- 1Cooperative Innovation Center of Unconventional Oil and Gas, Yangtze University (Ministry of Education & Hubei Province), Wuhan, China

- 2School of Geoscience, Yangtze University, Wuhan, China

- 3Hubei Key Laboratory of Drilling and Production Engineering for Oil and Gas, Yangtze University, Wuhan, China

- 4Tianjin Branch of CNOOC Ltd., Tianjin, China

- 5CNPC Engineering Technology R&D Company Limited, Beijing, China

- 6Chuanxi Drilling Company, CNPC Chuanqing Drilling Engineering Co. Ltd., Chengdu, China

Introduction

In recent years, China’s reliance on petroleum has grown, while energy supplies are becoming increasingly scarce. According to rough statistics, the remaining recoverable resources of shale oil in China are about 55

Current Status of Shale Oil Extraction Technology

Shale oil resources abound across the world, with enormous exploitation potential. The recoverable resources of China’s oil shale are about 2400

Extraction technologies of shale oil are various, and different extraction technologies are used for different maturities of shale oil. China’s shale oil is divided into two categories according to the maturity level: medium-high maturity and medium-low maturity; horizontal well fracturing technology is the mainstream technology for the former, while above-ground extraction is for the latter. For example, in the early stage of above-ground extraction, dry distillation technology is applied, and the “Underground Refinery” in-situ conversion technology is used in the later stage. Due to the low-porosity and low-permeability characteristics of oil shale, fracturing technology is challenging to achieve high production. The dry distillation is harmful to environment and further research and development are needed.

Hydraulic Fracturing Technology

The development of medium-high maturity shale oil has experienced three stages: the conventional fracturing stage for straight wells, the volume fracturing stage for horizontal wells, and the seam-controlled fracturing stage (Lei et al., 2021). The main principle is to form an underground fracture network with horizontal well fracturing technology and use repeated fracturing to enhance recovery.

At present, the mainstream fracturing technology of medium-high maturity shale oil can be divided into the following five categories: subsection fracturing of horizontal wells has become the standard practice of shale oil well development. Horizontal well synchronous fracturing technology can increase the production of shale oil and gas. In the case of fewer water sources and paying attention to environmental protection, anhydrous fracturing technology is preferred. High-speed channel Hydraulic Fracturing technology can reduce water consumption by about 25% and discharge by nearly 32 million pounds, compared with ordinary Hydraulic Fracturing treatment technology. Also, Re-fracturing technology can meet the requirements of increasing production capacity and reducing cost.

In-Situ Conversion Technology

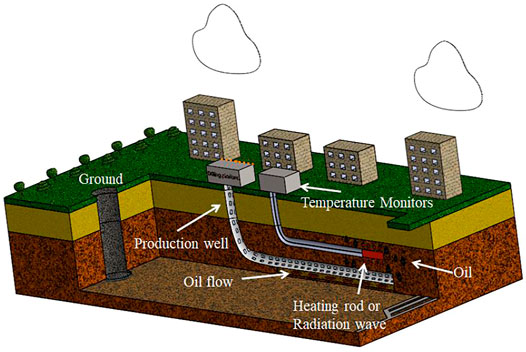

For medium-low maturity shale oil, the conversion of the original above-ground extraction to an “Underground Refinery” guarantees that the extraction process satisfies the standards of energy conservation and environmental protection. Heat is continuously input to the formation through hot fluid or an underground heating device. Oil and gas will be produced by pyrolysis when the temperature reaches the kerogen pyrolysis temperature. The “underground refinery” is shown in Figure 1.

The underground in-situ conversion extraction technology has attracted extensive attention. Its development is generally divided into three stages (Sun et al., 2021):

1) Early stage (1940–1970): In 1940, Sweden was the first to propose in-situ oil shale extraction technology and invented the “electric heating” in-situ extraction method (Ryan et al., 2010). In 1953, Sinclair Oil and Gas Company has developed an in-situ extraction technology using natural fractures in the formation and inter-well burning and field tests were conducted in the Pishance Basin, Colorado, United States, which are obtained small amounts of oil shale oil (Lee et al., 2014).

2) Development stage (1970–2000): In the late 1960s, in the context of the rapid rise in the world’s crude oil prices, the US Energy Agency and others have invested heavily in the development of many in-situ conversion technologies. They have developed two mainstream technologies: True In-Situ technology (TIS) technology and Modified In-Situ technology (MIS) technology. Finally, in the indoor experiment and outdoor demonstration projects, these technologies have produced exceeding 10,000t of shale oil (Hutchinson, 1981; Miller and Howell, 1967).

