- 1Key Laboratory of Modern Power System Simulation and Control and Renewable Energy Technology, Northeast Electric Power University, Jilin, China

- 2State Grid Liaoning Electric Power Supply Co, Ltd, Shenyang, China

- 3Changchun Power Supply Company, State Grid Jilin Electric Power Co, Ltd, Changchun, China

- 4Jilin Thermal Power Plant of Guoneng Jilin Longhua Thermal Power Co, Ltd, Jilin, China

To solve the problem of the large gap in the regulation resources of the power system due to the large number of wind power connected to the grid and to help achieve the strategic energy goal of “carbon neutrality and carbon peaking,” the demand-side adjustable energy-intensive load is taken as the research object in this paper, and a two-stage low-carbon economic scheduling method of the wind power system with multi-form energy-intensive load (MEL) is proposed. First, the operating characteristics of the system with MEL are analyzed. At the same time, a refined mathematical model that conforms to the actual operation characteristics is established. Then, the complementary low-carbon characteristics of the source-charge side and the difference in the response characteristics of the demand-side MEL are considered. Meanwhile, combining with the energy storage system, a day-ahead and intra-day two-stage low-carbon economic scheduling model of the wind power system with MEL is constructed. Finally, an example of the improved IEEE-39 bus system is analyzed to verify the effectiveness of the proposed scheduling method in the low-carbon economic scheduling of wind power systems and to provide a reference for power grid scheduling.

1 Introduction

On 22 September 2020, China announced at the 75th United Nations General Assembly that “China strives to peak its carbon dioxide emissions by 2030 and works to achieve its carbon neutrality goal by 2060.” The decarbonization of the power system is one of the most important means of achieving this goal. On the one hand, to achieve the goal of ”carbon peaking and carbon neutrality,” it is necessary to explore the low-carbon characteristics of the source side of the power system, to transform conventional thermal power units into carbon capture units on the power side, and to use CO2 produced by them for storage, so that carbon capture units can be used as an ideal complementary power source for wind power (Guo et al., 2022; Jiaming et al., 2015). On the other hand, the goal of “carbon neutrality and carbon peaking” will inevitably lead to the rapid development of wind power, which has a low marginal cost of system generation and no carbon emissions. According to the “List of Basic Electricity Statistics for 2020” published by the China Electricity Council, the installed capacity of wind power in 2020 will be as high as 281.65 million kilowatts, a year-on-year increase of 34.66%. While wind power output has day-to-day variability, uncertainty, and anti-regulation characteristics (Luo et al., 2014; Bao et al., 2016; Ge et al., 2019), its large-scale grid connection will lead to a large gap in power system regulation resources.

The demand side of important components in the power system as a regulating resource is an effective way to solve the aforementioned problem and has achieved rapid development in recent years (Jia et al., 2022; Afzalan and Jazizadeh, 2020; Tindemans et al., 2015; Teng et al., 2015). The representative energy-intensive load in the controllable load has attracted much attention from regulatory resources because of its characteristics of large monomer volume, fast response speed, and high level of production automation (Yang et al., 2020; Liao et al., 2018; Li et al., 2019). In 2022, the total electricity consumption of China’s four major energy-intensive industries was 2,301.9 billion kWh. Among them, the electricity consumption of the chemical industry was 546.1 billion kWh, the electricity consumption of the building materials industry was 401.7 billion kWh, the electricity consumption of the ferrous metal smelting industry was 609 billion kWh, and the electricity consumption of the non-ferrous metal smelting industry was 745.2 billion kWh. China has built energy-intensive enterprises near large-scale new energy bases in the northwest, northeast, and Inner Mongolia Autonomous Region, which has practical engineering significance for local wind power consumption. Therefore, the participation of energy-intensive industries in power grid regulation has huge economic and environmental benefits.

The participation of high energy load in power grid regulation has existed at home and abroad, and good results have been achieved. Peng et al. (2017) comprehensively considered the high energy load and the operating characteristics of wind power and established a source–load coordinated multi-objective optimization model with the goal of maximum wind power consumption and minimum system operating cost, which provides a reference for dispatchers. Liu et al. (2015) considered the cross-sectional power constraint and load matching upward adjustment capacity and the degree of load participation and proposed a quantitative pre-assessment method for wind/photovoltaic capacity of power grid with energy-intensive load participation, which has important engineering practical significance for improving the wind power consumption level of the system. Based on the actual situation of new energy in Gansu Province, Li et al. (2016) analyzed its local consumption potential, relying on the “double alternative” strategy and considering the operation characteristics of high energy load of smart parks, and maximized the local consumption level of new energy. From the aforementioned research, it can be seen that the participation of energy-intensive load in system regulation is of far-reaching significance. The researchers have made in-depth discussions on source–load coordinated scheduling, market assistance, evaluation methods, energy policies, etc., which have slowed down the regulation pressure of conventional units, reduced the operating cost of the power system, and improved the wind power consumption level of the power system. However, the aforementioned literature mainly focuses on the research of single-form energy-intensive load, and relatively few studies consider the actual operating characteristics of energy-intensive enterprises. The analysis of MEL is relatively rare, and the impact of response differences and actual operation characteristics of MEL on power grid regulation and control is not considered. Therefore, to more accurately tap the adjustment potential and flexibility of system demand-side resources, this paper considers those MELs that meet the actual operation characteristics and use them to regulate for low-carbon economic optimization and dispatch of the wind power system.

At the same time, with the constant maturity of energy storage technology, new energy storage technologies have many advantages, such as high security, high flexibility, and high economy; combined with the successive introduction of national energy-storage-related policies and the increasingly perfect business model of energy storage, the market prospect of energy storage participation in grid regulation and control has become increasingly broad, which is of far-reaching significance for the safe and flexible operation of the power grid economy (Neubauer and Simpson, 2013; Shi et al., 2022). At the same time, carbon capture technology is constantly improving, and operating costs are decreasing (Ji et al., 2013; Akbari-Dibavar et al., 2021). At present, ordinary carbon capture technologies mainly include carbon capture and storage (CCS) and carbon capture, utilization, and storage (CCUS). Two technologies are suitable for different scenarios. Research has shown that in the context of low carbon prices, promoting CCS technology that focuses on storage is constrained and limited by high costs. Compared to CCS, CCUS technology, which considers carbon dioxide as a resource and focuses on recycling, has a greater likelihood of being promoted and applied in the future. At the same time, the country should vigorously support CCUS technological innovation, carry out CCUS pilot demonstrations in key industries in an orderly manner, and provide preferential financial and tax policies for carbon capture projects. Its large-scale application is possible, which will bring substantial breakthroughs to the low-carbon operation of the power system at the source.

