- 1Faculty of Business, Economics and Real Estate, University of Regensburg, Regensburg, Germany

- 2Department of Logistics and Supply Chain Management, HTU Business School, Ho Technical University, Ho, Ghana

- 3Faculty of Business and Management, Ostbayerische Technische Hochschule Regensburg, Regensburg, Germany

The enactment of due diligence legislation, such as the German Act on Corporate Due Diligence Obligations in Supply Chains, in German Lieferkettensorgfaltspflichtengesetz (LkSG), is reshaping global supply chain management by compelling companies to tackle heightened human rights and environmental risks in their supply chain. This study addresses the need for a comprehensive sustainability supplier evaluation framework by employing a systematic literature review with an expert survey of practitioners from German companies subject to LkSG. This methodology aligns academic findings with real-world practice and legal requirements, enriching the literature with practical insights. The results reveal that business practice prioritizes economic and social dimensions, whereas the literature focuses on economic and environmental dimensions. Although the most relevant economic and environmental criteria are consistent across both domains, the key social criteria show a notable misalignment. Managers can utilize the most relevant sustainability supplier evaluation criteria identified in this study to promote sustainable supply chains and ensure compliance with due diligence requirements. This research also highlights the high relevance of human rights as a social criterion, a dimension that has been historically under-recognized or implicitly addressed in the literature.

1 Introduction

In the past, companies had the option to voluntarily implement due diligence on human rights within their supply chains (Bundesministerium für Arbeit und Soziales, 2025). However, with the enactments of due diligence acts for supply chains, such as the German Act on Corporate Due Diligence Obligations in Supply Chains, in German Lieferkettensorgfaltspflichtengesetz (LkSG), the French Loi de Vigliance, or the US Uyghur Forced Labor Prevention Act, companies are compelled to adopt more sustainable practices along their supply chains (Bundesrepublik Deutschland, 2021; République Francaise, 2017; U.S. Congress House, 2022).

These regulations aim to prevent and combat human rights and environmental abuse (Bundesrepublik Deutschland, 2021), particularly at the origin of supply chains, where high risks are prevalent, such as in the extraction and cultivation of raw materials (Agyemang et al., 2022; Dou et al., 2023; Umpula and Dummett, 2024). For instance, the extraction of cobalt in the Democratic Republic of the Congo is characterized by significant challenges, including child labor, forced eviction, and water and soil pollution (MVO Nederland, 2025b; Umpula and Dummett, 2024). Concurrently, the cultivation of cashew nuts in West African countries, such as Nigeria, Ghana, and Côte d'Ivoire, is associated with child and forced labor, deforestation, and biodiversity loss (Agyemang et al., 2022; MVO Nederland, 2025c). Consequently, companies must consider the legal requirements they fall under when evaluating existing or potential suppliers to ensure compliance (Bundesrepublik Deutschland, 2021; Kraft et al., 2024). This is especially crucial for suppliers in regions with heightened human rights and environmental risks (Berthet et al., 2024; Han et al., 2024; Kraft et al., 2024). However, LkSG does not explicitly define how to evaluate the company's own business unit and suppliers. According to § 5 LkSG, a risk analysis must be performed annually or on occasion for an organization's own business unit and its tier-1 suppliers, with the objective of identifying potential human rights and environmental risks or violations as defined in § 2, para. 2 and 3 LkSG. It does not require an analysis of all tier-1 suppliers, but only those with typically heightened human rights and environmental risks (Bundesamt für Wirtschaft und Ausfuhrkontrolle, 2025). Therefore, identifying the most relevant sustainability criteria for evaluating suppliers to comply with these regulations is essential; accordingly, this study examines these criteria within the context of LkSG. Within this study, a criterion is a specific, distinguishing attribute used to evaluate a supplier's sustainability performance. Criteria capture information at various levels, from high-level indicators (e.g., environmental management system) to granular operational metrics (e.g., working hours).

Sustainability has become an increasingly prominent topic in the literature. For example, Goggin et al. (2025) highlighted how the reliance of the biopharmaceutical sector on single-use plastics, despite their operational advantages, increasingly conflicts with sustainability objectives and the transition to a circular economy. The authors emphasize that prevailing life-cycle analyses often overlook post-use impacts and reveal limited industry engagement with more sustainable alternatives. In contrast, the study by Le et al. (2024) proposed a model for detecting tomato plant diseases that enables real-time detection in resource-limited settings, supporting early intervention, reduced pesticide use, and more sustainable agricultural practices for tomato cultivation. Another example, Pedersen et al. (2024), explored consumer perceptions of sustainability in food production and preferences for sustainability labels. The research revealed that consumers lack clear information and prioritize different sustainability indicators, such as pollution, animal welfare, and fair wages. The findings highlight the need for transparent labeling and greater responsibility from retailers and producers to support informed, sustainable food choices. This growing emphasis on sustainability across various disciplines is also evident in the realm of supply chain management (Kuruneri, 2025; Putsche et al., 2023; Seuring and Müller, 2008). The importance of sustainable practices in supply chains is increasing, driven by regulations, customer demand, and corporate reputation (Truant et al., 2024; Quintana-García et al., 2021). Despite the growing research and practical focus on sustainability, a gap exists between theoretical frameworks and business practice in the context of sustainable supply chains (Rajeev et al., 2017; Vörösmarty and Dobos, 2020). This gap is increasingly pronounced due to new regulations such as LkSG and the upcoming European Corporate Sustainability Due Diligence Directive (CSDDD), which have not yet been comprehensively addressed in the literature (Brandenburg et al., 2024; Dupont et al., 2024; Trindade et al., 2025). A critical issue is the lack of clarity in the literature regarding the actual application of the most relevant sustainability criteria for supplier evaluation in practice. This is especially pertinent in addressing heightened human rights and environmental risks, particularly in light of new regulatory requirements.

Literature review, which has been the most widely used methodology, presents some weaknesses. They are associated with selection bias and a lack of critical analysis (Haddaway et al., 2020; Snyder, 2019). To address these shortcomings, this study combines a systematic literature review (SLR) with content analysis from both literature and practical perspectives to examine the sustainability criteria for supplier evaluation in the context of due diligence acts, using LkSG. The findings will support companies in enhancing their supplier evaluation processes, promoting the selection and development of suppliers with lower human rights and environmental risks. Ultimately, this will contribute to the fostering of sustainable supply chains and ensure compliance with evolving due diligence regulations. In this context, this study aims to answer the following research questions (RQ):

• RQ 1: What are the most relevant sustainability criteria for supplier evaluation according to the literature?

• RQ 2: Which of these sustainability criteria do companies consider in evaluating suppliers with heightened human rights and environmental risks in the context of LkSG?

• RQ 3: What additional sustainability criteria do companies consider in evaluating suppliers with heightened human rights and environmental risks in the context of LkSG?

The paper is structured as follows. Section 2 reviews the state of research on sustainable supply chains, supplier evaluation and sustainability criteria for supplier evaluation. Subsequently, Section 3 describes the research methodology and data collection. Next, the research findings will be presented and discussed in Sections 4 and 5. Finally, a conclusion in Section 6 will be provided.

2 Literature review

2.1 Sustainable supply chains and supplier evaluation

The growing demand for goods and services has driven companies to undertake production activities with severe social and environmental impacts (Quayson et al., 2023; Rajeev et al., 2017). The 1987 Brundtland Report (World Commission on Environment and Development, 1987) highlighted the need for changes in industrial practices and consumption to ensure sustainability. It popularized the concept sustainable development, defined as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs” (World Commission on Environment and Development, 1987). Building on the concept of sustainable development, 10 years later, Elkington (1997) introduced the Triple Bottom Line (TBL) as a framework for assessing business performance across three dimensions: economic, environmental, and social. TBL broadens the environmental agenda by integrating these aspects, encapsulated in the terms profit, planet, and people (Elkington, 1997). In the context of the supply chain, sustainability refers to embedding economic, environmental, and social considerations as raw materials are sourced, converted to products, and delivered to the customers (Seuring and Müller, 2008; Stevens, 1989).

The literature has increasingly published articles on sustainability in supply chains, with the topic gaining steady importance in recent years (Eisen et al., 2024; Kellner, 2022; Linton et al., 2007; Seuring and Müller, 2008). Particularly, supplier selection has been a prominent subject in academia over the past decades (Sarkis, 2003; Schramm et al., 2020; Wetzstein et al., 2019). This is due to the fact that suppliers play a crucial role for the buying company, providing the right materials, components, and solutions at the right time and place, all while keeping costs competitive (Igarashi et al., 2013). To foster sustainability in the supply chain, the social and environmental performance of a supplier is crucial (Igarashi et al., 2013; Rajeev et al., 2017). Therefore, selecting the right supplier is of paramount importance (Genovese et al., 2013). Not only economic criteria but also environmental and social criteria must be considered, introducing multiple criteria into the evaluation process (Genovese et al., 2013; Karakoç et al., 2024; Schramm et al., 2020). For this reason, a wide spectrum of methodologies have been developed in recent years in academia, especially various multi-criteria decision making (MCDM) methods that play an important role in supplier selection approaches (Karakoç et al., 2024; Štreimikienė et al., 2024; Tronnebati et al., 2022). However, a literature review by Vörösmarty and Dobos (2020) concerning Data Envelopment Analysis (DEA) for supplier selection and evaluation notes a significant gap: most research focuses solely on the environmental dimension, and practice-oriented studies are scarce. Additionally, other studies (Rajeev et al., 2017; Rashidi et al., 2020) indicate that a comprehensive focus on all three dimensions of sustainability is limited, with economic and environmental aspects dominating the research. Our study integrates all three dimensions, with an additional special focus on supplier selection criteria in the context of the due diligence acts.