3) Emerging of new technology stage (2000-): Since the 21st century, many new technologies for in-situ transformation of oil shale have emerged, including ICP underground electric heating technology, Electro-fractTM conductive proppant fracturing technology, convective heating crushing technology, on-site steam injection extraction technology (Zhang et al., 2022), Radio Frequency heating technology (Wang et al., 2019), Super-Critical Water method and Magnetic Separation Technology (Huang and Gong, 2021). These emerging extraction technologies have provided important ideas for the in-situ extraction of shale oil in China.

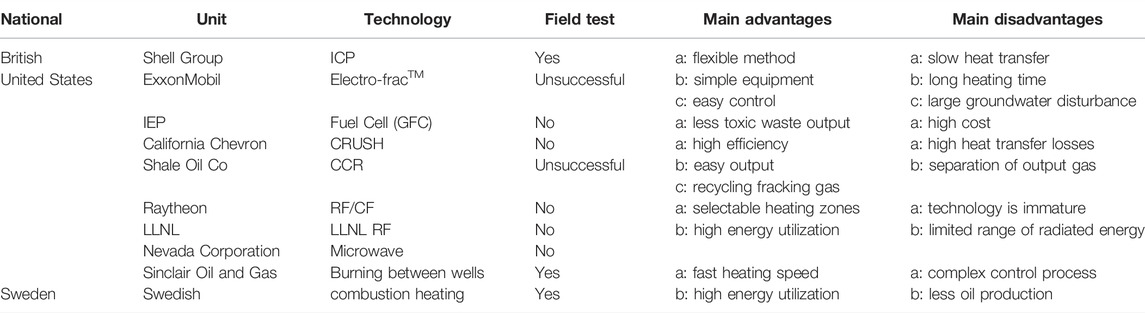

At present, medium-low maturity shale oil is converted to residual value by in-situ heating conversion method for stagnant heavy hydrocarbons and kerogen. This test method is in the preliminary stage of underground in-situ conversion technology. The underground heating conversion technology has achieved good preliminary results from medium-low mature shale oil. Therefore, it promotes the further progress of in-situ conversion technology. The shale oil in-situ extraction technologies are divided into reaction heat heating, conduction heating, convection heating and radiation heating according to heat source and heat transfer mode (Melton and Cross, 1968). The international technology comparison is shown in Table 1.

In 2005, China cooperated with Shell to study the feasibility of in-situ conversion technology of oil shale, which was verified it through field drilling and production tests. Since 2013, the Institute of Petroleum Exploration and Development has been conducting basic research on organic-rich shales in the Junggar and Ordos Basins. In 2014, Zhongcheng Company carried out the pilot test of oil shale in-situ transformation and chemical retorting in the Fuyu Changchun. The oil production during the preliminary test period was 5.20t, and the oil production during the pilot test period was 3.66t more than that during the preliminary test period. In 2015, Jilin University cooperated with Israel to carry out the pilot test of in-situ conversion of oil shale by the Super-Critical Water method (SCW) method, which produced a small amount of crude oil.

Challenges

Compared with conventional oil exploration and development, China’s shale oil exploration and development still face a series of challenges. The goal of increasing production of shale oil must be achieved through continuous technological innovation. Currently, the stability of high-quality reserves and production of shale oil have encountered difficulties:

1) With the continuous improvement of China’s oil resource exploration, the difficulty of oil and gas basin exploitation lies in the exploitation technology. The water content of shale oil increases year by year and the characteristics of low porosity and low permeability are obvious, which poses a challenge to the stable production of China’s oilfield development.

2) The extraction technology is also faced with numerous difficulties. Radio Frequency heating for extraction of medium-low mature shale oil has the advantage of realizing commercial application faster than microwave heating and induction heating. But it is difficult to develop an electric heater with a small size and shape and high-power output. There are problems with adsorbent optimization and uneven pyrolysis in shale oil extraction by magnetic separation technology.

3) The volatility of oil prices has led to a decline in the efficiency of oil companies and increased production pressure.

Prospects

The development of shale oil in China has a long way to go. The advancement of in-situ extraction technology is extremely important, and it will always be the key to increasing efficiency and reducing cost. Therefore, we should combine technology and theory to achieve a breakthrough in the large-scale extraction of shale oil, which would strengthen national energy security.

Author Contributions

All authors contributed to this study. Writing-original draft, JH; Review, XX; Editing, WL.

