- 1VTT Technical Research Centre of Finland Ltd., Espoo, Finland

- 2Department of Design, Aalto University, Espoo, Finland

The transition to a circular plastic economy is a priority within the European policy landscape, necessitating enhanced recycling and market uptake for recycled plastics. However, the plastics industry remains governed by linear business models with little focus on circularity, and limited recyclability and markets for recycled plastics often leave incineration and export as the primary methods of waste management. This study examines the current barriers that impede the circularity of plastics in the EU, focusing specifically on non-packaging plastic waste from the automotive, construction, and electronics sectors. We assess value-chain perceptions gathered from a series of semi-structured interviews and workshops conducted within the EU Horizon 2020 NONTOX project, to identify barriers and potential solutions and to produce overarching recommendations for action. These recommendations include enhanced collection and recycling, expansion of recycling capacity, better positioning of new recycling technologies, improved recyclability of products, and support for markets for recycled plastics. The results also highlight the need for high-impact policies to promote a circular plastic economy in the EU. Not only would this support plastics circularity, it would also prevent material loss due to incineration and the export of plastic waste, while contributing to the EU's self-sufficiency in raw materials.

1 Introduction

Plastics can be found in all types of products, and they form a main part of the contemporary material portfolio (Lebreton and Andrady, 2019; Hsu et al., 2021). Global plastic production has now reached 400 million tons per year and is increasing (Plastics Europe, 2024). Plastics also form a significant share of annually produced post-consumer waste. However, only 30% of plastics are recycled in Europe and significant volumes of plastic waste are still landfilled (23%), incinerated (42%) and exported for recycling (5%) (Plastics Europe, 2022) due to lack of European capacity and incentives for recycling (zu Castell-Rüdenhausen et al., 2024).

Plastics recycling reduces the extraction of fossil raw materials and mitigates the environmental impacts of plastics consumption and end-of-life treatment (Geyer et al., 2017; Hahladakis et al., 2018; Tenhunen-Lunkka et al., 2022). However, plastic waste recycling is significantly limited by technical difficulties such as the complex composition of plastic waste (Ragaert et al., 2017; Lase et al., 2023). Furthermore, the lack of ecodesign considerations in product design and manufacture (Brezet and Van Hemel, 1997; UNEP, 1998) has led to poor recyclability at end-of-life phase for most products with embedded plastics (Material Economics, 2018).

Studies of the external barriers to plastic circularity highlight e.g., poor recyclability (heterogeneous waste streams with complex plastic products containing multiple materials), hazardous contents (e.g., flame retardants and plasticisers), poor traceability (uncertain recycled plastic quality), high costs (low costs of primary materials compared to high costs of recycling), and quality degradation in mechanical recycling (damage to the polymer) (Material Economics, 2018; Wahlstrom et al., 2019; European Environment Agency, 2021; zu Castell-Rüdenhausen et al., 2022). However, the internal barriers within the plastic sector remain unclear, as do the means for overcoming these barriers to facilitate the systemic transition to a circular plastics economy (Karayilan et al., 2021).

The present study examines recycling and recyclability from a multidisciplinary perspective, including policies, technologies, business models, and design. The aim is to find solutions to facilitate reaching the targets of the European Strategy for Plastics in a Circular Economy (COM/2018/028), specifically focusing on the 2030 targets to recycle more than half of plastics waste generated in Europe, increasing the demand for recycled plastics in Europe by four-fold, and phasing out exports of plastic waste (European Commission, 2018a). The analysis centers on non-packaging plastics in end-of-life vehicles (ELV), waste electronics and electrical equipment (WEEE) and construction and demolition waste (C&DW) sectors. Although representing significant non-packaging plastic sectors, agricultural plastics and textiles were beyond the scope of the present study as these possess significant systemic distinctions from the targeted sectors. The targeted automotive, construction and electronics sectors, however, display some similarities in material characteristics and have somewhat interconnected material flows. Furthermore, in this study, the use phase has been excluded from the scope as the use-phase is highly connected to consumer behavior and would require investigation from different perspectives.

The 2030 deadline for achieving the targets for plastics circularity as detailed in the Plastics Strategy are rapidly approaching and systemic changes remain absent. Consequently, the aim of the present study is to examine the current barriers to plastics circularity for the targeted sectors, to generate recommendations about how to improve circularity, and to assess how actions should be targeted to yield best results. More specifically, the objectives of the study were (i) to identify barriers currently hindering plastics circularity, (ii) to identify solutions that facilitates circularity in the targeted sectors, (iii) to understand the internal decision-making regarding circularity in the value chain; and (iv) to derive targeted actions for supporting the transition to plastics circularity in Europe.

This article is structured in four sections, with this introduction discussing the context of the study, followed by a section on materials, methodology and data, then on results and recommendations, and finally a section including discussion and conclusions.

2 Materials and methods

This study investigates the barriers currently hindering plastics circularity, to present solutions and to generate recommendations that would support the transition toward plastics circularity in Europe. We approached the topic via thematic assessment of challenges and solutions amongst a broad selection of different value-chain actors in connection to different phases of circular plastics in the context of ELV, WEEE, and C&DW. The study is based on data collection in the form of semi-structured interviews and facilitated workshops. Semi-structured interview is the most frequently used method in qualitative research (DiCicco-Bloom and Crabtree, 2006; Saunders et al., 2007). Our interviews were planned in line with a framework presented by Kallio et al. (2016). The workshop activities were utilized to first expand the overall understanding of value chain actors and their needs, then for data collection, and finally for validating the findings of the study (see Annex A).

When planning the stakeholder engagement, a literature study on the addressed topics, including policy and legal landscape, plastic waste management and recycling, as well as barriers to circularity was conducted, aiming to generate insight into the known drivers for and barriers to plastics circularity. The thematic background generated an understanding of knowledge gaps and how to focus the data collection to support formulating the outline for stakeholder engagement.

2.1 Thematic background

2.1.1 Circular economy policies and legal landscape for plastics

Increasing recycling rates and well-functioning markets for secondary raw materials are preconditions for the implementation of a circular economy, as also highlighted in the European Green Deal (COM/2019/640), Circular Economy Action Plan (COM/2015/0614), New Circular Economy Action Plan (COM/2020/98) and the Plastics Strategy (European Commission, 2015, 2018a, 2019a, 2020a). The promotion of a circular economy has resulted in increasing emphasis on product recyclability and the uptake of recycling practices, including the use of recycled materials and products, at producer and consumer level across the EU.

The promotion of a circular economy has also resulted in increasing pressure on closing material loops in the EU, with particular focus on plastics (European Commission, 2018a, 2019a, 2020a). There has been a significant number of new plastic policies and legislation in Europe in recent years, aiming to reduce the unsustainable plastic consumption and to improve its recycling rates while preventing exports of plastic waste (European Commission, 2018b,c,e, 2019b, 2020b, 2022b,c, 2023, 2024a). Some of the most recent actions have focused on packaging waste (European Commission, 2019b, 2022c).

In recycling, meeting the end-of-waste criteria stated in The Waste Framework Directive (EC/2008/98) results in the waste be reclassified from being a waste to being a product and being subject to product legislation instead of waste legislation (European Commission, 2018b; zu Castell-Rüdenhausen et al., 2021). In the EU, several sectors of production are covered by Extended Producer Responsibility (EPR) schemes, in which the producer's responsibility for a product is extended to the post-consumer stage of a product's life cycle.

Chemical recycling technologies are not yet included in the legislative framework for calculating recycling rates as stated in the waste directives (European Commission, 2018b,e,d, 2020b). Technology development enhancing the efficiency of recycling processes is expected to tackle many of the recyclability problems of plastic waste (Cardamone et al., 2021, 2022). The proposed Packaging and Packaging Waste Regulation (COM/2022/677) is currently the only legislative document including chemical recycling for calculating recycling rates (European Commission, 2022c).

In plastics circularity, the legislative focus has been primarily on waste management (zu Castell-Rüdenhausen et al., 2021). The EU has very recently adopted the Ecodesign for Sustainable Products Regulation (EU/2024/1781), ESPR, to improve the circularity and sustainability aspects on products placed on the EU market. The ESPR is the main mechanism in the EU to push producers to increase the use of secondary raw materials. Objectives of the ESPR is to enable setting ecodesign requirements on products, facilitating the implementation of ecodesign (European Commission, 2024b).

