- 1Professorship Waste and Resource Management, University of Rostock, Rostock, Germany

- 2West African Service Center for Climate Change and Adaptive Land Use (WASCAL), University of Lomé, Lomé, Togo

End-of-life tyre (ELT) management presents significant challenges in West Africa, particularly in Togo where an estimated 30,500 tonnes accumulate annually from imported used tyres and second-hand vehicles. Current disposal practices create substantial environmental and public health risks, with 65% of tyres burned and 25% dumped. Comprehensive field investigations examined the origin and manufacturer profiles of ELTs in Togo, while various Extended Producer Responsibility (EPR) models were assessed for local applicability. A novel three-pronged approach was developed combining import levies on tyres, manufacturer-centric responsibility mechanisms, and government financial incentives. This integrated framework addresses the imbalance where multinational tyre manufacturers benefit economically while contributing minimally to waste management costs. Analysis indicates that successful implementation requires adaptation to local economic, social, and infrastructural realities. The proposed EPR model targets environmental degradation mitigation while creating sustainable economic opportunities within the region. The framework offers potential application as a template for similar initiatives across West Africa.

Introduction

End-of-life tyres (ELTs) represent a significant waste management challenge globally, with particular severity in West Africa where comprehensive waste management systems are often lacking due to missing infrastructure and undefined regulatory frameworks. Togo exemplifies the region’s challenges, with more than 90% of tyres imported as either used tyres or components of second-hand vehicles from Europe, North America and Asia (Schenck et al., 2024). The imported second-hand tyres typically have limited lifespans due to poor transportation infrastructure, leading to rapid waste accumulation. Urban areas like Lomé experience concentrated tyre waste accumulation in informal dumpsites, with an estimated 30,500 tonnes of ELTs accumulating annually across the country (Narra et al., 2024). Current disposal practices exacerbate environmental degradation and public health risks, as 65% of ELTs are burned for purposes including animal carcass singeing and metal recovery, while 25% are simply dumped (Narra et al., 2024, 2025).

Extended Producer Responsibility (EPR) represents a policy approach that extends a producer’s responsibility for a product to the post-consumer stage of its lifecycle (Yang, 2020). While EPR schemes for tyre waste management have proven effective in numerous developed countries, their application in developing countries, with specific focus on West African countries, requires careful adaptation to local economic, social and infrastructural realities.

Academic and grey literature reveals significant implementation challenges when applying EPR frameworks in developing country contexts, particularly in Asia, Africa, and Latin America. The effectiveness of EPR implementation in developed countries has been attributed to the availability and proximity of original producers, making it relatively easy for consumers to return unwanted products for recycling and management (Kaya et al., 2020). However, in many developing economies, original producers are rare or non-existent, as they typically export finished products through retailers rather than establishing direct market presence (Kumar et al., 2020). This absence shifts EPR adoption responsibility to retail firms, creating additional complexity in implementation (Hilton et al., 2019; Tong and Yan, 2013).

Research on EPR policies in developing Asian countries identifies complications including difficulties in identifying producers, import of used products and waste, and the existence of strong informal waste sectors (Ongondo et al., 2011). A study on EPR adoption in Colombia revealed that financial constraints, operational responsibility limitations, lack of incentives and tax waivers, and insufficient collaboration among producers constitute major implementation hurdles (Faibil et al., 2021). The Colombian case suggests that effective EPR adoption in developing economies requires establishing comprehensive achievable targets and roadmaps, with analytical frameworks to understand hierarchical relationships among promoting factors.

European case studies from Belgium, Italy and the Netherlands demonstrate that EPR for tyres effectively reduces fly-tipping and illegal stockpiling while increasing resource efficiency, with quantitative targets proving essential for optimal recycling outcomes (Winternitz et al., 2019). However, Southeast Asian implementations face distinct challenges including logistics issues in remote areas lacking efficient waste collection infrastructure and resulting high transportation costs. The contrast between developed country successes and developing country constraints underscores the need for context-specific adaptations that address infrastructural limitations, informal sector dynamics, and economic realities prevalent in West African contexts. According to Ezeudu (2024), the main barriers to successful EPR implementation in developing countries are the absence of waste data, ineffective legislature and unavailable producers.

The implementation of producer responsibility for end-of-life tyre (ELT) management is alas becoming increasingly necessary due to the significant environmental burden placed on developing countries that lack proper waste management infrastructure (Aslam, 2020). A manufacturer-focused extended producer responsibility (EPR) model is particularly relevant in the context of Togo, as multinational tyre manufacturers benefit economically from market access while contributing little to the costs of managing waste tyres at the end of their life cycle. This imbalance makes it necessary to establish responsibility mechanisms that cover the entire product lifecycle, so that the environmental costs, which are currently carried by Togolese society and environment, are internalized.

It needs to be stressed that depending only on manufacturers’ initiatives may not be enough to develop a complete and efficient system.

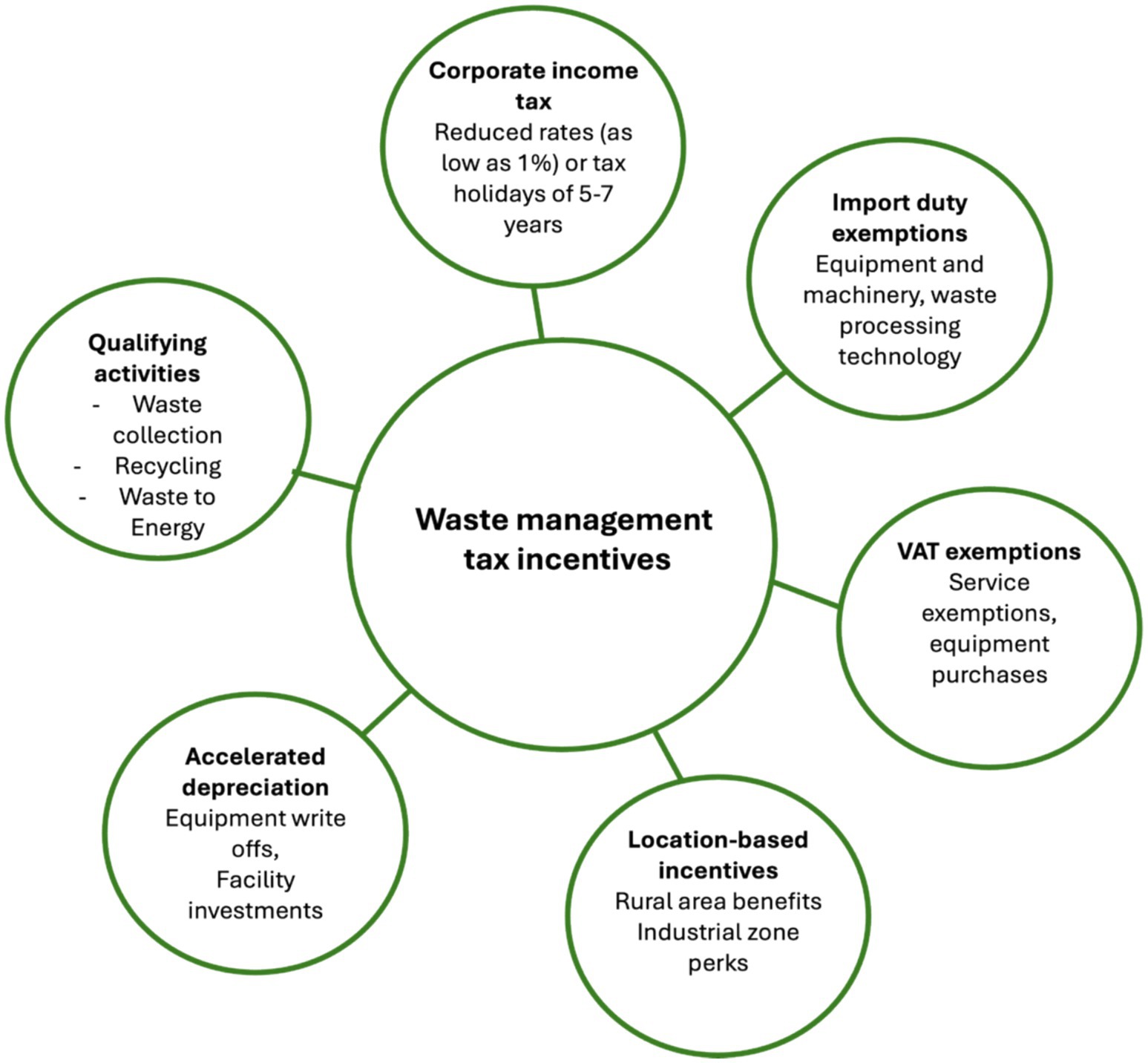

Therefore, government financial incentives are also needed to encourage broader market participation and ensure long-term sustainability. Tax benefits for recycling businesses, reduced import duties for processing equipment, lower value-added tax (VAT) rates, and accelerated depreciation allowances can create economic conditions that encourage investment in recycling. These subsidies help to correct the market failures in waste management that are common in developing economies, where immediate financial returns may not always justify private investment, even though there are important benefits for society.

Additionally, introducing a special tax on tyre imports is an important third component of this integrated approach. Such a tax would create a direct financial link between the importation of tyres and the funding of their end-of-life management. This approach is particularly important because many tyres enter Togo as part of second-hand vehicles, which might otherwise be excluded from producer responsibility systems that focus only on direct tyre imports.

This study is situated within the theoretical framework of circular economy (CE) principles, given its focus on promoting sustainable end-of-life tyre (ELT) management whilst reducing environmental pollution. The circular economy is defined as a systems-based approach to economic development whereby waste is designed out, products and materials are maintained in use, and natural systems are regenerated (Ellen Mac Arthur Foundation, 2025). These principles are reflected in the proposed model through its emphasis on material recirculation and lifecycle accountability. The necessity for integrated strategies and institutional support to operationalise CE in low- and middle-income countries has been emphasised by Ghisellini et al. (2016). The systemic approach advocated by these authors is aligned with through the proposition of infrastructure, policy, and economic instruments that support the circular flow of resources—specifically through tyre reuse, recycling, and responsible import management.

This paper addresses these challenges by developing a suitable EPR model with stakeholder support, examining the advantages and limitations of various solutions while proposing system implementation recommendations. The research analyses the origin and manufacturer profiles of ELTs in Togo through comprehensive field investigation, assesses the feasibility of various EPR models within the Togolese context, and develops recommendations for context-appropriate EPR frameworks that could enhance sustainable ELT management across the region.

