- 1Neol Copper Technologies Ltd., London, United Kingdom

- 2Ingram Tribology Ltd., Johnstown, United Kingdom

Premature bearing failures in large electric machines such as wind turbines and locomotives are often caused by White Etching Cracks (WEC), White Etching Areas (WEA), and White Structure Flaking (WSF)—phenomena that, despite extensive study, remain not fully understood. This work introduces a new hypothesis of WEC, WEA and WSF formation combining Garkunov’s scientific discoveries of “hydrogen wear of metals” and the “wearlessness effect” with the existing knowledge and offers a possible solution. To test this hypothesis and solution, a prototype lubricant containing oil-soluble copper salts was evaluated using an electrically induced WEC test on a three ring-on-roller tribometer. The test applied high contact pressures and direct current to simulate operating conditions, followed by subsurface serial sectioning to examine material degradation. The results showed that the reference lubricant exhibited typical WEC and WEA damage, while the copper-based candidate lubricant prevented such failures entirely. This outcome supports the idea that hydrogen activity plays a central role in damage formation, and that targeted additives can prevent it by reducing surface temperatures and forming protective film, which blocks hydrogen diffusion. These findings offer a scientifically grounded and practically viable solution to extend bearing life and prevent costly failures in high-load, high-reliability applications.

1 Introduction

Premature bearing failure in large electric machines—such as wind turbine gearboxes and traction locomotives—often manifests as unexpected, accelerated wear or damage of rolling elements and raceways, leading to reduced service life and unplanned downtime. Wear of the roller and raceway after a period of use is the most common cause of rolling element bearing failure (Patil et al., 2022). The result is not only costly maintenance, component replacement and power production shutdown, but also significant reliability and safety risks within critical power-generation and transportation applications. Despite extensive research and considerable advancements in bearing technology, engineers still grapple with this issue. Statistics show that almost 50% of all bearing damage comes from inadequate lubrication (Desnica et al., 2023). At the same time, numerous studies (reviewed in (Evans, 2016)) indicate that the primary cause of early failures of bearings, particularly in wind turbine gearboxes, is the destruction of bearing assembly components due to White Structure Flaking (WSF), which results from axial cracking and the formation of White Etching Cracks (WEC). These cracks are accompanied by corresponding microstructural changes in the form of White Etching Areas (WEA) (Evans, 2012). WEA formation is also widely observed in marine propulsion systems, automotive alternators, railway tracks, heavy machinery, hydrogen fuel cell system bearings, air conditioner compressors, etc. (Evans, 2016) According to the recent Position Paper by the German Society for Tribology on White Etching Cracks, damage to rolling bearings associated with WECs may occur with all types and sizes of rolling bearings and in widely varying applications (Hosenfeldt et al., 2024). This multifaceted phenomenon is believed to result from a combination of mechanical, tribochemical, and electrical effects.

Although the WSF, WEC, and WEA phenomena and their manifestations are well-described by multiple groups of researchers in various fields of science and technology, the driving forces and mechanisms of their formation remain highly debated and not fully understood (Hosenfeldt et al., 2024; Stadler et al., 2018).

There are two fundamental groups of hypotheses that have been described in the literature to date. The first one relates WEC formation to purely mechanical effects, including stress and stress resistance, identifying it as a form of surface fatigue.

The Hertz theory, a stress-based hypothesis, proposes that cracks originate below the surface, coinciding with the region of maximum stress—an area also identified as potentially having a high concentration of hydrogen. Observed in a temporal sequence, cracks form first then white etching areas appear afterwards. Another “mechanical” hypothesis proposes that, exposed to rolling stress, WEC form due to pure fatigue and at inclusions and precipitations below the surface. A series of influencing factors (including material and lubricant composition, current passage, water contamination, hydrogen, vibration and friction) positively or negatively affects stress resistance. The obvious shortfall of both is that they do not really explain the discoloration of steel present in WEC and WEA.

The second fundamental group of hypotheses relates WEC, WEA and WSF to hydrogen activity. Conducting a desorption analysis Richardson et al. measured the concentration of permeable hydrogen in 100Cr6 bearing steel (Richardson et al., 2018a). Measurements found a significant correlation between WECs and hydrogen permeation. Ruellan et al. suggested that hydrogen permeated into the material through newly forming surfaces caused by wear or by means of a non-closed tribolayer (Ruellan et al., 2015). Two common hypotheses (HEDE (Hydrogen Enhanced Decohesion) and HELP (Hydrogen Enhanced Local Plasticity)) summarised these observations by postulating that hydrogen concentrates in the location of maximum stress. This phenomenon locally reduces the stress resistance of the microstructure and ultimately leads to WEC formation. These hypotheses were supported by experimental studies, where rolling bearings initially loaded with hydrogen ions failed prematurely due to WEC formation (Ruellan et al., 2014). A key challenge in this context is detecting elevated hydrogen concentrations in the material, especially when there is a significant delay between WEC formation and subsequent analysis—by which time the original hydrogen contamination may no longer be traceable.

