- 1Department of Biosystem Engineering, Faculty of Agricultural Technology, Universitas Brawijaya, Malang, East Java, Indonesia

- 2Department of Agroindustrial Technology, Faculty of Agricultural Technology, Universitas Brawijaya, Malang, East Java, Indonesia

- 3Sunan Giri Academy of Pharmaceutical and Food Analysis, Ponorogo, Indonesia

- 4Sunan Giri Islamic Institute, Ponorogo, Indonesia

- 5Department of Public Administrtion, Faculty of Administration, Universitas Brawijaya, Malang, East Java, Indonesia

Small-scale rice farming plays a vital role in Indonesia’s food security but presents considerable environmental challenges due to inefficient energy use and high greenhouse gas (GHG) emissions. This study investigates energy inputs and GHG emissions in smallholder rice farms in Tulungagung, East Java, to identify inefficiencies and recommend sustainable interventions. Data were collected from 16 farms across four subdistricts during the second planting season using structured surveys. Energy inputs—derived from fertilizers, machinery, fuel, and labor—were quantified using standardized coefficients, while GHG emissions were estimated based on the use of fertilizers, pesticides, and fuel. The results showed that fertilizers, particularly nitrogen-based ones, accounted for 96.6% of total energy inputs (18,270.96 MJ/ha). Average GHG emissions reached 21,431.6 kg CO2-eq/ha, with significant contributions from pesticides (31.8%) and fertilizers. Additional emissions stemmed from methane in flooded fields and nitrous oxide from fertilizer overuse. The system exhibited low energy efficiency (0.61%) and high specific energy consumption (127 MJ/kg), indicating substantial inefficiencies. These findings underscore the need for integrated nutrient management, site-specific mechanization, and renewable energy adoption to enhance the environmental sustainability of rice farming. Future studies should focus on the implementation of precision agriculture and biofertilizers to mitigate environmental impacts while improving productivity.

1 Introduction

Rice (Oryza sativa L.) is a fundamental agricultural commodity and a primary staple food for more than half of the global population, with Southeast Asia being a major hub for rice production and consumption. In Indonesia, rice occupies a central role in food security and economic sustainability, making its cultivation a critical focus for agricultural development. Despite contributing 9% of the world’s total rice production, Indonesia faces challenges in maintaining productivity due to limitations in land availability and farming practices. Specifically, smallholder farming, prevalent in regions like Tulungagung East Java, presents unique challenges related to land fragmentation, limited mechanization, and environmental impacts.

Tulungagung, a district in East Java, exemplifies the high dependency on rice as a source of livelihood, with the region contributing significantly to provincial and national rice outputs. However, the dominance of small-scale farming (<0.5 ha) restricts the adoption of advanced mechanized techniques, resulting in suboptimal energy utilization and significant time losses during cultivation processes. For instance, the shape and size of land plots constrain the maneuverability of agricultural machinery, exacerbating inefficiencies and increasing Greenhouse gas (GHG) emissions. These emissions, primarily carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O), are substantial contributors to global warming, particularly when associated with fossil fuel combustion, fertilizer application, and residue decomposition in flooded rice fields (Pagani et al., 2017).

The reliance on synthetic fertilizers and mechanization in agriculture has been widely reported to exacerbate environmental challenges. Studies by (Elsoragaby et al., 2019) highlighted that the overuse of nitrogen-based fertilizers contributes significantly to GHG emissions, with nitrogen oxides possessing a global warming potential 298 times greater than CO2. In rice cultivation, fertilizers such as urea are essential for productivity but can lead to unintended environmental consequences when used excessively (Salazar and Rand, 2020). Similarly, mechanization—though pivotal for enhancing productivity—requires significant energy inputs, leading to heightened emissions from fossil fuels. According to (Bakhshandeh et al., 2022) energy-intensive agricultural practices increase the carbon footprint, necessitating the need for energy audits to identify inefficiencies and propose mitigation strategies.

Small-scale rice farming, which dominates Tulungagung, exhibits unique energy and emission profiles. For example, hand tractors and combine harvesters are often used despite their inefficiency in small fields. The frequent turning and maneuvering of machinery result in wasted fuel and higher emissions, further exacerbating environmental challenges. Studies, such as those by Arunrat and Pumijumnong (2017) underline the inefficiencies associated with mechanization in fragmented lands, noting that such operations can double CO2 emissions compared to larger, contiguous fields. Moreover, the use of manual labor for transplanting and other operations, although reducing mechanical energy inputs, can indirectly increase emissions due to extended operational times and less efficient input utilization (Soni and Soe, 2016).

The emission of methane from low-land rice paddies field is another significant concern, given its global warming potential, which is 28 times higher than CO2 over a 100-year horizon (Soni and Soe, 2016). Methane emissions predominantly result from anaerobic decomposition of organic matter in flooded conditions, exacerbated by excessive use of organic fertilizers. Additionally, the application of synthetic nitrogen fertilizers leads to the volatilization and leaching of nitrous oxide, further contributing to the overall GHG burden. The combined effect of methane and nitrous oxide emissions from rice farming highlights the critical need for sustainable practices to balance productivity with environmental conservation (Zhong et al., 2016).