Materials and methods

The study collected a randomised sample of 196,78 tons of end-of-life tyres (ELTs) from the greater Lomé region to assess their origin and age. The primary objective of the sampling was to ensure an unbiased representation of ELTs available in the market at the time of sampling. The ELTs were sampled in May and June 2024 in the greater Lomé region of Togo as randomised purchases.

The tyre collection protocol was as following:

Information dissemination: one week before the sampling event, an announcement was made to inform potential sellers (individuals, collectors, or businesses) that a truck would arrive to purchase ELTs. The announcement ensured broad participation, minimising selection bias and ensuring a diverse supply of tyres.

Purchasing process: a truck travelled through designated locations in the greater Lomé region, purchasing ELTs. The sellers were not pre-selected; anyone with ELTs to offer had the opportunity to sell. Tyres were purchased randomly, meaning no specific type, brand, or condition of ELT was preferred. Tyres up to a external diameter of 120 cm were purchased, as bigger tyres cannot be accepted in a planned tyre recycling plant.

Payment Standardisation: Each car tyre was bought for a fixed price of 300 CFA (approx. 0.45 €) per unit, smaller tyres (from Autorickshaws or Abobayas) were bought for 150 CFA (approx. 0.23 €) and bigger tyres (bus, trucks) of sizes up to 120 cm were bought for 1,100 CFA (approx. 1.68 €).

Randomisation strategy: tyres were selected without preference for origin, condition, or type. This ensured that the sample reflected the natural distribution of ELTs available at the time of collection.

A unique feature of ELTs as waste materials is that each tyre is equipped with a DOT (Department of Transportation) number, also referred to as Identification number or TIN (tyre identification number), in which the manufacturer and the date of manufacturing can be easily identified (see Figure 1). A DOT number on a tyre is a standardised alphanumeric code that provides key information about the tyre’s manufacturer, plant of origin, and production date. The DOT number is generally divided into section as explained below:

1. Plant Code (F1): This identifies the manufacturing facility. F1 indicates the Manufacturer as Michelin Tyre PLC in Dundee, Scotland.

2. Size Code (TA): This represents information about the tyre size, but in a manufacturer-specific format. It does not directly translate to standard tyre size markings that can be seen on the sidewall.

3. Optional Code (HFV): This is the manufacturer’s code that could identify the tyre model, line, or specific characteristics.

4. Date Code (3205): The last digits explain the manufacturing date. From 3,203, 32 refers to week 32 and 03 refers to the year 2003.

This means that this tyre was produced between August 08th–14th in Dundee, Scotland by Michelin Tyre PLC, making it almost 20 years old.

The DOT number of a randomised sample of the purchased tyres was manually identified and protocolled. Only after protocolling, the ELT was transferred into stockpiling. The ELTs purchased for this study will be used as processing material in the planned tyre recycling facility in Davié, 10 km north of Lomé, near to the national highway N1. The identified DOT numbers were analysed for their production company, their country of production and the production year.

Additionally import data for tyres were obtained from the Port of Lomé, Office Togolais des Recettes (Togo Customs Authority) in order to understand from which countries tyres and cars (including their tyres) were imported from and where the tyres and cars were exported further to landlocked countries such as Burkina Faso.

In May 2024, trial sampling in Togo has been started with one dipper truck. The trial sampling is carried out to determine the optimum collection logistics, including pre-sourcing for the final ELT recycling plant. 88.18 tons of ELTs were purchased for a cost of 2.538.950 CFA (approx. 3.870,60 €) in the month May 2024, accounting a total number of 8,807 ELTs. Similarly, 108.6 tons ELTs were purchased for a total cost of 3.269.650 CFA (approx. 4.984,55 €) in the month June 2024, amounting for a total number of 9,653 ELTs (Table 1). The tyres were bought from a newly formed tyre collection company. The mentioned costs did not include their transportation costs, toll fees, pre-sourcing costs or any other items.

Of the 18.460 collected ELTs in May and June 2024, 18.24% of the tyres (3,368 tyres) were analysed for their DOT number in order to identify their manufacturer, country of production and age. The selection of this subsample was guided by a combination of methodological intent and practical constraints. From a scientific perspective, sampling approximately 15–20% of a large population is generally considered acceptable for exploratory studies, especially when the aim is to detect broad trends or dominant patterns (Ahmed, 2024). The sample size of 3,368 tyres is statistically sufficient to produce meaningful descriptive insights. The risk of sampling bias is limited, provided that the selection of tyres was randomised and evenly distributed across different collection sites and dates.

Moreover, it is acknowledged that the chosen sample size reflects the maximum number of tyres that could be realistically analysed within the allocated research timeframe and resource constraints. DOT number retrieval and decoding is a labour-intensive process that requires careful inspection and cross-referencing against manufacturer databases.

Despite these limitations, the size and diversity of the analysed sample provides a sufficiently robust empirical basis for identifying key patterns in the origin, age structure, and manufacturer distribution of ELT tyres in Togo.

It is acknowledged that the sampling strategy applied in this study may be affected by certain limitations concerning geographic scope and market characteristics. All ELT samples were collected within the greater Lomé region, which, as the primary urban and economic hub of Togo, hosts the country’s main port of entry for both new and used tyres. The majority of second-hand tyres entering Togo arrive through the Port of Lomé, and subsequently circulate within the capital and surrounding areas before being redistributed further inland (Narra et al., 2024).

Although this location represents a critical node in the national tyre flow system, the exclusive focus on Lomé introduces a potential urban-centric sampling bias. No data has been collected from the more remote northern regions or from rural areas, where transportation infrastructure is more limited and vehicle maintenance practices differ significantly. In such areas, it is reasonable to assume that tyres remain in use for longer periods due to reduced availability of replacements, higher transport costs, and economic constraints. Anecdotal and field-based observations suggest that practices such as multiple retreadings, repairs, and prolonged use are even more common in rural zones. Consequently, it is likely that even older tyres than those recorded in this study would be found in these regions.

Results

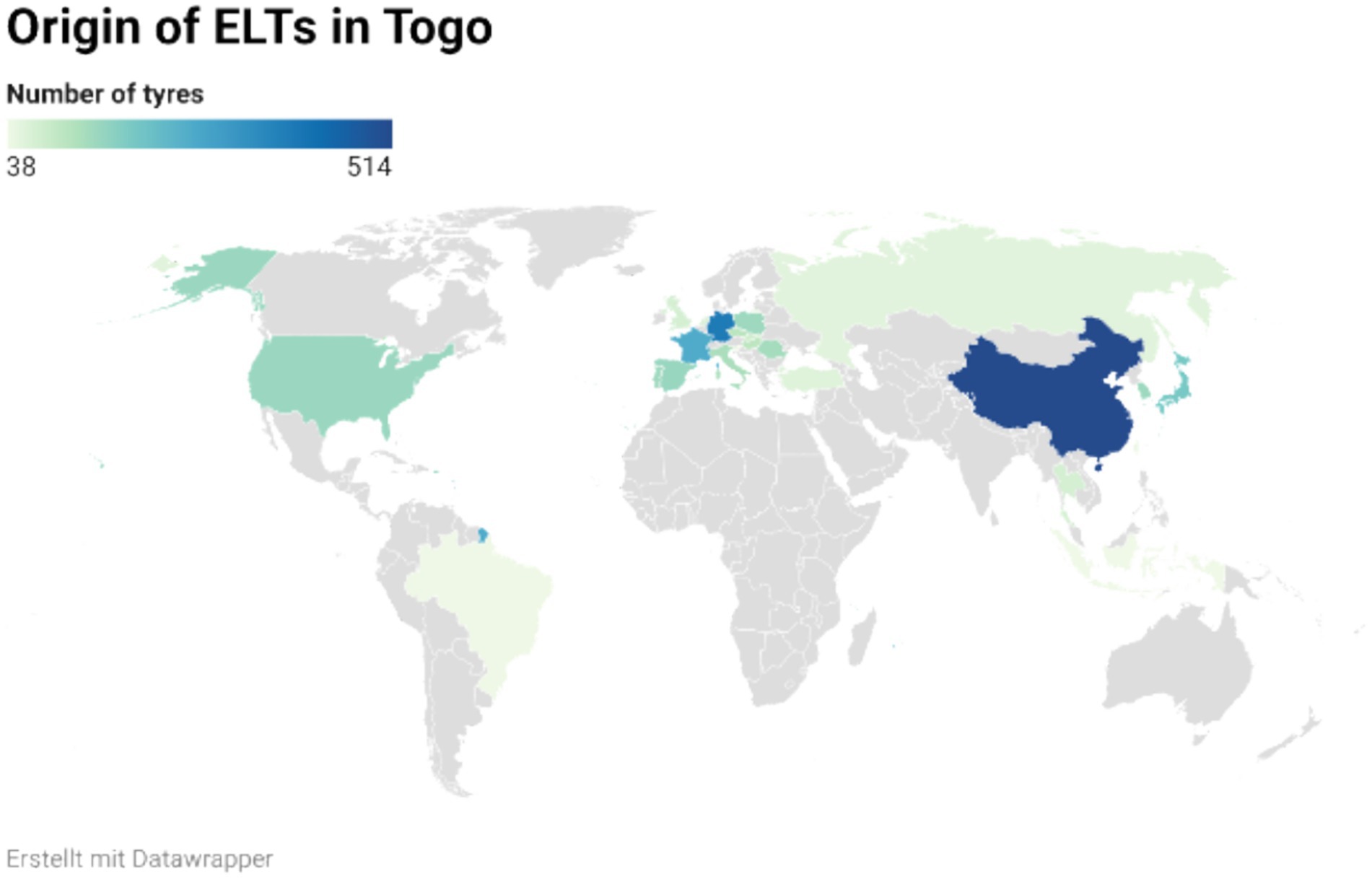

The analysis of 3,368 ELTs revealed their origin from 47 different countries across six continents, with notable geographic concentration patterns (Figure 2). European nations collectively contributed the largest proportion at approximately 55% of all ELTs, followed by Asian manufacturers at 31%, and North American production at 5.5%. South American, African, and Oceanian origins each represented less than 3% individually, with only 23 ELTs identified from Africa (22 from South Africa, 1 from Ethiopia).

Figure 2. World map highlighting the countries of production of the imported ELTs analysed in Togo for this study. The darker colours indicate higher number of ELTs being originated from those countries. Only countries where more than 1% of the total analysed tyres were produced are highlighted.

At the country level, China emerged as the predominant manufacturing source, accounting for 514 tyres (15.26%), followed by Germany with 390 tyres (11.58%) and France with 269 tyres (7.99%). These three countries collectively represented 34.83% of the sample. The concentration pattern was pronounced: the top 5 countries accounted for 45.16% of all tyres, while the top 10 countries were responsible for 67.57% of the sample.