The key challenge for plastics circularity is that reuse and recycling of end-of-life plastics remains very low, and the demand for recycled plastics is still low (European Commission, 2018a), accounting for only around 10% of plastics demand in Europe (Plastics Europe, 2022). A key objective of the Plastics Strategy is to increase the recycling capacity and the demand for recycled plastic content in production. Overall, the strategy has set a 10 million ton target for recycled plastics to be used in products in the EU by 2025 (European Commission, 2018a). Many brand owners and manufacturers have pledged to reduce their consumption of virgin material and use more recycled content (Lisiecki et al., 2023) and reducing plastic pollution (Diana et al., 2022). The European Commission launched the Circular Plastics Alliance in 2018 to increase the demand and facilitate the uptake for recycled plastics (European Commission, 2018a, 2022a), other voluntary pledges are e.g., the Ellen MacArthur Foundation's New Plastics Economy Global Commitment (Ellen MacArthur Foundation, 2022), and the UN treaty to end plastic pollution (United Nations, 2021).

2.1.2 Managing plastics recycling in the EU

Plastic waste can be managed either by sorting it at the source and collecting it through a specific scheme or as mixed waste without sorting. For mixed waste, the initial step involves separating different materials and polymers. When plastics are combined with other materials, such as in electronic devices or vehicles, the sorting process includes detachment or shredding. Once sorted by polymer type, the materials undergo mechanical or chemical recycling to produce secondary raw materials. In the EU, mechanical recycling is the dominant method for plastic recycling (Plastics Recyclers Europe, 2023). The capacity for mechanical recycling in Europe has grown significantly, from 3 million tons in 2014 to 11.3 million tons in 2021 (Plastics Recyclers Europe, 2022, 2023). This growth has also led to a reduction in plastic waste exports from the EU, decreasing from 2.6 million tons in 2016 to 1.1 million tons in 2022 (Eurostat, 2023).

Mechanical recycling is effective for clean, uncontaminated single-material plastic waste. This process involves shredding, washing, drying, and remelting the plastic to create recycled pellets for new manufacturing (Al-Salem et al., 2009; Hopewell et al., 2009; Ragaert et al., 2017). Conversely, mixed and contaminated plastics are unsuitable for mechanical recycling; instead, chemical recycling technologies are more appropriate for these lower-quality materials (Ragaert et al., 2017; Rahimi and Garcia, 2017; Lase et al., 2023). Chemical recycling technologies are being developed to eliminate contaminants, such as brominated flame retardants, and to handle mixed waste streams (Ardolino et al., 2021; Vollmer et al., 2020). In chemical recycling, polymers are broken down into monomers through processes like pyrolysis, hydrolysis, or solvolysis; the resulting products can be used as petrochemical feedstocks or re-polymerized into virgin-grade plastics (Ragaert et al., 2017). However, recycling incurs losses, and the volume of collected plastics does not match the volume of secondary plastics produced (zu Castell-Rüdenhausen et al., 2024), with approximately 35% of the material lost during recycling (Amadei and Ardente, 2022).

The design stage determines 80% of a product's environmental impacts (Kamp Albæk et al., 2020), making design particularly important for plastics circularity (ECOS, 2019). Design from recycling refers to promoting the use of recycled materials in products and components. Design for recycling, on the other hand, refers to design strategies in product development that promote sustainable end-of-life management, aiming to make the product better suitable for recycling. However, complex product design results in products containing multiple materials. Furthermore, most plastic products are designed to be used only once without considerations for proper recyclability (zu Castell-Rüdenhausen et al., 2022). The optimization of recyclability includes selecting non-toxic, recyclable materials that are easily separated and sorted for recycling and reuse (Brezet et al., 1997). Consequently, design for recycling facilitates plastics circularity by enhancing end-of-life recyclability already at planning stage, enabling products entering the market to better fit into existing recycling systems (ECOS, 2019). Currently, enhanced eco-design considerations are gaining importance, in particular in reducing the overall material usage and in simplifying disassembly to facilitate improved recycling (Preka et al., 2022). However, besides understanding on eco-design the circularity in plastics calls for an interplay of policy action, market incentives, and technology development.

The plastics consumption of the construction (22.9%), automotive (8.3%), and electronics (5.7%) sectors are exceeded only by the packaging (39.0%) sector in Europe. The packaging sector also displays highest recycling rates, at 37.8%, followed by the electronics sector at 20.0%, automotive at 18.8%, and the construction sector at 17.4%. The construction sector has the highest circular materials use rate, with 22.7% recycled content, compared to the circular materials use rates of the packaging sector (9.7%), the automotive at 4.6% and the electronics sector at 3.2% (Plastics Europe, 2025).

2.1.3 Barriers to circularity

Today, the plastics industry is still dominated by linear business models with little focus on circularity (European Environment Agency, 2021). Barriers to plastic circularity are not just technical, but stem from a combination of policy, market, societal and industry features throughout the whole value chain of plastics use (EASAC, 2020; zu Castell-Rüdenhausen et al., 2022). Both systemic and technological innovation is needed for moving toward more circular and sustainable business models in the plastics production and consumption system (European Environment Agency, 2021).

The production of plastics involves the use of chemical additives to improve specific technical properties, as well as color and stability. However, some of these additives, including many flame retardants and plasticizers, are hazardous (Singh et al., 2017). This complicates recycling efforts, as various grades of the same polymer, each with different additives, are mixed during collection (European Environment Agency, 2021; zu Castell-Rüdenhausen et al., 2022). Additionally, plastic products can become contaminated during their use and collection, for example, through contact with food waste or chemicals; this contamination can cause discoloration and odors, reducing the quality of the recycled plastic and sometimes making recycling impossible (Material Economics, 2018), as there are strict regulations on the allowable content of hazardous substances in recycled plastics (European Environment Agency, 2021; zu Castell-Rüdenhausen et al., 2022).

To produce high-quality recycled plastics, it is essential to separate polymers into mono-polymer streams and remove any other materials before recycling (Material Economics, 2018). The effectiveness of recycling processes largely depends on the quality of the waste, which is often heterogeneous, containing various polymers, additives, and sometimes other materials like metals and paper (Dahlbo et al., 2018; zu Castell-Rüdenhausen et al., 2022). Mixing different grades during recycling further diminishes the quality of the recycled plastics (Klotz et al., 2022). Additionally, the mechanical recycling process can damage the polymers, limiting the number of times they can be recycled, with the extent of degradation varying between different polymers (zu Castell-Rüdenhausen et al., 2022). These degradations result in recycled plastics of average quality, which are unsuitable for high-end applications but may be adequate for standard uses with fewer requirements (Wiesinger et al., 2021; Klotz et al., 2022). To compensate for quality degradation, virgin materials are often added to the recycled plastics (zu Castell-Rüdenhausen et al., 2022).

Virgin plastics can seldom be fully replaced with recycled plastic (Klotz et al., 2022). Different applications can utilize different ratios of recycled plastics, and the rates of substituting virgin plastics are not static (Astrup et al., 2018; Haupt et al., 2018; Vadenbo et al., 2017; Zink et al., 2016) but depend on both the technical properties of the secondary materials and the quality requirements of the substituted materials, as well as by other restrictions, including economic, socio-economic and legislative conditions (Vadenbo et al., 2017). The uptake of secondary materials in products can also be limited by requirements on e.g., aesthetics, odor, hygiene, safety, costs, and technical requirements such as stability and resistance to wear, fatigue, and to chemicals, as well as processing characteristics and degradation (Klotz et al., 2022).

The costs of recycling plastics (including both investment and operational costs) remain somewhat high in comparison to the low market price of virgin plastics (Letcher, 2020; zu Castell-Rüdenhausen et al., 2022). Different polymers have different market demand, and the value is further determined by material quality, where also color and odor have impact on the price (zu Castell-Rüdenhausen et al., 2022). Consequently, recycled plastics can rarely compete with prices and quality of virgin plastics—yet recyclers operate in the same market as virgin plastic producers (EASAC, 2020; Letcher, 2020). The barriers to increase the demand of recycled plastics also link to challenges finding sufficient and stable volumes of recycled plastics at the right quality (Nordin Ljungkvist et al., 2019). A highly developed waste incineration sector can compete for feedstock with the recycling sector (Wahlstrom et al., 2019). The potentially high cost, low quality, and limited availability of recycled plastics result in limited demand, resembling a chicken-and-egg dynamic where the lack of demand is holding back investments for improvement (European Environment Agency, 2021). Consequently, the high recycling rates according to current EU targets may also result in economic loss (Cimpan et al., 2023).

