- 1Faculty of Industrial Management, Universiti Malaysia Pahang Al-Sultan Abdullah, Kuantan, Pahang Darul Makmur, Malaysia

- 2Department of Business Administration, University of Gothenburg, Gothenburg, Sweden

- 3Faculty of Engineering and Sustainable Development, University of Gávle, Gávle, Sweden

- 4School of Technology Management and Logistics, College of Business, Universiti Utara Malaysia, Sintok, Malaysia

- 5Department of Mechanical and Manufacturing Engineering, Faculty of Engineering, Universiti Putra Malaysia, Serdang, Malaysia

Manufacturing enterprises are currently facing radical challenges with the new concept of smart manufacturing. While most multinational enterprises have initiated their journey toward adopting smart manufacturing technologies, small and medium enterprises (SMEs) that are the mainstay of many manufacturing economies are still struggling to understand the complexities of smart manufacturing. Many of these enterprises are not ready to embrace the concept owing to the large initial investment required for technological advancement. Furthermore, failure to assess the readiness and current capabilities of the SMEs may obstruct achievement of their full potential in smart manufacturing. Therefore, the present study aims to explore essential criteria that must be included in the design of a readiness assessment tool for adopting smart manufacturing in automotive SMEs. Accordingly, we adopt a design and development research method along with the fuzzy Delphi technique to accomplish the research objectives. A self-administered questionnaire was then developed as an instrument to collect research data. A panel of 15 experts comprising government agency representatives, smart manufacturing practitioners, academic researchers, and SME consultants participated in the study. Data analysis revealed that the experts accepted all of the proposed criteria, as indicated by an expert consensus value exceeding 75%, a threshold value (d) ≤ 0.2, and a fuzzy score (A) ≥ the α-cut value of 0.5. These findings demonstrate that the suggested criteria have gained expert consensus and are necessary for designing and developing an E-smart manufacturing readiness assessment tool for automotive SMEs. Our research holds tremendous implications for small and medium automotive manufacturers intending to adopt smart manufacturing at their production facilities as well as policymakers designing further policies, aid, and future development strategies to enhance the business performances of SMEs.

1 Introduction

Given the rapidly evolving global economic landscape at present, we cannot overstate the roles of small and medium enterprises (SMEs) in driving economic growth and innovation (Mustapha and Sorooshian, 2019). In Malaysia, where SMEs constitute a staggering 98.5% of all businesses, the ability to stay competitive while adapting to the demands of the digital age is crucial (SME, 2019; Wong and Kee, 2022); as the nation aspires to ascend to the ranks of developed and high-income countries by 2024 (Industry4WRD, 2018). It has become more imperative to equip SMEs with the tools necessary for transformation and innovation. Smart manufacturing has often been touted as the future of production processes and holds the key to the transformation needed for Malaysian SMEs (Rahamaddulla et al., 2021); it offers a paradigm shift in manufacturing practices by integrating cutting-edge technologies such as artificial intelligence (AI) with the Internet of Things (IoT) and automation to increase efficiency, productivity, and competitiveness (Varriale et al., 2023; Allioui and Mourdi, 2023). However, for SMEs and particularly those in Malaysia, swift adoption of such revolutionary manufacturing approaches pose formidable challenges (Ahadi et al., 2023; Abdulaziz et al., 2023).

The transition from conventional manufacturing systems to advanced technology-driven smart manufacturing entails many uncertainties and complexities. Assessing the readiness of the SMEs serves as a vital step in recognizing the technological, organizational, and strategic gaps precisely. Understanding these disparities beforehand can help SMEs mitigate potential risks due to unprepared adoption; further, it helps with the development of a well-conversant transition strategy that could prevent costly setbacks and operational disruptions while promoting smoother and more secure integration of smart manufacturing technologies (Rahamaddulla et al., 2021). Next, readiness assessments could provide valuable insights to the SMEs relevant to the resources required for smart manufacturing adoption (Yang et al., 2022). The evaluation outcomes also influence strategic resource allocation and investments for technological upgrades, employee training, and infrastructure development; this minimizes the complexity often associated with sudden shifts in manufacturing and methodically reduces the likelihood of being overwhelmed by rapid changes (Bumbarger, 2015). Readiness measurements could also enhance adaptability and resilience, where the readiness assessment outcomes may foster adaptability by enabling anticipation and the ability to manage unforeseen challenges with greater agility. Thus, the readiness tool should be able to capture the uncertainties in each smart technology. These uncertainties encompass technological, organizational, and strategic dimensions and can significantly impede the seamless implementation and operation of smart manufacturing practices within SMEs. Therefore, the need of the hour is a tailored readiness assessment tool that is specifically designed to measure the preparedness of SMEs for embracing smart manufacturing.

The present study endeavors to address this critical need through the development of a comprehensive self-readiness assessment tool. This tool is based on the innovative fuzzy Delphi technique (FDT) and is poised to capture and account for the inherent complexities characterizing the journey toward smart manufacturing adoption in Malaysian SMEs. The primary objective of this research is to conceive and construct a holistic readiness assessment tool calibrated to the unique challenges faced by SMEs when embracing smart manufacturing. By integrating the power of the FDT, the proposed tool aims to provide a nuanced and adaptable instrument that can discern and quantify readiness levels across various dimensions. The significance of this study lies in its profound implications for both industry and policymaking; the outcomes of this work are expected to revolutionize the development of tailored readiness assessment tools, casting a spotlight on the intricate facets of smart manufacturing that may otherwise remain obscured by the associated complexities. Policymakers can leverage the insights garnered from this assessment tool to draft future policies, incentives, and programs to incentivize SMEs to embark on their smart manufacturing journeys. Furthermore, this assessment tool serves as an invaluable compass for researchers seeking to explore the contours of complexity within the smart manufacturing realm from the perspective of SMEs. Our work not only contributes to a more profound understanding of the challenges faced by SMEs but also motivates them to embrace the future of manufacturing, thereby catalyzing Malaysia’s quest as a high-income and developed nation.

The scope of this study encompasses application of the design and development research (DDR) approach to create a readiness assessment tool tailored to the context of automotive SMEs transitioning to E-smart manufacturing. DDR is characterized by its formative nature and systematic process, which align with the research strategies employed in this research. The present study is examined in three distinct phases, where the first phase involves conducting a needs analysis for the assessment tool, second phase is focused on the actual design and development of the tool, and third phase is used to validate the developed tools. However, it is important to note that the we focus more on the second phase in this work as it constitutes the central and most significant component of the DDR approach to design and develop the E-smart manufacturing readiness assessment tool for automotive SMEs.

2 Literature review

2.1 Industrial revolution and smart manufacturing

The evolution from the first to the Fourth Industrial Revolution evidences the continuous progress achieved in manufacturing processes (Sorooshian and Panigrahi, 2020). This evolution initially started with mechanization of production and has developed to the current era of smart interconnected systems. Each phase of growth during this process has resulted in transformative changes: from steam and mechanized systems in the first industrial revolution to mass production empowered by electricity in the second, digitalization in the third, and cyberphysical systems (CPSs) in the current Industry 4.0. This historical perspective emphasizes the incremental progress and sets the stage for smart manufacturing. As manufacturing systems are becoming increasingly complex, there is a need for unified data-driven technologies that underscores the importance of smart manufacturing for navigating this new landscape. The smart manufacturing of today is dependent on several key pillars, including IoT, big data analytics and cybersecurity (Schaupp et al., 2017; Sufian et al., 2021); these pillars are not only integral to understanding the nature of smart manufacturing but also essential for SMEs to successfully transition and thrive in this new industrial paradigm.

The terms “smart manufacturing” and “Industrial 4.0” are often used interchangeably. In the United States, smart manufacturing is referred to as Industrial 4.0, while Germany officially introduced this concept at the Hannover Fair in 2011; similarly, Korea uses the term Industrial 4.0 to describe a “smart factory.” Regardless of the terminology used, these three phrases share a common goal: to enhance businesses and their manufacturing environments in various countries by embracing advancements in information and operational technologies. In essence, ten key pillars have been widely discussed in the context of smart manufacturing. Notably, scholars like Machado et al. (2020), Jones et al. (2019), Piccarozzi et al. (2018), Vaidya et al. (2018), Erboz (2017), and Rüßmann (2015) have provided detailed insights into these pillars within the framework of the Fourth Industrial Revolution. These pillars include IoT, collaborative robots, cloud computing, virtual reality, big data analytics, system integration, additive manufacturing, cybersecurity, simulation, and CPSs. Collectively, these components serve as the foundational pillars driving the evolution of smart manufacturing.