An open question remains: which specific mechanisms must be activated within the material to initiate WEC damage? As concluded by the German Society for Tribology, the wide range of influencing factors suggests that the formation and propagation of WECs represent a systemic response rather than a singular damage event with a clearly identifiable root cause (Hosenfeldt et al., 2024). It appears that a crucial piece of information has been missing, preventing researchers from developing a unified, viable hypothesis for the mechanisms behind WEC, WEA, and WSF formation—and, consequently, from finding a definitive solution to the problem.

Something that has not been considered in the ongoing investigations to date is a rich vein of research done by Professor Dmitry N. Garkunov and his followers on the phenomena of “the hydrogen wear of metals” (scientific discovery NO. 378, USSR, 1967) and “the wearlessness effect” (scientific discovery NO. 41, USSR, 1964). Professor Dmitry N. Garkunov found that hydrogen was the primary cause of metal surface deterioration in the process of friction. This is how Garkunov described his discovery: “Hydrogen wear (hydrogen-induced wear) is wear caused by the release of hydrogen in the friction zone. It is a process of metal degradation at the site of frictional contact, where the determining factors are the mechanisms of hydrogen embrittlement in the microscale layers of frictional interaction, due either to hydrogen adsorption on the contact surfaces or to hydrogen diffusion from the bulk of the metal into the friction zone” (Garkunov, 2024). Further extensive research provided strong evidence that the described electrochemical activity of hydrogen was an underlying factor in most of the known types of wear (Garkunov, 2024; Shpenkov, 1995).

2 Materials and methods

2.1 Scientific information analysis and new hypothesis formation

The authors of this article conducted a thorough study of the above scientific knowledge and developed a comprehensive hypothesis on the possible mechanism of WSF, WEC and WEA formation that has been rigorously tested and confirmed to explain these phenomena. In order to understand the mechanism of WSF, WEC and WEA it is necessary to observe the micro-molecular processes taking place in the friction zone of bearings.

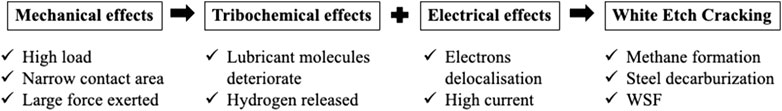

Before beginning, it is critical to define, what each of the above-mentioned mechanical, tribochemical, and electrical effects mean in the context of bearing assemblies. Mechanical effects leading to WSF and WEC formation are associated with the demanding operating conditions of machinery such as variable loads (due to wind gusts in case of wind turbines), load reversals, braking, high impact loads, vibrations, and sliding. Tribochemical effects are linked to hydrogen release and diffusion into the bearing steel (from moisture, lubricating oil, and lubricant additives). Finally, electrical effects are related to high electromagnetic fields and the resulting electrical currents. These may seem vastly different from each other, but in reality, they are all a part of one cycle. This is how it looks through the prism of knowledge about the hydrogen wear. The below process constitutes the new hypothesis of WSF, WEC and WEA formation.

