- 1Rundian Energy Science and Technology Co., Ltd., Zhengzhou, China

- 2North China University of Water Resources and Electric Power, Zhengzhou, China

With the development of new energy and the proposal of the “double carbon” target, accelerating the flexibility transformation of coal-fired generating units and guiding coal-fired generating units to participate in deep peak shaving have become an effective means of absorbing new energy to ensure the stability of the grid. In this paper, the operation performance of a supercritical 630 MW coal-fired unit with 16.67%–100% rated load is obtained through experiments. The results show that: when the unit load is greater than 50% rated load, the economy is higher; when the unit load continues to decline from 50% rated load, the unit heat rate, absolute electrical efficiency, standard coal consumption and other economic indicators drop rapidly, and the operation economy becomes worse. When the load of the unit is reduced to 105 MW, which is 16.67% of the rated load, the absolute electrical efficiency is reduced to 38.54%, the heat of the unit is increased to 9,340 kJ/(kW·h), and the standard coal consumption of the power generation is increased to 359.25 g/(kW·h). The test results of the unit can provide a reference for the flexibility adjustment and operation optimization of the same type of units.

1 Introduction

In September 2020, China clearly proposed the goals of “carbon peak” by 2030 and “carbon neutral” by 2060. Developing green and renewable new energy such as wind power and solar power is an effective means to promote energy transformation (Wang Y. et al., 2021; Liu et al., 2023; Lei et al., 2024). With the increasing proportion of new energy, the randomness, intermittency and volatility of new energy will bring significant challenges to the reliability of power supply of power system (Ou et al., 2024). In 2022, the power generation of thermal power plants accounted for 66.5% in China, to absorb new energy, which requires thermal power plants need to further tap the peak shaving capacity, and give full play to the role of “ballast stone” (He et al., 2022; Tong et al., 2022; Yan et al., 2022). The National Development and Reform Commission of China and the National Energy Administration jointly issued the Notice on the Transformation and Upgrading of National Coal power Units, which puts forward the requirements of flexible transformation to meet the requirements of deep peak regulation, so as to absorb new energy on a larger scale, and the deep peak regulation of coal-fired power plants will become normal (Pan et al., 2022).

The conventional operating load of coal-fired units is 50%–100% of rated load, and the load is reduced to 30% or even lower when deep peak shaving (Gu et al., 2016; Hui et al., 2024). When coal-fired units operate at low load, their safety and economy are significantly reduced. Re-searchers have conducted a large number of studies on the performance of coal-fired units in deep peak shaving (Wang J. et al., 2021). Cong et al. studied the operation characteristics of the 660 MW ultra-supercritical secondary reheating unit at 100%, 75%, 50% and 30% rated load through experimental methods and found that the operation parameters were stable and the emission of flue gas pollutants reached the standard, but the economy was significantly reduced (Cong et al., 2021). Liu et al. showed that the load can be adjusted to 30% of rated load and operate stably without equipment modification through experimental re-search (Liu et al., 2019). Shi et al. conducted an experimental study on the performance of a 600 MW supercritical air-cooled coal-fired unit under different depth peak shaving load, and the results showed that when the load of the unit was reduced from 100% to 30% of the rated load, the heat of the unit increased by 15.33%, the coal consumption increased by 51.33 g/(kW·h), and the plant power rate also increased significantly (Shi et al., 2023). Zhao et al. studied the thermal economy of the unit when the load of the unit is reduced from 50% to 30%, and the results showed that the economy is better when the peak shaving depth is more than 40% of the load of the unit (Bin et al., 2022). Wang et al. conducted an experimental study on the main equipment characteristics and unit economy of 1050 MW ultra-supercritical unit in the process of peak shaving operation at 30% and 20% load depth. The results show that when the load of the unit is below 30%, the boiler efficiency, steam turbine efficiency, plant electricity rate, and heat and coal consumption of the unit show a significant downward trend with the increase of depth peak shaving amplitude (Wang et al., 2023).

The above research results show that the deep peak shaving in the literature can achieve the goal of 20% deep target. In order to help achieve the “double carbon” goal and further tap the potential of deep peak shaving, this paper takes the 630 MW super-critical unit of a power plant as an example. The thermal characteristics of the unit under the normal operation range of 100 %–50% rated load and the deep peak shaving operation conditions of 50%–17% rated load are studied, which provides a reference for the wide load flexibility adjustment of coal-fired units and the improvement of new energy consumption capacity.

