- Hangzhou Vocational and Technical College, Fair Friend Institute of Intelligent manufacturing, Hangzhou, China

The bucket of industrial hydraulic excavator is one of the key components in the excavator. Considering the poor model construction ability of the current bucket strength and fatigue simulation method of industrial hydraulic excavator, which leads to the large difference between the simulation results and the measured results, a new bucket strength and fatigue simulation method of industrial hydraulic excavator is designed. The parametric design of bucket of industrial hydraulic excavator is completed by using ADAMS/View technology. Referring to the actual digging force of the bucket, the bucket strength of industrial hydraulic excavator is simulated. The cumulative fatigue damage reliability analysis algorithm is used for bucket fatigue simulation, and the simulation results are statistically analyzed. The experimental results show that the simulation results of the method are closer to the measured results, the relative error is controlled within 5%, and the computational efficiency is improved by about 80% compared with the traditional method. The method provides a new technical means for the design and optimization of hydraulic excavator bucket, which has high application value.

1 Introduction

Natural disasters and other situations occur frequently in modern society. The existing traditional and general-purpose construction machinery have a small working range and may not be able to enter the core area of the disaster area. At this time, relying on manpower for rescue is inefficient and easy to cause large casualties. Therefore, an excavator with a larger working range is needed to deal with these situations. Single bucket hydraulic excavator is the most widely used mechanical equipment in engineering machinery and equipment. It is widely used in industrial construction, transportation, housing construction, railway construction, bridge engineering, water conservancy construction, mining, national defense engineering and other engineering construction. Hydraulic excavator plays an important role in accelerating construction speed, shortening operation period, reducing workers’ labor and improving work efficiency (Niskanen et al., 2020; Arai et al., 2021). General hydraulic excavators include power mechanism, slewing mechanism, operating mechanism, traveling mechanism, transmission mechanism, working device and some auxiliary mechanisms. The working device is the direct executing device for hydraulic excavators to complete various excavation tasks, and its main structure is mainly composed of boom the operation process of the whole machine is realized through the compound action of three groups of oil cylinders and the interaction between the bucket and the operation object. The research and development of hydraulic excavator in China is relatively late, and its core technology is basically in the hands of foreign R and D teams, while the design and development of domestic hydraulic excavator mostly learn from or imitate foreign mature products. At present, the foreign excavator industry attaches importance to the adoption of new technologies, new processes, new structures and new materials, and speeds up the pace of standardization, serialization and generalization. However, the hydraulic excavator’s working device faces the combined effects of various loads, such as tension, pressure, bending moments, and torque, in complex working environments. The alternating loads under different working postures and positions place high demands on the strength and fatigue performance of the working device. The development of domestic hydraulic excavators lags behind international leading levels, mainly relying on foreign technology and often learning from and imitating mature foreign products (Park et al., 2021). Therefore, it is urgently necessary to introduce advanced production technologies and adopt cutting-edge design and development techniques to enhance core technologies.

Due to the poor working conditions and complex and changeable excavation actions of the hydraulic excavator, the working device needs to bear the comprehensive effects of various loads such as tension, compression, bending and torsion and impact load in the process of completing various tasks, and bears varying degrees of alternating loads under different working positions and postures, which puts forward high requirements for the structural performance of the working device of the hydraulic excavator (Tri Cuong et al., 2020; Niraj et al., 2021). Excavator is an engineering equipment to ensure the survivability, mobility and anti mobility of the army. With the development of modern science and technology, especially information technology, we must innovate ideas, break through the traditional development ways and modes, and realize a qualitative leap in the performance and quality of military engineering equipment. Therefore, only by ensuring that the working device can meet the strength and fatigue performance requirements under long-term use, can ensure that the excavator has high operation efficiency and make it competitive in the market (Liu et al., 2025). If the domestic excavator industry wants to break through and realize industrialization, marketization and scale, it must first gradually get rid of its dependence on foreign products, master the core technology of production and R and D and realize independent innovation.

In the process of continuous innovative design of industrial hydraulic excavator, the bucket strength has a direct impact on its use effect. Once the device has poor strength or fatigue resistance, it is easy to cause equipment damage and threaten the personal safety of workers. Therefore, it is necessary to systematically analyze it and determine the performance parameters of the bucket of industrial hydraulic excavator. Because the bucket device of industrial hydraulic excavator is large and the actual analysis needs to consume a lot of cost, the bucket strength and fatigue simulation of industrial hydraulic excavator is carried out in this study in order to obtain more reliable analysis results and promote the development of bucket manufacturing industry of industrial hydraulic excavator. Although parametric design and fatigue cumulative damage analysis have been widely used in the engineering field, the existing methods are still insufficient in dealing with the strength and fatigue simulation of hydraulic excavator buckets under complex working conditions. The existing methods cannot accurately reflect the multi-factor coupling effect in the actual working conditions when simulating the dynamic response of the bucket under complex loads. In addition, the balance between simulation accuracy and computational efficiency of the existing methods still needs to be improved. In order to overcome these limitations, the study innovatively combines advanced parametric modeling techniques and improved fatigue cumulative damage reliability analysis algorithms to achieve high-precision simulation of hydraulic excavator buckets.

