- Department of Biotechnology, Faculty of Biosciences, University for Development Studies, Tamale, Ghana

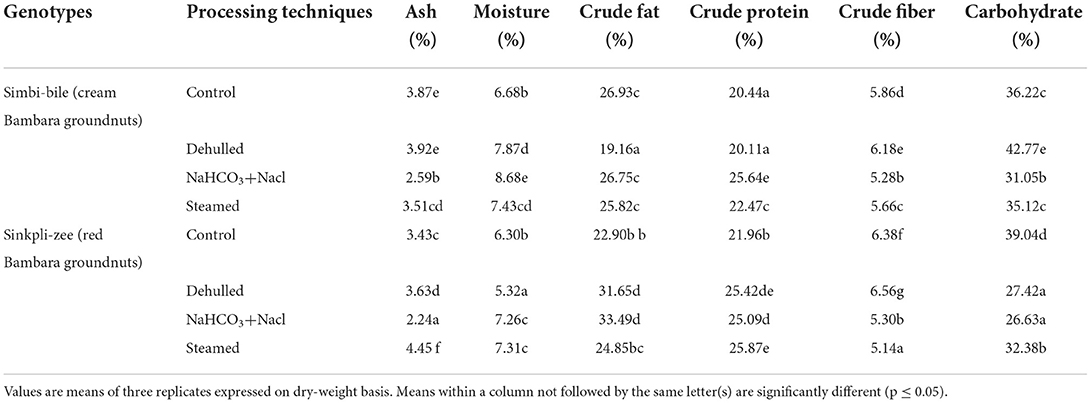

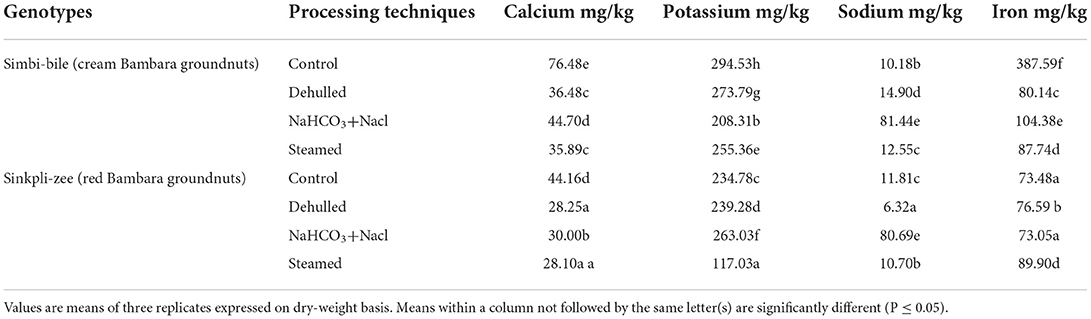

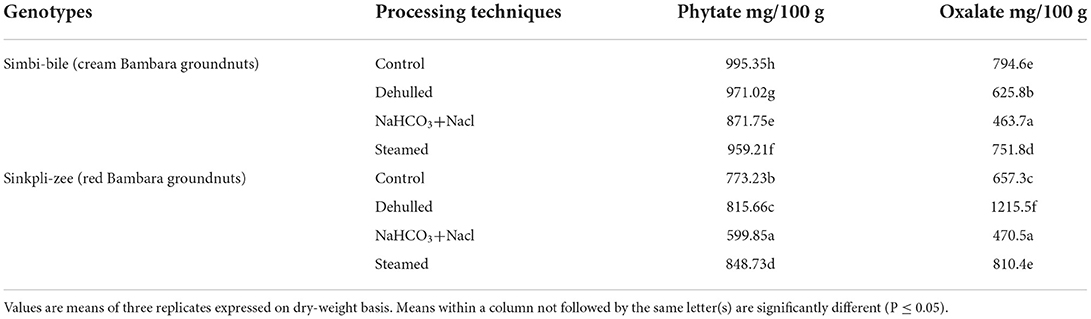

Bambara groundnut (Vigna subterranea (L) Verdc.) is a leguminous plant that is widely cultivated in West Africa for its nutritious seeds. However, the hard-to-cook phenomenon of this legume affects its patronage by consumers. The quality and bioavailability of nutrients are affected by processing techniques during cooking. This study evaluated the effects of processing techniques on the nutritional quality of two Bambara groundnut varieties (namely, Simbi-bile and Sinkpili-zee). For this, each variety was subjected to four processing techniques, namely, (i) dehulled and soaked in water, (ii) dehulled and soaked in 1% NaHCO3 + 1% NaCl, (iii) dehulled and steamed, and (iv) Control. After sample processing, the Association of Official Agricultural Chemists (AOAC) standard protocols were used for chemical analysis. The results on proximate composition, anti-nutritional factors, and seed minerals composition showed significant variations among treatments. The main effects of variety and processing technique markedly influenced the parameters measured. Soaked Bambara groundnut with NaHCO3 reduced anti-nutritional factors. Steamed treatments yielded highest amount of protein (25.87%) while dehulled treated Bambara groundnut produced the highest amount of carbohydrate (42.77%). Calcium, potassium, and iron showed significant reduction (p ≤ 0.05) when dehulled. Additional sodium in processing Bambara increased mineral content of the crop. Anti-nutritional factor levels were also reduced significantly in simbi-bile when soaked. Proximate components (crude protein, crude fat, crude fiber, carbohydrate, and water) had significant changes in their compositions across all the processing techniques. From the correlation analysis, oxalate and phytate have some levels of effect in all varieties on every nutritional or mineral component. Total ash correlated negatively with crude fat and positively with phytate and oxalate. Dehulled and control did not reduce the anti-nutritional factors compared to NaHCO3 + NaCl. From the results, soaking of Bambara groundnuts in 1% NaHCO3 + 1% NaCl prior to cooking was effective in improving nutritional quality while overcoming the hard-to-cook phenomenon. The findings highlight the need to adopt correct processing techniques that conserve the nutritional benefits of these edible seeds. Soaking Bambara groundnut in NaHCO3 + NaCl as a processing technique increases mineral content while reducing anti-nutritional factors, and hence should be adapted.

