- School of Business, Shandong Jianzhu University, Jinan, China

Introduction: Artificial Intelligence (AI) has become a key driving force for promoting the development of Manufacturing 4.0 and enhancing new quality productivity - an economic model that emphasizes high efficiency, innovation-driven growth, and sustainable development. Although the transformative potential of AI is increasingly recognized, how to effectively unleash its role in enhancing new quality productivity at the enterprise level remains a question that requires in-depth research. This study aims to investigate the impact of AI applications on the new quality productivity of Chinese manufacturing enterprises, explore its underlying mechanisms, and assess its heterogeneous effects and spatial spillover effects across different regions and industries.

Methods: This paper is based on the panel data of Chinese A-share listed manufacturing enterprises from 2015 to 2023, and employs multiple econometric models to analyze the relationship between AI and new quality productivity. The empirical strategies include: a benchmark regression model to estimate the basic impact; a spatial Durbin model (SDM) constructed under a 0-1 adjacency matrix and a geographical distance matrix to capture spatial spillover effects; a dynamic panel GMM model to address endogeneity and dynamic persistence issues; heterogeneity and mechanism analysis through group regression and mediation effect tests. The robustness of the results is ensured through a series of robustness tests and endogeneity tests.

Results: The research findings indicate that AI has significantly enhanced the new quality productivity of manufacturing enterprises, and this conclusion remains robust under different model settings and endogeneity treatments. The mechanism analysis reveals that AI boosts new quality productivity through three pathways: promoting green innovation, alleviating financing constraints for enterprises, and optimizing the structure of human capital. Heterogeneity tests show that the promoting effect of AI is more pronounced in enterprises in the eastern region, non-heavy-polluting industries, and high-tech industries. Additionally, the spatial econometric results confirm that AI not only contributes to the improvement of local new quality productivity but also generates significant positive spatial spillover effects in surrounding areas.

Discussion: The above findings highlight the crucial role of artificial intelligence as a key engine driving the development of new quality productivity, especially demonstrating remarkable effectiveness in promoting the green transformation of manufacturing and the development of a circular economy. To fully unleash the potential of artificial intelligence in driving green productivity, policymakers should accelerate the construction of a “digital-green” collaborative innovation ecosystem. At the same time, the leading and radiating role of advanced regions should be fully leveraged to build cross-regional technology sharing platforms and data resource networks, forming a regional development pattern of “leading by points and advancing in coordination”, and comprehensively promoting the realization of new industrialization and the dual carbon goals.

1 Introduction

In China, the traditional economic growth model has long relied on high investment, high consumption and high emissions. This crude development path is no longer sustainable, and there is an urgent need to accelerate the cultivation of new growth momentum to promote high-quality development. High-quality development is an economic model centered on innovation-driven growth, structural optimization, green and low-carbon practices, and equitable sharing. It emphasizes efficiency gains and sustainability, rather than solely pursuing GDP growth. Against this backdrop, General Secretary Xi Jinping proposed the concept of “new quality productivity” during his research visit to Heilongjiang Province in September 2023 to lead the economy to achieve more efficient and sustainable transformation and upgrading, and the State Council's Government Work Report in 2024 re-emphasized the importance of accelerating the development of new quality productivity. As a pillar of the nation, manufacturing not only directly contributes to the growth of the country's GDP but also drives the development of other industries through the associated effects of the upstream and downstream of the industrial chain, creating a multiplier effect. Therefore, how to fully stimulate the subjective initiative of manufacturing enterprises and effectively enhance their new quality productivity level is of great practical significance and research value.

New quality productivity are not merely an extension of digital transformation or a superficial reconstruction of business models. Instead, they represent a fundamental leap in productivity driven by artificial intelligence as the core force. This marks a profound transformation of the productive force system from quantitative accumulation to qualitative breakthrough. It is a fusion of the “new” and “quality” of productive forces, led by new production factors and new production methods, promoting the advancement of productive forces toward higher quality (Jiang and Qiao, 2024; Ren and Dou, 2024). The “new” in New quality productivity is reflected in the intelligent reconfiguration of production factors. Artificial intelligence not only gives rise to new types of workers with high skills and qualities but also transforms labor tools into intelligent entities with perception, learning, and decision-making capabilities. Meanwhile, data, as a new type of labor object, is transformed into high-value intelligent assets under the impetus of artificial intelligence (Huang and Sheng, 2024). The “quality” of New quality productivity is mainly embodied in the transformation of production methods empowered by artificial intelligence. It is not only an improvement in the quality of products or services but also a production method that features high-tech content, high efficiency, and a deep satisfaction of the demands for innovation, sustainability, and personalization, representing the advancement and efficiency of productive forces (Zhang L., 2024).

In contrast, digital transformation focuses on digitizing existing processes, essentially optimizing efficiency; the transformation of new business models centers on the innovation of value delivery methods, which is a strategic adjustment. New quality productivity, however, involve a systematic reconstruction of the three elements of productive forces (laborers, means of labor, and objects of labor), emphasizing the development of strategic emerging industries and future industries through key and disruptive technological breakthroughs, covering new technologies, new economies, and new business forms. Against the backdrop of promoting high-quality economic development in China, enhancing the level of New quality productivity in all industries has become a key path (Tan et al., 2024).

The continuous development of emerging digital technologies represented by the Internet, big data, blockchain and artificial intelligence has accelerated the in-depth integration of digital technology and the real economy, providing strong support for the rapid formation of new quality productivity (Zhao and Li, 2024). As the core driving force of the new technological revolution and industrial transformation, artificial intelligence is reshaping the global production and lifestyle with its extensive penetration and profound influence. It constantly gives birth to new business models and industrial forms, becoming the key engine for cultivating new quality productivity. The new quality productivity represents a profound change based on the traditional productivity, which achieves a qualitative leap by innovating the factors of production. This new mode of production no longer relies solely on manpower and machines, but leads the way to high-quality development with science and technology innovation as the core driving force (Liu et al., 2025; Wu, 2024). Fundamentally, the new quality productivity integrates the improvement of workers' skills, the optimisation of labor means and the advanced integration of labor objects, and its key features are its innovativeness and forward-looking vision, which provides the possibility for countries to explore new momentum and new directions for sustainable development in the rapidly changing global landscape (Esfahani et al., 2024; Yue et al., 2024).

As the world's second-largest economy, China's promotion of new quality productivity carries profound international significance. Though emerging within China's policy context, the core essence of this concept aligns closely with global advanced development philosophies, particularly synergizing deeply with the strategic direction of the circular economy. As emphasized, the essence of the circular economy is a new economic paradigm centered on closed-loop resource flows. It aims to break away from the traditional linear “extract-manufacture-dispose” model and transition toward a full-lifecycle closed-loop system encompassing “design-production-use-recovery-reuse” (Geissdoerfer et al., 2017; Ellen MacArthur Foundation, 2015).

First, new quality productivity emphasizes the revolutionary reshaping of production methods through cutting-edge technologies like artificial intelligence and big data—the very technological foundation for achieving circular economy closed-loop management. Initiatives ranging from Germany's “Industry 4.0” and America's “Smart Manufacturing” to the EU's “Digital Europe Program” and “Circular Economy Action Plan” all strive to enhance resource efficiency through digital means. China's development of new quality productivity represents a practical pathway to transform these technological capabilities into intelligent resource flow management.

Second, new quality productivity are inherently green productive forces, with the circular economy serving as the core vehicle for achieving green transformation. The Chinese government has explicitly set “carbon peak and carbon neutrality” goals, positioning green development as a vital component of new quality productivity. This manifests in the promotion of clean energy and low-carbon technologies, alongside the establishment of a full-lifecycle resource circulation system. These initiatives align closely with the United Nations' 2030 Sustainable Development Goals (SDGs).

Third, many developing nations face the developmental dilemma of “insufficient old drivers and unestablished new drivers.” Traditional resource-intensive growth models are unsustainable, while green transitions are constrained by technological and institutional bottlenecks. By developing new quality productivity, China has pioneered a development path driven by technology, institutional coordination, and industrial restructuring. This has enabled a shift from “following” to “keeping pace” and even “leading” in certain sectors. This process has propelled the intelligent upgrading of domestic industries and accelerated the large-scale implementation of circular economy models, offering replicable and scalable transformation paradigms for other emerging economies.

Thus, new quality productivity is not merely a Chinese concept but China's proactive response to the global wave of technological revolution and industrial transformation. It integrates internationally advanced digitalization and sustainable development concepts while leveraging China's institutional strengths and developmental characteristics. More importantly, new quality productivity breaks through marginal bottlenecks in resource utilization through technological innovation, providing critical momentum for advancing the circular economy from concept to systematic practice. Vigorously promoting the development of new quality productivity is not only an intrinsic requirement for China's transition from high-speed growth to green, high-quality development but also a vital strategic initiative to stimulate new global economic drivers and address complex challenges like resource constraints. Simultaneously, it offers a key pathway for achieving coordinated and sustainable economic development worldwide (Li and Liao, 2023; Huang and Sheng, 2024).

As an important antecedent for the development of new quality productivity in enterprises, research on artificial intelligence in the academic circle is relatively scarce at present, which restricts our in-depth understanding of how artificial intelligence drives the development of new quality productivity. First, most scholars have focused on the strategic significance, connotation characteristics, formation logic and realization path of new quality productivity (Liu, 2024; Ren, 2024; Xue et al., 2024). A few scholars believe that theoretically, artificial intelligence can promote human-machine collaborative models, drive technological innovation, and empower new industries to enhance new quality productivity through its digital and intelligent attributes, but the conclusions lack empirical verification (Qi and Shen, 2024). Second, most studies have concentrated on the impact of artificial intelligence on traditional productivity (such as total factor productivity) or employment structure (Li and Zhou, 2025; Yang et al., 2024), while the attention paid to new quality productivity, a new form of productivity characterized by innovation, greenness, efficiency, and sustainability, is still at an initial stage. Third, as a general-purpose technology, artificial intelligence has significant spatial spillover effects, but existing literature rarely examines its spatial spillover effects across regions, neglecting the geographical proximity and network connectivity in technology diffusion. Moreover, most empirical studies rely on short-term data or static models, making it difficult to capture the dynamic evolution process and sustained effects of artificial intelligence's influence, especially lacking systematic case verification of the empowerment paths of artificial intelligence in the context of developing countries.

Based on the above research gaps, the marginal contributions of this paper are reflected in the following three aspects: First, taking new quality productivity as the core explained variable, a theoretical analysis framework of AI driving new quality productivity is constructed, expanding the research boundary of the economic effects of AI and clarifying the promoting effect of AI on the new quality productivity of manufacturing enterprises; Second, through the mediation effect, the multiple pathways through which AI promotes new quality productivity via green technological innovation, alleviating financing constraints, and optimizing the structure of human capital are systematically revealed, opening the “micro black box” of AI's impact on enterprise new quality productivity; Third, by comprehensively applying the Spatial Durbin Model (SDM) and dynamic panel GMM method, not only endogeneity problems are effectively controlled, but also the spatial spillover effects of AI on new quality productivity are further identified, providing new empirical evidence for understanding the network characteristics of technological diffusion and regional collaborative innovation. This research not only helps relevant enterprises to understand and deploy AI more accurately but also provides decision-making basis and policy implications for relevant management departments to accelerate the formation of new quality productivity in a context-specific manner.

