- 1College of Intelligent Construction, Wuchang University of Technology, Wuhan, China

- 2CITIC General Institute of Architectural Design and Research Co., Ltd., Wuhan, China

Introduction: At present, the gradual reduction of sand and gravel stock is very unfavorable to the preparation of recycled concrete.

Methods: Therefore, this study focused on alkali excited recycled concrete with different dosage of copper slag, and set different high temperature methods to test its mechanical properties.

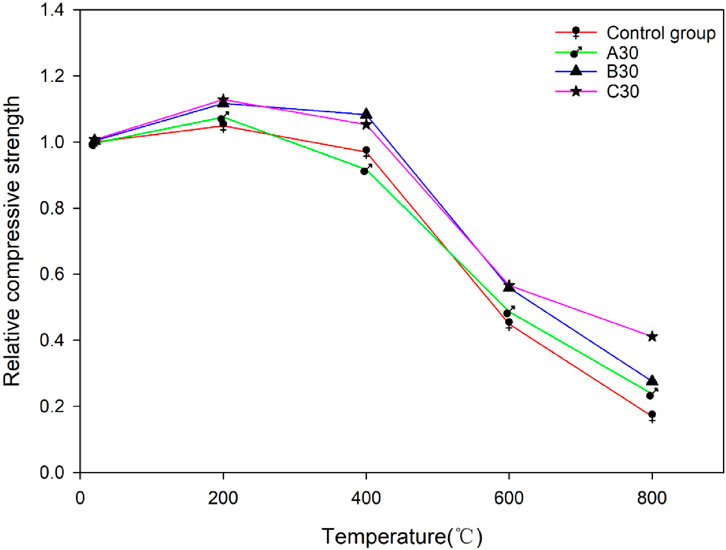

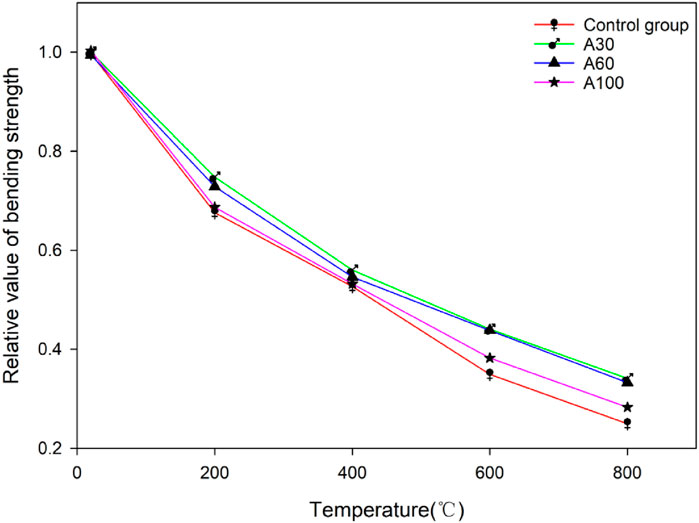

Results: The results showed that: 1) The residual compressive strength of the control group was not as good as that of the experimental group under other high temperature effects except for the experimental group under 400°C; 2) After high temperature action at 200°C, the ratios of A30, B30 and C30 relative to normal temperature are 1.07, 1.11 and 1.12 respectively, which are slightly higher than those after high temperature action at 400°C, indicating that the use of a certain amount of copper slag to replace fine aggregate quartz sand is helpful to improve the performance of alkali-stimulated recycled concrete at high temperature; 3) The flexural strength of A30 and A60 was 1.410 times and 1.371 times that of the control group after high temperature reaction at 800°C, indicating that the addition of copper slag had a positive impact on the flexural strength of alkali stimulated recycled concrete. 4) After treatment at 200°C, the bending strength ratios of control groups, A30, A60 and A100 were 0.676, 0.748, 0.728 and 0.687, respectively, while after treatment at 600°C, the corresponding ratios were 0.349, 0.440, 0.437 and 0.382, respectively, indicating that the addition of copper slag in high temperature environment, the bending strength ratio of control groups was 0.676, 0.748, 0.728 and 0.687, respectively.

Discussion: It can improve the flexural strength of alkali excited recycled concrete. Through this research, we can make due contributions to the sustainable development of the construction industry. The novelty lies in the qualitative and quantitative analysis of the mechanical properties of this recycled concrete doped with steel slag under high temperature conditions, and the results obtained are better than the high temperature resistance of conventional recycled concrete, which has a new breakthrough in performance.

