- Department of Chemical Engineering, College of Engineering and Technology, Wachemo University, Hossana, Ethiopia

Biogas, a renewable energy, is produced by the anaerobic digestion of organic materials into methane-rich combustible gas. In this context, this study evaluated biogas production from cafeteria food waste (CFW) and cow dung (CD) via co-digestion under mesophilic conditions using a batch digester. To assess the effectiveness of the process, key physicochemical parameters, including total solids, volatile solids, moisture content, carbon-to-nitrogen ratio, and pH, were determined before and after digestion. Furthermore, optimization of biogas production was performed using the response surface methodology with a three-factor, three-level Box–Behnken design to analyze the effects of CFW-to-CD ratio, pH, and temperature. Accordingly, 17 experimental runs were conducted in triplicate, and the optimal conditions were determined to be a CFW-to-CD ratio of 3, pH 7.0°C, and 37.5°C, which resulted in the maximum biogas yield of 197 mL with 62.5% methane. These findings suggest that co-digestion of CFW and CD holds significant potential for enhancing the biogas yield and methane composition. Therefore, this approach offers an efficient and sustainable solution for renewable energy production, effectively transforming organic waste into a beneficial energy resource.

1 Introduction

Energy is the backbone of modern civilization as it drives every aspect of human life, from industrial production to technological innovation and household activities (Bui et al., 2016). Moreover, with increasing population, urbanization, and industrialization, the global demand for energy has risen (Akram et al., 2024; Onwe et al., 2024; Siddique and Alvi, 2025). Currently, this demand is substantially being met by fossil fuels, which include coal, oil, and natural gas, binding together as the major constituents of global energy production (Abdin, 2024; Fanchi, 2023). Fossil fuels have been integral to economic development for over a century, but further reliance on them presents several challenges. First, reserves of fossil fuels are finite and are depleting at a rapid rate, raising concerns about energy security and the sustainability of current consumption patterns. Moreover, combustion of fossil fuels significantly contributes to greenhouse gas emissions, which have been associated with global climate changes marked by elevated temperatures, variable weather patterns, and sea-level rise. Another concern is that the extraction and use of fossil fuels often result in environmental damage, including deforestation, soil erosion, and water contamination (Wang and Azam, 2024; Zhironkin and Abu-Abed, 2024). These drawbacks underline the need for an urgent move toward implementation of environmentally friendly and renewable energy sources that can meet the ever-growing demands without compromising on the environmental integrity.

Renewable energy resources are advocated as a sustainable solution to address energy security, climate change, and environmental degradation (Ainou et al., 2023; Axon and Darton, 2021). Primary renewable energy sources are generated from natural and replenishable resources, including solar, wind, hydroelectric, geothermal, and biomass. Moreover, each primary renewable energy source has distinct advantages; for example, solar and wind energy do not produce greenhouse gases, while hydropower provides a secure and reliable energy supply in areas with abundant water supply (Agrawal and Soni, 2021; Haldorai, 2022; Rahman et al., 2022). The replacement of renewable energy systems has contributed significantly to reducing the amount of greenhouse gas emissions, responsible for climate change (Olabi and Abdelkareem, 2022; Quaschning, 2019). Furthermore, renewable energy contributes to energy independence through reducing the dependence on use of imported non-renewable fuels while expanding the diversification of energy supply (Carfora et al., 2022; De Rosa et al., 2022; Ikevuje et al., 2024). Other economic benefits involve job creation during the manufacture, installation, and maintenance of systems supplying renewable energy. Biomass, especially from waste materials such as agricultural residues, food waste, and municipal solid waste, offers a unique advantage over other renewable energy sources by simultaneously addressing two critical challenges: waste management and energy production (Ifaei et al., 2023; Kumar et al., 2024). Biomass-based energy, particularly in the form of biogas, is produced by processing organic waste into a valuable energy resource, making it both effective and environmentally friendly (Siwal et al., 2021; Tran et al., 2024). Moreover, biogas systems use organic wastes from sources such as agriculture, municipalities, and industries to provide a clean, versatile energy source for cooking, heating, and electricity generation (Kabeyi and Olanrewaju, 2022b; 2022a).

Biogas is a type of renewable energy produced through the anaerobic digestion (AD) of organic matter by microorganisms (Czekała, 2022; Obileke et al., 2021). This biochemical process, carried out in an oxygen-free environment, generates a gas that mainly consists of methane (50%–75%) and carbon dioxide, with trace amounts of other gases such as hydrogen sulfide (Jameel et al., 2024; Thirumalaivasan et al., 2024). Biogas could serve as a clean, sustainable energy source and is used in place of fossil fuels for electricity, heating, and cooking purposes (Czekała, 2022; Kabeyi and Olanrewaju, 2022a). All the precursors for biogas production are different in nature, which includes agricultural residues, animal manure, food waste, and municipal solid waste. These materials are widely available and often treated as waste; therefore, biogas production is cost-effective and eco-friendly (Bhatia et al., 2023; Chhandama et al., 2022). Agricultural waste, for example, contributes to biogas energy production while reducing the environmental impact of waste disposal (El-Ramady et al., 2022; Rani et al., 2023). Similarly, food waste, which is generated in substantial amounts from households, restaurants, and food processing industries, has a high methane yield resulting from its rich organic composition (Bhatia et al., 2023; Pour and Makkawi, 2021). On the other hand, efficiency in biogas production depends on the feedstock type and composition and also on specific conditions of AD such as temperature, pH, and retention time (Bong et al., 2018; Panigrahi and Dubey, 2019). Therefore, proper management of the aforementioned parameters ensures maximum yields of biogas and, at the same time, reduces any probable operational problems to a minimum (Issah et al., 2020; Kasinath et al., 2021; Obaideen et al., 2022).

Among the various feedstocks for biogas production, cow dung (CD) and cafeteria food waste (CFW) stand out as promising options due to their availability and complementary properties (Hoyos-Seba et al., 2024; Singh et al., 2022). Cow dung is an abundant and easily accessible substrate, particularly in rural and agricultural regions. It has a stable composition and contains microorganisms that naturally facilitate the AD process, making it a reliable feedstock for biogas production (Fasake and Dashora, 2021; Yuvaraj et al., 2021). However, its energy content is relatively low, resulting in modest biogas yields when used as a sole substrate (Tucho and Nonhebel, 2015; Yang et al., 2019). On the other hand, CFW is abundant in carbohydrates, fats, and proteins, making it a high-energy feedstock with substantial biogas production potential (Panahi et al., 2022; Zeng et al., 2022). This waste, generated in large quantities by institutions, offices, and food-service establishments, can help address the growing issue of food waste disposal (Martin-Rios et al., 2018; Thyberg and Tonjes, 2016). However, food waste is often heterogeneous and may contain contaminants or inhibitory substances that can affect the AD process (Ambaye et al., 2021; Zhao et al., 2021).

Numerous attempts have been made to harness the complementary benefits of CD and CFW for the generation of biogas through their co-digestion (Abbas et al., 2023; Chibueze et al., 2017; Gashaw and Teshita, 2014; Malik et al., 2020; Mhlanga et al., 2023; Mohammed, 2015). However, most previous studies have employed the one-variable-at-a-time design method, which lacks a comprehensive optimization of operating variables and their interaction effects. These interactions play a substantial role in influencing biogas yield and methane composition. Moreover, the specific CFW and CD used reflect locally available substrates with unique biochemical properties, which is particularly relevant to institutional settings in developing countries. Therefore, this research aims to optimize biogas production through the co-digestion of CFW and CD using the Box–Behnken approach of the response surface methodology. Blending CD and CFW offers a synergistic solution, leveraging the strengths of both feedstocks (Garg et al., 2024; Rame et al., 2023; Taneja et al., 2023). The high-energy content of food waste compensates for the lower biogas yield of CD, while the stable composition of CD provides buffering capacity and enhances the entire efficiency of the digestion process (Kadam et al., 2024; Ngabala and Emmanuel, 2024). This combination enhances biogas yield, reduces waste disposal challenges, and provides a sustainable approach for energy production (Kabeyi and Olanrewaju, 2022a; Kasinath et al., 2021; Mishra et al., 2021). Additionally, co-digestion can improve the quality of the digestate, which could be used as a nutrient-rich organic fertilizer, contributing to sustainable agricultural practices (Chojnacka and Moustakas, 2024; Tiong et al., 2024).

