- 1Rubber Technology Centre, Indian Institute of Technology Kharagpur, Kharagpur, India

- 2Product Development, Apollo Tyres Ltd. Global R&D Centre - Asia, Sriperumbudur, India

A Corrigendum on

Characterization of ply bulge failures in truck bus radial tyres

by Yadav A, Jiju CM, Kumar P and Das NC (2025). Front. Mech. Eng. 11:1576195. doi: 10.3389/fmech.2025.1576195

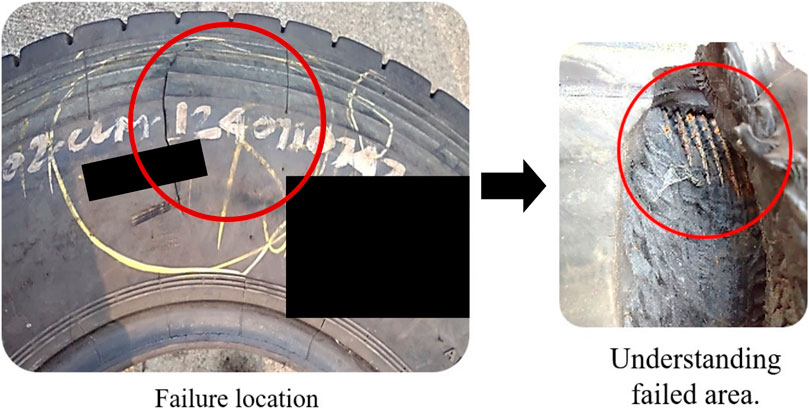

In the published article, there was an error in Figure 1 as published.

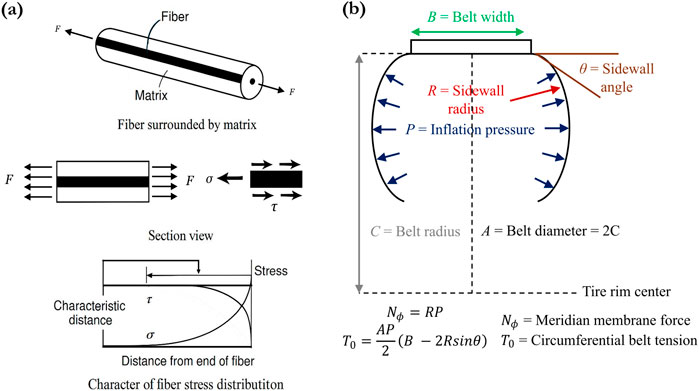

Figure 2. (a) Load transfer process when fiber in tension (Hyer and White, 2009), (b) Tension at carcass ply and belt in radial tyre (Yamagishi et al., 1987).

The corrected Figure 1 and its caption appear below.

In the published article, there was an error in Figure 4 as published.