2 The unit overview

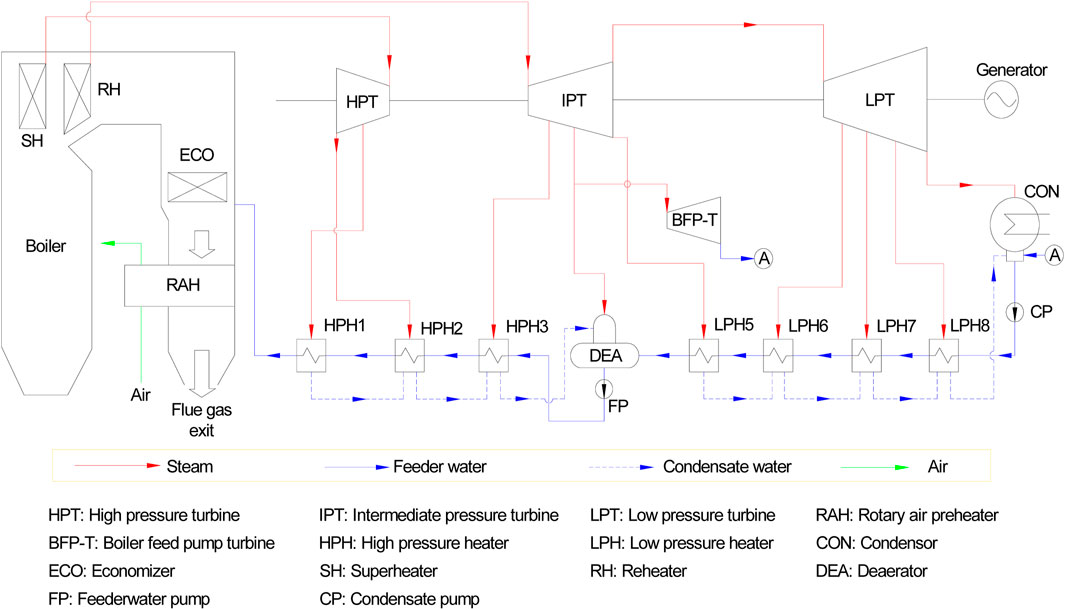

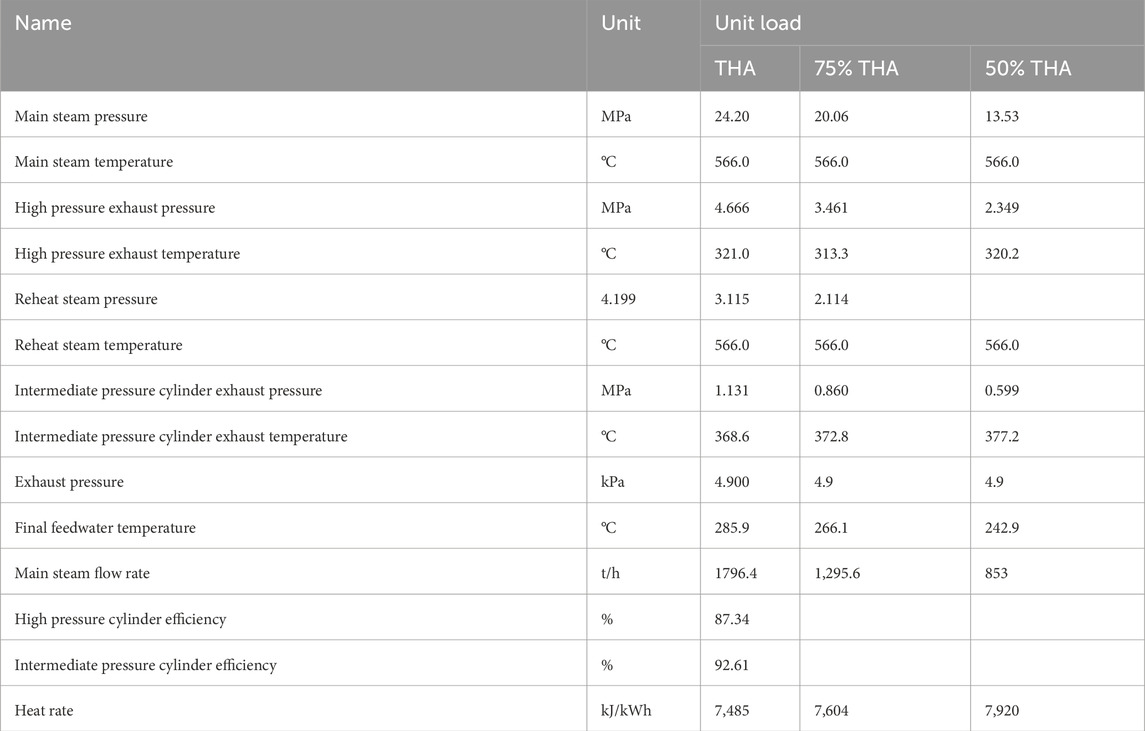

A 630 MW ultra-supercritical reheat coal-fired power plant in China is taken as the reference unit. The system diagram of the reference unit is shown in Figure 1. The boiler of the 630 MW unit adopts the supercritical transformer DC boiler with the model of HG-1970/25.4-PM18, the burner adopts the swirling pulverized coal burner with the front and back wall combustion mode, and the preparation system adopts the pulverized system of double inlet and double outlet steel ball mill. The steam turbine is a super-critical, single intermediate reheat, condensing steam turbine with model N630-24.2/566/566. The parameters under the different turbine heat acceptance (THA) condition of this stage group are shown in Table 1.

