- 1Electric Power Research Institute of Guangxi Power Grid Co., Ltd., Nanning, China

- 2Guangxi Key Laboratory of Intelligent Control and Maintenance of Power Equipment, Nanning, China

Introduction: The rapid expansion of wind and photovoltaic power has intensified the demand for deep peak shaving in coal-fired power units. Conventional extraction steam heating units are constrained by thermal–electric coupling, limiting their ability to operate flexibly at low loads. To support low-carbon energy transformation, there is a pressing need to develop optimization methods that enhance both flexibility and economic efficiency of combined heat and power operations.

Methods: This study focuses on 300 MW and 600 MW extraction steam heating units. A thermodynamic simulation platform was established in EBSILON to evaluate multiple steam extraction schemes. A dual-objective optimization framework was developed, aiming to minimize power generation and coal consumption rates under peak shaving conditions. The framework integrates thermoelectric decoupling technologies, including thermal storage tanks, molten salt storage, and electric boilers, and applies a genetic algorithm to solve multi-scenario optimization problems in single- and dual-unit coordinated operations.

Results: Simulation results demonstrate that thermal storage tanks and molten salt storage improve system economy at shallow peak shaving depths, while electric boilers provide superior flexibility for deeper peak shaving despite higher costs. In dual-unit operation, designating the smaller 300 MW unit as the base-load unit and the larger 600 MW unit as the peak-shaving unit significantly enhances system performance. Under this configuration, net revenue increased by 67.3% compared with the reverse arrangement. Furthermore, equipping the peak-shaving unit with an electric boiler achieved deeper peak shaving without compromising heating demand, though excessive deployment of electric boilers reduced overall thermal economy.

Discussion: The proposed comprehensive optimization method enables practical balancing of technical feasibility and economic returns in combined heat and power systems. By coupling thermodynamic modeling with genetic algorithm-based optimization, the study provides quantitative evidence for selecting suitable unit configurations and decoupling technologies. These findings offer guidance for improving coal consumption efficiency, expanding renewable energy accommodation, and advancing the low-carbon transition of thermal power plants under high renewable penetration scenarios.

1 Introduction

With the rapid growth of installed capacity for renewable energy sources such as wind power and photovoltaic power, the peak-to-valley load difference in the power grid has significantly increased (Lin et al., 2022), leading to a growing demand for the power grid’s ability to perform deep peak shaving with thermal power units (Wang J. et al., 2021). Renewable energy sources represented by wind power and photovoltaic power exhibit volatility and intermittency, resulting in frequent imbalances between supply and demand in the power grid and causing prominent issues of “curtailment of wind and solar power” (Haijiao et al., 2023). Coal-fired power plants must frequently participate in deep peak shaving to balance the intermittency and volatility of renewable energy generation (Zhang et al., 2022). In this context, Coal-fired power plants need to undergo flexibility upgrades to enable operation at lower loads (e.g., 30%–40% of rated load), thereby creating space for renewable energy grid integration (Zhiqiang et al., 2020).

Coal-fired power plants face two major issues during low-load operation: first (Haijiao et al., 2021), heating demand requires the unit to maintain a certain steam extraction volume, while deep peak shaving necessitates reducing power generation, leading to difficulties in thermal-electric decoupling for heating units. (Hou et al., 2024). Their peak shaving capacity is severely constrained by heating demand, resulting in limited load adjustment ranges under conventional steam extraction modes (Chen et al., 2020); second, under low-load conditions, unreasonable extraction pressure settings can reduce the unit’s thermal efficiency and economic performance (Gao et al., 2020). Steam extraction heating units urgently need to overcome this bottleneck through thermal-electric decoupling technology (Zheng et al., 2021; Song et al., 2021a).

Existing research indicates that technologies such as electric boilers (Wenping et al., 2018), thermal storage tanks (Sun, 2024), and molten salt thermal storage (Yang et al., 2024) can partially alleviate the thermal-electric decoupling contradiction,but their applicability to extraction heating units varies significantly: Electric boilers have fast response but high energy consumption; thermal storage tanks are suitable for short-term peak shaving with low initial investment; molten salt storage has large capacity but high operational costs (Wang C. et al., 2021). Additionally, the economic efficiency of steam extraction heating is influenced by main steam parameters, cylinder efficiency, and heat load distribution schemes (Elwardany, 2024), and when multiple units operate in coordination, mode combinations must be optimized to balance peak-shaving capacity and economic benefits (Song et al., 2021b).

In summary, under the requirements of low-carbon and flexibility (Jianglong et al., 2022), studying the regulation capacity, energy consumption characteristics, load distribution, and thermal economy of renovated heating units is of great significance (Weinberger et al., 2021; Zhang et al., 2024). So the objective of this study is to enhance the deep peak shaving performance and economic efficiency of thermal power heating units by developing an optimization model integrating decoupling technologies. The novelty lies in the construction of a dual-objective optimization framework, the integration of multiple thermal-electric decoupling schemes, and detailed scenario-based evaluation of dual-unit coordination strategies under different load conditions. This provides reference for the operation and profitability of Coal-fired power plants, promotes the consumption of new energy, reduces carbon emissions, and contributes to the realization of green and low-carbon energy development.

2 Single reheat steam turbine and speed control system model

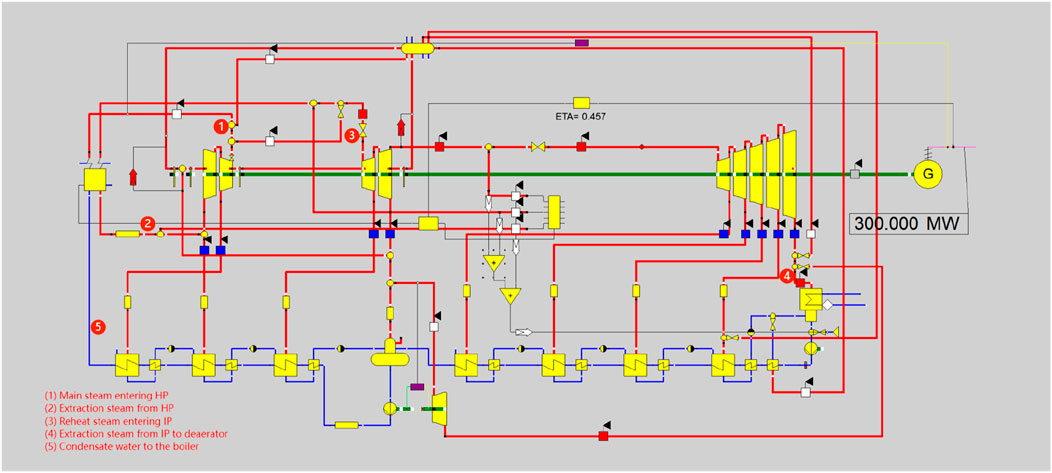

When performing thermodynamic modeling, the design operating conditions of the unit are typically used as the rated operating conditions (Huang et al., 2025). Under these conditions, various thermodynamic parameters—including main steam and reheat steam parameters, turbine extraction port parameters, condenser parameters, deaerator parameters, shaft seal parameters, and others—as well as data such as turbine pressure loss, heater parameters, and drain end difference, are all determined through the thermodynamic system’s heat balance diagram (Xilin et al., 2024). Based on the thermal balance diagram, a complete thermal power plant simulation model can be constructed in the EBSILON software. The simulation model of a 300 MW heating unit is shown in Figure 1. The 300 MW heating unit simulation model (Figure 1) includes core components: high-pressure cylinder (HP), intermediate-pressure cylinder (IP), low-pressure cylinder (LP), deaerator, heaters, and condenser. Key streams in Figure 1 are labeled as follows: (1) Main steam entering HP; (2) Extraction steam from HP; (3) Reheat steam entering IP; (4) Extraction steam from IP to deaerator; (5) Condensate water to the boiler, which together form the closed thermodynamic cycle of the unit.

