- 1Department of Chemical and Biomedical Engineering, Florida A&M University–Florida State University (FAMU-FSU) College of Engineering, Tallahassee, FL, United States

- 2Aero-propulsion, Mechatronics and Energy (AME) Center, Florida A&M University–Florida State University (FAMU-FSU) College of Engineering, Tallahassee, FL, United States

This review focuses on charged polymer membranes motivated by their growing importance in membrane-based separation technologies. Charged polymers have a long history in ion exchange chromatography, and thus charged polymer membranes are commonly termed ion-exchange membranes (IEMs). IEMs can be used in energy-efficient reverse osmosis desalination and are being studied for recovering valuable minerals from aqueous waste streams. Types of IEMs are first introduced, categorized by charge type, charge distribution and porosity. Synthesis of charged polymers is briefly discussed. Considerable attention is given to important membrane properties and methods for characterizing them. These properties include ion-exchange capacity (IEC), water content, structure, ionic conductivity, permeability, selectivity, and thermal and mechanical properties. A key challenge in membrane design is achieving high IEC, which is desired for high IEM selectivity. This is a challenge due to the high water uptake that accompanies high IEC. Relevant aspects of membrane structure include percolated ion channels, porous morphology and inert mechanical reinforcement phases. Membrane structure is essential in addressing the challenge of achieving high IEC and optimizing membrane performance. Structure is predominantly dictated by membrane processing. Thus, membrane processing methods, their benefits and drawbacks and their impact on structure are described in detail. These methods include solution casting, the paste method, extrusion, electrospinning, phase inversion, and an emerging method to form a composite IEM. Finally, specific IEM applications are discussed that hold great promise for circular economies. These applications include lithium extraction from battery waste, mining of desalination brine, and mineral recovery from semiconductor waste. A major driver for the growing interest in these applications is the demonstrated cost-effectiveness of membranes in commercial desalination. With on-going research advances, such success is probable in these extraction and recovery applications.

1 Introduction - membrane technology

The development of sustainable resources is one of the key global challenges to prevent the depletion of finite subterranean resources, alleviate environmental pollution, and mitigate climate change (Lenkiewicz, 2024; Garcia-Gutierrez et al., 2023). While numerous studies are being conducted in both industry and academia, particularly focusing on the advancement of renewable energy technologies and energy storage systems, resource recovery from industrial waste is also gaining significant attention, given its potential for economic value (Cath et al., 2021). Common recovery methods include precipitation, evaporation, and pyrolysis; however, membrane-based separation technologies are well-aligned with sustainability goals owing to their low energy consumption and operating cost (Sharkh et al., 2022; Panayotova and Panayotov, 2021).

Charged polymer membranes are commonly utilized across a range of industrial applications, including water treatment/desalination (Kitto and Kamcev, 2023; Geise et al., 2014b; Werber et al., 2016b), mineral harvesting (Sharkh et al., 2022), biomedical products (Oh et al., 2019; Chen et al., 2016), energy conversion/storage (Hallinan and Balsara, 2013; Ramon et al., 2011; Doan et al., 2015), and chemical processing (Jaroszek and Dydo, 2016), thanks to their unique ion transfer and separation abilities. Unlike neutral polymer membranes, the processing of charged polymer membranes poses challenges due to the interactions between the charged species and due to the more complex syntheses involved in creating charged polymers (Ran et al., 2017; Tang et al., 2014). Therefore, selecting the right manufacturing technology is crucial to achieve uniformly controlled charge density, improved physical and chemical stability, increased mechanical strength, and uniform membrane thickness.

Membrane separation performance, first and foremost, relies on the ability of a membrane to transport desired species while blocking undesired ones. Material/membrane properties such as charge density, thickness uniformity, chemical stability, and mechanical strength are crucial in determining the membrane transport properties. For charged membranes, not only is charge density important, but also the charge distribution offers ion transport pathways and governs the absorption of water and ions (Geise et al., 2014b; Voigt et al., 2002). Improved uniformity of the membrane thickness facilitates surface modification and enhances the thermomechanical properties by evenly distributing thermal and physical stress across the membrane, increasing its durability (Tsou et al., 1992; Oh et al., 2004; Cakmak and Simhambhatla, 1995). Enhanced surface smoothness enables efficient and consistent surface treatment to address fouling, contamination, and wetting issues (Khoiruddin et al., 2017; Sagle et al., 2009). With enhanced durability, the membranes can be used in many challenging environments such as high-voltage cathodes, high- or low-temperature separation processes or the treatment of highly concentrated waste solvents, where high electrochemical, thermal, or mechanical stress is applied (Tanaka et al., 2010; Tanaka et al., 2011). Membrane thickness and surface uniformity are controlled by the manufacturing processes, which thus play an important role in enhancing transport, membrane longevity, and versatility of these membranes.

Bulk physical properties of polymer membranes are also important players in designing membranes with selective transport capability. Bulk physical properties are primarily determined by the chemical composition, the chain architecture, and any micro- to meso-structures that are present. Processing plays a significant role, in particular due to its effect on micro- and meso-structures (Kim K. et al., 2023). For example, nanophase separation of subsections of a charged polymer can occur, in particular charged and polar components separate from inert portions of the polymer. The solvent quality in solution-casting-based membrane processing, largely dictates the nanostructure that forms (Lee et al., 2011; Slade et al., 2010). Another example of how processing affects structure is in polymer blend membranes. In partially miscible polymers the phase-separated structure strongly depends on processing conditions that can trap the membrane in out-of-equilibrium states that affect the thermal stability and mechanical properties (Nguyen et al., 2022; Hosseini et al., 2012; Kim K. et al., 2023). Membrane extrusion is another example in which the processing conditions such as the screw design or screw configuration, barrel temperature, flow rate, post-extrusion calendering, and roll-to-roll tension should be carefully controlled and optimized to reduce thickness variation, surface roughness, and avoid film failure and thermal degradation (Giles et al., 2004).

The processing method should be carefully selected, considering the purposes and demands of the membranes as well as the characteristics and properties of the materials. Understanding the functionality of the charged polymers, capabilities and limitations of conventional processing technologies and the requirements from the industry will pave the way for design and development of optimal membrane processing while providing reduced cost and environmental impact. However, research in processing techniques focusing on charged membranes are limited and have not been thoroughly reviewed. The manufacturing processes have only been addressed in subchapters in a few reviews (Kusoglu and Weber, 2017; Xu, 2005; Ran et al., 2017). The reviews on preparation of charged polymer membranes are focused primarily on the synthesis techniques (Depuydt and Van der Bruggen, 2024; Nagarale et al., 2006; Ryoo et al., 2024). In this review, we explore the various processing technologies such as solution casting, paste method, extrusion, electrospinning and phase inversion, involved in the production of charged polymer membranes. The unique aspects, applications, capabilities and limitations of several polymer membrane processing technologies are discussed in detail. We also present an overview of membrane properties and characterization, emphasizing ion transport, permeability, and selectivity. Additionally, we discuss the feasibility of charged polymer membranes in practical applications in energy and sustainability sectors, specifically for recovery of materials from battery and desalination waste.

2 Charged polymer membranes

There is a long history of using charged polymer networks as ion-exchange resins, for example, in ion chromatography. Charged polymers have expanded into membrane formats, that are used in fuel cells, flow batteries and other battery types, surface coatings, and reverse-osmosis desalination. More recently, charged polymer membranes have been identified as playing a crucial role in extracting valuable materials from battery and other mineral wastes. Cationic and anionic membranes, which selectively absorb or block specific charges, enable the separation of various ionic components. Membrane-based methods, such as nanofiltration and electrodialysis (ED), are of interest for extracting valuable minerals, such as bromine, magnesium, and lithium, from concentrated desalination brines (Aghaei et al., 2024; Sharkh et al., 2022). Membranes play an important role in concentrating brines in target ions, e.g., via nanofiltration, but IEMs require further development before electrodialysis and other membrane-based methods are ready for commercialization. These methods could potentially also be used to extract lithium and other valuable elements from battery waste (Hyder et al., 2025; Wamble et al., 2022).

2.1 Types of charged polymer membranes

We define IEMs as non-porous polymer films that contain ionic functional groups. Their ionic conductivity, hydrophilicity, and immobilized charge carriers make them suitable for a wide range of applications. Since the first synthetic ion-exchange resin was reported by Adams and Holmes (1935), extensive research has been conducted on the synthesis methods of IEMs, theoretical explanations of membrane phenomena, and their industrial applications.

