pseudostem into a renewable raw material for eco-friendly paper production, the proposed process supports rural entrepreneurship, waste reduction, and resource efficiency. Additionally, it offers a low-cost and scalable alternative to wood-based paper, reducing pressure on forest resources and aligning with circular bioeconomy principles. These benefits make this approach socially inclusive and environmentally responsible, contributing to both local livelihoods and global sustainability efforts.

5 Limit

One of the main limitations of this study is related to the method of forming the paper sheets, which was performed by manual pressing using a hand roller. Although a constant weight of the equipment was maintained (approximately 1.2 kg), a standardized control mechanism over the pressure applied during the process was not implemented. This could have caused variations in fiber density, thickness and cohesion in the samples tested. The difference in applied force, which depended on operator manipulation, introduced a degree of variability in compaction conditions, potentially affecting the uniformity and comparability of results. These variable conditions limit the precision with which the different treatments and replicates of the experiment can be compared.

On the other hand, the drying process was carried out in sunlight under open environmental conditions, without specific control of parameters such as temperature or ambient humidity. This drying modality, by its nature, could have produced differences in the speed and uniformity of the evaporation process, which could have negatively influenced the cohesion of the fibers, as well as the final mechanical properties of the paper. Such variations in the drying process make it difficult to objectively compare different samples and treatments, and consequently, limit the reproducibility of the results under different experimental conditions.

For future research, it is recommended to use mechanical pressing equipment that allows precise control of the pressure applied, thus ensuring greater consistency in the compaction of the samples. Likewise, the use of controlled drying systems, such as evaporation chambers with regulated temperature and humidity, would contribute to reduce variations induced by environmental factors and would facilitate obtaining more reproducible and comparable results.

Additionally, the relatively small number of replicates per treatment limits the ability to generalize the findings. While the observed effects are consistent with patterns reported in the literature, the limited dataset size reduces the statistical power and robustness of comparisons. Therefore, the conclusions drawn from this work should be considered exploratory. Future studies should aim to expand the dataset and include standardized commercial paper references to improve benchmarking and validation.

6 Conclusion

This study demonstrated that banana pseudostem is a promising renewable raw material for sustainable papermaking, offering favorable physical and mechanical properties when subjected to appropriate processing treatments. The experimental design, combined with the application of X-STATIS (Partial Triadic Analysis), enabled the identification of structural patterns that explain performance variability across treatments and replicates.

The findings highlighted that natural fermentation improved fiber cohesion, increasing basis weight and caliper, while starch addition significantly enhanced tear resistance. These improvements were achieved without relying on synthetic additives, reinforcing the viability of natural and low-cost treatments. Conversely, excessive mechanical homogenization negatively affected fiber integrity, emphasizing the importance of optimizing processing intensity.

X-STATIS proved to be an effective tool for integrating multiblock data and identifying optimal experimental configurations, providing insights that conventional analyses might overlook. This methodological contribution supports more informed decision-making in the development of sustainable material processing.

From a practical perspective, this research contributes to circular economy strategies by valorizing banana pseudostem, an abundant agro-industrial byproduct in tropical regions, transforming it into a value-added material for eco-friendly paper production. This approach promotes waste reduction, resource efficiency, and local economic development.

Future research should explore additional natural additives, controlled drying conditions, and the long-term performance of the produced paper, including biodegradability and durability assessments. Advancing these investigations will help scale the process to industrial levels, positioning banana pseudostem-based paper as a competitive and environmentally responsible alternative in the global paper industry.

Statements

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

ER-C: Formal analysis, Methodology, Writing – review & editing. BR-R: Data curation, Formal analysis, Investigation, Writing – review & editing. DT-N: Investigation, Writing – original draft. XZ-S: Conceptualization, Writing – review & editing. JV-C: Conceptualization, Writing – review & editing, Conceptualization, Writing – review & editing, Supervision, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by the Universidad Estatal de Milagro (UNEMI).

