- UCL Plastic Waste Innovation Hub, University College London, London, United Kingdom

The world is facing an increasing challenge with the accumulation of Waste Electrical and Electronic Equipment leading to a wide range of negative environmental and social impacts. Supporting higher priority circular economy activities such as repair and extending the lifespan of electrical and electronic equipment (EEE) will help to reduce WEEE's negative impacts, create skilled jobs, and improve supply chain resilience. This requires citizens to be able to identify EEE products as repairable, have basic repair skills, access to repair services (including diagnostics) and motivation to repair. Using a citizen science approach over a 32-month period from January 2022 to September 2024, the Big Repair Project collected 5,958 survey responses and 473 detailed logs of repair activities from people geographically spread across the UK. The data was analyzed to better understand issues that currently exists with household maintenance and repair of home appliances and electronics. Findings reveal a gap between consumer expectations of product lifespan and existing legislation, challenges related to cost and accessibility of repair services, and a desire for improved repair information and spare parts availability. The findings emphasize the need for policy and industry action to diversify local repair economies, extending statutory warranty periods, support diagnostics and repair transparency, and incentivize repair businesses. By fostering a culture of repair, this work aims to inform the development of UK Right to Repair laws and broader circular economy initiatives, contributing to the reduction of electronic waste and the promotion of sustainable consumption practices.

Introduction

The growing accumulation of Waste Electrical and Electronic Equipment (WEEE) poses significant environmental, social, and economic risks globally (Purkiss et al., 2024). With the United Kingdom (UK) generating ~24.5 kg of WEEE per capita (Baldé et al., 2024)—among the highest globally—the consumption and disposal of electrical and electronic equipment (EEE) are on unsustainable trajectories. These trends are leading to exacerbated greenhouse gas emissions, depleted critical materials (NEPC, 2024), and adverse social and health impacts globally (World Health Organization, 2021). The circular economy offers a framework to mitigate these challenges through processes like maintenance, reuse, refurbishment, remanufacture and recycling of electrical and electronic equipment (Ellen MacArthur Foundation, 2025), thereby promoting sustainable production and consumption, and minimizing health risks, in alignment with the UN Sustainable Development Goals (UN, 2015). While recycling remains an important circular economy activity, it cannot keep pace with the growth rate of electronic waste (Forti et al., 2020), requires significant energy use and is a source of emissions (Green Alliance, 2020b). Instead, other circular economy activities such as reduction, reuse, repair and remanufacture are becoming critical priorities (Bakker et al., 2014; Green Alliance, 2018; HM Government, 2022).

Historically, repair was integral to society partly due to the simpler product designs, widespread repair skills and affordable labor (Perzanowski, 2022). However, technological advancements during the digital era, planned obsolescence, and societal shifts have made repairs increasingly complex and cost-prohibitive (Bisschop et al., 2022; European Parliament, 2016). Coupled with the convenience and cost-effectiveness of purchasing new electronics and the influence of fashion and advertising, these factors have diminished repair culture, fueling a throwaway economy (Hernandez et al., 2020). Recognizing these challenges, global policy developments—such as Right to Repair laws—have sought to re-prioritize repair as a cornerstone of circular economy strategies. There is also growing recognition that to support such policy developments and address the challenge of EEE waste, greater awareness, consumer behavior and culture are critical (Baldé et al., 2024). However, the analysis of existing studies discussed in this paper demonstrates that up-to-date data on citizen attitudes, opinions and behaviors toward maintenance and repair of home appliances and electronics in the UK remains limited.

This paper investigates the UK repair system, focusing on citizen attitudes, opinions, and behaviors toward the maintenance and repair of home appliances and electronics. The work explores the Right to Repair and Ecodesign regulations, product health and safety standards and other legislation influencing user behaviors, professional or home repairs in the UK. A review of existing literature on repair user behavior is used to cross reference findings from the Big Repair Project, which uses a citizen-science approach (Haklay et al., 2020) featuring 5,958 survey responses and 473 logged repair activities. The findings reveal a gap between consumer expectations of product lifespan and existing legislation, challenges related to cost, software support and accessibility of repair services, and a desire for improved repair information and spare parts availability. The study emphasizes the need for policy and industry action to diversify local repair services, extend statutory warranty periods, support diagnostics and repair transparency, and incentivize repair businesses. Additionally, fostering repair skills, engaging diverse demographic groups and exploring circular economy business models could help grow a repair economy and reduce WEEE generation.

Repair legislation and standards

Repair is a relatively diverse sphere of activity with different social, contractual, and legal relations depending on the actors involved, whether repair is conducted under consumer law (right to repair or replacement or faulty goods), servicing contracts (e.g., warranties), for personal benefit outside of consumer/contractual protection or for commercial purposes and resale.

The Big Repair Project predominantly focuses on repair activities conducted by private individuals on personal property intended for personal use, or via contracting an independent repair professional to undertake the repair for them, outside of a servicing contract. In each of these scenarios there are laws, regulations and standards specific to the UK that influence repair behavior and thus become important context within which findings should be analyzed. In addition, in the context of UK home repairs there are concerns that repaired products are more likely to develop faults, be sold or passed onto others via second-hand marketplaces, leaving users more vulnerable to health and safety e.g., electrical injuries or liability risks (National Audit Office, 2021; EEESafe, 2025). This section offers a review of relevant legislation and standards that should be considered in the context of the Big Repair Project as they influence, enable or inform repair activities. These include laws, regulations and standards applicable to repair more widely such as (1) Right to Repair and Ecodesign; and (2) product health and safety standards; and also laws, regulations and standards which specifically apply to (3) professional repair services and (4) home repair.

Right to repair and Ecodesign

A measure that has been introduced in the UK and other countries to reduce WEEE waste and reduce greenhouse gas emissions are Ecodesign Regulations, which contain provisions colloquially referred to as “Right to Repair” Regulations (House of Commons Library, 2021; Green Alliance, 2020a). These regulations apply to products introduced onto the market by producers, either directly by manufacturers or by importers—while these do not directly apply to repair activities, they influence and enable them.

UK “Right to Repair” regulations came into force in July 2021 as part of the Ecodesign for Energy-Related Products and Energy Information Regulations 2021 (SI 2021 No. 745) (House of Commons Library, 2021). These Regulations apply to Great Britain, with Northern Ireland subject to EU Ecodesign requirements under the Northern Ireland Protocol (House of Commons Library, 2021). These Regulations aim to increase producer responsibility, reduce energy usage and electrical waste, and enable citizens to identify more energy efficient products (House of Commons Library, 2021). They also increase the responsibilities of electronics manufacturers to provide spare parts and technical repair information and aim to increase consumer product lifespans by up to 10 years by giving professional repairers access to spare parts and technical information from July 2021 (manufacturers have a grace period of up to 2 years to make parts available). The law also requires manufacturers to make specific spare components available to the general public, although these are limited to easy-to-replace parts (e.g. drawers for refrigerators); components requiring more complex installation procedures can be restricted to qualified professionals only.

Currently the UK's “Right to Repair” Regulations do not cover the full range of electrical and electronic equipment (EEE) goods contributing to WEEE waste. They only cover dishwashers, washing machines, washer-dryers, refrigeration appliances as well as televisions and electronic displays. Several organizations are calling for UK Government to include more electronics and appliances within scope, in particular laptops and smartphones (House of Commons Library, 2021) and to better regulate the cost and accessibility of spare parts (House of Commons Library, 2021). The Regulations also do not include a requirement to publish information about the repairability or durability of products based on an agreed repairability and durability assessment framework.

In Europe, Parliament has taken a proactive approach to making repair easier and more accessible to consumers with recent changes to EU Ecodesign Regulations designed to ensure manufacturers repair products for a reasonable price and within a reasonable timeframe, improve access to spare parts, tools and repair information for consumers, introduce incentives such as repair vouchers and funds to opt for repair and propose new forms and platforms to help consumers assess and compare repair services (European Parliament, 2024).

In addition, a wider adoption of a Durability Index is being considered by the European Commission alongside the future European Energy Label which will both include a repairability index. The Durability Index is already mandatory in France and covers products such as smartphones, televisions and washing machines, which were previously covered under the French Repairability Index and policies. The Durability Index incorporates repairability and extends criteria to include trustworthiness, robustness, and upgradeability (France, 2024).

Voluntary ecolabels can also provide citizen information on repairability of specific products. For example, the Germany-based Blue Angel uses individual award criteria for different product types, however repairability is not uniformly covered across products. For example, the DE-UZ 219 criteria for imaging equipment (such as printers) includes requirements for manufacturers to maintain access to spare parts and repair information for at least 7 years and the DE-UZ 78 for computers and keyboards include requirements for repairability and upgradeability (Blue Angel, 2024).

Repair activities globally have been influenced by Intellectual Property (IP) Law. Whilst IP Law is important to ensure a product is not illegally copied, reproduced or sold, however commonly identified manufacturer activities and interpretations of IP Law include limiting the repair of electronic products, restricting access to product manuals, parts numbering, software restrictions and locks, and planned obsolescence (European Commission, 2022; Perzanowski, 2022).

Product health and safety standards

Standards are documents, “established by consensus and approved by a recognized body, that provides, for common and repeated use, rules, guidelines or characteristics for activities or their results, aimed at the achievement of the optimum degree of order in a given context” (International Standards Organisation, 2020). Standards have been developed by the European Committee for Standardization (CEN and CENELEC) and the British Standards Institution (BSI) in response to circular economy and material efficiency initiatives that cover the reuse, repair, and remanufacture of electronic products.

Several standards outline general safety requirements for different categories of electrical products. For example, BS EN 60335-1:2012+A15:2021 covers household and similar electrical appliances, BS EN 60950-1:2006+A2:2013 covers information technology equipment, BS EN 61010-1:2010+A1:2019 covers electrical equipment for measurement, control, and laboratory use, and BS EN 60950-1:2006+A2:2013 sets out different requirements for operators, lay people and for service people to reduce risks of fire, electric shock or injury. These standards provide guidelines to reduce risks such as fire, electric shock, and injury for operators and laypeople. However, they do not specifically address repair activities.