The energy profile of small-scale rice farming in Tulungagung further underscores inefficiencies that affect both economic and environmental sustainability. For instance, energy inputs such as fossil fuels, fertilizers, pesticides, and human labor are often utilized without optimization, leading to elevated costs and emissions. According to Kazemi et al. (2015) energy consumption in smallholder farms can be disproportionately high due to the lack of economies of scale. This phenomenon is particularly pronounced in regions where access to energy-efficient machinery and renewable energy resources is limited (Singh et al., 2019). Furthermore, the reliance on fossil fuels for irrigation, transportation, and field operations magnifies the environmental impact, with CO2 emissions constituting the majority of the GHG profile in these systems.

The challenges faced by small-scale rice farmers in Tulungagung reflect broader trends in developing agricultural regions. As noted by Mardani Najafabadi et al. (2022) the transition towards sustainable agriculture requires comprehensive energy audits and the adoption of best practices tailored to local contexts. In particular, the promotion of renewable energy sources, precision farming technologies, and integrated nutrient management can mitigate the environmental impact while enhancing productivity. However, these interventions require significant investments in capacity building, infrastructure, and policy support, areas that are currently underdeveloped in Tulungagung.

This study seeks to address these gaps by providing an in-depth analysis of energy use and greenhouse gas emissions in small-scale rice farming in Tulungagung. By employing a robust analytical framework, the research aims to quantify energy inputs, identify emission hotspots, and evaluate the efficiency of current practices. The findings will contribute to the growing body of literature on sustainable agriculture, offering practical insights for policymakers, researchers, and practitioners. Moreover, the study emphasizes the need for a balance between productivity and environmental stewardship, aligning with global sustainability goals (Chaudhary et al., 2017).

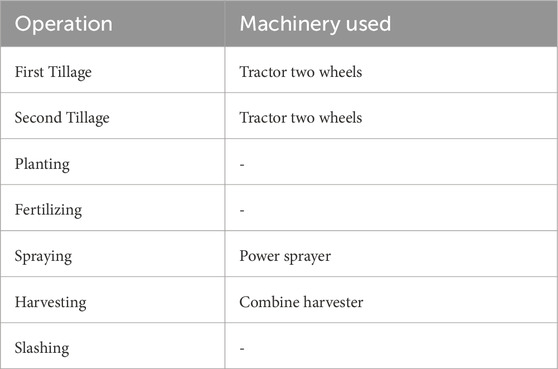

In conclusion, rice cultivation in Tulungagung represents both an opportunity and a challenge for sustainable agricultural development. While small-scale farming supports local economies and food security, its environmental footprint necessitates urgent attention. This research provides a critical assessment of the energy and emission dynamics of rice farming, highlighting pathways for achieving sustainable intensification in the region. By addressing the inefficiencies and environmental costs of small-scale rice farming, this study contributes to the broader discourse on sustainable agriculture and climate resilience. The decreasing availability of agricultural land has resulted in limitations for rice cultivation, which is now increasingly conducted on small plots of less than 1 ha. The energy input requirements for rice cultivation on small land differ significantly from those on larger land areas (Yuan and Peng, 2017). Farmers’ low awareness in utilizing energy efficiently on small plots leads to high energy input. These inputs include fertilizer energy, seed energy, chemical energy, agricultural machinery, and fuel. High energy input leads to increased greenhouse gas emissions, which pose a high risk of global warming and crop failure. This study aims to analyze the effect of energy inputs on productivity (output) and emissions in small-scale rice farming in Tulungagung Regency. The work operations and the machinery used are presented in Table 1.

2 Materials and methods

2.1 Study area

The research was conducted in Tulungagung, East Java, Indonesia, a district characterized by predominantly small-scale rice farming on fragmented land parcels of less than 0.5 ha. The study area includes four subdistricts: Boyolangu, Tulungagung, Campurdarat, and Kauman. The average land area used is 0, 27 ha.

2.2 Energy conversion coefficients

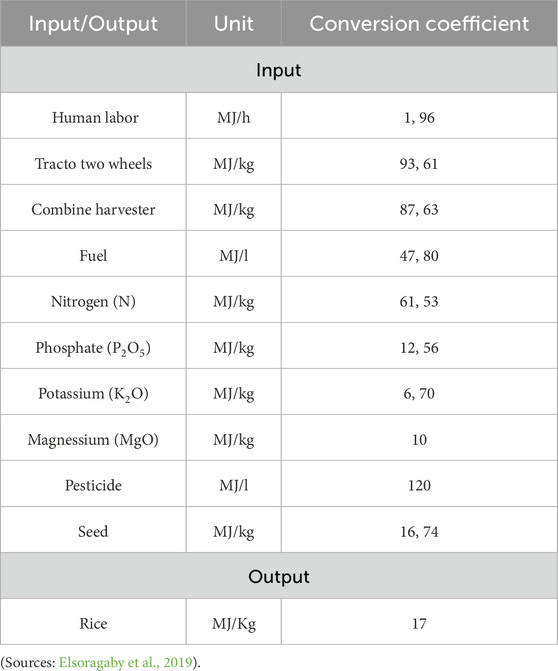

Inputs and output are assessed in rop production and then converted to energy values using appropriate energy conversion factors. The energy conversion coefficient is a value that expresses the energy input spent in the production and distribution of the physical material of the unit. Classical mathematical equations from Equations 1–7 are then used to estimate the equivalent energy sources of the production of the crops. The energy coefficients for different type of material inputs in crop production were reported in Table 2.

