- 1Department of Energy, Politecnico di Torino, Turin, Italy

- 2Department of Applied Science and Technology, Politecnico di Torino, Turin, Italy

- 3INFN—Sez. Torino, Turin, Italy

- 4Eni SpA—Renewable, New Energies and Material Science Research Center, Novara, Italy

Electronic waste generation has been following a continuously rising trend. With electronics containing a myriad of materials some of which are hazardous, toxic, extremely rare, or precious combined with more stringent legislative laws which encourage the reuse and optimised recycling of the materials included in WEEE, the need for a holistic approach is inevitable. In the context of this research, the term holistic refers to the three aspects of material, technology, and hazard. This work aims to develop an approach that identifies the materials found in the various types of WEEE and their respective quantities as well as highlights the possible handling techniques and their respective impacts and associated hazards whether to the environment or human health. Performing such a task manually would be exasperating and costly while requiring extensive resources that might not be met with a justifiable economic gain; thus, the use of the advancement in computational sustainability to draw a complete framework and aid in an informed decision-making process is crucial. The WEEE ontology developed in this paper is one way of addressing the problem since it covers the treatment domain, the hazard and the materials contained within the different types of WEEE. The ontology developed in this research is part of a Decision Support System that is yet to be integrated, however, the ontology can be directly used from the commercial Protégé software.

1 Introduction

Electronics have become an integral part of everyday life, from wearable devices to smart homes fitted with sensors and remote controls to optimize consumption and facilitate daily household tasks. The advancement in electronics, especially computers, has also allowed simplifying many complex multi-factor tasks. However, electronics have become a double-edged weapon, with the constant advancement of technology and electronics and their involvement in most daily tasks leading to the continuous upgrading of electronic devices and equipment while discarding used ones and consequently bringing about the problem of electronic waste, or e-waste for short.

In 2019, the amount of e-waste generated globally reached 53 Mt., with that number projected to become 75 Mt. in the next decade (Lahtela et al., 2022). Its generation is estimated to continue increasing at a rate of 3–5% per year (Kumar et al., 2017). One of the e-waste streams that recently started raising flags is solar Photovoltaics (PVs). The installation of solar PVs has grown to reach 627 GW in 2019, rising from 1.4 GW in 2000, and the increase is expected to reach 10-fold over the next 30 years (Khalifa et al., 2022). It is estimated that between 60 and 78 million tons of waste solar PV modules will be generated by the year 2050 (Thomassen et al., 2022). Similarly, an estimation of the waste related to Solar PVs and their balance of systems, which includes the inverter, cables and mountings, predicts that India alone will face 295 million tons between the years 2020 and 2047 with a recoverable materials value of 452 billion dollars (Gautam et al., 2022). The problem of WEEE lies in the lack of proper handling and recycling schemes, which leaves the sector heavily controlled by informal collectors and handlers. The percentage of officially handled and reported e-waste generated globally in 2019 was only 17.4%, with the remainder being illegally and unsafely handled (Ramprasad et al., 2022). Much of the unhandled waste which is not reported by official bodies can end up in the municipal waste streams (0.6 Mt), local dumps, recycled under unfavourable conditions (1.12 Mt), handled as mixed metal scrap (1.1 Mt) or even exported legally (0.29 Mt) and illegally to developing countries (almost 2.09 Mt) (Habib et al., 2022).

WEEE contains a mix of materials, over one thousand different materials (Lahtela et al., 2022), with varying properties, some of which are non-degradable, hazardous, ferrous and non-ferrous or ozone-depleting chemicals. Among the materials included are heavy metals, precious and rare earth metals, as well as plastics, glass, and persistent organic pollutants (POPs) (Habib et al., 2022; He et al., 2022; Tansel, 2017).

Attempts to take advantage of the advancement in computational power and to simplify the complexity of the intertwined conditions of sustainability gave rise to the branch of computational sustainability, a field that uses the recent advancements in computation and modelling to help solve the complex problem of sustainability with its numerous variables, primarily the aspects of the environment, social and legal boundaries as well as the economy and financial viability.

A branch of computational sustainability is the development of Decision Support Systems (DSSs) which consider the various constraints and the relations between the various factors to recommend scenario-based solutions. DSSs can help support policy and decision-makers in making a more profound decision based on the suppositions of the multifactor model. Since the use of DSSs in tackling waste problems, especially the collection phase, has been demonstrated to be effective (Faye et al., 2019), therefore they can be used to confront the complexity of electronic waste and offset its impacts.

In the e-waste sector, there has been ongoing research that addresses the technological advancement in WEEE recycling techniques (Dean Kang et al., 2023; He et al., 2022; Priya, 2023; Yu E. et al., 2023) highlights and proposes solutions to efficient collection and handling, as well as underlines the economic and environmental gains achieved from an optimised WEEE management system (Dean Kang et al., 2023; Habib et al., 2022; He et al., 2022; Mori de Oliveira et al., 2021; Pekarkova et al., 2021; Preetam et al., 2022; Priya, 2023; Yu E. et al., 2023). Still, these works are mostly disconnected and there is a lack of a system that includes what has been achieved so far in the various fields of sustainability concerning WEEE. Among the challenges faced in the technology adoption in the field of WEEE are the availability of data, mainly due to copyrights and data protection, the return from recycling WEEE, as well as the knowledge of sustainable technologies (Udage Kankanamge et al., 2024). This work aims to address the gap and design a DSS that would ultimately collect the recent findings and practices that lead to a more sustainable WEEE management cycle and make it available to decision-makers, whether policymakers or business owners, to enhance an informed decision-making process and exploit the recent advancements in the various fields of sustainability. The DSS would consider the technologies available for WEEE handling using a holistic approach by including the environmental and health hazards associated with the handling processes, and the quantification of materials included within different WEEE items. This contributes to the goal of achieving a holistic solution, which in the context of work refers to the three domains of technology, material, and hazard.

Based on this goal, the research questions (R) for this work are:

R1: How feasible is it to implement a holistic system that represents the WEEE domain from various aspects by connecting the already existing knowledge in literature?

R2: How can such a DSS for WEEE be built with scalability and reusability of its components?

One way of developing DSSs is using ontologies to build the framework. An ontology can be described as a single universal language that is agreed upon and understood by the different domains, which allows the easy integration of knowledge bases (Hitzler, 2021; Kebede et al., 2024). Another definition of an ontology is a way of describing a domain of knowledge semantically. The way an ontology is developed makes it uniform and reusable across different domains and among industries within the same domain (Keet, 2018; Sattar et al., 2020).

The originality of this work lies in the design of an ontology-based DSS that is scalable, expandable, and puts together a multi-domain knowledge at the disposal of non-domain experts, simplifying and supporting the decision-making process. The DSS, unlike others already developed, takes into consideration the technological domain, materials domain, and hazards and impacts domain. Yet, it can be integrated with other ontologies such as those in the business or legislative domain to give a more panoramic view of the WEEE issue. The fact that the DSS is ontology-based allows the reasoning and automatic deriving of relations between the various categories and aspects of WEEE, whether within the developed ontology or in future cases when the ontology is integrated with other ontologies of different domains.

The ontology is developed using Protégé (RRID:SCR_003299) and OWL language (Musen, 2015a, 2015b). Although the software allows viewing the ontology, both as XML and graphically and extracting data from the ontology, as will be shown in later sections, Protégé is not targeted to be used as the user interface for the DSS as it is complex and requires previous knowledge of the software and querying languages to extract data. The structure of both the DSS and the ontology, the development methodology of the ontology in addition to the use cases of the DSS are further detailed in Section 2. In section 3, the developed ontology is discussed and the results from testing it are further elaborated. Section 4 validates the ontology against the research questions and highlights the challenges faced during the ontology development. Finally, in section 5 the key outcomes of this work are summarized.

2 Materials and methods

2.1 Decision support system structure and development

Since DSSs are used to simplify and aid in making informed decisions, being user-friendly is fundamental. Therefore, it is important to define the objectives based on the problem tackled, the nature of users, and the potential uses of the DSS before starting with the development process to ensure that the developed solution is tailor-made and meets its objectives.

For this purpose, the methodology mentioned in Keet (2018) and followed by Hou et al. (2015) during the development of the OntoSCS are taken as a guide to obtain a well-structured design and help clearly define the key aspects of the developed ontology.

In this study, the DSS aims to bring together the disconnected knowledge regarding the sustainable handling of WEEE. The scope of this DSS covers the technological domain, the materials domain, and the hazard domain. The selection of these domains as a core for the DSS directly fulfils the 3 main pillars of sustainability. The materials domain can be directly integrated with business models, and the technological domain is connected to the various environmental and health impacts drawing a full picture of the level of sustainability the proposed process has.

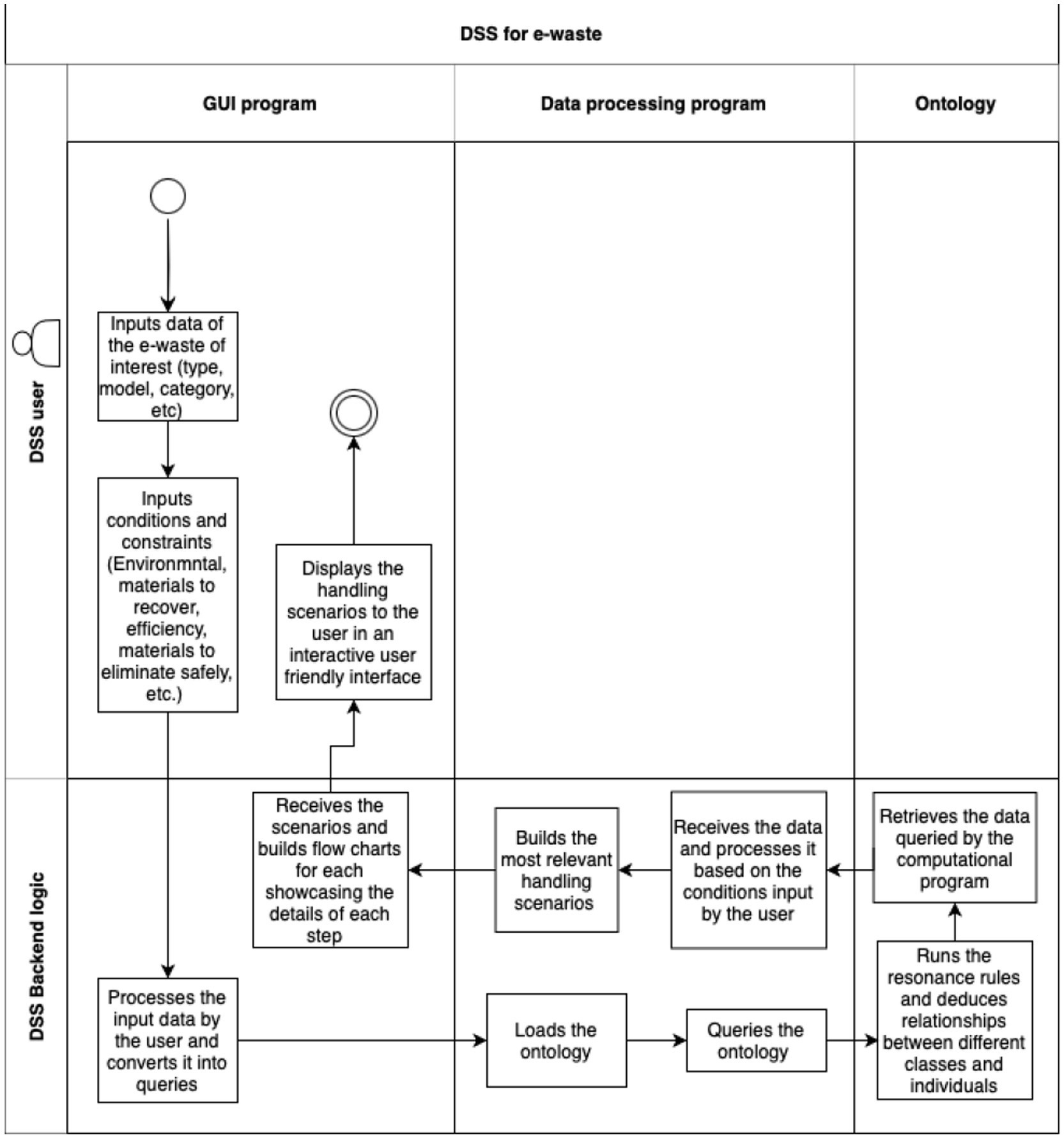

A DSS is typically a multilayered system. The current DSS in this research consists of 3 layers. A base layer made up of the ontology and serves as a core to the DSS where all data is structured and relations and interactions between the domains are defined. A top layer consisting of the Graphical User Interface (GUI), and an intermediate computational layer that connects the top and base layers and processes the data to construct the potential solutions.