2.2 Readiness models for smart manufacturing adoption

Germany has become a global leader in smart manufacturing, having successfully integrated Industry 4.0 principles like IoT, Internet of Services, enterprise resource planning, social product development, and radio frequency identification (Fonseca, 2018; Georgakopoulos et al., 2016; Lin et al., 2016; Lom et al., 2016; Lu, 2017; Sony and Naik, 2020). These technologies enable mass customization, cost-effective product planning, and real-time manufacturing process control (Mittal et al., 2019; Tao et al., 2018; Zheng et al., 2018). While many manufacturers have sought these benefits to remain competitive (Kang et al., 2016), others have struggled in their adoption of smart manufacturing practices. In countries like Malaysia, most companies have remained at the Industry 3.0 stage (Abod, 2017). In the particular case of SMEs, the adoption of Industry 4.0 remains a significant challenge (Rauch et al., 2020). Readiness assessments entail evaluating several dimensions on a scale to measure readiness levels (Rockwell Automation, 2014). Commonly, all these models are equipped with readiness level stages. Most readiness models share common dimensions of measurement; nevertheless, the purpose of each model is distinct, offering different levels of complexity and depth with regard to scope and methodology (Horvat et al., 2018). Generally, readiness level 1 indicates lack of the attribute and level 5 represents an advanced level or required attribute (Schumacher et al., 2016). Several authors like Tavana et al. (2024), Sorooshian (2021), Akdil et al. (2018), Gökalp et al. (2017), Sony and Naik (2020), and Lichtblau (2023), have confirmed that there is no standard and perfectly consented model in this area; therefore, there is no universally agreed upon guide for developing the readiness model, which evidences a notable research gap. To date, there are many well-known readiness models for reference; Supplementary Appendix 1 shows some previous works related to readiness assessments from 2014 to the present. Herein, the readiness level implies that the currently existing tools are designed to suit large companies, whereas SMEs and multinational enterprises (MNEs) have different starting conditions. There are well-established arguments that models based on large enterprises may not perform optimally owing to the distinct characteristics of smaller businesses (Sorooshian, 2017; Sorooshian and Suffian, 2017; Mustapha et al., 2016). Moreover, the extant tools assume that the companies performing readiness assessments are well-established, with connected machinery, advance systems, dedicated departments, and integrated IT systems with established IT departments. Many extant readiness assessments require high complexity and substantial investments, both operationally and financially, which are unsustainable for SMEs and MNEs (Haug et al., 2011). This is contradictory to the starting conditions of SMEs, whose IT departments are often outsourced to third-party service providers. Correspondingly, Mittal et al. (2018) have highlighted that SMEs and MNEs, particularly those in the manufacturing sector, are in need of their own assessment frameworks.

Readiness assessments are crucial for SMEs that are considering smart manufacturing implementation. As noted by Schumacher et al. (2016), the key challenges are as follows:

• Failure to assess readiness that leads to costly consequences

• Uncertainties regarding the benefits and costs of technology implementation

• Lack of strategic guidance and knowledge gaps about Industry 4.0.

Readiness assessments can help SMEs address these critical challenges. The high investment stakes involved in Industry 4.0 transitions make it essential for SMEs to evaluate their preparedness before implementation (Mittal et al., 2019; Basl and Doucek, 2019). However, many business owners lack clarity on the benefits and implementation processes for such digital transformations (Sony and Naik, 2020; Canetta et al., 2018; Rajnai and Kocsis, 2018). Readiness assessments also offer an approach to enhance the competitiveness of an enterprise (Choi et al., 2017). These self-assessments measure factors like organizational understanding, awareness, and current practices. However, existing assessments are limited to IT readiness (Gökalp et al., 2017; Gill and VanBoskirk, 2016; Leyh et al., 2016; Menon et al., 2016) that necessitate a broader approach (Schumacher et al., 2016) given the potential uncertainties of smart manufacturing technology implementation (Akdil et al., 2018).

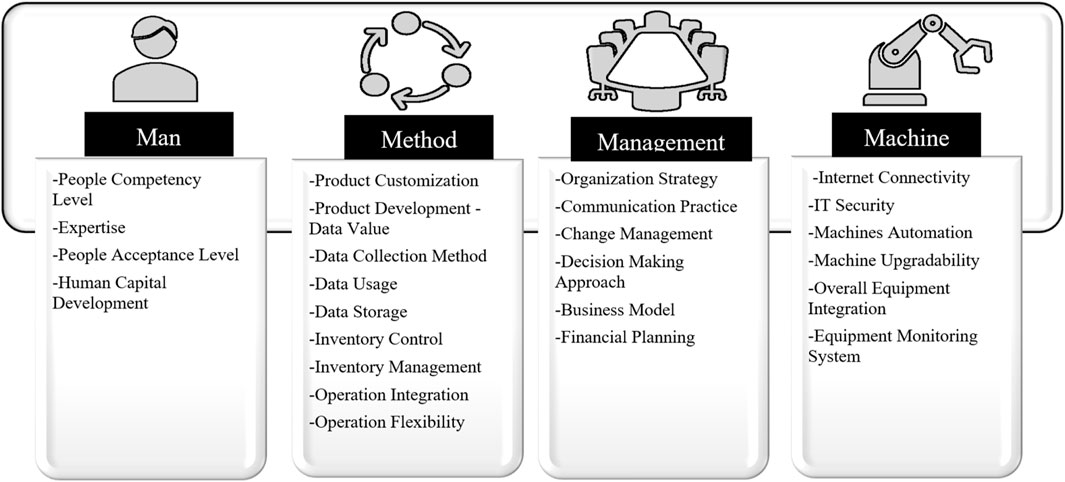

Currently, there is no universal standard for measuring Industry 4.0 readiness (Schumacher et al., 2016; Rajnai and Kocsis, 2018). Given the high investment and potential changes across organizational strategy, infrastructure, and worker adaptation, a comprehensive readiness model should address core areas like management, machines, methods, and (hu)man, which are referred to as 4M. This 4M framework is based on Ishikawa’s fishbone diagram and is widely used in management for solving problems (Knop and Mielczarek, 2018; Liliana, 2016).

2.3 4M framework for SMEs and smart manufacturing

In contrast to larger companies, SMEs are more prone to limited financial resources and constrained managerial capacity, often operating their businesses with smaller workforces. According to Hansen et al. (2024), SMEs still lack several competencies in terms of their technical, methodological, social, and personal dimensions. The 4M framework is considered well-suited in such instances as it can help SMEs foster accessible assessments. Here, the 4M framework acts as a comprehensive yet focused approach that provides structured assessment elements across all critical areas of smart manufacturing adoption; it is a holistic approach that serves as an effective tool for measuring readiness in the context of smart manufacturing transformation of SMEs. The four core dimensions play pivotal roles in helping SMEs advance toward smart manufacturing, especially when they have limited resources and unique operational constraints.

A. Management

Relevance: This element includes strategic alignment, leadership, and decision-making capabilities; it embeds top management commitment and promotes alignment of the limited resources of SMEs toward the demands of smart manufacturing.

Comparison with other models: Based on the reviewed models (Supplementary Appendix 1), most tools are largely IT centric and minimally address the managerial component. In contrast, the 4M framework ensures management readiness as a fundamental pillar by recognizing the influence of organizational change.

B. Machine

Relevance: This element incorporates equipment, IT infrastructures, and the capability for automation; it includes the ability of the machines and equipment of SMEs to adapt and integrate well via IoT devices and sensors.

Comparison with other models: Some models ultimately focus on IT readiness, where the machines and other relevant equipment are often neglected; the 4M framework offers an inclusive approach by incorporating the integrability of the machinery to achieve smart manufacturing readiness levels beyond IT infrastructure.

C. Method

Relevance: This element includes all operational processes and workflow integration; SMEs should gain sufficient knowledge to optimize their processes and could achieve alignment with new technologies by redesigning their methods for greater efficiency and adaptability. This element ensures easier re-engineering of the processes of SMEs for adopting smart manufacturing practices.

Comparison with other models: While some models are more attentive to the narrow goal of digital readiness, the 4M framework examines readiness through an operational lens; as this framework is pragmatically relevant to SMEs, it can gradually help them adapt their existing methods to incorporate smart manufacturing practices.

D. (Hu)man

Relevance: This element encompasses all people-centric resources by primarily focusing on human skills, the ability to accept changes, and adaptability toward new technologies and changes; it is a crucial element for SMEs owing to its nature to understand the capacity for extensive training when incorporating specialized talent. This element is important for identifying the skill gaps and training needs with respect to smart manufacturing technologies.

Comparison with other models: Most readiness models do not adequately examine the human dimension and its impacts on SMEs; the inclusion of this element in the 4M framework fosters smoother transition toward smart manufacturing.

Addressing the importance of the 4M framework ensures inclusive evaluations across the management, machine, method, and man dimensions that encapsulate the key needs of SMEs for smart manufacturing motivation. Moreover, the 4M framework flexibly facilitates SMEs to address their capabilities and strategic goals, making the assessment tool highly adaptable (Botha, 2018; Günther et al., 2020; Jamwal et al., 2023). Overall, the 4M framework addresses the challenges encountered by SMEs across managerial, technological, operational, and human resources. Similar findings reported by Amaral and Peças (2021) and Chonsawat and Sopadang (2020) indicate that the readiness assessments available for SMEs today may be skewed narrowly toward the area of technology; these works highlight and support the need for an assessment tool that covers lower readiness levels for SMEs.

The literature review presented herein reveals a clear need for a comprehensive and accessible smart manufacturing readiness assessment tool that is specifically tailored to SMEs. Existing models often lack standardization, focus narrowly on IT readiness, or fail to address the unique challenges of SMEs (Nair et al., 2019). The limitations of the current approaches, coupled with the significant potential benefits of smart manufacturing for SMEs, underscore the need for a new model. From the detailed review on readiness assessment models presented in Supplementary Appendix 1, it is evident that the existing models still lack an inclusive approach addressing the organizational, operational, and human factors that are critical for SMEs to transition to smart manufacturing. Additionally, the extant frameworks typically do not provide the flexibility required for SME-specific challenges, such as limited resources and contrary organizational structures.

To address the aforementioned limitations, Rahamaddulla et al. (2021) have invited study contributions and encourage selecting subindicators for each of the 4M dimensions to develop an Industry 4.0 readiness framework. They argue that the human dimension could emphasize the digital skills and training of employees; the machine dimension could include automation, IoT interoperability, and data analytics capability; the method dimension could consider process integration and workflow digitalization; and the management dimension could highlight strategic alignment and leadership commitment. Accordingly, the present study adds to the work initiated by Rahamaddulla et al. (2021) and uses the 4M framework to support SME readiness assessment in the Industry 4.0 era, thereby ensuring a comprehensive assessment of the key organizational dimensions affected by Industry 4.0 implementation. The goal of the present work is to offer SMEs a useful readiness assessment tool for making informed decisions about technology adoption and successful navigation of their transition to smart manufacturing. The methodology employed to achieve this goal is elaborated in the next section.

3 Research design

Our research entails various research strategies that are aligned with the DDR approach, which is a formative research type that is ideally suited for studies with small sample sizes and is characterized by the purpose (Akker et al., 1999). As emphasized by Richey and Klein (2007), the DDR method follows a comprehensive and systematic process encompassing the design, development, and evaluation of models, tools, or products. In this study, the DDR approach serves as the foundational framework for the creation of a readiness assessment tool tailored to the context of transition of automotive SMEs to E-smart manufacturing. As noted previously, this work unfolds in three distinct phases: an initial needs analysis of the assessment tool, followed by the pivotal design and development, and culminating in the validation of the developed tool. It is important to note that the main focus of this work is the second phase involving the design and development of the E-smart manufacturing readiness assessment tool, which we recognize as the central and most substantial component of the DDR approach.

The design and development phase represents a systematic process commencing with the identification and establishment of the model elements and components. Subsequently, it involves a confirmation process and culminates in the actual development of the model. The initial phase of searching and establishing these elements involves a comprehensive literature review, a series of group discussions, and benchmark visits to solidify the core components of the model. The components assembled during this preliminary stage are then organized and presented to an expert panel using the FDT. The consensus achieved by these experts is instrumental in shaping and refining the model. To illustrate this process, a detailed flowchart is presented in Figure 1 that delineates the intricate steps in the second phase of this research centering on the design and development of the readiness assessment tool. Furthermore, to validate the developed tool, five SMEs were recruited from the automotive sector of Malaysia to test the final tool and provide feedback. We also submitted the tool to the Malaysia Productivity Corporation (https://www.mpc.gov.my/) for review to ensure that the tool could actually help SMEs in the real world. The Malaysia Productivity Corporation was first established in 1962 as the National Productivity Corporation, a project between the federal government and the United Nations, and was made an autonomous body in 1966; it was renamed the National Productivity Corporation in 1991 and amended again in 2008 to emphasize its status as a government body for national productivity.

Notably, the application of the FDT serves a dual purpose: it facilitates expert consensus while simultaneously aiding in the selection and validation of model elements to ensure practicality and feasibility. Therefore, the selection of experts is vital and must be aligned with the specific context of the research. In this study, the experts were recruited from diverse backgrounds, including industrial practitioners, academicians, consultants, and government agency representatives, to ensure a comprehensive and holistic perspective. As noted by Niederberger and Spranger (2020), a group of experts representing a range of associated perspectives is more likely to yield valid results compared to relying solely on the judgment of a single expert, regardless of their individual expertise. According to the guidelines proposed by Jones and Twiss (1978), the ideal number of experts in a Delphi survey typically ranges from 10 to 50. In another FDT study conducted by Abhijith and Bijulal (2024), the authors chose 10 experts to complete the survey. However, Ocampo et al. (2018) argued that having an excess number of experts can result in dominant viewpoints, making it challenging to achieve uniformity in the study results. Therefore, following Ocampo et al. (2018) and Taylor (2020), we formed a panel of 15 experts to participate in our fuzzy Delphi survey.

The selection of these experts was in accordance with the particular context of this study (Mohd Jamil and Mat Noh, 2020). The experts are typically individuals who possess professional competence, skills, and extensive training in a specific field or subject (Swanson and Falkman, 1997). An individual can be considered a subject matter expert if they have consistently worked in a particular field for at least 5 years (Berliner, 2004; Jorm, 2015). In accordance with these criteria, careful consideration was given to the selection of experts in this study to ensure the suitability of their expertise. The following criteria were applied for expert selection:

1. Government agency representatives involved in policymaking related to SMEs and the automotive industry

2. Experienced high-tech industry players, including business owners, engineers, and managers, who were involved in smart manufacturing technology projects

3. Academic experts with knowledge in smart manufacturing subjects and experience in high-tech research

4. SME consultants and training providers with a track record of successful projects helping SMEs transition from conventional manufacturing to modern manufacturing practices.

Table 1 summarizes the demographic information of the 15 experts recruited for this study.

4 Fuzzy Delphi survey

The fuzzy Delphi survey was conducted to facilitate a detailed evaluation of each assessment element gathered through literature review, benchmark visits, and group discussions by experts. The primary objective of this process was to achieve consensus through expert opinions, which were collected via an online questionnaire. The questionnaire employed a 7-point Likert scale to ensure consistency and reliability of the expert responses. This choice aligns with the recommendations made by Chang et al. (2011), who argued that employing a 7-point scale could mitigate fuzzy disparities in the assessment of accepted items among the experts. Subsequently, the responses from the questionnaire were recorded, and the linguistic variables were transformed into fuzzy triangular numbers using Table 2 as a reference.

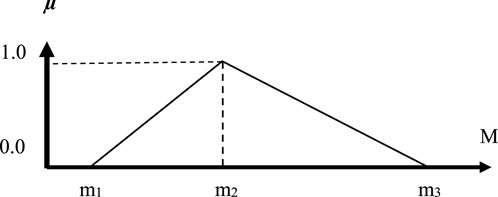

5 Fuzzy Delphi analysis technique

Based on the responses obtained from the expert survey, a Fuzzy triangulation calculation was performed to obtain the threshold value (d), consensus percentage, and fuzzy score before the construct of the tool can be “accepted” or “rejected.” The FDT results are expected to meet three rules before the expert decisions can be excepted: first, the average threshold value should be d ≤ 0.2; second, the overall threshold value d has to reach at least 75% before a construct can be accepted; third, the Fuzzy aggregate (A) score (α-cut) value must exceed 0.5. Figure 2 exhibits the graph of the Fuzzy number triangulation. In the FDT, there are two main approaches for analyzing the data: the first is the Fuzzy triangular number, and the second is the defuzzification process. Fuzzy triangular numbers consist of m1, m2, and m3 component values, where m1 is the minimum value, m2 indicates the most plausible value, and m3 is the maximum value.

The triangulation must obey two rules for process completion: first, the threshold value d must be ≤ 0.2 (Manakandan et al., 2017; Abalkina, 2024); second, the expert acceptance percentage of each element tested must be at least 75% for the consensus to be accepted. The threshold value d value is calculated as follows:

The second approach in the FDT is the defuzzification process, which is a ranking step to help researchers identify important constructs, components, or elements used in model development based on expert judgment. The ranking can be used to determine the priority of each element at the development stage. Any of the following three formulas can be used to perform the defuzzification:

i.

ii.

iii.

The fuzzy triangulation method is used to handle imprecise data by defining functions using three points: a lower limit, a peak (most likely) value, and an upper limit. Using these values, the threshold value d can be calculated to serve as a cutoff point for making decisions. This threshold is crucial for filtering out options or criteria that do not meet the required standards. The present study employs d values ≤ 0.2 based on the study by Chu and Hwang (2008). Next, the expert consensus percentage is considered before the results can be accepted. The opinions from multiple experts will be aggregated in this step to achieve consensus. This rule enhances the credibility and reliability of the decision-making processes. The expert consensus percentage provides a quantitative measure of confidence for the decision-making process. The collective wisdom from the experts must have a minimum consensus of 75% for each element before it can be accepted in the FDT. Finally, the fuzzy score A is obtained before an element can be absolutely accepted in the FDT; this is a comprehensive metric that allows decision makers to rank their alternatives by combining various factors into a single score and simplify the complex evaluation, which in turn helps to compare and prioritize options. In this study, we employed a calculation formula based on the studies by Abalkina (2024) and Tang and Wu (2010), where

6 Results

In this section, we present the results of the collective opinions of experts on the smart manufacturing readiness assessment criteria. Figure 3 provides an integrative visualization of the 4M framework, linking each dimension with its validated criteria and offering a holistic overview of the segmented results.

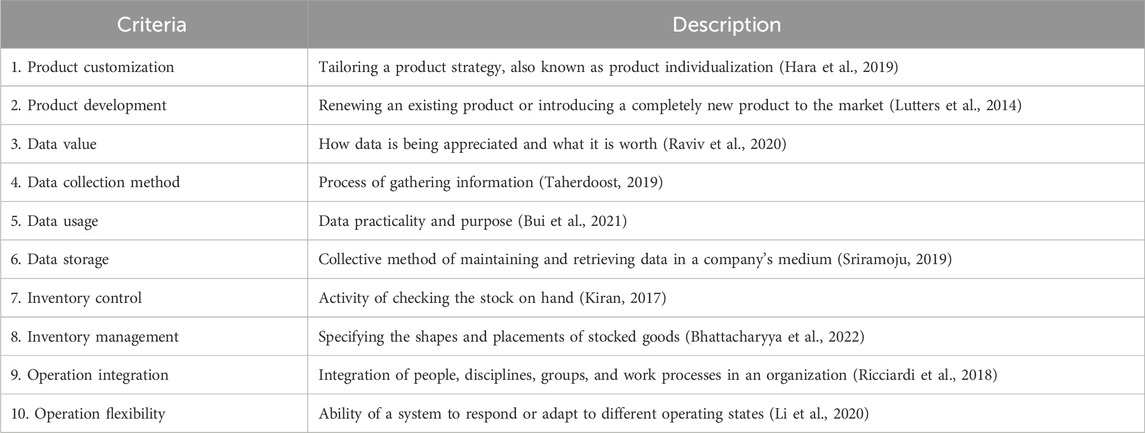

6.1 Fuzzy Delphi results on the method construct

The method element determines how an enterprise executes, builds, governs, and manages its operations; the experts were asked to evaluate 10 criteria under this construct (Table 3).

The threshold values, expert consensus percentages, defuzzification, and item positions for the method criteria are shown in Table 4.

Based on the results presented in Table 4, all criteria exceeded the threshold of d ≤ 0.2, except for the first criterion (i.e., product customization). These results prove that the entire list of criteria achieved the necessary expert consensus (Mohd et al., 2018). Although product customization exceeded the threshold, only one expert disagreed while the other experts unanimously or strongly agreed that this element should be included as a criterion under this construct. The method construct has an average threshold of d = 0.165, with an overall consensus average of 95.3% and average fuzzy score of 0.819. This means that all experts consensually agreed with all 10 criteria proposed as the items under this construct.

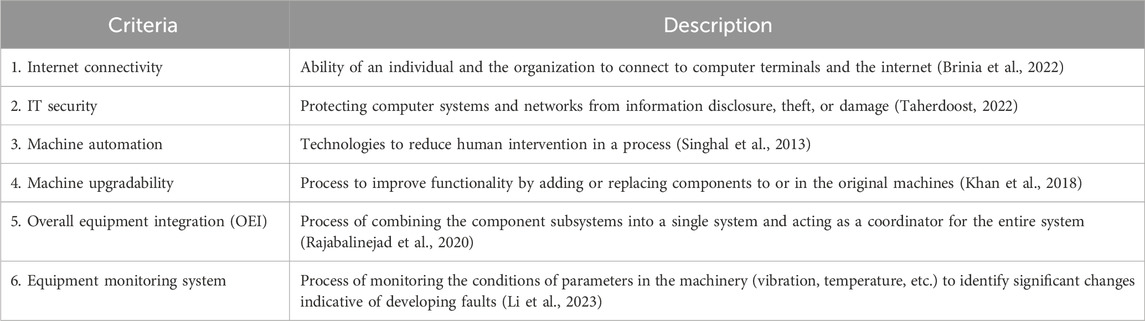

6.2 Fuzzy Delphi results on the machine construct

The machine construct represents how SMEs manage their internet connectivity and IT security; here, the experts were asked to evaluate six criteria (Table 5).

Table 6 shows the threshold and fuzzy score values of each of the elements in the machine construct, along with the individual expert consensus percentages.

Based on the results in Table 6, all criteria achieved the threshold of d ≤ 0.2, indicating that they have gained the necessary expert consensus (Mohd et al., 2018). The experts unanimously agreed that all of the proposed elements needed to be included as criteria under the machine construct.

6.3 Fuzzy Delphi results on the man construct

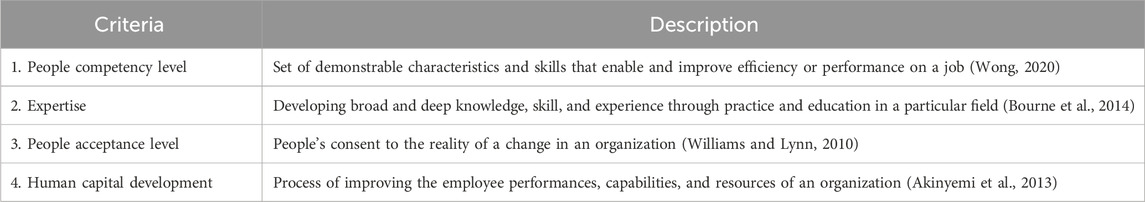

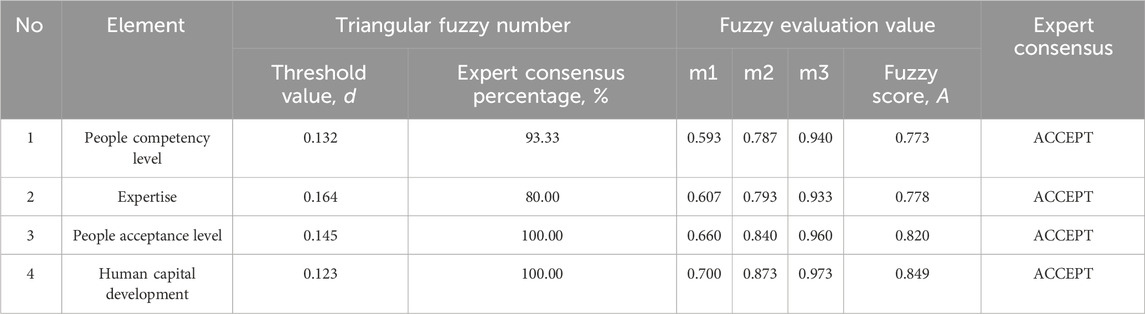

The man construct focuses on the roles of humans (employee) as change agents in an organization; here, experts were asked to evaluate four criteria (Table 7).

Table 8 shows the detailed results of the fuzzy Delphi analysis for the man construct.

Based on the results in Table 8, the expert opinions indicate the suitability of including the proposed criteria as part of the readiness assessment tool under the man construct. Two of the elements here have 100% consensus, whereas the other two only managed to reach 80% and 93.33%, respectively.

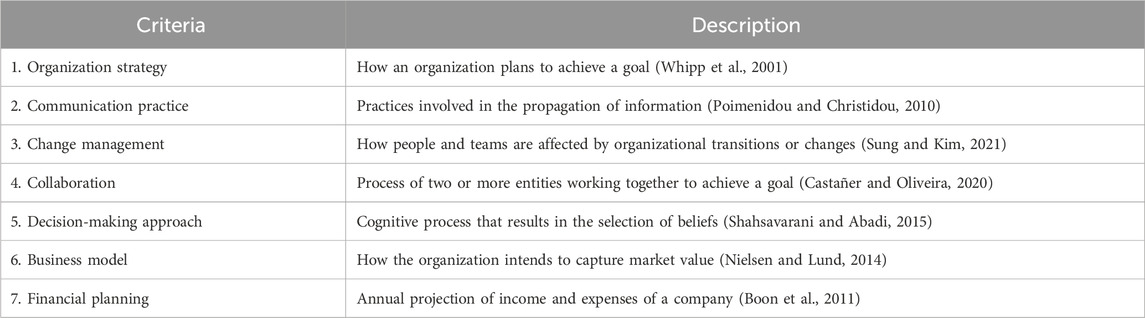

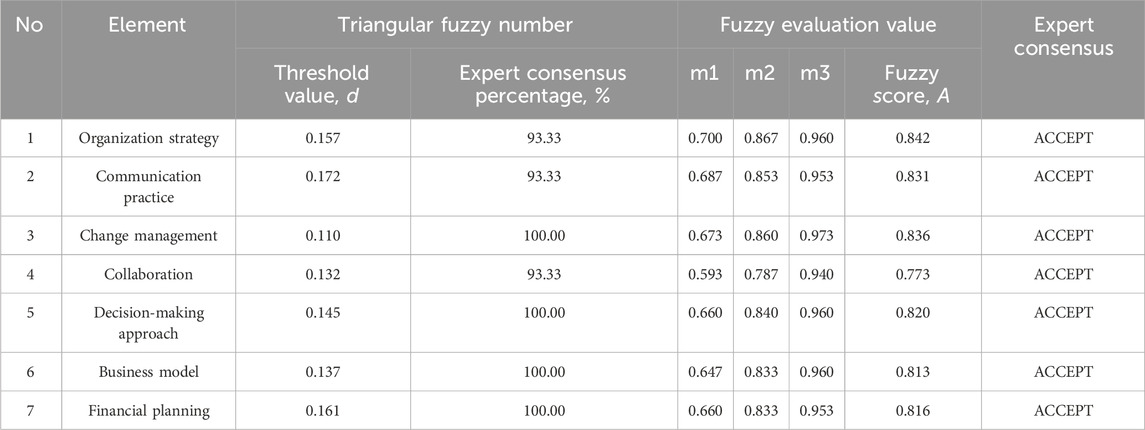

6.4 Fuzzy Delphi results on the management construct

The management construct focuses on collective efforts in assembling and organizing resources as well as integrating them effectively; here, the experts were asked to evaluate seven criteria (Table 9).

The detailed responses to the fuzzy Delphi analysis for the management construct are shown in Table 10, wherein the fuzzy triangulation results indicate that all criteria recorded fuzzy scores of A > 0.5.

From the results in Table 10, it is evident that the management construct has the highest consensus rates among all the constructs. Here, four out of seven criteria achieved 100% expert consensus, while the other three reached 93.33% consensus each. Although one expert scored individual threshold values of more than 0.2 for organization strategy and communication practice, the average thresholds for these subdomains range from 0.110 (minimum) to 0.172 (maximum). Therefore, it can be concluded that none of these items have exceeded the 0.2 threshold value. Regarding the fuzzy scores, the values range between 0.733 (low) and 0.836 (high), fulfilling the criteria of the FDT and reaching consensus on acceptance of these criteria as the measures of the management construct. To satisfy the requirement of empirical validation, the smart manufacturing readiness assessment tool developed herein was evaluated at five Malaysian SMEs in the automotive industry. These businesses participated in the validation phase to evaluate the usability, feasibility, and alignment of the tool with their particular requirements from a business perspective. To evaluate the practical applicability of the proposed tool in real-world settings, we used these case studies for comparisons with extant readiness assessment tools. The feedback from these five SMEs supports the feasibility of the proposed tool, which ensures that the tool not only considers the consensus of experts and professionals but also incorporates enough implementation feasibility feedback from the end users. To demonstrate the relevance and utility of the tool in assisting SMEs with their transition to smart manufacturing, the SMEs each completed an assessment of their readiness and received a detailed report on their progress.

Our research approach solicits and compiles feedback from a diverse panel of experts relevant to SMEs. Herein, we considered the inherent uncertainties and variabilities in SME environments while also reflecting expert consensus. Further, we integrated an additional feedback channel as a validation process. To ensure that the tool could actually help SMEs in the real world, we invited a team from the Malaysia Productivity Corporation to review and examine our tool and offer feedback. The response letter received from the team states that “the tool not only assesses the readiness of SMEs to adapt smart manufacturing practices but also helps identify possible issues that may arise, allowing SMEs to proactively address potential challenges and save a significant amount of time, effort, and resources that may otherwise be wasted.” The team also endorsed the proposed tool as an “invaluable resource for SMEs seeking success in their smart manufacturing initiatives.”

7 Conclusion

The main contribution of the present study is the development of readiness assessment criteria intended to measure the readiness levels of automotive SMEs in achieving a smart manufacturing status. The existing tools for gauging the readiness levels of SMEs are limited and often more suitable for large companies, while neglecting the specific requirements of SMEs. Many of these tools include criteria and constructs that are not relevant to SMEs, and the necessary functions are lacking in these tools. The E-smart manufacturing readiness assessment tool developed in this study fills this gap and serves as a self-assessment tool to guide SMEs in achieving readiness to transition to smart manufacturing practices. The proposed tool is a pioneering effort for transforming automotive SMEs into smart companies and utilizes the FDT as its foundation.

The tool emphasizes four fundamental areas of management (i.e., man, machine, method, and management) to provide practitioners with a clear framework for monitoring the readiness levels before embarking on smart manufacturing transformation. This tailored approach is suited to capture the nuanced readiness levels of smaller businesses undergoing smart manufacturing transformations. In contrast to existing assessment tools that frequently use complex terminology, the proposed E-smart manufacturing readiness assessment tool is intended to be easily understood by SMEs. Our tool has been specifically tailored to SME conditions and is expected to assist manufacturing SMEs, particularly those in Malaysia, in gaining a better understanding of the smart manufacturing initiative framework. Automotive SMEs in Malaysia typically operate as tier-two or tier-three suppliers (Wad, 2009; Awheda et al., 2014; Hudin et al., 2017) with little bargaining power and reliance on government assistance programs. Malaysian SMEs supply both local assemblers and international markets by frequently competing on cost and flexibility (Hashim, 2012; Razali et al., 2018). This creates an environment of hybrid dependency that influences how new technologies are adopted. Our E-smart manufacturing readiness assessment tool is specifically designed for Malaysia, but the framework is also expected to have broader applicability. The tool assists SMEs in anticipating and aligning with original-equipment-manufacturer-driven technological adoption in supplier-dominated environments. In more open and export-oriented environments like Europe, it can also help SMEs independently benchmark their readiness against global buyer requirements. Thus, the 4M-based criteria remain valid but may need to be contextualized to reflect local supplier–buyer dynamics.

Similarly, the insights gathered from the research are expected to support policymakers in formulating future policies aimed at assisting SMEs in crucial areas. Overall, our research contributes to the advancement of smart manufacturing adoption in the automotive SME sector while providing valuable guidance for both SMEs and policymakers. In addition to its current contributions, the practicality of this tool can be further tested in industries outside the automotive sector. By evaluating and comparing the results with the findings presented herein, the tool can be further enhanced and tailored to different industry contexts. Furthermore, extended development of the readiness assessment tool could involve converting it into assessment software, which would allow the inclusion of additional features like calculated recommendations for each level of readiness. These recommendations would provide SMEs with actionable insights on improving their readiness for smart manufacturing adoption.

Relying solely on expert opinions could undermine the validity of the proposed E-smart manufacturing readiness assessment tool; however, we successfully employed the FDT in this study to achieve consensus on the suggested criteria. Notwithstanding its value, expert consensus cannot replace the need for empirical validation, particularly from end users and subject matter experts. Herein, the FDT was supplemented with an empirical validation phase involving actual SMEs to alleviate concerns regarding reliance on expert opinions. This phase was considered essential to bridge any potential gaps between theoretical development and practical application, which would ensure that the tool remains effective for its intended users. This establishes a connection between the development and actual implementation of the tool in the real world. Future researchers should perform empirical evaluations of the tool in practical settings by incorporating insights from subject matter experts. The practical utility and comparative efficacy of the tool relative to the existing models could be enhanced through direct feedback from such evaluations. This iterative process will assist SMEs in their smart manufacturing transformation through a tool that is extensively utilized and rigorously validated for readiness assessments. For future research, it would be valuable to explore the effectiveness of the readiness assessment tool in different industries and regions to validate its applicability across various contexts and ensure usefulness for a broader range of SMEs. Additionally, further studies could focus on refining the criteria and constructs in the tool to better suit the needs of SMEs in different sectors. This could involve conducting more extensive surveys and consultations with industry experts to ensure the relevance and accuracy of the tool.

We suggest that future research could focus on piloting tools across various SMEs within the automotive sector as well as exploring the impacts of using the readiness assessment tool on the adoption of smart manufacturing practices by SMEs. The authors believe that broader empirical validations are necessary to test the tool. Longitudinal studies could track the progress of SMEs over time and assess how the tool contributes to their success in implementing smart manufacturing initiatives. Moreover, future studies could expand the assessment tool across various industries, refine criteria weighting through advanced methodologies, and integrate data analytics capabilities. Comparative studies with existing methods can also enhance understanding of the adaptability and practical efficacy in diverse SME contexts.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors without undue reservation.

Author contributions

SR: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Validation, Visualization, Writing – original draft, Writing – review and editing. SS: Conceptualization, Formal analysis, Methodology, Writing – original draft, Writing – review and editing. AO: Data curation, Formal analysis, Methodology, Writing – review and editing. AK: Data curation, Investigation, Writing – review and editing. ZL: Project administration, Supervision, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was funded by Universiti Malaysia Pahang Al-Sultan Abdullah under grant number RDU230307.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Correction note

A correction has been made to this article. Details can be found at: 10.3389/fmech.2025.1731677.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fmech.2025.1540287/full#supplementary-material

References

Abalkina, A. (2024). Challenges posed by hijacked journals in Scopus. J. Assoc. Inf. Sci. Technol. 75 (4), 395–422. doi:10.1002/asi.24855

Abdulaziz, Q. A., Mad Kaidi, H., Masrom, M., Hamzah, H. S., Sarip, S., Dziyauddin, R. A., et al. (2023). Developing an IoT framework for industry 4.0 in Malaysian SMEs: an analysis of current status, practices, and challenges. Appl. Sci. 13 (6), 3658. doi:10.3390/app13063658

Abhijith, R., and Bijulal, D. (2024). Heuristic biases influencing individual stock investment decisions: a hybrid fuzzy DELPHI-AHP-DEMATEL approach. J. Adv. Manage. Res. 21, 627–648. doi:10.1108/jamr-03-2024-0093

Ahadi, N., Monametsi, G., Sorooshian, S., and Virutamasen, P. (2023). “Industry 4.0 adoption in supply chain financing for small and medium enterprises: a systems theory approach,” in The global conference on entrepreneurship and the economy in an era of uncertainty (Springer), 321–334.

Akdil, K. Y., Ustundag, A., and Cevikcan, E. (2018). “Maturity and readiness model for industry 4.0 strategy,” in Industry 4.0: managing the digital transformation (Cham: Springer International Publishing), 61–94.

Akinyemi, G. M., Abiddin, N. Z., and Malaysia, P. (2013). Human capital developments an interdisciplinary approach for individual, organization advancement and economic improvement. Asian Soc. Sci. 9 (4). doi:10.5539/ass.v9n4p150

Akker, J., Branch, R. M., Gustafson, K., Nieveen, N., and Plomp, T. (1999). Design approaches and tools in education and training. Dordrecht, Netherlands: Springer Dordrecht.

Allioui, H., and Mourdi, Y. (2023). Unleashing the potential of AI: investigating cutting-edge technologies that are transforming businesses. Int. J. Comput. Eng. Data Sci. (IJCEDS) 3 (2), 1–12. Available online at: https://www.ijceds.com/ijceds/article/view/59.

Amaral, A., and Peças, P. (2021). A framework for assessing manufacturing SMEs Industry 4.0 maturity. Appl. Sci. 11 (13), 6127. doi:10.3390/app11136127

Awheda, A., Rahman, M. N. A., Ramli, R., and Arshad, H. (2014). Impediments of collaborative relationships in automotive SMEs in Malaysia. Appl. Mech. Mater. 663, 638–643. doi:10.4028/www.scientific.net/amm.663.638

Basl, J., and Doucek, P. (2019). A metamodel for evaluating enterprise readiness in the context of Industry 4.0. Information 10 (3), 89. doi:10.3390/info10030089

Berliner, D. C. (2004). Describing the behavior and documenting the accomplishments of expert teachers. Bull. Sci. Technol. Soc. 24 (3), 200–212. doi:10.1177/0270467604265535

Bhattacharyya, A., Chanu, A. I., and Dutta, S. (2022). A study on inventory management practices: a review. J. Posit. Sch. Psychol. 6 (2s), 587–601. Available online at: https://journalppw.com/index.php/jpsp/article/view/12280/7961.

Boon, T. H., Yee, H. S., and Hung, W. T. (2011). Financial literacy and personal financial planning in Klang valley, Malaysia. Int. J. Econ. Manage. 5 (1), 149–168. Available online at: https://www.researchgate.net/profile/Hui-Boon-Tan/publication/268183126_Financial_Literacy_and_Personal_Financial_Planning_in_Klang_Valley_Malaysia/links/54f1a0f40cf2b36214ac8bd5/Financial-Literacy-and-Personal-Financial-Planning-in-Klang-Valley-Malaysia.pdf.

Botha, A. P. (2018). Rapidly arriving futures: future readiness for Industry 4.0. South Afr. J. Ind. Eng. 29 (3), 148–160. doi:10.7166/29-3-2056

Bourne, L., Kole, J., and Healy, A. (2014). Expertise: defined, described, explained. Front. Psychol. 5, 186. doi:10.3389/fpsyg.2014.00186

Brinia, V., Selimi, P., Dimos, A., and Kondea, A. (2022). The impact of communication on the effectiveness of educational organizations. Educ. Sci. 12 (3), 170. doi:10.3390/educsci12030170

Bui, D., Yao, Y., Shin, K. G., Choi, J.-M., and Shin, J. (2021). Consistency analysis of data-usage purposes in mobile apps. Comput. Commun. Security, 2824–2843. doi:10.1145/3460120.3484536

Bumbarger, B. K. (2015). Readiness assessment to improve program implementation: shifting the lens to optimizing intervention design. Prev. Sci. 16 (8), 1118–1122. doi:10.1007/s11121-015-0591-6

Canetta, L., Barni, A., and Montini, E. (2018). “Development of a digitalization maturity model for the manufacturing sector,” in 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), 1–7. doi:10.1109/ICE.2018.8436292

Castañer, X., and Oliveira, N. (2020). Collaboration, coordination, and cooperation among organizations: establishing the distinctive meanings of these terms through a systematic literature review. J. Manage. 46 (6), 965–1001. doi:10.1177/0149206320901565

Chang, P.-L., Hsu, C.-W., and Chang, P.-C. (2011). Fuzzy Delphi method for evaluating hydrogen production technologies. Int. J. Hydrogen Energy 36 (21), 14172–14179. doi:10.1016/j.ijhydene.2011.05.045

Choi, S., Jung, K., and Ju, Y. L. (2017). Development of an assessment system based on manufacturing readiness level for smart manufacturing and supplier selection. Int. J. Comput. Appl. Technol. 56 (1), 87–98. doi:10.1504/ijcat.2017.086573

Chonsawat, N., and Sopadang, A. (2020). Defining SMEs’ 4.0 readiness indicators. Appl. Sci. 10 (24), 8998. doi:10.3390/app10248998

Chu, H.-C., and Hwang, G.-J. (2008). A Delphi-based approach to developing expert systems with the cooperation of multiple experts. Expert Syst. Appl. 34 (4), 2826–2840. doi:10.1016/j.eswa.2007.05.034

Erboz, G. (2017). “How to define industry 4.0: main pillars of industry 4.0” presented at the managerial trends in the development of enterprises in globalization era, Nitra, Slovak Republic. Available online at: https://www.researchgate.net/publication/326557388_How_To_Define_Industry_40_Main_Pillars_Of_Industry_40.

Fonseca, L. M. (2018). Industry 4.0 and the digital society: concepts, dimensions and envisioned benefits. Proc. Int. Conf. Bus. Excell. 12 (1), 386–397. doi:10.2478/picbe-2018-0034

Georgakopoulos, D., Jayaraman, P. P., Fazia, M., Villari, M., and Ranjan, R. (2016). Internet of Things and edge cloud computing roadmap for manufacturing. IEEE Cloud Comput. 3 (4), 66–73. doi:10.1109/MCC.2016.91

Gill, M., and VanBoskirk, S. (2016). “The digital maturity model 4.0,” in Benchmarks: digital transformation playbook (Cambridge, MA). Available online at: http://forrester.nitro-digital.com/pdf/Forrester-s%20Digital%20Maturity%20Model%204.0.pdf.

Gökalp, E., Şener, U., and Eren, P. E. (2017). “Development of an assessment model for industry 4.0: industry 4.0-MM,” in Software process improvement and capability determination (Cham: Springer International Publishing), 128–142.

Günther, S., Reiner, A., Roman, D., Antonio, K., and Michael, H. (2020). “Industrie 4.0 maturity index,” in Managing the digital Transformation of companies – UPDATE 2020. Munich, Germany: acatech – national academy of science and engineering.

Hansen, A. K., Christiansen, L., and Lassen, A. H. (2024). Technology isn't enough for Industry 4.0: on SMEs and hindrances to digital transformation. Int. J. Prod. Res. 63, 6585–6605. doi:10.1080/00207543.2024.2305800

Hara, T., Sakao, T., and Fukushima, R. (2019). Customization of product, service, and product/service system: what and how to design. Mech. Eng. Rev. 6 (1), 18-00184–00184. doi:10.1299/mer.18-00184

Hashim, F. (2012). Challenges for the internationalization of SMEs and the role of government: the case of Malaysia. J. Int. Bus. Econ. 13 (1), 97–122. doi:10.51240/jibe.2012.1.5

Haug, A., Pedersen, S. G., and Arlbjørn, J. S. (2011). IT readiness in small and medium-sized enterprises. Ind. Manage. Data Syst. 111 (4), 490–508. doi:10.1108/02635571111133515

Horvat, D., Stahlecker, T., Zenker, A., Lerch, C., and Mladineo, M. (2018). A conceptual approach to analysing manufacturing companies’ profiles concerning Industry 4.0 in emerging economies. Procedia Manuf. 17, 419–426. doi:10.1016/j.promfg.2018.10.065

Hudin, N. S., Hamid, A. B. A., Chin, T. A., and Habidin, N. F. (2017). Exploring supply chain risks among Malaysian automotive SMEs. Int. E-J. Adv. Soc. Sci. 3 (8), 666–674. Available online at: https://dergipark.org.tr/en/download/article-file/339835.