1 Introduction

In today’s architectural field, the concept of sustainable development makes recycled concrete become one of the research hotspots (Song et al., 2025; Ren and Yu, 2025; Shi, 2025; Yan et al., 2025). On this direction, domestic scholars have made a lot of research, specifically as follows: Scholars, in order to explore the water absorption and chloride ion penetration resistance characteristics of reclaimed sand concrete, The effects of water-binder ratio (0.37, 0.45, 0.58), recycled sand content (0, 30%, 50%, 70%, 100%), fine powder content (3%, 7%, 10%), mineral admixture variety and content, pre-humidification degree of reclaimed sand (0, 50%, 100%) and other factors on the volume water absorption and softening coefficient of reclaimed sand concrete were studied The influence of different factors on water absorption and chloride penetration resistance of reclaimed sand concrete is compared. The results show that with the increase of recycled sand content and fine powder content, the water absorption performance of concrete is enhanced, the water resistance and the chloride ion penetration resistance are decreased. However, the water absorption and chloride ion penetration resistance of reclaimed sand concrete can be improved to varying degrees by adding multiple composite mineral admixtures (15% fly ash +15% mineral powder +8% silica fume), reducing the water-binder ratio and increasing the prehumidification degree of reclaimed sand (Yi et al., 2024). Scholars conducted a study on the influence of the mixing ratio of solid waste recycled concrete in high-content buildings on the strength. The results showed that compared with HQD-22.5 test group, HLX test group had no obvious advantage in terms of splitting tensile strength, because the strength of coarse aggregate itself had a greater impact on the splitting tensile strength. In addition, the strength of hardened cement mortar has a greater influence. Coarse aggregate grade has little influence on it. In the design of mix ratio, part of natural coarse aggregate can be discarded and replaced by equal volume and smaller particle size brick containing recycled coarse aggregate (Zhang and Zhou, 2024). In the same year, in order to make full use of the waste concrete removed from structures along the Yellow River, scholars broke it into recycled aggregates and re-used it in the river slope protection project, which is a low-carbon development approach. The research results showed that the reclaimed aggregate concrete HDX70 had the best comprehensive performance and utilization rate, and could be used to prepare reclaimed concrete slope protection blocks for slope protection projects (Ma et al., 2024). In order to study the influence of prepreg carbonization treatment of recycled aggregate and the number of carbonization cycles on the dynamic mechanical properties of recycled concrete, scholars prepared recycled concrete specimens by 100% replacing natural aggregate with strengthened recycled aggregate, and carried out static and dynamic compression tests respectively. The results show that under static loading, the compressive strength of the prepreg carbonization group increases with the increase of the number of carbonization cycles, while the compressive strength of the direct carbonization group only increases after the first carbonization cycle. Under dynamic loading, the prepreg carbonized recycled concrete showed obvious strain rate strengthening effect, and the dynamic compressive strength and dynamic increase factor both increased with the increase of strain rate. The dynamic compressive strength of the reclaimed concrete specimen prepared after three prepreg carbonization cycles of recycled aggregate increased by 23.8%, while that of the direct carbonization group only increased by 5.7%, and the dynamic increase factor had a good linear relationship with the logarithm of the strain rate, which increased linearly with the strain rate lg10. When the strain rate is the same, the dynamic compressive strength increases with the increase of the number of carbonization cycles (Liu et al., 2024). In order to study the flexural performance of recycled concrete beams strengthened by CFRP, the authors selected nine recycled concrete beams with different regenerated aggregate substitution rates and designed them. The initial damage of the test beam was caused by preloading the bending load. After unloading, the bottom of the damaged beam was reinforced with carbon fiber cloth of different widths, and then the bending capacity test was carried out on the test beam. The results show that the ultimate bearing capacity and deflection of recycled concrete beams reinforced by CFRP do not change significantly, and the calculated flexural bearing capacity is consistent with the experimental value (Yan et al., 2024). From the above research, it can be seen that, recycled concrete uses waste concrete as recycled aggregate, which effectively solves the problem of construction waste disposal and saves natural aggregate resources. However, similar to ordinary concrete, recycled concrete may face high temperature conditions such as fire in practical applications, and its mechanical properties at high temperature are directly related to the safety and stability of the structure (Wang F. J. et al., 2024; Liu and Lei, 2024; Yan et al., 2023). Alkali excitation, as an effective means to improve the performance of recycled concrete, produces gelling products through the chemical reaction between alkali activator and the active ingredients in recycled concrete, and then improves its strength and other properties (Wan et al., 2024a; Wan et al., 2024b; Li, 2024; Wang B. et al., 2024; Wan et al., 2023). However, the conventional alkali-stimulated recycled concrete is not good at high temperature. In order to enhance the high temperature resistance of alkali excited recycled concrete, it is necessary to make some changes in the material, so as to strengthen the high temperature resistance of alkali-stimulated recycled concrete (Wang F. J. et al., 2024; Yang, 2024). Among them, the proportion of aggregate in concrete is the largest. The use of industrial waste instead of natural or artificial aggregate as aggregate is an important issue for building energy saving and emission reduction and promoting green development. According to statistics, in recent years, due to large-scale construction and infrastructure construction, the global amount of sand and gravel extraction is much higher than that of fossil fuels (Yang and Zeng, 2020). With the increase in demand, the mining rate of sand and stone has increased exponentially, far exceeding the rate of its natural regeneration. This means that there will be a shortage of sand and stone. Sand and stone is one of the indispensable aggregate materials in concrete, and it is also the raw material with the most content in concrete. However, the large amount of sand and stone resources used in the construction industry has attracted wide attention. Therefore, this study will analyze the mechanical properties of different parameters of copper slag alkali stimulated recycled concrete under high temperature environment, aiming to improve the temperature resistance of alkali stimulated recycled concrete through this study, reduce the mining of sand and gravel, improve the secondary utilization rate of construction waste.

