- Escuela de Ingeniería en Ciberseguridad, Facultad de Ingeniería y Ciencias Aplicadas, Universidad de Las Américas, Quito, Ecuador

In the era of Industry 4.0, the integration of advanced technologies such as digital twins represents a strategic opportunity for process optimization in the metalworking industry. Although their potential has been widely acknowledged, many companies face significant challenges in implementation, particularly in terms of operational efficiency, predictive maintenance, and economic feasibility. This study addresses how a digital twin can be effectively deployed within metalworking operations to solve concrete production issues, enhance decision-making, and optimize resource utilization. The proposed system models critical processes, such as milling, welding, and material flow, and integrates real-time data to enable continuous improvement. Through a longitudinal evaluation, the implementation of the digital twin resulted in a 30% reduction in material waste, a 40% decrease in the rejection rate of milled parts, and a return on investment of 233% over 5 years. These results provide empirical evidence of the digital twin’s capacity to drive both operational excellence and economic return. This work contributes to the existing literature by offering a robust quantitative assessment of digital twin deployment in metalworking, emphasizing its practical benefits and strategic relevance.

1 Introduction

Digital twins have emerged as a transformative paradigm within Industry 4.0, particularly in the metalworking sector, where the demands for precision, operational efficiency, and adaptive control are exceptionally high. A digital twin is defined as a dynamic and continuously updated virtual counterpart of a physical process, product, or system, leveraging real-time data acquisition and advanced simulation (Hyre et al., 2022). In metalworking operations, where methods such as machining, welding, and surface treatment coexist with tight tolerances and complex workflows, the integration of digital twins enables unprecedented visibility and control over industrial assets and performance.

The maturity of enabling technologies—such as the Internet of Things (IoT), edge computing, big data analytics, and artificial intelligence (AI)—has facilitated the scalable deployment of digital twins in industrial contexts (Tancredi et al., 2022). These systems provide predictive insights, enable real-time anomaly detection, and allow the testing of operational strategies in silico, reducing risks and accelerating decision-making. In the context of the metal industry, digital twins provide tangible solutions to persistent challenges, including high rejection rates, inefficient maintenance cycles, and suboptimal resource utilization. Their implementation enables a shift from reactive to predictive and adaptive manufacturing practices.

Despite the conceptual advancement and technological feasibility of digital twins, the literature reveals critical gaps regarding their quantitative impact and practical implementation across diverse production environments (Mateev, 2020; Guerra-Zubiaga et al., 2021). Prior studies have emphasized theoretical frameworks and isolated use cases—mainly in predictive maintenance or energy monitoring—but comprehensive evaluations grounded in real industrial data remain scarce (Moiceanu and Paraschiv, 2022; Wang and Wang, 2019). This lack of applied evidence limits the generalizability of previous findings and hinders informed adoption strategies by stakeholders in the manufacturing sector.

This study addresses that gap by presenting an in-depth evaluation of a digital twin implemented in a metalworking facility, analyzing its operational, economic, and strategic effects over a sustained period. By integrating sensor data, high-fidelity simulations, and predictive models, the system was embedded into the daily production workflow, providing not only monitoring capabilities but also direct input into decision-making processes. The methodology adopted combines quantitative metrics such as cycle time, productivity, energy usage, and material waste with qualitative observations from maintenance, quality control, and operational feedback loops (Bellavista et al., 2023). This hybrid approach ensures a robust and multi-layered understanding of the technology’s real impact.

This research bridges the gap between conceptual frameworks and real-world applications of digital twins in the metalworking industry. By grounding the study in empirical observations and system-level deployment, it contributes to the growing body of work that aims to demonstrate the effectiveness and scalability of digital twin technologies beyond isolated use cases.

This article is structured as follows. Section 3 details the materials and methods, including the architecture of the digital twin, data acquisition, and experimental setup. Section 4 presents a comprehensive overview of the results, with a focus on operational performance, maintenance reliability, and quality improvements. Section 5 discusses the implications of the findings in light of current literature and industrial trends. Finally, Section 6 concludes the study by summarizing the key contributions, practical implications, and future research directions.

2 Literature review

The literature review studies the digital twin’s application in the metalworking industry. It highlights previous research and how our work is incorporated into and dialogues with these findings. The analyzed works demonstrate the breadth and depth with which the digital twin concept has been explored, focusing on its ability to improve operational efficiency, decision-making, and sustainability in industrial processes.

Stavropoulos and Mourtzis, (2021) provide one of the broadest perspectives on the digital twin, defining it as a virtual entity replicating a physical system’s structure and behavior. This work highlights the potential of the digital twin to perform detailed simulations to predict and optimize the performance of production systems. Our study aligns with this vision, demonstrating how implementing the digital twin in the metalworking industry replicates production processes and allows for significant optimization and continuous improvement.

Shahzad et al. (2022) explore how digital twins can be used for mass customization and product quality improvement in manufacturing. Although their research provides a solid understanding of the benefits of digital twins in terms of personalization and quality enhancement, it lacks a detailed quantification of economic outcomes. Our work extends these observations by explicitly measuring the financial impact of digital twin implementation, as demonstrated by our ROI analysis, which reveals a significant return on investment.

In the study by Kenett and Bortman, (2022), the importance of the digital twin is analyzed in the context of Industry 4.0, highlighting its role in integrating physical and virtual systems. However, despite providing a theoretical understanding of the digital twin, there is a need for more applied and industry-focused studies, such as metal-working. Our study addresses this gap, providing an applied analysis of how the digital twin can transform operations in the metalworking industry, evidencing tangible improvements in efficiency and productivity.

Other research, such as that of Pang et al. (2021), who coined the term “digital twin,” focuses on this technology’s conceptual and fundamental aspects. While these works laid the theoretical foundation, there is a growing need for studies demonstrating practical applications and specific results. Our approach builds on these foundations to examine the tangible and measurable impact of the digital twin in a specific industrial environment.

The literature review determines the importance and potential of the digital twin in improving manufacturing and industrial management. Although significant progress has been made in the conceptual and theoretical understanding of the digital twin, our study contributes to the literature by providing empirical evidence of its economic and operational impact on the metalworking industry (Zhong et al., 2023). Through detailed and quantitative analysis, we demonstrate how the digital twin not only optimizes processes and improves decision-making but also results in a significant return on investment, affirming its value as a strategic tool in the era of Industry 4.0.

Recent research has expanded the scope of digital twin applications into adjacent domains with high potential for transference to discrete manufacturing. Arowoiya et al. (2024) developed a digital twin architecture for optimizing thermal comfort and energy efficiency in buildings, emphasizing real-time calibration through sensor fusion and predictive control techniques that are equally applicable to thermal regulation in industrial processes. Similarly, Kang and Mo, (2024) proposed a comprehensive digital twin framework for building monitoring, with a focus on data connectivity, bidirectional communication, and model updating—all core requirements in digital twins for manufacturing systems. Although developed for the built environment, these frameworks illustrate key architectural components (e.g., dynamic state synchronization, real-time sensing) that are directly transferable to production-line digital twins. In the manufacturing domain, Yan et al. (2024) proposed an adaptive machining method for carbon fiber-reinforced plastic and titanium stacks, utilizing feedback-driven interface recognition to optimize helical milling. This technique aligns with the core objectives of digital twin-based machining optimization. These empirical studies underscore the importance of validated, data-driven architectures and adaptive control models in real-world deployments.

Literature demonstrates increasing adoption of digital twin technologies specifically tailored to the steel and metal industries, highlighting both their practical benefits and implementation challenges. Kasper et al. (2024) develop an adaptive optimization system based on digital twins for waste heat recovery in green steel production, demonstrating how real-time calibration and data-driven control can enhance energy efficiency and sustainability in high-temperature industrial environments. Similarly, Panagou et al. (2022) propose a hybrid digital twin framework for predictive maintenance in steelmaking, integrating real-time monitoring with physics-based and data-driven models. Their work illustrates not only the technical feasibility of digital twins in harsh industrial settings, but also the importance of simulation–reality alignment and system interoperability. Moreover, Shi et al. (2024) explore the development and application of digital twins in steel structures, focusing on structural integrity, lifecycle monitoring, and integration with Building Information Modeling (BIM) systems. Their findings highlight how digital twin approaches can be applied to operational intelligence across various construction and manufacturing contexts. These studies reinforce the relevance and urgency of domain-specific investigations, such as the present work, which evaluates the systemic implementation of a digital twin in a metalworking facility and its impact across operational, economic, and organizational dimensions.

3 Materials and methods

The development and deployment of the digital twin solution for the metalworking industry follows a technically rigorous, multi-phase process that integrates physical modeling, simulation, and real-time data acquisition to replicate and optimize metallurgical operations. This implementation is grounded in principles of solid mechanics, computational fluid dynamics (CFD), thermodynamics, and control theory, which collectively enable accurate simulation of the behavior and interaction of machine elements and thermal-fluid processes intrinsic to the metal transformation domain (Muthuswamy and Shunmugesh, 2023). Finite Element Analysis (FEA) is employed to evaluate the mechanical response of structural components subjected to operational loads, thermal stresses, and vibration profiles. At the same time, CFD is used to model heat dissipation and lubricant flow in machining operations, particularly in cooling channels and regions of surface contact.