IEMs can be classified based on the type of fixed ion-exchange groups: cation-exchange membranes (CEMs), anion-exchange membranes (AEMs), and amphoteric membranes. In addition, advanced processing techniques can be used to form bipolar membranes, charge mosaic membranes, and porous polymer membranes from IEM building blocks. CEMs possess negatively charged functional groups, allowing the selective transport of cations through the membrane. The functional groups in CEMs typically include sulfonate/sulfonic acid (most common), carboxylic acid, phosphonic acid, phosphoric acid ester, and various sulfonamides/sulfonimides (common in polymer electrolytes for batteries). Various backbone chemistries have also been examined, with the most common being crosslinked styrene copolymers, poly(ether ether ketones) (PEEK), polysulfone (PSf)/poly(ether sulfone) (PES), and modified polyethylene (PE). Specific examples of charge-backbone combinations include sulfonated styrene-based derivatives (Safronova et al., 2016; Galizia et al., 2017), carboxylic acid installed on PE, polynorbornene, or PEEK via grafting or side-chain functionalization (Wang et al., 2017; Yang et al., 2024; Choi et al., 2000), phosphonic acid functionalized styrene derivatives (Sata et al., 1996), sulfonic acid functionalized hyperbranched PES (Kakimoto et al., 2010), mono- and di-phosphoric acid ester functionalized styrene derivatives (Selzer and Howery, 1986), perfluorinated polymers with sulfonic and carboxylic acid groups (Kirsh et al., 1990), sulfonamide functionalized acrylic acid-based polymer (Kojima et al., 1995), as well as commercially available membranes, such as Nafion, Aquivion, Fumasep, and Neosepta (Nagarale et al., 2006; Yee et al., 2012). AEMs contain positively charged functional groups, permitting the selective transport of anions. AEMs incorporate functional groups such as primary, secondary, and tertiary amines (Komkova et al., 2004), quaternary ammonium (Pham et al., 2017; Dekel et al., 2017), tertiary sulfonium (Lindenbaum et al., 1958), quaternary phosphonium (Kumari et al., 2021), cobaltocenium (Lin et al., 2023), and other positively charged moieties in aqueous or mixed aqueous-organic solvents, including complexes of alkali metals with crown ethers (Chen et al., 2023; Yang et al., 2021; Ryoo et al., 2024; Shaik et al., 2024). In commercial IEMs, sulfonic acid and carboxylic acid groups are most commonly used as cation-exchange groups, while quaternary ammonium groups are typically used as anion-exchange groups (Shaik et al., 2024; Henkensmeier et al., 2021).

Amphoteric IEMs have both cationic and anionic exchange groups distributed throughout the membrane. Bipolar IEMs consist of a bilayer structure composed of a cation-exchange layer and an anion-exchange layer. Charge mosaic membranes have domains of cationic and anionic exchange groups coexisting in the cross-sectional area of the membrane, often surrounded by insulating materials. Porous membranes are an effective strategy to increase permeability and flux in applications where this is of paramount importance.

2.1.1 Cation-exchange membranes

Adams and Holmes first synthesized a synthetic ion-exchange resin using the condensation polymerization of a formaldehyde-phenol complex (Adams and Holmes, 1935). Sulfonated phenol formaldehyde was chemically unstable due to the decomposition of C–H bonds caused by the formation of hydroperoxide radicals. Nafion is the first commercialized ion-exchange polymer membrane consisting of fluorinated backbone and sulfonic acid functional group (Mauritz and Moore, 2004). Nafion is a branched perfluorosulfonic acid (PFSA) polymer in which sulfonic acid groups are covalently bonded to fluorine-substituted alkyl ether side chains, with a backbone resembling the structure of Teflon. Because the acidic groups are covalently bound to the polymer backbone, there is no risk of the ion-conducting sites being leached from the membrane. Nafion exhibits exceptional ionic conductivity due to the high mobility of protons that are dissociated by water from sulfonate groups located at the end of flexible, saturated side chains. Due to its excellent ionic conductivity, chemical stability, and ion selectivity, PFSAs are widely used in fuel cells, seawater-based NaOH production, and electrodialysis of oxidizing solutions (Banerjee and Curtin, 2004).

Although PFSAs exhibit excellent ionic conductivity, chemical stability, and anion rejection, they face challenges such as high cost and poor selectivity, e.g., methanol and ion crossover are problems in direct methanol fuel cells and flow batteries, respectively (Hallinan and Elabd, 2007; Doan et al., 2015). To address these issues, hydrocarbon-based polymers are being developed as potential alternatives. Polymer membranes with various types of aromatic main chains, that can be sulfonated, have been attempted to improve chemical stability. Polyimide, PSf, and poly(ether ketone) (PEK) are gaining attention for their stability against strong acids and redox agents (Nagarale et al., 2006). Polyimide has excellent thermal stability, but its sensitivity to hydrolysis reaction is a drawback. For PEK and PEEK, a disadvantage is that the ketone group is reduced or forms an unstable benzyl group by active radicals generated from hydrogen peroxide at platinum catalyst (used in fuel cells) (Karimi et al., 2020; Vogel et al., 2010). PES is an amorphous polymer with a diphenyl sulfone, diphenyl ether, and aromatic isopropylene structure, and has flexible chain, excellent thermal and mechanical properties, as well as high resistance to hydrolysis and hydrogenation reactivity (Zhao et al., 2013). The limitation of using PES in fuel cells is its low proton conductivity (Shah et al., 2024).

2.1.2 Anion-exchange membranes

The most common use of AEMs is in fuel cells and water electrolysis, but unlike CEMs, far fewer have been commercialized largely due to challenges associated with the instability of cationic functional groups. Strongly basic environments occur in AEM fuel cells, that require exceptional chemical stability offered by fluorination, but fully fluorinated AEMs have not yet been commercialized due to synthetic challenges (Gottesfeld et al., 2018). Most of the fluorinated AEMs reported so far are hydrocarbon-based polymers in which fluorine is partially substituted. An example of a fully fluorinated AEM is a polymer built from decafluorobiphenyl and 4,4'-(hexafluoroisopropylene) diphenol, which showed high ionic conductivity and excellent mechanical strength and chemical stability (Gao et al., 2020).

Quaternary ammonium is commonly used as the cationic group in AEMs. Operational lifetime is limited primarily by degradation of quaternary ammonium. The quaternary ammonium ions are prone to degradation under alkaline conditions by competing mechanisms of Hofmann elimination (E2) and bimolecular nucleophilic substitution (SN2) (Bauer et al., 1990). E2 is dominant when the sidechain has two or more carbons between the polymer backbone and the quaternary ammonium. Transformation of the quaternary ammonium group to tertiary amine through ylide intermediates is another degradation mechanism of cationic polymers (Espiritu et al., 2018). Heterogeneous membranes of alkyl/aryl blends or copolymers can provide steric hindrance to reduce the exposure of the quaternized ammonium to hydroxide ions (OH−) (Bauer et al., 1990). Marino et al. showed that the chain length and ring architecture of side chains play an important role to prevent the attack of hydroxide ions (Marino and Kreuer, 2015). Ether-free polymers can enhance the alkaline stability due to the absence of ether groups that are weak to hydrolysis and chain scission (Hu et al., 2025; Sankar et al., 2023). The alkaline stability was found to be highly dependent on the chemical nature of the R groups in the quaternary ammonium cations due to their effect on degradation mechanisms (Ye et al., 2013; Arges et al., 2012).

Since the improvement of alkaline stability typically includes significant modifications of material design, selecting an appropriate processing method for an AEM may rely on the specific mitigation strategy employed. The properties of reinforced AEMs with ether-free architecture, alkyl-aryl spacing or stable cation groups can largely impact the processability of the membranes. For example, ether-free polymers and polyarylene-containing membranes typically have higher modulus but lower flexibility and solubility in polar solvents. These materials can require higher processing temperatures for melt processing and can have limited solvent selection for solution casting. The miscibility of polymer blends and the thermal properties of the materials with different cation groups should also be considered when selecting the processing methods for AEMs.

Hydrocarbon-based AEMs can be categorized into two main groups: ether-containing and ether-free polymers (Shaik et al., 2024). Ether-containing AEMs include poly(arylene ether ketone) bearing cyclic ammonium or imidazolium groups, poly(2,6-dimethyl-1,4-phenylene oxide) with aliphatic cationic side chains, and quaternary ammonium-functionalized PSf. These ether-containing AEMs suffer from high production cost and poor long-term durability due to degradation of both the ether groups in the polymer backbone and the cationic groups (Parrondo et al., 2014; Ryoo et al., 2024).

Ether-free AEMs are generally divided into polyethylene-based and polyarylene-based AEMs. Polyethylene-based AEMs are composed of C–C bonds in backbones with high number-average molecular weights. Zhang et al. synthesized polyethylene-based AEMs functionalized with ammonium chloride groups, with or without crosslinking (Zhang et al., 2011). The crosslinked membranes exhibited excellent tensile modulus (273 MPa) and strength (20 MPa) and high ionic conductivities in HCl and CuCl2 solutions at room temperature.

Polyarylene-based AEMs are ether-free membranes with aromatic ring backbones. A high-performing polyarylene-based AEM example was developed by Soni et al., based on poly(fluorene-alt-tetrafluorophenylene) functionalized with aromatic trimethylammonium groups. It exhibited a high performance for alkaline water electrolysis, high OH− conductivity, and excellent durability (Soni et al., 2020). Chen et al. reported the development of a poly(fluorenyl-co-aryl piperidinium) (PFAP)-based anhydrous anodic AEM water electrolyzer. The system achieved a high current density of 7.68 A/cm2 at 2.0 V and 80 °C, with excellent water diffusivity (9.38 × 10−8 cm2/s) and ionic conductivity (160 mS/cm at 80 °C). It also demonstrated outstanding durability, maintaining a stable voltage of 0.5 V for 1,000 h at 60 °C under a current density of 0.5 A/cm2 (Chen et al., 2021).

In a rare study of separation with AEMs, Bryjak et al. examined Boron separation (Bryjak et al., 2007). Boron permeation through an AEM was driven by the Donnan potential between a concentrated feed slurry containing a Boron-selective resin and a dilute receiving solution. This Donnan dialysis was able to regenerate the Boron selective resin and demonstrates that AEMs may also hold potential for mineral harvesting via membrane separation.