In summary, to solve the problem of the large gap in power system regulation resources caused by a high proportion of new energy connected to the grid and to accelerate the realization of the strategic goal of “dual carbon,” this paper takes the load of the load-side multi-form adjustable energy-intensive industry as the regulatory object. At the same time, by transforming conventional units into carbon capture units and load-side energy storage to further tap the low carbon and flexibility of the system, a low-carbon economic dispatching method of wind power systems considering MEL is proposed. It improves the level of wind power consumption of the system, alleviates the pressure of regulating resources, and concurrently takes into account the economy, low carbon, and flexibility of the system to provide a reference for power grid dispatching.

The remainder of the paper is organized as follows: in Section 2, the operating characteristics of polymorphic MEL are analyzed and a mathematical model that conforms to the actual operating characteristics is established, comprehensively considering the flexibility of low-carbon complementarity of source–load storage. In Section 3, a day-ahead and intra-day low-carbon economic dispatch model for wind power systems with MEL is established. The improved IEEE-39 node is used to conduct a case analysis to verify the effectiveness of the proposed method in Section 4. Conclusion is drawn in Section 5

2 Analysis and modeling of MEL

2.1 Analysis of characteristics

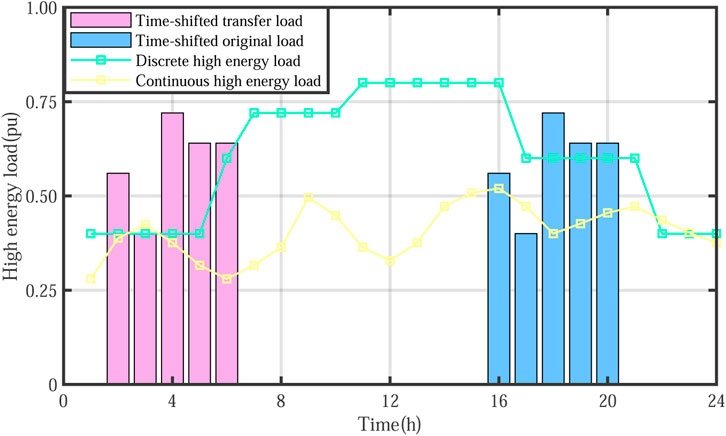

Energy-intensive load is the load whose energy value accounts for more than 30%. According to the differences in operation and regulation characteristics, the energy-intensive load can be divided into discrete, continuous, and time-shifted forms, as shown in Figure 1. Its main distribution is in several industries, such as ferrous metals, non-ferrous metals, machining, petrochemicals, and construction materials.

Discrete adjustable energy-intensive loads have many characteristics, such as large regulation capacity, small load fluctuations, stable regulation characteristics, and relatively slow response times, and cannot be continuously regulated. In contrast, minimum regulation intervals should be met. The regulation characteristics of the continuous adjustable energy-intensive load are as follows: small adjusting capacity, short adjusting interval time, and can make rapid adjustment repeatedly according to the demand. The adjustment characteristics of the time-shift type with the adjustable energy-intensive load are as follows: the adjustment speed is relatively slow; in the scheduling period, the load power waveform is unchanged before and after adjustment; and at the same time, the minimum transfer duration constraint should be satisfied. A comparison of the regulation characteristics of the three forms of energy-intensive load is shown in Table 1.

2.2 Modeling of MEL

Since energy-intensive load has complex operating characteristics and the enterprise has the pursuit of profit maximization behavior, the modeling should take into account not only the operating characteristics of the energy-intensive load but also the operating costs of the enterprise. The cost of regulation comprises the cost incurred by the time-of-use electricity price before and after load regulation and the subsidy paid by the electricity supplier to customers participating in incentivized demand response. An advanced modeling of each form of energy-intensive load according to its operational and regulatory characteristics is given as follows:

1) Discrete adjustable energy-intensive load. Considering the operational characteristics and cost constraints of the discrete adjustable energy-intensive load, the model is established as follows:

Power constraint:

Adjust the upper and lower limit constraints:

State constraint:

Number of adjustment constraints:

Adjusting the duration constraints:

Planned production constraint:

Adjusting cost:

where Plsh (t) is the power of the discrete adjustable energy-intensive load after regulation at time t, P1s-bass(t) is the base load at time t, Pls-up(t) is the amount of upward adjustment at moment t, and Pls-down(t) is the amount of downward adjustment at moment t; S1(t) is the discrete adjustable energy-intensive load up-regulation state decision variable, S2(t) is the load down state decision variable, Pls-up-min is the minimum value of upregulation, Pls-up-max is the maximum value of upregulation, Pls-down-min is the minimum value of downregulation, Pls-down-max is the maximum value of downregulation, and M is the maximum number of regulation; T1 is the maximum upregulation duration and T2 is the maximum downregulation duration; λ1 is the regulated efficiency and Els-plan is the daily planned output; and Cls is the total cost of load regulation, C(t) is the load time-of-use price at time t, and Kls(t)) is the response subsidy cost at time t.

2) Continuous adjustable energy-intensive load. Considering the operational characteristics and cost constraints of the continuous adjustable energy-intensive load, the model is established as follows:

Power constraint:

Output upper and lower bound constraints:

Regulation rate constraint:

Upper and lower regulation limit constraints:

State constraint:

Production constraint:

Adjusting cost:

where Plxh (t) is the power at time t after the regulation of the continuous regulated energy-intensive load, Plx-up (t) is the upregulation at time t, and Plx-down (t) is the downregulation at time t; Plx− min is the minimum output value and Plx-max is the maximum power output; Plx-down (t) is the regulated downhill rate and Plx-up (t)is the regulated uphill rate; S3(t) is the load up decision variable and S4(t) is the load down decision variable; and λk is the regulated efficiency and Elx-plan is the continuous energy-intensive load daily production plan; Clx is the total cost of regulating the load, C(t) is the load time-of-use electricity price at time t, and Klx(t) is the response subsidy cost at time t.

3) Time-shifted adjustable energy-intensive load

Considering the operational characteristic and cost constraints of time-shifted adjustable energy-intensive load, the model is established as follows:

Power constraint:

Time-shift time constraint:

Planned production constraint:

Adjusting cost:

where Psyq(t) is the load capacity at moment t before regulation and Psyh (t) is the load capacity at moment t after regulation; λj is the regulated work efficiency and S5(t) is the time-shifted decision variable at moment t; Tmin is the minimum shift duration constraint; Esy-plan is the time-shifted energy-intensive load daily production plan; and Csy is the total cost of regulating the load and Ksy(t) is the response subsidy cost at moment t.

