- 1School of Application of Artificial Intelligence, Shanghai Urban Construction Vocational College, Shanghai, China

- 2School of Architecture and Transportation Engineering, Guilin University of Electronic Technology, Guilin, China

Introduction: In complex industrial environments, traditional industrial robot control systems are difficult to meet the requirements of automated production for industrial parts sorting and assembly tasks.

Methods: For this purpose, this study constructs an industrial robot sorting and assembly control system based on Ethernet bus. Its innovation lies in the deep coupling of Profinet real-time Ethernet with self-tuning fuzzy PID control, compressing communication jitter to the sub-millisecond level. Introduce the greedy visual hybrid algorithm; A four-layer integrated framework of “hardware - communication - algorithm - human-machine” has been constructed, which can directly reuse the existing Siemens PLC and I/O ecosystem, significantly reducing deployment costs.

Results: The experimental results show that when the time of the fusion control algorithm is 4.0 seconds, the position tracking deviation is 0.012mm. The position tracking deviation of the deep deterministic policy gradient algorithm is 0.018mm, and its performance is inferior to that of the fusion algorithm. The sorting recall rate of the fuzzy sliding mode industrial sorting and assembly control system is 93.67%, which is lower than that of the fusion control system.

Discussion: The research findings provide a reusable technical paradigm for the next generation of highly flexible and scalable intelligent production lines, which are expected to be rapidly implemented in scenarios such as micro-nano electronic assembly, flexible pharmaceuticals, and circular remanufacturing.

1 Introduction

As the core equipment of modern intelligent manufacturing, industrial robots have been widely applied in various fields such as metal processing and automotive manufacturing, continuously driving industrial upgrades and social development. In the field of automated sorting and assembly, industrial robots are capable of efficiently and accurately sorting products such as pharmaceuticals and food, with speeds far exceeding those of manual labor (Luo and Qiao, 2024). However, traditional industrial robot sorting and assembly control systems often use decentralized bus architectures, resulting in issues such as high communication delays and limited high-speed dynamic tracking capabilities (Peta et al., 2023). Current improvements in sorting and assembly control technologies include target visual detection technologies based on the “You Only Look Once” (YOLO) series and trajectory planning motion control technologies, among others. The trajectory planning motion control technology can plan reasonable movement paths for the robot based on sorting or assembly task requirements (Bogue, 2023; Kiyokawa et al., 2022). Although these technologies enable industrial robots to determine the position of objects with different shapes, issues such as unstable motion still remain. The Process Field Network (Profinet) bus, as a high-performance industrial Ethernet standard, can not only connect various types of devices and communication protocols but also meet the real-time application requirements of industrial automation motion control. Therefore, in response to the weak real-time communication capabilities of industrial robots and low sorting and assembly accuracy, this study proposes an industrial robot sorting and assembly control system based on the Profinet bus, with the aim of improving sorting efficiency and providing technical support for efficient collaboration on smart manufacturing production lines. The innovation of this system lies in the combination of the Profinet bus with fuzzy Proportion-Integral-Differential (PID) control, designing a new control algorithm to enhance the system’s adaptive control of parameters. Additionally, a greedy algorithm is used to make optimal choices for information such as workpiece path locality, improving the system’s sorting and assembly control capabilities.

2 Related works

To meet the real-time interaction requirements in industrial robot sorting and assembly processes, many scholars have conducted research on industrial robot control systems. Nguyen Q et al. developed a laser structured light vision system for industrial welding manipulators to address issues such as weak welding precision. Experimental results showed that the system performed significantly well in welding tasks with curved profiles and small gaps in butt joint seams, with an average welding error of 1.7 mm (Nguyen Q. C. et al., 2024). Hoebert et al. proposed a knowledge-driven framework based on industrial robot systems to solve problems related to time-consuming robot programming and high costs. Experimental results showed that this method reduced the amount of programming required for robots in automated production, making it easier to adapt to personalized production (Hoebert et al., 2023). Pan H et al. studied and designed a method for predicting and compensating non geometric errors using an optimized optimal pruning limit learning machine in order to improve the absolute positioning accuracy of six degree of freedom industrial robots. The results showed that the average absolute position error of the center point of the robot end effector decreased from 1.229 mm to 0.164 mm, and the maximum absolute position error decreased from 1.938 mm to 0.275 mm (Pan et al., 2025). Although the above methods perform well in terms of positioning accuracy and are suitable for high-precision positioning tasks, they have high computational overhead and poor real-time performance; And this research method combines high precision and low latency through the low latency characteristics of Profinet bus and the adaptability of fuzzy PID control algorithm. Zhang C et al. proposed an industrial robot positioning method based on an improved Monte Carlo algorithm to address the problem of inaccurate positioning in complex environments using existing positioning techniques, such as Monte Carlo positioning methods. The method was optimized using scanning matching technology. The experimental results show that in simple environments, the average positioning error of the proposed improved Monte Carlo algorithm is 1.55 cm; in complex environments, the optimization method combined with scan matching maintains a positioning accuracy of over 95.00% (Zhang and Zhang, 2025). Liu F et al. designed a novel error model based on vector inner product to improve the positioning accuracy in the workpiece coordinate system. The research results show that compared with existing distance error models and position error models, the positioning accuracy in the calibrated workpiece coordinate system has been improved by 36% and 15%, respectively (Liu et al., 2025). The above method performs well in the accuracy of kinematic models and can effectively improve the positioning accuracy of robots. However, it requires high requirements for model establishment and parameter adjustment, and has high computational complexity; The fuzzy PID control algorithm used in this research can dynamically adjust control parameters based on the real-time state of the system, thereby improving the adaptability and stability of the system.

