- 1Department of Mechanical and Production Engineering, Guru Nanak Dev Engineering College, Ludhiana, Punjab, India

- 2Jadara Research Center, Jadara University, Irbid, Jordan

- 3Department of Mechanical Engineering, Graphic Era (Deemed to be University), Dehradun, India

- 4University Centre for Research and Development, Chandigarh University, Gharuan, Mohali, India

- 5Centre for Research Impact AND Outcome, Chitkara University Institute of Engineering and Technology, Chitkara University, Rajpura, Punjab, India

- 6The Islamic University, Najaf, Iraq

- 7FH Campus Wien - University of Applied Sciences, Department of Engineering, Vienna, Austria

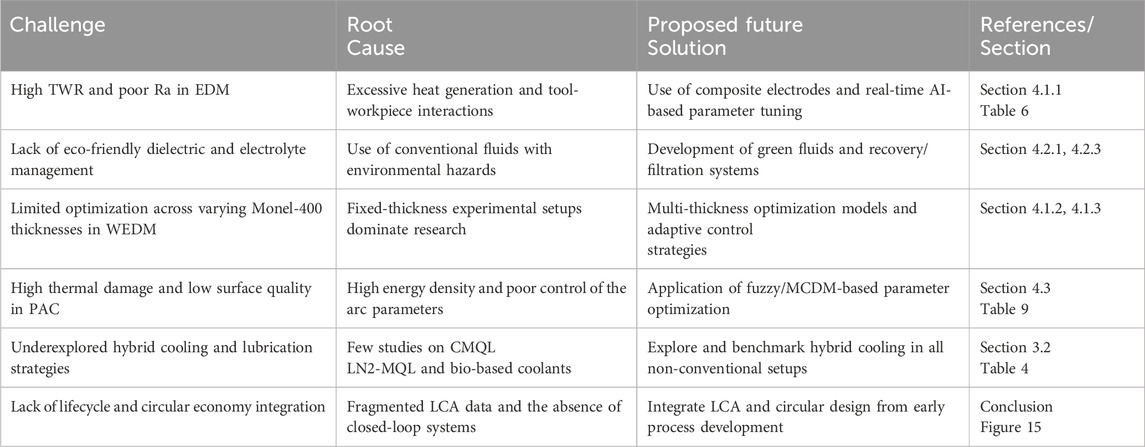

Monel-400, a nickel-copper-based alloy, is renowned for its exceptional corrosion resistance, high strength, and toughness across diverse operating environments. However, these desirable properties also make Monel-400 a challenging material to machine using conventional techniques, leading to excessive tool wear, poor surface finish, and high thermal stresses. There is currently no comprehensive review that systematically consolidates and compares non-conventional machining approaches applied to Monel-400 alloy. This review critically examines the non-conventional machining methods employed to address these challenges, including Electric Discharge Machining (EDM), Wire EDM (WEDM), Electrochemical Machining (ECM), Plasma Arc Cutting (PAC), Abrasive Water Jet Machining (AWJM), Photochemical Machining (PCM), and Hot Machining. A systematic comparison of process performance, surface integrity, material removal rate (MRR), Tool Wear Rate (TWR), Surface Roughness (Ra), and optimization strategies is presented. Key advancements such as hybrid dielectrics, cryogenic treatments, near-dry machining, and AI-based optimization techniques are discussed. Challenges related to surface defects, environmental sustainability, tool degradation, and process scalability are highlighted, along with identified research gaps. Future research directions emphasize the development of eco-friendly machining solutions, hybrid machining systems, real-time adaptive control, and life cycle assessments to enable sustainable industrial applications. This review consolidates fragmented knowledge, provides a roadmap for future innovation, and supports the advancement of efficient, precise, and environmentally responsible machining practices for Monel-400.

1 Introduction

Monel-400 and similar Ni-Cu alloys account for around 12% of specialty alloys utilized in the global marine, chemical processing, and oil and gas industries. Their adoption is projected to increase steadily at a CAGR of 3.5% from 2024 to 2030, fueled by the growing demand for corrosion-resistant materials (Jaiswal, 2025). Nonetheless, machining high-strength nickel alloys such as Monel-400 is both costly and challenging, resulting in tool wear rate (TWR) that are 20%–30% higher and production times that are 15% longer than conventional materials like stainless steel. This situation has considerable economic repercussions in the manufacturing sectors (Demirbaş et al., 2025). The global nickel market, vital for producing Ni-based alloys like Monel-400, is expected to expand from $36 billion in 2024 to over $46 billion by 2030, driven by energy, aerospace, and marine industry applications (Bothare, 2024). This growth emphasizes the necessity for more efficient machining practices to enhance industrial advancement.

Monel was the first ever commercially developed Nickel-based alloy that served as the basis of Ni-Cu-based alloys. Its history dates back to the early 1900s when D.H. Browne working with Robert Stanley at International Nickel Company (Inco) found a way to refine Ni/Cu alloy from matte ore of Sudbury Mines that resulted in a silvery white alloy which later came to be known as ‘Monel’, named after company president ‘Ambrose Monell’. Two years after its discovery in 1906, Monel was extensively employed in architectural buildings and roofs in New York because it resisted atmospheric corrosion well. It was also heavily used by the U.S. Navy during World War I (Hodge, 2006; Shoemaker and Smith, 2006). The alloy was first patented on 30 January, 1906, by Ambrose Monell (U.S. patent 811,239) (Monell, 1906) and is now a Trademark of the Special Metals Corporation.

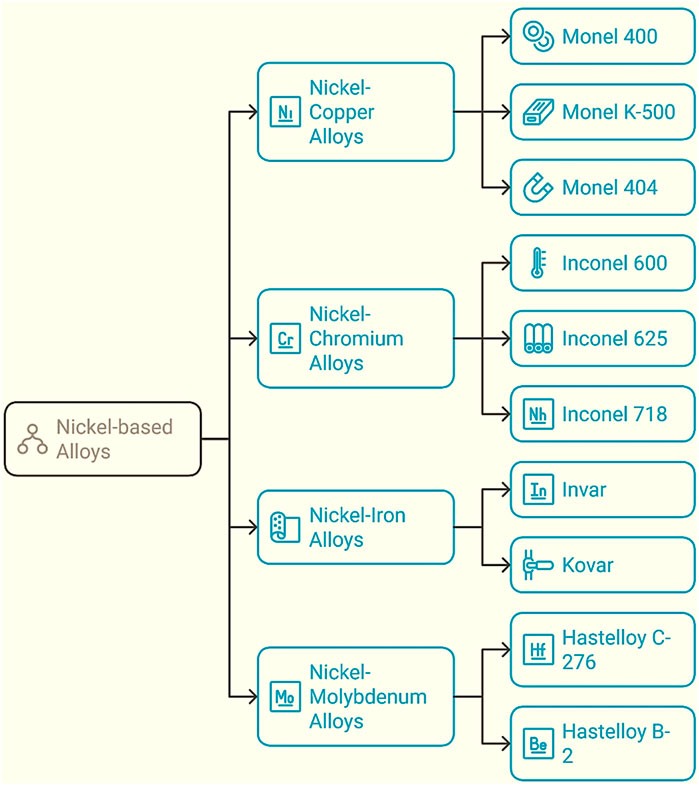

The main constituent element in Monel-400’s composition is Nickel (Ni), a versatile transition metal. Around 61% of the global production of nickel is utilized in making stainless steel. In comparison, 12% of the world production of Ni is used for processing Ni-based alloys (the rest is used to fabricate batteries, alloy steels, etc.) (Rebak, 2014). Ni can readily alloy with various elements and enhance corrosion resistance and strength at elevated temperatures (Ulutan and Ozel, 2011). This characteristic is a key factor contributing to the exceptional stability of Monel Alloy 400. Commercially fabricated Ni-based alloys can be mainly classified into two categories: High temperature alloys (HTAs), which are primarily employed for their capacity to withstand high temperatures, and corrosion-resistant alloys (CRAs), which are mainly targeted for use in aggressive corrosive environments such as marine equipment. At the same time, little focus is given to their mechanical strength (Sequeira et al., 2016; Klapper et al., 2017). Among the corrosion-resistant Alloys, Ni-Cu alloys are known for their resistance to acidic and alkaline corrosive media, weldability, and toughness across a wide temperature range (Rathi et al., 2023). Ni-Cu alloys are alloys with generally over 50% Nickel by weight percentage. Nickel and Copper are both transition metals sharing a lot of similarities, such as the same lattice structure (FCC), similar electronegativity, and valence state, resulting in complete solubility of Copper in Nickel and formation of a single-phase homogeneous Ni-Cu solid solution over the entire composition range (Marenych and Kostryzhev, 2020). Monel-400 is a nickel-copper solid solution demonstrating excellent resistance to acidic and alkaline corrosive environments. The Monel Family mainly consists of five commercially available alloys: Monel-400, Monel-401, Monel-404, Monel R-405 and Monel K-500, with Monel-400 being the most popular and oldest. A classification of Monel family as Ni-based Alloys is presented below, along with the chemical composition of Monel Alloy 400, Figure 1.

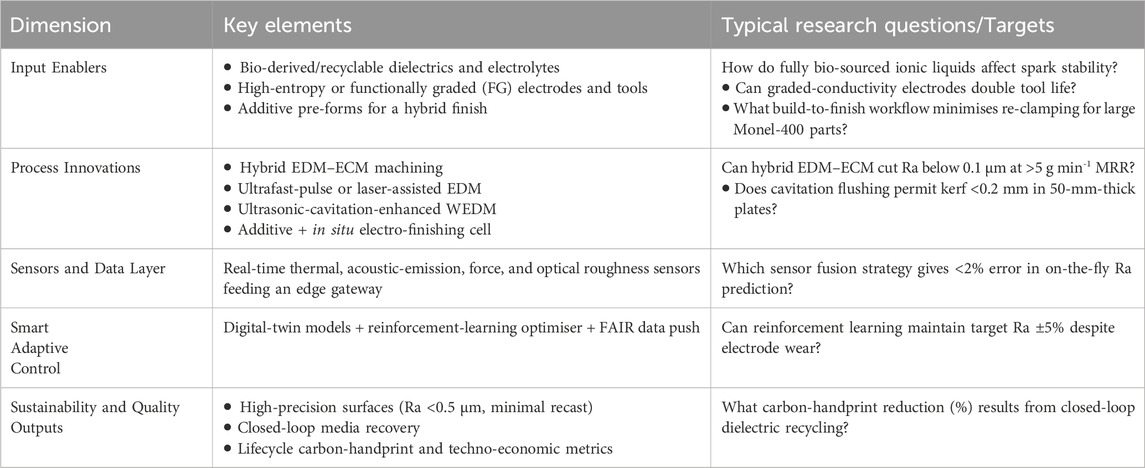

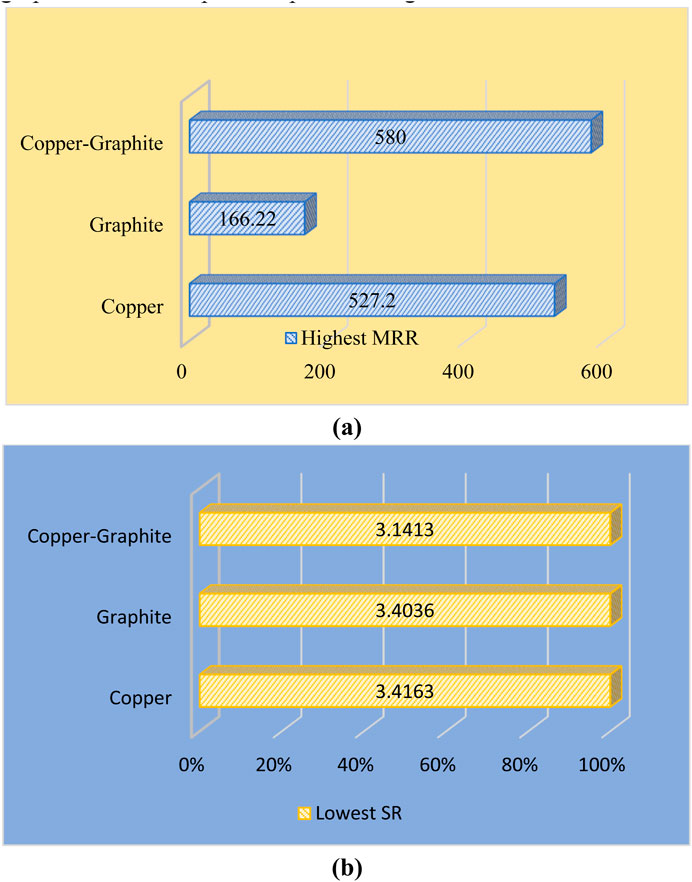

The chemical composition of Monel Alloy 400, as shown in Table 1, reveals the dominance of Nickel and Copper, which are primarily responsible for its excellent corrosion resistance and mechanical properties.

Table 1. Chemical Composition of Monel Alloy 400 (by wt%) (Special Metals, 2005).

Monel Alloy 400 is assigned UNS (Unified Number System) N0440. Monel Alloy 400 is exceptionally resistant to corrosion in sea water, as ascertained in several test experiments conducted by (Laque, 2009). Moreover, Wrought Monel is one of the best alloys used for handling mild reducing solutions such as Hydrofluoric acids (Rebak and Crook, 2000). It can also be sustained well in Dead Sea Water, de-aerated Sodium Sulphate solution (Al-Abdallah, 1996), and in aerated and de-aerated sodium chloride solutions (Ali and Ambrose, 1992; Sherif, 2012). It has even been found resistant to chloride-induced SCC (Stress Corrosion Cracking), unlike Austenitic SS (Stainless Steel) (Dutta, 2009). These unique corrosion-resistant properties of Monel, together with its higher strength and toughness derived from Nickel, enable its applications in heat pipes (Anderson et al., 2007; Rosenfeld and Gernert, 2008), Bipolar plates of proton exchange membrane fuel cells (PEMFCs) (Matboo Ghorbani et al., 2019; Sanjid et al., 2019), heat exchanger tubing (Rahoi et al.; Al-Hashem and Carew, 1995), steam generator tubing materials (De and Ghosal, 1981; Padma et al., 2001; Naraine and Riznic, 2017), Hydrogen Evolution Reaction (HER) Cells (Nady and Negem, 2016; Wang et al., 2019), oil and petrochemical industry (Katsamas et al., 2004; Knyazeva et al., 2020) and many more.

Recently, dissimilar Monel weldments have also become a subject of widespread research interest (Sabeeh et al., 2023; Yelamasetti et al., 2023). These applications demand the fabrication of Monel into intricate and complex shapes via machining with overall sound quality and Surface Finish, which is a rather challenging matter.

Monel-400, along with other nickel-based and Ni–Cu alloys, exhibits exceptional corrosion resistance at elevated temperatures in both acidic and alkaline environments. It also possesses high mechanical strength and excellent ductility at sub-zero temperatures. While a range of other alloys, such as Inconel (Ni-Cr-based) and Hastelloy (Ni-Mo-based), are widely employed in extreme operating conditions, the superior resistance of Monel-400 to hydrofluoric acid, seawater, and stress-corrosion cracking renders it particularly suitable for marine, chemical processing, and oil and gas applications. Its continued relevance is further highlighted by its historical significance as the first commercial nickel alloy and its sustained use in critical industrial applications.