2.3 Energy sources of rice production

2.3.1 Machinery energy

Machinery energy is total of average the energy generated from agricultural machinery used in cultivating rice crops on small plots of land. The machinery used includes tractors for the first and second soil tillage and rice harvesting machines. The formula used for machinery energy input is provided in Equation 1.

Where ME is machinery input energy (MJ/ha), Cf is the energy coefficient (MJ/kg), W is the weight of the machinery (Kg), Fc is the effective field capacity (ha/hour), and L is the economic life of the machinery (year).

2.3.2 Fuel energy

Fuel energy is total of average the energy input used for rice cultivation derived from diesel fuel. The formula used for fuel energy input is provided in Equation 2.

Where FE is fuel energy (MJ/ha), f con is quantity of the consumed fuel (l), fc is the energy conversion coefficient of the full (MJ/l) and A is the farm covered area (ha).

2.3.3 Human energy

Human energy is total of average the labor energy used in all operational activities for rice cultivation on small plots of land. The formula used for human energy input is provided in Equation 3.

Where HE is human energy (MJ/ha), n is the number of workers engaged in the operation, H is the time spent in the performing the operations (h), lc is the energy conversion coefficient of the human worker (MJ/h), and A is the cultivated area (ha).

2.3.4 Fertilizer energy

Fertilizer energy is total of average the energy input from fertilizers used in the basic fertilization, first fertilization, and second fertilization. The formula used for fertilizer energy input is provided in Equation 4.

Where FTE is fertilizer energy (MJ/ha), FTq is the fertilizer quantity used (kg), FTi is the percentage of the composition of the ith element, FTCi is the energy conversion coefficient of the fertilizer element (MJ/kg) and A is the cultivated area covered (ha).

2.3.5 Chemical energy

Chemical energy is the total of average energy input derived from the use of chemical pesticides, where the application of chemical pesticides can occur two to three times during a single growing season of rice cultivation on small plots of land. The formula used for chemical energy input is provided in Equation 5.

Where PE is the energy of pesticide (MJ/ha), Pq is the pesticide quantity used (kg), Pc is the energy conversion coefficient of the pesticides (MJ/kg), and A is the cultivated area (ha).

2.3.6 Seed energy

Seed energy is total of average the energy input from rice seeds used for rice cultivation on small plots of land. The formula used for human energy input is provided in Equation 6.

Where SE is total average the energy of crop seed (MJ/ha), Sq is the seed quantity used (kg), sc is the energy conversion coefficient of the seed, and A is the cultivated area covered (ha).

2.3.7 Total energy input

Total energy input is the sum of all the average energy used in rice cultivation on small plots of land. Equation 7 was used to determine the total energy input on small plots of land.

Where TEI is the total of the average energy input (MJ/ha) and ME, FE, HE, PE, FTE, SE were defined previously.

2.3.8 Energy output

Energy output is the average rice output of rice cultivation on small plots of land. The formula used for rice energy output is provided in Equation 8.

Where Re is average the energy rice output (MJ/ha), Sp is quantity output, sc is the energy conversion coefficient of the rice, and A is the cultivated area covered (ha).

2.4 Energy index of rice production

2.4.1 Energy ratio

Energy use efficiency represents the amount of energy generated for each unit of energy consumed and is calculated as the ratio between output energy and input energy.

2.4.2 Specific energy

Specific energy represents the energy required to produce one unit of crop yield and is calculated as the ratio of energy input to the crop yield.

2.4.3 Energy gain

The increase in net energy is the difference between the average energy output and the average energy input.

2.4.4 Energy productivity

Energy productivity quantifies the amount of crop produced per unit of energy consumed. It is calculated as the ratio of yield (kg/ha) to input energy (MJ/ha).

2.5 Mechanization index

An evaluation of the mechanization status in the rice production system highlights the extent of machinery energy utilized in wetland paddy cultivation and identifies key operations that require mechanization to improve paddy yields through efficient and timely execution of tasks. The mechanization status of the crop production process is represented by the mechanization index. The mechanization index (Im) is defined as the percentage of machinery energy relative to the total energy from human labor, animal power, and machinery, as outlined in the given equation.

Where IM is the mechanization index, EEM is the average energy of machinery (MJ/ha), EEH is the average energy of human labor (MJ/ha).

2.6 Greenhouse gas emission (GHG)

In crop production, CO2 emissions are generated from the combustion of fossil fuels, the use of machinery, chemical fertilizers, and chemical pesticides. To calculate GHG emissions for fossil fuels, machinery, chemicals fertilizer, and chemicals pesticide the standard coefficients were applied (Table 3). The amount of GHG emissions was obtained by multiplying the input rate by its corresponding emission coefficient using Equations 14–18.