Digital models of machines and assemblies are constructed using advanced CAD/CAM software, incorporating exact geometrical constraints, material properties, and kinematic behaviors to serve as the foundation for virtual replication. These models, once validated, are integrated into dynamic simulation environments where toolpath trajectories, actuator cycles, and workstation interactions are virtually tested to optimize process parameters before physical deployment (Moreno et al., 2023). The simulation outputs provide critical feedback for minimizing cycle times, reducing tool wear, improving energy efficiency, and enhancing operational ergonomics across production cells.

Real-time operational data is acquired via IoT sensors embedded in CNC machines and other production equipment, capturing variables such as spindle temperature, vibration amplitude, tool load, and lubrication flow. This sensor data is transmitted to the digital twin platform, where it is used to update model states, recalibrate predictive functions, and validate the accuracy of simulations. The continuous feedback loop between the physical and virtual environments ensures high-fidelity synchronization and supports adaptive control strategies based on real-time deviations and process anomalies.

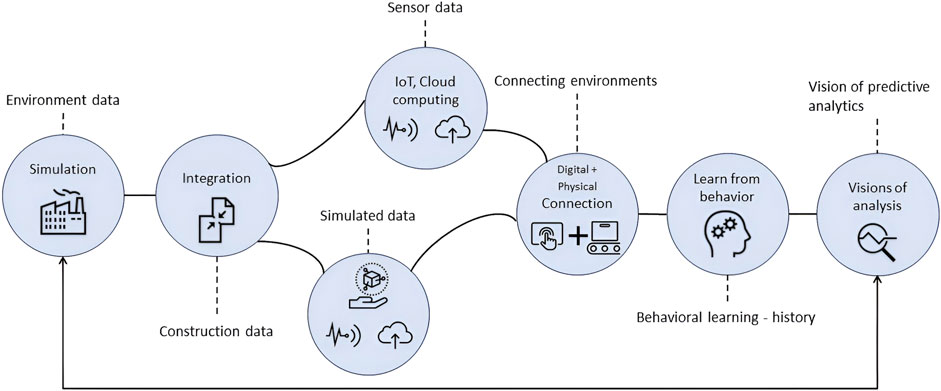

Figure 1 presents a schematic overview of the complete digital twin lifecycle, from the initial conceptual modeling and simulation stages to the integration and synchronization with the physical system. This architecture enables a cyber-physical continuum in which environmental, operational, and simulation data converge to support advanced monitoring, early failure detection, and predictive maintenance (Stavropoulos and Mourtzis, 2021). Furthermore, the integration of multisource data into a unified virtual model enhances the system’s capacity to react dynamically to production shifts and external disruptions, enabling sustained optimization of metallurgical processes (Singh et al., 2021).

To ensure terminological precision throughout the analysis, the following definitions are adopted in the context of this implementation. Efficiency is used as a general descriptor of output-to-input ratio across energy, time, or resources, depending on context. Overall Equipment Effectiveness (OEE) is defined as the product of availability, performance, and quality rates, offering a standardized composite measure of equipment productivity. Cycle time refers to the total elapsed time required to complete one production unit or machining sequence, inclusive of tool engagement, repositioning, and idle periods. Finally, production efficiency denotes the ratio between actual output and the maximum achievable output under ideal conditions, accounting for losses related to delays, speed reductions, and partial load operation. These definitions are consistently applied in all subsequent analyses and interpretations of performance metrics.

3.1 Selection and characterization of metal-mechanical systems

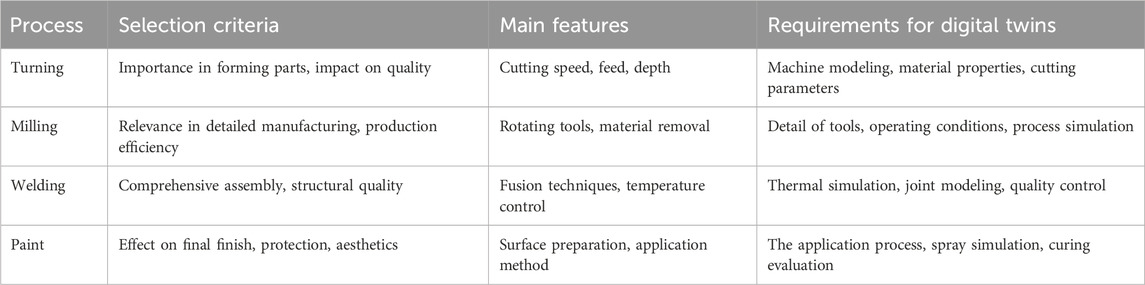

The metalworking domain analyzed in this study encompasses high-precision transformation processes, including turning, milling, welding, and surface finishing, as well as painting. These processes are central to the manufacturing of structural and functional components. They are selected based on their operational significance, complexity in physical modeling, and data richness for integration into digital twin environments (Howard et al., 2021). Table 1 summarizes the specific selection criteria, inherent characteristics, and modeling requirements associated with each process.

Table 1. Selection criteria and requirements for implementing digital twins in metalworking processes.

Turning and milling are prioritized due to their foundational role in shaping and dimensional control, as well as the availability of high-frequency process data suitable for model calibration. These operations demand precise regulation of cutting variables, tool geometry, and spindle dynamics, which must be virtually reproduced to capture energy consumption, tool wear progression, and vibration profiles.

Welding processes are integrated due to their critical influence on structural integrity and their complexity in terms of thermal gradients and joint behavior. The digital twin implementation includes thermal field simulation, fusion zone analysis, and stress propagation modeling, supporting predictive quality control and defect identification (Hu et al., 2022).

The painting stage is incorporated based on its relevance to lifecycle durability and compliance with visual and protective standards. The virtual representation encompasses modeling of spray trajectories, fluid deposition patterns, and post-application curing behavior to assess coating performance and pinpoint process deviations. Collectively, these selected processes provide a representative sample of the metalworking production chain, offering sufficient complexity and variability to validate the applicability of digital twin architectures in real industrial contexts.

3.2 Development of the digital twin

The construction of the digital twin follows an iterative and modular development framework, grounded in the integration of multi-source data, simulation models, and feedback control loops. This development process aligns with the principles of Industry 4.0, emphasizing adaptability, interoperability, and real-time responsiveness to dynamic manufacturing conditions (Rasheed et al., 2020). The implementation pipeline is supported by CAD-based geometric modeling, physical process simulation, sensor-based data acquisition, and validation cycles, ensuring that the digital replica maintains high fidelity and operational relevance.

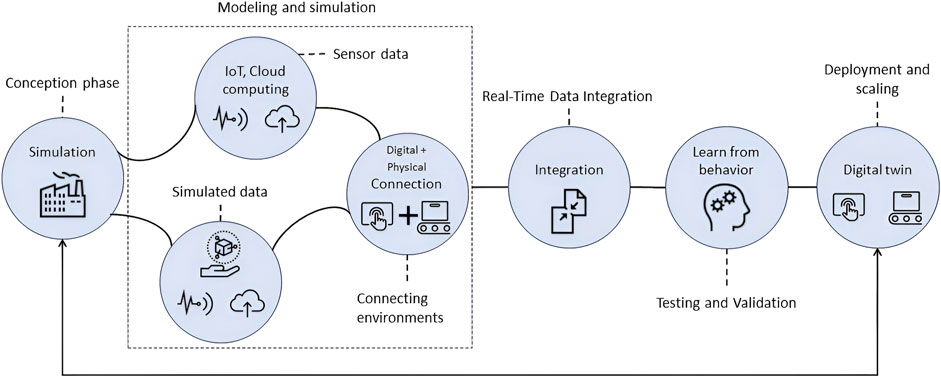

Figure 2 disaggregates the workflow into five functional stages. These stages are presented sequentially but are interconnected by feedback loops that facilitate continuous model improvement. In the conception phase, the functional scope, modeling objectives, and required granularity are defined based on constraints and key performance indicators (KPIs) specific to the metal-mechanical domain (Madubuike et al., 2022). This includes identifying critical variables, such as spindle torque, thermal gradients, or feed rate, and determining the spatial and temporal resolution required to simulate them accurately.

Subsequently, the modeling and simulation stage involves constructing domain-specific physics-based models. These include finite element representations for mechanical structures and CFD models for thermal-fluid interactions. Virtual prototypes are executed under controlled conditions to evaluate operational behavior, failure points, and process sensitivity.

The environment connection phase enables the alignment of these models with field-deployed systems through standardized communication protocols (e.g., OPC UA, MQTT), ensuring that the virtual environment mirrors real-time behavior. The core real-time integration module ingests streaming data from IoT sensors and controllers, which are then processed and mapped to the simulation parameters to update the model state continuously. This mechanism supports data-driven refinements, enabling the digital twin to adapt to production fluctuations and unanticipated disturbances.