In contrast, Monel K-500 offers enhanced strength but reduced ductility relative to Monel-400. Consequently, Monel-400 is preferable in applications where a balance of high corrosion resistance and superior formability is required, particularly in mildly alkaline environments (pH 6–9). This review, therefore, aims to systematically examine unconventional machining processes as they pertain specifically to the unique material behavior of Monel-400.

1.1 Rationale for non-conventional machining of Monel-400

Monel-400 (UNS N04400) is a nickel–copper-based alloy renowned for its exceptional corrosion resistance, mechanical strength, and toughness across a broad temperature range. These attributes have led to its widespread application in highly critical and demanding industries, including marine engineering, petrochemical and chemical processing, aerospace, and nuclear energy systems. However, the very characteristics that render Monel-400 so valuable, such as high work hardenability, low thermal conductivity, and considerable ductility, also contribute to the tremendous difficulties encountered during conventional machining. Traditional machining processes often result in severe tool wear, thermal damage, compromised surface quality, and elevated manufacturing costs.

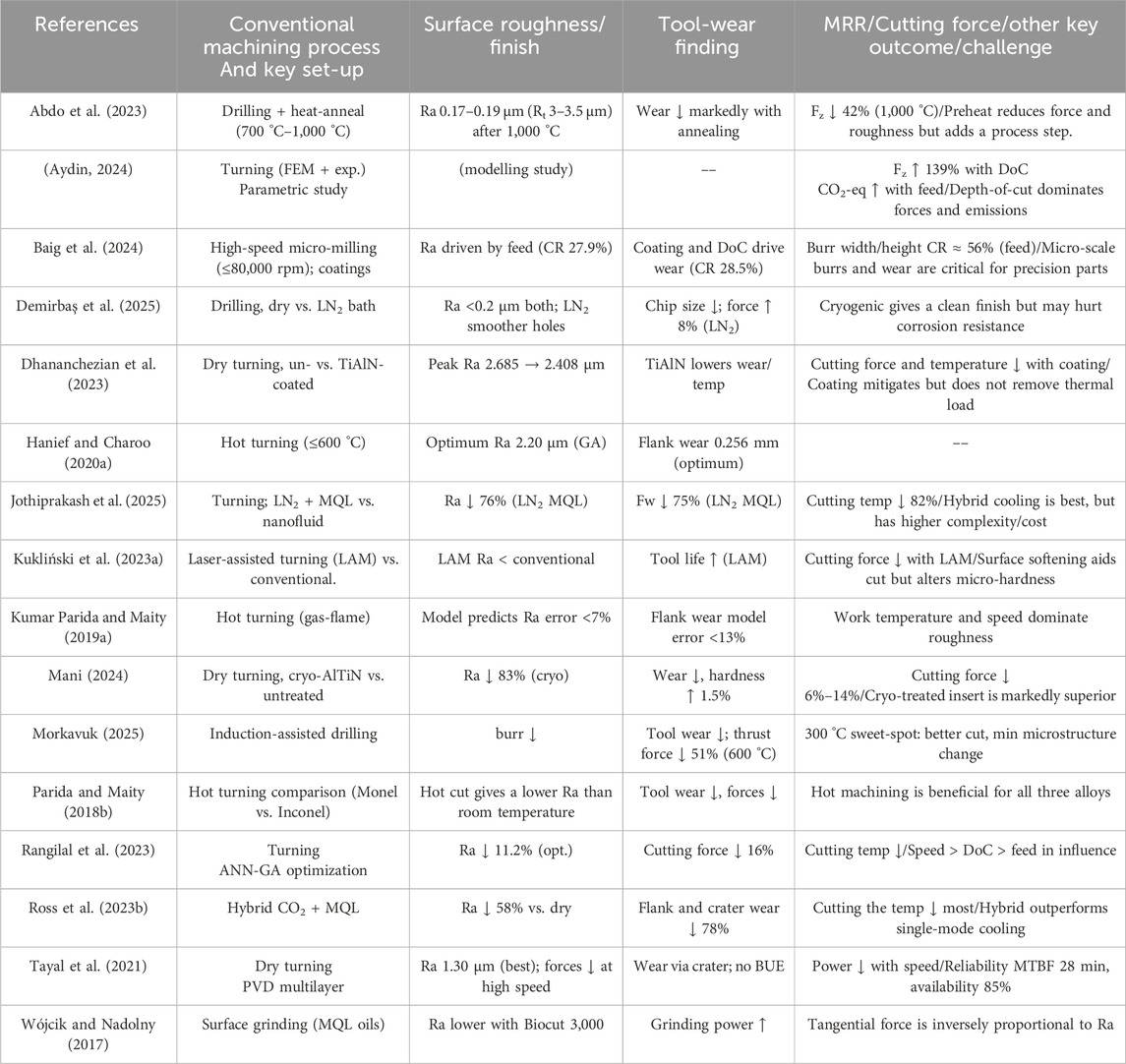

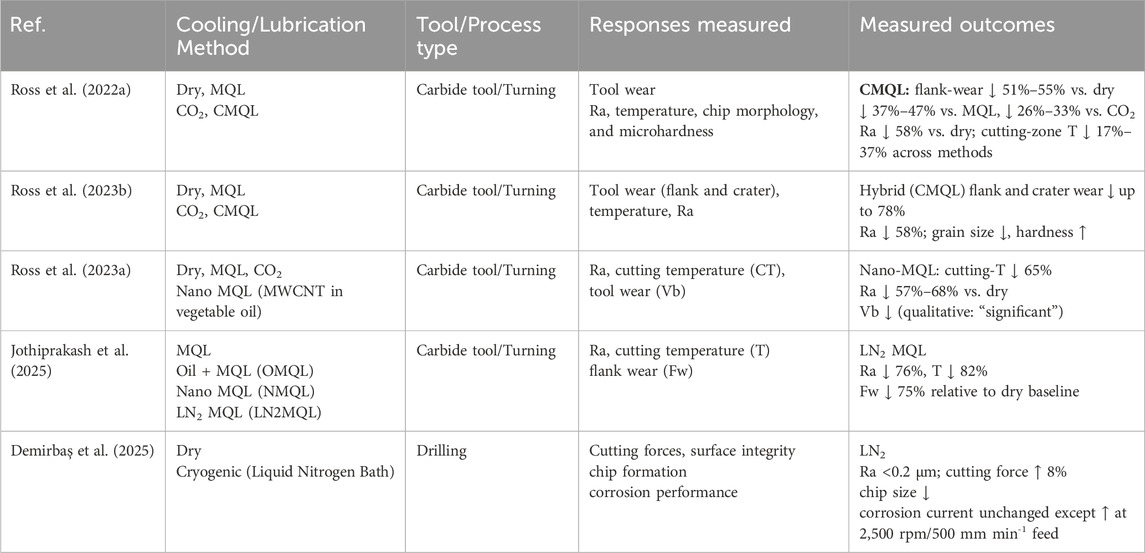

Despite notable advancements in cutting tool coatings and cooling/lubrication strategies, conventional machining methods still fall short in achieving the requisite surface integrity and dimensional tolerances for Monel-400. As evidenced in Table 2, even the use of coated tools and cryogenic or hybrid cooling techniques has proven insufficient in consistently delivering the desired surface finish. Conventional machining further suffers from excessive material wastage, prolonged cycle times, and frequent tool replacements, thereby rendering it economically unfeasible for precision and high-volume applications.

To address these challenges, non-conventional machining methods such as Electric Discharge Machining (EDM), Wire EDM (WEDM), Electrochemical Machining (ECM), Plasma Arc Cutting (PAC), Abrasive Water Jet Machining (AWJM), Photochemical Machining (PCM), and Hot Machining have been proposed as viable alternatives. These techniques provide specific advantages in processing difficult-to-machine materials by mitigating mechanical stresses and thermal deformations, minimizing tool wear, and enhancing both surface finish and dimensional accuracy.

Unlike conventional methods that rely on direct mechanical interaction, non-conventional techniques operate based on thermal, chemical, or abrasive principles, thereby enabling low-contact or tool-wear-free machining. This facilitates the fabrication of intricate geometries, micro-scale features, and otherwise inaccessible regions with minimal damage and high precision. Furthermore, many of these processes can be integrated into hybrid or intelligent systems, offering scalable, repeatable, and sustainable manufacturing solutions. Thus, a comprehensive review of these non-conventional techniques is warranted to assess their applicability, optimization potential, and industrial readiness for machining Monel-400.

1.2 Challenges in conventional machining of Monel-400

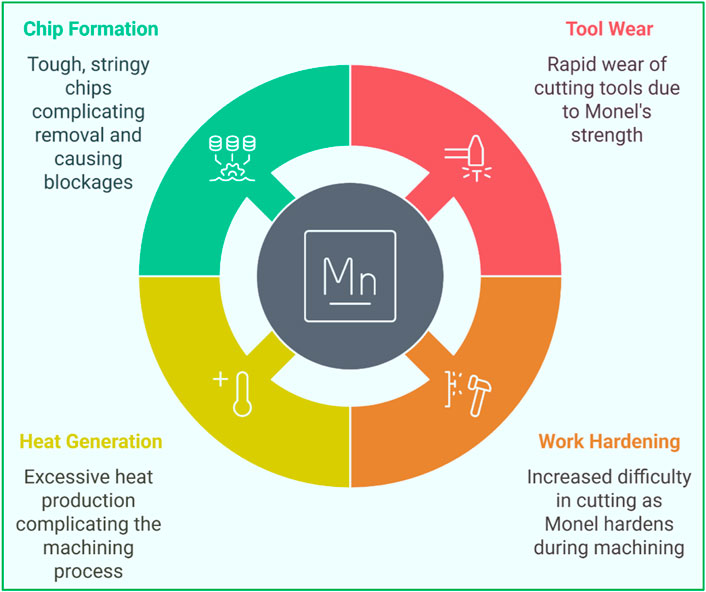

Monel-400 alloy is widely recognized as a difficult-to-machine material when employing conventional machining methods, despite its favorable attributes such as mechanical strength, corrosion resistance, and extended service life. Hard turning of this alloy poses significant challenges due to its pronounced work hardenability, low thermal conductivity, and strong affinity for cutting tools. These material properties often lead to adverse phenomena, including rapid tool wear, substandard surface finish, burr formation, poor dimensional accuracy, and elevated cutting forces. Such machining difficulties are further exacerbated in applications requiring precision machining and environmentally sustainable manufacturing, particularly within critical sectors such as aerospace, marine engineering, and nuclear power.

In response, various researchers have explored strategies to enhance the traditional machining performance of Monel-400, including pre-processing techniques (e.g., heat treatment), the application of advanced tool coatings, implementation of cryogenic cooling, and the optimization of machining parameters. Nevertheless, these approaches have not fully overcome the inherent limitations. Table 2 provides a summary of the machining challenges reported in the literature, focusing on key metrics such as surface roughness, material removal rate (MRR), tool wear, and aspects of process sustainability.

Despite the rising number of studies on non-conventional machining of Monel-400, there is no comprehensive review that critically compiles these findings, assesses optimization methods, identifies research gaps, and outlines future research paths. Existing research tends to be patchy and mainly concentrates on specific machining techniques. It does not offer a comprehensive or comparative overview and is, as a result, unable to guide researchers and industry professionals in selecting, enhancing, and integrating processes.

The present review seeks to fill this significant knowledge void by accumulating the current research on non-conventional machining of Monel-400. It methodically evaluates machining results, challenges, and optimization strategies and can provide side-by-side comparisons of various techniques. The review emphasizes the advantages and disadvantages of each method. It also frames a direction for future research and industrial progress in the practical and sustainable machining of Monel-400.400.

1.3 Research questions

To systematically guide this critical review on the non-conventional machining of Monel-400, the following research questions (RQs) were formulated.

• RQ1: What non-conventional machining processes have been explored for the efficient machining of Monel-400 alloy?

• RQ2: How do different non-conventional machining techniques influence key performance metrics such as MRR, Ra, TWR, and dimensional accuracy in Monel-400?

• RQ3: What optimization strategies (parametric adjustments, hybrid techniques, coolant selection) have been employed to enhance machining efficiency and surface integrity?

• RQ4: What are the primary challenges, limitations, and environmental concerns associated with non-conventional machining of Monel-400?

• RQ5: What are the critical research gaps and future directions to further advance the non-conventional machining processes for Monel-400 towards industrial scalability and sustainability?

These research questions set the analytical scope, guarantee a complete exploration of current research, and aid in determining areas of need for future research and innovation.

Machining Monel-400, an essential process in many industries, is highly challenging because of its strength, work-hardening, and low thermal conductivity. Though various experimental studies have researched non-traditional machining processes to overcome these challenges, the research is unorganized and incomplete. This paper attempts to fill this gap by organizing systematically, analyzing, and critically reviewing the non-traditional machining processes like EDM, WEDM, ECM, PAC, AWJM, PCM, and Hot Machining for Monel-400 specifically.

By identifying critical process parameters, optimization techniques, material reactions, and technical constraints, the review provides an integrated framework for understanding the present status of Monel-400 machining. By giving researchers straightforward insights into performance trends in various machining processes, the review also highlights open technical problems. For practitioners, the research is a reference guide for selecting appropriate machining processes, optimizing operating conditions, and adopting improved and sustainable approaches. By suggesting future research directions, the review inspires innovation in hybrid machining technologies, green processing, intelligent manufacturing integration, and scalability in industrial processes. The research makes theoretical contributions and practical applications to the precision machining of advanced nickel-based alloys such as Monel-400.

2 Review methodology

This review uses a structured approach to analyze the non-conventional machining techniques used in Monel-400. A systematic literature search and selection process ensured relevance, quality, and comprehensiveness.

2.1 Literature search strategy

A thorough literature search was conducted across major scientific databases (Scopus, Web of Science, Google Scholar, and ScienceDirect). The keywords and Boolean operators were employed to retrieve relevant studies as follows:

“Machining Monel-400”, “Monel non-conventional machining”, “EDM for Monel-400”, “Wire EDM for Monel-400”, “ECM for Monel-400”, “PAC for Monel-400”, “AWJM for Monel-400”, “PCM for Monel-400”, “Hot machining of Monel-400”, “Cryogenic machining for Monel”, “Surface integrity in Monel-400”

Most documents published between 2000 and 2025 were considered to capture foundational studies and the latest advancements.

2.1.1 Inclusion and exclusion criteria

The selection of articles was based on the following criteria.

• Material:

Inclusion: Studies focusing on the machining of Monel-400.

Exclusion: Studies primarily related to other Ni-Cu alloys without a specific focus on Monel-400.

• Process:

Inclusion: Studies centered on non-conventional machining techniques such as EDM, WEDM, ECM, PAC, AWJM, PCM, and Hot Machining.

Exclusion: Studies based solely on conventional machining processes.

• Output Parameters:

Inclusion: Studies reporting at least one of the key performance metrics, MRR, Ra, TWR, Overcut (OC), Kerf Width, or Surface Integrity.

Exclusion: Articles that lack experimental validation or measurable outcomes.

• Language:

Inclusion: Articles published in English.

Exclusion: Non-English publications.

• Document Type:

Inclusion: Peer-reviewed journal articles and conference papers.