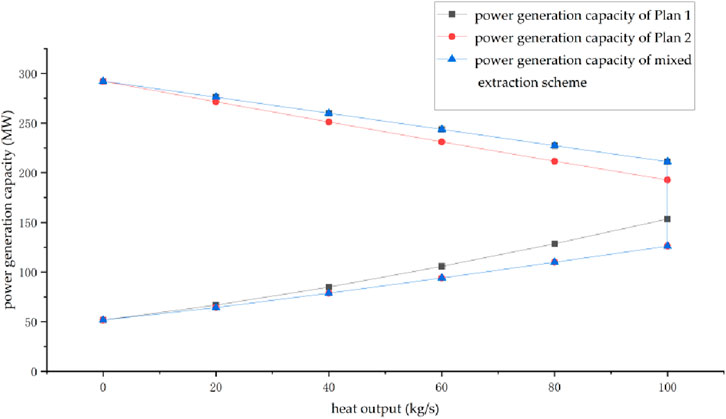

The feasible range for mixed extraction heating of a 300 MW unit is shown in Figure 2.

As can be seen from the heating feasibility domain, by complementing Scheme 1 with Scheme 3, Scheme 1 is prioritized under THA conditions to ensure power generation efficiency. When pressure is insufficient, the system switches to Scheme 3, leveraging its lower power threshold to enhance peak-shaving flexibility, thereby balancing heating demand with the power generation adjustment range. This demonstrates that the coordinated operation of multiple schemes is an effective approach to achieving a flexible balance between heating and power generation.

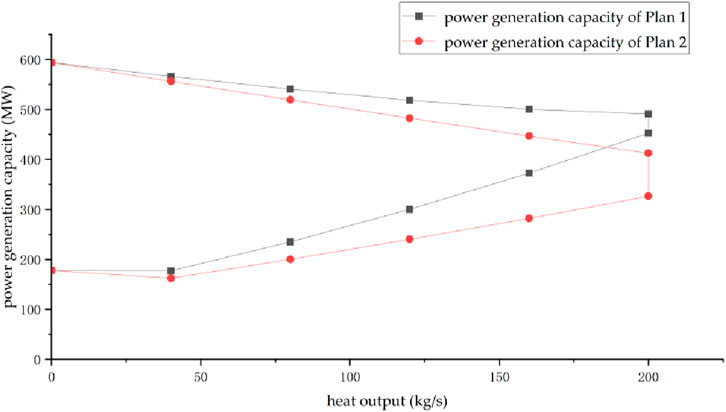

The heating feasibility domain for the 600 MW unit is shown in Figure 3.

When using mixed steam extraction for heating, the feasible heating range cannot necessarily be determined by the maximum power generation range, and some operating conditions may not be achievable.

3 Comprehensive analysis of the deep peak shaving performance of heating units with thermoelectric coupling

To analyze the economic efficiency of heating units, it is first necessary to construct an economic evaluation model that takes into account factors such as electricity sales revenue, heat sales revenue, peak load compensation, fuel costs, and investment costs for heat-electricity decoupling equipment. The economic evaluation model is shown in Equation 1.

In the formula, E represents the net revenue of the thermal power plant, in yuan; Ce represents the revenue from electricity sales, in yuan/kWh; Pe represents the electricity generation of the thermal power plant, in MWh; Ch represents the revenue from heat sales, in yuan/t; Qh represents the heat supply of the thermal power plant, in t; Cp represents the peak shaving compensation, in yuan/kWh; ∆Ppeak is the deep peak shaving power generation capacity, measured in MWh; Ccoal is the standard coal price, measured in yuan/t; Bcoal is the coal consumption, measured in t; COM is the investment cost of the thermal-electric decoupling equipment, measured in yuan/kWh; VOM is the capacity of the thermal-electric decoupling equipment, measured in MWh.

The low point of the case study unit’s electrical load occurs during the 8-h period from 23:00 to 7:00 at night, while the daytime peak load lasts for 16 h. During calculations, the electricity sales revenue is set at 0.36 yuan/kWh, the heat sales revenue at 200 yuan/ton, the peak shaving compensation at 0.396 yuan/kWh, and the standard coal price at 900 yuan/ton of standard coal.

When using a thermal storage system for thermal-electric decoupling, this scheme considers the daytime 16 h as the thermal storage system’s charging time and the nighttime 8 h as the thermal storage system’s discharging time, fully utilizing the thermal storage system’s peak-shaving and valley-filling regulatory role in the heating process.

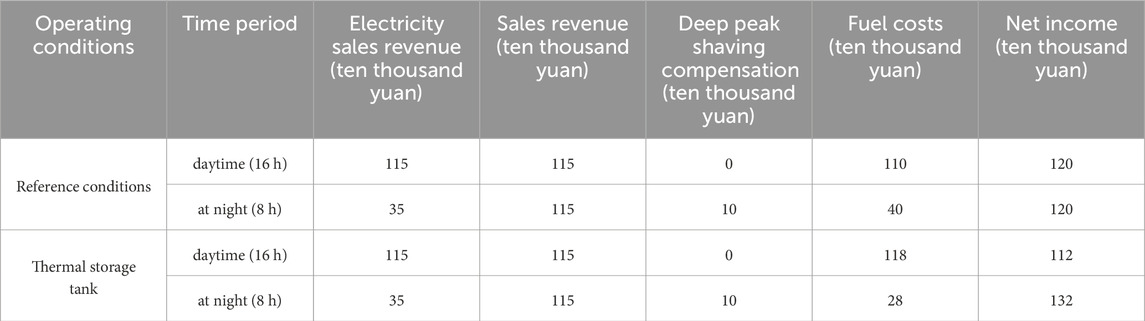

Based on the unit’s operational conditions, it is assumed that the average power generation capacity of the unit is 200 MW, and the average heating capacity is 100 kg/s. The thermal storage tank has a capacity of 1,000 MWh. During the daytime 16 h, in addition to supplying 100 kg/s of heating steam externally, the unit provides 25 kg/s of heating steam to the thermal storage tank. During the night, the unit supplies 50 kg/s of heat externally for 8 h, with the remaining 50 kg/s supplemented by the thermal storage tank (Zhou et al., 2025). The specific calculation results for the unit’s performance indicators before and after the thermal storage tank are shown in Table 1.