2.1.3 Amphoteric polymers

Amphoteric polymers are another class of IEMs that are functionalized with both positively and negatively charged groups. Amphoteric polymers contain a uniform distribution of cationic and anionic functional groups, which distinguishes them from charge mosaic membranes, in which cationic and anionic functionalities are relegated to separate nanostructured regions. Amphoteric IEMs have been used as separators in Vanadium redox flow batteries (Liu et al., 2021). Amphoteric IEMs have been synthesized by modifying commercial AEMs with cation-exchange polymer, either via surface modification or by incorporation into crosslinking moieties, and evaluated in permselective electrodialysis (Liao et al., 2019). Zwitterionic IEMs (ZwIEMs) are a specific subset of amphoteric IEMs. A zwitterionic functional group contains both a cation and an anion. Thus, the cationic and anionic functionalities are collocated in ZwIEMs. Zwitterions are widely used to modify the surface of membranes by treating the surface of the base membrane with grafting or dip coating a substance with a zwitterionic functional group such as phosphobetaine, carboxylbetaine, and sulfobetaine in which quaternary ammonium and acid are bound to the polymer. The pH at which the surface charge of ZwIEM becomes zero is called the isoelectric point, where both positive and negative ionic species are prevented from binding to the surface. The surface modification prevents membrane fouling and improves performance (Schlenoff, 2014). It can also be applied to ion-exchange resins (Ghoussoub et al., 2018).

2.1.4 Bipolar membranes

Bipolar membranes are IEMs that integrate cation-exchange layers and anion-exchange layers in a single structure. These membranes have various structures depending on their applications. The cation-exchange layer can pass hydrogen ions and the anion-exchange layer can pass hydroxyl ions. To produce acids and bases from aqueous salt solutions, electrodialysis can be used to decompose water at the contact surface of the bipolar membrane. In adjacent liquid chambers, the H+ and OH− from water decomposition combine with anions and cations from salt forming acids and bases, respectively (Kovalev et al., 2022; Mazrou et al., 1998). In the energy conversion process, the neutralization of protons and hydroxide ions at the bipolar membrane interface induces a potential difference generating electrical energy and assisting in fuel cell hydration (Daud et al., 2022). While bipolar membrane fuel cells are a new research area, their use in electrodialysis-based systems is more developed.

Bipolar membranes are fabricated by hot pressing a CEM and an AEM together with catalyst and polymer binder in between (Kovalev et al., 2022). Bipolar structure can also be formed by casting an anion-exchange solution on top of a CEM (or vice versa) after applying a catalyst, followed by drying. Grafting methods can be employed, in which ion-exchange groups are grafted onto the surface of a prepared membrane.

2.1.5 Porous IEMs

In general, IEMs possess nanoscale ion channels but no pores for fluid flow. Therefore, compared to porous membranes, IEMs have low water transmittance and high energy consumption. Porous IEMs are being investigated for ion-exchange processes where enhanced permeation rates are desired and high ionic selectivity is not a critical requirement. Kim et al. applied a porous IEM to a microbial fuel cell (MFC) (Kim et al., 2014). A porous membrane was fabricated via one-step phase inversion method using poly(vinylidene fluoride) (PVDF). The pores were activated through grafting reaction using benzoyl peroxide as an oxidizing agent and then sulfonated. The resulting membrane exhibited an average pore size of approximately 10 nm, and the proton transference number was 0.97. The membrane demonstrated excellent long-term performance in MFC operation.

There are a variety of approaches to synthesizing porous IEMs. One method involves ionic functionalization of polymers of intrinsic microporosity (PIMs) (Li et al., 2025). PIMs contain a significant amount of free volume due to steric constraints in their chemical design that endow them with three-dimensional porous structures and increased specific surface area. These features can be leveraged to facilitate gas release or absorption at the surface of electrodes or capacitors. The application of PIMs has expanded from early use in gas separation to batteries, fuel cells and flow batteries, driven by advances in the precise control of pore architecture and the incorporation of ion-conducting functionality.

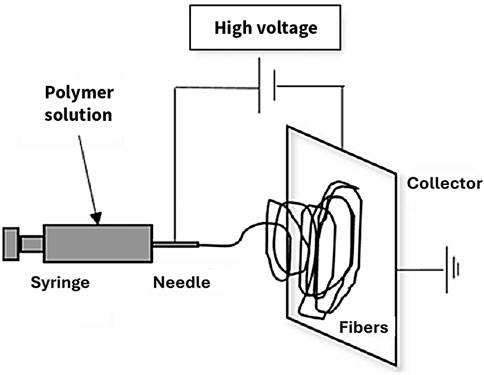

More conventional methods of forming porous polymer membranes include 1) attaching ion-exchange groups to a porous support membrane, 2) electrospinning ion-exchange polymers, or 3) mixing ion-exchange polymer solution with a non-solvent to induce phase separation (non-solvent induced phase separation, NIPS). The porous support membrane requires sufficient pore size and porosity to allow infiltration of the ion-exchange polymer, and compatibility of the porous matrix and the ion-exchange polymer to prevent graft detachment or leaching of the functional groups during operation. In electrospinning, parameters such as nozzle size, solution concentration, and spinning speed determine the fiber diameter, pore size, and porosity. For NIPS, pore size and porosity can be controlled by the miscibility and concentration of the non-solvent (Bridge et al., 2022b). Both electrospinning and NIPS are discussed in detail in Section 4 Processing Techniques.

2.2 Synthesis of charged membranes

The synthesis methods of charged polymers have been extensively studied and reviewed (Nagarale et al., 2006; Depuydt and Van der Bruggen, 2024; Ryoo et al., 2024). Therefore, we will only briefly mention a few of the most important synthetic approaches. These include: 1) polymerization of charged monomers (Adams and Holmes, 1935; Vijayakrishna et al., 2008; Wiley and Reed, 1956), 2) functionalization of neutral polymers using, for example, amination or sulfonation (Alexandrova and Iordanov, 1995; Alexandrova and Iordanov, 2001; Yee et al., 2013; Gohil et al., 2006), and 3) grafting substrate polymer membranes with ionic groups (El-Rehim et al., 2000; Kim et al., 2014; Mokrini and Huneault, 2006).

The presence of ionic functionality makes the polymer hydrophilic, the degree of hydrophilicity increasing with charge density. Most applications of IEMs are in aqueous environment, which requires consideration of water uptake (to be discussed in detail below). Swelling due to water uptake can adversely affect membrane mechanical strength, which is problematic in purification or separation processes (Kamcev and Freeman, 2016). Swelling can be controlled via copolymerization and/or crosslinking (Nagarale et al., 2006). Preparation of crosslinked charged polymer membranes includes two main methods: one involves crosslinking ionized polymers directly (Brijmohan et al., 2005), while the other introduces functional groups into a crosslinked polymer substrate (Shahi et al., 2000). Composite or blend membranes can also be formed by mechanically mixing charged species with non-charged matrix to compensate the weakened mechanical properties of charged polymers in aqueous environments, see Section 4.2 Paste Method (Kim S. et al., 2023; Bulejko and Stránská, 2018).

Due to the plethora of routes for synthesizing charged polymers, one must first consider the thermal, physical, and chemical characteristics of the membrane that are required for the application of interest. For example, the ion-exchange functional group(s) should have chemical stability in the operating conditions of interest, such as under strong acid or strong base conditions. Moreover, the choice of polymer repeat unit(s) will impact the maximum achievable IEC, which is inversely proportional to monomer molecular weight. For example, the IEC of fully sulfonated polystyrene (sPS) is 5.43 meq/g, whereas the bulkier repeat unit of sulfonated PEEK (sPEEK) is 2.72 meq/g. Of course, addition of neutral comonomers and/or crosslinking agents will further reduce the maximum achievable IEC, but are often necessary to prevent dissolution/swelling of the membrane as discussed above. Only after considering what is the appropriate chemistry to achieve thermal, mechanical, and chemical stability, can the best synthetic method be selected.

For the purposes of this review, we focus on the subsequent selection of the processing method (Section 4) that best complements the selected polymer chemistry to arrive at optimal performance properties. Important considerations in this regard include the effect of polymer chemistry on 1) its solvent solubility, 2) its softening temperature, and 3) its ability to flow. For example, ionization of a hydrophobic polymer dramatically affects its solubility, often requiring a transition from a hydrocarbon solvent to a polar solvent such as water. This positively impacts considerations such as volatile organic content. It also is likely to require the use of a solvent with lower volatility that will slow evaporation and thus membrane formation rate in solution-based processing. These tradeoffs should be considered when deciding whether to ionize before or after membrane formation. Another consideration is the molecular weight of the polymer, which strongly affects solution viscosity and thus how the solution spreads. Polymer chemistry design and membrane process engineering are coupled to the extent that they constrain each other. For example, approaches to control swelling, such as crosslinking, will also prevent flow, requiring that the membrane be formed prior to crosslinking.

2.3 Ion channels

Compared to neutral polymers, charged polymers exhibit significant dependence of physical properties on water content, which is strongly influenced by the nature and density of their ionic functional groups. The incorporation of charged groups imparts hydrophilicity to the polymer increasing both ionic conductivity and water solubility. By regulating the composition of hydrophobic and hydrophilic moieties, nanostructures can be achieved which consists of two distinct domains: a hydrophobic polymer backbone (or segment) and a hydrophilic phase with ionized functional groups. The hydrophobic components prevent dissolution in aqueous media and provide required membrane mechanical stability. Water molecules associate with the ionized groups to form hydrated ion clusters, which are segregated from the hydrophobic phase. These hydrated clusters are interconnected forming nanochannels which serve as continuous pathways for ion and water transport (Li et al., 2025).