3 Wide load depth peak shaving test of the unit

In order to fully understand the performance of the 630 MW coal-fired unit, the wide load performance test of the unit was carried out, which included seven pure condensation conditions: 630 MW, 475 MW, 300 MW, 240 MW,180 MW,140 MW and 105 MW. During the test, we should maintain the coal quality stable and meet pollutant emission standards. The main and auxiliary equipment were put into operation normally, the low temperature economizer was put into operation, and the heater was withdrawn from operation. In order to ensure the safety of the unit, deep peak shaving is carried out, that is, when the unit load starts to decrease from 300 MW, the load drop rate should be strictly controlled, each load condition operated stably for at least 2 h, and relevant data are collected until the load condition reaches 105 MW finally. Analysis of the unit under different operation load of boiler and steam turbine thermal efficiency indicators to explore the sliding pressure operation way the impact on the economy. Boiler efficiency was calculated using the Performance Test Code (PTC) developed by the American Society of Mechanical Engineers (ASME): ASME PTC-4 2013 (ASME, 2013). Steam turbine efficiency was calculated using the ASME PTC-6 2004 (ASME, 2004).

According to the standards, the boiler efficiency calculation method is expressed as:

where ηb (%) expresses the boiler efficiency, Qloss (kJ/kg) denotes the energy losses in the daily operation of a coal-fired boiler. Qr (kJ/kg) represents the low calorific value of 1 kg coal. q2∼q6 (%) stand for the percentage corresponding to the heat loss of flue gas, unburnt carbon monoxide (CO), unburnt carbon, boiler surface and sensible heat loss from hot cinder respectively.

Turbine cylinders efficiency calculation method is expressed as:

where ηi (%) expresses the turbine cylinders (HPT, IPT, LPT) efficiency, h0 (kJ/kg) represents the enthalpy at the entrance state, h1 (kJ/kg) represents the enthalpy at the exit state for the actual process, h′1 (kJ/kg) represents the enthalpy at the exit state for the isentropic process.

Heat rate value calculation method is expressed as:

where HR (kJ/kg) stands for the power output, Pe (MW) stands for the power output; Wms (t/h), Wsh (t/h), Whr (t/h), Wrh (t/h) stand for the mass flow of main steam, superheated spray water, reheated steam, reheat spray water; hms (kJ/kg), hfw (kJ/kg)), hhr (kJ/kg), hcr (kJ/kg), hsh (kJ/kg), hrh (kJ/kg) stand for the enthalpy of main steam, feed water, reheated steam, main steam, superheated spray water, reheated steam, reheat spray water, superheated spray water, reheat spray water.

Absolute electrical efficiency ηel (%) is calculated by:

Power consumption rate ηau (%) is calculated by:

where Pau (MW) stands for the auxiliary power consumption.

Standard coal consumption for power generation

where

Power supply standard coal consumption

4 The experimental results and analysis

4.1 The change of boiler efficiency

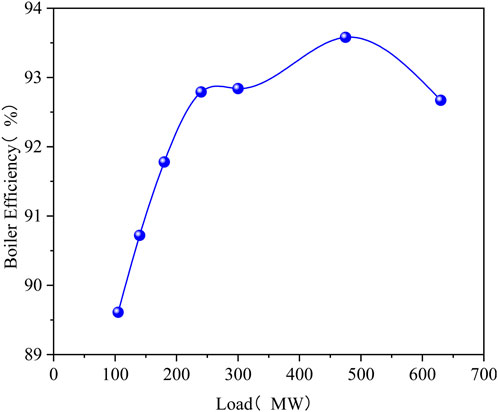

With the reduction of unit load, the loss and thermal efficiency of coal-fired boilers also decrease (Yue et al., 2023). When the unit is in the range of 630 MW–105 MW with wide load peak shaving, the variation of boiler thermal efficiency with unit load is shown in Figure 2.

As can be seen from Figure 2, with the unit load decreasing from 630 MW to 105 MW, the boiler efficiency increases first and then decreases. When the unit load is 475 MW rated load, the boiler efficiency reaches the highest. When the boiler efficiency de-creases from 475 MW to 105 MW, the boiler efficiency decreases obviously. When the unit load decreases from 475 MW to 240 MW, the boiler efficiency decreases from 93.58% to 92.79%, which decreased by 0.79%. When the unit load decreases from 240 MW to 105 MW, the boiler efficiency decreases to 89.61%, and the boiler decreases significantly by 3.18%. The boiler efficiency at 105 MW decreases by 3.97% compared with that at 475 MW.