2 Materials and methods

2.1 Raw materials and sample preparation

CFW and CD were collected from Wachemo University, in which food waste was obtained from the student cafeteria and CD from the campus cattle farm. These materials were used as feedstocks for the AD process to produce biogas, as illustrated in Figures 1, 2. Ten kilograms each of food waste (Figure 1) and of fresh CD (Figure 2) were collected using plastic bags and buckets. The food waste was manually chopped into small pieces, oven-dried, and milled into fine particles to ensure uniformity during mixing and digestion. Similarly, CD was dried (using oven and sun-drying methods) and then further processed by chopping and crushing to sizes ranging from 10 to 30 mm. The materials were subsequently milled to a particle size of 0.2–2 mm using a ball mill machine (Monlau et al., 2013). The milled material was sieved with a 0.5-mm mesh to ensure consistency. Finally, 3,500 g of the powdered substrate from each material was stored under low-density polyethylene (LDP) plastic in desiccators before being utilized for biogas production.

The inoculum for this study was fresh rumen fluid collected from the Wachemo University slaughterhouse, containing active microbes for AD. The fluid was filtered (0.5-mm cloth), pre-incubated, and degassed at 38°C to degrade easily degradable organic matter and remove the dissolved methane (Kharchenko, 2011).

2.2 Raw material characterization

Characterizing the feedstock is crucial for efficient biogas production, and therefore, the total solids (TS), volatile solids (VS), and pH of both the substrate and digestate were analyzed using standard methods prescribed by the American Public Health Association (APHA) (Jigar, 2015).

2.2.1 Total solids

Forty grams of freshly collected CD and CFW samples was weighed using an electronic beam balance and placed in a crucible inside an electric hot-air oven set at 105°C. The crucible was left in the oven for 24 h, then removed, cooled in desiccators, and weighed. Finally, the percentage of TS was calculated using Equation 1.

Here, A is the total weight of the dish and the dry sample after drying at 105°C for 24 h, B is the weight of the empty dish, and D is the total weight of the dish and the fresh (sun-dried) sample before drying, all measured in grams (Mahmoodi et al., 2018; Sawyerr et al., 2019).

2.2.2 Total volatile solids

The VS percentages of CD, CFW, and their co-digested mixtures, both before and after AD, were determined through the SFS 3008 protocol established by the Finnish Standards Association (1990). In this method, the sample is first dried at 105°C to determine its TS. Then, the dried sample is ignited in a muffle furnace at 550°C for 2 h to combust the organic fraction. The residue remaining after ignition is considered the ash content, while the loss in mass during this process represents the VS. The VS content reflects the proportion of organic matter present in the sample and serves as an essential parameter to evaluate the biodegradability of the substrate and the efficiency of the AD process. Then, the VS % was calculated using Equation 2 (Odejobi et al., 2022).

2.2.3 Carbon-to-nitrogen ratio (C/N)

2.2.3.1 Carbon determination

The carbon content of the feedstock was determined by evaluating the VS content, which is expressed as a percentage. The total carbon content was then derived from the VS data using the empirical Equation 3 (Jigar, 2015).

2.2.3.2 Nitrogen determination

The Kjeldahl method was used for determination of total nitrogen content. A known mass of the feedstock was mixed with 6 mL of concentrated sulfuric acid (H2SO4), 3.5 mL of 30% hydrogen peroxide (H2O2), and 0.3 g of the selenium catalyst. The mixture was then digested at 370°C for 4.5 h until the solution became clear, indicating complete digestion of organic matter. After digestion, the solution was cooled, and 50 mL of water was added to prevent sulfur precipitation. During the distillation step, 25 mL of 40% sodium hydroxide (NaOH) was added to alkalize the digest, and the mixture was distilled into a flask containing 25 mL of boric acid (H3BO3), water, and an indicator until the volume of 250 mL was reached. The distillate was titrated with 0.1 N hydrochloric acid (HCl) to a reddish endpoint. The nitrogen content was then calculated using Equation 4.

Here, V represents the volume of H2SO4 (in mL) consumed during titration, N is the normality of H2SO4 (0.1 N), 0.014 is the mill equivalent weight of nitrogen in grams, Mcf is the moisture correction factor, and Wo denotes the sample weight on a dry matter basis in grams. The carbon-to-nitrogen (C/N) ratio was then calculated using the determined nitrogen and carbon values (de Oliveira Paiva et al., 2024; Hickmann et al., 2024).

2.2.3.3 Determination of pH

The pH of each sample was measured directly using a digital pH meter (HANNA HI 8314, Romania) before and after AD. For the pre-digestion measurement, the electrode was inserted into substrate samples diluted with distilled water before inoculating with rumen fluid. The pH values of the digester contents were maintained between 6.8 and 7.4, which is the optimal range for methanogenic bacteria. Post-digestion pH was also measured using the pH electrode, which was inserted into the substrate samples undergoing anaerobic digestion (Fattah, 2024; Jabin et al., 2023).

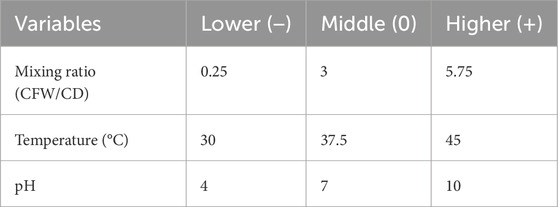

2.3 Design of the experiment

The experimental design for biogas production from the co-digestion of CFW and CD includes three independent variables: the mixing ratio (CFW:CD), temperature, and pH. The response variables were biogas volume and methane composition. Optimization was performed using Design Expert software with the Box–Behnken approach of the response surface methodology. Each independent variable was tested at three levels (low, middle, and high), resulting in 17 experimental runs. All experiments were conducted in triplicate, with the average response variable results reported, as shown in the experimental design presented in Table 1.

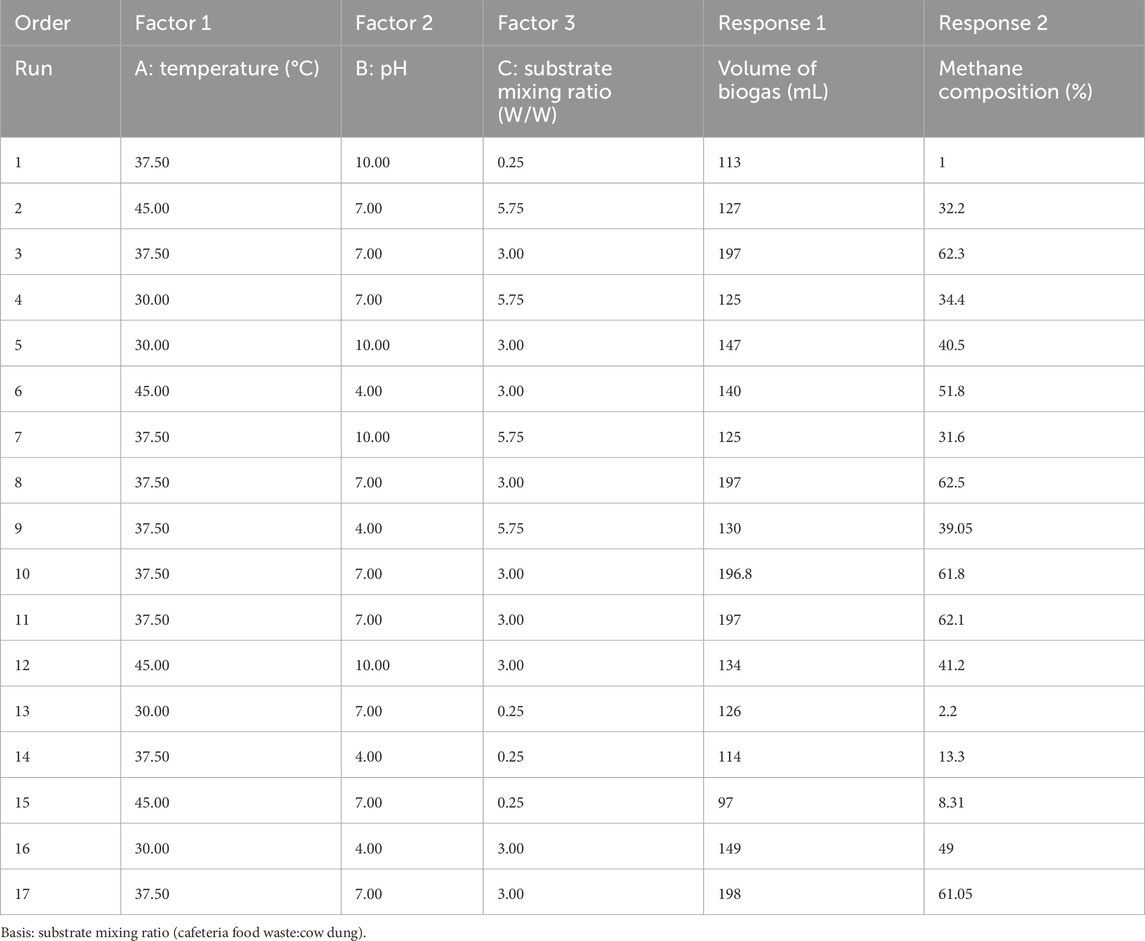

Table 1. Design of the experiment for biogas production from co-digestion of cafeteria food waste and cow dung.