The study proposes a novel method for simulating the strength and fatigue of excavator buckets, combining advanced parametric modeling techniques with an improved fatigue cumulative damage reliability analysis algorithm. This method more accurately reflects the stress characteristics and fatigue life of the bucket under complex working conditions, providing new technical means for the design and optimization of hydraulic excavator buckets. The method outperforms existing technologies in both simulation accuracy and computational efficiency, offering high application value. Not only does it improve simulation accuracy, but it also enhances computational efficiency, increasing it by approximately 80% compared to traditional methods under complex load conditions. Furthermore, this research provides new ideas and methods for simulation analysis in the field of construction machinery, promoting the development and application of related technologies.

2 Simulation design of bucket strength and fatigue of industrial hydraulic excavator

2.1 Parametric design of bucket of industrial hydraulic excavator

In this study, the bucket of industrial hydraulic excavator will be parameterized first. The relationship between bucket joint Angle and space pose is obtained by kinematic analysis of excavator working device. In excavator operation, the bucket through the rotary motor and hydraulic cylinder control to achieve the target task. According to this principle, the MATLAB model is established, and the ADAMS/View technology is used to parameterize the model. At the same time, the key geometric parameters of the bucket are the core parameters that directly affect the working performance of the bucket, such as the size of the bucket, the length of the connecting rod and the joint angle (Wang et al., 2024). The movement track and attitude change of the bucket during the working process are determined by its interaction with the hydraulic cylinder and the rotating motor. Therefore, the relationship between bucket joint angle and spatial attitude obtained from kinematics analysis is also included in the category of design variables (Jinguang et al., 2024). In addition, the actual working scene of industrial hydraulic excavator is considered, and the parameters directly related to digging force, working range and operating efficiency are selected.

ADAMS/View provides three kinds of parameterization methods: expression parameterization, parameter parameterization and design variable parameterization. The three parameterization methods have corresponding differences. According to the structural characteristics and research objectives of industrial hydraulic excavator, parametric parameterization treatment method is selected as the parameterization treatment technology. It is used to simulate the position relationship between the driving Angle of each component and the bucket space of the excavator in the working process, and the variable relationship between the working devices is analyzed. According to the changes of spatial variables, the movement track of the bucket in the working process is analyzed. When creating the bucket parameterization model of industrial hydraulic excavator, firstly choose the parameterization method to be adopted in the model and the parameterization variables to be introduced. When the input value of this variable is changed, the dependent model properties are automatically updated.

To establish three-dimensional solid model of hydraulic excavator is crucial for accurate simulation of the operating cycle, so when modeling should be carried out in accordance with the actual size of parts of hydraulic excavator, and on the full analysis and clear the position and the constraint relationship between components of the assembly into the final model of the machine. At the same time, the whole machine model as the bucket 3d model design basis.

There are motion tools and structure-point parametric tools in the ADAMS/View main toolbox, and special parametric tools in the application module. The motion tool sets the motion of one model object relative to another. ADAMS/View provides two kinds of parameterized motion tools: position function

A reasonable model can provide more reliable data for the subsequent simulation process. In order to control the difficulty of calculation in the subsequent research, the parametric model will be simplified in this link. The shape of parts and the number of holes are simplified without affecting the movement and simulation results of the working device. In ADAMS, driving can be added to realize the operation of the working device, so the electric push rod, motor and other parts are omitted. Although some components have been omitted, the key components that directly affect the force and motion of the bucket have been retained to ensure that the simulation results can accurately reflect the actual working conditions. In order to meet the simulation requirements, only the bucket, support frame, and control rod were parameterized in 3D (Reza et al., 2021).

In this study, the abscissa and ordinate of the relevant design structure points

During the parametric simulation analysis, it is necessary to measure some characteristics of the bucket model which can be calculated by ADAMS/View, and regard them as the objective function in the parametric analysis. Transmission ratio of bucket connecting rod mechanism is the objective function of this parametric analysis, which can be expressed as:

In the Formula 1,

2.2 Industrial hydraulic excavator bucket strength simulation

The main purpose of the research on excavator bucket strength is to determine the external force acting on the working device in operation. Excavation resistance refers to the soil resistance encountered by the bucket in the excavation process. It is necessary to analyze and calculate the excavation resistance of hydraulic excavator because of the significant influence of excavation resistance on excavator reliability and excavation capacity. In the dynamic analysis of excavator, the excavation resistance is one of the external loads involved, and only by systematic analysis, can the bucket strength simulation analysis be realized.

The bucket is subjected to the gravity of the material and the digging resistance of the material to the bucket teeth (Wang et al., 2021; Liu et al., 2024). The bucket capacity is set as