2 Literature review

This chapter is the literature review section, aiming to systematically sort out the theoretical and empirical research results related to the research topic of this paper, providing a theoretical basis and research entry point for subsequent analysis.

2.1 Influencing factors of artificial intelligence

General Secretary Xi Jinping pointed out that it is necessary to deeply grasp the characteristics of the development of the new generation of artificial intelligence, promote the deep integration of artificial intelligence and industrial development, and inject new kinetic energy for new quality productivity. This assertion effectively summarizes the strategic position of AI in the current economic development, which is reshaping the productivity structure and development model from multiple levels, such as techno-economy, productivity, employment, sustainable development, etc., and provides a solid support for the cultivation and development of new quality productivity. From the viewpoint of techno-economic characteristics, AI, as a key technology with information processing capabilities and general technology attributes, has significant permeability and synergy (Fadziso, 2018), and can be widely applied to various industries, promoting the optimisation and upgrading of industrial structure and positively contributing to economic growth. Vocke et al. (2019) further pointed out that the relationship between AI and enterprises is a two-way interaction; AI not only enhances the technological innovation ability of enterprises, but the needs of enterprises also drive the continuous evolution and optimization of AI technology. In terms of productivity, several studies have shown that AI drives overall economic growth by enhancing enterprise labor productivity (Acemoglu and Restrepo, 2020; Graetz and Michaels, 2018). The study by (Xu 2022) further emphasizes that AI not only promotes economic growth, but also may bring exponential growth effects and become a key force driving long-term economic development. In addition, AI not only improves productivity levels, work quality and operational efficiency (Agrawal et al., 2019), but also drives product innovation and technological advancement (Babina et al., 2024), and plays an important role in decision support systems, providing scientific evidence and intelligent analyses (Dwivedi et al., 2021). From the employment level, although the widespread application of AI may replace some jobs, (Cai and Chen 2019) argue that with the increase in innovation activities, new jobs will be created. The empirical study of (Bessen 2019) also shows that although enterprises have improved their productivity in the process of introducing new technologies, they have not led to a decline in employment, but have instead promoted employment growth. Yin et al. (2023) also pointed out that AI has a significant positive effect on employment, which will give rise to a large number of new jobs, new business forms and new modes, thereby expanding the demand for labor. In terms of sustainability, Del Río González's (2007) study further points out that while increasing productivity, AI also helps to achieve more efficient allocation of resources and environmental protection goals, promoting green and sustainable development.

2.2 Driving factors of new quality productivity

In recent years, scholars have conducted in-depth explorations from various dimensions into the pivotal roles of data elements, technological innovation, and digital finance in cultivating and developing new quality productivity. These studies provide robust theoretical underpinnings and practical guidance for achieving industrial upgrading and sustainable development in the context of the new era. In terms of data elements, Liu (2025) points out that data elements have become a key factor driving the development of new quality productivity by cultivating new quality workforce, improving labor means and enriching labor objects. In the field of scientific and technological innovation, Yin et al. (2024) pointed out that scientific and technological innovation has a central leading role in the development of new quality productivity, and that the cultivation and development of new quality productivity by means of scientific and technological innovation is an important strategic choice that integrates the practical exploration and theoretical logic, and responds to the needs of the times, and Zhang and Liu (2025) also emphasized the key role played by digital innovation in the evolution process of promoting new quality productivity. Zhang and Ma (2024) further suggest that generative AI, as a typical representative of current technological innovation, is comprehensively empowering the development of new quality productivity by promoting innovation at multiple levels such as strategic decision-making, manufacturing, marketing services, and organizational structure. In the field of digital finance, Zhu and Zhai's (2025) study shows that digital finance can effectively promote the enhancement of new quality productivity of enterprises by alleviating the financing constraints of enterprises, enhancing the growth capacity of enterprises, and optimizing the structure of financial leverage and other paths. In addition, with the increasing depth of use and breadth of coverage of digital finance, the efficiency of financial service enterprises is significantly enhanced. This not only provides stronger financial support for enterprises to carry out innovative activities, but also promotes the diversification of innovation modes, which helps to realize the development path with innovation as the core driving force, and further enhances the development of new quality productivity of enterprises (Zhang R. W., 2024).

The aforementioned literature has actively explored the economic consequences of artificial intelligence and the driving factors of new quality productivity, laying a solid theoretical foundation for this study. In contrast, existing research has largely focused on the application effects of AI at the individual enterprise level, emphasizing its role in enhancing corporate efficiency while overlooking the strong externalities and spatial spillover effects inherent in AI as a general-purpose technology. This paper defines AI as the core technological variable driving new quality productivity, distinguishing it from general digitalization or intelligentization concepts. By introducing the Spatial Durbin Model (SDM) and dynamic GMM methods, it not only reveals AI's direct effects on new quality productivity but also captures its spatial spillovers and long-term dynamic impacts across regions, thereby expanding the research boundaries of AI's influence on new quality productivity.

3 Theoretical analysis and research hypothesis

This chapter will explore the enabling effect of artificial intelligence on new quality productivity and propose corresponding research hypotheses. It will specifically discuss from the following four aspects: artificial intelligence and new quality productivity, artificial intelligence and green innovation and new quality productivity, artificial intelligence and financing constraints and new quality productivity, as well as artificial intelligence and human capital structure and new quality productivity.

3.1 Artificial intelligence and new quality productivity

In the context of accelerating the fourth scientific and technological revolution, artificial intelligence, as the core driving force of the new round of industrial change, is profoundly reconstructing the production mode and organizational form of enterprises. Its characteristics of extensive permeability, data-driven and system intelligence make it not only an important part of new labor tools, but also a key supporting force to promote the development of new quality productivity (Hu and Du, 2020). New quality productivity is a specific manifestation of the modernization of productivity in the new development stage, and the new quality productivity of manufacturing enterprises is a high level, high efficiency, high technology, high quality and sustainable productivity. Artificial intelligence helps to cultivate and develop new quality productivity by empowering manufacturing enterprises to improve productivity and sustainable development. First of all, production tools are the basic conditions for enterprises to carry out production activities, and their advanced degree directly determines the production efficiency and output level. Traditional production tools are mainly mechanized and electrified, while artificial intelligence, with its highly intelligent, automated and networked characteristics, has become a representative of new modern labor tools. It can be deeply embedded in all aspects of research and development, manufacturing, management and service, significantly improving the enterprise's resource allocation efficiency and value creation ability. Browder's study (Browder et al., 2022) further points out that AI, combined with other advanced automation technologies, not only optimizes the existing processes, but also stimulates a large number of subsequent innovations and ultimately achieves sustained productivity growth. Secondly, AI transforms massive information into usable digital assets through data collection, correlation analysis and deep mining, thus unleashing the potential of data and driving enterprises to achieve a shift from empirical decision-making to data-driven management (Mi et al., 2024). The enhancement of this ability makes enterprises more forward-looking and flexible in product design, process improvement, market response, etc., and lays the foundation for the leap in innovation capability. At the same time, with policy support and institutional guidance, enterprises have increased their investment in AI-related technology research and development and talent training (Lu et al., 2024). Through tax incentives, special support, and platform construction, the government has reduced the costs and risks of enterprises applying AI and enhanced their technology absorption and integration capabilities. This process not only promotes the reconstruction of the internal capacity system of enterprises, but also provides sustainable technology and talent guarantee for the development of new quality productivity. Finally, the deep integration of artificial intelligence with traditional industries has optimized conventional production processes, enhancing product quality, resource utilization efficiency, and environmental sustainability. Simultaneously, it has spawned a range of emerging and future industries—such as smart manufacturing, intelligent services, and digital twins—creating new economic growth drivers and industrial ecosystems (He and Yuan, 2025). In addition, AI has a certain substitution effect on low-skilled labor, prompting workers to continuously improve their skills and quality (Autor and Salomons, 2018; Calvino and Virgillito, 2018), thus promoting the optimisation of the human capital structure on the whole and enhancing the endogenous momentum of industrial development. Accordingly, this paper proposes hypothesis 1:

H1: Artificial intelligence can empower the development of new quality productivity in manufacturing enterprises.

3.2 Artificial intelligence, green innovation and new quality productivity

Driven by sustainable development, the new quality productivity is given a profound green connotation. As a new type of production mode centered on technological innovation and based on the efficient use of resources, new quality productivity is essentially a green productivity. As the key main body in China's economic system, the green innovation ability of manufacturing enterprises directly determines whether they can realize the new kinetic energy transformation from the traditional growth mode to innovation-driven, low-carbon and environmental protection, and also determines whether the new quality productivity can continue to emerge or leap up (Wang et al., 2025). Research based on the theory of technological availability has shown that digital resources significantly enhance the innovation potential of enterprises by enhancing their information processing capabilities, knowledge integration capabilities and resource allocation efficiency (Xie W. H. et al., 2023). This enhancement is not only reflected in the level of technological innovation, but also extends to business models, organizational synergy and other dimensions, injecting new momentum for green innovation. However, the process of green innovation is full of uncertainty, especially in the stage of technology development and market application, AI can build a highly realistic scenario simulation system to provide enterprises with an innovation test platform close to the real environment, helping enterprises to make more scientific R&D decisions in the complex and volatile market environment (Kakatkar et al., 2020), which is conducive to breaking down the restrictions of enterprise boundaries, and realizing the sharing of knowledge, collaboration, innovation and value co-creation among different organizations (Wang and Tang, 2024). This capability effectively reduces the probability of green innovation failure and increases the innovation willingness and investment intensity of enterprises, thus enhancing the possibility of their green technology breakthroughs. Artificial intelligence is called the ‘invention of invention', which is not only a tool, but also a new way of knowledge creation (Agrawal et al., 2018). In the scientific research process, AI can automatically retrieve and analyze huge amounts of literature and data, identify potential technology paths and innovation opportunities, thus greatly reducing the knowledge burden of researchers (Jones, 2009). This human-machine collaborative innovation mode not only improves the efficiency of R&D, but also accelerates the iterative updating of green technology, providing continuous technical support for the development of new quality productivity. Li et al.'s (2023) empirical study shows that the application of AI significantly optimizes the efficiency of enterprise resource allocation and enhances the technological innovation of the production system. This demonstrates that AI not only serves as a catalyst for green technologies but also functions as a practical vehicle for green management concepts. It facilitates the formation and leap forward of new quality productivity, propelling the manufacturing sector toward a new phase of development that is greener, smarter, and more sustainable. Accordingly, this paper proposes hypothesis 2:

H2: Artificial intelligence empowers the development of new quality productivity in manufacturing enterprises by promoting green innovation capability.