As industrial robot control technologies have advanced, the demands for industrial robot sorting and assembly have increased. Not only is high sorting efficiency required, but precise target detection must also be achieved in complex and dense environments. Consequently, researchers have focused on industrial robot sorting and assembly technologies. Zhang et al. proposed an intelligent assembly line sorting method based on robotic arm visual positioning and model predictive control to address problems related to the difficulty of adjusting the posture of steering devices on fruit and vegetable packaging lines. Experimental results showed that this method could stably and quickly grasp lettuce at different speeds (Zhang et al., 2023). Mogro et al. proposed a machine vision system based on a Logitech C920 HD Pro camera and force and torque sensors to meet the requirement for quick and accurate classification of stacking objects. Experimental results showed that the system effectively improved productivity and safety in collaborative industrial environments (Mogro et al., 2024). Setiawan et al. developed an automatic sorting conveyor system using Arduino technology and pneumatic actuators to solve issues related to the time-consuming nature of industrial automatic sorting systems. Experimental results showed that the system successfully improved the efficiency and accuracy of industrial sorting processes (Setiawan et al., 2024). Schmidbauer et al. set up a collaborative robot demonstrator with real industrial assembly use cases to enable collaborative robots to efficiently perform sorting tasks. Experimental results showed that the collaborative robot could increase the productivity of monotonous sorting tasks (Schmidbauer et al., 2023). Farsi et al. used multi-objective dragonfly optimization and non-dominated sorting genetic algorithms to balance robotic assembly lines with hybrid model assembly lines. Experimental results showed that the hybrid algorithm improved the efficiency of the assembly line, reducing robot idle time and energy consumption (Farsi et al., 2024).

Based on the above content, it can be concluded that significant progress has been made in the research of industrial robot sorting and assembly control systems in terms of real-time performance, accuracy, and adaptability in recent years. However, there are still several key technical bottlenecks that urgently need to be overcome. On the one hand, existing technologies rely on complex neural networks or machine learning algorithms. Although they can improve the accuracy of the system, they may bring high computational costs and communication delays in practical applications, thereby affecting the real-time performance of the system. On the other hand, it lacks adaptability to complex dynamic environments, making it difficult to meet the diverse needs of industrial automation production. Therefore, this research proposes the design of an industrial robot sorting and assembly control system based on the Profinet bus to detect targets with different scale features. It is expected that this system will meet the high precision requirements of sorting and assembly in manufacturing and improve its applicability in future scenarios.

3 Optimization of industrial robot sorting and assembly control system

3.1 Control algorithm based on Profinet bus and fuzzy PID

With the development of technology, robots have become one of the indispensable tools in manufacturing (Zhao et al., 2024). Robots can not only automatically grasp industrial components such as glass and ceramic parts, but also perform high-precision welding on electronic products. Although robots can complete precision assembly tasks, they still lag behind in flexibility and adaptability (Ayyıldız et al., 2024). Compared to dedicated real-time Ethernet such as EtherCAT and Sercos III, Profinet IRT can stably achieve deterministic jitter of <1 ms without the need for additional dedicated ASICs, reducing hardware costs and maintenance complexity. At the same time, Profinet supports multi protocol compatibility, seamlessly integrates heterogeneous devices such as vision systems and force sensors, and maintains stable transmission in interference environments through deterministic communication mechanisms. In testing, the overshoot is as low as 22.16%, and the adjustment time is only 4.37 ms. In addition, its open architecture provides an extended foundation for future industrial Internet of Things (IIoT) and collaborative robot applications. Although Profinet is a common standard for industrial Ethernet, its optimized performance in specialized scenarios such as motion control makes it an ideal choice for improving the efficiency of industrial robot sorting and assembly. To address issues such as poor assistance ability and unstable safety of robots, a control algorithm based on Profinet bus and fuzzy PID is proposed to improve the performance of intelligent robot control. Fuzzy PID is a control algorithm that combines fuzzy control with traditional PID, which can automatically adjust PID parameters based on different operating states, providing high control accuracy and strong adaptability (Nguyen H. T. et al., 2024). The fuzzy PID membership function of the fuzzy layer is shown in Equation 1.

In Equation 1, the number of input variables is

In Equation 2, the error and error rate are

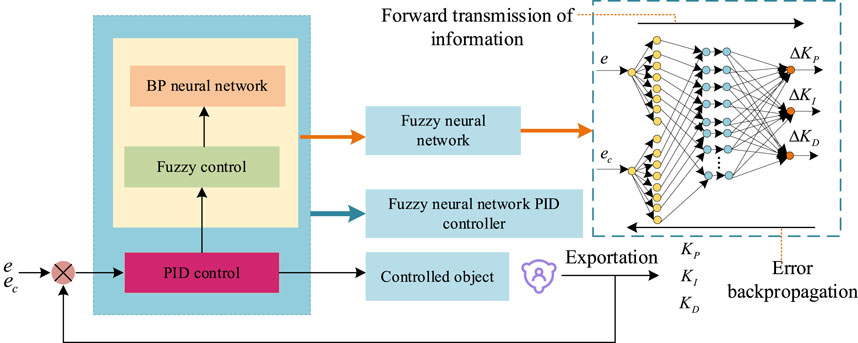

From Figure 1, it can be seen that the improved fuzzy PID control principle mainly uses the system error

In Equation 3, the fuzzy decryption output values and related membership function input variables are