The ion permeation and selectivity significantly depend on the dimensional factors of the ion channels: channel diameter (dc) and Debye length (λD). Debye length represents the effective thickness of electric double layers (EDL) developed in the vicinity of channel walls due to the attraction of counter-ions by the charged groups. When the channel diameter is smaller than the Debye length (dc < λD), the counter-ion transport is promoted while the co-ion is rejected, resulting in increased selectivity. For dilute solutions in a homogeneous dielectric medium, the Debye length is determined by many factors such as dielectric constant of the solution (

where

Nafion exhibits an interesting nanostructured, percolated network, that can explain its high ionic conductivity with low water uptake, which is contrary to the general trend of ionic conductivity as a function of water content, as many other especially hydrocarbon IEMs exhibit. The high ionic conductivity of Nafion is explained by its well-organized cluster-channel network (Gierke and Hsu, 1982). Hsu and Gierke theoretically described the relationship between ionic cluster formation and ion transport phenomena in PFSA membranes through which estimation of cluster diameters was enabled based on key parameters such as water uptake, equivalent weight, and cation type (Hsu and Gierke, 1983). According to their percolation model, Nafion exhibited sharply increased conductivity over a critical hydration threshold. Interestingly, carboxylated fluorinated polymers showed higher Na+ and Cs+ diffusion coefficients but lower water uptake than Nafion, due to more sharply defined ion channels (Yeager et al., 1982).

3 Membrane properties and characterization

As mentioned in the introduction, numerous material properties affect membrane characteristics. Here, we focus on membrane properties that determine suitability for salt and ion separation methods. Membrane charge density is a paramount consideration that is quantified by IEC. IEC largely dictates not only how well a membrane excludes co-ions, but also how much water it takes up. IEC is important because membranes used in water treatment processes, such as electrodialysis, must have a high selectivity in which cations or anions pass while co-ions are excluded (Werber et al., 2016a). The charged and hydrophilic nature of IEMs can lead to considerable swelling when they are exposed to aqueous environment. Swelling affects the membrane structure, which plays a significant role in transport properties (ionic conductivity and permeability) and can weaken the membrane. It is important for a membrane to prevent mixing of the retentate and permeate streams in a separation process in which high flow rates and/or pressure gradients are often present. Thus, their mechanical integrity, even in the hydrated state, must be maintained, which requires that degree of swelling and mechanical properties are considered when designing them. Finally, thermal properties of the membrane are important for maintaining functionality at the operating temperature of the separation process. In this section, the properties that are required for water treatment and ion separation are discussed, as well as how the properties are characterized.

3.1 Ion-exchange capacity

Ion-exchange capacity is the millimoles of charge fixed to the membrane (often termed milliequivalents) per gram of dry membrane (meq/gdry). There are several ways to determine the IEC of an IEM. These include direct measurement of atomic composition, nuclear magnetic resonance spectroscopy (NMR), and ion-exchange followed by titration, which is the most common approach (Leo et al., 2024). For the titration approach in a CEM, the counter-ions associated with the polymer are exchanged with counter-ions from a salt or acid solution. If the membrane is in acid form salt should be used and if the membrane is in ionic form acid should be used so that the amount of protons released into or consumed from the solution can be measured with a pH-based titration. Similarly, the IEC of an AEM can be measured by exchanging the anions associated with cationic functional groups with counter-ions in a salt or alkaline solution and then titrating the final solution to determine change in OH−. AEM should not be used with strong base due to the low chemical stability of their functional groups under high-pH conditions. In addition, when titrating in air, carbonic acid that forms from dissolution of CO2 in water will partially neutralize the basic solution, causing error in the titration.

A more accurate IEC can be measured using NMR. The molar fraction of the ionized group can be calculated by comparing the peak areas of ionized and non-ionized groups (Equation 2). Dividing the fraction by the weighted sum of molecular weights of ionized and neutral functional groups yields the IEC,

where

3.2 Water content

The water content (WC) is an important parameter that affects the permselectivity and mechanical properties of IEMs. The WC of an IEM is measured gravimetrically as the ratio of water mass in the hydrated membrane (

It is important to measure water content under the conditions in which the membrane will be used, because it is a function of the composition of the external solution. For this reason, it is common not only to measure WC when equilibrated with pure deionized water, but also in equilibrium with aqueous solutions, 1 mol/L salt in water being a commonly used condition. An osmotic pressure difference exists between the external solution and the membrane, and it is this that drives water sorption into the membrane, resisted primarily by the entropic penalty associated with stretching of the polymer chains that comprise the membrane (Flory, 1953). The moles of solutes in the external solution reduce the osmotic pressure, which is why WC should be measured under appropriate conditions. It is best practice to measure not only gravimetric but also volumetric sorption, as the swollen volume (or equivalently density) is needed to calculate molar concentration of fixed charges and of co-ions. Co-ion concentration in the membrane can play a major role in carrying ionic current and in permselectivity, discussed below. Co-ion concentration is most easily quantified with desorption measurements. After the equilibration in an aqueous solution and drying required for measuring WC, the membrane is placed in a known amount of pure water to draw sorbed co-ions (and their associated counter-ions that ensure electroneutrality) out of the membrane. The moles of desorbed co-ions is then measured to determine what had been the co-ion concentration in the membrane. The gold standard for this measurement is ion chromatography.

3.3 Structure

In the dry state, IEMs are dense materials that lack pores and ion channels. Nanometer-scale ion channels develop when IEMs are hydrated, and these channels enable the transport of ions. Ion channels are interconnected network structures with non-uniform diameter, typically of ∼1–5 nm, containing water molecules, ions and other hydrophilic components of the polymer (Wang et al., 2021; Li et al., 2025). Ion channels act as electrolytes that absorb solutions and transfer ions along connected charged functional groups. Permeability and selectivity of the membranes are governed by structural factors such as the volume fraction of nanochannels that affect their connectivity and tortuosity. When charge density increases, the water volume fraction increases resulting in higher permeability of both water and ions. However, higher water volume fractions cause selectivity to decrease due to reduced membrane potential, and the physical integrity of the membrane can be compromised by extreme amounts of swelling. When a crosslinked IEM is formed, swelling due to water uptake is suppressed and the mechanical properties are reinforced, but permeability and flexibility decrease. Increased volume fraction of hydrophobic blocks in a block copolymer has a similar effect to increased crosslinking. Thus, the permeability, selectivity, and mechanical properties of IEMs can be balanced by controlling the degree of crosslinking or volume fraction of the hydrophobic phase.

The hierarchical structure of nanophase-separated IEMs can be characterized by transmission electron microscopy (TEM), atomic force microscopy (AFM), wide-angle x-ray scattering (WAXS), small-angle x-ray scattering (SAXS), and small-angle neutron scattering (SANS) (Gao et al., 2020; Baird et al., 2025; Hensley and Way, 2007; Chan et al., 2020; Gebel and Diat, 2005). TEM is a powerful tool to directly visualize the size, shape and distribution of ion clusters through the membranes, but has limitations of ultrathin sample size (<100 nm) and weak contrast due to the low atomic numbers of elements in the polymers (Xue et al., 1989). Surface images of the membranes can be achieved by AFM as well as the surface roughness. Additionally, areas with different properties can be differentiated by using tapping mode AFM (James et al., 2000). WAXS is used to study the crystal structure of the polymer within nanostructured domains, while SAXS is used to study domain size of the nanophase-separated structure itself (Jokela et al., 2002). SANS is particularly powerful for characterizing hierarchical structures because contrast matching can be used to selectively examine parts of the structure using well-designed deuteration of the polymer and/or water (Fanova et al., 2024). It has been used to identify various correlation lengths present in dry and hydrated states of AEMs and CEMs (Chan et al., 2020). An emerging technique that has similar capability to SANS, regarding selectively controlling scattering contrast, is resonant soft x-ray scattering in which the x-ray energy is tuned to specifically interact with certain elements in the IEM (Su et al., 2020; Zhong et al., 2021).

3.4 Ionic conductivity

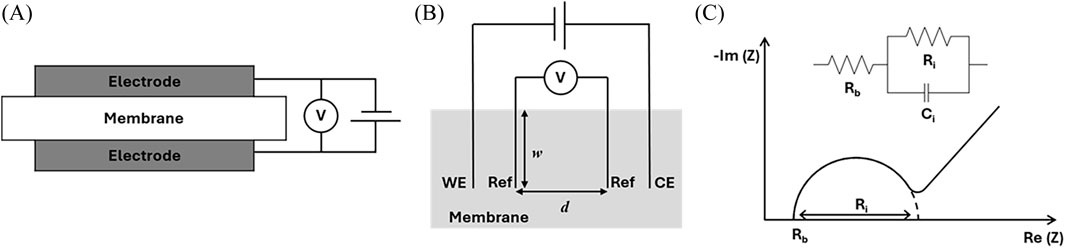

In water treatment processes such as electrodialysis, an electric field is used as a driving force to induce migration of ions through IEMs. Low resistance of the IEM facilitates rapid permeation of ions. The resistance of an IEM is determined by Ohm’s law and can be used to calculate ionic conductivity. The resistance of the membrane depends on the type and amount of ions present (i.e., IEC plus free ions absorbed from solution), as well as the water content and membrane structure. Ionic conductivity can be measured using electrochemical impedance spectroscopy (EIS) where an alternating potential/voltage is applied, generally in the frequency range of 1 MHz–1 mHz, using a potentiostat. An example equivalent circuit for the ionic conductivity measurement of an IEM is shown in the inset of Figure 1C. Here,

where

Figure 1. Schematics of setups for electrochemical impedance spectroscopy (EIS) of IEMs to measure ionic conductivity: (A) two-electrode format in which the current is carried by and voltage is measured between the same two electrodes and (B) four-electrode format with alternating current applied between the working electrode (WE) and the counter electrode (CE) and alternating voltage measured between the two reference (Ref) electrodes. Due to the alternating nature of the measurement, it is also possible to conduct EIS by applying voltage and measuring current, in either format. (C) Schematic of a Nyquist plot representation of the complex impedance from an EIS measurement that extends from high frequency on the left-hand side of the figure to a low-frequency diffusive tail on the right-hand side of the figure. An equivalent circuit is shown in the inset for the high-frequency data that includes a resistor representing bulk membrane resistance (

In membrane separation processes, the transport of ions takes place in a direction perpendicular to the surface of the membrane, and the conductivity in the thickness direction affects the actual process. Two-electrode setups, such as that shown in Figure 1A, are used for through-plane ionic conductivity measurements. The membrane is placed between two electrodes. The membrane thickness is

If the electrochemical properties of the IEM are isotropic, the in-plane ionic conductivity can be measured using the four-electrode method. Four electrodes are arranged in parallel on the membrane surface. The two electrodes on the outsides that apply alternating current are the working electrode (WE) and counter electrode (CE), and two electrodes in the middle are reference (Ref) electrodes where the voltage is measured.