3.3 Artificial intelligence, financing constraints, and new quality productivity

Financing constraints, as one of the key factors restricting the innovation activities of enterprises, have become an important bottleneck affecting the improvement of new quality productivity. Firstly, the lack of resources has directly weakened the ability of enterprises to invest in technological innovation, especially for the breakthrough innovation of key technologies, the lack of sufficient financial support will lead to the difficulty of starting R&D projects or put them on hold, which will seriously impede the leap of the technological level of enterprises. Secondly, financing constraints exacerbate the imbalance in the allocation of market resources. Even if enterprises have the ability to identify innovation opportunities, they may miss good opportunities due to the inability to obtain the necessary financial support, thus inhibiting their willingness to conduct R&D and innovation ability, and ultimately dragging down the innovation level of the whole industry (Yu et al., 2025a). Further, the cultivation of new quality productivity requires a large amount of upfront investment, including the introduction of technology, equipment updating, talent reserves, etc. If enterprises face persistent financing difficulties, it will slow down the pace of industrial upgrading and hinder the steady development of new quality productivity forces. Against this backdrop, artificial intelligence is reshaping the operational logic and service models of financial services. The online and intelligent financial service process has significantly improved financing efficiency, reduced transaction costs, and provided manufacturing enterprises, especially small and medium-sized micro-enterprises, with more opportunities to obtain capital support (Feng and Yu, 2025). Artificial Intelligence is able to efficiently integrate and accurately analyze multi-dimensional data of enterprises, which significantly improves the ability of financial institutions to judge the credit status of enterprises (Feng, 2024). This improvement in information processing efficiency can help alleviate the “information silo” problem that exists in the traditional financial system, so that more high-quality but undervalued enterprises can obtain due credit support. With the help of big data analysis, AI can build a more scientific risk assessment model to help financial institutions more accurately predict the probability of default and formulate differentiated lending strategies. This not only improves the efficiency of credit approval, but also reduces the cost of supervision of loan funds and the cost of default, and enhances the enthusiasm of financial institutions to lend money. Artificial intelligence not only empowers financial institutions, but also inversely improves the information acquisition and analysis capabilities of enterprises. Through the introduction of AI-driven intelligent management systems, enterprises are able to identify market opportunities and assess the risks of investment projects more efficiently, so as to optimize the management's investment decision-making process and improve the efficiency of capital use and output level (Huang et al., 2023). Accordingly, this paper proposes hypothesis 3:

H3: Artificial intelligence empowers the development of new quality productivity in manufacturing enterprises by alleviating corporate financing constraints and thus empowering the development of new quality productivity in manufacturing enterprises.

3.4 Artificial intelligence, human capital structure, and new quality productivity

Advancements in artificial intelligence have shifted enterprises from relying on traditional low-skilled labor toward demanding highly skilled, innovative talent. This transformation drives continuous growth and optimization in both the quantity and quality of local talent, fueled by corporate self-motivation. As the most dynamic and proactive element of social productive forces, and given that worker quality constitutes a key component of new quality productivity, laborers will further propel the development of these new quality productivity. With the introduction of high-tech innovations like informatization and intelligentization, labor processes have become more complex and technical, placing higher demands on workers‘ operational skills and technical comprehension abilities (Xu and Zhang, 2024). Enterprise adoption of AI can alter internal labor demand structures and generate substitution effects (Wang and Dong, 2020). Automation and intelligent technologies replace most procedural manual labor, significantly reducing demand for low-skilled workers (Sun and Hou, 2019). Simultaneously, the intelligent transformation drives upgrades in production technologies and equipment. To adapt to new technologies and manage complex systems, enterprises will increase investment in highly skilled, innovative labor (Xiao et al., 2022), thereby boosting demand for highly skilled workers. The skill-biased nature of enterprise intelligent development continuously drives the upgrading and optimization of human capital structures, increasing the proportion of employees holding bachelor's degrees or higher within enterprises (Ye et al., 2022). Deeply optimizing human capital structures promotes specialized division of labor among workers with different skill and education levels, reduces production costs, and unleashes enterprises' innovative potential. Higher-educated workers demonstrate greater flexibility and faster adoption of new technologies, enabling better adaptation to new organizational models and fostering collaborative innovation within enterprises (Niu and Jin, 2024). The integration of highly skilled talent signifies the incorporation of high-quality knowledge capital in digital technology alongside skilled labor capital into production and operations. Enterprises increasingly emphasize cross-departmental collaboration and knowledge sharing, generating technology diffusion effects that enhance innovation capabilities and thereby promote the intelligent development of organizational structures. Changes in labor demand structures, combined with technological application and organizational transformation, drive the advancement of new quality productivity. Based on this, hypothesis 4 is proposed:

H4: Artificial intelligence empowers the development of new quality productivity in manufacturing enterprises by optimizing human capital structures.

4 Research design

This chapter will systematically expound the empirical research framework of this paper from three aspects: model construction, variable definition, and data sources and description, laying a solid foundation for the subsequent empirical analysis.

4.1 Model construction

4.1.1 Benchmark regression model construction

In order to verify the relationship between artificial intelligence and new quality productivity in manufacturing, the benchmark regression model is established as follows:

Where Nproi, t denotes the new quality productivity level of a listed company i in year t. AIi, t denotes the level of enterprise AI development; Xit denotes a series of control variables, and the model also contains province fixed effects μi, time fixed effects yt. In this paper, we adopt enterprise-level clustering robust standard errors to cope with potential heteroskedasticity and autocorrelation problems, and εi, t denotes the random perturbation term.

4.1.2 Mediating effects model construction

In order to screen the transmission effects of green innovation, financing constraints, and human capital structures in the development of AI for new quality productivity in manufacturing, this paper refers to the two-step method of Jiang (2022) to construct the following mediating effect model:

Where Medi, t is the mechanism variables (green innovation, financing constraints, human capital structures).

4.1.3 Spatial Durbin model construction

Since the spread and diffusion of AI between regions has a strong spillover effect, to further verify the spatial spillover effect of AI on new quality productivity in manufacturing, the spatial Durbin double fixed model (SDM) is constructed as follows:

Where: Nproi, t with WNproi, t denotes the level of new quality productivity and its spatial lag term in year t in region i, respectively; AIi, t with WAIi, t is the level of artificial intelligence and its spatial lag term; W represents the spatial weight matrix. This paper employs a 0–1 adjacency matrix and a spatial geographic distance matrix.

4.1.4 Dynamic panel model construction

However, the traditional benchmark model does not take into account the continuity and dynamics of the development of new quality productivity; therefore, this paper establishes a dynamic panel model (GMM) as follows:

Where Nproi, t − 1 denotes the first-order lag term of the level of new quality productivity in each province.

4.2 Definition of variables

4.2.1 Explained variable: new quality productivity

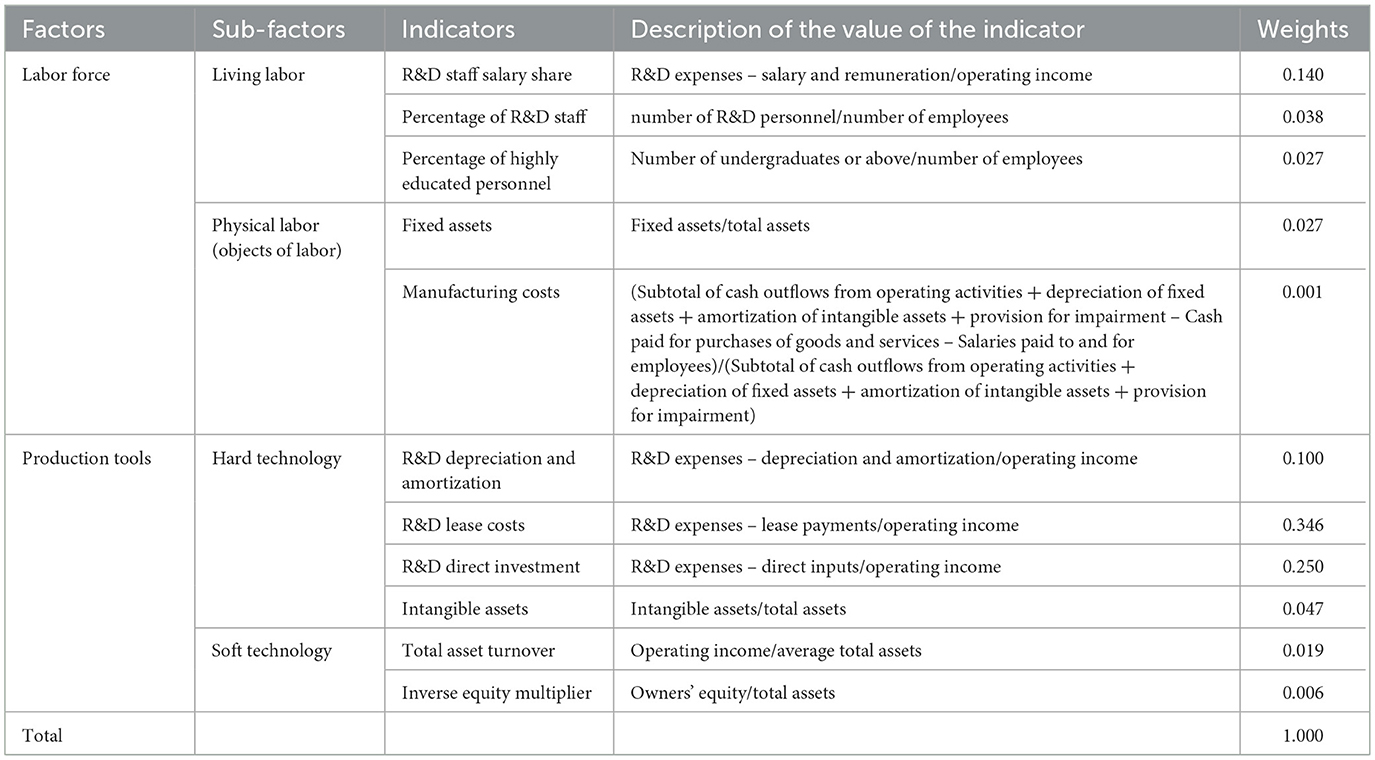

The explanatory variable in this paper is the new quality productivity (NPro) of enterprises. Following the approach of Song et al. (2024) and Wang and Wang (2024), based on the two-factor theory of productivity and considering the role and value of the object of labor in the production process, the entropy method is used to weight and synthesize the indicators in Table 1 thereby constructing a scientifically reasonable quality productivity indicator system. The specific steps are as follows:

In order to eliminate the influence of the number and scale of raw indicators and improve the performance of the model, it is necessary to standardize and pre-process the data of each raw indicator. In this paper, the extreme value method is used to process the data, and the specific formulas are as follows:

Calculate the weight of the indicator value of the ith year under the jth indicator as a percentage of the sum of all sample values of the indicator (pij).

Calculate the information entropy of the indicator (ej), where m is the number of years evaluated:

Calculate the information entropy redundancy (dj):

and the required indicator weights (wj):

Calculate the new quality productivity level based on the indicator share (pij) and the corresponding weights (wj):

4.2.2 Explanatory variable: artificial intelligence

The explanatory variable in this paper is artificial intelligence (AI). Existing literature typically measures corporate-level AI development by analyzing annual reports of listed companies (Li et al., 2024). However, textual descriptions in annual reports are highly context-dependent, making it difficult to accurately distinguish the stage of AI technology adoption within enterprises and potentially introducing measurement bias. In contrast, patent data offers greater objectivity and technical substance, providing a more authentic reflection of technological innovation and actual investment in AI by enterprises. Therefore, this paper adopts the AI keyword dictionary constructed by Yao et al. (2024). It obtains patent application information from Chinese listed companies through the National Intellectual Property Administration (CNIPA). By performing bulk keyword matching on patent titles and abstracts, it identifies patent records related to AI technology. Based on this, the number of AI-related patents applied for by each company in each year is aggregated. Subsequently, this sum is incremented by 1 and the natural logarithm is taken to construct a proxy variable for the company's AI development level.