4.2 Analysis of turbine performance

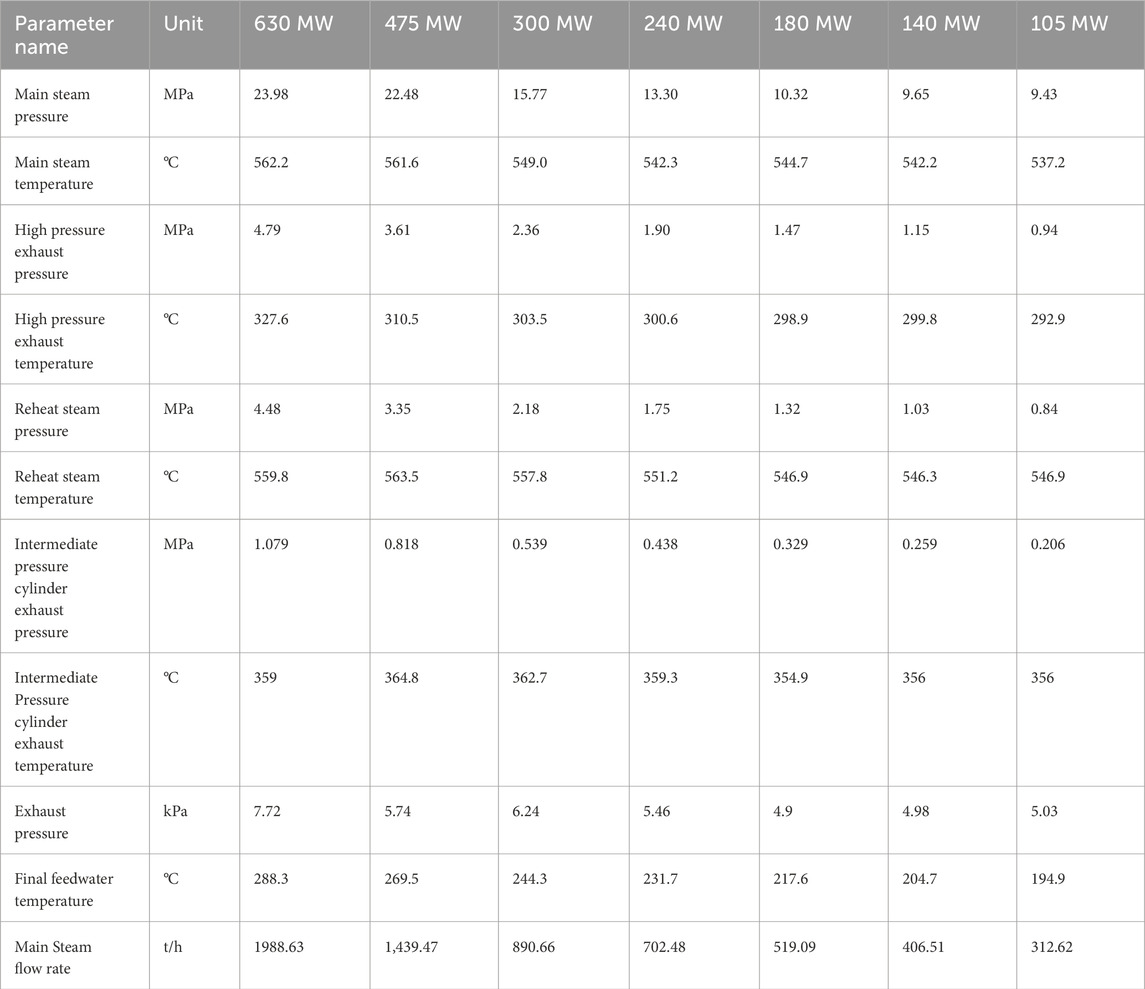

The level of unit load has a great influence on the heat rate of steam turbine (Huang et al., 2022). When operating at rated load, three high pressure regulating valves are fully open and one regulating valve is closed. When the load of the unit gradually decreases from the rated load, one regulating valve of the turbine is closed, and the opening degree of three regulating valves is gradually reduced. When the load of the unit is reduced to 180 MW, the two high-pressure regulating valves of the steam turbine are closed, and the opening of the two inlet regulating valves is small. As the load of the unit continues to decrease, the two high-pressure regulating valves of the steam turbine are closed, and the opening degree of the two inlet regulating valves continues to decrease. As the unit operation mode has a great impact on the economy, in this performance experiment, the unit load adjustment adopts the sliding pressure operation mode, and the operation parameters of the steam turbine under different loads are shown in Table 2.

It can be seen from the test results in Table 2 that the main steam pressure, the pressure of reheated steam and the temperature of reheated steam gradually decrease with the gradual reduction of the load of the unit in the process of wide load peak shaving. When the load of the unit is lower than 50% of the rated load, the main steam temperature of the unit is controlled in the range of 537 °C–549 °C, which is 20 °C–30 °C lower than the design value, and the decrease is more. When the load of the unit is less than 300 MW, the temperature of the reheated steam is controlled in the range of 546 °C–557 °C, about 10 °C–20 °C lower than the design value, and the feed water temperature decreases with the reduction of the load of the unit.

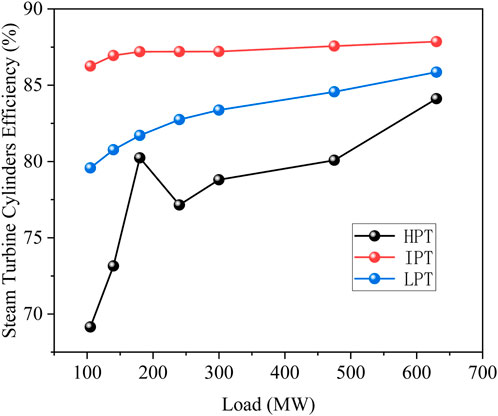

The change of steam turbine operating parameters has a certain degree of influence on the economic performance of steam turbine, which is mainly reflected in the change of cycle thermal efficiency and relative internal efficiency (Wang and Gu, 2023). According to the actual operating parameters of the unit under different working conditions, the efficiency of the turbine high, intermediate and low-pressure cylinders is calculated, and the results are shown in Figure 3.