2.2 Sustainability criteria for supplier evaluation

The evaluation and selection of suppliers are pivotal for organizations, as they influence both product quality and adherence to sustainability responsibilities (Ageron et al., 2012; Rashidi et al., 2020). With the recent introduction of due diligence acts in supply chains, such as LkSG or the upcoming CSDDD, organizations are legally required to comply with due diligence obligations (Bundesrepublik Deutschland, 2021; European Union, 2024). If they fall within the scope of these regulations, they must adhere to the prescribed requirements to avoid legal sanctions and reputational damage resulting from negative media coverage (Bundesrepublik Deutschland, 2021; Kraft et al., 2024). To foster a sustainable supply chain and comply with LkSG, companies must consider human rights and environmental expectations when selecting direct suppliers (Bundesrepublik Deutschland, 2021). This involves rigorously applying sustainability criteria to evaluate existing and potential suppliers, ensuring they meet heightened human rights and environmental protection standards. By doing so, companies can mitigate and eliminate violations and risks, promoting a more sustainable supply chain.

As sustainability considerations in supply chains have gained prominence, research on sustainable supplier evaluation has expanded accordingly (Bai and Sarkis, 2010; Jain and Singh, 2020; Khan et al., 2018; Singh et al., 2025; You and Song, 2024). A study by Ageron et al. (2012) found that, despite the introduction of sustainability criteria for supplier evaluation over a decade ago, quality and price remained the most important criteria, while social responsibility was given the least priority. Rashidi et al. (2020) presented similar findings eight years later. The study revealed that economic criteria remain the most frequently used, followed by environmental criteria, with social criteria being the least applied. They identified quality, delivery, and cost as the most frequently used economic criteria (Rashidi et al., 2020), representing the traditional criteria (Genovese et al., 2013; Liao and Rittscher, 2007). For environmental criteria, the most applied criteria are the environmental management system, followed by recycling and pollution control. Regarding social criteria, the authors found that work safety and labor health are the most commonly used, followed by employment practices and social responsibility (Rashidi et al., 2020). However, the study by Kuo et al. (2021) yielded different results. Unlike Ageron et al. (2012) and Rashidi et al. (2020), who did not focus on a specific industry, Kuo et al. (2021) concentrated on the palm oil industry. Their findings indicate that in the palm oil industry, environmental criteria receive the highest priority when evaluating sustainable suppliers, followed closely by economic criteria, while social criteria lag significantly behind (Kuo et al., 2021). Similarly, the research by Mubarik et al. (2021), which focused solely on green supplier selection in the automobile industry—specifically on economic and environmental dimensions–revealed that the most important criteria differ from traditional ones. Notably, environmental management systems, technology, and pollution take precedence, while delivery time, although traditionally considered, remains a key criterion (Mubarik et al., 2021).

Most researchers use the TBL framework—economic, environmental, and social—to cluster criteria for supplier evaluation (Ghadimi et al., 2017; Luthra et al., 2017; Tong et al., 2022). Some scholars have expanded this framework, for instance, Ghamari et al. (2022) introduced a resilience dimension, while Khalili Nasr et al. (2021) incorporated a circular dimension. Conversely, other researchers have opted not to use any classification of the criteria (Castro e Silva et al., 2022; Garcia et al., 2021). Notably, some researchers categorize the criteria into main and sub-criteria (Fallahpour et al., 2017; Ghadimi et al., 2017; Jain and Singh, 2020), while others adopt a more holistic approach without such distinctions (Aslani et al., 2021; Khan et al., 2018). The variation in classification, ranging from broad to granular, was highlighted in a comprehensive literature review by Rashidi et al. (2020), emphasizing the absence of a standard framework in the field.

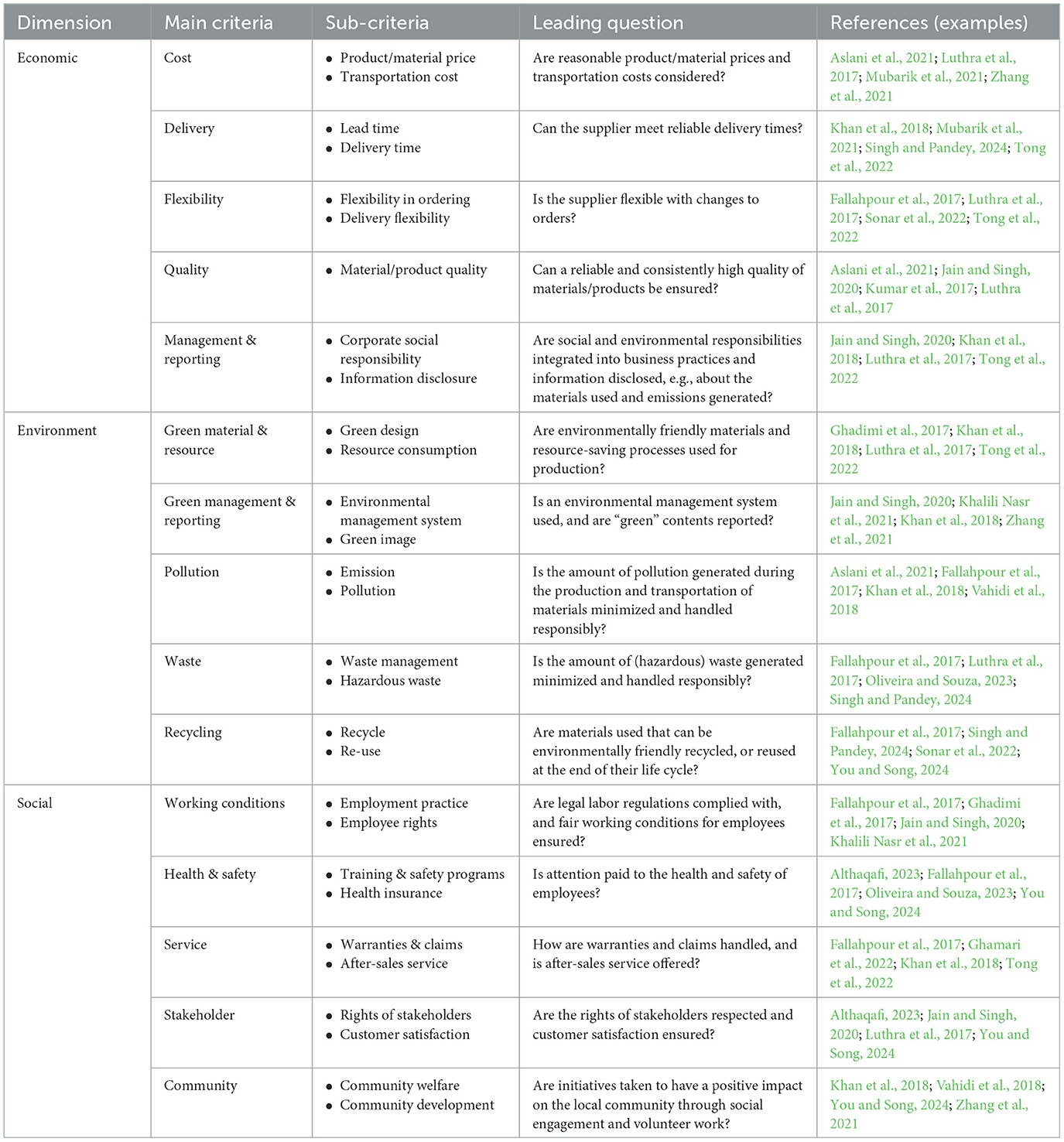

This section synthesized key findings from the existing literature on sustainability criteria for supplier evaluation, establishing a foundational basis for our study. It is not an exhaustive systematic review but rather a focused selection of relevant findings. A comprehensive, ungrouped list of all criteria identified by the authors cited in this review is available in the Supplementary material, which illustrates their full variety and total count. In contrast, the most relevant sustainability criteria, as determined by our SLR, can be found in Table 1.

2.3 Gaps in the literature

Although extensive research exists on sustainable supplier evaluation (Bai et al., 2019; Govindan et al., 2013; You and Song, 2024), Rashidi et al. (2020) highlight a persistent gap between business practice and academia that needs to be bridged to gain deeper insights into sustainable supplier evaluation. Additionally, Rajeev et al. (2017) and Vörösmarty and Dobos (2020) emphasize that studies rarely focus on all three dimensions of sustainability, with the social dimension being particularly underrepresented. They underscore the need for more practice-focused studies to address this gap. Furthermore, various scholars have identified numerous criteria essential for sustainable supplier evaluation (Ageron et al., 2012; Castro e Silva et al., 2022; Fallahpour et al., 2017; Kuo et al., 2021). However, there is no universally accepted classification framework for these criteria (Ghamari et al., 2022; Rashidi et al., 2020).

Also, historically, due diligence was largely voluntary for organizations (Bundesministerium für Arbeit und Soziales, 2025; United Nations, 2011) but given the recent legal developments that require companies to comply with sustainability-related regulations, there are limited studies that examine which criteria companies apply. While due diligence acts in supply chains emphasize human rights and environmental risks, academic research has yet to thoroughly examine the sustainability criteria by which suppliers with heightened human rights and environmental risks should be evaluated.