Exclusion: Review articles, patents, theses, and book chapters.

After screening based on titles and abstracts, the relevant documents were selected for full review. They mainly addressed non-conventional machining processes for Monel-400.

2.1.2 Data extraction and analysis

The selected documents were analysed critically, and the key information was extracted as follows.

• Type of machining process

• Input process parameters

• Output performance metrics (MRR, Ra, TWR, OC, etc.)

• Tool materials and electrode characteristics

• Coolant or dielectric types

• Optimization strategies and techniques

• Reported challenges, limitations, and surface characteristics

The extracted data were systematically compared and critically analyzed to identify trends, performance improvements, research gaps, and future opportunities in the non-conventional machining of Monel-400.

3 Critical review of research studies

3.1 Effect of tool coatings on machinability and surface quality of Monel-400

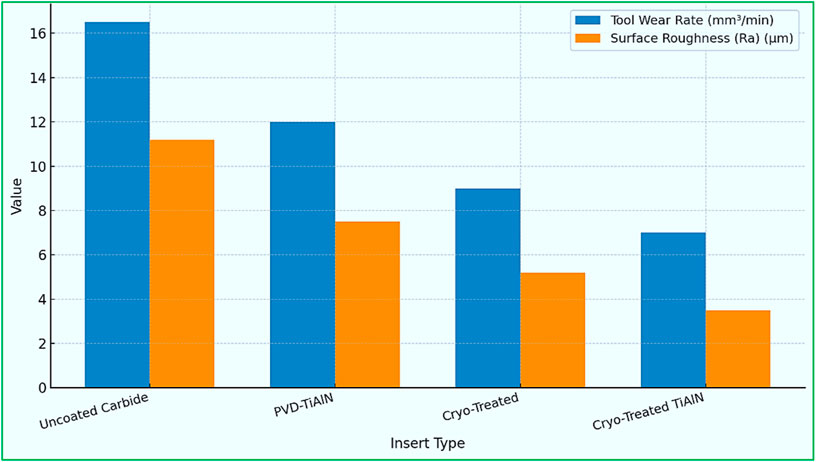

When Monel-400 is machined under dry machining conditions with uncoated carbide inserts, cutting zone temperatures as high as 230 °C are reached due to the low heat carrying capacity of Monel and limited conductivity of the uncoated tool, as shown in Figure 2. The peak of ≈230 °C corresponds to the highest cutting velocity investigated 114 m min-1; temperatures of 400 °C–600 °C are commonly reported when speeds exceed 150–200 m min-1 in dry turning of Monel-400 with uncoated or standard-coated inserts (Hanief and Charoo, 2020a). This leads to flaking and high-notch wear on the tool’s face and edge. Due to high heat generation at the cutting point, material particles from the workpiece deposit on the tool surface, initiating the diffusion wear mechanism (Dhananchezian et al., 2023). Also, when this Ni-Cu alloy was machined via single-point carbide PVD-coated (TiAlN-TiN) inserts, burnt chips tended to stay on the tool’s rake face, causing an adhesion wear mechanism. When removed, these sticky particles peel off a portion of a tool insert, leading to crater wear (Tayal et al., 2021). Mani (Mani, 2024) investigated dry turning performance with untreated and cryo-treated PVD-AlTiN inserts on Monel-400. Serrated (jaw-like) chips were obtained when machined with both inserts, but the chip size was comparatively smaller for cryo-treated inserts. Also, Untreated AlTiN inserts showed micro-cracks on cutting edges, increased flaking, and extensive coating delamination compared to cryo-treated inserts.

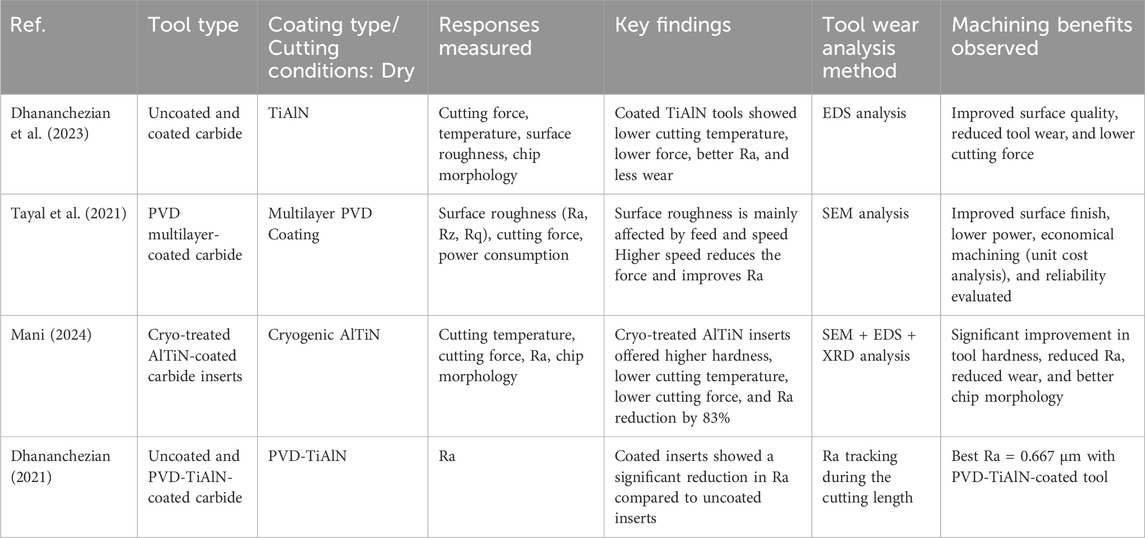

The studies reviewed in Table 3 indicate significant benefits of using coated carbide tools compared to uncoated tools during the machining of Monel 400 alloy in dry conditions. Coated TiAlN tools consistently displayed lower cutting forces, decreased cutting temperatures, and improved surface finish than their uncoated alternatives, as noted in (Dhananchezian et al., 2023; Dhananchezian, 2021). The use of multi-layer PVD coatings, examined by (Tayal et al., 2021) enhanced Ra and reduced power consumption, increasing the reliability and cost-effectiveness of machining processes. Additionally, the implementation of cryogenic treatment on AlTiN coatings, demonstrated by (Mani, 2024) Notably improved tool hardness and wear resistance, resulting in an 83% decrease in Ra and significant changes in chip morphology. Across all investigations, coated tools showcased less wear progression, better surface integrity, and higher machining efficiency, emphasizing the importance of surface engineering and tool treatment advancements for optimizing the machinability of difficult materials, Monel 400.

3.2 Effect of cooling and lubrication strategies on machining performance of Monel-400

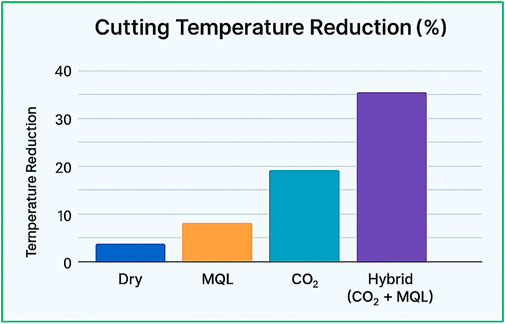

(Ross et al., 2023b) explored three different cooling strategies: MQL, Cryogenic CO2, and hybrid (CO2 + MQL), along with dry turning of Monel Alloy 400. Results showed that adhesion, abrasion, and chipping were standard wear mechanisms in dry, Cryogenic, and MQL environments. Cutting temperature directly affects Ra and tool wear in machining. Compared to dry environmental conditions, a reduction in cutting temperatures was observed to be 17.1% for MQL, 28.9% for CO2, and 37.1% for hybrid conditions. Similarly, another research also explored four different cooling environments: Dry, MQL, CO2, and CMQL (Combo of CO2 and MQL) in the machining of turning of Monel-400 by PVD-TiAlN inserts. It was observed that wear mechanisms such as BUE were predominantly observed in dry and MQL environments due to the inability of coolant to reach the high temperature cutting zone (caused by evaporation in case of MQL), while coating delamination and Abrasion wear effects were observed in the CO2 environment due to the absence of lube. Deteriorated surface (grooves, smearing, adherence of chip flakes) was observed in dry machining, followed by CO2 and MQL. Meanwhile, no primary wear mechanisms or surface defects were indicated in the CMQL machining conditions. Also, CMQL achieved the minimum Ra, which made it more efficient than other conditions (Ross et al., 2022a).

It can be observed from the literature that coated (and treated) inserts and hybrid cooling environments have shown some promise to limit the challenges in conventional machining of Monel Alloy 400. However, they further add to the machining cost, disturbing the process’s financial aspects. This led researchers worldwide to explore the Potentiality, feasibility, and reliability of advanced/non-conventional machining processes on Monel-400 alloy, viz., EDM, ECM, PAC, AWJM.

The reviewed studies in Table 4 constantly show the significant effect of advanced cooling and lubrication strategies on improving the machinability of Monel 400 alloy. The simultaneous application of cryogenic carbon dioxide and minimum quantity lubrication (CMQL), as realized by (Ross et al., 2022a; Ross et al., 2023b), led to the maximum flank and crater wear reductions, Ra, and cutting temperatures in comparison to dry, MQL, or CO2 alone, with maximum flank wear decrease by 78%. Nano-cutting fluid application, especially multi-walled carbon nanotube (MWCNT) based Nano MQL, also increased cooling efficiency by decreasing cutting temperature by 65% and improving surface finish and tool life remarkably (Ross et al., 2023a). Moreover (Jothiprakash et al., 2025), revealed that LN2MQL produced the maximum improvement in surface quality, temperature regulation, and tool wear reduction among all methods compared. In drilling processes (Demirbaş et al., 2025), demonstrated that surface finish and chip control were enhanced by cryogenic cooling, but at a minor compromise in corrosion resistance. Hybrid and cryogenic-based lubrication methods generally significantly improve machining performance, each method having unique advantages based on operation type and performance priority.

4 Non-conventional machining of Monel-400 alloy

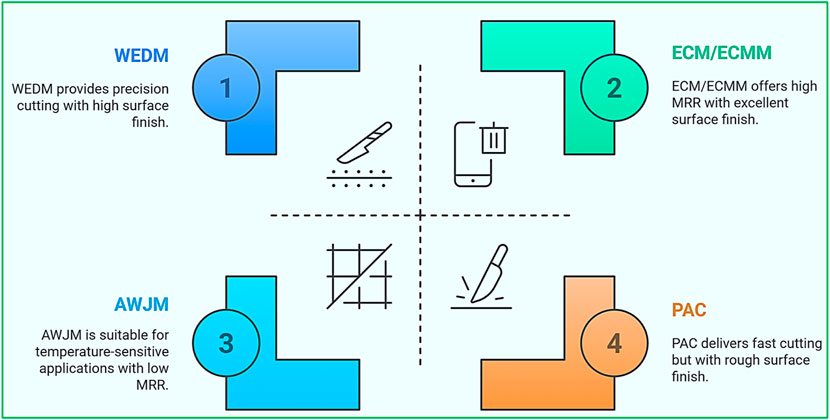

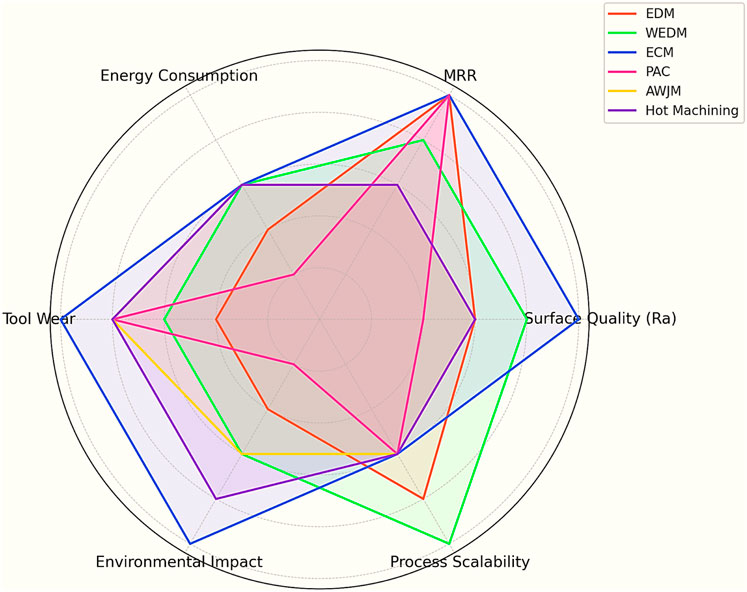

Despite being the ‘first’ ever commercial Ni-based alloy and its vast pool of applications, there has been no literature review reported on this alloy’s (Monel-400) non-conventional machining processes. Figure 3 illustrates the major unconventional machining processes for processing the Monel-400 alloy: EDM, WEDM, ECM/ECMM, PAC, AWJM, and Hot Machining. Each method is outlined with its major advantages, common difficulties, and significant breakthroughs based on knowledge from recent literature.

For example, EDM is highlighted for its maximum MRR and composite electrode usage, whereas WEDM is recognized for its accurate cutting with improved path modification. ECM/ECMM processes are known for tool wear-free machining and enhanced surface finish through electrolyte optimization. Techniques such as PAC and AWJM are classified as thermal and non-thermal, respectively, while hot machining is noted for minimizing tool wear through preheating techniques. The diagram above serves as a pictorial outline for Section 4, facilitating comparative assessments of each process’s suitability and performance for machining Monel-400.

4.1 Die-sinking Electric Discharge Machining: Tool and dielectric optimization

The origin of EDM can be traced back to the study of electricity and magnetism in the 18th and 19th centuries. Still, it was in 1943 when the destructive properties of electric discharges were first exploited (Uhlmann et al., 2005).