Introduction

Leguminous crops are the primary and most important source of plant proteins which is not only cheaper but also a better alternative to animal products. Some examples of mostly used legumes are cowpea, soybeans, groundnut, and Bambara groundnut (Chinedu and Nwinyi, 2012). Bambara groundnuts are one of the most important leguminous crops across their growing zones (Poulter and Caygill, 1980), they possess relevant qualities such as drought resistance, pest resistance, and disease resistance (Nono et al., 2018), but then it succumbs to fungal contamination in damp conditions (Difo et al., 2015). Regardless of this, it is a complete food that is honored across Africa with immeasurable importance to humans as food and the environment as a mitigator of climate change when utilized (Mayes et al., 2019). There is an undeniable fact that many African homes resort to Bambara groundnuts as their sole meal due to its significance as a complete and an inexpensive food (Willard, 1950), and an essential leguminous food commodity after cowpea and groundnut (Mayes et al., 2019). Bambara seeds are normally hard when matured, and hence, it is always appropriate to subject them to processing (boiling, soaking, dehulling, etc.,) to facilitate its conversion into flour and used to prepare nutritious local delicacies such as beans cake (koose), beans paste steamed in leaves (Tubani), and boiled bean paste (Gablee) (Ayogu et al., 2017; Mubaiwa et al., 2018a). Despite all the relevance, it faces existential threat within its center of origin due to serious underutilization (National Research Council, 2006). As reported by Mubaiwa et al. (2017), Bambara groundnuts underutilization arises from the hard-to-cook (HTC) phenomenon. Hard-to-cook (HTC) is a structural weakness that affects legume seeds that have been kept in poor conditions (Garcia et al., 1998), and this predisposes the seeds to longer cooking time as well as causing a decrease in nutritional quality (Paredes-lopez et al., 1991). This highly nutritive crop is referred to as “complete food” due to its balanced macronutrient constituents. It contains approximately 64.4% carbohydrate, 23.6% protein, 6.5% fat, and 5.5% fiber and is rich in minerals (Razlin et al., 2018).

The typical structure of Bambara groundnut is a round-shaped hardened seed with an obvious colored eye spot. Generally, the embryo is the largest portion of a matured Bambara seed and it is enclosed by a seed coat (hull). This seed coat is tightly bound to the embryo and cast an impermeable surface over the seed, hence preventing easy absorption of water, protecting internal structures from injury, and continuing to hard with prolonged storage time. The seed coat is formed from the outer integument, which forms several cell layers (Do and Singh, 2018). Generally, seed coat is composed of the cuticle, epidermis, hypodermis, and interior parenchyma as indicated by Do and Singh (2018). Various processing techniques have varying extents of physiological and morphological alterations that they cause to the seed. Thus, solubilization of cellular components result in the degradation of certain proteins, separation of cellular walls, and breakdown of cell wall and release of intracellular substances (Berg et al., 2012). These effects are mostly observed from the application of various household or indigenous techniques such as steaming, soaking, dehulling, and milling (Souza and Marcos, 2001; Do and Singh, 2018).

Processing HTC Bambara groundnut seeds into various handy goods would ease the utilization of this complete food. Thus, implementing sustainable processing techniques for Bambara groundnut could help communities cope with food insecurity. Processing methods have reportedly been noted for significantly affecting the nutrient and anti-nutrient content in Bambara groundnut; in particular, soaking with an alkali salt and dehulling are reportedly effective in reducing the anti-nutrient levels and reduces cooking time as well (Abdulsalami and Sheriff, 2010; Adebowale et al., 2013).

The feasibility of some of these methods has been demonstrated (Adeleke et al., 2017; Mubaiwa et al., 2017; Margaret et al., 2019). However, soaking, steaming, and dehulling are the processing treatments that are basically used in various households to pre-treat legumes prior to cooking for obvious reasons of breaking hardness to cook, reduce flatulence, and also reduce cooking time. These processing techniques are therefore very common household practices and it is important to build on these sustainable techniques and indigenous knowledge systems to provide culturally acceptable healthy meals made from Bambara groundnuts. Previous studies have reported on the nutritional quality, minerals, and anti-nutrient content without necessarily performing comparative assessment of how processing techniques and varietal differences could affect quality. Given the reported high nutritional value of Bambara groundnut seeds, the objectives of this study were to assess the effects of processing techniques on the nutritional quality of Bambara groundnut (Vigna subterranea (L) Verdc.) varieties by determining the proximate components of Bambara groundnuts, oxalate and phytate contents, and detection and quantification of some mineral constituents. These findings would deepen the utilization of Bambara groundnuts from the perspective of fully benefiting from the high nutrients even after subjecting it to some processing prior to its end use.

Materials and methods

Study location

The samples were prepared in the Spanish laboratory of the University for Development Studies (UDS) whereas the nutritional analysis was carried out at the food science laboratory of Kwame Nkrumah University of Science and Technology (KNUST).

Source of Bambara groundnuts

The varieties of Bambara Groundnut (Vigna subterranea (L) Verdc.) were obtained from farmers in Wa, Upper West region of Ghana, and Tamale, Northern region of Ghana to constitute two sampled varieties. These varieties from Wa and Tamale are as follows: “Simbi-bile” (small Bambara beans) cream colored with white-spotted eyes while “Sinkpili-zee” (Red Bambara beans) appears red with white patches and white eyes, respectively. The samples were packaged in zip-lock bags and sent to the Spanish laboratory complex of the University for Development Studies, Nyankpala campus.

Processing of Bambara groundnuts

The Bambara groundnuts seeds were manually sorted to remove broken, insect-infested seeds and other foreign materials. Each variety was divided into four samples.

Sample one

Each variety of Bambara groundnuts was dried to moisture content of 12% and below and then milled using the Blender (food mixer, 2-speed glass blender) into gritty flour and labeled as raw un-dehulled (Control). The moisture content was determined using the AGRATRONIX MT-16 GRAIN MOISTURE TESTER.

Sample two

Bambara groundnuts were soaked for 24 h to facilitate dehulling; thereafter, it was oven-dried at 70°C for 14 h to obtain moisture content of 12% and below. The samples were milled into gritty flour and labeled raw dehulled (Dehulled). The dehulling process was done manually by passing the seeds through the fingers to slide off the seed coat.