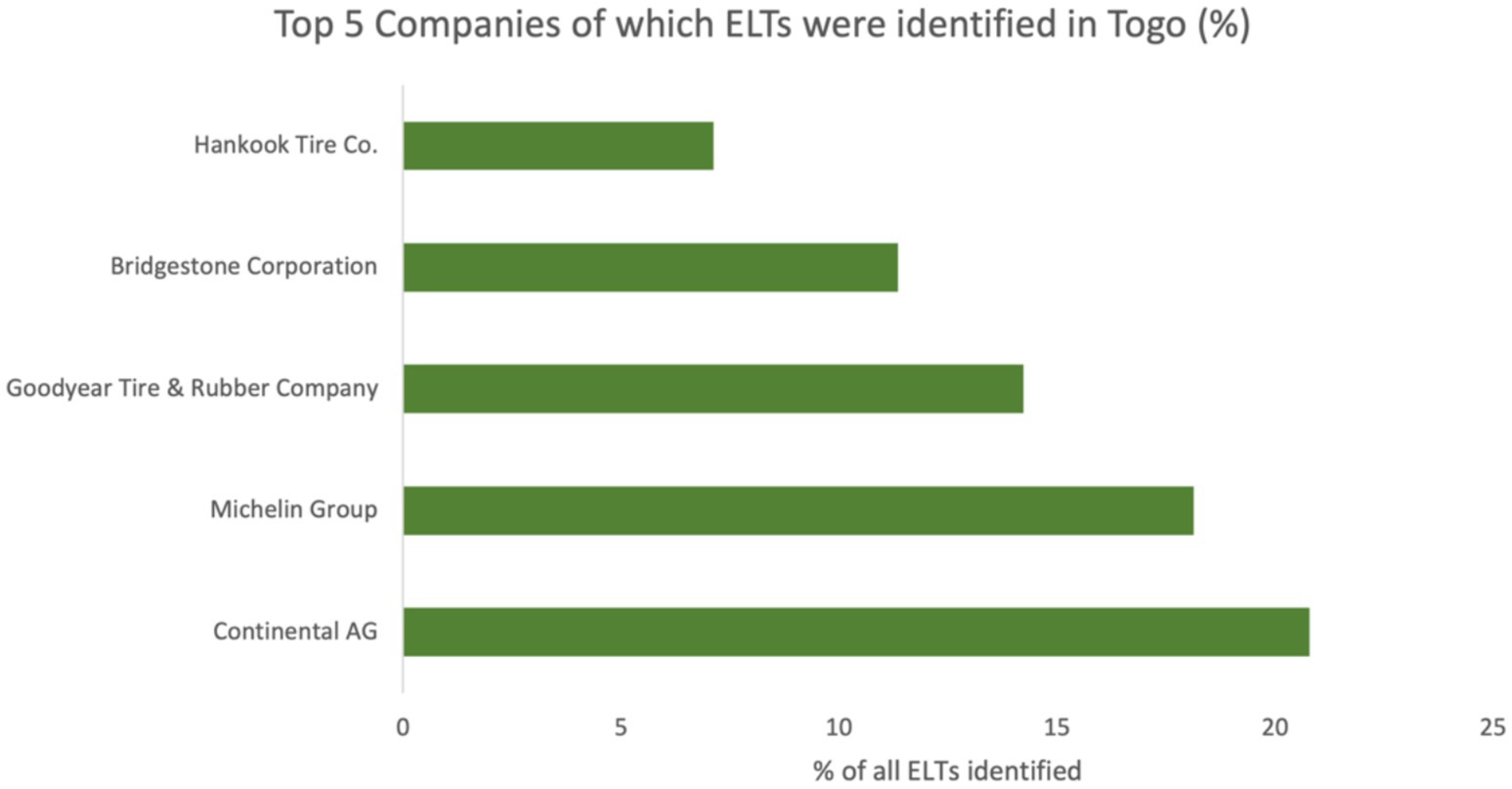

Analysis of DOT identification numbers revealed significant concentration among multinational tyre manufacturers. Of the 3,368 ELTs examined, 3,022 tyres with identifiable manufacturers were included in detailed analysis (threshold: >5 tyres per company).

The analysis revealed significant concentration among a relatively small number of multinational tyre manufacturers. Continental AG (Germany) was identified as the predominant manufacturing source, accounting for 628 tyres (18.6%) of the total sample (Figure 3). This was followed by Michelin Group (France) with 548 tyres (16.3%) and Goodyear Tire & Rubber Company (USA) with 430 tyres (12.8%). These three multinational corporations collectively represented 47.7% of the entire sample.

When analysed by the location of corporate headquarters:

• European-headquartered companies contributed the largest proportion, with Continental AG (Germany) and Michelin Group (France) being particularly prominent

• Asian manufacturers demonstrated significant presence, with Bridgestone Corporation (Japan) and Hankook Tire Co. (South Korea) among the top five contributors

• North American representation was primarily through Goodyear Tire & Rubber Company (USA)

• Chinese manufacturers, whilst individually contributing smaller quantities, collectively represented a significant portion of the total

The data demonstrated a pronounced concentration pattern, with the top 5 manufacturing companies accounting for 64.5% of all identifiable tyres. At the same time the top 10 companies were already responsible for 78.5% of the sample. A notable “long tail” distribution where numerous companies contributed relatively small quantities has been observed. It is noteworthy that 9 companies with fewer than 10 identified tyres each were from China (see Annex 1), indicating significant fragmentation in the Chinese tyre manufacturing sector reaching the Togolese market.

Age of tyres

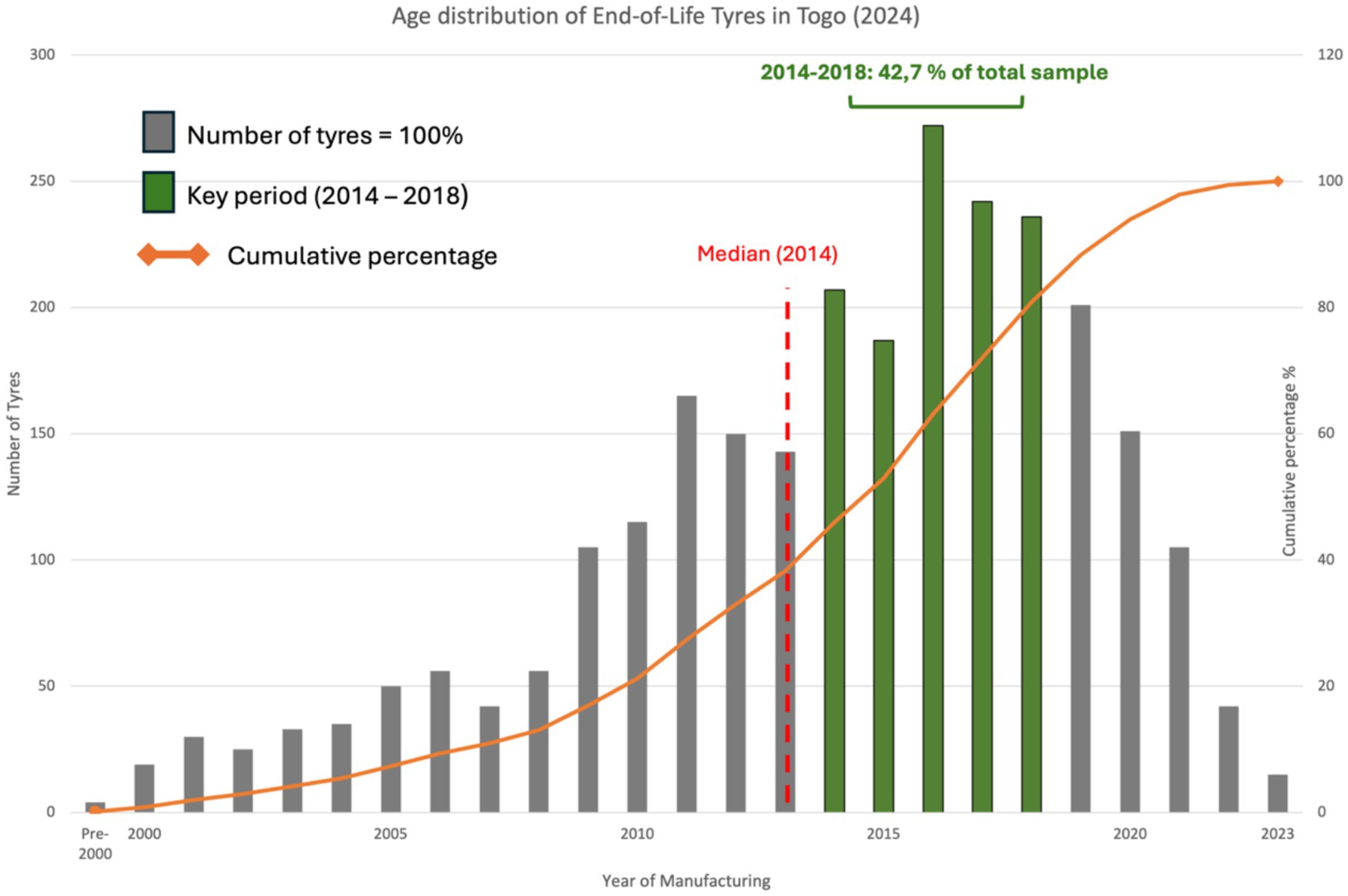

Of the 3,368 tyres sampled, the manufacturing date was unidentifiable on 682 tyres. A total of 2,686 end-of-life tyres were analysed to determine their age distribution based on the printed manufacturing year. The manufacturing dates ranged from 1981 to 2023, spanning a period of 42 years. The earliest tyres in the sample were manufactured in 1981 and 1983, each represented by a single specimen. A noticeable increase in the number of tyres was observed in the beginning of 2000 with 19 different tyres from this manufacturing year.

The data revealed a general upward trend in the number of ELTs from 2000 to 2016, with the peak observed in 2016 (n = 272). Following this peak, as highlighted in Figure 4, a gradual decline was noted from 2017 (n = 242) to 2023 (n = 15). The most recent years (2022–2023) showed a sharp decrease in the number of ELTs collected, with only 42 and 15 tyres, respectively. The sharp decrease in the recent years can be due to the tyres being still in use.

The period between 2009 and 2019 accounted for the majority of the samples, representing 71.8% of the total (1928 tyres). The highest concentration of end-of-life tyres was observed in the five-year period from 2014 to 2018, comprising 42.7% of the total sample (1,144 tyres).