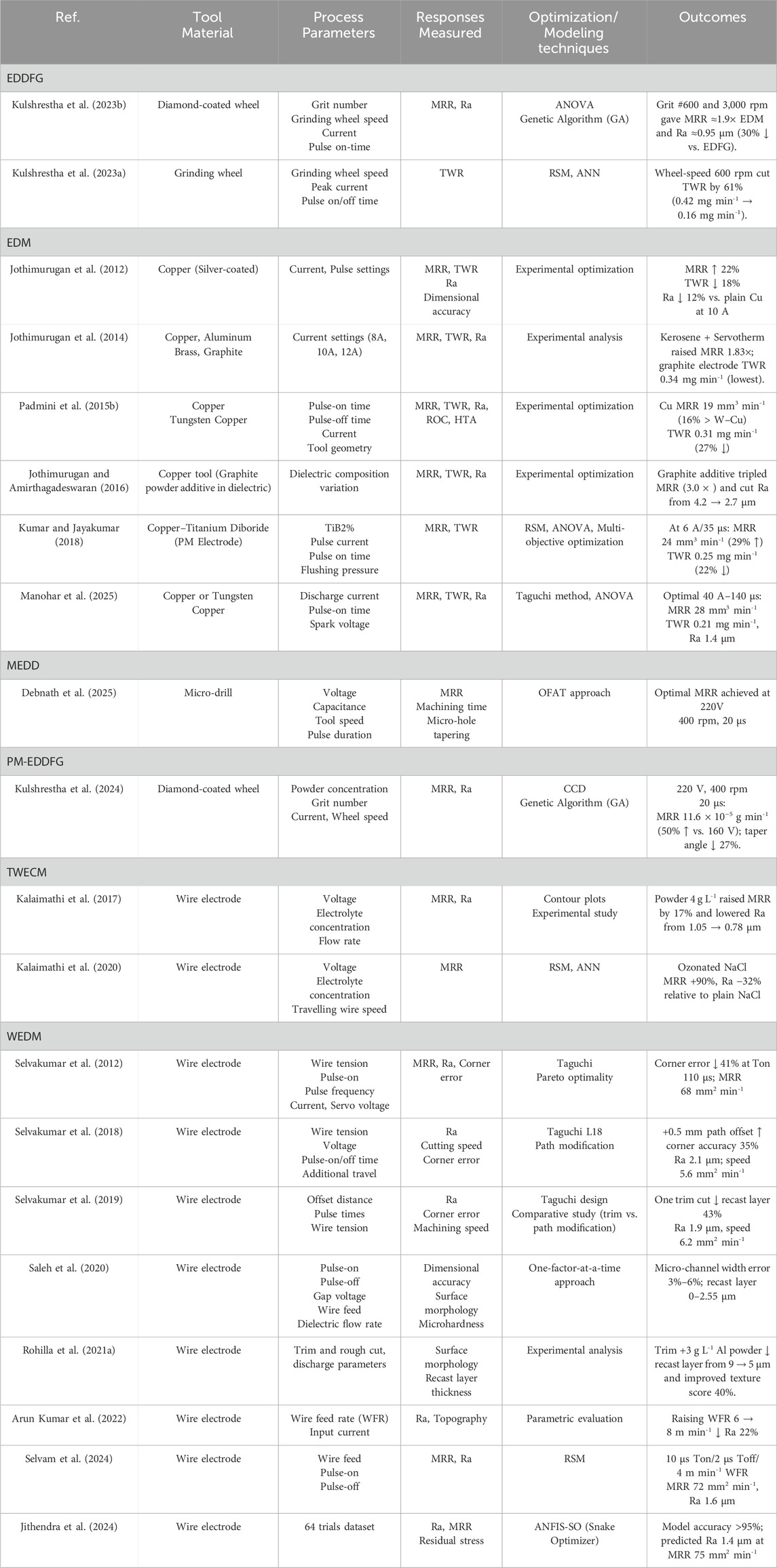

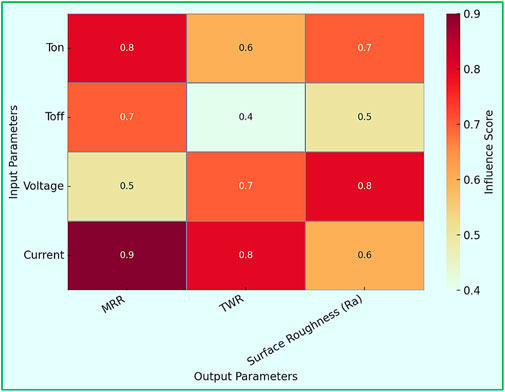

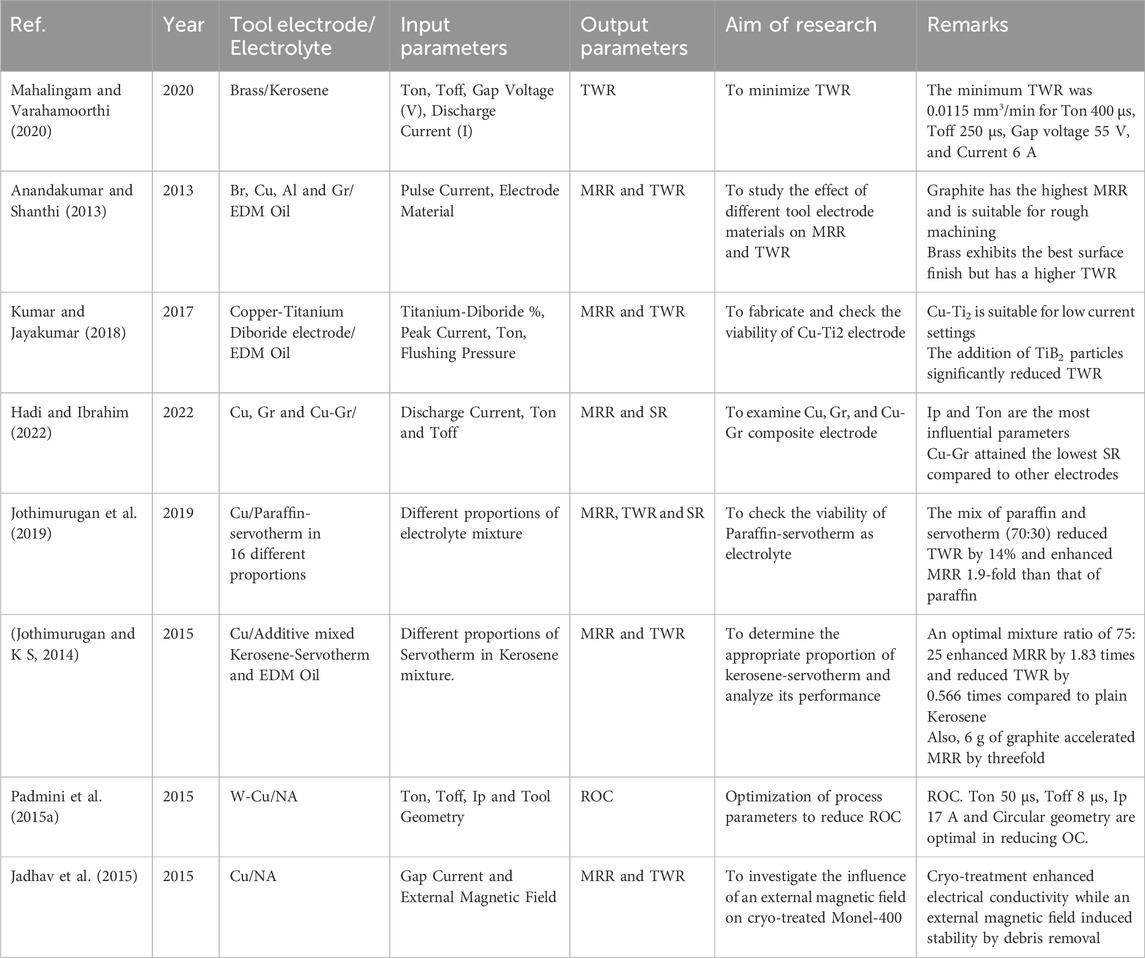

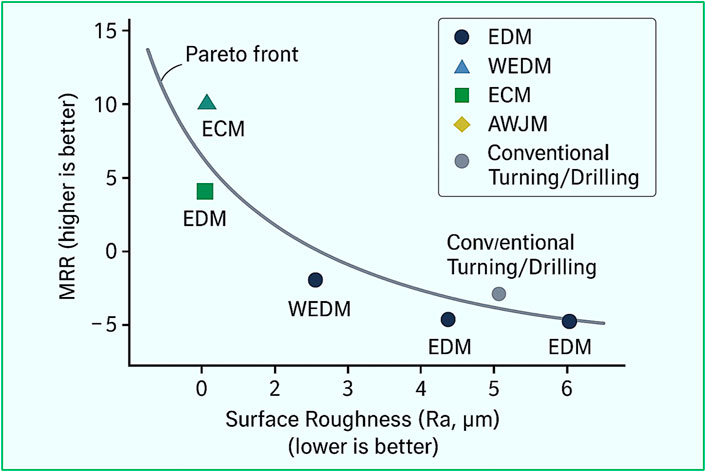

The combined research work in Table 5 from 2012 to 2025 offers remarkable progress in the non-conventional machining of Monel 400 and Monel K500 alloys through EDM, WEDM, ECM, TWECM, EDDFG, and PM-EDDFG processes. EDM research showed that tool material optimization (e.g., silver-coated copper, titanium diboride composites) and dielectric fluids (e.g., kerosene-servotherm with graphite additives) significantly improved MRR, minimized TWR, and enhanced surface quality. Adjusting pulse parameters, using path modification techniques, and employing multi-pass cutting methods constantly enhanced surface integrity, corner accuracy, and dimensional precision in WEDM. TWECM and ECM research proved that employing ozonated and optimized electrolytes significantly increased MRR and surface smoothness.

Sophisticated hybrid grinding processes such as EDDFG and PM-EDDFG demonstrated better machining performance than traditional EDM and grinding, significantly minimizing Ra and maximizing tool life, particularly through using diamond-coated wheels and MWCNT powders. Predictive modeling strategies such as RSM, ANN, Genetic Algorithms, and the new ANFIS-SO framework performed high-accuracy Ra, MRR, and residual stress forecasting, making the optimization process easier. Integrating intelligent optimization and hybrid processing approaches significantly increased machining efficiency, surface integrity, and predictive reliability, developing successful methodologies for hard-to-machine Monel alloy processing.

The variations of this process are categorized as follows.

4.1.1 Die-sinking EDM

EDM is one of the most widely adopted non-conventional machining processes for machining complex shapes and difficult-to-cut electrically conductive materials, such as Ni-based superalloys, Ti-based alloys, Co-based alloys, etc., by continuous spark generation and erosion (Benedict, 1987).

4.1.1.1 Studies on electrode material

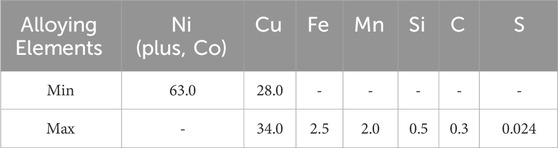

Copper, Graphite, and Brass are the least commonly used tool electrodes in EDM, but the high TWR of Copper, Brass, and low mechanical strength of Graphite pose a challenge (Czelusniak et al., 2018). In this regard, M. Mahalingam et al. investigated process parameter optimization to minimize the TWR of Brass electrode for EDM of Monel-400. A study revealed that the Wear Rate of Brass increases with an increase in discharge current (due to the presence of low-melting zinc in Brass) and decreases with an increase in pulse-on time. Not only that, but an increase in gap voltage also drastically reduced the TWR, as shown below (Mahalingam and Varahamoorthi, 2020). An experimental investigation of P. Anand Kumar in EDM of Monel 400 using different electrode materials revealed that graphite has the highest MRR and is suitable for rough machining. At the same time, Brass, on the other hand, exhibits the best surface finish but has a higher TWR (Anandakumar and Shanthi, 2013). It can be noted that these conventional electrodes can only be optimized to a limited extent. Hence, various researchers are extensively employing cutting-edge materials such as composites and alloys as tool electrodes for machining superalloys. The study was conducted to obtain optimal setting parameters for composite copper titanium diboride powder metallurgy electrodes by desirability multi-response optimization in the EDM of Monel-400. This investigation revealed a considerable reduction in TWR, mainly due to the addition of titanium diboride, and this electrode was found most efficient at a low current setting. Optimality was achieved at 16% of titanium diboride, pulse current of 6 A, flushing pressure of 1 MPa, and pulse on time of 35 µs (Kumar and Jayakumar, 2018). Mustafa et al. explored the utilization of copper, graphite, and copper graphite electrodes in the EDM drilling of Monel-400 with MRR and Ra as output responses. Data from experiments concluded that Ra was lowest when drilling was done with the Composite Copper-Graphite electrode. Parameters corresponding to the maximum MRR were also calculated (Hadi and Ibrahim, 2022). A novel high-pressure flushing scheme lowered the WEDM spark gap to 0.109 mm and surface roughness to 2.2 µm on complex Inconel-718 profiles (Farooq et al., 2024).

Figures 4a,b demonstrate that the Cu-graphite composite electrode simultaneously yields the highest material-removal rate and the lowest surface roughness compared with pure Cu and pure graphite under the specified pulse settings.

Figure 4. (a) Peak MRR values for Copper, Graphite, and Copper-Graphite composite electrode at Ip = 42 A, Toff = 25 µs, and Ton = 200 µs, (b) Lowest SR values for Copper, Graphite and Copper-Graphite composite electrode at Ip = 10 A, Toff = 12 µs and Ton = 50 µs.

4.1.1.2 Studies on the impact of dielectric fluids

The type of dielectric used dramatically influences the machining efficiency and output in EDM. Synthetic and hydrocarbon oil-based dielectric fluids emit fumes and vapors containing PAHs, Aliphatic hydrocarbons, Benzene, and various other toxic byproducts, causing health and environmental issues (Gupta and Gupta, 2018; Biswas and Rahul, 2021). Also, use of conventional dielectric fluids (such as Kerosene) results in deposition of carbon layer (Recast layer) over work surface causing low MRR and poor surface finish (Ekmekci, 2007). To overcome the drawbacks of conventional dielectrics, R. Jothimurugan et al. investigated 16 different proportions of Paraffin–Servotherm mixture as an electrolyte by machining holes in Monel–400 plate via EDM. They concluded the optimal ratio for paraffin–servotherm mixture to be 70:30, which not only enhanced MRR by 1.9-fold but also reduced TWR by 14% than that of Paraffin alone (mainly due to the deposition of nickel from workpiece to tool surface, thereby providing electric resistance) (Jothimurugan et al., 2019). (Jothimurugan and K S, 2014) screened 16 kerosene–servotherm formulations (additives: Si, Gr, Al, Cr, Ni) and identified a 75 : 25 vol% base mixture that increased MRR by 1.83 × and lowered TWR to 0.56 × relative to plain kerosene. Subsequently, dispersing 6 g L-1 of graphite in this optimised mixture boosted MRR even further from 10.4 mm3 min-1 with plain kerosene to 31.2 mm3 min-1 (≈3 ×) while cutting surface roughness from 4.2 µm to 2.7 µm.

4.1.1.3 Studies to augment machining efficiency

Another aspect is developing control over dimensional parameters to enhance efficiency in EDM, which can be challenging due to the underlying difficulties of overcutting (OC). The research efforts conducted to analyze the effect of the circle, rectangle, triangle, and square tool geometries and the process parameters in minimizing Radial Overcut (ROC). P et al., for EDM of Monel-400. Circular geometry of the tool was found to be the most optimal in reducing ROC, henceforth, honing machining efficiency and dimensional accuracy. Taguchi optimization and the corresponding parametric combination were also calculated (Padmini et al., 2015a). Moreover, an investigation found that cryogenic treatment improves tool life, reduces OC and improves surface quality (Grewal and Dhiman, 2019). In this context, the study on MRR and TWR for cryo-treated Monel-400 in the presence of an external magnetic field compared to untreated Monel-400. They found that cryogenic treatment enhanced electrical conductivity, thereby reducing power losses and TWR, while the magnetic field, on the other hand, effectively removed debris, thereby enhancing machining efficiency (Jadhav et al., 2015).

Upon reviewing the results presented in Table 6, it is clear that several strategies have been investigated to improve the machining efficiency of Monel-400 with EDM. The research primarily emphasizes optimizing tool materials, modifying dielectrics, controlling tool geometry, and applying cryogenic treatment alongside external magnetic fields. Each strategy aims to enhance critical output parameters, including MRR, TWR, Ra, and dimensional accuracy.

Table 6. Summary of strategies for enhancing the machining efficiency of Monel-400 in EDM operations.