Acknowledgments

The authors are grateful to the Universidad Estatal de Milagro (UNEMI).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

1

AbdiH.WilliamsL. J.ValentinD.Bennani-DosseM. (2012). STATIS and DISTATIS: optimum multitable principal component analysis and three way metric multidimensional scaling. WIREs Computational Statistics. marzo de4, 124–167. doi: 10.1002/wics.198

2

AithalS. (2016). A study on history of paper and possible paper free world. Int. J. Manag. IT Eng.6, 337–355. doi: 10.5281/zenodo.161141

3

AryalG. M.KandelK. P.BhattaraiR. K.GiriB.AdhikariM.WareA.et al. (2022). Material properties of traditional handmade paper samples fabricated from cellulosic fiber of Lokta bushes. ACS Omega.7, 32717–32726. doi: 10.1021/acsomega.2c04398

4

BarbuM. C.RehR.ÇavdarA. D. (2014). “Non-wood lignocellulosic composites” in Research developments in wood engineering and technology. Eds. A. Aguilera and J. Paulo Davim (IGI Global), 281–319.

5

BoonJ. G.LiewJ. X.LiewJ. Y. (2024). Effect of commercial cationic starch on paper properties made from recycled pulp. Malays. J. Bioeng. Tech.1, 1–4. doi: 10.70464/mjbet.v1i1.1179

6

CarvalhoKCCdeMontoroSRCioffiMOHVoorwaldHJC. Polyhydroxyalkanoates and their nanobiocomposites with cellulose nanocrystals. Design and applications of nanostructured polymer blends and nanocomposite systems. Eds. S. Thomas, R. Shanks, and S. Chandrasekharakurup Elsevier; (2016). p. 261–285.

7

ÇiçeklerMTutusA. Challenges in paper industry: Addressing environmental, economic, and social concerns. (2023).

8

DadvarV.GolabL.SrivastavaD. (2022). Exploring Data Using Patterns: A Survey. Information Systems, 108:101985. doi: 10.1016/j.is.2022.101985

9

DarkwaN. A. (1988). “Plantain (Musa paradisiaca L) pseudostem; a fibre source for tropical countries” in The pulping conference in Montreal Quebec, book 2 (TAPPI Press), 645–649.

10

DrayS.DufourA. B. (2007). The ade4 package: implementing the duality diagram for ecologists. J. Stat. Softw.22. doi: 10.18637/jss.v022.i04

11

EscoufierY. (1973). Le Traitement des Variables Vectorielles. Biometrics29:751.

12

GhazoulJ. (2013). “Deforestation and land clearing” in Encyclopedia of biodiversity. Ed. S. A. Levin (Waltham, MA, USA: Academic Press, Elsevier), 447–456.

13

GuptaJ.KumariM.MishraA.AkramM.ThakurI. S. (2022). Agro-forestry waste management- a review. Chemosphere287:132321. doi: 10.1016/j.chemosphere.2021.132321

14

HarrisonRShonoKGitzVMeybeckAHoferTWertz-KanounnikoffSMainstreaming biodiversity in forestry. (2022) Rome, Italy and Bogor, Indonesia: FAO and CIFOR. 175. doi: 10.4060/cc2229en

15

HubbeM. (2006). Bonding between cellulosic fibers in the absence and presence of dry-strength agents – a review. Bioresources1, 281–318. doi: 10.15376/biores.1.2.281-318

16

IglesiasA.CancelaÁ. (2025). Synergistic integration of invasive alien species Tradescantia fluminensis residual biomass with commercial pulp for enhanced sustainable paper production. Appl. Sci.15:1135. doi: 10.3390/app15031135

17

International Organization for Standardization (ISO). (1990). ISO 187:1990 Paper, board and pulps — Standard atmosphere for conditioning and testing and procedure for monitoring the atmosphere and conditioning of samples. 2nd Edition, Geneva, Switzerland: ISO.