Table 1. Specific calculation results for various indicators of the unit before and after adding the thermal storage tank.

After installing a thermal storage tank, compared to a conventional heating scheme: during the day, an additional 90 tons of standard coal will be consumed over 16 h, but at night, 126 tons of standard coal will be saved, resulting in a total reduction of 36 tons in coal consumption; fuel costs will decrease by 40,000 yuan, with significant savings at night, and net profits will increase by 40,000 yuan. However, considering the initial investment cost of the thermal storage tank is 500,000 yuan, plus subsequent operational and maintenance costs, the thermal storage tank must be used long-term for peak shaving to achieve benefits.

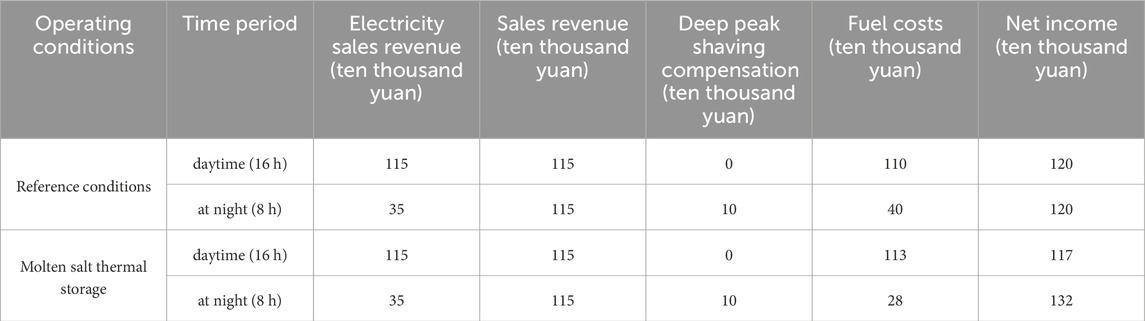

The molten salt thermal storage system has a capacity of 1,000 MWh. During the daytime 16 h, the unit supplies 100 kg/s of heating steam externally and provides 25 kg/s of heating steam to the molten salt thermal storage system. During the nighttime 8 h, the unit supplies 50 kg/s of heating steam externally, with the remaining 50 kg/s supplemented by the molten salt thermal storage system. The specific calculation results of the unit’s various indicators before and after the addition of the molten salt thermal storage system are shown in Table 2.

Table 2. Specific calculation results for various indicators of the unit before and after adding molten salt thermal storage.

After adding molten salt thermal storage, compared to the conventional heating scheme: during the day, an additional 28 tons of standard coal will be consumed over 16 h, but at night, 126 tons of standard coal will be saved, resulting in a total reduction of 98 tons of coal consumption; fuel costs will decrease by 90,000 yuan, with significant savings at night, and net profits will increase by 90,000 yuan. However, considering the initial investment cost of 1.5 million yuan and the relatively high subsequent operational and maintenance costs, long-term use of auxiliary peak shaving is required to achieve benefits.

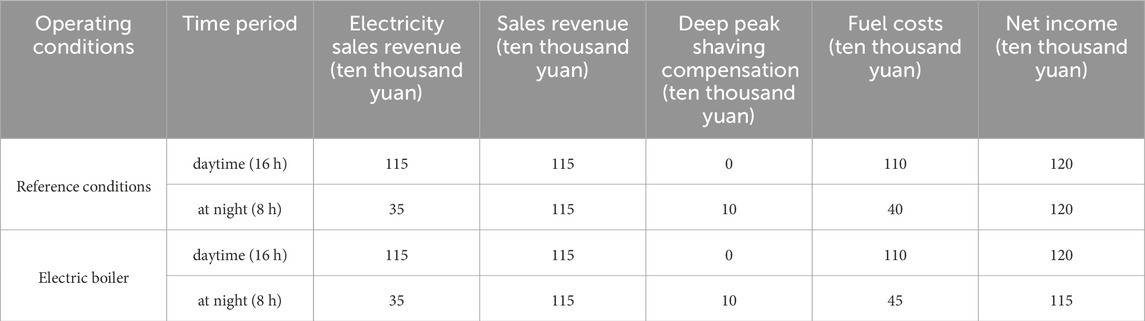

The electric boiler has a capacity of 1,000 MWh. During the daytime 16 h, the unit supplies heat at a rate of 100 kg/s, with the electric boiler remaining idle. During the nighttime 8 h, the unit supplies heat at a rate of 50 kg/s, with the remaining 50 kg/s provided by the electric boiler. At this point, the unit’s power output is 150 MW. The specific calculation results for various indicators of the unit before and after the addition of the electric boiler are shown in Table 3.

Table 3. Specific calculation results for various indicators of the unit before and after adding an electric boiler.

After installing an electric boiler, compared to the conventional heating scheme: the standard coal consumption during the day remains the same at 16 h, but an additional 57 tons of standard coal will be consumed at night; fuel costs increase by 50,000 yuan, net profits decrease by 50,000 yuan, and the initial investment cost for the electric boiler is 800,000 yuan, with ongoing operational and maintenance costs. However, the electric boiler has superior deep peak shaving performance, making it suitable for use when a significant increase in peak shaving depth is required.

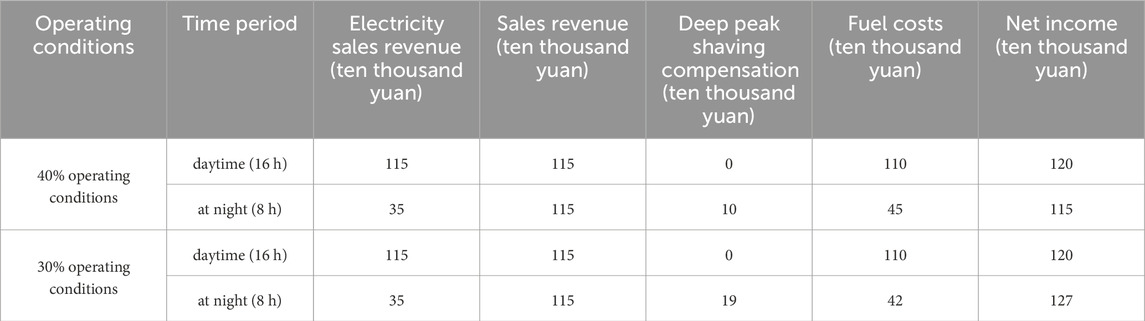

To further leverage the deep peak shaving performance advantages of the electric boiler, the nighttime unit peak shaving depth was reduced from 40% to 30%. The specific calculation results for all indicators are shown in Table 4.

Table 4. Specific calculation results for various indicators of the 30% deep peak shaving unit of the electric boiler.

Under 30% load conditions, compared to 40% load conditions: nighttime consumption will be reduced by 32 tons of standard coal; fuel costs will decrease by 30,000 yuan, deep peak shaving compensation will increase by 90,000 yuan, and net benefits will increase by 120,000 yuan.