In terms of electrode materials, studies (Anandakumar and Shanthi, 2013; Kumar and Jayakumar, 2018; Hadi and Ibrahim, 2022) reveal that graphite electrodes achieve the highest MRR and are well-suited for rough machining operations. However, they suffer from high wear, making them less favorable for finishing applications where surface quality is critical. Brass electrodes, in contrast, produce a superior surface finish but exhibit higher TWR. Researchers have introduced composite electrodes like Copper-Graphite and Copper-Titanium Diboride (Cu-Ti2) to overcome these trade-offs, significantly enhancing performance by reducing TWR and achieving a better balance between MRR and surface finish. Cu-Ti2 electrodes were highly efficient at low current settings, offering promising results for precision EDM.

Dielectric modifications also play a critical role in improving EDM outcomes. Studies (Jothimurugan et al., 2019) and (Jothimurugan and K S, 2014) demonstrate that mixing paraffin and servotherm in optimal proportions, or adding graphite particles to the kerosene-servotherm mixture, leads to remarkable enhancements in MRR (up to 1.9–3 times higher) while simultaneously reducing TWR. These modified dielectrics promote better spark stability and heat dissipation, minimizing electrode wear and improving material removal efficiency. Nevertheless, they introduce additional challenges related to fluid management and environmental considerations.

Optimization of tool geometry has also shown a direct impact on dimensional accuracy. Study (Padmini et al., 2015a) reported that circular tool geometries, coupled with appropriate pulse parameters (Ton, Toff, and Ip), are most effective in minimizing ROC. By reducing ROC, machining precision improves, and material wastage decreases, making the process more efficient. Although effective, adopting circular geometries may add to tool fabrication complexity in practical applications. Cryogenic treatment and magnetic field assistance represent another emerging area for machining improvement. Studies (Grewal and Dhiman, 2019; Jadhav et al., 2015) show that cryogenic treatment enhances the electrical conductivity of Monel-400 and extends tool life by reducing thermal-induced defects. Simultaneously, applying an external magnetic field during EDM operations improves debris evacuation from the spark gap, increasing machining stability and better surface quality. Although these techniques provide significant benefits, they also introduce additional costs and setup complexity, which must be considered during industrial application.

Optimizing tool materials and modifying dielectrics enhance MRR and surface quality, while optimizing tool geometry primarily concentrates on dimensional control. Techniques like cryogenic treatment and magnetic fields enhance the machining environment by reducing wear and increasing process stability. Each method tackles unique machining challenges, and their combined use can lead to synergistic benefits.

These advancements in tool material and dielectric selection demonstrate EDM’s effectiveness in machining Monel-400. Nevertheless, issues such as recast layers and tool wear underscore the need for ongoing optimization and alternative techniques like WEDM and ECM.

The machining efficiency of Monel-400 using EDM can be significantly enhanced through a comprehensive approach that includes optimizing electrode materials, employing hybrid or additive-based dielectric fluids, selecting appropriate tool geometries, and utilizing advanced techniques like cryogenic processing and magnetic field assistance. Although considerable advancements have been achieved, it is crucial to carefully evaluate process costs, operational complexity, and environmental sustainability for practical industrial application. Thoughtful integration of these strategies can result in highly efficient, precise, and sustainable EDM machining of Monel-400.

4.1.2 Wire EDM of Monel-400: Surface integrity and process optimization

WEDM is a spin–off EDM process that was first introduced in the late 1960s, but it was in the 1970s that CNC-assisted WEDM gained popularity (Mandal, 2014). Wire EDM or WEDM is one of the most effective and widely used non-conventional processes in the manufacturing sector for machining various steels, carbides, alloys, and superalloys (Ho et al., 2004). But problems associated with the WEDM process, such as the White layer (or recast layer), emission of hazardous fumes in wet dielectric, and poor surface integrity, are significant shortcomings.

4.1.2.1 Studies on recast layer (or white layer)

Recast layer refers to the layer of unexpelled metal solidified on a work surface that melted as a result of very high temperatures produced by electric discharges, and this recast layer serves as a source of Tensile and Compressive residual stresses, porosity, and poor surface finish (Newton et al., 2009). In this study, Vinod Kumar et al. highlighted the importance of trim cut and powder mixed dielectric in reducing recast layer and improving surface finish for WEDM of Monel-400. They found that a trim cut successfully reduced the recast layer to 43% after the rough cut. On top of that, the addition of 3 g/L of Aluminum powder in the dielectric significantly improved the surface integrity and also reduced the recast layer from 9 μm to 5 µm (Rohilla et al., 2021a).

4.1.2.2 Studies on parametric optimization

Optimization is crucial to obtain the best MRR and surface integrity of the workpiece, which is time-consuming and tedious. Consequently, Vinod et al.'s desirability approach obtained optimal parametric conditions for a rough cut and trim cut (after one rough cut) for Monel-400 when machined via WEDM. Conclusions drawn from this experiment stated that increasing Ip and Ton increases MRR, but it adversely affects the SR. Also, increasing Toff decreases the MRR but improves the surface finish (Kumar et al., 2015). It can also be observed that research, as mentioned above, has only been carried out with a fixed thickness of the workpiece, which may or may not be suitable for the industry. For this Rationale, a research investigation to find optimal settings of WEDM of Monel-400 alloy in a range of thickness was carried out by G. Selvakumar et al., and a table for optimal machining of workpiece thickness was presented for individual optimal thickness settings (Gurusamy et al., 2012a). N.E. Arun Kumar et al. employed a different approach of cryogenic treatment to improve MRR and Ra values for WEDM of Monel 400 alloy. They conducted a comparative study of untreated and cryo-treated Brass Wire electrode by varying WEDM parametrics (Wire Tension, Ton, Toff, Peak Current, Servo Feed). It was observed that Wire Tension, Servo Feed, and Ton were the most predominant factors. As for electrodes, cryo-treated brass electrodes attained low MRR values but a superior surface finish compared to untreated electrodes. Cryogenic treatment reduces atomic vibrations and makes a structured atomic arrangement (Kumar N. E. A. et al., 2023).

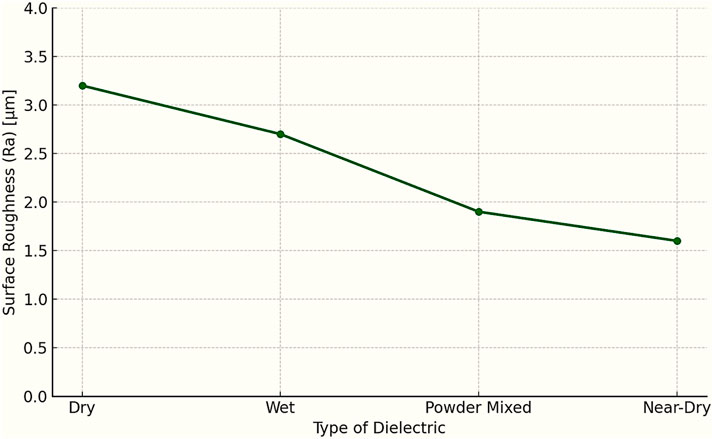

4.1.2.3 Studies on the effect of liquid dielectric

Another major challenge hampering WEDM is the impact of liquid dielectric on the environment and Personnel health. Studies revealed that wet EDM with liquid dielectric produces hazardous fumes and gaseous byproducts. Hydrocarbon-based dielectrics (such as kerosene) have the worst effect in this case (Valaki et al., 2014). Kumar et al. adopted the Near-dry WEDM approach to minimize environmental and health hazards. An analysis was conducted to trace how parameters affected MRR and Ra of machined Monel-400 in Near-dry and wet WEDM. Although MRR was highest in wet WEDM, the Ra for near–dry EDM was always better than that of wet EDM. The surface plots shown below shed light on the same (Kumar et al., 2020). Yet another research study aimed to explore the influence of near-dry WEDM operational metrics on the kerf-width of the Monel-400 superalloy. They concluded that pulse-off is requisite in controlling kerf-width (Arun Kumar et al., 2021).

4.1.2.4 Studies on corner accuracy

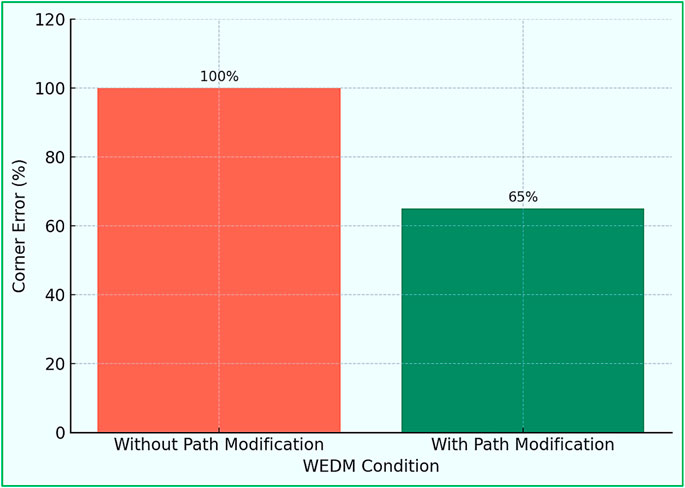

Wire electrodes in WEDM deform owing to their flexibility and gap force lagging behind the wire guide, which gives birth to corner errors (CE) and imperfect machined parts (Sarkar et al., 2011). Wire lag can be reduced either by path modification or pulse modification strategy as reported in literature (Haron et al., 2001; Puri and Bhattacharyya, 2003; Schumacher, 2004; Ji et al., 2012; Bergaley and Sharma, 2013). G Selvakumar et al. implemented a path modification strategy to minimize CE in WEDM of Monel–400. They found that an additional travel of 0.5 mm increased corner accuracy by 35% (Selvakumar et al., 2016). Another research study was conducted to study the impact of pulse modification strategy for Monel–400 with WEDM controllable and uncontrollable factors. This research study elucidates the effectiveness of the pulse modification strategy for improving MRR, but it is a waste of time for improving corner accuracy (Gurusamy et al., 2012b).

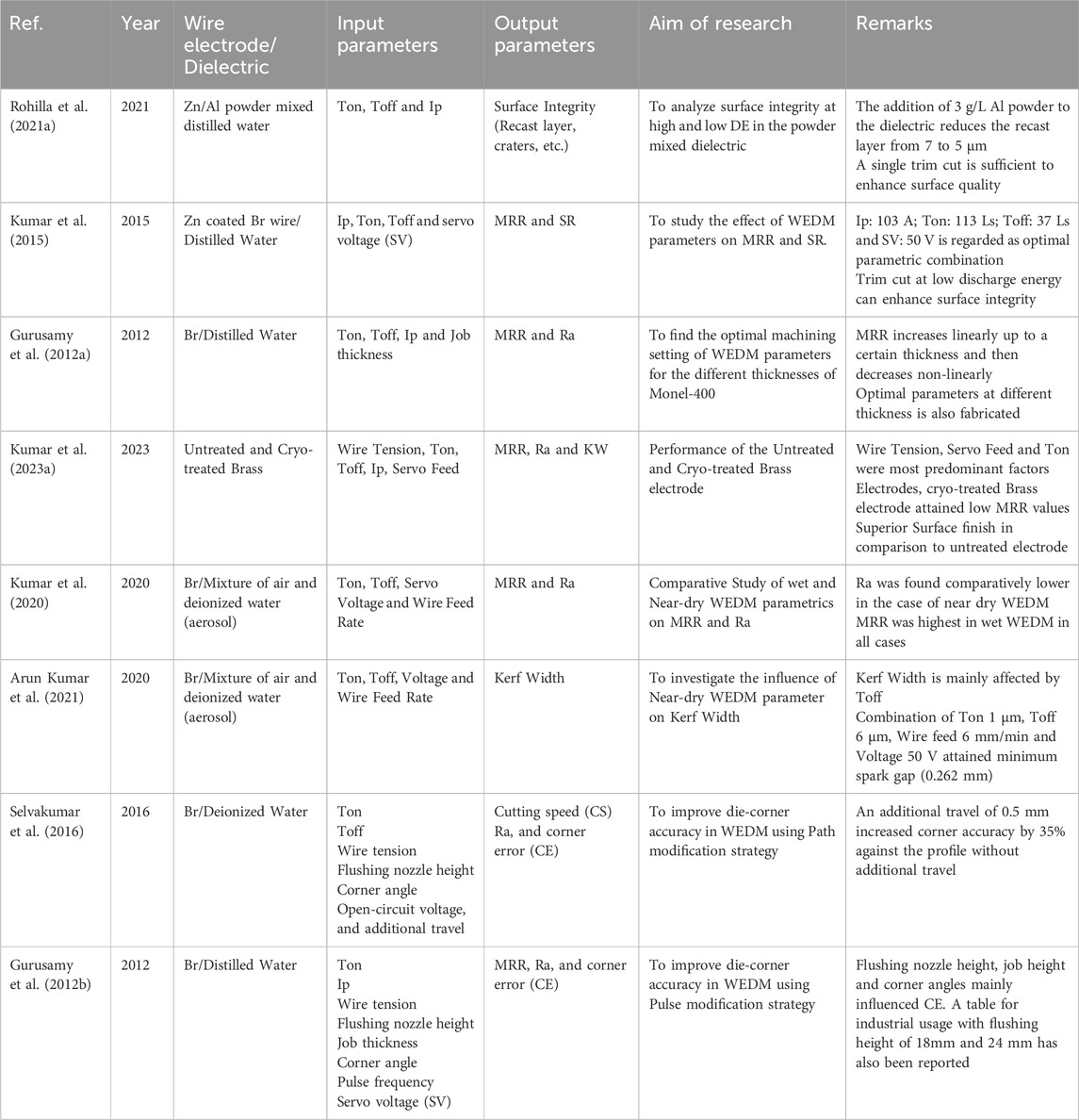

Table 7 summarizes various studies to enhance the performance of Wire Electrical Discharge Machining (WEDM) for Monel-400 alloy by optimizing factors such as pulse timing, wire properties, dielectric environment, and cutting conditions. The research examines the impact of adjusting input parameters like pulse-on time (Ton), pulse-off time (Toff), peak current (Ip), servo voltage (SV), wire tension, and auxiliary methods like near-dry machining or cryogenic wire treatment on output metrics like MRR, Ra, kerf width (KW), and corner accuracy (CE).

Table 7. Summary of parametric optimization and surface integrity improvements in WEDM of Monel-400 alloy.

The reviewed studies highlight that surface integrity is essential for WEDM of Monel- 400. Incorporating aluminum powder into the dielectric, explored in (Rohilla et al., 2021a), notably enhanced surface quality by reducing the recast layer thickness from 7 to 5 μm, with a single trim cut adequate for improving surface finish. Concurrently, another study (Kumar et al., 2015) investigated the optimization of WEDM parameters without powder-mixed dielectrics, revealing that high peak current (103 A), Ton (113 µs), and well-optimized Toff (37 µs) achieved a favorable balance between MRR and Ra, although surface quality improved with additional trim cutting at lower discharge energy.

Additionally, the effect of workpiece thickness on WEDM performance was critically examined. A study (Gurusamy et al., 2012a) found that MRR initially increased linearly with thickness but exhibited a nonlinear decrease beyond a specific threshold. Optimal parameters were established for various thickness ranges to maintain consistent machining quality. Furthermore, research in (Kumar N. E. A. et al., 2023) revealed that cryogenic treatment of brass wires enhanced surface finish, albeit with a slight reduction in MRR, attributed to improved atomic ordering in the cryo-treated wires, allowing for better discharge process control.