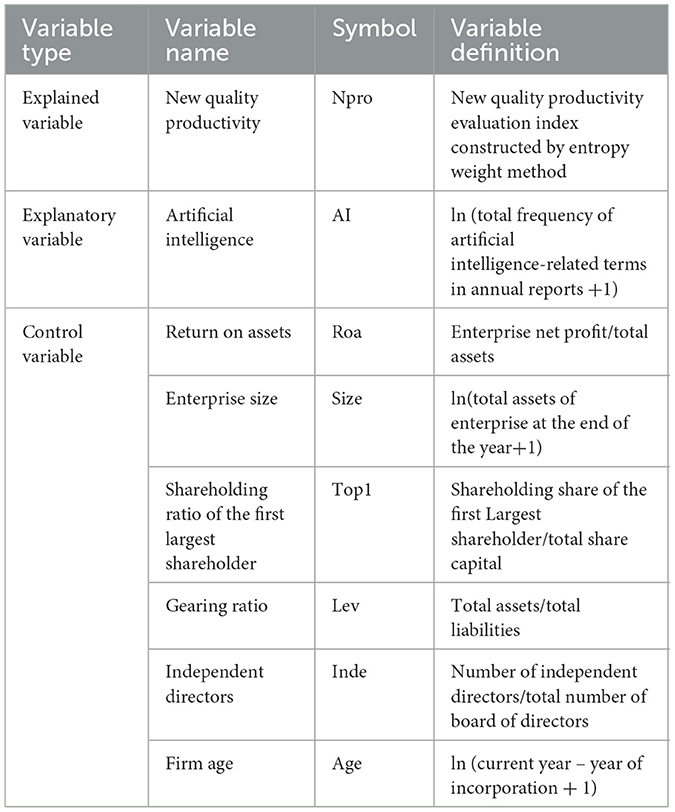

4.2.3 Control variables

In order to control other variables that have an impact on the new quality productivity, the following control variables are selected: return on assets (Roa), enterprise size (Size), proportion of shares held by the first largest shareholder (Top1), gearing ratio (lev), proportion of independent directors (Inde), and age of the enterprise (Age), as shown in Table 2.

4.3 Data source and description

4.3.1 Data source

Based on the research content and data availability of this paper, this paper selects A-share listed manufacturing enterprises from 2015 to 2023 as the research object, and processes the relevant data as follows:(1) Excluding all enterprises belonging to the financial industries such as banking, insurance and securities, in order to focus on analyzing the manufacturing industry. (2) Insolvent enterprises were excluded to ensure that the sample contained only enterprises with relatively stable financial conditions. (3) Enterprises labeled as ST, *ST and PT were removed to avoid influencing the results of the study due to the special operating status of these enterprises. (4) To mitigate the influence of extreme outliers on the regression results, winsorization at the 1% and 99% percentiles was applied to all continuous variables, resulting in a final sample of 24,302 observations. The data used in this study comes from the Wind database and the China State Intellectual Property Office.

4.3.2 Data description

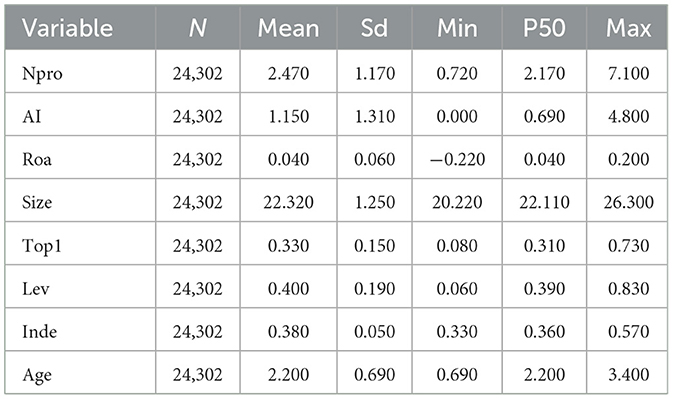

Table 3 lists the descriptive statistics of the main variables in this paper. Among them, the mean value of new quality productivity (Npro) is 2.470, the standard deviation is 1.170, and the data distribution has a certain degree of dispersion relative to the mean. The minimum value is 0.720, the median is 2.170, and the maximum value is 7.100, which reflects that the overall new quality productivity of Chinese manufacturing enterprises is still at a low level, and there are large differences in new quality productivity among enterprises, further indicating that Chinese manufacturing enterprises have a large space for development and potential to improve new quality productivity. The mean value of Artificial Intelligence (AI) is 1.150, and the standard deviation is 1.310, indicating that the data distribution is more dispersed. The minimum value is 0, the median value is 0.690, and the maximum value reaches 4.800, which means that although AI technologies have gained widespread attention and development globally, a large portion of enterprises have not yet begun to take advantage of these technologies when actually applying them to the manufacturing sector, but this also means that there is a vast space and opportunity for development in the future. The descriptive statistics of other control variables are basically consistent with the findings in the existing literature.

5 Results

This chapter will systematically present and discuss the research results from six aspects: benchmark regression, robustness test, endogeneity treatment, mechanism test, heterogeneity analysis, and spatial spillover effect.

5.1 Benchmark regression

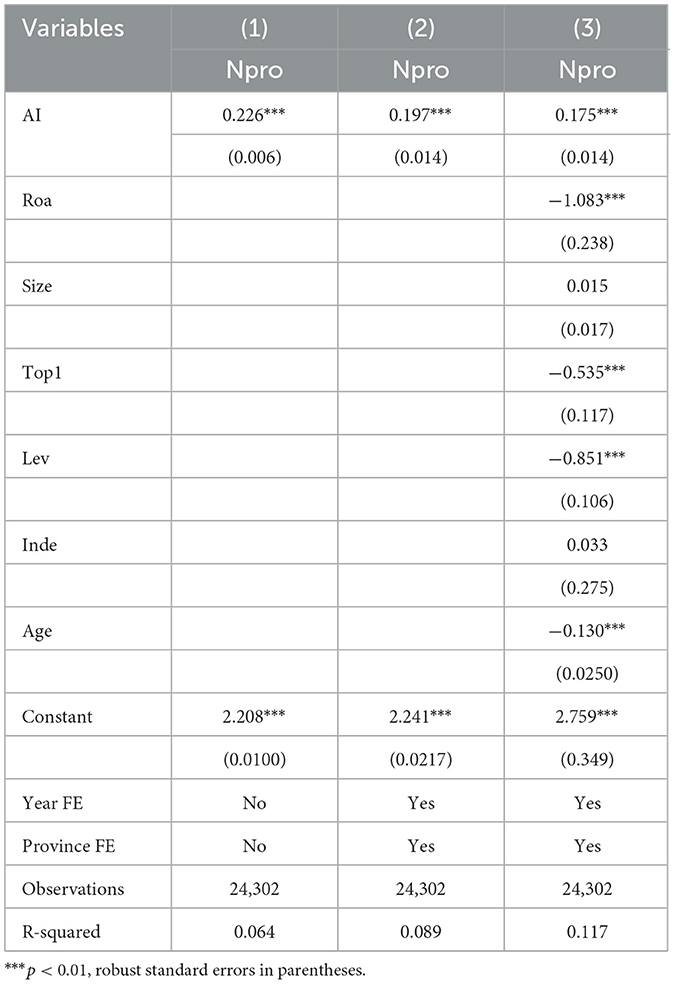

Table 4 verifies the direct effect of AI on the new quality productivity of manufacturing companies. Column 1 shows the univariate regression results, and the coefficient of artificial intelligence (AI) is 0.2257, which is significantly positive at the 1% level, indicating that AI can promote the development of new quality productivity in the manufacturing industry. Column 2 adds time and province fixed effects, and on this basis, column 3 adds control variables, and the regression coefficients of artificial intelligence (AI) are adjusted to 0.1970 and 0.1746, respectively, and both of them are significant at the 1% level. Thus, hypothesis 1 is proved, that is, artificial intelligence can promote the new quality productivity of the manufacturing industry.