Since the aim of the DSS is facilitating and simplifying the complex domains of WEEE in one place, the GUI would inevitably allow users to interact with the ontology as a base layer, submit inputs to the system and retrieve relevant data in a simplified manner. The base layer and the top layer are connected through a querying and computational program that processes the inputted data, draws relations among the various domains and categories in the ontology based on the inputs from the user and the relations defined in the ontology between the various components as well as feeds the results to the GUI to be represented to the user, an illustrative structure of the DSS can be seen in Figure 1 which describes the functions of each layer and the interactions between one another. In this paper, only the building of the base layer ontology will be presented in depth while the intermediate computational layer and the GUI will not be covered.

2.1.1 Objectives and scope of the DSS

The definition of WEEE is any electronic or electrical equipment that reach their end of service life and is discarded by the consumer whether because the device no longer functions or because the device has been replaced by a new one. Different guidelines and legislations categorize WEEE differently. For instance, they can be categorised into six main categories; namely: 1. Temperature exchange equipment, 2. Screens and monitors, 3. Lamps, 4. Large equipment, 5. Small equipment, and 6. Telecommunication equipment as defined by the E-waste Statistics Guidelines on Classification Reporting and Indicators (He et al., 2022). Another classification by the WEEE directive in the EU that is more internationally recognized groups WEEE into ten different groups: Large household appliances, Small household appliances, IT and telecommunications equipment, Consumer equipment and photovoltaic panels, Lighting equipment, Electrical and electronic tools, Toys, leisure and sports equipment, Medical devices, Monitoring and control instruments, and Automatic dispensers [Directive 2012/19/EU on Waste Electrical and Electronic Equipment (WEEE), 2012]. Regardless of the classification of choice, under these categories lies the different devices with all variabilities and technological differences they might have.

These categorizations do not simplify the fact that WEEE contains a myriad of materials. Since the quantity and type of materials contained within each device vary by model and category, it is important to start building the ontology for the DSS with a focus on a certain category and type of WEEE to be able to model the various processes followed in handling this type of WEEE and their respective impacts and then subsequently expanding the ontology to cover other categories and WEEE types. As a result, the DSS is developed in phases allowing continuous feedback and improvement of the structure as the ontology is expanded and avoiding the impracticality of modelling all types at once. However, at the end of all the development phases of the DSS, its scope would cover all types of WEEE.

The starting point of the ontology in this paper is the handling of solar PVs. This choice was guided by the previously demonstrated estimations regarding the increase in both the installation of solar PV systems as well as the expected generation of solar PV systems-related waste (Thomassen et al., 2022). The ontology is developed with a focus on scalability. This permits the subsequent integration of other ontologies as well as the further expansion of this ontology to include other WEEE items and their treatment methods in addition to enabling the seamless updating of current methodologies for solar PV treatment as they evolve.

The domains covered by the ontology are the treatment processes, hazards including both environmental as well as human health, and materials with all their classifications. The ontology developed is generic and allows its subsequent usage to model other categories using already defined items. For instance, the metal housing of a solar PV that is defined in the current ontology is left generic as metal housing and does not specify that it is specifically for solar PVs, consequently it can be reused for other WEEE items such as a refrigerator that has metal housing. In addition, the reasoning rules defined using SWRL, as discussed later in section 2.2.4 allow the automatic deduction of relations among the ontology components as the ontology is expanded.

2.1.2 DSS and ontology design methodology

The methodology for developing the ontology aligns with that of the entire DSS. It starts by:

• Defining the objectives of the DSS

• Defining the use cases

• Identifying the operations that will be performed by the system

• Identifying how these operations will be performed on the ontology.

Based on these requirements, the objectives of the ontology are then defined answering the question of why this ontology is needed and what questions it should be able to answer. Then the ontology is assessed continuously while being developed to answer the question whether all entities within the scope of this ontology are captured.

Further on, the ontology is assessed on whether it is reusable, how it models the domain, and whether the represented entities are fully described well enough using annotations to allow for reusability and interoperability. This methodology is the result of the adaptation of the Modular ontology modelling (MOMo) methodology described and used by Kebede et al. (2024) in developing an ontology for digital product passports as well as the methodology suggested by Keet (2018) regarding the ontology lifecycle model and the micro-level development of ontologies.

2.1.3 Data sources and challenges

The data used for the development of the ontology are mainly secondary data found in the literature, this applies to both the technologies domain and the environmental and health domain. As for the materials domain, secondary data has been used. Another gap was identified along the process, which is the lack of precise data for the material content of the different types of WEEE and the various models of the same type of WEEE.

2.1.4 Potential users

The domains previously mentioned to be covered by the ontology help fulfil the scope of giving an overall idea about a specific WEEE item, a treatment method or a target material. This includes technical handling specifics in addition to the potential environmental and human hazards associated with these techniques and the materials involved.

Ideally, when the DSS is fully developed, it is envisioned to be a simple software tool with a user-friendly GUI. The usage of the DSS should not require any help from language engineers or subject knowledge of ontologies. Thus, the GUI should be straightforward. The target users of the DSS software are non-expert users in the field of WEEE, this can be decision-makers, policymakers, business owners, and investors exploring new opportunities. The tool serves to simplify WEEE handling, support a greener circular economy and inform interested parties, thus there is no need for a technical background in the use of ontologies or complex software.

2.1.5 Use cases

The use cases of the DSS are initially three. First, by entering the type of WEEE item, the user is interested in learning about its contents and possible treatment methods as well as the respective impacts of each treatment method. This serves in the case where the user already has an idea about the WEEE items at hand and is interested in the best way to handle it, ensuring both high material recovery efficiency and mitigating the environmental and health impacts. The system would show various potential scenarios listing for each scenario the amount of materials included per kilogram of this WEEE item, the hazards associated with this handling method, the detailed process flow with the materials and equipment used in this scenario, the time needed for each step and the operating conditions.

Alternatively, the user can choose a specific component of the WEEE item, such as choosing the housing of solar PVs, with the expected outcome being the materials included and the retrieval methods along with their impacts.

Finally, if the user is interested in a specific material, such as rare earth metals, choosing that material would show them the WEEE items with the highest content of this material. Despite this being more of an informative aspect of the DSS, it helps put the user in the picture and disseminate information enriching the decision-making process. This is specifically useful in the case of urban mining and exploring new opportunities to use WEEE and generate profits from an otherwise obsolete and burdensome problem.

An initial design of the GUI is shown in Figure 2. It is important to clarify at this point that the GUI in Figure 2 is up to the present time not fully developed and it only aims to clarify the use cases of the DSS and how the users are going to interact with the ontology and the DSS. When completed, the user will input the data based on the use case in mind, as previously mentioned, in one of the three tabs on the leftmost column. Upon submitting the data, the different scenarios will appear in the middle panel in an interactive flowchart which permits clicking on its various nodes. Clicking on a node would show in the right-most column the details related to this step such as the materials, process efficiency, operating conditions, hazards associated with that node, and so on.

2.2 Ontology definition

Typically, an ontology comprises classes, relations, and instances of the classes. A class is usually describing a concept within the domain, and an instance of the class is an object belonging to that specific class. Different classes and instances can be connected or disjoined using the relations defined (Eibeck et al., 2019; Keet, 2018). To develop an ontology, various languages exist such as DAML+OIL, DAML- ONT and OWL. OWL is among the most popular since it meets the standardisation criteria set by the W3C, which include interoperability, internationalization, ease of use, and compatibility with existing standards; hence, it has been widely used by recently developed ontologies. Ontologies allow reasoning, which automatically draws direct and indirect relations between the components of an ontology based on predefined rules, allowing for continuous development and expandability of the ontology (Hitzler, 2021; Keet, 2018).

Ontologies were recently developed and incorporated into solutions to tackle various problems in the sustainability field. For instance, in the construction field, an ontology was developed based on Life Cycle Analysis (LCA) to evaluate the cement-steel-slag stabilized soft soils (Yu C. et al., 2023), and another was developed to evaluate the energy and carbon impacts of concrete structures (Hou et al., 2015). Moreover, a group of modular ontologies was developed to support digital product passports in the building sector (Kebede et al., 2024). In the field of product life cycle, an ontology was created to represent semantically the product life cycle and facilitate the carrying out of LCA (Zhang et al., 2015). In process optimization, a cross-domain solution was developed which takes into consideration the various domains of weather, buildings, and process engineering to tackle industrial air pollution (Eibeck et al., 2019), while another framework was developed for eco-industrial parks to help share resources and decrease waste and pollution (Zhou et al., 2018). In the nexus between Water, Energy and Food, an ontology was used to project a system’s sustainability and to aid decision-makers in optimizing the system inputs to minimize the trade-offs and guarantee sustainable growth (Babaie et al., 2019). In the field of urban sustainability, USDA ontology was developed to join domain-specific ontologies and permit their integrated usage in a single high-level ontology (Kuster et al., 2020).

In the field of waste management, ontologies have been used as a base for DSSs for municipal solid waste (Kultsova et al., 2016; Yang et al., 2020), for the selective sorting of waste and their subsequent recycling (Sinha and Couderc, 2012), for waste treatment plant optimization (Muñoz et al., 2013) and even in specific cases of WEEE handling such as disassembly of LCD monitors (Foo et al., 2021).