2.2 Methodology

The stakeholder interaction was conducted within the NONTOX project (EU Horizon 2020 programme grant agreement No 820895) that aimed for increasing recycling of plastics from the targeted sectors (NONTOX Project, 2019). The interviewees were selected within the project consortium affiliate networks to represent all targeted sectors as well as all value chain actors. For the waste management and collection phase (A), the construction sector was represented by a recycler, the electronics and automotive sectors by producer responsibility organizations. The phase of material recycling and secondary raw material (SRM) markets (B) is not differentiated into sectors, as this phase is represented by non-packaging plastics recyclers. For the product design and manufacture phase (C), the electronics sector is represented by brand owners and design experts and all sectors by manufacturers (see Annex B for the interview details). The value chain outline was generated based on a literature study and further explored and validated in the first workshop with key stakeholders (Workshop #1; see workshop programs in Annex A). The value chain activities and actors were defined to ensure the interviewees would represent the targeted plastic sectors in Europe, as well as the whole value chain of actors.

2.2.1 Value chain phases and actors

The value chain phases and actors in a circular plastics system vary between sectors. In the context of ELV, WEEE, and CDW, this study assesses a simplified circular plastics value chain that reflects the characteristics of the focus sectors (see Figure 1), wherein the use phase of products and components and the subsequent waste generation is followed first by post-consumer collection, including on-site sorting, then by pre-treatment and material recycling, including dismantling, shredding and sorting, and the production of recycled plastics, as well as sales and the markets for recycled plastics. Finally, the third phase of the simplified value chain is comprised of product and component design, as well as the production of these. The use phase has been excluded from the scope of this study.

Figure 1. Simplified value chain for circular plastics, excluding the use phase (Modified from zu Castell-Rüdenhausen and Marttila, 2023).

The first value chain phase (A) is represented by actors related to end-of-life collection and management of waste. These are connected to the producers through producer responsibility organizations (PROs), which represent producers and have responsibility for end-of-life management through the mandatory extended producer responsibility (EPR) in the EU for both the WEEE and ELV sectors. The second value chain phase (B) is represented by actors in the recycling industry, with the core objective to produce secondary raw materials from waste feedstocks (van der Harst et al., 2016), but also with potential for upcycling and value addition to the recycled plastics to answer market dynamics. The third value chain phase (C) constitutes product design by brand owners and original equipment manufacturers (OEMs), as well as the production of products and components by plastic converters, including also the eventual utilization of recycled plastics in the production of new products and components.

2.2.2 Data collection

Data collection was implemented through stakeholder events, namely through expert interviews and in a specific workshop for data collection (Workshop #2), using a structured outline that was distributed prior to the events together with complementary materials on the policy landscape in the EU. The interviews lasted 1.5–2 h, enabling in-depth conversation of all topics addressed. All interviews were recorded and transcribed.

The first topic of data collection addressed the first research objective of identifying barriers currently hindering plastics circularity. The objective was both to identify internal barriers that prevent change from within, as well as to explore external barriers perceived by the stakeholders. This topic was further divided into four sections, with the first section addressing market challenges (pricing and cost as key questions) covering the transition to a profitable recycling industry, the second section addressing technology challenges and feedstock quality, the third section addressing design addressed topics such as the use of recycled plastics in manufacturing and design for recycling, and the last section addressing information availability focused on traceability and the management of data. The role of policy instruments and the impacts of transboundary movements of waste were also discussed.

The second topic addressed the second research objective of identifying solutions that facilitates circularity in the targeted sectors. The objective was to identify means for overcoming barriers and bottlenecks related to legislation, technology, and economics. The focus was on instruments that are known to improve the recyclability of products, recovery rates of collection systems, and market demand for recovered materials.

The third topic addressed the third research objective of understanding the internal decision-making regarding circularity in the value chain. The objective was to enhance understanding of where decisions regarding circularity are made to enable the efficient targeting of actions that drive plastics circularity. The focus was on the use of recycled plastics, and the recyclability of products. To enable an understanding of where decisions on circularity are being made and how it impacts other stages of the value chain, the stakeholders were also asked to elaborate on the implementation and follow-up on decisions, and on key bottlenecks for decision-making and implementation.

2.2.3 Data analysis

To answer the objective of mapping external and also internal barriers to plastics circularity, identified barriers were thematically grouped under preliminary codes, grouping similar topics and highlighting topics identified by several stakeholders. After this, the solutions to the barriers, as suggested by the stakeholders, were compared to existing knowledge (see Section 2.1), and the solutions that had been allocated to specific barriers were analyzed to find patterns regarding how problems and solutions were paired by the stakeholders. Barriers and solutions that had not been highlighted by several stakeholders were discarded as not relevant in comparison to those that got more attention. This enabled extraction of a set of specific barriers and their potential solutions.

In the next step, overlapping solutions were coded and grouped, enabling one solution to answer multiple barriers. Once the solutions were grouped, recommendations for implementing the solutions in practice were assigned to all solutions. The assignment of recommendations was based on literature review and further examined in an expert workshop (Workshop #3). Based on the nature of the recommendations, they were categorized into actions for legislative revision, policy implementation and standardization activities.

The actors to which the recommendations were targeted were identified by assessing which actors were affected by the recommendations and where in the value chain the implementation of the recommendations would lead to a systemic change. To address the fourth research objective of generating targeted actions for supporting the transition to plastics circularity in Europe, the recommended actions were traced back to the original recommendation and barrier. The recommendations and actions were then targeted to the identified actors and outlined along the simplified value chain.

Finally, to validate the results of the data analysis, an internal data validation workshop (Workshop #4) was organized, where the results were presented to stakeholders and discussed in a round table discussion.

3 Results

The current barriers to plastics circularity for the targeted sectors, as well as solutions for overcoming these, were mapped in stakeholder interaction activities, including expert interviews and workshops. Solutions and recommendations for targeted actions are outlined along the simplified value chain (see Figure 1).