5.2 Robustness test

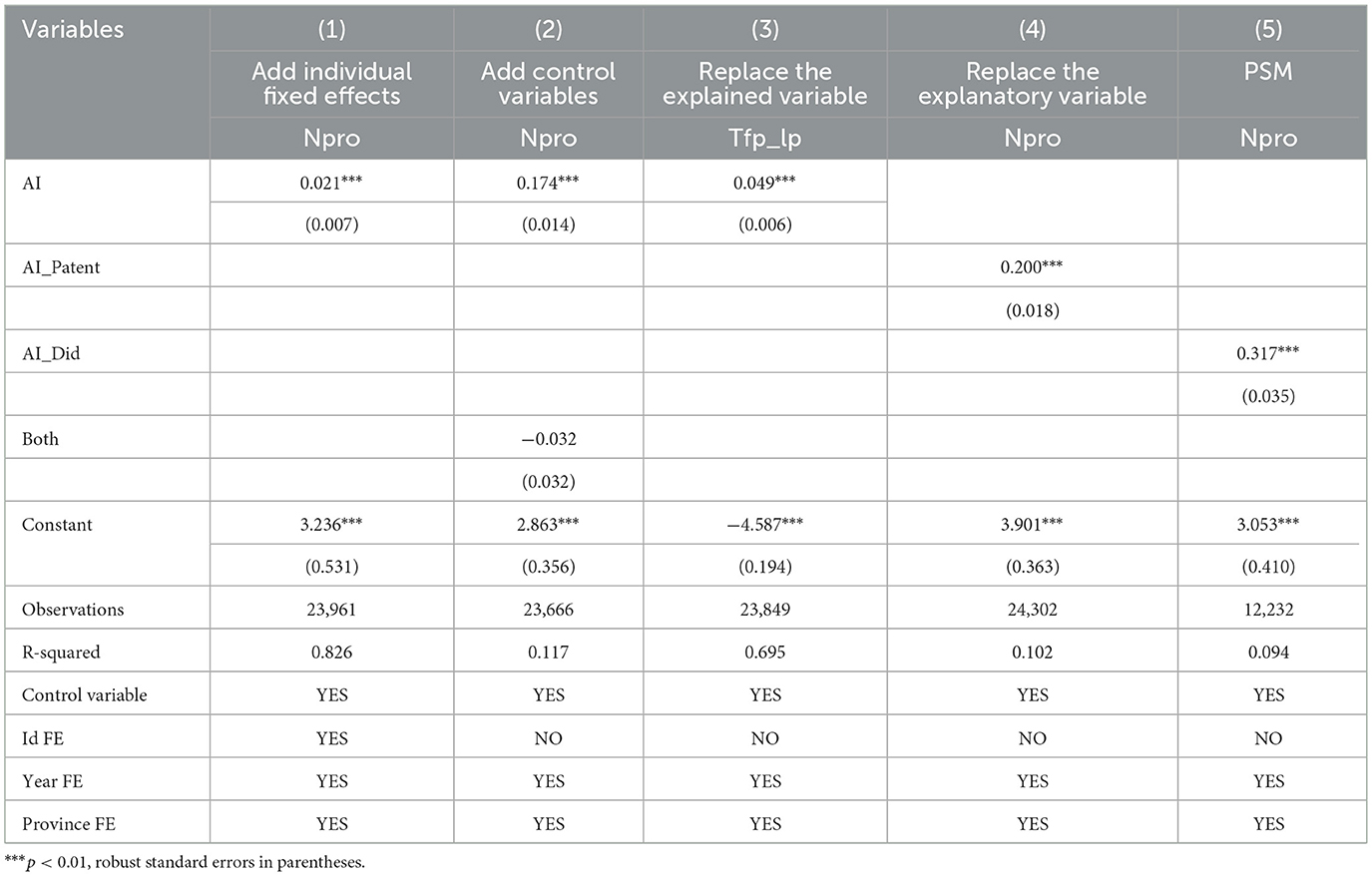

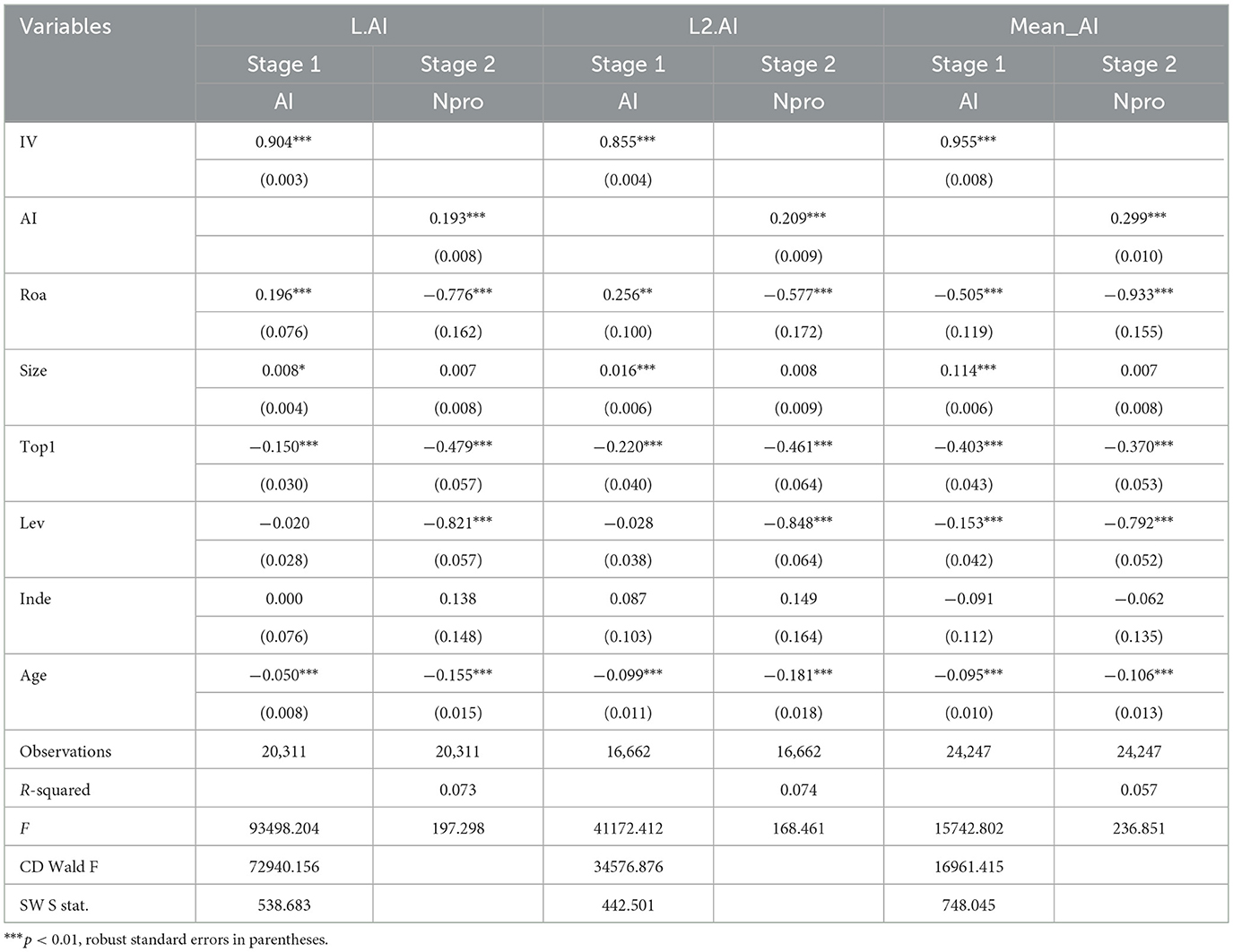

In order to ensure the robustness of the empirical results, this paper adopts the following methods to test the robustness of the empirical results. (1) Add Individual Fixed Effects. To further eliminate interference from firm-specific characteristics, Table 5 column (1) presents regression results after adding individual fixed effects. (2) Addition of control variables. In order to enhance the explanatory power and robustness of the model, the control variable of two jobs in one (Both) is further introduced on the original basis, and column (2) of Table 5 demonstrates the regression results of this method. (3) Replace the explanatory variables. Column (3) of Table 5 demonstrates the results of regression using total factor productivity (Tfp_lp) calculated by the LP method instead of the explanatory variables; (4) Replacement of explanatory variables. This paper draws upon the research of Zhai and Liu (2023). Based on the IPC classifications in the “Reference Table for Strategic Emerging Industries Classification and International Patent Classification (2021),” patents belonging to artificial intelligence were identified. The level of artificial intelligence (AI_Patent) was measured using the natural logarithm of the sum of the number of AI patent applications filed by a company in the current year plus one. Column (4) in Table 5 presents the regression results of this method. After adopting the above robustness test method, all the empirical results are consistent with the benchmark regression results, thus indicating that the conclusions of this study are robust.

5.3 Endogeneity test

5.3.1 Instrumental variables method

Considering that the empirical results may have potential problems of reverse causality and measurement error, the article adopts the two-stage least squares (2SLS) method, referring to the studies of Xie W. L. et al. (2023) and Ren et al. (2023) to lag the artificial intelligence (AI) variable (AI) by one period (L.AI) and two periods (L2.AI), respectively (Xie W. L. et al., 2023; Ren et al., 2023), and introduces the average level of AI of the same industry in the same year ( Mean_AI) as a strong instrumental variable (IV) to be included in the model to identify causality. The reasons for the selection are as follows: lagged AI cannot be influenced by the new quality productivity in the current period, which meets the requirement of exogeneity; the development of AI technology is based on the establishment of the previous technology, so the AI level of the lagged one and two periods has a high correlation with the current AI level. The mean value of AI in the same industry can reflect the level of AI development of enterprises in the industry, but it does not directly affect the new quality productivity, which meets the requirements of relevance and exogeneity, and the results of the endogeneity test are shown in Table 6.

From the first stage regression results in columns (1), (3), and (5) of Table 6, it can be seen that the coefficients of the selected instrumental variables are all significantly positive at 1% level and the values of the F-tests are all much larger than the critical value of 10. Combined with the results of the weak instrumental variables and the identifiable tests in the second stage of columns (2), (4), and (6), the instrumental variables have been selected in accordance with the criteria. The results of columns (2), (4), and (6) show that the AI coefficients are all significant at the 1% level, and after controlling for endogeneity AI still promotes the development of new quality productivity, which once again verifies Hypothesis 1 and illustrates that the findings of the benchmark study are robust.

5.3.2 PSM test method

Although this paper employs two-stage least squares (2SLS) and selects lagged AI values and industry-average AI values as instrumental variables to mitigate endogeneity issues, it remains necessary to carefully assess whether the exogeneity assumption of these instrumental variables holds. Specifically, if historical AI adoption rates or industry-level AI development trends are correlated with unobservable productivity shocks affecting firms, these instrumental variables may influence output by affecting potential productivity. This would violate the exclusion restriction required for instrumental variables, leading to biased estimation results.

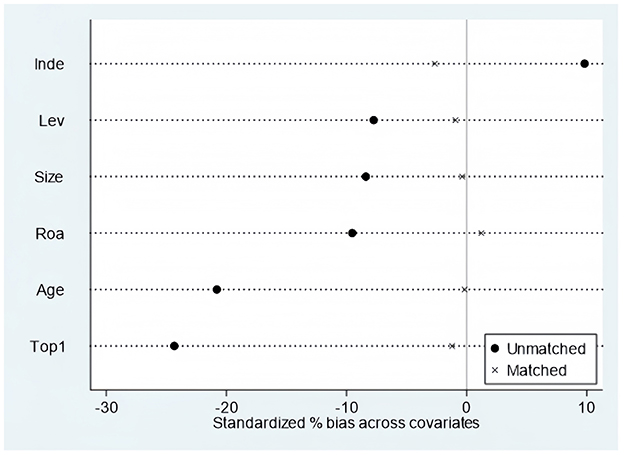

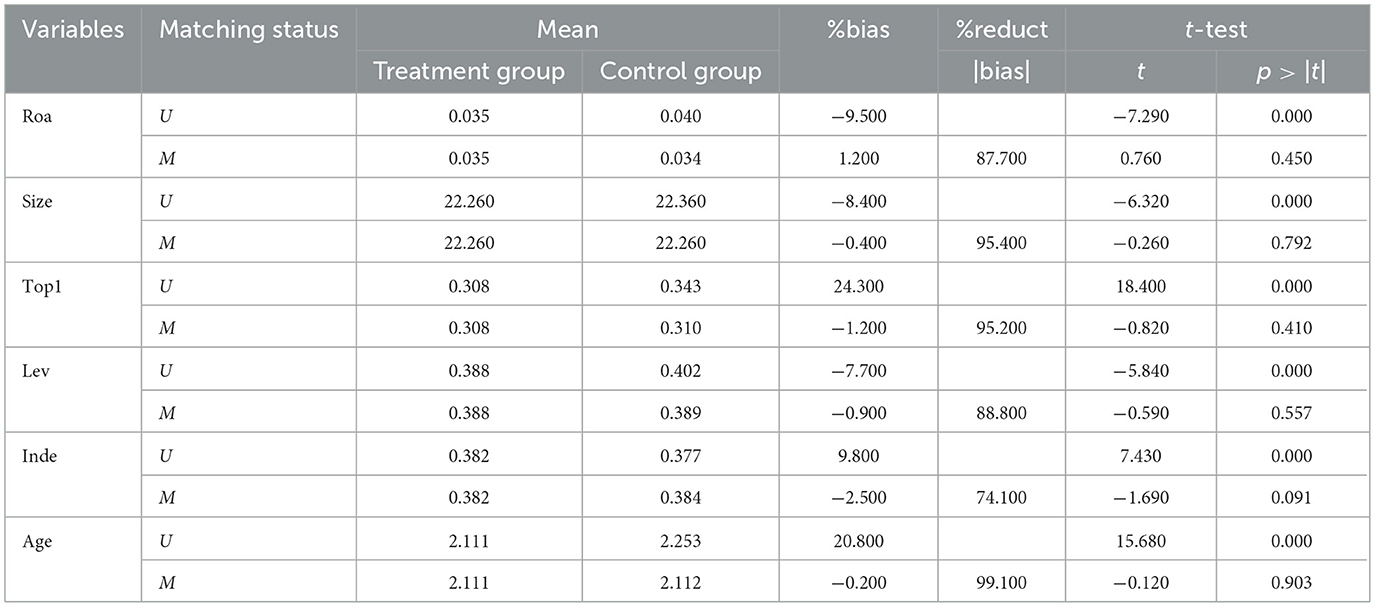

To mitigate this issue, this paper further employs propensity score matching (PSM) for endogeneity testing. When constructing the dummy variable (AI_Did) indicating whether a firm develops AI, the mean level of AI development is chosen as the cutoff value. The control variables used in this study's model serve as matching covariates for 1:1 nearest-neighbor matching, with a caliper range of 0.01. Figure 1 shows that after propensity score matching, the differences between the treatment and control groups in both samples have narrowed. Matching results (Table 7) show that the standard deviation of covariates is less than 10%, indicating satisfactory propensity score matching. The results in column (5) of Table 5 demonstrate that after re-running regression analysis on the propensity score-matched sample, corporate AI still promotes the development of new quality productivity, confirming the robustness of the study's conclusions.