The testing and validation block focuses on comparing simulated outputs with absolute sensor data using statistical error metrics (e.g., RMSE, MAE). This enables iterative tuning of simulation fidelity, providing confidence in predictive outputs. The deployment and scaling stage incorporates the refined digital twin into the operational infrastructure. Depending on computational requirements, this may involve cloud or edge deployment and integration with manufacturing execution systems (MES) or ERP platforms. This ensures both scalability and real-time synchronization with plant operations.

3.2.1 Project phase

The conception phase of the digital twin project begins with a comprehensive analysis of the production layout to identify the primary systems, interdependencies, and performance bottlenecks to be digitally replicated. This process involves establishing a set of performance indicators

In the development and testing phase, the digital twin is enriched with sensor data streamed from IoT devices. Let

The instantaneous modeling error is then defined as described in Equation 1:

Over a time horizon

Model calibration is formulated as an optimization problem to minimize this error metric over the parameter space

Gradient descent, Levenberg–Marquardt, or evolutionary algorithms may be used to solve this minimization depending on the complexity and differentiability of the digital twin simulation. The calibration loop is run iteratively until convergence criteria

To account for dynamic time-varying behavior, an online identification model can be embedded using recursive least squares (RLS) or Kalman filter-based estimators, where:

and

In the scaling and refinement stage, the calibrated twin is deployed across the entire production workflow. Continuous performance metrics are extracted to validate consistency with operational baselines. In the implementation, the digital twin is embedded into the supervisory control system, integrated with MES/ERP layers, and actively supports predictive diagnostics and production reconfiguration tasks (VanDerHorn and Mahadevan, 2021).

3.2.2 Existing platforms and tools

The implementation of the digital twin architecture leverages state-of-the-art software platforms for modeling, simulation, and real-time data integration, selected based on criteria such as interoperability, precision, simulation depth, and scalability within industrial environments. These tools not only accelerate deployment but also ensure adherence to standardized engineering workflows and robust system integration practices.

For geometric modeling and multiphysics simulation, platforms such as Autodesk Fusion 360, SolidWorks, and Siemens NX are utilized. These environments provide integrated CAD/CAM/CAE functionalities, enabling the construction of high-fidelity three-dimensional models of machines and assemblies. The simulation modules support finite element and kinematic analyses, allowing the evaluation of mechanical stress, thermal loads, and motion trajectories under variable boundary conditions. This is essential for reproducing the behavior of critical subsystems and validating virtual prototypes before integration with the digital twin core.

Real-time data acquisition and operational synchronization are handled through industrial IoT (IIoT) platforms such as PTC ThingWorx and Siemens MindSphere. These platforms support secure data ingestion from distributed sensor arrays using industrial protocols (e.g., OPC UA, MQTT) and enable edge and cloud-level data processing. Time series data from sensors (temperature, torque, spindle speed, energy consumption) is mapped to the simulation model to update state vectors and compute prediction deviations as defined in the model calibration framework.

Customization and process adaptation are conducted through the configuration of digital threads and API-level integration. Simulation engines are parameterized to reflect the technical specifications of each machine unit (e.g., tool rigidity, maximum spindle load, thermal expansion coefficient), and embedded scripts or external algorithms are integrated to enable predictive analytics and failure forecasting specific to the metal-mechanical domain (Jia et al., 2022). This modular architecture facilitates future expansion with AI-enhanced modules, including anomaly detection, reinforcement learning-based optimization, or adaptive scheduling modules aligned with Industry 4.0 requirements.

3.2.3 Use of existing platforms and tools

The iterative refinement of the digital twin follows a model-driven and data-informed cycle, grounded in continuous feedback from both simulated results and real-time operational data. The initial digital twin is constructed based on static system specifications and historical performance data, and serves as the baseline model for functional testing. Each development iteration includes parameter reconfiguration, simulation re-execution, and comparative evaluation between the predicted and observed behavior of system components.

Testing is conducted at multiple levels of abstraction. Unit-level validation assesses individual subsystem models (e.g., toolpath fidelity, thermal response, actuator kinematics), while integration-level testing examines interdependencies and emergent system behavior. For each test, deviation metrics—such as temporal alignment error, frequency domain distortion, or maximum residual error—are computed. Let

where

Feedback mechanisms are integrated via data pipelines from industrial sensors, operator logbooks, and system event logs. Structured feedback from domain experts (e.g., maintenance engineers, production supervisors) is incorporated into model updates through formal issue tracking and parameter tuning reports. The iterative framework is managed using digital engineering environments that support version control, model rollback, and test traceability, ensuring rigorous validation and traceable evolution of the twin across development cycles (Tuhaise et al., 2023).

The overall refinement strategy follows a test-driven development (TDD) approach adapted to cyber-physical systems, where each iteration reduces modeling error and improves predictive robustness under operational variability. This methodology ensures that the digital twin progressively converges towards an accurate, responsive, and scalable representation of the physical production environment in the metal and mechanical industries.

3.3 Implementation and testing

The implementation phase of the digital twin involves deploying software and communication middleware into the plant’s technological ecosystem. Secure and low-latency communication protocols, such as MQTT and OPC UA, are configured to enable bidirectional data exchange between physical sensors, actuators, and the simulation layer of the digital twin (He and Bai, 2021). These protocols are selected based on their support for Quality of Service (QoS) levels, compatibility with industrial hardware, and robustness under high-frequency sampling rates.

Sensor calibration is conducted using process-specific reference standards. Let

The adjusted signal

Operational workflow mapping involves encoding production sequences, machine states, and event logic into the digital twin’s execution model. This includes process identifiers, inter-process dependencies, and time-based triggers. Custom user interfaces, designed by human-machine interaction (HMI) principles, provide real-time feedback loops and control elements for supervisors and operators.

A multilayer validation protocol is defined to ensure the operational readiness and robustness of the digital twin. The validation space

The test case is considered valid if

where

This validation framework is applied across functional, performance, and stress testing categories. Functional tests verify that control logic and state transitions execute as expected; performance tests assess the system’s capacity to process streaming data within bounded latency (e.g.,

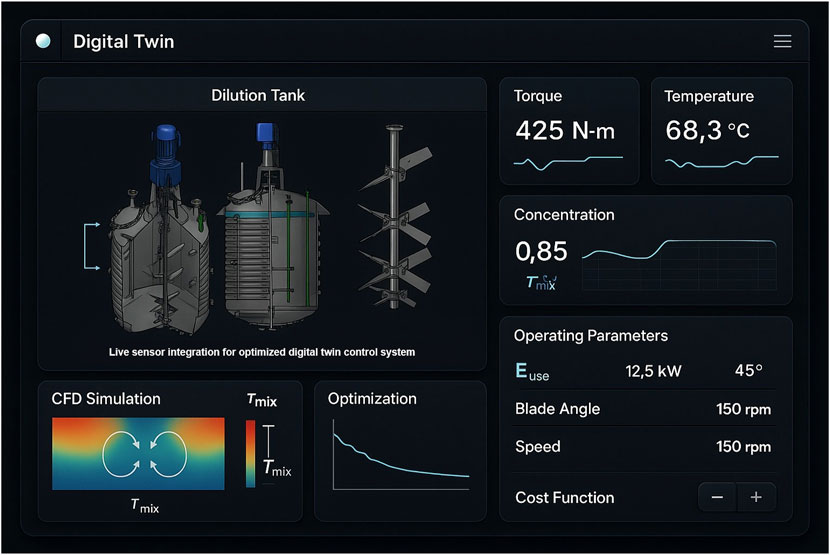

3.4 Industrial case study: digital twin deployment in a dilution tank system

Although not directly a machining or metallurgical transformation unit, the dilution tank system is a critical component within the broader metalworking facility, supporting the chemical preparation and regulation of industrial fluids essential to thermal and surface treatment stages. The implementation framework, including sensor integration, calibration methodology, computational simulation, and optimization routines described in the previous section, was fully applied and validated within this subsystem. This controlled subsystem was selected for digital twin validation due to its well-instrumented nature and dynamic behavior, which allow for accurate modeling, simulation, and feedback testing before broader deployment.

To validate the digital twin implementation process in a real industrial scenario, a case study was conducted on a dilution tank system used in chemical processing operations. This tank is part of a surface treatment line for flat steel products, where precise chemical concentration and thermal regulation are essential to ensure uniform coating and resistance properties. The system consists of a vertical cylindrical tank equipped with a multi-level agitator and internal flow deflectors. The digital twin was developed to replicate the mixing dynamics, energy usage patterns, and operational parameters of the physical system.