Another relevant standard is The UK Conformity Assessment (CA) Certification, introduced in 2021 to replace the EU Conformité Européene (CE) Certification for products sold in Great Britain (England, Wales and Scotland). In 2023, the UK government announced that the recognition of the CE marking for placing most goods on the market in Great Britain would be extended indefinitely (HM Government, 2023).

These standards exist within the wider Health and Safety legislative framework, which includes the Electrical Equipment (Safety) Regulations. These regulations define “spares” and clarify that products repaired, refurbished, or exchanged without changing their original performance, purpose or type are not considered “new” and do not require recertification or re-marking (HM Government, 2016). This creates a gap in clear, applicable standards for the repair of electrical and electronic equipment.

In response to this gap, standards from grassroot organizations such as EEESafe are gaining momentum. The EEESafe and White Goods Safety Standard alongside the community-focused Training Qualification/Certification are aimed at independent repairers and domestic repairers in the community, setting a higher standard for electrical competency and testing to ensure overall safety of the repair process and the repaired product (LocalitEEE, 2024).

Professional repair services

Professional repair services are covered by the Consumer Rights Act 2015, under “contracts to supply a service”, stipulating that such services must be undertaken with reasonable skill and care and that information provided about a service is legally binding, reasonably priced, and carried out within a reasonable time. Under the Consumer Rights Act 2015 Act all products must be of satisfactory quality, fit for purpose and as described. Consumers have the right to refuse, claim repair or replacement of faulty goods under the Act if the product they have purchased fails to meet any one of the above criteria under a 6 year breach of contract period. Rights vary according to when a claim is made from date of purchase (up to 30 days, between 30 days to 6 months, and 6 months to 6 years) (HM Government, 2015). Subsections (14) and (15) of the Act provide that if the breach e.g., a fault, arises in the first 6 months from delivery it is presumed to have been present at the time of delivery unless the trader proves otherwise, making it easier for consumers to exercise their right to repair or replacement. However, after the 6 month period and up to 6 years after purchase the burden is on the consumer to prove that the fault existed at time of purchase (HM Government, 2015).

Parts used during repair are also covered by the Act, and consumers are entitled to remedies in case of underperformance. During repair, spare parts may come from different sources: new spares manufactured by the original equipment manufacturer (OEM), aftermarket (third-party manufactured) spares made to the same specification, or used spares harvested from end-of-life models—as well as fulfilling expected performance requirements, under the Unfair Trading Regulations 2008, repairers cannot mislead customers over work done, e.g., installing 3rd-party spares after claiming that they are using ones manufactured by the OEM, or installing used spares after claiming to be installing new ones.

During repair, professional repairers must observe the Electricity at Work Regulations 1989 which stipulate that electricity workers have a responsibility to ensure that electrical systems do not give rise to danger either during the work, or after (e.g., ensuring live wires are suitably insulated). Liability for defective products was introduced by the Consumer Protection Act 1987: if a defective product leads to injury, any person injured (not just the person who bought it) may bring a claim against the producer demonstrating proof that the product caused the injury. Additionally, claims in negligence may also be brought against producers. In the case of repaired products under the Act, there is a legal question over whether the repairer would be classified as a “producer”—if a part repaired by a 3rd party is involved in the defect, the original manufacturer will not be liable. In the case of the repair going beyond restoring the product to its original functionality, then the party undertaking the repair would be classified as a producer. If bringing a claim under either the Act or negligence, the injured party would need to clearly demonstrate that the repair process caused the defect which caused injury. Additionally, if the injury is caused by a suitable spare part which was shown to be correctly installed by the repairer, the manufacturer of the spare part would become liable under the Consumer Protection Act.

Home repair (non-professional)

Personal repair activities of products for personal use are not regulated under UK law, and there are no requirements for individuals to meet particular standards.

However, there are requirements in the case of electrical appliances being owned and supplied by landlords to rental properties, which may affect repair of goods by non-accredited persons (e.g., by the landlord or tenant themselves). In the UK, electrical equipment provided by landlords must be safe and fit for purpose and there is an overarching obligation to comply with Health and Safety legislation. In England and Wales, there are no testing requirements for electrical appliances (regulations only apply to fixed electrical installations such as lighting and circuitry)—while in Scotland, the Repairing Standard Housing (Scotland) Act 2006, Chapter 4 requires landlords to carry out regular PAT testing of supplied electrical appliances (Scottish Government, 2024).

In the case of private individuals selling repaired goods in a private sale, the principle of caveat emptor (otherwise known as “buyer beware”) applies (Catalyst Law, 2021; Britannica, 2024). In this case, it is up to the buyer to carry out due diligence on the item and identify potential problems, although under The Misrepresentation Act, the seller must provide an accurate description of the item (e.g., not declaring a second-hand item to be new). However, if this is the case, the onus is on the buyer to collect and document evidence demonstrating this.

However, if a repaired item is being sold by a trading entity (i.e., not a private sale), consumer protections apply via the Consumer Rights Act 2015 (and the Consumer Contracts Regulations 2013 if purchased from an online retailer). This is particularly relevant where individuals may donate repaired EEE to charities or non-profits for re-sale.

Repair user behavior

Understanding product performance and user behavior is vital to the success of circular economy models of material and product use (Wastling et al., 2018). In the context of the circular economy, repair is defined as the mending or reconditioning of human-made products to restore their form or function (Perzanowski, 2022); activities that extends a product's lifespan (including maintenance) (Hernandez et al., 2020); and part of preparing for re-use activities in the waste hierarchy framework (DEFRA, 2011).

Several studies outside the UK have examined user behaviors toward repair of electrical and electronic products. In the United States (US), several studies have sought to analyse data from users of online platforms such as Amazon Mechanical Turk and most commonly iFixit, an online platform promoting user repair of electronic products (iFixit, 2025). These studies seek to understand economic and technical challenges of repair and user attitudes toward repair (Scott and Weaver, 2014; Raihanian Mashhadi et al., 2016; Sabbaghi and Behdad, 2018; Sabbaghi et al., 2016). Common findings highlight barriers to repair such as high repair costs relative to initial item cost, uncertainty in labor costs, lack of repair manuals, unavailability of spare parts and complicated repair processes. Recommendations to address these barriers including more formal training, better access to spare parts and more accurate cost estimation (Scott and Weaver, 2014; Raihanian Mashhadi et al., 2016; Sabbaghi et al., 2017). Another US based study focuses on user willingness to pay for repair of mobile phones via an online survey of 208 students, calling for manufacturers to improve accessibility and affordability of repair services (Sabbaghi and Behdad, 2018).

In Norway, a smaller scale study, including a survey of 1,196 respondents and 15 interviews with actors in the repair economy, identified several barriers to increasing repair rates. These included the low prices, poor quality and short lifespans of new products, the low profitability of repair businesses and a lack of access to skilled personnel (Laitala et al., 2021). Furthermore, the convenience and affordability of purchasing new electronics, coupled with the influence of fashion and advertising, have contributed to a decline in repair behaviors in favor of consumption (Hernandez et al., 2020). In Ireland, a study involving 208 individuals with pro-environmental inclinations also highlights affordability, access to skills, knowledge and support, and safety concerns as key influencing factors for user repair behaviors (Lefebvre et al., 2018).

UK-based academic studies of repair behavior highlight technical barriers such as accessibility to materials, spare parts and necessary skills, as well as motivators for repair such as emotional attachment, functional and symbolic value (Nazli, 2021). However, these studies generally address a broad range of products or focus on specific repair activities, such as clothing repair, and have not specifically investigated repair behaviors related to electrical and electronic equipment.

Repair behaviors in the UK have been informally observed through initiatives such as the Restart Project's Fixing Factory and Restarters.net platform which run community repair hubs offering repair services and skills training for local residents. These initiatives have reportedly repaired 54,571 devices (Fixing Factory, 2024). Similarly, Tech-Takeback in Brighton and Hove operates a high-street repair shop, provides waste electricals collection, repair and skills training services and has repaired and redistributed 6,500 devices (Tech-Takeback, 2024). Insights from Fixing Factories and Tech Takeback were shared with the Big Repair Project during roundtable discussions in 2023 and 2024. These discussions highlighted additional barriers such as the need for data erasure and cyber security concerns when handling electronic devices, as well as broader benefits such as social inclusion, skills development and wellbeing.

In London, academic studies into enabling repair choices for citizens are ongoing with initial findings highlighting key barriers to repair as perceived time-consumption of repair, cost and justification against initial quality of product (Aurisicchio et al., 2023). In 2023, a smaller study of seven households in London explored consumer behaviors of product life extension in the context of the UK's Cost-of-Living Crisis and highlighted how communication-based interventions can positively influence consumers' attitudes (Reynolds et al., 2024).

Data from YouGov exploring the Right to Repair Regulations, shows men were much more comfortable in undertaking repair than women, with toparticipants feeling most comfortable repairing vacuum cleaners (42%), laptops (30%), kettles (23%), towashing machines (22%), with under a fifth of participants willing to repair a mobileto phone (YouGov, 2021). In a 2020 study of electronic devices, YouGov reported that people are less likely to repair a tablet or a mobile phone device than to buy a new one, with cost of repair, the age of devices and the relative inconvenience of repair being the key reasons for choosing not to repair (YouGov, 2020).

However, more recent consumer data from a nationally representative sample of more than 2,000 UK adults aged 18+, shows changing behaviors where durability (58%) and repairability (37%) are becoming the top two considerations when making a purchase (Deloitte, 2023).

Based on the review of existing user behavior data, to our knowledge the Big Repair Project is the largest citizen science study combining large-scale collection of data on home appliances and electronics repair and behavior across the UK.