2.4 Biogas production from co-digestion of cafeteria food waste and cow dung

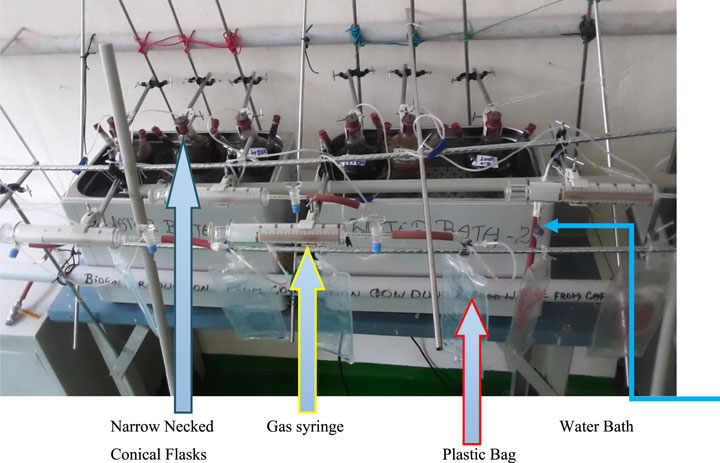

The experimental setup for the batch digestion study consisted of narrow-necked conical flasks sealed with rubber stoppers, as shown in Figure 3. The flasks were placed in three different water baths maintained at temperatures of 30°C, 37.5°C, and 45°C. All anaerobic digesters were operated as bench-scale experiments, with each flask having a capacity of 1 L. Each flask was fitted with a rubber stopper containing a single outlet. This outlet was connected to a branched connector: one branch was linked to a gas syringe for biogas measurement, while the other was attached to a plastic bag for biogas collection. The digesters were manually agitated daily by shaking each flask manually to ensure proper mixing of the substrate. Biogas production began after 4 days of operation, and the volume produced in each treatment was monitored using a gas syringe over a period of 35 days. Simultaneously, the gas was collected in plastic gas bags for storage, and its composition was analyzed using a Geo-Tech GA5000 gas analyzer (Khumalo, 2020).

3 Results and discussions

3.1 Composition and characterization of the wastes

3.1.1 Characterization of the individual raw waste

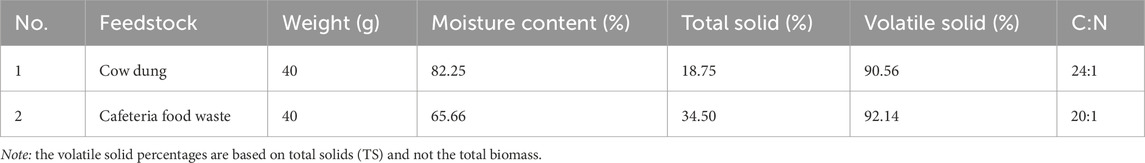

The data on TS, moisture content, VS, and the C:N ratio of the wastes used in the study are summarized in Table 2. The results indicate that CD had a higher moisture content (82.25%), while CFW had a lower moisture content of 65.66%. Cafeteria food waste had the highest TS content (34.50%). The VS values, representing a significant portion of the total solids, were 90.56% for CD and 92.14% for CFW, which corresponds to approximately 16.77% and 31.81% of the total waste composition, respectively. These findings are consistent with values reported in previous studies (Aragaw, 2013). The high moisture content in organic waste is beneficial for AD, as it facilitates the process (Prema et al., 2009). As shown in Table 2, the C/N ratios of CFW and CD were analyzed separately. The C/N ratios were calculated as 24 for CD and 20 for CFW, with both falling within the optimal range of 20–30 for AD (Shefali and Themelis, 2002). These results confirm that the feedstock used in this experiment meets the required C/N ratio for effective AD.

3.1.2 Values of total solid, volatile solid, pH, and C/N ratio of substrate co-digestion

3.1.2.1 Total solid and volatile solid

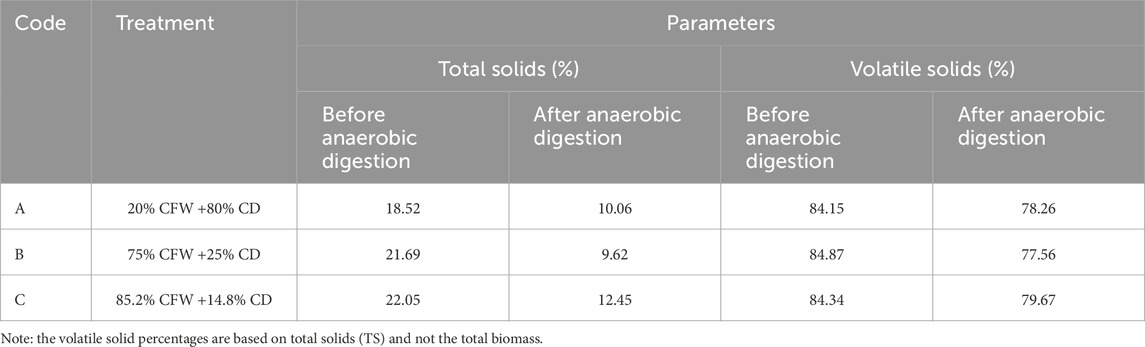

The percentage composition of TS for the 20% CFW +80% CD, 75% CFW +25% CD, and 85.2% CFW +14.8% CD mixtures was approximately 20.06%, 18.52%, and 17.06%, respectively. The TS content for this experiment, ranging from 22.05% to 18.06%, falls within the reported range of 5%–70% for various feedstocks (Steffen et al., 2000). The maximum TS was recorded for CFW (22.05%), while the minimum TS was observed for CD (18.52%) (Table 3). Although CFW alone had the highest TS percentage among the feedstocks, the 75% CFW +25% CD mixture demonstrated a significant reduction in TS, decreasing from 21.69% to 9.62%. Similarly, the 85.2% CFW +14.8% CD treatment resulted in a notable reduction in TS from 21.06% to 11.64%. As shown in Table 3, TS decreased after digestion for all mixtures, with the most significant reduction observed in the 75% CFW +25% CD mixture compared to the other treatments.

Table 3. Comparison of total solids and volatile solid content before and after anaerobic digestion (AD) of the various substrates.

The results revealed notable differences in VS reduction among the substrates before and after AD. The highest reduction in VS was observed in the 75% CFW (CFW) + 25% CD (CD) mixture, with a decrease of 12.07% (Table 3). TS and VS values before digestion increased with higher proportions of CFW in the mixture, indicating that blending substrates helps optimize TS and VS levels for digestion. The reduction in VS after AD indicates the effective conversion of the organic material into biogas. Both TS and VS are reliable indicators of digestion efficiency, with VS particularly reflecting the extent of organic matter breakdown and biogas production (Wu et al., 2021). Generally, VS includes carbohydrates, proteins, lipids, and other organic compounds, all of which are biodegraded by microorganisms during AD. The observed reduction in VS after digestion signifies the breakdown of these organic materials into biogas, demonstrating successful degradation.

3.1.2.2 pH

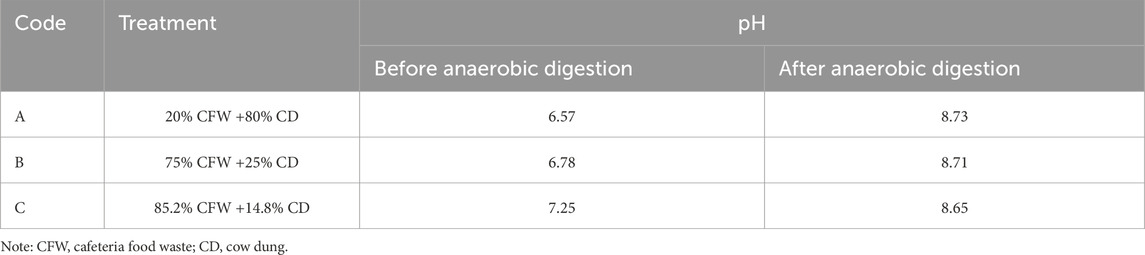

pH is a critical parameter for assessing the efficiency of anaerobic digesters and was included as an independent variable in the experimental design due to its significant impact on AD. It regulates microbial activity, controls volatile fatty acid accumulation, enhances biogas yield, and improves co-digestion synergy. By optimizing pH, process stability was maintained, leading to improved biodegradability and maximum methane output, thereby enhancing the accuracy of the predictive biogas model. As shown in Table 4, the pH values increased after digestion, rising from 6.57 to 8.73 for A, 6.78 to 8.71 for B, and 7.25 to 8.65 for C. This indicates a consistent trend of pH increase with progression in digestion. Ayu and Aryati (2010) found that the optimal pH range for biogas production lies between 6.6 and 7.6, with production typically starting at approximately pH 7.0 and peaking at that level.