The configuration includes real-time sensor integration for key variables, such as agitator shaft torque (measured via strain gauges), motor rotational speed (measured via encoders), internal fluid temperature (measured via thermocouples), and concentration distribution (measured via conductivity probes placed at multiple depths). These signals

Once calibrated, the adjusted values

The digital twin integrates a computational fluid dynamics (CFD) module to simulate the velocity field

where

For validation, a test suite

A test case is valid if

This validation framework confirms the fidelity of the twin under varying operational scenarios.

Figure 3 presents the integrated interface used during deployment, which displays the dilution tank structure, sensor data streams, and control modules. This environment allows operators to monitor real-time variables, compare system states, and interactively adjust key parameters such as impeller speed and flow rate.

Figure 3. Digital twin interface for the dilution tank system, integrating process visualization, real-time sensor data, simulation overlays, and parameter control modules.

3.5 Analysis and optimization of processes

The digital twin architecture enables the detailed simulation and evaluation of production processes, allowing for the identification of inefficiencies and the testing of improvements without physical risk or downtime. In machining operations, the twin simulates tool–material interactions by modeling cutting speed, feed rate, depth of pass, and thermal conditions. Through simulation loops, suboptimal parameters are identified, such as unstable cutting speeds or inefficient tool paths, which contribute to increased tool wear or cycle delays.

The optimization routine is structured around a multi-objective function (Equation 13).

where

In assembly processes, the digital twin evaluates workstation ergonomics, tool accessibility, and component alignment. Motion planning algorithms simulate the joining sequences under different configurations. Ergonomic impact is assessed using metrics derived from reachability, force exertion, and cycle repetition. The system proposes optimized assembly paths and tool placements to minimize task complexity and reduce operator fatigue.

Material waste reduction is addressed by simulating alternative cutting strategies and nesting configurations to optimize resource utilization. The optimization focuses on maximizing raw material utilization by minimizing the area of the residual scrap matrix. A layout function

where

3.6 Predictive maintenance and anomaly detection

The predictive maintenance module embedded in the digital twin architecture is designed to minimize unplanned downtime through early anomaly detection, fault diagnosis, and optimized intervention scheduling. This module operates as an integral component of the virtual representation, using synchronized sensor data and real-time simulation to anticipate mechanical and operational failures.

The process begins with the deployment of IoT sensors across critical components, capturing variables such as vibration acceleration, spindle and bearing temperatures, oil pressure, and volumetric flow rates (Fulle et al., 2020). The digital twin computes a prediction

where

The residual vector

To improve sensitivity under varying conditions, an adaptive anomaly threshold is employed, as described in Equation 17.

where

The fault diagnosis stage classifies the anomaly by projecting the residual into a fault signature space using a mapping matrix

The resulting vector

This probabilistic model combines expert-encoded failure modes with classification trees trained on historical residual patterns.

Once a fault is identified, the digital twin initiates a maintenance scheduling module formulated as a constrained optimization problem. For each asset

The cost function, Equation 21, incorporates risk-aware penalties:

where

To prioritize interventions under limited resources, a criticality index

where

3.7 Evaluation of results and feedback

The evaluation framework for the digital twin implementation integrates quantitative performance metrics with qualitative feedback to assess system effectiveness, user acceptance, and operational improvements. This dual approach ensures that both objective process enhancements and subjective user experiences are systematically captured and analyzed. To ensure that user feedback is based on meaningful operational experience, the digital twin was deployed in its active phase for a minimum period of 4 weeks before survey administration. This interval allowed plant personnel to interact with the system across varied scenarios, ensuring that qualitative responses reflected informed judgments.

From a quantitative perspective, a set of key performance indicators (KPIs) is defined before system deployment. These indicators are monitored over two operational phases: baseline (pre-deployment) and digital twin-enhanced (post-deployment). Let

Four primary KPIs are selected based on domain relevance:

A paired-sample statistical hypothesis test (e.g., Wilcoxon signed-rank test or t-test, depending on the distribution’s normality) is performed for each KPI to assess the significance of the observed changes. The null hypothesis

Complementarily, qualitative data is collected through structured interviews, Likert-scale surveys, and field observations involving plant operators, technicians, and supervisory personnel. Questions address usability, perceived accuracy of the simulations, responsiveness of the system, and its contribution to decision-making and task execution.

The qualitative responses are encoded and analyzed via thematic coding and sentiment quantification. A satisfaction index

where

A value of

Finally, a comparative analysis is conducted between actual operational data streams and simulated outputs generated by the digital twin. Let

This metric provides insight into the fidelity of the digital representation and supports iterative calibration.

The joint analysis of

4 Results

The deployment of the digital twin within the metalworking facility was carried out following the multi-layered methodology previously described. This included the integration of calibrated IoT sensor networks, low-latency communication protocols (MQTT/OPC UA), simulation-validation pipelines, and predictive maintenance logic. These components ensured accurate and real-time mirroring of the physical environment in the virtual model.

The system was fully embedded into the plant’s operational workflow, interfacing with supervisory control, process scheduling, and maintenance routines. Through this integration, the digital twin transitioned from a passive simulation tool to an active cyber-physical agent capable of anomaly detection, process optimization, and feedback-based control.

4.1 Operational performance evaluation

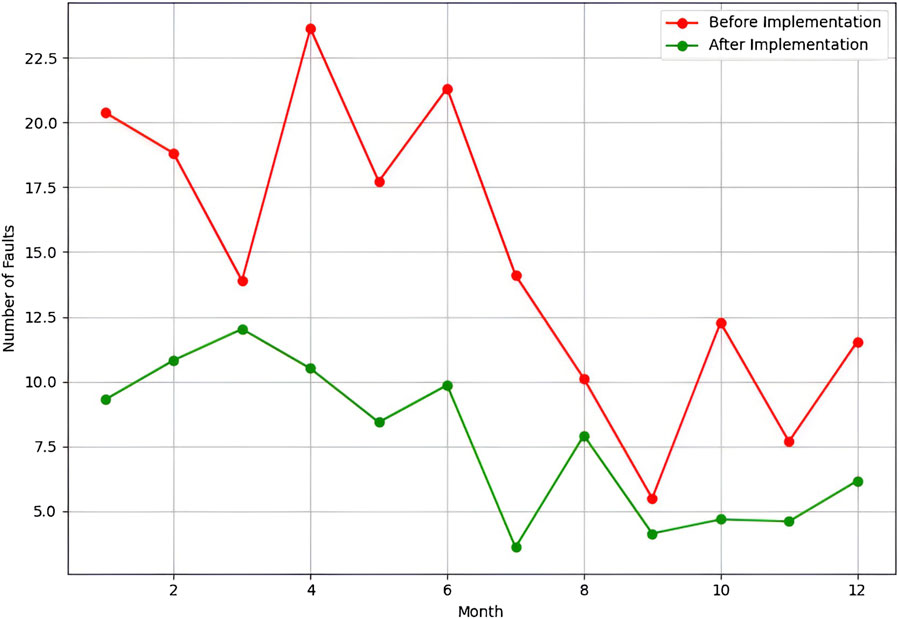

The operational impact of the digital twin was evaluated using a longitudinal dataset spanning 12 months, divided into a baseline phase (months 1–6) and a post-implementation phase (months 7–12). This temporal segmentation enables a robust comparative analysis before and after, under equivalent operational conditions.

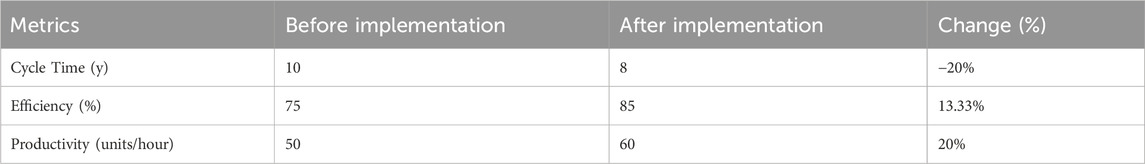

Operational data were extracted from synchronized sources, including machine-level IoT sensors, process logs, and supervisory control and data acquisition (SCADA) reports. The variables analyzed include average cycle time per unit, system efficiency rate, and hourly productivity. The data acquisition frequency and format remained consistent across both periods to ensure methodological validity. Table 2 summarizes the observed changes in key performance indicators. The integration of the digital twin is correlated with improvements in all measured metrics, including a 20% reduction in average cycle time, a 13.33% increase in efficiency, and a 20% gain in productivity rate.

To statistically validate these differences, an Analysis of Variance (ANOVA) was performed on grouped monthly values, confirming that the differences in all metrics between the two phases are significant at

A linear regression model was used to evaluate the degree of association between the presence of the digital twin and each operational metric, adjusting for seasonal effects and production shifts. Time-series decomposition also revealed inflection points corresponding to the first whole month of digital twin integration, reinforcing causal alignment between implementation and performance improvements.

Figure 4 illustrates the evolution in system faults as a representative indicator of reliability. The chart presents the monthly fault counts before and after implementation, highlighting a marked reduction in fault occurrences. This aligns with the predictions derived from the predictive maintenance and anomaly detection modules.