In Equation 4, the input module data size is

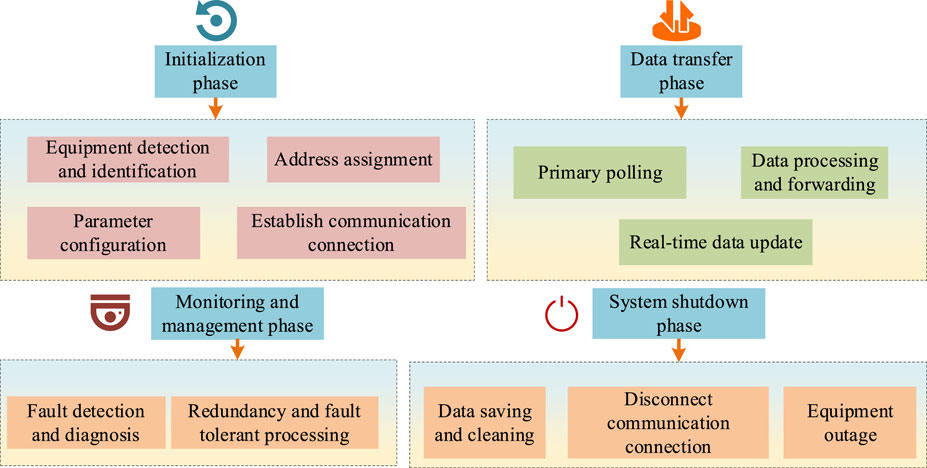

As shown in Figure 2, the Profinet bus application flow is mainly divided into four stages: initialization, data transmission, monitoring management, and system shutdown. The initialization stage scans Siemens ET 200SP distributed I/O devices on the bus to obtain device type, address, and other information. In the data transmission stage, the master station queries the slave stations sequentially to see if data needs to be transmitted, and after receiving the response frame from the slave station, the data is processed and forwarded, with real-time updates and interactions. The monitoring and management stage mainly detects communication status, identifies device faults, electromagnetic interference, etc., and corrects the data. The system shutdown stage refers to the master and slave stations saving and clearing the current device status, and the entire Profinet bus system stops running. The calculation method of Profinet bus real-time communication cycle time is shown in Equation 5.

In Equation 5, the data exchange time is

In Equation 6, the control output is

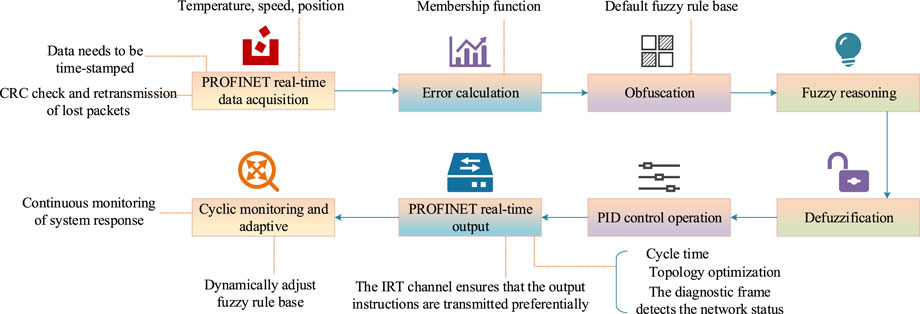

As shown in Figure 3, the process of the control algorithm based on Profinet bus and fuzzy PID begins with the master station periodically reading sensor data from the slave stations via Profinet, and collecting data such as temperature and position in real-time. During the data collection process, timestamps are needed to ensure time synchronization. Then, the error, fuzzification, and fuzzy inference calculations are performed. During fuzzy inference, PID parameter adjustment quantities are generated based on the pre-set fuzzy rule base. The fuzzy output is then defuzzified to update the PID parameters in real-time. After the PID control calculation, the control output is sent via Profinet to the actuator, ensuring priority transmission of the output command through isochronous synchronized real-time channels. Finally, the output data is continuously monitored and dynamically adjusted.

3.2 Design of the sorting and assembly control system integrated with Profinet bus

Although the control algorithm combining Profinet bus and fuzzy PID can meet the real-time control requirements in industrial production, there are still certain shortcomings in industrial robot sorting and assembly. Therefore, to address issues such as insufficient precision and limited visual recognition ability in industrial robot sorting and assembly, the study proposes a control system that integrates vision and greedy algorithms based on the Profinet bus and fuzzy PID control algorithm, in order to improve the sorting assembly efficiency and positioning accuracy of robots. The greedy algorithm significantly improves algorithm execution efficiency by making optimal choices based on current local information (Daneshmand et al., 2023). The optimal strategy of the industrial robot assembly path using the improved greedy algorithm is shown in Equation 7.

In Equation 7, the optimal assembly path corresponding strategy and search factor are

In Equation 8,

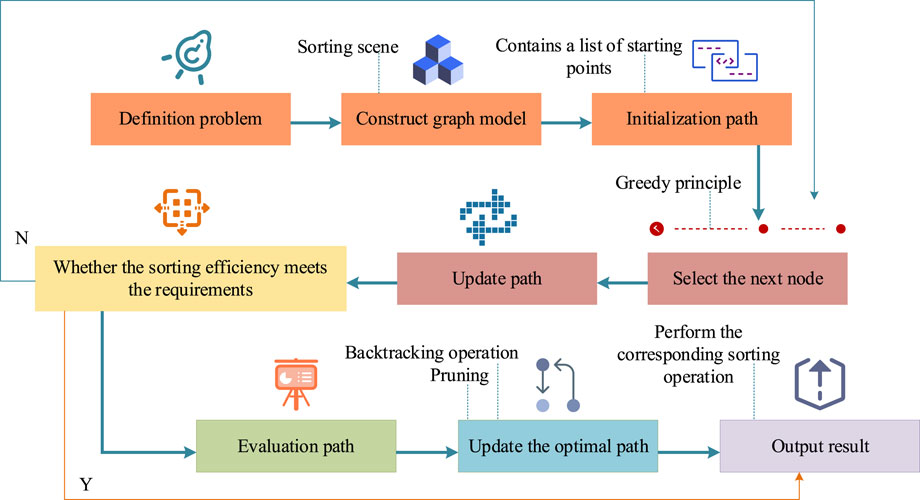

As shown in Figure 4, the steps for selecting the optimal sorting path for the industrial robot based on the greedy algorithm begin with defining the sorting problem, including specifying the item set, location distribution, and other sorting tasks. The sorting scenario is then constructed into a directed graph model, and the path is initialized starting from the robot’s current position. Then, based on the greedy principle, the next node is selected and the priority of the target workpiece is calculated. The selected path node is added to the path list, forming a new path. The sorting efficiency of the robot is then evaluated by determining whether the robot’s path yields an efficient sorting process. If the sorting efficiency meets the required criteria, the final result is output. The sorting efficiency calculation is shown in Equation 9.