3.1 Barriers to plastics circularity

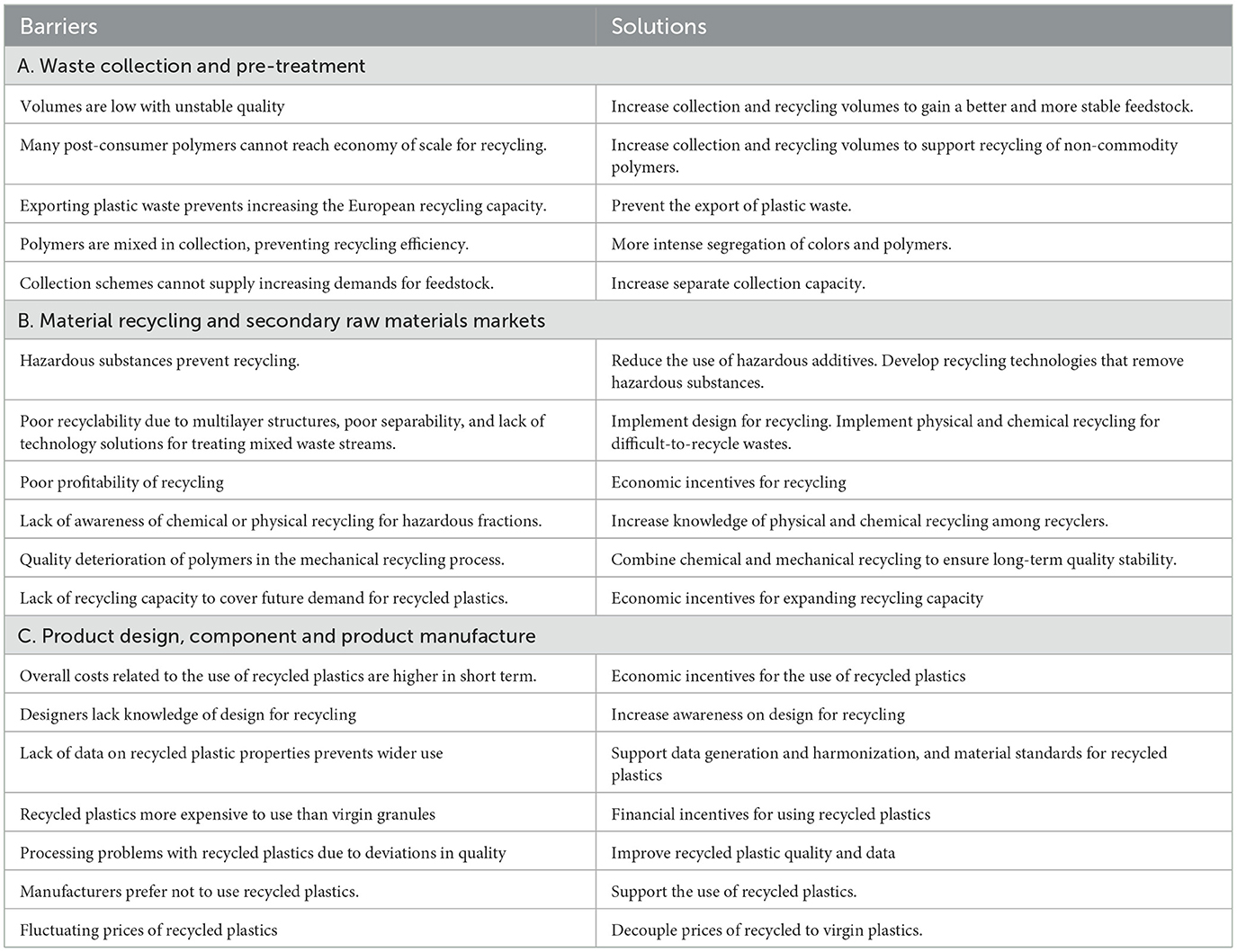

The first research objective of identifying barriers currently hindering plastics circularity as perceived by different stakeholders was explored both through the internal barriers that prevent change from within, as well as through external barriers. The identified barriers were outlined along the simplified circular value chain as presented in Table 1.

Table 1. The identified barriers and solutions for plastics circularity outlined along the simplified value chain (zu Castell-Rüdenhausen and Marttila, 2023).

Firstly, the value chain stage for waste collection and pre-treatment (A) was shown to encounter several barriers, such as problems with collection volumes being small and vulnerable for changes in quality. A key barrier presented in the stakeholder interaction was that post-consumer recycling often cannot reach economy of scale; small volumes and poorly sorted waste prevents recycling of other than commodity polymers. It was highlighted that today, mainly post-consumer recycled polyolefins and PET are available on the market, whereas other recycled plastics are mainly post-industrial. The quality of the collected waste was stated to be affected by most products being designed without consideration for end-of-life. Mixing of polymers occurs at collection since collection systems do not separate polymers. It was highlighted that a non-stable feedstock quality results in variances in the produced recycled plastics. So far, obligatory material specific recycling targets were only introduced for packaging. Although many waste streams have obligatory recycling targets, they are not specifically targeting plastic recycling. Furthermore, plastic waste is exported from Europe for treatment both due to lack of capacity and economic incentives for recycling. Reporting allows including waste that is exported for recycling to attain the recycling targets. Today significant volumes of exported plastic waste are reported as recycled, preventing investments in European recycling capacity.

Secondly, the value chain stage for material recycling and secondary raw materials markets (B) was shown to encounter barriers mainly related to the profitability of recycling and poor recyclability of materials, as well as barriers related to technology efficiency and capacity. The lack of awareness among recyclers of the option of utilizing emerging recycling technologies, such as chemical or physical recycling, was believed to prevent the recycling of mixed plastic fractions and hazardous fractions. These fractions are now lost to incineration, landfilling and export. Furthermore, quality deterioration of the polymers in the mechanical recycling process was seen to prevent use in other than simple applications. Chemical recycling was believed to potentially support the mechanical recycling and ensure stability of polymer quality in the long run. However, the stakeholders highlighted that the categorization of emerging recycling technologies is not straight-forward. Where mechanically recycled plastics have a clear route for catergorization as recycling, the categorization of other recycling routes is not fully clear. Related to the uptake of secondary raw materials in products, mandatory recycled content requirements for products or producers (also known as mixing obligations) were seen as a key policy for increasing the demand for recycled plastics. However, the stakeholders underlined that if mixing obligations were introduced, some key bottlenecks need to be addressed, such as meeting supply and demand, and control of feedstocks to prevent mismanagement. In addition, mixing obligations should be considered on a case-to-case basis as they may be prevented by strict safety requirements for certain products. Today, there is no EU wide end-of-waste criteria. Thus, a recycled plastic that is accepted as a product in one member state, is seen as a waste in another member state, this was seen as an obstacle for the EU-wide trade of recycled plastics.

Lastly, the value chain stage for product design, component and product manufacture (C), was shown to encounter a major obstacle due to manufacturers preferring not to use recycled plastics. Another key barrier to increasing recycling rates that was emphasized by the stakeholders was designers' lack of knowledge of the requirements of the recycling processes. It was stated that today most products are designed without consideration for end-of-life, and even when designers aim for recyclability, they often fail due to lack of proper understanding of the requirements of the recycling process. The absence of end-of-life considerations, such as the use of hazardous substances, multilayer materials and some manufacturing methods, such as gluing materials together, was viewed as a significant issue. Problems related to higher costs from the use of recycled plastics were associated with lack of technical data for recycled plastics, and deviations in recycled plastic quality. Although recycled plastics may be less expensive to purchase, the overall costs increase in the short term as processes need to be redesigned for new material properties. The stakeholders all favored increasing the use of recycled plastics, despite some extra expenses related to recycled plastic use. However, the image benefits from using recycled plastics were not perceived as yielding sufficient monetary value to cover expenses due to changing raw material. For implementing plastics circularity, it is not sufficient to increase recycling volumes alone, the market demand for recycled plastics is needed to incentivise investments in recycling infrastructure. Currently recycled plastics cannot compete with prices and quality of virgin plastics, policies for creating a demand-pull to support the recycled plastics market is lacking.

3.2 Solutions facilitating plastics circularity

The second research objective was to identify solutions that facilitate circularity by overcoming the identified barriers. The barriers that were highlighted by several stakeholders were paired with potential solutions from the data and presented along the simplified value chain as presented in Table 1. Overall, the solutions are developed to improve the recyclability of products, recovery rates of collection systems, and market demand for recovered materials.

As shown in Table 1, the solutions for the value chain stage for waste collection and pre-treatment (A) focus on increasing collection and recycling volumes and separate collection capacity to gain a better and more stable feedstock, enabling recycling of non-commodity polymers. The solutions for the value chain stage for material recycling and SRM markets (B) focus on developing and increasing knowledge of recycling processes that could remove hazardous substances and recycle difficult-to-recycle wastes. The solutions for the value chain stage for product design, and component and product manufacture (C) include incentives for using recycled plastics and improving data availability and harmonized material qualities for recycled plastics. The solutions to the identified barriers exhibit some overlap. The solutions reoccurring in all value chain stages but focusing on the second stage (B) in the value chain are the incentives to promote recycling, such as incentives for expanding recycling capacity, preventing exports, improving recyclability, and economic incentives for recycling. The solutions target different actors, and they have also varied social, economic and environmental implications.