Citizen science

We used a citizen science method to collect data on attitudes, opinions and behaviors toward maintenance and repair of home appliances and electronics. Citizen science is a flexible concept which can be adapted and applied within diverse situations and disciplines, however its main aim is to actively involve the general public in the production of scientific knowledge (ECSA, 2015). Following best practice, our study, The Big Repair Project, was designed in accordance with the ten citizen science principles as outlined by the European Citizen Science Association (ECSA, 2015). The ambition for the project was to maximize diverse citizen participation from across the UK. The chosen format for involving the general public builds on previous research (Purkiss et al., 2022) and consists of a publicly accessible website containing a 10-min online survey and an optional home repair logbook facilitated through an online personal login. The logbook asked participants to record details about maintenance and repair activities on home appliances and electronics. The website also allowed citizens to sign up to newsletters and webinars in order to receive progress updates and feedback from the project which are also shared publicly on the website via blog posts, reports and video links. The project was publicized via a media campaign which included features on national radio and news outlets, and social media posts. Significant efforts were made to reach groups from all socio-economic backgrounds. These activities drove recruitment via the project website and were supplemented by word of mouth and direct outreach via professional networks.

Materials and methods

Before participating, citizens are directed to website information relevant to consent: participant information including project aims, data protection, withdrawal rights, image guidelines, use of results, health and safety information and where to direct questions and complaints; and logbook guidelines including additional photography guidelines. Ethics Approval for the study was granted by the UCL Research Ethics Committee (Project ID/Title: 16747/002: Big Repair Project) until 25 November 2024.

Method part 1—survey

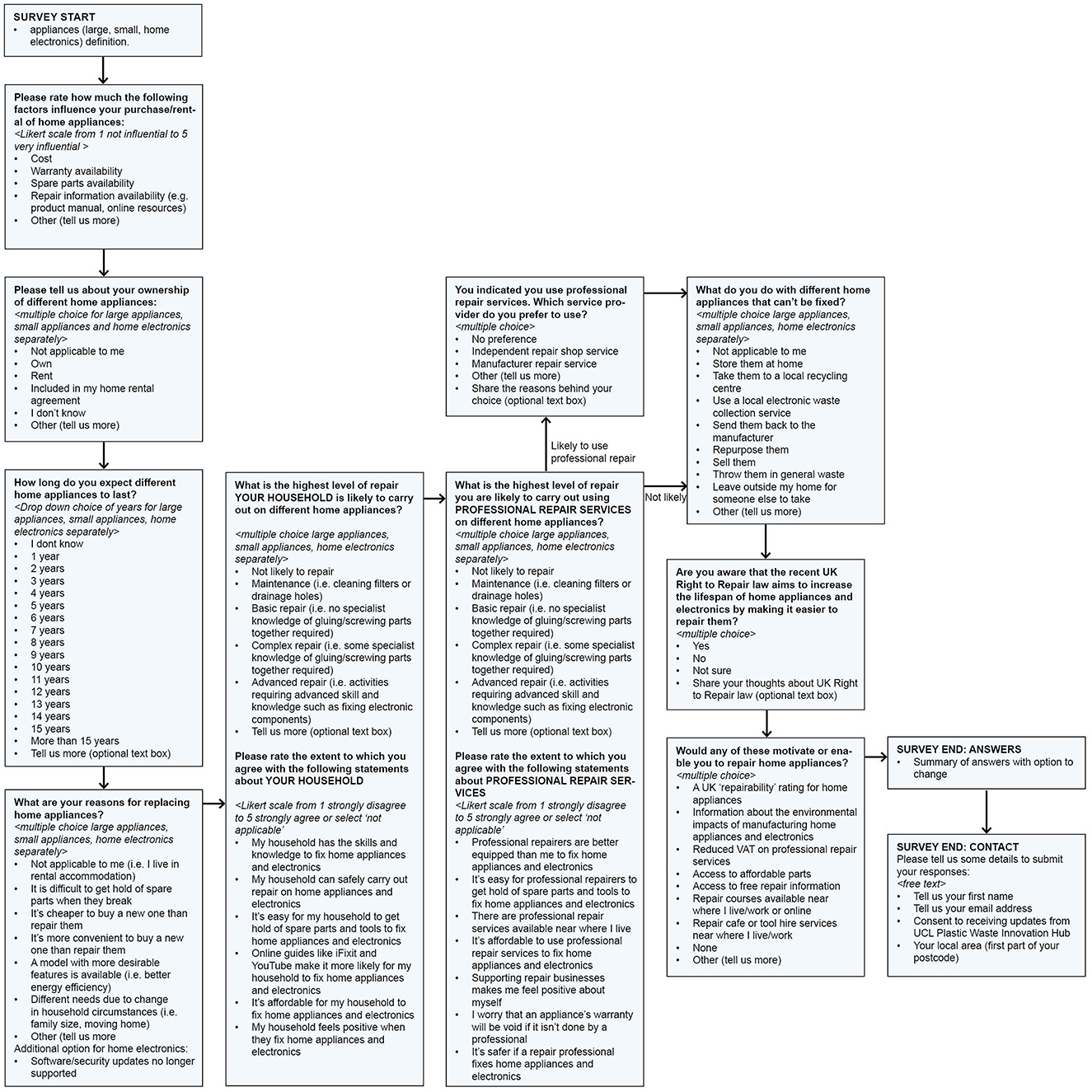

The survey began with illustrated definitions of the types of home appliances, followed by questions enquiring about ownership of appliances, influences for purchasing, life expectancy, reasons for replacement, household home repair capability, use of professional repair services, disposal behaviors, Right to Repair Law, motivation for repair (see Figure 1). At the end of the survey, a participant was asked to review their responses and submit by entering their name, email and location. Participants were given the option to sign-up for the Big Repair Project Newsletter at the end of the survey.

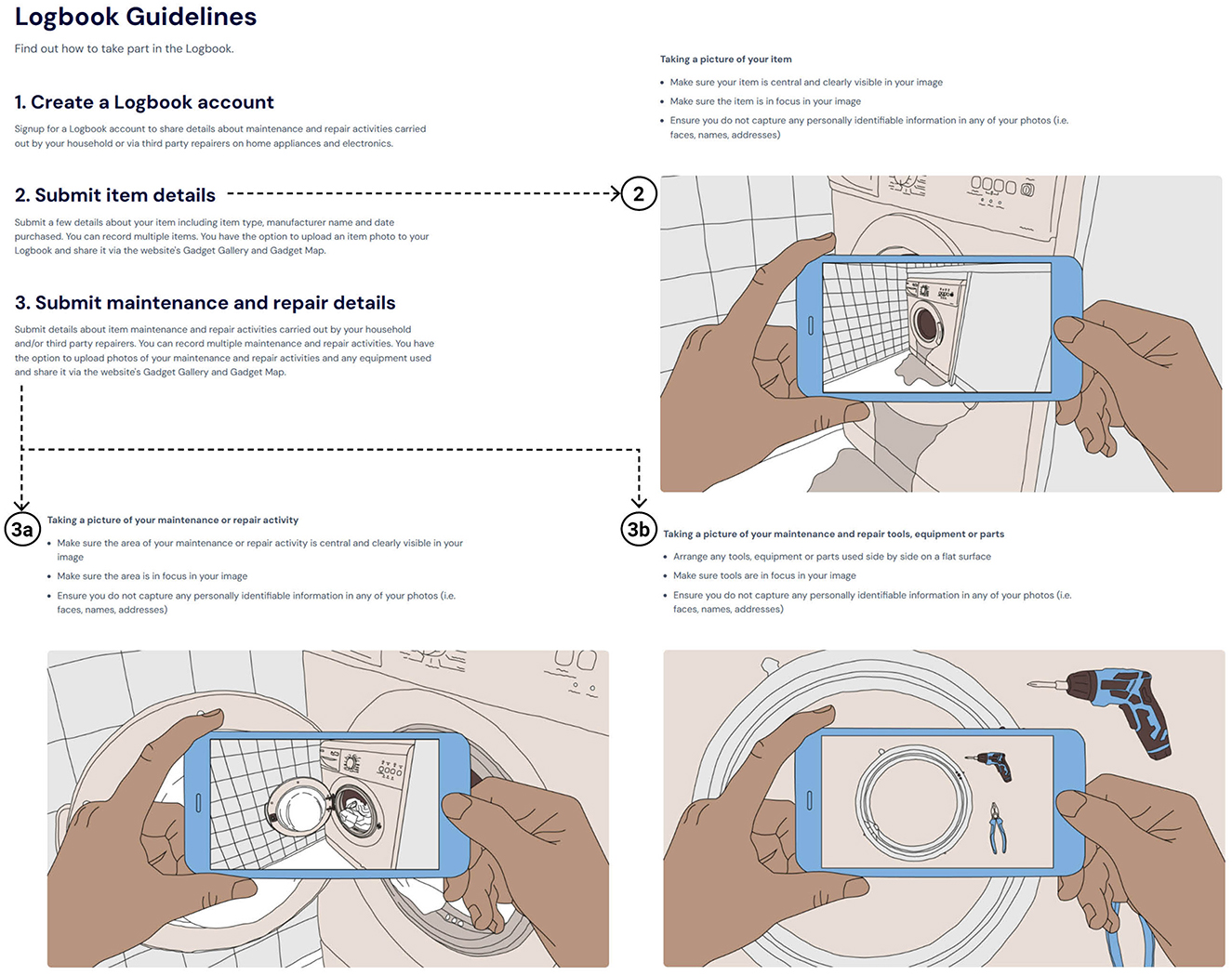

Method part 2—logbook

Participants were offered the option of recording details about the maintenance and repair activities they have undertaken on home appliances by setting up a user login account (see Figure 2).