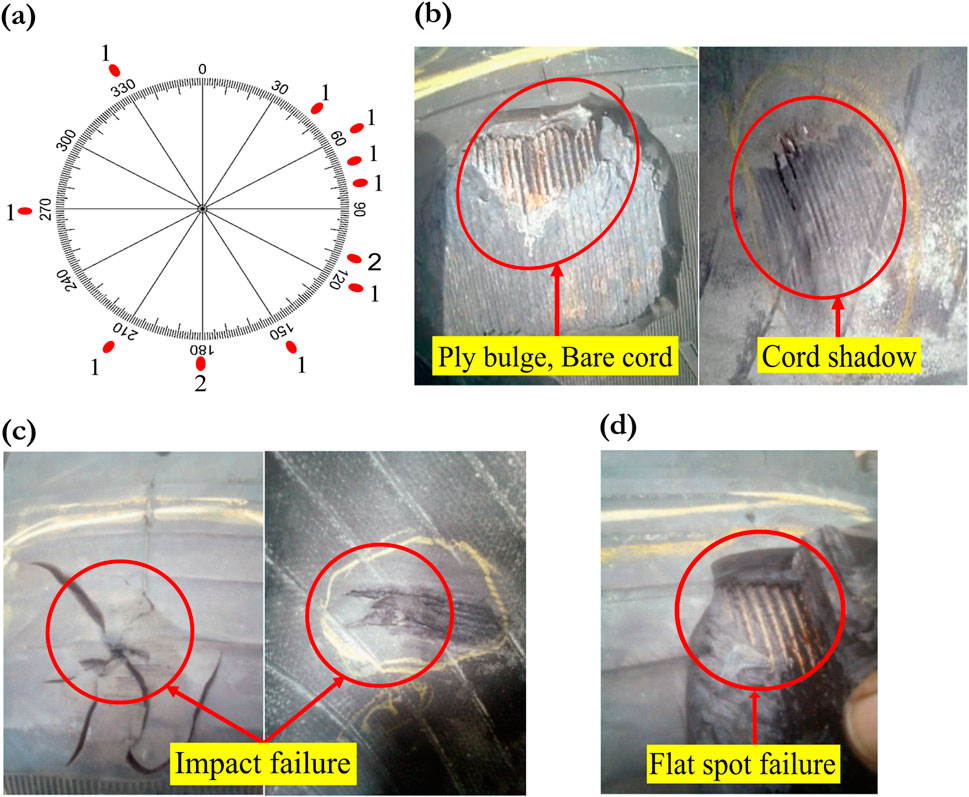

Figure 4. Visual analysis: (a) Failure location at different circumferential positions of the tyre, (b) Bare cord and cord shadow at the failure location, (c) Failure due to impact, (d) Failure due to flat spot.

The corrected Figure 4 and its caption appear below.

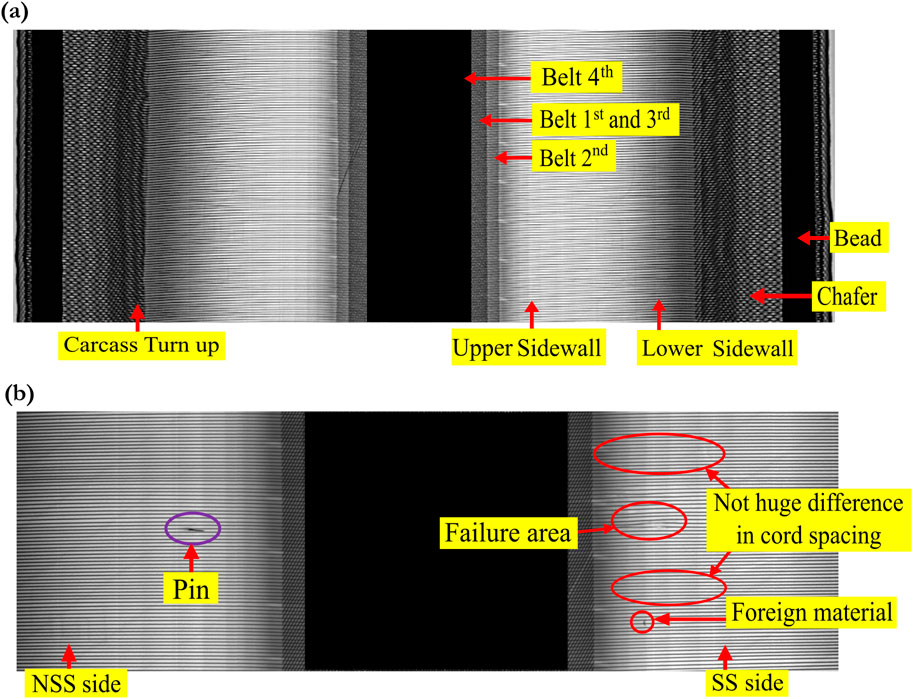

In the published article, there was an error in Figure 5 as published. The corrected Figure 5 and its caption appear below.

Figure 5. (a) Identifying different components from the X-ray image, (b) X-ray image of failed tyre.

In the published article, there was an error in the first paragraph of subsection 4.1 under section Results and discussion.

This sentence previously stated:

These failures were not restricted to any specific side, whether NSS or SS, and could occur at any circumferential location around the tyre. For reference, the barcode location was designated as 0◦, and the inner liner (IL) splice was marked at 180◦, as shown in Figure 4a.

The corrected sentence appears below:

These failures were not restricted to any specific side, whether NSS or SS, and could occur at any circumferential location around the tyre, as shown in Figure 4a.

The authors apologize for this error and state that this does not change the scientific conclusions of the article in any way. The original article has been updated.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Keywords: ply bulge, truck and bus radial (TBR), x-ray, shearography, FTIR, 90°peel test, adhesive failure

Citation: Yadav A, Jiju CM, Kumar P and Das NC (2025) Corrigendum: Characterization of ply bulge failures in truck bus radial tyres. Front. Mech. Eng. 11:1626849. doi: 10.3389/fmech.2025.1626849

Received: 11 May 2025; Accepted: 14 May 2025;

Published: 02 June 2025.

Edited and reviewed by:

Mohit Goswami, Technion Israel Institute of Technology, IsraelCopyright © 2025 Yadav, Jiju, Kumar and Das. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ankush Yadav, eWFkYXZhbmt1c2g5NDhAZ21haWwuY29t

Ankush Yadav

Ankush Yadav C. M. Jiju2

C. M. Jiju2 Narayan Chandra Das

Narayan Chandra Das