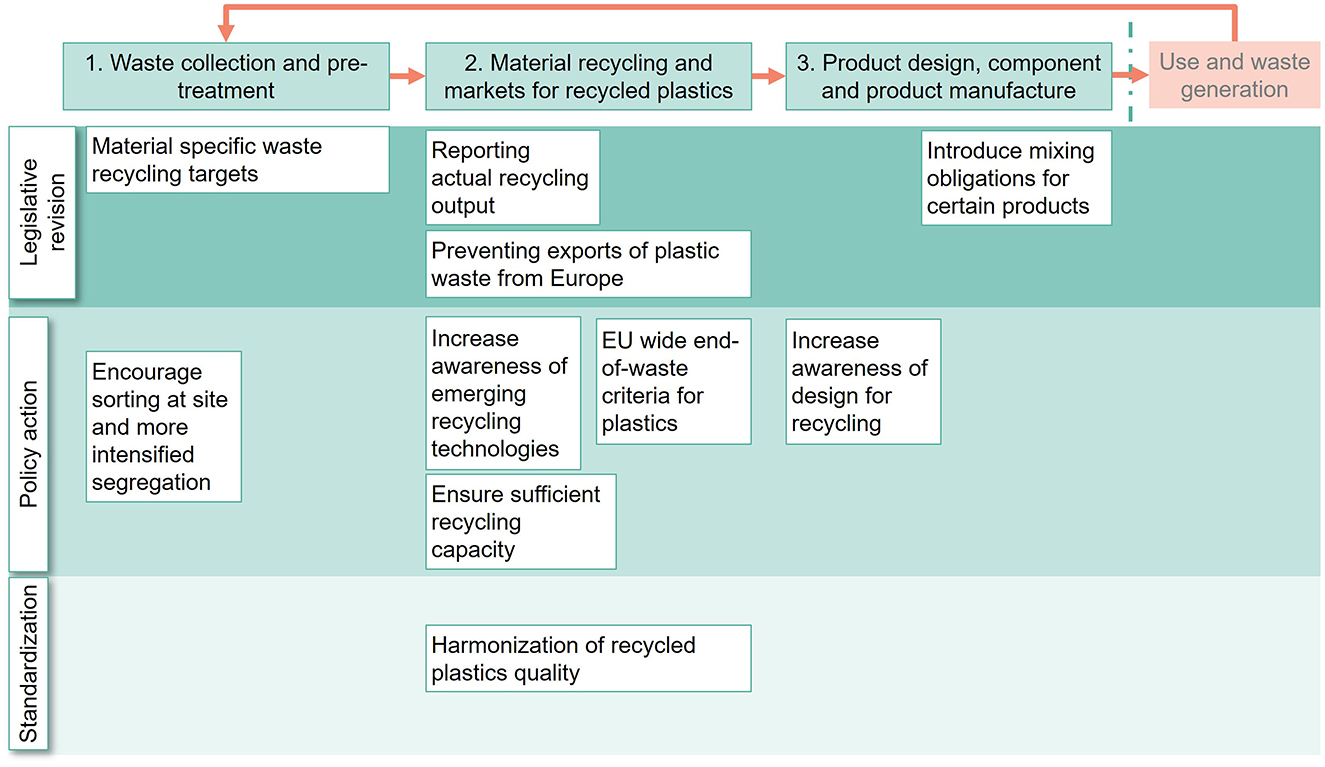

3.3 Recommendations for actions

To enable the fourth research objective of generating targeted actions, the solutions were first translated into general recommendations for practical action with no reflection on the context of implementation. Instead, the overlapping solutions were grouped into categories, allowing one solution to respond to more than one barrier and disregarding the preliminary value chain division of the barriers and solutions in Table 1. Recommendations for practical implementation were derived for each category, such as actions for legislative revision, policy implementation and standardization activities (see Table 2). The five identified categories focus on the following:

Enhancing collection and recycling efficiency (1): at present, collection volumes are very low and exhibit fluctuating quality. Inefficient collection of waste results in losses of valuable materials. To achieve a better feedstock quality for recycling, increased focus on end-of-life management, increased collection volumes and intensified segregation (into polymers and colors) is needed. Larger and better sorted feedstock volumes would enable recycling of also other than commodity polymers reach economy of scale. Recommendations include legislative revisions for material specific recycling targets and the reporting of actual recycled output using revised calculation methodologies. Site specific sorting and more intensified segregation can be promoted with policy actions.

Supporting increasing the recycling capacity (2): significant volumes of plastic waste are exported from Europe due to lack of European capacity and economic incentives for recycling. The stakeholders stressed that export of plastic waste is currently a key obstacle preventing recycling and investments in European recycling infrastructure. The prevention of exports through legislative revisions can support infrastructure investments that would increase the EU's recycling capacity. Furthermore, increasing the demand for recycled plastics would also create incentives to increase the recycling capacity. Recommendations to support increasing the recycling capacity include changes in the waste legislation and waste shipment legislation to prevent export of plastic waste from Europe.

Enhance the positioning of emerging recycling technologies (3): problems related to security of supply could be solved by pushing the implementation of emerging technologies that could recycle both hazardous and mixed waste streams, such as chemical or physical recycling. In particular, chemical recycling can support the long-term stability of polymer quality. Overall, on a policy level, there is a need to increase awareness of innovative, emerging recycling technologies.

Enhancing recyclability of waste (4): by increasing knowledge of design for recycling, end-of-life management could be addressed by manufacturers in product design. Suggestions for incentives to promote design for recycling were such as ecolabels for circularity and ecomodulation on EPR fees. Recommendations to increase awareness of design for recycling include toolkits, guidelines, and policies.

Enhance recycled plastic markets and demand for recycled plastics (5): to increase the demand for recycled plastics, policies need to support sufficient recycled plastic supply and harmonized recycled plastic quality. For recycled plastics to compete with virgin plastics, policies on mandatory recycled content requirements in products could create a demand-pull further supported if also implementing harmonized quality standards would support the recycled plastic markets. EU-wide end-of-waste criteria for plastics could serve to remove the administrative burdens associated with wastes and harmonize the quality of recycled plastics.

3.4 Internal decision-making and targeting the actions

The third research objective was to understand the internal decision-making regarding circularity in the value chain. In this section the brand owners were identified as key stakeholders in promoting circularity in the sector, as they are responsible for design both with respect to the use of recycled plastics as raw materials, and for the products end-of-life recyclability. It was, however, found that brand owners must actively promote the use of secondary raw materials, although manufacturers have the final choice as to which materials to use in production. Consequently, it was concluded that large brand owners can influence raw material choices, whereas smaller brand owners cannot.

The data highlighted that policies are a key to steering the actions of key stakeholders. Although several brand owners are driven by the potential to enhance brand value, actively seeking circular solutions, they are significantly restricted by economic profitability. It was also highlighted that policies to support market uptake of secondary raw materials are needed in addition to policies supporting recycling.

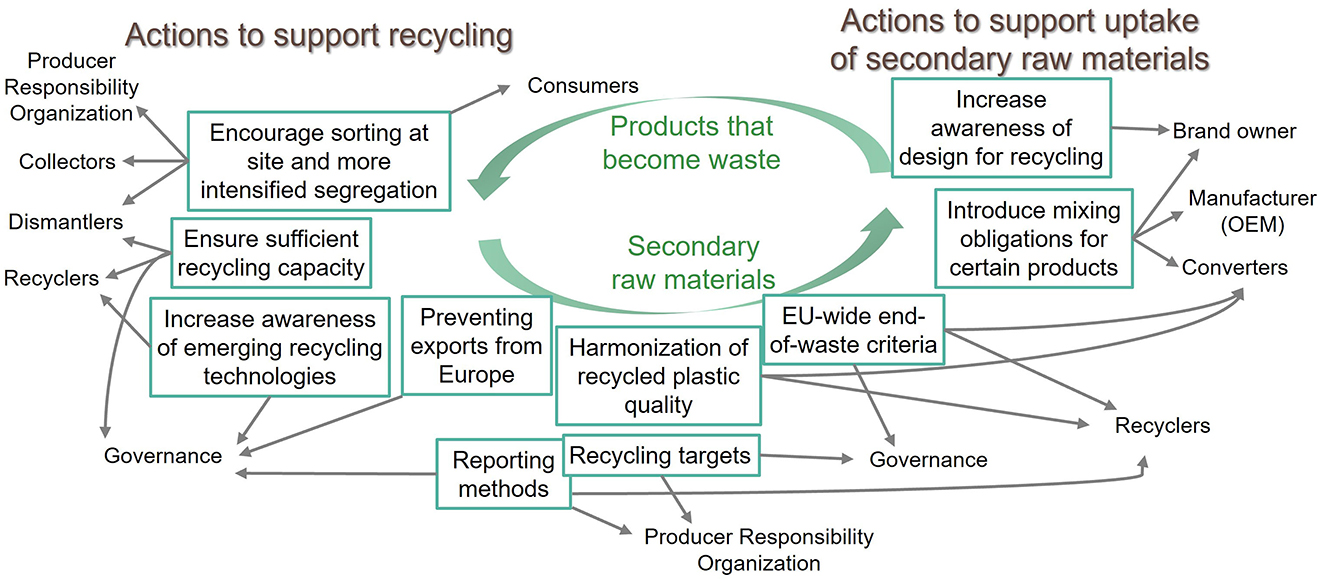

Finally, to tackle the fourth research objective of generating targeted actions, the actions that had been created were now assigned implementation responsibility by tracing the location in the value chain where the original barrier had been identified. The results of the targeted recommendations along the value chain is presented in Figures 2, 3.

Figure 2. Recommendations for enhancing plastics circularity in Europe presented along a simplified value chain.

The impacts of the recommended actions on value chain actors were also assessed by analyzing the systemic changes that each recommendation would require and the impacted stakeholders. As a result, the recommendations clearly highlight the important role of governance actors and recyclers.

4 Discussion

Since 2015 plastics have been a priority area in the EU for promoting a circular economy (European Commission, 2015) with increasing pressure on closing plastic material loops (European Commission, 2018a, 2019a,b, 2020a). Today we have some understanding of the external barriers to plastic circularity, but the internal barriers within the plastic sector remain unclear. We also are yet to solve the problem on how to overcome these barriers. This study set out to identify barriers preventing widespread plastics circularity and to present targeted solutions to overcome them.