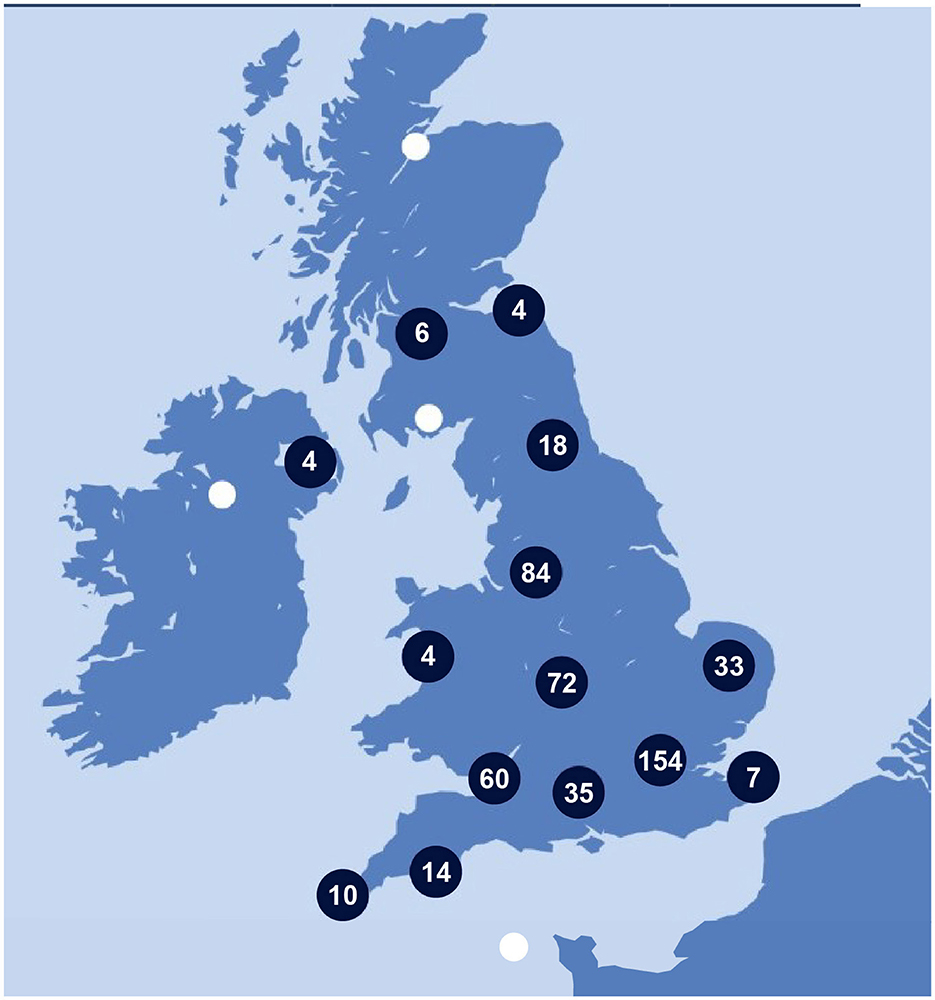

The account setup asked for optional personal information such as age range, gender, occupation, home ownership status and local area postcode to better understand repair behavior amongst different groups and geographic locations. It was explained to participants that the local area postcode information would be used to generate a Live UK Repair Map which would also be available on the website (Figure 3).

To log a new repair activity, participants were asked to input information about the item subject to repair. Participants could choose from pre-defined item categories and manufacturers names and were also asked about the item's model or serial number, date of acquiring the item, and who owns the item with an option to submit a photograph of the item pre-repair. Participants were then asked about the repair activity including the date it took place, how the problem was diagnosed, what level of maintenance and repair was required, who carried out the activity, where the resolution information was found, how much it cost, and the result of the activity. Participants were also asked about how they felt about the activity (was it difficult and overall experience) and what happened with the item at the end with the option to upload photographs of the repair process and tools. Participants could submit multiple items to their account and add multiple repair activities per each item. The Big Repair Project website automatically logged this information to a database.

Results

The data presented and analyzed were collected over 32 months from 19th January 2022 to 19th September 2024, during that time 5,958 survey responses and 473 logbook repair activity entries were made from across the UK. The difference in responses between the survey and the logbook is attributed to the difference in data collection method and level of engagement required which is also observed in similar previous studies (Purkiss et al., 2022). Whilst the survey takes a few minutes and can be completed without creating an account, the logbook requires additional information from participants including creating an account, uploading details and images of repairs and answering additional questions.

The geographical distribution of the repair activities is shown in Figure 3, demonstrating good coverage across the UK with the highest proportion in Southeast (Greater London) and Northwest (Greater Manchester) of England. This roughly correlates with the distribution of population density in the UK. There are no major regional differences in the findings, highlighting a consistency of dominant barriers and motivations across the UK. Over 50% of Big Repair Project (BRP) respondents reported that their household is likely to carry out basic or complex repair to large and small appliances and home electronics; and from those who recorded detailed repair activities the most common item types were washing machines, cookers/ovens, dishwashers and computers. This contrasts with market research data from 2021 reporting that over 60% of UK adults have not attempted to repair one of these items themselves previously, and would not feel comfortable doing so (YouGov, 2021). However, the recent cost-of-living crisis and increased knowledge of circularity has had an impact on how citizens are adopting more sustainable lifestyles with more recent UK consumer data showing 55% people repaired an item instead of buying a new equivalent (Deloitte, 2023). Additionally, BRP respondents were primarily male (72% compared to 51% national average) and over the age of 55 (66.4% compared to 28.5% national average). This is an indication that the BRP sample is not representative of the general population and that the people attracted to take part in the BRP were those who are already interested in repair. This is also evidenced by the fact that participants in the logbook indicated that they already knew what the problem was rather than relying on online resources or the product manual and that they were carrying out complex or advanced repair.

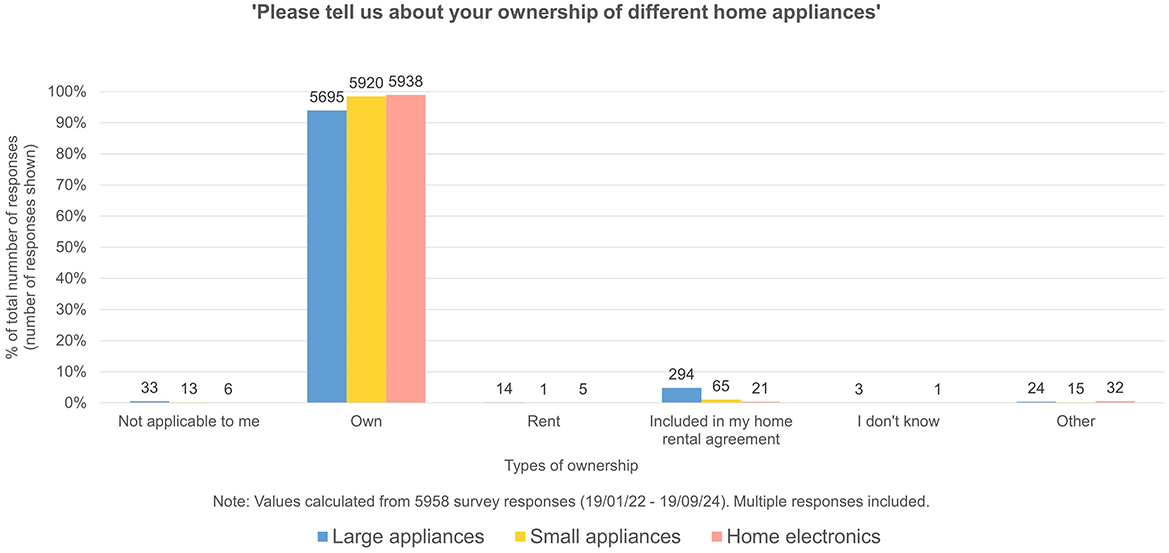

BRP participants were also asked about whether they owned or rented home appliances to investigate whether this influenced their attitude to repair. A majority of BRP participants own home appliances (94% large appliances, 98% small appliances, 99% home electronics), with only a small number of participants who rent appliances or have them included in their home rental agreement (Figure 4). This is an indication that circular economy business models (pay-per-use, product lease, subscription and shared access) are not scaled-up in the UK's electrical appliances sector in comparison to parts of Europe (Sigüenza et al., 2021).

Figure 4. Responses to survey question “Please tell us about your ownership of different home appliances”.

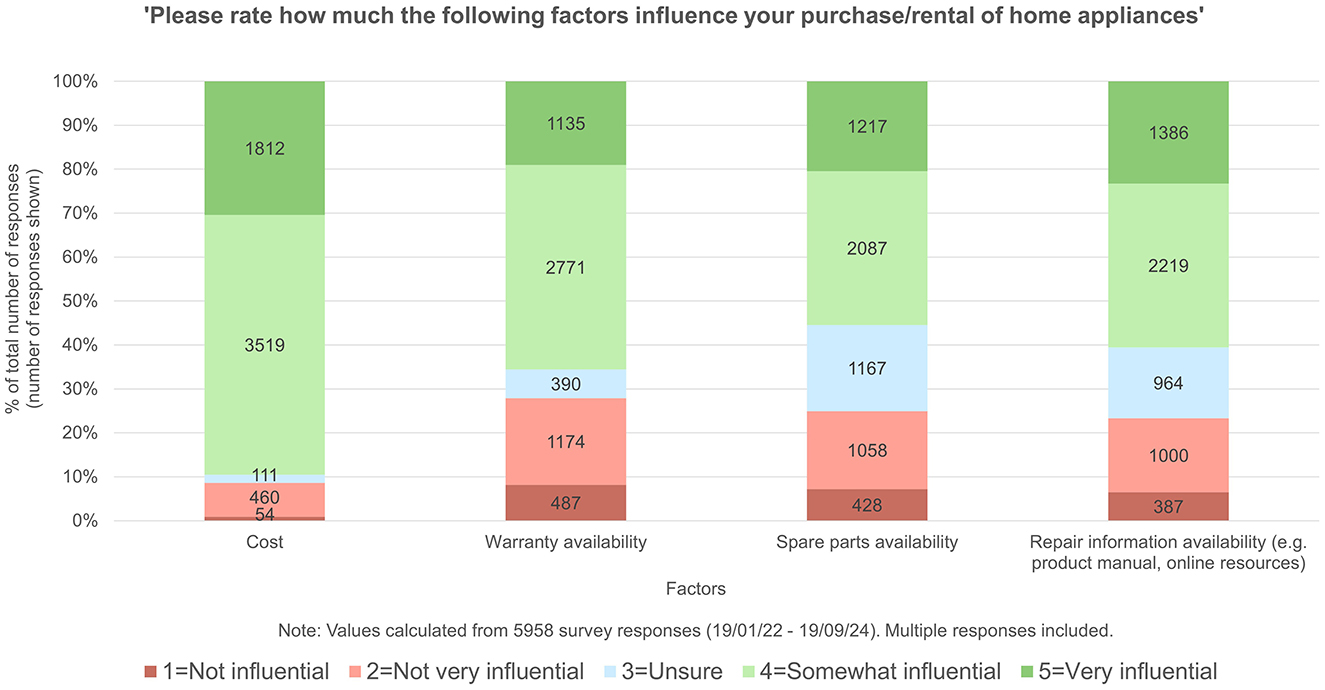

The most influential factors when buying (or renting) an appliance were cost (90%), warranty availability (66%) and repair information availability (61%) (Figure 5).