Sample three

About 1 g each of NaHCO3 and NaCl was dissolved in 100 ml of distilled water to give 1% NaHCO3 and 1% NaCl. The solutions were then added to 150 ml of water. The Bambara groundnuts were then soaked in the water containing 1% NaHCO3+1% NaCl and allowed to stand for 24 h. After 24 h, the excess water was strained and the Bambara beans were then dried in the oven at 70°C for 14 h to reach moisture content of 12% and below. The samples were milled into gritty flour and labeled as dehulled and soaked (DS).

Sample four

Batch four of Bambara groundnut was dehulled and steamed over boiling water (about 80 °C) for 40 min, and then, it was dried in the oven at 70°C for 14 h to reach moisture content of 12% and below. The samples were milled into gritty flour and labeled as dehulled steamed (DSt).

Chemical analysis

Proximate and mineral components were determined as follows:

Fat content using Soxhlet extraction

A previously dried (air oven at 100°C) 250-folded filter paper was accurately weighed. Then, about 2.0 g of dried sample was weighed into the folded filter paper. The filter paper containing the sample was then placed into the chamber. About 150 ml of petroleum spirit B.P 40–60°C was added to the round bottom flask and the apparatus assembled. The condenser was connected to the Soxhlet extractor and reflux for 4–6 h on the heating mantle. After extraction, the filter paper is removed and dried in an air-dried oven at 105°C for an hour. The filter paper was then cooled in a desiccator and weighed afterward. The weight of fat/oil collected was determined.

Protein determination

Digestion

To the digestion flask, 0.25 g of sample was added and a pinch of selenium-based catalyst powder. About 5 ml of concentrated H2SO4 was added and the flask was shaken, so that the entire sample is thoroughly wet. The flask was placed on digestion burner and heated slowly until boiling ceases and the resulting solution was clear. The solution was cooled to room temperature, and then, the digested sample solution was transferred into a 50-ml volumetric flask and made up to the mark.

Distillation

To flush out the apparatus before use, the distilled water was boiled in a steam generator of the distillation apparatus with the connections arranged to circulate through the condenser, for at least 10 min. The tip of the condenser was beneath the surface of the distillate; the receiving flask was lowered and continuously heated for 30 s to carry over all liquid in the condenser.

To 250-ml conical flask, 20 ml of 2.5% boric acid was pipetted and 3 drops of mixed indicator added. The conical flask and its contents were placed under the condenser in such a position that the tip of the condenser was completely immersed in the solution. About 10 ml of the digested sample solution was measured into the decomposition flask of the Kejdahl unit and fixed, and excess of 40% NaOH (about 40 ml) was added to it. The ammonia produced was distilled into the collection flask with the condenser tip immersed in the receiving flask till a volume of about 100 ml was collected. Before distilling other samples and on completion of all distillations, the apparatus was flushed as in step 1 above. Steam needs to be passed only until 5 ml of distillate was obtained.

Titration

The distillate was titrated with 0.1N HCL solution. The acid was added until the solution was colorless. When additional acid was added, the solution became pink. The nitrogen content was then determined in duplicate, and a blank determination was run using the same amount of reagents as used for the sample. The blank was to correct for the traces of nitrogen in the reagents and was included in the digestion as well as distillation.

Calculation

Va- Volume in ml of standard acid used in titration

Vb- Volume in ml of standard acid used in blank

NA- Normality of acid

W- Weight of sample taken

V- volume of digested sample

% CrudeProtein = % Total Nitrogen * Protein Conversion Factor (6.25)

Moisture content and total solids: Oven drying method

About 5 g of sample was transferred to a previously dried and weighed dish. The dish was placed in an oven thermostatically controlled at 105° for 5 h. The dish was removed and placed in a desiccator to cooled down to room temperature and weighed. It was dried again for 30 min, cooled down, and weighed. Repeated drying, cooling and weighing were done until a constant weight was reached.

Calculations

Ash content

About 2 g sample was weighed into tarred crucibles. Crucibles were placed in a cooled muffle furnace. Tongs, gloves, and protective eyewear were used when the muffle furnace was warm. It is ignited for 2 h at about 600°. The muffle furnace is turned off and then allowed to be open when the temperature dropped to at least 250° preferably lower. The door was carefully opened to avoid losing fluffy ash. Using safety tongs, the crucibles were quickly transferred to a desiccator with a porcelain plate and desiccant. The desiccator was closed and allowed the crucibles to cool before they were weighed.

Calculations

Carbohydrate

This is calculated as a difference of the other proximate components from 100. Thus;

Fiber

To about 2 g of the flour, 50 ml of 1.25% H2SO4 was added. The solution in the flask was mixed and brought to boil for 30 min with intermittent shaking to ensure thorough mixing of the solution even with the use of the magnetic stirrer. It was then filtered through cotton cloth fixed on a funnel. This was later washed with boiling water to completely remove the acid. The residue was then boiled in a round bottomed flask with 50 ml of 1.25% sodium hydroxide (NaOH) for another 30 min with periodic agitation and filtered. This was then washed with hot water to remove the NaOH. The residue (fiber) was then collected into a crucible. Excess water was evaporated from the residue after heating. Afterward, it was dried in an oven for 100°C, and this was taken out and cooled before weighing. It was placed in the muffle furnace for 2 h at 600°C. Afterward, the crucible containing the sample was weighed. Then, crude fiber was calculated as follows:

W1 = Weight of crucible with fiber

W2 = Weight of crucible with ash after burning

W3 = Original weight of sample

Minerals analysis

The residual ash from ash content determination was leached with 5 ml of 6 M HCl. The volume was made up to 20 cm3 with distilled water. The resulting solution was used directly for the analysis. Calcium, potassium, iron, and sodium were determined with an automatic Atomic Absorption Spectrophotometer (Unicam Model 929, Unicam Cambridge, England).

Total oxalate was determined according to Day and Underwood (1986) procedure. About 1 g of the grounded sample and 75 ml of 15N H2SO4 were added. The solution was carefully stirred intermittently with a magnetic stirrer for 1 h and filtered using Whatman No1 filter paper. About 25 ml of the filtrate was then collected and titrated against 0.1N KMnO4 solutions till a faint pink color appeared that persisted for 30 s.