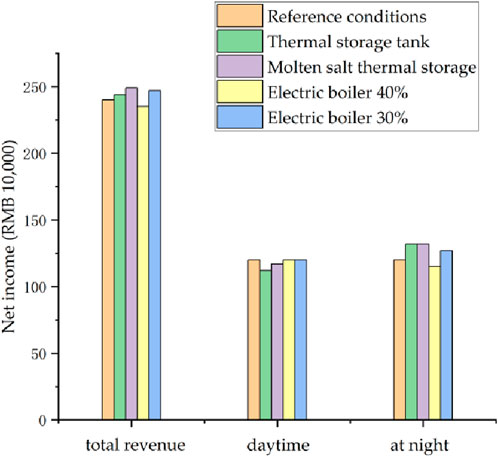

As shown in Figure 4, based on the comparison and analysis of the above four sets of data, it can be concluded that when the depth of peak shaving for heating units is small, using thermal storage tanks and molten salt thermal storage yields better returns. Among these, thermal storage tanks require lower initial investment and have lower operational costs, but molten salt thermal storage offers better long-term returns. Electric boilers do not yield good returns when the depth of peak shaving is small, but as the depth of peak shaving increases, the returns gradually improve.

4 Technical and economic comprehensive optimization method for deep peak shaving performance of online heating units

The core objective of constructing a dual-machine online operation system is to synergistically optimize thermodynamic efficiency and economic indicators. The fixed maximum load unit serves as the base load unit, continuously outputting stable thermal energy while maintaining optimal efficiency. The parallel variable load unit assumes the peak shaving function, dynamically adjusting to respond to load changes. The key advantages of this configuration are: 1) Base-load units avoid efficiency penalties caused by frequent load adjustments; 2) Peak-shaving units limit their operating range to control the decline in combustion efficiency; 3) The dual-heat-source parallel structure enhances system redundancy, enabling the system to maintain 50% heating capacity even in the event of a single-unit failure, significantly improving supply reliability (Yi and Wen, 2024). This coordinated operation strategy fundamentally achieves a Pareto improvement between static efficiency optimization and dynamic response capability, providing a feasible engineering solution for flexible regulation of heating units under high renewable energy penetration scenarios.

Optimization objective 1 function is to optimize deep peak shaving performance, i.e., minimize the power generation of the interconnected system:

In the Formula 2: N represents the number of heating units in the online operation system; PL represents the generating capacity of the heating units in the online operation system (unit: MW); Pi represents the generating capacity of the ith unit (unit: MW);.

Optimization objective 2 is to minimize the power generation coal consumption rate. The power generation coal consumption rate is a parameter that characterizes the energy consumption characteristics of power generation units. In heating units, selecting the power generation coal consumption rate as the optimization objective not only reflects the characteristics of energy utilization in a cascade system but also allows the power generation coal consumption rate of units under the same load demand to serve as an evaluation criterion for assessing the thermal economic efficiency of different units. When calculating the coal consumption rate for power generation, the thermal consumption of the unit must first be calculated, and the heating quantity subtracted to obtain the thermal consumption for power generation. The formula for calculating the thermal consumption rate for power generation of the unit is:

In the Formula 3: qt,i is the thermal consumption rate of the ith unit (unit: kJ/kWh); QT,i is the thermal consumption of the ith unit (unit: kJ); Qg,i is the heat supply of the ith unit (unit: kJ); ηB,i is the boiler efficiency of the ith unit; ηP,i is the pipeline thermal efficiency of the ith unit.

The formula for calculating the coal consumption rate of the unit is:

In the Formula 4: bt,i is the coal consumption rate per unit of electricity generated by the ith unit (unit: g/kWh); Q0 is the lower heating value of standard coal (unit: kJ/kg), which is taken as 29271.2 kJ/kg according to data from the National Bureau of Statistics.

The objective function for Optimization Goal 2 is to minimize the total coal consumption rate per unit of electricity generated by the online operation system is:

In the Formula 5: bt is the total coal consumption rate of the online operating system (unit: g/kWh).

1.Peak load demand constraint: The total power generation PL of the heating units in the online operating system meets the external peak load demand.

In the Formula 6: PT is the rated total power generation capacity of the online operation system (unit: MW); k is the peak shaving depth.

2.Heating balance constraint: The total heating capacity ML of the heating units in the online operation system is equal to the heat load demand of the surrounding industrial parks.

In the Formula 7: Mi is the heat supply of the ith unit (unit: kg/s).

3.Single unit heat supply constraint: There is a maximum value for the heat supply of each heating unit.

In the Formula 8: Mi,max is the maximum heat supply capacity of the ith unit (unit: kg/s).

4.Minimum steam flow constraint for the low-pressure cylinder: The steam flow into the low-pressure cylinder of the steam turbine must be maintained above the minimum steam flow required for safe operation of the low-pressure cylinder.

In the Formula 9: Mi,IL,min represents the minimum steam flow rate required for the safe operation of the low-pressure cylinder of the ith unit (unit: kg/s); Mi,IL represents the steam inlet flow rate of the low-pressure cylinder of the ith unit (unit: kg/s).

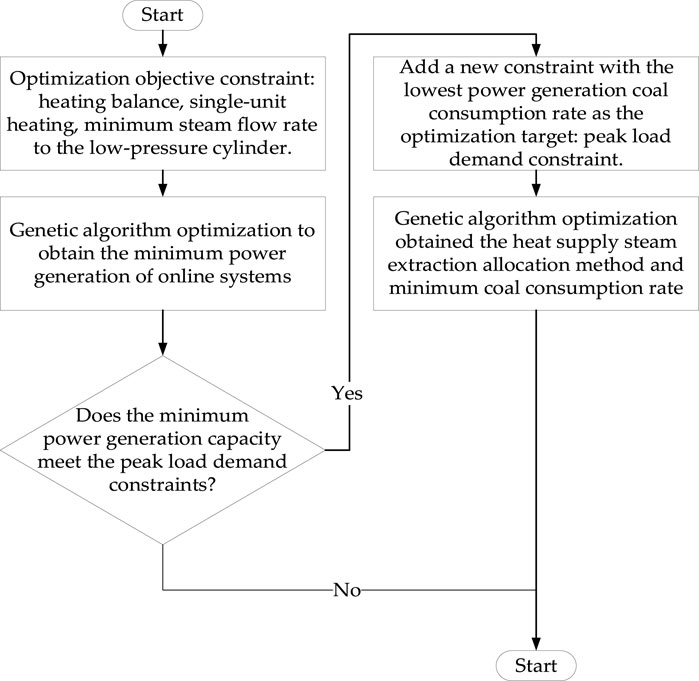

First, the minimum power generation of the online operation system is set as the optimization objective, with heating balance constraints, single-unit heating constraints, and minimum low-pressure cylinder steam inlet flow rate constraints as the constraint conditions. The genetic algorithm is used as the solution algorithm to optimize the minimum power generation of the online operation system. It is then determined whether the minimum power generation meets the peak shaving demand constraints. If it does not meet the constraints, the process is terminated directly. If it meets the constraints, the minimum coal consumption rate of the online operation system is set as the optimization objective. with peak shaving demand constraints, heating balance constraints, single-unit heating constraints, and minimum steam inlet flow rate constraints for the low-pressure cylinder as constraint conditions, and using a genetic algorithm as the solution algorithm, the optimal allocation of heating steam extraction volume for the heating units and the minimum power generation coal consumption rate of the online operation system when meeting peak shaving demand are optimized. The optimization process is shown in Figure 5.