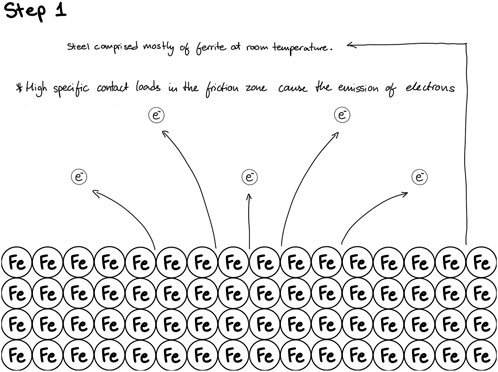

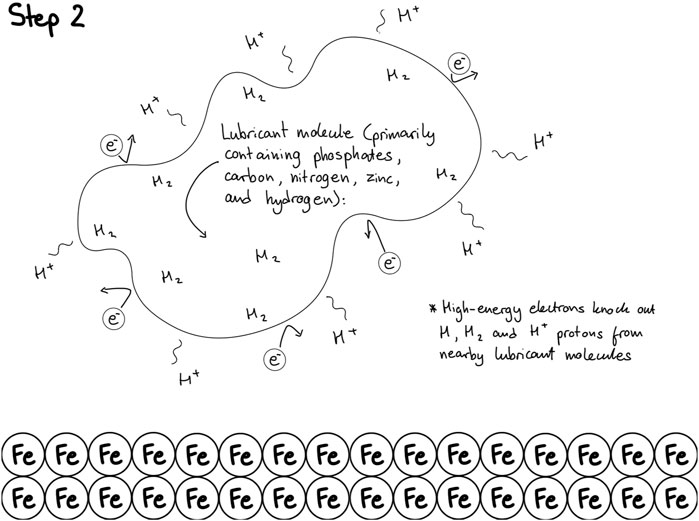

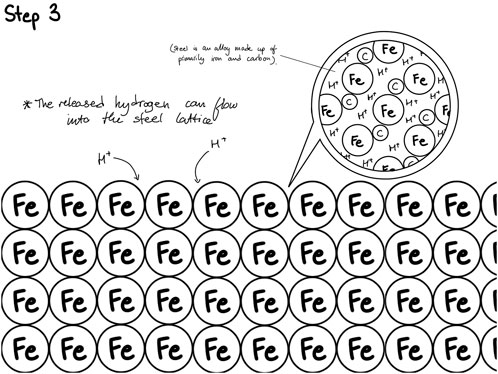

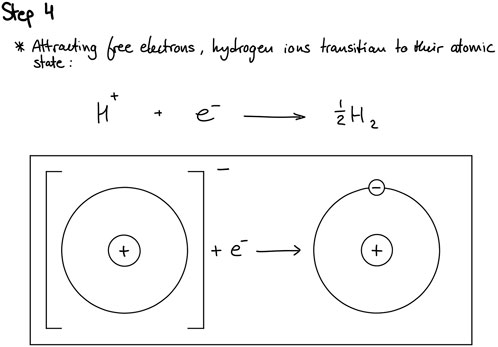

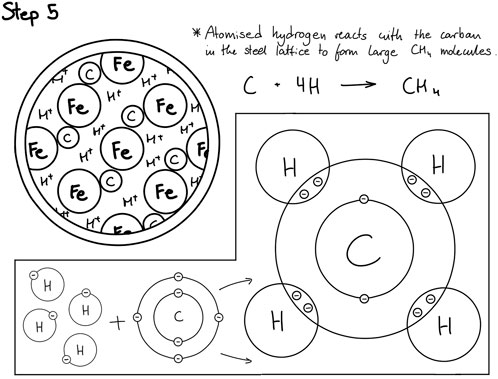

During normal operation of a rolling bearing, sliding steel surfaces experience high contact forces. This intense asperity contact leads to a significant increase in heat, and if the iron polymorphism temperature is reached, exo-emission of electrons occurs from the metal surface in the friction zone. These delocalised electrons contribute to the deterioration of nearby lubricant and water molecules, releasing free hydrogen. This hydrogen initially appears as a single proton (H+); the e- gained being one of the electrons delocalised from the steel surface due to iron polymorphism. Under the influence of strong directed electromagnetic fields, hydrogen H+ is transported into the depths of the bearing raceway or roller metal. Additionally, current accelerates the hydrogen, allowing it to penetrate deeper below the metal surface.

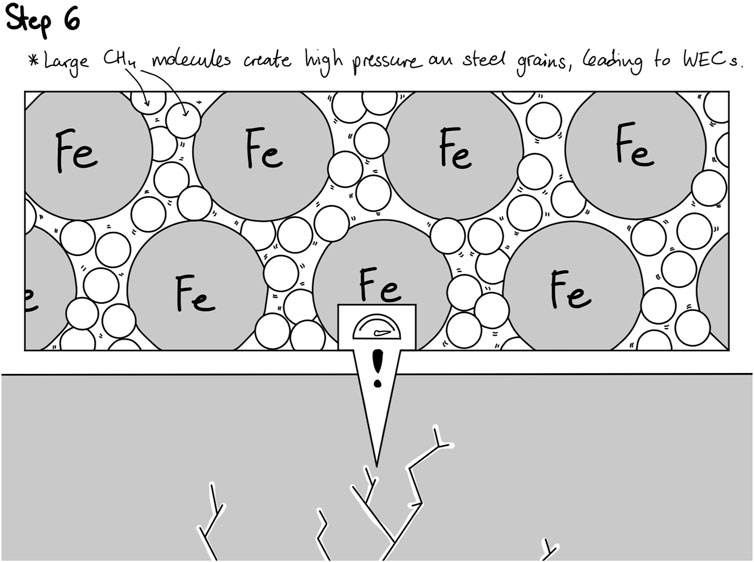

Inside the metal, hydrogen transitions into an atomic state in the intergranular space, where it reacts with free carbon, forming methane (CH4) molecules. The formation of methane induces high specific stresses between steel grains, causing multiple WEC cracks (Evans, 2016; Stadler et al., 2018; Evans, 2013; Evans et al., 2013a; Evans et al., 2013b). Furthermore, hydrogen bonds with carbon from ferrite, forming a layer of amorphous white iron transformed along the crack walls, resulting in the WEA effect (Evans et al., 2013c; Grabulov et al., 2007). A similar phenomenon is observed on the friction surface. Due to the decarburization of the thinnest uppermost layers of the friction surface, WSF occurs (Evans, 2016).

Based on this, the process of WEC, WEA, and WSF formation could be described as follows:

1. High specific contact loads in the friction zone at the micro-level cause the emission of electrons (Figure 1).

2. High-energy electrons bombard the lubricant molecules, contributing to their degradation and releasing hydrogen protons (Figure 2).

3. The released hydrogen penetrates the steel (Figure 3).

4. Attracting free electrons, these hydrogen protons can transition to an atomic state (Figure 4).

5. Hydrogen atoms can easily bond with carbon in the intergranular space, forming large CH4 molecules (Figure 5).

6. The large CH4 molecules create high pressure on steel grains, leading to the formation of cracks (WEC) (Figure 6).

7. More hydrogen is transported into the cracks (forming more CH4), causing cracks to grow until they reach the friction surface.

8. CH4 formation decarburizes the thinnest steel layers along the crack boundaries, forming amorphous iron with a white silver color (WEA).