2.6.1 Fuel emission

Where Cf is CO2 average the emission due to fuel combustion (kgCO2eq/ha), ccf is CO2 conversion coefficient for fuel combustion (kgCO2eq/l) as indicated in Table 3, fcon is quantity of fuel consumed (l) and A is farm area covered (ha).

2.6.2 Machinery emission

Where Cm is CO2 average emission due to machinery utilizing for an operation (KgCO2eq/ha), ccm is CO2 conversion coefficient for machinery (kCO2eq/MJ) as indicated in Table 3, me is machinery energy (MJ), and A is farm area convered (ha).

2.6.3 Fertilizer emission

Where Cch is CO2 average emission due to fertilizer dor an operation (kgCO2eq/ha), ccch is CO2 conversion coefficient for fertilizer (kgCO2eq/MJ) as indicated in Table 3, chq is fertilizer quantity (kg), and A is farm area covered (ha).

2.6.4 Chemical emission

Where cch is CO2 average emission due to chemical pesticide for an operation (kgCO2eq/ha), ccch is CO2 conversion coefficient for chemical pesticide (kgCO2eq/MJ) as indicated in Table 3, chq is chemical pesticide quantity (kg), and A is farm area covered (ha). The average total greenhouse gas emissions generated from rice cultivation on small plots of land were summed up to obtain the average greenhouse gas emissions for the region.

To determine the relationship between energy inputs and rice yield, a multiple linear regression function was used. Multiple linear regression was applied to analyze the relationship between energy inputs on 16 small rice field plots and the resulting yields (Equation 18).

Where ‘X1’ is a human labor’ ‘X2’ is a machinery; ‘X3’ is a seed; ‘X4’ is a fuel; ‘X5’ is a chemical pesticide; ‘X6’ is a fertilizer pesticide, ‘α0’ the constant term ‘αi’ represent coefficients of inputs which are estimated from the model, ‘ei’ is the error term, and ‘Y’ is rice yield.

All data on energy input, GHG emission, and rice yield were calculated and entered into MS Excel 2019.

2.7 Methodology

The research methodology used is a social approach analysis. The data collection process was carried out randomly in 5 different areas in Tulungagung Regency. Each energy input used was calculated in real time during the rice cultivation process. These inputs were then converted using energy coefficients based on Table 2, following Elsoragaby et al., 2019. Meanwhile, the energy output and greenhouse gas emissions generated from rice cultivation were calculated based on the energy inputs and GHG emission coefficients in Table 3, also according to Elsoragaby et al., 2019. The energy inputs and outputs in rice cultivation were then used to calculate energy efficiency, specific energy, energy gain, and energy productivity.

3 Result and discussion

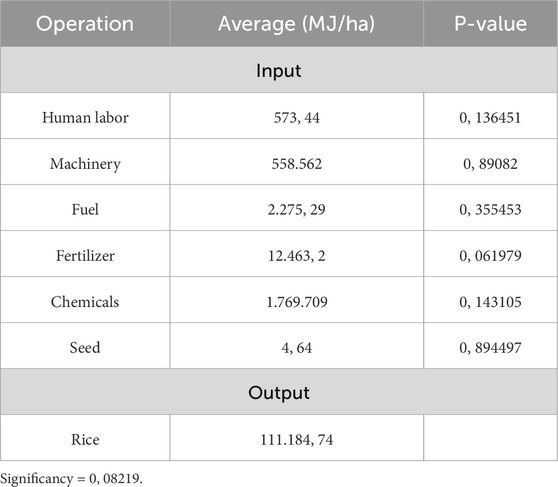

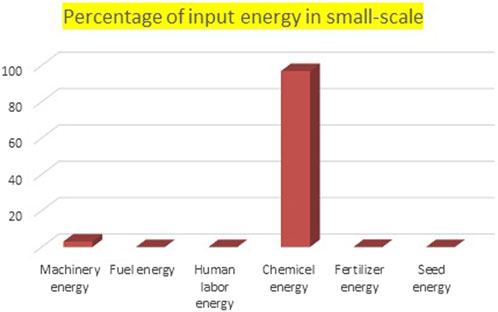

Based on Table 4, energies used in rice cultivation in small scales are chemical energy from the use of pesticides (1,769,709 MJ/ha); machine energy (558,562 MJ/ha); fertilizer energy (12,463.2 MJ/ha); fuel energy (2,275.29 MJ/ha); labor energy (573.44 MJ/ha); and seed energy (4.64 MJ/ha). Figure 1 shows the percentage of each type of energy used in the total energy consumption. The highest energy input in cultivating rice plants in small-scale is pesticide chemical energy. The excessive use of pesticides is caused by farmers’ limited knowledge of the environmental hazards of pesticides and their belief that it does not affect rice production (Wachid and Mintono, 2017). The pesticide used consist of herbicides, fungicides, and insecticides.