In the Formula 2,

In the formula,

In the above Formula 5,

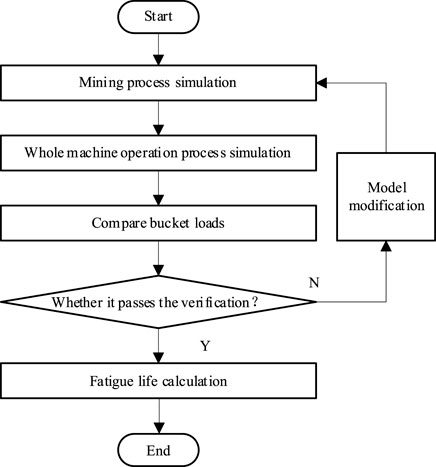

2.3 Bucket fatigue simulation based on cumulative fatigue damage reliability analysis algorithm

In the actual operation process, the hydraulic excavator mainly bears alternating load, and fatigue damage is the main cause of its failure. It is very necessary and meaningful to study its fatigue life. Based on the above work, this chapter will use the advanced fatigue analysis software ANSYS FE-SAFE to study the fatigue life of the working device of hydraulic excavator (Sun et al., 2024; Dewa and Kepka, 2021). A stochastic material model is introduced in the modelling process, which fully considers the effects of batch differences in material properties such as modulus of elasticity, yield strength and fatigue limit, wear and tear evolution, and environmental changes such as temperature and corrosion on structural performance. The probabilistic fatigue life prediction model was established by setting probability distributions for key material parameters and combining the Monte Carlo method with multiple random sampling analysis. Considering that the damage in the working device is mainly wear damage of the bucket teeth and bottom plate, this study focuses on the boom, stick, and bucket teeth as the main objects for fatigue analysis. In this study, SimMechanics is selected as the main module in this link simulation. As a mechanical simulation module in Simulink, SimMechanics is an important module library in MATLAB simulation. At the same time, it has the functions of Simulink and MATLAB. The block diagram in simechanics module can be used to build a simulation module for the motion of mechanical structure, realize dynamic simulation through input parameters, and establish the relationship between them through module association, so as to build a mechanism system (Tserpes and Floros, 2019). The SimMechanics module group has its own module library, which can directly build the mechanism system in Simulink. During simulation, the mechanism system of excavator working device is simplified to the direct display of mechanism structure. Therefore, the setting of fatigue simulation analysis process in this study is shown in Figure 1.

According to the above Figure 1, select the appropriate method to complete the analysis process. Cumulative fatigue damage reliability analysis algorithm and equivalent load method are the two most commonly used methods when dealing with non constant amplitude load. Among them, cumulative fatigue damage reliability analysis algorithm is widely used because it is more in line with engineering practice. Its principle is to convert variable amplitude spectrum into equal amplitude spectrum through equivalent conversion of fatigue damage (Takahashi et al., 2019; Wang and Roger, 2021). Therefore, in this study, the bucket cumulative fatigue damage reliability analysis model is designed as the main simulation analysis method.

According to the relevant theories of fatigue fracture and cumulative fatigue damage reliability analysis algorithm (Nie et al., 2019), the cyclic loading times required for fatigue failure of mechanical structure have a corresponding relationship with the stress level (Sakai, 2023):

In the Formula 6,

When subjected to various stress levels, the total fatigue damage degree

According to the fatigue cumulative damage theory, in case of fatigue failure of the structure, the following formula exists:

In the above Formula 9,

By integrating the above Formula 10, the simulation calculation formula of bucket fatigue damage of industrial hydraulic excavator can be obtained, including:

In the Formula 11,

3 Experimental analysis

In this study, a new bucket strength and fatigue simulation method of industrial hydraulic excavator is proposed. In order to verify that this method has corresponding application value, corresponding experimental links are constructed to verify its application effect.

3.1 Experimental object selection

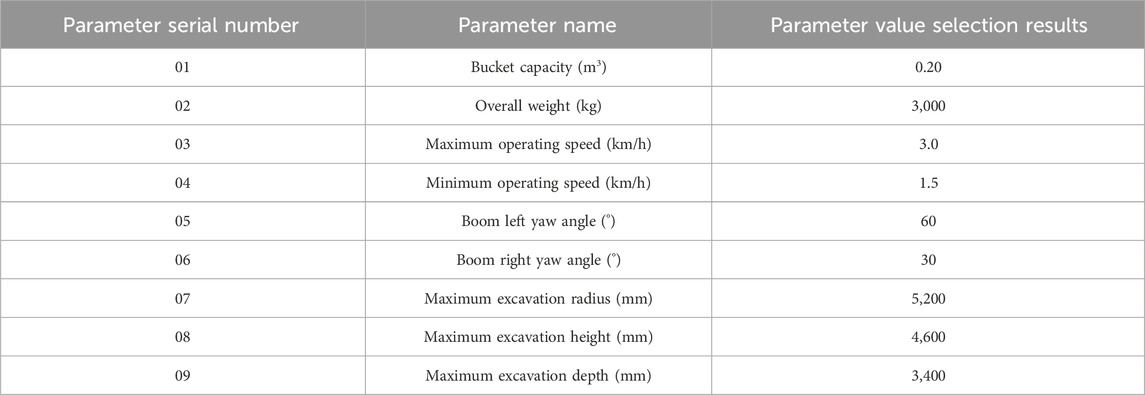

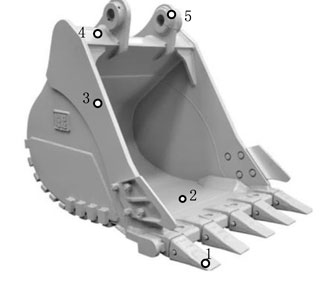

In this experiment, the experimental object is set as the bucket of a brand of industrial hydraulic excavator, and the working parameters of the experimental object are shown in Table 1.

Table 1, the bucket capacity directly affects the excavation efficiency and load capacity of the excavator. Based on the actual engineering requirements and the design specifications of the excavator, 0.20 m3 is selected as the bucket capacity for the experimental object. The overall weight refers to the total weight of the bucket and its ancillary structures, which affects the carrying capacity and operational stability of the excavator. The maximum operating speed refers to the maximum travel speed that the excavator can reach during normal operation, reflecting the mobility of the excavator. The offset angle of the boom determines the working coverage range of the excavator on both sides, with a right side of 30° and a left side of 60° meeting the excavation needs in most industrial scenarios. The above parameters are the working parameters of the experimental object, and the physical parameters of the experimental object are shown in Figure 2.