3 Research methodology and data collection

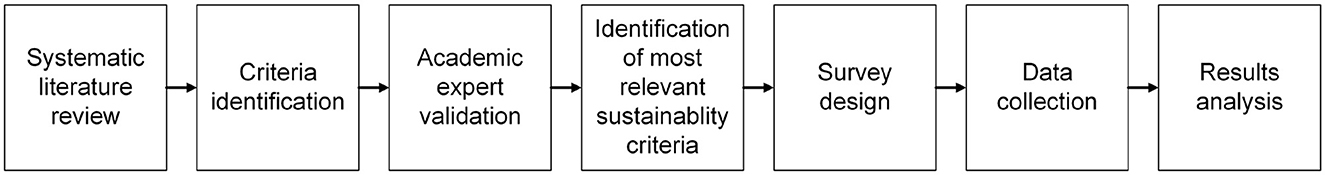

The first objective of this study is to develop a comprehensive, structured list of the most relevant sustainability criteria for supplier evaluation, derived from an SLR (see Section 3.1). The second and third objectives are to assess which of the identified criteria from the literature are also relevant in practice and to identify additional criteria for evaluating suppliers with heightened human rights and environmental risks in the context of LkSG. To achieve this, we conducted a survey with experts (see Section 3.2). Figure 1 presents a concise overview of our research process, which will be detailed in the following sections.

We apply the TBL framework, which advocates for a balanced consideration of economic, environmental, and social dimensions (Elkington, 1997). Although LkSG primarily focuses on human rights and, to a lesser extent, specific environmental protections, it does not explicitly address economic criteria. Despite this, the TBL remains the appropriate theoretical framework for our study due to the inherent interconnectedness of these dimensions, where, e.g., social and environmental risk have an impact on economic performance (Nogueira et al., 2025). For instance, a supplier's commitment to fair labor practices and safe working conditions often leads to a more skilled and motivated workforce. This directly contributes to higher product quality, which presents an economic criterion (Gazi et al., 2024; Yuen et al., 2018). Therefore, applying the TBL framework allows us to develop a holistic sustainability framework for evaluating suppliers, recognizing that addressing human rights and environmental risks is not merely a matter of compliance but a critical component of strategic economic management. This approach strengthens the theoretical foundation of our study, demonstrating that due diligence is an indispensable part of a company's comprehensive sustainability and risk management strategy.

3.1 Systematic literature review

A SLR is employed as a method for structured and transparent data gathering and assessment from existing literature (Seuring and Gold, 2012). While SLRs are typically used for synthesizing knowledge in established fields (Durach et al., 2021; Snyder, 2019), our study utilizes it to establish a foundational understanding of sustainability criteria for supplier evaluation from the existing literature. This provides a comprehensive academic baseline, crucial for addressing the nascent research that links these criteria with the business practice and LkSG, bridging the current gap in their practical application for suppliers with heightened human rights and environmental risks. This systematic identification and assessment of the available literature lay the theoretical groundwork for our subsequent empirical investigation into business practice. Consequently, this section examines the sustainability criteria in the literature for supplier evaluation through a systematic review and structured content analysis.

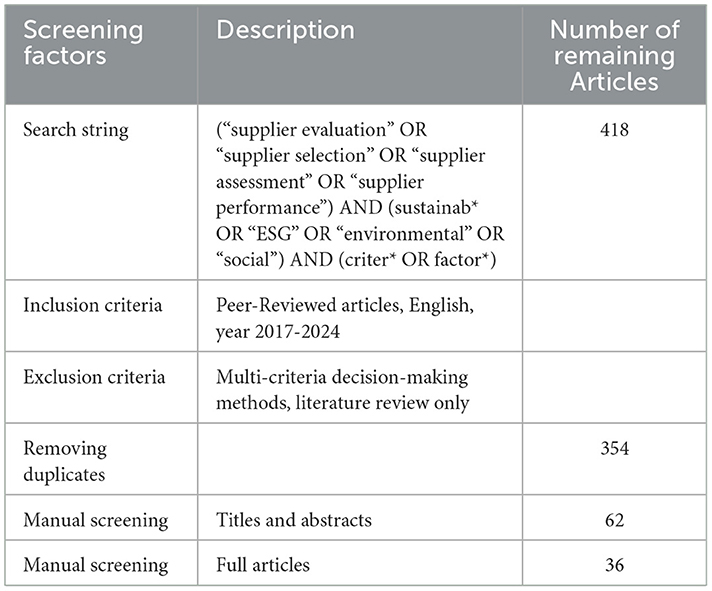

Following a framework ensures that the review is conducted rigorously, enhancing both the transparency and applicability of the research (Seuring and Gold, 2012; Snyder, 2019). Therefore, a four-phase literature review process is conducted, following the framework of Seuring and Gold (2012) with the following phases: (1) collection of materials, (2) descriptive analysis, (3) definition of categories, and 4) evaluation of the materials. For a more comprehensive result, we used the two major databases of peer-reviewed articles: Elsevier's Scopus (Scopus) and Clarivate Analytics' Web of Science (WoS) for the SLR. Both databases are currently recognized as the primary sources for bibliographic data searches in academia (Kumpulainen and Seppänen, 2022; Pranckutė, 2021). The screening factors of the reviewed literature were determined (see Table 2), the sample was collected, and the articles were selected and analyzed following the first research question. Relevant data were identified using the search string topic (“supplier evaluation” OR “supplier selection” OR “supplier assessment” OR “supplier performance”) AND (sustainab* OR “ESG” OR “environmental” OR “social”) AND (criter* OR factor*). By combining keywords with the Boolean operator AND, we identified articles that discuss supplier evaluation and sustainability criteria. The OR operator was used to include synonym terms for supplier evaluation, sustainability, and criteria. A broad word stem was used to avoid bias and ensure a comprehensive sample. All articles included in this study were peer-reviewed, written in English, and published between 2017 and 2024. The year 2017 was selected to capture the latest advancements and trends in the field. According to the studies by Tasdemir and Gazo (2018) and Rashidi et al. (2020), publications in the field of sustainability in supply chains fundamentally increased in 2017, making it a suitable starting point for our analysis. Articles that focused solely on MCDM methods without addressing sustainable supplier evaluation criteria, as well as those limited to literature reviews, were excluded from our analysis (see Table 2). This exclusion aligns with the objective of our study, which is to provide a comprehensive examination of sustainability criteria in supplier evaluation. To ensure the relevance of the identified criteria, we included only those studies that explicitly addressed sustainability criteria in the context of supplier evaluation. This approach was necessary because MCDM studies (e.g., Guo and Zhao, 2017; Ulutaş et al., 2022) often adopt criteria from a single source or use criteria without transparency regarding their selection method, which can introduce bias and compromise the robustness of our findings. However, some MCDM studies (e.g., Althaqafi, 2023; Jain and Singh, 2020) focus on sustainability criteria. Therefore, we designed our search string to also capture articles that address both MCDM approaches and sustainability criteria to avoid overlooking relevant studies that contribute valuable findings for our study. Using the search string, we identified 252 articles on Scopus and 166 articles on WoS, in total 418 articles in September 2024. After removing duplicates, 354 articles remained. These remaining articles were manually screened based on their titles and abstracts to ensure they addressed sustainability criteria for supplier evaluation. In the last step, the final sample (n = 36) was fully manually analyzed to retrieve the identified sustainability criteria.

3.1.1 Descriptive analysis

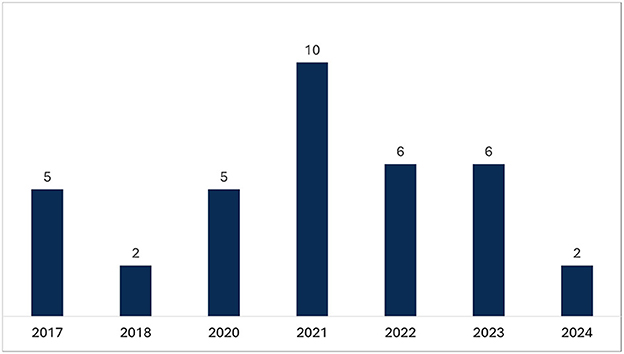

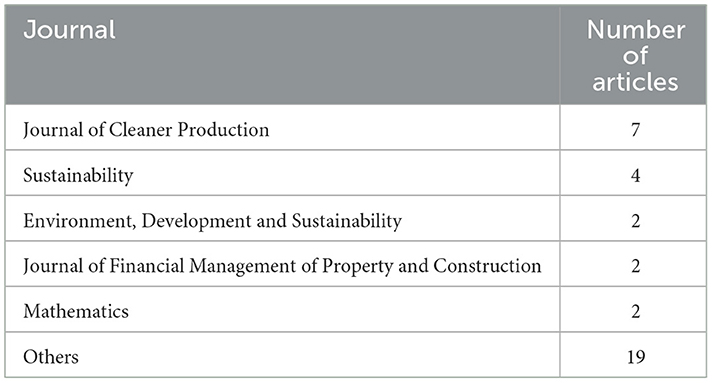

This section presents the descriptive characteristics of the reviewed literature, with publication dates ranging between 2017 and 2024 (see Figure 2). The articles were published in 24 different journals, spanning various disciplines and geographical contexts. 19% of the articles were published in the Journal of Cleaner Production, followed by the journal Sustainability with 11%, and 6% each in the Environment, Development and Sustainability and Journal of Financial Management and Property and Construction. Most journals published only one article, collectively accounting for over half of the total publications (see Table 3). Figure 2 illustrates that the peak of the publications occurred in 2021.

3.1.2 Categorization and validation of the identified sustainability criteria

We identified the sustainability criteria from the final sample of the SLR without distinguishing between main criteria and sub-criteria, as no uniform standard in literature exists (see Section 2.2). We then grouped all the identified criteria derived from logical relationships and coherence and then developed a main criterion for each group. Afterwards, we categorized the main criteria with their sub-criteria within the three dimensions of the TBL (see Section 4.1). Subsequently, we sought approval from five academic experts in sustainable supply chain management for both the categorization within the dimensions of the TBL and the alignment of sub-criteria with the main criteria, aiming to mitigate any potential bias. To enhance meaning and clarity, we designed a leading question for each sub-criterion. The allocation to the three dimensions was not predetermined and had to be assigned by the experts. While we initially assigned the sub-criteria to the main criteria, the experts had the option to modify these assignments as well.