Figure 5. Responses to survey question “Please rate how much the following factors influence your purchase/rental of home appliances”.

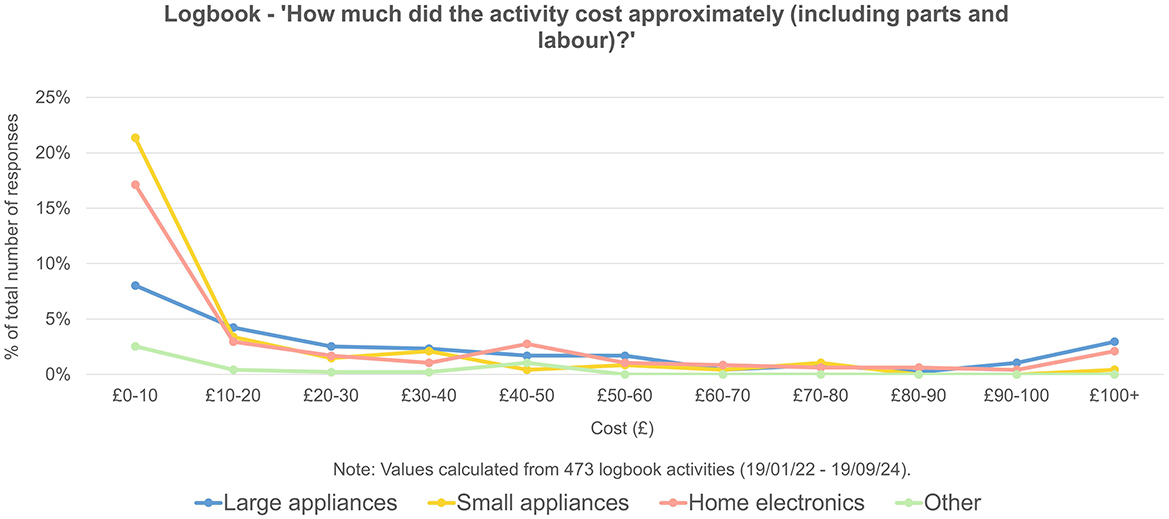

When participants in the logbook activities were asked about the cost of the repair activity (do-it-yourself repair not professional repair), largest number reported £0–10. This may be significant obstacle to repair in the context of small appliances (basic kettle costs in the UK £10–30), but less so in the context of large appliances especially when considering alternatives such as professional repair or replacement (average price of a new washing machine in the UK is £400; Airtasker reporting average cost of professional repair of a washing machine to be between £63–250 or a fridge £78–104 or a dishwasher £150) (Figure 6).

Figure 6. Logbook responses to the question “How much did the activity cost approximately (including parts and labor)?”.

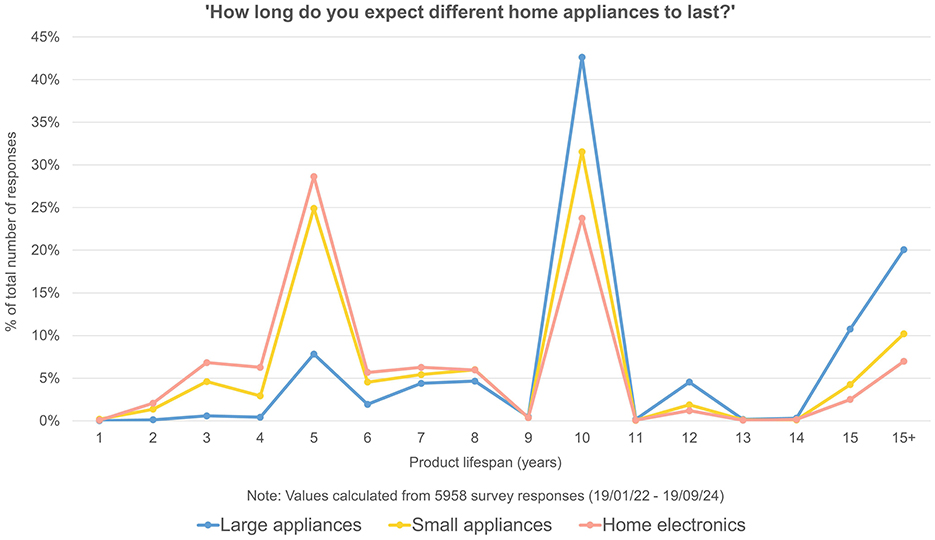

With regards to life expectancy, most respondents are expecting large and small appliances to last 10 years and small appliances to last 5 years (Figure 7). This is in sharp contrast to the current legislative framework in the UK (refer to Repair Legislation and Standards section) which offers effective statutory consumer protection of 6 months for faulty goods (HM Government, 2015).

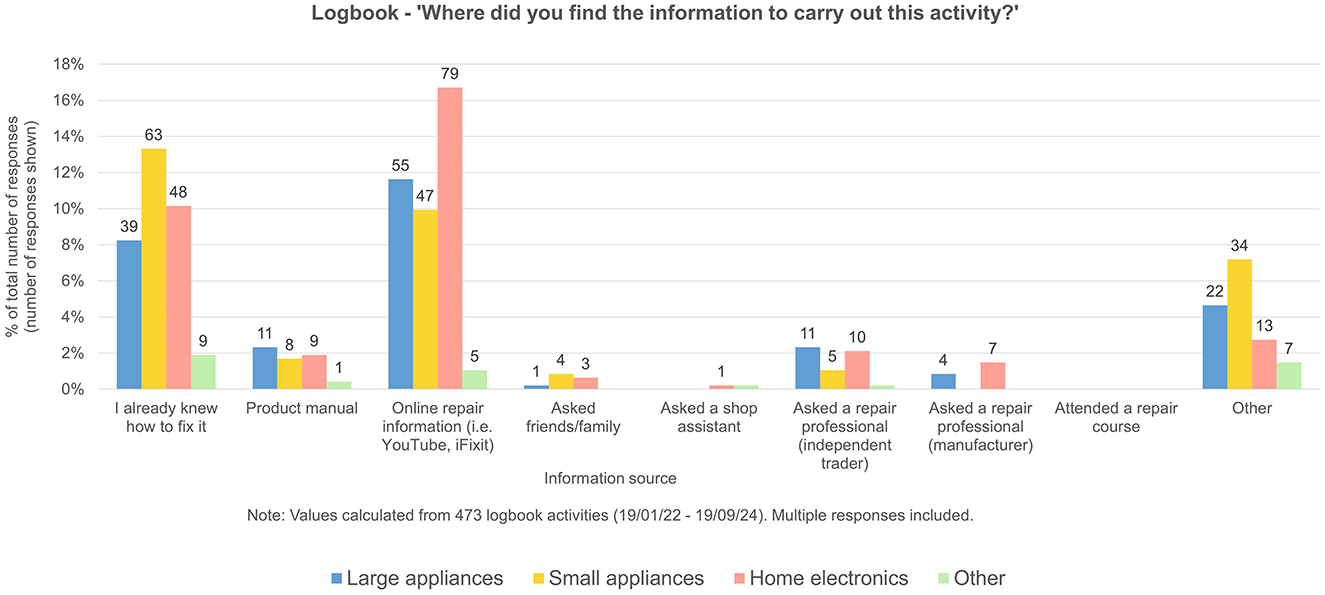

And with regards to access to repair information, logbook respondents indicated that they are most likely to rely on online repair information (i.e., YouTube, iFixit) for home electronics or that they already had the knowledge for small appliances (Figure 8). This is highlighting the importance of online resources and general repair skills training.

Figure 8. Logbook responses to the question “Where did you find the information to carry out this activity?”.