This study focused on plastics in the automotive, construction and electronics sectors. Although displaying some similarities in material characteristics and despite having somewhat interconnected material flows, these sectors have some key differences when it comes to plastics circularity. The plastics recycling rates of the three sectors are somewhat similar at ~17–20%, but the circular materials use rate is significantly higher for the construction sector than for the other two sectors. The construction sector has even higher uptake of secondary raw materials than the packaging sector. This could partially result from lower quality requirements in construction products in comparison to the other product categories.

Related to design, we noted major differences noted between the sectors as the electronics and automotive sectors have quite good control of the product design, implementing also sustainable design principles. This might stem from the producer responsibility legislation in these sectors, but also from the control of the brand owners. In construction, there are no strong brand owners claiming ownership for the final products. In construction, contractors use components from different suppliers, whereas in the automotive and electronics sector, the brand over is involved in the design of components. However, in construction it is not the imported components, but the actual buildings, that compose the major material use. Thus, design is quite local as buildings are designed domestically and constructed on site.

4.1 Results and limitations

Our results indicate that policies, focused specifically on the recycling and secondary materials market are key to supporting the circular economy transition. The recommendations include enhancing the collection and recycling efficiency, supporting the expansion of the recycling capacity, enhancing the positioning of emerging recycling technologies, enhancing recyclability of products, and supporting the demand and markets for recycled plastics.

The results tie well with previous studies of EASAC (2020) and Material Economics (2018), including such recommendations as promoting design for recycling, optimizing collection systems to meet the demands of the recycling process, promoting emerging recycling technologies, enabling EU-regional markets for plastic waste, preventing exports of plastic waste from Europe, as well as introducing mixing obligations to create a demand-pull on the secondary materials market. This study, on the other hand, lack recommendations related to pricing of recycled plastics, which the other two studies included. Sure, many stakeholders compared secondary plastics price to virgin, but highlighting the operational costs when using recycled materials, stating that the operational costs have more impact than the raw material costs when it comes to using recycled plastics in production.

Although the main focus of this study is to find solutions to reach the recycling and secondary materials use targets stated in the Plastics Strategy (COM/2018/028), studies on the impacts of policy interventions for implementing circular economy policies indicate that there is not a clear consensus on the economic and socioeconomic benefits (Ferrão et al., 2014; AndreasiBassi et al., 2021; Cimpan et al., 2023). Thus, it is of importance to understand and clearly define the motives for studying circularity—may it be from an economic, social, environmental, or material perspective—the latest being key focus in this study. In general, if aiming for sustainability, it is worth highlighting that circular solutions may not always serve as the most sustainable option. To find the most environmentally, socially or economically sustainable solutions, the recommendations need to be studied further by using suitable methods for that specific purpose.

It is evident that circularity is mainly driven by policies in the EU. However, EU-policies may create some tensions on international markets. Ever stricter policymaking may well reduce the competitiveness of the European industry. A good example of this is the reduction in plastic waste exports. In principle, the export of plastic waste to countries where recycling is cheaper could prove to be a sustainable solution. Although it would indeed require some extra monitoring, such as audits, to ensure the waste is managed in an environmentally sound manner. Stricter policies, nevertheless, require some balancing, as the EU is already accused of over-regulation.

The research methodology may be subject to some biases and limitations. The overall focus was systemic, and the limited number of stakeholder interaction activities, as well as time constraints, may have limited the depth of data collected. Further, the representation of stakeholder groups was not evenly distributed, and the subjective nature of the data collected using this methodology may impact reliability of data. Findings from stakeholder interaction require cautious interpretation, as the specific formulation of questions during interviews, and the presence of other stakeholders in workshops may impact the collected data. The limitations in perspective of the study, i.e., from a technical and a design standpoint, may present some bias toward the distribution of barriers and solutions. Based on these biases, the results from the present study should be seen as indicative and require validation in further studies.

Another major limitation of this study could be the strong focus on the design and manufacture phase of the value chain when mapping the barriers. However, the focus on this specific value chain phase but yet a lack of a broader range of recommendations derived from the stakeholder interaction may indicate a lack of insight into other solutions of the stakeholders, or a bias of the stakeholders leading them to focus more on this specific topic.

Despite its qualitative nature, we believe that it is well justified to support the findings of this study, that to reach plastics circularity in Europe within a set time frame, rapidly enacted and high-impact policies are required. Policies must facilitate the growth of the EU's plastics recycling sector, as well as the demand for secondary raw materials to enable closing of material loops.

4.2 Conclusions

The objective of this work was to assess the barriers to and solutions for plastics circularity in the WEEE, ELV, and CDW sectors by collecting data through stakeholder interaction throughout the value chain. The current drivers and barriers were mapped alongside the mapping of internal decision-making processes concerning circularity in the value chain, and solutions with practical recommendations for targeted actions that would enable the development of a well-functioning plastic recycling system in Europe were outlined.

The main findings show that policies are key to support the growth of the European recycling sector, as well as the uptake of secondary materials in production and closing of material loops. Further, it highlights the role of design, both for the use of recycled plastics as raw materials, as well as for the recyclability of products at end-of-life, as well as the role of key stakeholders in the value chain, specifically brand owners and manufacturers, related to the choice of raw materials. Actions for enhancing plastics circularity in Europe were targeted to specific value chain actors. It was seen that governance actors and recyclers are targeted by most recommendations. However, rapid action is necessary to accelerate the transition to plastics circularity in Europe to meet targets outlined in the European Plastics Strategy. New, high impact policies need to be enacted quickly to allow the industry to react and follow through.

Overall, this study provides knowledge concerning key actions to support the transition to plastics circularity in Europe. The presented recommended actions would contribute to the growth of the EU's recycling sector and diverting of plastic waste away from exports, while also supporting the markets for recycled plastics. Not only would this support the transition to plastics circularity, it would prevent loss of materials due to incineration and export of plastic waste, while also contributing to EU's self-sufficiency for raw materials.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

MC-R: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Resources, Software, Validation, Visualization, Writing – original draft, Writing – review & editing, Project administration. TM: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Resources, Software, Supervision, Validation, Visualization, Writing – review & editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. The study was conducted within the NONTOX project funded by EU Horizon 2020 programme grant agreement no 820895.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/frsus.2025.1531428/full#supplementary-material

References

Al-Salem, S. M., Lettieri, P., and Baeyens, J. (2009). Recycling and recovery routes of plastic solid waste (PSW): a review. Waste Managem.29, 2625–2643. doi: 10.1016/j.wasman.2009.06.004

Amadei, A., and Ardente, F. (2022). Modelling Plastic Flows in the European Union Value Chain. Brussels: JRC Publications Repository.

AndreasiBassi, S., Tonini, D., Saveyn, H., and Astrup, T. F. (2021). “Environmental and socioeconomic impacts of poly(ethylene terephthalate) (PET) packaging management strategies in the EU,” in Environmental Science & Technology (Washington, DC: American Chemical Society).

Ardolino, F., Cardamone, G. F., and Arena, U. (2021). How to enhance the environmental sustainability of WEEE plastics management: An LCA study. Waste Managem. 135, 347–359. doi: 10.1016/j.wasman.2021.09.021

Astrup, T. F., Pivnenko, K., Eriksen, M. K., and Boldrin, A. (2018). Life cycle assessment of waste management: are we addressing the key challenges ahead of us? J. Indust. Ecol. 22, 1000–1004. doi: 10.1111/jiec.12811

Brezet, H., and Van Hemel, C. (1997). Ecodesign: a Promising Approach to Sustainable Production and Consumption., 1. ed. Paris: UNEP.

Brezet, H., Van Hemel, C., Brezet, H., and Rathenau Instituut eds. (1997). Ecodesign: a Promising Approach to Sustainable Production and Consumption. Paris: UNEP.

Cardamone, G. F., Ardolino, F., and Arena, U. (2021). About the environmental sustainability of the European management of WEEE plastics. Waste Managem. 126, 119–132. doi: 10.1016/j.wasman.2021.02.040

Cardamone, G. F., Ardolino, F., and Arena, U. (2022). Can plastics from end-of-life vehicles be managed in a sustainable way? Sustain. Prod. Consumpt. 29, 115–127. doi: 10.1016/j.spc.2021.09.025

Cimpan, C., Bjelle, E. L., Budzinski, M., Wood, R., and Strømman, A. H. (2023). “Effects of circularity interventions in the european plastic packaging sector,” in Environmental Science & Technology (Washington, DC: American Chemical Society).