4.2 Product quality analysis

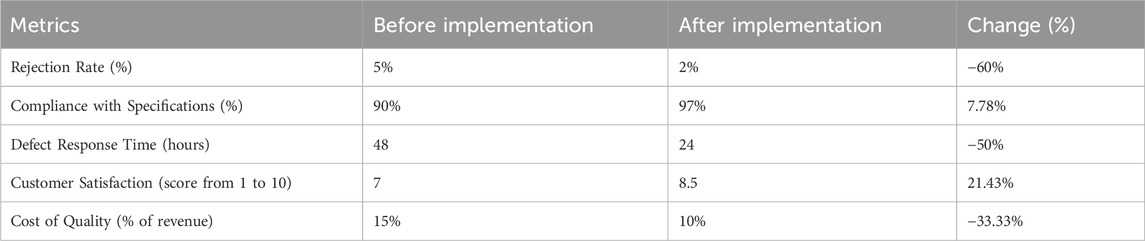

During the pre-implementation phase, baseline metrics were established using existing quality assurance records, customer service evaluations, and financial audits. Metrics included rejection rate, compliance with specifications, response time to quality issues, customer satisfaction index, and quality-related operational costs.

Following the deployment of the digital twin, the same indicators were systematically tracked, now enhanced by the system’s real-time analytical capabilities. The digital twin’s integration enabled continuous monitoring of quality parameters, root cause analysis via simulation, and predictive modeling to anticipate deviations from quality standards.

Table 3 summarizes the comparative evolution of quality-related metrics. Notably, the rejection rate decreased by 60%, while compliance with specifications improved by 7.78%, indicating a measurable increase in process precision. Response time to quality issues was reduced by 50%, reflecting increased operational responsiveness. Customer satisfaction scores rose from 7.0 to 8.5 (+21.43%), and quality-related costs decreased from 15% to 10% of revenue, suggesting better resource allocation and a decline in rework or waste.

Table 3. Improvements in quality and customer satisfaction after implementation of the digital twin.

Customer perception was also evaluated through a targeted satisfaction survey, administered post-implementation to a representative sample of clients across multiple industry sectors. The survey captured both quantitative ratings and open-text feedback on aspects such as product consistency, support experience, and delivery compliance. To ensure attribution of changes to the digital twin implementation, the survey was conducted under the same customer service protocols, pricing conditions, and delivery schedules as before, with the digital twin being the only operational enhancement during the survey window.

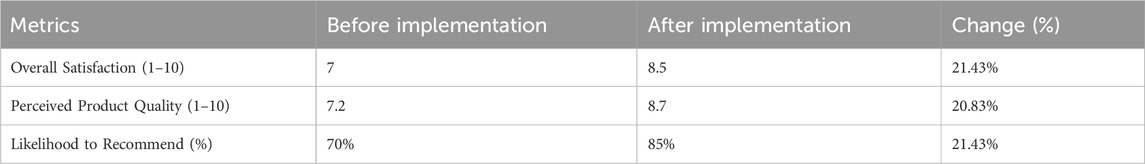

Table 4 reports the numerical outcomes of this customer perception assessment. The average satisfaction score increased from 7.0 to 8.5, and the perceived quality score rose from 7.2 to 8.7, yielding an improvement of 20.83%. Moreover, the likelihood of customers recommending the company increased from 70% to 85%, indicating a substantial enhancement in brand trust and product value perception.

Table 4. Comparison of satisfaction and perceived quality before and after the implementation of the digital twin.

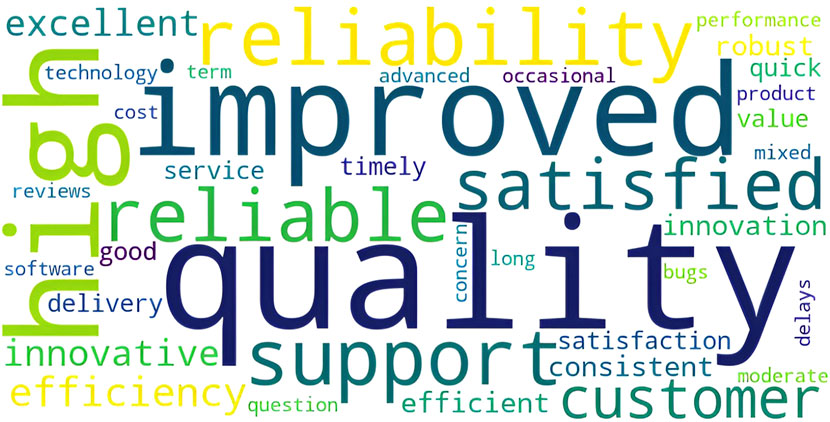

To complement the quantitative evaluation, qualitative feedback was analyzed using natural language processing techniques. Figure 5 shows a word cloud generated from customer comments, visually representing the frequency of key terms mentioned. The survey covered dimensions such as product durability, service responsiveness, and process reliability.

To collect representative data, the survey was distributed to several clients, spanning different market segments and geographies. The questions were formulated to capture both quantitative assessments, such as numerical scores on satisfaction scales, and qualitative responses that offered insights into the customer’s perception in their own words. Once the surveys were completed, qualitative responses were compiled and analyzed using natural language processing techniques.

The resulting word cloud displays the most frequently mentioned terms, with word sizes proportional to their frequency of occurrence in survey responses. Words such as “quality,” “efficiency,” and “support” appear prominently, indicating a positive perception in these areas. However, some neutral or negative terms, such as “delays” or “software bugs,” highlight areas where the customer experience may require further attention.

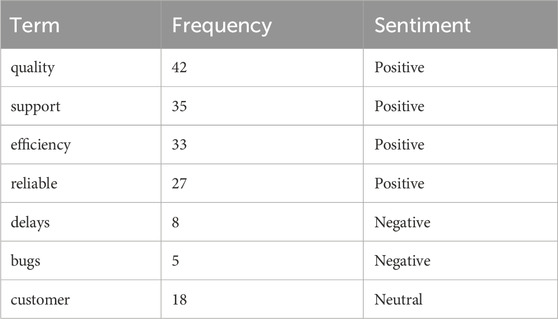

Table 5 presents the most frequently occurring terms along with their assigned sentiment polarity (positive, neutral, or negative), determined through a lexicon-based sentiment model. This analysis provides a quantitative perspective on the qualitative feedback, confirming the dominance of positive perceptions while also highlighting specific points of concern mentioned by customers.

The prominence of these terms suggests that customers experienced tangible improvements in core quality and support dimensions, in line with the quantitative gains reported. In contrast, less frequent mentions of terms like “delays” and “bugs” were classified as negative, representing residual areas for optimization, particularly in software stability and logistics performance. Interestingly, the term “customer” was often associated with neutral sentiment, typically appearing in generic statements or suggestions rather than evoking strong emotional valence.

4.3 Impact on machine maintenance and reliability

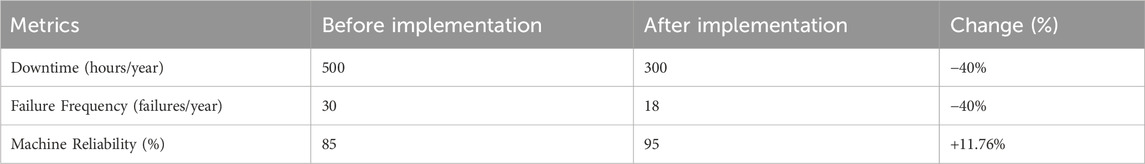

The implementation of the digital twin introduced a predictive maintenance and failure analysis approach, substantially enhancing equipment operation and maintenance practices. Before deployment, the machinery park recorded an annual downtime of 500 h and a failure frequency of 30 events per year. These figures reflected the limitations of reactive and scheduled maintenance strategies, which lacked the real-time adaptability necessary to respond to equipment conditions.

Upon integration, the digital twin enabled a continuous monitoring infrastructure that supported predictive modeling based on sensor data, operational logs, and simulation feedback. This shift toward predictive maintenance resulted in measurable operational improvements, as summarized in Table 6. Annual downtime decreased by 40%, from 500 to 300 h, indicating a significant gain in equipment availability and overall plant efficiency. The failure frequency also declined by 40%, resulting in a reduction from 30 to 18 breakdowns annually. Additionally, equipment reliability, defined as the proportion of operational time without failure, improved from 85% to 95%, which corresponds to an 11.76% increase.

Table 6. Improvements in downtime, failure frequency, and machine reliability after digital twin implementation.

To reinforce the validity of these findings, control charts (X-bar and R) were used to monitor the stability of process variability and verify that the observed improvements were not due to random fluctuations. In parallel, the Mean Time Between Failures (MTBF) was calculated to assess operational consistency:

This 69.9% increase in MTBF confirms a substantial extension of failure-free operation time, consistent with the reliability improvements measured.