To ensure reproducibility, several things should be considered. First, the electrodes should either be blocking electrodes or allow only reversible reactions to occur. The best practice is to use platinum electrodes. Reproducible clamping pressure should be used to guarantee intimate contact between the IEM and the electrodes. To further ensure accuracy, it is a good idea to repeat measurements with various thicknesses, thus allowing the bulk membrane resistance to be separated from the interfacial resistance between the electrodes and sample that remains when extrapolating to zero thickness. This is particularly important in highly conductive IEMs. Due to the strong dependence of IEM conductivity on water content, it is extremely important to control the degree of hydration during EIS measurements. Drying of fully hydrated samples should be avoided during measurement, and other levels of hydration can be maintained by using humidity control implemented in conjunction with the EIS set-up. Stray electromagnetic fields can impact EIS measurements and can be prevented by shielding all wires. This is standard with many commercially available EIS instrumentations, often using coaxial cables for this purpose. For custom experiments, it is usually sufficient to utilize twisted pairs, whereby working and counter reference leads are twisted around each other. For highly sensitive measurements, it is necessary not only to shield the electrical leads, but also the sample cell. This is readily achieved using a Faraday cage, which is a grounded conductive housing. Finally, when reporting results it is essential that the measurement method (two-electrode or four-electrode) be specified and the dimensions reported so that both conductivity [

3.5 Permeability and selectivity

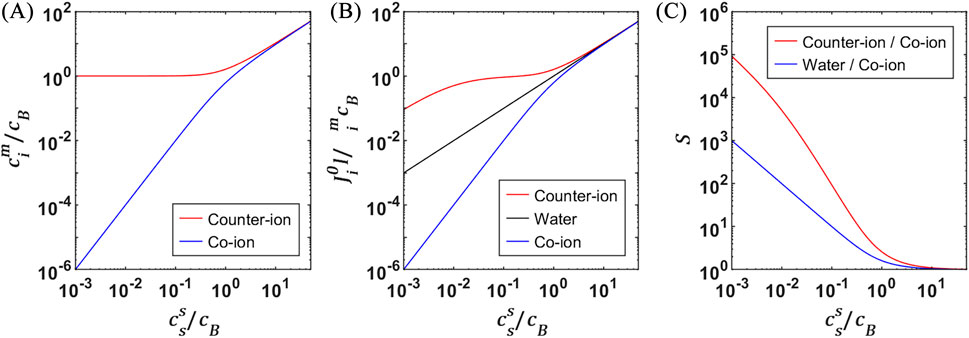

In an IEM, selective permeation of counter-ions and exclusion of co-ions arise from the electrostatic interactions between mobile ions and fixed charged groups, a phenomenon known as Donnan exclusion. Assuming an ideal monovalent binary electrolyte, Donnan equilibrium relates concentration in the membrane to that in the external electrolyte as follows:

where

Figure 2. (A) Dimensionless counter- and co-ion concentrations in an IEM calculated using Donnan equilibrium for the ideal case of an IEM with monovalent counter-ions that are the same as the counter-ions in the external, binary, monovalent electrolyte. Ion concentrations in the membrane (

Transport of water molecules and ions through IEMs is driven by osmotic pressure in forward osmosis (FO), applied hydraulic pressure in reverse osmosis (RO) or applied electric field in ED which induces an electrochemical potential gradient. In particular, transport of neutral species such as water molecules and neutral ion pairs (e.g., salt) can be driven by osmotic pressure or concentration gradient as well as hydraulic pressure for volatile species. All of these gradients induce a chemical potential gradient across the membrane. Transport of charged species (i.e., ions) can be driven by these gradients as well as electric potential gradient. All species can be rejected by structural factors such as pore size, but only ions are excluded by the fixed charge in the membrane. The overall flux of a species through the membrane,

where

The solution-diffusion theory describes mass transport of a species through nonporous membranes as a process involving absorption from solution to membrane, diffusion in the membrane and desorption from the membrane to external solution. This can be expressed more simply than Equation 6 for the diffusion of neutral species in a membrane, neglecting convection and assuming ideality, using Fick’s first law,

Helfferich derived an expression (see Equations 7, 8 in his book) that he termed “self-diffusion flux.” It considers resistance to diffusion both in the membrane and in the solution boundary layer immediately adjacent to the membrane by considering equilibrium between phases. The expression comes from integrating across the regions assuming a linear concentration gradient (that is expected at steady state). A parametric representation of this self-diffusion flux in dimensionless form is shown Figure 2B, for a boundary layer velocity 200 times that in the membrane (i.e., boundary layer resistance affects only counter-ions at low concentration). This parametric representation emphasizes how IEM fixed charge content affects the flux of various components. Counter-ion flux far exceeds co-ion flux in ED. Water flux considerably exceeds salt flux, which is limited by co-ion transport, in RO and FO. These can be better visualized using selectivity (Figure 2C), which is simply the ratio of desired component (counter-ion or water) over undesired component (co-ion). From the perspective of selectivity, clearly it is desirable to maximize the IEC of IEMs, which is a challenge due to the diluting effect of increased water uptake with increasing IEC.

It is possible to explicitly express the steady-state water flux in terms of applied pressure difference (

The Equation 8 is most commonly used to quantify phase equilibrium. The permeability coefficient of species

This convention means that permeability coefficient has the same units as diffusion coefficient (e.g.,

which modifies the units of permeability as well as the definition of the partition coefficient (and its units) (Helfferich, 1995; Xie et al., 2010; Sagle et al., 2009) The condensed phase convention will be used throughout this review.

Permeation can be evaluated using two-chamber cells, an example of which is shown in Figure 3. For a typical experiment, one side is filled with a concentrated solution (Chamber 1, donor cell) and either pure water or a dilute solution is placed on the other side (Chamber 2, receptor cell). The two chambers are separated by the IEM whose permeabilities are in question. An approach to quantify water flux is to measure volume via the relative meniscus position in the capillary shown in inset 1 of Figure 3. This water flux can be due to an applied pressure or the osmotic pressure difference between the two solutions. In either case, water flux,

where

Figure 3. Apparatus for permeation measurement. A concentration, electric field, or pressure gradient is applied across the membrane. The feed/retentate side (Chamber I in this schematic) is at higher electrochemical potential for the transporting species, and the permeate side (Chamber II) is at lower electrochemical potential, which drives permeation across the membrane (from Chamber I to Chamber II). For the case of a concentration gradient, Chamber I is filled with a concentrated solution and Chamber II is filled with a dilute solution. Various detection strategies can be employed to measure change in variables such as volume, concentration, or conductivity using 1) graduated capillaries for volume change, 2) a detector in-line with a circulating closed loop to/from Chamber II, or 3) an in-situ detector. Examples of in-line and in-situ detectors include spectroscopy, conductivity and pressure measurement.

Salt flux due to a concentration gradient can also be described as in Equation 12 by Fick’s first law,

The third and fourth expressions assume a linear concentration gradient, which is a good assumption during steady-state permeation. The final equality assumes that the partition coefficient is constant, i.e., not a function of concentration. Ion permeability can also be determined using a two-chamber permeation setup. As salt diffuses through the membrane from donor to receptor cell, the diffused salt gradually increases the conductivity of the receptor cell. Conductivity is recorded over time, e.g., via inset 2) or 3) in Figure 3, and used to calculate the salt concentration using a calibration curve. The salt permeability

where

In order to handle multicomponent transport in nonideal charged electrolytes, including membranes, it is necessary to use a system of equations similar to the Stefan-Maxwell framework that was first developed by Onsager, but rather than considering gradients of chemical potential, it is necessary to consider electrochemical potential. Mass balance, current flow, and electroneutrality equations are needed to solve the coupled set of flux equations. The reader is referred to Newman’s book for a detailed description of this system and to Geise, Paul, and Freeman’s article for application specifically to membranes (Newman and Thomas-Alyea, 2004; Geise et al., 2014b).

Selectivity is generally defined as the ratio of flux of a desired species to that of an undesired species. The selectivity of an IEM is often quantified by its ability to preferentially exclude co-ions while facilitating the transport of counter-ions, but it could also apply to the ability to differentiate two different types of counter-ions or even the transport of neutral species such as water and methanol. Precisely engineered IEMs discussed below demonstrate selectivity not only between counter-ions and co-ions but also among counter-ions with differing valences. This selectivity is critical for the efficiency and performance of various electrochemical and separation processes, including redox flow batteries, desalination, and electrodialysis. Selectivity for different polar, neutral molecules or for different ions of the same valence remains a challenge in IEM design.