18

International Organization for Standardization (2012). Paper determination of tearing resistance Elmendorf method. Geneva, Switzerland: International Organization for Standardization.

19

JaénJJJ. (2015). Restoring wetlands to remove agricultural pollution in surface waters: assessment and monitoring through partial triadic analysis (PTA). Proceedings of the 9th Symposium for European Fresh Water Sciences (SEFS 2015). p. 5–10.

20

JaffrenouPAMalécotG. (1978). Sur l’analyse des familles finies de variables vectorielles: bases algébriques et application à la description statistique. éditeur non identifié. 97. Available at: https://books.google.com.ec/books?id=mc4GOgAACAAJ

21

KaroliaA.MalhanS. (2005). Eco friendly printing on minor fibre fabrics (jute and banana)14, 83–86.

22

KhanM. Z. H.SarkarM. A. R.Al ImamF. I.KhanM. Z. H.MalinenR. O. (2014). Paper making from banana pseudo-stem: characterization and comparison. J. Nat. Fibers.11, 199–211. doi: 10.1080/15440478.2013.874962

23

KumarV.ChakrabortyP.JanghuP.UmeshM.SarojiniS.PasrijaR.et al. (2023). Potential of banana based cellulose materials for advanced applications: a review on properties and technical challenges. Carbohydrate Polymer Technol. Appl.6:100366. doi: 10.1016/j.carpta.2023.100366

24

LlobellF.CariouV.VigneauE.LabenneA.QannariE. M. (2020). Analysis and clustering of multiblock datasets by means of the STATIS and CLUSTATIS methods. Application to sensometrics. Food Qual. Prefer.79:103520. doi: 10.1016/j.foodqual.2018.05.013

25

LowL. Q.IlyasR. A.JalilR.HawanisH. S. N.IbrahimR.AzrienaH. A. A.et al. (2021). Physical and mechanical properties enhancement of beaten oil palm trunk pulp and paper by optimizing starch addition: towards sustainable packaging solutions. Ind. Crop. Prod.:119232.

26

LuciaL.BanW.RagauskasA. (2003). Green liquor pretreatment of chips could boost Kraft pulping efficiency. Pap. Age.118, 24–26.

27

MałachowskaE.LipkiewiczA.NiemczykM.DubowikM.BoruszewskiP.PrzybyszP. (2021). Influences of Fiber and pulp properties on papermaking ability of cellulosic pulps produced from alternative fibrous raw materials. J. Natural Fibers18, 1751–1761. doi: 10.1080/15440478.2019.1697994

28

MelesseE. Y.BedruT. K.MesheshaB. T. (2022). Production and characterization of pulp from banana pseudo stem for paper making via soda anthraquinone pulping process. Int. J. Eng. Res. Afr.58, 63–76. doi: 10.4028/www.scientific.net/JERA.58.63

29

MurthyB. (2013). Physical and chemical properties of Banana fibre extracted from commercial Banana cultivars grown in Tamilnadu state. Agrotechnology1, 1–3. doi: 10.4172/2168-9881.S11-008

30

MusombiS. K.KisatoJ.WanduaraM. (2024). Properties of sustainable packaging paper fabricated from banana fibers using banana peel lye as a pulping delignification reagent. J. Nat. Fibers.21:2364263. doi: 10.1080/15440478.2024.2364263

31

PannalaN. M.KarunarathneP. K. D. M. C. (2022). Utilization of waste banana pseudostem for paper production via organosolv pulping. FESYMPO26, 49–53. doi: 10.31357/fesympo.v26.5691

32

ParkJ.JonesB.KooB.TuckerM.YuJ. H.PschornT.et al. (2015). Use of mechanical refining to improve the production of low-cost sugars from lignocellulosic biomass. Bioresour. Technol.199, 59–67. doi: 10.1016/j.biortech.2015.08.059

33

PastoreC. (2003). Paper before print: the history and impact of paper in the Islamic world. Sixteenth Century J.34, 613–614. doi: 10.2307/20061516