Tyres manufactured before 2000 were scarcely represented in the sample, with only 4 tyres (0.15%) dating from this period.

The median manufacturing year was calculated to be 2014, indicating that half of the sampled tyres were manufactured before and half after this year.

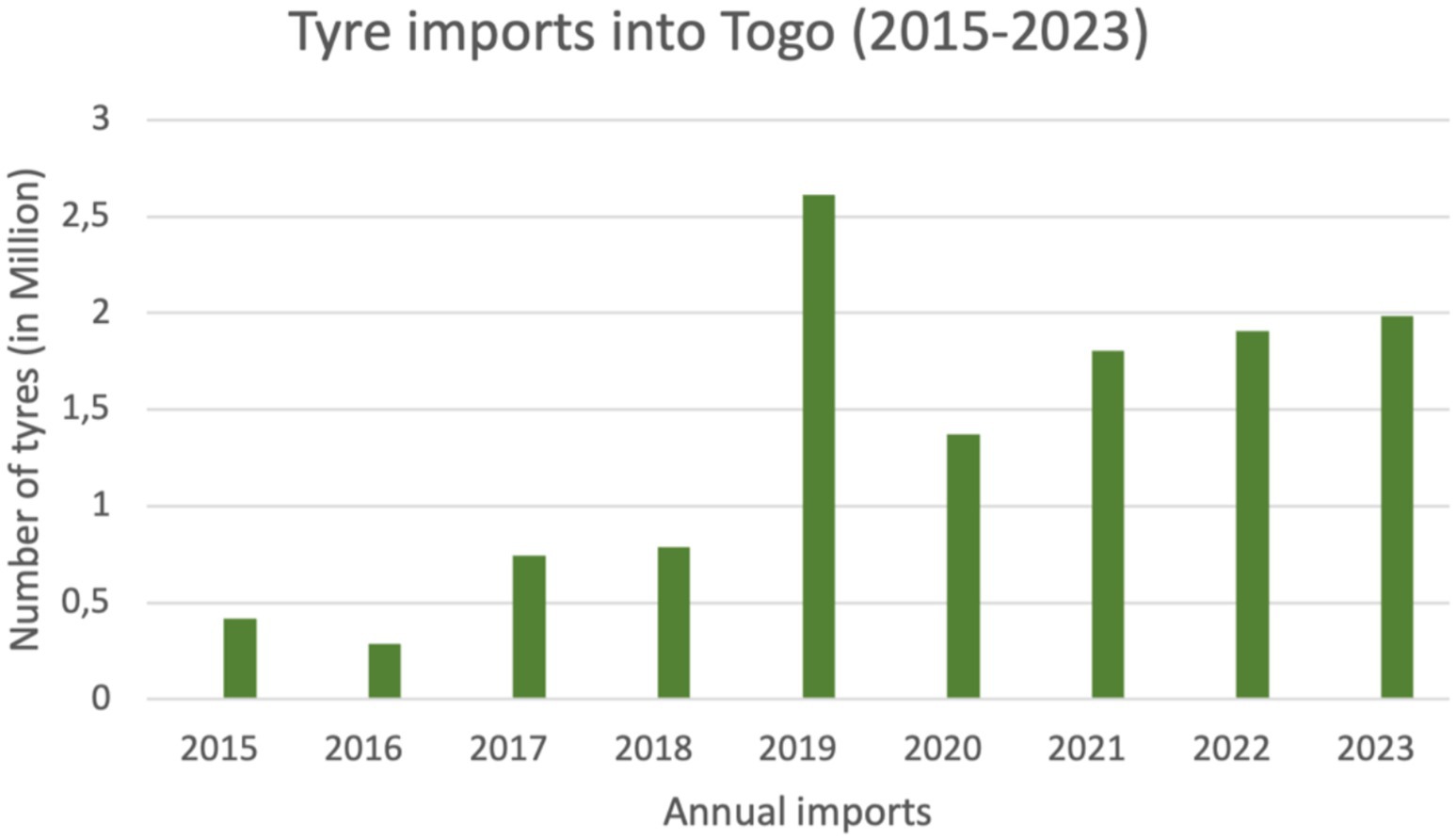

The data on tyre imports into Togo from 2015 to 2023 was analysed to identify trends and patterns. A significant fluctuation in import volumes was observed across the nine-year period (Figure 5).

Figure 5. Annual import numbers (in million) of tyres into Togo, data obtained from OTR, Port of Lomé.

Import data from the Port of Lomé (2015–2023) revealed significant fluctuations, from 419,081 tyres in 2015 to a peak of 2,611,865 in 2019, followed by a COVID-19 related decline to 1,371,869 in 2020. The period 2021–2023 showed stabilization around 1.8–2.0 million tyres annually (Figure 5). Despite fluctuations, the overall compound annual growth rate was 21.4% over the nine-year period. Additionally, approximately 21,900 cars imported annually contribute an estimated 87,346 tyres to the market. Considering the imported cars and assuming that a vehicle consists at least four tyres per vehicle on average is selected for calculations (conservative choice, as many vehicles such as buses, trucks etc. have more number of tyres), an additional sum of 87,346 tyres annually are imported into the Togolese markets.

Export numbers via the Port of Lomé for tyres and vehicles are extremely low. Tyre exports are typically below 10.000 tyres a year and are also exported to the neighbouring countries. Vehicle exports numbers are in the lower hundreds and also to other West African states.

Limitations of the study

This analysis was restricted to tyres containing legible DOT numbers, which might introduce selection bias if certain manufacturers’ identification numbers degrade differently over time. Additionally, corporate ownership in the tyre industry has changed over time, with acquisitions and mergers potentially complicating the accurate attribution of corporate origin for older tyres. The inclusion threshold of more than 5 identified tyres for detailed analysis, whilst necessary for analytical clarity, means that comprehensive information on the numerous smaller contributors (predominantly Chinese manufacturers) is not fully presented in the tabulated results.

The authors are writing from a European/African background and research availabilities, insights into Chinese tyre manufacturing combinations/agglomerations/business relations are limited to English translations and online research availabilities.

Discussion

The findings reveal several notable patterns in the tyre importation and utilisation lifecycle in Togo. The analysis of the production countries shows a diverse supply chain with 47 distinct manufacturing origins being identified for tyres entering the Togolese market. There is an Asian-European Dominance in the tyre production. The predominance of Chinese, German and French manufacturing origins suggests string trade relationships or market penetration strategies by these nations respective tyre industries within West Africa.

A distinct Global North Influence is visible. Despite the geographic distance, manufacturing centres in Europe and Asia contribute significantly more to Togo’s tyre market than proximate African manufacturers, with South Africa (0.68%) being the highest African contributor. The minimal presence of tyres manufactured within Africa (approximately 1% collectively) highlights the limited regional tyre production capacity serving the Togolese market.

The predominance of major multinational tyre manufacturers (Continental, Michelin, Goodyear, Bridgestone, Hankook) suggests the already established and significant market of certain brands into the West African market. European-headquartered companies contribute to the largest proportion of tyres with German (Continental) and French (Michelin) corporations being prominent.

The dichotomy between large multinational corporations and numerous small Chinese manufacturers suggests potential market segmentation and is dependent on different price points and quality tiers being served by these corporate entities. The minimal presence of African-headquartered tyre manufacturers highlights the limited regional tyre production capacity serving the Togolese market.

The dominance of multinational tyre manufacturers in the Togolese market leads to a significant flow of valuable secondary raw materials into the country. The current lack of systematic ELT recovery systems causes considerable inefficiencies in resource economics, where high-value polymers, carbon black, steel, and textile components are lost permanently to landfills, uncontrolled burning, or environmental dispersal. This disruption of material flow is worsened by the large importation of second-hand tyres from the Global North, which often enter the Togolese market near the end of their useful life. It can be observed that this creates a de facto material transfer, where valuable rubber compounds and reinforcing materials, initially produced in industrialized countries, are left abandoned in Togo without recovering their residual value (Roychowdhury, 2018).

The economic consequences of this resource loss are especially notable when considered in the context of the limited tyre manufacturing capacity based in Africa. The potential for a circular economy remains largely unfulfilled, as materials that could otherwise be redirected into regional manufacturing processes or alternative uses are instead discarded. Additionally, the ongoing one-way flow of materials from global production centres to Togolese end-of-life disposal represents a structural inefficiency in global resource utilisation, which could be significantly reduced through the proposed transitional framework, shifting responsibility from manufacturers to government market support.

Import numbers show a stable trend in car imports and an increasing trend in tyres import. Global trends in vehicle ownership and in West Africa show that a further increase of the Togolese vehicle fleet is expected (Button et al., 1993). The increase in the vehicle fleet and import of tyres is directly associated to future increase in the production of the ELTs.

The age distribution highlights the fact that half of the identified ELTs were manufactured prior to 2014, exceeding the recommended maximum 10-year usage period advocated by most tyre manufacturers. These ELTs demonstrate that a substantial stockpile of aged tyres exists in Togo and requires appropriate management. Compounding to the accumulation of “legacy” ELTs is the increasing importation of both new and pre-used tyres. Research conducted by Arthur et al. (2020) and Narra et al. (2024) indicates that the typical operational lifespan of a passenger vehicle tyre in West Africa is approximately 7.4 months, suggesting a rapid transition from imported tyres to ELTs.

Necessity for producer engagement in ELT management

Based on the obtained results, it is imperative that tyre producers, dealers and distributors have to assume proportionate responsibility for the environmental implications of their products in West African markets. The dominance of multinational corporations in Togo’s tyre market (Continental, Michelin, Goodyear, Bridgestone, Hankook) presents both an obligation and opportunity for these entities to extend their established European and Asian producer responsibility programmes. The establishment of such programmes ELTs to support the recycling and reduce pollution would not only give them benefits such as carbon certificates but also enhance the company’s sustainability efforts globally.

The significant disparity between the origin of tyres (97% non-African) and the location of their end-of-life management challenges highlights a substantial environmental accountability gap. This imbalance necessitates the implementation of Extended Producer Responsibility (EPR) frameworks on an international context wherein these predominantly European and Asian manufacturers contribute financially and technically to the sustainable management of their products’ waste stream in Togo and in West Africa.

Furthermore, the accelerated lifecycle degradation of tyres in West Africa (7.4 months versus multiple years in manufacturing countries) indicates a disproportionate waste management burden relative to product utilisation (Narra et al., 2024). This compressed usage timeframe suggests that producers should develop specially adapted EPR models for West African markets that account for this expedited transition to waste status, being based on the import of pre-used tyres and second-hand vehicles.