9. Active decarburization of the steel surface layers leads to the formation of an amorphous iron layer on the friction surface and, due to its plasticity, to White Structure Flaking (WSF).

From the information above it has been established that the mechanical, tribochemical, and electrical effects that contribute to WSF, WEC and WEA formation are heavily interconnected. Think of it in terms of this diagram (Figure 7).

Previous attempts to address this problem focused heavily on the mechanical effects, when high-viscosity lubricants aimed at reducing wear by preventing asperity contact. This does not solve the problem. Most industrial lubricants target well-known adhesive, abrasive, corrosive and surface fatigue types of wear, while they remain suppliers of free hydrogen generated in the friction zone.

2.2 Solution proposal: a new method of preventing electrically induced types of hydrogen wear

In the previous section it has been established that in order to protect bearing assemblies, gearbox components, railroad wheelsets, rails, etc. from the negative effects of WSF, WEC and WEA phenomena, as well as micro/macro-pitting, it is necessary to prevent hydrogen formation in the friction zone and its penetration into the steel surfaces during normal operation. To achieve this, the asperity contacts in the friction zone must be reduced to a level where, during micro-level contact, the surface does not reach iron polymorphing temperature. The most effective way to achieve this is by increasing the surface area of the contact plates at the micro level. This will decrease the pressure exerted on the point of contact and thereby reduce the temperature, preserving the original structure of the iron lattice.

We can attain this by introducing a special additive into a lubricant, which targets the highest surface asperities and effectively reduces roughness of the surface. As a result, the contact area dilates. This leads to substantial decrease in local flash temperatures on the asperities and could reduce the electron emission from the friction surface, preventing lubricant degradation and free hydrogen release (and its penetration into the subsurface layers). The second task of the introduced additive is to prevent the induced electric currents from penetrating the metal depths of the bearing raceway or rollers, allowing them to pass along the surface, and thus prevent hydrogen transport into the depths of the steel friction surfaces.

The solution is prompted by “the wearlessness effect”, which Professor Dmitry N. Garkunov describes as follows: “Selective transfer during friction (the wearlessness effect) is a phenomenon fundamentally opposite in nature to wear. While wear involves processes in the contact zone that lead to surface destruction, selective transfer during friction can involve evolutionary processes in which surface degradation becomes secondary. The key feature is the constructive nature of friction, driven by the exchange of energy and matter between the frictional contact and the external environment, as well as the collective behavior of metal ions that form a thin film protecting the contact surfaces from wear. Selective transfer is a type of friction characterized by the spontaneous formation, in the contact zone, of a thin, non-oxidizing metallic film with low shear resistance, which is incapable of accumulating dislocations under deformation” (Garkunov, 2024).

The solution is achieved by introducing organic oil-soluble copper salts into a lubricant. The Cu2+ ions supplied by the salt coat the top of the metallic friction surface, increasing the contact area and alleviating a significant amount of pressure. The temperature in the point of contact decreases, meaning the iron present in steel bearings will not polymorph. This solves the mechanical component of wear, but what about the other two?

Firstly, the additive itself does not serve as a source of hydrogen, so even if subjected to the bombardment of delocalised electrons, it will not release any hydrogen. Copper sits to the right of hydrogen on the reactivity series, meaning their interactions are minimal. This ensures that the copper barrier incorporated into the ferrate lattice will keep the free hydrogen radicals out. Moreover, copper is an excellent electrical conductor. This will allow current to flow with a lower resistance along the copper-coated surface.

Most importantly, the electrochemical properties of copper ions allow them to easily embed into the crystal iron lattice and fill in any openings made by hydrogen wear, forming self-sustaining nano-sized protective film. This anti-wear mechanism significantly reduces the risk of premature failure and extends the life of machinery. And this is why understanding how the new copper-based chemistry works in a fully-formulated lubricant is vital in solving the problems caused by WSF, WEC and WEA phenomena.

For the below investigation a fully-formulated lubricant containing an additive package consisting of an oil-soluble organic copper salt, an aromatic amine, a succinimide derivative and an antifoam agent was used.

2.3 Investigations - electrically induced WEC test

2.3.1 Aim of test

To test the ability of the lubricants to resist the formation of WECs.

2.3.2 Test method, equipment and setup

A three ring-on roller test machine is used. The Micropitting rig (MPR) is manufactured by PCS Instruments in London, UK. In this instrument, three 54.15 mm diameter outer rings are loaded against a centrally located 12 mm diameter roller. The rings and roller are driven independently by electric motors, allowing the application of any slip ratio. The shaft driving the roller is electrically insulated and the roller is chamfered, with a 1 mm cylindrical area making contact with the three rings.