Permselectivity,

where

where

3.6 Thermal and mechanical properties

The thermal properties of IEMs are important not only for high-temperature applications such as fuel cells, but also for setting temperature conditions during membrane fabrication and assessing thermal degradation (Bébin and Galiano, 2006a; Bébin and Galiano, 2006b; Yao and Wilkie, 1999). Thermogravimetric analysis (TGA) is used to measure water content, assess chemical decomposition, and evaluate thermal stability. In polymer-based IEMs, weight loss is observed as temperature increases due to the evaporation of water, decomposition of ion-exchange functional groups, degradation of the polymer backbone, and combustion of the polymer.

Glass transition temperature (Tg) and melting temperature (Tm) are two other important thermal properties. Below Tg, the membrane is glassy and permeating species move through the free volume. Glassy materials tend to have a high modulus and fail in a brittle fashion. Above Tg, the membrane is rubbery and transport is coupled with segmental dynamics if the membrane is not highly swollen (Geise et al., 2014b). Segmental dynamics correlate with how far the operating temperature is above Tg. Rubbery materials tend to have a low modulus and exhibit toughness due to failing at large strains. In either case (glassy or rubbery), reinforcement is often required and can be achieved by various means that include porous support, combination of glassy and rubbery microdomains, crosslinking, or crystallinity. Semicrystalline polymers tend to have desirable mechanical properties due to the inclusion of rigid crystallites in a flexible amorphous matrix. Crystallinity is lost at Tm. This may or may not be desirable, for although crystals yield a mechanical benefit, they also block the transport of permeants. Differential scanning calorimetry (DSC) is used to analyze the crystallinity, Tm and Tg of polymers. Exo- and endothermic heat flow are measured as a function of temperature while heating or cooling the specimen at a constant rate. The heat flow is recorded relative to an inert reference under identical conditions.

The mechanical performance of IEMs can be significantly affected by the nature and concentration of solvents and salts, as they are typically operated in electrolyte-saturated environments. Ion-exchange and separation processes require the membrane to maintain sufficient mechanical robustness to withstand physical and chemical stress during operation. Since most IEMs swell upon water absorption, resulting in reduced mechanical strength, they are commonly supported with a reinforcing substrate or backing layer to enhance durability and dimensional stability. To fabricate free-standing membranes, crosslinked polymers, block copolymers, or polymer blends (Hosseini et al., 2012) are employed as mentioned earlier. The mechanical properties of polymers are characterized by tensile and puncture strength using a universal testing machine (UTM) or by rheological analysis using dynamic mechanical analysis (DMA).

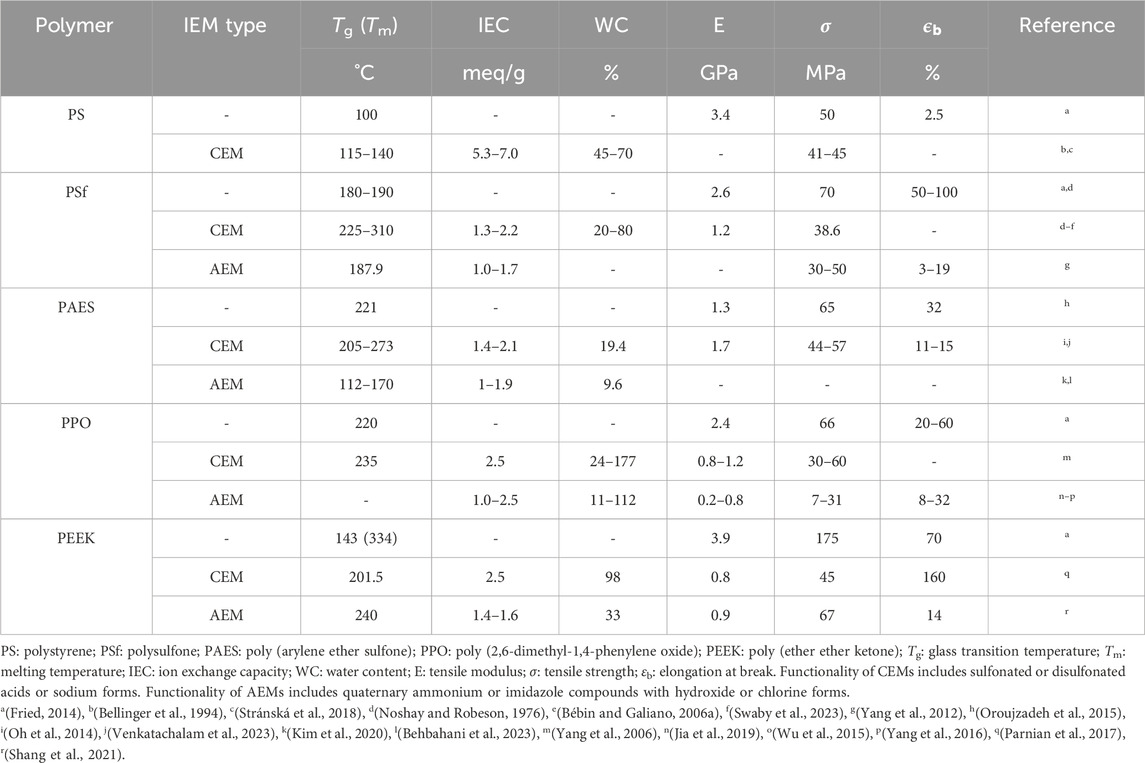

Table 1 represents the thermal, physical and mechanical properties of charged polymers for IEMs. The properties of neutral polymers were included for comparison. Quaternization of amorphous polymer backbones decreases Tg (or Tm) due to bulky and flexible side chains while sulfonation increases Tg due to the rigid aromatic rings in the functional groups and strong molecular interaction. Quaternized PEEK shows increased Tg compared to neutral material, but it is lower than Tm of PEEK and this behavior is due to the chain flexibility and crystallinity of PEEK. The thermal, physical and mechanical properties of IEMs vary greatly depending on the type of functional groups and counterions. For example, sulfonated PSf with sodium form exhibited notably higher Tg (310 °C) compared to its acid form (225 °C). Due to the hydrophilicity of IEMs, hydration also largely impacts on the thermal properties and, consequently, the processability. The influences of thermal properties and hydration on the membrane preparation are further discussed in Section 4.

Charged polymers showed lower tensile modulus and tensile strength than neutral polymers. The change of thermal and mechanical properties must be considered when designing manufacturing procedure. For example, for melt processing, film fabrication with neutral polymer followed by functionalization seems to be preferable because of lower Tg and higher mechanical strength to avoid thermal decomposition of the functional groups or film failure during the manufacturing.

4 Processing techniques

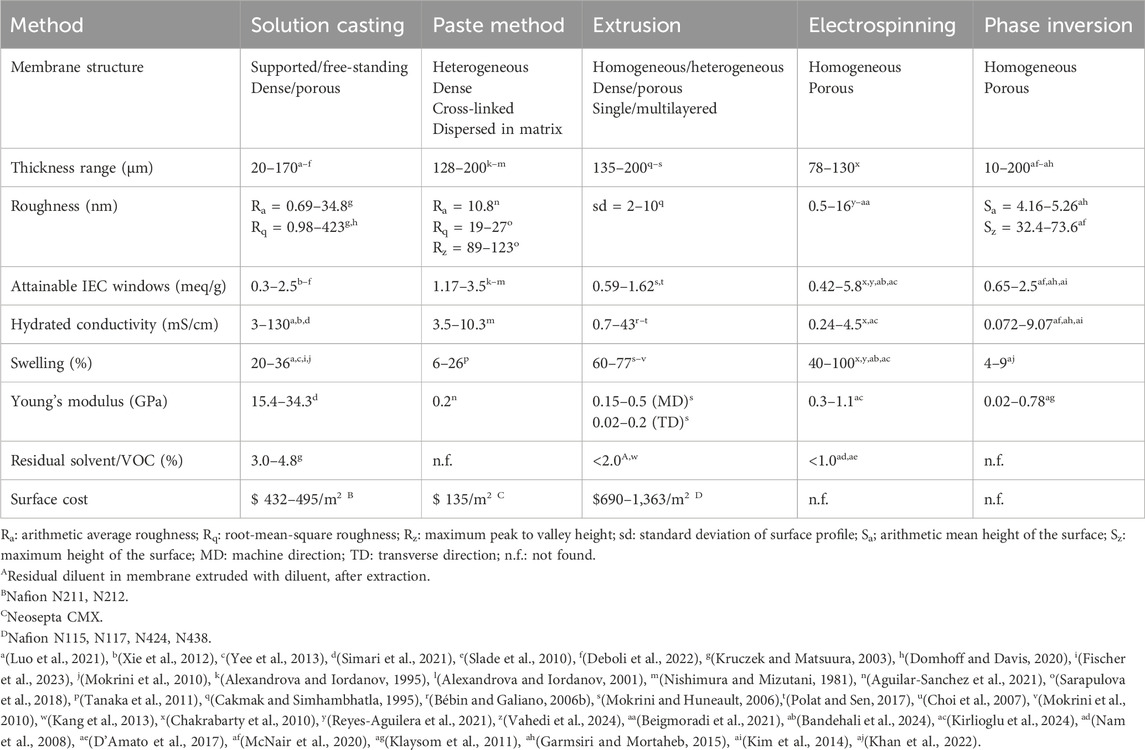

Conventional and emerging membrane processing techniques are introduced. The comparison of IEMs prepared with different processing methos is given in Table 2.