These results state that the energy input for cultivating rice plants on narrow land has no effect on the output results with an R square result of 0.0648922, where the value is >0.05. The high use of energy input for pesticide chemicals is due to the fact that plants are often attacked by pests and plant diseases such as insects and fungi. Farmers assume that high energy input will reduce the risk of crop failure due to pest attacks and plant diseases. Meanwhile, the lowest energy input is seed energy, namely, 4.64 MJ/ha. The low seed energy input is due to the narrow land area of <0.5 ha and farmers’ limited access to obtaining superior seeds. The seed varieties cultivated in small scales are local seed varieties. This energy input was obtained from an average land area of 0.27 ha and produced a rice energy output of 111,184.74 MJ/ha. The results of similar research conducted by (Elsoragaby et al., 2019) showed that energy input had no effect on rice yields using the transplanting and seed spreading methods. Similar research conducted by (Muazu et al., 2014) shows that there is an influence of labor energy input, fuel, agricultural machinery, fertilizer and pesticides, but there is no influence of seed energy input on the productivity of rice plants obtained in Malaysia. Similar research conducted by (Nabavi-Pelesaraei et al., 2018) showed that in 1 out of 11 experiments there was an influence of energy input on rice yields in Iran.

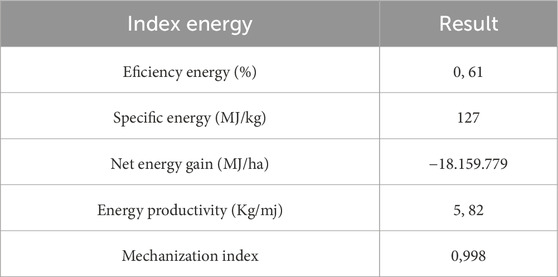

Based on Table 5, it is known that the energy efficiency in cultivating rice plants on narrow land is 0.61%; specific energy 127 MJ/kg; increase in clean energy −18,159,779 MJ/ha; energy productivity 5.82 kg/mj; and a mechanization index of 0.998. The energy efficiency results obtained are in line with the energy efficiency of rice production in Iran, namely, 0.858% for technical rice cultivation and 0.953% for direct rice cultivation. Differences in energy efficiency results are influenced by different cultivation methods so that the amount of input used and the output produced are different. The specific energy produces 127 MJ/kg which is above the specific energy of rice plants in Iran, which is 11.56 MJ/kg. The differences in specific energy values in each country are influenced by the treatment of farmers in the cultivation series as well as climatic conditions which influence crop yields (Kazemi et al., 2015). Similar research conducted in Malaysia obtained specific energy results of 8.35 MJ/kg using full mechanization. The specific energy results are not completely influenced by input energy which includes machine energy, fuel energy, fertilizer energy, pesticide energy, seed energy and labor energy. Only part of the input energy is used by rice plants for production and the rest will become residue in the soil, air and irrigation water (Shafie, 2016). A similar study conducted by Soni et al. (2013) in Myanmar stated that energy efficiency in rice farming there was 5.55 MJ for irrigated systems and 5.92 MJ for rain-fed systems. Meanwhile, energy efficiency in rice cultivation in Japan ranged from 0.732% on land areas of 1–2 ha to 0.988% on land areas >15 ha. Differences in energy efficiency across regions and countries are influenced by farmers’ knowledge of energy requirements, the availability of energy and labor, and the use of agricultural machinery. The irrigation system used in small-scale rice farming in Tulungagung Regency is technical irrigation utilizing river flow.

The result of increasing clean energy in cultivating rice plants on narrow land is −18,159,779 MJ/ha, which means it does not result in an increase in clean energy. These results can be at higher risk of environmental pollution energy than the energy obtained from the harvest. Factors that influence the clean energy results produced are the doses of pesticides and fertilizers used during the rice cultivation series as well as the use of agricultural mechanization (Ekel, 2017). Another factor that influences the increase in clean energy is environmental conditions which include weather, climate and soil conditions (Kazemi et al., 2015). From these results, an energy productivity of 5.82 kg/Mj and a mechanization index of 0.988 were obtained. The factor that influences energy productivity is the rice cultivation method used. Conventional rice cultivation methods in Vietnam produce energy productivity of 0.15–0.16 kg/MJ, while the SRI method produces energy productivity of 0.22–0.23 kg/MJ. The difference in energy productivity results of 43% indicates that cultivation methods influence energy productivity (Truong et al., 2017). Meanwhile, the mechanization index obtained is above the average mechanization index for rice cultivation in Malaysia, namely, 0.76 for the transplanting rice planting method and 0.65 for the seed spreading rice planting method. These results state that the higher the use of agricultural mechanization in rice cultivation, the higher the resulting mechanization index. The results of the mechanization index are in line with research on rice cultivation in Malaysia, where tillage has a higher mechanization index compared to other stages of rice cultivation using the seed distribution system (Elsoragaby et al., 2019). Energy use in the agricultural sector is influenced by economic factors and the availability of adequate facilities. This is evident in farmers’ use of fertilizers and agricultural machinery. Farmers tend to use subsidized fertilizers available at affordable prices and agricultural machines provided by the government to minimize economic costs. According to Rajah et al. (2024), energy use in agriculture must be supported by the use of clean energy to reduce the risk of greenhouse gas emissions by 184 tons of CO2, which is equivalent to the carbon absorption of a 16.9-ha forest.