In the next step, the criteria were selected in accordance with the number of articles that identified each criterion. Thereby, equal significance is attributed to all criteria, regardless of whether they are main or sub-criteria categorized by us. Subsequently, we calculated a total count for each main criterion by summing the number of its associated sub-criteria with the number of times the main criterion itself was mentioned. This total count was then used to determine a percentage weighting for each main criterion within its respective sustainability dimension. Finally, for each dimension, we selected the five main criteria with the highest percentage weighting (see Section 4.1).

3.2 Expert survey

This study aims to align the most relevant sustainability criteria from the literature with practical applications through an anonymous online survey conducted with selected company experts. In addition, we investigate whether companies apply further sustainability criteria that were not considered in the literature. Therefore, we exclusively involved experts who work in companies across various industries in Germany that are subject to LkSG and are engaged in supplier evaluation.

Involving experts from diverse industries allows us to identify the main sustainability criteria used across different sectors. While the specific risks and their surface-level manifestations may vary, the structural challenges, particularly those at the origin of the supply chain, are fundamentally consistent (International Labour Office, United Nations Children's Fund, 2025; International Labour Organization, 2024). This approach ensures that our study develops a comprehensive and adaptable framework for sustainable supplier evaluation in the context of LkSG that is not limited to a specific industry.

We used LinkedIn to identify experts who have professional experience in evaluating suppliers, based on their position and company. For the position, we selected experts in procurement, supply chain management, and sustainability. Regarding the company, we did research if the company falls under LkSG by identifying the number of employees, since all companies with more than 1,000 employees fall under it (see § 1, para 1 LkSG). If the company was obliged under LkSG and the expert's profile fit, we contacted the expert by a personal message, where we first described the background and goal of the survey and then asked if they are willing to take part in it. When they replied positively, we sent them a link to our online survey. Before engaging with the experts, we conducted a pretest of the online survey with both expert and non-expert participants to ensure clarity and functionality.

The survey is structured into six parts. The first part introduces the study to the experts. The second part collects general information and includes a screening question to ensure the suitability of the respondents. This question was designed to confirm that the expert works in procurement, supply chain management, or sustainability and is actively involved in supplier evaluation. Experts who answered yes could proceed with the survey and were then asked for general information, including their company's industry, their role, and their years of experience.

In the third part, we asked experts to identify the product groups and countries where their company faces heightened human rights and environmental risks. The purpose of this section was twofold: first, to obtain an overview of these heightened risk areas across the participants, and second, to make the experts aware of their company's specific risks, which they were asked to keep in mind when assessing the criteria in the subsequent sections.

The fourth and fifth parts constitute the main body of the survey. In these sections, experts were asked to assess 15 main sustainability criteria and two corresponding sub-criteria, which were identified from our SLR (see Section 4.1). To facilitate this assessment, leading questions were included to place experts in specific scenarios and to enhance their understanding of each criterion. Using a five-point Likert scale (no relevance, very low relevance, low relevance, high relevance, and very high relevance), the experts had the option to evaluate each main criterion. This categorization aligns with the Content Validity Index, which is a crucial metric used in research and measurement development to assess the relevance and clarity of items in an instrument like a survey (Ebnehoseini et al., 2021; Lynn, 1986). The distinction between the fourth and fifth parts is that in the fourth part, experts assessed the criteria based on product groups with heightened human rights and environmental risks, while in the fifth part, they assessed the criteria based on countries. This separation was implemented to account for companies that may differentiate their criteria based on either the product category or the country. If a company did not make this distinction, experts were asked to assess the criteria only once for both parts. For each assessment, a note was included to remind the expert to consider the heightened-risk product groups and/or countries they had identified in the third part.

After assessing the criteria in the fourth and/or fifth part, experts were also given the opportunity to identify additional criteria not mentioned in the literature. Furthermore, experts were asked if certifications and/or scores play a role in their supplier evaluation and, if so, which specific ones.

Upon the completion of the expert survey, the results were analyzed based on the responses. For each criterion, we calculated the percentage weights for each of the five Likert scale points. To validate these findings, the median was also calculated for each criterion's Likert scale evaluations. The findings are presented in Section 4.2.

4 Analysis and results

This section presents the analysis and findings of the SLR and the expert survey. Section 4.1 identifies the most relevant sustainability main-criteria from the literature. Subsequently, Section 4.2 presents the results of the expert survey, which aims to link these theoretical insights with practical applications. These findings will be discussed in Section 5.

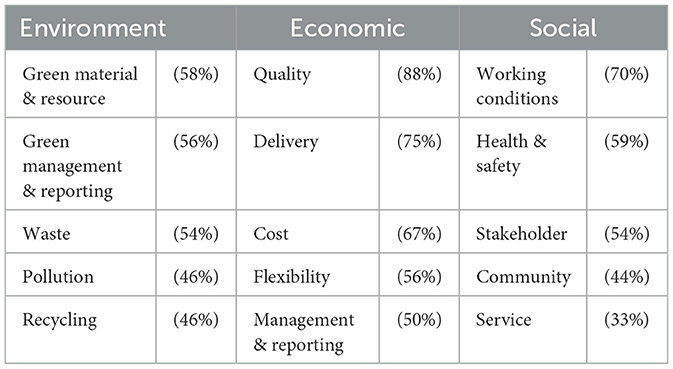

4.1 Systematic literature review

In the course of the SLR, we identified a total of 137 sustainability criteria. As explained in Section 3.1.2, we did not distinguish between main and sub-criteria when identifying the criteria. These criteria were clustered, resulting in the formation of 41 main criteria. These main criteria were subsequently categorized within the dimensions of the TBL. Notably, nearly half of the main criteria fall under the economic dimension, followed by the environmental dimension, which constitutes approximately 30%, and the social dimension, which has the smallest share at around 20%. Table 1 represents the most relevant main sustainability criteria for supplier evaluation, as identified in the existing literature. For each main criterion, we have identified and listed the two most significant sub-criteria according to the literature. In addition, for each main criterion, we formulated a leading question to enhance clarity and understanding (see Table 1).1 According to our analysis of the SLR, the most relevant sustainability criteria for evaluating sustainable suppliers are as follows. For the economic dimension, the most relevant main criteria identified are cost, delivery, quality, flexibility, and management and reporting. Together, these criteria account for over 60% of all identified main economic criteria, determined by their weighted proportional values. For the environmental dimension, the relevant main criteria are green material and resources, green management and reporting, pollution, and waste, which together constitute over two-thirds of all main criteria in the environmental category. In the social dimension, the criteria include working conditions, health and safety, service, stakeholder, and community, which represent over 84% of the total main social criteria. Interestingly, human rights, including issues such as child and forced labor, rank sixth with a weighting of less than 8% of the total main social criteria.

In this study, we adhere to the concept of main and sub-criteria and focus on the most relevant main criteria in the analysis. By prioritizing these main criteria, we aim to provide a clearer understanding. Nevertheless, it is also interesting to look at all the criteria without our categorization into main criteria and sub-criteria. The five highest-weighted criteria are quality, closely followed by green design, emission, environmental management system, and delivery time. Cost ranks sixth. It is noteworthy that among the top five highest-weighted criteria, no social criteria appear. The highest-weighted social criterion, health and safety, ranks seventh. This further highlights that social aspects are currently given less importance in the literature compared to economic and environmental aspects.

4.2 Expert survey

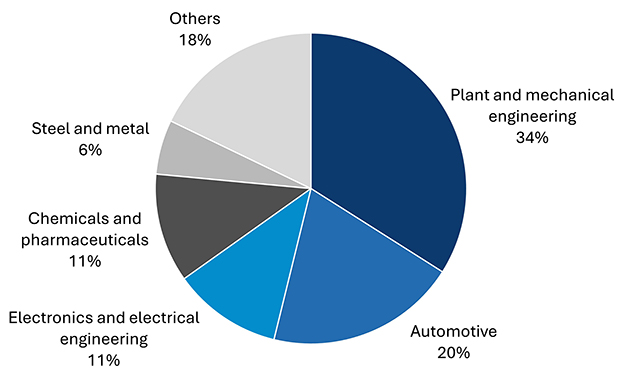

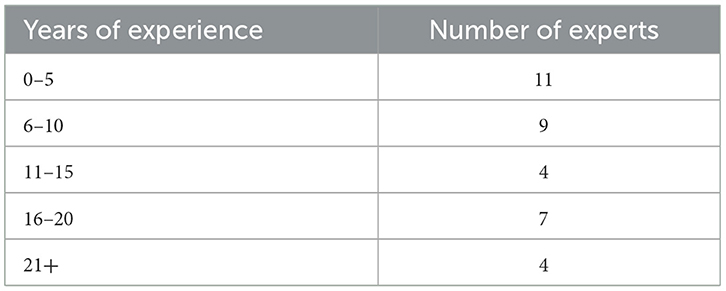

The survey was conducted from February 2025 to March 2025. A total of 170 experts were personally approached, with a response rate of 20.6% (n = 35). We received expert responses from 11 different industries, with nearly 80% coming from the four sectors: plant and mechanical engineering, automotive, electronics and electrical engineering, and chemicals and pharmaceuticals (see Figure 3). Out of the surveyed experts, 25% are sustainability specialists, 14% are purchasing managers, and 11% each are strategic buyers and project buyers. More than 69% of the experts have over 6 years of professional experience in the fields of supply chain management, sustainability, and/or procurement (see Table 4).