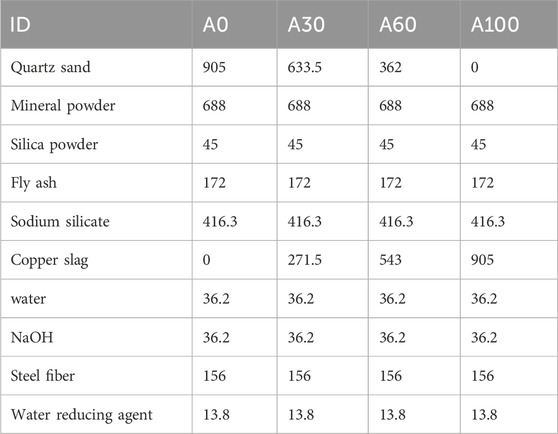

2 Design of raw materials and mix ratio of alkali excited recycled concrete

In this study, the required raw materials are: S95 mineral powder, silica ash, fly ash, fine quartz sand, copper slag, alkali activator, liquid polycarboxylic acid superplasticizer. After consulting relevant literature, based on a large number of trial adaptation experiments, a benchmark ratio suitable for test design was formulated (Jiang et al., 2024; Yin et al., 2014). In the design reference ratio, the water-binder ratio is 0.32, the cemb-sand ratio is 1.0, and the alkali content (Na2O) is 7%. The test mix ratio of alkali excited recycled concrete can be divided into three categories: A, B and C. The first is alkali excited recycled concrete with different content of fine copper slag; The second is the recycled concrete excited by ultrafine copper slag alkali with different dosage. The third is the recycled concrete excited by different dosage of copper slag powder and alkali. See Table 1 for specific mix ratio.

It should be noted that the parameter values in Class B mix ratio and Class C mix ratio are the same as those in Class A mix ratio in the above table. The Class B mix contains B30, B60 and B100, which are mixed with 30%, 60% and 100% ultrafine copper slag respectively. The Class C mix includes C30, C60 and C100, which are blended with 30%, 60% and 100% copper slag powder, respectively.

3 Performance test

The performance test of alkali excited recycled concrete is divided into compressive test and bending test. The test tool is WAW-1000 type electro-hydraulic testing machine with a loading rate of 1.8 kN/s.In order to ensure the feasibility of the test, the compressive test needs to go through three times in total, and the average value of these three tests is calculated as the compressive strength value of this test, as shown in Formula 1.