Other already developed ontologies were assessed to be adapted and further developed for this DSS based solution. Ontologies specifically made for WEEE could not be found. Alternatively, for waste management, OntoWM (Ahmad et al., 2018), and SWM-PnR (Sosunova et al., 2017) were found, yet they focus on collection and monitoring, while the scope of this DSS is the handling and urban mining phase, which comes after collection. OntoWEDSS (Ceccaroni et al., 2004) deals with wastewater treatment plants; it focuses on the diagnosis of malfunctions within treatment plants and microbiological processes, hence has little overlap with the domain of WEEE treatment and the scope of this ontology. Not to be overseen is the usefulness of the building layers for their DSS and its potential adaptation. On the other hand, OntoCAPE (Morbach et al., 2007) is focused on mainly chemical and process engineering, and in the process of developing the ontology for this objective, some supporting modules such as SI units and materials were developed. These modules are of the upper level, with little use to the objective of our current ontology, which requires a more detailed approach (Morbach et al., 2007). With a different taxonomy followed it was less complicated to build the ontology from scratch instead of reusing the few overlapping modules from OntoCAPE. Other ontologies developed in the waste management sector, in general, have limited modularity (Sattar et al., 2020). On that account, their usage and integration into a new WEEE ontology would be challenging. Accordingly, the building of a new ontology for WEEE from scratch would be favorable.

It can be argued that most of these solutions, whether on the ontological level or the DSS level, are specific to handling a single case and lack interoperability and scalability. As they were not designed with extensibility in mind, hence expanding them to include the large umbrella of WEEE with its complex components, materials, treatment and handling technologies, and hazards is not plain sailing. Therefore, the design of an ontology as a base layer to the DSS would allow scalability and integration with other ontologies to permit a more holistic understanding of WEEE management and promote an informed decision-making process whilst building up on what research has achieved so far and embracing any future findings by allowing a seamless continuous development and integration process.

2.3 Structure of the ontology

Protégé is widely used for the development of ontologies, Protégé is widely used (Eibeck et al., 2019; Muñoz et al., 2013; Sinha and Couderc, 2012; Yang et al., 2020; Zhou et al., 2018). It is an open-source software that uses the OWL language to develop the ontology (Musen, 2015a, 2015b). The software allows the use of reasoners that deduce the inferences and new relations among the different classes and instances based on their descriptions and properties added. The software also permits exporting the ontological model to be further incorporated into Decision Support Systems or integrated with other models.

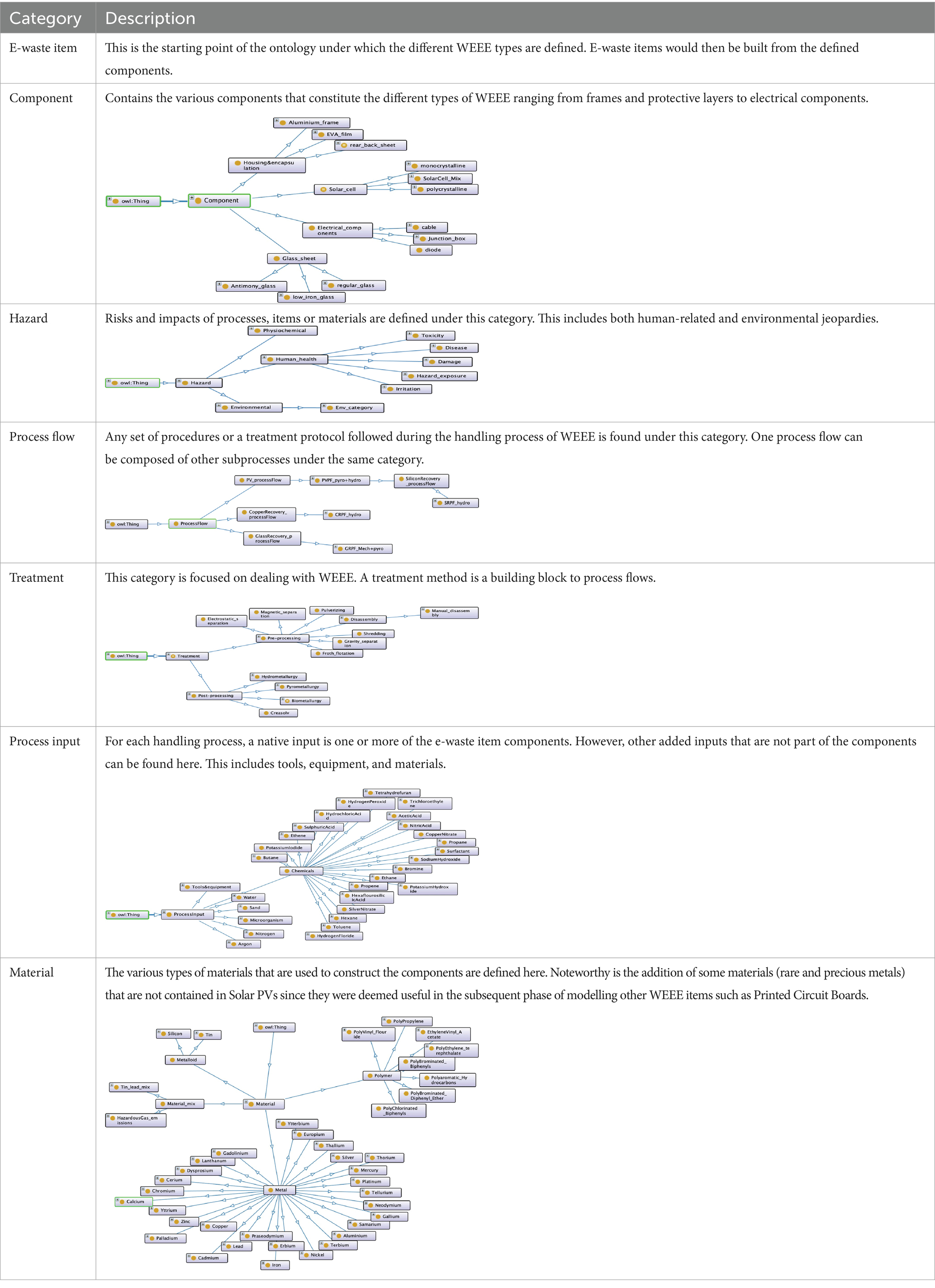

Protégé (RRID: SCR_003299, V5.5) is used in developing the ontology (Musen, 2015a, 2015b). To represent the three domains in the scope of the DSS, the ontology is defined by 7 main categories: 1. Component, 2. E-waste item, 3. Hazard, 4. Material, 5. Process flow, 6. Process input, and 7. Treatment. These categories are generic to allow modularity and possible integrations with other ontologies that are specifically focused on one of these domains. Each of these categories is then detailed in an expanding manner from the top down to maintain the ontology scalability and allow continuous development and integration. For instance, the technological domain is represented by the Process Flow, Process Input and Treatment categories, while the environmental and health hazard domain is represented by the Hazard category. Moreover, as the name implies, the Material category covers the material domain. The component and E-waste item categories are essential for the modelling of the different WEEE categories and items.

Such a division simplifies the reusability of the various defined categories to model different scenarios of multiple WEEE items which could be sharing a step or more along their handling cycle without the need to define the step multiple times.

2.3.1 Defining the classes

In an ontology, a class is a category and under each class, there can be subclasses that divide the parent class into further subcategories. This process of classes and subclasses is what allows the ontology to be scalable since the classes become more specific and focused as they are further down the taxonomy (Keet, 2018).

Based on the previously defined structure of the ontology, the parent classes are created. In the current phase of ontology development, classes have been created to model various types of solar PV, which was selected as the initial WEEE case study to support the development and understanding of the ontology. As ontology evolves and scales, additional WEEE items, along with their handling technologies, associated hazards, and corresponding components, will be incorporated. Some general data was added as well, especially under the materials and treatment classes; these were thought to be useful for the immediate subsequent expansion phases. The description and hierarchy of each class category are shown in Table 1, which also shows snapshots from the ontology for each category illustrating its structure, some of its main constituents and the relations that define them. The blue arrow line used to connect the different classes in the various categories represents the relationship of subclass, for example, in the component category Aluminium_frame is a subclass of housing&encapsulation which is a subclass of component.

2.3.2 Object properties and data properties

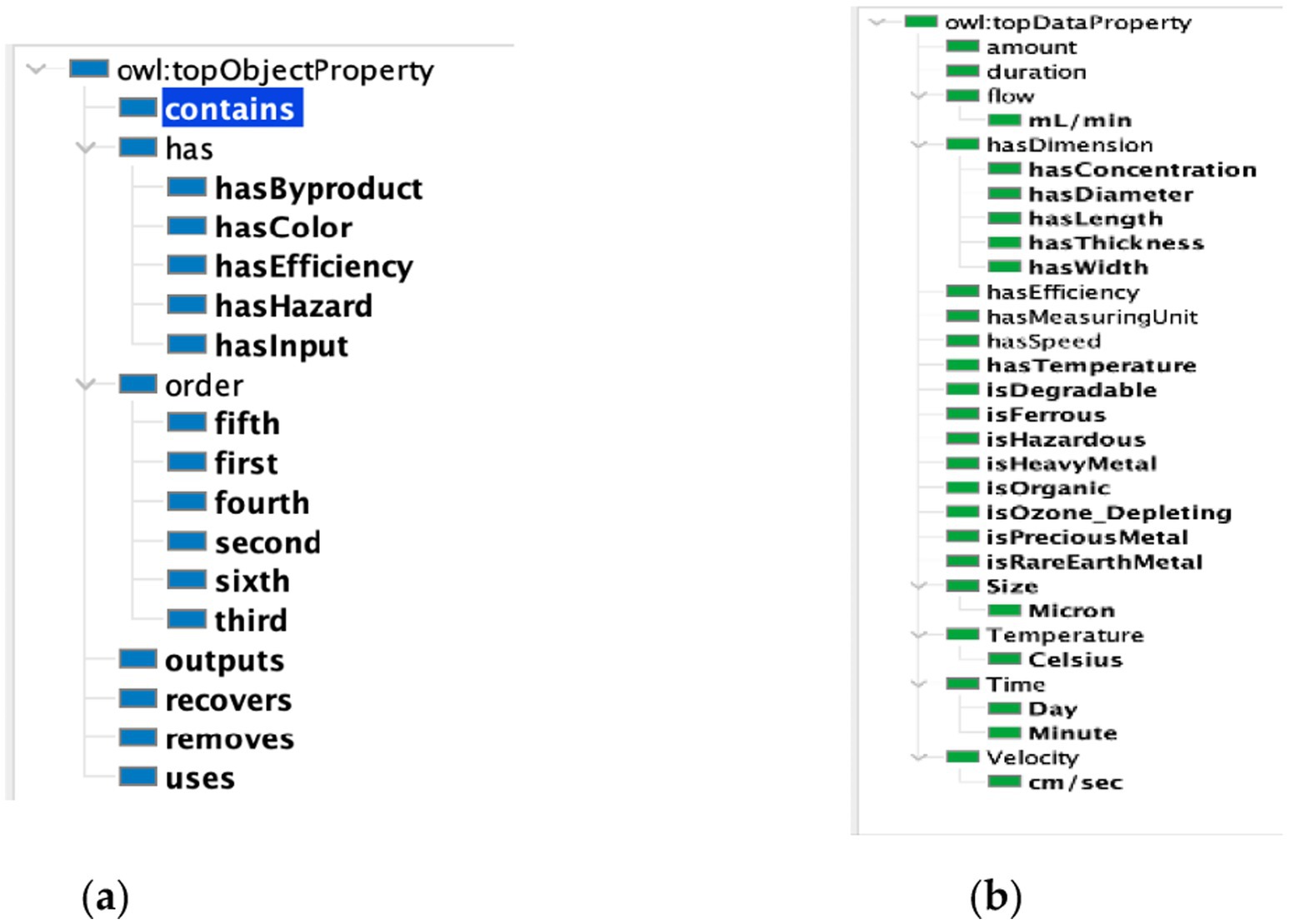

Each class category can contain a group of individuals that belong to this class. When individuals are created (as further explained in section 2.2.3), their relations with other individuals across the ontology are established using object properties. Otherwise, individuals can be described using data properties which typically have values (Keet, 2018). The lists of object properties and data properties defined for the WEEE ontology are shown in Figures 3a,b.