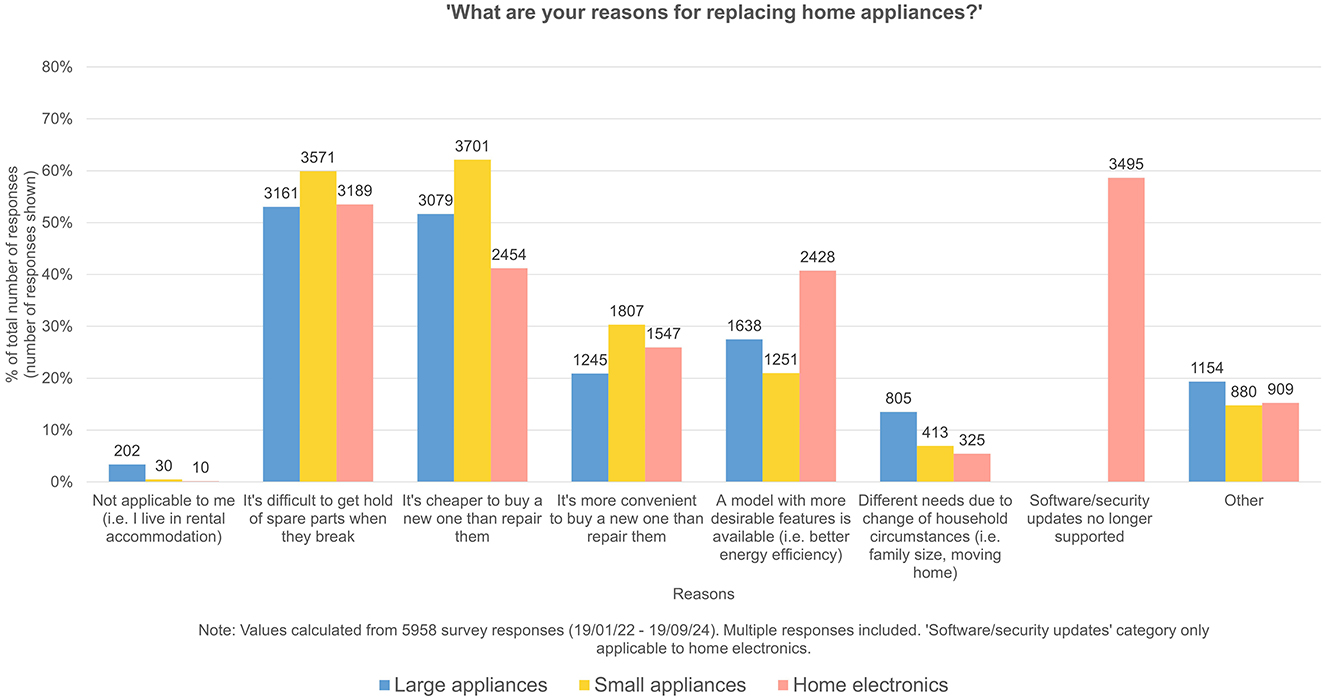

Reasons to replace home appliances vary depending on the type of product. For large and small appliances, highest number of responses received were for “It's cheaper to buy a new one than to repair” (52% responses for large appliances and 62% responses for small appliances) followed by “It's difficult to get hold of spare parts when they break” (53% responses for large appliances and 60% responses for small appliances). For home electronics the highest number of responses received was for “Software/security updates no longer supported” (59%) followed by “It's difficult to get hold of spare parts when they break” (54%) (Figure 9).

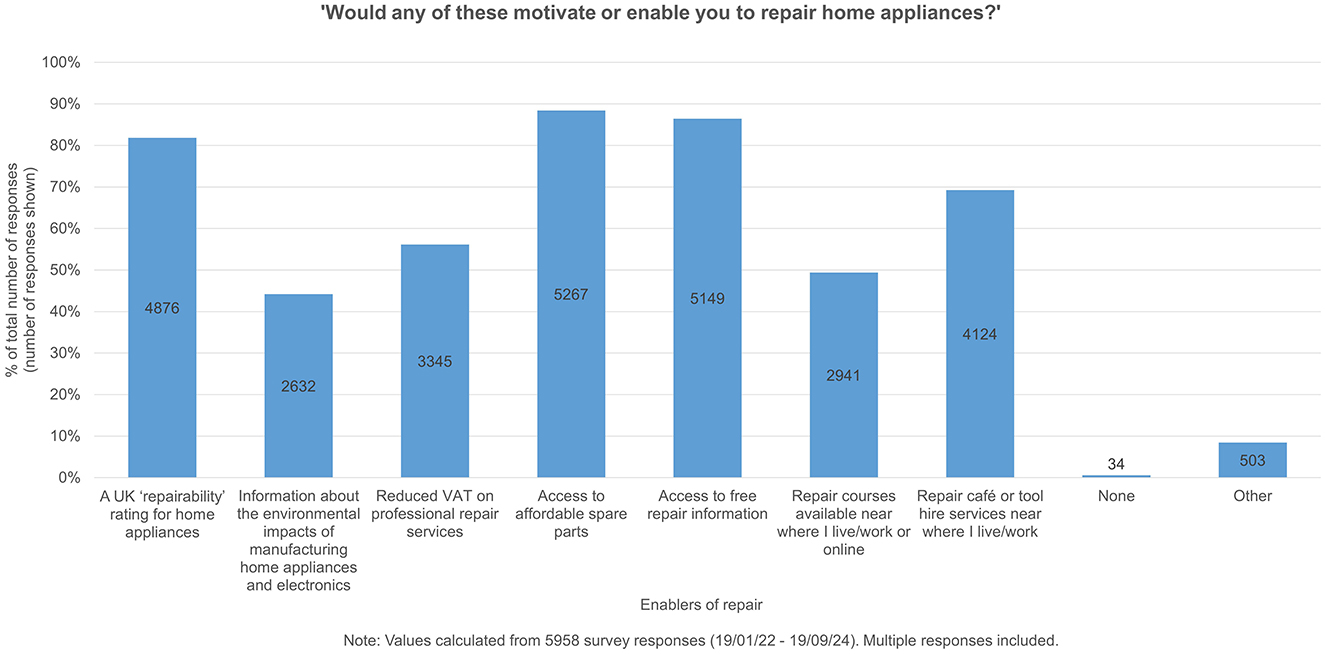

When asked about what would enable and increase their motivation for repair, highest number of responses pointed to access to affordable parts (88%) and free repair information (86%) alongside a UK repairability rating for appliances (82%) (Figure 10).

Figure 10. Responses to survey question “Would any of these motivate or enable you to repair home appliances?”.

A majority of participants stated that they would use professional repair services for advanced repairs of large appliances (69%) and for basic to advanced repair of home electronics (32% and 18% respectively) and that when using a professional repairer they would prefer to use an independent repair shop service (59%). Whilst data as to why participants chose that option was not gathered findings on lack of trust in repair services and perceived inconvenience of repairs as key barriers (Lefebvre et al., 2018; Scelfo, 2009; Scott and Weaver, 2014) can be associated with the preference for independent, trusted and convenient local services.

Overwhelmingly 86% of survey respondents stated that they feel positive when they fix appliances, indicating wider co-benefits of the repair economy with regards to wellbeing. Whereas 77% of activity logs in the logbooks led to the items remaining in use after the repair, 5% were recycled and remaining either sold or given away, salvaged/disassembled for spare parts, stored at home or returned to owner, new supplier or manufacturer.

Discussion

The UK consumes circa 1.7 million tons of EEE per year and is the second largest producer of WEEE at circa 24.5 kg per capita (Baldé et al., 2024). The production of new EEE requires vast quantities of Critical Raw Materials, the majority of which are lost if WEEE is exported for dumping, sent to landfill, incinerated or shredded and smelted which is the most common way of recycling (Green Alliance, 2020a). Until advanced recycling technologies are available that can extract all the materials from WEEE and economically put them back into the supply chain the only viable option to reduce waste is to keep products in use for longer through repair and reuse. However, to promote increased repair and reuse, it is necessary to identify the obstacles that prevent repair from being the easiest and cheapest solution for people. Identifying these obstacles in the UK was the aim of our citizen science project. Our results show that there are social, cultural, knowledge and economic obstacles to repair. These influence the repairability of EEE products, their longevity and thus their environmental impact.

Globally, awareness of the environmental impact of WEEE remains low, and there is significant gap between awareness and action (Baldé et al., 2024). Findings from the Big Repair Project confirm that even when awareness exists, and despite the vast amount of online information and the Right to Repair regulations aimed at increasing manufacturer's responsibilities to provide information, access to practical repair information remains a key barrier to action.

Currently in the UK, at the point of purchase there is limited information about the product's durability and/or repairability which can lead to overall lack of awareness and transparency about product's lifespan, maintenance, repair and disposal. Our results show there is significant appetite for this information (86% would like repair information, 82% would like a UK repairability rating for appliances, Figure 5). Our participants were not fully representative of the whole UK population but nevertheless, other indicators such as the popularity of the French repairability index (HOP, 2022) give credence to this result.

In addition, more transparency is required when it comes to legal guarantees and warranties, as people may confuse rights under the Consumer Rights Act with warranties and many people do not realize that there is no statutory warranty in the UK. Our data further revealed that participants care about warranty availability and expect products to last longer than standard warranties offered by manufacturers (see Figures 1, 2). A Government review of statutory warranties and legal guarantees could grow the repair economy and decrease WEEE. But more data and analysis would be needed to do a full analysis this policy opportunity and identify the impact on the manufacturing and retail sectors. This would need an approach different from our citizen science study, it would need to gather data systematically form the whole population with representation from all socio-economic sectors, not just from those who voluntarily take part.

Furthermore, at the point of product fault there is limited information about diagnostics, repair options and costs. The barrier to diagnostics is a significant limiting factor as it also contributes to perceived “inconvenience” of repair as well as to the costs of repair (Scott and Weaver, 2014; Raihanian Mashhadi et al., 2016). This is also linked with the barriers associated with accessing warranties. This is a process which can be both obscure and time consuming depending on the product, seller and particular situation. For instance, manufacturers sometimes outsource warranty services making it unclear who is responsible for which aspects of the repair (Scelfo, 2009). More should be done to democratize diagnostics so that citizens can make informed decisions and are able to assess repair options and costs. These challenges are currently being targeted by the European Parliament in the latest updates do the Ecodesign Regulations (European Parliament, 2024) but are yet to be translated by the UK legislators e.g., a UK Durability index. We acknowledge the complications to manufacturers of making product information, assembly and repair more accessible, and recommend that further research and trials are needed in different national and cultural contexts to inform next steps (Purkiss et al., 2024). Nevertheless, there is a market for this as our data shows.

When asked about diagnostics, majority of participants in the Big Repair Project logbook activities noted that they “already knew what the fault was” rather than relying on online resources or product manuals. This might be evidence that perceived barriers to cost, and convenience can be overcome through improving practical repair education and skills training through the formal education system or through more community-centered initiatives such as the repair events run by the Restart Project (The Restart Project, 2024).