Case 1: Welding Section Failure Reduction In the welding area, a high incidence of process failures had previously been detected, including cold joints, porosity, and inadequate penetration. These issues contributed to a rejection rate of approximately 20 defective welds per month, creating significant inefficiencies in production and quality assurance. After the deployment of the digital twin, which enabled root cause analysis through thermographic and sensor data, corrective actions were simulated and validated before application. These included adjustments to heat input and arc travel speed. Toward the end of the evaluation period, failures in this section were reduced to an average of five per month, demonstrating a 75% improvement in process reliability.

Case 2: Milling Process Optimization In milling operations, dimensional deviations and surface roughness inconsistencies led to a high rejection rate of manufactured parts. Analysis by the digital twin identified irregularities in feed rates and spindle speeds. Virtual simulations revealed that lowering the pass depth and increasing cooling flow would reduce tool vibration and wear. After applying these modifications, the rejection rate of milled components decreased by 40%. Quality audits confirmed improved geometric accuracy and surface consistency, supporting the effectiveness of data-driven process refinement.

Case 3: Injection Molding Material Efficiency For plastic components, excessive material waste during injection molding was a persistent issue. The digital twin modeled the molding process using real-time temperature and pressure data, detecting suboptimal mold fill dynamics. After adjusting thermal profiles and injection pressure curves based on digital simulations, the plant observed a 30% reduction in material waste without compromising part integrity. This not only improved sustainability indicators but also contributed to operational cost reductions.

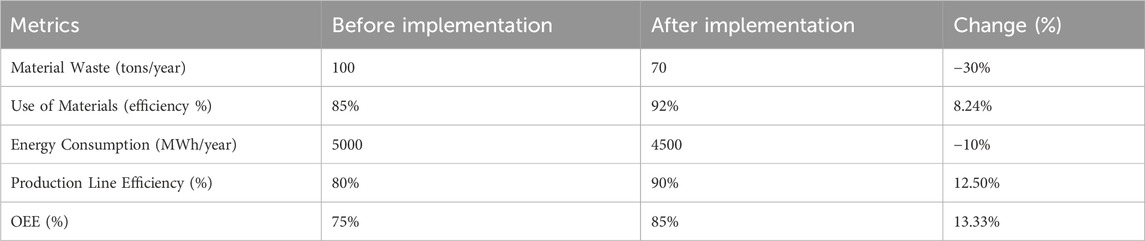

4.4 Process optimization and resource efficiency

The evaluation process was based on analyzing operational and production data collected before and after implementing the digital twin to determine improvements in several key areas. The analysis began by quantifying material waste, usage, and energy consumption before digital twin integration, as presented in Table 7. This data established a baseline to compare post-implementation changes. The introduction of the digital twin enabled detailed monitoring and analysis of processes, resulting in significant optimization. For example, the 30% reduction in material waste and 8.24% improvement in material use efficiency were achieved through precision in production processes and minimization of surpluses and defects.

Table 7. Improvements in production efficiency and sustainability after the implementation of the digital twin.

Additional metrics evaluated were production line efficiency and the OEE. These metrics reflect the teams’ performance and the processes’ overall efficiency. A 12.5% increase in production line efficiency and a 13.33% improvement in OEE were observed, evidencing that the digital system allowed for more effective production management, reduced downtime, and improved productivity process quality.

4.5 Feedback from operators and technicians

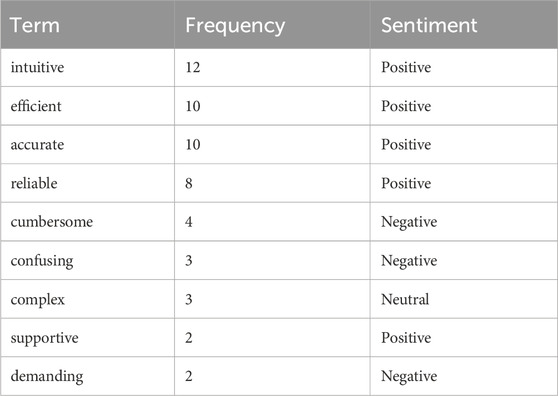

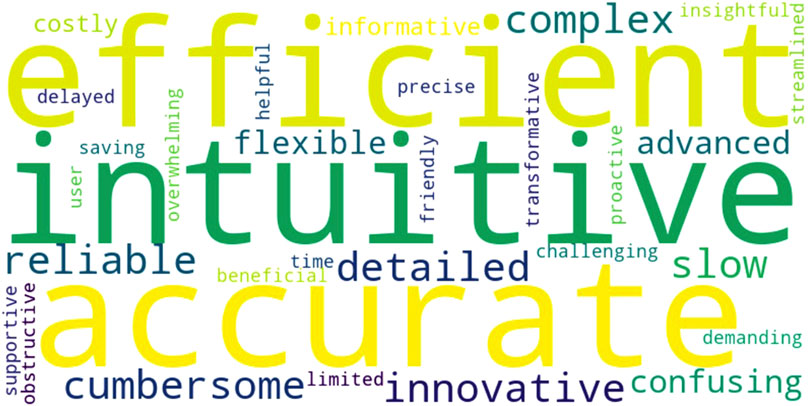

For the Operator and Technician Comments section, a word cloud was generated based on the qualitative comments collected from digital twin users. Figure 6 presents a word cloud that includes a variety of terms representing user perceptions, including positive, negative, and neutral. The qualitative evaluation of the feedback from operators and technicians was carried out through surveys and interviews, focused on the simulations’ usability and precision and their impact on operational decision-making. Participants provided ratings and feedback on their experience with the digital twin, covering aspects such as ease of use, precision of data and simulations, and effectiveness of the system in supporting operational decisions.

Figure 6. Operator and technician feedback word cloud: key insights into digital twin implementation.

Table 8 presents a structured summary of the most frequently mentioned terms in operator and technician feedback, categorized by sentiment. The predominance of terms such as “intuitive,” “efficient,” and “accurate” reflects a generally positive perception of the system’s usability and technical performance, particularly in terms of data clarity and interface responsiveness. These findings are consistent with high usability scores collected through structured Likert-scale items in the survey.

Conversely, terms such as “cumbersome,” “confusing,” and “demanding” were reported with lower frequency but still reveal specific friction points. These comments were primarily related to advanced simulation controls and the interpretation of real-time analytics, indicating a learning curve in more complex operational contexts. Interestingly, the presence of both positive and negative sentiment terms indicates a realistic and balanced user perspective, reinforcing the credibility of the evaluation.

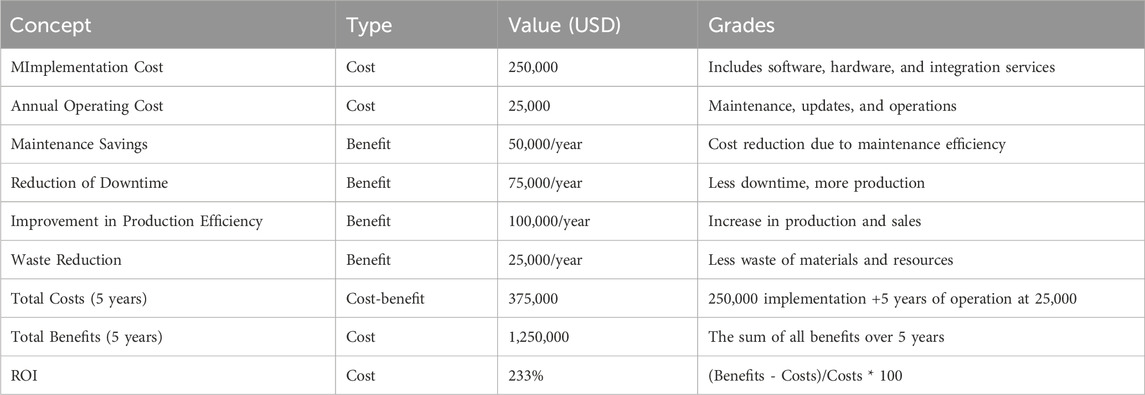

4.6 Return on investment analysis

When evaluating the return on investment (ROI) for digital twin implementation in a budget-constrained environment, an analysis was performed to capture the associated costs and benefits realized. This included a detailed breakdown of implementation and operation expenses and a quantitative evaluation of the savings and improvements generated by the technology (Madubuike et al., 2022). The process began with identifying and quantifying digital twin implementation costs, including software and hardware acquisition and integration services, adjusting to $250,000 to reflect the limited purchasing power of factories in the study region. An annual operating cost of $25,000 was estimated, covering maintenance, upgrades, and system operations.

At the same time, the tangible benefits of the digital twin for the organization were analyzed. This analysis revealed that predictive maintenance and process optimization resulted in significant savings and improvements in production efficiency. Annual maintenance savings were estimated at $50,000, while reduced downtime and improved production efficiency contributed $75,000 and $100,000 annually, respectively. Additionally, implementing the digital system led to a reduction in waste, valued at $25,000 annually. Adding the benefits over 5 years and subtracting the total costs accumulated over the same period calculated a return on investment of 233%. This result was obtained using the standard return on investment formula, which divides the difference between benefits and total costs by the total costs and then multiplies by 100 to get a percentage, as presented in Table 9.