Phytate was determined using Reddy and Love (1999) method. About 4 g of the grounded sample was soaked in 100 ml of 2% HCl for 5 h and filtered. About 25 ml of the filtrate was measured and 5 ml 0.3% ammonium thiocyanate solution was added. The mixture was then titrated with Iron (III) chloride solution until a brownish-yellow color that persisted for 5 min was obtained.

Statistical analysis

The data obtained from the experiment were arranged in Microsoft Excel 2016 and subjected to the analysis of variance (ANOVA) using GenStat version 18. Means were separated using Fisher‘s protected method at a significance level of p ≤ 0.05. Spearman's rank correlation was performed using STATA.

Results and discussion

Proximate analysis

Legumes are primarily subjected to various processing methods to enhance their utilization by consumers. As characteristic of legumes, they possess hard and fairly brittle cellular arrangements that bar the entry of water and other tenderizers in most cases. When this barrier is broken, there is disruption of these interlinkages, and hence, vital nutritional components present in the seeds tend to be favored by getting increased or decreased in the process. The proximate composition of the two varieties (Simbi-bile and Sinkpili-zee) indicated significant (p ≤ 0.05) changes after processing (soaking and dehulling, soaking in 1% NaHCO3+1% NaCl as well as steaming). As presented in Table 1, there was a significant (p ≤ 0.05) increase in the moisture content of Simbi-bile and Sinkpili-zee across all the processing regimes except the soaked and dehulled samples of Sinkpili-zee. The amount of moisture present in Simbi-bile ranged from 6.68 to 8.68 (%), and this was recorded from all the processing techniques. With the Sinkpili-zee variety, the moisture content was 5.32–7.31 (%), and this range falls below that of Simbi-bile. However, the moisture content recorded in all processed and unprocessed varieties was within the acceptable storage percentage (12%) (Hawes, 2003). This study finds agreement with the research of Ndidi et al. (2014a), and they observed that there was a substantial change in the moisture content of Bambara groundnut after processing. Similarly, Abdulsalami and Sheriff (2010) recorded incremental changes after processing of legumes. This could be attributed to the removal of the seed coat which usually makes it difficult for water to penetrate; hence, its removal allows for much imbibition. The varied moisture content could be attributed to the processing techniques as well as the innate water holding capacity of the individual varieties. Despite the differences in the moisture content, it is highly appropriate for maintaining a longer shelf life of seeds as well as flour without any observance of microbial degradation. Furthermore, the lowest moisture contents recorded in Simbi-bile and Sinkpili-zee indicate that the varieties could be better preserved in the raw state or dehulled, respectively, as compared to the other processes.

Soaked and dehulled processing of Simbi-bile did not record a significant change from the control; however, all the processing techniques had significant effects on the ash content of the Bambara groundnuts. Notably from Table 1, there was significant reduction in the samples that were subjected to soaking in 1% NaHCO3+1% NaCl. The reduction could be a result of leaching, where the ash components are lost in the soaked water due to the ease of solubility of the components (Ndidi et al., 2014a). Additionally, anti-nutrients have been reported to have a negative impact on the level of ash in foods (Ndidi et al., 2014a); therefore, the reported ash levels in this study could be due to the presence of these factors. Furthermore, it is worth noting that this reduction could affect the mineral content of the legume (Raes et al., 2014).

As presented in Table 1, samples of soaked and dehulled Simbi-bile had significant effect on the amount of crude fat in the seeds. Contrarily, there was no significant effect from the other processing methods on Simbi-bile. With the Sinkpili-zee variety, there were significant differences between the various techniques, and thus, samples dehulled as well as those soaked in 1% NaHCO3+1% NaCl had significant increase in the amount of crude fat. Meanwhile, the steamed process did not show significant difference from the control. Despite the differences, the content of crude fat in this study far exceeds the reports of other researchers. The findings from the study were higher than those of previous studies by Nti (2009), Adebowale et al. (2013), and Mubaiwa et al. (2018b). These higher levels observed could be attributed to the genetic variation in the seeds as well as the physical conditions to which they were exposed to. To add to, the fat contained in Bambara groundnuts is largely monosaturated fatty acids which are greatly affected by the availability of water (Safoora and Kahrizi, 2021), and therefore, the recorded values could be linked to the presence or absence of water during cultivation. Bambara groundnuts are the best-suited legumes for providing optimum dietary fat, therefore highly recommendable for consumption (Alhassan et al., 2015), and these findings affirm that.

Protein levels (20.11–25.87%) determined from this study (Table 1) showed significant differences across all the processing techniques that were applied to the two varieties. The range of crude protein from this study falls within the reported range of Pandey et al. (2016), and he reported a range of 20–40% of protein present in legumes. Abdulsalami and Sheriff (2010) documented in their study an initial level of 20.27% and final level of 23.63% after processing. Undoubtedly, variations in protein contents between the varieties could be ascribed to the processing techniques of Bambara groundnuts, variations in species, soil conditions in agricultural regions, and analytical methodologies used to determine the protein content. Importantly, as soil nitrogen plays a role in protein formation in crops, the state of the soils in the growing regions of these varieties (savannah agro-ecological zone) has had issues with soil nitrogen (Kermah et al., 2018), and this might have affected the amount of protein as well. Even with the amounts presented, the protein quotient of Bambara groundnuts made scientists describe it as a more complete food (Enwere and Hung, 1996). These levels put Bambara groundnut in the position as a “savior” crop which could be maximally utilized to the benefit of humans, particularly Africans.

The amount of crude fiber reported from this study ranged from 5.14 to 6.56% with significant effects been observed between the processing techniques. Samples soaked in 1% NaHCO3+1% NaCl had significantly the same effect on both varieties. However, the other processing techniques had significantly different effects on the various samples. Even with these findings, all recorded amounts were within the range (1.98–7.22%) as estimated by Farinde (1990). Similarly, the levels noted from these samples follow through with 4.74–6.85% as reported by Abdulsalami and Sheriff (2010). Importantly, the smaller levels of dietary fiber are desired because non-digestible dietary fiber can attach to minerals and provide a physical border to digestive enzymes, decreasing the bioavailability of critical minerals and therefore compromising nutritional security (Rousseau et al., 2020). Therefore, it would be prudent to process Bambara seeds in an attempt to reduce the fiber content.