The data presented within this paper also highlights that people who are already interested, experienced and engaged in repair tend to be predominantly male and from older age groups 55+. In addition, whilst participants indicated that they take part in a variety of different levels of repair complexity and engage with some repair themselves, when using a professional repairer participants prefer to use an independent repair service. This indicates that to grow the UK repair economy in the long-term (up to and beyond 2050), engagement and inclusion of more diverse groups of people (age, gender and abilities) will be required alongside providing support and incentives to diversify independent repair services and local access to professional repairers. There is a considerable skills gap to enable these sectors to grow (NEPC, 2024), furthermore there are electrical safety and regulatory issues that must be addressed (Purkiss et al., 2024).

Most participants in the Big Repair Project stated that they owned electronic and electrical equipment (94% large appliances, 98% small appliances, 99% home electronics) rather than renting or leasing it, which cross references with the age profile of the participants being 55+ and the latest English Housing Survey showing that older citizens are more likely to own their property (DLUHC, 2023). However, government data shows that a high proportion of the population (above 30%) rent from the social and private rented sector and that young people aged 16–34 predominantly rent. In rental properties where household goods are supplied by the landlord it will be their responsibility to repair them. This demonstrated the importance of engaging landlord groups alongside researching what circular economy business models can be deployed and scaled up to effectively support this group for example these may include pay-per-use, product lease, subscription and shared-access model which embed repair services as part of the model.

The research highlights that cost is a factor of purchasing but also a key barrier to repair. Participants in the Big Repair Project noted average costs of repair to be £0–10 which may preclude the involvement of professional repair in the context of small appliances (basic kettle costs in the UK £10–30). This re-emphasizes the need for upskilling to enable more people to undertake simple repairs on small home appliances themselves as well as more EEE products to be designed for repair and longevity. To reduce the costs of repair of small and large appliances and home electronics without putting undue pressure on capital costs for customers several different measures can be considered including VAT adjustments on parts and labor, subsidies repair vouchers as explored in Austria and parts of UK (Bundesministerium für Klimaschutz, 2023; Groupon, 2024) as well as business rate adjustments.

Beyond policy measures such as a Durability Index, extended warranties, and VAT reductions on repair, a broader macroeconomic shift is necessary to promote repair and reduce waste and pollution. Currently, disposability drives economic growth more effectively than a repair-based economy, which is why consumerism has been instrumental in increasing per capita income. This dynamic also explains why WEEE generation is highest in affluent countries. A repair economy can only compete with consumerism when the environmental costs of waste and pollution are factored into the price of goods. Mechanisms such as carbon taxes and extended producer responsibility (EPR) policies could help achieve this goal. However, such measures must also address unregulated loopholes, such as online marketplaces that allow the importation of cheap, often unsafe electrical goods into the UK (CTSI, 2024). These goods undermine both the repair economy and efforts to reduce global waste and pollution. While these policies may be environmentally necessary, they are likely to face resistance from customers, who perceive these marketplaces as providing affordable EEE products.

Product safety is another important consideration for a growing repair economy. Brands have legitimate concerns about the safety of repaired appliances where the repairs have not been carried out by skilled professionals. This is one of the stated reasons why the supply of spare parts for 10 years, as specified by Right to Repair regulations in the UK, only makes them available to professional repairers. Whether or not this is the best way to ensure safety of repaired products it disputed by the Right to Repair movement (The Restart Project, 2024). However, it is clear from the long list of product safety regulations that we reviewed in the Introduction that this is a complex area for anyone to understand, whether they be a local professional repair person or a skilled product owner who chooses to home repair. The use of product passports, which give the owner information about the repair history of a product, may be a way forward for the sector. Others are advocate for professional accreditation for engineers in the repair sector to deal with safety concerns (LocalitEEE, 2024).

More research focused on national economic impact modeling and analysis is required in this field to support decision-making with regards to specific economic interventions. This includes macroeconomic modeling to understand the size and growth potential of the repair sector; social value modeling to establish repair benefits beyond direct monetary value e.g., jobs creation; and mental health and wellbeing improvements and environmental benefit (Purkiss et al., 2024).

Although participants in our survey expressed a clear preference for repair and more durable EEE goods, caution is needed when generalizing these findings to the broader population. As noted, the demographics of the Big Repair Project participants do not fully reflect society as a whole. Market evidence also reveals that highly repairable products—such as FairPhone—exist but hold a small market share (FairPhone, 2023), likely because consumers are guided by marketing trends and desire for acquiring the latest model. The joy and social status derived from acquiring new items are deeply rooted human motivations, which have underpinned the success of consumerism as an economic model. In contrast, environmental protection is less intrinsically linked to the human reward system. Shifting societal values will be essential for making repair as appealing as buying new products and further behavioral science research can support progress in this area (Purkiss et al., 2024).

There is, however, some cause for optimism. Our data shows that 86% of participants enjoy repair and report feelings of wellbeing associated with it. If these positive emotions can be leveraged to counteract the desire for constant consumption, manufacturers of durable and repairable products may gain a competitive edge. Such a cultural shift could lead to a reduction in per capita WEEE production and a more sustainable economic model.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

Ethics approval for the study was granted by the UCL Research Ethics Committee (Project ID/Title: 16747/002: Big Repair Project). The studies were conducted in accordance with the local legislation and institutional requirements. The participants provided their written informed consent to participate in this study.

Author contributions

PP: Data curation, Formal analysis, Project administration, Writing – original draft, Writing – review & editing. DP: Conceptualization, Data curation, Funding acquisition, Investigation, Methodology, Project administration, Supervision, Visualization, Writing – review & editing. RH: Writing – original draft. MM: Conceptualization, Funding acquisition, Methodology, Resources, Supervision, Validation, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by UKRI EPSRC under grant EP/V011804/1.

Acknowledgments

We would like to thank all members of the UCL Plastic Waste Innovation Hub, past and present, for their help developing the Big Repair Project and contributing to this research.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Gen AI was used in the creation of this manuscript.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aurisicchio, M., Latham, E., and Mundell, I. (2023). Making Repair the First Choice for Londoners with Broken Electrical Appliances. Available online at: https://www.imperial.ac.uk/news/248533/making-repair-first-choice-londoners-with/ (accessed August 21, 2024).

Bakker, C., Wang, F., Huisman, J., and den Hollander, M. (2014). Products that go round: exploring product life extension through design. J. Clean. Prod. 69, 10–16. doi: 10.1016/j.jclepro.2014.01.028

Baldé, C. P., Kuehr, R., Yamamoto, T., McDonald, R., D'Angelo, E., Althaf, S., et al. (2024). Global E-waste Monitor 2024. Geneva/Bonn: International Telecommunication Union (ITU) and United Nations Institute for Training and Research (UNITAR). Available online at: https://api.globalewaste.org/publications/file/297/Global-E-waste-Monitor-2024.pdf (accessed December 19, 2024).

Bisschop, L., Hendlin, Y., and Jaspers, J. (2022). Designed to break: planned obsolescence as corporate environmental crime. Crime Law Soc. Change 78, 271–293. doi: 10.1007/s10611-022-10023-4

Blue Angel (2024). The German Ecolabel. Available online at: https://www.blauer-engel.de/en (accessed August 15, 2024).

Britannica (2024). Caveat Emptor Law. Available online at: https://www.britannica.com/money/caveat-emptor (accessed August 15, 2024).

Bundesministerium für Klimaschutz (2023). Funding Campaign Repair Bonus. Available online at: https://www.reparaturbonus.at/ (accessed August 14, 2024)].

Catalyst Law (2021). Consumer Rights on Second Hand Goods. Available online at: https://www.catalystlaw.co.uk/blog/consumer-rights-on-second-hand-goods (accessed August 12, 2024).

CTSI (2024). Dangerous Electricals and the Wild, Wild, West of Online Marketplaces. Available online at: https://www.tradingstandards.uk/news-policy-campaigns/blogs/electrical-safety-first/ (accessed December 20, 2024).

DEFRA (2011). Guidance on Applying the Waste Hierarchy. Available online at: https://www.gov.uk/government/publications/guidance-on-applying-the-waste-hierarchy (accessed August 11, 2024).

Deloitte (2023). Sustainable Consumer 2023 – Sustainable Lifestyle. Available online at: https://www2.deloitte.com/uk/en/pages/consumer-business/articles/sustainable-consumer-what-consumers-do.html (accessed August 15, 2024).

DLUHC (2023). English Housing Survey 2022 to 2023: Headline Report. Available online at: https://www.gov.uk/government/collections/english-housing-survey-2022-to-2023-headline-report (accessed August 15, 2024).

EEESafe (2025). How do You Know a DIY Electrical Repair is Safe? Available online at: https://eeesafe.com/safety-diy/ (accessed February 20, 2025).

Ellen MacArthur Foundation (2025). What is a Circular Economy? Available online at: https://www.ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview (accessed February 20, 2025).

European Commission (2022). Towards an Effective Right to Repair for Electronics. Available online at: https://publications.jrc.ec.europa.eu/repository/handle/JRC129957 (accessed August 10, 2024).

European Parliament (2016). Planned Obsolescence: Exploring The Issue. Available online at: https://www.europarl.europa.eu/RegData/etudes/BRIE/2016/581999/EPRS_BRI(2016)581999_EN.pdf (accessed August 15, 2024).

European Parliament (2024). Right to Repair: Making Repair Easier and More Appealing to Consumers. Plenary Session. Available online at: https://www.europarl.europa.eu/news/en/press-room/20240419IPR20590/right-to-repair-making-repair-easier-and-more-appealing-to-consumers#:~:text=The%20new%20rules%20reinforce%20the,3%20against%20and%2014%20abstentions (accessed August 15, 2024).

FairPhone, B. V. (2023). Annual Report. Available online at: https://www.fairphone.com/wp-content/uploads/2024/06/Fairphone-BV-Annual-report-2023.pdf (accessed November 28, 2024).

Fixing Factory (2024). Fixing Factory. Available online at: https://www.fixingfactory.org/ (accessed August 15, 2024).

Forti, V., Baldé, C. P., Kuehr, R., and Bel, G. (2020). The Global E-waste Monitor 2020: Quantities, Flows and the Circular Economy Potential. Bonn/Geneva/Rotterdam: United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR) – co-hosted SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA).