In Equation 9, the horizontal distance from the start position to the target grab position of the industrial robot during task execution is

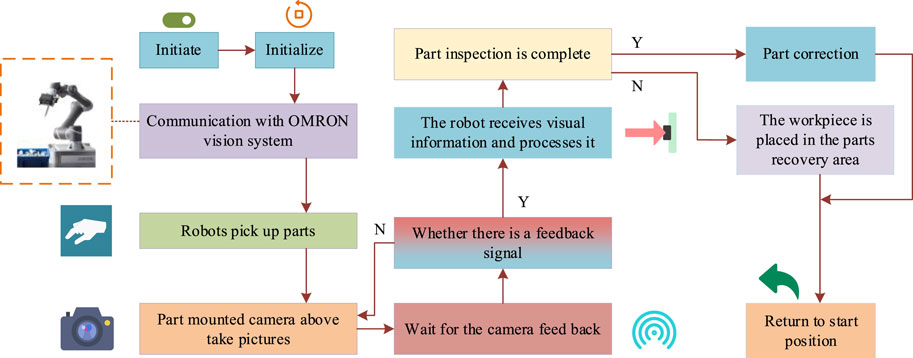

As shown in Figure 5, the robot sorting and assembly control process based on the OMRON vision system starts with calibrating the zero position of each joint of the robot arm and setting the motion parameters, such as maximum speed and acceleration. Then, a communication link between the OMRON vision system and the robot is established. The robot moves the picked part above the camera for imaging and then waits for the feedback signal from the vision system after image processing. Once the feedback signal is received, the robot processes the part image information provided by the vision system. The processed part is then further inspected, and if it passes the inspection, the assembly work is completed. Image matching detection is calculated as shown in Equation 10.

In Equation 10, the pixel value at sub-image coordinate

In Equation 11, the radius of the circle and the current position of the circular hole center are

In Equation 12, the offset of the industrial robot along the

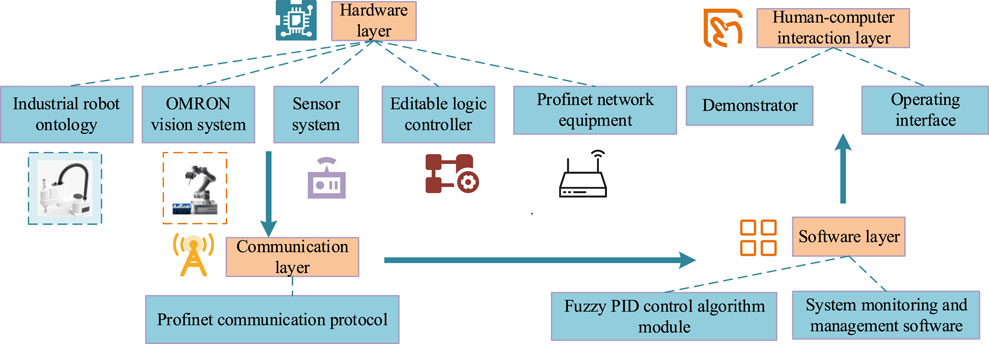

In Figure 6, the industrial robot sorting and assembly control system based on Profinet bus and fuzzy PID is divided into four parts: the hardware layer, communication layer, software layer, and human-machine interaction layer. The hardware layer mainly includes the SCARA industrial robot body, OMRON vision system, force sensors, and others. The OMRON vision system is used to identify the shape, position, and color of parts. Then, the system enters the communication layer, where the Profinet communication protocol is used for high-speed data transmission and real-time control between devices. The software layer mainly consists of the fuzzy PID control algorithm module and the system monitoring and management software, which adjust the robot’s control parameters in real-time. Finally, in the human-machine interaction layer, operators can manually control the robot through the teach pendant and view the robot’s status information.

4 Performance analysis of industrial robot sorting and assembly control system

4.1 Performance evaluation of control algorithm based on Profinet and fuzzy PID

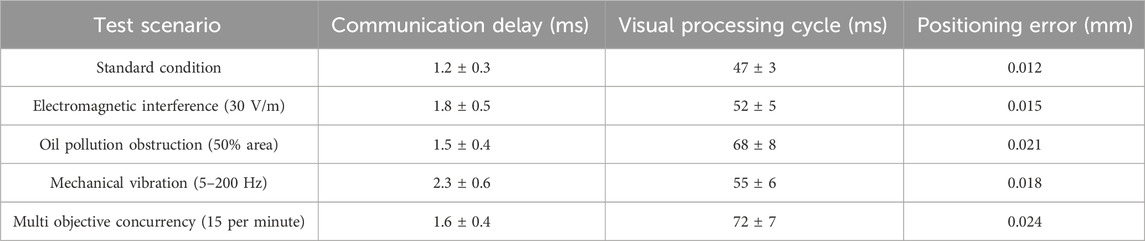

To verify the performance superiority of the Profinet bus fusion and fuzzy PID control algorithm, the study compared it with the fuzzy sliding mode control algorithm, Deep Deterministic Policy Gradient (DDPG) algorithm, and Whale Optimization PID control algorithm. The experimental hardware platform was Cortex-M4 + FPGA, and the software platform used was the Linux embedded operating system, with the Rviz visualization interface. For the experiments to be authentic and reliable, the study selected the Fourier ActionNet and RoboMIND datasets for testing and training. The process of network training is as follows: first, collect the input and output data of the system, including sensor readings, control instructions, and system response. These data are used to train a neural network that adopts a three-layer structure. The input layer receives the system’s error and error change rate, the hidden layer processes it through fuzzy rules, and the output layer generates the adjustment of PID parameters. During the training process, the backpropagation algorithm is used to adjust the network weights and optimize the fuzzy rule library by minimizing the prediction error. After training, the neural network can learn the dynamic characteristics of the system and generate optimal fuzzy rules, which are then solidified in the local memory of the PLC for online control. The Fourier ActionNet dataset contains imitation learning data for robotic hand tasks. The study performed a pose tracking deviation test with four control algorithms: Profinet bus fusion, fuzzy sliding mode, DDPG, and Whale Optimization PID. The test results are shown in Figure 7.

Figure 7. Position tracking deviation test results in different data sets. (a) Different algorithms track deviation test results in Fourier ActionNet dataset. (b) Different algorithms track deviation test results in RoboMIND dataset. (c) Attitude Angle tracking error results of different algorithms in Fourier ActionNet dataset. (d) Attitude Angle tracking deviation results of different algorithms in RoboMIND dataset.