It is essential to note that the ROI estimation is specifically tailored to the case of a chemical treatment and surface finishing line for flat steel products, operating under a discrete production model. The analysis considers only direct costs and quantifiable benefits, while excluding indirect expenses such as temporary production halts during system deployment, testing efforts, and internal labor reallocation. These factors were either minimal due to the modular integration strategy or absorbed within existing operational buffers. As such, the ROI figure provides a simplified economic approximation that enables benchmarking rather than a comprehensive financial projection. Caution is advised when extending these results to plants with higher operational interdependencies or continuous production constraints.

4.7 Discussion of case studies or specific examples

Implementing the digital twin has transformed several industries, solving complex operational problems, improving process efficiency, and supporting strategic decisions. For example, inefficiencies in the automotive component manufacturing sector were identified on the assembly line, resulting in delays and high operating costs (Kenett and Bortman, 2022). Introducing a digital twin made it possible to simulate and optimize the assembly process, reducing cycle time by 25%, from 4 to 3 h per unit, and increasing production by 20%, raising monthly output from 1,000 to 1,200 units. This translated into annual operating cost savings of $500,000.

In the oil refining space, a refinery faced high energy costs and excessive emissions. The digital twin was used to perform a detailed analysis of energy consumption and emissions, facilitating operational adjustments that improved energy efficiency by 15% and reduced emissions by 18%, decreasing energy costs from 10 million to 8.5 million dollars annually and guaranteeing compliance with environmental regulations. In the railway transport sector, a company experienced frequent breakdowns in its fleet, resulting in high corrective maintenance costs (Pang et al., 2021). By implementing a digital twin for monitoring and predictive analysis, it was possible to reduce breakdowns by 30%, reduce maintenance costs by 40%, and increase fleet availability by 15%, thus improving reliability and customer satisfaction.

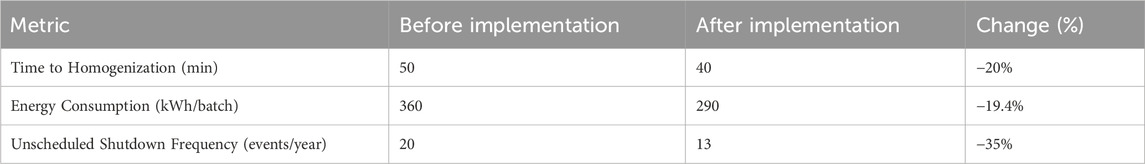

Another case study illustrating the transformative influence of digital twins is the optimization of dilution tanks used in chemical treatment processes. These tanks presented inefficiencies related to flow patterns and mixing quality. By simulating various operating scenarios, the digital twin identified stagnation zones and suboptimal blade configurations. Adjustments were proposed to the paddle geometry and deflector placement, which enhanced homogenization and improved energy efficiency.

Table 10 presents the quantified impact of these modifications. A 20% reduction in the time required to achieve product homogeneity was observed, accompanied by a 19.4% decrease in energy consumption. Additionally, the frequency of unscheduled shutdowns associated with the tank system decreased by 35%, highlighting the reliability gains and operational continuity enabled by the digital twin.

This case study demonstrates how the practical and focused application of the digital twin can yield significant improvements in the operation and design of industrial equipment. Not only were tangible financial savings achieved, but operational efficiency was also improved, thus demonstrating the value of digital twins as innovation and optimization tools in Industry 4.0.

5 Discussion

The integration of digital twin technology in the chemical treatment subsystem analyzed in this study has proven to be a transformative element in improving operational performance, aligning process behavior with the objectives of sustainability, precision, and efficiency. The digital twin enabled accurate diagnosis and correction of inefficiencies related to flow dynamics, mixing quality, and energy consumption. These outcomes are consistent with prior research that underscores the utility of digital twins for simulating, analyzing, and refining complex systems to minimize waste and elevate product quality (Ferko et al., 2022).

All improvements reported in this section derive specifically from the case implemented by the authors, which involved the design, deployment, and validation of a digital twin in a real-world industrial environment. Among the most notable results, a 20% reduction in homogenization time and a 19.4% decrease in energy consumption per batch were achieved. These improvements confirm the system’s ability to model complex behaviors and optimize operational parameters through virtual experimentation and predictive adjustments.

The relevance of this case is further reinforced by the 35% reduction in unscheduled shutdown frequency, which indicates increased reliability and improved planning capabilities. These findings align with the literature that supports the strategic use of digital twins to enhance resilience and system availability in dynamic production environments (Sacks et al., 2020; Javaid et al., 2023). Financially, the deployment demonstrated strong viability. The ROI analysis, strictly based on data from the implemented case, showed a return of 233% over 5 years. This reinforces the potential for digital twins to deliver value not only through technical improvements but also through long-term economic gains (Croatti et al., 2020).

Beyond the empirical data, the discussion highlights the digital twin’s role as an enabler of adaptive innovation. The ability to simulate process conditions in real-time and test hypothetical changes enables dynamic reconfiguration of operations to respond to evolving production demands (Singh et al., 2022; Li et al., 2021). This adaptive capacity not only improves quality and efficiency but also fosters greater resilience and agility in competitive and volatile industrial contexts.

Ultimately, the adoption of the digital twin reflects a paradigmatic shift in operational management. It transitions decision-making from a reactive to a predictive approach, grounded in accurate digital representations of physical systems. This approach enables early identification of anomalies, virtual validation of corrective actions, and optimized resource management (van Dinter et al., 2022), representing a significant advancement in industrial engineering and process optimization.

6 Conclusion

This study presents compelling evidence that implementing a digital twin in a real-world metalworking subsystem yields substantial operational improvements and strategic advantages. By enabling real-time simulation, data-driven parameter adjustments, and predictive diagnostics, the proposed digital twin contributed to a 30% reduction in material waste and a 40% improvement in the rejection rate of machined components. These outcomes confirm the system’s ability to dynamically refine production parameters, reduce variability, and maintain consistent product quality at scale.

The return on investment analysis, which reported a 233% ROI over 5 years, reinforces the digital twin’s ability even in resource-constrained environments. These results underscore not only the technological but also the financial justification for integrating digital twins into modern industrial operations. In addition, feedback from operators and technicians revealed a high degree of usability and perceived value, reinforcing the system’s alignment with on-site operational needs.

Beyond performance metrics, the digital twin catalyzed strategic transformation, shifting management practices from reactive troubleshooting to proactive and adaptive optimization. The system enabled the convergence of physical processes with virtual experimentation, fostering a more agile and intelligent production environment aligned with Industry 4.0 principles.

Future efforts will aim to expand the digital twin’s scope of integration with AI-based diagnostic and control modules, allowing for continuous learning and autonomous adaptation. Moreover, research will explore the interoperability of multiple digital twins within interconnected production ecosystems, addressing challenges such as coordination, emergent behavior, and systemic resilience. These directions will support the scalability and long-term sustainability of digital twin technologies in diverse industrial settings.

Data availability statement

The data supporting the reported results are available upon reasonable request from the corresponding author.

Author contributions

WV: Conceptualization, Formal Analysis, Investigation, Methodology, Validation, Visualization, Writing – review and editing. RG: Data curation, Formal Analysis, Methodology, Software, Validation, Visualization, Writing – original draft. JG: Data curation, Investigation, Methodology, Software, Validation, Visualization, Writing – original draft.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Arowoiya, V. A., Moehler, R. C., and Fang, Y. (2024). Digital twin technology for thermal comfort and energy efficiency in buildings: a state-of-the-art and future directions. Energy Built Environ. 5, 641–656. doi:10.1016/j.enbenv.2023.05.004

Bellavista, P., Bicocchi, N., Fogli, M., Giannelli, C., Mamei, M., and Picone, M. (2023). Requirements and design patterns for adaptive, autonomous, and context-aware digital twins in industry 4.0 digital factories. Comput. Industry 149, 103918. doi:10.1016/j.compind.2023.103918

Croatti, A., Gabellini, M., Montagna, S., and Ricci, A. (2020). On the integration of agents and digital twins in healthcare. J. Med. Syst. 44 (9), 161. doi:10.1007/s10916-020-01623-5

Ferko, E., Bucaioni, A., and Behnam, M. (2022). Architecting digital twins. IEEE Access 10, 50335–50350. doi:10.1109/ACCESS.2022.3172964

Ferré-Bigorra, J., Casals, M., and Gangolells, M. (2022). The adoption of urban digital twins. Cities 131, 103905. doi:10.1016/j.cities.2022.103905

Fuller, A., Fan, Z., Day, C., and Barlow, C. (2020). Digital twin: enabling technologies, challenges and open research. IEEE Access 8, 108952–108971. doi:10.1109/ACCESS.2020.2998358