4.1 Solution casting

Solution casting is a method to form membranes by evaporating solvent from a polymer solution that is spread on a substrate. This method can be used for either charged or neutral polymers. In the latter case, neutral polymer is ionized by chemical modification in the solid state after forming a membrane (Xie et al., 2012). The surface and morphological properties of solution-cast membranes depend on the properties of the solvent/polymer such as miscibility (Bridge et al., 2022a), solvent volatility (Bridge et al., 2022a; Fischer et al., 2023), and solution viscosity (which is affected by choice of solvent, molecular weight of polymer, and solution composition) (Bridge et al., 2022a; Kruczek and Matsuura, 2003). Important casting conditions include the use of a doctor blade or other spreading method, cast solution thickness (which affects the resulting membrane thickness), and substrate temperature (Yee et al., 2013). Polymer chains can be aligned by flow, e.g., when using a doctor blade, which results in anisotropic transport properties and can reduce the amount of water swelling (Simari et al., 2021). It is particularly important to consider the surface energy between the solution and the substrate. It must be sufficiently favorable for the solution to wet, but also sufficiently low to release the dry membrane. Various approaches can be used to facilitate release of the membrane from the substrate, such as dewetting the membrane with a nonsolvent or, in laboratory scale research, dissolving away the substrate with a preferential solvent. Finally, solvent removal is an important consideration that can be achieved by drying (e.g., with heat and vacuum), by exposing the solution to a non-solvent (often referred to as phase inversion), or by “activation” with another reagent that extracts residual solvent, e.g., via osmotic pressure. The third approach was used to remove residual solvent by soaking sPEEK membranes in 1 mol/L sulfuric acid, and found to be crucial for achieving optimal membrane properties (Jun et al., 2012).

In solution casting and other membrane formation methods, surface interactions can also affect membrane surface roughness and porosity. These include interaction between the solution and the substrate, as well as interactions between polymer and inorganic particles that are sometimes used in membranes. For example, shrinkage was found to be more significant when solutions of PSf in N-methylpyrrolidone were spread on hydrophobic substrates such as Teflon than when spread on hydrophilic substrates such as glass. The increased shrinkage resulted in lower water permeability. In this study, the membranes were formed from solution by immersion precipitation, rather than solvent evaporation (Aerts et al., 2006). Anisotropic micromorphology can appear when casting heterogeneous IEMs using nanofillers or via NIPS, based on the gravimetric effect and solution viscosity. Hierarchical membranes can be produced using the formation of anisotropic distribution of components (Bakangura et al., 2016; Liu et al., 2017; Bridge et al., 2022a).

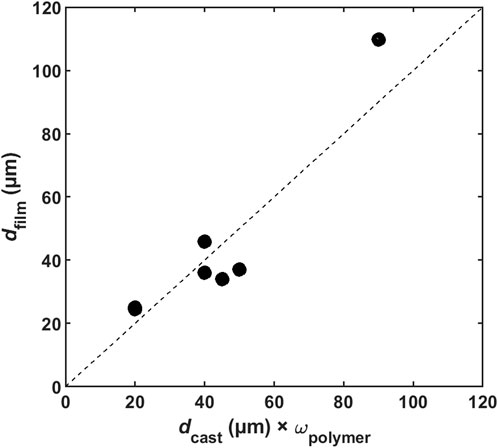

Yee et al. studied the effect of casting parameters on the degree of sulfonation (DS), IEC, swelling, film thickness and electrochemical properties. The DS, IEC and swelling showed temperature-dependence. The thickness of dry films (

Figure 4. Relationship between dry membrane thickness (

Xie et al. examined how pretreatment and counter-ion type affect water and ion transport in solution-cast disulfonated poly(arylene ether sulfone) (BPS) films (Xie et al., 2012). The membrane was treated with acid, heat, and ion-exchange in different manners. Soaking in sulfuric acid increased water uptake and permeability, while thermal treatment in water enabled tuning of transport properties. Boiling in sulfuric acid had the most pronounced effect, greatly enhancing water and salt transport. Counter-ion effects were minor compared to thermal treatment. Overall, the permeability and selectivity followed the expected trade-off relationship.

Slade et al. investigated the influence of processing methods on WC and resistivity by recasting extruded Nafion with different solvents, butan-1-ol and propan-2-ol (Slade et al., 2010). The recast Nafion membrane showed higher water uptake and lower resistivity than extruded membranes implying reorientation of ionic domains (Gebel, 2000). The different behavior of water content and resistivity was explained by the different physical properties of solvents: boiling point, vapor pressure and viscosity that changes evaporation rate affecting organization of microstructure.

Technical challenges of solution casting lie in the long evaporation time, difficulty of thickness control, and anisotropic microstructure. Accurate control of thickness is challenging due to the solution fluidity even when the solution is cast using a doctor blade (Yee et al., 2013; Harris and Walczyk, 2006; Chede et al., 2018). This problem can be addressed by using viscous solvent or higher polymer concentration, but extensive evaporation time, high temperature or vacuum are required to completely remove residual solvent. Faster evaporation using volatile solvent or heating can be considered, but it can cause defects, rough surface, and even breakage of the membrane (Bridge et al., 2022a).

Other strategies to evenly spread viscous solutions on support films are nip roller extrusion and slot die extrusion (Harris and Walczyk, 2006). These techniques can be applied to continuous process of solution casting (Chede et al., 2018; Siemann, 2005). The viscoelastic properties of the solution and the surface adhesion of the roller material were found to be key parameters to produce defect-free membranes with uniform thickness (Siemann, 2005; Harris and Walczyk, 2006). In slot die extrusion, critical processing parameters include flow rate, substrate speed, slot gap, etc., all of which must be precisely controlled to ensure uniform film quality.

4.2 Paste method

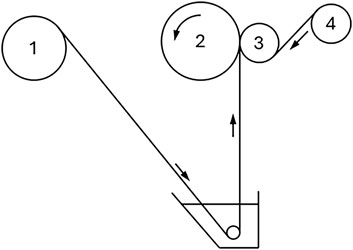

The paste method is the most widely used manufacturing process for the mass production of hydrocarbon-based IEMs (Mizutani, 1990). A paste solution is filled into a bath and coated onto a backing membrane to form a composite membrane that is wound onto a winding roll, as shown schematically in Figure 5. The paste solution contains monomers with functional groups, crosslinkers, initiators, and additives such as powders for mechanical strength or rubber for flexible properties. Polyvinylchloride (PVC) fibers or porous membranes (e.g., porous polyethylene films) are used as backing membranes. After winding, the roll is detached and undergoes thermal treatment to polymerize and crosslink the monomers in the paste. Two different types of composite membranes are used. For many applications, such as reverse osmosis, flux is of paramount importance such that the functional layer formed by the paste must be very thin (e.g., 100 nm). Transport through this thin dense layer occurs by the solution diffusion method, which provides the selectivity needed (e.g., to reject salt). In other applications in which selectivity is more important, such as electrodialysis, the IEM formed by the paste percolates through the entire porous support, providing longer transport pathways to take advantage of differences in the mobility of the species to be separated (e.g., counter-ions and co-ions). In either type of composite membrane, the primary role of the porous support is to provide mechanical integrity.

Figure 5. Simplified schematic diagram of paste method. PVC cloth is provided from the feed roll (1) and dipped into the paste bath. The amount of coated paste is controlled by the pressure applied to the winding roll (2) by pressing roll (3). A separation film is provided by roll (4) to prevent adhesion between layers.

The percolated structure of the composite membrane is determined by the composition, miscibility and solubility of the components (Mizutani, 1990). Like the solution casting method, neutral monomers can be used that are subsequently converted into an IEM after forming the composite membrane, or charged monomers can be used to directly fabricate a composite IEM. Mizutani et al. demonstrated that IEMs prepared by the paste method exhibited a finely interpenetrating network of PVC and ion-exchange resin, where the microphase-separated structure (≤50 nm) and controlled swelling through PVC confinement significantly enhances conductivity, mechanical stability, and overall membrane performance (Mizutani and Nishimura, 1970; Mizutani and Ikeda, 1987).

Another study of interpenetrating structure of PVC/styrene-divinylbenzene (St-DVB) was conducted in which St-DVB was incorporated into porous PVC supports and then treated to add ionic functionality via sulfonation (to form a CEM) or quaternization (to form an AEM) (Mizutani, 1990). The authors used TEM to visualize the distribution of crosslinked St-DVB in the interconnected micropores of the PVC gel. With increasing PVC pore volume fraction (Neosepta CL-25T < Neosepta CH-45T < Neosepta C66-5T), greater charge density could be formed in the composite membrane due to higher content of St-DVB. This resulted in larger IEC, higher water content, and lower resistance (Hori et al., 1986). The crystallinity of PVC in the backing materials and base membranes was not affected by the presence of ion-exchange resin (Mizutani and Ikeda, 1987). The authors claimed that the crystallites of PVC acts as crosslinking points to some extent providing dimensional stability and toughness to the membrane while still achieving high IEC.

The relationship between transport properties and crosslinking density in composite IEMs has been investigated by Sudoh and coworkers (Sudoh et al., 1990a; Sudoh et al., 1990b). The effect of crosslinking density was examined by correlating it with the volume fractions of pores, polyelectrolyte, and inert polymer. A model indicated that it is desirable to maximize the volume fraction of polyelectrolyte while selecting a backing material with reduced inert polymer volume fraction. It was found that there is an optimum point of crosslinking that maximizes polyelectrolyte volume fraction. In combination with the optimal backing material, the membrane conductivity approached that of the external solution (Sudoh et al., 1990a; Sudoh et al., 1990b; Alexandrova and Iordanov, 2001).