The cooling environment also significantly impacts WEDM performance. Studies (Kumar et al., 2020; Arun Kumar et al., 2021) contrasted conventional wet WEDM with near-dry conditions, utilizing a blend of air and deionized water. Near-dry WEDM consistently yielded lower Ra values, although MRR was marginally elevated in traditional wet settings. Specifically, Toff proved to be the most sensitive parameter influencing KW, with the optimal settings of Ton at 1 µs, Toff at 6 µs, a wire feed of 6 mm/min, and a voltage of 50 V achieving the minimum spark gap of 0.262 mm.

Corner accuracy is a crucial factor in dimensional control and has been thoroughly examined in sources (Selvakumar et al., 2016; Gurusamy et al., 2012b). A strategy that modifies the path by adding an extra 0.5 mm resulted in a 35% enhancement in corner accuracy compared to an unaltered path. Additionally, pulse modification techniques, which adjust Ton, Ip, and the height of the flushing nozzle, were investigated to reduce corner errors; among these, the flushing nozzle height and job thickness showed the most significant impact. These methods are especially beneficial for sectors that require complex die-corner profiles with minimal distortion.

When evaluating various strategies, powder-mixed dielectrics and trim cuts present the clearest enhancements to surface integrity, whereas cryogenic treatment improves surface finish, albeit slightly diminishing the MRR. Near-dry WEDM is recognized as an environmentally friendly option that delivers excellent surface quality, though it may not completely match the MRR achieved in wet conditions. Parametric optimization across different thicknesses guarantees adaptability to various component geometries. For applications demanding high precision, modifications to both the path and pulses are essential for improving corner fidelity.

The efficient machining of Monel-400 using WEDM involves various strategies customized for specific application outcomes. Employing powder-mixed dielectrics and applying cryogenic treatments to wires can effectively produce high-quality surfaces, while nearly dry WEDM techniques support sustainability efforts. Precise management of pulse settings, wire feed rates, and supplementary methods like path modifications greatly enhances both dimensional accuracy and surface quality. Future research should focus on hybrid methodologies that combine powder mixing, cryogenic treatments, and sophisticated control techniques to achieve high MRR and outstanding surface finishes in an environmentally friendly way.

4.1.3 Micro-WEDM for high-precision machining of Monel-400

The demand for smaller and thinner products in recent years necessitates the development of diverse micro-machining processes for their manufacturing. Micro-WEDM is one such process that can machine 3-D complex and intricate shapes with high aspect ratios (Taylor et al., 2019). Lack of literature in this field instigated to attempt milling Microchannels on Monel-400 with a one-factor-at-a-time approach on Ra, surface morphology, and dimensional accuracy. Ton, Toff, and VGAP were the most effective parameters. They concluded that using lower to middle levels of TON, moderate levels of TOFF, and moderate VGAP can produce microchannels with satisfactory channel width (CHW) and depth (CHD), smooth surface morphology, and low recast layer thickness (Saleh et al., 2020).

4.2 Electrochemical Machining (ECM) of Monel-400

4.2.1 Die-sinking ECM: Electrolyte effects and surface finish analysis

4.2.1.1 Studies on the type of electrolyte

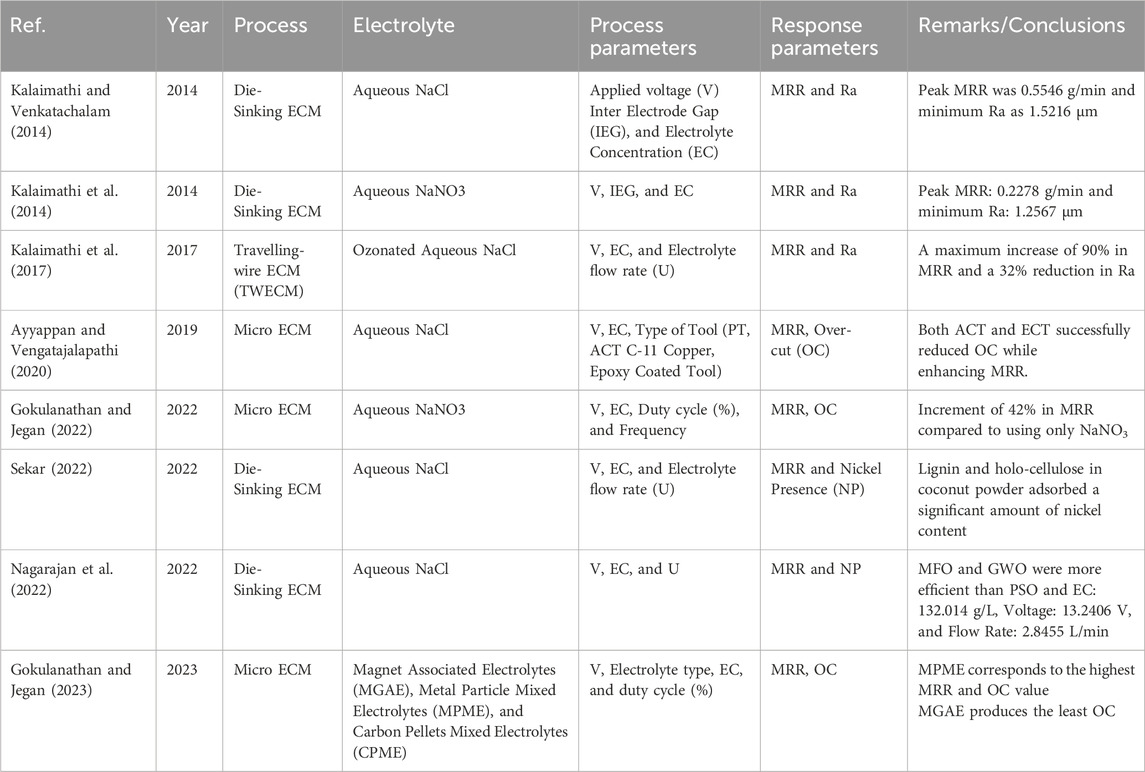

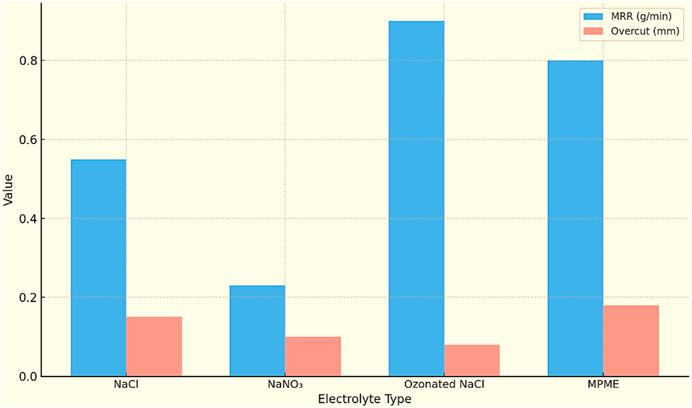

Experimental investigations have optimized process parameters to obtain the best MRR and Ra values in die-sinking ECM. Experimental investigations were conducted on the surface machining of Monel-400 alloy with a flat face tool electrode in flooded electrolyte conditions, employing two different electrolytes: aqueous NaCl solution and aqueous NaNO3 solution. Experimental results for optimal process parameters in both cases pointed out higher values of MRR with aqueous NaCl as an electrolyte, but comparatively lower Ra in the case of NaNO3 (Kalaimathi and Venkatachalam, 2014; Kalaimathi et al., 2014).

4.2.1.2 Studies on nickel presence

Further research has found that when this Ni-Cr superalloy is machined while immersed in an electrolyte, a toxic substance, Nickel-Hydroxide [Ni (OH2)], is formed in the sludge. To counter this problem, Metaheuristics: GWO (grey wolf optimizer), MFO (moth-flame optimization), and Nagarajan et al. employed PSO (particle swarm optimization) in devising optimal process parameters for minimizing nickel presence in the sludge with NaCl (+1% HCl) as electrolyte. They concluded that MFO and GWO were more efficient and resulted in the same parametric combination, i.e., EC of 132.014 g/L, Voltage of 13.2406V, and Flow Rate of 2.8455L/min for MRR = 0.242 g/min and NP = 57.7202 PPM (Nagarajan et al., 2022). Another approach to this problem was presented by Vengatajalapathi et al., who employed natural bio-adsorbents to adsorb Ni-ions from electrolytes after the ECM of the Monel-400 workpiece. Bio-adsorbents from natural environmental wastes such as coconut shell powder, wood dust powder, and bagasse were used as filtration material. It was observed that the lignin and holo-cellulose present in coconut powder adsorbed a significant amount of nickel content. Moreover, the voltage of 12.535V, electrolyte concentration (EC) of 130 g/L, and a flow rate of 1.768 L/min were found to discharge the minimum possible nickel contents of 49.8776 mg/L into the electrolyte (Sekar, 2022).

4.2.1.3 Environmental implications of electrolyte use in ECM

ECM is renowned for being tool-wear-free and machining hard materials with a perfect surface finish. ECM also generates serious environmental problems mainly because it employs electrolytes like NaCl, NaNO3, and hybrid chemical solutions. ECM produces toxic sludge with heavy metal ions like nickel hydroxide, which can pollute water sources if not appropriately treated. Spent electrolyte disposal is a cause for environmental concern in soil and aquatic environments. Some studies have tried to counter this by incorporating bio-adsorbents like coconut shell powder and bagasse or streamlining electrolyte concentration and flow to reduce nickel ion leaching. There is, however, a significant lack of closed-loop or recyclable electrolyte systems that are in accord with sustainable manufacturing practices. Future ECM developments must incorporate environmental protection mechanisms, like in situ filtration, electrolyte recovery units, and green electrolytes to fulfill the industry’s increasing demand for sustainable machining processes.

4.2.2 Electrochemical micro-machining: Tool design and overcut control

ECMM has shown promise in machining intricate and complex shapes on materials of any hardness with some electrical conductivity. It led researchers to explore the viability of this process for machining micro features in superalloys.

4.2.2.1 Studies on MRR and OC

Gokulanathan et al. drilled micro-holes in a 0.8 mm-thick plate of Monel-400 by utilizing a pulsed air supply and three different conditions regarding the use of three different electrolytes during machining: MGAE (Magnet Associated Electrolytes), MPME (Metal Particle Mixed Electrolytes), and CPME (Carbon Pellets Mixed Electrolytes). Conclusions pointed out that MPME corresponds to the highest MRR and OC value, while MGAE produces the least OC. Graphical analysis extends understanding of the effect of different electrolytes and process parameters on responses (Gokulanathan and Jegan, 2023). Furthermore, advances in micro–machining performance using aqueous NaNO3 as an electrolyte were studied with pulsed air supply through the tool holder. Three optimal techniques were applied: VIKOR, TOPSIS, and COPRAS, to grasp the best optimal combination for MRR and OC. They found that utilizing a pulsed air supply produced an increment of 42% in MRR compared to using only NaNO3 (Gokulanathan and Jegan, 2022). Additional exploration from research literature has pointed out that controlling OC in ECMM has been a challenging task and is essential for the growth of this process. S Ayyapan et al., employed ACT (Abrasive coated tool) and ECT (Epoxy coated tool) side insulation on copper tool electrode to check their usefulness in minimizing OC in ECMM of Monel-400. It was observed that ACT provided High MRR since it removed the passive metal oxide layer produced on the surface, while both ACT and ECT reduced OC because of the absence of electrochemical reaction from the tool side surface and workpiece (Ayyappan and Vengatajalapathi, 2020).

4.2.3 Travelling wire ECM (TWECM): Electrolyte enhancement and machinability

TWECM is a cutting-edge technology, similar to WEDM. Still, it has the edge over susceptibility to lower thermal damage to the workpiece and is an area worth delving into. Kalaimathi et al. have implemented an experimental investigation to assess the feasibility of ozonated aqueous NaCl solution on Monel-400 in TWECM. Results indicated a maximum increase of 90% in MRR and a 32% reduction in Ra of machined Monel-400. This was due to ozone decomposition into hydroxyl and peroxide radicals that undergo fast reactions with metal oxides and hydroxides, causing slug removal, thereby enhancing machining efficiency. SEM images of surface machined in ozonated electrolyte confirm better quality than with plain NaCl (Kalaimathi et al., 2017).

Table 8 summarizes important research initiatives that enhance the machining performance of Monel-400 through various ECM and Micro-ECM techniques. These studies examine several factors, including electrolyte selection, tool electrode types, pulse control strategies, and external enhancement techniques like pulsed air supply and electrolyte ozonation. The primary response parameters analyzed are MRR, Ra, Over-cut (OC), and Nickel Presence (NP) in sludge, aimed at achieving improved efficiency, superior surface quality, and environmental safety.

Table 8. Comparative analysis of process parameters and performance outcomes in ECM and Micro-ECM of Monel-400.

From the comparative evaluation, it is clear that electrolyte type significantly influences the machining characteristics. Studies (Kalaimathi and Venkatachalam, 2014; Kalaimathi et al., 2014) compared NaCl and NaNO3 electrolytes in die-sinking ECM, revealing that NaCl provides a higher MRR (0.5546 g/min) but at the expense of slightly rougher surfaces, whereas NaNO3, despite a lower MRR (0.2278 g/min), produced better surface finishes with Ra values as low as 1.2567 µm. This indicates that NaCl is preferable for bulk material removal applications, whereas NaNO3 is better suited for precision finishing operations.

Advanced techniques such as TWECM using ozonated NaCl electrolyte, explored in (Kalaimathi et al., 2017), demonstrated significant improvements in MRR (up to 90% increase) and Ra (32% reduction) compared to conventional NaCl solutions. The presence of ozone helped decompose metal oxides faster, thereby facilitating smoother machining and cleaner surfaces. Similarly, micro-ECM approaches with different electrolytic enhancements, such as magnet-associated, metal-particle mixed, and carbon-pellet mixed electrolytes (Gokulanathan and Jegan, 2023), highlighted that Metal Particle Mixed Electrolytes (MPME) yielded the highest MRR but at the cost of a larger OC. In contrast, Magnet Associated Electrolytes (MGAE) minimized OC, offering better dimensional control.

Electrode design modifications also played a key role. In the study (Ayyappan and Vengatajalapathi, 2020), abrasive-coated (ACT) and epoxy-coated (ECT) tools were used to reduce OC significantly while enhancing MRR in micro-ECM processes. This is attributed to suppressing stray currents and localized removal of oxide layers, thus improving machining precision. Furthermore, the application of pulsed air supply during micro-ECM with NaNO3 electrolyte, as studied in (Gokulanathan and Jegan, 2022), improved MRR by 42%, demonstrating that external interventions to promote electrolyte flow can dramatically influence process efficiency.

Another critical concern addressed was the environmental aspect, Nickel contamination in the electrolyte. Studies (Nagarajan et al., 2022; Sekar, 2022) applied optimization techniques (Metaheuristics like MFO and GWO) and bio-adsorbents like coconut shell powder to minimize nickel presence in sludge. These approaches not only maintained reasonable machining efficiency but also achieved significant reductions in heavy metal contamination, promoting eco-friendly machining practices.