Figure 3. (a) List of object properties added to the ontology and used to draw relations among the different class individuals. (b) List of data properties added to the ontology to describe the class individuals.

The choice of both the object and data properties to define was decided to allow flexibility in the model design and to account for scalability. For instance, under the object property, there are both “remove” and “recover” which from an operational point of view have a similar meaning but when modelling a process, it better describes the process. “Recover” is used when referring to a material of interest that can be collected. On the other hand, “Remove” is used when the material is not desired and thus might be eliminated in a way that does not allow its reclamation. For example, a process that eliminates the presence of lead would be modelled using “remove” as the lead is no longer of interest; whereas “recover” is used with a process that collects it, such as a hydrometallurgical process. The same applies to “output” which describes a process that produces a specific material as an output, except that it might need further processing to be recovered.

The “order” property and its sub-properties (first, second, etc.) are used to list the specific order of a process precisely; that is, the sequence of executing a process. Although the ‘order’ property has been defined up to the sixth step in the ontology, additional steps can be easily added as needed, highlighting the ontology’s flexibility and scalability.

Both the object and data property lists have a property reflecting hazard, i.e., “hasHazard” and “isHazardous” respectively. This approach offers greater flexibility in modeling, as a process or material can be described in detail by linking it to specific hazards using the object property or simply flagged as hazardous through the data property without specifying the type of hazard. Similarly, other seemingly duplicate properties in the list provide the option to model at varying levels of complexity, allowing for additional layers to be added to objects or classes and supporting future expansion and evolving requirements.

2.3.3 Creating the individual instances

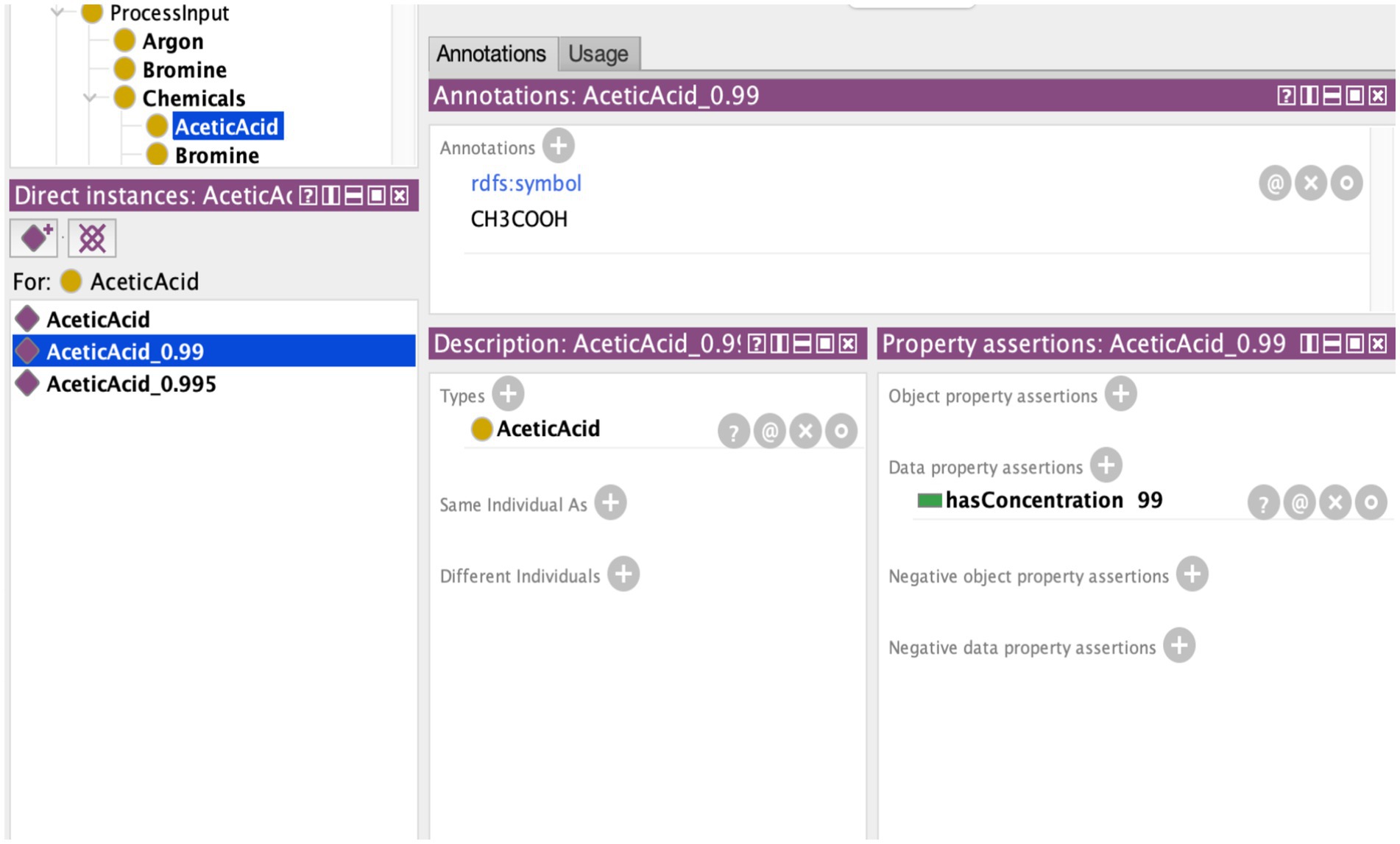

Individuals are at the endpoints of an ontology. They come to define a specific case of a class. For instance, under the class of “Process Input” there is a subclass for “Acetic Acid” under which several instances are created for various concentrations of acetic acid, illustrated in Figure 4. With this complexity in mind, a precise description of each individual is regarded as crucial to ensure clarity and avoid confusion in addition to securing clear-cut modelling of the instances in the ontology and how they relate to and interact with each other. For this purpose, annotations are used to provide the extra description needed for both classes and individuals. The annotations used in the defined WEEE ontology are:

• Reference, which documents the sources in the literature from which information was obtained.

• Symbol, which is added to individuals of materials or chemicals to report their chemical formula.

• Comment, to report any extra information.

• Amount, with subsequent sub-annotations which can be added to individuals to describe the quantity. Sub-annotations include: weight content, dimension, extraction efficiency, and concentration.

Figure 4. An example from the ontology showing the structure of similar individuals of Acetic acid with various concentrations.