The total mass of Bambara groundnut seeds is known to be carbohydrates, and this accounts for a larger proportion of macronutrients. Bambara groundnut varieties used in this study proved otherwise as they contained relatively lesser values as compared to those documented by previous researchers. Razlin et al. (2018) reported 64.40% of the total dry matter of Bambara groundnut to be made up of carbohydrates. Additionally, the report of Hillocks et al. (2012) noted a 63% carbohydrate content in Bambara groundnut seeds. Furthermore, 51.6–61.9% was recorded by Olaleye et al. (2013). From Table 1, it is observed that significant effects are noted in the various samples of the two varieties. Particularly, the technique of soaking and dehulling had greater effect on the level of carbohydrate in Simbi-bile and Sinkpili-zee. To account for these differences, Farinde (1990) reported a similar observation that legumes with higher amount of crude fat normally have a reduced carbohydrate content. Thus, fat content has a correlation with the amount carbohydrate present in legumes (Table 4). It could also be inferred that some residual carbohydrates were lost through the removal of the seed coat (thus for the dehulled samples), and hence, the use of any processing technique should be hinged on the intended nutritional demand of the consumer.

Mineral constituents

The effects of different processing methods and varietal differences on the mineral composition of Bambara groundnuts are presented in Table 2. Selected mineral constituents (calcium, potassium, iron, and sodium) were specifically observed. With the varieties considered, soaking and dehulling, dehulled and steamed as well as soaking in 1% NaHCO3+1% NaCl caused significant (p ≤ 0.05) reduction in the content of the samples. The sodium content of Simbi-bile variety showed significant increment across all the processing regimes. From Table 2, it can be observed that processing Bambara groundnuts in 1% NaHCO3+1% NaCl increased the levels of sodium significantly. This could be attributed to the absorption of the sodium ions from the soaking medium into the seeds to form complexes with the sodium available in the aleurone layer of the seeds (Raes et al., 2014). This observation is same for the Sinkpili-zee variety that was also processed in 1% NaHCO3+1% NaCl. Iron content in Sinkpili-zee behaved; that there was no significant difference between the original content and the content recorded after processing through soaking in 1% NaHCO3+1% NaCl; however, a higher level was recorded in the steamed sample. Omoikhoje et al. (2009) reported in their study that iron content of Bambara groundnuts increased when subjected to heat cooking as well as the variety of Bambara groundnuts as observed in this study. Undoubtedly, there were significant differences between the varieties and the other processing techniques, and these could be as a result of the milling of the seeds into flour; this breaks down the coat which adds up to fiber, leaving the endosperm with lesser amount of minerals. Also, the bioavailability of minerals has intricate factors surrounding them, soaking has been reported to have a great effect on mineral availability, either positive or negative since it facilitates the hydrolysis of anti-nutrients and in the same vein could lead to leaching. Generally, the minerals considered under this study had a clearly defined variation across the various processing techniques with continuous reduction from the original amounts. These findings solidify the point that minerals are easily leached into their soaking media (Mazahib et al., 2013), and also, heat processing (in this case steaming) could affect bioavailability by altering the solubility of minerals (Reddy and Love, 1999). This study also aligns with the findings of Duhan et al. (2002) and Lestienne et al. (2005) who made similar observations.

Anti-nutritional factors

Anti-nutritional factors are mostly deemed negative constituents when they are up to the levels that inhibit the metabolic activities of living systems. About 301 mg/100 g has been reported as a safe level for phytate (Agbai et al., 2021), which falls below the levels obtained from this study as indicated in Table 3. However, the amount of phytate recorded from this research aligned with the records of Margaret et al. (2019). Statistical difference (p ≤ 0.05) was observed in all the samples of each variety. Worthy of notice was the significant reduction (p ≤ 0.05) that was observed in samples soaked in 1% NaHCO3 + 1% NaCl, and these samples had an appreciable reduction of phytate which agreed with Margaret et al. (2019). The reduction could be attributed to the dehulling of the seeds since most of the anti-nutrients are found in the seed coat (Abiodun and Adepeju, 2011). Also, sodium bicarbonate and common salt are alkaline, and hence, they have the ability to weaken the bonds that hold these anti-nutrients in position, thereby releasing them from the seed into the soaking media (Mubaiwa et al., 2019). This reduction resulted in the liberation of other nutritional components such as protein and some mineral constituents.

Oxalate had the same fate as the phytate above; however, there was a high level of oxalate observed in the soaked and dehulled sample of Sinkpili-zee. This finding contradicts Atoyebi et al. (2018), who did not detect any oxalates in their study. Generally, the variations in these levels could arise from genotypic differences, climatic conditions in their growth zones, types of soil on which they are cultivated, and most especially the season of cultivation (Abiodun and Adepeju, 2011). The reduction recorded in the study was an indication of the presence of anti-nutritional factors in Bambara groundnuts and also, it informs that there were breakage of bonds and complexes to liberate nutrients and minerals that otherwise were trapped by these anti-nutrients which affected their bioavailability and accessibility (Ndidi et al., 2014b). All the processing techniques had reducing effects on the levels of anti-nutrients present in the Simbi-bile variety, contrary to that observation, there was no reducing effect of processing on the nutritional content of the Sinkpili-zee variety except for the samples soaked in 1% NaHCO3+1% NaOH. This observation could be grounded based on the fact that NaHCO3 and NaOH are salts which could influence the solubility and hydrolyzing rates of anti-nutrients.

