- 1Department of Mechanical Engineering, Faculty of Engineering, Hasanuddin University, Makassar, Indonesia

- 2Department of Applied Mechanics & Design, Faculty of Mechanical Engineering, Universiti Teknologi Malaysia, Skudai, Malaysia

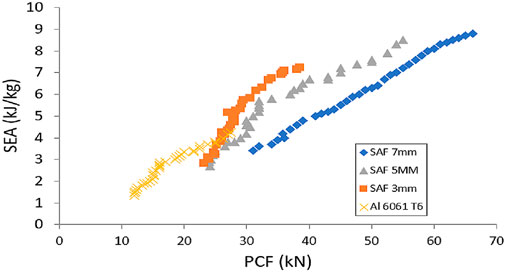

Improving amphibian aircraft landing performance is the primary goal of this paper, which aims to optimize the design of sandwich aluminum foam (SAF) energy absorbers. To determine how various configurations of the sandwich structure’s layers affected landing performance, extensive transient dynamic simulations were used. Using simulation methodologies, the impact performance of the SAF’s design parameters was rigorously investigated. The first step of the study was to characterize the SAF as a material for use in impact applications. The three SAF samples were subjected to testing in a water impact environment with a 3.5-ton airplane weight and a landing speed of 76 knots. The core thicknesses of the samples were 3 mm, 5 mm, and 7 mm, respectively. The numerical simulation findings showed that crash behavior indicators like peak crushing force (PCF) and total energy absorption (TEA) are greatly affected by core thickness and material density. Finite element model compares with experiment test, it is found that the differences less than 5%. These meshes are simulated to obtain convergent points of the simulated model mesh size with the error value is 3.08%. Surrogate models based on the Radial Basis Function (RBF) and the Non-dominated Sorting Genetic Algorithm II (NSGA-II) were used in a multi-objective optimization strategy to improve the float’s crashworthiness. According to the optimization findings, the SAF float was far more crashproof than the previous float design. These optimal results differ from those derived solely from crushing analyses in prior studies, providing a more robust reference for practical engineering applications.

1 Introduction

In recent years, the demand for amphibious aircraft has increased due to their ability to operate on both land and water, making them ideal for remote or coastal regions with limited airport infrastructure. One of the most critical components in these aircraft is the float or pontoon, which ensures buoyancy and absorbs the impact energy during water landings. The floats are equipped with water rudders for navigation and must contain at least four watertight compartments to prevent sinking in case of structural failure. During landing, the float is the first component that comes into contact with the water, and any hydrodynamic interaction leads to significant structural deformation (Carcaterra et al., 1999; Yu et al., 2022; Wang and Soares, 2017). The structural integrity of these floats is determined by their ability to withstand peak hydrodynamic forces, critical stress distributions, and maximum displacement. To study these phenomena, researchers have employed both experimental testing and numerical modeling. While experimental testing offers high accuracy, it is cost-intensive and requires specialized facilities (Hassoon et al., 2017; Judge et al., 2004; Stenius et al., 2013). In contrast, numerical modelling especially with finite element methods, offers a cost-effective alternative, though it demands considerable computational resources (Lu et al., 2000; Engle and Lewis, 2003; dong Xu et al., 2009). For high-fidelity simulations, fluid-structure interaction is often necessary but also computationally expensive. To address this, multi-scale modeling approaches such as complete shell, complete solid, multi-stage, and concurrent multi-scale modeling are employed (Shankar et al., 2020; Curreli et al., 2018; Said et al., 2018; Arai et al., 2015; Narvydas et al., 2021).

Multi-scale modeling increases computational efficiency while preserving accuracy. In multi-stage models, small zones of interest are refined using submodels, while concurrent models dynamically couple macro and micro-scale simulations to capture detailed structural behavior (Sun et al., 2019; He et al., 2020; He et al., 2021; Ali and Shimoda, 2022). For example, in modeling aircraft floats, shell elements can represent the skin, and solid elements can represent internal structures. ABAQUS software is widely used to simulate these configurations, providing tools for mesh refinement, contact interactions, and dynamic explicit analysis (Niknafs et al., 2022). The hydrodynamic impact problem is not limited to amphibious aircraft but also it appears in other sectors such as naval, offshore, and defense engineering (Abraham et al., 2014; Sun et al., 2021; Chen et al., 2023). High-speed water impact can cause severe structural damage, and accurate prediction of these forces is crucial for safety. Numerical methods such as Finite Element Method (FEM) and Smoothed Particle Hydrodynamics (SPH) are often combined for more robust simulations (Fernández et al., 2023; Zhang et al., 2020; Panciroli et al., 2012). Validating these models with experimental data ensures accuracy and enhances prediction capabilities (Engle and Lewis, 2003; Francesconi, 2009; Feng et al., 2021; Yan et al., 2018; Liu et al., 2023; Lu et al., 2000; Xia et al., 2023; Chaudhry et al., 2020; Li et al., 2021; Wu and Earls, 2022).

Given their lightweight and high-strength properties, composite materials especially those with sandwich configurations, are widely used in aerospace applications (Tao et al., 2019; Hernandez et al., 2017; Li et al., 2020). Sandwich panels consist of two stiff face sheets and a lightweight core, typically made from foam, honeycomb, or wood (Banhart and Seeliger, 2012; Banhart and Seeliger, 2008; Harte et al., 2000; Schwingel et al., 2007). Sandwich Aluminum Foam (SAF) structures offer high energy absorption and improved durability, especially when manufactured using integral-forming methods (Xia et al., 2013; Wang et al., 2015; Crupi and Montanini, 2007; Zhang et al., 2022; Xu et al., 2022; Liu et al., 2022; Yang et al., 2020). Recent studies have focused on optimizing these structures to enhance crashworthiness including marine structures (Catapano and Montemurro, 2014; Brückmann et al., 2017; Klanac et al., 2009; Dayyani et al., 2013) for weight reduction and structural efficiency.