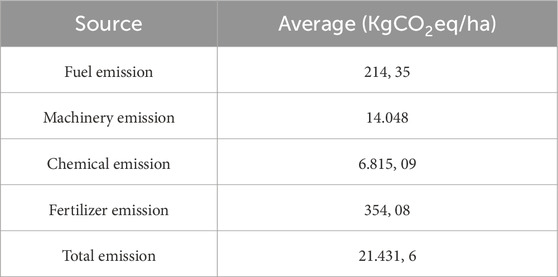

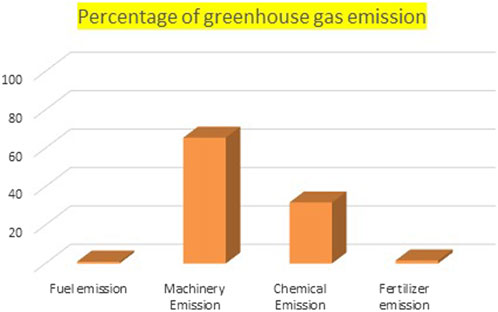

As shown in Table 6, the highest average greenhouse gas emissions were obtained from agricultural machinery sources (14,048 KgCO2eq/ha); source of pesticide chemicals (6,815.09 KgCO2eq/ha); fertilizer source (354.08 KgCO2eq/ha); and fuel source (214.3 KgCO2eq/ha) to obtain a total average greenhouse gas emission of 21,431.6 KgCO2eq/ha. The source of greenhouse gas emissions from excess fuel produced is lower than greenhouse gas emissions from the same source in Iran, namely, 948.94 KgCO2eq/ha out of total greenhouse gas emissions of 1,936.11 KgCO2eq/ha (Firouzi et al., 2016). Meanwhile, the average total CO2 emissions in rice cultivation in Northern Iran is 4,263 ± 1,547 Kg CO2 eq/ha (Arunrat and Pumijumnong, 2017). The difference in the two CO2 emission results in the two previous studies was due to differences in energy input treatment in the rice cultivation series. These differences can occur in the use of chemical pesticides, the use of fertilizers at different doses, and different mechanization (Wang et al., 2016).

As illustrated in Figure 2, the percentage of greenhouse gas emissions shows that the highest emissions come from agricultural machinery (65.55%), followed by pesticide use (31.80%), fertilizers (1.65%), and fuel consumption (1%). According to (Tran et al., 2018) gas emissions can be influenced by seasons, namely, the wet season and the dry season. In the dry season, the flow of hot air is higher, making it easier for residual agricultural energy input used to spread in the environment. The impact of these residues is water pollution, air pollution, and an increase in temperature which will result in crop failure. A greater risk of increasing carbon emissions is burning straw residue, as is done in the provinces of Guilan, Mazandaran and Golestan in Iran (Sharma and Brar, 2022). Straw burning in Iran results in a combustion carbon footprint of 402.8 kgCO2eq/ton respectively; 341.6 kgCO2eq/ton; and 369.3 kgCO2eq/ton (Rezaei et al., 2021). The straw burning carried out by farmers is due to the use of combine harvesting machines which chop and spread the straw in the fields, making it difficult to remove. Incomplete combustion of straw occurs in 5–10 kg of the total straw produced which causes large amounts of CO, CH4 emissions. In addition, chopping and burning straw in rice fields can increase the integration of straw into the soil (Arai et al., 2015). Allocation of rice straw that is not burned as animal feed can reduce the risk of air pollution by 30%–38%, however, during harvest in the rainy season there will be problems in transporting and transporting the straw, so many farmers choose to burn the straw when the land starts to dry out.

4 Conclusion

This study provides a comprehensive evaluation of energy utilization and greenhouse gas (GHG) emissions in small-scale rice farming systems in Tulungagung, Indonesia. The findings indicate significant inefficiencies and environmental challenges that require targeted interventions for sustainability. The analysis shows that fertilizers are the largest contributor to energy input, accounting for 96.6% of the total energy used (18,270.96 MJ/ha), followed by machinery and fuel. Overreliance on nitrogen-based fertilizers significantly contributes to inefficiencies and GHG emissions, highlighting the urgent need for integrated nutrient management strategies.

GHG emissions from rice farming in Tulungagung are relatively high, averaging 21,431.6 kg CO2-eq/ha, with the highest contributions from pesticide use (31.8%) and fertilizers (1.65%). Methane and nitrous oxide emissions, driven by anaerobic conditions in flooded fields and excessive fertilizer application, further exacerbate the environmental impact. Energy efficiency was recorded at 0.61% and specific energy consumption at 127 MJ/kg. These figures are significantly lower than similar studies in other regions. For instance, energy efficiency in rice farming in Iran is 0.858% for technical systems and 0.953% for direct seeding systems. In Japan, energy efficiency is 0.732% on 1–2 ha plots and 0.988% on plots >15 ha. These findings align with the literature on the environmental costs of small-scale farming while also highlighting the unique contextual challenges in Tulungagung.