Multinational tyre manufacturers, with their substantial technical expertise and established EPR programmes in other regions, are uniquely positioned to transfer knowledge, technology, and financial mechanisms to support Togo’s ELT management challenges. Given the concentration of market share among major multinational corporations, a coordinated producer responsibility approach could achieve significant coverage of the ELT waste stream through engagement with a relatively small number of corporate entities. These corporations could facilitate the establishment of collection systems, recycling infrastructure, and appropriate financing mechanisms based on successful models implemented in their primary markets or based on their corporate sustainability efforts.

Feasible support mechanism solutions for ELT recycling in Togo

The three companies Continental AG, Michelin Group and Bridgestone Corporation (including their subsidiaries) have the biggest share of all ELTs identified in Togo.

In Europe [home of Continental AG (DE) and Michelin Group (F)] nearly all tyres are collected and treated, which results in a 95% treatment rate in all of Europe (ETRMA and EURIC, 2021). In Japan, where the headquarters of Bridgestone Corporation is located, collection and treatment rates of 86% have been achieved (WBCSD - World Business Council for Sustainable Development, 2018). These high collection rates are due to the fact that ELT recycling markets worldwide are mainly driven by the regulatory context in each country. Government regulations are enacted to address environmental issues related to illegal dumping or importation of ELT as well as historical stock piles leading to public health and sanitary issues (WBCSD - World Business Council for Sustainable Development, 2018).

In Europe the most common regulatory management system is the Extended Producer Responsibility which is “a policy approach where a producer’s responsibility for a product is extended to the post-consumer stage of the product’s life cycle. The intention is to shift the physical and/or financial burden for end-of-life-products from the authorities to the producer” (Winternitz et al., 2019). These regulations typically do not transfer to the generated ELTs in Togo and Western Africa. The transboundary movement of tyres means that they are not capture d in the regulations of the countries of origin and turn into waste materials in their final destinations.

In some countries, such as Denmark and Croatia, the government is taking the responsibility of collecting and recycling ELTs. These government responsible systems are usually financed through a tax on production which is passed on to the consumers (WBCSD - World Business Council for Sustainable Development, 2018).

Another common system for the management of ELTs is the free market system, which Japan for example follows. Here the government sets up a policy regulation for ELTs, but there is no dedicated support or scheme for the management of ELTs. Market forces are the main drivers of the management and producers are less involved (WBCSD - World Business Council for Sustainable Development, 2018).

In Togo, which serves as a case study for the whole of West-Africa, a total number of generated ELTs are estimated to be at a total of 30,525.11 t/a (Narra et al., 2024). This is a substantial number of tyres for a country with a population of 8.243.094 people. Considering the population of the whole ECOWAS region (approx. 261 million people) and an increasing vehicle fleet, the waste potential of this singular specific waste material of ELTs is enormous and hardly untapped.

The Togolese Government has not specifically dedicated policies for the management of ELTs. They fall under the Law N° 2008–005 Framework Law on the Environment and are not further specified. There is, alas, a section on producer responsibility in Art. 40 of Law No. 88–14 of November 3, 1988, establishing the Environment Code, section III: Waste that states that: “The manufacture, import, holding for sale, offering for sale, sale and making available to the user, in any form whatsoever, of waste-generating products will be regulated with a view to facilitating the elimination of said waste, or prohibited where necessary. Manufacturers importers and sellers of these products will be obliged to provide for or contribute to the elimination of waste arising from them” (Code de l’Environnemnet, 1988, translated). No information on the enforcement of this law has been found by the authors.

While various countries, such as those in Europe and Japan, have established robust systems for managing ELTs, the regulatory frameworks that support these systems do not extend to regions like Togo, where ELT management remains a significant challenge (Torretta et al., 2015; Numfor et al., 2022). The lack of formal systems for collection and recycling in many parts of sub-Saharan Africa highlights the gap in global responsibility for managing the environmental impact of ELTs. As international tyre producers dominate the market in Togo, there is a growing need to explore frameworks that could encourage producer involvement in the management of ELTs beyond their home countries or countries with robust and supportive policies. This calls for a closer examination of potential mechanisms through which international producers can contribute to and support the sustainable management of ELTs in Togo.

In the following section, potential frameworks for international producer support in the Togolese context, focusing on how these frameworks could address the regulatory void and contribute to the development of a more sustainable system for ELT management will be discussed.

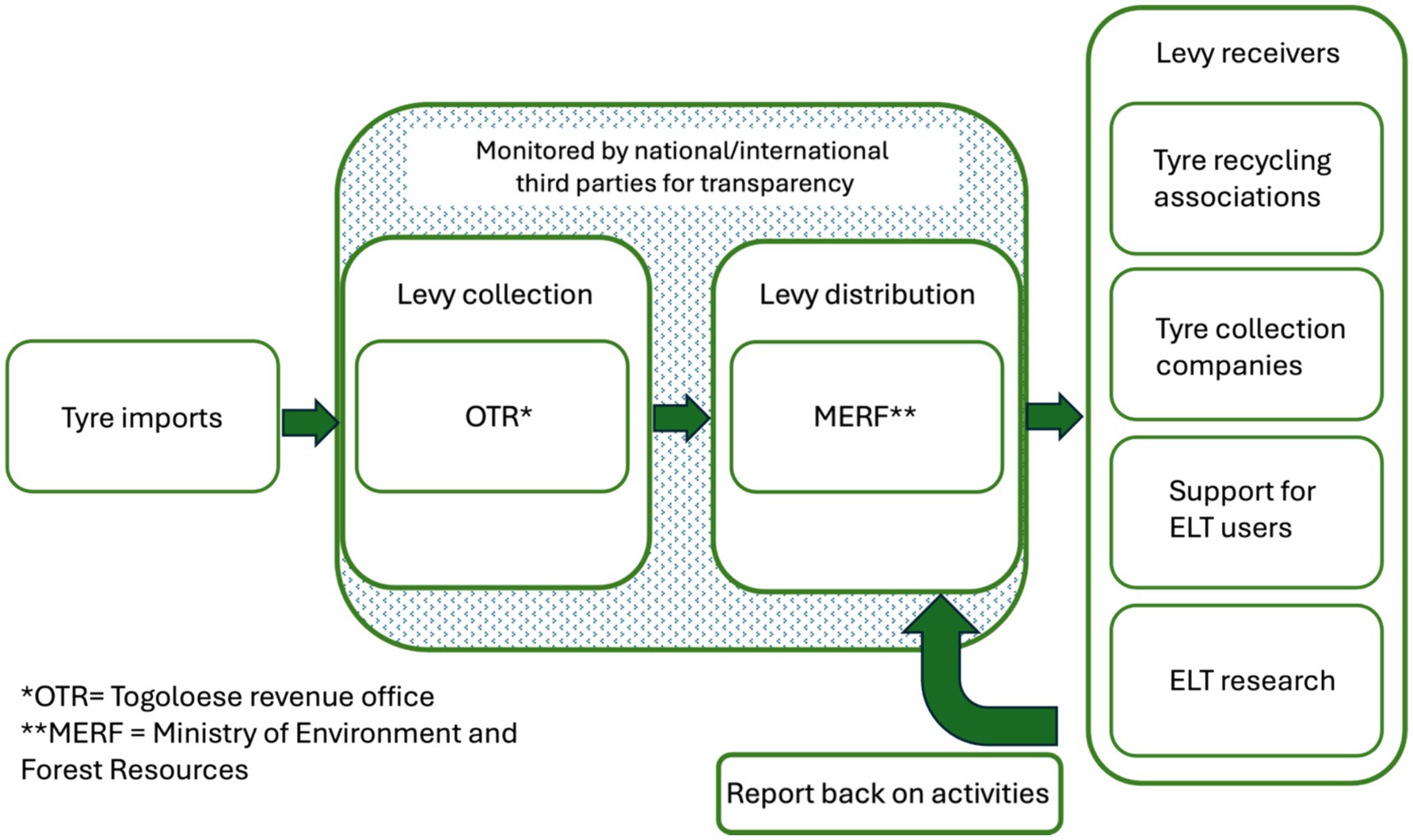

Environmental levy on tyres

An establishment of an environmental levy for tyres in Togo could be an important step toward managing ELTs and promoting sustainable recycling practices. The levy aims to generate funds for the collection, recycling, and proper disposal of tyres that are imported into the country. According to data from the Port Authority of Lomé, approximately 1.8 million tyres were imported annually between 2019 and 2023 (Figure 5, tyre imports). This volume of imported tyres presents a significant challenge and opportunity for waste management systems in Togo.

The key objectives of the proposed environmental levy for tyres in Togo are to generate funds for the management of ELTs, including collection, recycling, and environmentally sound disposal, to discourage illegal dumping and encourage proper recycling practices and to establish a sustainable waste management infrastructure for tyres that can improve environmental outcomes and create local economic opportunities.

The proposed levy would apply to all tyres imported into Togo, with a set fee imposed per tyre or per kilogram. Based on industry practices from other countries, such as South Africa and Ireland, the levy would apply to all types of tyres, including car, truck, motorcycle, and agricultural tyres.

The primary responsibility for collecting the tyre levy could lie with the Togo Customs Authority (OTR) (Figure 6), which is already tasked with regulating imports and collecting customs duties. Given their experience in monitoring and controlling imports at the Port of Lomé, the Customs Authority would be the ideal agency to ensure the levy is properly applied to all imported tyres.

The role of Togo Customs Authority would be to collect the levy at the point of entry (Port of Lomé) and to enforce compliance with levy payment by importers as well as to report the collected funds to the appropriate regulatory body.

The funds collected from the levy would be directed to a central environmental fund, which would be managed by the Ministry of Environment and Forest Resources (MERF) in collaboration with other relevant governmental bodies.

The role of MERF would be to oversee the allocation of funds to tyre recycling initiatives and to monitor the implementation of collection, recycling, and disposal operations. MERF would be needed to ensure transparency and accountability in the management of the levy funds.

A key focus would be the establishment of certified recycling facilities and collection centers across the country. As Togo is a small country one main recycling facility, which is currently under construction in Davié, north of Lomé, is sufficient for the country. Dedicated transfer and collection stations along the national highway, N1, for the ELT sourcing need to be established. The recycling facility and ELT sourcing companies would process the collected funds for the development of proper waste tyre management systems, including the support of the local tyre recycling plant and to encourage local businesses to process tyres into secondary materials, such as rubber crumb for construction or energy recovery.