Among them, the compressive strength value is represented by

Among them, the flexural strength value is represented by

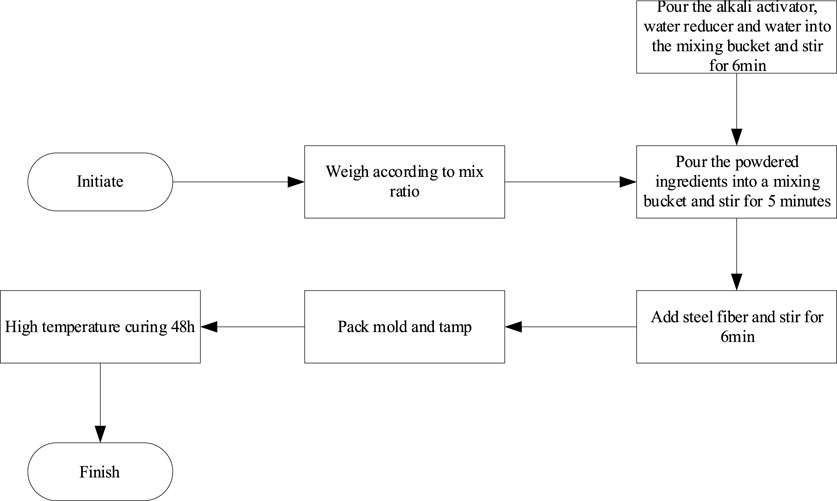

3.1 Instruments and test procedures

The experiment adopts Masterizer-2000 laser particle size meter with laboratory temperature of 10–35°C and relative humidity of 10%–90%. The quartz sand and granular silica manganese slag were put into the oven at 60°C to dry to constant weight, after cooling to room temperature, take a sample, and the particle size of the silica manganese slag was measured for three times continuously. When the average value of the measurement was not less than 75%, the measurement was qualified. The production process of alkali stimulated recycled concrete specimen is as follows: (1) Weigh raw materials according to the test mix ratio; (2) Pour powdered raw materials such as mineral powder, silica ash, fly ash, quartz sand and copper slag into the mixing bucket slowly and stir for 5 min (3) Mix the water, water reducer and pre-configured alkali activator and stir well, then slowly pour into the mixing bucket, stirring for 6 min (4) Finally, slowly add steel fiber and mix for 6 min (5) Quickly pour into the cube test block mold prepared in advance, and simply insert and pound it to make it compact. Because the water-binder ratio in this test has been optimized and efficient polycarboxylic acid water reducer has been added, the concrete prepared by the test has excellent fluidity and self-compacting, so it does not need to vibrate on the shaking table. The concrete test block should be placed flat under standard conditions, and the mold will be removed after 2 days. After that, the test block will be placed in the HJ-84 concrete accelerated curing box at 90°C and taken out after curing for 48 h. Sample preparation is carried out according to the mix ratio, and the preparation process is as follows.

3.2 Compressive strength

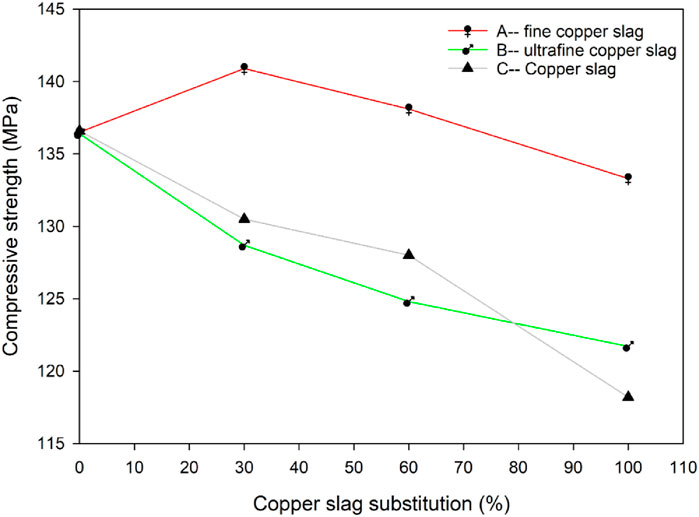

For the smooth conduct and comparison of subsequent tests, the compressive strength and flexure strength of recycled concrete excited by different parametric bases at normal temperature were tested here to understand the trend relationship and lay the foundation for subsequent data analysis. Among them, under normal temperature conditions, the compressive resistance of recycled concrete excited with different alkali content is shown in Figure 1.

It can be seen from Figure 2 that under normal temperature conditions, with the increase of copper slag content, the compressive effect increases first and then decreases. When the replacement rate of fine copper slag is 30%, its strength is increased by 4.4 MPa compared with that without copper slag. When the content is 60%, the strength is basically the same as that without copper slag, but when 100% fine copper slag is used, the compressive effect is reduced to 3.2 MPa. Therefore, the copper slag content is not the higher the better, the need for reasonable control, the current test results show that 30% of the content is the most ideal. Based on the test results, 30% of fine copper slag will be selected as the experimental group to prepare alkali-stimulated recycled concrete, which will lay the foundation for subsequent research.

3.3 Folding strength

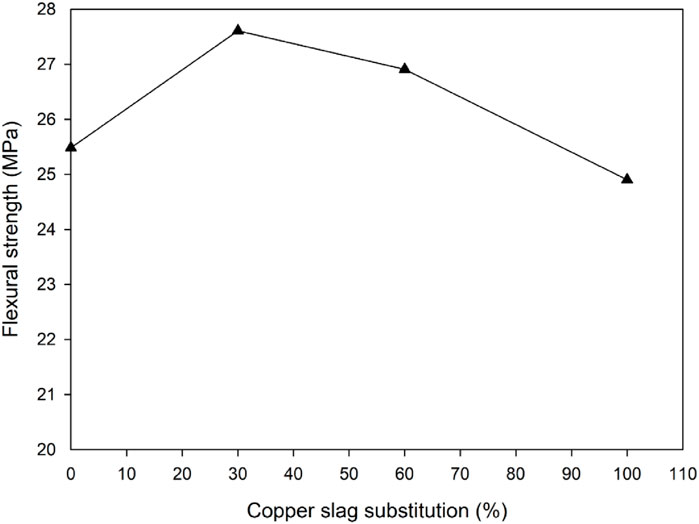

Under normal temperature conditions, the bending resistance trend of recycled concrete stimulated by different alkali content is shown in Figure 3.