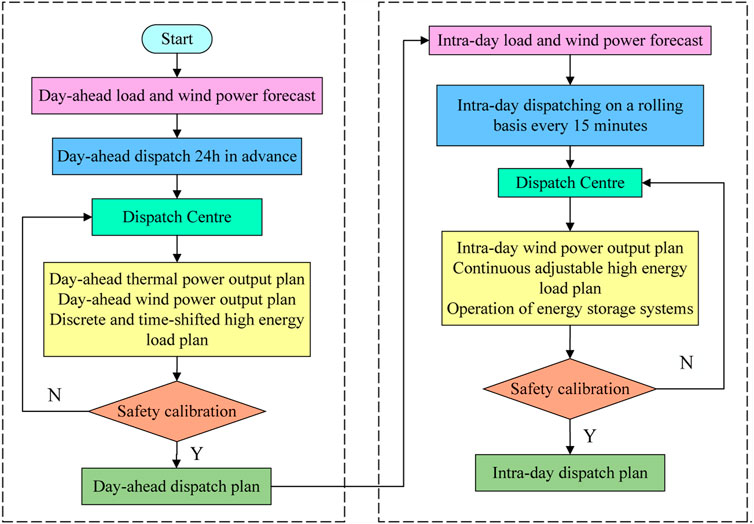

3 Day-ahead and intra-day two-stage low-carbon economic scheduling model

This paper comprehensively considers the energy time-shifting and low-carbon characteristics of carbon capture units under the comprehensive operation mode of the source side and the zero-carbon and low-cost characteristics of wind power, and MEL on the load side and the configured energy storage system are jointly incorporated into the low-carbon economic dispatch to realize the mining of low-carbon characteristics on both sides of the source and load. At the same time, to reduce the adverse impact caused by the error between the planned output of wind power and the intra-day forecast value through the difference in the response characteristics of MEL, it is reasonably arranged to participate in the scheduling plan of two different periods of day-ahead and intra-day. Then, a two-stage low-carbon economic dispatching method of the wind power system with MEL is proposed. In the day-ahead low-carbon economy dispatch stage, conventional and carbon capture units are taken as the control objects on the source side; on the load side, the discrete adjustable energy-intensive load, and time-shifted adjustable energy-intensive load with slow response speed and non-continuous adjustment suitable for regulation in a long time scale are taken as the control objects, and the wind power forecast and output in the previous stage are dynamically responded and a day-long low-carbon economic dispatching plan considering the source–load coordinated scheduling characteristics is formulated to deeply explore the low-carbon and economic nature of the system. In the intra-day stage, based on the day-ahead scheduling, the energy storage system with fast response speed and continuous regulation suitable for optimal regulation and control under a short time scale is taken as the adjustment object, and the dynamic response to the wind power forecast and output in the intra-day stage is formulated, taking into account the economy and flexibility of system operation to provide a reference for power grid dispatching. A two-stage low-carbon economic scheduling method for the wind power system with MEL is proposed. The process is shown in Figure 2.

3.1 Day-ahead scheduling model

During the day-ahead scheduling phase, the time-shifted adjustable energy-intensive load and the discrete adjustable energy-intensive load, which have a relatively slow response, are used as the regulation objects. The total operating cost of the system is minimized and used as the objective function, and the scheduling plan is made 24 h in advance, with a scheduling time scale of 1 h. In this case, the continuous adjustable energy-intensive load is considered part of the conventional load and does not participate in the system regulation.

Objective function:

where F1 is the total operating cost of the economic scheduling day-ahead of the system and Ccg is the operating cost of a conventional thermal power unit. Ui(t) is the start–stop state of the conventional thermal power unit i at time t. ai, bi, ci are the coal consumption cost coefficients for the conventional thermal power unit i. Pcg,i(t) is the output of the conventional thermal power unit i at time t, Ccb is the operating cost of the carbon capture unit, and Uj(t) is the start–stop state of the carbon capture unit j at time t. aj, bj, cj are the coal consumption cost coefficients of the carbon capture unit j and Pcb,j is the output of the carbon capture unit j at time t. Caw is the cost of wind abandonment. Kaw is the cost per unit of wind abandonment. Pwfore(t) is the predicted output of wind power at time t and Pw(t) is the planned day-ahead output value of wind power at time t. Cnh is the energy consumption cost of the carbon capture power plant, Ncb is the number of carbon capture units, PBj(t) is the operating energy consumption of the carbon capture unit j at time t, and PDj(t) is the fixed energy consumption of the carbon capture unit j. Czj is the depreciation cost, Nzj is the depreciation period, and alpha is the discount rate for the carbon capture unit project. Ctb is the total cost of capture equipment for the carbon capture plant and Vry is the cost per unit volume of solution memory. Nry is the volume of the solution memory and Nry is the solution memory depreciable life; Cfc is the total cost of sequestration of the carbon capture unit and Kfc is the cost per unit of CO2 sequestration. Ccb is the capture cost of the carbon capture unit and Ecb,j(t) is the total amount of CO2 produced by the carbon capture unit j at time t. Kcd is the carbon emission intensity of the carbon capture unit. Pcb,j(t) is the total output of the carbon capture unit j at time t. Ej,total−co,t) is the total amount of CO2 captured by the carbon capture unit j. β is the capture efficiency of carbon capture equipment and Kc is the unit cost of carbon emissions. Ccgc is the total cost of carbon emissions from conventional thermal power units.