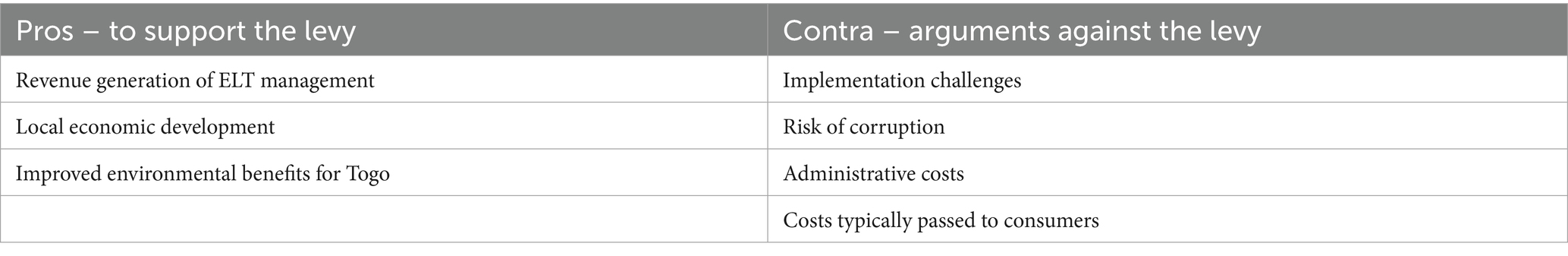

Table 2 describes the pros and cons of the proposed levy solution. The pros for the levy include the main aspect, the revenue generation for ELT management. Similar to South Africa’s tyre levy, the funds generated would be directed toward the proper management of ELTs, reducing the environmental burden associated with improper disposal (Sebola et al., 2018).

Similar to South Africa’s approach a tyre levy can encourage the creation of local recycling plants, generating jobs in the recycling and waste management sectors. This is particularly important in Togo, where economic development opportunities are essential.

The levy incentivizes the recycling of tyres and discourages illegal dumping. As seen in Ireland, the introduction of the levy has helped curb illegal stockpiling, which was previously a significant problem (O’Halloran, 2023).

The contra indications for a tyre levy imposed on the import of tyres into Togo are implementation challenges as the levy may face resistance from importers, as seen in Ghana, where the introduction of eco-levies was met with reluctance from stakeholders (Awere and Bonoli, 2021). Importers may also attempt to circumvent the levy or fail to comply with levy regulations, requiring effective enforcement mechanisms.

The risk of corruption, as experienced in South Africa, through improper management of funds is especially high when dealing with large amounts of money intended for waste management and environmental programs (Nkosi et al., 2019).

Transparency and oversight measures would need to be put in place to ensure that the funds are used as intended. The cost of setting up and maintaining the collection system (administrative costs), including monitoring and enforcement, could be significant. However, this could be minimised by leveraging existing customs and revenue collection infrastructure, but also needs to be made transparent in order to avoid corruption.

An additional contra point for the implementation of a tyre levy is that typically these additional costs, which are paid by the importers, are usually passed on to the consumers (WBCSD - World Business Council for Sustainable Development, 2018). Tyres in Togo are often sold by tyre dealers, not promising a continuous stream of income to most sellers (Narra et al., 2024), an additional financial burden would cause hardships for the sellers.

The establishment of an environmental levy for tyres in Togo represents a promising solution for addressing the environmental challenges posed by end-of-life tyres. By drawing from international examples such as South Africa and Ghana, Togo can implement a robust system for levy collection and fund distribution that encourages responsible waste management, supports local recycling industries, and mitigates the risk of illegal tyre disposal. The success of this levy will depend on effective enforcement, transparent fund management, and continuous engagement with stakeholders. Based on the examples of South Africa and Ghana, where the levies were dealing with oppositions, scandals and corruption allegations (Nkosi et al., 2021; Asare et al., 2023), strong transparency measures are needed to be introduced in order to be able to use an import levy as a funding mechanism for ELT management in Togo. National and international third parties would be needed to oversee the actions. Costs for the levy would increase the risk for sellers, increasing the burden for smaller tyre sellers.

Extended producer responsibility model for end-of-life tyres in Togo: a manufacturer-centric approach

In regions dependent on second-hand tyre imports, such as Togo, traditional extended producer responsibility (EPR) mechanisms encounter significant implementation barriers. Research from Nigeria (Ezeudu, 2024), Uganda (Ogenmungu et al., 2024) and Kenya (Oguge et al., 2024) conclude that a classic extended-producer responsibility scheme is not yet achieved in any of these countries, based on a lack of policies, inadequate implementation and a gap in data and accountability. In order to avoid these situations, the following analysis presents a novel approach wherein responsibility is placed exclusively on original equipment manufacturers (OEMs) rather than local economic actors.

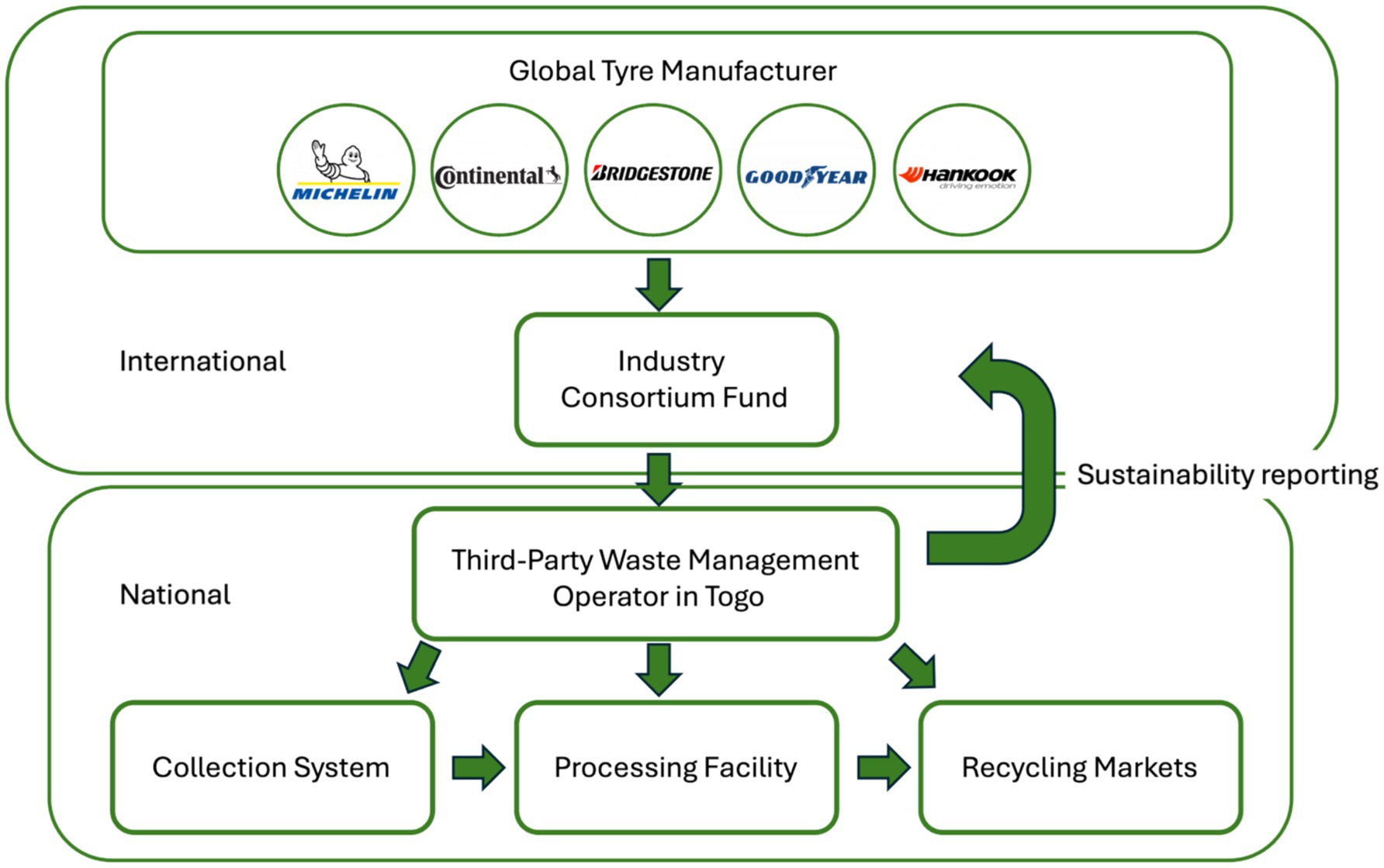

A manufacturer-centric EPR model for ELTs in Togo may be conceptualised wherein global tyre producers assume full responsibility for waste management irrespective of the second-hand nature of imports. It is proposed that major manufacturers including Michelin, Continental, and Bridgestone, as the main producers of tyres ending up as ELTs in Togo, could establish an international industry consortium with explicit waste management responsibilities in developing markets. Under such a framework, the financial burden would be distributed amongst consortium members proportionate to their global production volumes or estimated market representation in the region.

The financial mechanism would necessarily involve the integration of waste management costs into the manufacturers’ global pricing structures. A nominal fee could be incorporated into the retail price of new tyres sold in primary markets, effectively creating a cross-subsidisation model wherein consumers in developed nations partially fund waste management in secondary markets. This approach acknowledges the full lifecycle environmental impact of manufactured products beyond their first useful life.

For practical implementation, it would be advisable for manufacturers to work together to establish a third-party waste management organization to set up and manage the necessary infrastructure in Togo. This operational entity would function independently from local import and retail channels, thus avoiding the complications of regulating many small-scale operators. The system might feature a comprehensive buy-back scheme wherein the third-party operator purchases ELTs from any willing seller.

The economic sustainability of this model would require careful attention to brand identification methodologies for ELTs and accurate market share verification. This could be done via continuous monitoring of the DOTs or tyre identification number, or through annual random sampling. These challenges notwithstanding, the approach offers distinct advantages in terms of corporate social responsibility credentials and operational simplicity compared to models requiring extensive local regulatory frameworks.

International cooperation would be fundamental to this model’s success. The establishment of voluntary industry commitments through multilateral platforms such as the World Business Council for Sustainable Development could provide the necessary framework for manufacturer participation. Implementation would logically commence with thorough market analysis to determine brand distribution in the second-hand market, followed by a graduated approach beginning with basic collection and processing capabilities.