Despite these advances, limited work has been done to optimize sandwich aluminum foam (SAF) structures for amphibious aircraft floats under water impact conditions. Most previous studies have focused on axial or blast impact on dry land (Patel and Patel, 2024; Patel et al., 2023; Sawant and Patel, 2024; Ma et al., 2023; Kumar et al., 2021; Nagarjun et al., 2020; Kumar et al., 2019), lacking a specific investigation into Fluid-Structure Interaction (FSI) during water landings. Additionally, studies on hierarchical and auxetic structures (Fu et al., 2025; Xu et al., 2025; Fu et al., 2024; Guang et al., 2025) show potential for improved energy absorption but have not been fully explored in amphibious applications.

This study aims to fill that gap by investigating the crashworthiness of SAF floats under hydrodynamic impact using ABAQUS simulations. Multi-objective optimization is performed using Non-dominated Sorting Genetic Algorithm II (NSGA-II) and Radial Basis Function (RBF) surrogate modeling to analyze the effects of core thickness and material density on crash parameters such as peak crushing force (PCF) and Specific Energy Absorption (SEA). The goal is to identify the most effective SAF configuration that balances structural integrity, energy absorption, and weight efficiency for real-world amphibious applications.

2 Methods and materials

2.1 Crashworthiness indicator of float impact water

Crashworthiness indicators are critical parameters used to evaluate the ability of a structure to protect its occupants and minimize damage during a crash or impact event. Below are some of the key crashworthiness indicators:

a. Energy Absorption:

o Total Energy Absorption (TEA): The amount of energy a structure can absorb during a crash or impact. A higher value indicates better performance in terms of protecting the occupants by reducing the impact force.

o Energy Absorption Efficiency: The amount of energy that a material or structure is able to absorb, as a percentage of the total energy that an impact causes.

b. Peak Crushing Force (PCF):

o The greatest amount of force that a building or its inhabitants may endure in the event of an accident. A lower peak force is preferable as it signifies reduced acceleration and injury risk to the occupants.

c. Crush Force Efficiency (CFE):

o A measure of how much energy a building can absorb relative to the force needed to crush it. Higher CFE values indicate a more effective energy absorption capability.

2.2 Finite element models of the float

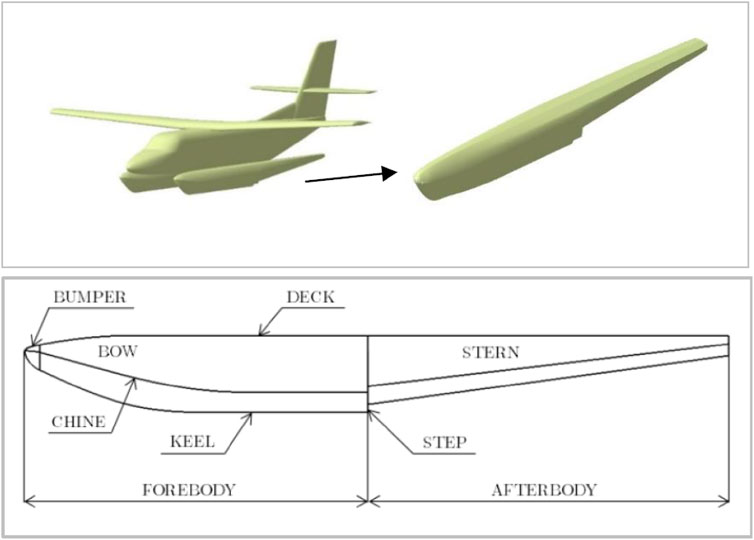

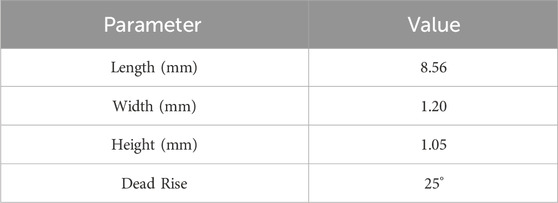

The amphibian aircraft designed for 19 passengers features twin floats, positioned on either side of the fuselage. The first series of floats for this aircraft is an imported product manufactured by WIPAIRE, Inc., a U.S.-based company specializing in floats for floatplanes and amphibious aircraft (Figure 1). The Twin Otter 300 series (Patel and Patel, 2024) has made use of these aluminum floats, which can sustain loads up to 6.5 tons apiece (see table 1 for dimensions).

Table 1. Float dimension (Shankar et al., 2020).

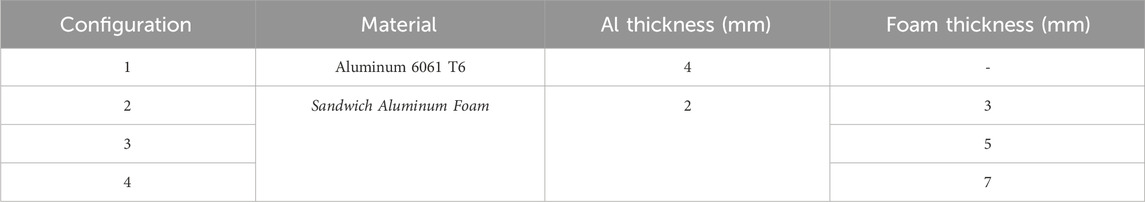

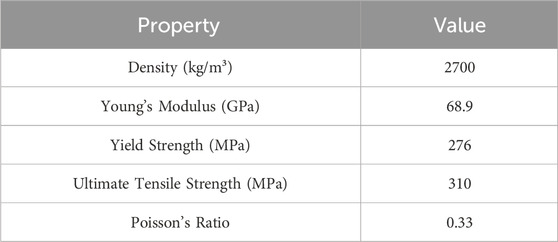

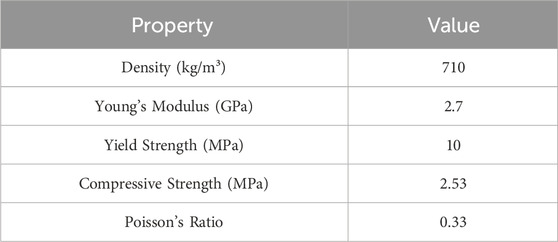

Because of its low weight, high strength-to-weight ratio, and great energy-absorbing qualities, sandwich foam constructions are finding more and more uses in amphibious aircraft. These floats are designed for water impact situations with a lightweight foam core sandwiched between two durable face sheets. They provide structural integrity and buoyancy as needed. Tables 2 and 3 show the mechanical characteristics of the core and face sheets used in sandwich foam systems (Dayyani et al., 2013; Patel and Patel, 2024).