The implications of these results go beyond academic understanding and lead to practical policy recommendations. Optimizing fertilizer use, promoting tailored mechanization, adopting renewable energy technologies, and enhancing farmer capacity can collectively address inefficiencies and reduce emissions. These actions align with global sustainable development goals, offering a path to improve food security while minimizing environmental harm.

This study contributes to scientific development by offering a localized perspective on energy and GHG dynamics in small-scale rice farming. It provides an empirical basis for designing interventions that balance productivity with environmental sustainability. The detailed analysis of energy and emissions enriches the discourse on sustainable agriculture and offers a replicable framework for similar contexts.

Future research should focus on longitudinal studies to capture temporal variations in energy use and emissions, as well as experimental designs to validate and refine the findings. Investigating the adoption of precision agriculture technologies, biofertilizers, and small-scale renewable energy systems could offer further insights into sustainable intensification for smallholder farming. In conclusion, this study highlights the urgent need for sustainable practices in small-scale rice farming. By addressing inefficiencies and environmental costs, these findings pave the way for policies and practices that support both local livelihoods and global climate resilience.

Based on the research findings, it is recommended to improve farmers’ knowledge and skills regarding energy use in small-scale rice cultivation. This effort can be realized through counseling and guidance in the use of clean energy that poses minimal risk of greenhouse gas emissions. According to the test results, the highest energy input comes from chemical fertilizers, which did not affect the output yields, thus increasing the risk of greenhouse gas emissions.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Ethics statement

The studies involving humans were approved by Faculty of Agricultural Technology Brawijaya University Indonesia. The studies were conducted in accordance with the local legislation and institutional requirements. Written informed consent for participation was not required from the participants or the participants’ legel guardians/next of kin because the research was conducted outside the affiliated institution.

Author contributions

ML: Writing – original draft, Writing – review and editing. NA: Data curation, Formal Analysis, Methodology, Resources, Writing – review and editing, Writing – original draft. AA: Data curation, Investigation, Methodology, Supervision, Writing – original draft, Writing – review and editing. SM: Data curation, Supervision, Validation, Writing – original draft, Writing – review and editing. AL: Project administration, Validation, Writing – original draft, Writing – review and editing. LM: Supervision, Validation, Writing – original draft, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Arai, H., Hosen, Y., Pham Hong, V. N., Thi, N. T., Huu, C. N., and Inubushi, K. (2015). Greenhouse gas emissions from rice straw burning and straw-mushroom cultivation in a triple rice cropping system in the Mekong Delta. Soil Sci. Plant Nutr. 61 (4), 719–735. doi:10.1080/00380768.2015.1041862

Arunrat, N., and Pumijumnong, N. (2017). Practices for reducing greenhouse gas emissions from rice production in northeast Thailand. Agriculture 7 (1), 4. doi:10.3390/agriculture7010004

Bakhshandeh, E., Jamali, M., Emadi, M., and Francaviglia, R. (2022). Greenhouse gas emissions and financial analysis of rice paddy production scenarios in northern Iran. Agric. Water Manag. 272, 107863. doi:10.1016/j.agwat.2022.107863

Chaudhary, V. P., Singh, K. K., Pratibha, G., Bhattacharyya, R., Shamim, M., Srinivas, I., et al. (2017). Energy conservation and greenhouse gas mitigation under different production systems in rice cultivation. Energy 130, 307–317. doi:10.1016/j.energy.2017.04.131

Ekel, F. S. (2017). Performance testing of the “Maxxi Corn Type-G Automatic” combine harvester machine for rice rice harvesting with two different transmissions in tababo village, Belang district southeast minahasa district.

Elsoragaby, S., Yahya, A., Mahadi, M. R., Nawi, N. M., and Mairghany, M. (2019). Analysis of energy use and greenhouse gas emissions (GHG) of transplanting and broadcast seeding wetland rice cultivation. Energy 189, 116160. doi:10.1016/j.energy.2019.116160

Firouzi, S., Nikkhah, A., Khojastehpour, M., and Holden, N. M. (2016). Energy use efficiency, Ghg emissions, and carbon efficiency of paddy rice production in Iran. Energy Equipment And Systems 4 (2), 169–176. doi:10.1016/j.scitotenv.2016.04.167

Kazemi, H., Kamkar, B., Lakzaei, S., Badsar, M., and Shahbyki, M. (2015). Energy flow analysis for rice production in different geographical regions of Iran. Energy 84, 390–396. doi:10.1016/j.energy.2015.03.005

Mardani Najafabadi, M., Sabouni, M., Azadi, H., and Taki, M. (2022). Rice production energy efficiency evaluation in north of Iran; application of robust data envelopment analysis. Clean. Eng. Technol. 6, 100356. doi:10.1016/j.clet.2021.100356

Muazu, A., Yahya, A., Ishak, W. I. W., and Khairunniza-Bejo, S. (2014). Yield prediction modeling using data envelopment analysis methodology for direct seeding, wetland paddy cultivation. Agric. Agric. Sci. Procedia 2, 181–190. doi:10.1016/j.aaspro.2014.11.026