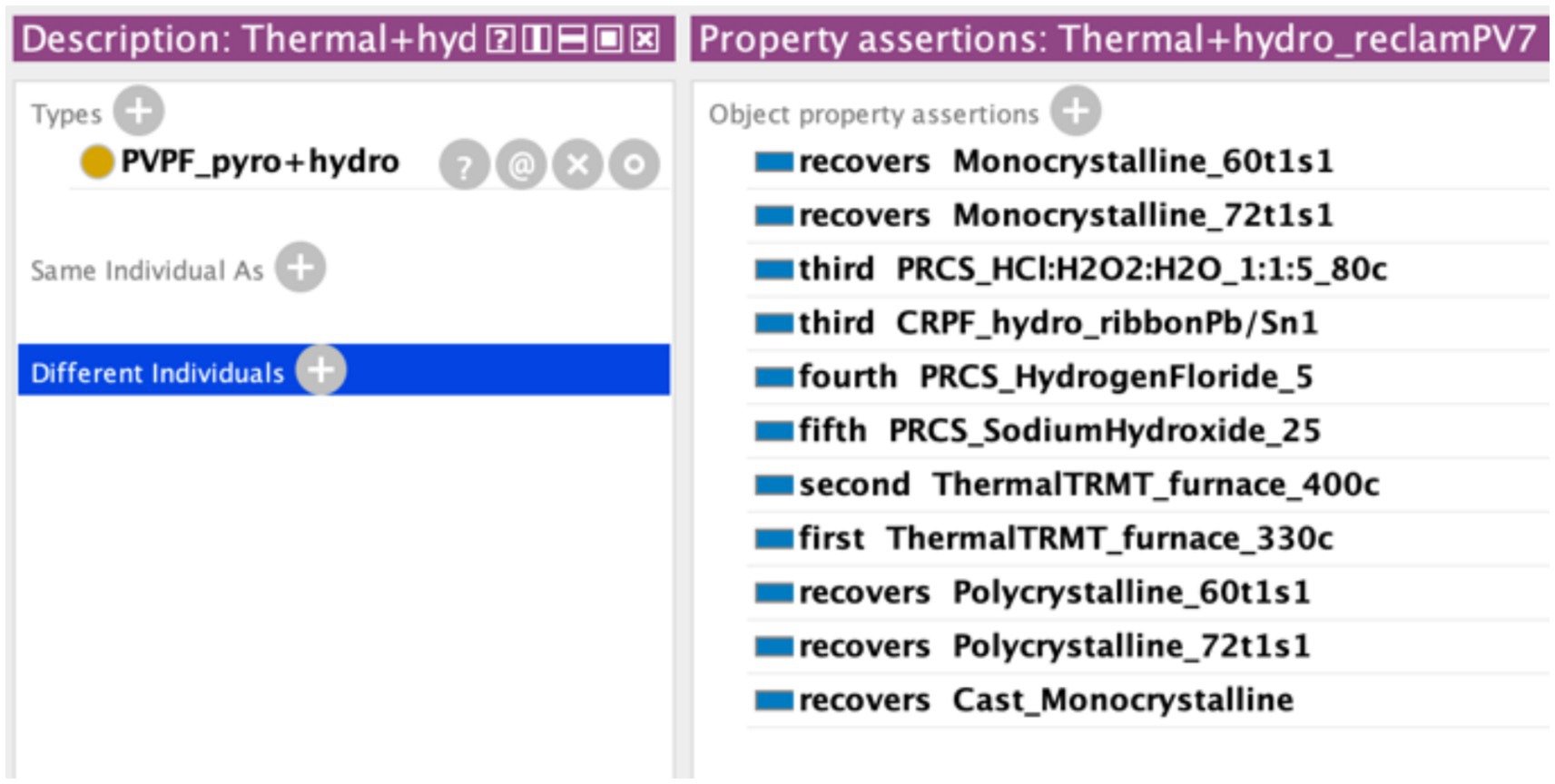

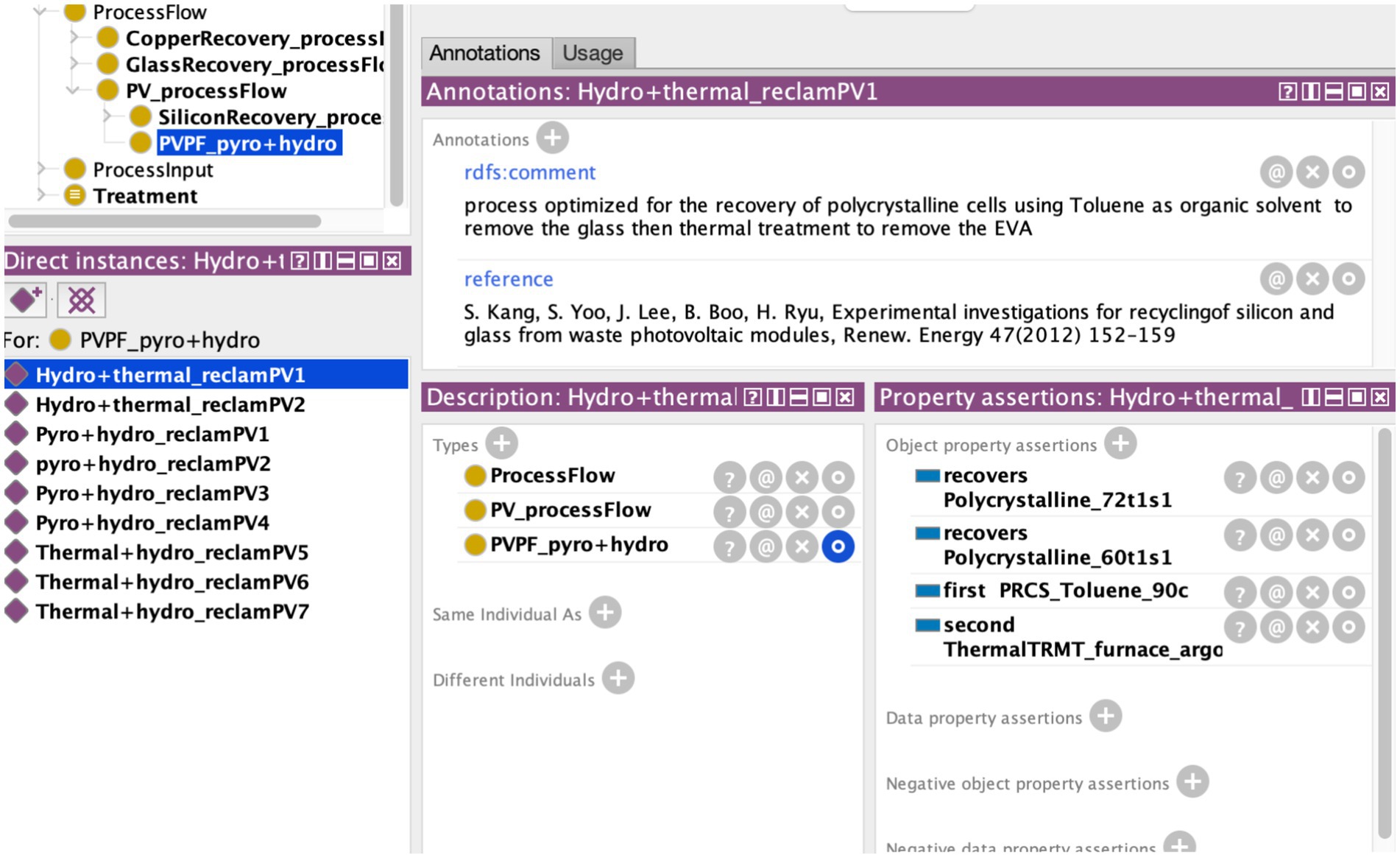

An example of using annotations to better describe the individual “Hydro+thermal_reclamPV1” is shown in Figures 4, 5.

Figure 5. An example from the ontology showing the use of annotations to better explain classes and individuals.

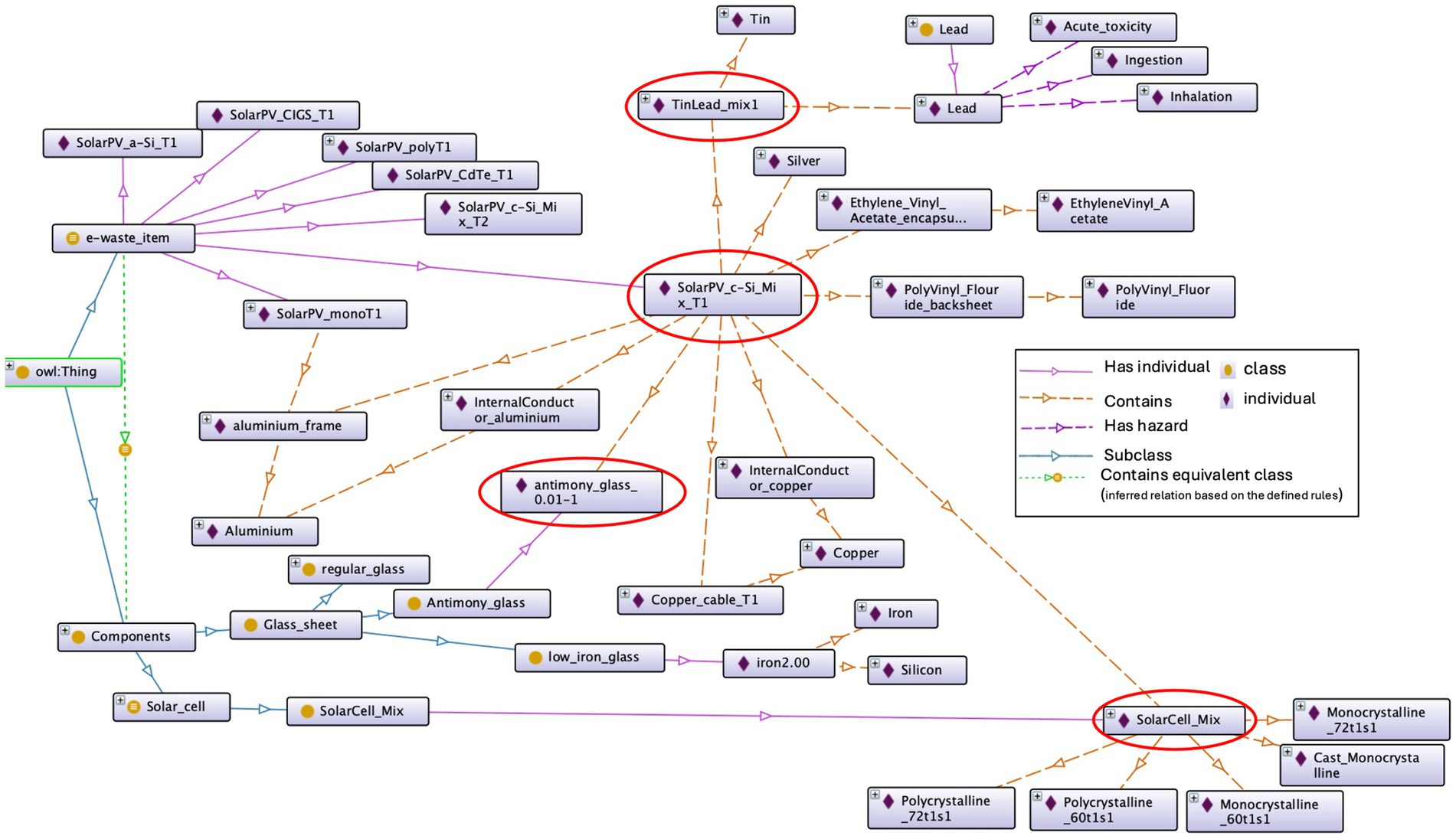

Firstly, the e-waste items and their constituent components are created to model the solar PVs. The individual “SolarPV_c-Si_Mix_T1” (in the centre of Figure 6), which belongs to the “e-waste item” category, models a mixture of solar PV of different types, hence the individual “SolarCell_mix” which contains other individuals that represent the different solar PV types such as monocrystalline, polycrystalline and cast monocrystalline cells, each with various versions that differ in size and/or number of cells found per panel. Tracing the “SolarCell_Mix” individual it belongs to the subclass “SolarCell_Mix” which is a child of the “Component” category. Under the same category, there is “Glass_sheet” which has the individual “antimony_glass_0.01–1” that is also used to model the original mixture of solar PV “SolarPV_c-Si_Mix_T1.” Another constituent of the mixture is the “TinLead_mix1” (top centre of Figure 6) which represents a mixture of tin and lead that was reported in the literature (Latunussa et al., 2016) but not specified under which component these materials were found. The individual “lead” has 3 individuals connected to it using the relation “hasHazard” to model the impacts of this material, in this case, acute toxicity, ingestion, and inhalation.

Figure 6. Snapshot of the ontology which models the case of solar PV mixture of different solar cell types.