Table 2. Mechanical properties of aluminum 6061 T6 (Dayyani et al., 2013).

Table 3. Mechanical properties of aluminum foam (Patel and Patel, 2024).

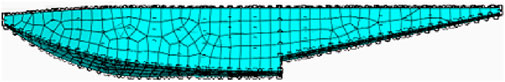

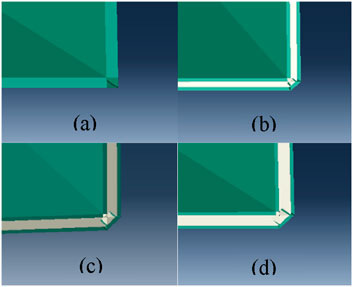

The plastic behavior responses of the aluminum core and aluminum face sheet materials used in the sandwich aluminum foam (SAF) structures (Figures 2, 3). The foam core absorbs energy primarily through progressive plastic collapse and aluminum face sheets contribute by plastically deforming under tensile and bending loads. The foam core plays a crucial role in absorbing impact energy, reducing peak crushing force and maintaining stability during operations. Additionally, the choice of materials and the optimization of parameters such as core density, thickness, and face sheet properties significantly influence the performance of the sandwich structure in crashworthiness and hydrodynamic contexts. The effectiveness and security of amphibious aircraft depend on these specialized sandwich foam floats. The float structure’s hydrodynamic influence on the water was simulated in this research using the ABAQUS finite element program. Accurately defining contact interactions such as cohesive or surface-to-surface bonding between dissimilar materials is essential to realistically capture interfacial behavior under dynamic loading. Moreover, the absence of a description of the mesh elements such as solid elements (C3D8R) for foam, shell elements (S4R) for face sheets and Eulerian elements for fluid domains. To ensure realistic simulation of hydrodynamic impact, specific boundary and loading conditions were defined. The float structure was assigned Lagrangian elements to model solid material deformation, while the surrounding water was modeled using Eulerian elements within a predefined Eulerian domain. The loading condition of the float was positioned above the water surface and then imparted an initial vertical velocity corresponding to 76 knots (approximately 39 m/s), representing the aircraft’s typical water landing speed. Gravity was applied as a body force, and no external constraints were applied to the float structure, enabling free-body motion during the initial contact phase. The float’s motion and impact behavior were governed by dynamic explicit analysis over a 0.01-s simulation period. The core and face sheet interaction is surface-to-surface contact and frictionless or low-friction contact to simulate realistic test conditions. For this study, there were 3 configuration of SAF and 1 original material in Table 4 and Figure 2.

Figure 2. Design float (a) Configuration 1 (b) Configuration 2 (c) Configuration 3 (d) Configuration 4.

Figure 4 shows the distribution of 500 data points dispersed uniformly across the course of the simulation, which pertain to speed. The data was taken at four nodes located at the top corners of the base frame.

2.3 Multi-objective optimization

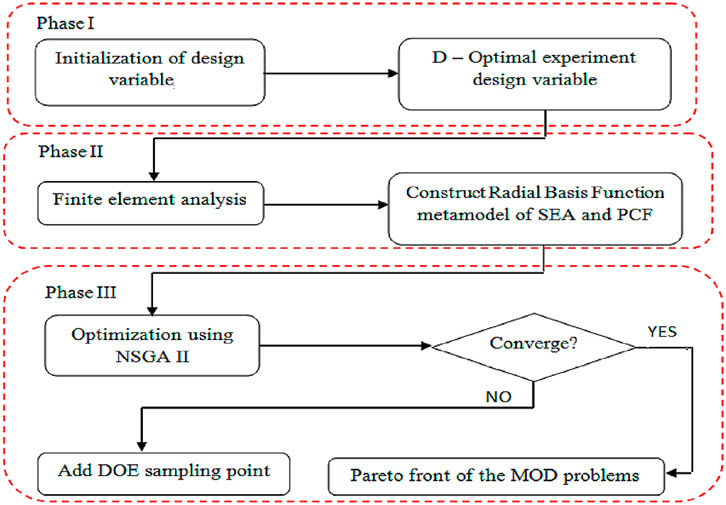

Sectional design parameters such as core thickness (

Figure 5 shows the procedure for making the double fender more impact resistant. Determining the design space and creating sample sites for different loading angles using the Design of Experiments (DOE) approach were the first steps. Phase two included using Finite Element Analysis (FEA) to find solutions for the design goals’ early D-optimal models. Phase three concluded with the determination of Pareto-optimal solutions for stressed systems by the use of the NSGA-II method to maximize performance under varying loads.

Figure 5. Flowchart of crashworthiness multi-objective optimization for tubes (Djamaluddin and Mat, 2023).