We asked the experts about their own product groups and supplier countries that pose heightened human rights and environmental risks. This was intended to create a scenario for the respondents to consider when evaluating the criteria. A total of 87 different product groups were specified, ranging from aluminum, electronic components, circuit boards, and palm oil to various cables. For better clarity, since companies often define product groups very specifically, we grouped the specified product groups according to the CSR Risk Check (MVO Nederland, 2025a), which is provided free of charge. This resulted in 17 categories to enhance the overall overview. While this classification is quite broad, it is sufficient for this study as it is intended to provide a general snapshot. Two-thirds of the highest human rights and environmental risk categories of the surveyed companies involve metal goods (48%), manufactured goods (13%), and rubber goods (6%). For supplier countries with heightened human rights and environmental risk, a total of 37 different countries were specified, with a few experts indicating entire continents such as Africa and Asia. More than one-third of the most frequently mentioned supplier countries with heightened risk are China (about 15%), followed by India (approximately 13%) and Brazil (around 6%). Among the continents, Asia is the most risk-prone, accounting for half of the mentions, followed by Africa and South America.

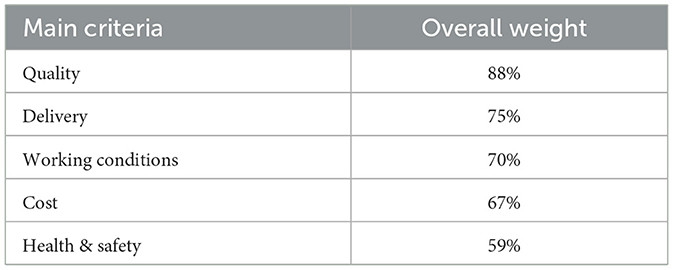

The five most relevant used criteria for evaluating suppliers with heightened risk due to product group and country can be clearly identified. While 43% of the surveyed companies distinguish between product group and country when applying these criteria, the set of the five most relevant criteria remains unchanged; only the weighting differs. While the ranking of the top five criteria rated as very high relevant varies depending on the weighting, the overall analysis (see Table 5) indicates that quality is assigned the highest relevance, followed by delivery, working conditions, cost, and health and safety. Notably, three of these five main criteria pertain to the economic dimension, while the remaining two fall within the social dimension. Interestingly, none of the top five main criteria in practice are from the environmental dimension. In the overall analysis, based on the expert's assessment of the product group and country, Table 6 presents the five main criteria by dimension, including the weighting provided by experts. The main criteria community and service were rated as having low relevance in the overall assessment. However, among companies that differentiate between product groups and countries in their evaluation, community remained of low relevance when evaluating based on the supplier country, whereas service was considered as relevant. All other main criteria were generally rated as having high relevance.

Beyond assessing the predefined criteria, experts were asked whether any additional criteria, not identified in literature, are used in practice. In response, experts mentioned a total of 39 distinct items, which primarily consisted of evaluation instruments rather than additional criteria. 30% of the most frequently mentioned instruments include the supplier code of conduct, EcoVadis Score, and certifications. For companies that differentiate between product groups and country, there was no distinction in this regard.

As observed with the additional criteria, certifications, and scores also play a significant role in the evaluation of suppliers facing heightened human rights and environmental risks. Nearly 95% of the companies surveyed indicated that certifications or scores are considered in their assessment process. In total, 30 different certifications and scores were mentioned, with ISO 14001 (environmental management systems) being the most frequently cited (approximately 21%), followed by the EcoVadis Score (around 14%) and the IntegrityNext Score (about 9%).

5 Discussion

In this section, we discuss the results of our SLR and expert survey by synthesizing them with each of the three dimensions of sustainability. We align these findings with LkSG and provide recommendations for the main sustainability criteria for evaluating suppliers with heightened human rights and environmental risks.

5.1 Findings from systematic literature review and expert survey

5.1.1 Economic dimension

Our SLR revealed that the economic dimension remains the most prevalent in academic discourse on sustainable supplier selection, accounting for nearly half of all identified criteria. This finding is consistent with prior research by Ageron et al. (2012) and Rashidi et al. (2020), which also highlight the dominance of economic factors.

Interestingly, our expert survey corroborates this academic emphasis, showing that economic criteria continue to hold significant weight in practice. The survey data reveals that quality (88%) and delivery (75%) were ranked as the top two most relevant criteria for supplier evaluation, with cost (67%) also cited among the top five (see Table 6). This finding highlights a potential gap between the growing discourse on sustainability and the enduring prioritization of traditional economic metrics within the industry. It suggests that economic performance may still be prioritized over environmental and social considerations in supply chain management, which points to an imbalance among the three dimensions of sustainability.

5.1.2 Environmental dimension

In the academic literature, the environmental dimension accounts for approximately 30% of the sustainability criteria identified in our SLR, which is similar to the findings of Ageron et al. (2012) and Rashidi et al. (2020).

In contrast, our expert survey revealed a notable imbalance: none of the top five criteria cited by practitioners stemmed from the environmental dimension. This is a critical finding, as it highlights a significant disconnect between academic emphasis and practical application. This could be due to the early academic research centered on concepts like green supply chain management (Hsu and Hu, 2008; Zhu et al., 2007) before the scope broadened to fully include social dimensions (Santos et al., 2021; Schramm et al., 2020). The prevalent focus on the environment can be attributed to its dimensions being more tangible and readily quantifiable compared to those in the social dimension (Ashby et al., 2012; Ahi and Searcy, 2015). The specific regulatory context of LkSG likely influences this imbalance. Although LkSG addresses both human rights and environmental protection, its legal requirements for the latter are less comprehensive. Consequently, companies subject to this act might have become more sensitive to social criteria, which could currently shift their prioritization away from environmental factors.

5.1.3 Social dimension

Based on our SLR, we find that the social dimension is the least represented in the academic literature, accounting for only about 20% of the criteria. This is consistent with previous studies that often rank social factors last (Kuo et al., 2021; Vörösmarty and Dobos, 2020).

However, our expert survey presents a compelling counter-narrative. Within LkSG context, social criteria like working conditions (70%) and health and safety (59%) were ranked among the top five most relevant in practice. This finding indicates a significant shift, where the legal obligation to protect human rights under LkSG directly elevates the importance of social criteria, making them a priority for companies. It is important to emphasize that we exclusively surveyed experts from companies subject to LkSG. This means that these companies have been required to implement LkSG for at least one or two years, making them more attuned to sustainable supplier evaluation.

5.1.4 Tools in practice

Besides the sustainability criteria, practitioners highlighted the use of instruments not frequently mentioned in the literature, such as sustainability ratings (e.g., EcoVadis), supplier codes of conduct, and certificates. These tools are crucial for conveying expectations and monitoring compliance, directly supporting the due diligence requirements under LkSG. This shows that the legal framework is not only shifting priorities but also influencing the practical tools and methods used for supplier selection. While these tools serve to verify compliance and build stakeholder trust, their effectiveness is a subject of ongoing debate in the academic literature, particularly concerning the potential for a checkbox mentality and the risk of green-washing (Amundsen, 2022; Nygaard, 2023). Therefore, these ratings and certifications should be used critically, serving as a support for, rather than a replacement for, comprehensive supplier evaluation.

5.2 Alignment with LkSG: recommendation for sustainability criteria

Building upon the sustainability criteria for supplier evaluation identified in the preceding SLR and through the expert survey, this section critically examines their alignment with LkSG. This legal review is paramount to ensure that the identified sustainability criteria comprehensively address all mandated human rights and environmental protection areas. Given that LkSG is a relatively recent legislative development and the extent of its practical implementation and understanding across companies is still evolving, this validation is essential. Therefore, to foster a sustainable supply chain and ensure compliance with LkSG, companies must integrate human rights and environmental expectations into their criteria when evaluating and selecting their direct suppliers (Bundesrepublik Deutschland, 2021).