From the bending results, the same as the above compressive results, both showed the situation of first reduction and then reduction. Among them, the bending resistance of the experimental group was slightly better than that of the control group (without adding copper slag) at 60%. At 30%, the maximum value was 27.6 MPa, which was 7.69% higher than 25.48 MPa in the control group. When the parameter is 100%, compared with 60% experimental group, the bending effect is reduced by 2.3%, although the bending effect is decreased, but the overall reduction effect is not obvious. Therefore, it is concluded that it is feasible to use copper slag to replace quartz sand completely as the fine aggregate of alkali stimulated regenerative energy concrete.

4 Data analysis and results

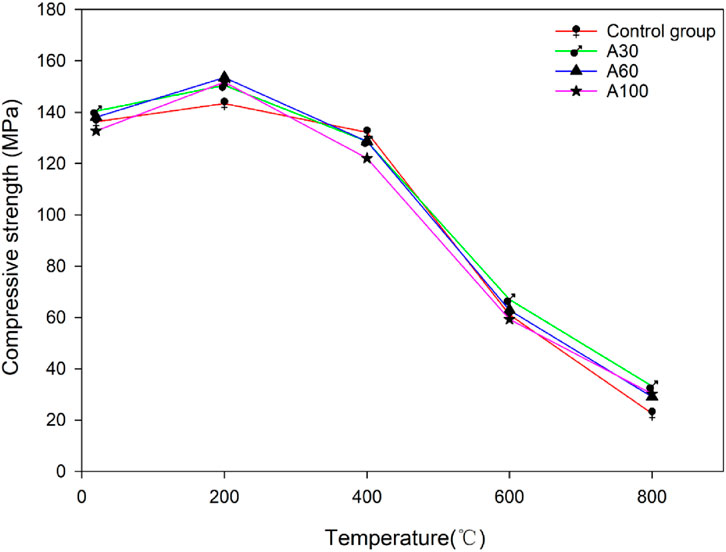

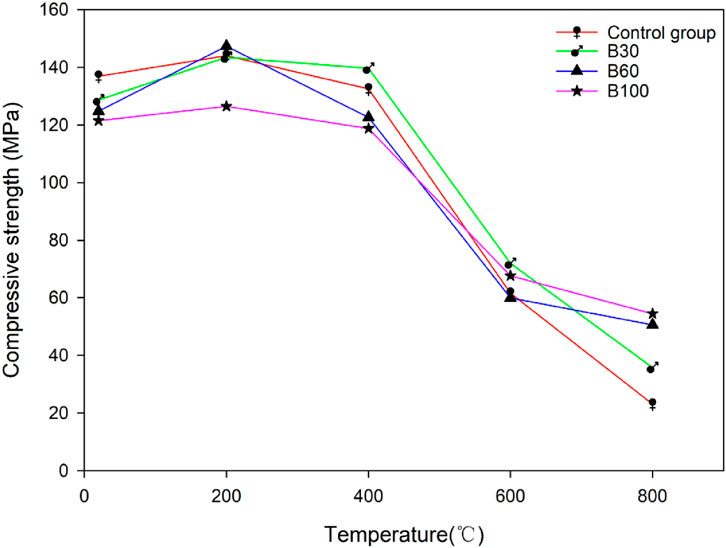

4.1 Compressive effect of recycled concrete stimulated by different amounts of alkali at high temperature

Based on the foundation mentioned above, a quantitative analysis of its pressure resistance is carried out here, and the results are shown in Figures 4–6.