The relevant constraints to be considered during the economic scheduling phase are as follows:

1) System power balance constraint:

2) Wind power output constraint:

3) Upper and lower output limit constraints for the conventional unit:

4) Climbing constraints for the conventional unit:

5) System rotation standby. The system rotation standby consists of conventional thermal and carbon capture units:

6) Operational constraint on the carbon capture unit. According to the energy consumption characteristics of carbon capture units, the related constraints such as the flue gas diversion ratio constraint, carbon capture quantity constraint, and energy consumption of carbon capture equipment are considered. Among them, the energy consumption of carbon capture equipment is mainly composed of fixed and operational energy consumption. In addition, the output and climbing constraints of the carbon capture units are the same as those of the conventional units, which are not explained here. The mathematical model of carbon capture units is as follows:

where Pcg(t) is the conventional load at time t,

7) Solution memory operation constraint. Ethanolamine solution is used in the solution memory of the carbon capture unit, and the mass of CO2 is calculated using the volume of the solution using the processing method, with the following relational formula:

where CCAj(t) is the solution volume of CO2 captured by the carbon capture unit j at time t, QGj(t) is the mass of CO2 captured by the carbon capture unit j at time t, MEA is the molar mass of ethanolamine solution,

8) The solution storage operation constraints of the carbon capture unit are as follows:

where VFj(t) is the solution volume of the enriched liquid storage of the carbon capture unit j at t time, VPj(t) is the solution volume of the carbon capture unit j lean liquid storage at t time, and VCAj(t) is the solution volume of the carbon capture unit j at t time.

9) Tie line power flow safety constraint:

where Pi and Pj are the injected power at neighboring nodes i and j, respectively. Pline,max is the limit value of the transmitted power required for the safe operation of the system.

3.2 Intra-day scheduling model

In the intra-day phase, based on the day-ahead phase, the scheduling plan is changed every 15 min. The energy storage system with faster demand response and continuous adjustable energy-intensive load is used as regulation targets. Participation in intra-day system regulation is reasonably arranged according to the system wind abandonment situation and the impact of the time-of-use electricity price of the load. To ensure low-carbon economic safety of the system, the objective function is to minimize the system operating costs and the adverse effects of errors between the day-ahead wind power plan and the actual measured intra-day wind power values.

The intra-day scheduling model objective function is as follows:

where F2 is the total operating cost of the system in the intra-day stage, Clx is the continuous adjustable energy-intensive load regulation cost, Ccn is the cost of operating the energy storage system, CΔaw is the cost of intra-day wind abandonment, and Kcn is the cost per unit of energy storage.

The continuous adjustable energy-intensive load operating constraints have been described previously and will not be repeated here.

1) Intra-day power regulation balance constraint:

2) Energy storage system operating constraints:

To ensure the lifetime of the energy storage system, its charge state constraint and charge/discharge power constraint should be considered. The mathematical model is as follows:

The state of charge of the energy storage system and its formula:

Charging and discharging power constraints for the energy storage system:

where ΔPw1(t) is the difference between the predicted wind power output value during the day and the planned wind power output value before the day, ΔPw(t)is the intra-day wind power consumption, Bsoc is the state of charge of the energy storage system, Eb is the current moment power of the energy storage system, and Cb is the total capacity of the energy storage system; Bsoc, min and Bsoc, max are the minimum and maximum values of the charge state of the energy storage system, respectively, and Bsoc(t) is the state of charge of the energy storage system at time t; Pcha(t) is the charging power of the energy storage system at time t and ηcha is the charging efficiency; Pdis(t) is the discharge power of the energy storage system at time t, ηdis is the discharge efficiency, and Pcha, min and Pcha, max are the upper and lower limits of the charging power of the energy storage system, respectively; and Pdis, min and Pdis, max are the upper and lower limits of the electrical power discharged from the energy storage system, respectively.

4 Case study

4.1 Overview of the case study

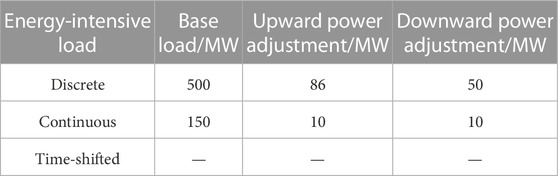

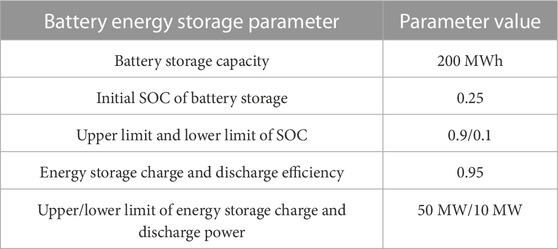

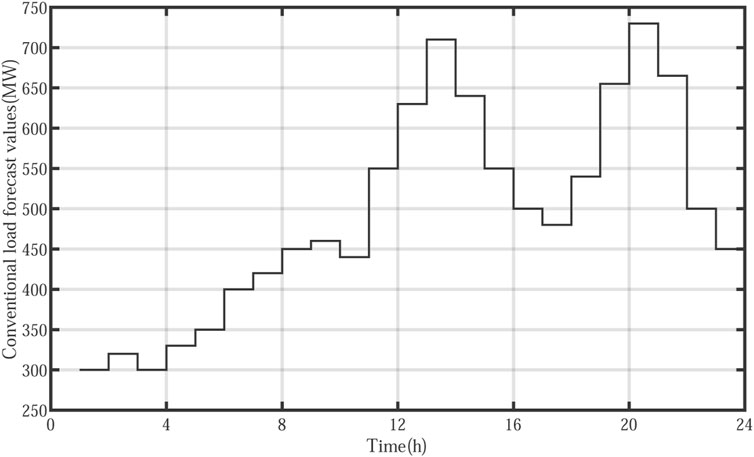

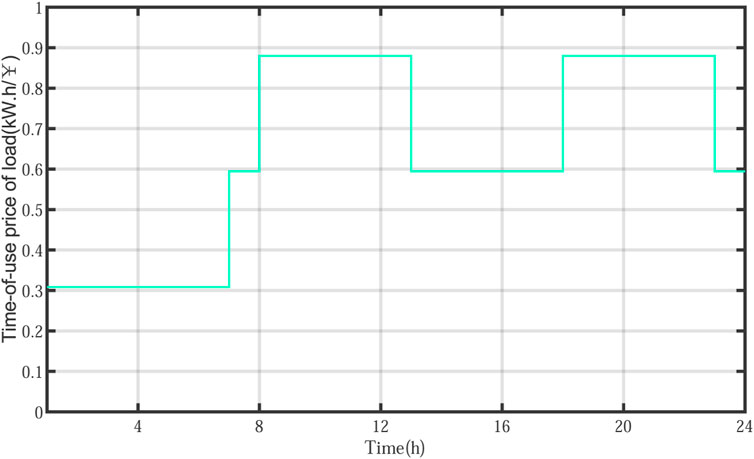

This paper presents a case analysis of the improved IEEE-39 node system. The system contains a 900 MW wind farm and four thermal power units, of which G1 is converted into a carbon capture unit, and the rest are conventional thermal units. The detailed parameters of the thermal units are shown in Table 2. Among the forms of MEL, the electro-melt magnesium load of the magnesia industry is taken as an example of the discrete adjustable energy-intensive load, and the ferroalloy load is taken as an example of the continuous adjustable energy-intensive load The regulation parameters are shown in Table 3, and the specific parameters are shown in Table 4 which shows that the system is equipped with 200 MWh energy storage system; the system day-ahead and intra-day wind power forecast values are shown in Figure 3; the conventional load forecast values are shown in Figure 4; and the load time-of-use price is shown in Figure 5. The problem studied in this paper is a mixed integer linear programming problem, which is solved using the optimization software CPLEX.