The following describes the online operation of heating units of different models, using a 300 MW unit and a 600 MW unit. Based on whether the units are operating under maximum boiler load conditions, two operational modes can be distinguished:

Operational Mode 1: The 300 MW unit serves as the base-load unit, operating under maximum boiler load conditions, while the 600 MW unit acts as the peak-shaving unit, operating under variable conditions to assist the 300 MW unit in deep peak shaving.

Operation Mode 2: The 600 MW unit operates as the base-load unit at the boiler’s maximum load condition, while the 300 MW unit operates as the peak-shaving unit, adjusting its operating conditions to assist the 600 MW unit in deep peak shaving.

The constraint conditions are set as follows:

1.Peak-shaving demand constraint: Peak-shaving depth is 50%; the rated generating capacity of the combined operation system is 900 MW.

2.Heating balance constraint: The heat load demand of the surrounding industrial park is 300 kg/s.

3.Single-unit heating constraint: The maximum heating capacity of the 300 MW unit is 100 kg/s, and the maximum heating capacity of the 600 MW unit is 200 kg/s.

4.Minimum steam flow rate constraint for the low-pressure cylinder: The minimum steam flow rate for the low-pressure cylinder of Unit 1 is 41.670 kg/s, and the minimum steam flow rate for the low-pressure cylinder of Unit 2 is 83.330 kg/s.

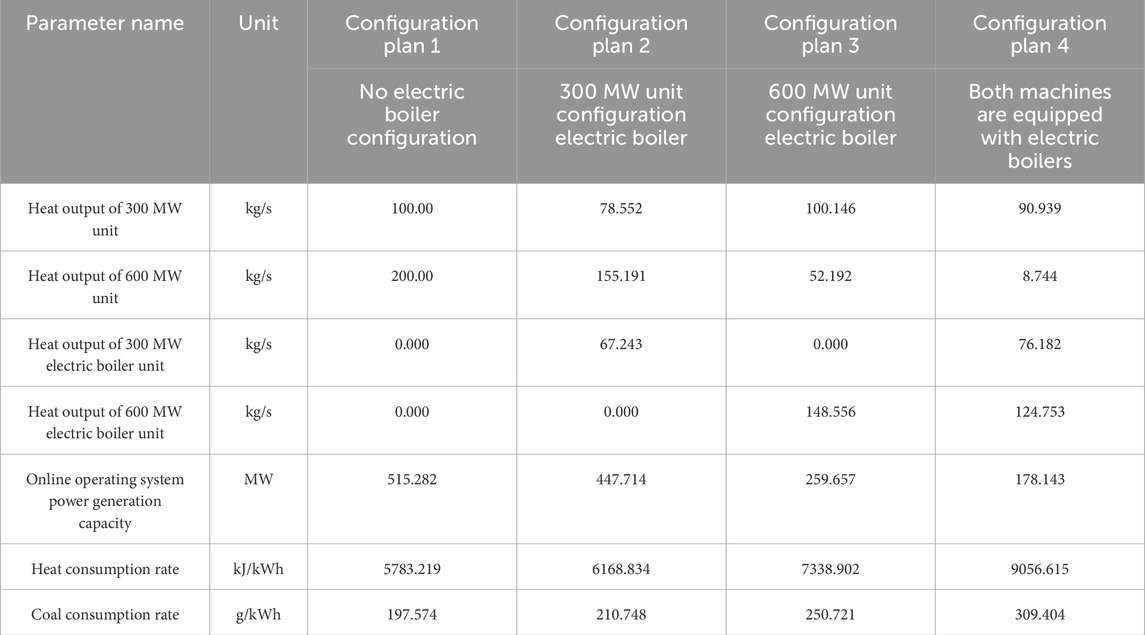

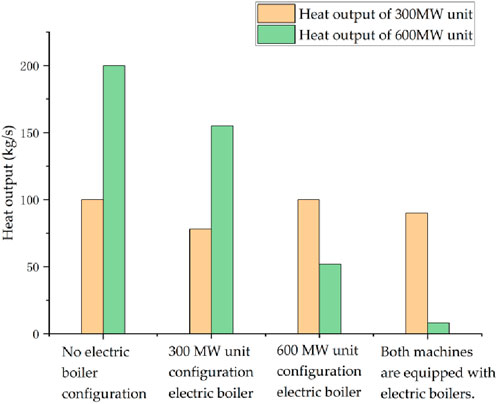

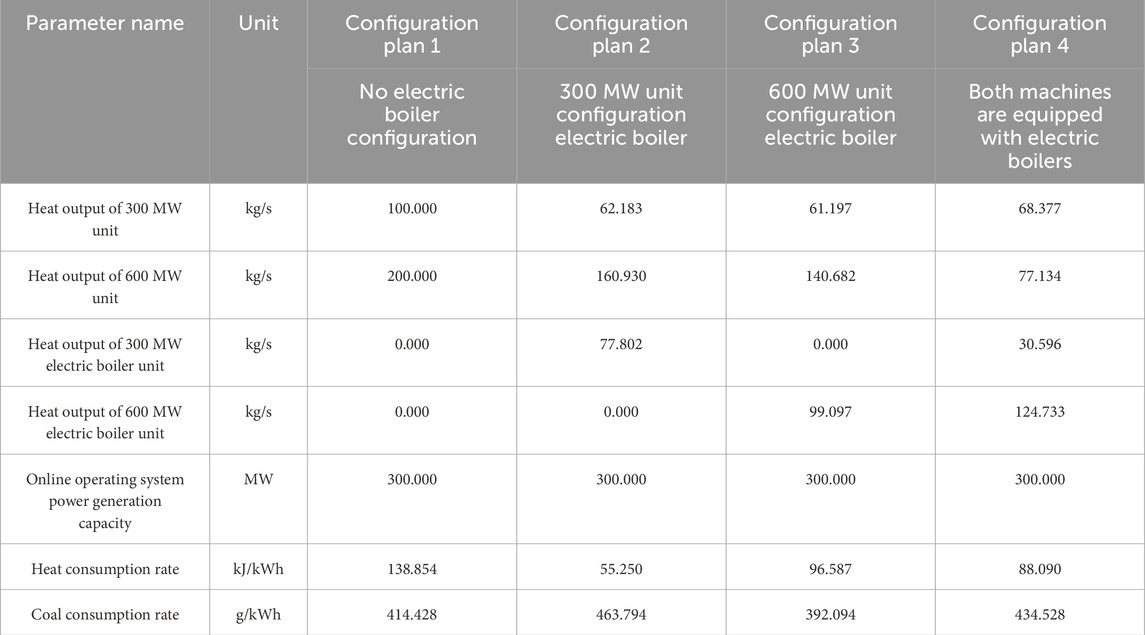

Based on the configuration of the electric boiler, four configuration schemes can be identified. Using Operation Mode 1, each of the four configuration schemes is optimized, with the optimization results shown in Table 5. This table is intended to compare the impact of four different electric boiler configurations on system output and efficiency under Operation Mode 1. The data helps determine which schemes satisfy deep peak shaving demands while balancing coal consumption.