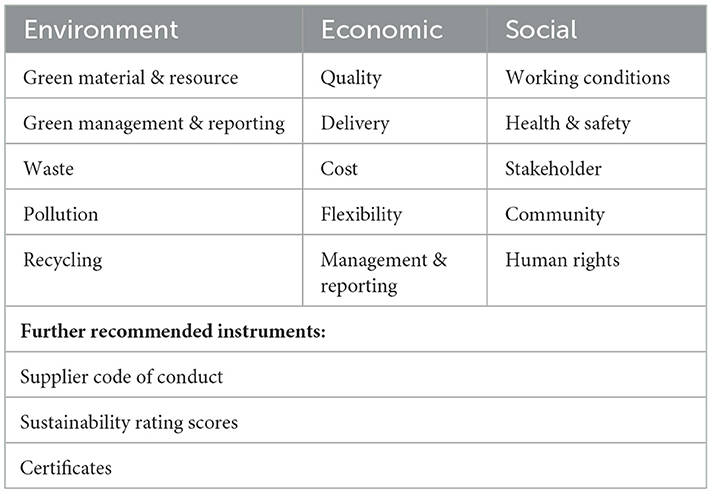

As highlighted earlier, the primary focus of LkSG is the protection of human rights. The legal text specifically addresses the following human rights issues: child labor, forced labor, slavery, occupational safety and health obligations, freedom of association, unequal treatment in employment, withholding adequate living wage, cause of harmful soil change, water and air pollution, harmful noice emissions, or excessive water consumption, unlawful eviction, deployment of security forces to protect business project with violation (Bundesrepublik Deutschland, 2021). It is noteworthy that neither the five most relevant criteria through the SLR nor those applied in practice consider human rights criteria, such as child labor, forced labor, slavery, and freedom of association, as highly relevant. Our SLR ranks human rights sixth within the social dimension, with a weighting of under 8%. Across all dimensions, its weighting is less than 2%. However, these are critical criteria for evaluating suppliers with heightened risk, particularly in the context of LkSG requirements. Therefore, we recommend establishing a main criterion of human rights with sub-criteria, including child labor, forced labor, slavery, freedom of association, the use of security forces to protect business projects, and excessive water consumption. Even though human rights were not explicitly mentioned in practice, this main criterion is covered within the framework of sustainability ratings. The two sustainability rating providers (EcoVadis, 2025; IntegrityNext, 2025) mentioned by the surveyed experts focus not only on human rights but also on the broader spectrum of environmental, social, and governance factors. Ultimately, companies using these scores gain a comprehensive overview, not only of human rights but also of all aspects of the environmental, social, and governance performance of the suppliers being evaluated. Therefore, it cannot be assumed that the issue is entirely overlooked in practice, even if it is not explicitly listed as a criterion. Nonetheless, we recommend incorporating human rights as one of the most relevant criteria by establishing it as a distinct main criterion. For the other human rights issues addressed in LkSG, we do not propose additional main criteria, as they can be assigned to the existing main criteria outlined in Table 1. In this study, we assign occupational safety and non-discrimination in employment, as referenced in LkSG, to the main criteria health and safety and working conditions, respectively. Similarly, harmful noise emissions are categorized under health and safety, while unlawful evictions fall under community. With regard to environmental protection, the aspects mentioned in LkSG correspond to the main criteria green materials and resources, pollution, and waste and are thus already among the relevant criteria in the literature and practice.

In summary, based on our SLR, we identified the five most relevant sustainability criteria for each dimension. This selection was based on the frequency with which each criterion was identified in the literature, which we then used to perform a percentage weighting to establish an initial set of main criteria (see Table 1). Next, we validated these criteria with an expert survey. As described in Section 3.2, experts assessed the 15 criteria using a five-point Likert scale, and we analyzed their responses (see Table 6). Finally, we aligned the results with the requirements of the LkSG. To ensure alignment with the LkSG's emphasis on human rights, we integrated this crucial social main criterion into our final framework and consequently removed the service criterion, which was identified as the least relevant (33%) based on our expert survey. This comprehensive process, combining insights from the SLR, expert validation, and legal alignment, allowed us to propose the most relevant sustainability criteria for evaluating suppliers with heightened human rights and environmental risks, as presented in Table 7.

This proposed framework offers implications for practitioners. The holistic supplier evaluation framework, which balances the economic, environmental, and social dimensions of sustainability, serves as a guide for companies. By adopting these criteria, companies can not only ensure compliance with LkSG, but also proactively mitigate supply chain risks and enhance their corporate social responsibility. To move beyond a checkbox mentality, top management must be actively involved and view sustainability not as a compliance task but as a source of long-term value. This requires integrating it into the company's core strategy and business processes (Abdul Basit et al., 2024; Bourini et al., 2024). Furthermore, building stronger supplier partnerships and investing in supplier development are essential for establishing authentic sustainability practices throughout the supply chain and enhancing the organization's overall sustainability performance (Kumar and Rahman, 2016; Zhang et al., 2017).

At first glance, a narrow focus on LkSG might suggest an unbalanced assessment of supply chain risks, with human rights taking precedence over environmental concerns. However, this view is incomplete for two reasons. First, the due diligence obligations within LkSG itself demonstrate that human rights and environmental risks are highly interlinked. For example, the law protects against harmful soil degradation or water pollution that denies communities access to safe food and drinking water (Bundesrepublik Deutschland, 2021), framing an environmental problem as a human rights violation. Second, organizations in Germany operate within a broader and evolving European regulatory landscape that extends beyond LkSG. For instance, the EU Deforestation Regulation, which takes effect in December 2025, mandates strict due diligence for commodities linked to deforestation (European Parliament and Council of the European Union, 2023). Similarly, the European Corporate Sustainability Reporting Directive obliges companies to report holistically on both environmental and social impacts across their value chains, e.g., including upstream and downstream emissions (European Parliament and Council of the European Union, 2022). When viewed in this wider context, LkSG is one piece of a larger regulatory puzzle that pushes for a more comprehensive risk assessment. Nevertheless, looking at LkSG in isolation, we argue that its framing could be enhanced. Policymakers should consider evolving legislation to give environmental due diligence the same explicit legal weight as human rights mandates, thereby clarifying and strengthening their interconnection.

6 Conclusion

This study examined the most relevant sustainability criteria and instruments for supplier evaluation within the framework of LkSG. To achieve this, we conducted an SLR to identify the most relevant sustainability criteria from the literature, which were then evaluated by experts to determine their relevance in practice and to assess whether additional criteria or instruments are being utilized. Despite the increasing focus on sustainability in the literature, two significant gaps remain unaddressed: (1) a comparison between the criteria discussed in the literature and those applied in practice, and (2) the identification of the most relevant sustainability criteria and instruments that should be applied when evaluating suppliers with heightened human rights and environmental risks in the context of due diligence acts.

Derived from our SLR, the study categorizes 41 main criteria within the TBL dimensions, with nearly half classified under the economic dimension, followed by environmental (30%) and social (20%). Expert survey results indicate that the most relevant criteria in practice are quality, delivery, working conditions, cost, and health and safety. Notably, among the five highest-rated main sustainability criteria, only economic and social dimensions are represented, while environmental aspects are absent. This suggests a shift in focus compared to the literature, where environmental considerations are more prominent.

Overall, the main criteria identified in the SLR align with practical applications in the environmental and economic dimensions. Furthermore, the environmental requirements of LkSG are implicitly covered within the five main environmental criteria we created through the results of the SLR. Regarding the social dimension, we recommend emphasizing human rights, working conditions, health and safety, stakeholders, and community as the most relevant main criteria. Interestingly, human rights did not emerge among the top five social criteria in either the SLR or the expert survey. Moreover, instruments like supplier code of conduct, sustainability ratings, and certifications are frequently applied in practice, reinforcing the recommendation to incorporate them into supplier evaluations. These insights provide a foundation for companies to refine their supplier evaluation frameworks, ensuring compliance with due diligence regulations while fostering a more sustainable supply chain.

Theoretically, this study reinforces the TBL framework in high-risk contexts. Specifically, the study empirically shows that balancing people, planet, and profit is non-optional in supply chains facing heightened human rights and environmental risks. Legal mandates force companies to prioritize people and planet, shifting the traditional dominance of profit-first decision-making. The study implies a need for greater transparency in corporate governance regarding the trade-offs inherent in profit maximization and more effective regulatory approaches that acknowledge the reality of profit prioritization. This research contributes to ongoing debates on the role of business in society, highlighting the tensions between profit-seeking behavior and societal objectives. This deepens balancing the TBL prioritization of sustainability criteria for supplier evaluation in the context of due diligence acts, using LkSG as an example from academic and practitioners' perspectives.

Additionally, this study makes two key contributions to the existing literature. (1) Unlike previous research that primarily focused on general sustainability criteria for supplier evaluations, this study specifically examines suppliers with heightened human rights and environmental risks in the context of due diligence regulations, particularly through the lens of LkSG. (2) This study also offers a valuable business practice perspective of the applied sustainability criteria and instruments for supplier evaluation in the context of due diligence acts, bridging the gap between academia and practice, thereby enriching the literature with insights from real-world application.

This study exclusively surveyed experts from companies subject to LkSG, with a sample of 35 companies. This represents only a fraction of the companies affected by LkSG, highlighting the need for future quantitative research to provide deeper insights. It also focused on selected literature that fell into the inclusion and exclusion criteria, ignoring other potential articles related to the subject. Given that LkSG is relatively new and does not explicitly prescribe supplier evaluation criteria, companies may need time to reassess their most relevant criteria, suggesting that a follow-up study over time would be valuable. Additionally, while this study focused on LkSG's due diligence requirements, future research should explore similar acts in other countries. Our study also did not differentiate between industries, and further investigation into industry-specific criteria would be insightful. The study only briefly addressed sustainability ratings and certifications; therefore, future research should critically examine their impact. This is crucial for both practice and academia to determine if those tools drive sustainable performance improvements or simply contribute certification fatigue and checkbox mentality. To bridge the gap between scholarly and practical perspectives, future research could focus on understanding and linking both. For example, using case studies to test theoretical frameworks in real-world situations would help to identify discrepancies (Chen, 2024). Furthermore, industry interviews could be used to understand the perspectives of professionals and connect them to theoretical constructs (Ortiz et al., 2020). Lastly, we emphasize that future research on sustainable supplier evaluation must move beyond static assessments to design studies that can quantitatively and qualitatively measure its enduring effects on supply chain environmental and social performance, without overlooking intangible measures of the social dimension. This is crucial because a significant gap exists in understanding the social dimension of sustainability, especially in developing economies where issues are contextual and dynamic (Mani et al., 2018; Marra, 2025).

Overall, despite these limitations, this study offers valuable insights into the most relevant sustainability criteria for evaluating suppliers with heightened human rights and environmental risks in the context of due diligence acts in supply chains. It bridges the gap between real-world applications and existing literature, providing a solid foundation for future research in this rapidly evolving field.