Among the above parameters, the maximum excavation radius, excavation depth, excavation height and bucket capacity will have a direct impact on the experimental data. Due to the existence of modeling error, the error between the simulation model and the real experimental object is controlled at about 3.0%, and the maximum error shall not exceed 4.0%. So as to ensure the consistency between the simulation results and the results obtained in the real application scenario.

3.2 Experimental process

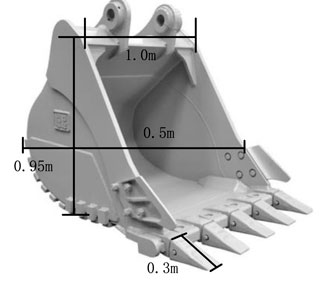

In this experiment, the simulation ability of this method is determined by comparing the simulation results with the real test results. The dynamic strain test system is used to test the dynamic strain of loader bucket. The test ambient temperature is set at 30°C, the relative humidity is no more than 95%, the wind speed is no more than 5 m/s, and there is no strong vibration, corrosive gas and strong magnetic field interference around. According to the structural characteristics of the experimental object, the measurement position of the experimental object is set as shown in Figure 3.

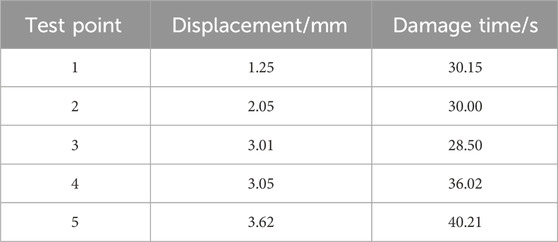

A total of 5 measuring points are set in this experiment, and the specific positions are shown in Figure 3. Because the loader bucket is in direct contact with materials in the working process, the stress conditions are complex and diverse. According to the stress characteristics of the bucket, the direction of the main stress on the bucket is difficult to predict. In general, 45° right angle strain flowers need to be selected for testing. The three strain gauges measure the displacement and damage time of the measuring points in the direction of 30°, 60° and 90°, and reflect the strength and fatigue test results of the measuring points through the displacement and damage time. The specific data statistical results are shown in Table 2. Because the bucket plays an active role and the bucket hydraulic cylinder plays an auxiliary role in this excavation process, coupled with the self-locking function of the hydraulic cylinder, the bucket thrust is relatively large. Therefore, the strength and fatigue of the bucket can be determined only by comparing the displacement of the bucket measuring point and the damage time.

Take the above data as the control data of this experiment, use this method to simulate the experimental object, and compare the simulation results with the control group to determine the use effect of this method.

3.3 Experimental result

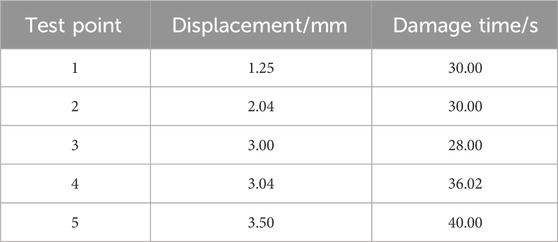

According to the simulation method set above, obtain the bucket strength and fatigue simulation results. The specific results are shown in Table 3.

In order to better analyze the above data and the measured data, the absolute errors of the two groups of results are compared. The specific results are shown in Table 4.

Compared with the above experimental results, it can be seen that in the process of excavation, the trend of bucket strength and fatigue simulation results is consistent with the actual test results. Only there are corresponding errors in the data, but the difference is small, which is in line with the law of data change. These errors mainly originate from the loss of details due to model simplification, uncertainties in material parameters, and approximate treatment of load application and boundary conditions. In addition, the numerical computation method itself may introduce errors, especially under complex working conditions, and these errors may be amplified, thus affecting the accuracy of the simulation results. After analyzing the absolute error and relative error of the simulation results, it can be seen that the relative error is controlled within 5.0%, indicating that the data reliability of this simulation method is relatively high. Using this simulation result, the strength and fatigue of excavator bucket can be analyzed with high precision. However, it is one-sided to determine the application effect of the simulation method only through the experimental results, so the simulation response time index is added to analyze the computing power of the simulation method. According to the current relevant regulations, the calculation standard value is set to 1.5 min. As long as it does not exceed this value, this method has high calculation speed. The specific experimental results are shown in Figure 4.