As shown in Figure 7a, the position tracking deviation of the Profinet bus fusion control algorithm was 0.006 mm less than that of the DDPG control algorithm. As shown in Figure 7b, when the Profinet bus fusion control algorithm was used with the RoboMIND dataset, the position tracking deviation was 0.012 mm at 4.0 s. As shown in Figure 7c, the attitude angle tracking deviation of the fuzzy sliding mode control algorithm was 2.89 rad at 5.0 s. As shown in Figure 7d, the Profinet bus fusion control algorithm had an attitude angle tracking deviation of 0.46 rad at 4.0 s. In summary, the Profinet bus fusion control algorithm enabled better operation of the robotic arm and showed stable overall performance. To further demonstrate the applicability of the Profinet bus fusion control algorithm, the study tested it for path obstacle avoidance and compared it with the fuzzy sliding mode, DDPG, and Whale Optimization PID control algorithms. The test results are shown in Figure 8.

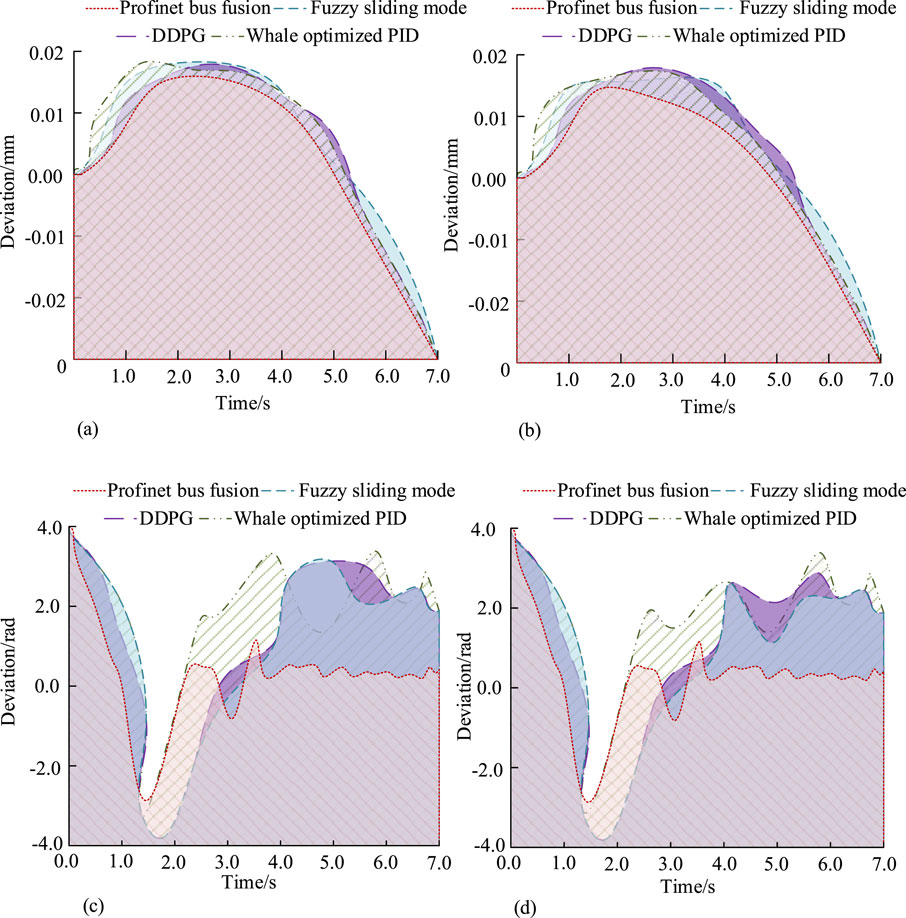

Figure 8. Robot path obstacle avoidance test results. (a) Profinet bus fusion path obstacle avoidance test results. (b) Fuzzy sliding mode path obstacle avoidance test results. (c) DDPG path obstacle avoidance test results. (d) Whale optimized PID path obstacle avoidance test results.

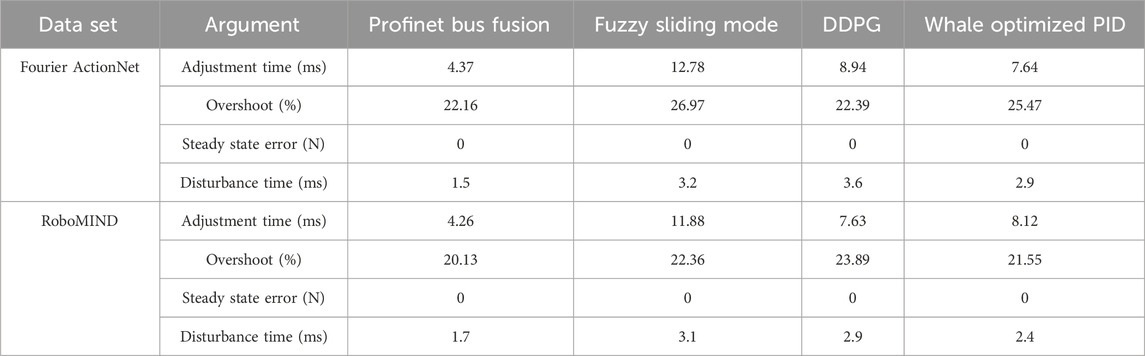

As shown in Figure 8a, when the robot using the Profinet bus fusion control algorithm had x = 18 m and y = 30 m, the proportion of the path near obstacles was 8.25%, indicating a relatively safe path. As shown in Figure 8b, when the fuzzy sliding mode control algorithm was used with the robot’s x = 42 m and y = 41 m, the proportion near obstacles was 75.36%, and the optimal path found was more dangerous. As shown in Figure 8c, the optimal path found using the DDPG control algorithm had many turns, and the distance to the target was larger. As shown in Figure 8d, when x was between 20 m and 43 m, and y between 38 m and 42 m, the robot using the Whale Optimization PID control algorithm had a more winding obstacle avoidance path, with a total of 79.69% of the path near obstacles. Additionally, the study performed interference tests on the four control algorithms, and the test results are shown in Table 1.