3 Result and discussion

3.1 Finite element analysis of float impact water

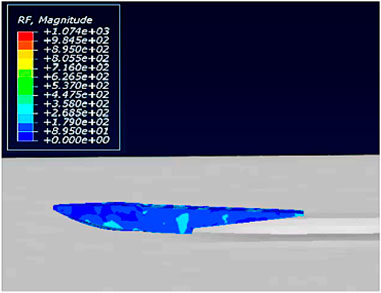

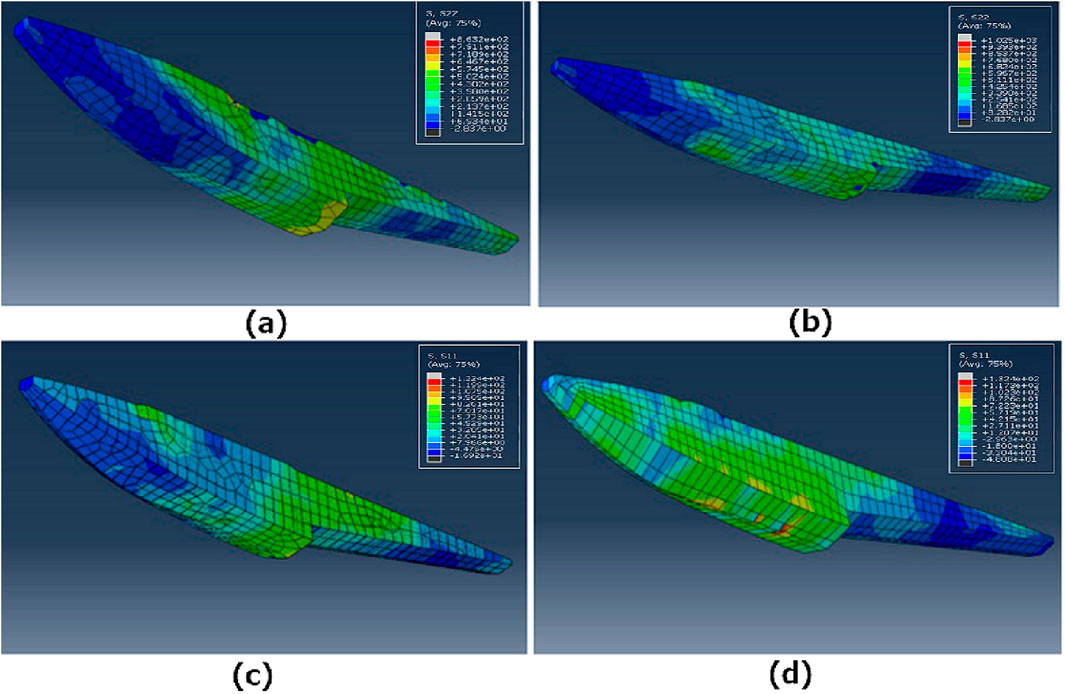

The deformation of float configurations during water impact is a critical aspect of evaluating their performance and safety (Figure 6). When the float structure comes into contact with the water surface, a combination of hydrodynamic and structural forces acts on it. The initial impact generates a high-pressure region, causing localized deformation, particularly at the leading edge of the float. This deformation is influenced by the material properties, structural design, and impact velocity.

The foam core in sandwich structures absorbs a significant portion of the impact energy, reducing peak forces transmitted to the aircraft. Simultaneously, the face sheets resist bending and prevent excessive structural collapse. The deformation pattern can vary, ranging from elastic bending to plastic deformation, depending on the float’s design and material configuration.

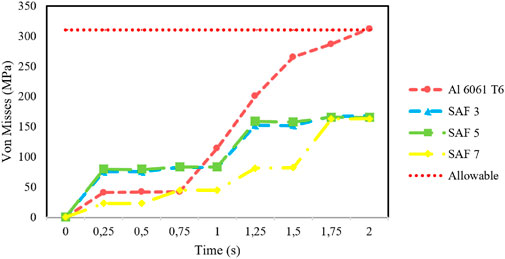

The Von Mises stress distribution in sandwich foam aluminum structures for float configurations is a key indicator of their mechanical performance under load (Figure 7). During water impact, the stress is distributed across the foam core and aluminum face sheets, with the Von Mises criterion used to predict yielding within the material. This analysis is crucial for understanding how the float structure withstands the combined hydrodynamic and structural forces.

In such configurations, the aluminum face sheets typically experience higher Von Mises stresses, especially in regions subjected to bending and direct impact. The foam core, on the other hand, helps to distribute and absorb stresses, preventing localized failure. By examining the Von Mises stress distribution, engineers can identify critical stress points, optimize material thickness, and enhance the overall structural integrity of the float. This ensures the design meets safety standards while maintaining a lightweight and efficient configuration suitable for amphibious aircraft applications.

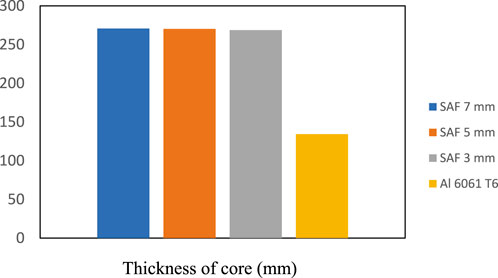

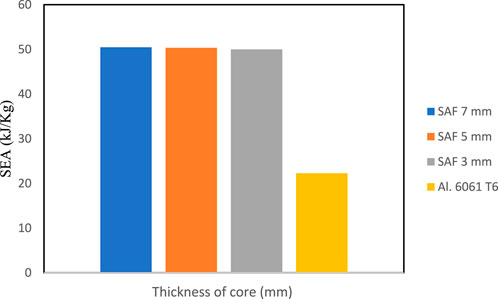

3.2 Crashworthiness parameters

When it comes to float arrangements, the Total Energy Absorption (TEA) and Specific Energy Absorption (SEA) of sandwich aluminum foam constructions change a lot depending on the thickness of the core. An important factor in a structure’s ability to dissipate energy is the thickness of its foam core, as this determines how much material is available to absorb impact forces (Figures 8, 9).

For thinner cores, the TEA and SEA is generally lower because there is less foam material to undergo deformation and dissipate energy during impact. While such configurations may be lighter, they often result in higher stress concentrations and reduced crashworthiness. Conversely, increasing the core thickness enhances the TEA, as the additional material allows for more progressive crushing and energy absorption. This reduces the peak forces transmitted to the structure and improves its ability to withstand repeated impacts.

However, excessively thick cores may lead to a significant increase in weight, which can compromise the buoyancy and efficiency of the float. Therefore, optimizing core thickness is essential to achieve a balance between lightweight design and maximum energy absorption. Analyzing TEA for different core thicknesses enables engineers to tailor sandwich aluminum foam configurations for improved safety and performance in amphibious aircraft applications.

3.3 Model verification

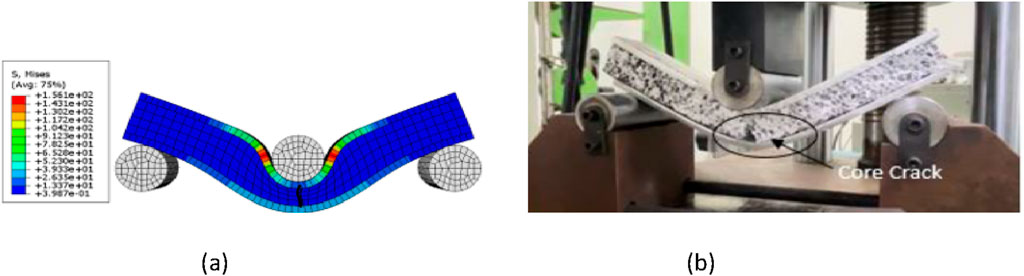

In both the experimental setup and the finite element simulation for validation, a three-point bending test configuration was adopted to evaluate the mechanical response of the sandwich aluminum foam (SAF) panel. The specimen dimensions matched those used in the float structure. In the experimental setup, the panel was simply supported at two ends, with a central load applied using a displacement-controlled actuator. The boundary conditions in the experiment replicated simply supported edges and a centrally applied quasi-static load, simulating impact-induced bending.