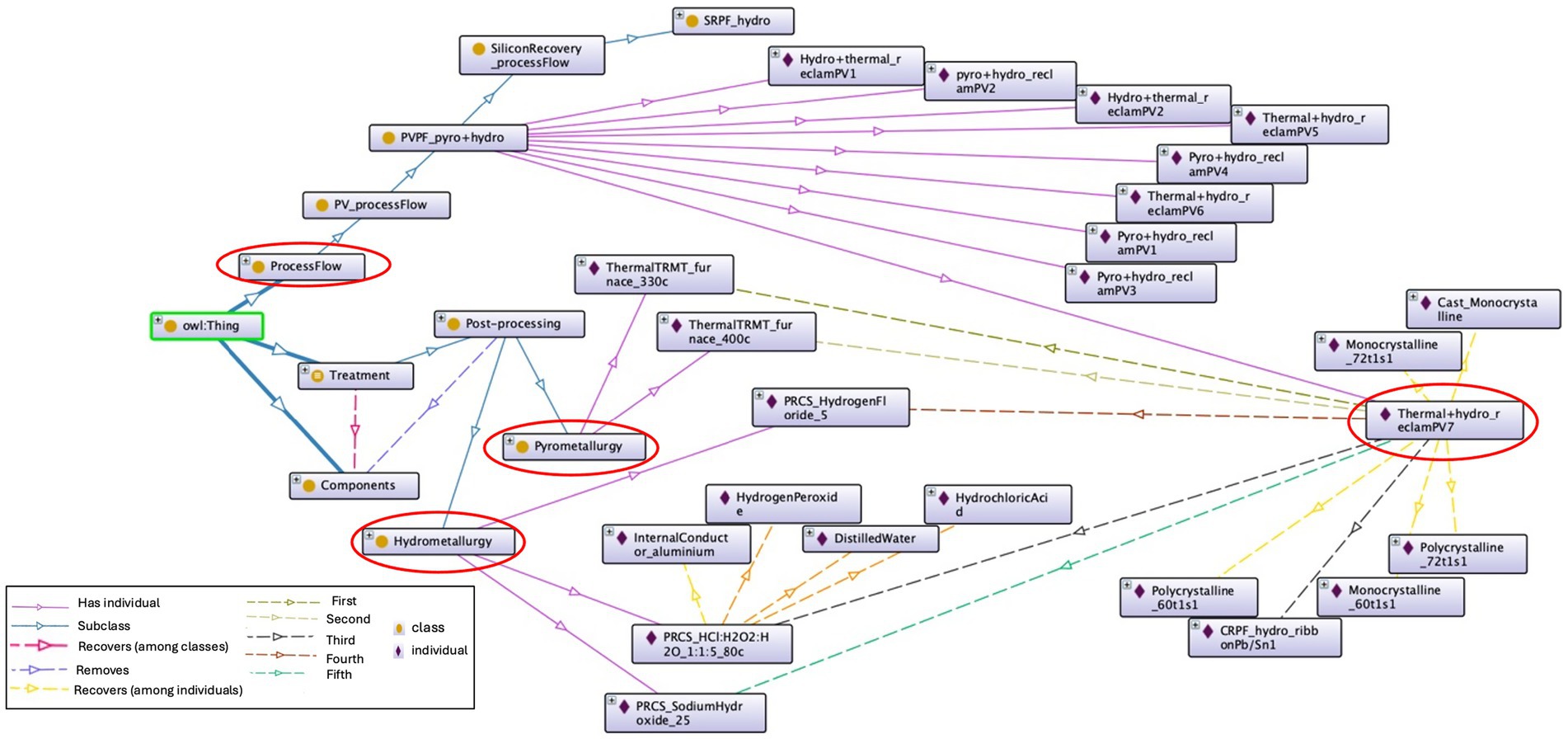

Consequently, to model the handling and treatment methods, individuals were created for each step of a treatment method and process specifics were detailed using annotations, object properties, and data properties. For example, to model a treatment method for solar PV which includes a multistage thermal treatment to remove the Ethyl vinyl acetate (EVA) encapsulation and Tedlar followed by multistage hydrometallurgical treatment using a mix of acids to recover the silicon and copper (Wang et al., 2012), the individual “Thermal+hydro_reclamPV7” is created (in the rightmost part of Figure 7). The individual belongs to the Process Flow class category, and it also connects to the components category through the relation “recovers” which ties it to the different instances of solar PV cells; namely: polycrystalline, monocrystalline, and cast monocrystalline with their various dimensions, belonging to the components category and are recovered by this method. In addition, the individual connects to the subclasses of “Hydrometallurgy” and “Pyrometallurgy,” which both descend from the main category “Treatment,” through the various individuals which each represent a step in the treatment process with its respective sequence which is represented in the mapping of the process through the various arrowed lines First through Fifth in Figure 7 (namely the “ThermalTRMT_furnace_330c” is the first stage of the process and the “PRCS_SodiumHydroxide_25” is the fifth stage); moreover, the construct of the individual is shown in Figure 8 showing the same sequence of the execution of the processes.

2.3.4 Defining the rules using semantic web rule language (SWRL)

The power of using ontologies lies in the ability to automatically derive relations, both direct and indirect, among individuals and classes. This can be realized using rules which guide the reasoner to deduce such relations. The reasoner used for this purpose is HermiT (RRID: SCR_016006, V1.4.3.456) and the rules are scripted using SWRL (Motik et al., n.d.).

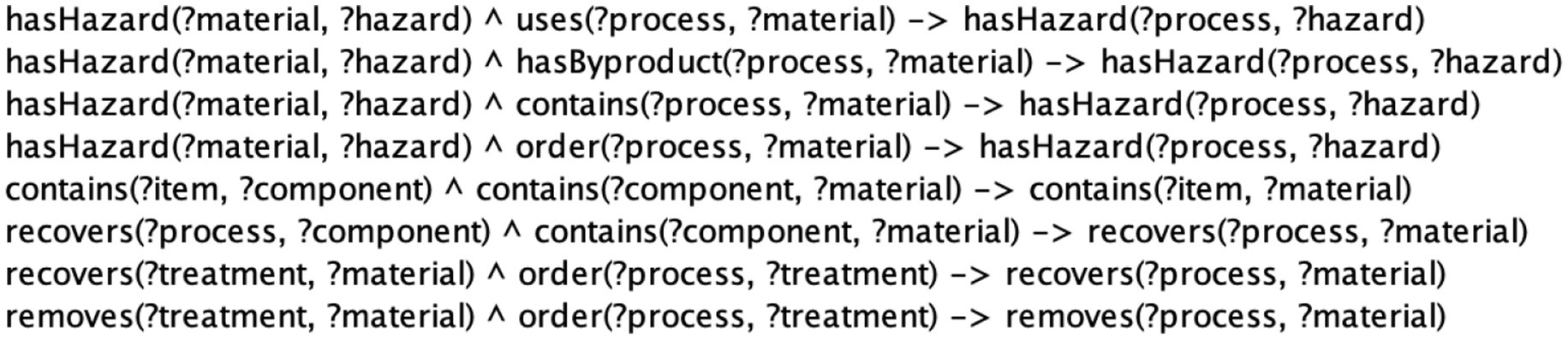

For the WEEE ontology, the rules defined focus on the associated hazards and impacts of the various components, processes, and materials. They also aim tokeenly describe the outputs of processes. For instance, the first rule shown in Figure 9 states that if a material has a hazard and a process uses that material, this makes the process have the same hazard. Consequently, the second rule in the list associates a hazard with a process in case a material produced as a byproduct from this process has that hazard. The third rule derives a similar relationship related to the hazard associated with materials contained in a process. Regarding the fourth rule, it associates hazard with a step of the treatment process in case that step contains a material with a hazard. Moreover, the fifth rule associates material content to an e-waste item in case it contains a component which contains that material. The final 3 rules are related to the recovery and material removal and deducing that a process recovers or removes material in case it contains a treatment step that does so. The list of rules defined for the WEEE ontology is shown in Figure 9. The rules defined have in mind connecting and better describing relations between the three domains in the scope of this DSS which span across materials, hazards, and treatment technologies.

3 Results

At this point, the WEEE ontology spans across the domains previously defined within the scope of the DSS and some of the solar PV-related processes have been extracted from the literature and modelled. To verify the first research question R1, it is essential to run the reasoner and verify the relations drawn between the various classes and individuals.

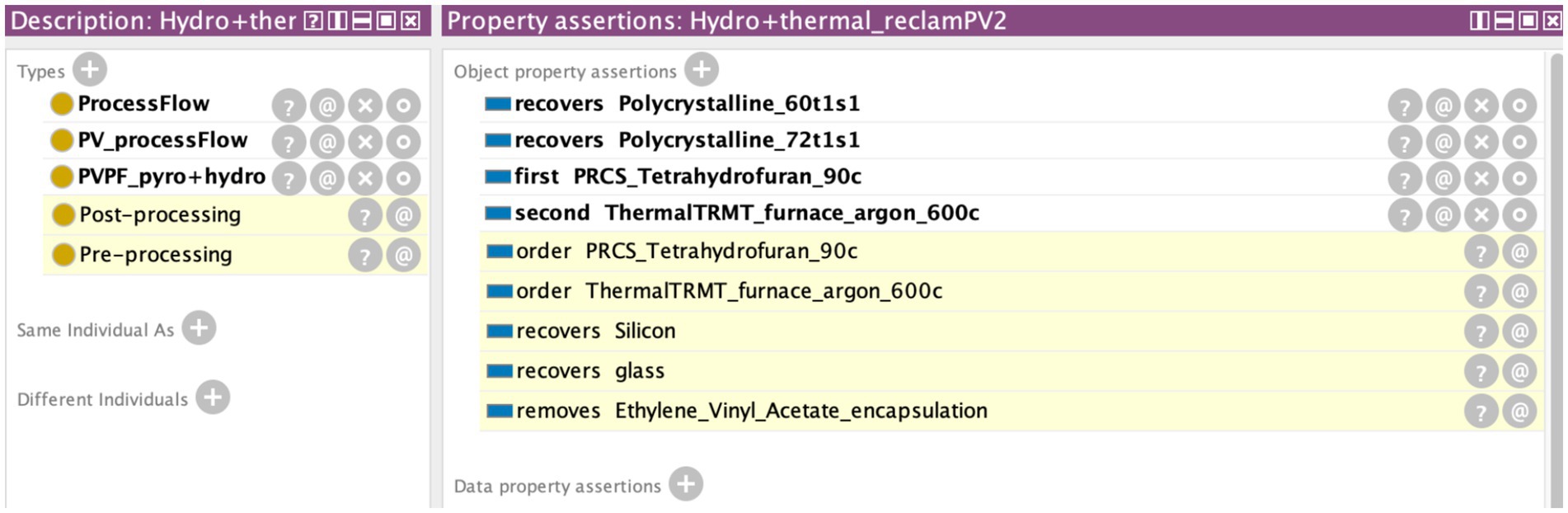

When running the reasoner, the ontology is expanded, and the new relations based on the predefined rules are associated. For example, highlighted in yellow in Figure 10 are the inferred connections related to the individual “Hydro+thermal_reclamPV2” which is a process flow that aims to reclaim the PV from the entire panel. The reasoner concluded that since the process recovers polycrystalline PV, then it also recovers Silicon, which is the material contained within the polycrystalline object, the same applies to the EVA removed by the process. It also decides that the process can be considered as both pre-processing and post-processing treatment depending on the sequence the process is applied during the entire handling process. These relations were deduced based on the defined relations between the entities and guided by the rules previously explained in section 2.2.4.

Figure 10. An example of the inferred relations among classes and individuals using the HermiT reasoner.

Although the deduced relations by the reasoner are on ontological level, they demonstrate the powerfulness of this DSS and the potential of this modelling approach. It connects the three domains that are usually represented in a disconnected manner (Udage Kankanamge et al., 2024). Even though the GUI layer of the DSS is not yet developed, by just taking a look at the relations derived in Figure 10 one can get an overview of the process and it becomes easier to understand the potential of the DSS when fully developed.

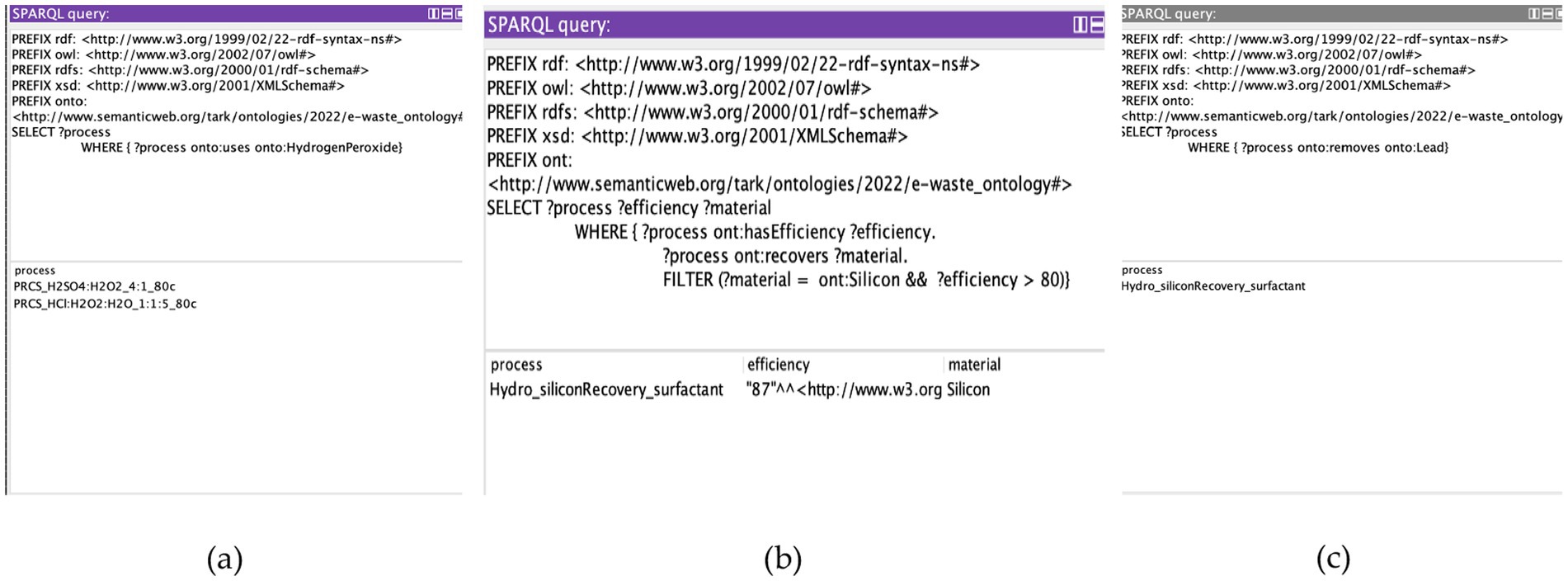

The potential of the developed ontology can be further demonstrated using the SPARQL querying functionality integrated into the Protégé software. SPARQL is a querying language that functions analogously to other database query languages such as SQL (Keet, 2018). SPARQL querying permits the raw usage of the developed ontology staunchly from the Protégé software without the need to embed it into another program or further develop software applications, although it requires the knowledge of the SPARQL language, as a result, it is not tailored for non-expert users. In this case, the SPARQL is only used to validate the model and not as part of the user interface with the DSS.