The efficiency of the high-pressure cylinder is 84.12% under the 630 MW working condition and 87.34% under the designed working condition, which is 3.22% lower than the designed value. When the load of the unit is in the range of 630 MW–240 MW, the efficiency of the intermediate pressure cylinder is 5%–6.5% higher than that of the high-pressure cylinder, the efficiency of the intermediate pressure cylinder decreases from 87.86% to 87.20%, and the efficiency of the high-pressure cylinder decreases from 84.12% to 77.15%. When the unit load is in the range of 240 MW–105 MW, the efficiency of the intermediate pressure cylinder decreases from 87.20% to 86.25%, a de-crease of 0.95%. Due to the sliding pressure operation, when the load of the unit de-creases from 240 MW to 180 MW, the efficiency of the high-pressure cylinder increases from 77.15% to 80.24%. This is because that the complete closure of the 3# regulating valve reduces the intake throttle loss. As the load of the unit continues to decrease, the efficiency of the high-pressure cylinder decreases from 80.24% to 69.15%. It can be seen that when the load of the unit is less than 50%, the operation economy decreases more, especially when the load is less than 30% of the rated load. Therefore, the operation mode of deep peak shaving should be further studied to improve the economy of the unit.

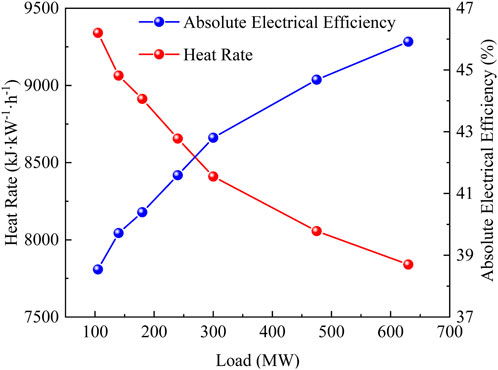

The steam turbine heat rate and absolute electrical efficiency of the unit are calculated according to the operating parameters, and the results are shown in Figure 4. The heat of the unit gradually increases with the decrease of the load. When the load of the unit is 630 MW, the heat rate is 7,840.32 kJ/(kW·h), and the absolute electrical efficiency is 45.92%. When the unit load is 300MW, the heat rate of the unit is 8,409.82 kJ/(kW·h), which is 569.5 kJ/(kW·h) higher than that of 630 MW and the absolute electrical efficiency is 42.81%, which is 3.11% lower than the 630 MW operating condition. When the load of the unit drops below 300 MW, the heat rate of the unit operation increases significantly, and the absolute electrical efficiency decreases greatly. When deep peak shaving is car-ried out, the heat rate and absolute electrical efficiency of the unit decrease significantly. When the load is reduced to 105 MW, the heat rate increases to 9,340 kJ/(kW·h), which is 1,499.9 kJ/(kW·h) higher than the rated working condition of 630 MW. The absolute electrical efficiency is reduced to 38.5%, which is 7.4% lower than the rated condition of 630 MW.

4.3 Analysis of power consumption and standard coal consumption of unit plant

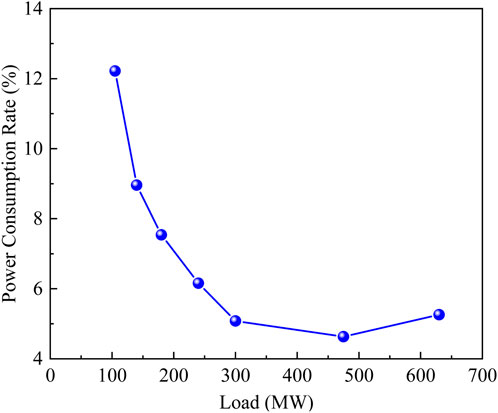

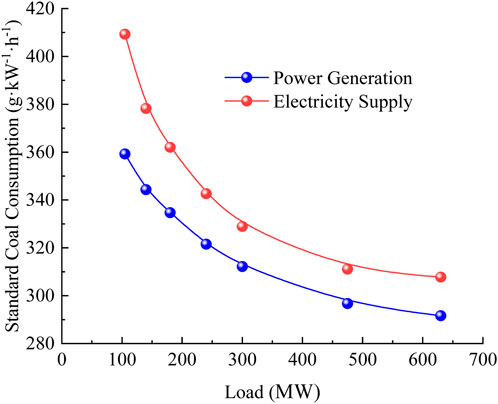

In the case of deep peak shaving of the unit, the deviation of the main engine and auxiliary machine from the designed operating condition leads to the decrease of efficiency, resulting in the increase of the power consumption rate of the unit (Wang et al., 2024). According to the measured data during the test, the power consumption of the plant, the standard coal consumption of power generation and the standard coal consumption of power supply are calculated. The variation curve of plant power consumption rate with unit load is shown in Figure 5, and the variation curve of standard coal consumption for power generation and standard coal consumption for power supply with unit load is shown in Figure 6.