In the simulation using ABAQUS/Standard, the same boundary conditions were modeled: two ends of the panel were constrained in the vertical direction using pinned supports, while a concentrated vertical displacement load was applied at the mid-span using a reference point connected to a rigid loading surface. The loading rate in the simulation matched the experimental displacement speed to ensure comparability. The face sheet–core interface was modeled with surface-to-surface contact and frictionless behavior to allow delamination, while solid (C3D8R) and shell (S4R) elements were used for the foam and face sheets, respectively. The panel deformation, core crushing, and peak force values were then compared between the simulation and experimental results, with less than 5% deviation, confirming model accuracy. To validate the model, the simulation results were compared with experimental data of foam core sandwich specimens for float in Figure 10.

Figure 10 shows the numerical simulation result showing Von Mises stress distribution in a bending test, and the experimental result where a core crack is visibly initiated under the same loading condition. In Table 5, the small percentage deviations (<5%) confirm that the FEA model accurately captures the mechanical response of the sandwich structure during water impact. These discrepancies because in experimental setups, measurements are subject to uncertainties and calibration limits of sensors and data acquisition systems, particularly in high-speed impact tests. Simulation results can be continued for optimization.

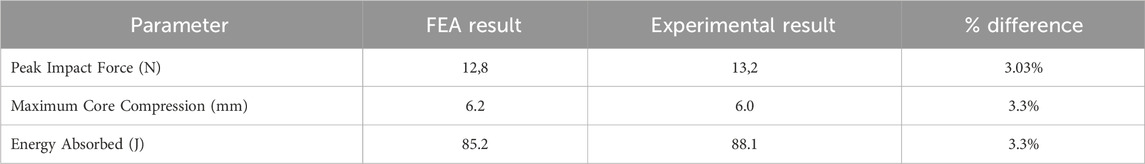

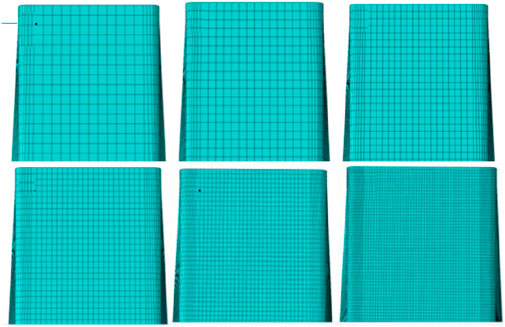

Convergence testing is very important to determine the effect of the number of elements used on the results obtained. In the float analysis, element sizes were tested ranging from 30 to 150 with an increase of 10 in each test (Figure 11). The element size itself is the general length of the element on a surface. The larger the value of the selected element size, the fewer the number of elements will be, and vice versa. The convergence investigation found that mesh sizes between 70 and 110 yielded the convergence value. However, when viewed from the error value, as the element size decreases, the error value becomes larger. The error on the graph is the difference in results between the current element measurement and the previous element. Therefore, in this modeling, an element size of 90 is used because it has the smallest error value (Figure 12) (Ardiansyah and Adhitya, 2019).

Figure 11. Mesh size (mm) (Ardiansyah and Adhitya, 2019).

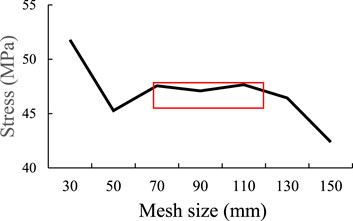

The development of a radial basis function (RBF) meta-model allowed for the precise identification of the sample locations. Also, five additional random locations were produced inside the design area. The cost-effective finite element (FE) and RBF models were validated using the SEA and PCF responses. In order to assess the degree to which the RBF meta-model resembles the outcomes of the finite element analysis (FEA), the following method was used:

In Figure 13, we can see the five randomly selected starting positions for the FEA and RBF samples. Because the validation values fall below 5% in the SAF float for this RBF meta-model estimate, we may infer that the RBF model achieves an acceptable level of accuracy for optimizing the design with respect to the objective functions (SEA and PCF).

3.4 Crashworthiness optimization design

The SAF float’s multi-objective optimization (MOD) equations were developed with the use of several parameters. Addressing trade-offs between conflicting objectives was done via multi-objective optimization. Design characteristics including core thickness (t), foam density (

Using the NSGA-II optimization method, the design space was explored using Radial Basis Function (RBF) meta-models. The Design of Experiments (DoE) technique was used to develop a collection of 200 design points for all MOD situations. Next, the SAF 7 mm model’s PCF vs. SEA Pareto front graphs were constructed using the NSGA-II approach. These graphs were based on the convergence of optimizations repeated over 20 generations. There was an unintended trade-off between the PCF and SEA criterion, since the data showed that increasing SEA caused PCF to rise.

In order to find inconsistencies between the RBF models and Finite Element Analysis (FEA), multi-objective optimization was used to the section design parameters, which core thickness (t), foam density (

4 Conclusion

This study has demonstrated the effectiveness of sandwich aluminum foam (SAF) structures in enhancing the crashworthiness of amphibious aircraft floats under water impact conditions. Through a combination of material characterization, finite element simulations, and experimental validation, the impact response of various core thickness configurations was thoroughly analyzed. The results highlight that core thickness and material density are critical parameters influencing the Total Energy Absorption (TEA) and peak crushing force (PCF). Among the three tested configurations (3 mm, 5 mm, and 7 mm core thickness), the 7 mm sample exhibited superior energy absorption performance while maintaining acceptable structural integrity.

• Based on simulations, experiments, and multi-objective optimization, the following conclusions can be drawn: The simulation results showed a difference of less than 5% compared to the experimental data.