The paste method is technologically mature and used in large-scale manufacturing processes. However, it has several limitations due to the necessity of using a backing membrane: 1) the volume fraction of the polyelectrolyte phase is less than 50%, 2) the ionic conductivity is below 10−2 S/cm, and 3) the overall membrane thickness is greater than 150 μm (Tanaka et al., 2011). Additionally, it requires extensive post-processing time–polymerization for greater than 10 h and ionization for more than 10 h (Sudoh et al., 1990a; Tanaka et al., 2011).

4.3 Extrusion

Commercial PE or polypropylene (PP) battery separators and PFSA IEMs are produced via extrusion (Kusoglu and Weber, 2017; Jana et al., 2018). Extrusion is a conventional polymer processing technique used to blend (Kim K. et al., 2023), compound (Eker et al., 2002) and shape (Rosato, 1998) thermoplastic polymer products. It is a continuous in-line process to profile polymeric materials including melting, mixing, conveying and profiling of the polymer and roll-to-roll processing of films (Hays and Pokorski, 2025).

Common extruders can be categorized by screw types: single-screw extruder (SSE) and twin-screw extruder (TSE). SSEs are preferable for the manufacturing of profiles or sheets that require stable output, whereas TSEs offer superior mixing capabilities. Figure 6 shows schematic images of an SSE, screw elements of TSEs, and the process of film formation through a T-shaped die (T-die) followed by roll-to-roll film casting. Polymers in pellet, powder or granule form are provided by a feeder and proceed from the conveying zone to melt and mixing zone (Figure 6A). In polymer blends and composites, additional components such as secondary polymer or inorganic fillers can be pre-mixed or introduced via a side feeder. The polymer melt needs to be compressed to maintain consistent thickness profile. The compression is achieved through screw design (SSE) – typically by increasing the screw diameter in the metering zone (Figure 6A) – or screw configuration (TSE) which involves various assembly of screw elements (Figure 6B). The polymer melt is extruded through T-die to form films (Figure 6C). The T-die has to be carefully designed considering the thermodynamic and rheological properties of the materials and processing parameters such as throughput and pressure drop. The film orientation is determined by the flow rate and casting roll speed. The cooling rate, determined by the cooling roll temperature and roll speed, significantly affects the film’s degree of crystallinity, which in turn influences its mechanical strength. The films are wound on a roll after trimming the edges with non-uniform thickness.

Figure 6. Schematics of (A) a single-screw extruder (Vlachopoulos and Polychronopoulos, 2019), (B) twin screw elements (Rao et al., 2021), and (C) film forming through T-die and roll-to-roll film casting.

Extrusion has merits of being a scalable and solvent-free process, but it is an energy-intensive technique due to the high thermal and mechanical energy required. Homogeneous membranes can be reinforced by extruding with additives or fillers. Heterogeneous membranes can be manufactured by blending polymers. The distribution and morphology of heterogeneous membranes are determined by material properties such as polymer blend miscibility and melt viscosity, and processing parameters such as processing time, barrel temperature and screw configuration. The temperature range must be carefully selected due to the thermal sensitivity of the IEM components such as plasticizer and sulfonate groups, particularly when scaled up, where increased retention time of the materials and viscous heating from higher machine torque exacerbate thermal stress (Bébin and Galiano, 2006a; Oh et al., 2014).

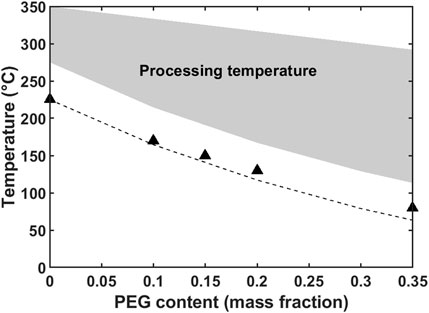

Bebin and Galiano demonstrated film extrusion of glassy sulfonated PSf (sPSf) using a low-molecular-weight poly(ethylene glycol) (PEG) as plasticizer to improve the processibility (Bébin and Galiano, 2006a; Bébin and Galiano, 2006b). The use of 20% plasticizer effectively depressed the glass transition temperature (Tg) of the acid form sPSf/PEG blends, from 225 °C to about 100 °C, and reduced the minimum melt processing temperature (Bébin and Galiano, 2006a). In Figure 7, filled areas indicate the safe processing temperature range for a sodium form sPSf/PEG blend. The upper limit of the processing temperature was determined by TGA where weight loss was less than 10%. In addition to improving processability, increased amount of plasticizer increased the porosity of the membrane after solvent extraction (Bébin and Galiano, 2006a; Bébin and Galiano, 2006b; Oh et al., 2017b) resulting in increased water uptake and ionic conductivity, but decreased selectivity (Bébin and Galiano, 2006a; Oh et al., 2018). Interestingly, the durability of the membrane in hot water was significantly affected by the processing method, where extruded membranes lasted two to three times longer than solvent cast membranes.

Figure 7. Determination of processing temperature of a sPSf/PEG blend. Data from Bébin and Galiano (2006a).

A comparative study of solution-cast Nafion (NR211) and extruded Nafion (N117) was conducted by Peron and coworkers (Peron et al., 2010). Isotropic swelling and conductivity were observed in NR211. Whereas, extrusion causes stress-induced orientation of Nafion chains in N117 that results in anisotropic swelling. Swelling is greater in the transverse directions, where the backbone distance between neighboring polymer chains is limited by weak van der Waals forces, than in the extrusion direction, where backbone bonds limit swelling. The water permeability of NR211 was higher than N117, despite the hydration number being lower, and the oxygen diffusion coefficient was also affected by membrane processing method. The hydration numbers of as-received NR211 and N117 at 25 °C were 12 and 22

A systematic study of the dependence of IEM permselectivity on the processing history was conducted by Oh and coworkers (Oh, 2015). Single-layer IEMs of BPS were prepared by extrusion using PEG as plasticizer which was extracted using water after forming films (Oh et al., 2017a). At least 20 wt% PEG was used to obtain defect-free, uniform membranes. The water-soluble PEG was completely extracted from the extruded film, indicating the potential for preparing CEMs using extrusion (Oh et al., 2017a), while BPS/PEG blends prepared by solution casting did not exhibit PEG extraction (Lee et al., 2011). Although the solution-casting study used slightly higher molecular weight PEG (600 compared to 400 g/mol), it is not clear why different processing methods led to this dramatic difference. Lee and coworkers did note that PEG was retained after 150 days in 30 °C deionized water due to the strong dipole-ion interaction between the potassium counter-ions of the sulfonate groups and ethylene groups in PEG. The extruded BPS polymer membrane demonstrated the expected trade-off between water permeability and water/salt selectivity (Figure 8). Notably, the extruded membrane showed higher water permeability but reduced selectivity compared to neat BPS membranes produced by solution casting. These findings indicate that processing history alone can significantly alter both permeability and selectivity.

Figure 8. Relationship between water/salt permselectivity and water permeability. The dashed line represents the upper bound in performance from Ref. Geise et al. (2011). Red area is cast BPS membranes and blue area is extruded membranes including BPS/PEG with different molecular weights (200 and 400 g/mol) and wt% (20 and 30 wt%) of PEG in which the PEG was subsequently extracted (Oh et al., 2018).

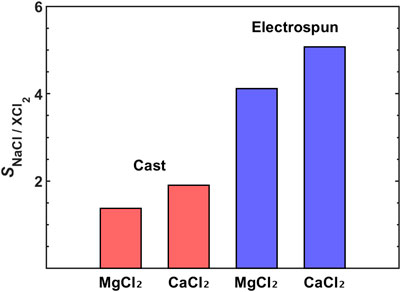

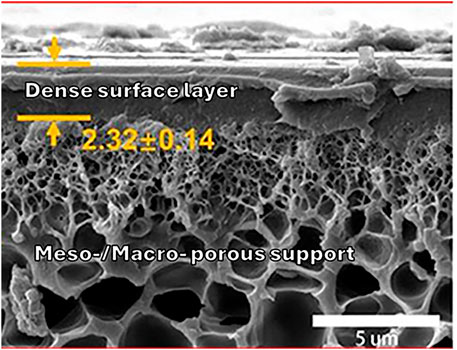

One drawback of extrusion is the high processing temperature required for melt processing, which can increase the risk of thermal degradation of charged polymers (Bébin and Galiano, 2006a; Oh et al., 2014). Charged polymers in their acid form typically exhibit poorer thermal stability compared to their neutral or metal salt counterparts. A strategy to address this problem that was discussed above is to ionize neutral polymer films in the solid state, e.g., after extrusion. In another study by Mokrini et al., sulfonic acid moieties were incorporated into a polymer blend membrane of PVDF and styrene-(ethylene-butylene)-styrene (SEBS) triblock copolymer (Mokrini and Huneault, 2006; Mokrini et al., 2006). Interface modification was carried out by adding 1 – 5 wt% of acrylate block copolymers to improve the miscibility of two polymers. Scanning electron microscopy (SEM) analysis revealed that the incorporation of the acrylate block copolymers markedly reduced phase segregation and enhanced mechanical properties with as little as 1 wt% of compatibilizer. The IEC and ionic conductivity increased with increasing SEBS and compatibilizer contents while exhibiting similar or lower water uptake.