5.4 Mechanism test

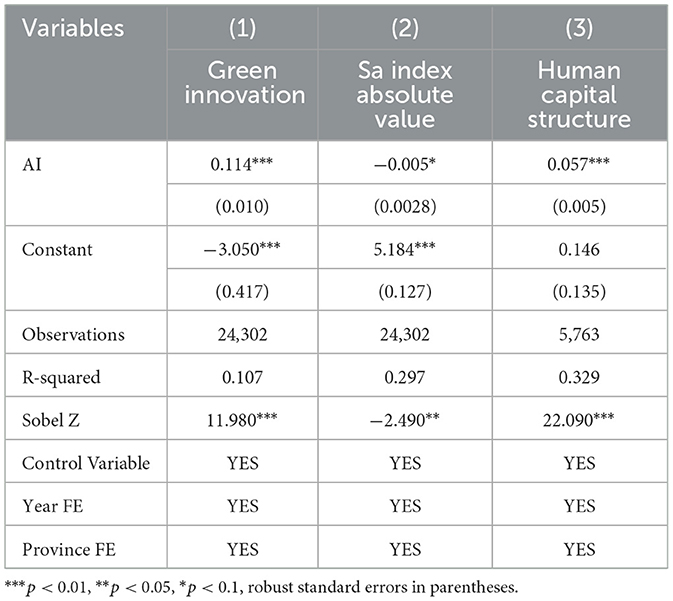

Based on the previous analysis, this paper further tests the specific impact of AI on the level of new quality productivity in the manufacturing industry, including the empowerment of green innovation, the alleviation of financing constraints, and the enhancement of analysts' attention. The regression results are shown in Table 8.

Green innovation. This paper takes the sum of the number of green invention and green utility model patents independently filed by enterprises in the year plus 1 and takes the logarithmic treatment as a measure of the green innovation mechanism variable, and column (1) of Table 8 shows the test results of this mechanism variable, and it can be seen from the regression results that the coefficient of AI on green innovation is significantly positive and passes the Sobel test, which indicates that AI has a positive influence on the green innovation level of enterprises, i.e., AI has a positive influence on the level of green innovation. Level has a positive impact, that is, artificial intelligence promotes the improvement of new quality productivity in the manufacturing industry by empowering green innovation, and hypothesis 2 is proved.

Financing constraints. This paper uses the absolute value of the Sa index as a proxy variable for financing constraints, and the larger the absolute value of the Sa index, the more serious the degree of financing constraints suffered by enterprises. Table 8 column (2) shows the test results of this mechanism variable, from the regression results AI on financing constraints coefficient significantly negative, and through the Sobel test, indicating that AI can use information transfer and technological advantages to obtain financing, that is, artificial intelligence can promote the development of new quality productivity in the manufacturing industry by alleviating financing constraints on enterprises., hypothesis 3 is proved.

Human Capital Structure. Drawing on the methodology of Jiang et al. (2024), using the ratio of employees holding bachelor's degrees or higher to the total workforce as a proxy variable for human capital structure. Table 8 Column (3) presents the test results for this mechanism variable. The regression findings indicate that the coefficient for AI on human capital structure is significantly positive and passes the Sobel test. This confirms that human capital structure plays a mechanism role in AI's contribution to the development of new quality productivity in manufacturing, thereby validating Hypothesis 4.

5.5 Heterogeneity tests

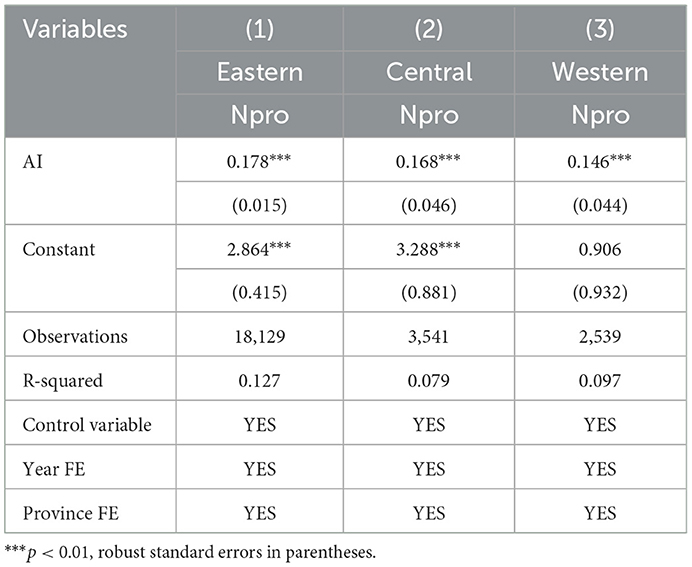

Regional heterogeneity. Differences in the natural environment, information technology level and population quality of each region lead to different impacts of AI on the new quality productivity of enterprises. In this paper, the sample is divided into three regions: east, central and west for regression analysis, and the results are shown in Table 9. The results show that AI has the most significant effect on the promotion of new quality productivity of enterprises in eastern regions, followed by central regions. This is attributable to their advanced digital infrastructure, abundant digital talent, and intense market competition. In contrast, less developed western regions need to further strengthen intelligent infrastructure development and provide policy support to narrow the regional “digital divide” and promote balanced development.

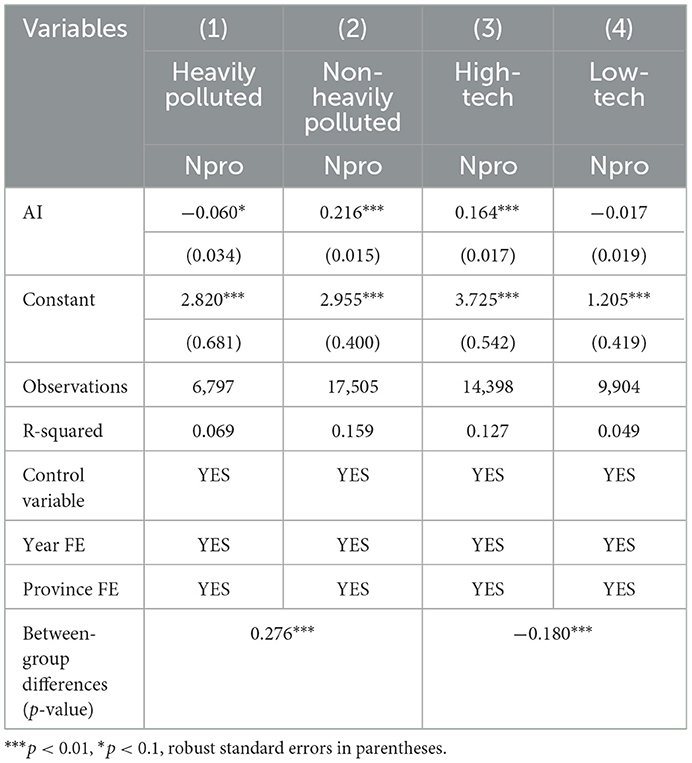

Heterogeneity of pollution industries. This study follows Li et al. (2021) in classifying industries into heavily polluting and low-polluting categories. The Fisher's exact test was applied to examine differences in regression coefficients between groups after propensity score matching. The estimated results are reported in Table 10 columns (1) and (2). The results indicate a p-value of 0.000, confirming a significant difference in regression coefficients between the two groups. Furthermore, the regression coefficient for the heavily polluting industry is −0.0603. This indicates that this sector exhibits strong path dependence toward traditional processes, faces greater challenges in integrating AI technology, and may be subject to stricter environmental regulations. Consequently, initial AI investments primarily focus on compliance-driven emissions reduction rather than immediate productivity gains. In contrast, the non-heavily polluting industry, characterized by high technological adaptability and asset-light operations, facilitates faster technological transformation and application. This enables AI to significantly enhance new quality productivity within non-heavily polluting industries.

Heterogeneity of technology industries. It has been shown that industrial intelligence can enhance the value chain position of national high-tech industries (Wei et al., 2024); however, the impact on enterprises at the micro level has not been explored. High-tech firms are more technologically sensitive, and the introduction of AI technology has a greater magnitude of new quality productivity gains. This paper adopts Bai's (2022) classification method, dividing industries into high-tech and low-tech categories, and conducts a Fisher's exact test. The results of the grouped regression analysis are presented in columns (3) to (4) of Table 10. From the results, it can be seen that the promotion effect of AI on new quality productivity is particularly significant in high-tech industries.

5.6 Spatial spillover effects of new quality productivity

With the improvement of networks and the development of information technology, the flow of knowledge, technology, and innovation factors between regions has become increasingly frequent. To accurately reveal the spatial distribution characteristics of new quality productivity and its influencing factors, this paper further employs spatial econometric models for empirical analysis to more comprehensively capture its potential spatial autocorrelation and regional interaction effects.

5.6.1 Correlation testing

According to econometric theory, the prerequisite for conducting empirical analysis using spatial econometric models is the existence of spatial correlation between the dependent variables. This paper uses Moran's I index to test whether there is spatial autocorrelation among new quality productivity across different regions. The Moran's I index ranges from (−1, 1). When Moran's I index > 0, it indicates positive spatial autocorrelation; when Moran's I index < 0, it indicates negative spatial autocorrelation. The specific calculation formula is as follows:

Where yi is the level of new quality productivity for province i, is the average level of new quality productivity across all provinces, and Wij is the element at the i-th row and j-th column of the spatial weight matrix W after row standardization.

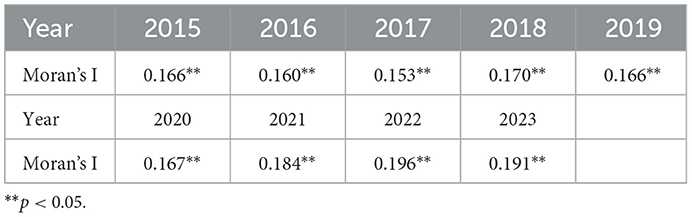

Based on the new quality productivity data for all provinces in China from 2015 to 2023, combined with the above formula, the Moran's I index and its significance for each year can be obtained, as shown in Table 11.

Table 11. Global Moran's I index for new quality productivity in all provinces in China from 2015 to 2023.