• Effect of Core Thickness such as the 7 mm core gave the highest SEA (8 kJ/kg) and Peak Crushing Force (PCF) up to 65 kN and the 3 mm core showed lower PCF (20–35 kN) with still good SEA (up to 7 kJ/kg). From optimization results found that increasing foam density from 2,700 to 7,100 kg/m3 improved impact resistance by 23%, but also increased weight by 12%.

• The optimized SAF float is a lightweight, strong, and safe solution for amphibious aircraft. These results provide a strong reference for the development of hybrid marine-aerospace structures and future experimental studies.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

FD: Conceptualization, Investigation, Writing – original draft, Writing – review and editing. ZA: Methodology, Validation, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. Funding from Hibah Thematic Research Group, Universitas Hasanuddin.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

CFE, Crush Force Efficiency; DOE, Design of Experiments; FEA, Finite Element Analysis; FEM, Finite Element Method; FSI, Fluid-Structure Interaction; MOD, Multi-objective Optimization Design; NSGA-II, Non-dominated Sorting Genetic Algorithm II; PCF, peak crushing force; RBF, Radial Basis Function; SAF, Sandwich Aluminum Foam; SEA, Specific Energy Absorption; SPH, Smoothed Particle Hydrodynamics; TEA, Total Energy Absorption.

References

Abraham, J., Gorman, J., Reseghetti, F., Sparrow, E., Stark, J., and Shepard, T. (2014). Modeling and numerical simulation of the forces acting on a sphere during early-water entry. Ocean. Eng. 76, 1–9. doi:10.1016/j.oceaneng.2013.11.015

Ali, M. A., and Shimoda, M. (2022). Investigation of concurrent multiscale topology optimization for designing lightweight macrostructure with high thermal conductivity. Int. J. Therm. Sci. 179, 107653. doi:10.1016/j.ijthermalsci.2022.107653

Arai, K., Yodo, K., Yodo, K., Okada, H., Yamada, T., Kawai, H., et al. (2015). Ultra-large scale fracture mechanics analysis using a parallel finite element method with submodel technique. Finite Elem. Analysis Des. 105, 44–55. doi:10.1016/j.finel.2015.07.006

Ardiansyah, R., and Adhitya, M. (2019). Simulation of float of 19 passenger aircraft during landing on water surface. J. Phys. Conf. Ser. doi:10.1088/1757-899X/694/1/012005

Banhart, J., and Seeliger, H. W. (2008). Aluminium foam sandwich panels: manufacture,metallurgy and applications. Adv. Eng. Mater. 10 (9), 793–802. doi:10.1002/adem.200800091

Banhart, J., and Seeliger, H. W. (2012). Recent trends in aluminum foam sandwich technology. Adv. Eng. Mater. 14 (12), 1082–1087. doi:10.1002/adem.201100333

Brückmann, S. M., Friedrich, H. E., Kriescher, M., Kopp, G., and G¨atzi, R. (2017). Lightweight sandwich structures in innovative vehicle design under crash load cases. Mater. Sci. Forum 879, 2419–2427. doi:10.4028/www.scientific.net/MSF.879.2419

Carcaterra, A., Ciappi, E., Iafrati, A., and Campana, E. F. (1999). Slamming of elastic structures on the water surface: a shock spectral approach.

Catapano, A., and Montemurro, M. (2014). A multi-scale approach for the optimum design of sandwich plates with honeycomb core. Part I: homogenisation of core properties. Compos. Struct. 118 (1), 664–676. doi:10.1016/j.compstruct.2014.07.057

Chaudhry, A. Z., Shi, Y., and Pan, G. (2020). Study on the oblique water entry impact performance of AUV under different launch conditions based on coupled FEM-ALE method. AIP Adv. 10 (11), 115020. doi:10.1063/5.0025741

Chen, Z., Jiao, J., Wang, S., and Guedes Soares, C. (2023). CFD-FEM simulation of water entry of a wedged grillage structure into stokes waves. Ocean. Eng. 275, 114159. doi:10.1016/j.oceaneng.2023.114159

Crupi, V., and Montanini, R. (2007). Aluminium foam sandwiches collapse modes under static and dynamic three-point bending. Int. J. Impact. Eng. 34 (3), 509–521. doi:10.1016/j.ijimpeng.2005.10.001

Curreli, C., Curreli, C., Puccio, F. D., Puccio, F. D., and Mattei, L. (2018). Application of the finite element submodeling technique in a single point contact and wear problem. Int. J. Numer. Methods Eng. 116, 708–722. doi:10.1002/nme.5940

Dayyani, I., Ziaei-Rad, S., and Friswell, M. I. (2013). The mechanical behavior of composite corrugated core coated with elastomer for morphing skins. J. Compos. Mater. 48 (13), 1623–1636. doi:10.1177/0021998313488807

Djamaluddin, F. (2023a). Optimization of multi cell fender under transverse loading ocean engineering. doi:10.1016/j.oceaneng.2023.113740

Djamaluddin, F. (2023b). Crash behavior and optimization of double tubes with different cross section. Int. J. Crashworthiness 26.

Djamaluddin, F. (2024). Optimization of foam-filled crash-box under axial loading for pure electric vehicle. Results Mater. 21, 100505. doi:10.1016/j.rinma.2023.100505

Djamaluddin, F., and Mat, F. (2023). Optimization and crush characteristic of foam-filled fender subjected to transverse loads ocean engineering.

dong Xu, G., Duan, W., and Duan, W. (2009). Review of prediction techniques on hydrodynamic impact of ships. J. Mar. Sci. Appl. 8, 204–210. doi:10.1007/s11804-009-8039-7

Engle, A., and Lewis, R. (2003). A comparison of hydrodynamic impacts prediction methods with two dimensional drop test data. Mar. Struct. 16, 175–182. doi:10.1016/s0951-8339(02)00026-6

Feng, S., Zhang, G., Moctar, O., Sun, Z., and Zhang, Z. (2021). A semi-analytical method to simulate hydroelastic slamming of 2D structural sections by coupling wagner theory with the finite element method. Ocean. Eng., 240.

Fernández, E., Février, S., Lacroix, M., Boman, R., Papeleux, L., and Ponthot, J. P. (2023). A particle finite element method based on level–set functions. J. Comput. Phys. 487, 112187. doi:10.1016/j.jcp.2023.112187

Francesconi, E. (2009). A numerical-experimental investigations on crash behaviour of skin panels during a water impact comparing ALE and SPH approaches.