Following AD, the pH values of all the treatments were found to be increased compared to their initial values. This increase in pH can be a result of the production of alkaline compounds, such as ammonium ions, during the degradation of organic matter in the digester (Gerard, 2016). The high pH values recorded in this study, particularly after digestion, could be linked to the higher abundance of organic matter in CFW than in CD (Gray et al., 1971). Moreover, the degradation of proteins contributes to ammonia formation, which increases the pH, while the accumulation of volatile fatty acids (VFAs) from the breakdown of organic matter lowers the pH.

3.1.2.3 Carbon-to-nitrogen ratio (C/N)

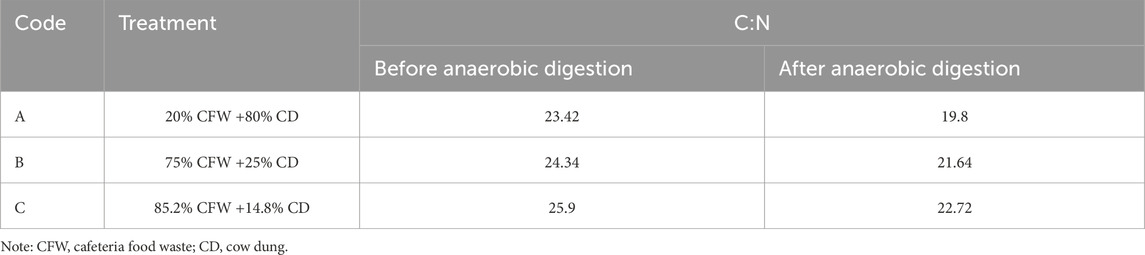

As demonstrated in Table 5, the initial C:N ratio values were 23.42 for A, 24.34 for B, and 25.9 for C, which decreased after AD to 19.8, 21.64, and 22.72, respectively. In the present study, the C:N ratios for all types of substrates were within the optimal range of 20:1 to 30:1, indicating that the nutritional profile of the substrates was suitable for methane production. The C:N ratio significantly influences the AD process, which directly impacts methane yield and production rates. Maintaining an appropriate C:N ratio in the feed material is crucial for ensuring bacterial growth and effective substrate degradation. During digestion, microorganisms utilize carbon 25 to 30 times faster than nitrogen, thus resulting in a C:N ratio between 20:1 and 30:1, ideal for sustaining microbial activity (Mitiku, 2018). Feedstocks are, therefore, selected to achieve this balance, categorized as either nitrogen- or carbon-rich based on their relative carbon and nitrogen content. If the C:N ratio is excessively high, methanogens will rapidly deplete nitrogen to meet their protein requirements, leaving the remaining carbon underutilized. This imbalance results in decreased biogas production. On the other hand, if the C:N ratio is too low, excess nitrogen is released as ammonia (NH3), increasing the pH of the slurry. High ammonia concentrations inhibit microbial growth, ultimately reducing biogas production (Bahl et al., 2019). The optimal C:N ratio for biogas production is widely recognized to be between 20:1 and 30:1 (Fricke et al., 2005) as it ensures the right balance for microbial activity and gas production.

In this work, the C:N ratio was 24.34 before digestion and decreased to 21.64 after digestion, which is a relatively high value attributed to the addition of CD to the food waste. High quantities of energy-rich, proteinaceous waste in the AD processes are not advisable due to the heightened risk of ammonia inhibition (Prakash et al., 2023; Selormey et al., 2021).

3.2 Experimental design results

The co-digestion of CFW and CD for biogas production was evaluated using the response surface methodology. In this work, the experimental runs were conducted according to the design plan formulated for the parameters under study (substrate mixing ratio, temperature, and pH). After each run, the biogas yield and methane composition were determined, and the responses for each run are shown in Table 6.

Table 6. Experimental matrix and observed responses for biogas production using the Box–Behnken design.

The studied responses were evaluated using various regression models to identify the best-fitting mathematical model and assess the significance of changing the process parameters. After comparison of all models, the quadratic model was determined to be the most suitable one for the studied responses. Furthermore, the relationship between biogas yield, methane composition, and the studied parameters (mixing ratio, temperature, and pH) is presented in Table 7.

Table 7. Statistical analysis of measured responses for biogas production from co-digestion of CFW and CD.

For biogas yield, the coefficients of the quadratic model equation indicated that an increase in temperature and pH resulted in a decrease in the percentage yield of biogas. On the other hand, a high substrate mixing ratio resulted in an increase in the biogas yield. The interaction between temperature and both pH and the substrate mixing ratio exhibited a negative effect on the biogas yield, which highlights the significant impact of temperature on biogas yield. These results suggest that both pH and temperature are key factors in the biogas yield at high substrate mixing ratios. Alternatively, the interaction between pH and the substrate mixing ratio resulted in a positive impact on biogas yield, indicating that the substrate mixing ratio significantly influenced the biogas yield.

Both temperature and substrate mixing ratio demonstrated a positive impact on the composition of methane, while increasing the pH had a negative impact. The interaction of temperature with both pH and substrate mixing ratio showed significant negative effects on methane composition, while the interaction of pH and substrate mixing ratio had a positive effect. Thus, at low pH, the increase in both the temperature and substrate mixing ratio leads to the production of methane-rich biogas as these conditions likely optimize the activity of methane-producing microorganisms. The synergistic influence of temperature and substrate composition ensures favorable conditions for microbial metabolism, thus improving the efficiency and quality of biogas production.

Analysis of variance (ANOVA) was performed to evaluate the significance of the model at a 95% confidence interval. A model is considered significant if the probability value (p-value) is less than 0.05, and the p-values presented in Table 7 for the studied responses indicate that the model is a good fit. The lack-of-fit test showed a desirable nonsignificant lack-of-fit (p > 0.05), with p-values of 0.0669 for biogas yield and 0.4764 for methane composition. Furthermore, the statistical analysis revealed high coefficients of determination (R2) for both responses. The adjusted R2 values were 0.9995 for biogas yield and 0.9993 for methane composition, which closely aligned with the predicted R2 values of 0.9969 and 0.9977, respectively, for biogas yield and methane composition.