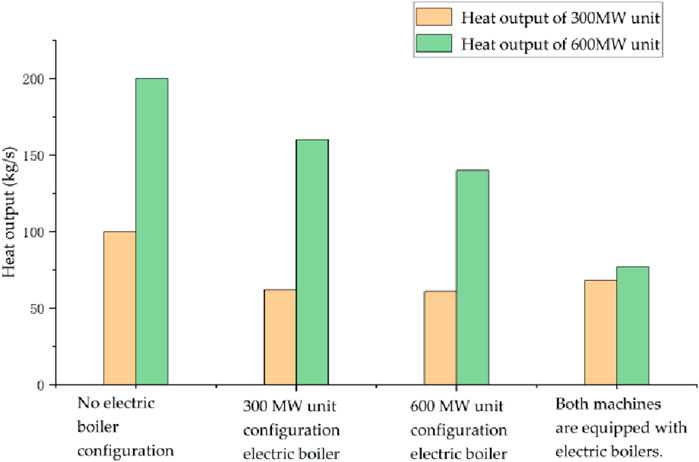

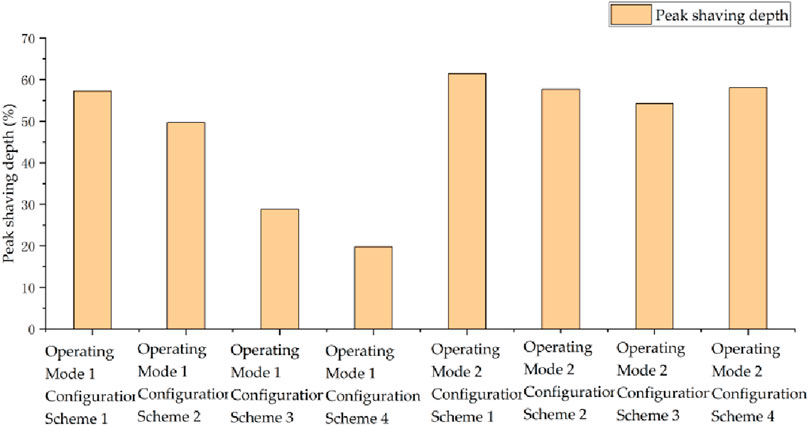

The optimization results indicate that when the online operation system is not equipped with an electric boiler, the power generation capacity is 515.282 MW, which does not meet the 50% deep peak shaving requirement. This conclusion is consistent with that of a case study involving the online operation of two units of the same model. To meet the deep peak shaving requirement, the online operation system needs to be equipped with thermal-electric decoupling technology. Among the configuration schemes that meet the 50% deep peak shaving requirement, Configuration Scheme 2 lacks further peak shaving capability, while Configuration Schemes 3 and 4 have good deep peak shaving capability. Configuration Scheme 3 can achieve a 30% peak shaving depth, and Configuration Scheme 4 can achieve a 20% peak shaving depth. Analyzing the optimization results of the four configuration schemes, as shown in Figure 6, it can be observed that when different models of dual units operate in Mode 1, the system prioritizes allocating thermal load to the 300 MW heating unit to achieve the minimum coal consumption rate, thereby keeping the 300 MW heating unit in maximum heating mode.

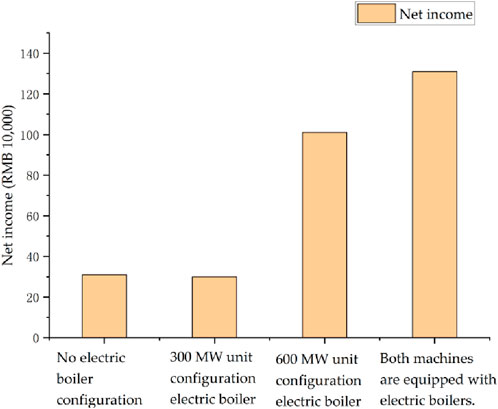

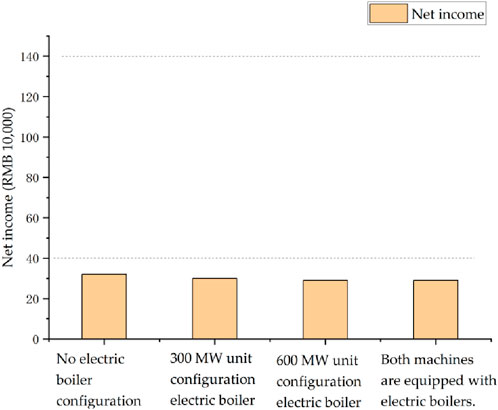

An analysis of the economic efficiency of the above four configuration schemes per unit of time is shown in Table 6. Configuration scheme 1 does not meet the deep peak shaving requirements and does not receive deep peak shaving compensation. As shown in Figure 7, configuration schemes 3 and 4 rely on deep peak shaving compensation and have good net returns.

Using operating mode 2, the four configuration schemes were optimized separately, and the optimization results are shown in Table 7. This table evaluates the same configuration schemes under Operation Mode 2. It illustrates the variation in heating output and system coal consumption when roles of the 300 MW and 600 MW units are reversed.

The optimization results indicate that when the online operation system adopts Operation Mode 2, Configuration Scheme 1, Configuration Scheme 2, and Configuration Scheme 4 cannot meet the 50% deep peak shaving requirement. Although Configuration Scheme 3 can meet the 50% deep peak shaving requirement, it lacks the ability for further peak shaving. Analyzing the optimization results of the four configuration schemes, as shown in Figure 8, it can be observed that when different models of dual-unit systems operate in online mode using Operation Mode 2, the system adjusts the 300 MW heating unit to operate at 70% heating capacity to achieve the minimum coal consumption rate.

An analysis of the economic efficiency of the four configuration schemes mentioned above within a unit of time is shown in Table 8. None of the four configuration schemes in Operation Mode 2 met the peak shaving requirements. As shown in Figure 9, the net profit was at a relatively low level in the absence of peak shaving compensation.

A comprehensive analysis of the above eight sets of optimized data, as shown in Figure 10, reveals that operating mode 1 has better peak shaving performance than operating mode 2. Under this operating mode, both configuration scheme 3 and configuration scheme 4 have good deep peak shaving performance, with the latter having superior deep peak shaving capabilities.