Figure 5 shows that with the decrease of unit load, the plant electricity consumption rate gradually increases. When the unit load decreases from 630 MW to 475 MW, the plant electricity rate decreases from 5.26% to 4.63%, the main reason is the improvement of boiler efficiency. When the unit load continues to decrease from 475 MW and the unit adopts sliding pressure operation, the boiler load decreases and the plant electricity consumption rate gradually increases. When the unit load is reduced to 300 MW, the plant electricity consumption rate increases to 5.08%. When the unit load is reduced to less than 300 MW, the power consumption rate of the plant increases significantly. When the unit load is reduced to 105 MW, the plant electricity rate rises to 12.22%, increasing by 7.14%. This is because when the load of the unit is low, the proportion of power consumption of the main auxiliary machinery increases significantly, resulting in a gradual increase in the power consumption rate of the unit plant.

Figure 6 shows that the standard coal consumption for power supply and power generation can be divided into two stages: the 630 MW–300 MW stage and the less than 300 MW stage. When the unit load is 630 MW rated load, the standard coal consumption for power generation and power supply are 291.59 g/(kW·h) and 307.78 g/(kW·h) respectively. When the unit load decreased from 630 MW to 300 MW, the standard coal consumption for power generation and power supply increased to 312.21 g/(kW·h) and 328.92 g/(kW·h), increasing by 20.62 g/(kW·h) and 21.14 g/(kW·h) respectively, and the increase of coal consumption is relatively gentle in this stage. When the unit is deeply peak-shaving and the load is reduced to 105 MW, the standard coal consumption for power generation and power supply increases to 359.25 g/(kW·h) and 409.26 g/(kW·h) respectively. Compared with the rated working condition of 600MW, the standard coal consumption for power generation and power supply increased by 47.04 g/(kW·h) and 80.34 g/(kW·h), respectively, and the coal consumption increased sharply at this depth peak shaving stage. In conclusion, when the unit load is lower than 300 MW, the economy of unit operation decreases significantly.

5 Benefit analysis of depth peak regulation

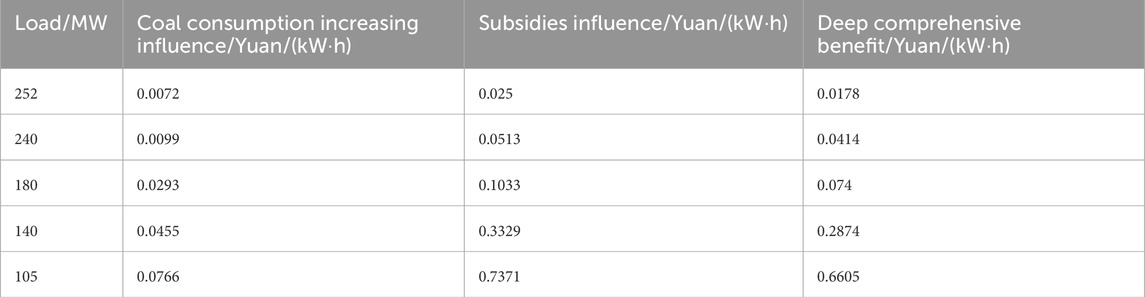

According to the Henan Provincial Energy Regulatory Office’s 2019″Henan Power Peak Balancing Auxiliary Service Trading Rules (Trial)” and the “Notice on Revising and Improving some provisions of the Provincial Power Peak Balancing Auxiliary Service Rules” issued in 2024: In the principle of deep peak load compensation in Henan Province, when the unit load rate is 40 %–45% (excluding 45%), the upper limit of the quotation is 0.2 yuan/(kW·h); When the unit load rate is 30%–40%, the upper limit of the quotation is 0.5 yuan/(kW·h); When the unit load rate is less than 30%, the quotation limit is 0.7 yuan/(kW·h). The benchmark on-grid electricity price in Henan province is 0.3779 yuan/(kW·h), and the depth peak charging period is 15 min. According to the above criteria, the peak-regulating benefits of the unit in different peak-regulating intervals for 1 h were analysed.

Figure 6 Test results show that as the load decreases, the coal consumption for power generation and power supply of the unit increases significantly. Therefore, when analysing the benefit of deep peak regulation, besides calculating the deep regulation service fee, the influence of coal consumption cost should also be calculated, and the unit price of standard coal is calculated at 1,000 yuan/ton. Deep adjustment income (yuan/h) is calculated based on the decrease of power supply cost caused by service fee subsidy minus the increase of power supply cost caused by the increase of coal consumption in deep adjustment. Since there is no subsidy when the load is 45%, the calculation is based on 45%. The increase of coal consumption under deep adjustment load affects the in-crease of power supply cost according to the following formula:

Where, S is the effect of increasing coal consumption, yuan/(kW·h); Bst is the coal consumption of deep adjustment load, g/(kW·h); B45 is the coal consumption of 45% load, g/(kW·h); Sc is the unit price of standard coal, yuan/t.