Fu, Q., Deng, X., Xu, S., and Cai, Z. (2024). Energy absorption characteristics of asymmetric tree-like fractal gradient-hierarchical structures. Mech. Adv. Mater. Struct. 31, 13036–13052. doi:10.1080/15376494.2024.2331600

Fu, Q., Deng, X., and Xu, S. (2025). Theoretical and numerical study of crashworthiness of asymmetric gradient-hierarchical bi-hexagonal tubes. Compos. Struct. 321, 119033. doi:10.1016/j.compstruct.2025.119033

Guang, X., Huang, H., and Deng, X. (2025). In-plane dynamics of symmetric reentrant tetrachiral auxetic metamaterials. Compos. Commun. 40, 102428. doi:10.1016/j.coco.2025.102428

Harte, A. M., Fleck, N. A., and Ashby, M. F. (2000). Sandwich panel design using aluminum alloy foam. Adv. Eng. Mater 2 (4), 219–222. doi:10.1002/(sici)1527-2648(200004)2:4<219::aid-adem219>3.0.co;2-#

Hassoon, O., Tarfaoui, M., Tarfaoui, M., Alaoui, A. E. M., and Moumen, A. E. (2017). Experimental and numerical investigation on the dynamic response of sandwich composite panels under hydrodynamic slamming loads. Compos. Struct. 178, 297–307. doi:10.1016/j.compstruct.2017.07.014

He, C., Ge, J., Zhang, B., Gao, J., Zhong, S., Liu, W. K., et al. (2020). A hierarchical multiscale model for the elastic-plastic damage behavior of 3d braided composites at high temperature. Compos. Sci. Technol. doi:10.1016/j.compscitech.2020.108230

He, C., Ge, J., Gao, J., Liu, J., Liu, J. P., Chen, H., et al. (2021). From microscale to mesoscale: the non-linear behavior prediction of 3d braided composites based on the sca2 concurrent multiscale simulation. Compos. Sci. Technol. 213, 108947. doi:10.1016/j.compscitech.2021.108947

Hernandez, E., Alfano, M., Pulungan, D., and Lubineau, G. (2017). Toughness amplification in copper/epoxy joints through pulsed laser micro-machined interface heterogeneities. Sci. Rep. 7 (1), 16344–12. doi:10.1038/s41598-017-16471-6

Judge, C. Q., Troesch, A. W., and Perlin, M. (2004). Initial water impact of a wedge at vertical and oblique angles. J. Eng. Math. 48, 279–303. doi:10.1023/b:engi.0000018187.33001.e1

Klanac, A., Ehlers, S., and Jelovica, J. (2009). Optimization of crashworthy marine structures. Mar. Struct. 22 (4), 670–690. doi:10.1016/j.marstruc.2009.06.002

Kumar, M. A., Shunmugasundaram, M., Palanivelu, A., and Santhanam, V. (2019). Static axial crushing response on the energy absorption capability of hybrid kenaf/glass fabric epoxy composite tube. Mater. Today Proc. 33, 2835–2840. doi:10.1016/j.matpr.2019.12.246

Kumar, M. A., Shunmugasundaram, M., Palanivelu, A., and Santhanam, V. (2021). Potentiality of MWCNT fillers on the lateral crashworthiness performance of composite tubes. J. Compos. Mater. 55 (11), 1473–1486. doi:10.1177/1528083721997927

Li, X., Tao, R., Alfano, M., and Lubineau, G. (2020). How variability in interfacial properties results in tougher bonded composite joints by triggering bridging. Int. J. Solids Struct. 191–192, 87–98. doi:10.1016/j.ijsolstr.2019.11.021

Li, Y., Sun, T., Zong, Z., Li, H., and Zhao, Y. (2021). Dynamic crushing of a dedicated buffer during the high-speed vertical water entry process. Ocean. Eng. 236, 109526. doi:10.1016/j.oceaneng.2021.109526

Liu, N., Zhang, Z., Xia, X., Xu, T., Wang, Z., Ding, J., et al. (2022). Local deformation on damping performance of integral-forming aluminum foam sandwich. Mater. Lett. 323, 132545. doi:10.1016/j.matlet.2022.132545

Liu, X., Luo, K., Yuan, X., and Qi, X. (2023). Numerical study on the impact load characteristics of a trans-media vehicle during high-speed water entry and flat turning. Ocean. Eng. 273, 113986. doi:10.1016/j.oceaneng.2023.113986

Lu, C., He, Y., Wu, G., and Wu, G. (2000). Coupled analysis of nonlinear interaction between fluid and structure during impact. J. Fluids Struct. 14, 127–146. doi:10.1006/jfls.1999.0257

Ma, Y., Dong, L., Sun, J., Jiang, Y., Zhang, Y., and Zhang, J. (2023). Axial and radial crushing behaviour of thin-walled carbon fiber-reinforced polymer tubes fabricated by the real-time winding angle measurement system. Forces Mech. 14, 100170. doi:10.1016/j.finmec.2023.100170

Nagarjun, G., Selvakumar, N., Manickam, M., and Santhanam, V. (2020). Dynamic crushing and energy absorption performance of newly designed multitubular structures. Mater. Today Proc. 27 (Part 2), 1743–1748. doi:10.1016/j.matpr.2020.04.103

Narvydas, E., Puodziuniene, N., and khan Thorappa, A. (2021). Application of finite element sub-modeling techniques in structural mechanics. Mechanika 27, 459–464. doi:10.5755/j02.mech.25962

Niknafs, S., Silani, M., Concli, F., and Aghababaei, R. (2022). A coarse-grained concurrent multiscale method for simulating brittle fracture. Interna-tional J. Solids Struct. 254-255, 111898. doi:10.1016/j.ijsolstr.2022.111898

Panciroli, R., Abrate, S., Minak, G., and Zucchelli, A. (2012). Hydroelasticity in water-entry problems: comparison between experimental and SPH results. Compos. Struct. 94 (2), 532–539. doi:10.1016/j.compstruct.2011.08.016

Patel, M., and Patel, S. (2024). A comparative blast-mitigation performance evaluation of metallic sandwich panels with honeycomb, corrugated, auxetic, and foam cores. Int. J. Struct. Stab. Dyn. 24 (5), 2550186. doi:10.1142/S021945542550186X