3.3 Interaction effects

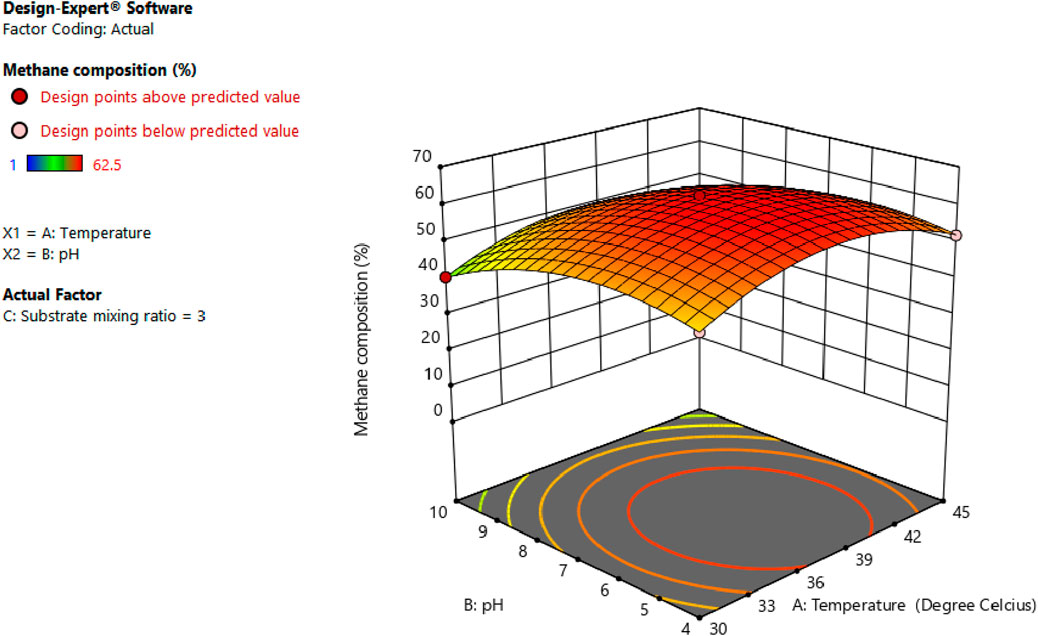

3.3.1 Interaction effects of temperature and pH on methane composition

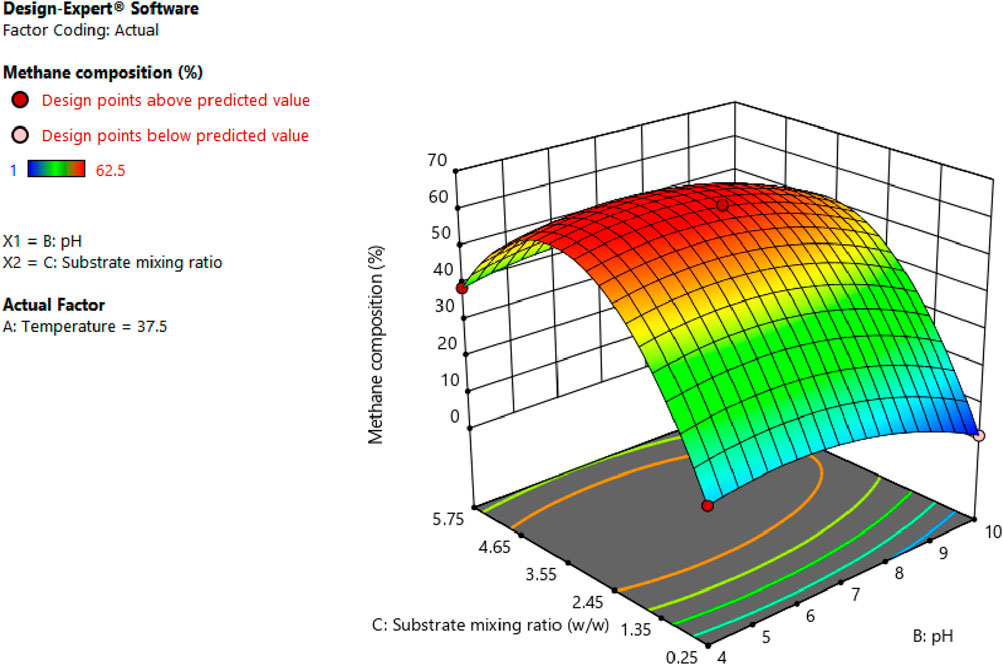

Figure 4 presents the three-dimensional (3D) response surface plot showing the interaction effect of temperature and pH on methane composition at a fixed substrate mixing ratio of 3 w/w (75% CFW: 25% CD). Methane composition initially increased with both temperature and pH, reaching a maximum at approximately 37.5°C and pH 7. These conditions are ideal for methanogenic microorganisms, as moderate temperatures enhance the enzymatic activity and neutral pH stabilizes microbial communities (Hilkiah Igoni et al., 2008). However, despite this trend, the general cumulative ANOVA model revealed a negative interaction between temperature and pH (interaction term AB), indicating that when both variables are increased simultaneously, their combined effect suppresses methane yield rather than enhancing it. This could be due to synergistic stress on microbial populations (Schwitzguébel, 2009), where elevated temperatures combined with high pH levels promote the accumulation of free ammonia or VFAs, ultimately reducing methane production (Babaei and Shayegan, 2019).

Figure 4. Interaction effects of temperature and pH on methane composition at a constant substrate mixing ratio of 3.

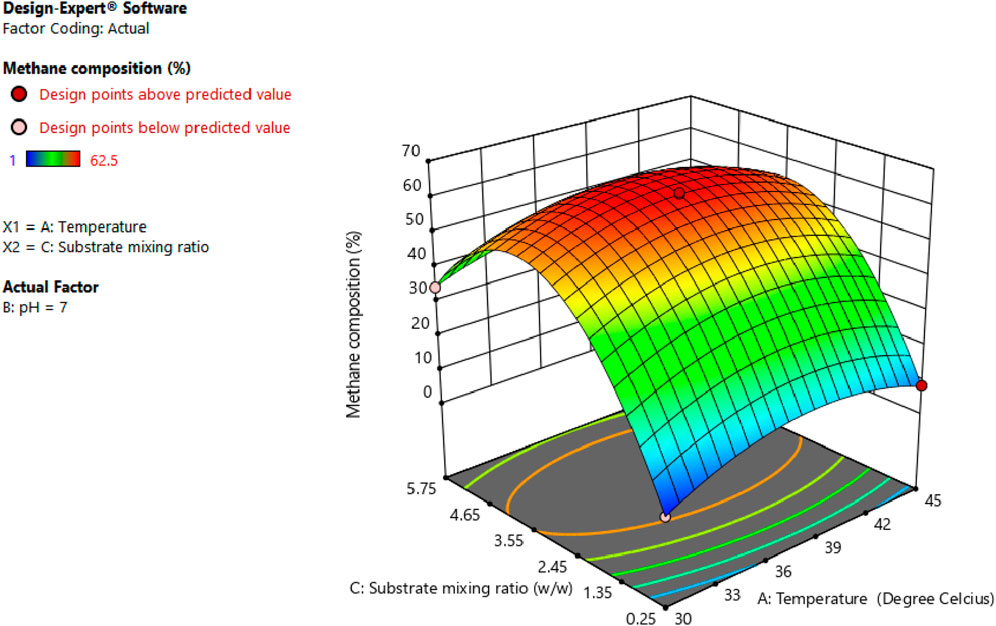

3.3.2 Interaction effect of temperature and substrate mixing ratio on methane composition

As shown in Figure 5, the interaction of temperature and substrate mixing ratio was assessed while maintaining pH at 7. Methane composition increased with both temperature and mixing ratio up to 37.5°C and 3 w/w, respectively. This suggests that moderate thermal conditions and a well-balanced co-digestion substrate (CFW and CD) are optimal for microbial activity and digestion efficiency. However, the general cumulative effect, as indicated by the ANOVA results, shows a negative interaction between these two factors (interaction term AC), implying that their combined increase leads to a reduction in methane yield. This statistical result may be explained by the increased release of ammonia and system overload due to higher proportions of protein-rich CFW at elevated temperatures, which can inhibit methanogenesis despite each factor being individually beneficial (Xue et al., 2020). Hence, although each factor supports methane production on its own, their combination beyond optimal levels negatively impacts the outcome.

Figure 5. Interaction effects of temperature and substrate mixing ratio on biogas yield at constant pH of 7.00.

3.3.3 Interaction effect of pH and substrate mixing ratio on methane composition

Figure 6 illustrates the response surface plot for the interaction between pH and the substrate mixing ratio, with temperature held constant at 37.5°C. Methane composition increased steadily with both pH and the substrate mixing ratio, reaching optimal points at pH 7 and a substrate ratio of 3 w/w, which aligns with ideal conditions for methanogenic bacteria and balanced nutrient availability. The ANOVA model revealed a positive interaction (interaction term BC) between pH and the substrate mixing ratio, indicating that increasing both factors simultaneously enhances methane production. This positive interaction suggests that a balanced increase in pH and substrate mixing ratio fosters favorable conditions for microbial growth, enhancing the degradation process. With pH approximately 7 and the substrate mixing ratio at 3 w/w, both variables contribute synergistically to improving biogas production and methane composition as long as they remain within the optimal pH ranges (Kainthola et al., 2019).

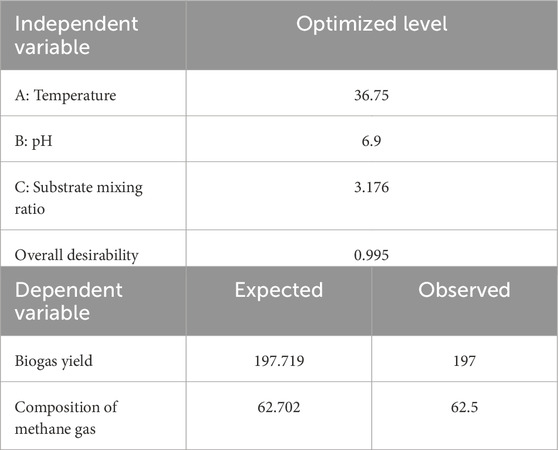

3.4 Optimization of biogas yield and methane gas composition from co-digestion of CFW and CD

A point that maximizes the desired function was identified through numerical optimization. As shown in Table 8, the optimal conditions for methane composition, considering pH, temperature, and the substrate mixing ratio, were determined to achieve the maximum methane yield and biogas production. Consequently, the optimum conditions were identified as a substrate mixing ratio of 3.176 (–75% CFW and 25% CD), with a pH of 6.900 and a temperature of 36.750°C. These conditions resulted in the highest desirability value of 0.995, indicating optimal methane composition and biogas production per feeding volume. Furthermore, experimental results demonstrated that under conditions of pH 7, a temperature of 37.5°C, and a substrate mixing ratio of 3 w/w (75% CFW and 25% CD), the biogas volume and methane composition were 197 mL and 62.5%, respectively. In comparison, the model-predicted values for these conditions were 197.72 mL and 62.702%, showing excellent agreement between the experimental and predicted results. Consequently, this confirms the accuracy and reliability of the model in predicting the outcomes.