A load of 500 N is applied through the top ring, resulting in a maximum Hertzian contact pressure of 1.9 GPa. The speed of the parts is 1.3 m/s, with a slide/roll ratio of 0.3, resulting in the rings rotating with a linear speed of 1.105 m/s and the roller 1.495 m/s. The rings manufactured from AISI 52100 have a surface roughness of 0.15 μm Ra and a hardness of 750 Hv. The roller is also manufactured from AISI 52100 and has a hardness of 650 Hv and a surface roughness of 0.15 μm Ra. The test is conducted at 100°C, with the temperature being controlled in the bulk lubricant. As the roller is softer than the rings, it is expected to become polished and have a reduced surface roughness early in the test. At these test conditions, an ISO VG 320 gear oil is estimated to have an EHD film thickness of approximately 150 nm, resulting in a Lambda ratio close to 1. The roller generates 0.4282 M contact cycles every hour. A runout limit is set at 200 M contact cycles, or on the generation of significant spalling and vibration. The torque on the central roller is measured on the roller shaft with an inline torque meter by HBM. The vibration of the top cradle (which holds the top ring and applies the load) is monitored using an accelerometer.

Throughout the test a DC is applied and controlled with a custom circuit board. The induced potential difference is controlled to maintain a set current throughout the test. The DC is set at 250 mA, which is known to induce WECs (Gould et al., 2021). This results in a current density of approximately 750 mA/mm2. Both the applied DC and voltage are monitored constantly throughout the experiment. The MPR instrument utilised has been modified to incorporate the electrical current application system, with a modified door assembly on the front side and a carbon brush on a ring driving shaft. This modified door uses a rotating assembly consisting of a flexible shaft, a seal, and two ceramic bearings, which ensure that the shaft remains electrically insulated from the door. A Mercotac liquid metal brushless slip ring and a flexible coupling is used to establish a powerful electrical connection between the test roller and shaft.

On the ring side, the electrical contact is made through a carbon brush loaded with a spring onto the ring shaft. A screw is used to vary the force through the spring and slip ring to ensure a good connection. The measured current throughout the test varies between 245 to 255 mA.

Upon completion of the test, the rollers are analysed with a subsurface serial sectioning method. First, the excess material from the front of the roller is removed by slicing up to 0.5 mm from the edge of the wear track. The cut roller is then mounted in resin. A series of controlled steps of grinding and polishing are then conducted to reach the edge of the wear track. The newly exposed surface is then etched with Nital, after which the circumference of the sample is inspected with a microscope and any subsurface features are recorded. A further series of five cuts is then performed with grinding, polishing, etching and microscopy at 0.1 mm intervals throughout the sample up to the centre of the wear track. This results in the destruction of approximately half of the area of interest, with the second half being stored for further analysis if needed.

3 Results and discussion

Two lubricants have been tested using the method described above. The lubricants are both ISO VG 320 and formulated for use in wind turbine gearboxes. The reference oil has been approved for use by several OEMs in wind turbines and is currently used in the field. It has a synthetic base oil and is formulated with ashless type additives. The candidate oil is a prototype oil, mentioned above, containing a copper-based additive package.

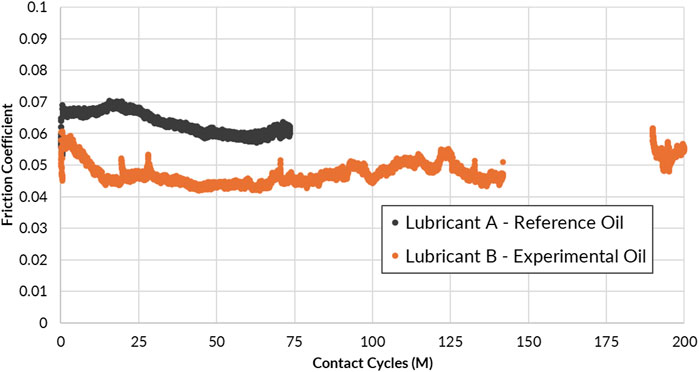

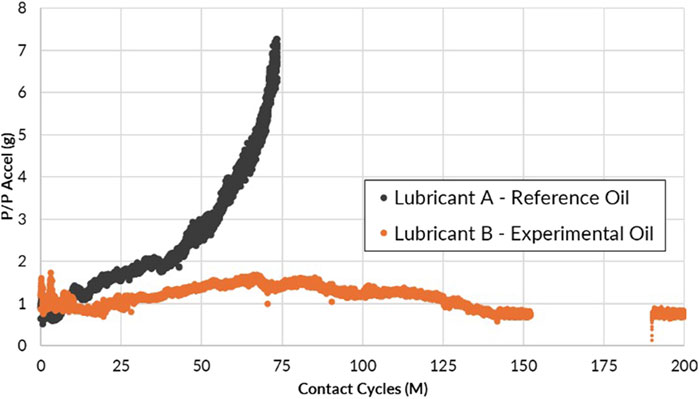

The measured friction and vibrations of the two tests are shown in Figures 8, 9.

NOTE - There was some data loss due to a power outage at ∼ 155 M contact cycles. The instrument was monitored throughout the test and can safely be expected to have been operating correctly to the point of the power outage.

Lubricant B maintained a low vibration throughout the scheduled 200 M contact cycles test. Lubricant A showed a gradual increase in vibration until the measured vibration reached a cut off in the software and the test was stopped. This is caused by the development of surface cracks and pitting. The halting of this type of test can be with the formation of one large pit, which leads to an instantaneous large increase in vibration. In the case there is a gradual increase in the vibration of the system, due to the more gradual formation of surface cracks and small pits. Lubricant B also maintained a slightly lower friction throughout the test.