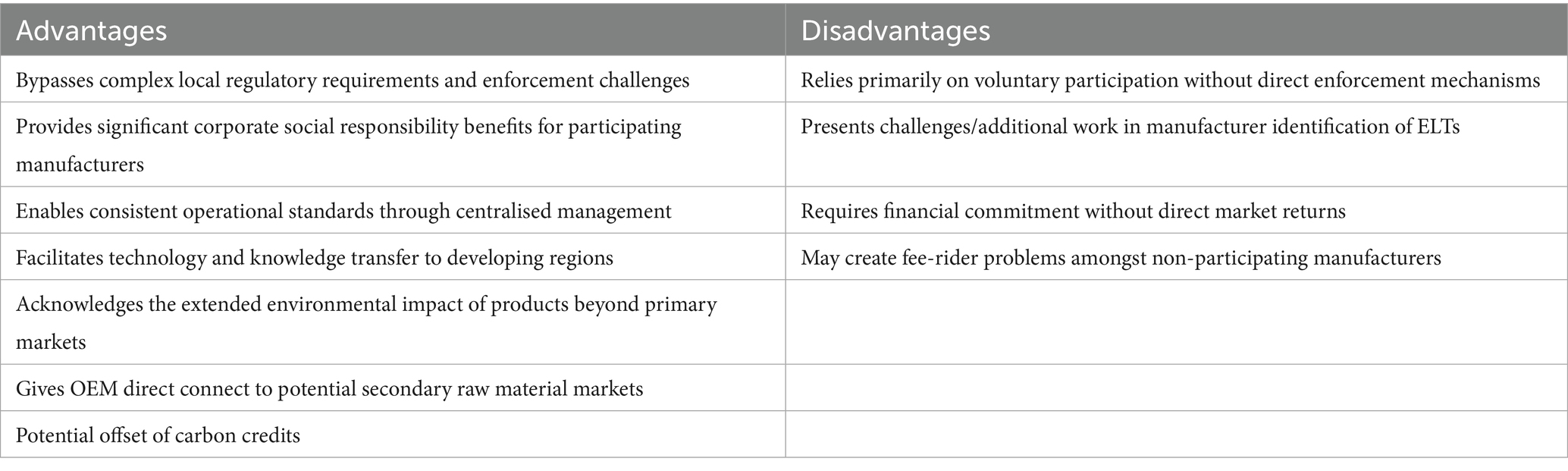

From a policy perspective, this model (depicted in Figure 7) represents a significant shift from traditional EPR frameworks by acknowledging that in globalised product lifecycles, producer responsibility cannot be terminated when products enter secondary markets. Instead, it proposes an extended view of manufacturer obligations that spans the complete product lifecycle regardless of multiple ownership transfers.

Figure 7. Overview of the management scheme for the proposed manufacturer-centric EPR approach. The global tyre manufacturers only serve as an example (top 5 manufacturers identified in Togo in this study) and are not limited.

Recycling costs are already factored into the retail prices of tyres sold in countries with EPR. These costs are not used when the tyres are exported as second-hand tyres to Togo and saved by the manufacturers. This model would ask for these savings to be used for Togolese tyre recycling.

It needs to be acknowledged that this manufacturer-centric approach presents significant challenges, particularly regarding voluntary participation and economic sustainability. The absence of direct regulatory enforcement mechanisms necessitates reliance on corporate sustainability commitments and potential international pressure. Furthermore, the model requires manufacturers to accept financial responsibility for waste management without direct market returns in the region, a proposition that may face resistance without compelling incentives.

Nevertheless, when compared to locally administered EPR systems, this model offers distinct advantages in implementation simplicity and operational consistency (see Table 3). By bypassing the need for complex local regulatory frameworks and enforcement mechanisms, it presents a potentially viable pathway for regions with limited administrative capacity or significant informal economic sectors.

In conclusion, whilst not without substantial challenges, a manufacturer-centric EPR model offers a theoretically viable approach to addressing the growing challenge of ELT management in Togo. Its success would ultimately depend upon securing meaningful commitments from major manufacturers and establishing effective operational mechanisms for ELT collection and processing.

Potential implementation pathway

• International agreement: Industry-led commitment through a platform like the World Business Council for Sustainable Development

• Pilot program: Start in Togo with plans to expand regionally if successful

• Research phase: Conduct market studies to determine brand distribution in the second-hand market

• Graduated approach: Begin with collection and basic processing, expanding to full recycling

• Global reporting: Integrate results into manufacturers’ global sustainability reporting

This approach could be a larger global commitment to tyre lifecycle management in developing countries lacking legislation and enforceability for sustainable ELT management. Togo, as a small country in West Africa, is in the infancy stages of ELT management. Due to its small size and population, a thorough investigation of the systemic ELT management chain model can be easily piloted and established in Togo as well as propagate it to whole west African region. For a deployment in Togo, only a small monetary investment would be necessary to set the processes in motion. Depending on the success in Togo, the model could be gradually extended to West Africa and beyond.

Transitional framework: from manufacturer-centric EPR to government-subsidised market model for end-of-life tyre management in Togo

The establishment of a manufacturer-centric Extended Producer Responsibility (EPR) programme for end-of-life tyres (ELT) in Togo represents an initial foundation upon which a more sustainable, market-driven waste management system may be developed. Whilst the manufacturer-centric approach addresses immediate concerns regarding collection and basic processing infrastructure, a gradual transition toward a government-subsidised market model is envisaged as the recycling industry matures and the recycling benefits are proven to the decision-makers. The proposed transitional framework acknowledges the developing nature of waste management systems in developing economies.

Once the basic collection networks and processing capabilities are established through investments by manufacturers, government financial support can be introduced to strengthen the developing recycling industry and promote wider market involvement. A comprehensive waste management incentive structure, as illustrated in Figure 8, would encompass multiple fiscal instruments. Corporate income tax incentives, including significantly reduced rates or extended tax holidays, would serve to attract additional commercial entities to the ELT management sector or ease the tax burden of existing entities. These measures could be particularly impactful in contexts where profit margins for recycling operations remain constrained during early market development.

Import duty exemptions for specialised equipment and machinery would substantially reduce capital expenditure requirements for new market entrants. Such exemptions are especially pertinent for technological solutions that may not be manufactured domestically but are essential for advanced ELT processing and valorisation.

Value-added tax exemptions on both services and equipment acquisitions further reduce operational costs and enhance financial viability. The introduction of accelerated depreciation allowances for equipment and facilities would help to cover the large initial investments needed for recycling infrastructure, thus improving the return-on-investment calculations for possible investors. Location-based incentives deserve special attention. Different benefits for rural facilities could encourage the spread of processing plants across various regions, while incentives for industrial zones might support the creation of integrated recycling clusters with shared infrastructure and logistical benefits.

The criteria for qualification for these fiscal benefits would have to cover all aspects of ELT management activities, from collection to recycling and material usage or waste-to-energy processes. This broad approach ensures that all parts of the value chain receive the necessary support.

This transition from manufacturer responsibility to governmental fiscal support represents a logical progression toward market sustainability. The initial manufacturer-centric EPR programme establishes essential infrastructure and operational protocols whilst the subsequent government incentive framework creates conditions for market expansion and diversification.

The Togolese context offers particularly favourable conditions for this transitional approach. The relatively modest scale of initial investment required for the EPR programme means that fundamental systems can be established without prohibitive costs. Subsequently, the implementation of targeted fiscal incentives would leverage this foundation to stimulate broader market participation.

It should be noted that the proposed transition is not abrupt but rather represents a gradual evolution wherein manufacturer responsibility and governmental support may temporarily coexist, with the balance shifting progressively toward the latter as market conditions mature (Ghisellini et al., 2016).

The regional implications of this approach are significant. A successfully demonstrated transition in Togo could provide a replicable model for neighbouring West African nations facing similar ELT management challenges but lacking robust legislative frameworks. The relatively standardised nature of fiscal policy instruments means that successful interventions could be adapted to regional contexts with appropriate modifications.

In summary, whilst a manufacturer-centric EPR programme provides an effective initialisation strategy for ELT management in Togo, its long-term sustainability and expansion may be optimally achieved through a transition to a government-subsidised market model incorporating comprehensive fiscal incentives. This evolutionary approach acknowledges both the immediate need for producer responsibility and the long-term requirement for broader market participation supported by appropriate fiscal frameworks.

The frameworks proposed for Togo demonstrate significant potential for adaptation across West African nations and other Sub-Saharan countries with similar dependency on second-hand tyre imports and limited domestic manufacturing capacity. Countries which exhibit comparable vehicle fleet patterns, making them natural candidates for adapted versions of these management systems.

A critical barrier to implementing systematic ELT management across Sub-Saharan Africa lies in the limited quantitative understanding of ELT generation volumes. Unlike Togo, where this study uses established baseline data, most regional countries lack comprehensive waste stream assessments (Debrah et al., 2022). The lack of data limits recycling efforts to small-scale artisanal practices, which are insufficient to tackle the scale of the regional problem and also hinder the development of economic models needed to attract commercial investment in formal recycling infrastructure. The proposed manufacturer-centric EPR approach offers particular advantages in addressing these data limitations. Standardised monitoring through international manufacturer consortiums could facilitate systematic ELT data collection across multiple countries simultaneously, enabling regional economies to understand the scale of their ELT waste streams.

Policymakers could adapt these frameworks through strategic modifications based on national capacity. Countries with stronger economies might implement hybrid models combining manufacturer responsibility with local regulatory frameworks, whilst nations with limited infrastructure could prioritise the manufacturer-centric approach before transitioning to government-supported market models.

Regional implementation could benefit from coordination through existing platforms such as ECOWAS. A harmonised framework could facilitate cross-border cooperation whilst establishing consistent manufacturer participation standards. Countries could sequence implementation based on development levels, with early adopters providing demonstration effects and knowledge transfer to neighbours, ultimately establishing West Africa as a comprehensive model for ELT management in developing economies dependent on second-hand tyre imports.

This study underscores the urgency of addressing ELT management in West Africa through the implementation of international EPR mechanisms. By fostering a shared responsibility for tyre lifecycle management. Togo and similar nations can mitigate environmental impacts, reduce public health risks, and transit toward a circular economy that prioritises sustainability and resource efficiency.

Conclusion

This research has thoroughly investigated the challenges and potential solutions for end-of-life tyre (ELT) management in Togo. The findings demonstrate that current practices of tyre waste disposal, primarily dumping and burning, pose significant environmental and public health risks. The study has successfully achieved its objectives through comprehensive field investigations of ELT origins and manufacturer profiles and development of context-appropriate recommendations.

It has been suggested that the implementation of a structured manufacturer-centric Extended Producer Responsibility (EPR) framework represents a viable approach to address the ELT management challenges in Togo. The analysis reveals that a three-pronged strategy, which suggests starting with manufacturer responsibility and the introduction of a levy system and goes over into governmental financial incentives, offers the most promising pathway toward sustainable ELT management in the Togolese context.