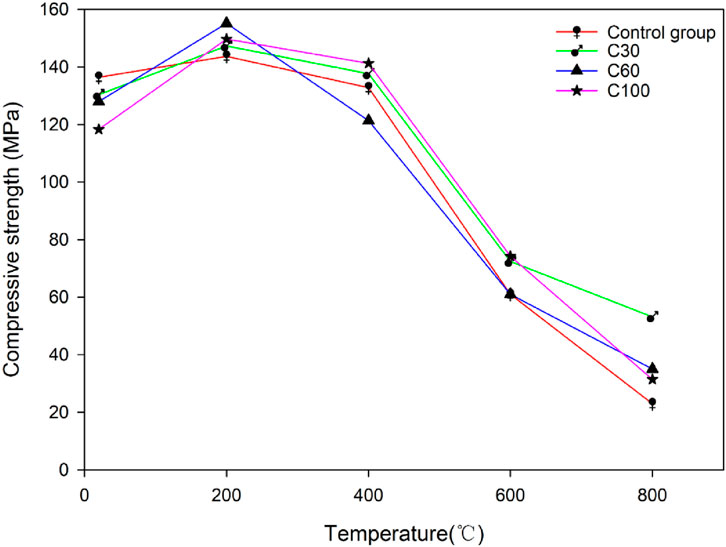

Figure 4. Compressive strength of recycled concrete doped with fine copper slag alkali excited at high temperature.

Figure 5. Compressive strength of recycled concrete doped with ultrafine copper slag alkali excited at high temperature.

Figure 6. Compressive strength of recycled concrete doped with copper slag alkali excited at high temperature.

Among them, compared with the compressive strength at room temperature, the compressive strength of recycled concrete excited by different parameter bases is significantly improved at 200°C. At 400°C, although the compressive strength of recycled concrete excited by the same parametric alkali decreases slightly, it is still close to the compressive strength at room temperature. As the temperature continues to rise, the compressive strength of the specimen decreases obviously when it reaches 600°C and 800°C. It can be seen that the residual compressive strength of the experimental group with low copper slag content is greater than that of the control group without copper slag under the action of other high temperatures except the experimental group with 400°C. The conclusion from this is that, It is not difficult to find that although the size of copper slag is different, its compressive effect is consistent with the change of dosage and temperature.

4.2 Relative compressive strength values of recycled concrete excited by different parametric bases

In order to more clearly show the compressive strength of alkali-stimulated recycled concrete with different parameters, the ratio of the compressive strength of alkali-stimulated recycled concrete A30, B30 and C30 groups at high temperature to the compressive strength at normal temperature is given, that is, the relative value results, as shown in Figure 7.

It is not difficult to find that after the high temperature action of 200°C, the ratio of A30, B30 and C30 relative to normal temperature is 1.07, 1.11 and 1.12, respectively, which is slightly higher than that after the high temperature action of 400°C. It can be seen from the above values that the ratio of C30 of copper slag powder is higher than that of A30 of fine copper slag and B30 of superfine copper slag. Therefore, C30 shows the best compressive strength ratio after high temperature action of 200°C. However, after the high temperature action of 600°C, the relative compressive strength of alkali stimulated recycled concrete decreases by 50%. At 800°C, the compressive strength of A30, B30 and C30 was higher than that of the control group. Therefore, it can be concluded that the use of a certain amount of copper slag instead of fine aggregate quartz sand can help improve the performance of alkali excited recycled concrete at high temperatures.