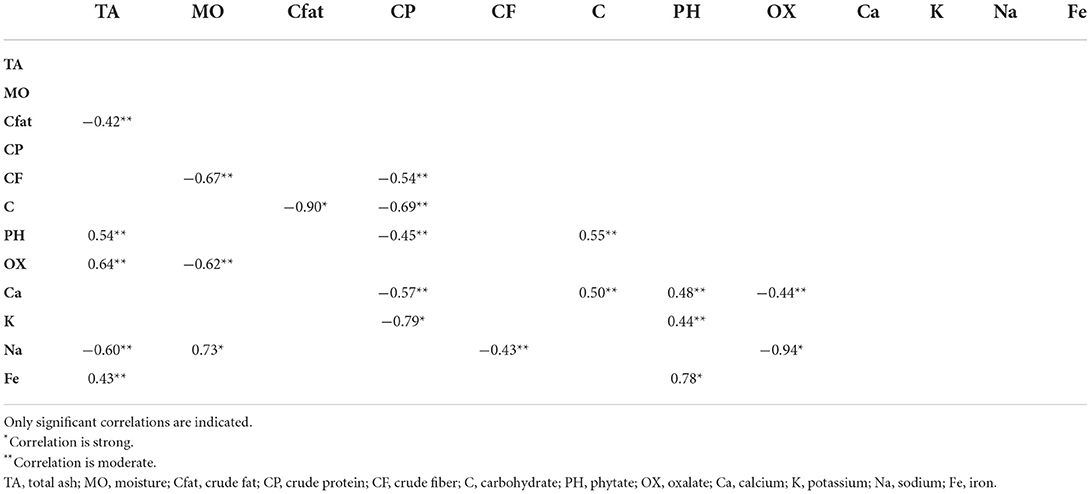

Correlation analysis

Generally, strong positive relationship was observed in moisture (MO) and sodium (Na) as well as phytate (PH) and iron (Fe) (Table 4). With OX and Na, carbohydrate (C) and crude fat (Cfat), and potassium (K) and crude fiber (CF), a strong negative correlation existed. Considering the other components, a low to moderate correlation (positive or negative) existed among them. From the analyses, a vivid effect of the anti-nutrients is seen; thus, OX and Na show a strong negative correlation which means that this bioavailability of Na would be greatly affected by the presence of OX. OX is known to always form complexes with minerals, and this finding is in agreement with Adegunwa et al. (2014). Also, a strong positive relationship was exhibited between PH and Fe, this indicates that both would show increasing presence at any time, and this would subsequently affect the bio-utilization of the legume (Ndidi et al., 2014b). Overall, OX and PH had some levels of effect on every proximate or mineral component even though it might not be significant; based on this, it could be inferred that the processing does not totally eliminate anti-nutrients from Bambara groundnuts (Ndidi et al., 2014b).

Table 4. Correlations of nutritional, mineral and anti-nutritional components of Bambara groundnut (Vigna subterranea (L) Verdc.).

Conclusion

In a nutshell, Bambara groundnut seeds should be processed (soaked in 1% NaHCO3+1% NaCl or steamed) prior to their utilization. This would help to reduce anti-nutrients in Bambara groundnut to safer levels while improving the nutrients and mineral quality of the seeds. Even though there are diverse varieties of this crop, they tend to have very similar nutritional profiles. Bambara groundnut is a significant legume based on its completeness and should be an inclusion in feeding regimes, especially in malnourished areas and should also be an incorporation in poultry feed. Soaking Bambara groundnut in NaHCO3 + NaCl should be adapted because it increased mineral content (calcium, potassium, and iron) and reduced anti-nutritional factors (oxalate and phytate) in the treatments tested. Further research should be conducted to identify appropriate time for soaking with NaHCO3 + NaCl that give maximum reduction of anti-nutritional factors.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

DY: conceived the idea for the study, provided literature, financial support, performed the analysis of data, and reviewed the manuscript. OS: procurement of samples, preparation of samples for analysis, contributed financially, and drafting of manuscript. MI: preparation of samples for analysis and contributed financially to the work. CT: assisted in sample preparation, funding, and equipment aids. All the authors read and approved the manuscript.

Acknowledgments

We wish to thank the Laboratory technicians at the Spanish Laboratory complex of the University for Development Studies (UDS) for the support and also Mr. Redeemer Kofi Agbolegbe of the Food processing laboratory at Kwame Nkrumah University of Science and Technology (KNUST), for his assistance in the chemical analysis process.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher's note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abdulsalami, M., and Sheriff, H. (2010). Effect of processing on the proximate composition and mineral content of Bambara groundnut (voandezeia subterranean). Bayero J. Pure Appl. Sci. 3, 188–190. doi: 10.4314/bajopas.v3i1.58781

Abiodun, O., and Adepeju, A. B. (2011). Effect of processing on the chemical, pasting and anti-nutritional composition of Bambara nut (Vigna subterranea L. Verdc) flour. Adv. J. Food Sci. Technol. 3, 224227. Available online at: https://www.researchgate.net/publication/267388835

Adebowale, A. A., Awolala, F. M., Fetuga, G. O., Sanni, S. A., Adegunwa, M. O., and State, O. (2013). Effect of soaking pre-treatments on nutritional composition and functional properties of bambara groundnut (Vigna Subterranea). Acta Horticulturae. 979, 139146. doi: 10.17660/ActaHortic.2013.979.12

Adegunwa, M. O., Adebowale, A. A., Bakare, H. A., and Kalejaiye, K. K. (2014). Effects of treatments on the antinutritional factors and functional properties of bambara groundnut (Voandzeia Subterranea) flour. J. Food Process. Preserv. 38, 1875–1881. doi: 10.1111/jfpp.12159

Adeleke, O. R., Adiamo, O. Q., Fawale, O. S., and Olamiti, G. (2017). Effect of processing methods on antinutrients and oligosaccharides contents and protein digestibility of the flours of two newly developed bambara groundnut cultivars. Int. Food Res. J. 24, 1948–1955. doi: 10.24925/turjaf.v5i9.1006-1014.949

Agbai, C. M., Olawuni, I. A., Ofoedu, C. E., Ibeabuchi, C. J., Okpala, C. O. R., Shorstkii, I., et al. (2021). Changes in anti-nutrient, phytochemical, and micronutrient contents of different processed rubber (Hevea brasiliensis) seed meals. PeerJ. 9, 1–26. doi: 10.7717/peerj.11327