Another way to validate the developed ontology against the first research question R1 is by running SPARQL queries and verifying the obtained results. For instance, querying the ontology for processes that use a specific chemical agent such as hydrogen peroxide returns a list of the defined processes as shown in Figure 11. The queries can be as general as just listing all processes which use a specific material or help remove a material of interest such as in Figures 11a,c, which can be used in case of a preliminary search to define a starting point for a more well-defined search, or they can be more complicated such as in Figure 11b which specifies different properties and categories for the search to narrow down the options to include only the ones with the highest desirability of the decision-maker (in this case, the desired process recovers silicon material with efficiency over 80%).

Figure 11. SPARQL query results (a) from querying the treatment processes which use hydrogen peroxide; (b) from querying processes that have a material recovery of silicon at an efficiency of at least 80%; (c) from querying the processes which help remove lead.

The results obtained from the queries as well as the relations derived by the reasoner were as expected and no anomalies were detected. Although these queries are simple, they demonstrate that the WEEE domain can be simplified into one system that covers the various aspects of sustainability. As per the flow diagram of the DSS logic previously presented in Figure 1, the information extracted in the examples in Figure 11 represents the step where the ontology retrieves the data.

This data in the DSS backend would then be processed to represent it in the interactive GUI which would not only show the name of the process or its efficiency but would list the steps of the process and the conditions of each step, along with the associated hazards and impacts that were defined in the ontology. This can be achieved through successive queries, each building on the results of the previous one, gradually uncovering deeper layers of the argument and providing a comprehensive overview.

4 Discussion

Regarding the DSS developing methodology adopted, it can be argued that the output from the ontology fits the methodology. To begin with, the methodology defines the objectives and use cases of the DSS which can be translated into operations performed on the ontological level. The DSS aims to simplify the WEEE domain and give a holistic overview of the WEEE problem; the ontology helps to achieve this target. It bridges the gap between the various domains covered by the WEEE sector and gives almost complete data regarding a specific argument of interest in the WEEE domain, a challenge that faces the WEEE sector (Udage Kankanamge et al., 2024).

The second part of the methodology is to assess whether the entities within the ontology capture the full scope of the ontology. The defined classes, annotations, and object and data properties modelled easily the various processes from the technological, material and hazards points of view. The current classification of the taxonomy of the ontology permitted it to easily expand as new technologies were added during the developing phase. The classes covered all three targeted domains, and the object and data properties made relating the various entities in the ontology a simple task. It was also demonstrated during the data extraction phase using SPARQL that the current taxonomy enables the easy extraction of the data regarding the three domains in the scope of this ontology.

Based on the current taxonomy, which demonstrated the scalability of the ontology, the ontology also exhibits significant potential for the reusability of some of the already defined entities. Given the fact that the class categories divide each of the three domains into small building blocks, it is easy to mix and match various blocks together to model different cases. For instance, the “component” category which currently contains the building blocks to model solar PVs and assessing its reusability to model other items shows that the “housing&encapsulation,” the “Glass_sheet “and the “Electrical_components” can all be reused to model other WEEE items such as and limited to mobile phones or screens which both have an external housing, a glass screen and contain electrical components such diodes and wires. Other types of components might need to be added under already existing components, or a new component would be created in case it does not fit under any of the existing ones, in both cases the current taxonomy permits this addition without the need to restructure the entire ontology. In addition, the components that will be reused will already have the previously defined materials and hazards associated with them, cutting down the time needed to redefine them from scratch. As for the new components, in case they contain materials that were already defined during the current development phase, they will automatically get associated with their respective hazards when the reasoner is run. This valuable reusability feature of the ontology can be applied to other class categories such as the “treatment” and “process_input” classes and their respective individuals.

A real-life example of scalability and reusability can be demonstrated when adding a different category of WEEE such as Printed circuit boards (PCBs) to the ontology. PCBs contain a myriad of materials but predominantly are made of resin, silicon, copper and, aluminum with some containing small percentages of gold, silver, and lead (Priya, 2023). The majority of these materials were already defined under the Materials class as shown in Table 1. In the case of “Resin” material; although it was not already defined during the initial phase of building the ontology, it is still easy to add that to the ontology. Since a “polymer” class already exists and a “Resin” subclass can be added under the “Polymer” class with further classification of the types of resin used in PCBs being added as subclasses of Resin. The amount of each material found in the PCB is then added as an annotation using the previously defined annotation “weightContent” which is a sub-annotation of “Amount.”

Furthermore, the extraction of data from the ontology, which represented one of the core operations of the DSS logic, was shown using the SPARQL queries directly in protégé simulating the ontology query phase that would take place in the backend of the DSS when it is fully developed.

After validating the functionality and usability of the developed ontology it is evident how the WEEE DSS would be useful and will simplify the decision-making process by extracting all the needed data to draw a crystal-clear picture of an WEEE stream and what would be the optimized approach to handle it as well as connecting the various domains of sustainability by drawing relations among them. This addresses both research questions, R1 and R2, that inspired this study, highlighting the practicality of the adopted methodology, which emphasizes scalability and reusability.

Future validation of the processes extracted from the model would be done after the expansion of the ontology to cover other WEEE items. The validation is proposed to be through the comparison of the results obtained from the laboratory experimental implementation of the recommended treatment processes for different WEEE items against the expected results shown in the model to check the accuracy of the results obtained. This validation methodology would have a two-fold benefit to the developed system. First, it will help confirm the accuracy of the data provided by the DSS such as the quantity of materials included and the efficiency of the processes. Second, it will provide feedback on whether the modelling of the processes is detailed enough to be directly implemented without the need for further research into the conditions and risks. This contributes to fulfilling the main objective of the DSS to cluster the knowledge about WEEE and ensuring its availability and accessibility for informed decisions.

While working on the WEEE ontology, a group of challenges were identified. Firstly, the process of data extraction from the literature, beginning with finding the relevant literature passing through extracting the data, analysing it and finally feeding it into the ontology, is time-consuming as well as requires lots of human resources in case of expanding the ontology to cover a wider scope whether under the WEEE umbrella or even beyond WEEE and into other waste types. This makes the development process quite slow and resource intensive. Fortunately, with the current advancement in AI, automating the data identification and extraction process can be a viable solution to mitigate such hindrances. Automating the process would permit greater coverage of what is reported in the literature, identify duplicates, and minimise human error. Undoubtedly, automation of the data extraction process will still require the intervention of domain experts to verify the data and insert them into the model, at least until the AI model is adequately developed and trained to perform such an intricate operation; especially that such an approach is still in its natal phase and is currently a subject of research.

Another challenge which was identified is the lack of accurate data on the compositional level of WEEE concerning the material content. In most literature found and used in this ontology, material contents of different components were estimates and usually, the main categories of components were handled without diving deeper into whether there is a significant variance amongst the different models of the same components or different types of components that have similar functionalities. Such a gap thwarts the development of an ontology which would offer accurate data on the material content of the different WEEE items directly affecting the viability of some of the considered solutions.

5 Conclusion

This study aims to develop a WEEE ontology as a first step towards a DSS for WEEE management given the complexity of the domain and the lack of such a system, which can be used by various stakeholders who are not experts in the subject.

The methodology followed to develop the DSS, and the ontology provided a systematic approach to the development of the system satisfying the defined scope of the DSS to connect the three domains of sustainability, providing accessible information to the WEEE domain and improve the informed decision making. This methodology was inspired by the MOMo methodology.

The ontology was built in a way that adapts it to the continuously evolving nature of the domain and permits the perpetual update and integration with other projects and ontologies. The results demonstrated the scalability of the ontology and the reusability of the entities that are defined within the ontology. The defined rules and the use of the HermiT reasoner further elaborate the potential of the ontology and its powerfulness as a tool to automatically draw relations across the three domains of interest: technology, materials and hazards.

In addition to the integration of the ontology within a WEEE DSS, the ontology on its own can be used by experts or users with specific knowledge in the usage of ontologies and the Protégé software in order to exploit the ontology’s standalone potential and extract data from the ontology.

The ontology development has also highlighted some shortcomings such as the extensive time consumption for data extraction from literature review and the lack of accurate data on the different types and models of WEEE and their materials content.

Upon the completion of the ontology and its expansion to cover further types of WEEE, the system would contribute both directly and indirectly to the fulfilment of the UN SDGs by promoting responsible consumption and production, combating climate change, establishing new industries and developing better solid waste handling infrastructure which would indirectly contribute to wellbeing and good health as well as economic growth.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

AI: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Software, Validation, Visualization, Writing – original draft, Writing – review & editing. FL: Formal analysis, Funding acquisition, Methodology, Project administration, Supervision, Validation, Writing – review & editing. DF: Funding acquisition, Project administration, Supervision, Writing – review & editing. FR: Data curation, Methodology, Supervision, Validation, Visualization, Writing – review & editing. CT: Data curation, Formal analysis, Supervision, Validation, Visualization, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by Eni S.p.A. and the NODES project, which received funding from the MUR–M4C2 1.5 of PNRR funded by the European Union—Next Generation EU (grant agreement no. ECS00000036).

Acknowledgments

AT, Francesco Laviano and Debora Fino acknowledge the support provided by Eni SpA and the PNRR NODES project. This work was conducted using Protégé.

Conflict of interest

This study was funded by Eni SpA. The funder had the following involvement in the study: study design, the interpretation of the data, the writing of this article, the decision to submit it for publication. FR and CT were employed by Eni SpA—Renewable, New Energies and Material Science Research Center.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abbreviations

DSS, Decision support system; Solar PV, Solar Photovoltaic; Mt., Million tons; POPs, persistent organic pollutants; OWL, Web Ontology Language; XML, Extensible Markup Language; GUI, Graphical User Interface; EU, European Union; MOMo, Modular ontology modelling; LCA, Life Cycle Analysis; LCD, Liquid crystal display; EVA, Ethyl vinyl acetate; SWRL, Semantic Web Rule Language; PCB, Printed Circuit Board; UN SDGs, United Nations Sustainable Development Goals.