4.3 Absolute bending strength of alkali excited recycled concrete

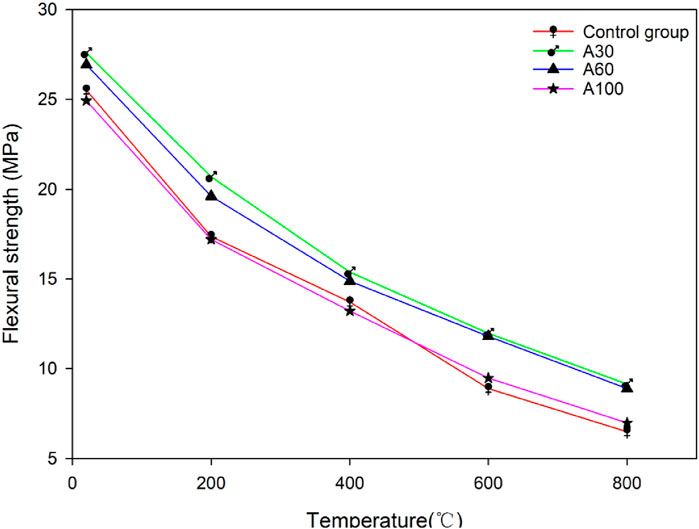

The bending strength changes of alkali excited recycled concrete at high temperature are shown in Figure 8. As the temperature increases, the flexural strength of alkali activated recycled concrete shows a continuous decreasing trend. After high temperature treatment at 200°C, 400°C, 600°C and 800°C, the bending strength of control groups (without copper slag) decreased by 31%, 47%, 62% and 72%, respectively. Compared with the test results of compressive strength mentioned above, the bending strength decreases more obviously after high temperature action. This is because the flexural strength has a stronger dependence on the cracking properties of concrete than the compressive strength. After the action of high temperature, the water inside the concrete is lost seriously, and the decomposition of hydration products is intensified. After the action at 200°C, the bending strength of concrete decreases mainly because the hydration products start to partially dehydrate, the free water content in concrete increases, the free water evaporates, the matrix pores increase, and the microstructure is further damaged. As the heating temperature rises to 400–600°C, the free water and bound water inside the concrete are completely evaporated, and the hydration products begin to decompose. Small cracks caused by the expansion caused by the evaporation of bound water will make a small gap between the aggregate and the slurry, as a result, its flexural performance decreases. After experiencing the effect of extreme high temperature environment greater than 600°C, the hydration products are completely decomposed, the volume is severely shrunk by water evaporation, and the difference in thermal expansion performance between the aggregate and the slurry will also cause irregular deformation. The influence of both leads to serious deterioration of the internal structure of concrete.

Figure 8. Folding strength of recycled concrete under high temperature excitation by doped fine copper slag alkali.

As can be seen from Figure 8, adding copper slag as fine aggregate to replace quartz sand in alkali stimulated recycled concrete can significantly improve its residual bending strength after high temperature. Compared with the control group, the flexural properties of A30 and A60 were 1.410 times and 1.371 times higher at 800°C. It is concluded that the addition of copper slag can improve the bending resistance of alkali excited recycled concrete, and this effect is more and more prominent with the increase of temperature.

4.4 Relative bending strength of alkali stimulated recycled concrete

In order to further analyze the folding strength of alkali excited recycled concrete, the ratio of the absolute Compression resistance of the control group, groups A30, A60 and A100 at high temperature to the normal temperature compressive strength was tested, that is, the relative value analysis, and the results were obtained (Figure 9).

The results showed that the bending strength ratios of control groups, A30, A60 and A100 were 0.676, 0.748, 0.728 and 0.687 at 200°C, and 0.349, 0.440, 0.437 and 0.382 at 600°C, respectively. The experimental data show that adding copper slag to concrete as fine aggregate can significantly improve the bending strength after high temperature, especially in high temperature environment. In addition, at high temperatures, the type of aggregate in the concrete may significantly affect its flexural strength. According to the experimental results, compared with the conventional alkali-excited recycled concrete, the alkali-excited recycled concrete designed in this paper has considerable high temperature resistance.

5 Conclusion

In summary, this article conducted compressive strength tests and bending tests on alkali activated recycled concrete with different parameters at high temperatures, and studied and analyzed its mechanical properties after high temperatures. After the temperature increases, the compressive and flexural properties of alkali stimulated recycled concrete show the same trend of first increasing and then decreasing, reaching a peak at 200°C. After treatment at 800°C, the compressive and flexural properties of the control group were lower than those of the experimental group. In addition, the relative compressive strength and bending strength of copper-doped slag were higher than those of non-copper-doped slag at 800°C. For A30 test group, after experiencing 600°C and 800°C, the residual compressive strength and flexion strength show the best mechanical properties, which confirms the view that the alkali stimulated recycled concrete prepared by copper slag with different parameters has better high temperature resistance than the traditional alkali stimulated recycled concrete, and can reduce the mining of sand and gravel, which is conducive to environmental protection. It also further strengthens the road of green development of the construction industry. Although the research has made some achievements, there are still some limitations in theoretical writing and expression of results, and these deficiencies will be deepened in the future. In the future, based on this study, we will analyze the compressive form, residual strength retention rate, high temperature strengthening coefficient and microstructure of the sample, so as to improve the depth and progress of the research and promote the application of copper slag in alkali excited recycled concrete.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

QS: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing–original draft, Writing–review and editing. ZT: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This study was supported by Natural Science Foundation project of Hubei Province (No. 2022CFB459).

Conflict of interest

Author ZT was employed by CITIC General Institute of Architectural Design and Research Co., Ltd.

The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Jiang, L. L., Wan, X. M., and Che, X. P. (2024). Review on design method of mix ratio of alkali excited concrete. Concrete (01), 139–143.

Li, B. H. (2024). Study on optimization of mix ratio of alkali excited slag cement regeneration. Sci. Technol. Inf. 22 (08), 174–176. doi:10.16661/j.cnki.1672-3791.2312-5042-1961

Liu, C., Hao, H. Y., Liu, L. X., and Zhu, C. (2024). Test study on dynamic mechanical properties of pre-impregnated carbonized recycled aggregate concrete. J. Vib. Shock 43 (19), 117–125 + 193. doi:10.13465/j.cnki.jvs.2024.19.014

Liu, S. B., and Lei, S. J. (2024). Research progress on mechanical properties of fiber reinforced recycled concrete after high temperature. Compos. Sci. Eng. (11), 133–142. doi:10.19936/j.cnki.2096-8000.20241128.019

Ma, C. Y., Meng, B. J., Wang, X. L., Li, M. D., Wang, G. Y., and Chang, H. L. (2024). Application performance of high-content recycled aggregate concrete for structures along the Yellow River. Concrete (11), 176–179+186.