To verify the effectiveness of the proposed method, four different operational scenarios are set up for validation analysis:

1) Conventional scheduling: The power side participates in the regulation of the system, but the load side does not.

2) Coordinated power and load scheduling: All thermal units in the system are conventional units, with time-shifted adjustable energy-intensive and discrete adjustable energy-intensive loads participating in system regulation for day-ahead low-carbon economic scheduling.

3) Coordinated power and load scheduling considering low-carbon characteristics of carbon capture units: Power-side participation in system regulation and conversion of one thermal power unit to a carbon capture unit, as well as time-shifted adjustable energy-intensive load and discrete adjustable energy-intensive load participation in system regulation for day-ahead economic scheduling.

4) Day-ahead and intra-day two-stage economic scheduling: Based on the aforementioned Scenario 3, continuous adjustable energy-intensive load in the system combined with an energy-storage system participates in system regulation for day-ahead and intra-day economic scheduling.

4.2 Result analysis

4.2.1 Comparative analysis of different operational scenarios

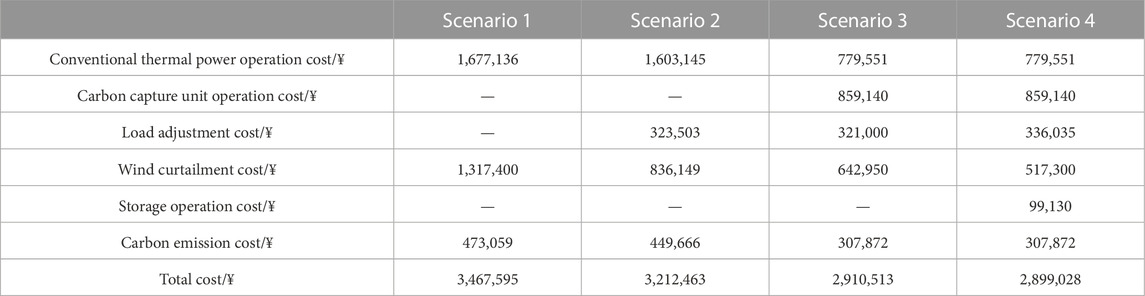

The system is analyzed according to the aforementioned scenarios, and the operating costs for each scenario are shown in Table 5.

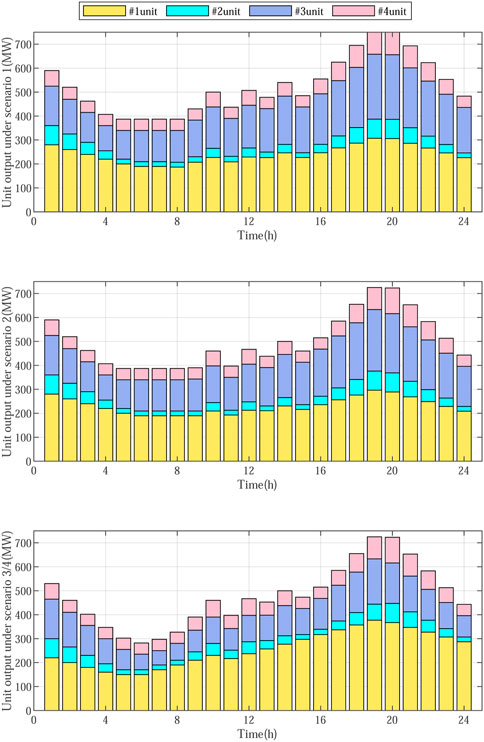

A comparison of the costs of the systems in different scenarios shows that in Scenario 1, the conventional scheduling method of regulation results in the largest amount of abandoned wind, the most serious carbon emissions, and the highest operating costs. In Scenario 2, regulation is carried out using power–load coordination, involving time-shifted adjustable energy-intensive and discrete adjustable energy-intensive loads in the day-ahead phase of the system, resulting in a 7.36% reduction in total system costs, a 36.53% reduction in wind abandonment costs, and a 4.95% reduction in carbon emission costs compared to Scenario 1. Compared to Scenario 1, the advantages of co-coordinated power and load scheduling are demonstrated in Scenario 2. In Scenario 3, a carbon capture unit with low-carbon characteristics is introduced into the system. By using the scheduling method in Scenario 2, the operating cost of the unit increases, but there is a decrease in system adjustment and carbon emission costs. Overall, the total system cost is reduced by 9.39%, and the carbon emission cost is reduced by 31.53%. In Scenario 4, based on Scenario 3, continuous adjustable energy-intensive load and energy storage system are used as regulation resources to participate in the intra-day phase of system regulation, maximizing the elimination of the difference between the forecasted intra-day wind power output and the planned day-ahead wind power output. Using the method proposed in this paper, the operating cost of the system is reduced by 16.4% and the carbon emission cost is reduced by 34.92% compared to Scenario 1, proving the effectiveness of the method proposed in this paper, which ensures the safe operation of the system while taking into account the low-carbon and economic aspects of the system. The power output of each unit in each scenario is shown in Figure 6. In the conventional scheduling mode in Scenario 1, only the output of thermal units is regulated to cope with load and wind power, and there is greater pressure to regulate conventional thermal units. In Scenario 2, the regulation pressure on conventional thermal units is further reduced as the time-shifted and discrete adjustable energy-intensive loads on the supply side participate in the demand response; scenarios 3 and 4 show the same scheduling results. By converting unit 1 to a carbon capture unit, the output of unit 1 accounts for a larger proportion of the capacity than scenarios 1 and 2 due to the low-carbon and economic operation of the carbon capture unit, and the output of other high-carbon units is compressed, resulting in a further reduction in the carbon emissions and operating costs of the system.