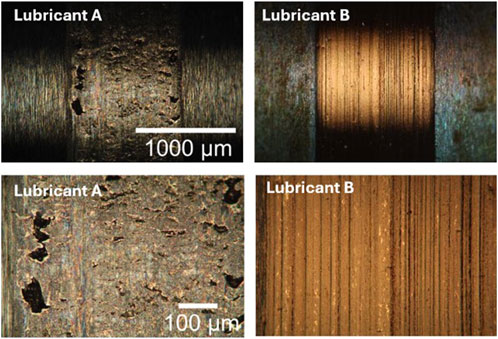

The surfaces of the rollers at the end of the tests are shown below in Figure 10.

Figure 10. “End of test microscopy of the roller surface with two magnifications (top row and bottom row). Lubricant A shows significant pitting on the surface; lubricant B showed no pitting.”

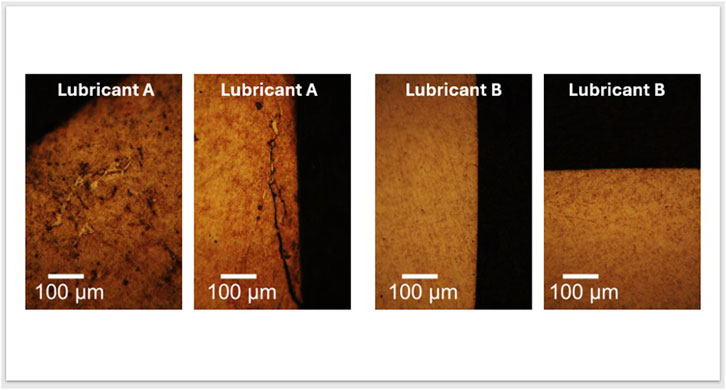

Lubricant A showed multiple small subsurface initiated pits, distributed across the surface of the wear track. It should be noted that the appearance of these small pits is different to those observed during micropitting tests–where there is a clear surface initiation site and a gradual sloping of the pit floor into the depth of the material. Lubricant B shows a relatively smooth surface, with some striations in the direction of sliding. No pits or cracks were found over the entire surface of the roller.

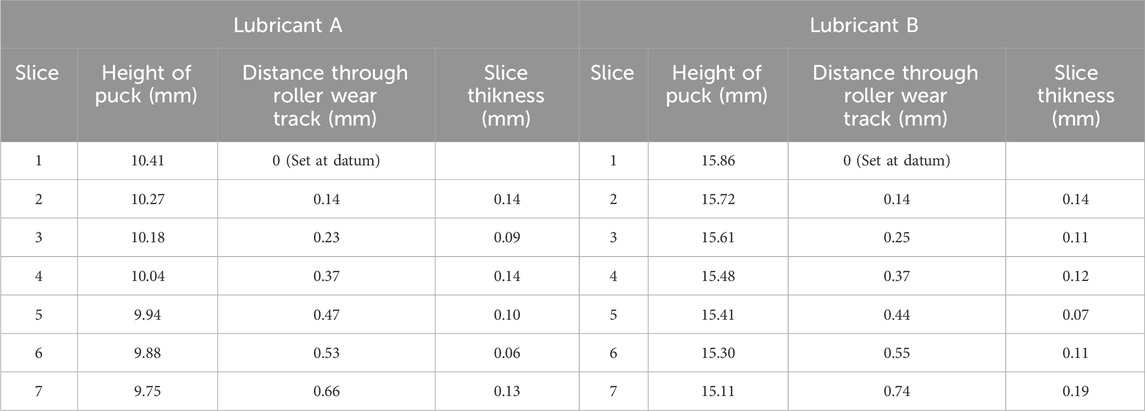

The roller was then analysed by serial sectioning. Table 1 shows the details of the distance through the roller for each analysis slice.

Multiple subsurface features were found in the roller of Lubricant A, including white etching areas, white etching cracks, surface-initiated cracks and dark etching areas. Also found were areas of cracks which were close to or made contact with the surface. These would be expected to form a large spall soon, if the rolling contact fatigue test was continued.

No subsurface features were found in any of the seven slices for Lubricant B. Some example images of the subsurface for the two rollers are shown in Figure 11.

Figure 11. “Example microscopy images from the subsurface analysis. Lubricant A had multiple area of subsurface features; lubricant B had none.”