As shown in Table 1, when the Profinet bus fusion control algorithm was tested in the Fourier ActionNet dataset under interference, the adjustment time was 4.37 ms, with an overshoot of 22.48%. When tested with the RoboMIND dataset, the overshoot of the Profinet bus fusion control algorithm was 20.13%, which was 2.23%, 3.76%, and 1.42% lower than the fuzzy sliding mode, DDPG, and Whale Optimization PID control algorithms, respectively. This is because of the propagation mechanism of the network, where the system collects sensor data in real-time and calculates the error and error rate based on it. These data are then input into the fuzzy PID control algorithm. The fuzzy rule library generates the adjustment amount of PID parameters through fuzzy inference based on the input error and error change rate. These adjustments are applied to the PID controller to update the PID parameters in real-time. The updated PID parameters are used to generate control instructions, which are sent to the robot controller through the Profinet bus to drive the robot to perform corresponding actions. This process ensures that the system can dynamically adjust control parameters based on real-time status, thereby improving control accuracy and system stability.

4.2 Validation of the sorting and assembly control system integrated with multiple methods

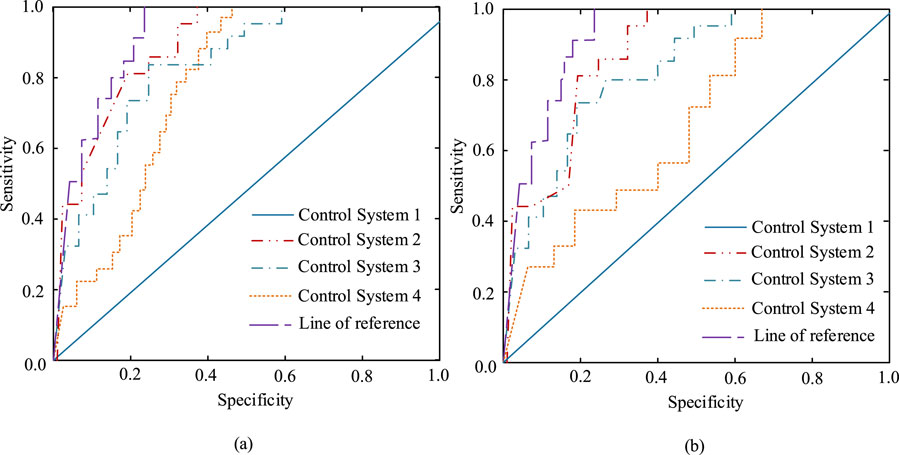

To further explore the effectiveness of the algorithm based industrial robot sorting and assembly control system in practical applications. The system was compared with the industrial robot sorting and assembly control systems constructed using the fuzzy sliding mode, DDPG, and Whale Optimization PID algorithms. The experimental object was the German LBR iiwa 7 R800 industrial robot, with the main controller being the Siemens CPU1214C AC/DC/RlyPLC, and the network master station set as the CPU1214C, extended with a CJ1W-ID211 (DI) switch input/output module. The datasets selected were the Caltech 256 and CIFAR-100 datasets, which contained 256 and 100 classes of object image data, respectively, and helped the industrial robot recognize different types of parts. The detailed process of the research system in practical application is as follows: firstly, the conveyor belt continuously transports the workpiece to be processed into the working area, and the OMRON vision system captures the workpiece image in real time and performs high-precision positioning analysis. The coordinate data is transmitted to the main control system through the Profinet bus; Secondly, the control core is based on a greedy algorithm to quickly calculate the optimal grasping path, while the fuzzy PID controller dynamically adjusts the motion parameters based on feedback from the force sensor; Then the industrial robot executes precise grasping actions according to the planned trajectory, completes sorting, and transports it to the designated assembly station. During the assembly process, real-time monitoring of contact force and fine-tuning of pose are carried out; Finally, all device status data is exchanged in real-time through the Profinet network, and the system continuously monitors the operating status of each link to ensure the efficient and stable execution of the entire sorting and assembly process. Different control systems adopt a unified actual deployment scenario, with the following specific settings: an industrial robot is installed on an earthquake resistant base, with a working radius covering a 2-m-wide conveyor belt and four surrounding assembly stations; The OMRON FH series intelligent camera is fixed at a 45° angle 1.5 m above the conveyor belt, and is paired with a circular light source to ensure imaging quality; The Siemens CPU1214C PLC controller is networked with robot controllers, distributed I/O modules, and HMI operation terminals through Profinet industrial Ethernet. The network topology adopts a star structure to ensure real-time communication. In actual operation, the system works continuously at a rate of 60 gear components per minute, and the conveyor belt speed remains stable at 0.5 m/s. The vision system takes multi angle photos and locates each gear component that reaches the detection area. The robot completes the picking according to the real-time calculated grasping path and accurately assembles it to the designated position of the gearbox housing. The Profinet network maintains a synchronous control cycle of 1 ms throughout the entire process to ensure the coordinated operation of all devices. The study performed part grabbing environment sensitivity tests on the four sorting and assembly control systems (Profinet bus fusion - Control System 1, fuzzy sliding mode - Control System 2, DDPG - Control System 3, and Whale Optimization PID - Control System 4), and the test results are shown in Figure 9.

Figure 9. Part grabbing environmental sensitivity test results. (a) Sensitivity and specificity test results of different systems in the Caltech 256 dataset. (b) Sensitivity and specificity test results of different systems in the CIFAR-100 dataset.

As shown in Figure 9a, when the specificity of Control System 1 was 0.21, the sensitivity was 0.37. For Control Systems 2, 3, and 4, when the specificity was 0.62, the sensitivity exceeded 1.00. Control System 1 showed higher sensitivity and stronger ability to recognize positive cases. As shown in Figure 9b, when the specificity of Control System 1 was 0.43, the sensitivity was 0.49. Compared to Figure 9a, the sensitivity slightly decreased. In the CIFAR-100 dataset, Control System 4 showed sensitivity and specificity both close to 0.8. In summary, Control System 1 achieved a good balance between sensitivity and specificity, with a low probability of false positives when recognizing objects. Furthermore, the study tested the actual assembly operation trajectories of the four control systems. The test results are shown in Figure 10.