References

Ahmad, M. N., Badr, K. B. A., Salwana, E., Zakaria, N. H., Tahar, Z., and Sattar, A. (2018). An ontology for the waste management domain. PACIS 2018 Proceedings. Available online at: https://aisel.aisnet.org/pacis2018/12

Babaie, H., Davarpanah, A., and Dhakal, N. (2019). Projecting pathways to food–energy–water systems sustainability through ontology. Environ. Eng. Sci. 36, 808–819. doi: 10.1089/ees.2018.0551

Ceccaroni, L., Cortés, U., and Sànchez-Marrè, M. (2004). OntoWEDSS: augmenting environmental decision-support systems with ontologies. Environ. Model Softw. 19, 785–797. doi: 10.1016/j.envsoft.2003.03.006

Dean Kang, K., Ilankoon, I., Nan Chong, M., and Ta Yeong, W. (2023). Exfoliation of coarse printed circuit boards using dimethylacetamide: production of copper concentrates. Miner. Eng. 191:107963. doi: 10.1016/j.mineng.2022.107963

Directive 2012/19/EU on Waste Electrical and Electronic Equipment (WEEE), Pub. L. No. 197, official journal of the European Union 38 (2012). Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32012L0019

Eibeck, A., Lim, M. Q., and Kraft, M. (2019). J-park simulator: an ontology-based platform for cross-domain scenarios in process industry. Comput. Chem. Eng. 131:106586. doi: 10.1016/J.COMPCHEMENG.2019.106586

Faye, S., Melakessou, F., Mtalaa, W., Gautier, P., AlNaffakh, N., and Khadraoui, D. (2019). SWAM: a novel smart waste management approach for businesses using IoT. Proceedings of the 1st ACM international workshop on technology enablers and innovative applications for smart cities and communities, 38–45.

Foo, G., Kara, S., and Pagnucco, M. (2021). An ontology-based method for semi-automatic disassembly of LCD monitors and unexpected product types. Int. J. Automation Technol., 15, 168–181.

Gautam, A., Shankar, R., and Vrat, P. (2022). Managing end-of-life solar photovoltaic e-waste in India: a circular economy approach. J. Bus. Res. 142, 287–300. doi: 10.1016/J.JBUSRES.2021.12.034

Habib, H., Wagner, M., Baldé, C. P., Martínez, L. H., Huisman, J., and Dewulf, J. (2022). What gets measured gets managed – does it? Uncovering the waste electrical and electronic equipment flows in the European Union. Resour. Conserv. Recycl. 181:106222. doi: 10.1016/J.RESCONREC.2022.106222

He, Z., Yue, Y., and Wang, Y. (2022). The hazards, treatment measures and sustainable development of electronic waste. IOP Conf. Series 1011:12023. doi: 10.1088/1755-1315/1011/1/012023

Hou, S., Li, H., and Rezgui, Y. (2015). Ontology-based approach for structural design considering low embodied energy and carbon. Energ. Buildings 102, 75–90. doi: 10.1016/J.ENBUILD.2015.04.051

Kebede, R., Moscati, A., Tan, H., and Johansson, P. (2024). A modular ontology modeling approach to developing digital product passports to promote circular economy in the built environment. Sustain. Prod. Consumpt. 48, 248–268. doi: 10.1016/J.SPC.2024.05.007

Keet, M. (2018). An Introduction to Ontology Engineering. available online at: https://open.umn.edu/opentextbooks/textbooks/590

Khalifa, S. A., Mastrorocco, B. V., Au, D. D., Ovaitt, S., Barnes, T. M., Carpenter, A. C., et al. (2022). Dynamic material flow analysis of silicon photovoltaic modules to support a circular economy transition. Prog. Photovolt. Res. Appl. 30, 784–805. doi: 10.1002/pip.3554

Kultsova, M., Rudnev, R., Anikin, A., and Zhukova, I. (2016). An ontology-based approach to intelligent support of decision making in waste management. 2016 7th international conference on information, intelligence, systems & applications (IISA), 1–6.

Kumar, A., Holuszko, M., Crocce, D., and Espinosa, R. (2017). E-waste: an overview on generation, collection, legislation and recycling practices. Resour. Conserv. Recycling 122, 32–42. doi: 10.1016/j.resconrec.2017.01.018

Kuster, C., Hippolyte, J.-L., and Rezgui, Y. (2020). The UDSA ontology: an ontology to support real time urban sustainability assessment. Adv. Eng. Softw. 140:102731. doi: 10.1016/J.ADVENGSOFT.2019.102731

Lahtela, V., Hamod, H., and Kärki, T. (2022). Assessment of critical factors in waste electrical and electronic equipment (WEEE) plastics on the recyclability: a case study in Finland. Sci. Total Environ. 830:155627. doi: 10.1016/J.SCITOTENV.2022.155627

Latunussa, C. E. L., Ardente, F., Blengini, G. A., and Mancini, L. (2016). Life cycle assessment of an innovative recycling process for crystalline silicon photovoltaic panels. Sol. Energy Mater. Sol. Cells 156, 101–111. doi: 10.1016/j.solmat.2016.03.020

Morbach, J., Yang, A., and Marquardt, W. (2007). OntoCAPE—A large-scale ontology for chemical process engineering. Eng. Appl. Artif. Intell. 20, 147–161. doi: 10.1016/J.ENGAPPAI.2006.06.010

Mori de Oliveira, C., Marini, P., and Bellopede, R. (2021). Study of metal recovery from Printed Circuit Boards by physical-mechanical treatment processes (Politecnico Di Torino). Available online at: https://webthesis.biblio.polito.it/17217/1/tesi.pdf

Motik, B., Shearer, R., Glimm, B., Stoilos, G., and Horrocks, I. (n.d.). HermiT Reasoner (1.4.3.456). Department of Computer Science in the university of oxford. Retrieved July 10, 2024. Available online at: http://www.hermit-reasoner.com/index.html

Muñoz, E., Capón-García, E., Hungerbühler, K., Espuña, A., and Puigjaner, L. (2013). Decision making support based on a process engineering ontology for waste treatment plant optimization. Chem. Eng. Trans. 32, 277–282. doi: 10.3303/CET1332047

Musen, M. A. (2015a). Protégé (5.5.0). Stanford center for biomedical informatics research. Stanford center for biomedical informatics research.

Musen, M. A. (2015b). The protégé project: a look back and a look forward. AI Matters 1, 4–12. doi: 10.1145/2757001.2757003

Pekarkova, Z., Williams, I. D., Emery, L., and Bone, R. (2021). Economic and climate impacts from the incorrect disposal of WEEE. Conserv. Recycl. 168:105470. doi: 10.1016/j.resconrec.2021.105470

Preetam, A., Modak, A., Jadhao, R., Naik, S. N., Pant, K. K., and Kumar, V. (2022). A comprehensive study on the extraction of transition metals from waste random access memory using acetic acid as a chelating solvent. J. Environ. Chem. Eng. 10, 2213–3437. doi: 10.1016/j.jece.2022.108761

Priya, A. (2023). Management of electronic waste: Resource recovery, technology and regulation (Wiley, Ed.). Available online at: https://www.wiley.com/en-us/Management+of+Electronic+Waste%3A+Resource+Recovery%2C+Technology+and+Regulation-p-9781119894339

Ramprasad, C., Gwenzi, W., Chaukura, N., Izyan Wan Azelee, N., Upamali Rajapaksha, A., Naushad, M., et al. (2022). Strategies and options for the sustainable recovery of rare earth elements from electrical and electronic waste. Chem. Eng. J. 442:135992. doi: 10.1016/J.CEJ.2022.135992

Sattar, A., Ahmad, M. N., Salwana, E., Mahmood, A. K., and Ismail, M. I. M. (2020) Issues in designing ontology for waste management: a systematic review TEST Eng. Manag. 82 11889–11897. Available online at: https://www.testmagzine.biz/index.php/testmagzine/article/view/2749

Sinha, A., and Couderc, P. (2012). Using OWL Ontologies for Selective Waste Sorting and Recycling. Available online at: http://www.inria.fr/en/en/teams/aces

Sosunova, I., Zaslavsky, A., Anagnostopoulos, T., Fedchenkov, P., Sadov, O., and Medvedev, A. (2017). SWM-PnR: ontology-based context-driven knowledge representation for IoT-enabled waste management. Internet of Things, Smart Spaces, and Next Generation Networks and Systems. 10531.

Tansel, B. (2017). From electronic consumer products to e-wastes: global outlook, waste quantities, recycling challenges. Environ. Int. 98, 35–45. doi: 10.1016/j.envint.2016.10.002

Thomassen, G., Dewulf, J., and Van Passel, S. (2022). Prospective material and substance flow analysis of the end-of-life phase of crystalline silicon-based PV modules. Resour. Conserv. Recycl. 176:105917. doi: 10.1016/J.RESCONREC.2021.105917

Udage Kankanamge, A. K. S., Erdiaw-Kwasie, M. O., and Abunyewah, M. (2024). Towards a taxonomy of E-waste urban mining technology design and adoption: a systematic literature review. Sustainability 16:6389. doi: 10.3390/su16156389

Wang, T.-Y., Hsiao, J.-C., and Du, C.-H. (2012). Recycling of materials from silicon base solar cell module. 2012 38th IEEE photovoltaic specialists conference, 002355–002358.

Yang, Q., Zuo, C., Liu, X., Yang, Z., and Zhou, H. (2020). Risk response for municipal solid waste crisis using ontology-based reasoning. Int. J. Environ. Res. Public Health 17:3312. doi: 10.3390/ijerph17093312

Yu, E., Jan, K., and Chen, W.-T. (2023). Separation and solvent based material recycling of polycarbonate from electronic waste. ACS Sustain. Chem. Eng. 11, 12759–12770. doi: 10.1021/acssuschemeng.3c03152

Yu, C., Yuan, J., Cui, C., Zhao, J., Liu, F., and Li, G. (2023). Ontology framework for sustainability evaluation of cement–steel-slag-stabilized soft soil based on life cycle assessment approach. J Mar Sci Eng 11:1418. doi: 10.3390/jmse11071418

Zhang, Y., Luo, X., Buis, J. J., and Sutherland, J. W. (2015). LCA-oriented semantic representation for the product life cycle. J. Clean. Prod. 86, 146–162. doi: 10.1016/J.JCLEPRO.2014.08.053

Keywords: ontology, WEEE, decision support system, waste management, computational sustainability, circular economy

Citation: Ismail Mohamed AT, Laviano F, Fino D, Rubertelli F and Toscano C (2025) A sustainable approach tackling WEEE management using ontology-based DSS. Front. Sustain. 6:1523114. doi: 10.3389/frsus.2025.1523114

Edited by:

Susan Krumdieck, Heriot-Watt University, United KingdomReviewed by:

Medani Bhandari, Akamai University, United StatesChristian Spreafico, University of Bergamo, Italy

Copyright © 2025 Ismail Mohamed, Laviano, Fino, Rubertelli and Toscano. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ahmed Tarek Ismail Mohamed, YWhtZWQubW9oYW1lZEBwb2xpdG8uaXQ=

Ahmed Tarek Ismail Mohamed

Ahmed Tarek Ismail Mohamed Francesco Laviano

Francesco Laviano Debora Fino

Debora Fino Francesca Rubertelli4

Francesca Rubertelli4