4 Conclusion

In this study, an alternative energy source was explored through the production of biogas via the anaerobic co-digestion of organic wastes, specifically CFW and CD. To determine the optimal mixing ratio for co-digestion, anaerobic digestion experiments were conducted using three treatments with different mixing ratios. The experiment was conducted over 35 days in a 1-L batch test digester operating under mesophilic conditions at 37.5°C. The results indicated that the maximum biogas production, 197 mL, was achieved with a mixing ratio of 75% CFW to 25% CD, with methane gas constituting 62.5% of the biogas. Based on these findings, it can be concluded that the co-digestion of CD and CFW biomass offers a promising solution to address solid waste management and energy deficiency challenges.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material; further inquiries can be directed to the corresponding author.

Author contributions

GB: data curation, formal analysis, software, validation, visualization, writing – original draft, writing – review and editing, conceptualization, investigation, and methodology. ES: conceptualization, supervision, validation, visualization, writing – original draft, and writing – review and editing. MG: data curation, formal analysis, software, validation, visualization, writing – original draft, and writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abbas, Y., Yun, S., Mehmood, A., Shah, F. A., Wang, K., Eldin, E. T., et al. (2023). Co-digestion of cow manure and food waste for biogas enhancement and nutrients revival in bio-circular economy. Chemosphere 311 (P2), 137018. doi:10.1016/j.chemosphere.2022.137018

Abdin, Z. (2024). Bridging the energy future: the role and potential of hydrogen co-firing with natural gas. J. Clean. Prod. 436, 140724. doi:10.1016/j.jclepro.2024.140724

Agrawal, S., and Soni, R. (2021). Renewable energy: sources, importance and prospects for sustainable future. Energy Crises, Challenges Solutions, 131–150. doi:10.1002/9781119741503.ch7

Ainou, F. Z., Ali, M., and Sadiq, M. (2023). Green energy security assessment in Morocco: green finance as a step toward sustainable energy transition. Environ. Sci. Pollut. Res. 30 (22), 61411–61429. doi:10.1007/s11356-022-19153-7

Akram, H., Li, J., and Watto, W. A. (2024). The impact of urbanization, energy consumption, industrialization on carbon emissions in SAARC countries: a policy recommendations to achieve sustainable development goals. Environ. Dev. Sustain., 1–32. doi:10.1007/s10668-024-05365-z

Ambaye, T. G., Rene, E. R., Nizami, A.-S., Dupont, C., Vaccari, M., and van Hullebusch, E. D. (2021). Beneficial role of biochar addition on the anaerobic digestion of food waste: a systematic and critical review of the operational parameters and mechanisms. J. Environ. Manag. 290, 112537. doi:10.1016/j.jenvman.2021.112537

Aragaw. (2013). Co-digestion of cattle manure with organic kitchen waste to increase biogas production using rumen fluid as inoculums. 8(11), 443–450. doi:10.5897/IJPS2013.3863

Axon, C. J., and Darton, R. C. (2021). Sustainability and risk–a review of energy security. Sustain. Prod. Consum. 27, 1195–1204. doi:10.1016/j.spc.2021.01.018

Ayu, A., and Aryati, V. D. (2010). Biogas production using anaerobic biodigester from cassava starch effluent with ruminant bacteria as biocatalyst. 55.

Babaei, A., and Shayegan, J. (2019). Effects of temperature and mixing modes on the performance of municipal solid waste anaerobic slurry digester. J. Environ. Health Sci. Eng. 17 (2), 1077–1084. doi:10.1007/s40201-019-00422-6

Bahl, H., Andersch, W., Braun, K., and Gottschalk, G. (2019). Effect of pH and butyrate concentration on the production of acetone and butanol by Clostridium acetobutylicum grown in continuous culture. Eur. J. Appl. Microbiol. Biotechnol. 14 (1), 17–20. doi:10.1007/BF00507998

Bhatia, L., Jha, H., Sarkar, T., and Sarangi, P. K. (2023). Food waste utilization for reducing carbon footprints towards sustainable and cleaner environment: a review. Int. J. Environ. Res. Public Health 20 (3), 2318. doi:10.3390/ijerph20032318

Bong, C. P. C., Lim, L. Y., Lee, C. T., Klemeš, J. J., Ho, C. S., and Ho, W. S. (2018). The characterisation and treatment of food waste for improvement of biogas production during anaerobic digestion–A review. J. Clean. Prod. 172, 1545–1558. doi:10.1016/j.jclepro.2017.10.199

Bui, X. T., Vo, T. P. T., Ngo, H. H., Guo, W. S., and Nguyen, T. T. (2016). Multicriteria assessment of advanced treatment technologies for micropollutants removal at large-scale applications. Sci. Total Environ. 563, 1050–1067. doi:10.1016/j.scitotenv.2016.04.191

Carfora, A., Pansini, R. V., and Scandurra, G. (2022). Energy dependence, renewable energy generation and import demand: are EU countries resilient? Renew. Energy 195, 1262–1274. doi:10.1016/j.renene.2022.06.098

Chhandama, M. V. L., Chetia, A. C., Satyan, K. B., Ao, S., Ruatpuia, J. V. L., and Rokhum, S. L. (2022). Valorisation of food waste to sustainable energy and other value-added products: a review. Bioresour. Technol. Rep. 17, 100945. doi:10.1016/j.biteb.2022.100945

Chibueze, U., Okorie, N., Oriaku, O., Isu, J., and Peters, E. (2017). The production of biogas using cow dung and food waste. Int. J. Mater. Chem. 7 (2), 21–24. doi:10.5923/j.ijmc.20170702.01

Chojnacka, K., and Moustakas, K. (2024). Anaerobic digestate management for carbon neutrality and fertilizer use: a review of current practices and future opportunities. Biomass Bioenergy 180, 106991. doi:10.1016/j.biombioe.2023.106991

Czekała, W. (2022). Biogas as a sustainable and renewable energy source. Clean Fuels Mobil., 201–214. doi:10.1007/978-981-16-8747-1_10

de Oliveira Paiva, I., de Morais, E. G., Jindo, K., and Silva, C. A. (2024). Biochar N content, pools and aromaticity as affected by feedstock and pyrolysis temperature. Waste Biomass Valorization 15, 3599–3619. doi:10.1007/s12649-023-02415-x

De Rosa, M., Gainsford, K., Pallonetto, F., and Finn, D. P. (2022). Diversification, concentration and renewability of the energy supply in the European Union. Energy 253, 124097. doi:10.1016/j.energy.2022.124097

El-Ramady, H., Brevik, E. C., Bayoumi, Y., Shalaby, T. A., El-Mahrouk, M. E., Taha, N., et al. (2022). An overview of agro-waste management in light of the water-energy-waste nexus. Sustainability 14 (23), 15717. doi:10.3390/su142315717

Fasake, V., and Dashora, K. (2021). A sustainable potential source of ruminant animal waste material (dung fiber) for various industrial applications: a review. Bioresour. Technol. Rep. 15, 100693. doi:10.1016/j.biteb.2021.100693

Fattah, M. A. (2024). Evaluating the impact of magnetized and filtered wastewater on irrigation water quality. Water Conservation Sci. Eng. 9 (2), 47. doi:10.1007/s41101-024-00278-4

Fricke, K., Santen, H., and Wallmann, R. (2005). Comparison of selected aerobic and anaerobic procedures for MSW treatment. Waste Manag. 25 (8), 799–810. doi:10.1016/j.wasman.2004.12.018

Garg, A., Basu, S., Shetti, N. P., Bhattu, M., Alodhayb, A., and Pandiaraj, S. (2024). Biowaste to bioenergy nexus: fostering sustainability and circular economy. Environ. Res. 250, 118503. doi:10.1016/j.envres.2024.118503

Gashaw, A., and Teshita, A. (2014). Co-digestion of Ethiopian food waste with cow dung for biogas production. Int. J. Res. (IJR) 1 (7), 475–500.