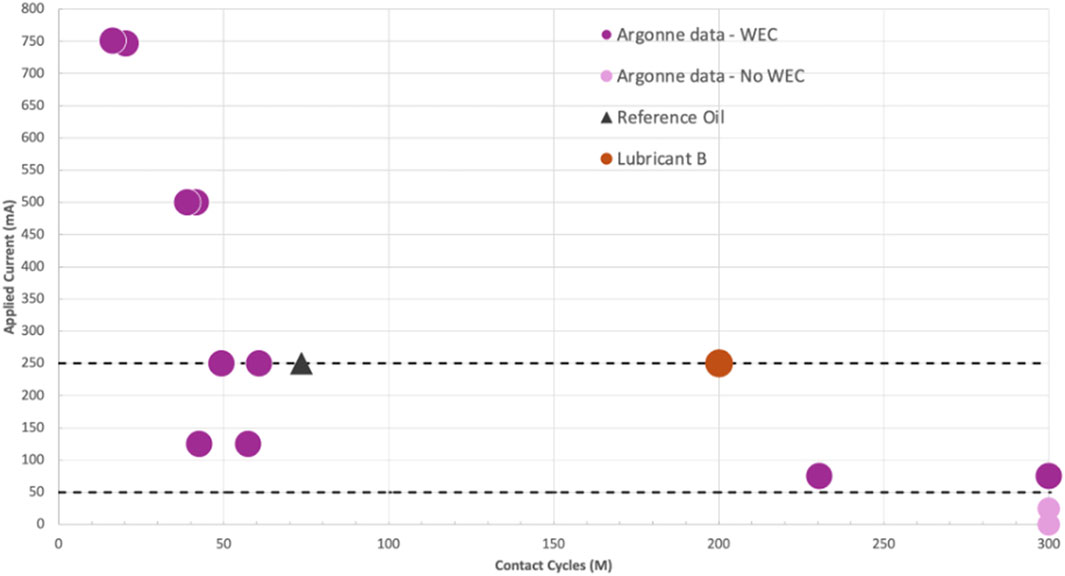

As little work has been published on WEC testing and electrically induced WEC testing, the results from these two tests have been plotted against a publication which maps out the failure of wind turbine type oils in a comparable test set-up (Gould et al., 2021). Lubricant A shows a failure at a similar number of contact cycles and applied current to Gould, B., et al., whilst lubricant B shows a significant improvement in performance at this level of applied current.

Figure 12 shows the result of candidate oil compared to test results of other lubricants described in the work by Gould et al. (2021).

There is clearly a significant improvement, with the reduction or prevention of WECs in this experiment with the addition of Cu salts in a wind turbine type formulation.

The authors believe that the formation of a Cu film on the surface results in the prevention of the formation of subsurface features in the steel and the formation of surface pits. The Cu salts act to increase the contact area along with the prevention or reduction of hydrogen entering the steel subsurface. The findings suggest that WSF, WEC, and WEA phenomena can be reduced by controlling the surface tribofilms and the emission of hydrogen from the lubricant, followed by its penetration into the steel. Further work will be attempted to measure and quantify the level of hydrogen in the steel for similar tests, to confirm the mechanism. But nevertheless, initial tests are encouraging and demonstrate the practical relevance of Cu salts in formulations to prevent WEC type failures in industry. Ultimately, these insights could help prevent critical equipment failures in real-world applications.

4 Conclusion

This study introduces a novel hypothesis for the formation of White Etching Cracks (WEC), White Etching Areas (WEA), and White Structure Flaking (WSF) in bearing components, based on a combination of existing knowledge and Garkunov’s concepts of “hydrogen wear of metals” and the “wearlessness effect,” which have not been considered in prior studies. The hypothesis establishes a coherent link between mechanical, tribochemical, and electrical stressors, suggesting these phenomena are not isolated but part of a unified cycle driven by hydrogen activity in the friction zone. The hypothesis was experimentally validated using a modified three-ring-on-roller tribometer under conditions known to induce WEC formation.

The experimental results demonstrated that a prototype lubricant containing oil-soluble copper salts significantly inhibited the formation of WECs and related damage compared to a reference oil. The absence of subsurface defects in specimens lubricated with the copper-based formulation—alongside reduced friction and vibration levels—indicates that the copper additive plays a critical role in preventing hydrogen diffusion and subsequent microstructural transformation in steel.

Copper ions supplied by the additive are shown to suppress electron-induced hydrogen generation and form protective films that block hydrogen ingress. These processes align with the theoretical framework of selective transfer phenomenon, offering a material-based solution to a system-level reliability challenge.

The incorporation of copper-based additives into lubricant formulations represents a scientifically grounded, technically feasible strategy for extending the operational life of critical components in electric machines, wind turbines, and other high-load applications.

Future work should aim to quantitatively assess hydrogen concentration changes in steel substrates and validate the proposed mechanism across a broader range of operational conditions and material configurations. These efforts will be critical for refining additive chemistry and ensuring its scalability and effectiveness in real-world industrial environments.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

SM: Conceptualization, Supervision, Writing – original draft, Writing – review and editing. MI: Investigation, Methodology, Writing – original draft, Writing – review and editing. LA: Project administration, Writing – review and editing. VP: Visualization, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. The work was funded by Neol Copper Technologies Limited. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article, or the decision to submit it for publication.

Conflict of interest

Authors SM, LA, and VP were employed by Neol Copper Technologies Ltd. Author MI was employed by Ingram Tribology Ltd.