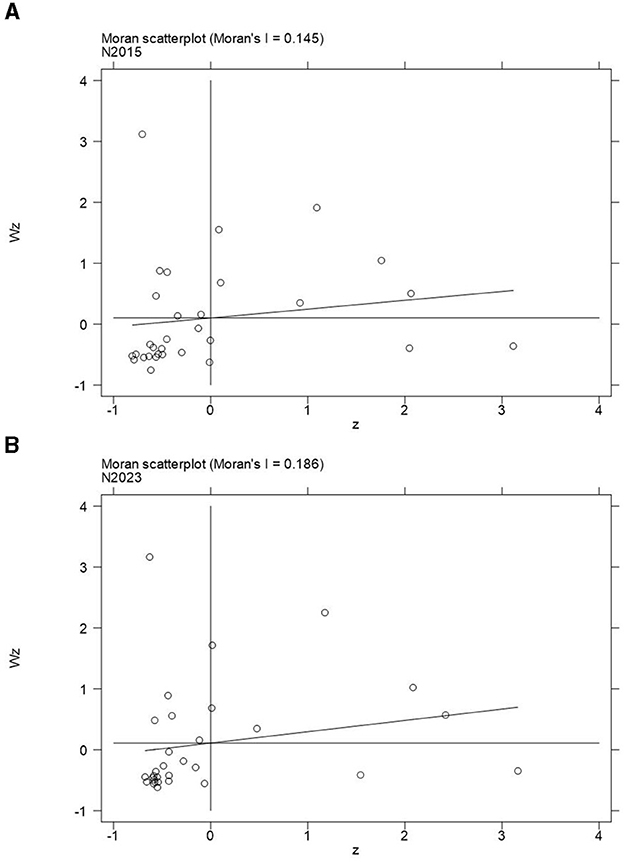

From the results of the Moran's I index, the new quality productivity levels of China's 31 provinces from 2015 to 2023 all passed the 5% significance test and were greater than 0, indicating that there is a highly significant spatial positive correlation between the new quality productivity levels of different regions, i.e., there is a significant spatial spillover effect between new quality productivity levels. To identify the spatial aggregation patterns of new quality productivity in specific regions, local Moran's I scatter plots for new quality productivity in 2015 and 2023 were plotted (see Figure 2). The provinces primarily cluster in the first and third quadrants, indicating that China's new quality productivity development currently predominantly exhibits low-low and high-high aggregation patterns. This suggests that China's new quality productivity exhibits significant local spatial aggregation characteristics.

Figure 2. (a) Local Moran's I index scatter plot of new quality productivity in China in 2015; (b) Local Moran's I Index scatter plot of new quality productivity in China in 2023.

5.6.2 Spatial econometric model results and analysis

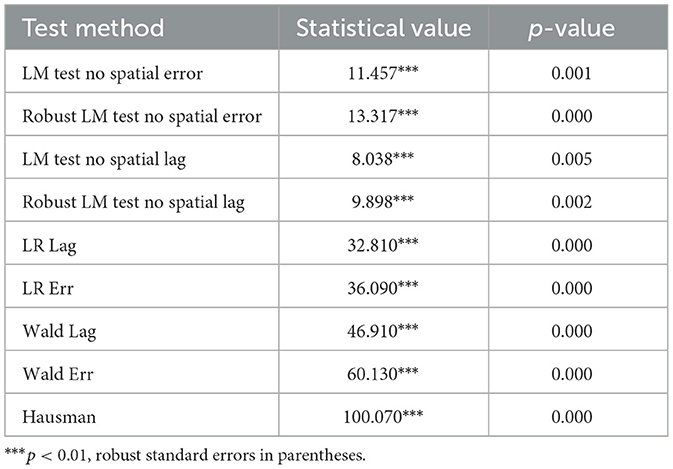

As can be seen from the above, there is spatial correlation between the new quality productivity of each province. Therefore, a spatial weight matrix needs to be introduced into the model, and a spatial econometric model should be selected for estimation to ensure more accurate results. First, Table 12 presents the results of general OLS regression and LM tests for artificial intelligence. The results show that the p-values under the LM test and Robust-LM test both pass the 1% significance level, indicating the presence of spatial error effects and spatial lag effects. Therefore, the mixed panel regression is rejected, and the spatial Durbin model is preliminarily selected. Second, the Hausman test is used to determine whether to adopt a fixed-effects model or a random-effects model. Based on the test results in Table 12, the null hypothesis that ‘the difference in coefficients is not systematic' is rejected, and the fixed-effects model is adopted. Finally, post-hoc tests are conducted, with the two most important steps being the LR test and the Wald test to determine whether the initially selected spatial Durbin model can be reduced to the SAR model and the SEM model. As shown in Table 12, the results of the LR test and the Wald test both support the selection of the spatial Durbin model.

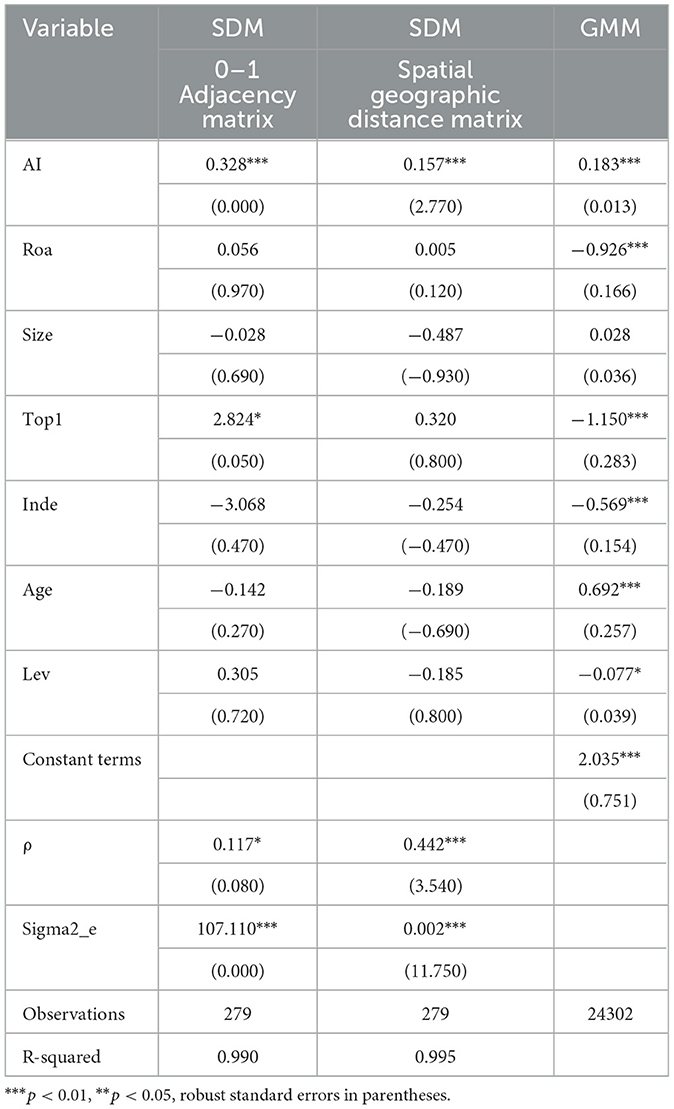

Based on the aforementioned inspection results, spatial econometric regression was conducted using a spatial Durbin model with fixed effects. Table 13 columns (1) and (2) present the estimation results of the spatial Durbin model constructed using the 0–1 adjacency matrix and the spatial geographic distance matrix. Furthermore, this study compares the regression results obtained from the SDM model with those from the GMM model, as shown in Table 13 column (3).

According to the results in columns (1) and (2) of Table 13, the SDM models incorporating the 0–1 adjacency matrix and spatial geographic distance matrix achieved values of 0.99 and 0.995, respectively, indicating a high degree of goodness-of-fit for the SDM model in capturing the relationships among variables. The spatial autocorrelation coefficients are 0.117* and 0.442***, respectively, indicating that Npro exhibits spatial spillover effects. That is, the development of new quality productivity in a given region influences surrounding areas, further validating the presence of significant spatial autocorrelation and spatial spillover effects in new quality productivity. Column (3) of Table 13 presents the regression results from the GMM model. The findings reveal that artificial intelligence explains 0.183% of the variance in new quality productivity, with this effect being statistically significant at the 1% level. This implies that a 1% increase in artificial intelligence levels leads to a 0.183% increase in regional new quality productivity.

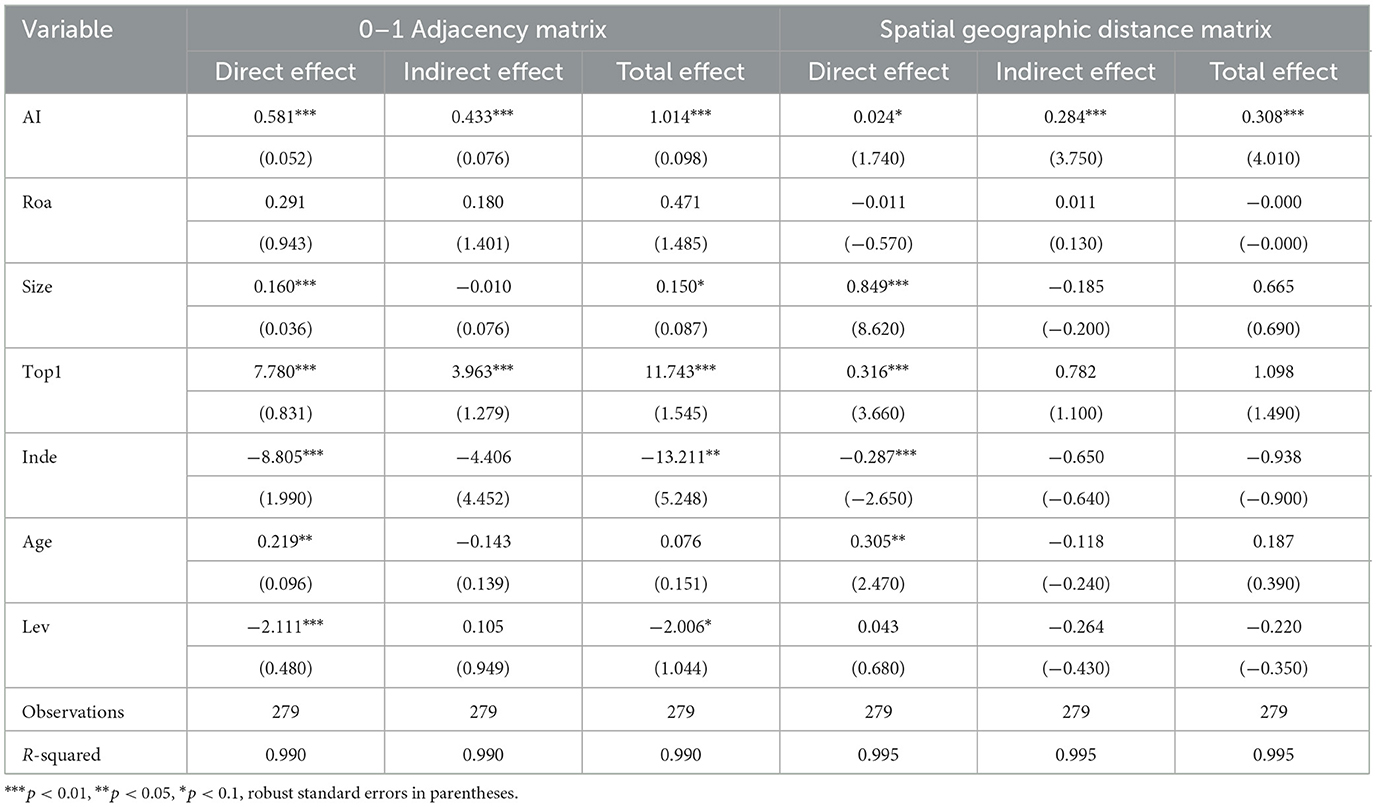

Table 14 provides the decomposed direct effects, indirect effects, and total effects from the model regression results. When employing a 0–1 adjacency matrix, AI exhibits a direct effect of 0.581, an indirect effect of 0.433, and a total effect of 1.014—all significantly positive at the 1% level. This indicates that the application and development of local AI technologies demonstrably promote the enhancement of new quality productivity within the region, while advancements in neighboring regions also generate positive spillover effects. When employing the spatial geographic distance matrix, the direct effect of AI is 0.024, which is significantly positive at the 10% level, while the indirect effect and total effect are 0.284 and 0.308, respectively, both significantly positive at the 1% level. Although the spatial geographic distance matrix yields weaker effects compared to the 0–1 adjacency matrix, it further validates the robustness of the results.