Funding

This work was supported by the Open Foundation of Cooperative Innovation Center of Unconventional Oil and Gas, Yangtze University (Ministry of Education & Hubei Province), No. UOG 2022-03; Supported by Open Fund of Hubei Key Laboratory of Drilling and Production Engineering for Oil and Gas (Yangtze University), No. YQZC202206.

Conflict of Interest

Author WL is employed by Tianjin Branch of CNOOC Ltd. Author KZ is employed by CNPC Engineering Technology Research Institute Co., Ltd. Author LT is employed by Chuanxi Drilling Company, CNPC Chuanqing Drilling Engineering Co. Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Huang, F., and Gong, T. (2021). In-situ Extraction Experiment of Oil Shale Based on Magnetic Separation Technology--An Example of Oil Shale in Huadian City, Jilin Province. Daqing Petroleum Geology and Development

Hutchinson, D. (1981). Investigation of the Geokinetics Horizontal In-Situ Oil-Shale Retorting Process. Concord,CA (USA): Fourth Annual ReportGeokinetics, Inc.

Lee, S, James, S., and Loyalka, S. (2014). Handbook of Alternative Fuel Technologies. Boca Raton: CRC Press.

Lei, Q., Weng, D., and Luo, J. (2019). Achievements and Future Work of Oil and Gas Production Engineering of CNPC. Petroleum Explor. Dev. 46 (1), 139–145. doi:10.1016/s1876-3804(19)30014-x

Lei, Q., Weng, D., Xiong, S., Liu, H., and Guan, B. (2021). Progress and Development Directions of Shale Oil Reservoir Stimulation Technology of China National Petroleum Corporation. Petroleum Explor. Dev. 48 (05), 1035–1042. doi:10.1016/s1876-3804(21)60102-7

Li, G., and Zhu, R. (2020). Progress, Challenges and Key Issues of Unconventional Oil and Gas Development of CNPC. China Pet. Explor. 25 (2), 1–13. doi:10.3969/j.issn.1672-7703.2020.02.001

Melton, N., and Cross, T. (1968). Fracturing Oil Shale with Electricity. J. Petroleum Technol. 20 (1), 37–41. doi:10.2118/1969-pa

Miller, J. S., and Howell, W. D. (1967). Explosive Fracturing Tested in Oil Shale. Colo. Sch. Mines Q. 62 (3), 63–73.

Ryan, R. C., Fowler, T. D., Beer, G. L., and Nair, V. (2010). Shell's In Situ Conversion Process−From Laboratory to Field Pilots. Oil Shale: A Solution To the Liquid Fuel Dilemma. ACS Publications, 161–183. doi:10.1021/bk-2010-1032.ch009

Sun, Y., Guo, W, and Deng, S. (2021). The Status and Development Trend of In-Situ Conversion and Drilling Exploitation Technology for Oil Shale. Drill. Eng. 48 (01), 57–67. doi:10.12143/j.ztgc.2021.01.008

Wang, Z., Gao, D., Diao, B., and Zhang, W. (2019). The Influence of Casing Properties on Performance of Radio Frequency Heating for Oil Sands Recovery. Appl. Energy 216, 114453. doi:10.1016/j.apenergy.2019.114453

Yang, Y. (2021). Us Energy Information Administration Predicts that Shale Oil Production Will Rise in 2022. Sinopec (03), 9.

Yi, M. (2012). China's Recoverable Oil Shale Resources Amount to 240 Billion Tons. Nat. gas Technol. Econ. 6 (04), 27.

Keywords: shale oil, hydraulic fracturing, in-situ heating, underground refinery, unconventional oil and gas

Citation: Hu J, Xia X, Li W, Zhang K and Tan L (2022) Rapid Development of Unconventional Oil and Gas: Status, Challenges and Prospects of Shale Oil Extraction Technology. Front. Energy Res. 10:919966. doi: 10.3389/fenrg.2022.919966

Received: 14 April 2022; Accepted: 05 May 2022;

Published: 09 June 2022.

Edited by:

Hui Pu, University of North Dakota, ChinaReviewed by:

Hao Wang, China University of Petroleum, Beijing, ChinaPeng Huang, Henan University of Urban Construction, China

Copyright © 2022 Hu, Xia, Li, Zhang and Tan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xueqin Xia, eGlheHVlcWluMjAyMkAxNjMuY29t

Jiajia Hu1,2

Jiajia Hu1,2 Xueqin Xia

Xueqin Xia Wenlong Li

Wenlong Li