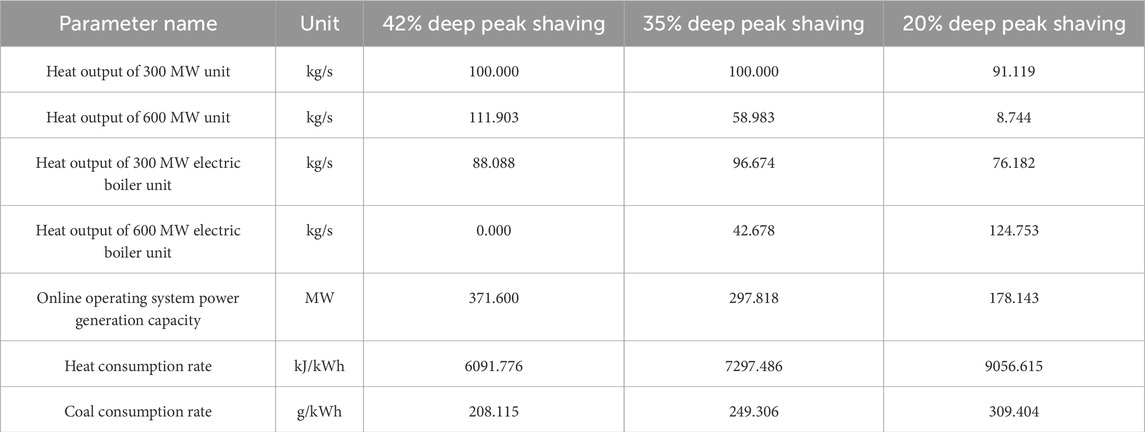

In order to conduct a comprehensive technical and economic comparison of Configuration Scheme 3 and Configuration Scheme 4 under Operating Mode 1, the peak shaving demand was segmented and restricted, and Configuration Scheme 4 was optimized. The optimization results are shown in Table 9.

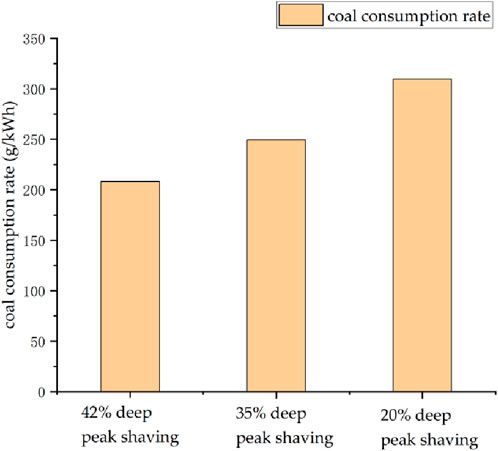

As shown in Figure 11, the optimization results indicate that as the power generation capacity of the online operating system decreases, the coal consumption rate of the system gradually increases. When the peak shaving depth of Configuration Scheme 4 is 35%, the coal consumption rate of the system is 249.306 g/kWh. When the coal consumption rates are comparable, Configuration Scheme 3 demonstrates superior peak shaving performance.

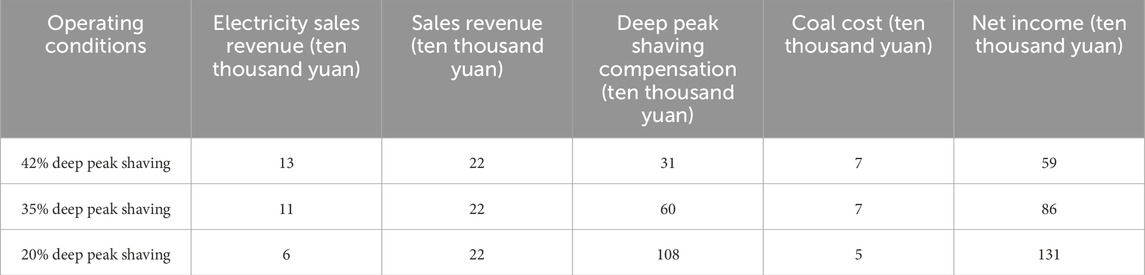

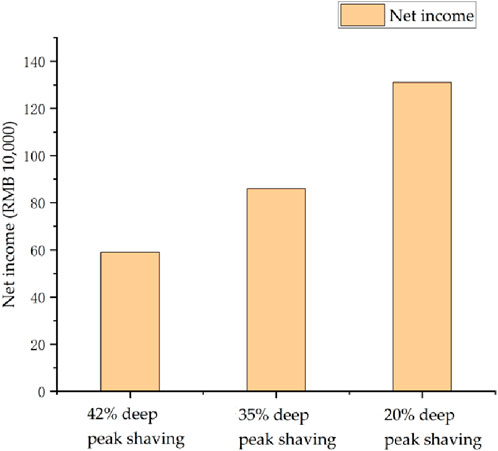

An analysis of the economic efficiency of the above three configuration schemes per unit time is shown in Table 10. As the peak shaving depth increases, the net revenue of the online operation system relying on peak shaving compensation continues to increase, as shown in Figure 12.

Based on the above analysis, it can be concluded that when operating dual-unit systems of different models, to optimize the technical and economic benefits of the system, the smaller-scale heating unit should be designated as the base-load unit, operating at the maximum boiler load condition, while the larger-scale heating unit should serve as the peak-shaving unit, operating under variable conditions to assist the base-load unit in deep peak shaving. When meeting deep peak shaving requirements, equipping the peak shaving unit with an electric boiler can optimize the system’s thermal economic efficiency. Equipping both units with electric boilers can further enhance the system’s deep peak shaving capability, but this will significantly reduce the system’s thermal economic efficiency.

5 Conclusion

Based on multi-objective collaborative optimization theory, this study systematically investigates the key technical issues related to enhancing the deep peak-shaving performance and optimizing the thermal economy of online-operating heating units. By constructing a dual-objective optimization model that minimizes power generation and coal consumption rates, combined with genetic algorithms and a thermal system simulation platform, global optimization of unit operating parameters under multiple steam extraction schemes was achieved. The study focused on dual-unit online systems of the same and different models, conducting multi-scenario simulation experiments to reveal the mechanisms by which thermal-electric decoupling technology influences system peak shaving capacity and energy consumption characteristics. The simulations were carried out using the EBSILON software.

A comprehensive technical and economic optimization method for deep peak regulation performance of heating units based on genetic algorithms and multiple steam extraction schemes was proposed. It was demonstrated that fixing the base-load unit at the maximum boiler load condition can maintain the optimal thermal efficiency range, which improves simulation accuracy by 8.7% compared to traditional method. While adopting a sliding pressure regulation strategy for the peak regulation unit can reduce the system’s power generation capacity by 23.6%–41.2%, verifying the technical feasibility of differentiated operation strategies.

A coupling pattern between unit capacity ratios and operating modes was identified: when 300 MW and 600 MW units adopt the “small units base load + large units peak shaving” mode, the system’s net revenue increases by 67.3% compared to the reverse configuration, providing important reference value for optimizing systems with mismatched units.

The novelty of this study lies in that the proposed comprehensive technical and economic optimization method provides quantitative basis for selecting interconnection system configuration schemes and lays the theoretical foundation for establishing coordinated operation modes between power and heat systems under the new power system framework. Furthermore, this method has potential practical significance in reducing operational costs, enhancing the adaptability of power plants under fluctuating renewable generation scenarios, and supporting policy-driven targets for carbon emission reduction.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

LW: Formal Analysis, Writing – original draft, Conceptualization. ZS: Writing – original draft, Methodology. HH: Formal Analysis, Conceptualization, Writing – original draft. JX: Writing – original draft, Methodology, Formal Analysis.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. Science and Technology Project of Guangxi Power Grid Co., Ltd. (No. GXKJXM20230090).