Dahlbo, H., Poliakova, V., Mylläri, V., Sahimaa, O., and Anderson, R. (2018). Recycling potential of post-consumer plastic packaging waste in Finland. Waste Managem. 71, 52–61. doi: 10.1016/j.wasman.2017.10.033

Diana, Z., Reilly, K., Karasik, R., Vegh, T., Wang, Y., Wong, Z., et al. (2022). Voluntary commitments made by the world's largest companies focus on recycling and packaging over other actions to address the plastics crisis. One Earth 5, 1286–1306. doi: 10.1016/j.oneear.2022.10.008

DiCicco-Bloom, B., and Crabtree, B. F. (2006). The qualitative research interview. Med. Educ. 40, 314–321. doi: 10.1111/j.1365-2929.2006.02418.x

EASAC (2020). Packaging Plastics in the Circular Economy. Halle (Saale): EASACSecretariat, Deutsche Akademie der Naturforscher Leopoldina - German National Academy of Sciences.

ECOS (2019). For Better Not Worse: Applying Ecodesign Principles to Plastics in the Circular Economy. Available online at: https://ecostandard.org/wp-content/uploads/2019/06/APPLYING-ECODESIGN-PRINCIPLES-TO-PLASTICS.pdf (accessed October 10, 2024).

Ellen MacArthur Foundation (2022). The Global Commitment 2022. Available online at: https://www.ellenmacarthurfoundation.org/global-commitment-2022/overview (accessed February 22, 2024).

European Commission (2015). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Closing the loop - An EU action plan for the Circular Economy (COM/2015/0614). Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52015DC0614 (accessed May 28, 2021).

European Commission (2018a). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A European Strategy for Plastics in a Circular Economy COM/2018/028 final. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1516265440535&uri=COM:2018:28:FIN (accessed January 12, 2022).

European Commission (2018b). Consolidated text: Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098 (accessed October 17, 2023).

European Commission (2018c). Consolidated text: Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE) (recast). Available at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02012L0019-20180704 (accessed March 21, 2023).

European Commission (2018d). Consolidated text: Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE) (recast) (Text with EEA Relevance). Available online at: http://data.europa.eu/eli/dir/2012/19/2018-07-04/eng (accessed April 7, 2022).

European Commission (2018e). Consolidated text: European Parliament and Council Directive 94/62/EC of 20 December 1994 on Packaging and Packaging Waste. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A01994L0062-20180704 (accessed February 24, 2023).

European Commission (2019a). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. The European Green Deal (COM/2019/640). Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1588580774040&uri=CELEX:52019DC0640 (accessed May 28, 2021).

European Commission (2019b). Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment. Available online at: https://eur-lex.europa.eu/eli/dir/2019/904/oj (accessed March 21, 2023).

European Commission (2020a). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A New Circular Economy Action Plan For a cleaner and more competitive Europe (COM/2020/98). Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed May 28, 2021).

European Commission (2020b). Consolidated text: Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on end-of Life Vehicles. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02000L0053-20200306 (accessed March 21, 2023).

European Commission (2022a). Circular Plastics Alliance. Available online at: https://single-market-economy.ec.europa.eu/industry/strategy/industrial-alliances/circular-plastics-alliance_en (accessed November 24, 2023).

European Commission (2022b). Commission Regulation (EU) 2022/1616 of 15 September 2022 on Recycled Plastic Materials and Articles Intended to Come into Contact With Foods, and Repealing Regulation (EC) No 282/2008. Available online at: https://eur-lex.europa.eu/eli/reg/2022/1616/oj (accessed August 13, 2024).

European Commission (2022c). Proposal for a Regulation of the European Parliament and of the Council on Packaging and Packaging Waste COM(2022) 677 Final. Available online at: https://environment.ec.europa.eu/system/files/2022-11/Proposal%20for%20a%20Regulation%20on%20packaging%20and%20packaging%20waste.pdf (accessed March 15, 2023).

European Commission (2023). Proposal for a Regulation of the European Parliament and of The Council on Circularity Requirements for Vehicle Design and on Management of End-of-Life Vehicles, COM/2023/451 Final. Available online at: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52023PC0451 (accessed February 22, 2024).

European Commission (2024a). Regulation (EU) 2024/1157 of the European Parliament and of the Council of 11 April 2024 on Shipments of Waste, Amending Regulations (EU) No 1257/2013 and (EU) 2020/1056 and Repealing Regulation (EC) No 1013/2006 (Text with EEA relevance). Available online at: http://data.europa.eu/eli/reg/2024/1157/oj/eng (accessed August 5, 2024).

European Commission (2024b). Regulation (EU) 2024/1781 of the European Parliament and of the Council of 13 June 2024 Establishing a Framework for the Setting of Ecodesign Requirements for Sustainable Products, Amending Directive (EU) 2020/1828 and Regulation (EU) 2023/1542 and Repealing Directive 2009/125/EC (Text with EEA Relevance). Available online at: http://data.europa.eu/eli/reg/2024/1781/oj/eng (accessed August 5, 2024).

European Environment Agency (2021). Plastics, the Circular Economy and Europe's Environment: a Priority for Action. LU: Publications Office. Available online at: https://data.europa.eu/doi/10.2800/5847 (accessed February 24 2023).

Eurostat (2023). ds-056120 Sold Production, Exports and Imports. Available online at: https://ec.europa.eu/eurostat/databrowser/product/page/DS-056120__custom_6306626 (accessed September 5, 2024).

Ferrão, P., Ribeiro, P., Rodrigues, J., Marques, A., Preto, M., Amaral, M., et al. (2014). Environmental, economic and social costs and benefits of a packaging waste management system: A Portuguese case study. Resour. Conservat. Recycl. 85, 67–78. doi: 10.1016/j.resconrec.2013.10.020

Geyer, R., Jambeck, J. R., and Law, K. L. (2017). Production, use, and fate of all plastics ever made. Sci. Adv. 3:e1700782. doi: 10.1126/sciadv.1700782

Hahladakis, J. N., Velis, C. A., Weber, R., Iacovidou, E., and Purnell, P. (2018). An overview of chemical additives present in plastics: migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 344, 179–199. doi: 10.1016/j.jhazmat.2017.10.014

Haupt, M., Kägi, T., and Hellweg, S. (2018). Modular life cycle assessment of municipal solid waste management. Waste Managem. 79, 815–827. doi: 10.1016/j.wasman.2018.03.035

Hopewell, J., Dvorak, R., and Kosior, E. (2009). Plastics recycling: challenges and opportunities. hilos. Trans. R. Soc. Lond. B Biol. Sci. 364, 2115–2126. doi: 10.1098/rstb.2008.0311

Hsu, W.-T., Domenech, T., and McDowall, W. (2021). How circular are plastics in the EU?: MFA of plastics in the EU and pathways to circularity. Cleaner Environm. Syst. 2:100004. doi: 10.1016/j.cesys.2020.100004

Kallio, H., Pietil,ä, A., Johnson, M., and Kangasniemi, M. (2016). Systematic methodological review: developing a framework for a qualitative semi-structured interview guide. J. Adv. Nurs. 72, 2954–2965. doi: 10.1111/jan.13031

Kamp Albæk, J., Shahbazi, S., McAloone, T. C., and Pigosso, D. C. A. (2020). Circularity evaluation of alternative concepts during early product design and development. Sustainability 12:9353. doi: 10.3390/su12229353

Karayilan, S., Yilmaz, Ö., Uysal, Ç., and Naneci, S. (2021). Prospective evaluation of circular economy practices within plastic packaging value chain through optimization of life cycle impacts and circularity. Resour. Conserv. Recycl. 173:105691. doi: 10.1016/j.resconrec.2021.105691

Klotz, M., Haupt, M., and Hellweg, S. (2022). Limited utilization options for secondary plastics may restrict their circularity. Waste Managem. 141, 251–270. doi: 10.1016/j.wasman.2022.01.002

Lase, I. S., Tonini, D., Caro, D., Albizzati, P. F., Cristóbal, J., Roosen, M., et al. (2023). How much can chemical recycling contribute to plastic waste recycling in Europe? An assessment using material flow analysis modeling. Resour. Conserv. Recycl. 192:106916. doi: 10.1016/j.resconrec.2023.106916

Lebreton, L., and Andrady, A. (2019). Future scenarios of global plastic waste generation and disposal. Humanit. soc. sci. commun. 5:6. doi: 10.1057/s41599-018-0212-7

Letcher, T. M. (2020). Plastic Waste and Recycling: Environmental Impact, Societal Issues, Prevention, and Solutions. Cambridge: Elsevier.