34

PengJ.FuX.YuX.YuanZ.QianX.NiY.et al. (2025). Engineering cellulosic paper into a bending strain sensor using chemical additives: metal salt-based treatment and ethanol-assisted processing. Carbohydr. Polym.358:123439. doi: 10.1016/j.carbpol.2025.123439

35

PereiraA. L. S.do NascimentoD. M.SouzaM. S. M.CassalesA. R.Saraiva MoraisJ. P.de PaulaR. C. M.et al. (2014). Banana (Musa sp. cv. Pacovan) pseudostem fibers are composed of varying lignocellulosic composition throughout the diameter. Bioresources9, 7749–7763. doi: 10.15376/biores.9.4.7749-7763

36

PlantesHL. Structuration des Tableaux à Trois Indices de la Statistique. (1976).

37

QuintanaGJaramilloNOsorio DelgadoMCastroCRestrepoM. A science-driven approach to handmade paper obtention from fique lignocellulosic residues. (2024). Available online at: https://www.ssrn.com/abstract=5078488 (Accessed June, 27, 2025).

38

Serrano-MartínezV. M.Pérez-AguilarH.Carbonell-BlascoM. P.Arán-AisF.Orgilés-CalpenaE. (2024). Steam explosion-based method for the extraction of cellulose and lignin from rice straw waste. Appl. Sci.14:2059. doi: 10.3390/app14052059

39

SinghR.DasR.SangwanS.RohatgiB.KhanamR.PeeraS. K. P. G.et al. (2021). Utilisation of agro-industrial waste for sustainable green production: a review. Environ. Sustain.4, 619–636. doi: 10.1007/s42398-021-00200-x

40

SuzukiT.IsogaiA.OnabeF. (1997). Properties of handsheets containing starch pulp prepared with various wet-end additives. Sen'i Gakkaishi53, 438–445.

41

TaleatAAkanfeFGbadamosiT. (2021). International Journal of Sciences, Engineering & Environmental Technology (IJOSEET). 6, 115–121.

42

TianH.YanJ.RajuluA. V.XiangA.LuoX. (2017). Fabrication and properties of polyvinyl alcohol/starch blend films: effect of composition and humidity. Int. J. Biol. Macromol.96, 518–523. doi: 10.1016/j.ijbiomac.2016.12.067

43

Van DeunK.SmildeA. K.Van Der WerfM. J.KiersH. A.Van MechelenI. (2009). A structured overview of simultaneous component based data integration. BMC Bioinformat.10:246.

44

VivienM.SuneF. (2009). Two four-way multiblock methods used for comparing two consumer panels of children. Food Qual. Prefer.20, 472–481. doi: 10.1016/j.foodqual.2009.04.004

Summary

Keywords

banana pseudostem fibers, sustainable papermaking, agricultural waste valorization, circular bioeconomy, partial triadic analysis, lignocellulosic materials

Citation

Romero-Cárdenas E, Romero-Romero BR, Tapia-Núñez DW, Zúñiga-Santillán XL and Valenzuela-Cobos JD (2025) Sustainable paper from agricultural residues: differentiating treatment effects in banana pseudostem fibers using X-STATIS multiblock analysis. Front. Sustain. 6:1628095. doi: 10.3389/frsus.2025.1628095

Received

13 May 2025

Accepted

07 July 2025

Published

23 July 2025

Volume

6 - 2025

Edited by

Ahmed Ibrahim Osman, Queen’s University Belfast, United Kingdom

Reviewed by

Efstratios Livanis, University of Macedonia, Greece

Annalisa Santucci, University of Siena, Italy

Updates

Copyright

© 2025 Romero-Cárdenas, Romero-Romero, Tapia-Núñez, Zúñiga-Santillán and Valenzuela-Cobos.

This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Juan Diego Valenzuela-Cobos, jvalenzuelac@unemi.edu.ec

Disclaimer

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.