Alhassan, A., Dangambo, M., and Abdulmumin, T. (2015). Evaluation of the proximate contents of bambara groundnut Vigna subterranean (L.) Verdc grown in MadobiLGA, Kano State, Nigeria. Br. J. Appl. Sci. Technol. 8, 361–365. doi: 10.9734/BJAST/2015/16577

Atoyebi, O. J., Osilesi, O., Abberton, M., Adebawo, O., and Oyatomi, O. (2018). Quantification of selected anti-nutrients and bioactive compounds in African Bambara groundnut (Vigna subterranea(L.) Verdc.). Am. J. Food Nutr. 6, 88–95. doi: 10.12691/ajfn-6-3-5

Ayogu, R., Edeh, R., Madukwe, E., and Ene-Obong, H. (2017). Commonly consumed foods. Food Nutr. Bull. 38, 65–77. doi: 10.1177/0379572116689627

Berg, T., Singh, J., Hardacre, A., and Boland, M. J. (2012). The role of cotyledon cell structure during in vitro digestion of starch in navy beans. Carbohydr. Polym. 87, 1678–1688. doi: 10.1016/j.carbpol.2011.09.075

Chinedu, S. N., and Nwinyi, C. O. (2012). Proximate analysis of Sphenostylis stenocarpa and Voadzeia subterranean consumed in South - Eastern Nigeria. J. Agric. Biotechnol. Sustain. Dev. 4, 16. doi: 10.5897/JABSD11.012

Day, R. A., and Underwood, A. (1986). Quantitative Analysis. 5th ed. Hoboken, NJ: Prentice Hall Publication.

Difo, V. H., Onyike, E., Ameh, D. A., Njoku, G. C., and Ndidi, U. S. (2015). Changes in nutrient and antinutrient composition of Vigna racemosa flour in open and controlled fermentation. J. Food Sci. Technol. 52, 6043–6048. doi: 10.1007/s13197-014-1637-7

Do, D. T., and Singh, J. (2018). Legume microstructure. In: Encyclopedia of Food Chemistry. Amsterdam: Elsevier.

Duhan, A., Khetarpaul, N., and Bishnoi, S. (2002). Changes in phytates and HCL extractability of calcium, phosphorus, and iron of soaked, dehulled, cooked, and sprouted pigeon pea cultivar (UPAS-120). Plant Foods Hum. Nutr. 57, 275–284. doi: 10.1023/A:1021814919592

Enwere, N. J., and Hung, Y. (1996). Some chemical and physical properties of bambara groundnut (Voundzeia subterrunea Thouars) seed and products. Int. J. Food Sci. Nutr. 469–475. doi: 10.3109/09637489609031875

Farinde, E. O. (1990). Proximate, minerals and antinutritional factors of some underutilized grain legumes in south-western Nigeria. Nutr. Food Sci. 36, 18–23.

Garcia, E., Filisetti, T. M. C. C., Udaeta, J. E. M., and Lajolo, F. M. (1998). Hard-To-Cook Beans (Phaseolus vulgaris): Involvement of Phenolic Compounds and Pectates. J. Agri. Food Chem. 46, 2110–2116. doi: 10.1021/jf970848f

Hawes, G. (2003). Chemical Food Analysis a Practical Manual. Brisbane, QLD: A University of Queensland Publication. p. 67.

Hillocks, R. J., Bennett, C., and Mponda, O. M. (2012). Bambara nut: a review of utilisation, market potential and crop improvement. Afr. Crop Sci. J. 20, 116. Available online at: https://www.ajol.info/index.php/acsj/article/view/78601

Kermah, M., Franke, A. C., Adjei-Nsiah, S., Ahiabor, B. D. K., Abaidoo, R. C., and Giller, K. E. (2018). N2-fixation and N contribution by grain legumes under different soil fertility status and cropping systems in the Guinea savanna of northern Ghana. Agri. Ecosyst. Environ. 261, 201–210. doi: 10.1016/j.agee.2017.08.028

Lestienne, I., Icard-Vernière, C., Mouquet, C., Picq, C., and Trèche, S. (2005). Effects of soaking whole cereal and legume seeds on iron, zinc and phytate contents. Food Chem. 89, 421–425. doi: 10.1016/j.foodchem.2004.03.040

Margaret, O., Nwadi, M., and Okonkwo, T. M. (2019). Effect of processing methods on the antinutrient reduction of Bambara Sky Journal of Food Science Effect of processing methods on the antinutrient reduction of Bambara groundnut: a review. Sky J. Food Sci. E. 7, 037041. Available online at: https://www.researchgate.net/publication/338585546

Mayes, S., Ho, W. K., Chai, H. H., Gao, X., Kundy, A. C., Mateva, K. I. (2019). Bambara groundnut: an exemplar underutilised legume for resilience under climate change. Planta 250, 803–820. doi: 10.1007/s00425-019-03191-6

Mazahib, A. M., Nuha, M. O., Salawa, I. S., and Babiker, E. E. (2013). Some nutritional attributes of bambara groundnut as influenced by domestic processing. Int. Food Res. J. 20, 11651171. Available online at: http://www.ifrj.upm.edu.my/20(03)2013/18IFRJ20(03)2013ElFadil(456).pdf

Mubaiwa, J., Fogliano, V., Chidewe, C., Jan Bakker, E., and Linnemann, A. R. (2018a). Utilization of bambara groundnut (Vigna subterranea (L.) Verdc.) for sustainable food and nutrition security in semi-arid regions of Zimbabwe. PLoS ONE 13, 1–19. doi: 10.1371/journal.pone.0204817

Mubaiwa, J., Fogliano, V., Chidewe, C., and Linnemann, A. R. (2018b). Bambara groundnut (Vigna subterranea (L.) Verdc.) flour: A functional ingredient to favour the use of an unexploited sustainable protein source. PLoS ONE 13, 1–19. doi: 10.1371/journal.pone.0205776

Mubaiwa, J., Fogliano, V., Chidewe, C., and Linnemann, A. R. (2019). Influence of alkaline salt cooking on solubilisation of phenolic compounds of bambara groundnut (Vigna subterranea(L.) Verdc.) in relation to cooking time reduction. Lwt 107, 49–55. doi: 10.1016/j.lwt.2019.02.067

Mubaiwa, J., Fogliano, V., Chidewe, C., Linnemann, A. R. (2017). Hard-to-cook phenomenon in bambara groundnut (Vigna subterranea (L.) Verdc.) processing: Options to improve its role in providing food security. Food Rev. Int. 33, 167194. doi: 10.1080/87559129.2016.1149864

National Research Council (2006). Lost crops of Africa. In: Lost Crops of Africa (Vol. 2). Washington, DC: The National Academies Press.