Gerard, M. H. (2016). The microbiology of pneumonia, 15. Moscow, Russian Federation: Publishing House of the Academy of Medical Sciences of the USSR.

Gray, S. G., Hoover, W. G., and Johnson, K. W. (1971). Thermodynamic properties of the fluid and solid phases for inverse power potentials. J. Chem. Phys. 55 (3), 1128–1136. doi:10.1063/1.1676196

Haldorai, A. (2022). A survey of renewable energy sources and their contribution to sustainable development. J. Enterp. Bus. Intell. 2 (4), 211–222. doi:10.53759/5181/jebi202202021

Hickmann, F. M. W., Salahshournia, B., Andretta, I., Létourneau-Montminy, M.-P., and Rajagopal, R. (2024). Impact of lowering nitrogen content in pig manure through low crude protein diets on anaerobic digestion process stability, biogas yields, and digestate composition. Sci. Total Environ. 953, 175957. doi:10.1016/j.scitotenv.2024.175957

Hilkiah Igoni, A., Ayotamuno, M. J., Eze, C. L., Ogaji, S. O. T., and Probert, S. D. (2008). Designs of anaerobic digesters for producing biogas from municipal solid-waste. Appl. Energy 85 (6), 430–438. doi:10.1016/j.apenergy.2007.07.013

Hoyos-Seba, J. J., Arias, N. P., Salcedo-Mendoza, J., and Aristizabal-Marulanda, V. (2024). Animal manure in the context of renewable energy and value-added products: a review. Chem. Eng. Processing-Process Intensif. 196, 109660. doi:10.1016/j.cep.2023.109660

Ifaei, P., Nazari-Heris, M., Charmchi, A. S. T., Asadi, S., and Yoo, C. (2023). Sustainable energies and machine learning: an organized review of recent applications and challenges. Energy 266, 126432. doi:10.1016/j.energy.2022.126432

Ikevuje, A. H., Kwakye, J. M., Ekechukwu, D. E., and Benjamin, O. (2024). Optimizing the energy mix: strategies for reducing energy dependence. Open Access Res. J. Multidiscip. Stud. 8 (01), 94–104. doi:10.53022/oarjms.2024.8.1.0051

Issah, A.-A., Kabera, T., and Kemausuor, F. (2020). Biogas optimisation processes and effluent quality: a review. Biomass Bioenergy 133, 105449. doi:10.1016/j.biombioe.2019.105449

Jabin, S., Kapoor, J. K., Jadoun, S., Chandna, N., and Chauhan, N. P. S. (2023). Synthesis and characterization of polyamine-based polyelectrolytes for wastewater treatment in the sugar industry. J. Mol. Struct. 1275, 134573. doi:10.1016/j.molstruc.2022.134573

Jameel, M. K., Mustafa, M. A., Ahmed, H. S., jassim Mohammed, A., Ghazy, H., Shakir, M. N., et al. (2024). Biogas: production, properties, applications, economic and challenges: a review. Results Chem. 7, 101549. doi:10.1016/j.rechem.2024.101549

Kabeyi, M. J. B., and Olanrewaju, O. A. (2022a). Biogas production and applications in the sustainable energy transition. J. Energy 2022 (1), 8750221–8750243. doi:10.1155/2022/8750221

Kabeyi, M. J. B., and Olanrewaju, O. A. (2022b). Technologies for biogas to electricity conversion. Energy Rep. 8, 774–786. doi:10.1016/j.egyr.2022.11.007

Kadam, R., Jo, S., Lee, J., Khanthong, K., Jang, H., and Park, J. (2024). A review on the anaerobic Co-digestion of livestock manures in the context of sustainable waste management. Energies 17 (3), 546. doi:10.3390/en17030546

Kainthola, J., Kalamdhad, S. A., and Goud, V. V. (2019). Optimization of methane production during anaerobic co-digestion of rice straw and hydrilla verticillata using response surface methodology. Fuel 235 (February 2018), 92–99. doi:10.1016/j.fuel.2018.07.094

Kasinath, A., Fudala-Ksiazek, S., Szopinska, M., Bylinski, H., Artichowicz, W., Remiszewska-Skwarek, A., et al. (2021). Biomass in biogas production: pretreatment and codigestion. Renew. Sustain. Energy Rev. 150, 111509. doi:10.1016/j.rser.2021.111509

Kharchenko, O., and Kharchenko, D. O. (2011). Abnormal grain growth in nonequilibrium systems: effects of point defect patterning. Phys. Rev. E. 89, 042133. doi:10.1103/physreve.89.042133

Khumalo, S. C. (2020). Anaerobic co-digestion of abattoir and winery solid waste for enhanced biogas production. Cape Town, South Africa: Cape Peninsula University of Technology.

Kumar, D. S., Agrawal, M., Kasulla, M. S., and Kumar, A. (2024). A textbook on fundamentals of renewable energy and green Technology. Academic Guru Publishing House.

Mahmoodi, P., Farmanbordar, S., and Karimi, K. (2018). “Analytical methods in biogas production,” in Biogas: fundamentals, process, and operation, 221–238.

Malik, W., Mohan, C., and Annachhatre, A. P. (2020). Community based biogas plant utilizing food waste and cow dung. Mater. Today Proc. 28, 1910–1915. doi:10.1016/j.matpr.2020.05.312

Martin-Rios, C., Demen-Meier, C., Gössling, S., and Cornuz, C. (2018). Food waste management innovations in the foodservice industry. Waste Manag. 79, 196–206. doi:10.1016/j.wasman.2018.07.033

Mhlanga, P., Marenya, M. O., Tavengwa, N. T., and Tinarwo, D. (2023). Anaerobic co-digestion of canteen food waste and cow dung. Energy Sources, Part A Recovery, Util. Environ. Eff. 45 (4), 11341–11348. doi:10.1080/15567036.2023.2257149

Mishra, A., Kumar, M., Bolan, N. S., Kapley, A., Kumar, R., and Singh, L. (2021). Multidimensional approaches of biogas production and up-gradation: opportunities and challenges. Bioresour. Technol. 338, 125514. doi:10.1016/j.biortech.2021.125514

Mohammed, G. (2015). Biogas production from cow dung and food waste. Glob. J. Pollut. Hazard. Waste Manag. 3 (1), 103–108.

Monlau, F., Barakat, A., Trably, E., Dumas, C., Steyer, J. P., and Carrère, H. (2013). Lignocellulosic materials into biohydrogen and biomethane: impact of structural features and pretreatment. Crit. Rev. Environ. Sci. Technol. 43 (3), 260–322. doi:10.1080/10643389.2011.604258

Ngabala, F. J., and Emmanuel, J. K. (2024). Potential substrates for biogas production through anaerobic digestion-an alternative energy source. Heliyon 10 (23), e40632. doi:10.1016/j.heliyon.2024.e40632

Obaideen, K., Abdelkareem, M. A., Wilberforce, T., Elsaid, K., Sayed, E. T., Maghrabie, H. M., et al. (2022). Biogas role in achievement of the sustainable development goals: evaluation, Challenges, and Guidelines. J. Taiwan Inst. Chem. Eng. 131, 104207. doi:10.1016/j.jtice.2022.104207

Obileke, K., Nwokolo, N., Makaka, G., Mukumba, P., and Onyeaka, H. (2021). Anaerobic digestion: technology for biogas production as a source of renewable energy—a review. Energy and Environ. 32 (2), 191–225. doi:10.1177/0958305x20923117

Odejobi, O. J., Odekanle, E. L., Bamimore, A., Falowo, O. A., and Akeredolu, F. (2022). Anaerobic digestion of abattoir wastes for biogas production: optimization via performance evaluation comparison. Cogent Eng. 9 (1). doi:10.1080/23311916.2022.2122150

Olabi, A. G., and Abdelkareem, M. A. (2022). Renewable energy and climate change. Renew. Sustain. Energy Rev. 158, 112111. doi:10.1016/j.rser.2022.112111

Onwe, J. C., Ullah, E., Ansari, M. A., Sahoo, M., and Dhayal, K. S. (2024). Industrialization meets sustainability: analysing the role of technological innovations, energy efficiency and urbanisation for major industrialized economies. J. Environ. Manag. 372, 123297. doi:10.1016/j.jenvman.2024.123297

Panahi, H. K. S., Dehhaghi, M., Guillemin, G. J., Gupta, V. K., Lam, S. S., Aghbashlo, M., et al. (2022). Bioethanol production from food wastes rich in carbohydrates. Curr. Opin. Food Sci. 43, 71–81. doi:10.1016/j.cofs.2021.11.001