According to the test results in Figure 5, the coal consumption change of power supply in different intervals is analyzed according to the linear change. When the unit load is in the range of 240 MW–300 MW, the coal consumption increases by 1.44 g/(kW·h) when the load is reduced by 1%. When the load of the unit is in the range of 180 MW–240 MW, the coal consumption increases by 2.03 g/(kW·h) for each 1% reduction in load, and the corresponding cost is 0.0343 yuan/(kW·h). When the unit load is in the range of 140 MW–180 MW, the coal consumption increases by 2.56 g/(kW·h) for each 1% reduction in load. When the load of the unit is in the range of 105 MW–140 MW, the coal consumption increases by 5.58 g/(kW·h) for every 1% reduction in load. The comprehensive benefit of deep peak regulation is calculated, and the results are shown in Table 3. It can be seen from the table that when the coal price is 1,000 yuan/ton and the peak regulation service fee is subsidized according to the upper limit, the greater the depth of peak regulation, the greater the benefit.

6 Conclusion

For supercritical 630 MW coal-fired unit at 16.67%–100% rated load wide load tests are carried out to explore the thermal efficiency under different operating conditions, the main conclusions are as follows:

1. When the unit load is greater than 40%, the boiler efficiency changes little, and achieves 93.58% of the maximum boiler efficiency when the load is 475 MW. When the unit load is less than 40% for depth peak shaving, the thermal efficiency of the boiler decreases continuously. When the unit load is 105 MW, the boiler efficiency is only 89.61%.

2. During the sliding pressure operation of the unit, when the load decreased from 630 MW to 105 MW, the efficiency of the turbine cylinders changed as follows: the intermediate-pressure cylinder efficiency decreased slightly from 87.86% to 86.25%; the low pressure cylinder efficiency dropped more significantly from 85.86% to 79.58%; due to the influence of the opening and closing of the control valves, the high pressure cylinder efficiency fluctuated considerably, showing a trend of 84.12% → 77.15% → 80.24% → 69.19%.

3. By comparing the performance indexes of the unit load at 100%–50% rated load and less than 40% rated load deep adjustable peak shaving, the various economic indexes of the unit do not change much, when operating within 630 MW–300 MW load. When the unit is in depth peak-shaving, the performance indicators gradually become worse, the heat rate of the unit increases significantly, the standard coal consumption of power generation and power supply increases obviously, and the operation economy of the unit decreases significantly.

4. The impact of deep peak shaving on the revenue of power plants is analyzed from three aspects: unit heat consumption, standard coal consumption for power generation and power supply, and deep peak shaving subsidies. The greater the depth of peak shaving, the greater the revenue, which conforms to the requirements of market rules. However, from the perspective of safety, the greater the depth of peak shaving of the unit, the worse the stability and the greater the operational risk. Therefore, the extent to which the unit participates in deep peak shaving should be comprehensively determined based on safety and economy.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

HZ: Conceptualization, Formal Analysis, Investigation, Methodology, Project administration, Visualization, Writing – original draft, Writing – review and editing. YP: Conceptualization, Investigation, Methodology, Writing – original draft. HC: Formal Analysis, Writing – review and editing. JL: Formal Analysis, Writing – review and editing. WW: Investigation, Writing – review and editing. ZZ: Resources, Supervision, Writing – review and editing, Writing – original draft. ZT: Data curation, Writing – original draft. LH: Formal Analysis, Investigation, Writing – original draft.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. The present study is supported by Rundian Energy Science and Technology Corporation Limited (20230320).

Acknowledgments

The authors thank the editors and reviewers for their comments on this paper.

Conflict of interest

Authors HZ, YP, HC, and JL were employed by Rundian Energy Science and Technology Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bin, Z., Zhe, W., and Chenshuai, Y. (2022). Thermal economy analysis on deep peak regulation operation of supercritical 600MW coal-fired unit. Therm. Power Gener. 51, 109–114. doi:10.19666/j.rlfd.202110197

Cong, X., Xie, H., Su, Y., Zhang, J., and Cheng, Y. (2021). Experimental study on deep peak-load shaving of a 660 MW ultra-supercriticalsecondary reheating unit. Integr. Intell. Energy 43, 64–69. doi:10.3969/j.issn.1674-1951.2021.05.010

Gu, Y., Xu, J., Chen, D., Wang, Z., and Li, Q. (2016). Overall review of peak shaving for coal-fired power units in China. Renew. Sustain. Energy Rev. 54, 723–731. doi:10.1016/j.rser.2015.10.052

He, C., Shan, M., Li, X., Zhang, H., and Yang, Y. (2022). “Exploration and research on the development path of the power capacity market,” in 2022 5th international conference on energy, electrical and power engineering CEEPE, 989–993.