Author contributions

SK: Conceptualization, Project administration, Methodology, Writing – review & editing, Validation, Writing – original draft, Visualization. MQ: Writing – review & editing, Validation. FK: Supervision, Writing – review & editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Gen AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frsus.2025.1677700/full#supplementary-material

Abbreviations

CSDDD, Corporate Sustainability Due Diligence Directive; LkSG, Lieferkettensorgfaltspflichtengesetz; MCDM, Multi-Criteria Decision Making; RQ, Research Question; Scopus, Elsevier's Scopus; SLR, Systematic Literature Review; TBL, Triple Bottom Line; WoS, Clarivate Analytic's Web of Science.

Footnotes

1. ^During the validation of the main and sub-criteria by academic experts, we deliberately formulated a leading question for each sub-criterion in order to better validate the assignment to the main criterion. As this assignment has already been determined and we are primarily concerned with the main criteria in this study, we developed a leading question only for each main criterion.

References

Abdul Basit, S., Gharleghi, B., Batool, K., Hassan, S. S., Jahanshahi, A. A., and Kliem, M. E. (2024). Review of enablers and barriers of sustainable business practices in SMES. J. Econ. Technol. 2, 79–94. doi: 10.1016/j.ject.2024.03.005

Ageron, B., Gunasekaran, A., and Spalanzani, A. (2012). Sustainable supply management: an empirical study. Int. J. Prod. Econ. 140, 168–182. doi: 10.1016/j.ijpe.2011.04.007

Agyemang, M., Kusi-Sarpong, S., Agyemang, J., Jia, F., and Adzanyo, M. (2022). Determining and evaluating socially sustainable supply chain criteria in agri-sector of developing countries: insights from West Africa cashew industry. Prod. Plan. Cont. 33, 1115–1133. doi: 10.1080/09537287.2020.1852479

Ahi, P., and Searcy, C. (2015). Measuring social issues in sustainable supply chains. Measur. Bus. Excel. 19, 33–45. doi: 10.1108/MBE-11-2014-0041

Althaqafi, T. (2023). Environmental and social factors in supplier assessment: fuzzy-based green supplier selection. Sustainability 15:15643. doi: 10.3390/su152115643

Amundsen, V. S. (2022). From checking boxes to actual improvement: a new take on sustainability certification. Aquaculture 548:737672. doi: 10.1016/j.aquaculture.2021.737672

Ashby, A., Leat, M., and Hudson-Smith, M. (2012). Making connections: a review of supply chain management and sustainability literature. Supply Chain Manage. Int. J. 17, 497–516. doi: 10.1108/13598541211258573

Aslani, B., Rabiee, M., and Tavana, M. (2021). An integrated information fusion and grey multi-criteria decision-making framework for sustainable supplier selection. Int. J. Syst. Sci. Operat. Logist. 8, 348–370. doi: 10.1080/23302674.2020.1776414

Bai, C., Kusi-Sarpong, S., Badri Ahmadi, H., and Sarkis, J. (2019). Social sustainable supplier evaluation and selection: a group decision-support approach. Int. J. Prod. Res. 57, 7046–7067. doi: 10.1080/00207543.2019.1574042

Bai, C., and Sarkis, J. (2010). Integrating sustainability into supplier selection with grey system and rough set methodologies. Int. J. Prod. Econ. 124, 252–264. doi: 10.1016/j.ijpe.2009.11.023

Berthet, E., Lavalley, J., Anquetil-Deck, C., Ballesteros, F., Stadler, K., Soytas, U., et al. (2024). Assessing the social and environmental impacts of critical mineral supply chains for the energy transition in Europe. Global Environ. Change 86:102841. doi: 10.1016/j.gloenvcha.2024.102841

Bourini, I., Khassawneh, O., and Mohammad, T. (2024). Towards sustainability in the services industry: does green top management support stimulate an organization's green operational performance? A moderated mediation model. Bus. Strat. Environ. 33, 7788–7799. doi: 10.1002/bse.3897

Brandenburg, M., Warasthe, R., and Seuring, S. (2024). Impact pathways: improving supply chain sustainability by due diligence acts? Insights from a German case. Int. J. Operat. Prod. Manage. 44, 859–874. doi: 10.1108/IJOPM-03-2023-0200

Bundesministerium für Arbeit und Soziales (2025). NAP International. Eschborn: Bundesamt für Wirtschaft und Ausfuhrkontrolle. Available online at: https://www.csr-in-deutschland.de/DE/Wirtschaft-Menschenrechte/NAP/Ueber-den-NAP/NAP-International/nap-international.html (Accessed 04 March, 2025).

Bundesrepublik Deutschland (2021). Gesetz über die unternehmerischen Sorgfaltspflichten in Lieferketten. LkSG.

Castro e Silva, A., Seleme, R., de Assis Silva, W., Zattar, I. C., Nara, E. O. B., Júnior, O. C., et al. (2022). Evaluation and choice criteria of sustainable suppliers in the construction industry: a comparative study in Brazilian companies. Sustainability 14, 15711. doi: 10.3390/su142315711

Chen, Y. (2024). How blockchain adoption affects supply chain sustainability in the fashion industry: a systematic review and case studies. Int. Trans. Oper. Res. 31, 3592–3620. doi: 10.1111/itor.13273

Dou, S., Xu, D., Zhu, Y., and Keenan, R. (2023). Critical mineral sustainable supply: challenges and governance. Futures 146:103101. doi: 10.1016/j.futures.2023.103101

Dupont, V., Pietrzak, D., and Verbrugge, B. (2024). A step in the right direction, or more of the same? A systematic review of the impact of human rights due diligence legislation. Hum. Rights Rev. 25, 131–154. doi: 10.1007/s12142-024-00724-9

Durach, C. F., Kembro, J. H., and Wieland, A. (2021). How to advance theory through literature reviews in logistics and supply chain management. Int. J. Phys. Distrib. Logist. Manage. 51, 1090–1107. doi: 10.1108/IJPDLM-11-2020-0381

Ebnehoseini, Z., Jangi, M., Tara, M., and Tabesh, H. (2021). Investigation the success rate of hospital information system (HIS): development of a questionnaire and case study. J. Healthc. Qual. Res. 36, 103–112. doi: 10.1016/j.jhqr.2020.03.010

EcoVadis (2025). Nachhaltigkeitsratings für globale Lieferketten. Available online at: https://ecovadis.com/de/solutions/ratings/ (Accessed 27 March, 2025).

Eisen, C., Schenten, J., Theis, A., Rehn-Groenendijk, J., Helferich, M., Müller, H., et al. (2024). Toward system innovation for more sustainable chemistry: insights into consumers' perceptions, knowledge, and behavior related to traceability and product design strategies along leather supply chains. Front. Sustain. 5:1351638. doi: 10.3389/frsus.2024.1351638

Elkington, J. (1997). Cannibals with Forks: The Triple Bottom Line of 21st Century Business. Oxford: Capstone.

European Parliament and Council of the European Union (2022). Directive (eu) 2022/2464 of the European Parliament and of the Council of 14 December 2022 Amending Regulation (EU) no 537/2014, Directive 2004/109/ec, Directive 2006/43/ec and Directive 2013/34/eu, as Regards Corporate Sustainability Reporting. Brussels: European Union.

European Parliament and Council of the European Union (2023). Regulation (eu) 2023/1115 of the European Parliament and of the Council of 31 May 2023 on the Making Available on the Union Market and the Export from the Union of Certain Commodities and Products Associated with Deforestation and Forest Degradation and Repealing Regulation (EU) no 995/2010. Brussels: European Union.

European Union (2024). Directive (EU) 2024/1760 of the European Parliament and of the Council of 13 june 2024 on Corporate Sustainability Due Diligence and Amending Directive (EU) 2019/1937 and Regulation (EU) 2023/2859. Brussels: European Union.

Fallahpour, A., Udoncy Olugu, E., Nurmaya Musa, S., Yew Wong, K., and Noori, S. (2017). A decision support model for sustainable supplier selection in sustainable supply chain management. Comp. Indust. Eng. 105, 391–410. doi: 10.1016/j.cie.2017.01.005

Garcia, B., León, V., and Hidalgo Gallardo, A. (2021). Supplier selection for Mexican manufacturing MSMEs: a study-based on multi-criteria approach. J. Int. Council Small Bus. 2, 347–354. doi: 10.1080/26437015.2021.1939199

Gazi, M. A. I., Yusof, M. F., Islam, M. A., Amin, M. B., and Senathirajah, A. R. b. S. (2024). Analyzing the impact of employee job satisfaction on their job behavior in the industrial setting: an analysis from the perspective of job performance. J. Open Innov. Technol. Market Compl. 10:100427. doi: 10.1016/j.joitmc.2024.100427

Genovese, A., Lenny Koh, S. C., Bruno, G., and Esposito, E. (2013). Greener supplier selection: state of the art and some empirical evidence. Int. J. Prod. Res. 51, 2868–2886. doi: 10.1080/00207543.2012.748224

Ghadimi, P., Dargi, A., and Heavey, C. (2017). Making sustainable sourcing decisions: practical evidence from the automotive industry. Int. J. Logist. Res. Appl. 20, 297–321. doi: 10.1080/13675567.2016.1227310

Ghamari, R., Mahdavi-Mazdeh, M., and Ghannadpour, S. F. (2022). Resilient and sustainable supplier selection via a new framework: a case study from the steel industry. Environ. Dev. Sustain. 24, 10403–10441. doi: 10.1007/s10668-021-01872-5

Goggin, M., Fleming, A., MacMahon, C., and Owende, P. (2025). Exploring the sustainability of single use plastics in the biopharmaceuticals sector: a scoping review of challenges, opportunities, and impacts. Front. Sustain. 6:1536382. doi: 10.3389/frsus.2025.1536382

Govindan, K., Khodaverdi, R., and Jafarian, A. (2013). A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Cleaner Prod. 47, 345–354. doi: 10.1016/j.jclepro.2012.04.014

Guo, S., and Zhao, H. (2017). Fuzzy best-worst multi-criteria decision-making method and its applications. Knowl.Based Syst. 121, 23–31. doi: 10.1016/j.knosys.2017.01.010

Haddaway, N. R., Bethel, A., Dicks, L. V., Koricheva, J., Macura, B., Petrokofsky, G., et al. (2020). Eight problems with literature reviews and how to fix them. Nat. Ecol. Evol. 4, 1582–1589. doi: 10.1038/s41559-020-01295-x

Han, C., Jia, F., Jiang, M., and Chen, L. (2024). Modern slavery in supply chains: a systematic literature review. Int. J. Logist. Res. Appl. 27, 1206–1227. doi: 10.1080/13675567.2022.2118696

Hsu, C. W., and Hu, A. H. (2008). Green supply chain management in the electronic industry. Int. J. Environ. Sci. Technol. 5, 205–216. doi: 10.1007/BF03326014

Igarashi, M., de Boer, L., and Fet, A. M. (2013). What is required for greener supplier selection? A literature review and conceptual model development. J. Purchas. Supply Manage. 19, 247–263. doi: 10.1016/j.pursup.2013.06.001

IntegrityNext (2025). Umfassende Abdeckung von ESG-Themen. Available online at: https://www.integritynext.com/de/plattform (Accessed March 27, 2025).