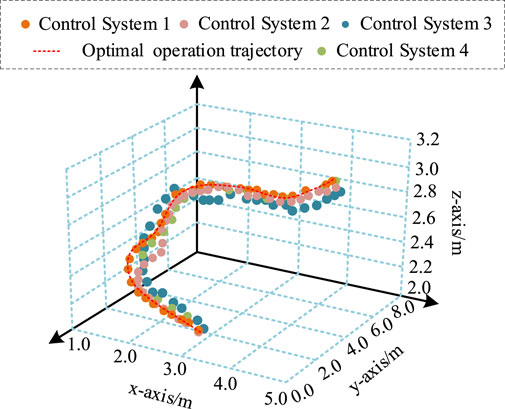

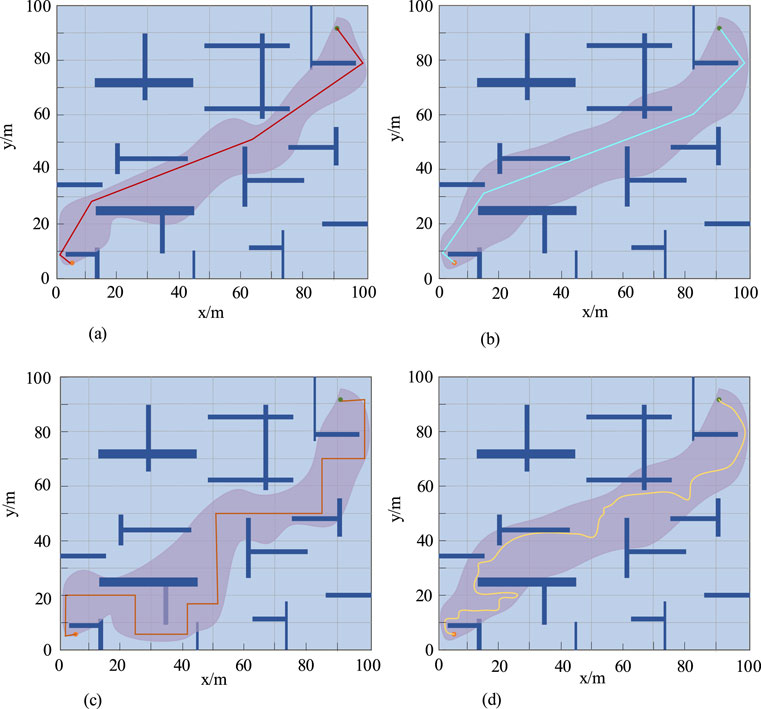

As shown in Figure 10, the actual optimal operation trajectory showed a significant turning tendency. When the x-axis was 3.0 m, the actual assembly operation trajectory of the industrial robot with Control System 1 matched the optimal trajectory. When the x-axis was 3.2 m, the y-axis was 8.0 m, and the z-axis was 2.6 m, the actual assembly operation trajectory of the industrial robot with Control System 1 was consistent with the optimal trajectory. When the x-axis was 2.8 m, the y-axis was 4.1 m, and the y-axis was 2.4 m, the actual assembly operation trajectory of the industrial robot with Control System 3 showed a 0.1 m error in the y-axis compared to the optimal trajectory. To investigate the communication delay and visual feedback response of Profinet in complex environments, an oscilloscope was used to capture the Profinet frame transmission time difference between PLC and robot controller. The results are shown in Table 2.

Table 2 shows that in strong electromagnetic interference scenarios, the system communication delay is always controlled within 2.4 ms, thanks to the precise clock synchronization mechanism and professional grade shielded cable design. In the face of oil pollution conditions, the visual system can maintain stable recognition ability even under harsh conditions where the lens transmittance drops to 72%, and the positioning accuracy fluctuates by no more than 0.02 mm, demonstrating the strong environmental adaptability of the research system. In a mechanical vibration environment, the system can effectively suppress trajectory deviation caused by vibration in just 3 ms by dynamically adjusting control parameters. High load testing shows that the overall response speed of the system can still be maintained within the acceptable range of engineering at a pace of processing 15 workpieces per minute. The excellent performance of the research system in real-time may be due to Profinet IRT’s hardware level time synchronization and frame scheduling mechanism, which ensures data transmission within the specified time window. This low latency and high stability provide a fundamental guarantee for the real-time performance of the control system. The fuzzy PID control algorithm combines the advantages of fuzzy control and traditional PID control, and can dynamically adjust control parameters based on the real-time state of the system, thereby improving control accuracy and adaptability. The combination of real-time data transmission via Profinet bus and dynamic adjustment of fuzzy PID control algorithm enables the system to quickly respond and adjust control strategies within each control cycle, thereby significantly improving the real-time performance of the system. The excellent real-time communication capability, intelligent environmental adaptability, and stable high load performance of the research method make it a breakthrough solution in the field of industrial automation, especially suitable for production scenarios with strict requirements for reliability and accuracy. In summary, the Profinet bus fusion industrial robot sorting and assembly control system proposed in the study showed good assembly control performance and superior path planning capability.

5 Conclusion

To address the issues of low sorting efficiency in industrial robots, the study built an industrial robot sorting and assembly control system based on the integration of Profinet bus and fuzzy PID control algorithms. During the system construction, a greedy algorithm was also used to optimize local information to improve the positioning accuracy of the industrial robot. The experimental results show that the real-time control framework integrating Profinet deterministic communication and fuzzy PID adaptive regulation reduces position deviation by 33% compared to DDPG. Integrated OMRON vision and force sensor software and hardware collaborative design, achieving millimeter level operational accuracy. The experiment verified the superiority of the system in terms of tracking error with an accuracy of 0.012 mm and interference recovery with a reliability of 1.5 ms. In summary, the industrial robot sorting and assembly control system based on Profinet bus and fuzzy PID control algorithms was able to better perform precision operation tasks and adaptively adjust related parameters in a timely manner when problems were detected. However, there are still certain limitations in the research, as the experiment did not test the detection of micro scale assembly parts. Therefore, in future research, further testing of micro scale assembly detection can be conducted to explore its applicability in precision manufacturing scenarios such as semiconductors and microsensors. Secondly, combined with the real-time communication capability of Profinet bus, it can be extended to human-machine collaborative production lines to improve flexible manufacturing efficiency. Finally, research a multi robot collaborative control framework to improve the overall efficiency of large-scale production lines.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