Huang, Q., Yan, W., Yang, H., and Peng, Z. (2022). Key technology for reducing heat rate of large capacity coal-fired power generation steam turbines in peak-shaving operation under. J. Of Chin. Soc. Of Power Eng. 42, 1161–1166. doi:10.19805/j.cnki.jcspe.2022.11.020

Hui, J., Zhu, S., Li, Z., Lin, J., Cao, X., and Lyu, Q. (2024). Experimental study on peak shaving during preheating combustion for different coal ranks: thermal modification and variable load operation. Fuel 373, 132324. doi:10.1016/j.fuel.2024.132324

Lei, Y., Yin, Z., Lu, X., Zhang, Q., Gong, J., Cai, B., et al. (2024). The 2022 report of synergetic roadmap on carbon neutrality and clean air for China: accelerating transition in key sectors. Environ. Sci. Ecotechnology 19, 100335. doi:10.1016/j.ese.2023.100335

Liu, W., Lv, H., Cai, J., and Wang, M. (2019). Experimental Study on 30% rated depth Peak-load for a 600 MW Sub-critical Boiler. Boil. Technol. 50, 59–65. doi:10.3969/j.issn.1672-4763.2019.04.012

Liu, L., Wang, X., and Wang, Z. (2023). Recent progress and emerging strategies for carbon peak and carbon neutrality in China. Greenh. Gases Sci. Technol. 13, 732–759. doi:10.1002/ghg.2235

Ou, K., Gao, S., Wang, Y., Zhai, B., and Zhang, W. (2024). Assessment of the renewable energy consumption capacity of power systems considering the uncertainty of renewables and symmetry of active power. Symmetry 16, 1184. doi:10.3390/sym16091184

Pan, J., Chen, X., Luo, X., Zeng, X., Liu, Z., Lai, W., et al. (2022). Analysis of the impact of China’s energy industry on social development from the perspective of low-carbon policy. Energy Rep. 8, 14–27. doi:10.1016/j.egyr.2022.05.052

Shi, P., Kang, C., Wang, S., Zhang, Z., Zhang, W., and Liu, Z. (2023). Study on thermal economy of a 600 MW supercritical air-cooled coal-fired unit for deep peak regulating operation. Electr. Power Technol. Environ. Prot. 39, 147–156. doi:10.19944/j.eptep.1674-8069.2023.02.007

Tong, J., Liu, W., Mao, J., and Ying, M. (2022). Role and development of thermal power units in new power systems. IEEE J. Radio Freq. Identif. 6, 837–841. doi:10.1109/jrfid.2022.3205465

Wang, S., and Gu, X. (2023). Discussion and research on the boiler design of the deep peak regulation for coal-fired power units. Boil. Technol. 54, 13–17.

Wang, J., Huo, J., Zhang, S., Teng, Y., Li, L., and Han, T. (2021a). Flexibility transformation decision-making evaluation of coal-fired thermal power units deep peak shaving in China. Sustainability 13, 1882. doi:10.3390/su13041882

Wang, Y., Guo, C.-H., Chen, X.-J., Jia, L.-Q., Guo, X.-N., Chen, R.-S., et al. (2021b). Carbon peak and carbon neutrality in China: goals, implementation path and prospects. China Geol. 4, 720–746. doi:10.31035/cg2021083

Wang, X., Shi, P., Lin, B., Feng, Y., and Yao, L. (2023). Study on operating economy and Safety of the final stage blade of a 1 050 MW ultra-supercritical coal-fired unit with deep peaking. Electr. Power Environ. Prot. 39, 429–435.

Wang, Q., Liu, J., Fan, H., Qin, T., Huang, Y., Wang, Y., et al. (2024). Novel technologies of flexible coal-fired power generation to support China energy transition: Boiler system and turbine generator system. Zhongguo Dianji Gongcheng Xuebao 44, 7136–7166. doi:10.13334/j.0258-8013.pcsee.240234

Yan, J., Yang, W., Min, Z., and Yang, M. (2022). Innovation strategy for green development and carbon neutralization in guizhou—an overview. Sustainability 14, 14377. doi:10.3390/su142114377

Keywords: deep peak shaving, supercritical unit, heat rate, power generation coal consumption, thermal economy analysis

Citation: Zhang H, Pang Y, Cui H, Li J, Wang W, Zhang Z, Tang Z and Hao L (2025) Thermal economy analysis on deep peak regulation operation of supercritical 630 MW coal-fired unit. Front. Energy Res. 13:1611001. doi: 10.3389/fenrg.2025.1611001

Received: 16 April 2025; Accepted: 07 October 2025;

Published: 16 October 2025.

Edited by:

Xianbo Wang, Hainan Institute, Zhejiang University, ChinaReviewed by:

Artur Wojciech Rusowicz, Warsaw University of Technology, PolandHaijiao Wei, China North Vehicle Research Institute Department of Propulsion Systems Technology, China

Copyright © 2025 Zhang, Pang, Cui, Li, Wang, Zhang, Tang and Hao. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Zhen Zhang, emhhbmd6aGVuQG5jd3UuZWR1LmNu

Hongquan Zhang1

Hongquan Zhang1 Zhen Zhang

Zhen Zhang