Conflict of interest

Authors LW, ZS, HH, and JX were employed by Electric Power Research Institute of Guangxi Power Grid Co., Ltd.

The authors declare that this study received funding from Guangxi Power Grid Co., Ltd. The funder had the following involvement in the study: Research on grid security assessment and performance enhancement technologies for deep peaking heating units.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Chen, X., Gao, J., and Zheng, F. (2020). Comparative analysis of various deep peak regulation modes for thermal power units. J. Eng. Therm. Energy Power 35 (12), 26–30. doi:10.16146/j.cnki.rndlgc.2020.12.004

Elwardany, M. (2024). Enhancing steam boiler efficiency through comprehensive energy and exergy analysis: a review. Process Saf. Environ. Prot. 184, 1222–1250. doi:10.1016/j.psep.2024.01.102

Gao, K., Bao, W., and Ding, Y. (2020). Economical analysis for a large-sized unit of steam extraction under deep regulating load. J. Eng. Therm. Energy Power 35 (9), 16–21. doi:10.16146/j.cnki.rndlgc.2020.09.00

Haijiao, W. E. I., Lu, Y., Yang, Y., Zhang, C., He, C., Wu, Y., et al. (2021). Research on influence of steam extraction parameters and operation load on operational flexibility of coal-fired power plant. Appl. Therm. Eng. 195, 117226. doi:10.1016/j.applthermaleng.2021.117226

Haijiao, W. E. I., Lu, Y., and Liu, J. (2023). Research on large-scale renewable energy power consumption by peak. Therm. Power Gener. 52 (02), 79–89. doi:10.19666/j.rlfd.202210251

Hou, J., Ding, W., and Ransheng, Li (2024). “Research and application of new feedwater heating technology based on deep peak shaving of thermal power units,” in 2024 4th International Conference on Energy, Power and Electrical Engineering (EPEE) (IEEE), 20–27. doi:10.19929/j.cnki.nmgdljs.2021.0049

Huang, Y., Sun, Q., Chen, Z., Wenzhong Gao, D., Bach Pedersen, T., Guldstrand Larsen, K., et al. (2025). Dynamic modeling and analysis for electricity-gas systems with electric-driven compressors. IEEE Trans. Smart Grid 16, 2144–2155. doi:10.1109/tsg.2025.3527221

Jianglong, Li, Sing, Ho M., Xie, C., and Stern, N. (2022). China's flexibility challenge in achieving carbon neutrality by 2060. Renew. Sustain. Energy Rev. 158, 112112. doi:10.1016/j.rser.2022.112112

Lin, B., Chen, J., Wesseh, J. R., and Presley, K. (2022). Peak-valley tariffs and solar prosumers: why renewable energy policies should target local electricity markets. Energy Policy 165, 112984. doi:10.1016/j.enpol.2022.112984

Song, H., Chen, X., and Gao, J. (2021a). Research on selection of heating modes for 600 MW supercritical units. Northeast Electr. Power Technol. 42 (12), 30–32.

Song, H., Chen, X., and Gao, J. (2021b). Study on the technical route of multi-mode deep peak-shaving cooperative operation of multi-heating units. Turbine Technol. 63 (06), 448–450+457.

Sun, J. (2024). Analysis of heating flexibility transformation technology for a 350MW coal-fired power unit. Dist. Heat. (05), 139–146. doi:10.16641/j.cnki.cn11-3241/tk.2024.05.016

Wang, J., Zhang, S., Huo, J., Zhou, Y., Li, L., and Han, T. (2021). Dispatch optimization of thermal power unit flexibility transformation under the deep peak shaving demand based on invasive weed optimization. J. Clean. Prod. 315, 128047. doi:10.1016/j.jclepro.2021.128047

Wang, C., Song, J., Zhu, L., Zheng, W., Liu, Z., and Lin, C. (2021). Peak shaving and heat supply flexibility of thermal power plants. Appl. Therm. Eng. 193, 117030. doi:10.1016/j.applthermaleng.2021.117030

Weinberger, G., Amiri, S., and Moshfegh, B. (2021). Investigating techno-economic effects and environmental impacts of energy renovation of residential building clusters on a district heating system. Energy Build. 251, 111327. doi:10.1016/j.enbuild.2021.111327

Wenping, J. U., Lyu, K., and Tingshan, M. A. (2018). Comparison of thermo-electric decoupling techniques for heating units. Therm. Power Gener. 47 (9), 115–121. doi:10.19666/j.rlfd.201801008

Xilin, LUAN, Ma, J., Dong, X., Yang, Y., and Nie, S. (2024). Analysis of heating load distribution and operation optimization for 350MW high back pressure double extraction series units. Therm. Sci. 28 (5 Part A), 3801–3816. doi:10.2298/tsci231211097l

Yang, Z., Ouyang, J., and Chen, H. E. (2024). Comparison of technical routes for thermoelectric decoupling of coal-fired power units. Energy Energy Conservation (07), 68–71+78. doi:10.16643/j.cnki.14-1360/td.2024.07.038

Yi, T., and Wen, X. (2024). Robust low-carbon scheduling optimization for energy hub amidst bilateral uncertainties in source-side and load-side conditions. J. Renew. Sustain. Energy 16 (5), 056301. doi:10.1063/5.0210059

Zheng, F., Chen, X., and Gao, J. (2021). Research on flexible transformation technology for deep peak regulation of steam extraction and heating units. Turbine Technol. 63(02), 144–146.

Zhang, X., Yang, X., and Gang, X. I. N. (2022). Experimental study on deep peak regulation operation of coal-fired thermal power unit. Clean. Coal Technol. 28 (4), 144–150. doi:10.13226/j.issn.1006-6772.21081904

Zhang, N., Gang, L., Xiaoxin, M., and Wang, Q. (2024). Discussion on the characteristics and renovation technologies of the heating system in Chinese urban residential areas from perspectives of heat sources. Energy Build. 307, 113966. doi:10.1016/j.enbuild.2024.113966

Zhiqiang, L. I., Chen, X., and Gao, J. (2020). Research on deep peak regulation technology of thermo-electrolytic coupling for 350MW thermal power units. Turnine Technol. 62, 389–392.

Keywords: extraction steam heating unit, deep peak shaving, heat-electricity decoupling technology, parallel operation, load optimization

Citation: Wen L, Sun Z, Hu H and Xi J (2025) A comprehensive optimization method for peak shaving performance of combined cycle steam heating units. Front. Energy Res. 13:1642715. doi: 10.3389/fenrg.2025.1642715

Received: 07 June 2025; Accepted: 27 August 2025;

Published: 30 September 2025.

Edited by:

Haoran Zhao, Shandong University, ChinaReviewed by:

Yujia Huang, Northeasten University, ChinaBayu Rudiyanto, State Polytechnic of Jember, Indonesia

Copyright © 2025 Wen, Sun, Hu and Xi. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hong Hu, aDE3ODc4NDYxNjg2QDE2My5jb20=

Libin Wen

Libin Wen Zhiyuan Sun1,2

Zhiyuan Sun1,2 Hong Hu

Hong Hu