Overall, the total effect of AI on new quality productivity not only aligns directionally with the decomposed direct and indirect effects but also exhibits significantly larger numerical values, indicating a stronger overall driving force. The total effect indicates that the development of AI in a particular region not only enhances the local level of new quality productivity but also drives innovation and development in surrounding regions through spatial spillover effects, thereby exerting a broader positive impact on the growth of new quality productivity across the entire region. A larger total effect signifies a more prominent role of AI in promoting regional coordinated development and overall enhancement. Therefore, we should further strengthen independent innovation and technological breakthroughs in the field of artificial intelligence, enhance our ability to independently control key core technologies, accelerate the widespread application of artificial intelligence achievements in production, services and daily life, amplify the spatial spillover effects of artificial intelligence on new quality productivity.

6 Discussion

Research findings indicate that artificial intelligence has significantly enhanced the new quality productivity of manufacturing enterprises in China. This impact is not only confined to internal efficiency improvements within enterprises but also exhibits a significant positive spatial spillover effect. This result suggests that AI is an important engine driving the advancement of science and technology as well as the coordinated development of regions. This discovery aligns with recent studies, highlighting the crucial role of AI in promoting the development of new quality productivity (Qi and Shen, 2024; Yuan and Han, 2024; Li et al., 2025). The promotion of new quality productivity by AI largely stems from its empowerment of key capabilities in the circular economy. Developing a circular economy represents a new economic operation model for humanity to achieve sustainable development (Niu, 2004). Salminen et al. (2017) found that the management and analysis of various data sources are carried out through data-to-service, leading to the co-evolution of circular economy businesses. During this transformation, AI is playing a key enabling technology role, by reconfiguring production processes, optimizing resource allocation, and enhancing system resilience (Bitzenis et al., 2025), driving the manufacturing industry from a “high input, high emission” model to a “low consumption, high recycling” new quality development model.

Specifically, mechanism analysis shows that AI mainly enhances new quality productivity through three major pathways: promoting green innovation, alleviating financing constraints, and optimizing human capital structure. This effect is particularly significant in eastern regions, high-tech industries, and non-heavy-polluting enterprises. This conclusion has also been verified in previous literature (Yu et al., 2025b; Wu and Du, 2024; Wu and Zhou, 2025). These mechanisms integrate technological efficiency gains with the circular economy's imperative for resource optimization, closed-loop design, and long-term value sustainability.

Firstly, AI significantly promotes the development of new quality productivity through green technological innovation. Compared to traditional technologies, green technologies aim to reduce environmental pollution and lower energy and raw material consumption (Guo et al., 2020), and are key tools for achieving sustainable development goals (Jordaan et al., 2017; Abbas, 2019). As a key tool for building a circular economy system, AI can support the research and development of clean technologies, optimize product recyclability design, and enhance supply chain transparency and reverse logistics efficiency through intelligent algorithms. In this process, AI not only improves resource utilization efficiency but also extends product service life, effectively reducing waste emissions. Particularly in non-heavy-polluting and high-tech industries, the promoting effect of AI is more significant, as these enterprises are more inclined to adopt green design and remanufacturing technologies, thereby fully leveraging the potential of AI in circular economy practices.

Secondly, artificial intelligence helps enterprises obtain the funds needed for green investment and sustainable development projects by alleviating financing constraints, thereby supporting their investment in circular economy infrastructure. Financial funds act as a major obstacle in implementing a circular economy, causing enterprises to generally encounter difficulties when developing a circular economy (Fabian et al., 2023; Kirchherr et al., 2018). Meanwhile, the transformation of enterprises toward a circular economy usually requires substantial investment in areas such as technological research and development, organizational structure optimization, production process renovation, and the distribution system of circular products (Kumar et al., 2019), and the investment return cycle is relatively long, further intensifying the financial pressure. This paper finds that the application of artificial intelligence technology helps alleviate the financing pressure of enterprises, reduce investment risks, and thus effectively assist enterprises in overcoming financing obstacles, promoting the efficient circulation and closed-loop management of resources.

Finally, the optimization of the human capital structure by artificial intelligence provides organizational guarantees for enterprises to build circular economy capabilities. Lieder and Rashid (2016) clearly pointed out that one of the key obstacles for enterprises to implement a circular economy is the lack of multidisciplinary talents with cross-disciplinary knowledge. Glaeser (1999) found that knowledge is more likely to spread among industries where high-tech and highly educated groups are concentrated. In these groups, there is a greater tendency to learn new knowledge and imitate new technologies. Through communication, high-quality human resources not only generate knowledge spillovers in the form of information transmission and technology sharing, but also generate new ideas and concepts, promoting innovation and technological progress. Artificial intelligence contributes to the optimization of the human capital structure in multiple ways: it absorbs high-skilled digital talents and effectively attracts and allocates green technology talents. Equipped with digital skills and a strong sense of sustainability, these talents are capable of operating intelligent systems while comprehensively understanding the environmental and resource implications throughout the product life cycle, positioning them as key drivers of organizational transformation.

Therefore, artificial intelligence is not only a technical tool for improving production efficiency, but also a strategic fulcrum for promoting the evolution of new productive forces toward sustainability, circularity, and intelligence. It systematically supports the fundamental transformation from a linear economy to a circular economy by empowering green innovation, breaking through financing bottlenecks, reconfiguring human capital, and forming a regional green technology diffusion network through spatial spillovers.

6.1 Limitations

This research provides valuable insights and perspectives on the impact of artificial intelligence on China's new quality productivity. However, some limitations still need to be addressed to offer references and directions for subsequent studies. Limitations in the selection of variable indicators. In this paper, the core explanatory variable of artificial intelligence is measured by the natural logarithm of the total frequency of artificial intelligence-related terms in the annual reports of enterprises plus one, which, although having a certain representativeness, may not fully reflect the intensity of the implementation of artificial intelligence in their operations; Limitations of the research sample data. This paper selects the data of A-share listed manufacturing companies in China from 2015 to 2023, mainly reflecting the characteristics of large and medium-sized manufacturing enterprises. However, the relationship between artificial intelligence and new quality productivity in other industries, small and micro enterprises, and non-listed companies remains unclear; Limitations of the research context. Given China's unique development path, policy environment, and cultural background, its experience may not be directly applicable to other countries and regions, which to some extent weakens the wide applicability of the research results.

6.2 Future research directions

Given the limitations of this study in terms of variable measurement, sample scope, and research context, the following directions for future research improvements are proposed: Further optimize the measurement methods for artificial intelligence variables. First, subsequent studies could attempt to use more precise indicators, such as the investment amount or usage density of enterprises in AI-related software, algorithm systems, or intelligent robot equipment, to enhance the measurement validity of the core explanatory variables and thereby more accurately examine the impact mechanism of AI on new quality productivity. Second, expand the sample coverage. Incorporate a wider range of enterprise data to enhance the representativeness and universality of the research, thereby comprehensively revealing the variations in AI's role across different organizational scales and industry contexts. Third, consider conducting cross-national comparative analysis. Incorporating economic systems and policy support levels of different countries or regions into the research framework, to explore the applicability and differences of the paths driven by AI to new quality productivity in international contexts, thereby enhancing the external validity and global explanatory power of the theory.

7 Conclusions

Artificial intelligence, leveraging its powerful driving force and enabling capabilities, has become a key driver propelling the new quality productivity in manufacturing toward higher levels of development. This study, based on the panel data of Chinese A-share listed manufacturing enterprises from 2015 to 2023, explores the impact effect and transmission mechanism of artificial intelligence on the new quality productivity of the manufacturing industry. The findings indicate: First, AI significantly enhances firms' new quality productivity, with this conclusion holding after robust and endogeneity tests. The promotional effect of AI on new quality productivity is stronger in eastern regions, non-heavy-pollution industries, and high-tech sectors. Second, green technological innovation, financing constraints, and human capital structure play significant roles in enhancing the new quality productivity level of enterprises through artificial intelligence. Third, artificial intelligence exhibits significant spatial dependence and spillover effects on new quality productivity across provinces. The development of AI technology not only elevates local new quality productivity levels but also stimulates its growth in surrounding regions. GMM model results similarly confirm that AI application plays a positive role in advancing new quality productivity.

Based on the research findings, this study proposes the following recommendations: First, the government should continue to increase investment and support for artificial intelligence technology. As concluded earlier, AI can significantly boost the advancement of new quality productivity, though its impact exhibits certain regional and sectoral heterogeneity. Therefore, the government should further enhance AI's role in promoting new quality productivity through measures such as building intelligent infrastructure, optimizing resource allocation efficiency, and strengthening the cultivation of digital technology talent. Simultaneously, considering the heterogeneous impact of AI, policy formulation should establish differentiated support systems tailored to the characteristics of different regions and industries. This approach enhances the effectiveness of coordinated regional development and the precision of industry guidance. For instance: Eastern regions, with relatively well-developed digital infrastructure, should prioritize accelerating the integration and exchange of technological innovations and the industrial application of technologies. Central regions can strengthen data resource integration and supply, provide financial support for promising projects, and cultivate leading enterprises. while western regions can leverage resource advantages to deepen the “East Data, West Computing” initiative, narrowing the AI development gap with central and eastern areas. Second, enterprises should optimize innovation chains, capital chains, and talent chains to elevate new quality productivity through multiple approaches. As indicated by prior research, AI enhances corporate new quality productivity by advancing green technology innovation, alleviating financing constraints, and optimizing human capital structures. Therefore, enterprises should first increase capital investment to establish a robust equipment foundation for R&D, strengthen breakthroughs in key technologies, and engage in strategic collaborations with other enterprises. Through technology sharing and joint R&D, they can leverage complementary strengths to enhance independent innovation capabilities. Second, financial regulators must strengthen oversight of the digital finance sector to safeguard corporate capital and information security. Tax incentives should be offered to enterprises actively adopting AI to alleviate financing pressures. Finally, enterprises should further strengthen talent development by prioritizing training and recruitment, offering competitive compensation packages, designing clear career advancement pathways, and streamlining talent acquisition channels to attract high-caliber professionals from diverse backgrounds, thereby optimizing human capital structures. Third, fully leverage the spillover and driving effects of new quality productivity. Empirical research indicates that artificial intelligence possesses significant spatial radiation capabilities and synergistic effects on new quality productivity. Consequently, national and local governments should promptly leverage the leading role of key regions to achieve a new pattern of coordinated development where points drive the whole. Regions with advanced levels of new quality productivity development should be granted greater policy exploration space and institutional innovation authority. They should be encouraged to pioneer new approaches in institutional mechanisms and management models, forming replicable and scalable best practices that serve as high-quality development models for the nation. Furthermore, governments should systematically advance coordinated regional development by fully leveraging spatial spillover effects. Localities should actively engage in cross-regional technological exchanges and cooperation, promoting the interconnectivity of technologies, data, and experiences. This will facilitate the establishment of unified technology exchange platforms and resource-sharing networks, ultimately fostering a collaborative regional development framework.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions