- 1Department of Civil Engineering, School of Engineering, Kyushu University, Fukuoka, Japan

- 2Department of Civil Engineering, Universitas Malikussaleh, Lhokseumawe, Indonesia

- 3Urban Institute, Kyushu University, Fukuoka, Japan

Hydrogen is a low or zero-carbon energy source that is considered the most promising and potential energy carrier of the future. In this study, the energy sources, feedstocks, and various methods of hydrogen production from power generation are comparatively investigated in detail. In addition, this study presents an economic assessment to evaluate cost-effectiveness based on different economic indicators, including sensitivity analysis and uncertainty analysis. Proton exchange membrane fuel cell (PEMFCs) technology has the most potential to be developed compared to several other technologies. PEMFCs have been widely used in various fields and have advantages (i.e., start-up, zero-emissions, high power density). Among the various sources of uncertainty in the sensitivity analysis, the cost estimation method shows inflationary deviations from the proposed cost of capital. This is due to the selection process and untested technology. In addition, the cost of electricity and raw materials, as the main factors that are unpredictable.

Introduction

Hydrogen is a low or zero-carbon energy source that is considered the most promising and potential energy carrier of the future (Hanley et al., 2018). The current global demand for pure hydrogen is estimated to be around 70 million tons (Bourne, 2012), whereas the global hydrogen demand is expected to reach more than 300 million tons in 2050 (International Energy Agency., 2015). It has been forecasted that hydrogen will be a leading change in the global energy system toward a sustainable energy system (Staffell et al., 2019). Hydrogen can be produced from renewables, such as hydro, wind, wave, solar, biomass, and geothermal, as well as non-renewables such as coal, natural gas, and nuclear energy sources. Due to its energy carrier's nature, hydrogen offers high flexibility because it is easily converted to electricity in fuel cells for power generation, transportation, etc., (Hosseini and Wahid, 2016). In addition, hydrogen has the potential to deliver economically viable, monetarily, socially, and energy-efficient solutions to challenges related to the rising global energy demand, such as global warming (Dutta, 2014).

Power generation from renewable energy sources has been discovered and studied for decades and has been implemented on a large scale in many countries (IEA., 2016). Renewable energy is the fastest-growing source of electricity generation, and it has been predicted that its share will increase to 39% by 2050. Economic considerations are vital to evaluate the feasibility of an energy system while providing clear and cost-effective criteria. Techno-economic feasibility assessment of a particular technology considers several aspects such as technological appropriateness, economic viability, and financial incentives (Jamil et al., 2012; Rajendran and Murthy, 2019). In specific, techno-economic and sensitivity analysis of the hydrogen production methods is needed to improve the economic aspects of hydrogen. Among others will substantially impact future hydrogen production project designs and the development of innovative approaches to cut total production costs to make the fuel more affordable (Yukesh Kannah et al., 2021).

Although there have been several recent systematic reviews of the techno-economic assessment of hydrogen production, they have not principally been in the context of the techno-economic assessment of various hydrogen production methods of power generation. First (Yukesh Kannah et al., 2021), reviewed the sensitivity of various hydrogen production processes, such as (i) thermochemical conversion (e.g., pyrolysis, gasification, and steam reforming of natural gas), (ii) electrolysis water, (iii) renewable liquid reforming, and (iv) biochemical conversion. In terms of economics, steam reforming of natural gas is an economical and effective method for hydrogen production, as it has low operational (70 to 80%), feedstock (0.3 USD/kg H2), and production (1.25 to 3.50 USD/kg H2) costs. Second (El-Emam and Özcan, 2019), highlighted the techno-economic of hydrogen production and the environmental aspect of selected routes. The study found that geothermal, biomass, and nuclear-driven electrolysis and thermochemical technologies may replace conventional methods for hydrogen generation. Third Abe et al. (2019), viewed hydrogen as an appropriate long-term energy carrier for the economy. Solid-stage storage systems based on metal hybrids are a promising alternative to storing hydrogen in a hydrogen-powered system. Metal hybrids cannot store large quantities of hydrogen and are unable to release hydrogen at low temperatures.

Therefore, the main focus of our review discusses various hydrogen production methods, including their techno-economic aspects, sensitivity analysis, and uncertainty analysis. In addition, the current study addresses the following research question: “What are the economic performance indicators of the hydrogen energy systems for power generation?” This study aims to determine the economic performance indicators of hydrogen energy systems for power generation.

The remainder of this paper is organized as follows. Section Methods—systematic review of the literature introduces the method systematic of the literature review. Section Results presents the main results, including feedstock, hydrogen production methods, techno-economic performance, sensitivity, and uncertainty analyses. Finally, Section Discussion contains the discussion.

Methods—systematic review of the literature

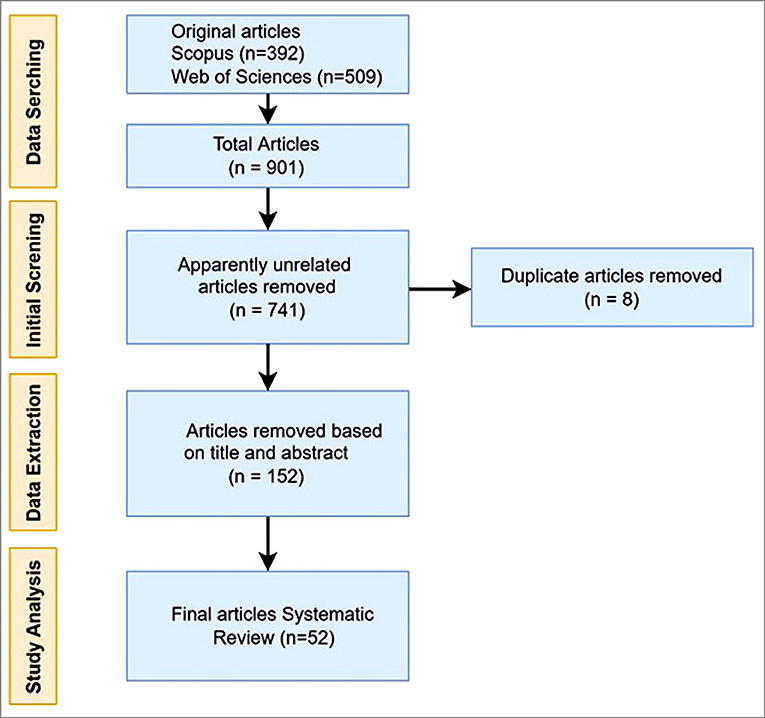

The general systematic review of the literature is carried out based on the method suggested by Tranfield et al. (2003), Thürer et al. (2018) for retrieving and selecting published data sets from Scopus and the Web of Science (WoS). The primary goal is to find and choose articles that describe hydrogen production methods, power generation, and techno-economic performance indicators. The articles are gathered by conducting a thorough search of Scopus and the WoS. The selection of articles is based on the title, keywords, abstracts, highlights, and type of document. This study uses different keywords for the search, such as “economic simulation AND hydrogen OR cost energy” in Scopus and “hydrogen OR H2 AND economic simulation OR energy cost” in the WoS. The document type is restricted to articles and reviews, excluding conference papers and books. In addition, the publication year is restricted to 2000–2020.

The selected articles are those that are relevant to the topic of this review and are grouped based on the quality of the research, that is, whether the article answers a series of questions related to the research and describes the facts based on real research scenarios. The analysis is carried out based on energy sources, feedstock, various hydrogen production processes, technique production, power generation, techno-economics in commercialization, and the economics of various hydrogen production processes. The following research questions are added based on the various researches and the analysis of articles:

• What is the source or primary energy of hydrogen production?

• What is the feedstock of hydrogen production?

• What are the types of hydrogen production methods?

• What is the technique of hydrogen conversion?

• What are the types of hydrogen production methods for power generation?

• What are the economic performance indicators of the hydrogen energy system for power generation?

The original sample of 901 articles comprises 392 articles in Scopus and 509 articles in the WoS (eight articles were removed because they were duplicates). After excluding apparently unrelated articles, that is, articles that are not related to hydrogen production and techno-economic, the number was reduced to 741 articles. The high number of unrelated articles is due to the use of the common keyword hydrogen. The articles were further reduced by 152 after screening them based on title and abstract. Finally, the total number articles that are used for the analysis is 52 (Figure 1).

Results

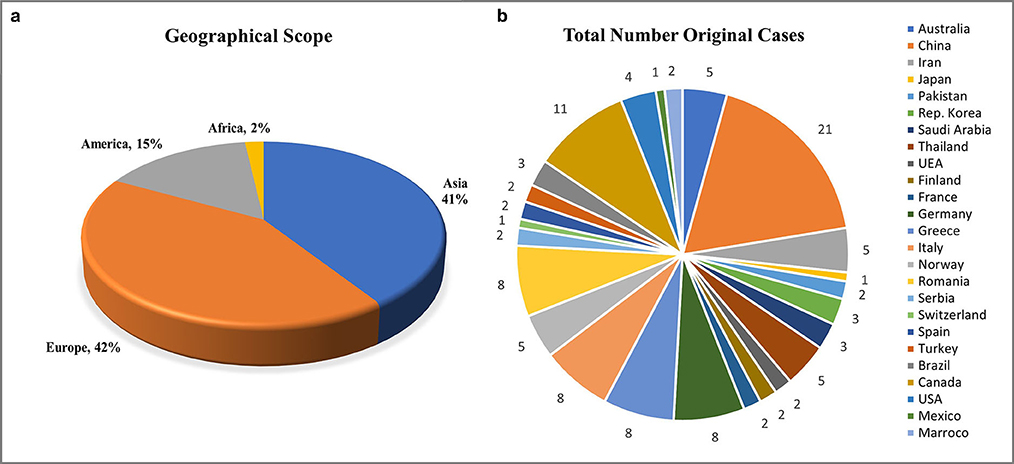

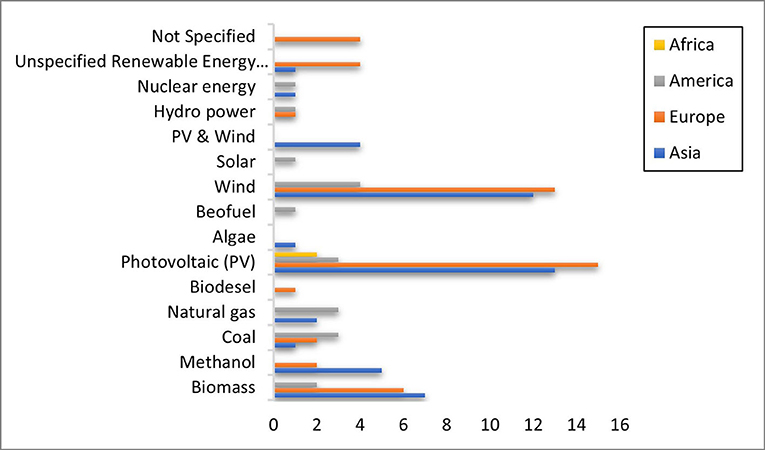

The review results of the techno-economic assessment of various hydrogen production are obtained from 116 case studies, which were mostly about countries in Europe (48/166) (Figures 2a,b). The country-wise distribution is as follows: Italy (8/48), Greece (8/48), Germany (8/48), Romania (8/48), Norway (5/48), France (2/48), Finland (2/48), Turkey (2/48), Spain (2/48), Switzerland (1/48), and Serbia (1/48). The country-wise distribution of the techno-economic assessment of various hydrogen production studies on Asia (42/116) is as follows: China (21/42), Iran (5/42), Thailand (5/42), Republic of Korea (3/42), Saudi Arabia (3/42), Pakistan (2/47), and UEA (2/42), and that of the American continent is 19/116, including Canada (11/19), USA (4/19), Brazil (3/19), and Mexico (1/19). However, the contribution from Australia (5/116) and Africa—represented by Morocco (2/116)—are comparatively small. The primary energy sources in Europe are dominated by photovoltaic (15/48), followed by wind (13/48), unspecified renewable energy sources (4/48), coal (2/48), biodiesel (1/48), hydropower (1/48), and unspecified sources (4/48). The primary energy sources in Asia are photovoltaic (11/42), wind (9/42), biomass (7/42), methanol (5/42), photovoltaic/wind (4/42), natural gas (2/42), as well as coal (1/42), algae nuclear energy (1/42), and renewable energy sources (1/42). Finally, the primary energy sources in Australia comprise wind (3/5) and photovoltaic (2/5), and the primary energy source in Africa is photovoltaic (2/2) (Figure 3).

Feedstock

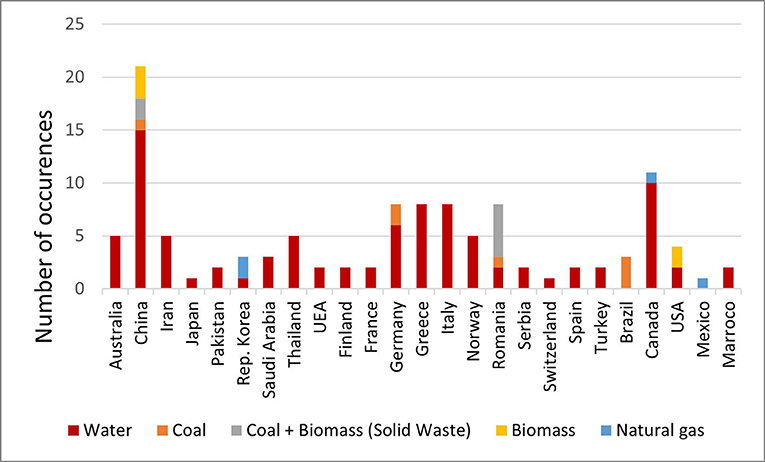

Hydrogen is not a source of energy, but it is a pure form that functions as an energy carrier or as an industrial raw material (Ozbilen et al., 2011). Hydrogen can be combined with other materials to produce hydrogen-based fuels (Bourne, 2012). Hydrogen feedstocks can be produced from sources such as natural gas, coal, water, biomass, and fossil fuels and can be readily used in engines or turbines (Donaldson et al., 2012; Ren et al., 2013; Yao et al., 2017; Li et al., 2018; Nurdiawati et al., 2019) (Figure 4). Figure 4 reveals that water is the most widely used hydrogen feedstock in countries such as China, Canada, Italy, Brazil, the USA, and the Republic of Korea, followed by other feedstocks, such as coal, coal plus biomass (soil waste), biomass, and natural gas.

Hydrogen production methods

Hydrogen elements can be found abundantly in nature, such as freshwater, seawater, biomass, hydrogen sulfide, and fossil fuels. However, to produce hydrogen with zero or low environmental impact, it must be extracted from fossil fuels. In general, the process of extracting hydrogen from natural resources can be classified into four categories—thermal, electrical, photonic, and biochemical. Thermal and electrical energy can be produced from renewable energy (such as solar, wind, geothermal, hydro, and biomass), fossil energy, or nuclear energy. Photonic energy can be obtained from solar radiation only. Biochemical energy reserved in organic matter can be processed by microorganisms that produce hydrogen from sundry substrates, or it can be chemically transferred to thermal energy (Dincer, 2012; Dincer and Acar, 2014). Previous studies grouped all the case studies into the following four categories based on the classification of various hydrogen production methods: electrochemical, thermochemical, biochemical, and thermal-electrochemical (Dincer, 2012; Dincer and Acar, 2014).

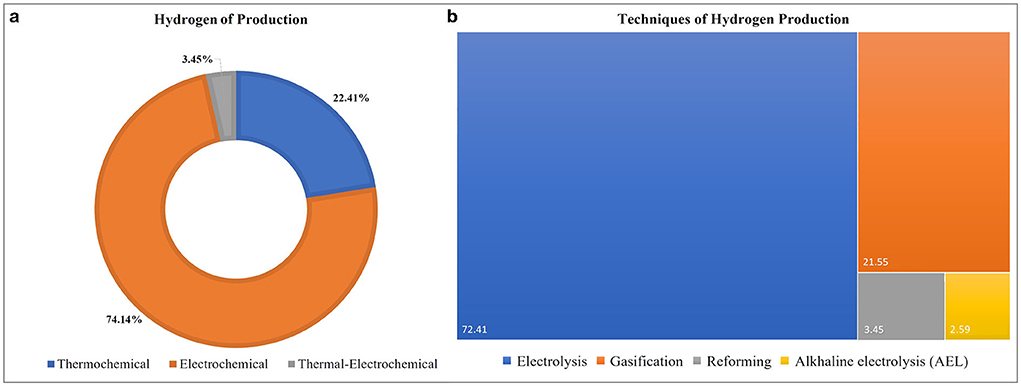

First, the hydrogen production methods in the electrochemical category include electrolysis technologies, such as alkaline electrolyzer (AEL) and proton exchange membrane electrolyzer (PEMEL). AEL and PEMEL are mature and commercially available. AEL is the world's oldest and most widely utilized technology for large-scale systems. PEMEL are generally used for hydrogen production on a modest scale. While PEMEL offers some advantages compared to AEL, including high current densities, voltage efficiency, and quick system response when working dynamically (David et al., 2019) (Yodwong et al., 2020). Electrolysis is the process through which electricity is used to split water into its components (i.e., oxygen and hydrogen). Hydrogen production processes through nuclear-based thermochemical cycles and renewable energy base electrolysis have much lower effects on the environment than steam reforming (Ozbilen et al., 2011). Water is infiltrated into the proton exchange membrane electrolysis cell; then, hydrogen ions are absorbed by the membrane, and this recombining process forms the hydrogen molecules. Proton exchange membrane electrolyzes are considered an alternative to producing hydrogen from renewable energy sources (Silva et al., 2010). Plasma decomposition of natural gas was included in the electrochemical category. In the reviewed studies, electrochemical technology was the most extensively used method in hydrogen production, accounting for approximately 74.14% of all the case studies, followed by thermochemical technology (22.41%) and thermal-electrochemical technology (3.45%) (Figure 5a). Furthermore, electrolysis was the most frequently used method in the electrochemical category, accounting for 84%, and alkaline electrolysis accounts for 3% of all the case studies. Second, the thermochemical category includes aqueous stage reforming, auto thermal reforming, steam reforming, gasification (coal or biomass), thermal cracking of fossil hydrocarbons, and water splitting. Thermochemical is the process of separating water using a heater to obtain hydrogen. The thermochemical hydrogen production process is an immature technology that must be refined over time. Gasification and reforming based on thermochemical account for 21.55 and 2.59% of all the case studies (Figure 5b). The thermochemical cycle normally does not require catalysts as a driver of chemical reactions. Chemical materials involved in the process are recycled and are the material source from which hydrogen is derived. The water-splitting thermochemical cycle is as follows: (i) it does not require hydrogen–oxygen separation membranes; (ii) it does not require overestimating thermal energy source (600–1,200 k); (iii) it does not require extra electrical energy to drive the process (Dincer, 2012). Third, the biochemical category includes fermentation and dark fermentation. The Biochemical category includes photolytic (direct water separation), photosynthetic bacteria (solar-assisted organic decomposition), dark fermentation (organic decomposition), and microbial-assisted electrolysis (electrical-assisted organic decomposition).

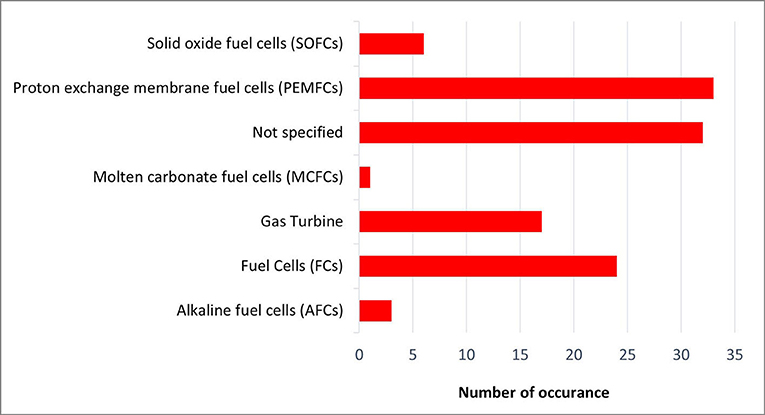

Power generation

The development of renewable energy sources (RES) is important for the sustainable growth of any nation due to the depletion of fossil fuels, the rising cost of fossil fuels worldwide, and the need to reduce emission levels. The selection and deployment of hydrogen-based power generation conversion technology are mostly governed by the electricity-requiring application. Technologies that use hydrogen as a fuel cell for power generation must provide flexible energy to ensure stability and resilience. According to the type of electrolyte used, fuel cells (FCs) can be categorized as phosphoric acid fuel cells (PAFCs), molten carbonate fuel cells (MCFCs), solid oxide fuel cells (SOFCs), and proton exchange membrane fuel cells (PEMFCs), molten carbonate fuel cells (MCFCs). The hydrogen that reacts with oxygen in the fuel to supply electrical energy consists of a piston engine and a gas turbine (Figure 6). A fuel cell is a device that converts the chemical energy of a fuel into electrical energy through an electrochemical reaction. Fuel cells are a flexible power generation technology with 50–60% electrical efficiency. Fuel cell stacks have a shorter technical lifetime (10.000 to 40.000 operating hours). However, compared to PEMFCs, and hydrogen is available, PEMFCs have the most potential for development (Bourne, 2012; Wang et al., 2017). Now-a-days, PEMFCs are applied extensively in numerous fields. PEMFCs provide the advantages of practically zero emissions, high power density, high efficiency, and low operating temperature compared to other fuel cell types. In addition, PEMFC providing short start and response times at the stack level appears to be the optimal technology for application drives.

Hydrogen gas turbine power generation technology is designed for large-scale power generation. Incorporating hydrogen is a potential pathway for gas turbine decarbonization by replacing natural gas with hydrogen. Each gas turbine model has a specific capability for hydrogen combustion, mainly determined by the combustion system. Gas turbine technology has three main components: a compressor, a combustion chamber, and a turbine stage. The central part of the energy is the turbine stage, which drives the compressor and gives the generator the power to run and generate electricity (Wang et al., 2021). Showed that the output of the introduction cycle is composed of a wind turbine, solar energies, and AFCs was 10.5 kW of electricity, and the electrical efficiency was 56.9%. In addition, the electrolyzer uses 9.9 kW of electricity to produce 221.3 grams of hydrogen fuel.

Techno-economic performance indicator

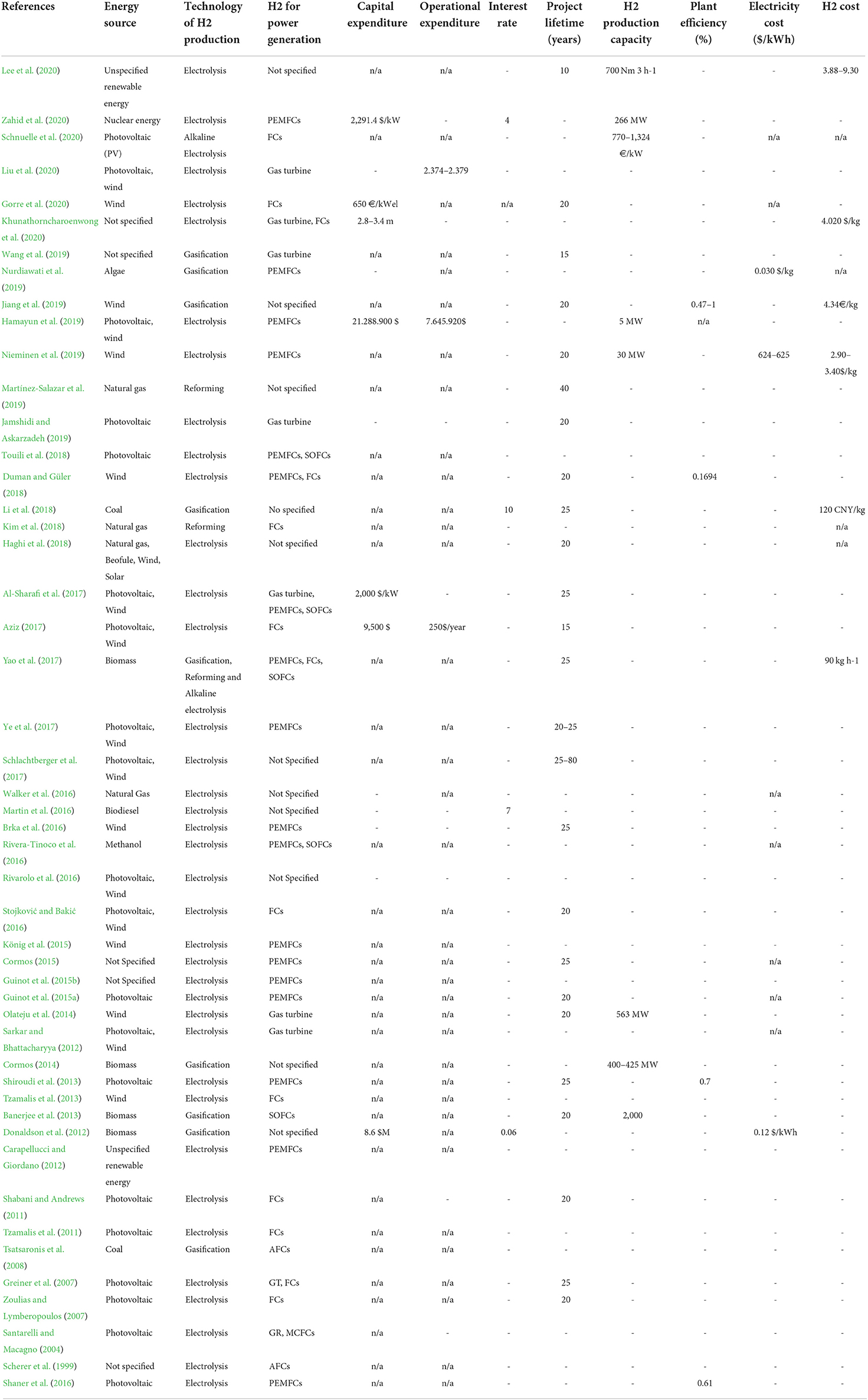

This section discusses the techno-economic analysis, including profitability, sensitivity, and uncertainty analysis, using various simulation results, such as Monte Carlo simulation, Aspen HYSYS (Kim et al., 2018), Aspen Plus, MATLAB, and HOMER simulation. The Aspen HYSYS simulation model is used to determine the effect of various operating conditions on the performance of the packed-bed reactor and membrane reactor (Kim et al., 2018). Moreover, it is used to determine the future risk and uncertainty in prediction (Zahid et al., 2020). Techno-economic assessment is a methodological framework for examining the technical and economic performance of a process, product, or service and includes the study of the economic impact of technology. A techno-economic assessment (TEA) is a cost-benefit comparison that considers technological and economic factors. An economic summary of hydrogen production is presented in Table 2, where each cost component is presented including capital expenditure (CAPEX), operating expenditure (OPEX), and other variables.

The CAPEX and OPEX are the main costs in a techno-economic assessment. The key issue is to minimize the CAPEX and OPEX of various hydrogen generation systems while simultaneously increasing production volume. This allows for a reduction in the cost of producing hydrogen from several energy sources. The expenditures involved with building a new facility are referred to as CAPEX. Fixed-capital investment (FCI) is the funds used to finance a facility. FCI in the first and second years is 60% and 40% of total FCI, respectively, while working capital cost is 15% of total FCI (Lee et al., 2020). Likewise, OPEX represents the various day-to-day expenses required to maintain sustainable business operations. It can also be said that they refer to the enormous costs involved in maintaining plant operations. OPEX consists of the costs of raw materials, operating labor, maintenance, and utilities. Annual expenses are considered based on items related to operating expenses and general and administrative expenses. In many cases, CAPEX values are estimated using software such as Aspen Plus or Aspen Hysys to simulate processes and perform economic analysis. The influence of plant size and capacity on CAPEX is substantial. The larger the facilities, the more the CAPEX, but the lower the production expenses. In addition, environmental influences such as integrated carbon capture and storage systems have a major impact on total production costs, resulting in an increase in CAPEX due to the use of additional equipment.

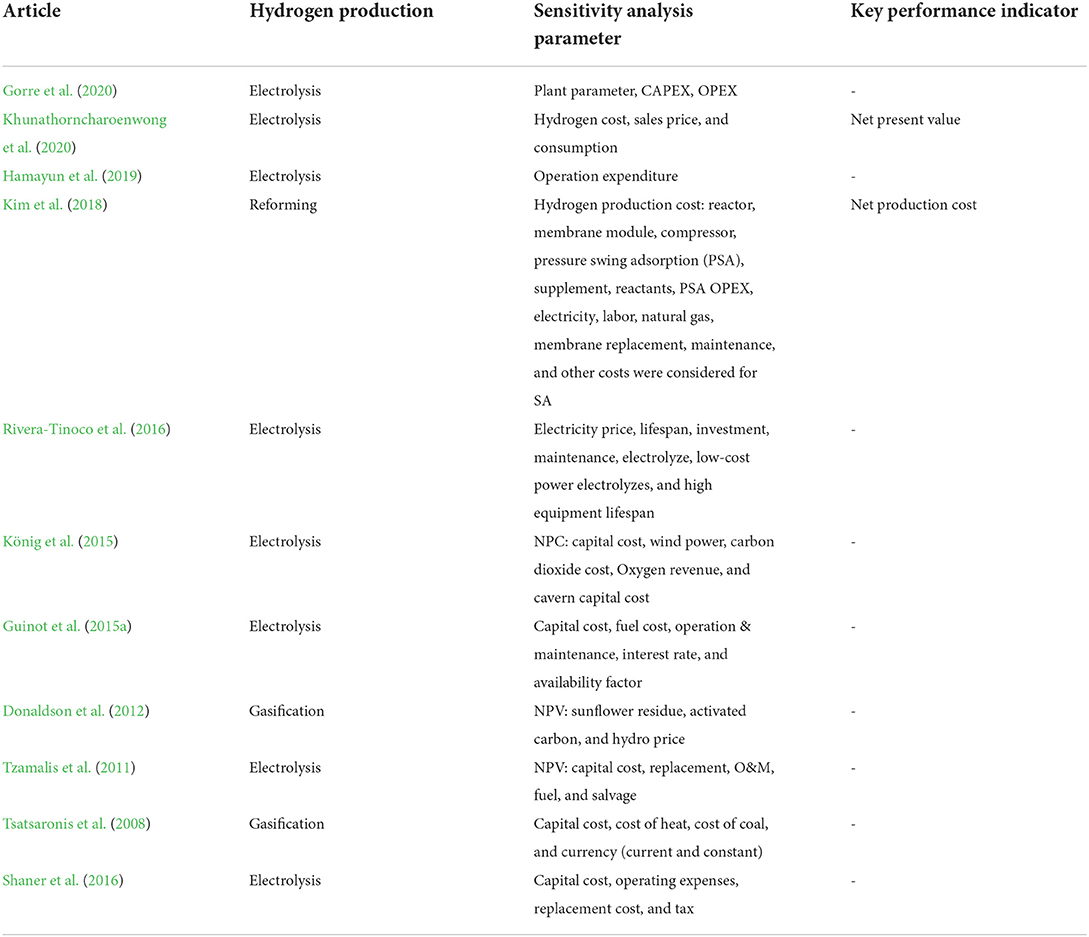

Sensitivity analysis

The main objective of the sensitivity analysis (SA) is to obtain the effect of various economic factors on the cost of a unit of hydrogen produced and determine some influential factors, including ensuring the surroundings and conditions of any operating plant after investment (Kim et al., 2018). The SA can provide information on the factor that is most sensitive and has a significant impact, including making decisions before investing. Generally, the sensitivity indicators to consider include sensitivity to capital cost, sensitivity to feedstock, and sensitivity to the internal rate of return (Khunathorncharoenwong et al., 2020; Yukesh Kannah et al., 2021). In some instances that renewables, such as wind, were used as the electricity source, several variable inputs were estimated, such as plant parameters (e.g., capacity and storage capacity), capital expenditure (CAPEX) parameters (e.g., hydrogen storage, electrolysis, and methanation), operation expenditure (OPEX) parameters (e.g., standby cost), and operating parameters (e.g., restart a level and restart time) (Rivera-Tinoco et al., 2016; Gorre et al., 2020).

The crucial parameter to perform sensitivity analysis depends on the hydrogen production process. Many studies consider capital cost, operating cost, replacement, operation & maintenance, and net present value (NPV) for process electrolysis. Other studies consider the parameters of hydrogen cost, sales price, consumption, operation expenditure, fuel, and savagery, including taxes. Reforming process parameters consist of hydrogen production costs: reactor, membrane module, compressor, pressure swing adsorption (PSA), supplement, reactants, PSA OPEX, electricity, labor, natural gas, membrane replacement, maintenance, and other costs were considered for sensitivity analysis. Finally, the gasification process only considers the NPV (Table 1).

The wind is the basic concept of SA in the application of power to gas technology to convert renewable electricity into molecular form. Electrolysis costs are reduced by 54%, and gas production costs are reduced by 40% implying a lower average price for hydrogen, thus allowing for reduced equipment costs. A reduced methanation CAPEX can reduce the amount of hydrogen that is not converted into synthetic natural gas. Thus, synthetic natural gas (SNG) production costs are more sensitive to CAPEX electrolyzed than CAPEX methanation (Gorre et al., 2020). Hydrogen price is the most sensitive parameter and is more economical in the conventional process than low-pressure steam consumption (Khunathorncharoenwong et al., 2020). A heavier load on the electrolysis section results in higher power plate CAPEX and OPEX. However, the system efficiency can impact the high cost reduction process of all systems because of the areal dependencies of most of the components (Shaner et al., 2016; Hamayun et al., 2019). When the overloaded functionality of the installed capacity is 5.0%, the cost can be reduced, leading to a capital cost reduction of 3.6%. NPC was reduced by 0.9% due to the high cost of the electricity component. The output electricity cost is highly sensitive to the efficiency of the power plant (Zahid et al., 2020). Furthermore, lesser by-product yield is substantial from an economical perspective.

An NPV is considered one of the indicators to decide the feasibility of the target technology (Lee et al., 2020). When the NPV is zero, the project is not expected to generate significant profits or losses. Therefore, a project with a positive NPV is considered profitable and acceptable, while a project with a negative NPV means that this technology needs to be developed to obtain economic gains. The NPV decreases as the price of renewable electricity or the rate of degradation increases in relation to the cost of the system. On the other hand, the internal rate of return (IRR), is the discount rate that corresponds to an NPV equal to zero. IRR is a financial risk indicator used to assess the profitability of an investment. Where IRR involves comparing more than one potential project, the level of internal investment indicates the one that is most profitable, regardless of project size and technology. According to established practice, an internal rate of return (IRR) of 10% is assumed, consisting of the interest rate for own capital and credit capital. Hydrogen production costs are calculated iteratively using a plant cash flow analysis that includes total annual expenses and revenues.

Uncertainty analysis

The evaluations built on assumptions and estimates inevitability produce uncertainty in results. TEA describes uncertainty caused explicitly by errors in data input, the tension in the model itself, and the characteristic of the context in which the analysis is carried out. In the initial step of uncertainty analysis, it is always important to systematically identify the variables that generate uncertainty. The second step is determining the number of computations necessary to confirm compliance with the acceptance criteria and standard tolerance limit. In addition, TEA performs an uncertainty analysis to evaluate the parameters that most influence the project's economic performance. For example, the sensitivity parameter might vary by up to 20% relative to the baseline value (van der Spek et al., 2020). Sensitivity analysis assesses the influence of a single parameter at a time. In the meantime, a Monte Carlo simulation was conducted to examine the combined effect of numerous parameters on the economic performance of an investment. This simulation forecasts economic indicator uncertainty by randomly generating parameter values within the ranges above. In addition, the simulation examines the process's uncertainty and calculates the chance that the developed system will be profitable. Here, (Lee et al., 2020) conducted an uncertainty analysis to identify changes in the unit price of electricity and the selling price of H2 in the net present value range. The uncertainty analysis reveals that, economically, the selling price of hydrogen is more influential than renewable electricity prices, such as hydro and onshore wind energy, which is considered promising renewable power source for reducing the cost of producing hydrogen.

Discussion

This section examines the techno-economic assessment of various hydrogen productions for power generation studies included in this systematic review. Natural gas and coal are the two most crucial feedstock sources for hydrogen generation. The technology for producing hydrogen from these two feedstocks is highly developed, and there is a lot of experience operating these plants. The cost of hydrogen from various energy sources depends on the energy conversion and production costs. Most hydrogen production techniques require either thermal or electrical energy input from the energy source. Concurrently, this energy source is supplied by the energy conversion plant, representing the increase in energy's final cost. These expenses are typically the most significant contributors to the total cost of hydrogen.

Compared to other fuel cells (FCs), proton exchange membrane fuel cells (PEMFC) have become a power source for many applications and a possible option for reducing greenhouse gas emissions. PEMFCs combined with photovoltaics and batteries are now considered an excellent alternative to power generation. The application of the independent control mode can realize the optimal economical operation of the hybrid power generation system (HPGS) without a communication network. It can reduce marginal cost by up to 19.08% compared to traditional droop control. Furthermore, the cooperative control mode can achieve minimum generation costs and a difference in battery energy storage devices' charge balance state, even when the line resistance effect is quite significant (Yang et al., 2019; Okonkwo et al., 2021).

A techno-economic assessment is important now-a-days, but there are many different uncertainties in how to calculate it. The use of non-standard procedures, assumptions, and data of varying quality makes it difficult to compare the values of the literature with each other and draw rational conclusions. Several assumptions are made when calculating TEA, such as type of financing, cost and space of land acquisition, cost of raw materials, the yield of raw materials, factory life, construction time, labor costs, product costs, and utility costs. However, these assumptions do not reflect the actual reality. It affects the calculation. On the other hands, Sensitivity analysis helps determine the state and condition of each plant operating after the investment. It is more beneficial to decide before investing. The sensitivity to the cost of capital can be determined by calculating the return on investment. This is a key parameter to identify the technology running from start to finish and the return on investment at each stage of growth.

In closing, numerous researches focus on hydrogen production sources, systems, and distinct hydrogen storage alternatives. In addition, studies focusing on the social and environmental implications of the sources and systems necessary for hydrogen production are scarce. Another drawback of this study is that it concentrates on metrics that cannot be compared to others get more definitive results. Future research might include hydrogen end-use possibilities, such as various fuel cells, to improve the analysis of the long-term viability of hydrogen-based energy systems.

Data availability statement

The datasets presented in this study can be found in online repositories. The names of the repository/repositories and accession number (s) can be found in the article/supplementary material.

Author contributions

Z carried out the experiment with support from AK and ST. Z and AK wrote the manuscript. SM helped supervise the project. All authors contributed to the article and approved the submitted version.

Funding

This research was supported by JSPS KAKENHI Grant Number JP20H00648 and the Environment Research and Technology Development Fund (JPMEERF20201001) of the Environmental Restoration and Conservation Agency of Japan.

Acknowledgments

Z would like to thank Malikussaleh University, Asian Development Bank (ADB) and The Ministry of Research, and Technology and Higher Education of the Republic of Indonesia for the full support through the Doctoral Degree Scholarship Program (Grant No. L3749-INO).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Author disclaimer

Any opinions, findings, and conclusions expressed in this paper are those of the authors and do not necessarily reflect the views of the funding agency.

References

Abe, J. O., Popoola, A. P. I., Ajenifuja, E., and Popoola, O. M. (2019). Hydrogen energy, economy and storage: review and recommendation. Int. J. Hydrog. Energy 44, 15072–15086. doi: 10.1016/j.ijhydene.2019.04.068

Al-Sharafi, A., Sahin, A. Z., Ayar, T., and Yilbas, B. S. (2017). Techno-economic analysis and optimization of solar and wind energy systems for power generation and hydrogen production in Saudi Arabia. Renew. Sust. Energ. Rev. 69, 33–49. doi: 10.1016/j.rser.2016.11.157

Aziz, A. S. (2017). Techno-economic analysis using different types of hybrid energy generation for desert safari camps in UAE. Turk. J. Electr. Eng. Comput. Sci. 25, 2122–2135. doi: 10.3906/elk-1602-159

Banerjee, S., Tiarks, J. A., Lukawski, M., Kong, S. C., and Brown, R. C. (2013). Technoeconomic analysis of biofuel production and biorefinery operation utilizing geothermal energy. Energy Fuels 27, 1381–1390. doi: 10.1021/ef301898n

Bourne, S. (2012). The future of fuel: the future of hydrogen. Fuel Cells Bull. 2012, 12–15. doi: 10.1016/S1464-2859(12)70027-5

Brka, A., Al-Abdeli, Y. M., and Kothapalli, G. (2016). Predictive power management strategies for stand-alone hydrogen systems: operational impact. Int. J. Hydrog. Energy 41, 6685–6698. doi: 10.1016/j.ijhydene.2016.03.085

Carapellucci, R., and Giordano, L. (2012). Modeling and optimization of an energy generation island based on renewable technologies and hydrogen storage systems. Int. J. Hydrog. Energy 37, 2081–2093. doi: 10.1016/j.ijhydene.2011.10.073

Cormos, C. C. (2014). Techno-economic and environmental analysis of hydrogen and power co-generation based on co-gasification of coal and biomass / solid wastes with carbon capture. Chem. Eng. Trans. 37, 139–144. doi: 10.3303/CET1437024

Cormos, C. C. (2015). Biomass direct chemical looping for hydrogen and power co-production: process configuration, simulation, thermal integration and techno-economic assessment. Fuel Process. Technol. 137, 16–23. doi: 10.1016/j.fuproc.2015.04.001

David, M., Ocampo-Martínez, C., and Sánchez-Peña, R. (2019). Advances in alkaline water electrolyzers: a review. J. Energy Storage 23, 392–403. doi: 10.1016/j.est.2019.03.001

Dincer, I. (2012). Green methods for hydrogen production. Int. J. Hydrog. Energy 37, 1954–1971. doi: 10.1016/j.ijhydene.2011.03.173

Dincer, I., and Acar, C. (2014). Review and evaluation of hydrogen production methods for better sustainability. Int. J. Hydrog. Energy 40, 11094–11111. doi: 10.1016/j.ijhydene.2014.12.035

Donaldson, A. A., Kadakia, P., Gupta, M., and Zhang, Z. (2012). Production of energy and activated carbon from agri-residue: sunflower seed example. Appl. Biochem. Biotechnol. 168, 154–162. doi: 10.1007/s12010-011-9358-0

Duman, A. C., and Güler, Ö. (2018). Techno-economic analysis of off-grid PV/wind/fuel cell hybrid system combinations with a comparison of regularly and seasonally occupied households. Sustain. Cities Soc. 42, 107–126. doi: 10.1016/j.scs.2018.06.029

Dutta, S. (2014). A review on production, storage of hydrogen, and its utilization as an energy resource. J. Ind. Eng. Chem. 20, 1148–1156. doi: 10.1016/j.jiec.2013.07.037

El-Emam, R. S., and Özcan, H. (2019). A comprehensive review on the techno-economics of sustainable large-scale clean hydrogen production. J. Clean. Prod. 220, 593–609. doi: 10.1016/j.jclepro.2019.01.309

Gorre, J., Ruoss, F., Karjunen, H., Schaffert, J., and Tynjäl,ä, T. (2020). Cost benefits of optimizing hydrogen storage and methanation capacities for Power-to-Gas plants in dynamic operation. Appl. Energy 257, 113967. doi: 10.1016/j.apenergy.2019.113967

Greiner, C. J., KorpÅs, M., and Holen, A. T. (2007). A Norwegian case study on the production of hydrogen from wind power. Int. J. Hydrog. Energy. 32, 1500–1507. doi: 10.1016/j.ijhydene.2006.10.030

Guinot, B., Champel, B., Montignac, F., Lemaire, E., Vannucci, D., Sailler, S., et al. (2015a). Techno-economic study of a PV-hydrogen-battery hybrid system for off-grid power supply: impact of performances' aging on optimal system sizing and competitiveness. Int. J. Hydrog. Energy 40, 623–632. doi: 10.1016/j.ijhydene.2014.11.007

Guinot, B., Montignac, F., Champel, B., and Vannucci, D. (2015b). Profitability of an electrolysis based hydrogen production plant providing grid balancing services. Int. J. Hydrog. Energy 40, 8778–8787. doi: 10.1016/j.ijhydene.2015.05.033

Haghi, E., Raahemifar, K., and Fowler, M. (2018). Investigating the effect of renewable energy incentives and hydrogen storage on advantages of stakeholders in a microgrid. Energy Policy 113, 206–222. doi: 10.1016/j.enpol.2017.10.045

Hamayun, M. H., Hussain, M., Maafa, I. M., and Aslam, R. (2019). Integration of hydrogenation and dehydrogenation system for hydrogen storage and electricity generation – simulation study. Int. J. Hydrog. Energy 44, 20213–20222. doi: 10.1016/j.ijhydene.2019.06.053

Hanley, E. S., Deane, J. P., and Gallachóir, B. P. Ó. (2018). The role of hydrogen in low carbon energy futures–a review of existing perspectives. Renew. Sustain. Energy Rev. 82, 3027–3045. doi: 10.1016/j.rser.2017.10.034

Hosseini, S. E., and Wahid, M. A. (2016). Hydrogen production from renewable and sustainable energy resources: promising green energy carrier for clean development. Renew. Sustain. Energy Rev. 57, 850–866. doi: 10.1016/j.rser.2015.12.112

IEA. (2016). Medium-Term Market Report 2016 Market Analysis and Forecasts to 2021. 278. Available online at: https://www.iea.org/publications/freepublications/publication/MTRMR2016.pdf (accessed June 28, 2021).

International Energy Agency. (2015). Energy Technology Perspectives 2015. International Energy Agency. Available online at: http://www.iea.org/termsandconditionsuseandcopyright/%5Cnhttp://www.oecd-ilibrary.org/energy/energy-technology-perspectives-2015_energy_tech-2015-en (accessed May 7, 2021).

Jamil, M., Kirmani, S., and Rizwan, M. (2012). Techno-economic feasibility analysis of solar photovoltaic power generation: a review. Smart Grid Renew. Energy 03, 266–274. doi: 10.4236/sgre.2012.34037

Jamshidi, M., and Askarzadeh, A. (2019). Techno-economic analysis and size optimization of an off-grid hybrid photovoltaic, fuel cell and diesel generator system. Sustain. Cities Soc. 44, 310–320. doi: 10.1016/j.scs.2018.10.021

Jiang, Y., Deng, Z., and You, S. (2019). Size optimization and economic analysis of a coupled wind-hydrogen system with curtailment decisions. Int. J. Hydrog. Energy 44, 19658–19666. doi: 10.1016/j.ijhydene.2019.06.035

Khunathorncharoenwong, N., Charoensuppanimit, P., Assabumrungrat, S., and Kim-Lohsoontorn, P. (2020). Techno-economic analysis of alternative processes for alcohol-assisted methanol synthesis from carbon dioxide and hydrogen. Int. J. Hydrog. Energy 46, 24591–24606. doi: 10.1016/j.ijhydene.2020.01.230

Kim, S., Ryi, S. K., and Lim, H. (2018). Techno-economic analysis (TEA) for CO2 reforming of methane in a membrane reactor for simultaneous CO2 utilization and ultra-pure H2 production. Int. J. Hydrog. Energy 43, 5881–5893. doi: 10.1016/j.ijhydene.2017.09.084

König, D. H., Freiberg, M., Dietrich, R. U., and Wörner, A. (2015). Techno-economic study of the storage of fluctuating renewable energy in liquid hydrocarbons. Fuel 159, 289–297. doi: 10.1016/j.fuel.2015.06.085

Lee, H., Lee, B., Byun, M., and Lim, H. (2020). Economic and environmental analysis for PEM water electrolysis based on replacement moment and renewable electricity resources. Energy Convers. Manag. 224, 113477. doi: 10.1016/j.enconman.2020.113477

Li, G., Liu, Z., Liu, T., Shan, J., Fang, Y., and Wang, Z. (2018). Techno-economic analysis of a coal to hydrogen process based on ash agglomerating fluidized bed gasification. Energy Convers. Manag. 164, 552–559. doi: 10.1016/j.enconman.2018.03.035

Liu, J., Sun, W., and Harrison, G. P. (2020). The economic and environmental impact of power to hydrogen/power to methane facilities on hybrid power-natural gas energy systems. Int. J. Hydrog. Energy 45, 20200–20209. doi: 10.1016/j.ijhydene.2019.11.177

Martin, S., Albrecht, F. G., Van Der Veer, P., Lieftink, D., and Dietrich, R. U. (2016). Evaluation of on-site hydrogen generation via steam reforming of biodiesel: Process optimization and heat integration. Int. J. Hydrog. Energy 41, 6640–6652. doi: 10.1016/j.ijhydene.2016.02.138

Martínez-Salazar, A. L., Melo-Banda, J. A., Coronel-García, M. A., García-Vite, P. M., Martínez-Salazar, I., and Domínguez-Esquivel, J. M. (2019). Technoeconomic analysis of hydrogen production via hydrogen sulfide methane reformation. Int. J. Hydrog. Energy 44, 12296–12302. doi: 10.1016/j.ijhydene.2018.11.023

Nieminen, H., Laari, A., and Koiranen, T. (2019). CO2 hydrogenation to methanol by a liquid-phase process with alcoholic solvents: A techno-economic analysis. Processes 7, 1–24. doi: 10.3390/pr7070405

Nurdiawati, A., Zaini, I. N., Irhamna, A. R., Sasongko, D., and Aziz, M. (2019). Novel configuration of supercritical water gasification and chemical looping for highly-efficient hydrogen production from microalgae. Renew. Sustain. Energy Rev. 112, 369–381. doi: 10.1016/j.rser.2019.05.054

Okonkwo, P. C., Ige, O. O., Barhoumi, E. M., Uzoma, P. C., Emori, W., Benamor, A., et al. (2021). Platinum degradation mechanisms in proton exchange membrane fuel cell (PEMFC) system: a review. Int. J. Hydrog. Energy 46, 15850–15865. doi: 10.1016/j.ijhydene.2021.02.078

Olateju, B., Monds, J., and Kumar, A. (2014). Large scale hydrogen production from wind energy for the upgrading of bitumen from oil sands. Appl. Energy 118, 48–56. doi: 10.1016/j.apenergy.2013.12.013

Ozbilen, A., Dincer, I., and Rosen, M. A. (2011). A comparative life cycle analysis of hydrogen production via thermochemical water splitting using a Cu-Cl cycle. Int. J. Hydrog. Energy 36, 11321–11327. doi: 10.1016/j.ijhydene.2010.12.035

Rajendran, K., and Murthy, G. S. (2019). Techno-economic and life cycle assessments of anaerobic digestion – a review. Biocatal. Agric. Biotechnol. 20, 101207. doi: 10.1016/j.bcab.2019.101207

Ren, J., Manzardo, A., Toniolo, S., and Scipioni, A. (2013). Sustainability of hydrogen supply chain. Part I: Identification of critical criteria and cause-effect analysis for enhancing the sustainability using DEMATEL. Int. J. Hydrog. Energy 38, 14159–14171. doi: 10.1016/j.ijhydene.2013.08.126

Rivarolo, M., Bellotti, D., Magistri, L., and Massardo, A. F. (2016). Feasibility study of methanol production from different renewable sources and thermo-economic analysis. Int. J. Hydrog. Energy 41, 2105–2116. doi: 10.1016/j.ijhydene.2015.12.128

Rivera-Tinoco, R., Farran, M., Bouallou, C., Auprêtre, F., Valentin, S., Millet, P., et al. (2016). Investigation of power-to-methanol processes coupling electrolytic hydrogen production and catalytic CO2 reduction. Int. J. Hydrog. Energy 41, 4546–4559. doi: 10.1016/j.ijhydene.2016.01.059

Santarelli, M., and Macagno, S. (2004). A thermoeconomic analysis of a PV-hydrogen system feeding the energy requests of a residential building in an isolated valley of the Alps. Energy Convers. Manag. 45, 427–451. doi: 10.1016/S0196-8904(03)00156-0

Sarkar, J., and Bhattacharyya, S. (2012). Application of graphene and graphene-based materials in clean energy-related devices Minghui. Arch. Thermodyn. 33, 23–40. doi: 10.2478/v10173-012-0026-8

Scherer, G. W. H., Newson, E., and Wokaun, A. (1999). Economic analysis of the seasonal storage of electricity with liquid organic hydrides. Int. J. Hydrog. Energy 24, 1157–1169. doi: 10.1016/S0360-3199(98)00177-3

Schlachtberger, D. P., Brown, T., Schramm, S., and Greiner, M. (2017). The benefits of cooperation in a highly renewable European electricity network. Energy 134, 469–481. doi: 10.1016/j.energy.2017.06.004

Schnuelle, C., Wassermann, T., Fuhrlaender, D., and Zondervan, E. (2020). Dynamic hydrogen production from PV and wind direct electricity supply – Modeling and techno-economic assessment. Int. J. Hydrog. Energy 45, 29938–29952. doi: 10.1016/j.ijhydene.2020.08.044