Lisiecki, M., Damgaard, A., Ragaert, K., and Astrup, T. F. (2023). Circular economy initiatives are no guarantee for increased plastic circularity: a framework for the systematic comparison of initiatives. Resour. Conserv. Recycl. 197:107072. doi: 10.1016/j.resconrec.2023.107072

Material Economics (2018). The Circular Economy a Powerful Force for Climate Mitigation. Available online at: https://www.sitra.fi/app/uploads/2018/06/the-circular-economy-a-powerful-force-for-climate-mitigation.pdf (accessed February 24, 2023).

NONTOX Project (2019). NONTOX Project – NONTOX Project. Available online at: http://nontox-project.eu/ (accessed October 26, 2023).

Nordin Ljungkvist, H., Lindkvist, L., Boss, A., Baumann, H., and Boberg, N. (2019). Kartläggning av plastavfallsflöden, återvinningsmetoder och marknader: kunskapsunderlag för ett returraffinaderi. Available online at: https://www.johannebergsciencepark.com/sites/default/files/Kartl%C3%A4ggning%20av%20plastavfallsfl%C3%B6den%2C%20%C3%A5tervinningsmetoder%20och%20marknader%20kunskapsunderlag%20f%C3%B6r%20ett%20returraffinaderi.pdf (accessed November 18, 2021).

Plastics Europe (2022). The Circular Economy for Plastics – A European Overview. Available online at: https://plasticseurope.org/knowledge-hub/the-circular-economy-for-plastics-a-european-overview-2%20/ (accessed October 17, 2023).

Plastics Europe (2024). “Plastics – the fast Facts,” in Plastics Europe. Available online at: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2023/ (accessed August 22, 2024).

Plastics Europe (2025). “The circular economy for plastics – a European Analysis 2024,” in Plastics Europe. Available online at: https://plasticseurope.org/knowledge-hub/the-circular-economy-for-plastics-a-european-analysis-2024/ (accessed February 22, 2025).

Plastics Recyclers Europe (2022). Plastics Recycling Industry in Europe. Mapping of Installed Plastics Recycling Capacities. 2020 Data. Available at: https://www.plasticsrecyclers.eu/wp-content/uploads/2022/10/plastics-recycling-industry-in-europe.pdf (accessed August 5, 2024).

Plastics Recyclers Europe (2023). Plastics Recycling Industry in Europe. Mapping of Installed Plastics Recycling Capacities. 2021 Data. Available at: https://www.plasticsrecyclers.eu/wp-content/uploads/2023/03/Statistics_2023_FINAL_V2.pdf (accessed August 5, 2024).

Preka, R., Fiorentino, G., De Carolis, R., and Barberio, G. (2022). The challenge of plastics in a circular perspective. Front. Sustain. Cities 4:920242. doi: 10.3389/frsc.2022.920242

Ragaert, K., Delva, L., and Van Geem, K. (2017). Mechanical and chemical recycling of solid plastic waste. Waste Managem. 69, 24–58. doi: 10.1016/j.wasman.2017.07.044

Rahimi, A., and Garcia, J. (2017). Chemical recycling of waste plastics for new materials production. Nat. Rev. Chemist. 1:46. doi: 10.1038/s41570-017-0046

Saunders, M. N. K., Lewis, P., and Thornhill, A. (2007). Research Methods for Business Students., 4th ed. Harlow, England; New York: Financial Times/Prentice Hall.

Singh, N., Hui, D., Singh, R., Ahuja, I. P. S., Feo, L., and Fraternali, F. (2017). Recycling of plastic solid waste: A state of art review and future applications. Composites Part B: Eng. 115, 409–422. doi: 10.1016/j.compositesb.2016.09.013

Tenhunen-Lunkka, A., Rommens, T., Vanderreydt, I., and Mortensen, L. (2022). Greenhouse gas emission reduction potential of European Union's circularity related targets for plastics. Circ. Econ. Sust. 3, 475–510. doi: 10.1007/s43615-022-00192-8

UNEP (1998). Cleaner production: a guide to sources of information., 2nd ed. Paris: United Nations Environment Programme, Industry and Environment.

United Nations (2021). Nations Agree to End Plastic Pollution. Available online at: https://www.un.org/en/climatechange/nations-agree-end-plastic-pollution (accessed February 22, 2024).

Vadenbo, C., Hellweg, S., and Astrup, T. F. (2017). Let's Be Clear(er) about substitution: a reporting framework to account for product displacement in life cycle assessment. J. Indust. Ecol. 21, 1078–1089. doi: 10.1111/jiec.12519

van der Harst, E., Potting, J., and Kroeze, C. (2016). Comparison of different methods to include recycling in LCAs of aluminium cans and disposable polystyrene cups. Waste Managem. 48, 565–583. doi: 10.1016/j.wasman.2015.09.027

Vollmer, I., Jenks, M. J. F., Roelands, M. C. P., White, R. J., van Harmelen, T., de Wild, P., et al. (2020). Beyond mechanical recycling: giving new life to plastic waste. Angewandte Chemie Int. Edition 59, 15402–15423. doi: 10.1002/anie.201915651

Wahlstrom, M., Pohjalainen, E., Teittinen, T., Van der Linden, A., Christis, M., and Manshoven, S. (2019). Are We Losing Resources When Managing Europe's Waste? Available online at: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/are-we-losing-resources-when-managing-europes-waste-1 (accessed February 24, 2023).

Wiesinger, H., Wang, Z., and Hellweg, S. (2021). Deep Dive into Plastic Monomers, Additives, and Processing Aids. Environmental Science & Technology (Washington, DC: American Chemical Society).

Zink, T., Geyer, R., and Startz, R. (2016). A market-based framework for quantifying displaced production from recycling or reuse. J. Indust. Ecol. 20, 719–729. doi: 10.1111/jiec.12317

zu Castell-Rüdenhausen, M., and Marttila, T. (2023). “Measures to enhance a circular plastic economy in Europe,” in Proceedings 5th Plate Conference (Aalto University publication series ART + DESIGN + ARCHITECTURE; Vol. 2023, No. 3), eds. K. Niinimäki and K. Cura (Espoo: Aalto University), 1189–1195.

zu Castell-Rüdenhausen, M., Tenhunen, A., Vincenti, N., Marttila, T., Wahlström, M., and Colzani, P. (2021). Review of the European Legislative and Policy Framework Affecting the Recycling of Hazardous Plastics from ELV, WEEE and C&DW. Otaniemi: VTT Technical Research Centre of Finland.

zu Castell-Rüdenhausen, M., Tenhunen-Lunkka, A., D'Amato, A., Almasi, A., Vanderreydt, I., Fogh Mortensen, L., et al. (2024). Measuring Europe's Plastics Circularity - Through the Lenses of the EEA Circularity Metrics Lab. Available online at: https://www.eionet.europa.eu/etcs/etc-ce/products/etc-ce-report-2024-6-measuring-europes-plastics-circularity-through-the-lenses-of-the-eea-circularity-metrics-lab (accessed August 5, 2024).

zu Castell-Rüdenhausen, M., Wahlstrom, M., Nelen, D., Dams, Y., Paleari, S., Zoboli, R., et al. (2022). Investigating Europe's Secondary Raw Material Markets. LU: Publications Office of the European Union. Available online at: https://data.europa.eu/doi/10.2800/48962 (accessed February 24 2023).

Keywords: plastics circularity, non-packaging plastics, circular economy, recycling, policy recommendations, stakeholder interaction

Citation: zu Castell-Rüdenhausen M and Marttila T (2025) Value chain actor perceptions to enhance plastics circularity in Europe—recommendations for future action. Front. Sustain. 6:1531428. doi: 10.3389/frsus.2025.1531428

Received: 20 November 2024; Accepted: 07 April 2025;

Published: 28 April 2025.

Edited by:

Vincenzo Piemonte, Campus Bio-Medico University, ItalyReviewed by:

Maria Angela Butturi, University of Modena and Reggio Emilia, ItalyCiprian Cimpan, University of Southern Denmark, Denmark

Copyright © 2025 zu Castell-Rüdenhausen and Marttila. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Malin zu Castell-Rüdenhausen, bWFsaW4uY2FzdGVsbEB2dHQuZmk=

Malin zu Castell-Rüdenhausen

Malin zu Castell-Rüdenhausen Tatu Marttila

Tatu Marttila