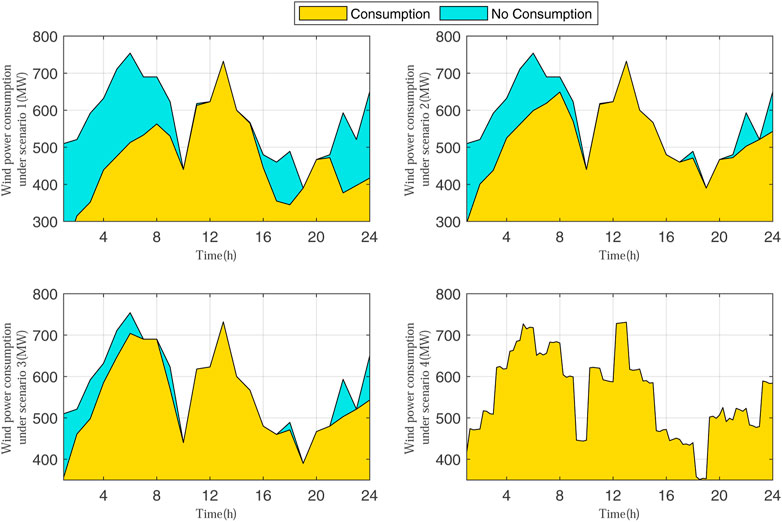

The wind and power consumption in each scenario is shown in Figure 7. Under the traditional scheduling model of Scenario 1, only the power side participates in scheduling, while the lack of system regulation resources leads to serious wind power abandonment in the system. In Scenario 2, both sides of the power supply and load participate together as regulating resources in the scheduling, and system wind abandonment is mitigated. The conversion of the conventional unit 1 to a carbon capture unit in Scenario 3 further increases the flexibility on the source side of the system, thereby mitigating the system wind abandonment to some extent. Scenario 4 builds on Scenario 3 by considering the prediction errors of day-ahead and intra-day wind power, while adding two regulation resources, an energy-storage system, and continuous energy-intensive load, to the intra-day phase, resulting in a significant reduction in system wind abandonment and achieving the goal of low-carbon and economical system operation.

4.2.2 Result analysis of the scheduling method proposed in this paper

To verify the effectiveness of the method proposed in this paper, the scheduling results are analyzed as follows:

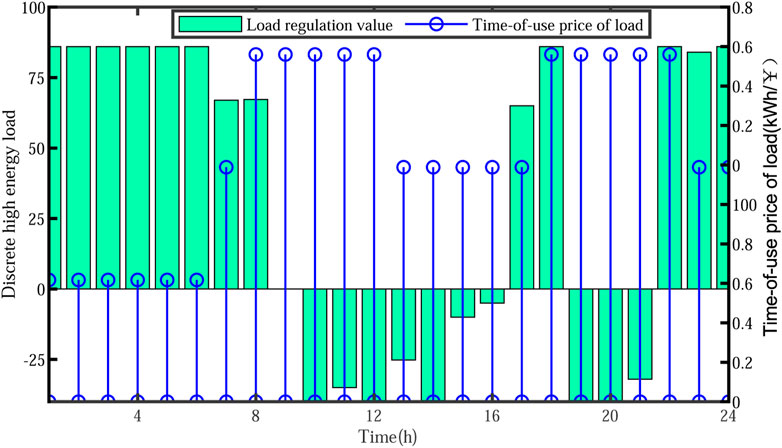

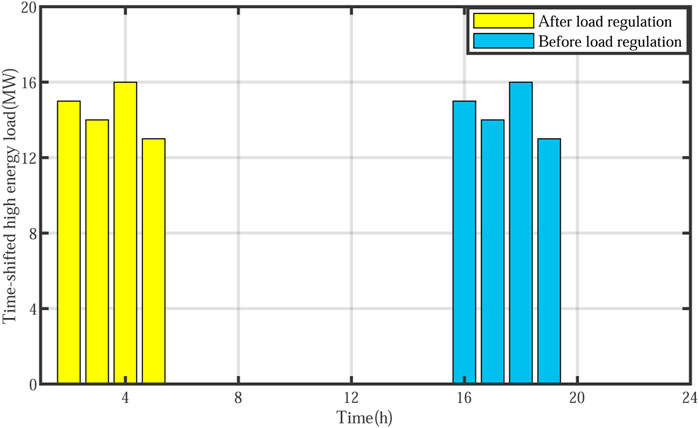

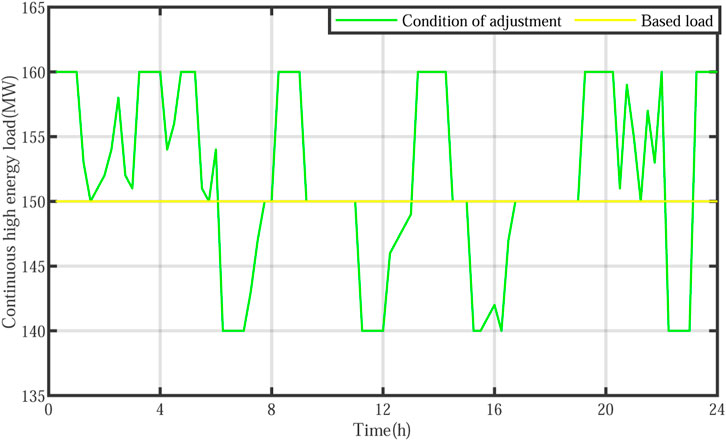

The regulation of discrete adjustable energy-intensive and the time-shifted adjustable energy-intensive loads during the day-ahead economic scheduling phase is shown in Figure 8 and Figure 9, respectively. During the day-ahead phase, the variation in discrete adjustable energy-intensive loads negatively correlates with the variation in electricity prices. In the adjustment process, the load is low at the stage of wind abandonment, and then the load is raised to absorb wind power; when there is no wind-abandoning load peak, the load is lowered to reduce the regulation pressure of conventional thermal power units. At the same time, by shifting the time-shifted adjustable high-energy peak hour load to the low-valley period, enterprises can make use of the peak–valley price differential for arbitrage based on their safe operation, making a profit of 24,856 CNY, thereby improving wind power consumption as well as reducing the cost of electricity for time-shifted high-energy enterprises.