International Labour Office United Nations Children's Fund (2025). Executive Summary. Child Labour: Global Estimates 2024, Trends and the Road Forward.

International Labour Organization (2024). Profits and Poverty: The Economics of Forced Labour. Geneva: International Labour Office.

Jain, N., and Singh, A. R. (2020). Sustainable supplier selection under must-be criteria through fuzzy inference system. J. Cleaner Prod. 248:119275. doi: 10.1016/j.jclepro.2019.119275

Karakoç, Ö., Memiş, S., and Sennaroglu, B. (2024). A review of sustainable supplier selection with decision-making methods from 2018 to 2022. Sustainability 16:125. doi: 10.3390/su16010125

Kellner, F. (2022). Generating greenhouse gas cutting incentives when allocating carbon dioxide emissions to shipments in road freight transportation. OR Spectrum 44, 833–874. doi: 10.1007/s00291-022-00675-y

Khalili Nasr, A., Tavana, M., Alavi, B., and Mina, H. (2021). A novel fuzzy multi-objective circular supplier selection and order allocation model for sustainable closed-loop supply chains. J. Cleaner Prod. 287:124994. doi: 10.1016/j.jclepro.2020.124994

Khan, S. A., Kusi-Sarpong, S., Arhin, F. K., and Kusi-Sarpong, H. (2018). Supplier sustainability performance evaluation and selection: a framework and methodology. J. Cleaner Prod. 205, 964–979. doi: 10.1016/j.jclepro.2018.09.144

Kraft, S. K., Quayson, M., and Kellner, F. (2024). Assessing the German act on corporate due diligence obligations in supply chains: a perspective from the smallholder cocoa farmer. Front. Sustain. 5:1376619. doi: 10.3389/frsus.2024.1376619

Kumar, D., and Rahman, Z. (2016). Buyer supplier relationship and supply chain sustainability: empirical study of Indian automobile industry. J. Cleaner Prod. 131, 836–848. doi: 10.1016/j.jclepro.2016.04.007

Kumar, D., Rahman, Z., and Chan, F. T. S. (2017). A fuzzy AHP and fuzzy multi-objective linear programming model for order allocation in a sustainable supply chain: a case study. Int. J. Comp. Integr. Manuf. 30, 535–551. doi: 10.1080/0951192X.2016.1145813

Kumpulainen, M., and Seppänen, M. (2022). Combining web of science and scopus datasets in citation-based literature study. Scientometrics 127, 5613–5631. doi: 10.1007/s11192-022-04475-7

Kuo, T.-C., Muniroh, M., and Fau, K. H. (2021). An integrated kano model, fuzzy analytical hierarchy process, and decision matrix for sustainable supplier selection in palm oil industries Indonesia, a case study. Processes 9:1078. doi: 10.3390/pr9061078

Kuruneri, J. (2025). Exploring the challenges of sustainable procurement implementation: insights from Botswana's public sector. Front. Sustain. 6:1645902. doi: 10.3389/frsus.2025.1645902

Le, A. T., Shakiba, M., and Ardekani, I. (2024). Tomato disease detection with lightweight recurrent and convolutional deep learning models for sustainable and smart agriculture. Front. Sustain. 5:1383182. doi: 10.3389/frsus.2024.1383182

Liao, Z., and Rittscher, J. (2007). A multi-objective supplier selection model under stochastic demand conditions. Int. J. Prod. Econ. 105, 150–159. doi: 10.1016/j.ijpe.2006.03.001

Linton, J. D., Klassen, R., and Jayaraman, V. (2007). Sustainable supply chains: an introduction. J. Oper. Manage. 25, 1075–1082. doi: 10.1016/j.jom.2007.01.012

Luthra, S., Govindan, K., Kannan, D., Mangla, S. K., and Garg, C. P. (2017). An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Cleaner Prod. 140, 1686–1698. doi: 10.1016/j.jclepro.2016.09.078

Lynn, M. R. (1986). Determination and quantification of content validity. Nurs. Res. 35:6. doi: 10.1097/00006199-198611000-00017

Mani, V., Gunasekaran, A., and Delgado, C. (2018). Enhancing supply chain performance through supplier social sustainability: an emerging economy perspective. Int. J. Prod. Econ. 195, 259–272. doi: 10.1016/j.ijpe.2017.10.025

Marra, M. (2025). Bridging the gaps in sustainability assessment: a systematic literature review, 2014-2023. J. Article Syst. Rev. 110:102557. doi: 10.1016/j.evalprogplan.2025.102557

Mubarik, M. S., Kazmi, S. H. A., and Zaman, S. I. (2021). Application of gray DEMATEL-ANP in green-strategic sourcing. Technol. Soc. 64:101524. doi: 10.1016/j.techsoc.2020.101524

MVO Nederland (2025a). CSR Risk Check. Available online at: https://www.mvorisicochecker.nl/en

MVO Nederland (2025b). CSR Risk Check. Risk Analysis. Available online at: https://www.mvorisicochecker.nl/en/check-your-risks/start-check/result?uuid=9f7a3e45-387b-485e-9c0e-ac6c2a3518f0

MVO Nederland (2025c). CSR Risk Check. Risk Analysis. Available online at: https://www.mvorisicochecker.nl/en/check-your-risks/start-check/result?uuid=9f7a3d62-69cc-4ebe-b790-c0418b25213e

Nogueira, E., Gomes, S., and Lopes, J. M. (2025). Unveiling triple bottom line's influence on business performance. Discov. Sustain. 6, 1–18. doi: 10.1007/s43621-025-00804-x

Nygaard, A. (2023). Is sustainable certification's ability to combat greenwashing trustworthy? Front. Sustain. 4:1188069. doi: 10.3389/frsus.2023.1188069

Oliveira, D. F., and Souza, R. G. (2023). Life cycle sustainability impact categories for sustainable procurement. J. Cleaner Prod. 383:135448. doi: 10.1016/j.jclepro.2022.135448

Ortiz, A., Carrillo, N., Elghannam, A., Escribano, M., and Gaspar, P. (2020). Views of farmers and industrial entrepreneurs on the Iberian pig quality standard: an in-depth interview research study. Animals 10:1772. doi: 10.3390/ani10101772

Pedersen, S., Benson, T., Tsalis, G., Futtrup, R., Dean, M., and Aschemann-Witzel, J. (2024). What consumers want in a sustainability food label: results from online co-creation workshops in the United Kingdom, Ireland and Denmark. Front. Sustain. 4:1342215. doi: 10.3389/frsus.2023.1342215

Pranckutė, R. (2021). Web of science (WOS) and scopus: the Titans of bibliographic information in today's academic world. Publications 9:12. doi: 10.3390/publications9010012

Putsche, V. L., Pattany, J., Ghosh, T., Atnoorkar, S., Zuboy, J., Carpenter, A., et al. (2023). A framework for integrating supply chain, environmental, and social justice factors during early stationary battery research. Front. Sustain. 4:1287423. doi: 10.3389/frsus.2023.1287423

Quayson, M., Bai, C., Mahmoudi, A., Hu, W., Chen, W., and Omoruyi, O. (2023). Designing a decision support tool for integrating esg into the natural resource extraction industry for sustainable development using the ordinal priority approach. Resources Policy 85:103988. doi: 10.1016/j.resourpol.2023.103988

Quintana-García, C., Benavides-Chicón, C. G., and Marchante-Lara, M. (2021). Does a green supply chain improve corporate reputation? Empirical evidence from European manufacturing sectors. Indust. Market. Manage. 92, 344–353. doi: 10.1016/j.indmarman.2019.12.011

Rajeev, A., Pati, R. K., Padhi, S. S., and Govindan, K. (2017). Evolution of sustainability in supply chain management: a literature review. J. Cleaner Prod. 162, 299–314. doi: 10.1016/j.jclepro.2017.05.026

Rashidi, K., Noorizadeh, A., Kannan, D., and Cullinane, K. (2020). Applying the triple bottom line in sustainable supplier selection: a meta-review of the state-of-the-art. J. Cleaner Prod. 269:122001. doi: 10.1016/j.jclepro.2020.122001

République Francaise (2017). Loi no 2017-399 du 27 mars 2017 relative au devoir de vigilance des sociétés mères et des entreprises donneuses d'ordre. Paris: République Francaise.