Patel, M., Patel, S., and Ahmad, S. (2023). Blast analysis of efficient honeycomb sandwich structures with CFRP/steel FML skins. Int. J. Impact Eng. 178, 104609. doi:10.1016/j.ijimpeng.2023.104609

Said, B. E., Daghia, F., Ivanov, D., and Hallett, S. R. (2018). An iterative multiscale modelling approach for nonlinear analysis of 3d composites. Int. J. Solids Struct. 132-133, 42–58. doi:10.1016/j.ijsolstr.2017.08.017

Sawant, R. Y., and Patel, S. (2024). Efficient design of composite honeycomb sandwich panels under blast loading. Proc. Institution Mech. Eng. Part C J. Mech. Eng. Sci. 238, 10515–10535. doi:10.1177/09544062241235567

Schwingel, D., Seeliger, H. W., Vecchionacci, C., Alwes, D., and Dittrich, J. (2007). Aluminium foam sandwich structures for space applications. Astronaut 61, 326–330. doi:10.1016/j.actaastro.2007.01.022

Shankar, S., Nithyaprakash, R., Santhosh, B. R., Uddin, M., Uddin, M., Uddin, M. N., et al. (2020). “Finite element submodeling technique to analyze the contact pressure and wear of hard bearing couples in hip prosthesis,” in Computer methods in biomechanics and biomedical engineering.

Stenius, I., Ros´en, A., Ros´en, A., Ros´en, A., Battley, M., Battley, M., et al. (2013). Experimental hydroelastic characterization of slamming loaded marine panels. Ocean. Eng. 74, 1–15. doi:10.1016/j.oceaneng.2013.09.007

Sun, Z., Korobkin, A., Sui, X. P., and Zhi, Z. (2021). A semi-analytical model of hydroelastic slamming. J. Fluids Struct. 101, 103200. doi:10.1016/j.jfluidstructs.2020.103200

Sun, Y., Zhai, J., Zhang, Q., and Qin, X. (2019). Research of large scale mechanical structure crack growth method based on finite element parametric submodel. Eng. Fail. Anal. 102, 226–236. doi:10.1016/j.engfailanal.2019.04.012

Tao, R., Alfano, M., and Lubineau, G. (2019). In situ analysis of interfacial damage in adhesively bonded composite joints subjected to various surface pretreatments. Compos. Part A Appl. Sci. Manuf. 116, 216–223. doi:10.1016/j.compositesa.2018.10.033

Wang, S., and Soares, C. G. (2017). Review of ship slamming loads and responses. J. Mar. Sci. Appl. 16, 427–445. doi:10.1007/s11804-017-1437-3

Wang, Y. Q., Ren, X. P., Hou, H. L., Zhang, Y., and Yan, W. (2015). Processing and pore structure of aluminium foam sandwich. Technol 275, 344–350. doi:10.1016/j.powtec.2015.01.066

Wu, W., and Earls, C. (2022). A new engineering theory describing oblique free surface impact by flexible plates. Ocean. Eng. 256, 111473. doi:10.1016/j.oceaneng.2022.111473

Xia, X., Hui, F., and Xin, Z. (2013). The compressive properties of closed-cell aluminium foams with different Mn additions. Mater. Des. 51, 797–802. doi:10.1016/j.apor.2023.103623

Xia, S., Wei, Y., Wang, C., and Cao, W. (2023). Asymmetric flow action on hydrodynamics and structural dynamics for high-speed oblique water entry of the semi-sealed cylindrical shell. Appl. Ocean Res. 138, 103623. doi:10.1016/j.apor.2023.103623

Xu, T., Zhang, Z., Ding, J., Liu, N. n., Wang, Z., Xia, X. c., et al. (2022). Dynamic and quasi-static compressive performance of integral-forming aluminum foam sandwich. J. Iron. Steel. Res. Int., 1–12. doi:10.1007/s42243-022-00770-y

Xu, S., Huang, H., Fu, Q., Guang, X., and Deng, X. (2025). Design, study and optimization of crashworthiness and energy absorption of symmetric and asymmetric offset hexagonal honeycombs. Thin-Walled Struct. 191, 113556. doi:10.1016/j.tws.2025.113556

Yan, G. X., Pan, G., Shi, Y., Chao, L. M., and Zhang, D. (2018). Experimental and numerical investigation of water impact on air-launched AUVs. Ocean. Eng. 167, 156–168. doi:10.1016/j.oceaneng.2018.08.044

Yang, D., Zhang, Z., Chen, X., Han, X., Xu, T., Li, X., et al. (2020). Quasi-static compression deformation and energy absorption characteristics of basalt fiber-containing closed-cell aluminum foam. Metal 10 (7), 921. doi:10.3390/met10070921

Yu, P., Xie, H., Liu, F., Li, P., and cheng Lv, G. (2022). Numerical investigation on the water entry of a 2d seaplane section with heel angles. Ocean. Eng. 262, 112236. doi:10.1016/j.oceaneng.2022.112236

Zhang, X., Shi, Y., Pan, G., and Huang, Q. (2020). Study on the impact performance of sandwich hollow cylinders hitting water based on SPH method. Ocean. Eng. 197, 106808. doi:10.1016/j.oceaneng.2019.106808

Keywords: float, optimization, crashworthiness, sandwich aluminium foam, amphibian aircraft

Citation: Djamaluddin F and Ahmad Z (2025) Optimizing sandwich foam floats for amphibious aircraft: enhancing performance under water impact. Front. Mech. Eng. 11:1701456. doi: 10.3389/fmech.2025.1701456

Received: 08 September 2025; Accepted: 13 October 2025;

Published: 30 October 2025.

Edited by:

Yijie Jiang, University of Oklahoma, United StatesReviewed by:

Pengfei Wang, University of Science and Technology of China, ChinaRavi Teja Undavalli, Segula Technologies, France

Copyright © 2025 Djamaluddin and Ahmad. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Fauzan Djamaluddin, ZmF1emFubWFuXzc3QHlhaG9vLmNvbQ==

Fauzan Djamaluddin

Fauzan Djamaluddin Zaini Ahmad

Zaini Ahmad