Panigrahi, S., and Dubey, B. K. (2019). A critical review on operating parameters and strategies to improve the biogas yield from anaerobic digestion of organic fraction of municipal solid waste. Renew. Energy 143, 779–797. doi:10.1016/j.renene.2019.05.040

Pour, F. H., and Makkawi, Y. T. (2021). A review of post-consumption food waste management and its potentials for biofuel production. Energy Rep. 7, 7759–7784. doi:10.1016/j.egyr.2021.10.119

Prakash, O., Mostafa, A., Im, S., Kang, S., Shi, X., and Kim, D.-H. (2023). Upflow anaerobic sludge blanket reactor operation under high pressure for energy-rich biogas production. Bioresour. Technol. 376, 128897. doi:10.1016/j.biortech.2023.128897

Prema, V., Sumithra Devi, S., and Nand, K. (2009). Anaerobic digestion of fruit and vegetable processing wastes for biogas production. Bioresour. Technol. 40 (1), 43–48. doi:10.1016/0960-8524(92)90117-G

Rahman, A., Farrok, O., and Haque, M. M. (2022). Environmental impact of renewable energy source based electrical power plants: solar, wind, hydroelectric, biomass, geothermal, tidal, ocean, and osmotic. Renew. Sustain. Energy Rev. 161, 112279. doi:10.1016/j.rser.2022.112279

Rame, R., Purwanto, P., and Sudarno, S. (2023). Biotechnological approaches in utilizing agro-waste for biofuel production: an extensive review on techniques and challenges. Bioresour. Technol. Rep. 24, 101662. doi:10.1016/j.biteb.2023.101662

Rani, G. M., Pathania, D., Umapathi, R., Rustagi, S., Huh, Y. S., Gupta, V. K., et al. (2023). Agro-waste to sustainable energy: a green strategy of converting agricultural waste to nano-enabled energy applications. Sci. Total Environ. 875, 162667. doi:10.1016/j.scitotenv.2023.162667

Sawyerr, N., Trois, C., and Workneh, T. (2019). Identification and characterization of potential feedstock for biogas production in South Africa. J. Ecol. Eng. 20 (6), 103–116. doi:10.12911/22998993/108652

Schwitzguébel, J. P. (2009). Accumulation and transformation of sulfonated aromatic compounds by rhubarb cells (Rheum palmatum). Int. J. Phytoremediation 1 (3), 255–271. doi:10.1080/15226519908500019

Selormey, G. K., Barnes, B., Kemausuor, F., and Darkwah, L. (2021). A review of anaerobic digestion of slaughterhouse waste: effect of selected operational and environmental parameters on anaerobic biodegradability. Rev. Environ. Sci. Bio/Technology 20 (4), 1073–1086. doi:10.1007/s11157-021-09596-8

Shefali, V., and Themelis, N. J. (2002). Anaerobic digestion of biodegradable organics in municipal solid waste.

Siddique, H. M. A., and Alvi, S. (2025). Impacts of industrialization, trade openness, renewable energy consumption, and urbanization on the environment in South Asia. Environ. Dev. Sustain., 1–24. doi:10.1007/s10668-024-05846-1

Singh, P. K., Mohanty, P., Mishra, S., and Adhya, T. K. (2022). Food waste valorisation for biogas-based bioenergy production in circular bioeconomy: opportunities, challenges, and future developments. Front. Energy Res. 10, 903775. doi:10.3389/fenrg.2022.903775

Siwal, S. S., Zhang, Q., Devi, N., Saini, A. K., Saini, V., Pareek, B., et al. (2021). Recovery processes of sustainable energy using different biomass and wastes. Renew. Sustain. Energy Rev. 150, 111483. doi:10.1016/j.rser.2021.111483

Steffen, W., Scholes, R. J., Boyle, E., Canadell, J., Canfield, D., Elser, J., et al. (2000). The global carbon cycle: a test of our knowledge of earth as a system. Science 290 (5490), 291–296. doi:10.1126/science.290.5490.291

Taneja, A., Sharma, R., Khetrapal, S., Sharma, A., Nagraik, R., Venkidasamy, B., et al. (2023). Value addition employing waste bio-materials in environmental remedies and food sector. Metabolites 13 (5), 624. doi:10.3390/metabo13050624

Thirumalaivasan, N., Nangan, S., Kanagaraj, K., and Rajendran, S. (2024). Assessment of sustainability and environmental impacts of renewable energies: focusing on biogas and biohydrogen (biofuels) production. Process Saf. Environ. Prot. 189, 467–485. doi:10.1016/j.psep.2024.06.063

Thyberg, K. L., and Tonjes, D. J. (2016). Drivers of food waste and their implications for sustainable policy development. Resour. Conservation Recycl. 106, 110–123. doi:10.1016/j.resconrec.2015.11.016

Tiong, Y. W., Sharma, P., Xu, S., Bu, J., An, S., Foo, J. B. L., et al. (2024). Enhancing sustainable crop cultivation: the impact of renewable soil amendments and digestate fertilizer on crop growth and nutrient composition. Environ. Pollut. 342, 123132. doi:10.1016/j.envpol.2023.123132

Tran, M. H., Paramasivam, P., Le, H. C., and Nguyen, D. T. (2024). Biomass: a versatile resource for biofuel, industrial, and environmental solution. Int. J. Adv. Sci. Eng. and Inf. Technol. 14 (1), 268–286. doi:10.18517/ijaseit.14.1.17489

Tucho, G. T., and Nonhebel, S. (2015). Bio-wastes as an alternative household cooking energy source in Ethiopia. Energies 8 (9), 9565–9583. doi:10.3390/en8099565

Wang, J., and Azam, W. (2024). Natural resource scarcity, fossil fuel energy consumption, and total greenhouse gas emissions in top emitting countries. Geosci. Front. 15 (2), 101757. doi:10.1016/j.gsf.2023.101757

Wu, D., Li, L., Peng, Y., Yang, P., Peng, X., Sun, Y., et al. (2021). State indicators of anaerobic digestion: a critical review on process monitoring and diagnosis. Renew. Sustain. Energy Rev. 148, 111260. doi:10.1016/j.rser.2021.111260

Xue, S., Wang, Y., Lyu, X., Zhao, N., Song, J., Wang, X., et al. (2020). Interactive effects of carbohydrate, lipid, protein composition and carbon/nitrogen ratio on biogas production of different food wastes. Bioresour. Technol. 312, 123566. doi:10.1016/j.biortech.2020.123566

Yang, Q., Wu, B., Yao, F., He, L., Chen, F., Ma, Y., et al. (2019). Biogas production from anaerobic co-digestion of waste activated sludge: co-substrates and influencing parameters. Rev. Environ. Sci. Bio/Technology 18, 771–793. doi:10.1007/s11157-019-09515-y

Yuvaraj, A., Thangaraj, R., Ravindran, B., Chang, S. W., and Karmegam, N. (2021). Centrality of cattle solid wastes in vermicomposting technology–A cleaner resource recovery and biowaste recycling option for agricultural and environmental sustainability. Environ. Pollut. 268, 115688. doi:10.1016/j.envpol.2020.115688

Zeng, J., Zeng, H., and Wang, Z. (2022). Review on technology of making biofuel from food waste. Int. J. Energy Res. 46 (8), 10301–10319. doi:10.1002/er.7868

Zhao, D., Yan, B., Liu, C., Yao, B., Luo, L., Yang, Y., et al. (2021). Mitigation of acidogenic product inhibition and elevated mass transfer by biochar during anaerobic digestion of food waste. Bioresour. Technol. 338, 125531. doi:10.1016/j.biortech.2021.125531

Keywords: biogas, co-digestion, cow dung, cafeteria food waste, methane, optimization, response surface methodology

Citation: Bidiko GB, Sangib EB and Gnaro MA (2025) Optimization of biogas production through co-digestion of cafeteria food waste and cow dung using the response surface methodology. Front. Energy Res. 13:1568478. doi: 10.3389/fenrg.2025.1568478

Received: 29 January 2025; Accepted: 27 May 2025;

Published: 17 June 2025.

Edited by:

Ranjeet Kumar Mishra, Manipal Institute of Technology, IndiaReviewed by:

Sanjeev Yadav, Shiv Nadar University, IndiaD. Jaya Prasanna Kumar, Ramaiah Institute of Technology, India

Copyright © 2025 Bidiko, Sangib and Gnaro. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mikiyas Abewaa Gnaro, bWlraXlhc2FiZXdhYTAyQGdtYWlsLmNvbQ==

Gezahegn Batebo Bidiko

Gezahegn Batebo Bidiko Mikiyas Abewaa Gnaro

Mikiyas Abewaa Gnaro