YZ: Conceptualization, Writing – original draft, Resources, Validation, Formal Analysis, Supervision, Data curation. TW: Project administration, Methodology, Supervision, Writing – review and editing, Investigation, Validation.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ayyıldız, M., Çiftçi, Y. K., Kilecioğlu, K., and Arslan, Ö. F. (2024). Fruit sorting automation; cartesian robot and conveyor design. Düzce Üniversitesi Bilim ve Teknol. Derg. 12 (3), 1627–1639. doi:10.29130/dubited.1400615

Bogue, R. (2023). The first half century of industrial robot: 50 years of robotic developments. Industrial Robot Int. J. robotics Res. Appl. 50 (1), 1–10. doi:10.1108/ir-10-2022-0251

Daneshmand, M., Noroozi, F., Corneanu, C., Mafakheri, F., and Fiorini, P. (2023). Industry 4.0 and prospects of circular economy: a survey of robotic assembly and disassembly. Int. J. Adv. Manuf. Technol. 124 (9), 2973–3000. doi:10.1007/s00170-021-08389-1

Farsi, A., Mokhtarzadeh, M., Rabbani, M., Manavizadeh, N., and Ghasempour Anaraki, M. (2024). Using parallel metaheuristics to solve a parallel U-shaped robotic mixed-model assembly line balancing and sequencing problem. Soft Comput. 28 (21), 12603–12621. doi:10.1007/s00500-024-10311-2

Hoebert, T., Lepuschitz, W., Vincze, M., and Merdan, M. (2023). Knowledge-driven framework for industrial robotic systems. J. Intelligent Manuf. 34 (2), 771–788. doi:10.1007/s10845-021-01826-8

Kiyokawa, T., Takamatsu, J., and Koyanaka, S. (2022). Challenges for future robotic sorters of mixed industrial waste: a survey. IEEE Trans. Automation Sci. Eng. 21 (1), 1023–1040. doi:10.1109/tase.2022.3221969

Liu, F., Gao, G., Na, J., and Zhang, F. (2025). Kinematic calibration for serial robots based on a vector inner product error model. IEEE Trans.72 (3), 2832–2841. doi:10.1109/tie.2024.3443962

Luo, H., and Qiao, H. (2024). Exploring the impact of industrial robots on firm innovation under circular economy umbrella: a human capital perspective. Manag. Decis. 62 (9), 2763–2790. doi:10.1108/md-02-2023-0285

Mogro, M. F., Jácome, F. A., Cruz, G. M., and Zurita, J. R. (2024). Sorting line assisted by a robotic manipulator and artificial vision with active safety. J. Robotics Control (JRC) 5 (2), 388–396. doi:10.18196/jrc.v5i2.20327

Nguyen, Q. C., Hua, H. Q. B., and Pham, P. T. (2024). Development of a vision system integrated with industrial robots for online weld seam tracking. J. Manuf. Process. 119 (1), 414–424. doi:10.1016/j.jmapro.2024.03.090

Nguyen, H. T., Dao, A. Q., Nguyen, Q. A., Dang, T. P., Tang, M. N., Le, V. H., et al. (2024). Experiment ball levitation with fuzzy PID and PID implementation. J. Fuzzy Syst. Control 2 (3), 129–134. doi:10.59247/jfsc.v2i3.221

Pan, H., Cai, Y., Jia, B., Li, L., and Chen, L. (2025). Improving the absolute positioning accuracy of industrial robots based on OP-ELM and an enhanced backtracking search algorithm. Intell. Serv. Robot. 18 (2), 247–260. doi:10.1007/s11370-024-00581-y

Peta, K., Wlodarczyk, J., and Maniak, M. (2023). Analysis of trajectory and motion parameters of an industrial robot cooperating with a numerically controlled machine tools. J. Manuf. Process. 101 (2), 1332–1342. doi:10.1016/j.jmapro.2023.06.063

Schmidbauer, C., Zafari, S., Hader, B., and Schlund, S. (2023). An empirical study on workers' preferences in human–robot task assignment in industrial assembly systems. IEEE Trans. Human-Machine Syst. 53 (2), 293–302. doi:10.1109/thms.2022.3230667

Setiawan, A. T., Suwandy, S., Wijayanto, H. L., and Arohman, A. W. (2024). Automated sorting conveyor using pneumatic actuators for industrial applications at morowali metal industry polytechnic. J. Teknol. Dan. Manaj. 22 (2), 37–48. doi:10.52330/jtm.v22i2.284

Zhang, C., and Zhang, C. (2025). Industry and artificial intelligence: industrial robot localization based on improved monte carlo algorithm. Int. J. Interact. Des. Manuf. (IJIDeM) 19 (7), 4895–4906. doi:10.1007/s12008-024-02085-6

Zhang, R., Lu, W., Jian, X., and Luo, H. (2023). Intelligent sorting method for assembly line based on visual positioning and model predictive control of robotic arm. Int. J. Agric. Biol. Eng. 16 (4), 206–214. doi:10.25165/j.ijabe.20231604.7908

Keywords: Profinet bus, sorting and assembly control system, industrial robot, fuzzy PID, greedy algorithm

Citation: Zhang Y and Wang T (2025) Design of industrial robot sorting and assembly control system based on Profinet bus. Front. Mech. Eng. 11:1635881. doi: 10.3389/fmech.2025.1635881

Received: 27 May 2025; Accepted: 22 August 2025;

Published: 05 September 2025.

Edited by:

Mohamed Arezki Mellal, University of Boumerdés, AlgeriaReviewed by:

Xinqing Xiao, China Agricultural University, ChinaXianlei Shan, Tianjin University, China

Copyright © 2025 Zhang and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Tao Wang, d3RnbGRuQDEyNi5jb20=

Yang Zhang1

Yang Zhang1 Tao Wang

Tao Wang