France (2024). Durability Index Decree. Available online at: https://www.legifrance.gouv.fr/jorf/id/JORFTEXT000049375942 (accessed August 15, 2024).

Green Alliance (2018). Less in, more out: using resource efficiency to cut carbon and benefit the economy. Available online at: https://green-alliance.org.uk/publication/less-in-more-out/ (accessed August 15, 2024).

Green Alliance (2020a). Design for a Circular Economy: Reducing the Impacts of the Products We Use. Available online at: https://green-alliance.org.uk/wp-content/uploads/2021/11/Design_for_a_circular_economy.pdf (accessed August 15, 2024).

Green Alliance (2020b). Fixing the System: Why a Circular Economy for all Materials is the Only Way to Solve the Plastic Problem. Available online at: https://green-alliance.org.uk/wp-content/uploads/2021/11/Fixing_the_system.pdf (accessed August 15, 2024).

Groupon (2024). Electronics Repair Voucher. Available online at: https://www.groupon.co.uk/vouchers/electronics-repair (accessed August 5, 2024).

Haklay, M., Motion, A., Balázs, B., Kieslinger, B., Bastian, T. G., Nold, C., et al. (2020). ECSA's Characteristics of Citizen Science.

Hernandez, R. J., Miranda, C., and Goñi, J. (2020). Empowering sustainable consumption by giving back to consumers the ‘right to repair'. Sustainability 12:850. doi: 10.3390/su12030850

HM Government (2015). Consumer Rights Act 2015. Available online at: https://www.legislation.gov.uk/ukpga/2015/15/contents/enacted (accessed August 9, 2024).

HM Government (2016). Electrical Equipment (Safety) Regulations 2016: Great Britain. Available online at: https://www.gov.uk/government/publications/electrical-equipment-safety-regulations-2016/electrical-equipment-safety-regulations-2016-great-britain#introduction (accessed August 15, 2024).

HM Government (2022). Resilience for the Future: The UK's Critical Minerals Strategy. Available online at: https://www.gov.uk/government/publications/uk-critical-mineral-strategy (accessed August 15, 2024).

HM Government (2023). UK Government Announces Extension of CE Mark Recognition for Businesses - GOV.UK. Available online at: https://www.gov.uk/government/news/uk-government-announces-extension-of-ce-mark-recognition-for-businesses (accessed August 23, 2024).

HOP (2022). The French Repairability Index: A First Assessment – One Year After Its Implementation. Available online at: https://www.halteobsolescence.org/wp-content/uploads/2022/02/Rapport-indice-de-reparabilite.pdf (accessed December 20, 2024).

House of Commons Library (2021). Right to Repair Regulations. Available online at: https://researchbriefings.files.parliament.uk/documents/CBP-9302/CBP-9302.pdf (accessed August 15, 2024).

iFixit (2025). iFixit: The Free Repair Manual. Available online at: https://www.ifixit.com/ (accessed February 27, 2025).

International Standards Organisation (2020). ISO/IEC 17000:2020 Conformity Assessment – Vocabulary and General Principles. Available online at: https://www.iso.org/standard/73029.html (accessed August 9, 2024).

Laitala, K., Klepp, I. G., Haugrønning, V., Throne-Holst, H., and Strandbakken, P. (2021). Increasing repair of household appliances, mobile phones and clothing: Experiences from consumers and the repair industry. J. Cleaner Product. 282:125349. doi: 10.1016/j.jclepro.2020.125349

Lefebvre, M., Lofthouse, V., and Wilson, G. (2018). “Towards a circular economy: exploring factors to repair broken electrical and electronics products by users with pro-environmental inclination,” in Design as a Catalyst for Change - DRS International Conference 2018, 25–28 June, Limerick, Ireland, eds. C. Storni, K. Leahy, M. McMahon, P. Lloyd, and E. Bohemia (London: Design Research Society). doi: 10.21606/drs.2018.556

LocalitEEE (2024). Building Skills in the Community EEESafe Qualification. Available online at: https://www.localiteee.com/ (accessed August 15, 2024).

National Audit Office (2021). Protecting Consumers from Unsafe Products. Available online at: https://www.nao.org.uk/wp-content/uploads/2021/02/Protecting-consumers-from-unsafe-products.pdf (accessed February 20, 2025).

Nazli, T. (2021). Repair motivation and barriers model: investigating user perspectives related to product repair towards a circular economy. J. Cleaner Prod. 289:125644. doi: 10.1016/j.jclepro.2020.125644

NEPC (2024). Critical Materials: Efficiency Measures for Sustainability and Resilience. Available online at: https://nepc.raeng.org.uk/media/kdynduhd/critical-materials-report.pdf (accessed December 19, 2024).

Purkiss, D., Allison, A. L., Lorencatto, F., Michie, S., and Miodownik, M. (2022). The Big Compost Experiment: Using citizen science to assess the impact and effectiveness of biodegradable and compostable plastics in UK home composting. Front. Sustain. 3:942724. doi: 10.3389/frsus.2022.942724

Purkiss, D., Pencheva, P., Munro, B., and Miodownik, M. (2024). A systems approach to growing the UK electronics and appliance repair economy. Front. Sustain. 5:1432655. doi: 10.3389/frsus.2024.1432655

Raihanian Mashhadi, A., Esmaeilian, B., Cade, W., Wiens, K., and Behdad, S. (2016). Mining consumer experiences of repairing electronics: product design insights and business lessons learned. J. Clean. Prod. 137, 716–727. doi: 10.1016/j.jclepro.2016.07.144

Reynolds, M., Salter, N., Muranko, Ż., Nolan, R., and Charnley, F. (2024). Product life extension behaviours for electrical appliances in UK households: can consumer education help extend product life amid the cost-of-living crisis? Resour. Conserv. Recycl. 205:107527. doi: 10.1016/j.resconrec.2024.107527

Sabbaghi, M., and Behdad, S. (2018). Consumer decisions to repair mobile phones and manufacturer pricing policies: The concept of value leakage. Resources, Conservation and Recycling 133, 101–111. doi: 10.1016/j.resconrec.2018.01.015

Sabbaghi, M., Cade, W., Behdad, S., and Bisantz, A. M. (2017). The current status of the consumer electronics repair industry in the U.S.: a survey-based study. Resour. Conserv. Recycl. 116, 137–151. doi: 10.1016/J.RESCONREC.2016.09.013

Sabbaghi, M., Esmaeilian, B., Cade, W., Wiens, K., and Behdad, S. (2016). Business outcomes of product repairability: a survey-based study of consumer repair experiences. Resour. Conserv. Recycl. 109, 114–122. doi: 10.1016/J.RESCONREC.2016.02.014

Scott, K. A., and Weaver, S. T. (2014). To Repair or Not to Repair: What is the Motivation? J. Res. Consum. 26, 1–6.

Scottish Government (2024). Repairing Standard: Statutory Guidance for Private Landlords. Available online at: https://www.gov.scot/publications/repairing-standard-statutory-guidance-private-landlords/pages/21/ (accessed August 15, 2024).

Sigüenza, C. P., Cucurachi, S., and Tukker, A. (2021). Circular business models of washing machines in the Netherlands: material and climate change implications toward 2050. Sustain. Prod. Consumpt. 26, 1084–1098. doi: 10.1016/j.spc.2021.01.011

Tech-Takeback (2024). Sustainable Solutions for Unwanted Electricals. Available online at: https://www.techtakeback.com/ (accessed August 15, 2024).

The Restart Project (2024). Restart Events. Available online at: https://therestartproject.org/ (accessed August 15, 2024).

UN (2015). THE 17 GOALS | Sustainable Development. Available online at: https://sdgs.un.org/goals (accessed April 22, 2025).

Wastling, T., Charnley, F., and Moreno, M. (2018). Design for circular behaviour: Considering users in a circular economy. Sustainability 10:1743. doi: 10.3390/su10061743

World Health Organization (2021). Children and Digital Dumpsites: E-Waste Exposure and Child Health. Available online at: https://www.who.int/publications/i/item/9789240023901 (accessed June 30, 2023).

YouGov (2020). 45% of Smartphone Owners Would Rather Upgrade than Repair. Available online at: https://yougov.co.uk/technology/articles/29581-45-smartphone-owners-would-rather-upgrade-repair?redirect_from=%2Ftopics%2Ftechnology%2Farticles-reports%2F2020%2F05%2F07%2F45-smartphone-owners-would-rather-upgrade-repair (accessed August 15, 2024).

YouGov (2021). Right to Repair: Which Appliances Would Brits be Willing to try to Repair. Available online at: https://yougov.co.uk/consumer/articles/36727-right-repair-appliances-brits-fix?redirect_from=%2Ftopics%2Fconsumer%2Farticles-reports%2F2021%2F07%2F01%2Fright-repair-appliances-brits-fix (accessed August 15, 2024).

Keywords: repair, economy, WEEE, electronics, electricals, circular economy, citizens

Citation: Pencheva P, Purkiss D, Hewlett R and Miodownik M (2025) Big Repair Project: using citizen science to better understand the factors affecting household maintenance and repair of home appliances and electronics across the UK. Front. Sustain. 6:1562615. doi: 10.3389/frsus.2025.1562615

Received: 17 January 2025; Accepted: 11 April 2025;

Published: 09 May 2025.

Edited by:

Ahmed Ibrahim Osman, Queen's University Belfast, United KingdomReviewed by:

Jessika Luth Richter, Lund University, SwedenMihaela Stefanescu, Ministry of Environment, Waters and Forests, Romania

Christine Majale, Kenyatta University, Kenya

Copyright © 2025 Pencheva, Purkiss, Hewlett and Miodownik. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Polina Pencheva, cC5wZW5jaGV2YUB1Y2wuYWMudWs=

Polina Pencheva

Polina Pencheva Danielle Purkiss

Danielle Purkiss Robert Hewlett

Robert Hewlett Mark Miodownik

Mark Miodownik