Nabavi-Pelesaraei, A., Rafiee, S., Mohtasebi, S. S., Hosseinzadeh-Bandbafha, H., and Chau, K. (2018). Integration of artificial intelligence methods and life cycle assessment to predict energy output and environmental impacts of paddy production. Sci. Total Environ. 631–632, 1279–1294. doi:10.1016/j.scitotenv.2018.03.088

Pagani, M., Johnson, T. G., and Vittuari, M. (2017). Energy input in conventional and organic paddy rice production in Missouri and Italy: a comparative case study. J. Of Environ. Manag. 188, 173–182. doi:10.1016/j.jenvman.2016.12.010

Rajah, K., Ghriss, O., Fguiri, A., and Jeday, M.-R. (2024). “Validation of techno-economic and environmental sustainability of solar PV technology in agriculture using RETScreen expert to assess its feasibility,” in Proceedings of the 2nd international conference on green energy conversion systems. Editors S. Bacha, M. R. Alfarra, and M. Kanj (Springer), 795–800.

Rezaei, M., Soheilifard, F., and Keshvari, A. (2021). Impact of agrochemical emission models on the environmental assessment of paddy rice production using life cycle assessment approach. Energy Sources, Part A Recovery, Util. Environ. Eff. 47, 4079–4094. doi:10.1080/15567036.2020.1864066

Salazar, C., and Rand, J. (2020). Pesticide use, production risk and shocks. The case of rice producers in Vietnam. J. Of Environ. Manag. 253, 109705. doi:10.1016/j.jenvman.2019.109705

Shafie, S. M. (2016). A review on paddy residue based power generation: energy, environment and economic perspective. Renew. Sustain. Energy Rev. 59, 1089–1100. doi:10.1016/j.rser.2016.01.038

Sharma, A., and Brar, A. S. (2022). Wheat drilling directly in combine harvested paddy fields: a comparative input-output energy analysis. J. Of Biosyst. Eng. 47 (3), 370–385. doi:10.1007/s42853-022-00152-y

Singh, P., Singh, G., and Sodhi, G. P. S. (2019). Energy auditing and optimization approach for improving energy efficiency of rice cultivation in south-western Punjab, India. Energy 174, 269–279. doi:10.1016/j.energy.2019.02.169

Soni, P., and Soe, M. N. (2016). Energy balance and energy economic analyses of rice production systems in Ayeyarwaddy region of Myanmar. Energy Effic. 9 (1), 223–237. doi:10.1007/s12053-015-9359-x

Soni, P., Taewichit, C., and Salokhe, V. M. (2013). Energy consumption and Co2 emissions in rainfed agricultural production systems of northeast Thailand. Agric. Syst. 116, 25–36. doi:10.1016/j.agsy.2012.12.006

Tran, D. H., Hoang, T. N., Tokida, T., Tirol-Padre, A., and Minamikawa, K. (2018). Impacts of alternate wetting and drying on greenhouse gas emission from paddy field in central Vietnam. Soil Sci. Plant Nutr. 64 (1), 14–22. doi:10.1080/00380768.2017.1409601

Truong, T. T. A., Fry, J., Van Hoang, P., and Ha, H. H. (2017). Comparative energy and economic analyses of conventional and system of rice intensification (SRI) methods of rice production in Thai Nguyen province, Vietnam. Paddy Water Environ. 15 (4), 931–941. doi:10.1007/s10333-017-0603-1

Wachid, A., and Mintono, M. (2017). Rice productivity variety Ir-64 using system of rice intensification (sri) method with several models (tegel and legowo). Nabatia 5 (2), 91–99. doi:10.21070/nabatia.v5i2.864

Wang, W., Lai, D. Y. F., Wang, C., Tong, C., and Zeng, C. (2016). Effects of inorganic amendments, rice cultivars and cultivation methods on greenhouse gas emissions and rice productivity in A subtropical paddy field. Ecol. Eng. 95, 770–778. doi:10.1016/j.ecoleng.2016.07.014

Yuan, S., and Peng, S. (2017). Input-output energy analysis of rice production in different crop management practices in central china. Energy 141, 1124–1132. doi:10.1016/j.energy.2017.10.007

Keywords: energy analysis, greenhouse gas emission effect, small scale, rice cultivation, input energy

Citation: Lutfi M, Astuti NP, Ahmad AM, Mustaniroh SA, Luqman A and Mindarti LI (2025) Energy and greenhouse effect emission analysis in small-scale rice cultivation: a case study in Tulungagung, Indonesia. Front. Energy Res. 13:1579617. doi: 10.3389/fenrg.2025.1579617

Received: 19 February 2025; Accepted: 28 July 2025;

Published: 29 August 2025.

Edited by:

A. S. M. Monjurul Hasan, University of Technology Sydney, AustraliaReviewed by:

Ali Fguiri, Gabes University, TunisiaSamira Alvandi, University of Technology Sydney, Australia

Copyright © 2025 Lutfi, Astuti, Ahmad, Mustaniroh, Luqman and Mindarti. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Musthofa Lutfi, bHV0ZmlAdWIuYWMuaWQ=

Musthofa Lutfi

Musthofa Lutfi Nining Pambudi Astuti1

Nining Pambudi Astuti1