Shabani, B., and Andrews, J. (2011). An experimental investigation of a PEM fuel cell to supply both heat and power in a solar-hydrogen RAPS system. Int. J. Hydrog. Energy 36, 5442–5452. doi: 10.1016/j.ijhydene.2011.02.003

Shaner, M. R., Atwater, H. A., Lewis, N. S., and McFarland, E. W. (2016). A comparative technoeconomic analysis of renewable hydrogen production using solar energy. Energy Environ. Sci. 9, 2354–2371. doi: 10.1039/C5EE02573G

Shiroudi, A., Taklimi, S. R. H., Mousavifar, S. A., and Taghipour, P. (2013). Stand-alone PV-hydrogen energy system in Taleghan-Iran using HOMER software: optimization and techno-economic analysis. Environ. Dev. Sustain. 15, 1389–1402. doi: 10.1007/s10668-013-9443-3

Silva, S. B., de Oliveira Marco, M. A. G., and Severino, M. M. (2010). Economic evaluation and optimization of a photovoltaic-fuel cell-batteries hybrid system for use in the Brazilian Amazon. Energy Policy 38, 6713–6723. doi: 10.1016/j.enpol.2010.06.041

Staffell, I., Scamman, D., Velazquez Abad, A., Balcombe, P., Dodds, P. E., Ekins, P., et al. (2019). The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 12, 463–491. doi: 10.1039/C8EE01157E

Stojković, S. M., and Bakić, V. V. (2016). Techno-economic analysis of stand-alone photovoltaic/wind/battery/hydrogen systems for very Small-Scale applications. Therm. Sci. 20, S261–S273. doi: 10.2298/TSCI150308195S

Thürer, M., Tomaševi,ć, I., Stevenson, M., Qu, T., and Huisingh, D. (2018). A systematic review of the literature on integrating sustainability into engineering curricula. J. Clean. Prod. 181, 608–617. doi: 10.1016/j.jclepro.2017.12.130

Touili, S., Alami Merrouni, A., Azouzoute, A., El Hassouani, Y., and Amrani, A.-I. (2018). A technical and economical assessment of hydrogen production potential from solar energy in Morocco. Int. J. Hydrog. Energy 43, 22777–22796. doi: 10.1016/j.ijhydene.2018.10.136

Tranfield, D., Denyer, D., and Smart, P. (2003). Towards a methodology for developing evidence-informed management knowledge by means of systematic review* introduction: the need for an evidence- informed approach. Br. J. Manag. 14, 207–222. doi: 10.1111/1467-8551.00375

Tsatsaronis, G., Kapanke, K., and María Blanco Marigorta, A. (2008). Exergoeconomic estimates for a novel zero-emission process generating hydrogen and electric power. Energy 33, 321–330. doi: 10.1016/j.energy.2007.10.007

Tzamalis, G., Zoulias, E. I., Stamatakis, E., Parissis, O. S., Stubos, A., and Lois, E. (2013). Techno-economic analysis of RES and hydrogen technologies integration in remote island power system. Int. J. Hydrog. Energy 38, 11646–11654. doi: 10.1016/j.ijhydene.2013.03.084

Tzamalis, G., Zoulias, E. I., Stamatakis, E., Varkaraki, E., Lois, E., and Zannikos, F. (2011). Techno-economic analysis of an autonomous power system integrating hydrogen technology as energy storage medium. Renew. Energy 36, 118–124. doi: 10.1016/j.renene.2010.06.006

van der Spek, M., Fout, T., Garcia, M., Kuncheekanna, V. N., Matuszewski, M., McCoy, S., et al. (2020). Uncertainty analysis in the techno-economic assessment of CO2 capture and storage technologies. Critical review and guidelines for use. Int. J. Greenh. Gas Control 100, 103113. doi: 10.1016/j.ijggc.2020.103113

Walker, S. B., Van Lanen, D., Fowler, M., and Mukherjee, U. (2016). Economic analysis with respect to Power-to-Gas energy storage with consideration of various market mechanisms. Int. J. Hydrog. Energy 41, 7754–7765. doi: 10.1016/j.ijhydene.2015.12.214

Wang, T., Li, Q., Chen, W., and Liu, T. (2017). “Application of energy management strategy based on state machine in fuel cell hybrid power system,” in 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific, ITEC Asia-Pacific, Harbin.

Wang, Y., Li, G., Liu, Z., Cui, P., Zhu, Z., and Yang, S. (2019). Techno-economic analysis of biomass-to-hydrogen process in comparison with coal-to-hydrogen process. Energy 185, 1063–1075. doi: 10.1016/j.energy.2019.07.119

Wang, Z., Zhang, X., and Rezazadeh, A. (2021). Hydrogen fuel and electricity generation from a new hybrid energy system based on wind and solar energies and alkaline fuel cell. Energy Rep. 7, 2594–2604. doi: 10.1016/j.egyr.2021.04.060

Yang, H., Li, Q., Wang, T., Qiu, Y., and Chen, W. (2019). A dual mode distributed economic control for a fuel cell– photovoltaic-battery hybrid power generation system based on marginal cost. Int. J. Hydrog. Energy 44, 25229–25239. doi: 10.1016/j.ijhydene.2019.02.180

Yao, J., Kraussler, M., Benedikt, F., and Hofbauer, H. (2017). Techno-economic assessment of hydrogen production based on dual fluidized bed biomass steam gasification, biogas steam reforming, and alkaline water electrolysis processes. Energy Convers. Manag. 145, 278–292. doi: 10.1016/j.enconman.2017.04.084

Ye, B., Zhang, K., Jiang, J. J., Miao, L., and Li, J. (2017). Towards a 90% renewable energy future: a case study of an island in the South China Sea. Energy Convers. Manag. 142, 28–41. doi: 10.1016/j.enconman.2017.03.038

Yodwong, B., Guilbert, D., Phattanasak, M., Kaewmanee, W., Hinaje, M., and Vitale, G. (2020). Proton exchange membrane electrolyzer modeling for power electronics control: a short review. C — J. Carbon Res. 6, 29. doi: 10.3390/c6020029

Yukesh Kannah, R., Kavitha, S., Preethi, Parthiba Karthikeyan, O., Kumar, G., Dai-Viet, N. V., et al. (2021). Techno-economic assessment of various hydrogen production methods – a review. Bioresour. Technol. 319, 124175. doi: 10.1016/j.biortech.2020.124175

Zahid, A. H., Amin, N., Nisar, F., and Saghir, S. (2020). Analysis of MTH-System (Methylcyclohexane-Toluene-Hydrogen-System) for hydrogen production as fuel for power plants. Int. J. Hydrog. Energy 45, 32234–32242. doi: 10.1016/j.ijhydene.2020.08.248

Keywords: hydrogen, energy primary source, hydrogen production technology, power generation, techno-economic assessment

Citation: Zulfhazli, Keeley AR, Takeda S and Managi S (2022) A systematic review of the techno-economic assessment of various hydrogen production methods of power generation. Front. Sustain. 3:943145. doi: 10.3389/frsus.2022.943145

Received: 13 May 2022; Accepted: 01 September 2022;

Published: 03 October 2022.

Edited by:

Yogendra Shastri, Indian Institute of Technology Bombay, IndiaReviewed by:

Obste Therasme, SUNY College of Environmental Science and Forestry, United StatesXinqiang YOU, Fuzhou University, China

Copyright © 2022 Zulfhazli, Keeley, Takeda and Managi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Shunsuke Managi, bWFuYWdpQGRvYy5reXVzaHUtdS5hYy5qcA==

Zulfhazli

Zulfhazli Alexander Ryota Keeley

Alexander Ryota Keeley Shutaro Takeda

Shutaro Takeda Shunsuke Managi

Shunsuke Managi