A comparison of the studies shows that the efficiency of ECM for Monel-400 can be adjusted according to specific priorities. If achieving a high MRR is the primary aim, selecting NaCl and electrolyte modifications such as ozonation or MPME is the most effective approach. For critical needs of surface precision and minimal dimensional fluctuations, it is advisable to utilize NaNO3 electrolyte in conjunction with MGAE and coated tools. When prioritizing environmental sustainability, employing optimized electrolytes and bio-filtration methods proves to be an effective strategy for mitigation.

ECM and Micro-ECM processes for Monel-400 have become highly customizable and have been influenced by electrolyte selection, tool surface engineering, and additional techniques like ozonation and air pulsing, significantly affecting machining results. To further advance ECM technology for industrial applications of Monel-400, it is essential to integrate material removal efficiency with surface quality control and environmental considerations. Future research should emphasize hybrid electrolyte systems, enhancing eco-friendly dielectric alternatives, and the development of real-time control systems that balance productivity with sustainability.

4.3 Plasma Arc Cutting: High-temperature machining characteristics

4.3.1 Studies on optimization

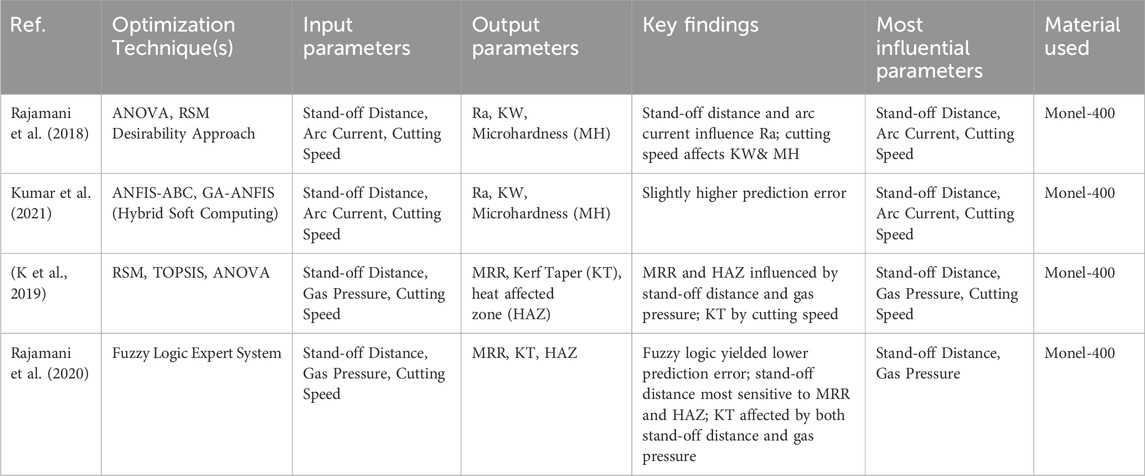

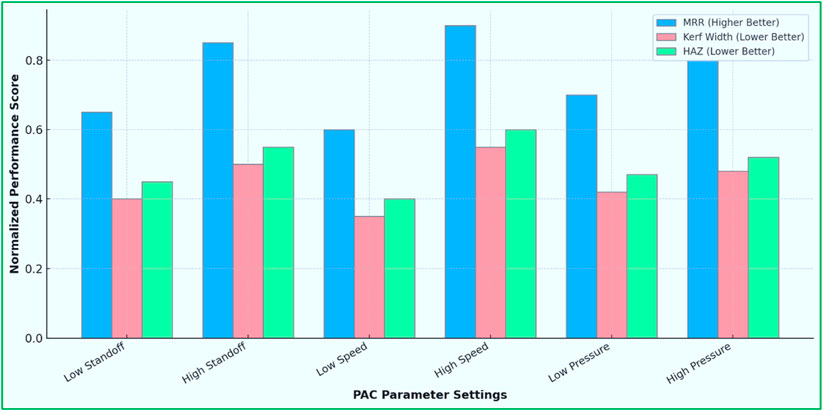

PAC, an innovative thermal-based machining technology, was initially patented in 1955 and has come a long way since then (Nemchinsky and Severance, 2006). Although PAC has potential benefits like rapid cutting and processing a wide range of materials, diverse PAC process parameters make it hard to optimize quality control and process. Hence, various optimization techniques have been adopted by researchers over time, such as regression, TOPSIS, GA, Hybrid, MCDM, etc., to study the influence of predominant PAC process variables. D. Rajamani et al. adopted the ANOVA and RSM desirability approach to observe the impact of chief PAC parameters on optimizing Ra, Kerf-Width, and MH. They confided that stand-off distance and arc current greatly influence Ra, meanwhile, Kerf-Width and MH can be primarily controlled by cutting speed (Rajamani et al., 2018). Yet, another research was conducted for multi-response optimization of processed Monel-400 alloy by adopting a soft computing hybrid approach of ANFIS-ABC and GA-ANFIS with the same input and output variables as in the case of D. Rajamani et al. It can be pointed out that the values of optimal parameters in both cases were mostly alike. However, error prediction in Optimal values was a little higher in the latter (Kumar et al., 2021).

K. Ananthakumar led an investigation to enhance PAC performance characteristics: MRR, KT and HAZ, and their optimization via RSM methodology and TOPSIS technique. ANOVA analysis of this study revealed that stand-off distance and gas pressure were most influential for controlling MRR and improving HAZ, whereas KT was primarily affected by a change in cutting speed (K et al., 2019).

Another study examined the impact and optimization of PAC input parameters on machined Monel-400. However, a fuzzy logic expert system was employed this time, which is relatively superior and less time-consuming than most optimization techniques. The experimental results of this investigation revealed that the prediction error with this system was considerably lower than that found in the studies mentioned earlier. Moreover, results from the sensitivity analysis suggested the stand-off distance was the most sensitive parameter to MRR and HAZ, whereas both the stand-off distance and gas pressure were highly sensitive to KT (Rajamani et al., 2020).

The research presented in Table 9 collectively investigates different optimization methods used on the PAC of Monel-400 alloy. D. Rajamani et al. employed ANOVA and RSM desirability approaches to evaluate the influence of parameters like stand-off distance, arc current, and cutting speed on outputs such as Ra, KW, and microhardness (MH). Their results indicated that stand-off distance and arc current had the largest impact on Ra, whereas KW and MH were under the primary influence of cutting speed (Rajamani et al., 2018). Kumar et al. applied hybrid soft computing methods—ANFIS-ABC and GA-ANFIS—with identical parameters and results, and obtained mainly similar optimal values, albeit with slightly greater prediction error (Kumar et al., 2021).

Table 9. Summary of optimization techniques and key findings for plasma arc cutting (PAC) of Monel-400 alloy.

K. Ananthakumar et al. maximized MRR, kerf taper (KT), and heat affected zone (HAZ) by applying RSM and TOPSIS. In their ANOVA test, stand-off distance and gas pressure were key parameters for maximizing MRR and HAZ, while KT was largely dependent on cutting speed (K et al., 2019). Another research work by Rajamani et al., using a fuzzy logic expert system, registered the least prediction error compared to all research works. This model classified stand-off distance as the most sensitive parameter to MRR and HAZ, and stand-off distance and gas pressure were highly sensitive regarding KT. Stand-off distance proved to be the most universally affecting parameter across optimization approaches and output responses (Rajamani et al.).

4.4 Abrasive Water Jet Machining of Monel-400: Process advantages and limitations

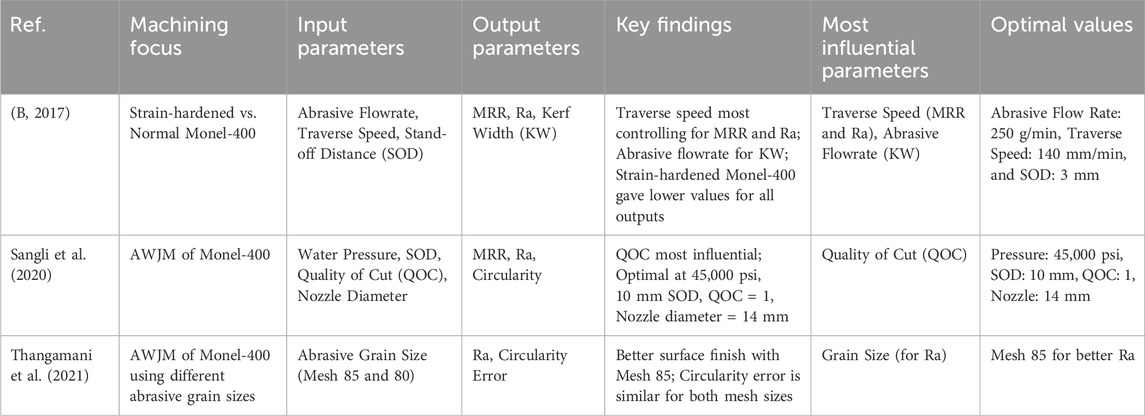

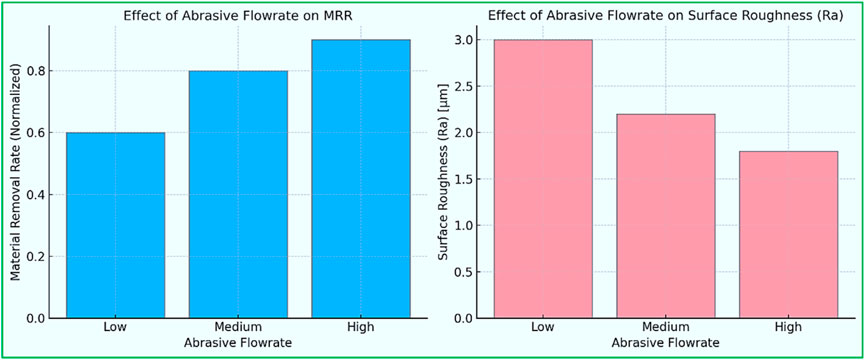

(Jonathan et al., 2017), instigated a comparative study for AWJM of strain hardened versus normal Monel-400. This study was conducted by varying the abrasive flow rate, Traverse speed, and SOD to enhance MRR, Ra, and KW. They observed that Traverse speed was the most controlling factor for MRR and Ra, while Abrasive flow rate was the most influential for KW. Secondly, results deduced that all three responses attained lower values in the case of strain-hardened Monel-400 compared to normal Monel-400.

(Sangli et al., 2020) analyzed the influence of AWJM parameters, namely, Water pressure, SOD, QOC (quality of cut), and Nozzle diameter, on MRR, Ra, and Circularity of machined Monel-400. The Grey analysis optimization technique was employed to find optimal input parameter values for the most efficient output. Peak performance was reached for pressure at 45,000 psi, standoff distance at 10 mm, quality of cut at 1, and nozzle diameter of 14 mm. Additionally, QOC was the most influential of all process parameters. A.C. Arun Raj et al. directed their study on minimizing Ra and circularity error for AWJM of Monel-400. For this purpose, they employed two different grain sizes (mesh 85 and mesh 80). They found that the surface finish of the workpiece was better when machined using 85 mesh grain, while the circularity value was almost similar in both cases (Thangamani et al., 2021).

Table 10 summarizes comparative studies on Abrasive Water Jet Machining (AWJM) of Monel-400. Arunkumar et al. made a comparative study of strain-hardened and regular Monel-400 by changing abrasive flow rate, traverse speed, and stand-off distance. They observed that traverse speed had a significant effect on MRR and Ra, whereas abrasive flow rate affected kerf width (KW). All values of output were lower for the strain-hardened type (B, 2017).

Grey analysis was used to optimize parameters like water pressure, stand-off distance, quality of cut (QOC), and nozzle diameter for outputs like MRR, Ra, and circularity. Their findings determined that QOC was the most significant parameter, and the best performance was at 45,000 psi pressure, 10 mm SOD, QOC level 1, and a 14 mm nozzle (Sangli et al., 2020). In another research, Arun Raj et al. examined the effect of abrasive grain size (mesh 85 vs. 80) on Ra and circularity error. Their results indicated that finer mesh (85) enhanced surface finish, whereas circularity was not significantly affected by grain size (Thangamani et al., 2021) The research highlights the central role of traverse speed, QOC, and abrasive characteristics in Monel-400’s AWJM performance.

4.5 Photochemical Machining: Precision etching for Monel-400

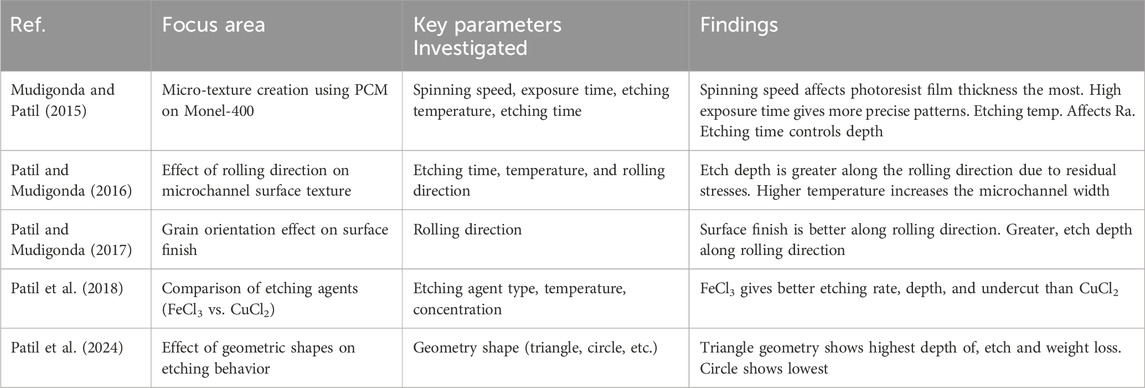

PCM is unmatched when fabricating highly intricate and complex cavities cost-effectively with low production rates. Mudigonda et al. (Mudigonda and Patil, 2015) explored the impact of Photolithography and parameters in creating micro-texture on Monel-400 sheets by PCM. This investigation concluded that spinning speed is most influential in deciding photoresist film thickness, while high exposure time results in more precise patterns. On top of that, Ra and depth of, etch of the machined workpiece were primarily dominated by etching temperature and etching time respectively.

(Patil and Mudigonda, 2016) accentuated the importance of rolling direction on the surface texture of machined microchannels. They focused on etching time, Temperature, and rolling direction effects on Undercut, Depth of, etch, Photoresist film thickness, and strength. Findings from this experiment indicated that the, etch depth along the rolling direction is greater than that across it, mainly due to residual stresses that cause a higher, etch rate along the rolling direction than across it. Also, an increase in the etching temperature increased the microchannel width. The same authors examined the effect of grain orientation on the Surface finish of Photochemically machined Monel-400. Results of this study corroborate prior research, showcasing that surface finish is higher when machined along the rolling direction. Subsequently, higher etching depth was observed along the rolling direction than across it (Patil and Mudigonda, 2017). PCM of Monel-400 was explored, employing the use of two contrasting etching agents: ferric chloride (FeCl3) and cupric chloride (CuCl2) at different temperatures and concentrations to obtain the best possible etching rate, etching depth, and undercut values. It was revealed that FeCl3 exhibits the best overall performance in all aspects as compared to CuCl2. Also, the effect of various geometric shapes was observed in terms of depth of, etch and weight loss. Triangular Geometry showed the highest depth of, etch and loss of weight, while the circle was the lowest (Patil et al., 2018; Patil et al., 2024).