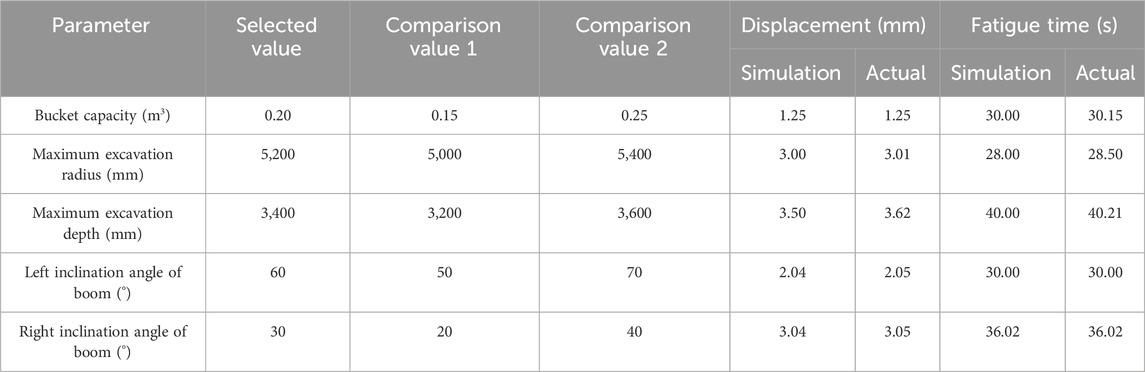

Meanwhile, the study compares the current simulation methods commonly used in the industry. The traditional methods usually require long computation time, especially when dealing with complex dynamic simulations, and the computational efficiency is low. In contrast, the method proposed in this paper significantly improves the computational efficiency by optimizing the algorithm and model simplification while ensuring the accuracy. The computation time of the traditional method was 37.86, 44.87, 57.88, 60.04 and 65.45 s for the five monitoring points, while the computation time of the proposed method of the study was 16.23, 22.33, 43.78, 37.98 and 32.56 s, respectively. Under complex excavation conditions, the method in this paper can be completed in only a few minutes. Through the analysis of the above experimental results, it can be seen that the calculation rate of the simulation method is relatively high and meets the preset requirements, which proves that this method has high application effect. It can be determined that this method has high application value in the analysis of practical problems. In order to verify the rationality and effectiveness of the selected parameter settings, further comparative analysis was conducted on the simulation results under different parameter settings. The material properties (e.g., modulus of elasticity, yield strength, and fatigue limit) remain unchanged during the variation of different working condition parameters, and the standard Q345 steel parameters are used uniformly. Only the external loads and loading conditions are adjusted in each scenario to evaluate the response of the structure to different operating conditions under the same material conditions. As shown in Table 5.

From Table 5, it can be seen that the selected bucket capacity (0.20 m3) achieves a balance between excavation efficiency and operational stability, and the error between simulation results and experimental data is controlled within 5%. The settings of maximum excavation radius (5,200 mm) and maximum excavation depth (3,400 mm) also effectively cover practical application scenarios, and the simulation and experimental results are highly consistent. In addition, the boom deflection angle (60° left/30° right) provides the excavator with optimal operational flexibility and coverage range, further demonstrating the scientific and effective nature of the selected parameters.

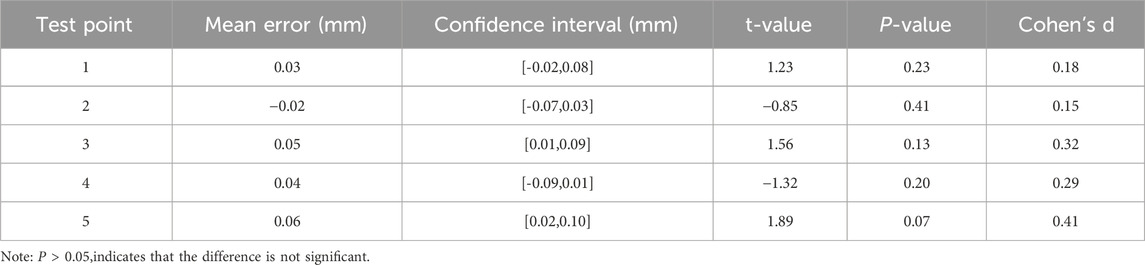

Finally, the study further analyzes the error between the simulation results and the experimental data QC, and based on this, 95% confidence intervals are constructed. At the same time, hypothesis testing was conducted. Setting the original hypothesis: there is no significant difference between simulation results and experimental data. Alternative hypothesis: there is a significant difference between simulation results and experimental data. The results of the statistical analysis of the proposed method are shown in Table 6.

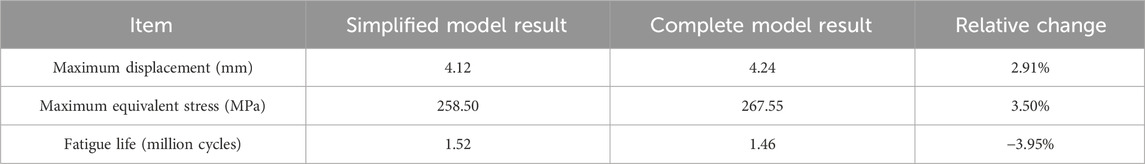

As can be seen from Table 6, the confidence intervals of all test points contain 0, indicating that there is no significant difference between the simulation results and the experimental data. And according to the t-test results, the P-value of all test points is greater than 0.05, indicating that there is no significant difference between the simulation results and the experimental data in these test points, and the original hypothesis is valid. The calculation results show that the Cohen’s d values of all test points are less than 0.5, indicating that the differences between the simulation results and the measured data are small, which further validates the practicality and reliability of the method. In order to assess the effect of omitting components such as the motor and the hydraulic cylinder on the simulation accuracy, a simplified model sensitivity analysis was carried out. Based on the simplified model, representative masses of the hydraulic cylinder and motor were added separately (assuming 150 kg for the hydraulic cylinder and 100 kg for the motor), and the static strength and fatigue simulations were re-run. The details are shown in Table 7.