Generative AI statement

The author(s) declare that Generative AI was used in the creation of this manuscript. To translate parts of the manuscript from Russian into English language.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Desnica, E., Ašonja, A., Radovanović, L., Palinkaš, I., and Kiss, I. (2023). “Selection, dimensioning and maintenance of roller bearings,” in 31st international conference on organization and technology of maintenance (OTO 2022). OTO 2022. Lecture notes in networks and systems. eds. D. Blažević, N. Ademović, T. Barić, J. Cumin, and E. Desnica (Cham: Springer), 592, 133–142. doi:10.1007/978-3-031-21429-5_12

Evans, M. (2012). White structure flaking (WSF) in wind turbine gearbox bearings: effects of ‘butterflies’ and white etching cracks (WECs). Materials 28 (1), 3–22. doi:10.1179/026708311x13135950699254

Evans, M.-H. (2013). White structure damage in bearings due to rolling contact fatigue. Southampton.

Evans, M.-H. (2016). An updated review: white etching cracks (WECs) and axial cracks in wind turbine gearbox bearings. Mat. Sci. Tech. 32, 1133–1169. doi:10.1080/02670836.2015.1133022

Evans, M.-H., Richardson, A., Wang, L., and Wood, R. (2013a). Effect of hydrogen on butterfly and white etching crack (WEC) formation under rolling contact fatigue (RCF). Wear 306 (1), 226–241. doi:10.1016/j.wear.2013.03.008

Evans, M.-H., Richardson, A., Wang, L., and Wood, R. (2013b). Serial sectioning investigation of butterfly and white etching crack (WEC) formation in wind turbine gearbox bearings. Wear 302 (1), 1573–1582. doi:10.1016/j.wear.2012.12.031

Evans, M.-H., Walker, J., Ma, C., Wang, L., and Wood, R. (2013c). A FIB/TEM study of butterfly crack formation and white etching area (WEA) microstructural changes under rolling contact fatigue in 100Cr6 bearing steel. Mater. Sci. Eng. A 570, 127–134. doi:10.1016/j.msea.2013.02.004

Garkunov, N. (2024). “Dmitry scientific discoveries in tribotechnologies,” in Wearlessness effect under friction. Hydrogen wear of metals. London.

Gould, B., Demas, N., Erck, R., Lorenzo-Martin, M. C., Ajayi, O., and Greco, A. (2021). The effect of electrical current on premature failures and microstructural degradation in bearing steel. Int. J. Fatigue 145, 106078. doi:10.1016/j.ijfatigue.2020.106078

Grabulov, A., Ziese, U., and Zandbergen, H. W. (2007). TEM/SEM investigation of microstructural changes within the white etching area under rolling contact fatigue and 3-D crack reconstruction by focused ion beam. Scr. Mater. 57 (7), 635–638. doi:10.1016/j.scriptamat.2007.06.024

Hosenfeldt, T., Bugiel, C., Leimann, D.-O., Loos, J., Luther, R., Merk, D., et al. (2024). White etching cracks - position paper of the German society for Tribology. doi:10.13140/RG.2.2.27783.41121

Patil, A. A., Desai, S. S., Patil, L. N., and Patil, S. A. (2022). Adopting artificial neural network for wear investigation of ball bearing materials under pure sliding condition. Appl. Eng. Lett. 7 (2), 81–88. doi:10.18485/aeletters.2022.7.2.5

Richardson, A. D., Evans, M.-H., Wang, L., Wood, R. J. K., and Ingram, M. (2018a). Thermal desorption analysis of hydrogen in non-hydrogen-charged rolling contact fatigue-tested 100Cr6 steel. Tribol. Lett. 66 (1), 4. doi:10.1007/s11249-017-0947-0

Ruellan, A., Kleber, X., Ville, F., Cavoret, J., and Liatard, B. (2015). Understanding white etching cracks in rolling element bearings: formation mechanisms and influent tribochemical drivers. Proc. Institution Mech. Eng. Part J J. Eng. Tribol. 229 (8), 886–901. doi:10.1177/1350650114557710

Ruellan, A., Ville, F., Kleber, X., Arnaudon, A., and Girodin, D. (2014). Understanding white etching cracks in rolling element bearings: the effect of hydrogen charging on the formation mechanisms. Proc. Institution Mech. Eng. Part J J. Eng. Tribol. 228 (11), 1252–1265. doi:10.1177/1350650114522452

Shpenkov, G. (1995). Friction surface phenomena, Amsterdam: ELSEVIER Science Publishers B.V., 29 343. Tribology Series.

Keywords: white etching area (WEA), white etching crack (WEC), large electric machines, bearings, hydrogen wear, no-wear effect, lubricants, lubricant additives

Citation: Mamykin S, Ingram M, Alieva L and Privalova V (2025) Preventing electrically induced subsurface initiated pitting failures (incl. WSF, WEC, WEA) with copper based lubricant additives. Front. Mech. Eng. 11:1585472. doi: 10.3389/fmech.2025.1585472

Received: 28 February 2025; Accepted: 12 May 2025;

Published: 21 May 2025.

Edited by:

Balasubramaniam Vengudusamy, Klüber Lubrication München GmbH & Co. KG, GermanyReviewed by:

Aleksandar Ašonja, Business Academy University, SerbiaBenjamin Lehmann, RWTH Aachen University, Germany

Copyright © 2025 Mamykin, Ingram, Alieva and Privalova. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Leyla Alieva, bGV5bGFAbmVvbGNvcHBlci5jb20=

Sergei Mamykin1

Sergei Mamykin1 Leyla Alieva

Leyla Alieva