Table 11 consolidates major studies on Photochemical Machining (PCM) of Monel 400. It emphasizes the impact of process parameters like spinning speed, etching time, temperature, and rolling direction on results such as photoresist film thickness, etch depth, and surface finish. Results always indicate that etching behavior is sensitive to material properties as well as processing conditions. Ferric chloride (FeCl3) is the most effective etchant, and triangular geometries lead to more aggressive etching compared to circular geometries.

Table 11. Summary of key findings in photochemical machining (PCM) of monel 400 based on various studies.

4.6 Hot machining: Preheating effects and tool life enhancement

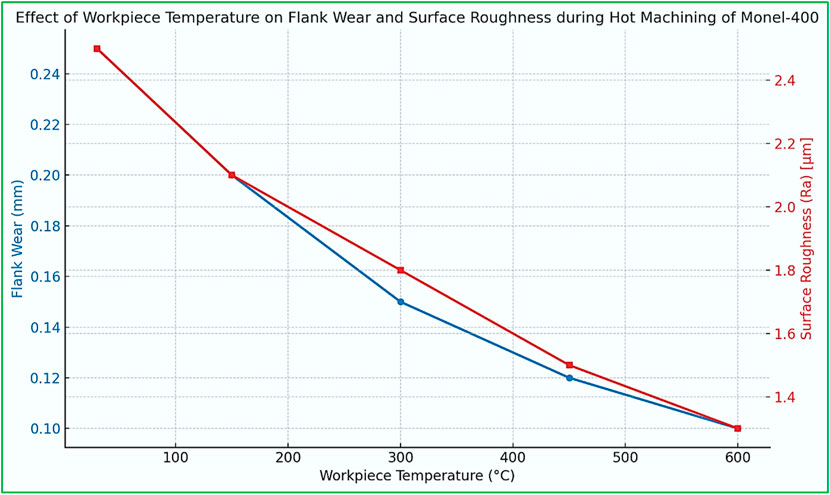

(Parida and Maity, 2018b) conducted a comparative study of hot turning (via flame heating) and turning at room temperature on Tool life, machining forces, Ra, and Microhardness of three Nickel-based alloys: Inconel 718, Inconel 625, and Monel-400. It was observed that hot turning (600 °C) improves tool life, machining forces, and Ra for all alloys compared to machining at ambient temperature (30 °C). This study entailed the importance of hot turning in significantly reducing machining forces (cutting, feed, and radial), all the while improving tool life, chiefly due to the reduction in shear strength of material when heated above recrystallisation temperature. The same authors studied the influence of machining parameters and heating temperatures in the hot turning operation of Monel-400. They found that as the temperature hit 600 °C, forces and flank wear reduced drastically. In addition, built-up-edge formation was primarily observed at low cutting speeds, whereas adhesion and diffusion wear were predominant under high-speed conditions (Parida A. and Maity K., 2018).

Another experimental study conducted an RSM-based analysis on the influence of hot machining (via flame heating) parameters on Ra and flank wear for Monel-400. They found out that temperature was the most influential factor affecting flank wear, whereas Ra was mainly affected by cutting speed, as evident from the plots below. Additionally, cutting speed of 87.88 m/min, feed rate 0.11 mm/rev, depth of cut 0.5 mm, and workpiece temperature of 93 °C were found to achieve minimum Ra and flank wear and were hence designated as optimal parametric combination (Kumar Parida and Maity, 2019b). Power law and ANN models were deployed to depict the influence of hot machining process parameters on Ra and Flank wear. They found that an increase in cutting speed and feed rate increased flank wear but decreased Ra. Secondly, a rise in temperature leads to an increase in both flank wear and Ra. What’s more, employed GA (Genetic Algorithm) found cutting speed, feed rate, depth of cut, and temperature at 99.2758 mm/min, 0.1014 mm/rev, 0.5003 mm, and 92.9177 °C respectively as optimal parametric combination corresponding to minimum Ra and Flank wear (Hanief and Charoo, 2020b).

A comparative study was carried out by Damian et al., on Laser Assisted Machining (LAM) and Conventional machining of laser-borided Monel-400. Laser Beam Scanning Velocity, Distance from surface, Time of machining, and feed rate were varied, and their influence on Microhardness, Cutting Force, Ra, and tool wear was studied. Results of this experiment surmised that high values of laser beam scanning velocities resulted in high microhardness. More importantly, the values of cutting force and Tool Wear were relatively lower in the case of LAM than conventional machining. Also, the surface topography of LAM was better than conventional (Kukliński et al., 2023b; Bhukya et al., 2023) employed the ANN-GA hybrid technique to predict/forecast optimal process parameter values in Laser Assisted Machining of Monel-400. Experimentally found optimal values from this experiment were closely related to expected values of Ra, cutting force, and cutting temperature, reflecting the efficiency of the ANN-GA technique. Furthermore, cutting speed was found to be the most influential factor as indicated by ANOVA methodology.

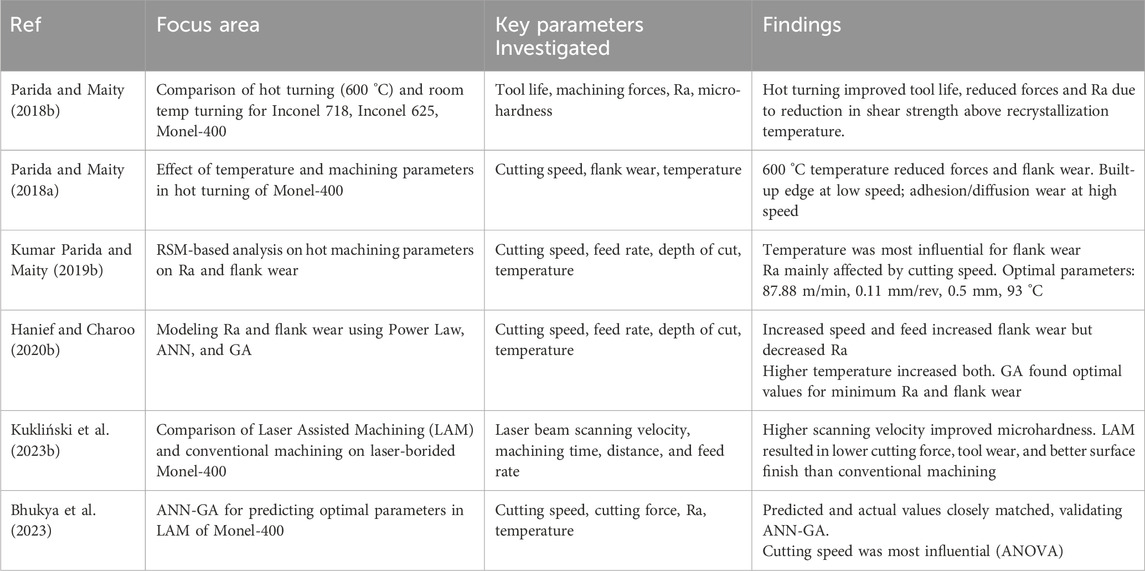

Table 12 consolidates studies on hot machining of Monel 400, considering hot machining effects at high temperatures and aided machining techniques such as Laser Assisted Machining (LAM). Research indicates that hot machining enhances tool life, lowers machining forces and Ra, particularly at 600 °C. The best parameters for minimum Ra and flank wear were determined using RSM, ANN, and GA methods. LAM was superior to traditional machining in having a better surface finish and less wear of tools, and ANN-GA methods accurately predicted optimal machining conditions.

5 Integrated outcomes and comparative discussion

While extensive research exists on various non-conventional machining techniques for Monel-400, a comprehensive comparison of these processes is essential for informing industrial decision-making. The following synthesis is derived from the analyzed studies.

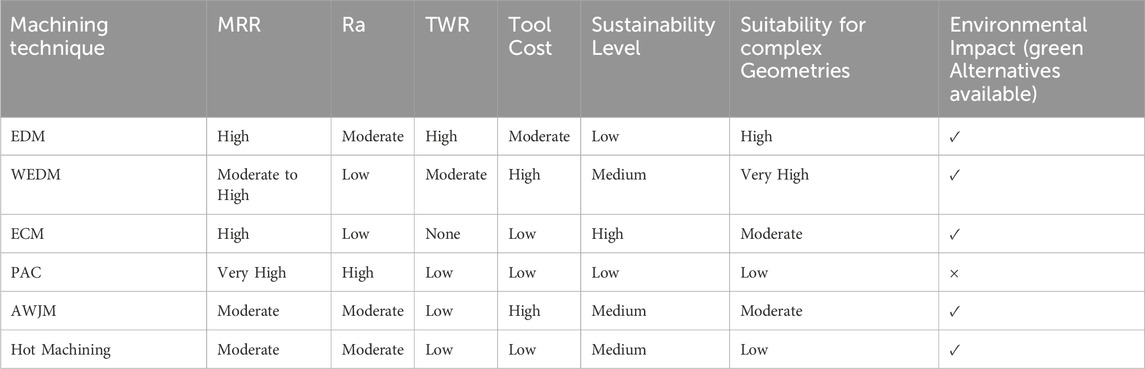

• EDM provides accurate machining of intricate shapes while maintaining a reasonable MRR. Nevertheless, challenges like recast layers, tool wear, and environmental issues from hydrocarbon-based dielectrics hinder its wider use unless optimization strategies like hybrid dielectrics and cryogenic treatments are implemented.

• WEDM offers superior surface integrity and dimensional accuracy, especially when utilizing powder-mixed dielectrics and trim cuts. Wire lag and white layer formation continue, requiring modifications in path/pulse strategies and near-dry methods to lessen environmental impacts.

• ECM and ECMM provide high MRR, minimal tool wear, and absent thermal damage. However, challenges such as sludge management (formation of nickel hydroxide) and environmental hazards linked to electrolyte disposal can be managed through eco-friendly filtration and improved flow dynamics.

• PAC achieves exceptionally high MRR, making it ideal for quick, large-scale operations. However, Ra and heat affected zone (HAZ) necessitate precise control of factors like stand-off distance and gas pressure, with hybrid soft-computing optimizations showing potential benefits.

• AWJM delivers good surface quality and slight thermal damage, offering a more environmentally safe alternative to EDM/PAC, yet attention to abrasive consumption costs and kerf control is critical.

• PCM and Hot Machining specialize in microfabrication and strength reduction before cutting. PCM is excellent for creating thin, intricate components with high precision, while hot machining improves tool lifespan and significantly lowers cutting forces in heavy-duty tasks.

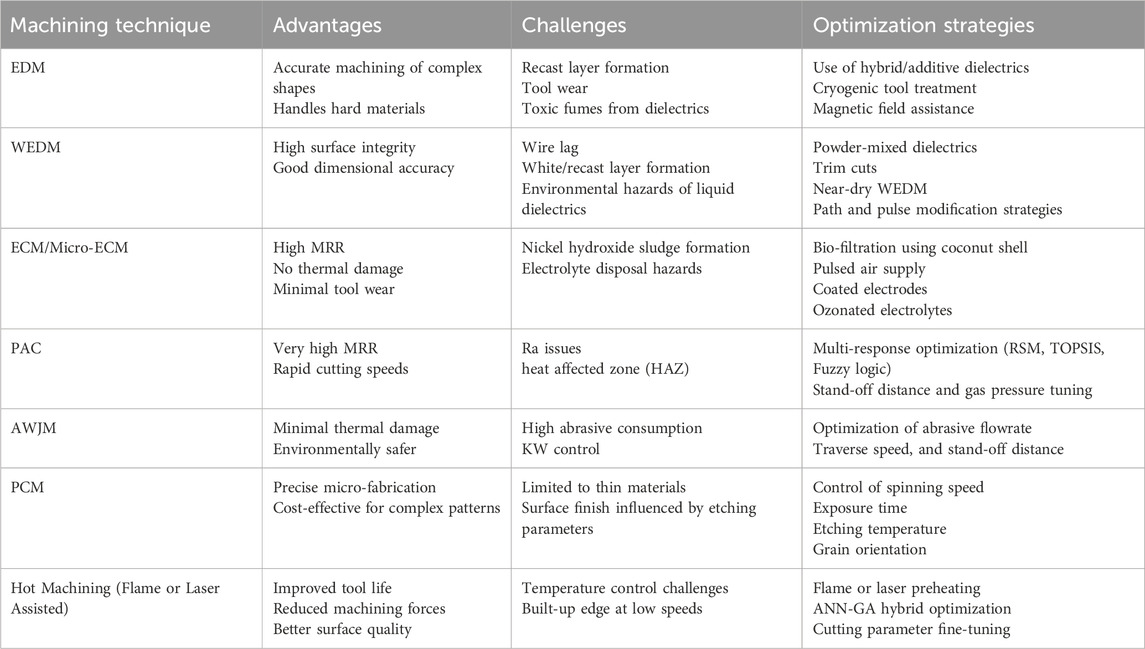

Table 13 offers a comparative analysis of key non-conventional machining methods investigated for Monel-400, highlighting their main benefits, intrinsic challenges, and optimization techniques to enhance machining efficiency and surface quality. It is synthesized from various sources analyzing EDM (Ekmekci, 2007; Anandakumar and Shanthi, 2013; Jothimurugan and K S, 2014; Jadhav et al., 2015; Padmini et al., 2015a; Gupta and Gupta, 2018; Kumar and Jayakumar, 2018; Grewal and Dhiman, 2019; Jothimurugan et al., 2019; Mahalingam and Varahamoorthi, 2020; Biswas and Rahul, 2021; Hadi and Ibrahim, 2022), WEDM (Haron et al., 2001; Puri and Bhattacharyya, 2003; Schumacher, 2004; Sarkar et al., 2011; Gurusamy et al., 2012a; b; Ji et al., 2012; Bergaley and Sharma, 2013; Valaki et al., 2014; Kumar et al., 2015; Selvakumar et al., 2016; Kumar et al., 2020; Arun Kumar et al., 2021; Rohilla et al., 2021b; Kumar N. E. A. et al., 2023), ECM (Kalaimathi and Venkatachalam, 2014; Kalaimathi et al., 2014; Kalaimathi et al., 2017; Ayyappan and Vengatajalapathi, 2020; Gokulanathan and Jegan, 2022; Nagarajan et al., 2022; Gokulanathan and Jegan, 2023), PAC (Rajamani et al., 2018; K et al., 2019; Rajamani et al., 2020; Kumar et al., 2021), AWJM (B, 2017; Sangli et al., 2020; Thangamani et al., 2021), PCM (Mudigonda and Patil, 2015; Patil and Mudigonda, 2016; Patil and Mudigonda, 2017; Patil et al., 2018; Patil et al.), and Hot Machining (Parida A. and Maity K., 2018; Parida A. K. and Maity K., 2018; Kumar Parida and Maity, 2019b; Hanief and Charoo, 2020b; Bhukya et al., 2023; Kukliński et al., 2023b). Choosing the right machining approach depends on application specifics, including requirements for high MRR, excellent surface finish, precision, or eco-friendliness.

Thus, the hybridization of techniques and environmentally friendly adaptations is increasingly crucial for the efficient and sustainable machining of Monel-400.