Industry4WRD (2018). Available online at: http://www.maa.org.my/pdf/NAP_2014_policy.pdf.

Jamwal, A., Agrawal, R., and Sharma, M. (2023). Challenges and opportunities for manufacturing SMEs in adopting Industry 4.0 technologies for achieving sustainability: empirical evidence from an emerging economy. Oper. Manage. Res. 18, 718–743. doi:10.1007/s12063-023-00428-2

Jones, H., and Twiss, B. C. (1978). Forecasting technology for planning decisions. London, UK: The Macmillan Press.

Jones, M., Zarzycki, L., and Murray, G. (2019). “Does industry 4.0 pose a challenge for the SME machine builder? A case study and reflection of readiness for a UK SME.” Cham: Springer International Publishing, 183–197. doi:10.1007/978-3-030-05931-6_17

Jorm, A. F. (2015). Using the Delphi expert consensus method in mental health research. Aust. N. Z. J. Psychiatry 49 (10), 887–897. doi:10.1177/0004867415600891

Kang, H. S., Lee, J. Y., Choi, S., Kim, H., Park, J. H., Son, J. Y., et al. (2016). Smart manufacturing: past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Green Technol. 3 (1), 111–128. doi:10.1007/s40684-016-0015-5

Khan, M. A., Mittal, S., West, S., and Wuest, T. (2018). Review on upgradability – a product lifetime extension strategy in the context of product service systems. J. Clean. Prod. 204, 1154–1168. doi:10.1016/j.jclepro.2018.08.329

Kiran, D. R. (2017). Terminology used in Japanese management practices. Total Qual. Manage. 2002, 499–511. doi:10.1016/b978-0-12-811035-5.00036-2

Knop, K., and Mielczarek, K. (2018). Using 5W-1H and 4M methods to analyse and solve the problem with the visual inspection process - case study. MATEC Web Conf. 183, 03006. doi:10.1051/matecconf/201818303006

Leyh, C., Bley, K., Schäffer, T., and Forstenhäusler, S. (2016). “SIMMI 4.0 - a maturity model for classifying the enterprise-wide it and software landscape focusing on Industry 4.0,” in 2016 federated conference on computer science and information systems (FedCSIS) (NY, United States: IEEE), 11–14.

Li, P., Wang, Y., Ji, H., Zhao, J., Song, G., Wu, J., et al. (2020). Operational flexibility of active distribution networks: definition, quantified calculation and application. Int. J. Electr. Power Energy Syst. 119, 105872. doi:10.1016/j.ijepes.2020.105872

Li, Q., Yang, Y., and Jiang, P. (2023). Remote monitoring and maintenance for equipment and production lines on industrial internet: a literature review. Machines 11 (1), 12. doi:10.3390/machines11010012

Liliana, L. (2016). A new model of Ishikawa diagram for quality assessment. IOP Conf. Ser. Mater. Sci. Eng. 161 (1), 012099. doi:10.1088/1757-899X/161/1/012099

Lin, F., Chen, C., Zhang, N., Guan, X., and Shen, X. (2016). Autonomous channel switching: towards efficient spectrum sharing for industrial wireless sensor networks. IEEE Internet Things J. 3 (2), 231–243. doi:10.1109/JIOT.2015.2490544

Lom, M., Pribyl, O., and Svitek, M. (2016). “Industry 4.0 as a part of smart cities,” in 2016 smart cities symposium Prague (SCSP), 1–6. doi:10.1109/SCSP.2016.7501015

Lu, Y. (2017). Industry 4.0: a survey on technologies, applications and open research issues. J. Ind. Inf. Integration 6, 1–10. doi:10.1016/j.jii.2017.04.005

Lutters, E. (2014). “Product development,” in CIRP encyclopedia of production engineering. Editors L. Laperrière, and G. Reinhart (Berlin, Heidelberg: Springer Berlin Heidelberg), 991–992.

Machado, C. G., Winroth, M. P., and Ribeiro da Silva, E. H. D. (2020). Sustainable manufacturing in Industry 4.0: an emerging research agenda. Int. J. Prod. Res. 58 (5), 1462–1484. doi:10.1080/00207543.2019.1652777

Manakandan, S. K., Ismail, R., Mohd Ridhuan, M., and Ragunath, P. (2017). Pesticide applicators questionnaire content validation: a fuzzy Delphi method. Med. J. Malay. 72, 228–235. Available online at: https://www.semanticscholar.org/paper/Pesticide-applicators-questionnaire-content-A-fuzzy-Manakandan-Ismail/370579ae8fd4a57259c55270043cb11f5911db95.

Menon, K., Kärkkäinen, H., and Lasrado, L. (2016). “Towards a maturity modeling approach for the implementation of industrial internet,” in Proceedings of the 20th Pacific Asia conference on information systems (NY, United States PACIS 2016), Chiayi, Taiwan (Association for Information Systems AIS) Available online at: https://aisel.aisnet.org/pacis2016/38.

Mittal, S., Khan, M. A., Romero, D., and Wuest, T. (2018). A critical review of smart manufacturing and Industry 4.0 maturity models: implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 49, 194–214.

Mittal, S., Khan, M. A., Romero, D., and Wuest, T. (2019). Smart manufacturing: characteristics, technologies and enabling factors. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 233 (5), 1342–1361. doi:10.1177/0954405417736547

Mohd, R., Siraj, S., and Hussin, Z. (2018). Aplikasi kaedah fuzzy Delphi dalam pembangunan modul pengajaran pantun Melayu berasaskan maksud al-Quran mengenai keindahan flora, fauna dan langit tingkatan 2. J. Pendidik. Bhs. Melayu 8 (3), 57–67. Available online at: https://spaj.ukm.my/jpbm/index.php/jpbm/article/view/184.

Mohd Jamil, M., and Mat Noh, N. (2020). Kepelbagaian Metodologi dalam penyelidikan reka Bentuk dan pembangunan. Bangi, MY: qaisar prestige resources.

Mustapha, N. M., and Sorooshian, S. (2019). SME performance measurement: a technical review of Malaysia. Int. J. Innov. Technol. Explor. Eng. 8 (8), 1808–1812. Available online at: https://www.ijitee.org/wp-content/uploads/papers/v8i8/H6846068819.pdf.

Mustapha, N. M., Sorooshian, S., and Azizan, N. A. (2016). “Innovation and growth: why Malaysian SME needs a new performance measurement system,” in Conference proceedings of the 2016 United States association for small business and entrepreneurship, DI1.

Nair, J., Chellasamy, A., and Singh, B. B. (2019). Readiness factors for information technology adoption in SMEs: testing an exploratory model in an Indian context. J. Asia Bus. Stud. 13 (4), 694–718. doi:10.1108/jabs-09-2018-0254

Niederberger, M., and Spranger, J. (2020). Delphi technique in health sciences: a map. Front. Public Health Methods 8, 457. doi:10.3389/fpubh.2020.00457

Nielsen, C., and Lund, M. (2014). “An introduction to business models,” in The basics of business models: ventus, 8–20.

Ocampo, L., Ebisa, J. A., Ombe, J., and Geen Escoto, M. (2018). Sustainable ecotourism indicators with fuzzy Delphi method – a Philippine perspective. Ecol. Indic. 93, 874–888. doi:10.1016/j.ecolind.2018.05.060

Piccarozzi, M., Aquilani, B., and Gatti, C. (2018). Industry 4.0 in management studies: a systematic literature review. Sustainability 10 (10), 3821. doi:10.3390/su10103821

Poimenidou, M., and Christidou, V. (2010). Communication practices and the construction of meaning: science activities in the kindergarten. Creat. Educ. 02, 81–92. doi:10.4236/ce.2010.12013

Rahamaddulla, S. R. B., Leman, Z., Baharudin, B. H. T. B., and Ahmad, S. A. (2021). Conceptualizing smart manufacturing readiness-maturity model for small and medium enterprise (SME) in Malaysia. Sustainability 13 (17), 9793. doi:10.3390/su13179793

Rajabalinejad, M., van Dongen, L., and Ramtahalsing, M. (2020). Systems integration theory and fundamentals. Saf. Reliab. 39 (1), 83–113. doi:10.1080/09617353.2020.1712918

Rajnai, Z., and Kocsis, I. (2018). “Assessing industry 4.0 readiness of enterprises,” in 2018 IEEE 16th World Symposium on Applied Machine Intelligence and Informatics (SAMI). doi:10.1109/SAMI.2018.8324844

Rauch, E., Vickery, A. R., Brown, C. A., and Matt, D. T. (2020). “SME requirements and guidelines for the design of smart and highly adaptable manufacturing systems,” in Industry 4.0 for SMEs: challenges, opportunities and requirements. Editors D. T. Matt, V. Modrák, and H. Zsifkovits (Cham: Springer International Publishing), 39–72.