Ren, C. Q., and Yu, J. (2025). Study on Mechanical Properties and Wear Resistance of pervious reclaimed concrete modified by wollaston-Mineral powder. Cem. Eng. (01), 91–96. doi:10.13697/j.cnki.32-1449/tu.2025.01.022

Shi, F. B. (2025). Application of recycled concrete aggregate in construction engineering. Geshe (05), 74–76.

Song, C. Z., Li, J. Q., and Kong, J. X. (2025). Review on performance of cement stable base containing recycled aggregate concrete. Chin. Foreign Highw. 45 (01), 88–99. doi:10.14048/j.issn.1671-2579.2025.01.011

Wan, F. X., Hou, J., and Tao, Z. H. (2024b). Study on stress-strain relationship of alkali slag recycled concrete under uniaxial compression. Chin. J. Water Resour. Archit. Eng. 22 (02), 114–121.

Wan, F. X., Jiang, G. L., and Wu, F. (2024a). Study on size effect of compressive strength of recycled concrete based on alkali excited slag and fly ash. J. Water Resour. Archit. Eng. 22 (03), 182–188+220.

Wan, X. M., Che, X. P., and Zhu, Y. G. (2023). Study on the effect of recycled concrete fine powder on alkali excited rubber system. Mater. Rev. 37 (19), 114–120.

Wang, B., Ding, H. Z., and Jin, J. J. (2024b). Study on mechanical properties of recycled coarse aggregate for alkali excited pervious concrete. Jiangxi Build. Mater. (S1), 102–105.

Wang, F. J., Wang, X. J., Zhu, P. H., and Liu, X. L. (2024a). Influences of coarse aggregate replacement ratios on high-temperature performance of recycled concrete with manufactured sand. Bull. Chin. Ceram. Soc. 43 (6), 2084–2092. doi:10.16552/j.cnki.issn1001-1625.20240228.003

Yan, J., Xing, G. B., and Feng, L. H. (2025). Ramie fiber strength of recycled concrete mechanics. Influ. Silic. Bull. 44 (02), 455–462. doi:10.16552/j.cnki.issn1001-1625.2024.1060

Yan, L. L., Wang, C. S., Liang, J. F., and Wangliu, H. X. (2023). Study on stress-strain curve of recycled concrete after high temperature. Concrete (08), 29–31+37.

Yan, Y. D., Wu, K. K., Lu, C. H., Liang, X. F., and Ji, G. Q. (2024). Damage of carbon fiber reinforced recycled concrete beams flexural performance study. J. Archit. Civ. Eng. 41 (5), 113–122. doi:10.19815/j.jace.2022.09023

Yang, J. C. (2024). Study on mechanical properties of alkali excited slag cement recycled aggregate. Sci. Technol. Inf. 22 (07), 138–140. doi:10.16661/j.cnki.1672-3791.2312-5042-7088

Yang, Z. X., and Zeng, L. Y. (2020). Research on the current situation of mining management of national sandy and stony soil mines. Natl. Resour. Econ. China 33 (05), 44–50. doi:10.19676/j.cnki.1672-6995.000390

Yi, H., Li, B. X., Yin, S., and Chen, P. B. (2024). Study on influencing factors of water absorption and chloride penetration resistance of reclaimed sand concrete. Concrete (11), 61–66+73.

Yin, Y. X., Wang, Y. H., Xu, L., and Yuan, X. H. (2014). Mix design analysis of alkali-activated slag concrete. World Build. Mater. 35 (05), 23–26.

Keywords: high temperature, alkali excited recycled concrete, mechanical property, diagnosis, structural durability

Citation: Su Q and Tao Z (2025) Study on the evolution mechanism of mechanical properties of recycled concrete excited by different alkali content at high temperature. Front. Mech. Eng. 11:1573936. doi: 10.3389/fmech.2025.1573936

Received: 10 February 2025; Accepted: 18 March 2025;

Published: 16 April 2025.

Edited by:

Vinod Ayyappan, King Mongkut’s University of Technology North Bangkok, ThailandReviewed by:

Oumaima Bili, UH2C, MoroccoSuthisa Onthong, Rajamangala University of Technology Thanyaburi, Thailand

Copyright © 2025 Su and Tao. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Qing Su, cXM4ODQyMkAxNjMuY29t

Qing Su

Qing Su Zhixiong Tao2

Zhixiong Tao2