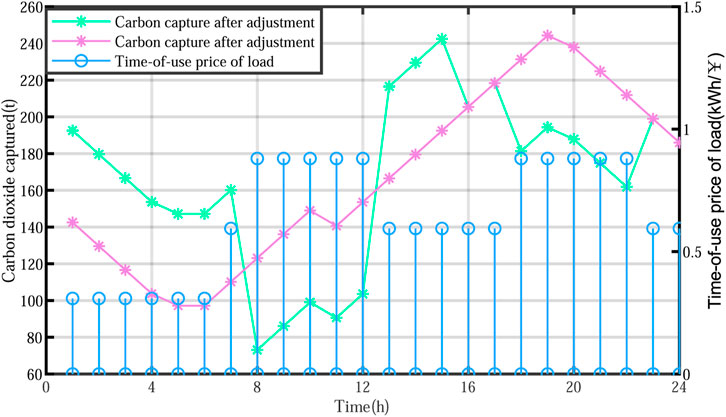

The carbon capture unit CO2 and time-of-use electricity price are shown in Figure 10. The carbon capture unit uses the solution memory for energy time shifting based on time-of-use electricity price and system wind abandonment. During low points, the price of electricity is lowered and the amount of carbon capture is increased; during peak hours, the price of electricity is raised and the amount of carbon capture is lowered. Therefore, peak shaving and valley filling in energy consumption of carbon capture equipment are achieved, thus ensuring low-carbon capture units and economic operation of the carbon.

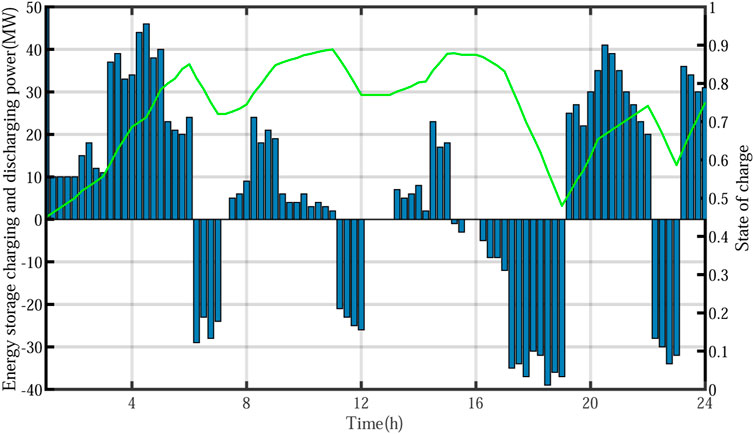

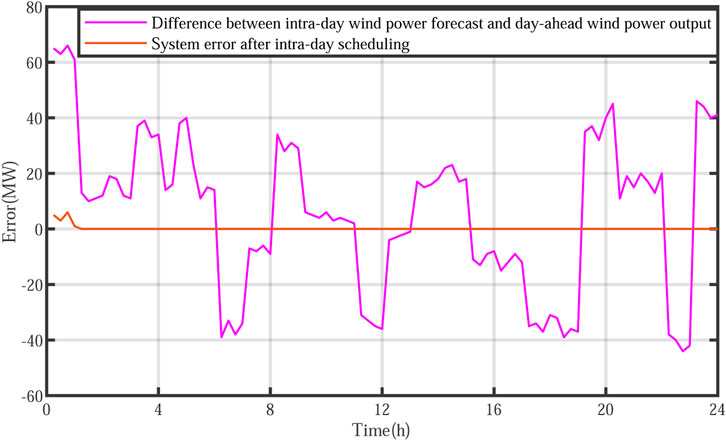

The continuous adjustable energy-intensive load and storage system operation during the intra-day economic scheduling phase are shown in Figure 11 and Figure 12, respectively. In the intra-day phase, the error between the intra-day wind power forecast and the day-ahead wind power metered output value is minimized by dynamically adjusting the continuous adjustable energy-intensive load and the energy storage system, thus ensuring low-carbon and economic operation of the system by completely utilizing the flexibility of demand-side scheduling resources. The dynamic error adjustment is shown in Figure 13.

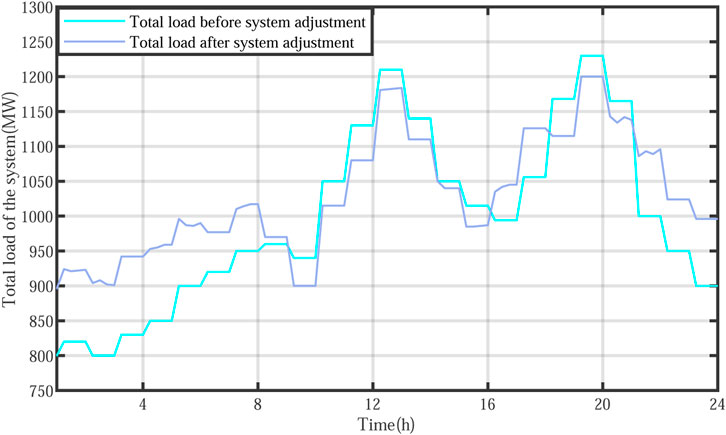

Figure 14 shows the comparison of the system load before and after scheduling. After scheduling by the method proposed in this paper, the system load increases during the wind abandonment hours (00:00–08:00 and 22:00–24:00) and decreases during the wind shortage hours; the daily peak-to-valley difference of the system load is reduced by 129.22 MW after scheduling. In summary, this paper makes full use of low-carbon characteristics of the complementary power and load sides and the flexibility of demand-side scheduling resources to ensure safe operation of the system, while taking into account the economy and low-carbon nature of the system.

To sum up, this paper mainly uses carbon capture technology at the source side and energy storage at the load side, supplemented by reasonable dispatching strategies and other technical means, ensuring the safe operation of the system. It fully exploits the flexibility and low-carbon nature of dispatching resources in the power system, improves the level of wind power consumption of the system, and takes into account the economy, low-carbon nature, and flexibility of system operation.

5 Conclusion

This article proposes a day-ahead and intra-day two-stage low-carbon economic dispatch method for wind power systems that consider MEL, and the following conclusions are drawn:

1) Based on classifying the differences in response characteristics of various adjustable MELs, this article provides a detailed analysis of the operational and regulatory characteristics of the adjustable MEL. It establishes a refined mathematical model that conforms to the actual operational characteristics of MEL.

2) This article introduces a carbon capture device with low-carbon characteristics into the system, which improves the low-carbon and economic performance of the system through proper scheduling. Simulation shows that compared to the situation without introducing carbon capture units, the total cost of the system is reduced by 9.39% and the carbon emission cost is reduced by 31.53%.