Guerra-Zubiaga, D., Kuts, V., Mahmood, K., Bondar, A., Nasajpour-Esfahani, N., and Otto, T. (2021). An approach to develop a digital twin for industry 4.0 systems: manufacturing automation case studies. Int. J. Comput. Integr. Manuf. 34 (9), 933–949. doi:10.1080/0951192X.2021.1946857

Gürdür Broo, D., and Schooling, J. (2023). Digital twins in infrastructure: definitions, current practices, challenges and strategies. Int. J. Constr. Manag. 23 (7), 1254–1263. doi:10.1080/15623599.2021.1966980

He, B., and Bai, K. J. (2021). Digital twin-based sustainable intelligent manufacturing: a review. Adv. Manuf. 9 (1), 1–21. doi:10.1007/s40436-020-00302-5

Howard, D. A., Ma, Z., Veje, C., Clausen, A., Aaslyng, J. M., and Jørgensen, B. N. (2021). Greenhouse industry 4.0 – Digital twin technology for commercial greenhouses. Energy Inf. 4, 37–16. doi:10.1186/s42162-021-00161-9

Hu, W., Lim, K. Y. H., and Cai, Y. (2022). Digital twin and industry 4.0 enablers in building and construction: a survey. Buildings 12 (11), 2004. doi:10.3390/buildings12112004

Hyre, A., Harris, G., Osho, J., Pantelidakis, M., Mykoniatis, K., and Liu, J. (2022). Digital twins: representation, replication, reality, and relational (4Rs). Manuf. Lett. 31, 20–23. doi:10.1016/j.mfglet.2021.12.004

Javaid, M., Haleem, A., and Suman, R. (2023). Digital twin applications toward industry 4.0: a review. Cogn. Robot. 3, 71–92. doi:10.1016/j.cogr.2023.04.003

Jia, W., Wang, W., and Zhang, Z. (2022). From simple digital twin to complex digital twin part I: a novel modeling method for multi-scale and multi-scenario digital twin. Adv. Eng. Inf. 53, 101706. doi:10.1016/j.aei.2022.101706

Kang, T. W., and Mo, Y. (2024). A comprehensive digital twin framework for building environment monitoring with emphasis on real-time data connectivity and predictability. Dev. Built Environ. 17, 100309. doi:10.1016/j.dibe.2023.100309

Kasper, L., Schwarzmayr, P., Birkelbach, F., Javernik, F., Schwaiger, M., and Hofmann, R. (2024). A digital twin-based adaptive optimization approach applied to waste heat recovery in green steel production: development and experimental investigation. Appl. Energy 353, 122192. doi:10.1016/j.apenergy.2023.122192

Kenett, R. S., and Bortman, J. (2022). The digital twin in industry 4.0: a wide-angle perspective. Qual. Reliab. Eng. Int. 38 (3), 1357–1366. doi:10.1002/qre.2948

Li, D., Wenbo, Y., and Zhenfeng, S. (2021). Smart city based on digital twins. Comput. Urban Sci. 1 (1), 6. doi:10.1007/s43762-021-00005-y

Li, L., Aslam, S., Wileman, A., and Perinpanayagam, S. (2022). Digital twin in aerospace industry: a gentle introduction. IEEE Access 10, 9543–9562. doi:10.1109/ACCESS.2021.3136458

Madubuike, O. C., Anumba, C. J., and Khallaf, R. (2022). A review of digital twin applications in construction. J. Inf. Technol. Constr. 27, 145–172. doi:10.36680/j.itcon.2022.008

Mateev, M. (2020). “Industry 4.0 and the digital twin for building industry.” IV International Scientific Conference “Industry 4.0”, Borovets, Bulgaria, December 2019, 29–32.

Moiceanu, G., and Paraschiv, G. (2022). Digital twin and smart manufacturing in industries: a bibliometric analysis with a focus on industry 4.0. Sensors 22 (4), 1388. doi:10.3390/s22041388

Moreno, T., Almeida, A., Toscano, C., Ferreira, F., and Azevedo, A. (2023). Scalable digital twins for industry 4.0 digital services: a dataspaces approach. Prod. Manuf. Res. 11 (1), 2173680–157. doi:10.1080/21693277.2023.2173680

Muthuswamy, P., and Shunmugesh, K. (2023). Artificial intelligence based tool condition monitoring for digital twins and industry 4.0 applications. Int. J. Interact. Des. Manuf. 17 (3), 827–841. doi:10.1007/s12008-022-01050-5

Panagou, S., Fruggiero, F., del Vecchio, C., Sarda, K., Menchetti, F., Piedimonte, L., et al. (2022). “Explorative hybrid digital twin framework for predictive maintenance in steel industry,” in IFAC-PapersOnLine (Elsevier B.V.), 289–294. doi:10.1016/j.ifacol.2023.01.087

Pang, T. Y., Pelaez Restrepo, J. D., Cheng, C. T., Yasin, A., Lim, H., and Miletic, M. (2021). Developing a digital twin and digital thread framework for an ‘industry 4.0’ shipyard. Appl. Sci. 11 (3), 1097. doi:10.3390/app11031097

Rasheed, A., San, O., and Kvamsdal, T. (2020). Digital twin: values, challenges and enablers from a modeling perspective. IEEE Access 8, 21980–22012. doi:10.1109/ACCESS.2020.2970143

Sacks, R., Brilakis, I., Pikas, E., Xie, H. S., and Girolami, M. (2020). Construction with digital twin information systems. Data-Centric Eng. 1 (6), e14. doi:10.1017/dce.2020.16

Shahzad, M., Shafiq, M. T., Douglas, D., and Kassem, M. (2022). Digital twins in built environments: an investigation of the characteristics, applications, and challenges. Buildings 12 (2), 120. doi:10.3390/buildings12020120

Shi, L., Ding, Y., and Cheng, B. (2024). Development and application of digital twin technique in steel structures. Appl. Sci. Switz. 14, 11685. doi:10.3390/app142411685

Singh, M., Fuenmayor, E., Hinchy, E. P., Qiao, Y., Murray, N., and Devine, D. (2021). Digital twin: origin to future. Appl. Syst. Innov. 4 (2), 36. doi:10.3390/asi4020036

Singh, M., Srivastava, R., Fuenmayor, E., Kuts, V., Qiao, Y., Murray, N., et al. (2022). Applications of digital twin across industries: a review. Appl. Sci. 12 (11), 5727. doi:10.3390/app12115727

Stavropoulos, P., and Mourtzis, D. (2021). “Digital twins in industry 4.0,” in Design and operation of production networks for mass personalization in the era of cloud technology (Elsevier). doi:10.1016/B978-0-12-823657-4.00010-5

Tancredi, G. P., Vignali, G., and Bottani, E. (2022). Integration of digital twin, machine-learning and industry 4.0 tools for anomaly detection: an application to a food plant. Sensors 22 (11), 4143. doi:10.3390/s22114143

Tuhaise, V. V., Tah, J. H. M., and Abanda, F. H. (2023). Technologies for digital twin applications in construction. Automation Constr. 152, 104931. doi:10.1016/j.autcon.2023.104931

van Dinter, R., Tekinerdogan, B., and Catal, C. (2022). Predictive maintenance using digital twins: a systematic literature review. Inf. Softw. Technol. 151, 107008. doi:10.1016/j.infsof.2022.107008

VanDerHorn, E., and Mahadevan, S. (2021). Digital twin: generalization, characterization and implementation. Decis. Support Syst. 145, 113524. doi:10.1016/j.dss.2021.113524

Wang, X. V., and Wang, L. (2019). Digital twin-based WEEE recycling, recovery and remanufacturing in the background of industry 4.0. Int. J. Prod. Res. 57 (12), 3892–3902. doi:10.1080/00207543.2018.1497819

Yan, C., Kang, R., Meng, F., Dong, Z., Bao, Y., and Yang, G. (2024). Adaptive machining method for helical milling of carbon fiber-reinforced plastic/titanium alloy stacks based on interface identification. Materials 17, 297. doi:10.3390/ma17020297

Keywords: data fusion, deep learning, industry 4.0, artificial intelligence, digital twin

Citation: Villegas-Ch W, Gutierrez R and Govea J (2025) Digital twin integration in metalworking: enhancing efficiency and predictive maintenance. Front. Mech. Eng. 11:1655565. doi: 10.3389/fmech.2025.1655565

Received: 28 June 2025; Accepted: 29 July 2025;

Published: 20 August 2025.

Edited by:

Mohanraj Thangamuthu, Amrita School of Engineering, IndiaReviewed by:

Elio Padoano, University of Trieste, ItalyMihael Debevec, University Of Ljubljana, Slovenia

Copyright © 2025 Villegas-Ch, Gutierrez and Govea. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: William Villegas-Ch, d2lsbGlhbS52aWxsZWdhc0B1ZGxhLmVkdS5lYw==

†These authors have contributed equally to this work

William Villegas-Ch

William Villegas-Ch Rommel Gutierrez†

Rommel Gutierrez†