Raviv, N., Jain, S., and Bruck, J. (2020). “What is the value of data? On mathematical methods for data quality estimation,” in 2020 IEEE International Symposium on Information Theory (ISIT), 2825–2830. doi:10.1109/ISIT44484.2020.9174311

Razali, R., Saraih, U. N., Shaari, M. S., Abd Rani, M. J., and Abashah, A. (2018). “The influences of effectiveness, competitive advantages and market accessibility on SME performance in Malaysia,” 150. Kuala Lumpur, Malaysia: EDP Sciences. doi:10.1051/matecconf/201815005023

Ricciardi, F., Zardini, A., and Rossignoli, C. (2018). Organizational integration of the IT function: a key enabler of firm capabilities and performance. J. Innov. Know. 3 (3), 93–107. doi:10.1016/j.jik.2017.02.003

Richey, R. C., and Klein, J. D. (2007). Design and development research: methods, strategies, and issues. 1st ed. New York, NY: Routledge.

Rockwell Automation, I. (2014). “How ready is your company to connect people, processes, and technologies for bigger profits?,” in The connected enterprise maturity model (Milwaukee, WI: Inc).

Rüßmann, M. (2015). “Industry 4.0: the future of productivity and growth in manufacturing industries,” in Digital transformation. Available online at: https://www.bcg.com/publications/2015/engineered_products_project_business_industry_4_future_productivity_growth_manufacturing_industries.

Schaupp, E., Abele, E., and Metternich, J. (2017). Potentials of digitalization in tool management. Procedia CIRP 63, 144–149. doi:10.1016/j.procir.2017.03.172

Schumacher, A., Erol, S., and Sihn, W. (2016). A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP 52, 161–166. doi:10.1016/j.procir.2016.07.040

Shahsavarani, A. M., and Abadi, E. A. M. (2015). The bases, principles, and methods of decision-making: a review of literature. Int. J. Med. Rev. 2 (1), 214–225. Available online at: https://www.ijmedrev.com/article_68259.html.

Singhal, K., Agrawal, V. K., and Liberatore, M. J. (2013). “Automation in manufacturing and services,” in Encyclopedia of operations research and management science. Editors S. I. Gass, and M. C. Fu (Boston, MA: Springer US), 88–95.

Sme, M. Y. (2019).“Corporation Malaysia,” in Small and medium enterprises. Malaysia: SME Corporation. Available online at: https://www.smecorp.gov.my/index.php/en/small-and-medium-sized-enterprises.

Sony, M., and Naik, S. (2020). Key ingredients for evaluating Industry 4.0 readiness for organizations: a literature review. Benchmarking Int. J. 27 (7), 2213–2232. doi:10.1108/BIJ-09-2018-0284

Sorooshian, S. (2021). Implementation of an expanded decision-making technique to comment on Sweden readiness for digital tourism. Systems 9 (3), 50. doi:10.3390/systems9030050

Sorooshian, S. (2017). Adaptation of a business performance measurement system for Malaysian smaller enterprises. Quality-Access Success 18 (157).

Sorooshian, S., and Panigrahi, S. (2020). Impacts of the 4th industrial revolution on industries. Walailak J. Sci. Technol. (WJST) 17 (8), 903–915. doi:10.48048/wjst.2020.7287

Sorooshian, S., and Suffian, N. I. A. (2017). Small and medium enterprises’ risk modelling. Int. Rev. Manage. Market. 7 (2), 197–201. Available online at: https://www.econjournals.com/index.php/irmm/article/view/4107.

Sriramoju, S. (2019). A comprehensive review on data storage. Int. J. Recent Technol. Eng. 6 (5), 236–241. doi:10.32628/IJSRST

Sufian, A. T., Abdullah, B. M., Ateeq, M., Wah, R., and Clements, D. (2021). Six-gear roadmap towards the smart factory. Appl. Sci. 11 (8), 3568. doi:10.3390/app11083568

Sung, W., and Kim, C. (2021). A study on the effect of change management on organizational innovation: focusing on the mediating effect of members’ innovative behavior. Sustainability 13 (4), 2079. doi:10.3390/su13042079

Swanson, R. A., and Falkman, S. K. (1997). Training delivery problems and solutions: identification of novice trainer problems and expert trainer solutions. Hum. Resour. Dev. Q. 8 (4), 305–314. doi:10.1002/hrdq.3920080406

Taherdoost, H. (2019). What is the best response scale for survey and questionnaire design: review of different lengths of rating scale/attitude scale/Likert scale. Int. J. Acad. Res. Manage. 8 (1), 1–10. Available online at: https://hal.science/hal-02557308/.

Taherdoost, H. (2022). Cybersecurity vs. information security. Procedia Comput. Sci. 215, 483–487. doi:10.1016/j.procs.2022.12.050

Tang, C.-W., and Wu, C.-T. (2010). Obtaining a picture of undergraduate education quality: a voice from inside the university. High. Educ. 60, 269–286. doi:10.1007/s10734-009-9299-5

Tao, F., Qi, Q., Liu, A., and Kusiak, A. (2018). Data-driven smart manufacturing. J. Manuf. Syst. 48, 157–169. doi:10.1016/j.jmsy.2018.01.006

Tavana, M., Sorooshian, S., Ashrafidehkordi, R., and Mina, H. (2024). A readiness assessment model for human systems management digitalization in industrial organizations. J. Ind. Prod. Eng. 42, 47–64. doi:10.1080/21681015.2024.2377183

Taylor, E. (2020). We agree, don’t we? The Delphi method for health environments research. HERD Health Environ. Res. Des. J. 13 (1), 11–23. doi:10.1177/1937586719887709

Vaidya, S., Ambad, P., and Bhosle, S. (2018). Industry 4.0 – a glimpse. Procedia Manuf. 20, 233–238. doi:10.1016/j.promfg.2018.02.034

Varriale, V., Cammarano, A., Michelino, F., and Caputo, M. (2023). Critical analysis of the impact of artificial intelligence integration with cutting-edge technologies for production systems. J. Intell. Manuf. 36, 61–93. doi:10.1007/s10845-023-02244-8

Wad, P. (2009). The automobile industry of southeast Asia: Malaysia and Thailand. J. Asia Pac. Econ. 14 (2), 172–193. doi:10.1080/13547860902786029

Whipp, R. (2001). “Strategy: organizational,” in International encyclopedia of the social and behavioral sciences. Editors N. J. Smelser, and P. B. Baltes (Oxford: Pergamon), 15151–15154.

Williams, J. C., and Lynn, S. J. (2010). Acceptance: an historical and conceptual review. Imagination Cognition Personality 30 (1), 5–56. doi:10.2190/IC.30.1.c

Wong, S.-C. (2020). Competency definitions, development and assessment: a brief review. Int. J. Acad. Res. Progressive Educ. Dev. 9 (3), 95–114. doi:10.6007/IJARPED/v9-i3/8223

Wong, A. P. H., and Kee, D. M. H. (2022). Driving factors of industry 4.0 readiness among manufacturing SMEs in Malaysia. Information 13 (12), 552. doi:10.3390/info13120552

Yang, T., Xun, J., and Chong, W. K. (2022). Complementary resources and SME firm performance: the role of external readiness and E-commerce functionality. Ind. Manage. Data Syst. 122 (4), 1128–1151. doi:10.1108/imds-01-2022-0045

Keywords: smart manufacturing, industrial revolution, readiness assessment, fuzzy Delphi technique, small and medium enterprise (SME)

Citation: Rahamaddulla SR, Sorooshian S, Osman AA, Kamar ANN and Leman Z (2025) Designing an E-smart manufacturing readiness assessment tool for small and medium automotive businesses. Front. Mech. Eng. 11:1540287. doi: 10.3389/fmech.2025.1540287

Received: 05 December 2024; Accepted: 17 September 2025;

Published: 20 October 2025; Corrected: 10 December 2025

Edited by:

Jiewu Leng, Guangdong University of Technology, ChinaReviewed by:

Jian Zhang, Shantou University, ChinaJuil Kim, Korea Institute of S&T Evaluation and Planning, Republic of Korea

Copyright © 2025 Rahamaddulla, Sorooshian, Osman, Kamar and Leman. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Shahryar Sorooshian, c2hhaHJ5YXIuc29yb29zaGlhbkBndS5zZQ==

Syed Radzi Rahamaddulla

Syed Radzi Rahamaddulla Shahryar Sorooshian

Shahryar Sorooshian Azim Azuan Osman

Azim Azuan Osman Ahmad Nazif Noor Kamar

Ahmad Nazif Noor Kamar Zulkiflle Leman

Zulkiflle Leman