3) This article proposes a day-ahead and intra-day two-stage low-carbon economic dispatch method for wind power systems that consider MEL. Taking into account the low-carbon characteristics and flexibility of regulating resources on the source load storage sides as well as the differences in response characteristics of demand-side scheduling resources, the low-carbon and economic performance of the system has been improved through reasonable scheduling of regulating resources on each side. The simulation results show that compared with traditional scheduling methods, the system operation cost is reduced by 16.4% and the carbon emission cost is reduced by 34.92%.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

ZY and YW contributed to the conception and design of the study. ZY performed the statistical analysis. ZY wrote the first draft of the manuscript. ZY, YX, CL, WG, GC, JZ, AS, XL, and BL wrote sections of the manuscript. All authors contributed to manuscript revision and read and approved the submitted version.

Conflict of interest

WG was employed by State Grid Liaoning Electric Power Supply Co., Ltd. AS and XL were employed by Changchun Power Supply Company, State Grid Jilin Electric Power Co., Ltd. BL was employed by Jilin Thermal Power Plant of Guoneng Jilin Longhua Thermal Power Co., Ltd.

The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The reviewer MY declared a shared affiliation with the authors ZY, YX, CL, GC, and JZ at the time of the review.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Afzalan, M., and Jazizadeh, F. (2020). Data-driven identification of consumers with deferrable loads for demand response programs. IEEE Embed. Syst. Lett. 12, 54–57. doi:10.1109/les.2019.2937834

Akbari-Dibavar, A., Mohammadi-Ivatloo, B., Zare, K., Khalili, T., and Bidram, A. (2021). Economic-emission dispatch problem in power systems with carbon capture power plants. IEEE Trans. Industry Appl. 57, 3341–3351. doi:10.1109/tia.2021.3079329

Bao, Y., Wang, B., Yang, L. I., and Yang, S. (2016). Rolling dispatch model considering wind penetration and multi-scale demand response resources. Proc. Csee 36 (19), 5103–5110.

Ge, X., Jin, Y., Fu, Y., Ma, Y., and Xia, S. (2019). Multiple-cut benders decomposition for wind-hydro-thermal optimal scheduling with quantifying various types of reserves. IEEE Trans. Sustain. Energy 1, 1358–1369. doi:10.1109/tste.2019.2925213

Guo, X., Lou, S., Wu, Y., and Wang, Y. (2022). Low-carbon operation of combined heat and power integrated plants based on solar-assisted carbon capture. J. Mod. Power Syst. Clean Energy 10, 1138–1151. doi:10.35833/mpce.2021.000046

Ji, Z., Kang, C., Chen, Q., Xia, Q., Jiang, C., Chen, Z., et al. (2013). Low-carbon power system dispatch incorporating carbon capture power plants. IEEE Trans. Power Syst. 28, 4615–4623. doi:10.1109/tpwrs.2013.2274176

Jia, Q., Chen, S., Yan, Z., and Li, Y. (2022). Optimal incentive strategy in cloud-edge integrated demand response framework for residential air conditioning loads. IEEE Trans. cloud Comput. 10, 31–42. doi:10.1109/tcc.2021.3118597

Jiaming, L. I., Wen, J., and Han, X. (2015). Low-carbon unit commitment with intensive wind power generation and carbon capture power plant. J. Mod. Power Syst. Clean Energy 3, 9.

Li, M., Hu, D., and Zhou, Y. (2016). “Research and practice of renewable energy local consumption mode in gansu province based on ”double alternative” strategy,” in Power system technology.

Li, X., Cao, X., Li, C., Yang, B., and Chen, D. (2019). A coordinated peak shaving strategy using neural network for discretely adjustable energy-intensive load and battery energy storage. IEEE Access 8, 5331–5338. doi:10.1109/ACCESS.2019.2962814

Liao, S., Jian, X., Sun, Y., Yi, B., and Tang, B. (2018). Control of energy-intensive load for power smoothing in wind power plants. IEEE Trans. Power Syst. 33, 6142–6154. doi:10.1109/TPWRS.2018.2834940

Liu, C., Liu, W., Wang, W., Zhu, D., Wen, J., and Meng, J. (2015). A quantitative method to pre-evaluate power grid’s capability of accommodation for wind/photovoltaic power under participation of high-energy load. Power Syst. Technol. 76, 177–194.

Luo, J. B., Chen, Y. H., and Liu, Q. (2014). Overview of large-scale intermittent new energy grid-connected control technology. Power Syst. Prot. Control 42, 140–146.

Neubauer, J., and Simpson, M. (2013). Optimal sizing of energy storage and photovoltaic power systems for demand charge mitigation. Golden, Colorado: National Renewable Energy Laboratory (U.S.). (poster).

Peng, G., Jing, W., Zhu, D., Wang, W., and Liu, W. (2017). The coordination control strategy for large-scale wind power consumption based on source-load interactive. Trans. China Electrotech. Soc. 32, 1–9.

Shi, Z., Wang, W., Huang, Y., Li, P., and Dong, L. (2022). Simultaneous optimization of renewable energy and energy storage capacity with the hierarchical control. CSEE J. Power Energy Syst. 8, 95–104. doi:10.17775/CSEEJPES.2019.01470

Teng, F., Marko, A., Danny, P., and Goran, S. (2015). Benefits of demand-side response in providing frequency response service in the future gb power system. Front. Energy Res. 3, 36.

Tindemans, S. H., Trovato, V., and Strbac, G. (2015). Decentralized control of thermostatic loads for flexible demand response. IEEE Trans. Control Syst. Technol. 23, 1685–1700. doi:10.1109/tcst.2014.2381163

Keywords: multi-form energy-intensive load, day-ahead and intra-day two-stage, wind power consumption, operating costs, low-carbon economic scheduling

Citation: Yuan Z, Wang Y, Xu Y, Liu C, Ge W, Cai G, Zhou J, Sun A, Liu X and Li B (2023) Day-ahead and intra-day two-stage low-carbon economic scheduling method considering multi-form energy-intensive load. Front. Energy Res. 11:1182737. doi: 10.3389/fenrg.2023.1182737

Received: 09 March 2023; Accepted: 12 April 2023;

Published: 10 May 2023.

Edited by:

Weijia Liu, National Renewable Energy Laboratory (DOE), United StatesReviewed by:

Hongxun Hui, University of Macau, ChinaMao Yang, Northeast Electric Power University, China

Copyright © 2023 Yuan, Wang, Xu, Liu, Ge, Cai, Zhou, Sun, Liu and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yibo Wang, d2FuZ3lpYm9mYW5neXVhbkAxMjYuY29t

Zhijun Yuan1

Zhijun Yuan1 Yibo Wang

Yibo Wang Chuang Liu

Chuang Liu