As can be seen from Table 7, the changes between the simplified model and the full model are all below 4.0%. This indicates that the changes in the results caused by the model simplification are small and do not affect the overall reliability of the simulation analysis, so the simplification treatment is reasonable and acceptable in this study.

3.4 Validation of additional simulation cases

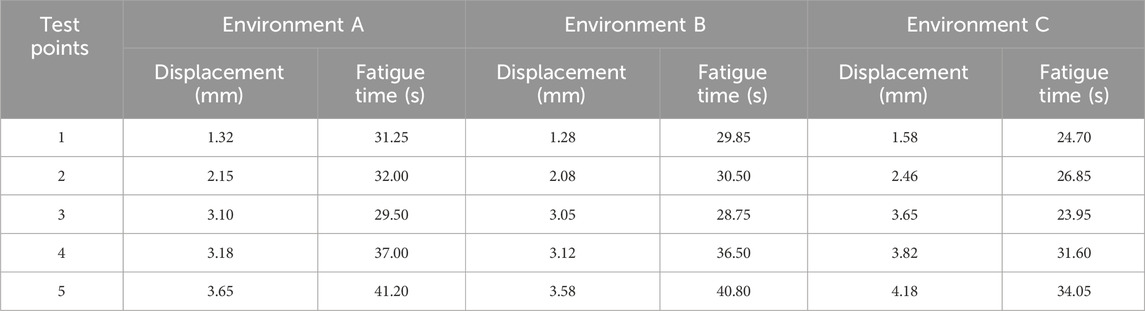

In order to further validate the effectiveness of the proposed bucket parametric modeling approach in different environments, the study conducts additional simulation cases and introduces statistical analysis methods (confidence intervals and hypothesis testing) to assess the reliability of the simulation results. Three operating environments are first set up for simulation testing. Among them, Environment A: simulates excavation operation under complex terrain conditions, with soil hardness class IV, maximum excavation depth of 3,600 mm, and maximum excavation radius of 5,400 mm. Environment B: simulates urban building demolition scenario, with soil hardness class II, maximum excavation depth of 3,200 mm, and maximum excavation radius of 5,000 mm. Environment C: The simulated soil is interspersed with rock and other hard materials, and the bucket is subjected to a transient impact phenomenon during excavation, resulting in drastic fluctuations in the load amplitude. The maximum digging depth is 3,600 mm, the maximum digging radius is 5,400 mm, and the peak value of impact load reaches 150% of the normal operating load. Five simulation tests were conducted in each environment. The displacement and fatigue time of the key test points were recorded. The details are shown in Table 8.

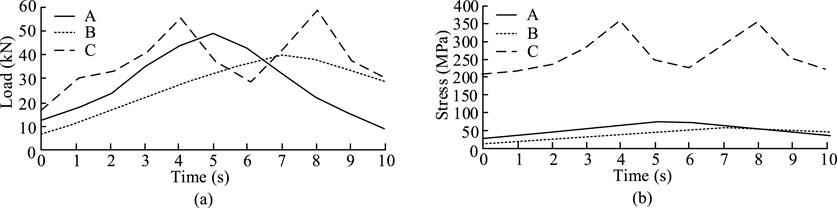

As can be seen from Table 8, the proposed bucket parametric modeling method has high consistency and reliability in predicting the displacement and fatigue time. The differences in the displacements are within 0.07 mm and the differences in the fatigue times are within 2.40 s for both environment A and environment B, which indicates that the method performs stably under different working conditions. Compared with environment A and B, the displacement generally increases and the fatigue life is shortened in environment C, reflecting the changes in the force and damage characteristics of the working device under complex working conditions. The dynamic load and stress variations under the two environments are shown in Figure 5.

Figure 5. Simulation results of bucket under different environments. (a) Dynamic load changes of bucket in two environments (b) Stress variation of bucket in two different environments.

As can be seen from Figure 5a, under the complex terrain condition (A), the load change of the bucket is more drastic. The initial load rises rapidly from 12.34 kN to 48.76 kN and peaks at the 5th second), which indicates that the bucket encounters a large resistance during excavation, which may be a hard soil layer or rock. Starting from the 6th second, the load gradually decreases and finally falls to 8.90 kN at the 10th second. In the urban building demolition scenario (B), the load changes are smoother. The initial load gradually increases from 6.78 kN to 39.87 kN, which indicates that the bucket encounters a gradual but more uniform change in resistance during the demolition process. Figure 5b shows the stress changes in the two environments, which shows that the bucket stress is concentrated when excavating hard soil or rock in complex terrain conditions, and the stress distribution is more uniform in the demolition process. Combined with Figures 5a,b, it can also be seen that in the 4th and 8th s, in the complex terrain condition (C), an obvious impact peak was generated due to the bucket contacting the hard interlayer, resulting in a large transient increase in load and stress, which reflects the typical sudden change in force characteristics in heterogeneous soil environments.