The manufacturer-focused EPR model has been found particularly relevant, as it establishes responsibility mechanisms covering the entire product lifecycle, thereby internalising environmental costs currently borne by Togolese society. However, it must be emphasised that manufacturer initiatives alone cannot, in the long-term, support a comprehensive system. Government financial support through tax benefits, reduced import duties, lower VAT rates, and accelerated depreciation allowances has been identified as crucial for creating favourable economic conditions that encourage investment in tyre recycling infrastructure.

This research contributes valuable insights into the adaptation of a manufacturer-centric EPR framework to developing economies, with particular relevance to West African contexts. The findings suggest that successful implementation requires careful consideration of local economic, social, and infrastructural realities. The recommendations provided herein serve as a foundation for policymakers, industry stakeholders, and environmental agencies to develop integrated ELT management systems that not only mitigate environmental pollution but also improve public health outcomes and create sustainable economic opportunities.

Future research should focus on pilot implementation projects to empirically validate the effectiveness of the proposed EPR framework and explore mechanisms for regional cooperation in ELT management across West Africa. Such initiatives would further enhance the sustainability of tyre waste management practices throughout the region and contribute to broader waste management improvements in developing economies.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

M-MN: Writing – original draft, Formal analysis, Project administration, Visualization, Data curation, Investigation, Writing – review & editing, Conceptualization. KA: Supervision, Writing – review & editing, Resources. SN: Project administration, Funding acquisition, Writing – review & editing. MN: Writing – review & editing, Supervision.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research has been funded by the German Federal Ministry of Research, Technology and Space under the project “Verbundvorhaben Waste2Energy: Hybrid Energie aus Abfall als nachhaltige Lösung für Ghana”.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The authors declare that no Gen AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frsus.2025.1631139/full#supplementary-material

References

Ahmed, S. (2024). How to choose a sampling technique and determine sample size for research: a simplified guide for researchers. Oral Oncol. Rep. 12, 100662–109060. doi: 10.1016/j.oor.2024.100662

Arthur, E., Dorfiah, P., Hilbert, I., Kyere, V. N., and Ocran, P. K. (2020). Waste Tyre management, baseline study for Ghana. Bern, Switzerland: Sustainable Recycling Industries.

Asare, D., Abubakari, M., Mahama, M., Mensah, D. A. O., Amponsah, I., Kwakye, A. D., et al. (2023). “How can Ghana transition from a linear to a circular economy of waste management? A conceptual analysis of policy approaches” in Circular economy strategies and the UN sustainable development goals. Sustainable development goals series. eds. M. O. Erdiaw-Kwasie and G. M. M. Alam (Singapore: Palgrave Macmillan).

Aslam, S. (2020). Sustainable collaboration; transforming alliances for EPR in non-OECD context. Lund, Sweden: IIIEE, Lund University.

Awere, E., and Bonoli, A. (2021). “Transforming the e-waste management sector in Ghana: Progress on regulatory and institutional strengthening” in Sustainable education and development. eds. J. N. Mojekwu, W. Thwala, C. Aigbavboa, L. Atepor, and S. Sackey (Cham: Springer).

Button, K., Ngoe, N., and Hine, J. (1993). Modelling vehicle ownership and use in low income countries. J. Transp. Econ. Policy 27, 51–67.

Code de l’Environnemnet, (1988), Loi no 88-14 du 3 novembre 1988, instituant Code de l'environnement. Available online at: https://faolex.fao.org/docs/pdf/tog5749.pdf (last accessed: 17.04.2025)

Debrah, J. K., Teye, G. K., and Dinis, M. A. P. (2022). Barriers and challenges to waste management hindering the circular economy in sub-Saharan Africa. Urban Sci. 6:57. doi: 10.3390/urbansci6030057

Ellen Mac Arthur Foundation. (2025). What is a circular economy?, Available online at: https://www.ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview (Accessed June 17, 2025).

ETRMA and EURIC. (2021). Position paper: the Tyre value chain is united and ready for EU-wide EoW criteria for end-of-life tyres (ELT) derived rubber. Available online at: https://euric.org/resource-hub/position-papers/euric-and-etrma-call-for-the-development-of-eu-wide-end-of-waste-criteria-for-the-end-of-life-tyre-derived-rubber-waste-stream (Accessed March 26, 2025).

Ezeudu, O. B. (2024). Harnessing the drivers and barriers to implementation of extended producer responsibility for circular economy in Nigeria. Circ. Econ. Sust. 4, 1461–1486. doi: 10.1007/s43615-023-00340-8

Faibil, D., Agyemang, M., Amponsah, O., Gupta, H., and Kusi-Sarpong, S. (2021). Assessing drivers of post-harvest losses: tangible and intangible resources’ perspective. Environ. Dev. Sustain. 23, 15785–15829. doi: 10.1007/s10668-021-01314-2

Ghisellini, P., Cialani, C., and Ulgiati, S. (2016). A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 114, 11–32. doi: 10.1016/j.jclepro.2015.09.007

Hilton, M., Sherrington, C., McCarthy, A., and Börkey, P. (2019). Extended producer responsibility (EPR) and the impact of online sales. Paris: OECD Publishing.

Kaya, A., Çiçekalan, B., and Çebi, F. (2020). Location selection for WEEE recycling plant by using Pythagorean fuzzy AHP. J. Intell. Fuzzy Syst. 38, 1097–1106. doi: 10.3233/JIFS-179471

Kumar, A., Wasan, P., Luthra, S., and Dixit, G. (2020). Development of a framework for selecting a sustainable location of waste electrical and electronic equipment recycling plant in emerging economies. J. Clean. Prod. 277:122645. doi: 10.1016/j.jclepro.2020.122645

Narra, M.-M., Gbiete, D., Agboka, K., Narra, S., and Nelles, M. (2024). Tracing the EoL Tyre management chain in Togo with focus on implementing a Tyre recycling plant. Sustain. For. 16:9193. doi: 10.3390/su16219193

Narra, M.-M., Gbiete, D., Kognine, D. M., and Nelles, M. (2025). “The case for integrated Tyre recycling Systems in West Africa: environmental and health impacts of Tyres as fuel for meat preparation” in African green transition through innovative pathways. World Sustainability Series. eds. M.-M. Narra and S. Narra (Cham: Springer).

Nkosi, N., Muzenda, E., Belaid, M., and Mateescu, C. (2021). A critical analysis of the integrated industry waste tyre management plan of South Africa. Adv. Sci. Technol. Eng. Syst. J. 6, 1046–1054. doi: 10.25046/aj0602119

Nkosi, N., Muzenda, E., Belaid, M., Mateescu, C., and Bilal, P. (2019). A review of the recycling and economic development initiative of South Africa (REDISA) waste Tyre management plan: successes and failure. 7th International Renewable and Sustainable Energy Conference (IRSEC), Agadir, Morocco, pp. 1–8

Numfor, S. A., Corder, G., Halog, A., and Matsubae, K. (2022). A review of end-of-life tire recycling in Australia, South Africa and Cameroon. Acad. Lett. 5115. doi: 10.20935/AL5115

O’Halloran,. (2023). Available online at: https://www.irishtimes.com/news/politics/oireachtas/over-1-600-firms-sign-up-to-scheme-to-prevent-dumping-of-old-tyres-1.3265034, last accessed: 20.03.2025.

Ogenmungu, C., Juma, S. N., Nyero, A. I., Kemigisha, S., and Onyinyi, B. (2024). Sustainability of electronic waste management in Uganda: driving factors for the extended producer responsibility systems. ORSEA J. 14, 138–158. doi: 10.56279/orseaj.v14i1.8

Oguge, N., Malcom, R. N., Steenmans, K., O’Meara, N., Oremo, F., and Peacock, M. (2024). Gap analysis on waste data management under the sustainable waste management act (2022) and draft extended producer responsibility regulations (2023): GAP ANALYSIS REPORT. National Environment Authority, nairobi, Kenya, MST id nr. 8295038.

Ongondo, F. O., Williams, I. D., and Cherrett, T. J. (2011). How are WEEE doing? A global review of the Management of Electrical and Electronic Wastes. Waste Manag. 31, 714–730. doi: 10.1016/j.wasman.2010.10.023

Roychowdhury, A. (2018). Clunkered: Combating dumping of used vehicles—A roadmap for Africa and South Asia. New Delhi: Centre for Science and Environment.

Schenck, C. J., Blaauw, D., Theodore, N., and Niyobuhungiro, R. (2024). Informal Tyre dealers in South Africa: an assessment of their contributions to a circular economy. Urban Forum 35, 65–81. doi: 10.1007/s12132-023-09502-1

Sebola, M. R., Mativenga, P. T., and Pretorius, J. (2018). A benchmark study of waste Tyre recycling in South Africa to European Union practice. Procedia CIRP 69, 950–955. doi: 10.1016/j.procir.2017.11.137

Tong, X., and Yan, L. (2013). From legal transplants to sustainable transition: extended producer responsibility in Chinese waste electrical and electronic equipment management. J. Ind. Ecol. 17, 199–212. doi: 10.1111/jiec.12013

Torretta, V., Rada, E. C., Ragazzi, M., Trulli, E., Istrate, I. A., and Cioca, L. I. (2015). Treatment and disposal of tyres: two EU approaches. A review. Waste Manag. 45, 152–160. doi: 10.1016/j.wasman.2015.04.018

WBCSD - World Business Council for Sustainable Development. (2018). Global ELT management – a global state of knowledge on collection rates, recovery routes, and management methods. Available online at: https://www.wbcsd.org/wp-content/uploads/2023/12/WBCSD_ELT_management_State_of_Knowledge_Report.pdf (last accessed: 14.03.2025)

Winternitz, K., Heggie, M., and Baird, J. (2019). Extended producer responsibility for waste tyres in the EU: lessons learnt from three case studies – Belgium, Italy and the Netherlands. Waste Manag. 89, 386–396. doi: 10.1016/j.wasman.2019.04.023

Keywords: end-of-life tyres, recycling, Togo, extended-producer-responsibility, circular economy

Citation: Narra M-M, Agboka K, Narra S and Nelles M (2025) Implementing extended producer responsibility for tyre waste in Togo: a circular economy perspective. Front. Sustain. 6:1631139. doi: 10.3389/frsus.2025.1631139

Edited by:

Konstantinos Salonitis, Cranfield University, United KingdomReviewed by:

George Tsironis, Technical University of Crete, GreeceDaniel Faibil, Beijing Institute of Technology, China

Copyright © 2025 Narra, Agboka, Narra and Nelles. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mona-Maria Narra, bW9uYS1tYXJpYS5uYXJyYUB1bmktcm9zdG9jay5kZQ==

Mona-Maria Narra

Mona-Maria Narra Komi Agboka2

Komi Agboka2