Ndidi, U. S., Ndidi, C. U., Aimola, I. A., Bassa, O. Y., Mankilik, M., and Adamu, Z. (2014a). Effects of processing (Boiling and Roasting) on the nutritional and antinutritional properties of Bambara groundnuts (Vigna subterranea [L.] Verdc.) from Southern Kaduna, Nigeria. J. Food Process. 2014, 1–9. doi: 10.1155/2014/472129

Ndidi, U. S., Ndidi, C. U., Olagunju, A., Muhammad, A., Billy, F. G., and Okpe, O. (2014b). Proximate, antinutrients and mineral composition of raw and processed (Boiled and Roasted) Sphenostylis stenocarpa Seeds from Southern Kaduna, Northwest Nigeria. ISRN Nutr. 2014, 280837. doi: 10.1155/2014/280837

Nono, C. T., Gouertoumbo, W. F., Wakem, G., Nkou, F., Youmbi, E., and Ntsomboh-Ntsefong, G. (2018). Origin and Ecology of Bambara Groundnut (Vigna Subterranea (L.) Verdc: A review. J. Ecol. Nat. Res. 2(4). doi: 10.23880/JENR-16000140

Nti, C. A. (2009). Effects of bambara groundnut (Vigna subterranea) variety and processing on the quality and consumer appeal for its products. Int. J. Food Sci. Technol. 44, 2234–2242. doi: 10.1111/j.1365-2621.2009.02064.x

Olaleye, A., Adeyeye, E., and Adesina, A. (2013). Chemical composition of bambara groundnut (V. subterranea L. Verdc) seed parts. Bangladesh J. Sci. Ind. Res. 48, 167–178. doi: 10.3329/bjsir.v48i3.17325

Omoikhoje, S. O., Aruna, M. B., and Bamgbose, A. M. (2009). Effect of cooking time on some nutrient and antinutrient components of bambaragroundnut seeds. Anim. Sci. J. 80, 52–56. doi: 10.1111/j.1740-0929.2008.00599.x

Pandey, M. K., Roorkiwal, M., Singh, V. K., Ramalingam, A., Kudapa, H., Thudi, M., et al. (2016). Emerging genomic tools for legume breeding: Current status and future prospects. Front. Plant Sci. 7, 1–18. doi: 10.3389/fpls.2016.00455

Paredes-lopez, O., Moreno, C. R., Carabez-Treo, A., and Palma-Tirado, L. (1991). Influence of hardening procedure and soaking solution on cooking quality of common bean. Plant Foods Hum. Nutr. 41, 155164. doi: 10.1007/BF02194084

Poulter, N. H., and Caygill, J. C. (1980). Vegetable milk processing and rehydration characteristics of Bambara Groundnut [Voandzeia subterranea (L.) Thouars]. J. Sci. Food Agric. 31, 11581163. doi: 10.1002/jsfa.2740311106

Raes, K., Knockaert, D., Struijs, K., and Van Camp, J. (2014). Role of processing on bioaccessibility of minerals: Influence of localization of minerals and anti-nutritional factors in the plant. Trends Food Sci. Technol. 37, 32–41. doi: 10.1016/j.tifs.2014.02.002

Razlin, A. H., Barkla, B., King, G. J., and Mayes, S. (2018). The potential of the underutilized pulse bambara groundnut (Vigna subterranea (L.) Verdc.) for nutritional food security. J. Food Composit. Anal. 77, 47–59. doi: 10.1016/j.jfca.2018.12.008

Reddy, M. B., and Love, M. (1999). The impact of food processing on the nutritional quality of vitamins and minerals. Adv. Exp. Med. Biol. 459, 99–106. doi: 10.1007/978-1-4615-4853-9_7

Rousseau, S., Kyomugasho, C., Celus, M., Hendrickx, M. E. G., and Grauwet, T. (2020). Barriers impairing mineral bioaccessibility and bioavailability in plant-based foods and the perspectives for food processing. Crit. Rev. Food Sci. Nutr. 60, 826–843. doi: 10.1080/10408398.2018.1552243

Safoora, B.orzoo, Mohsenzadeh, S., and Kahrizi, D. (2021). Water-deficit stress and genotype variation induced alteration in seed characteristics of Camelina sativa. Rhizosphere 20, 100427. doi: 10.1016/j.rhisph.2021.100427

Souza, B. D. E., and Marcos,-, L. I. O. (2001). The seed coat as a modulator of seed-environment relationships in Fabaceae. Braz. J. Bot. 24:365–375. doi: 10.1590/S0100-84042001000400002

Keywords: Bambara groundnuts, soaking, proximate analysis, minerals, anti-nutrients

Citation: Yahaya D, Seidu OA, Tiesaah CH and Iddrisu MB (2022) The role of soaking, steaming, and dehulling on the nutritional quality of Bambara groundnuts (Vigna subterranea (L) Verdc.). Front. Sustain. Food Syst. 6:887311. doi: 10.3389/fsufs.2022.887311

Received: 01 March 2022; Accepted: 07 July 2022;

Published: 12 August 2022.

Edited by:

B. N. Dar, Islamic University of Science and Technology, IndiaReviewed by:

Rajan Sharma, Punjab Agricultural University, IndiaAli Kee Zuan Tan, Putra Malaysia University, Malaysia

Copyright © 2022 Yahaya, Seidu, Tiesaah and Iddrisu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Damba Yahaya, eWRhbWJhQHVkcy5lZHUuZ2g=

Damba Yahaya

Damba Yahaya Osman Abdulai Seidu

Osman Abdulai Seidu Charlotte Hazaala Tiesaah

Charlotte Hazaala Tiesaah Musah Baba Iddrisu

Musah Baba Iddrisu