4 Discussion and analysis

The research and development of large hydraulic excavator has broken the monopoly of foreign products. The research on the load and structural strength of the working device of large hydraulic excavator provides a certain reference value for the design of the working device of large hydraulic excavator series. This paper takes hydraulic excavator as the research object, and establishes the simulation model of excavator bucket based on ADAM. Through kinematics and dynamics analysis, the strength and fatigue data in the application process are obtained, and the basic performance of the bucket is analyzed. In this study, the digging force of the digging bucket is an important analysis content in this study. Digging force is an important technical parameter of hydraulic excavator and the most important index to measure the performance of excavator. The digging force is determined by the extreme value of transmission ratio. Therefore, determining the parameters affecting the transmission ratio has become the key to the design of this chapter. The core contents of this study are as follows:

(1) The parametric mathematical model of excavator bucket is established by using ADAMS/View technology. The operation trajectory of excavator bucket is expressed by mathematical expression, and the spatial pose and joint angle of boom, stick and bucket are transformed in two directions. The simulation model of excavator working device is established in Simulink of MATLAB, the working parameters of excavator are set, and the working conditions of excavator are simulated.

(2) The excavation resistance of the hydraulic excavator is theoretically solved, and the specific values are loaded on the prototype model for simulation analysis. The stress conditions and relevant curves at each hinge point are obtained, which further reveals the variation law of the working performance and dynamic characteristics of the excavator working device, and makes preparations for the strength and fatigue analysis of parts.

(3) The experimental link is constructed to verify the application effect of the simulation method proposed in this study. It is proved that this method has high application value. This method can be used to obtain more reliable simulation results in future research.

Traditional simulation methods usually rely on a single finite element analysis, which can provide a more accurate static mechanical performance analysis, but has limitations when dealing with complex working conditions such as dynamic loading and multi-physical field coupling. In contrast, this paper combines the parametric modeling technique and the improved fatigue cumulative damage reliability analysis algorithm, which can more accurately reflect the dynamic response and fatigue performance of hydraulic excavator buckets in actual operation. In addition, the traditional method is low in computational efficiency, especially in the analysis of complex models and multiple working conditions, whereas the method in this paper improves the computational efficiency by optimizing the model structure and algorithm design, making it more suitable for rapid iteration and engineering applications. In recent years, hybrid simulation methods (e.g., combining finite element analysis with discrete element methods) have gradually gained attention in the field of construction machinery. By integrating the advantages of different simulation techniques, these methods are able to simulate complex working conditions and material behaviors more comprehensively. Future research could further explore the application of hybrid simulation methods in the design of hydraulic excavator buckets, such as combining FEA and discrete element methods to simulate bucket-soil interactions, thereby improving the accuracy and reliability of the simulation.

However, studying the proposed method in the practical application of complex working conditions may require a finer model to accurately reflect the mechanical behavior of the bucket. In practical engineering, the properties of bucket materials (e.g., modulus of elasticity, yield strength, and fatigue life) may change due to batch differences, environmental factors (e.g., temperature, humidity), or wear and tear during long-term use. This may lead to deviations between simulation results and actual performance. Therefore, more efficient computational methods will be explored in the future to optimize the model structure and enhance the experimental study of material properties. The introduction of stochastic analysis of material properties is considered to better reflect the material behavior under actual working conditions.

5 Conclusion

Using performance analysis simulation data in product design has become the development direction of machinery manufacturing and automobile manufacturing in the world. Performance analysis and simulation technology can analyze and evaluate part of the performance of the product only through the three-dimensional solid model and mechanical model of the mechanical system established by the computer without making a physical prototype after the mechanical design is completed, so as to provide parameter basis for product design and manufacturing. It greatly shortens the development cycle, reduces the number of physical prototypes and reduces the production cost. The method combines advanced parametric design technology and improved fatigue cumulative damage reliability analysis algorithm to realize high-precision simulation results. The parametric design of the bucket is completed by ADAMS/View technology, which can accurately express the geometric and kinematic characteristics of the bucket. Based on the actual digging force of the bucket, the strength of the bucket is simulated to ensure that the external force acting on the bucket can be accurately modeled. Subsequently, the improved fatigue cumulative damage reliability analysis algorithm is applied to simulate the fatigue performance of the bucket under complex working conditions. According to this technology, this study analyzes the correlation of excavator and obtains high-quality analysis results. The experimental results show that the simulation results of the present method are closer to the measured results than the existing methods. In addition, in terms of computational efficiency, the present method reduces the computation time by optimizing the algorithm and model simplification. Under complex working conditions, the traditional method may take several hours or even longer to complete the simulation, while the present method can be completed in only a few minutes, which improves the computational efficiency by about 80%. This result not only improves the accuracy of simulation, but also saves computational resources significantly, making it more suitable for practical engineering applications.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

WP: Conceptualization, Data curation, Formal Analysis, Methodology, Resources, Writing – original draft, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Arai, R., Sakai, S., Tatsuoka, A., and Zhang, Q. (2021). Analytical, experimental, and numerical investigation of energy in hydraulic cylinder dynamics of agriculture scale excavators. Energies 14 (19), 6210. doi:10.3390/en14196210

Dewa, R. T., and Kepka, M. (2021). Improved extrapolation method for the fatigue damage of bus structural steel under service loading. J. Mech. Sci. Technol. 35 (10), 4437–4442. doi:10.1007/s12206-021-0914-4

Feyijimi, A., Von, J. A., Phillips, B., Emmanuel, A., and Alex, Y. (2021). High performance electric vehicle powertrain modeling, simulation and validation. Energies 14 (5), 1493. doi:10.3390/en14051493

Jinguang, L., Liu, Y., Wang, L., and Sun, Y. (2024). A vision-based end pose estimation method for excavator manipulator. Multimedia Tools Appl. 83 (26), 68723–68741. doi:10.1007/s11042-024-18286-w

Lian, K., Hu, Z., Xiuhua, L., Zhang, Y., Xie, W., and Song, X. (2024). Adaptive neural network tracking control for unmanned electric shovel intelligent excavation system. Front. Mech. Eng. 19 (6), 1–16. doi:10.1007/s11465-024-0816-0

Liu, C., He, Q., Tang, Q., Ren, K., Jun, G., and Zhang, D. (2024). Novel control strategy for the energy recovery system of a hydraulic excavator. Int. J. Agric. Biol. Eng. 17 (2), 94–101. doi:10.25165/j.ijabe.20241702.7774

Liu, X., Huang, H., Chen, M., Fang, Y., and Yuwen, S. (2025). Optimization and performance analysis of a novel automatic planting-irrigating integrated robot. Proc. Institution Mech. Eng. Part C J. Mech. Eng. Sci. 239 (3), 899–929. doi:10.1177/09544062241278191

Michela, S., Antonio, C., Sergio, F., and Archimede, F. (2020). Experimental analysis and optimization to maximize ultimate tensile strength and ultimate elongation of friction stir welded AA6082 aluminum alloy. Metals 11 (1), 69. doi:10.3390/met11010069

Nie, Y., Xing, H., and Lei, Y. (2019). Optimization analysis for working device of hydraulicexcavators based on ADAMS. Comput. Simul. 36 (11), 300–304. doi:10.1007/978-981-10-6553-8_60

Niraj, R., Jaho, S., and Moohyun, C. (2021). Integrative tracking control strategy for robotic excavation. Int. J. Control, Automation Syst. 19 (10), 3435–3450. doi:10.1007/s12555-020-0595-2

Niskanen, I., Immonen, M., Makkonen, T., Keränen, P., Tyni, P., Hallman, L., et al. (2020). 4D modeling of soil surface during excavation using a solid-state 2D profilometer mounted on the arm of an excavator. Automation Constr. 112 (C), 103112. doi:10.1016/j.autcon.2020.103112

Park, S., Kim, J., Lee, S., and Seo, J. (2021). A comparative analysis of automated machine guidance and control systems for trench excavation. KSCE J. Civ. Eng. 25 (11), 4065–4074. doi:10.1007/s12205-021-0159-x

Reza, K., Kiana, P., and Masoud, T. (2021). Optimization of connecting rod design parameters for external fixation system: a biomechanical study. J. foot ankle Surg. 60 (6), 1169–1174. doi:10.1053/j.jfas.2021.02.013

Sakai, T. (2023). Historical review and future prospect for researches on very high cycle fatigue of metallic materials. Fatigue and Fract. Eng. Mater. and Struct. 46 (4), 1217–1255. doi:10.1111/ffe.13885

Sun, Y., Xu, Z., and Wang, Z. (2024). Assessment of fatigue life in H-type bridge hangers subjected to torsional vibration. J. Civ. Hydraulic Eng. 2 (3), 131–141. doi:10.56578/jche020301

Takahashi, A., Suzuki, A., and Kikuchi, M. (2019). Fatigue crack growth simulation of two non-coplanar embedded cracks using s-version finite element method. Fract. Struct. Integr. 13 (48), 473–480. doi:10.3221/igf-esis.48.45

Tri Cuong, D., Giap, N. D., Dung, D. T., and Ahn, K. K. (2020). A boom energy regeneration system of hybrid hydraulic excavator using energy conversion components. Actuators 10 (1), 1–10. doi:10.3390/act10010001

Tserpes, K., and Floros, I. (2019). Fatigue crack growth simulation in adhesively bonded composite joints. Fatigue and Fract. Eng. Mater. and Struct. 42 (7), 1430–1440. doi:10.1111/ffe.12969

Wang, C., Duan, H., and Long, L. (2024). Design, simulation, control of a hybrid pouring robot: enhancing automation level in the foundry industry. Robotica 42 (4), 1018–1038. doi:10.1017/s0263574723001881

Wang, X., Sun, H., Feng, M., Ren, Z., and Liu, J. (2021). Dynamic analysis of working device of excavator under limit digging force. J. Institution Eng. (India) Ser. C 102 (5), 1137–1144. doi:10.1007/s40032-021-00725-4

Wang, Y., and Roger, S. (2021). Vibration fatigue damage estimation by new stress correction based on kurtosis control of random excitation loadings. Sensors 21 (13), 4518. doi:10.3390/s21134518

Wang, Z., and Liu, G. (2025). Excavation path planning method for excavator based on fillability. Proc. Institution Mech. Eng. Part C J. Mech. Eng. Sci. 239 (5), 1723–1737. doi:10.1177/09544062241290991

Keywords: excavator, simulation analysis, adams, equipment performance analysis, fatigue analysis

Citation: Pan W (2025) A simulation study on strength and fatigue analysis of hydraulic excavator buckets. Front. Mech. Eng. 11:1591320. doi: 10.3389/fmech.2025.1591320

Received: 12 March 2025; Accepted: 12 May 2025;

Published: 30 May 2025.

Edited by:

Guorui Wang, University of Science and Technology of China, ChinaReviewed by:

Jerwin Prabu, Addverb Technologies, IndiaMehmet Akif Koç, Sakarya University of Applied Sciences, Türkiye

Copyright © 2025 Pan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Wenbin Pan, cGFud2VuYmluMTgyMDU4NUAxMjYuY29t

Wenbin Pan

Wenbin Pan